Page 1

INTERNATIONAL, INC.

159 PARIS AVENUE • NORTHVALE, NJ 07647 • PHONE 201-768-2400

TECHNICAL SERVICE BULLETIN

Date: 08/19/05 Number: 2005-03

Subject: KC1000 LOW NOx CONVERSION KIT INSTRUCTIONS

Page 1 of 42

1. INTRODUCTION

The KC1000 Low NOx Conversion Kit, Part No. 124918 contains all of the assemblies, cables and

attaching parts necessary to upgrade a KC1000 Boiler or Water Heater for Low NOx compliance.

When so equipped, the Boiler or Water Heater complies with the NOx emission standards outlined in:

• South Coast Air Quality Management District (SCAQMD), Rule 1146.2.

• Texas Commission on Environmental Quality (TCEQ), Title 30, Chapter 117, Rule

117.465.

NOTE

These Conversion Kit instructions are applicable to all KC1000 units,

regardless of the Control System and/or Safety Shutoff Valve (SSOV) installed

on your unit. Unless otherwise specified, the descriptions and procedures

contained in this Service Bulletin apply to all Natural Gas KC1000 Water

Heater and Boiler configurations. If you are not certain of your current unit

configuration, contact your nearest AERCO Representative.

1.1 General Description

In order to comply with the above-mentioned low NOx emission standards, the existing KC Burner

Assembly must be replaced with a new Low NOx Burner Assembly and a Staged Ignition Assembly.

In addition, several other assemblies must be modified to ensure low NOx emissions.

The Low NOx Conversion procedures provided in this Service Bulletin are divided into the following

main categories:

• Equipment Removal

• Equipment Modification/Rework

• Equipment Replacement/Reinstallation

• Post-Installation Setup and Calibration

The procedures in each of these categories are presented in Sections 2 through 5 respectively.

The following paragraphs in this Section describe the contents of the Low NOx Conversion Kit and the

tools and test equipment required to perform all procedures in this Service Bulletin.

1

Page 2

1.2 Conversion Kit Contents

KC1000 Low NOx Conversion Kit, Part No. 124918-( ) is available in four configurations, designated 1, -2, -3 and -4. The -1 and -2 Kits apply to newer KC1000 Water Heaters and Boilers respectively,

equipped with Siemens Safety Shutoff Valves (SSOVs) and C-More Control Systems. The -3 and -4

Kits apply to older KC1000 Water Heaters and Boilers respectively, equipped with Honeywell SSOVs.

Older KC1000 units may also be equipped with Modular or Digital Control Systems, instead of the CMore Control Systems used on current KC1000 units. The “Kit Dash Number” column in the following

Table indicates which parts are included in each Kit. As this Table shows, only minor differences exist

between the contents of the four Kit configurations.

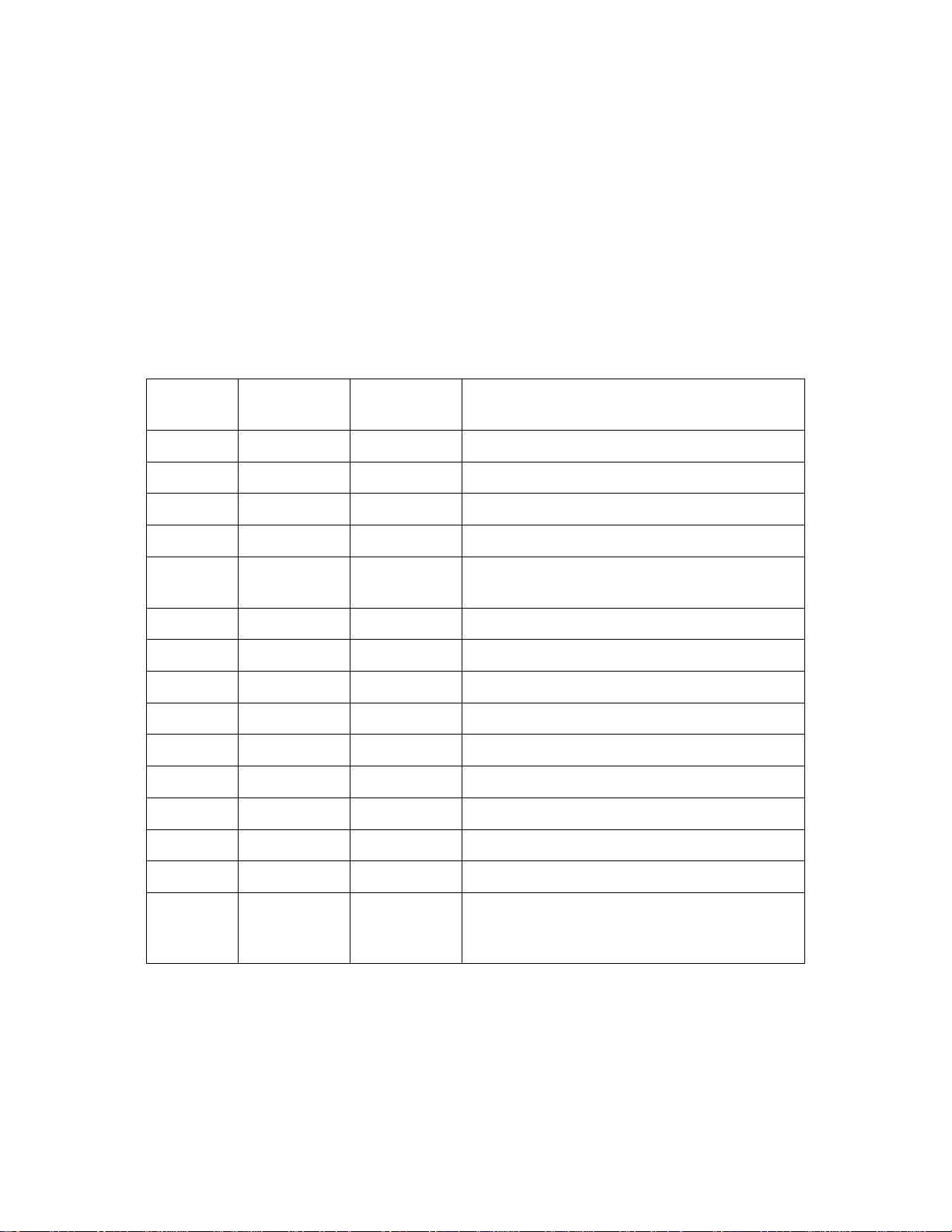

Conversion Kit, Part No. 124918-( ) Contents

Item No. Part No.

Kit Dash

Number

Description

1 201258 All Low NOx Burner Assembly

2 124715 All 5/16-18 x 1-3/4” Long Studs (Qty=6)

3 124867 -1, -2 Only Staged Ignition Assembly

4 124983 -3, -4 Only Staged Ignition Assembly

5 124991 All Low NOx Air/Fuel Valve Gas Plate

Assembly

6 161625 All Low NOx Air/Fuel Valve Butterfly

7 124803 All Low NOx Gas Regulator Plated Spring

8 124870 All Solenoid Valve Harness

9 124839 All Low NOx Combustion Chamber Liner

10 124570 All Low NOx Igniter Assembly

11 124837 All Low NOx Flame Rod Assembly

12 124919 All Low NOx Conversion Labels Sheet

13 124797 -1, -3 Only Low NOx Heater Specs. Label

14 124798 -2, -4 Only Low NOx Boiler Specs. Label

15 GF-111LN

or

GF-109LN

-1 Only

or

-2 Only

Low NOx Heater O & M Manual

or

Low NOx Boiler O & M Manual

2

Page 3

1.3 Tools and Test Equipment Required

The required tools and test equipment are listed in paragraphs 1.3.1 and 1.3.2 respectively.

1.3.1 Tools

The following tools are required to perform the conversion procedures specified in this Service

Bulletin:

• Wrenches: 3/16”, 7/16”, 1/2”, two 9/16”, 5/8”, 11/16”, 15/16”

• Vise-Grip Pliers

• Flat Tip Screwdriver, 1/2” - Inch Blade

• Phillips Head Screwdriver, No. 3

• AERCO Differential Gas Pressure Regulator Adjustment Tool, Part No. GM-122643

1.3.2 Test Equipment

Following installation of all Conversion Kit items, the following test equipment will be required to

perform combustion calibration of the modified KC1000 Boiler or Water Heater using the applicable

Operation & Maintenance Manual:

• Digital Combustion Analyzer – Oxygen accuracy to ±0.5 %, carbon monoxide and NOx

resolution to 1 ppm.

• One 16” W.C. Manometer and plastic tubing

• One 1/4 inch and two 1/8 inch NPT-to-barbed fittings for use with manometers

WARNING

HIGH VOLTAGE OF 120 VAC IS USED IN KC1000 SYSTEMS. USE

EXTREME CARE WHEN ACCESSING CIRCUITS AND ELECTRICAL

CONNECTIONS WITHIN THE EQUIPMENT. SERIOUS PERSONAL INJURY

OR DEATH MAY OCCUR IF THIS WARNING IS NOT OBSERVED.

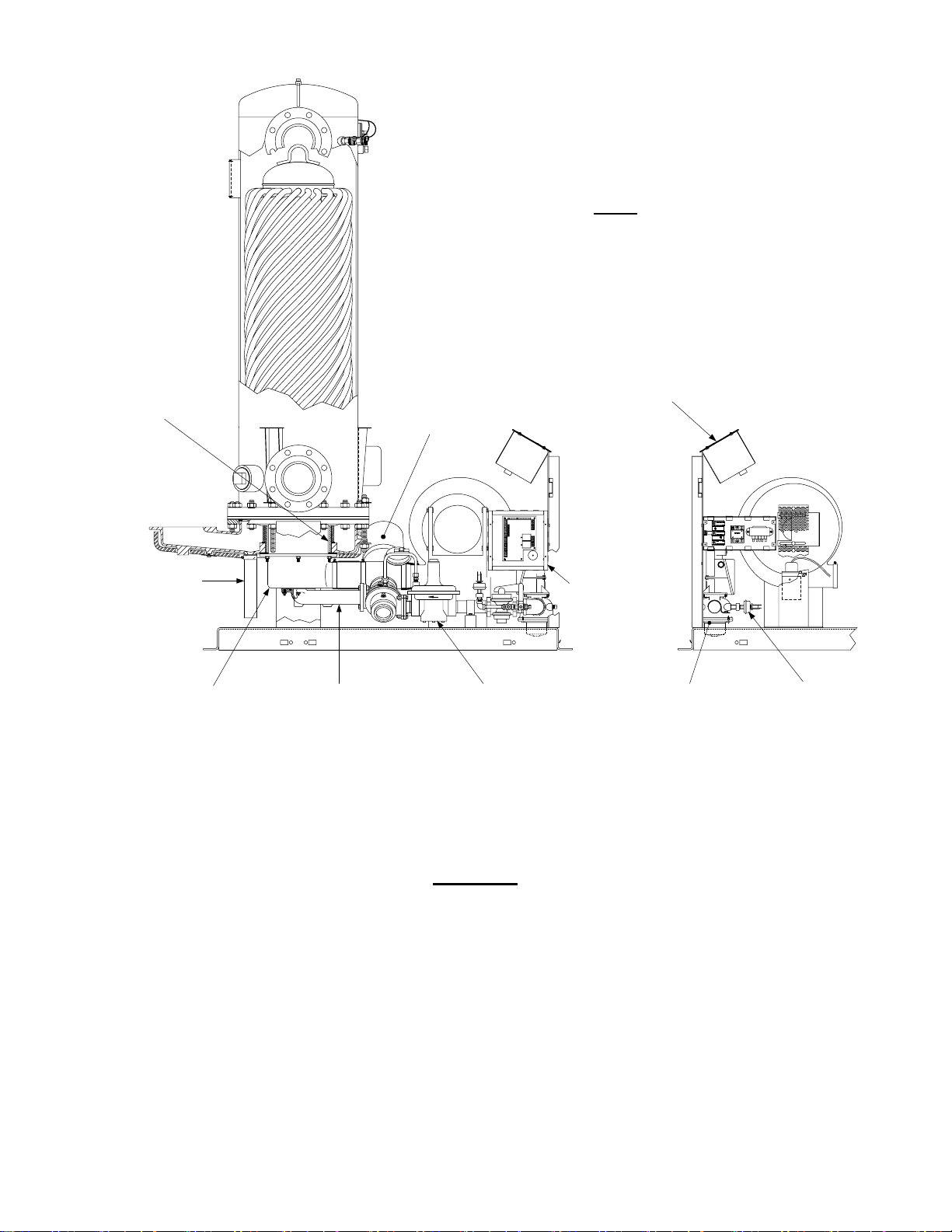

2. EQUIPMENT REMOVAL

The locations of the major items to be removed from the KC1000 are shown in Figure 1. These items

include the existing Burner Assembly, Combustion Chamber Liner, Gas Inlet Pipe and the Air/Fuel

Valve. The existing Burner and Combustion Chamber Liner will be replaced with new assemblies

provided in the Conversion Kit. The Air Fuel Valve will be modified using the applicable procedures in

Section 3.

3

Page 4

NOTE

ILLUSTRATION SHOWS KC BOILER WITH

COVERS REMOVED. THE LOCATIONS OF

THE AFFECTED ITEMS ARE IDENTICAL FOR

BOTH KC BOILERS AND WATER HEATERS

COMBUSTION

CHAMBER

LINER

CONDENSATE

DRAIN TUBE

BURNER

ASSEMBLY

CONTROL

AIR/FUEL

VALVE

I/O

BOX

GAS INLET

PIPE

DIFFERENTIAL

GAS PRESSURE

REGULATOR

Figure 1. KC1000 Component Locations

BOX

SSOV

LOW GAS

PRESSURE

SWITCH

Removal of the required items is accomplished as follows:

CAUTION

DO NOT DISCARD ANY OF THE REMOVED PARTS OR ASSEMBLIES

UNLESS IT IS SPECIFICALLY INDICATED THAT THEY WILL NO LONGER

BE USED. IT IS RECOMMENDED THAT ALL REQUIRED ITEMS BE

REMOVED AS INDICATED IN THE FOLLOWING STEPS PRIOR TO

PERFORMING ANY REPLACEMENT PROCEDURES IN SECTION 4.

1. Turn off the gas supply and disconnect AC power from the unit.

2. Remove the top and side sheet metal covers from the unit.

3. At the rear of the unit, disconnect the plastic tubing from the condensate cup to the drain.

4

Page 5

4. Remove the rear covers from the unit.

5. Remove the condensate cup from under the unit and disconnect the condensate drainage

tube from the exhaust manifold.

6. Disconnect the flame detector and igniter cable leads from the flame detector and igniter

contactor.

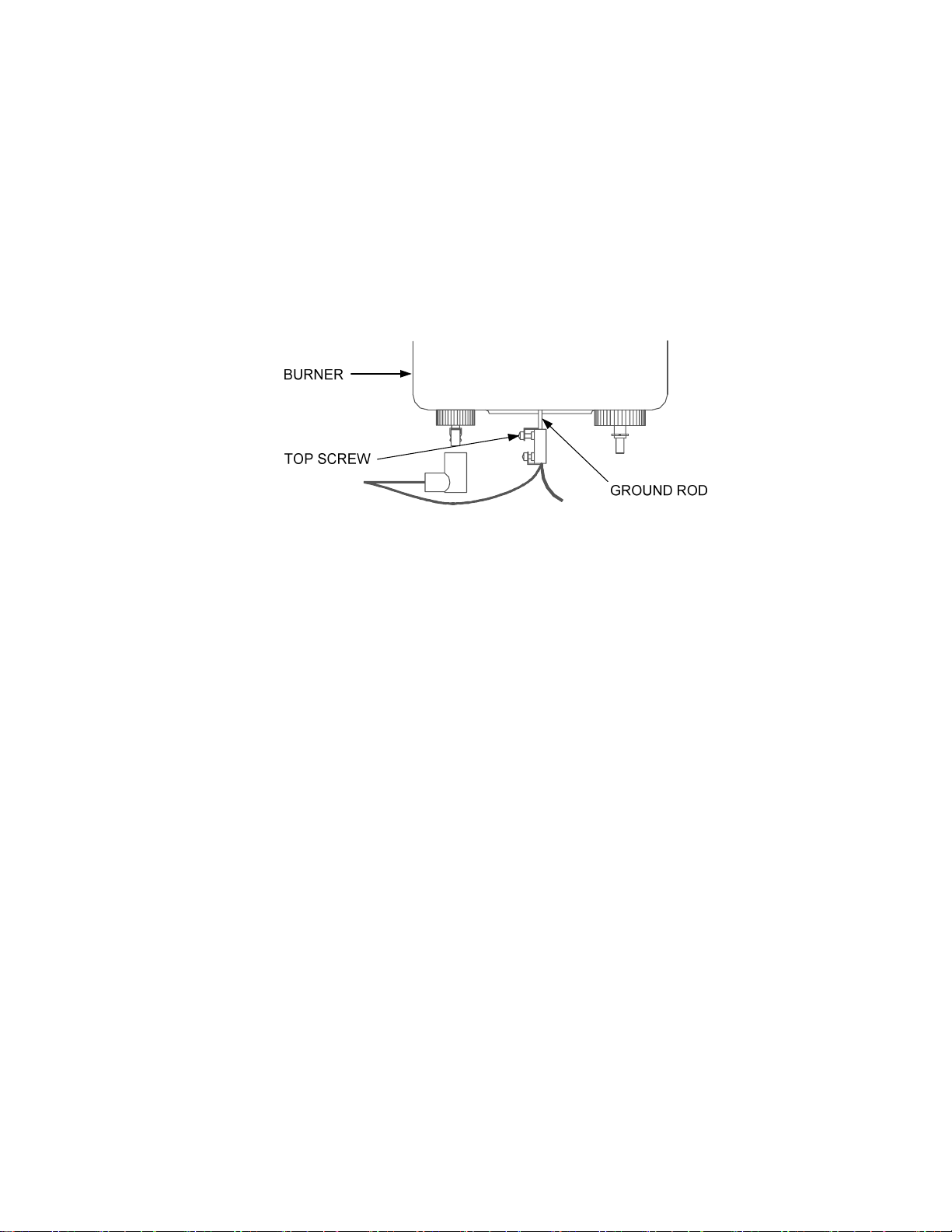

7. Remove the ground terminal connection from the Burner by loosening the top screw shown in

Figure 2. Slide the connector off the grounding rod.

Figure 2. Ground Terminal Location

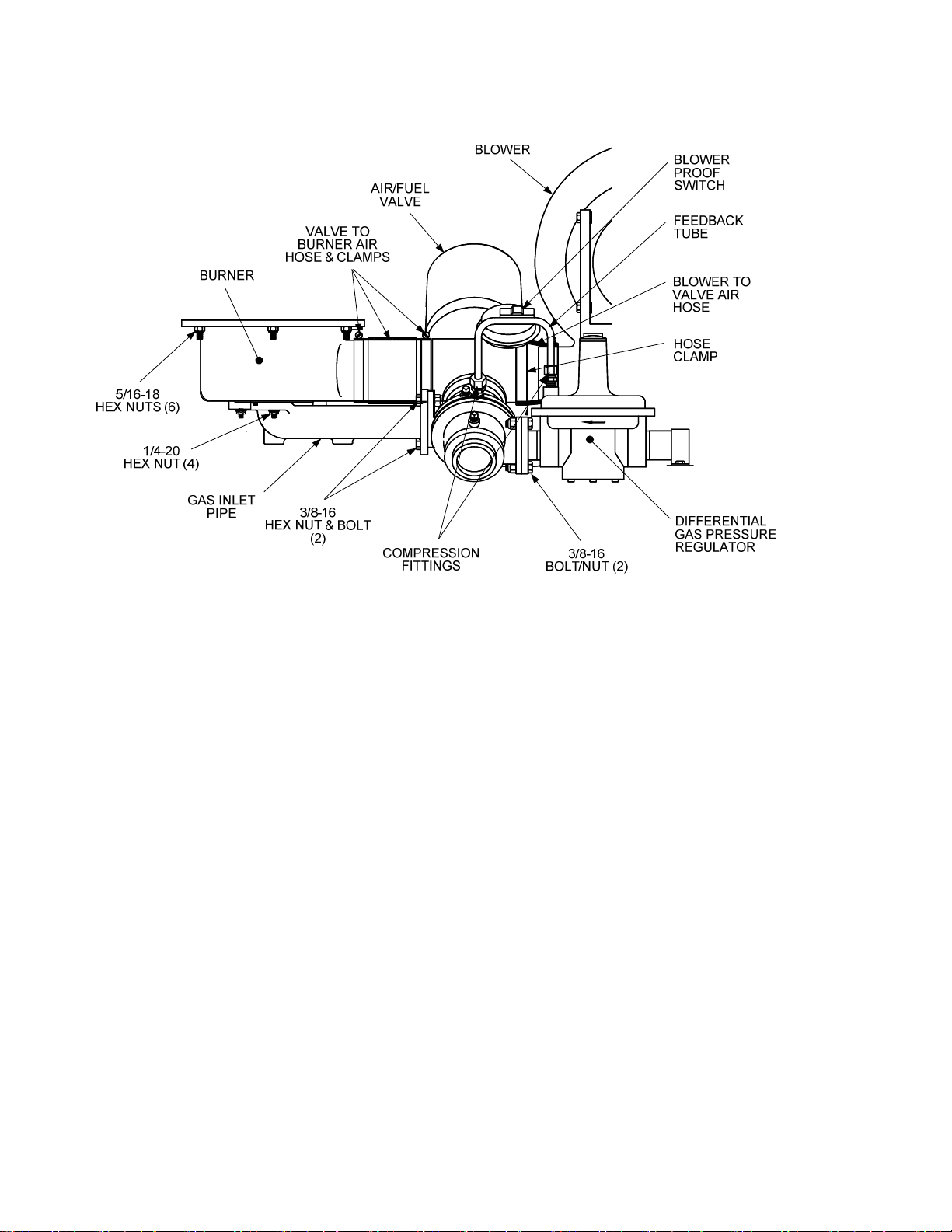

8. Using a 7/16 inch socket or open end wrench, remove the four 1/4 – 20 hex nuts on the gas

inlet pipe flange at the Burner. See Figure 3.

9. Using two 9/16 inch wrenches, remove the two 3/8” – 16 hex nuts and bolts on the gas inlet

pipe flange at the Air/Fuel Valve (Figure 3). Remove the gas inlet pipe and gaskets from the

unit.

10. Loosen the hose clamp on the Air/Fuel Valve side of the valve-to-burner air hose as shown in

Figure 3.

11. Using a 1/2 inch socket wrench, remove the six 5/16 – 18 hex nuts supporting the existing

Burner Assembly (Figure 3).

12. Lower the Burner Assembly while sliding the valve-to-burner air hose off the Air/Fuel Valve.

Completely remove the Burner from the rear of the unit.

13. Loosen the hose clamp on the removed Burner Assembly inlet and slide the valve-to-burner

air hose off the Burner. Retain the hose and clamp. These items will be reinstalled in Section

4. The removed Burner Assembly will be replaced with the new Low NOx Burner provided in

the Conversion Kit.

5

Page 6

Figure 3. Burner & Air/Fuel Valve Removal

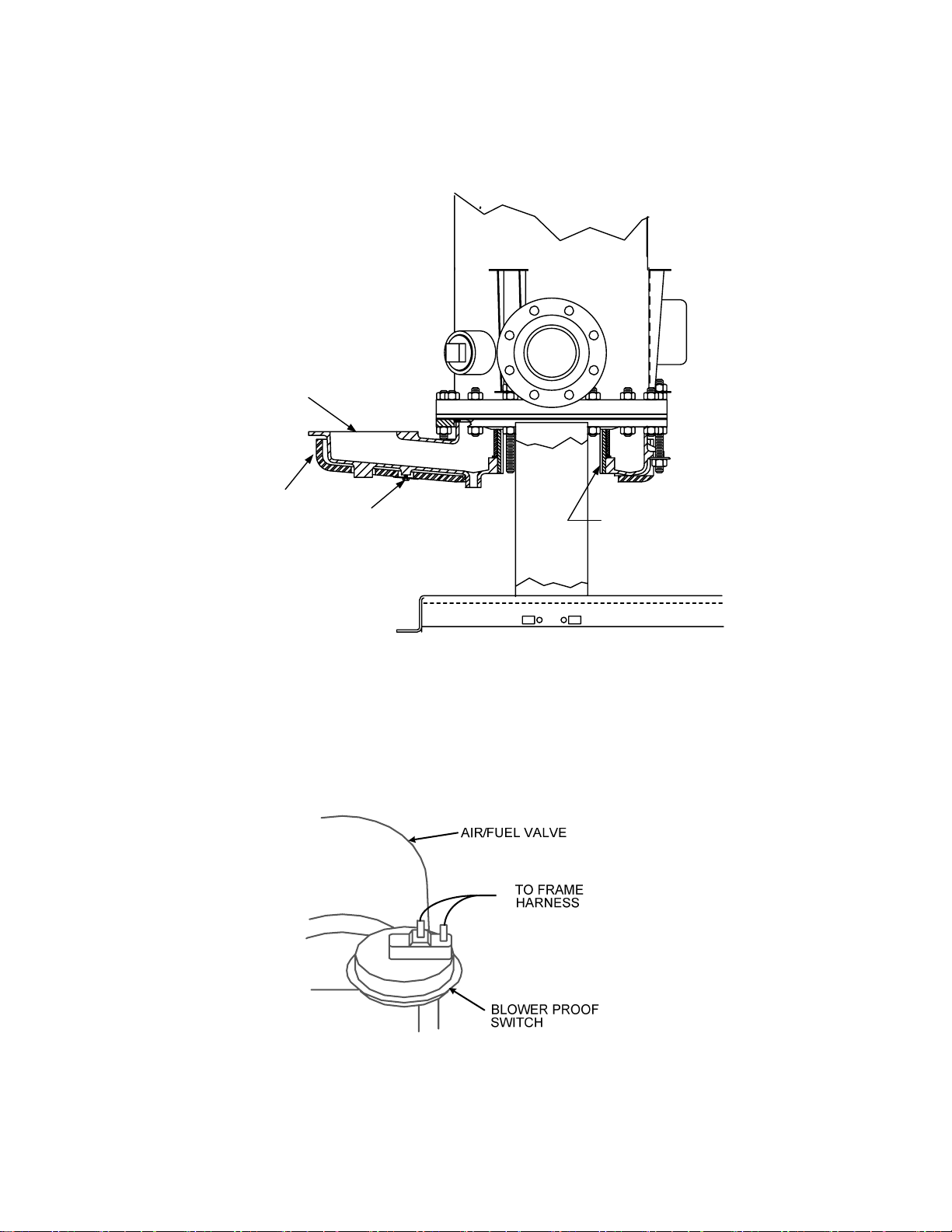

14. Remove the 8-inch Combustion Chamber Liner from the Heat Exchanger (Figure 4). Since

this liner will be replaced, It may be cut or broken to simplify removal.

NOTE

If difficulty is encountered during removal of the 5/16-18 studs, it may be

necessary to “Double-Nut” the studs to simplify the removal process.

15. Using vise-grip pliers, remove the six 5/16–18 x 1-1/2” long studs used to secure the removed

Burner Assembly to the Exhaust Manifold. These studs will be replaced with 1-3/4” studs

provided in the Conversion Kit.

16. Disconnect the Air/Fuel Valve wiring harness from the Control Box.

17. Disconnect the two wire leads from the Blower Proof Switch shown in Figure 5.

18. Loosen the hose clamp on the Air/Fuel Valve inlet side of the blower-to-valve air hose shown

in Figure 3.

19. Using an 11/16 inch wrench, loosen the two compression fittings securing the feedback tube to

the Air/Fuel Valve and Differential Pressure Regulator shown in Figure 3.

20. Using two 9/16 inch wrenches, remove the two 3/8–16 bolts and hex nuts securing the Air Fuel

Valve to the Differential Pressure Regulator (Figure 3).

6

Page 7

EXHAUST

MANIFOLD

INSULATION

1/4-20 SCREW &

FENDER WASHER

(3 PLACES)

COMBUSTION

CHAMBER LINER

Figure 4. KC1000 With Burner & Air/Fuel Valve Removed

Figure 5. Blower Proof Switch

7

Page 8

CAUTION

USE CARE WHEN REMOVING THE AIR/FUEL VALVE TO AVOID

DAMAGING OR LOSING THE FLANGE O-RING.

21. Completely remove the Air/Fuel Valve from the unit. This assembly will be modified in

Section 3.

22. Remove the Exhaust Manifold insulation (Figure 4) by removing the three 1/4-20 screws and

fender washers securing it in place.

NOTE

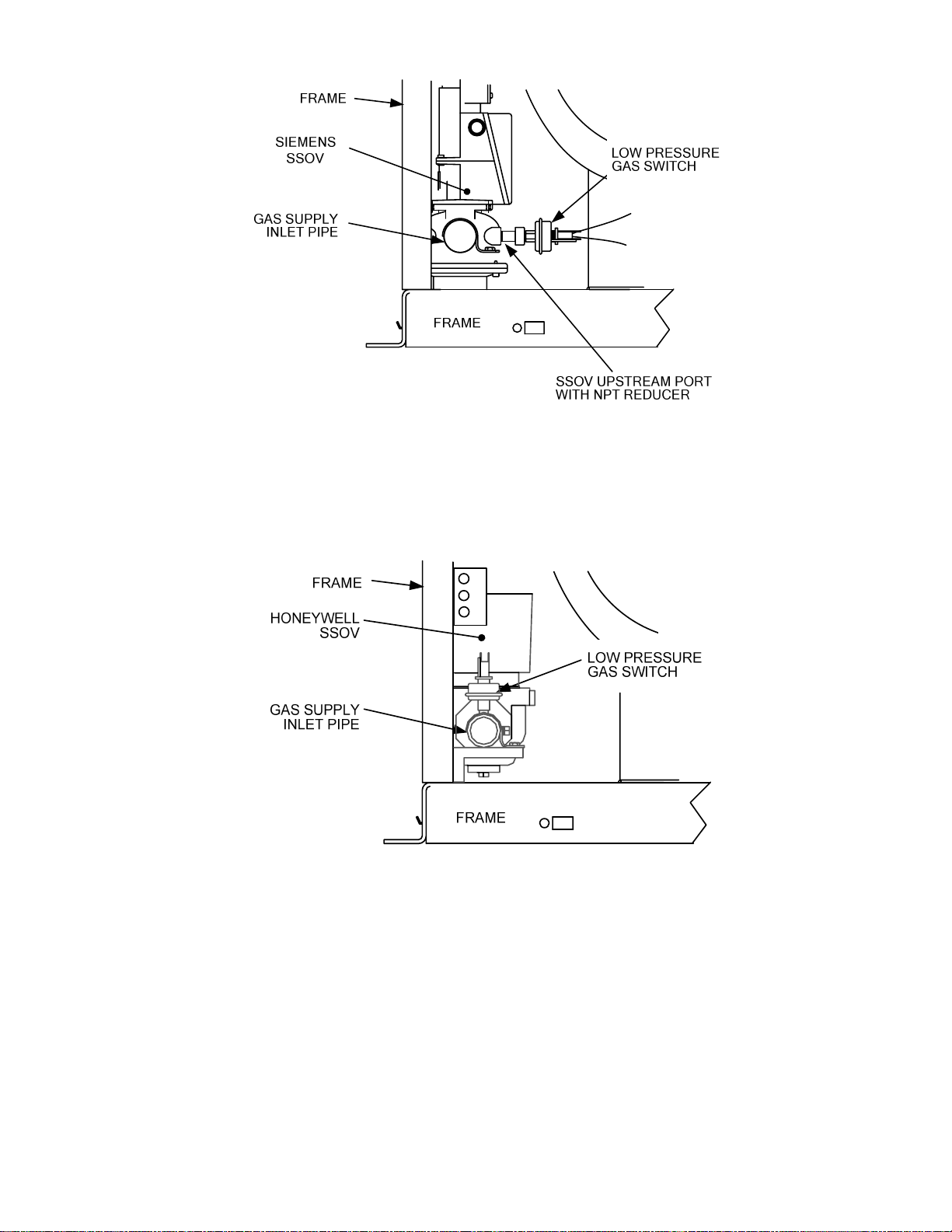

Current KC1000 units are equipped with Siemens Safety Shutoff Valves

(SSOVs). However, some earlier units may be equipped with Honeywell

SSOVs. The mounting location of the Low Pressure Gas Switch will differ

slightly, depending on the SSOV installed. Refer to Figure 6 (Siemens) or

Figure 7 (Honeywell) for the appropriate SSOV installed.

23. Next, refer to Figure 6 (Siemens SSOV) or Figure 7 (Honeywell SSOV) to locate the Low

Pressure Gas Switch on the right side of the unit. Disconnect the two wire leads from the

switch.

24. For Siemens SSOVs, the Low Pressure gas Switch is installed in the upstream SSOV port

using an NPT reducer. For Honeywell SSOVs, the Switch is installed directly in the gas supply

inlet pipe. Temporarily remove the Low Pressure Gas Switch as follows:

(a) For Siemens SSOVs, remove the switch (with NPT reducer attached) from the upstream

SSOV port using a 5/8” wrench.

(b) For Honeywell SSOVs, remove the switch from the tapped hole in the gas supply inlet

pipe using a 1/2” wrench.

The Low Pressure Gas Switch will be reinstalled in Section 4.

8

Page 9

Figure 6. Low Pressure Gas Switch Location With Siemens SSOV Installed

Figure 7. Low Pressure Gas Switch Location With Honeywell SSOV Installed

25. This completes the equipment removal procedures for the KC Boiler or Water Heater. Proceed

to the Modification/Rework procedures in Section 3.

9

Page 10

3. EQUIPMENT MODIFICATION/REWORK

The equipment items to be modified are the Air/Fuel Valve and Differential Gas Pressure Regulator.

The Air/Fuel Valve was removed from the unit in Section 2 of this Service Bulletin. The Differential

Gas Pressure Regulator can be modified in place without removal. The modification procedures for

these items are presented in paragraphs 3.1 and 3.2 which follow.

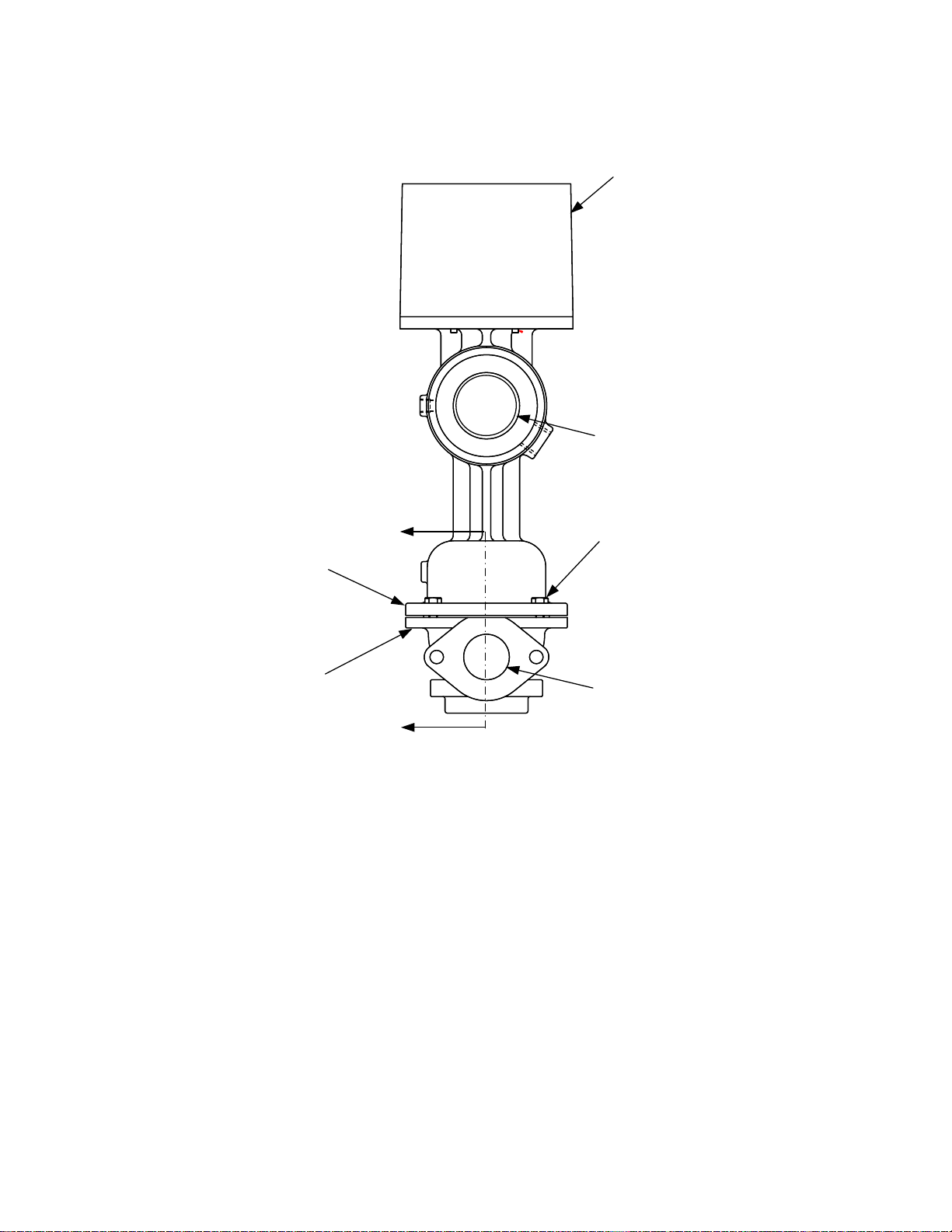

3.1 Air/Fuel Valve Modification

The modifications to be made to the Air/Fuel Valve consist of replacing the lower gas plate and the air

valve butterfly with the replacement items contained in the Conversion Kit. Place the Air/Fuel Valve

on a workbench and proceed as follows:

1. Rotate the Air/Fuel Valve butterfly so that the valve is in the fully closed position.

2. Using a 7/16 inch socket or wrench, remove the four 1/4-20 hex head machine screws

securing the lower portion of the Air/Fuel Valve body to upper valve body as shown in

Figure 8.

CAUTION

DO NOT ROTATE THE VALVE BUTTERFLY FROM THE FULLY CLOSED

POSITION AFTER SEPARATING THE UPPER AND LOWER VALVE BODY.

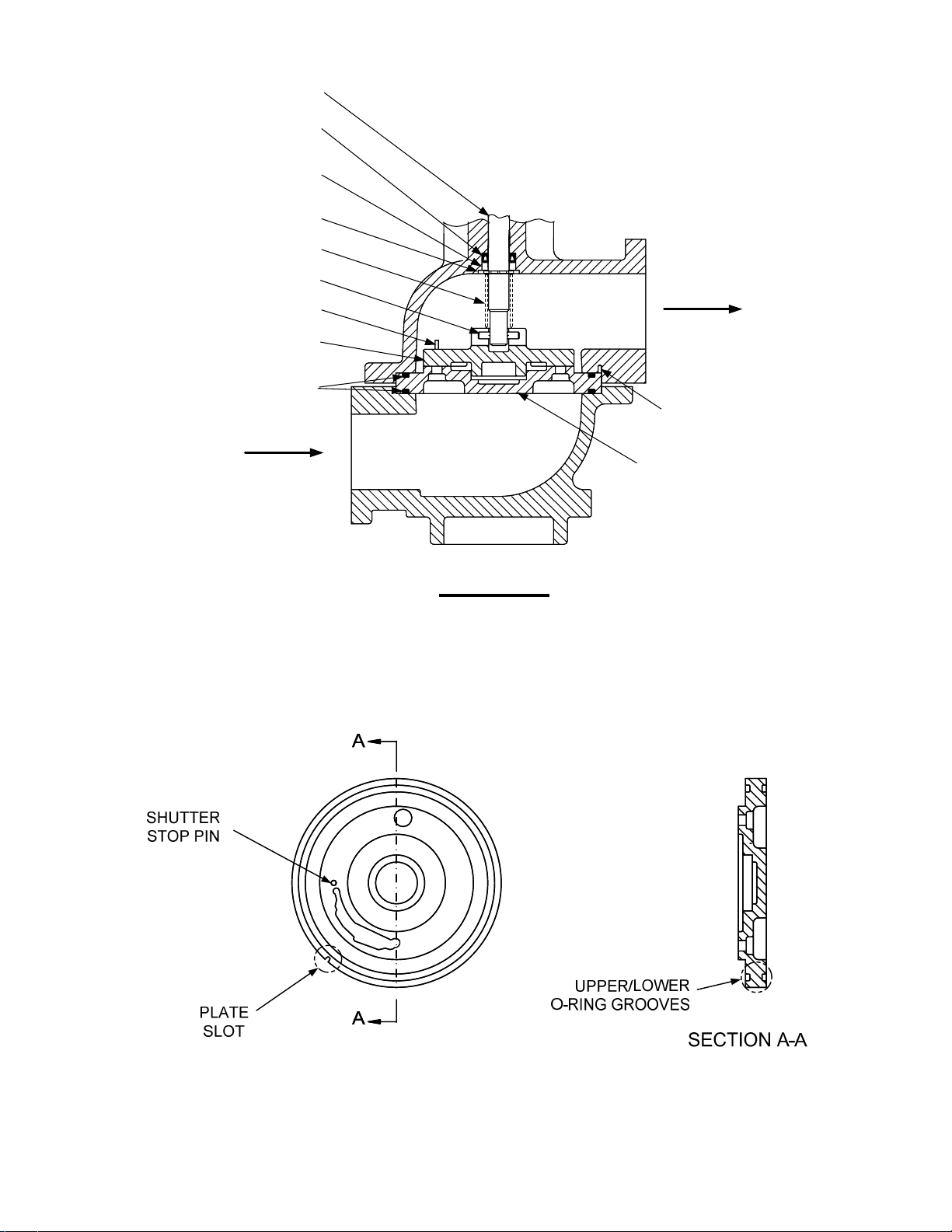

3. Separate the upper and lower portions of the valve body to access the gas plate as shown in

Figure 9.

4. Remove the existing gas plate with upper/lower O-rings from the Air/Fuel Valve.

5. Obtain the replacement low NOx gas plate and O-rings from the Conversion Kit. Apply O-ring

lube (Dow-Corning Compound #111, or equiv.) to the replacement O-rings and install them in

the grooves on the gas plate.(Figure 10).

6. Refer to the cut-away view in Figure 9. Ensure that the valve components are positioned as

shown in the upper valve body.

7. Position the low NOx gas plate so that the plate slot engages the locating pin in the upper

valve body (Figure 9). Also, ensure that the shutter stop pin (Figures 9 and 10) is facing the

upper portion of the valve body.

8. Apply LocTite No. 242 (Blue), or equivalent, to the threads of the four 1/4-20 hex head

machine screws removed in step 2. Reassemble and secure the lower and upper portions of

the valve body by alternately tightening the four 1/4-20 machine screws.

10

Page 11

STEPPER

MOTOR

COVER

AIR INLET

VALVE BODY

(UPPER)

VALVE BODY

(LOWER)

A

(SEE FIGURE 9)

A

1/4-20 HEX HEAD

SCREWS (4)

GAS INLET

Figure 8. Air/Fuel Valve Modification

11

Page 12

VALVE SHAFT

SPRING RING-

SHAFT SEAL

SHAFT SEAL-

BACKUP WASHER

RETAINING RING

PRE-LOAD SPRING

SHAFT DRIVE PIN

SHUTTER STOP PIN

GAS VALVE

SHUTTER

GAS PLATE

O-RINGS (2)

FUEL OUTLET

PLATE LOCATING

PIN

FUEL INLET

GAS PLATE

VIEW A - A

Figure 9. Air/Fuel Valve – Partial Cross-Sectional View

Figure 10. Low NOx Gas Plate

12

Page 13

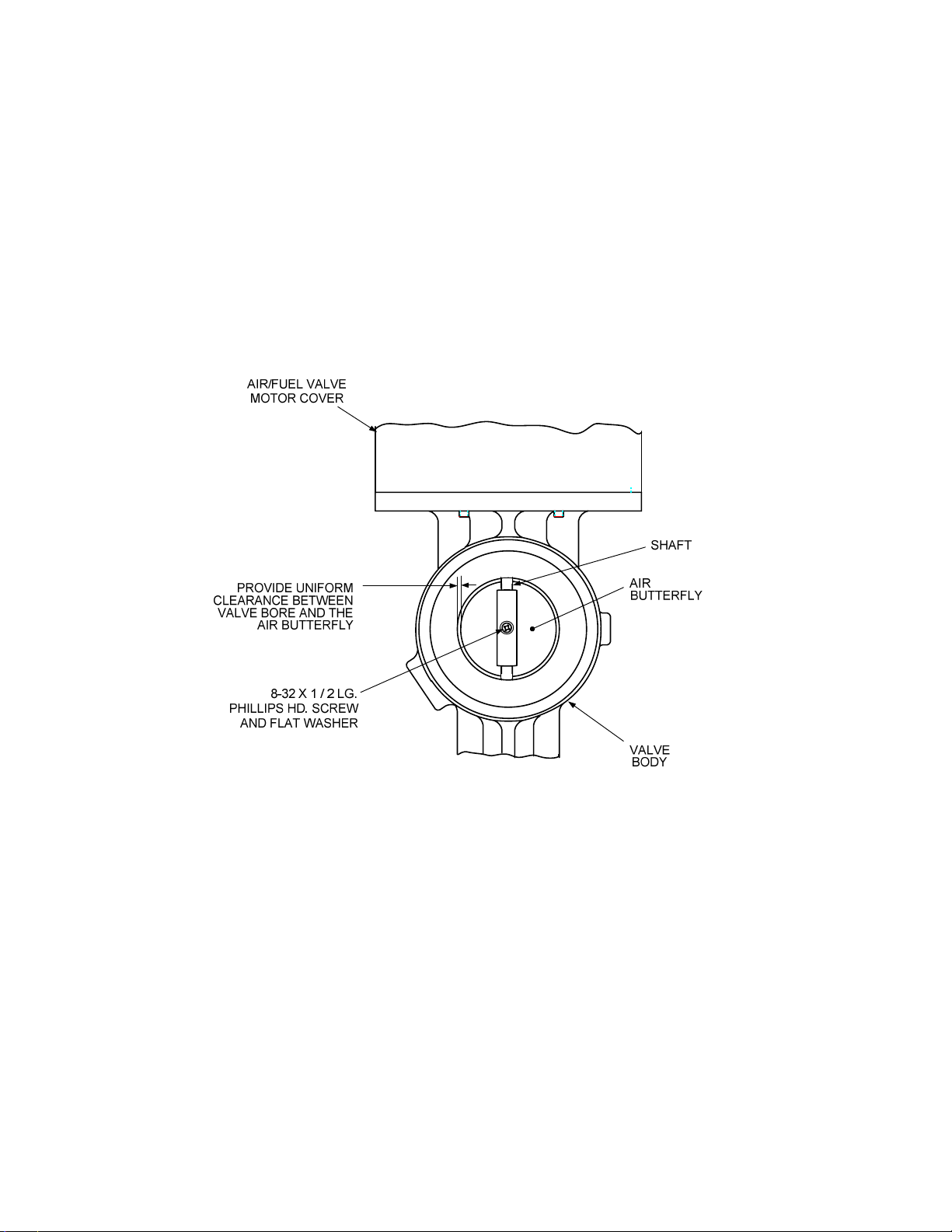

9. Next, remove the #8-32 screw securing the existing air butterfly to the Air/Fuel Valve shaft

(Figure 11) and remove the butterfly.

10. Apply a small amount of LocTite No. 222 (purple) to the #8-32 screw threads and install the

new air butterfly and flat washer provided in the Conversion Kit onto the shaft. Center the

butterfly so that there is equal clearance between the valve bore and the edges of the butterfly.

11. Manually open and close the butterfly several times to ensure that it is properly positioned on

the shaft with equal clearances around the valve bore

12. This completes the Air/Fuel Valve modifications. The modified Air/Fuel Valve is now ready to

be reinstalled using the procedures in Section 4.

Figure 11. Air Butterfly Replacement

3.2 Differential Gas Pressure Regulator Modification

The modification to be made to the Differential Gas Pressure Regulator consist of removing the exist

spring and replacing it with the new plated spring provided in the Conversion Kit. Proceed as follows:

1. Remove the cap on the Differential Gas Pressure Regulator (Figure 12).

2. Remove the adjustment screw and the installed regulator spring from the Differential Gas

Pressure Regulator.

3. Install the replacement plated spring provided in the Conversion Kit.

13

Page 14

IMPORTANT

It is important that the adjustment screw be installed to a depth of 2 inches

from the top of the regulator housing. This will simplify combustion calibration

of the unit after all low NOx modifications are completed.

4. Replace the adjustment screw and rotate the screw clockwise to a depth of 2 inches from the

top of the regulator housing.

5. Replace the regulator cap and gasket and ensure that the cap is firmly secured. This

completes the modification of the Differential Gas Pressure Regulator.

REGULATOR CAP

CAP GASKET

ADJUSTMENT

SCREW

SPRING

(PARTIALLY

REMOVED)

DIFFERENTIAL GAS

PRESSURE REGULATOR

Figure 12. Differential Gas Pressure Regulator Modification

14

Page 15

4. EQUIPMENT REPLACEMENT & REINSTALLATION

The parts provided in the Low NOx Conversion Kit will differ slightly, depending on whether the

KC1000 is equipped with a Siemens SSOV (-1 or -2 Kit) or a Honeywell SSOV (-3 or -4 Kit). See

paragraph 1.2 for kit contents. Following removal and/or modification of all the required parts and

assemblies, replace or reinstall these items as follows:

NOTE

Unless otherwise specified, the following steps apply to all KC1000 Boilers

and Water Heaters, regardless of the type of SSOV installed.

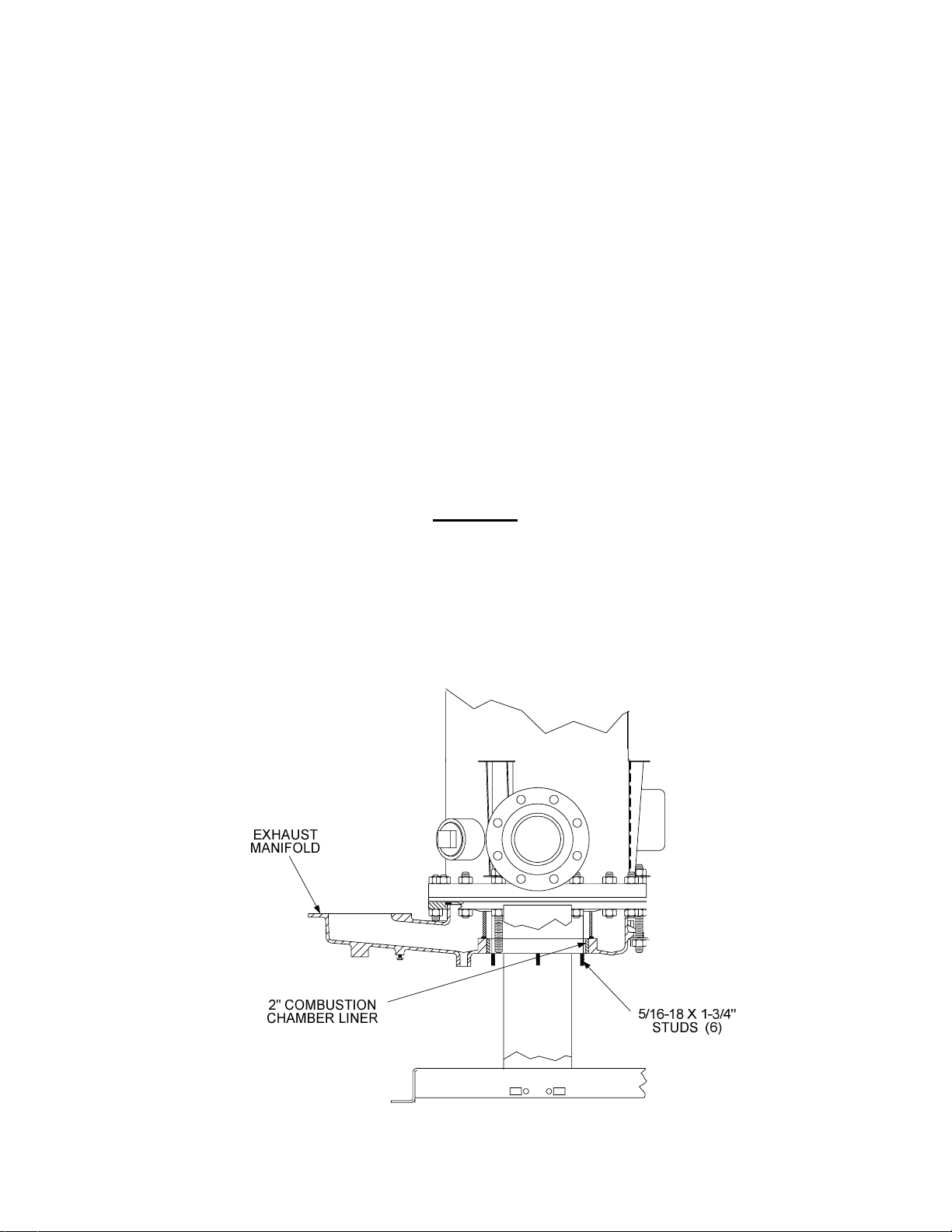

1. Install the six new 5/16”-18 x 1-3/4” studs provided in the Kit in the Exhaust Manifold as

follows:

(a) Apply LocTite 620 (or equivalent) to the manifold-end of the stud threads.

(b) Thread the ends of the studs into the tapped holes in the bottom of the Exhaust Manifold

as shown in Figure 13. Ensure that they are fully inserted and secure. These studs will

be used to secure the new Low NOx Burner to the manifold.

CAUTION

THE EXHAUST MANIFOLD OPENING IS SLIGHTLY TAPERED. THEREFORE, USE CARE WHEN INSTALLING THE COMBUSTION CHAMBER

LINER TO AVOID DAMAGE.

2. Position and install the new 2 inch Combustion Chamber Liner using the steps shown in

Figure 14. Position the Liner so it is flush with the bottom of the Exhaust Manifold (Figure 13)

Figure 13. Exhaust Manifold Studs and Combustion Chamber Liner Location

15

Page 16

Figure 14. Installation of Combustion Chamber Liner

NOTE

The next item to be installed is the new Low NOx Burner Assembly provided

in the Conversion Kit. To simplify installation and avoid component damage, it

will be necessary to temporarily remove several components from the Low

NOx Burner Assembly.

3. Remove the new Low NOx Burner from the Conversion Kit. Refer to Figure 15 and temporarily

remove the following components and assemblies from the Low NOx Burner:

(a) Remove the Igniter and Flame Detector Assemblies.

(b) Remove the 1/8” NPT nipple and the 1/4” O.D. tubing from the Burner Shell.

(c) Loosen the top screw on the two-way connector and slide it off the ground stud.

(d) Remove the 10-32 hex nut from the ground stud.

(e) Remove the two bolts securing the Burner Head to the Shell.

(f) Separate the Burner Head from the Burner Shell.

(g) Proceed to step 4.

16

Page 17

Figure 15. Low NOx Burner Components

17

Page 18

4. Due to space limitations, the new Low NOx Burner Head and Shell must be temporarily

separated as described in the previous step and installed as follows:

(a) First, insert the Burner Head inside the Heat Exchanger.

(b) While hold the Head in the raised position, place the Fiber Frax Gasket and Burner Shell

under the unit.

(c) Lower the Burner Head and align it so that the ground stud shown in Figure 16 is aligned

with the hole in the Shell flange. Also, ensure that the Shell air inlet is positioned as

shown.

(d) Raise the complete Low NOx Burner Assembly and secure it to the Heat Exchanger studs

using the six 5/16-18 hex nuts removed from the old burner.

(e) Next, install the 1/4” O.D. tube and 1/8” NPT nipple (3” long) as shown in Figure 17.

Ensure that the 1/4” tube is inserted into the staged ignition orifice piece. Thread the

nipple into the tapped hole in the bottom of the Burner Shell.

(f) Refer to Figure 19 and remove the 1/8” street elbow from the outlet end

of the Staged

Ignition Assembly provided in the Conversion Kit.

NOTE

The Staged Ignition Assembly part number provided in the Low NOx

Conversion Kit will depend on whether the unit being converted is equipped

with a Siemens or a Honeywell SSOV. Kits 124918-1 and -2 contain Staged

Ignition Assembly part no. 124867 for use with Siemens SSOVs. Kits 1249183 and -4 contain Staged Ignition Assembly part no. 124983 for use with

Honeywell SSOVs.

(g) Attach the street elbow to the 3” nipple and securely tighten the nipple to the Burner Shell.

18

Page 19

IGNITION

TRANSFORMER

EXHAUST

MANIFOLD

2" COMBUSTION

CHAMBER LINER

5/16-18 X 1-3/4"

STUDS (6)

STAGED IGNITION

ORIFICE PIECE

GROUND

STUD

Figure 16. Low NOx Burner Installation

BURNER

HEAD

FIBER FRAX

GASKET

AIR INLET

BURNER SHELL

19

Page 20

Figure 17. Installation of Staged Ignition Tube and Nipple

5. Reinstall the Exhaust Manifold insulation (Figure 4) using three 1/4-20 screws and fender

washers.

6. Reinstall the modified Air/Fuel Valve (Figure 18) as follows:

(a) Connect the blower-to-valve air hose and clamp at the Air/Fuel Valve inlet as shown in

Figure 18. Do Not tighten the hose clamp at this time.

(b) Ensure that the flange O-ring is installed between the Air/Fuel Valve gas inlet flange and

the Differential Gas Pressure Regulator outlet flange.

(c) Using two 9/16” wrenches, secure the Air/Fuel Valve to the Differential Gas Pressure

Regulator with two 3/8-16 bolts and hex nuts.

(d) Tighten the hose clamp on the blower-to-valve air hose at the Air/Fuel Valve inlet.

(e) Using an 11/16” wrench, secure the feedback tube between the Air/Fuel Valve and

Regulator by tightening the two compression fittings (Figure 18).

(f) Reconnect the two wire leads to the Blower Proof Switch.

(g) Reconnect the Air/Fuel Valve wiring harness to the Control Box.

7. Install the Gas Inlet Pipe (Figure 18) between the Air Fuel Valve gas outlet and the Low NOx

Burner gas inlet as follows:

(a) Insert flange O-rings in the inlet and outlet sides of the gas pipe.

(b) Position the Gas Inlet Pipe so it is aligned with the 1/4-20 studs on the Burner and the

Air/Fuel Valve gas outlet flange.

20

Page 21

(c) Secure the Gas Inlet Pipe to the Air/Fuel Valve with two 3/8-16 bolts and hex nuts.

(d) Secure the Pipe to the Burner with four 1/4-20 hex nuts.

(e) Reinstall the valve-to-burner air hose and clamps between the Air/Fuel Valve outlet and

Burner inlet. Tighten both clamps.

NOTE

Figure 18 shows the installation details for both the modified Air/Fuel Valve

and the Gas Inlet Pipe. Install these items in the order specified in steps 6

and 7.

Figure 18. Air/Fuel Valve and Gas Inlet Pipe Installation

The next item to be installed is the new Staged Ignition Assembly shown in Figure 19. As this

8.

Figure shows, there are two versions of this assembly; one for use with Siemens SSOVs (part

no. 124867) and one for use with Honeywell SSOVs (part no. 124983). Mechanically, the

outlet side of both Staged Ignition Assembly models connect to the Low NOx Burner.

However, the inlet side connections of Staged Ignition Assembly models differ as follows:

• Staged Ignition Assembly 124867 (used with Siemens SSOVs) inlet side connects to the

downstream port directly on the Siemens SSOV.

• Staged Ignition Assembly 124983 (used with Honeywell SSOVs) inlet side connects to the

port on the gas cock located downstream of the Honeywell SSOV.

Electrically, the solenoid valve on each of these assemblies is connected to the KC wiring

harness power leads going to the ignition transformer. The mechanical connections are

provided in steps 9, 10 and 11. The electrical connections are provided in step 13.

21

Page 22

Figure 19. Staged Ignition Assemblies – Part No. 124867 & 124983

22

Page 23

NOTE

The 1/8” street elbow shown in Figure 19 was previously removed in step 4(f)

and attached to the 3” nipple on the Low NOx Burner Shell.

9. The outlet side connection for the Staged Ignition Assembly is the same regardless which type

of SSOV (Siemens or Honeywell) is installed on the KC1000. Proceed as follows:

(a) Loosen the 1/4“ NPT union on the Staged Ignition Assembly (Figure 19) provided in the kit

and separate the 9” nipple and 1/4” to 1/8” reducing coupling from the assembly.

(b) Connect the reducing coupling to the 1/8” street elbow already attached to the Low NOx

Burner (Figure 20).

GROUND

CONNECTOR

1/8" NPT

NIPPLE

(3" LONG)

STREET

ELBOW

REDUCING

COUPLING

1/4" NPT NIPPLE

GAS INLET

(9" LONG)

PIPE

Figure 20. Staged Ignition Assembly Outlet Side Connection

10. The inlet side connection for the Staged Ignition Assembly depends on which type of SSOV

(Siemens or Honeywell) is installed in the KC1000. Proceed as follows:

(a) Refer to Figure 19. For the Staged Ignition Assembly provided in the kit, disconnect the

1/2” flex gas hose at the inlet side from the 1/2” to 1/4” reducing coupling shown in Figure

19 for the applicable assembly.

23

Page 24

(b) If the KC1000 is equipped with a Siemens SSOV, remove the 1/4” NPT plug from the

downstream port on the SSOV. Connect the inlet side (flex gas hose and nipple) of the

Staged Ignition Assembly (part no. 124867) to this 1/4” NPT port as shown in Figure 21.

LOW PRESSURE

GAS SWITCH WITH

NPT REDUCER

BLOWER

GAS

INLET

SSOV

STAGED IGNITION ASSY

FLEX GAS HOSE

CONNECT TO 1/4" NPT

DOWNSTREAM PORT

KC1000 PARTIAL TOP VIEW

Figure 21. Staged Ignition Assembly Inlet Connection For Siemens SSOV

(c) For a Honeywell SSOV, remove the 1/8” plug from the inboard side of the gas cock shown

in Figure 22. Connect the inlet side of the Staged Ignition Assembly (part no. 124983)

containing the 5” long 1/8” NPT nipple to the gas cock port.

24

Page 25

Figure 22 Staged Ignition Assembly Inlet Connection For Honeywell SSOV

11. After the Staged Ignition outlet and inlet connections are completed, reconnect the 1/4“ NPT

union at the Burner side (outlet) and the flex gas hose at the SSOV side (inlet) to the

remaining assembly components (Figure 19).

12. The Solenoid Valve on the Staged Ignition Assembly is electrically connected to the Ignition

Transformer power leads using the 2-Wire Solenoid Valve Harness provided in the Conversion

Kit (Figure 23). Proceed as follows:

(a) Connect the two Solenoid Valve power leads to the FASTON terminals of the wiring

harness.

(b) Remove the cover on the Ignition Transformer.

(c) Refer to Figure 23 and remove the two wire nuts connecting power leads 140 and 141 to

the Ignition Transformer. Connect the two stripped Solenoid harness leads to power leads

140 and 141 and the Transformer leads as shown.

(d) Resecure the wiring connections using the wire nuts.

(e) Replace the cover on the Ignition Transformer.

(f) Connect the Solenoid Valve Ground lead to the Ground connector on the Low NOx Burner

Shell flange (Figure 20).

25

Page 26

13. Next, install the Igniter and Flame Detector in the Low NOx Burner (Figure 24) as follows:

(a) Prior to installing the Igniter in the Low NOx Burner, a conductive

anti-seize compound

MUST be applied to the Igniter threads.

(b) Install the Igniter at the location shown in Figure 24. Do Not over-tighten.

(c) Connect the Igniter cable from the Ignition Transformer.

(d) Install the Flame Detector at the location shown in Figure 24. Do Not over-tighten.

(e) Reconnect the Flame Detector lead.

Figure 23. Solenoid Valve Wiring Harness and Connections

26

Page 27

Figure 24. Igniter and Flame Detector Installation

14. Reinstall the Low Pressure Gas Switch shown in Figure 6 (Siemens SSOV) or Figure 7

(Honeywell SSOV). Reconnect the two switch wire leads. There is no polarity to observe

when reconnecting these leads.

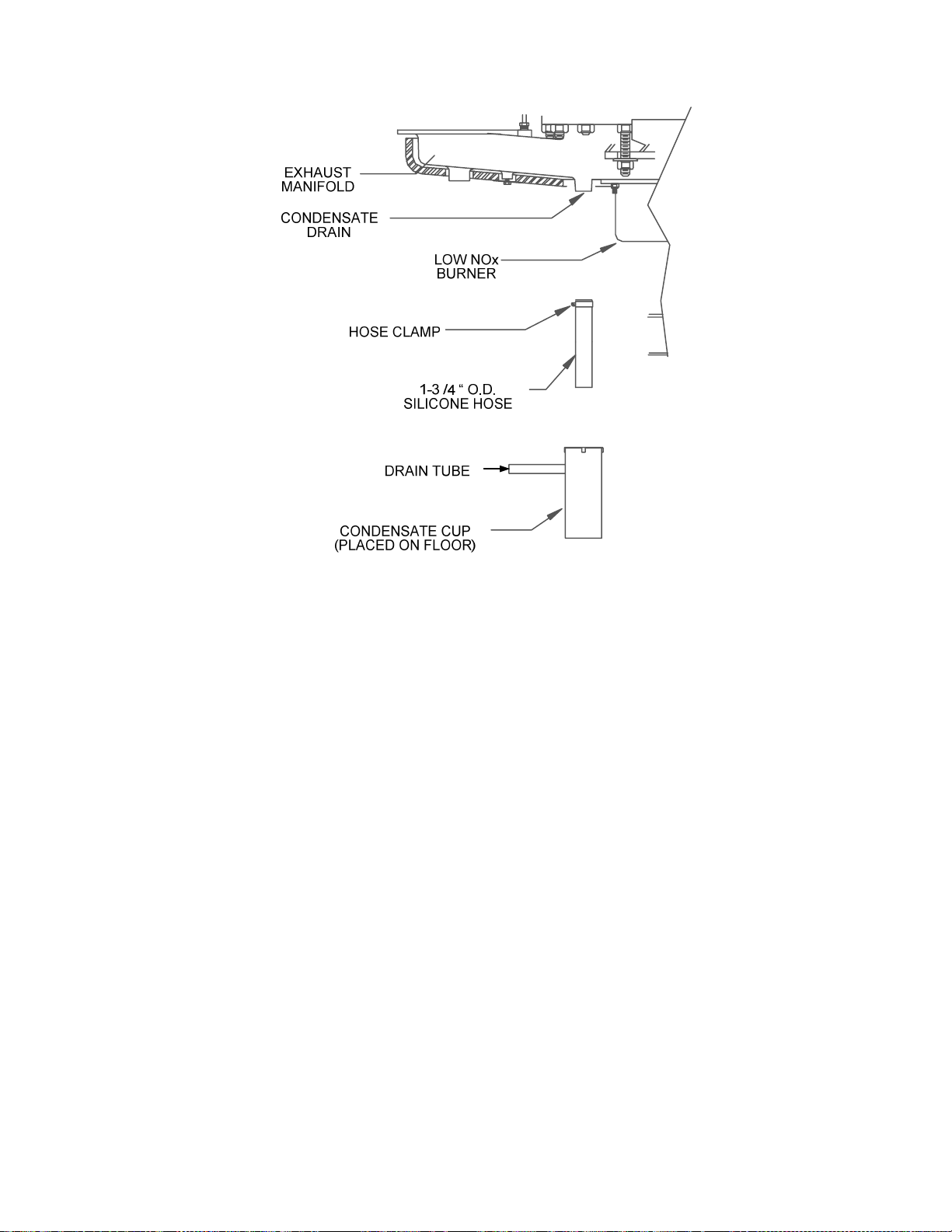

15. Refer to Figure 25 and install the condensate drain components at the rear of the unit as

follows:

(a) Attach the 1-3/4” O.D. condensate drain hose to the exhaust manifold (Figure 25) and

insert the hose into the condensate cup. Allow the cup to rest on the floor directly beneath

the condensate drain.

(b) Connect a length of 3/4” tubing to the condensate cup drain tube and route it to a floor

drain.

27

Page 28

Figure 25. Condensate Drain Assembly Location

16. Prior to proceeding to the next step, check to ensure that the igniter, flame detector and

ground leads are secure on the Low NOx Burner. Also, check to ensure that the ball valve in

the Staged Ignition Assembly (Figure 19) is in the open position.

17. Replace the rear covers, top cover and side panels on the unit.

18. Attach the appropriate Low NOx labels to the unit as follows:

(a) Attach the SCAQMD/TCEQ LOW NOx label to the front of the unit directly beneath the

“For parts replacement …” label as shown in Figure 26.

(b) Attach the appropriate Heater or Boiler UL Label and Specification Label to the front of the

unit (Figure 26).

(c) On the left side of the unit, attach the “Igniter & Flame Detector Replacement” label over

the currently installed replacement label at the location shown in Figure 27.

28

Page 29

Aerco KC Gas Fir ed

U

L

GAS-FIRED BOILER

FOR USE WITH INTEGRAL

CONTROLS

INTENDED FOR USE WITH UL LISTED SPECIAL GAS VENT

FOR USE WITH CATEGORY III OR IV GAS APPLIANCES WITH

MANUFACTURERS INSTRUCTIONS FOR F URTHER VENTING

DETAILS.

For parts assistan ce during norm al business ho urs

call your loca l sales repres entative or . ..

Aerco International at 1-800-526 -0288.

Hot Water Boiler

Aerco KC Gas Fired Hot Water Boiler

INVERSE EFFICIENCY CURVE

99%

THIS PRODUCT COMPLIES WITH NOx EMISSIONS

STANDARDS OUTLINED IN SOUT H COAST AIR

QUALITY MANAGEMENT DISTRICT ( SCAQMD )

RULE 1146.2 AND TEXAS COMMISION ON

ENVIRONMENTAL QUALI TY ( TCEQ ), TITLE 30,

CHAPTER 117, RULE 117.465, WHEN INSTALLED

AND OPERATED IN ACCORDANCE WITH AERCO

INSTALLATION, OPERATION, & MAINTENANCE

INSTRUCTIONS.

INTERNATIONAL INC.

86%

FIRING RATE

7%

Specifications

Net Input...................................................................

Net Output.................................................................

ASME Maximum Working Pressure............................

Electrical Requirements............................................

Maximum Water Flow................................................

Water Pressure

Drop..................................................

OR

Aerco KC Gas Fired Commercial Water Heater

Recovery Capacity

Temp. Rise (F)

60 70

80 90

GPH

15941860

Specifications

Net Input………………………………………….

Net Output………………………………………….

ASME Maximum Working Pressure...............

Electrical Requirements………………………..

Standby Power Consumption........................

Adjustable Control Range……………………...

Maximum Continuous Water Flow.............................

Water Pressure Drop………………………....

Water Volum e……………… …………………...

Gas Pressure Requirements..........................

1,000,000 BTU/Hr

860,000 to 930,000 BTU/Hr

150 PSIG @ 250F

120/1/60 20 AMP

50F to 220F

25 GPM

150 GPM

0.1 psi @ 100 GPM

23 gallons

9.5" WC min. @ full load

14" WC maximum static

100 110

111612401395

1014

1,000,000 BTU/Hr

930,000 BTU/Hr

160 PSIG @ 210F

120/1/60 20 AMP

40 watts

100F to 195F

30 GPM

0.7 psi @ 20 GPM

23 gallons

9.5" WC min. @ full load

14" WC maximu m stati c

100%

120

930

BOILER

140

130

797

859

HEATER

PARTIAL FRONT VIEW

Figure 26. Low NOx Labels – Front View

29

Page 30

Figure 27. Low NOx Labels – Side View

19. This completes replacement or reinstallation of all required parts and assemblies. Proceed to

Section 5 - Post-Installation Setup and Calibration.

30

Page 31

5. POST-INSTALLATION SETUP AND CALIBRATION

Following installation of all Low NOx Conversion Kit items, it will be necessary to adjust several

operating parameters using the unit’s Control System menus. In addition, combustion calibration

procedures MUST be performed to ensure Low NOx compliance, prior to placing the unit into service.

The procedures in this section are divided into the following main categories:

• Low NOx Operating Parameter Menu Changes

• Combustion Calibration Setup

• Combustion Calibration Procedures for Units With C-More or Modular Control Systems

• Combustion Calibration Procedures for Units With Digital (CCC) Control Systems

• Unit Reassembly

These procedures are provided in paragraphs 5.1 through 5.5 respectively. For more detailed

information on the operation of your KC1000 unit, refer to the applicable Operation & Maintenance

Manual for the installed Control System as follows:

Unit

KC1000 Boiler GF-109LN GF-106 GF-102

KC1000 Heater GF-111LN GF-105 GF-101

C-More Control

System

Modular Control

System

Digital (CCC) Control

System

NOTE

If the KC1000 is equipped with an older style Digital (CCC) Control System,

no menu changes are required.

5.1 Control System Menu Changes for Low NOx Operation

If the KC1000 is equipped with either a C-More or Modular Control System, several menu changes

may need to be made to ensure Low NOx compliance. These changes will depend on which type of

control system is installed and whether the unit is a boiler or water heater.

5.1.1 Post-Purge Timeout For C-More Control System

If the unit is equipped with a C-More Control System, adjust the Post-Purge Timer in the Factory

Menu to 10 seconds as follows:

1. Apply external AC power to the unit.

2. Set the Control Box ON/OFF switch to OFF.

3. Access the Password entry in the Setup menu.

4. Enter and store the Factory Password (2807). Password 3 will be displayed indicating that the

valid Factory password has been entered.

5. Next, scroll through the Factory Menu until Post Purge Timer is displayed.

6. Set the Post Purge Timer menu option to 10 sec. and store the entry.

31

Page 32

7. This completes the Post Purge Timer menu setting.

8. If the unit is a Water Heater, go directly to paragraph 5.1.2 (Breakpoints) before the entered

Factory Password times out (after 1 hour). If the unit is a Boiler, no further menu changes are

required.

NOTE

The Breakpoint Adjustment procedures specified in paragraph 5.1.2 apply

only to KC1000 Water Heaters containing either a C-More or Modular Control

System.

5.1.2 Water Heater Breakpoint Adjustments

The water heater breakpoint settings for a Low NOx KC1000 are different than the breakpoints for a

standard unit. Therefore, the appropriate menu items must be adjusted. For C-More Control

Systems, the breakpoints are adjusted for fire rate increments of 10% using the Tuning Menu. For

Modular Control Systems, the breakpoints are adjusted using the Secondary Menu. Adjust the

breakpoints to the values shown in the following Table for the firing rates shown:

IMPORTANT

Prior to adjusting the breakpoint settings shown in the following Table, ensure

that the Water Heater active setpoint is set to 130°F. Following completion of

the breakpoint adjustments, the active setpoint temperature can be readjusted

if necessary.

Water Heater Breakpoint Settings For Low NOx

Firing Rate

100% Breakpoint At 100% bp A 64°F

90% Breakpoint At 90% bp 0 63°F

80% Breakpoint At 80% bp 9 66°F

70% Breakpoint At 70% bp 8 74°F

60% Breakpoint At 60% bp 7 83°F

50% Breakpoint At 50% bp 6 93°F

40% Breakpoint At 40% bp 5 103°F

30% Breakpoint At 30% bp 4 112°F

20% Breakpoint At 20% bp 3 115°F

C-More Display

Modular

Display

Required

Breakpoint

10% Breakpoint At 10% bp 2 128°F

0% Breakpoint At 0% bp 1 135°F

32

Page 33

5.2 Combustion Calibration Setup

Prior to performing Combustion Calibration procedures in paragraph 5.3 or 5.4, the unit must be set

up as follows:

5.2.1 Installing The Supply Gas Manometer

1. Close the manual gas supply valve upstream of the unit.

2. Refer to Figure 28 and remove the 1/4” or 1/8” NPT pipe plug from the port on the inlet side of

the Siemens or Honeywell SSOV.

3. Install a barbed fitting into the pipe plug tapping.

4. Attach one end of a length of plastic tubing to the barbed fitting and one end to the 16" W.C.

manometer.

Figure 28. Installation of Supply Gas Manometer

5.2.2 Preparing the Flue Vent Probe Hole

1. If the unit has been installed using the recommended AL29-4C vent, there will be a 3/8” hole,

18” to 24” above the exhaust manifold. The outer vent section, that covers vent connections,

must be loosened and moved to uncover the hole (see Figure 29).

2. If so equipped, adjust the stop on the combustion analyzer probe so that it extends into the

flue gas flow without hitting the opposite wall of the flue. Do not insert the probe at this time.

33

Page 34

Figure 29. Analyzer Probe Hole Location

5.2.3 Installing The Differential Regulator Adjustment Tool

1. Remove the cap from the differential pressure regulator (see Figure 30).

2. Place the gasket from the regulator cap onto the regulator adjustment tool.

3. Prior to Installing the tools on the regulator, pull up the tool's screwdriver blade. Then, thread

the tool into the regulator.

4. Engage the tool’s screwdriver blade into the regulator’s adjustment screw slot.

Figure 30. Regulator Adjustment Tool Installation

34

Page 35

5.3 Combustion Calibration For Units With C-More or Modular Control Systems

The Combustion Calibration procedures for KC1000 Boilers or Water Heaters equipped with either CMore or Modular Control Systems are virtually identical. Using the following procedures will minimize

readjustment of combustion.

NOTE

For a review of the control panel operating procedures for the installed control

system, refer to Section 3 of the appropriate O & M Manual listed in paragraph

5.

1. Open the supply and return valves to the unit and ensure that the system pumps are running.

Open the gas supply valve(s) to the unit.

2. If a lockup style regulator is installed as a gas supply regulator, adjust the gas supply until a

reading of 12” W.C. static pressure is obtained.

3. Set the ON/OFF switch to the OFF position. Turn on AC power to the unit.

4. Set the unit to the Manual Mode.

5. Adjust the firing rate to 0%.

6. Set the ON/OFF switch to ON.

7. Change the firing rate to 25%. This will put the unit in the starting sequence.

NOTE

On initial start-up, or return to service from a fault condition, the unit will

remain at a 29% firing rate for two-minutes, although the control signal may

indicate a greater input.

8. Following the warm-up period, increase the firing rate in 20% increments while monitoring the

gas pressure after every increase. If gas pressure dips below 9.5” W.C. for FM gas trains and

9.9” for IRI gas trains at any input firing rate percentage, stop and raise the pressure. Once

100% is reached, adjust the gas pressure for 9.5” (FM) W.C. or 9.9” W.C. (IRI).

NOTE

If 9.5” W.C. for FM gas trains or 9.9” W.C. for IRI gas trains cannot be

obtained at the 100% firing rate, it will be necessary to stop calibration and

contact the local AERCO representative in your area. Running the unit on

insufficient gas pressure will void the warranty.

9. Once 9.5” W.C. or 9.9” W.C. is set at the 100% level change the firing rate to 30%. Insert the

combustion analyzer probe into the stack.

35

Page 36

NOTE

Always approach a firing rate percentage from the same direction, (i.e., 100%

to 30%, 30% to 20%, etc.). Whenever going to an increased firing rate from

below (i.e., 20% to 30%), first go above and then back down to the desired

firing rate. This is necessary due to hysteresis in the air/fuel stepper motor.

Hysteresis causes the air/fuel valve to stop in a slightly different position if the

firing rate percentage is approached from below or above. This results in a

difference in oxygen readings for the same firing rate percentage causing

unnecessary recalibration.

9. Allow enough time for the combustion analyzer to settle. Compare the measured oxygen level

to the oxygen range for intake air temperature in Table 1. Also, ensure that the carbon

monoxide (CO) and nitrogen oxide (NOx) readings do not exceed the values shown.

Table 1

Combustion Oxygen Levels for a 30% Firing Rate

Inlet Air

Temp

Oxygen

(±0.2%)

40°F 6.7 % <100 ppm <23.8 ppm

50°F 6.5 % <100 ppm <24.1 ppm

60°F 6.3 % <100 ppm <24.4 ppm

75°F 6.0 % <100 ppm <24.9 ppm

85°F 5.7 % <100 ppm <25.4 ppm

90°F 5.6 % <100 ppm <25.6 ppm

100°F 5.4 % <100 ppm <25.9 ppm

*Tabulated data are uncorrected ppm NOx values and will be less than or equal to 30 ppm of

NOx when corrected to 3% oxygen.

Carbon

Monoxide

*NOx

10. If the measured oxygen level, CO and NOx emissions are within the ranges shown in Table 1,

no adjustment is necessary. Proceed to step 16.

11. If the measured oxygen level is below the range in Table 1, rotate the differential regulator

adjustment tool counterclockwise 1/4 to 1/2 revolution to decrease gas flow.

12. Wait for the combustion analyzer to settle, then compare the new oxygen reading to Table 1.

Repeat adjustment until oxygen is within the specified range.

13. If the measured oxygen level is above the oxygen range in Table 1, rotate the differential

regulator adjustment tool clockwise 1/4 to 1/2 revolution to increase gas flow.

14. Wait for the analyzer reading to settle, then compare the new reading to Table 1. Repeat

adjustment until oxygen is within the specified range.

NOTE

Adjust only the differential regulator at 30% control signal; do not adjust the air

shutter.

15. Once the oxygen level is within the specified range at 30%, change the firing rate to 16%.

36

Page 37

16. Oxygen levels at the 16% firing rate should be as shown in Table 2. Also, ensure that the CO

and NOx readings do not exceed the values shown. No adjustment should be necessary.

Contact the Factory if the oxygen, CO or NOx levels are not within the specified ranges.

Table 2

Combustion Oxygen Levels for a 16% Firing Rate

Inlet Air

Temp

Oxygen

(± 0.2%)

40°F <10% <100 ppm <20 ppm

50°F <10% <100 ppm <20 ppm

60°F <10% <100 ppm <20 ppm

75°F <10% <100 ppm <20 ppm

85°F <10% <100 ppm <20 ppm

90°F <10% <100 ppm <20 ppm

100°F <10% <100 ppm <20 ppm

*Tabulated data are uncorrected ppm NOx values and will be less than or equal to 30 ppm of NOx

when corrected to 3% oxygen.

Carbon

Monoxide

*NOx

17. Change the firing rate to 100%. After the combustion analyzer has settled, compare the

measured oxygen level with the levels in Table 3.

18. If the measured oxygen reading is below the oxygen range in Table 3, loosen the two bolts

that secure the inlet air shutter to the unit using a 7/16” wrench (see Figure 31). Open the

shutter 1/4” to 1/2” to increase the oxygen level, then tighten the nuts.

19. Wait for the analyzer to settle then compare the new oxygen reading to Table 3. Repeat the

inlet air shutter adjustment until the oxygen is within the specified range. Also, ensure that the

CO and NOx emissions do not exceed the values shown. Firmly tighten the inlet air shutter

locking nuts when finished.

Table 3

Combustion Oxygen Levels for a 100% Firing Rate

Inlet Air

Temp

Oxygen

(±0.2%)

40°F 8.8 % <100 ppm <20.3 ppm

50°F 8.1 % <100 ppm <21.4 ppm

60°F 7.5 % <100 ppm <22.5 ppm

75°F 6.5 % <100 ppm <24.1 ppm

85°F 5.8 % <100 ppm <25.3 ppm

90°F 5.3 % <100 ppm <26.1 ppm

*Tabulated Data are uncorrected ppm NOx values and will be less than or equal to 30 ppm of

NOx when corrected to 3% oxygen.

100°F 4.8 % <100 ppm

Carbon

Monoxide

*NOx

37

Page 38

Figure 31. Air Shutter Locking Nut Location

NOTE

At 30% firing rate, adjust only the differential pressure regulator. At 100%

firing rate, adjust only the inlet air shutter.

20. If the measured oxygen reading is above the oxygen range in Table 3, loosen the two 7/16"

locking nuts securing the inlet air shutter. Close the air shutter 1/4” to 1/2” to decrease the

oxygen level and tighten the two nuts.

21. Allow the analyzer to settle then compare the new oxygen reading to Table 3.

22. Repeat the adjustment until the oxygen is within the specified range. Also, ensure that the CO

and NOx readings do not exceed the values shown. Firmly tighten the inlet air shutter locking

nuts when finished.

NOTE

Adjust the inlet air shutter only at 100% firing rate. Do not adjust the

differential pressure regulator.

23. Change the firing rate to 30%. Allow time for the combustion analyzer to settle. Check the

measured oxygen level, CO and NOx emissions to ensure that they are still within the ranges

shown in Table 1.

24. Continue these procedures until all oxygen levels are within the ranges specified in Tables 1, 2

and 3.

25. Record all readings on the AERCO start-up sheet provided with each unit. Proceed to

paragraph 5.5 when all natural gas combustion calibration procedures are completed.

38

Page 39

5.4 Combustion Calibration For Units With Digital (CCC) Control Systems

The Combustion Calibration procedures for KC1000 Boilers or Water Heaters equipped with older

style Digital (CCC) Control Systems differ from those used for C-More or Modular Control Systems.

The primary difference is that the combustion readings are checked at different low and mid-range fire

rates. In addition, the Control Panel display shows the manual fire rate in % for KC Boilers and in

Volts (1.0 to 5.0) for KC Water Heaters. Using the following procedures will minimize readjustment of

combustion.

NOTE

For a review of the control panel operating procedures for the installed control

system, refer to Section 3 of GF-101 (Water Heater) or GF-102 (Boiler).

1. Open the supply and return valves to the unit and ensure that the system pumps are running.

Open the gas supply valve(s) to the unit.

2. If a lockup style regulator is installed as a gas supply regulator, adjust the gas supply until a

reading of 12” W.C. static pressure is obtained.

3. Set the unit to the MANUAL mode.

4. With the display showing the Power Level, rotate the MANUAL adjustment to display 25%

(Boiler) or 2.0 volts (Water Heater).

5. Press the green ON button if the unit is not already ON.

NOTE

On initial start-up, or return to service from a fault condition, the unit will

remain at a 29% firing rate for two-minutes, although the control signal may

indicate a greater input.

In the following steps and Tables, firing rates for KC1000 Boilers are shown in

% and the corresponding firing rates for Water Heaters are shown in

parentheses in volts (V).

6. Following the warm-up period, increase the firing rate in 25% (1.0V) increments while

monitoring the gas pressure after every increase. If gas pressure dips below 9.5” W.C. for FM

gas trains and 9.9” for IRI gas trains at any input firing rate percentage, stop and raise the

pressure. Once 100% (5.0V) is reached, adjust the gas pressure for 9.5” (FM) W.C. or 9.9”

W.C. (IRI).

NOTE

If 9.5” W.C. for FM gas trains or 9.9” W.C. for IRI gas trains cannot be

obtained at the 100% firing rate, it will be necessary to stop calibration and

contact the local AERCO representative in your area. Running the unit on

insufficient gas pressure will void the warranty.

7. Once 9.5” W.C. or 9.9” W.C. is set at the 100% (5V) level, change the firing rate to 25%

(2.0V). Insert the combustion analyzer probe into the stack.

39

Page 40

NOTE

Always approach a firing rate percentage from the same direction, (i.e., 100%

to 25%, 25% to 20%, etc.). Whenever going to an increased firing rate from

below (i.e., 25% to 30%), first go above and then back down to the desired

firing rate. This is necessary due to hysteresis in the air/fuel stepper motor.

Hysteresis causes the air/fuel valve to stop in a slightly different position if the

firing rate percentage is approached from below or above. This results in a

difference in oxygen readings for the same firing rate percentage causing

unnecessary recalibration.

8. Allow enough time for the combustion analyzer to settle. Compare the measured oxygen level

to the oxygen range for intake air temperature in Table 4. Also, ensure that the carbon

monoxide (CO) and nitrogen oxide (NOx) readings do not exceed the values shown.

Table 4

Combustion Oxygen Levels for a 25% (2.0V) Firing Rate

Inlet Air

Temp

Oxygen

(±0.2%)

40°F 6.7 % <100 ppm <23.8 ppm

50°F 6.5 % <100 ppm <24.1 ppm

60°F 6.3 % <100 ppm <24.4 ppm

75°F 6.0 % <100 ppm <24.9 ppm

85°F 5.7 % <100 ppm <25.4 ppm

90°F 5.6 % <100 ppm <25.6 ppm

100°F 5.4 % <100 ppm <25.9 ppm

*Tabulated data are uncorrected ppm NOx values and will be less than or equal to 30 ppm of

NOx when corrected to 3% oxygen.

Carbon

Monoxide

*NOx

9. If the measured oxygen level, CO and NOx emissions are within the ranges shown in Table 4,

no adjustment is necessary. Proceed to step 14.

10. If the measured oxygen level is below the range in Table 4, rotate the differential regulator

adjustment tool counterclockwise 1/4 to 1/2 revolution to decrease gas flow.

11. Wait for the combustion analyzer to settle, then compare the new oxygen reading to Table 4.

Repeat adjustment until oxygen is within the specified range.

12. If the measured oxygen level is above the oxygen range in Table 4, rotate the differential

regulator adjustment tool clockwise 1/4 to 1/2 revolution to increase gas flow.

13. Wait for the analyzer reading to settle, then compare the new reading to Table 4. Repeat

adjustment until oxygen is within the specified range.

NOTE

Adjust only the differential regulator at 25% (2.0V) control signal; do not adjust

the air shutter.

14. Once the oxygen level is within the specified range at 25% (2.0V), change the firing rate to

10% (1.4V).

40

Page 41

15. Oxygen levels at the 10% (1.4V) firing rate should be as shown in Table 5. Also, ensure that

the CO and NOx readings do not exceed the values shown. No adjustment should be

necessary. Contact the Factory if the oxygen, CO or NOx levels are not within the specified

ranges.

Table 5

Combustion Oxygen Levels for a 10% (1.4V) Firing Rate

Inlet Air

Temp

Oxygen

(± 0.2%)

Carbon

Monoxide

*NOx

40°F <10% <100 ppm <20 ppm

50°F <10% <100 ppm <20 ppm

60°F <10% <100 ppm <20 ppm

75°F <10% <100 ppm <20 ppm

85°F <10% <100 ppm <20 ppm

90°F <10% <100 ppm <20 ppm

100°F <10% <100 ppm <20 ppm

*Tabulated data are uncorrected ppm NOx values and will be less than or equal to 30 ppm of NOx

when corrected to 3% oxygen.

16. Change the firing rate to 100%. After the combustion analyzer has settled, compare the

measured oxygen level with the levels in Table 6.

Table 6

Combustion Oxygen Levels for a 100% (5.0V) Firing Rate

Inlet Air

Temp

Oxygen

(±0.2%)

Carbon

Monoxide

*NOx

40°F 8.8 % <100 ppm <20.3 ppm

50°F 8.1 % <100 ppm <21.4 ppm

60°F 7.5 % <100 ppm <22.5 ppm

75°F 6.5 % <100 ppm <24.1 ppm

85°F 5.8 % <100 ppm <25.3 ppm

90°F 5.3 % <100 ppm <26.1 ppm

100°F 4.8 % <100 ppm

*Tabulated Data are uncorrected ppm NOx values and will be less than or equal to 30 ppm of

NOx when corrected to 3% oxygen.

17. If the measured oxygen reading is below the oxygen range in Table 6, loosen the two bolts

that secure the inlet air shutter to the unit using a 7/16” wrench (see Figure 4.4). Open the

shutter 1/4” to 1/2” to increase the oxygen level, then tighten the nuts.

18. Wait for the analyzer to settle then compare the new oxygen reading to Table 6. Repeat the

inlet air shutter adjustment until the oxygen is within the specified range. Also, ensure that the

CO and NOx emissions do not exceed the values shown. Firmly tighten the inlet air shutter

locking nuts when finished.

41

Page 42

NOTE

At 25% (2.0V) firing rate, adjust only the differential pressure regulator. At

100% (5.0V) firing rate, adjust only the inlet air shutter.

19. If the measured oxygen reading is above the oxygen range in Table 6, loosen the two 7/16"

locking nuts securing the inlet air shutter. Close the air shutter 1/4” to 1/2” to decrease the

oxygen level and tighten the two nuts.

20. Allow the analyzer to settle then compare the new oxygen reading to Table 6.

21. Repeat the adjustment until the oxygen is within the specified range. Also, ensure that the CO

and NOx readings do not exceed the values shown. Firmly tighten the inlet air shutter locking

nuts when finished.

NOTE

Adjust the inlet air shutter only at 100% (5.0V) firing rate. Do not adjust the

differential pressure regulator.

22. Change the firing rate to 25% (2.0V). Allow time for the combustion analyzer to settle. Check

the measured oxygen level, CO and NOx emissions to ensure that they are still within the

ranges shown in Table 4.

23. Continue these procedures until all oxygen levels are within the ranges specified in Tables 4, 5

and 6.

24. Record all readings on the AERCO start-up sheet provided with each unit. Proceed to

paragraph 4.4 when all natural gas combustion calibration procedures are completed.

5.5 Unit Reassembly Following Combustion Calibration

Once combustion calibration is set properly, the unit can be reassembled for permanent operation.

1. Set the ON/OFF switch to the OFF position. Disconnect AC power from the unit.

2. Shut off the gas supply to the unit.

3. Remove any regulator adjustment tools by first pulling up the screwdriver blade to disengage it

from the regulator adjusting screw, and then turning the tool out of the top of the regulator.

4. Apply a drop of silicone adhesive to the regulator adjusting screw to lock its setting.

Remove the gasket from the tool and place it back onto the regulator cap.

5. Reinstall the cap and gasket back on the regulator. Tighten the cap using a screwdriver or

wrench.

6. Remove all of the manometers and barbed fittings and reinstall the pipe plugs using a suitable

thread compound.

7. Remove the combustion analyzer probe from the vent hole. Seal the probe hole and replace

the vent connection cover.

8. Replace the unit’s panels and hood.

The KC1000 is now ready for Low NOx operation.

42

Page 43

Loading...

Loading...