Page 1

DIGITAL GROUND RESISTANCE

AND SOIL RESISTIVITY TESTER

6472

ENGLISH

Find Quality Products Online at: sales@GlobalTestSupply.com

User Manual

www.GlobalTestSupply.com

Page 2

Statement of Compliance

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

certifies that this instrument has been calibrated

using standards and instruments traceable to

international standards.

We guarantee that at the time of shipping your

instrument has met its published specifications.

An NIST traceable certificate may be

requested at the time of purchase, or obtained

by returning the instrument to our repair and

calibration facility, for a nominal charge.

The recommended calibration interval for this

instrument is 12 months and begins on the date of

receipt by the customer

Serial #: ________________________________

Catalog #: ______________________________

Model #: 6472

Please fill in the appropriate date as indicated:

Date Received:

Date Calibration Due: _______________________

_________________________________

Chauvin Arnoux®, Inc.

d.b.a AEMC® Instruments

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

READ CAREFULLY BEFORE

USING FOR THE FIRST TIME

Your instrument is equipped with a NiMH battery. This technology oers several

advantages:

• Long battery charge life for a limited volume and weight.

• Possibility of quickly recharging your battery.

• Signicantly reduced memory eect: you can recharge your

battery even if it is not fully discharged.

• Respect for the environment: no pollutant materials such as lead

or cadmium, in compliance with the applicable regulations.

After prolonged storage, the battery may be completely discharged. If so, it must

be completely recharged.

Your instrument may not function during part of this recharging operation.

Full recharging of a completely discharged battery may take several hours.

NOTE: In this case, at least 5 charge/discharge cycles will be necessary

for your battery to recover 95% of its capacity.

To make the best possible use of your battery and extend its eective service life:

• Only use the charger supplied with your instrument. Use of

another charger may be dangerous.

• Only charge your instrument at temperatures between 0° and 40°C.

• Comply with the conditions of use dened in the operating manual.

• Comply with the storage conditions specied in the operating

manual.

NiMH technology allows a limited number of charge/discharge cycles depending

signicantly on:

• The conditions of use.

• The charging conditions.

Please refer to § 9.5 for correct replacement of the battery.

Do not dispose of the battery pack with other solid waste. Used batteries

must be entrusted to a qualied recycling company or to a company

specialized in processing hazardous materials.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Table of Contents

1. INTRODUCTION ............................................................................... 6

1.1 International Electrical Symbols ...........................................................7

1.2 Denition of Measurement Categories .................................................7

1.3 Receiving Your Shipment .....................................................................7

1.4 Ordering Information ............................................................................7

1.4.1 Kits, Accessories and Replacement Parts ..............................8

2. PRODUCT FEATURES .................................................................... 10

2.1 Description .........................................................................................10

2.2 Key Features ...................................................................................... 11

2.3 Control Features ................................................................................12

2.4 Display ...............................................................................................13

2.5 Button Functions ................................................................................15

3. SPECIFICATIONS........................................................................... 16

3.1 Reference Conditions.........................................................................16

3.2 Electrical .............................................................................................16

3.2.1 Frequency Measurements ....................................................16

3.2.2 Voltage Measurements .........................................................16

3.2.3 Current Measurements .........................................................17

3.2.4 DC Resistance Measurements .............................................18

3.2.5 AC Earth Resistance Measurements ....................................19

3.2.6 Soil Resistivity Measurement ρ ............................................21

3.2.7 Earth/Ground Potential Measurements V Pot .......................22

3.2.8 Earth/Ground Measurements with 2 Clamps ........................23

3.3 Data Storage ......................................................................................23

3.4 Power .................................................................................................23

3.5 Mechanical .........................................................................................24

3.6 Environmental ....................................................................................24

3.7 Safety .................................................................................................25

4. OPERATION .................................................................................. 26

4.1 General Operating Instructions ..........................................................26

4.1.1 Automatic Mode ....................................................................26

4.1.2 Manual (Expert) Mode ..........................................................26

4.2 Instrument Conguration (SET-UP mode) .........................................27

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 5

5. AUTOMATIC MODE ........................................................................ 28

5.1 Switching the Test Voltage .................................................................28

5.2 Resistance Measurement mΩ (2-Wire) ..............................................28

5.2.1 Lead Compensation Measurement ......................................29

5.2.2 Alarm Function ......................................................................30

5.3 Resistance Measurement mΩ (4-Wire) ..............................................31

5.4 Earth/Ground Measurement (3-Pole) .................................................32

5.4.1 62% Method ..........................................................................32

5.4.2 Full Method ...........................................................................34

5.4.3 Recommendations for a Reliable Measurement ...................35

5.5 Earth/Ground Measurement (4-Pole) .................................................36

5.5.1 Measurement without a Clamp .............................................36

5.5.2 Measurements with a Clamp ................................................37

5.6 Soil Resistivity Measurements (ρ Position) ........................................39

5.6.1 Advantages/Disadvantages of Wenner and Schlumberger ..39

5.6.2 Changing the Measurement Method.....................................40

5.6.3 Programming the Distance for Electrode Placement ............40

5.6.4 Wenner Method ....................................................................41

5.6.5 Schlumberger Method...........................................................43

5.7 Potential Measurement (V pot) ..........................................................44

5.8 Earth/Ground Measurements with Two Clamps .................................46

6. MANUAL MODE ............................................................................ 48

6.1 Switching the Test Voltage .................................................................48

6.2 Measurement Frequency Selection ...................................................49

6.3 Manual Settings for mΩ Measurements ............................................49

6.3.1 Continuity Test ......................................................................50

6.4 3-Pole Earth/Ground Measurement & Coupling .................................. 50

6.4.1 3-Pole Earth/Ground Measurements ....................................50

6.4.2 Earth/Ground Coupling Measurements ................................50

6.5 4-Pole Earth/Ground Measurements .................................................52

6.6 Soil Resistivity Measurements ...........................................................52

6.7 Earth/Ground Potential Measurements ..............................................52

6.8 Measurements with Two Clamps .......................................................52

6.9 SWEEP Mode ....................................................................................53

6.10 Smoothing ..........................................................................................53

Ground Resistance Tester Model 6472

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

7. MEMORY FUNCTION ..................................................................... 54

7.1 Saving Measurements into Memory...................................................54

7.2 Recalling Measurements from Memory .............................................55

7.3 Erasing Measurements from Memory ................................................55

7.3.1 Erasing All Measurements ....................................................55

7.3.2 Erasing Selective Measurements .........................................56

8. DATAVIEW® SOFTWARE ................................................................ 57

8.1 Installing DataView® ...........................................................................57

8.2 Connecting the Model 6472 to your Computer ..................................60

8.3 Opening the Ground Tester Control Panel .........................................61

8.3.1 Establishing Communication to the Instrument.....................62

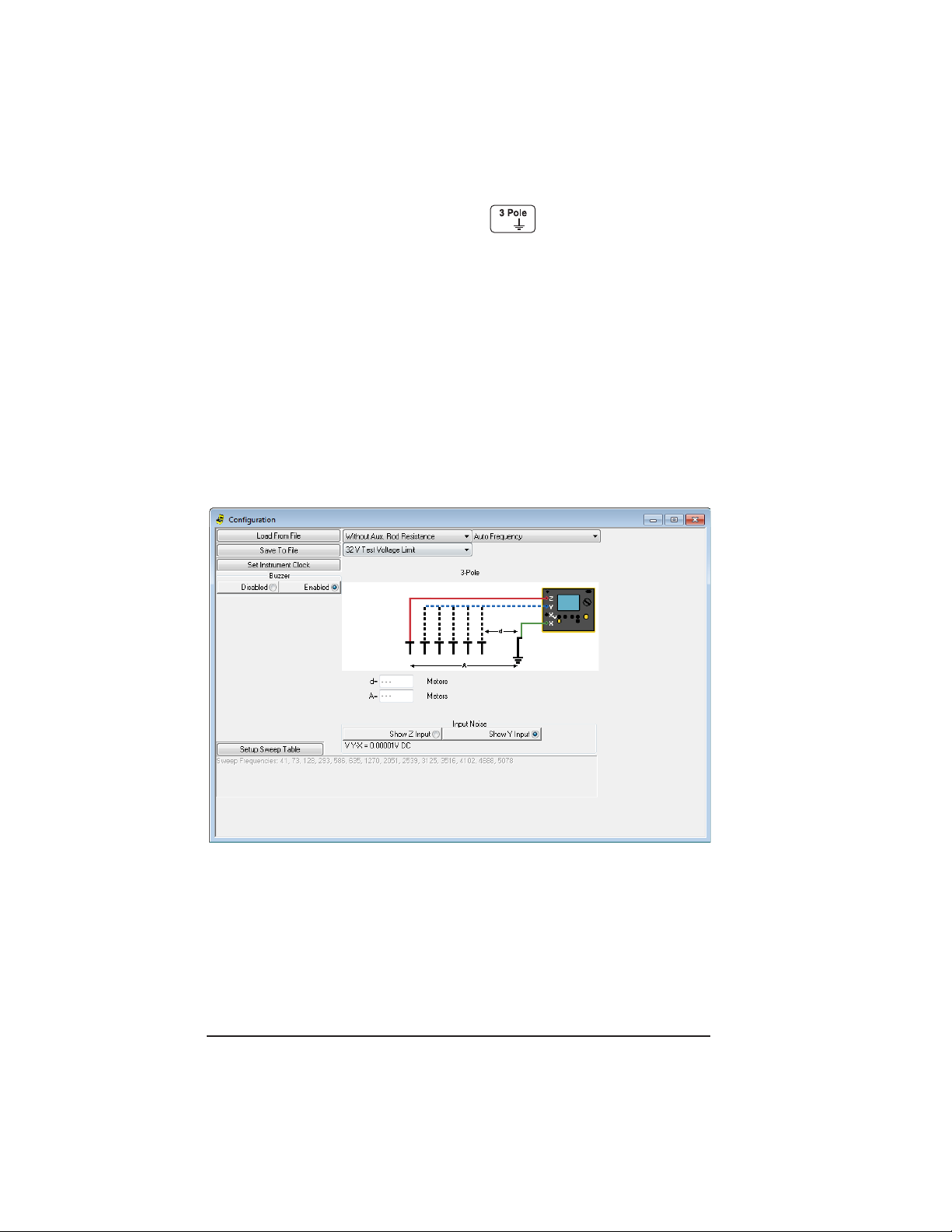

8.4 Conguring the Instrument .................................................................62

8.4.1 DC Continuity Test

8.4.2 3-Pole Ground Resistance Test

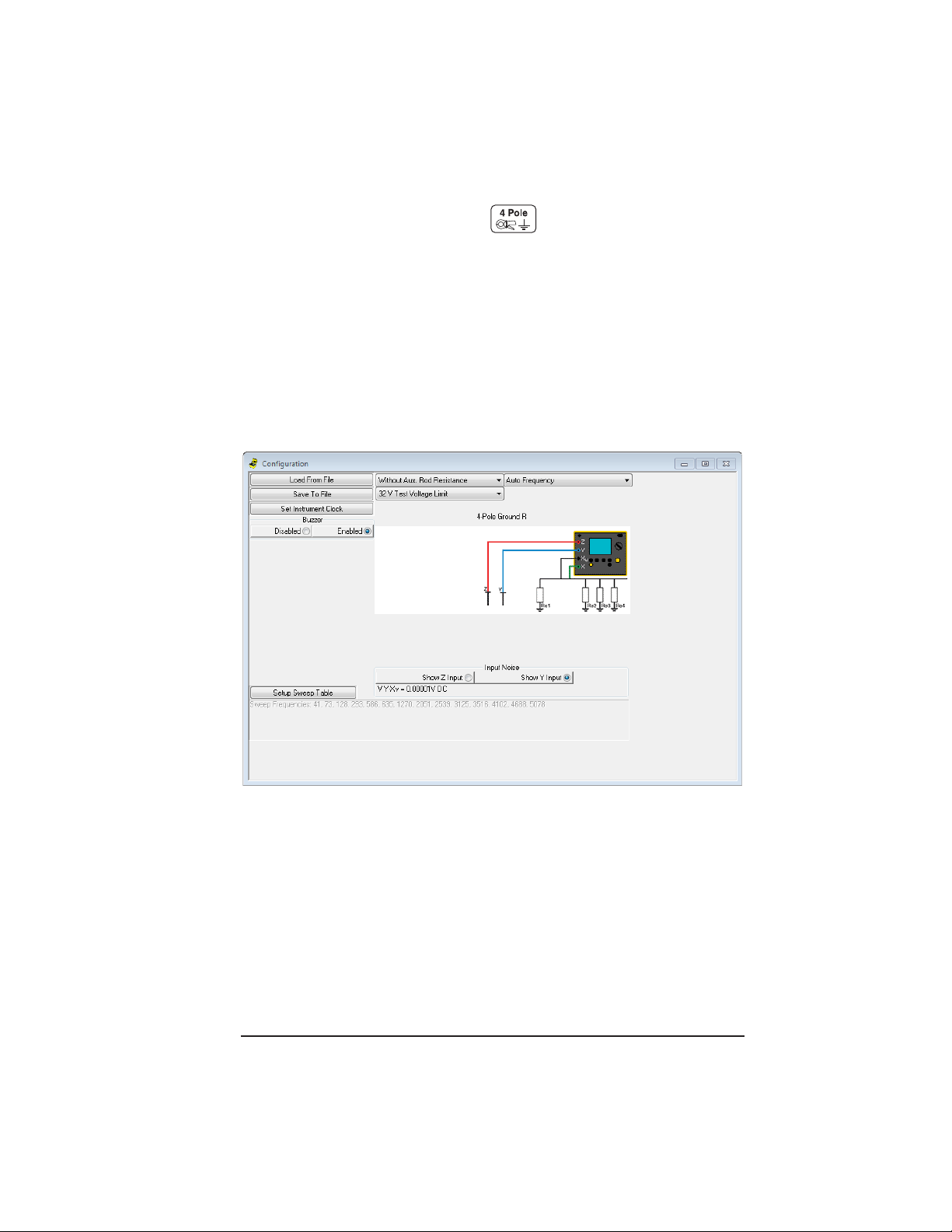

8.4.3 4-Pole Ground Resistance

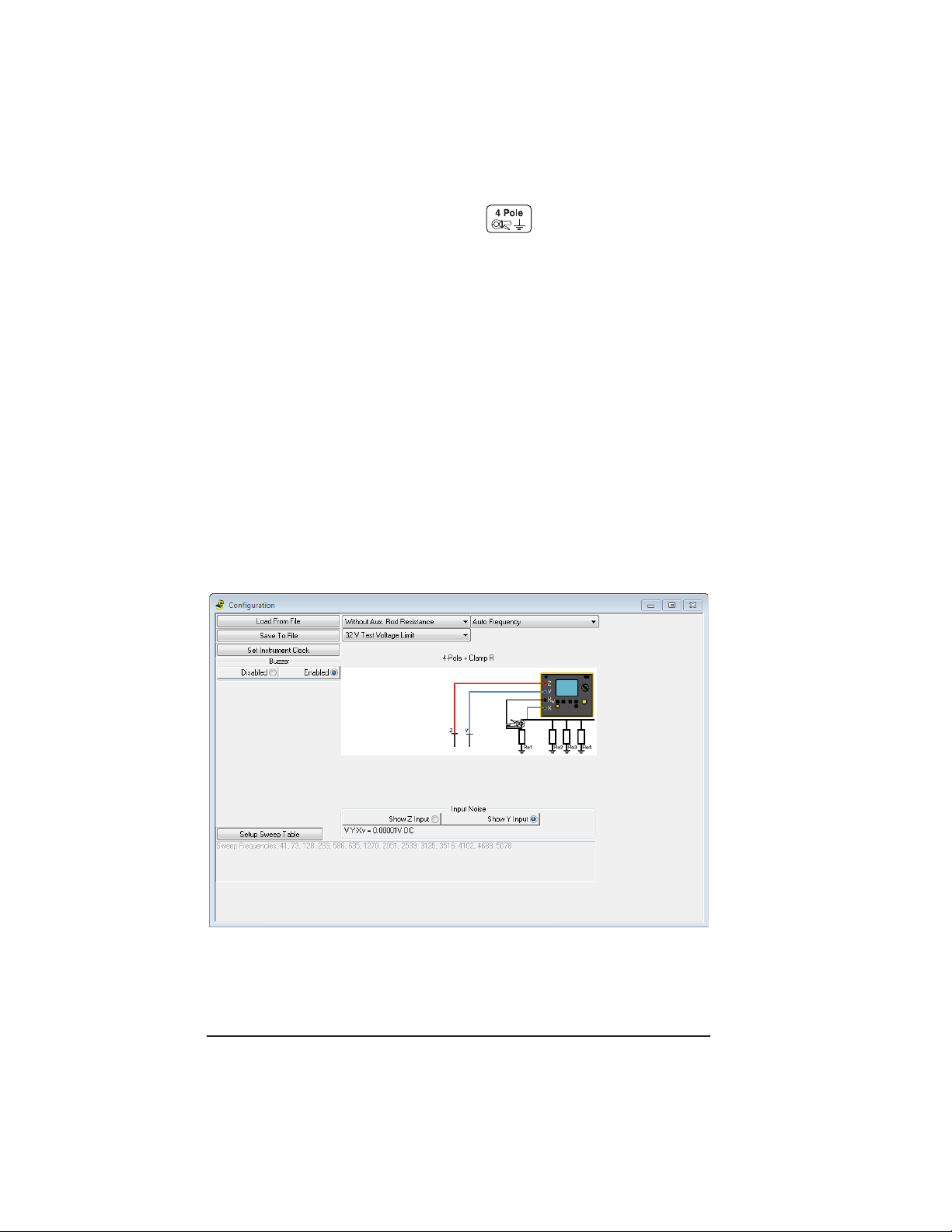

8.4.4 4-Pole Plus Clamp Resistance

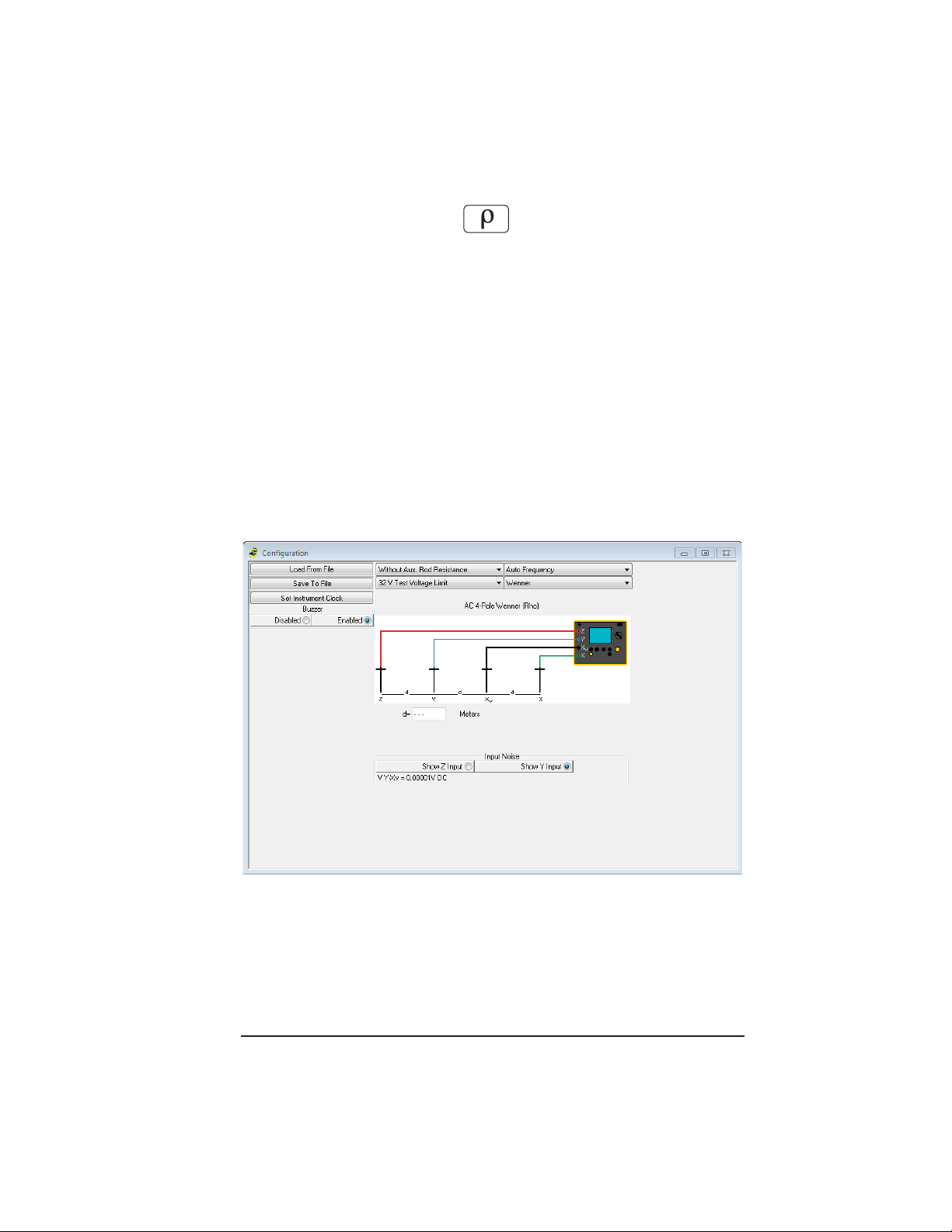

8.4.5 4-Pole Soil Resistivity

8.4.6 Ground Potential

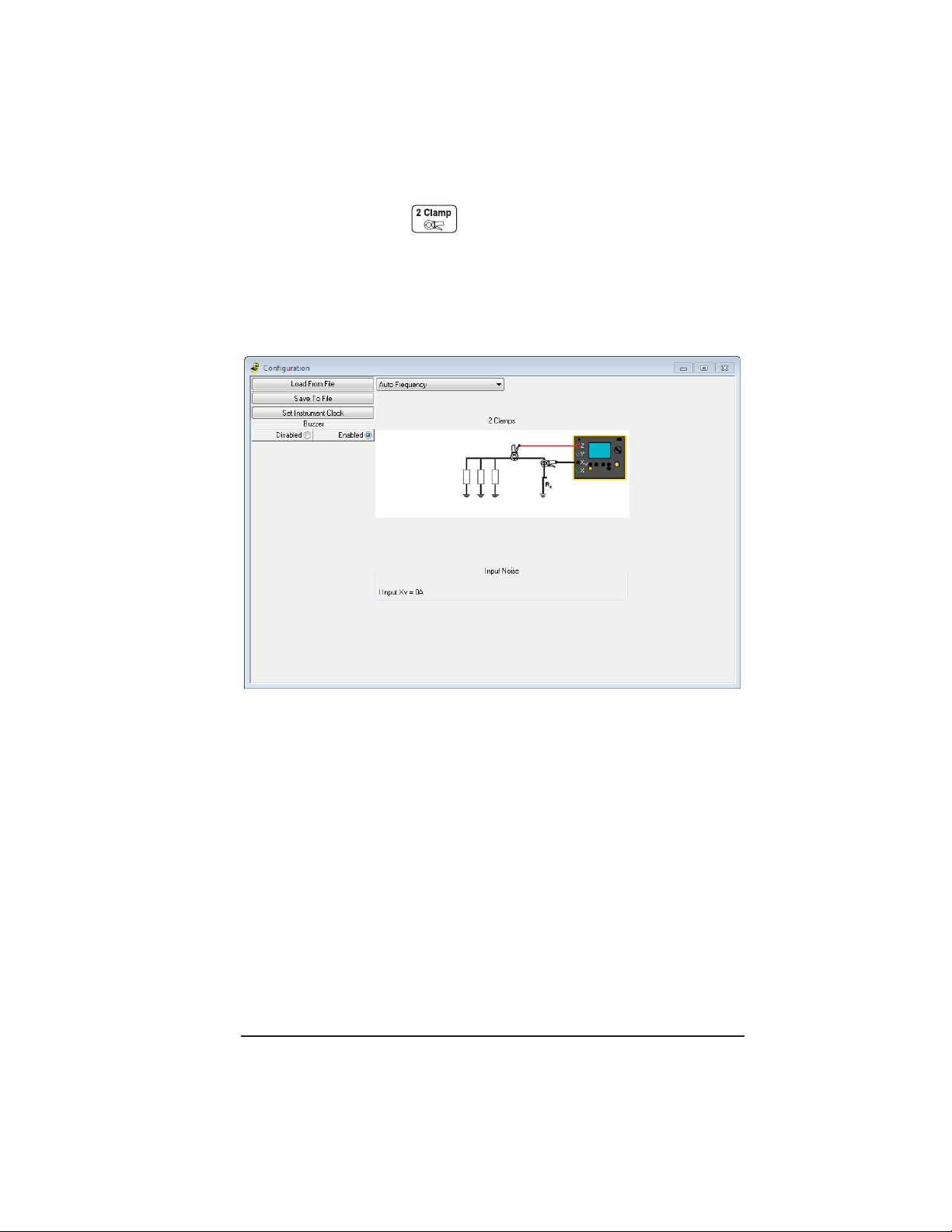

8.4.7 Ground Loop R

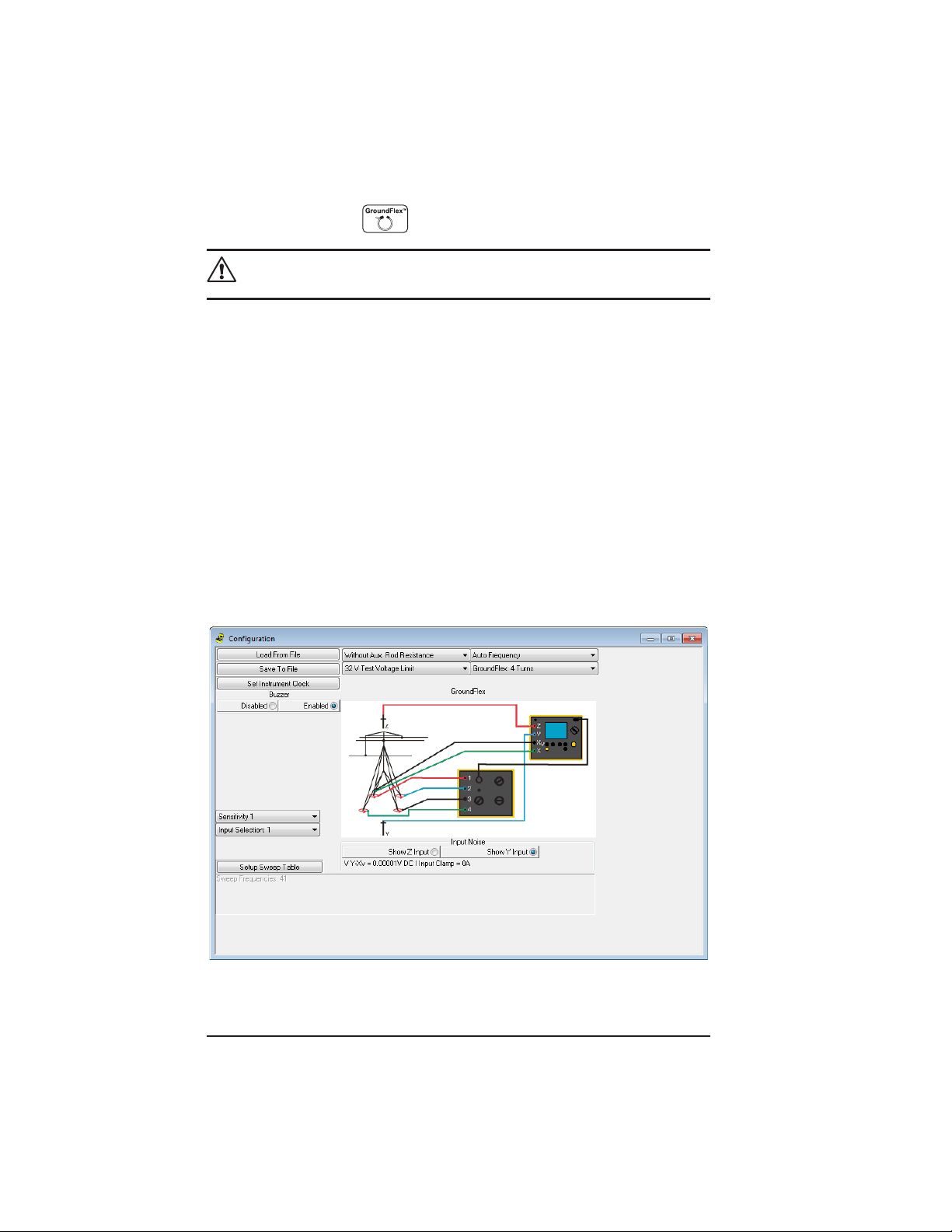

8.4.8 GroundFlex®

8.5 Tools Menu .........................................................................................71

8.5.1 Tools > Options .....................................................................71

8.5.2 Tools > Colors .......................................................................71

8.5.3 Tools > Recover Data ...........................................................71

8.6 Starting a Test ....................................................................................71

8.7 Downloading Data to Database .........................................................71

8.7.1 Recordings ............................................................................72

8.7.2 Session Properties ................................................................72

8.8 Exporting the Report to a PDF File ......................................................73

...............................................................63

...........................................64

...................................................65

............................................66

..........................................................67

..................................................................68

....................................................................69

.........................................................................70

9. MAINTENANCE ............................................................................. 74

9.1 Maintenance.....................................................................................74

9.2 Cleaning ...........................................................................................74

9.3 Fuse Replacement ...........................................................................74

9.4 Recharging the Battery ....................................................................76

9.5 Replacing the Battery .......................................................................77

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 7

10. TROUBLESHOOTING ...................................................................... 79

10.1 Error Reporting.................................................................................79

10.1.1 Electrode Resistance Too High .............................................79

10.1.2 Out of Range.........................................................................79

10.1.3 Misconnection ......................................................................79

10.1.4 Out of Limits Indicators .........................................................80

10.1.5 Error Messages .....................................................................82

APPENDIX A: GLOSSARY OF TERMS................................................... 83

Basic Terminologies ....................................................................................83

Glossary ......................................................................................................84

Repair and Calibration.................................................................................87

Technical and Sales Assistance ..................................................................87

Limited Warranty .........................................................................................88

Warranty Repairs ........................................................................................88

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

5

Page 8

CHAPTER 1

INTRODUCTION

WARNING

These safety warnings are provided to ensure the safety of personnel.

Please read and comply with these precautions:

• This instrument is protected from accidental voltages of not more than

50V with respect to earth in measurement CAT IV. The guaranteed level

of protection of this equipment may be compromised if used in a manner

not specied by the manufacturer.

• Safety is the responsibility of the operator.

• All metal objects or wires connected to the electrical system should be

assumed to be lethal until tested. Grounding systems are no exception.

• Never exceed the maximum rated voltage and current, and the mea-

surement category.

• Never exceed the protection limits, and always comply with the condi-

tions and place of use, indicated in the specications.

• Do not use the instrument or its accessories if they appear damaged.

• Use accessories that have overvoltage category and service voltages

greater than or equal to those of the instrument (CAT IV 50V). Use only

accessories that comply with safety standards (IEC 61010-2-031 & 32).

• Wear the appropriate protective gear (insulating boots and gloves).

• Check that no terminal is connected and the switch is set to OFF before

opening the device.

• Use only the charging unit supplied with the instrument to recharge the

battery.

• Troubleshooting and metrological verication procedures must only be

performed by qualied, approved personnel, or the factory.

• NOTE: The potentials on the various rods used for an earth measurement

may be dierent if a nearby electrical installation is defective or certain

weather conditions prevail (thunderstorms). It is up to the operator

to decide whether to continue or postpone measurements in these

situations.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 9

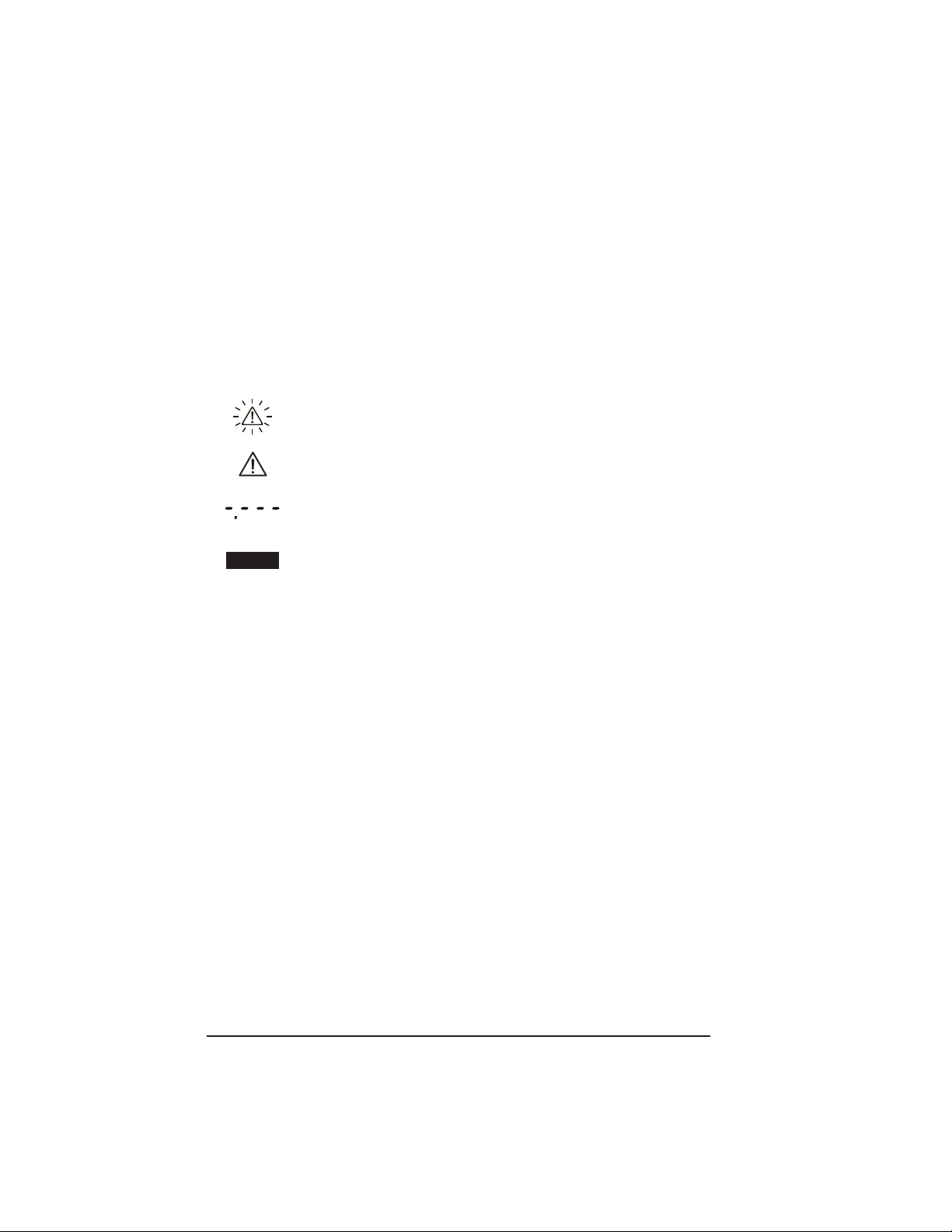

1.1 International Electrical Symbols

Signifies that the instrument is protected by double or reinforced insulation.

This symbol on the instrument indicates a WARNING that the operator must

refer to the user manual for instructions before operating the instrument. In

this manual, the symbol preceding instructions indicates that if the instructions

are not followed, bodily injury, installation/sample and/or product damage may

result.

Risk of electric shock. The voltage at the parts marked with this symbol may be

dangerous.

Ground/Earth symbol

In conformity with WEEE 2002/96/EC

1.2 Definition of Measurement Categories

CAT II: For measurements performed on circuits directly connected to the electrical

distribution system. Examples are measurements on household appliances or

portable tools.

CAT III:

CAT IV: For measurements performed at the primary electrical supply (<1000V) such

For measurements performed in the building installation at the distribution level

such as on hardwired equipment in xed installation and circuit breakers.

as on primary overcurrent protection devices, ripple control units, or meters.

1.3 Receiving Your Shipment

Upon receiving your shipment, make sure that the contents are consistent with the

packing list. Notify your distributor of any missing items. If the equipment appears

to be damaged, le a claim immediately with the carrier and notify your distributor

at once, giving a detailed description of any damage. Save the damaged packing

container to substantiate your claim.

1.4 Ordering Information

Ground Resistance Tester Model 6472 .........................................Cat. #2135.51

Includes carrying bag, 110/240V power adapter with US power cord, optical USB cable,

rechargeable NiMH battery pack, and a USB stick with DataView® software, ground tester

workbook and user manual.

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

7

Page 10

Ground Resistance Tester Model 6472 Kit (150 ft) ...................... Cat. #2135.52

Includes meter, two carrying bags, two 150 ft color-coded leads on spools (red/blue), one 30

ft lead (green), two 5 ft color-coded leads (red/blue), 110/240V power adapter with US power

cord, optical USB cable, two T-shaped auxiliary ground electrodes, set of ve spaded lugs,

one 100 ft tape measure, rechargeable NiMH battery pack, and a USB stick with DataView®

software, ground tester workbook and user manual.

Ground Resistance Tester Model 6472 Kit (300 ft) ...................... Cat. #2135.53

Includes meter, two carrying bags, two 300 ft color-coded leads on spools (red/blue), two 100

ft color-coded leads (hand-tied, green/black), two 5 ft color-coded leads (red/blue), 110/240V

power adapter with US power cord, optical USB cable, four T-shaped auxiliary ground

electrodes, set of ve spaded lugs, one 100 ft tape measure, rechargeable NiMH battery

pack, and a USB stick with DataView® software, ground tester workbook and user manual.

Ground Resistance Tester Model 6472 Kit (500 ft) ...................... Cat. #2135.54

Includes meter, two carrying bags, two 500 ft color-coded leads on spools (red/blue), two

100 ft color-coded leads (hand-tied, green/black), one 30 ft lead (green), two 5 ft colorcoded leads (red/blue), 110/240V power adapter with US power cord, optical USB cable,

four T-shaped auxiliary ground electrodes, set of ve spaded lugs, one 100 ft tape measure,

rechargeable NiMH battery pack, and a USB stick with DataView® software, ground tester

workbook and user manual.

1.4.1 Kits, Accessories and Replacement Parts

Test Kit for 3-Pole (3-Point) Testing (150 ft) ................................. Cat. #2135.35

Includes two 150 ft color-coded leads on spools (red/blue), one 30 ft lead (green), two 5 ft

color-coded leads (red/blue), two T-shaped auxiliary ground electrodes, set of ve spaded

lugs, one 100 ft tape measure and carrying bag.

Test Kit for 4-Pole (4-Point) Testing (300 ft) ................................. Cat. #2135.36

Includes two 300 ft color-coded leads on spools (red/blue), two 100 ft color-coded leads

(hand-tied, green/black), two 5 ft color-coded leads (red/blue), four T-shaped auxiliary ground

electrodes, set of ve spaded lugs, one 100 ft tape measure and carrying bag.

Test Kit for 4-Pole (4-Point) Testing (500 ft) ................................. Cat. #2135.37

Includes two 500 ft color-coded leads on spools (red/blue), two 100 ft color-coded leads

(hand-tied, green/black), one 30 ft lead (green), two 5 ft color-coded leads (red/blue), four

T-shaped auxiliary ground electrodes, set of ve spaded lugs, one 100 ft tape measure and

carrying bag.

Test Kit for 3-Pole (3-Point) Testing

(Supplemental for 4-Pole (4-Point) Testing) .............................................Cat. #2135.38

Includes two 100 ft color-coded leads (hand-tied, green/black), one 30 ft lead (green), two

T-shaped auxiliary ground electrodes, set of ve spaded lugs, one 100 ft tape measure and

carrying bag.

8

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Extra Large Classic Tool Bag ...........................................................Cat. #2133.73

Tape Measure (100 ft) ......................................................................Cat. #2130.60

Ground Tester DVD/Workbook Set ...................................................Cat. #2130.64

Set of two, 14.5" T-shaped Auxiliary Ground Electrodes ..................Cat. #2135.39

Replacement - Carrying Bag for Meter ............................................. Cat. #2135.40

Optical USB Cable............................................................................Cat. #2135.41

Inverter – 12V DC to 120V AC 200 Watt for vehicle use .................. Cat. #2135.43

AC Current Probe Model MN82........................................................Cat. #2135.71

AC Current Probe Model SR182 ...................................................... Cat. #2135.72

Replacement - Connection Lead for Models 6472/6474* ................. Cat. #2135.75

Replacement - Fuse, set of 5, 0.63A 250V 5x10 1.5kA ....................Cat. #2135.81

Replacement - Calibration Loop ....................................................... Cat. #2135.82

Safety Alligator Clip - Black (Rated 600V CAT IV, 10A) .................... Cat. #2140.53

Safety Alligator Clip - Green (Rated 600V CAT IV, 10A) .................. Cat. #2140.69

Replacement - Battery, Rechargeable NiMH 9.6V ...........................Cat. #2960.21

Replacement - Power Adapter 110/240V & Power Cord 115V US ...Cat. #5000.13

Replacement - Power Cord 115V US Plug .......................................Cat. #5000.14

*NOTE: The GroundFlex

Ground Resistance Tester Model 6472

®

Adapter Model 6474 is a factory supplied product only.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

CHAPTER 2

PRODUCT FEATURES

2.1 Description

The Ground Resistance Tester Model 6472 is a portable measurement instrument

designed to measure:

• Bond/Connection Resistance (2-Pole and 4-Pole Kelvin sensing)

• Ground Resistance (3-Pole or 4-Pole)

• Ground Coupling Resistance

• Selective Ground Resistance

• Soil Resistivity (Wenner or Schlumberger method)

• Ground Potential

• Ground Resistance with 2 clamps (no auxiliary rods)

• Ground Resistance of Pylons with the GroundFlex® Adapter Model 6474

and GroundFlex® sensors allow the system to measure leakage current and

ground resistance of tower legs without disconnecting the overhead ground

conductor.

The Model 6472 measures from 0.01 to 99.99kΩ and is auto-ranging, automatically

seeking out the optimum measurement range, test frequency and test current.

Easy-to-use - Simply connect the leads, select the test mode, press Start and read

the results. Up to 512 test results can be stored in internal memory for later recall

to the display or downloaded to a PC via DataView® software.

The large LCD is easy-to-read and indicates ground electrode resistance, test

voltage, current and frequency as well as individual electrode resistance, battery

status and more.

The Model 6472 is CAT IV rated to 50V and is over voltage protected to more than

250VAC against accidental connection to live circuits. The voltage is also displayed

on screen. In the event of a system fault, the Model 6472 can withstand 250VAC.

Additional features of the Model 6472 include a heavy-duty eld case sealed

against dust and water when closed (the test button is also sealed against the elements); manual and automatic test frequency selection from 41 to 5078Hz; user

selectable 3-Pole Fall of Potential or 4-Pole Soil Resistivity test methods and user

selectable 2-Pole or 4-Pole Bond Resistance test method.

10

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

The Model 6472 is powered by 9.6V, 3.5 Ah NiMH rechargeable batteries. An external recharger powered from 120/230V, 50/60Hz is included and provides for

testing while recharging.

The Ground Resistance Tester Model 6472 is rugged, easy-to-use and ideal for

maintenance crews performing numerous tests. It exceeds mechanical and safety

specications for shock, vibration and drop tests per IEC standards. The adjustable test frequency provides for rejection of high levels of interference, allowing

it to be used under dicult conditions such as high stray currents that aect ac-

curacy.

2.2 Key Features

• Ground Resistance testing using the 2 clamp method (no auxiliary rods

needed)

• 2- and 4-Pole Bond Resistance/Continuity Measurement (DC Resistance)

with automatic polarity reversal

• 3-Pole Fall-of-Potential measurement with manual or automatic frequency

selection

• 4-Pole soil resistivity measurement with automatic calculation of Rho (ρ) and

user selection of the Wenner or Schlumberger test method

• 3-Pole earth/ground coupling measurement

• Manual and automatic frequency scan from 41 to 5078Hz for optimum test

accuracy in electrically noisy environments

• Selectable test voltage of 16 or 32V up to 250mA of test current

• Auto-o power management

• Automatic recognition of all electrode connections and their resistance value

• Stores up to 512 complete test results in internal memory

• Optically isolated USB communication

• Remote set up and operation of all measurements using DataView® software

• Automatic report generation including the fall of potential plot

• Rechargeable NiMH batteries from wall charger or vehicle power

• Rugged dustproof and rainproof eld case – IP53 rated in closed position

• Grounding standards IEC 61557 parts 4 and 5 compliant

• Includes DataView® software for data storage, real-time display, analysis,

report generation and system conguration

Ground Resistance Tester Model 6472

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

2.3 Control Features

8

2 3

Ω

1

Figure 2-1

4

5

To Model 6474

6

7

1. Four terminals: H (Z) (auxiliary electrode), S (Y) (electrode), ES (Xv) (earth/

ground electrode) and E (X) (earth/ground electrode)

All terminals accept 4mm Ø banana plugs. Terminals H (Z) and ES (Xv) also

accept special plugs for current clamps. S (Y) will take a shielded cable.

2. Connector for charging the battery (see § 9.4).

3. 256 segment multi-line backlit LCD (see § 2.4).

4. Connector for an optical interface to a PC. Either an RS-232 or USB connection can be used (see § 8 - DataView®).

5. Connector to the GroundFlex® Adapter Model 6474 using a special adapter

cable .

6. Rotary switch: OFF position, 7 measurement functions (see § 5 and 6) and

SET-UP function (see § 4.2).

7. START/STOP button: Starts the measurement and compensates for the leads

(in the mΩ measurement function - see § 5.2.1).

8. Six function buttons - see § 2.5

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 15

2.4 Display

A1

A2

A3

NOTE: External voltages will be displayed only on the small displays (A2 and

A3) without the view of the main display (A1). This helps to rapidly recognize

that these are measurements of external voltages.

Backlight: The backlight turns ON automatically when entering a function and

turns OFF after the function is complete. Press the DISPLAY button to turn it back

on.

NOTE: In the Set-up mode, pressing the DISPLAY button also selects the

next configurable parameter.

A1

A2

A3

Top main display

Middle small display

Bottom small display

If this symbol blinks during a passive measurement, a voltage of more than

42V is present at the tester’s inputs.

If this symbol blinks during an active measurement, the limits of use have

been exceeded.

If the symbol appears constant during an active measurement, the values

to be measured are unstable.

Warning buzzer is activated

Ground Resistance Tester Model 6472

Figure 2-2

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

> or <

NOISE

EARTH

COUPLING

S x 1/10

OBJ:TEST

DISTANCE

FREQUENCY

A blinking symbol > (greater than) or < (less than) indicates that the

measurement range is exceeded.

If both symbols are blinking during a passive measurement, the values of

voltage and/or current are too small and are beyond the limits of use. The

resistance RPASS displayed by the tester is then highly uncertain.

If both symbols are blinking during an active measurement, the values

to be measured are strongly varying (remedy: switch on smoothing of

measured values with SMOOTH function).

Indicates the battery charge condition; the segments represent the energy.

Indicates whether the 3-Pole EARTH measurement or the EARTH COUPLING

measurement has been selected.

Indicates the sensitivity of the GroundFlex®: x1/10, x1, x10.

Display of the number of turns in GroundFlex® sensors (1 to 4).

Number of GroundFlex® sensors connected (1 to 4). If this symbol blinks,

the GroundFlex® may not be connected or the current ISEL measured by

the GroundFlex® sensor is too small and is outside the limits of use.

Object and test number for storage in memory.

Indicates lead compensation for 2-Pole measurement is active

If blinking, indicates the value is ready to be overwritten with a new value

or that a new value will be entered. If more than one value has to be

entered, use the CHANGE buttons to move to the next one.

Indicates the test frequency.

MANUAL

CONFIG

REMOTE

14

SWEEP

AUTO

MR

MEM

Indicates that the secondary function of a button will be used.

Indicates SWEEP mode - Used in 3-Pole and 4-Pole measurements.

Indicates MANUAL mode - the user has to stop the measurement,

otherwise the measurement keeps on running.

Indicates AUTO mode - measurement stops immediately after all results

are available.

If blinking, indicates the measurement had a disturbance when the measurement was started.

Indicates that the blinking value of AUTO/MANUAL mode, frequency,

voltage or DC current direction can be changed.

Memory recall - indicates the displaying of stored results is active

Indicates that there is recorded data in memory. When blinking, it indicates that the results need to be saved by pressing the MEM button.

Indicates the instrument is remotely controlled by the RS-232/USB

interface.

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

SMOOTH

Indicates SMOOTHing of the displayed measurement results.

Indicates that a clamp is (steady) or should be (flashing) connected to ES.

ALARM

Measured value (R, U, I).

Indicates that the measurement is running.

Indicates the alarm is activated. An audible alarm will sound if the value

measured is above the limit defined in the SET-UP mode.

Distances to be entered between earth electrode and supplementary

electrodes or between earth electrodes.

Clamp should be connected to H.

If this clamp symbol blinks, the instrument is refusing measurement

because the clamp is not connected correctly.

Symbolizes the soil resistivity value (Rho): W or S indicates that Wenner

or Schlumberger method is used for the measurement (changed by the

Hz/OPTIONS button).

2.5 Button Functions

Starts a measurement and compensates for lead resistance (§ 5.2.1).

START/STOP

Measurement stops automatically (AUTO) or is stopped by pressing this

button again (MANUAL).

Selects the second function highlighted in yellow under the buttons.

Increases or decreases the value of the flashing parameter displayed or

MEM/MR

DISPLAY/

SMOOTH

Hz/OPTIONS/

DISTANCE

Ground Resistance Tester Model 6472

selects the next parameter. Press the button for a longer time to increase

the change of value speed at a faster rate.

Selects the parameter to be modified or moves the cursor to the right.

MEM: Stores measurements to memory.

MR: Retrieves measurements from memory.

DISPLAY: Displays all parameters of a measurement.

SMOOTH: Smooths the display of measurement providing a more

stable result.

Hz/OPTIONS: Enables configuration of measurement functions.

DISTANCE: Available for soil resistivity and V potential measurements. It

allows the setting of values of distances used for Rho (ρ) calculation.

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

CHAPTER 3

SPECIFICATIONS

3.1 Reference Conditions

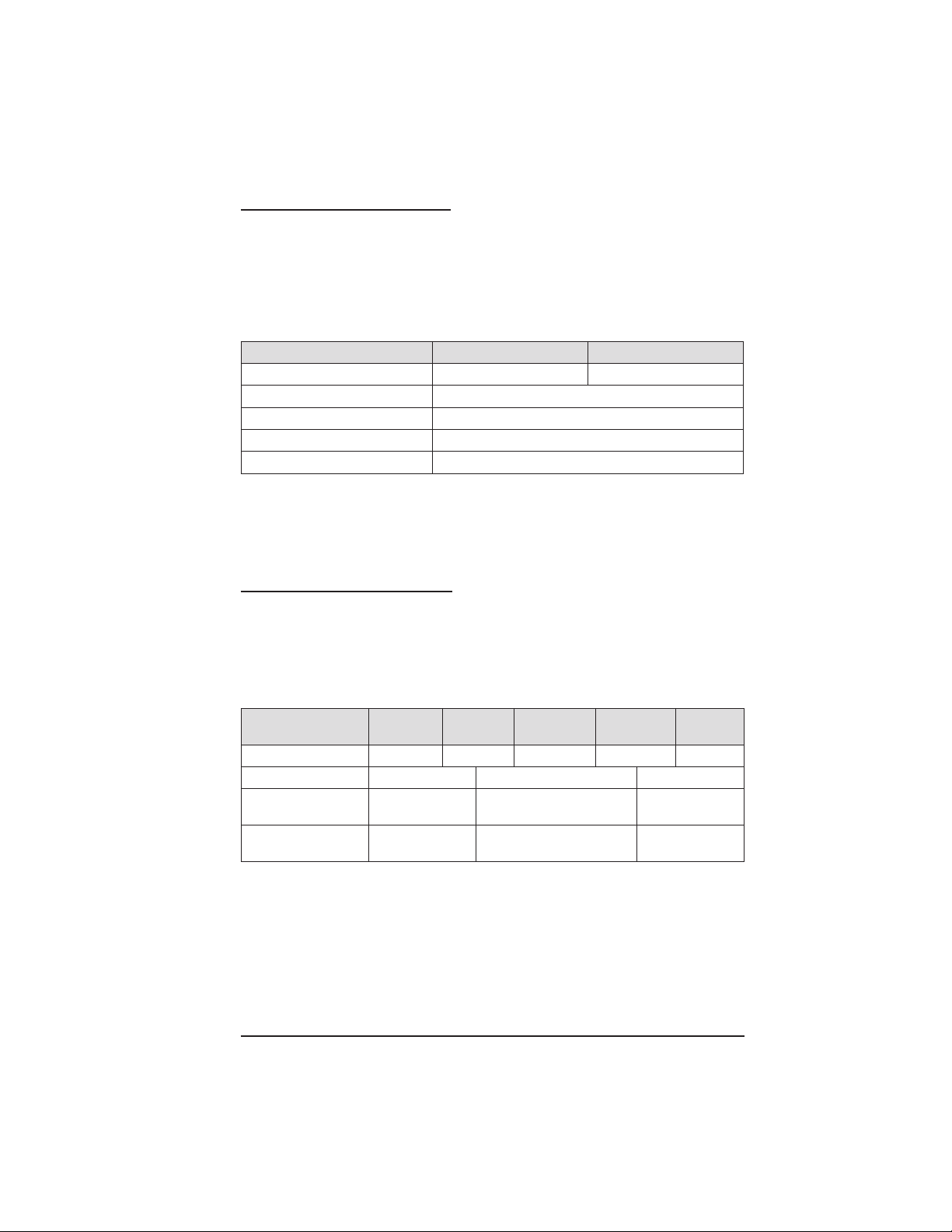

Influencing Parameters Reference Values

Temperature 68°F ± 5.5°F (20°C ± 3°C)

Relative Humidity 45 to 55% RH

Power Supply 9 to 11.2V

Frequency Range of Input Signal 0 to 440Hz

Capacitance Parallel to Input Resistance 0 uF

Electric Field <1 V/m

Magnetic Field < 40 A/m

3.2 Electrical

3.2.1 Frequency Measurements

Measuring method: Digital with a sampling frequency of 4028Hz, low pass, FFT.

The frequency of the strongest spectral component is displayed.

Measuring rate: Display updates approx. 3 times per s.

Measurement Range 5 to 450Hz

Resolution 1Hz

Operating error ± 2Hz

Min. input voltage 10mV

Min. current through a clamp 0.5mA

Min. signal strength for GroundFlex

®

5mA

3.2.2 Voltage Measurements

Overvoltages up to 75Vrms are displayed as ">65V". Permanent overvoltages

between 70 and 75V at terminals H (Z) and E (X) can cause overheating of the

overvoltage protection varistor.

Voltages of more than 75Vrms lead to error message 31 (excessive external

voltage) or 32 (voltage measurement overrange).

If terminals H (Z) and E (X) are put into contact with the line voltage, the protection

fuse will blow.

16

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

External Voltage Measurements

Measuring Method: Digital by sampling at 4028Hz, low pass lter, FFT.

The frequency of the strongest spectral component is displayed.

Measuring Rate: Display updates approx. 3 times per s.

Signal Conversion: TRMS or sum of all harmonics 10 to 450Hz during selective

earth measurements with clamp or by GroundFlex® sensors.

Measured Range 0.00 to 9.99V 10 to 65V

Resolution 0.01V 0.1V

Intrinsic error ± (2% + 1ct)

Operating error ± (5% + 1ct)

Input impedance Z

Operating frequency DC and 15 to 440Hz

, Z

(Z

H-E

) 1.2MΩ

S-E

S-ES

3.2.3 Current Measurements

External Current Measurements

Measuring Method: Digital by sampling at 4028Hz, low pass lter, FFT.

Measuring Rate: Display updates approx. 3 times per s.

Signal Conversion: Sum of all harmonics 10 to 450Hz

With Current Probe SR182

Measurement Range

Resolution 0.01mA 0.1mA 1mA 0.01A 0.1A

Frequency range 16 to 49Hz 50 to 99Hz 100 to 400Hz

Operating error from

0.5 to 100mA

Operating error from

0.1 to 40.0A

Ground Resistance Tester Model 6472

0.00 to

9.99mA

± (10% + 2cts) ± (5% + 2cts) ± (3% + 2cts)

> 20% ± (10% + 2cts) ± (5% + 2cts)

10.0 to

99.9mA

100 to

999mA

1.00 to

9.99A

10 to

40A

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

With Current Probe MN82

Measurement Range

Resolution 0.01mA 0.1mA 1mA 0.01A 0.1A

Frequency range 16 to 49Hz

Operating error from

0.5 to 100mA

Operating error from

0.1 to 40.0A

(1): The Model 6472 cannot detect whether a current clamp SR182 or MN82 is connected. In the case

of the MN82 clamp, with currents > 10A and frequencies < 100Hz the instrument will not display any

warning messages. It is the operator’s responsibility to observe the limits of use when using the MN82

clamp.

0.00 to

9.99mA

± (15% + 2cts) ± (7% + 2cts) ± (5% + 2cts)

> 20% ± (15% + 2cts) ± (7% + 2cts)

10.0 to

99.9mA

(1)

100 to

999mA

50 to 99Hz

1.00 to

9.99A

(1)

10 to

40A

100 to 400Hz

(1)

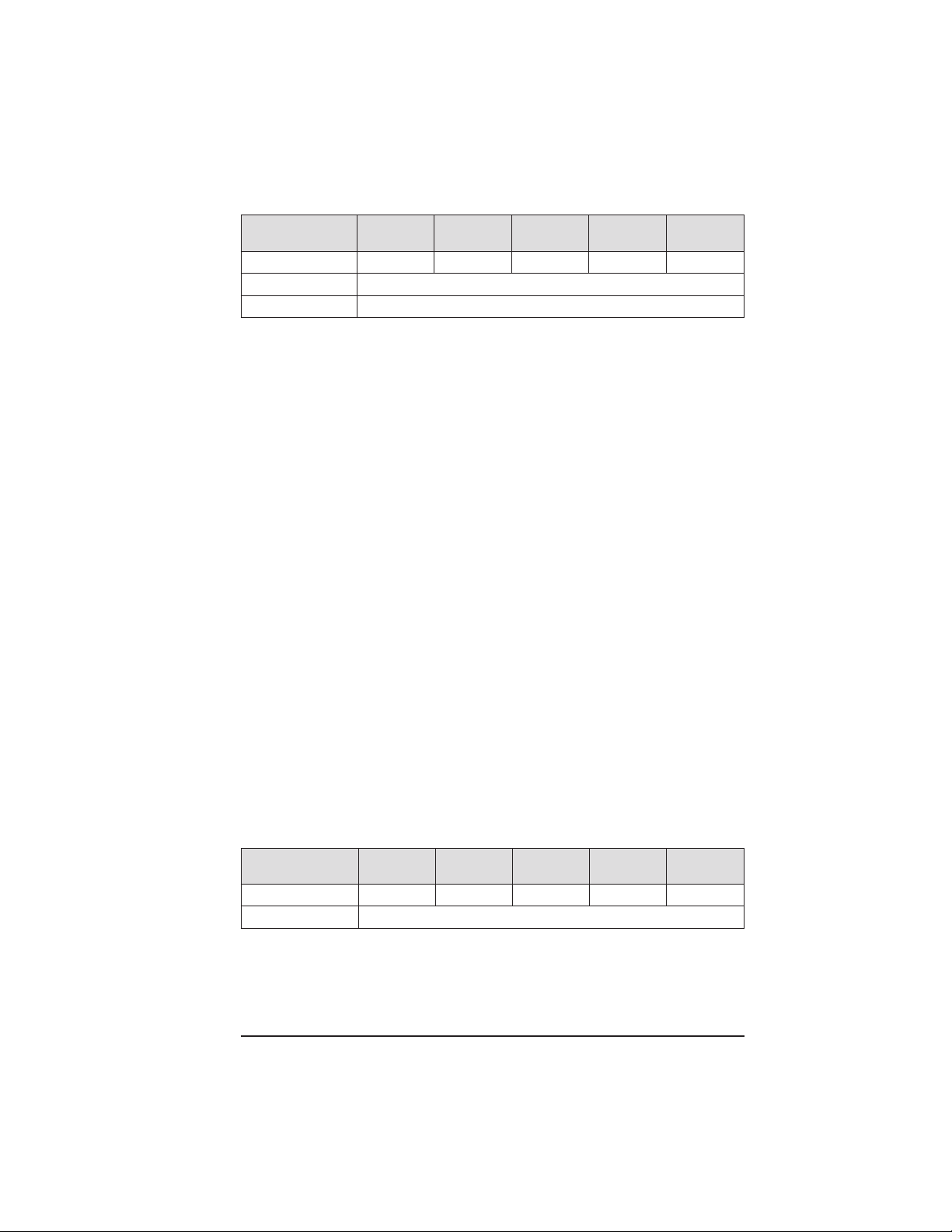

3.2.4 DC Resistance Measurements

Measuring Method: Voltage/Current measurement (Standard EN 61557 part 4)

Nominal Output Voltage: 16VDC (if resistance < 22Ω the output voltage is

reduced to 10VDC)

Max Output Current: > 200mADC for resistances < 20Ω

Max Overload (permanent): 50Vrms (protection up to 250V is guaranteed)

Max Inductive Load: 2 H

Max Interfering Voltage: 60Vpeak > 10Hz

Time for Auto Range Selecting: approx 5 s

Measuring Time: 8 s with automatic polarity inversion

Measuring Rate: 3 per s in manual mode

Lead Compensation: Possible from 0 to 5Ω

Alarm Setting: “>” or “<” from 1 to 999Ω (max 3 digits)

2-Pole mΩ measurement

Measurement

Range

Resolution 0.01Ω 0.1Ω 1Ω 10Ω 100Ω

Intrinsic error ± (2% + 2cts)

Operating error ± (5% + 3cts)

18

Find Quality Products Online at: sales@GlobalTestSupply.com

0.12 to

9.99Ω

10.0 to

99.9Ω

100 to

999Ω

Ground Resistance Tester Model 6472

1.00 to

9.99kΩ

www.GlobalTestSupply.com

10.0 to

99.9kΩ

Page 21

4-Pole mΩ measurement

Measurement

Range

Resolution 0.001Ω 0.01Ω 0.1Ω 1Ω 10Ω

Intrinsic error ± (2% + 2cts)

Operating error ± (5% + 5cts)

0.020 to

9.999Ω

10.00 to

99.99Ω

100.0 to

999.9Ω

1.000 to

9.999kΩ

10.00 to

99.99kΩ

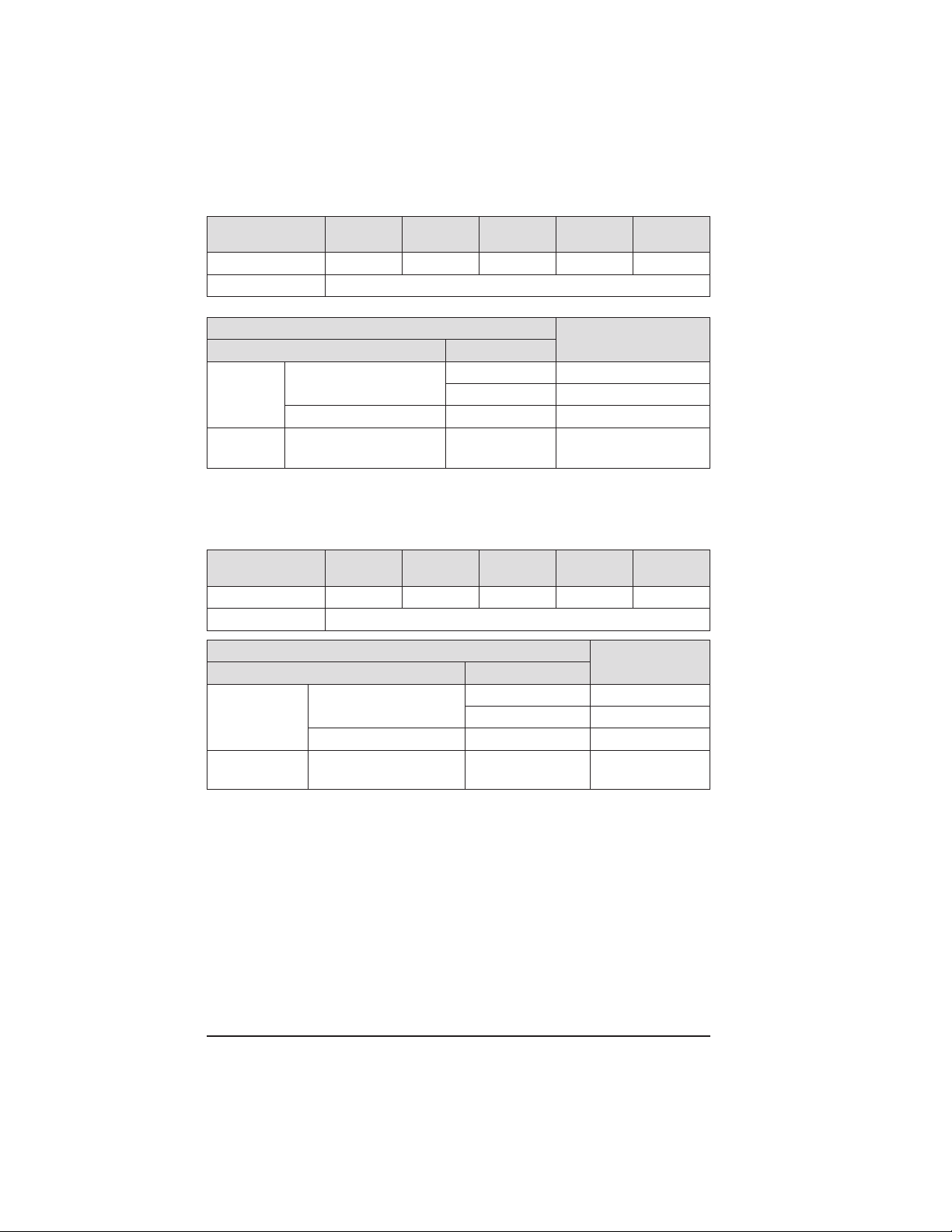

3.2.5 AC Earth Resistance Measurements

Measuring Method: Voltage/Current measurement (EN 61557 part 5)

Open circuit voltage: 16 or 32Vrms square wave (if current > 240mA the output

voltage is reduced to 10Vrms)

Test frequency: Selectable from 41 to 5078Hz (see table in § 6.2)

Short circuit current: > 200mAAC

Noise suppression: > 80 dB for frequencies 20% or more above or below the

test frequency

Max. overload: 250Vrms

Max. value for RH & RS: 100kΩ

Measuring time: Short push on START: approx. 7 s for rst value of RE at

128Hz, then 3 measurements per s.

Long push on START: approx. 15 s for rst value of RE at

128Hz, then 3 measurements per s.

The following error indications refer to reference conditions with a test voltage of

32V, test frequency of 128Hz, RH and RS = 1kΩ, no external voltage.

The operating error of AC resistance measurements can be less than that speci-

ed for voltage or current because frequency characteristics of the voltage channel

are matched to those of the current channel.

Measurement of auxiliary electrodes RH, RS, RES, RE

Measurement

Range

Resolution 0.1Ω 0.1Ω 1Ω 10Ω 100Ω

Operating error ± (10% + 2cts)

0.14 to

9.99Ω

10.0 to

99.9Ω

100 to

999Ω

1.00 to

9.99kΩ

10.0 to

99.9kΩ

The START button must be pressed for more than 2 s. For frequencies between

41 and 256Hz, the resistance of the auxiliary earth electrodes is measured at the

test frequency set. At higher frequencies the resistance is measured at 256Hz.

Ground Resistance Tester Model 6472

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

3-Pole earth resistance measurement RE

Measurement

Range

0.09 to

9.99Ω

10.0 to

99.9Ω

100 to

999Ω

1.00 to

9.99kΩ

10.0 to

99.9kΩ

Resolution 0.01Ω 0.1Ω 1Ω 10Ω 100Ω

Intrinsic error ± (2% + 1ct)

Operating conditions: RE < 3 x RH, U

Values for RH, RS and RE Frequency (Hz)

(RH + RS) / RE

< 3000

RH ≥ 0Ω, Rs ≤ 3kΩ

= 32V

OUT

Operating error for R

41 to 513 ± (3% + 2cts)

537 to 5078 ± (6% + 2cts)

RH > 3kΩ, Rs ≤ 30kΩ 41 to 513 ± (10% + 2cts)

(RH + RS) / RE

< 5000

Note: For a test voltage U

4-Pole earth resistance measurement R

Measurement

Range

RH > 30kΩ, Rs < 100kΩ 41 to 128 ± (10% + 3cts)

of 16V, halve the value for RH.

OUT

E

0.011 to

9,999Ω

10.00 to

99.99Ω

100.0 to

999.9Ω

1.000 to

9.999kΩ

10.00 to

99.99kΩ

Resolution 0.001Ω 0.01Ω 0.1Ω 1Ω 10Ω

Intrinsic error ± (2% + 1ct)

Values for RH, RS and RE Frequency (Hz)

(RH + RS) / RE

< 3000

Operating conditions: RE < 3 x RH, U

RH ≥ 0Ω, Rs ≤ 3kΩ

= 32V

OUT

Operating error for R

41 to 513 ± (3% + 2cts)

537 to 5078 ± (6% + 2cts)

RH > 3kΩ, Rs ≤ 30kΩ 41 to 513 ± (10% + 2cts)

(RH + RS) / RE

< 5000

RH > 30kΩ, Rs < 100kΩ 41 to 128 ± (10% + 3cts)

E

E

Note: With a test voltage U

of 16V, halve the value of RH.

OUT

Selective 4-Pole earth resistance measurement with SR182 or MN82 clamp

Same characteristics as 4-Pole earth measurements with the following particular

conditions:

Minimum current: SR182, IES >0.5mA

MN82, IES >2mA

Maximum R

MN82, (R

ratio: SR182, (R

SEL/RE

SEL/RE

SEL/RE

) <500

) <120

with RH + RE <20Ω

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 23

3.2.6 Soil Resistivity Measurement ρ

Measuring method: Voltage/Current measurement (EN 61557 part 5)

Open circuit voltage: 16 or 32Vrms square wave

Test frequency: Selectable from 41 to 128Hz (see table in § 6.2)

Short circuit current: > 200mAA

Noise suppression: > 80 dB for frequencies 20% or more above or below the

test frequency

Max. overload: 250Vrms

Max. value for RH, RS, RES, RE: 100kΩ

Calculation formula, Wenner: ρW = 2p d R

Calculation formula, Schlumberger: ρS = (p (d² - (A/2)²) / A) R

Maximum value of ρ: 999kΩm (display in kΩft is not possible)

Measuring time: Short push on START: approx. 8 s for rst value of R

128 Hz, then 3 measurements per s.

Long push on START: approx. 20 s for rst value of R

128 Hz, then 3 measurements per s.

C

S-ES

S-ES

at

S-ES

at

S-ES

Measurement

Range

0.00 to

9.99Ω

10.0 to

99.9Ω

100 to

999Ω

1.00 to

9.99kΩ

10.0 to

99.9kΩ

Resolution 0.01Ω 0.1Ω 1Ω 10Ω 100Ω

Intrinsic error ± (2% + 1ct)

The intrinsic error specied refers to reference conditions with a test voltage of

32V, test frequency of 128Hz, R

Operating conditions : R

R

is the resistance of the earth rods R

rod

cal.

R

R

electrode

R

electrode

R

electrode

electrode

R

R

S-ES

/ R

electrode

/ R

electrode

/ R

Note: With a test voltage U

Ground Resistance Tester Model 6472

, R

, R

ρ-H

< 3 x R

ρ-S

and: Operating error for R

ρ

-H

ρ-ES

and R

≤ 100kΩ

≤ 2000

S-ES

≤ 50kΩ

≤ 10,000

S-ES

≤ 10kΩ

≤ 20,000

S-ES

, R

ρ

-E

of 16V, halve the value of R

OUT

, R

ρ

-ES

= 1kΩ, no external voltage.

ρ-E

S-ES

± (7% + 2cts)

± (15% + 3cts)

± (20% + 1ct)

, R

ρ

assumed to be identi-

ρ

-E

-H

.

rod

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Measurement of auxiliary electrodes R

Measurement

Range

0.14 to

9.99Ω

10.0 to

99.9Ω

, R

, R

, R

ρ

ρ

-H

ρ

-S

-ES

100 to

999Ω

ρ

-E

1.00 to

9.99kΩ

10.0 to

99.9kΩ

Resolution 0.1Ω 0.1Ω 1Ω 10Ω 100Ω

Operating error ± (10% + 2cts)

The START button must be pressed for more than 2 s. For frequencies between

41 and 128Hz, the resistance of the auxiliary earth electrodes is measured at the

test frequency set. At higher frequencies the resistance is measured at 128Hz.

3.2.7 Earth/Ground Potential Measurements V Pot

Measuring method: Voltage/Current measurement

Open circuit voltage: 16 or 32Vrms square wave

Test frequency: Selectable from 41 to 5078Hz (see table in § 6.2)

Short circuit current: > 200mAAC

Noise suppression: > 80 dB for frequencies 20% or more above or below the

test frequency

Max. overload: 250Vrms

Max. value for RH & RS: 100kΩ

Measuring time: Short push on START: approx. 7 s for rst value of RE at

128Hz, then 3 measurements per s.

Long push on START: approx. 15 s for rst value of RE at

128Hz, then 3 measurements per s.

Measurement Range 0.00 to 99.99mV 100.0 to 999.9mV 1.000 to 9.999V 10.00 to 65.00V

Resolution 0.01mV 0.1mV 1mV 10mV

Intrinsic error U

S-E

± (5% + 1ct)

The intrinsic error specied refers to reference conditions with a test voltage of

32V, test frequency of 128Hz, RH, and RS = 1kΩ, no external voltage.

Operating conditions: RE < 3 x RH and :

R

H

< 3kΩ

R

S

≤ 1kΩ

Freq. (Hz) U

41 to 512 < 3mV ± (10% + 10cts)

41 to 5078

41 to 1025

3 to 60kΩ

1 to 3kΩ 41 to 512

3 to 10kΩ 41 to 128

Note: With a test voltage U

22

S-E

> 3mV

> 10mV

of 16V, halve the value for RH.

OUT

Operating error for U

S-E

± (5% + 4cts)

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

3.2.8 Earth/Ground Measurements with 2 Clamps

Measuring method: Voltage/Current measurement with a rectangular AC signal

Induced short circuit current: < 26Arms (with SR182) < 5Arms (with MN82)

Signal frequency: Automatic: 1611Hz - Manual: 128, 1367, 1611 or 1758Hz

Noise suppression: > 80 dB at frequencies diering by 20% or more from the

test frequency

Max. interfering current: 20A

Max. value for RH, RS: 100kΩ

Measuring time: approx. 7 s for the rst value of R

Measurement Range 0.10 to 9.99Ω 10.0 to 99.9Ω 100 to 500Ω

Measurement frequency 1367Hz - 1611Hz - 1758Hz

Resolution 0.01Ω 0.1Ω 1Ω

Operating error

(without external current)

Measurement Range 0.10 to 9.99Ω 10 to 30Ω

Measurement frequency 128Hz

Resolution

Operating error

(without external current)

(1)

(1)

peak

, then 3 meas. per s.

Loop

SR182 ± (10% + 1cts)

MN82 ± (20% + 2cts)

0.01Ω 0.1Ω

SR182 ± (20% + 2cts)

MN82 not specified

(1): Observe the minimum distance between the two clamps according to table in § 5.8.

3.3 Data Storage

Memory Capacity: 512 test results (64kB)

Communication: Optically isolated USB

3.4 Power

Power Source: Rechargeable 9.6V, 3.5Ah NiMH Battery Pack

Power Supply: 110/220, 50/60Hz external charger with 18VDC, 1.9A output or

12VDC vehicle power

Fuse: 0.63A, 250V, 5x20mm, 1.5kA

Ground Resistance Tester Model 6472

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Battery Life:

Function Power consumed Typical number of measurements

Device off < 5 mW —

Voltage Measurement 1.5 W 4500

(2)

mΩ

3-Poles, 4-Pole

V pot. 4.9 W 1500

2 Clamps 3.7 W 2000

GroundFlex

(1): Measurements in automatic mode at 25-s intervals - In sweep mode, the number of measurements is

divided by 3 or 4

(2): With R = 1Ω

(3): With RH + RE = 100Ω

(4): With RH + RS-ES = 100Ω

(3)

(4)

ρ

®

4.9 W 1500

4.9 W 1500

4.9 W 1500

5.5 W 1200

(1)

3.5 Mechanical

Dimensions: 10.7 x 9.76 x 5.12" (272 x 248 x 130mm)

Weight: 7 lbs (3.2kg) approx

Case Material: ULV0 Polypropylene

Terminals: 4mm recessed banana jacks

Case Protection: EN 60529 - IP53 (cover closed)

Drop Test: Per EN 61010-1

Vibration Test: Per EN 61557-1

3.6 Environmental

Operating Temperature: 32° to 113°F (0° to 45°C); 0 to 90% RH

Specied Operating Temperature

Storage Temperature: -40° to 158°F (-40° to 70°C); 0 to 90% RH

Altitude: < 3000m

(1): This range corresponds to the one defined by standard EN 61557, for which an operating error including the

quantities of influence is defined. When the device is used outside this range, 1.5%/10°C and 1.5% between

75 and 90% RH must be added to the operating error.

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

(1)

: 0° to 95°F (0° to 35°C); 0 to 75% RH

Ground Resistance Tester Model 6472

Page 27

3.7 Safety

Electromagnetic Compatibility

This instrument satises the EMC and LVD directives required for the CE marking

and product standard IEC 61326-1 (Ed. 97) + A1 (Ed. 98).

• Immunity in industrial environment

• Emissions in residential environment.

Electrical safety according to EN 61010-1 (Ed. 2 of 2001)

Measurement according to EN 61557 (Ed. 2 of 2007) parts 1, 4 and 5.

CAT IV, 50V

Pollution Degree 2

*Specications are subject to change without notice

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

25

Page 28

CHAPTER 4

OPERATION

NOTE: For detailed information regarding ground resistance testing, see

the Understanding Ground Resistance Testing Workbook CD that was

included with the instrument.

4.1 General Operating Instructions

The Model 6472 has operating modes:

• Automatic mode for routine applications.

• Manual (Expert) mode in which the user can change the parameters of the

measurement functions.

NOTE: Fully charge the battery before the first use (see § 9.4)

4.1.1 Automatic Mode

• Set the switch to the desired function.

• Make the connections appropriate to the function.

• Press the START/STOP button. The device makes the measurement and

stops automatically.

• Read the measurement result on the display and the relevant parameters

using the DISPLAY button.

• To save the information in memory, use the MEM button (see § 7.1).

4.1.2 Manual (Expert) Mode

• Set the switch to the desired function.

• Make the connections appropriate to the function.

• Select MANUAL mode.

• Choose various measurement parameters using the Hz/OPTIONS button.

• Press the START/STOP button. The measurement frequency or the direction of the current (resistance measurement) can be changed during the

measurement. To view their impact upon the measurement and the parameters relevant to the measurement use the DISPLAY button.

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 29

• When the measurement results are acceptable, stop the measurement by

pressing the START/STOP button.

• View the result on the display and toggle through the relevant parameters

using the DISPLAY button.

• To record the information into memory, use the MEM button (see § 7).

The instrument also incorporates a “SWEEP” mode (automatic execution of several measurements at several dierent frequencies) It is used to indicate how the

measurement varies as a function of frequency. In this case, the device operates

as in the automatic mode and the measurement process stops after taking the

measurement at the nal frequency.

4.2 Instrument Configuration (SET-UP mode)

To congure the Model 6472 parameters, turn the rotary switch to SET-UP:

• All the segments on the display are activated for 1 second and then the

“PUSH button” message appears on the display.

• Various parameters are accessible by pressing the corresponding button.

• The number or symbol which can be modied ashes. These are changed

using the SELECT button [►] and CHANGE buttons [▲▼].

• To exit SET-UP, turn the rotary switch to another position.

• All of the parameters that are modied are permanently saved until a new

instrument conguration is performed.

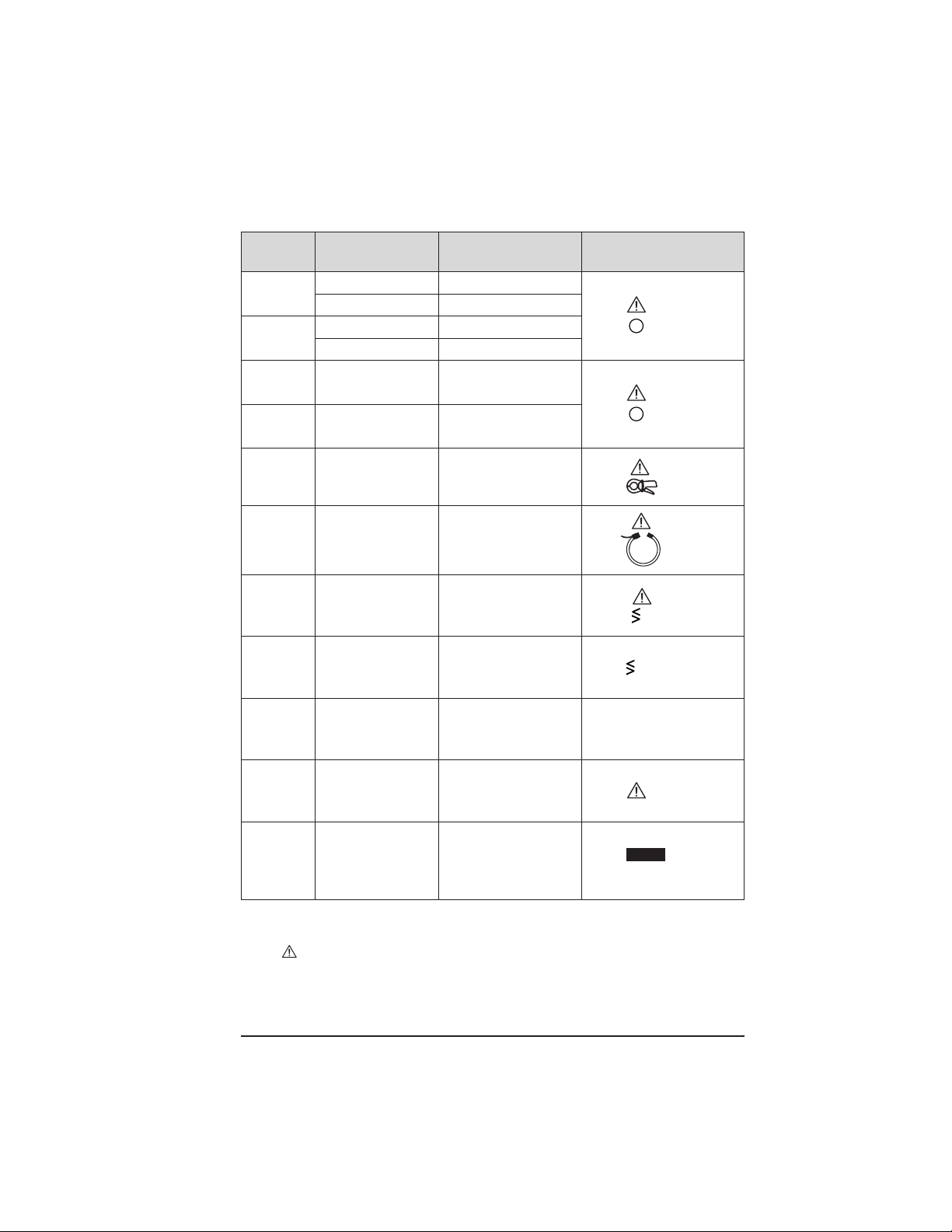

Parameter to be modified Button Possible values

Date and Month Hz/OPTIONS (1

Time Hz/OPTIONS (2

Baud Rate Hz/OPTIONS (3

Default configuration Hz/OPTIONS (4

GroundFlex® Adapter Model 6474

Hz/OPTIONS (5

Test Frequency

Test Voltage

Distance unit DISPLAY (1

Alarm (for mΩ and 2-Pole

DISPLAY (2

measurements only)

st

press) yyyy.mm.dd*

nd

press) hh : mm*

rd

press) 9.6k / 19.2k / 38.4k

th

press) yes / no

th

press)

55, 92, 110, 119, 128

16 or 32V

st

press) m (meter) or ft (feet)

nd

press) ON / OFF

direction (< or >)

value (1 to 999Ω)

Buzzer DISPLAY (3

Modbus address DISPLAY (4

Memory used MEM (1

rd

press) ON / OFF

th

press) 1 to 247

st

press) 000 to 512 (total

number of locations)

Memory location MR (1

st

press)

OBJ:TEST

*International format date and time only

Ground Resistance Tester Model 6472

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

CHAPTER 5

AUTOMATIC MODE

VOLTAGE CHECK: The tester first checks for possible interference. If there

is an external voltage of more than 42V, the warning triangle will be

displayed. If measurements are being performed in AUTO mode and a

disturbance frequency is detected, the tester will automatically look for a

frequency that is different from the default 128Hz.

5.1 Switching the Test Voltage

Available in all functions except mΩ and 2 Clamp.

If necessary, the test voltages can be switched to either 16 or 32V as follows:

• Press the Hz/OPTIONS button, then press it again to make the output volt-

age (Uout) blink.

• Use the ► button to switch to 16 or 32V, then press Hz/OPTIONS again.

This setting is retained when the unit is turned o.

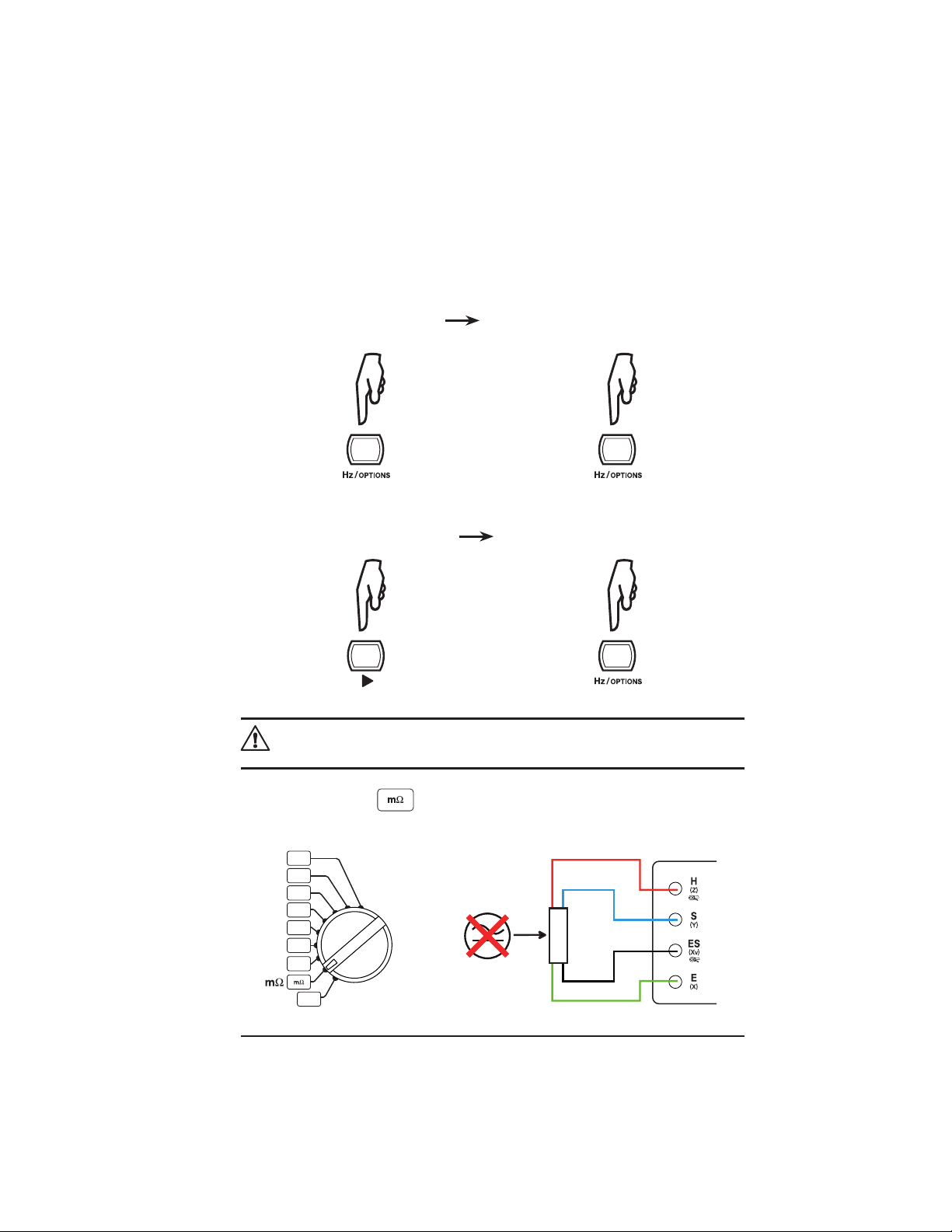

5.2 Resistance Measurement mΩ (2-Wire)

WARNING: Before performing the resistance test, verify that the sample

under test is not energized.

1. Set the switch to

2. Connect the resistance to terminals H (Z) and E (X).

28

.

R

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

3. The 6472 makes a measurement with a positive current (R+), then reverses the

direction of the current and makes another measurement with negative (R-).

H

ALARM

E

AUTO

±

DC

Ω

Ω

Ω

R =

(R+) + (R-)

2

H

ALARM

E

AUTO

±

DC

Ω

Ω

Ω

4. To display the measurement parameters, press DISPLAY several times.

The device displays the following parameters:

R+, R-, +U

H-E

, +I

H-E

, -U

H-E

, -I

H-E

, U-Act (U

and its frequency) and R∆0 if there

H-E

is compensation for the measurement leads.

5.2.1 Lead Compensation Measurement

Lead compensation subtracts the resistance of the test leads from the measured

result.

• Short the two measurement leads connected to H (Z) and E (X) terminals.

• Press the 2nd button, then the START/STOP button to start the measure-

ment.

• This value will be deducted from all resistance values measured thereafter

until the rotary switch is turned to another function.

H

ALARM

E

appears on the display after the compensation value has been measured.

AUTO

±

DC

AC

Ω

R

0

Ω

NOTE: If the compensation resistance is > 5Ω, or if the leads are not shorted

when the measurement is started, the value of compensation will be canceled.

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

29

Page 32

5.2.2 Alarm Function

2

3

This function is active only for 2-Pole resistance measurements. By default, the

visual alarm (ALARM symbol ashes) and the audible alarm (buzzer sounds for a

few seconds) are triggered when R < 2Ω.

This threshold can be changed using the SET-UP function:

ALARM

<

x

Ω

Turn the alarm

ON or OFF

Set the value of the alarm

between 1 and 999Ω

and

Access the

type of alarm

Choose a low (<) or

high (>) alarm

Complete the adjustment

of the alarm setting

x

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 33

5.3 Resistance Measurement mΩ (4-Wire)

This measurement is used to improve the resolution (10x better than the 2-Wire

measurement) for weak resistance values.

To perform a 4-Wire measurement:

Press Hz/OPTIONS

(AUTO will blink)

Press ►

(H, S, ES and E will all blink)

Press Hz/OPTIONS once again

(H and E will blink)

Conrm choice by pressing

Hz/OPTIONS again

WARNING: Before performing the resistance test, verify that the sample

under test is not energized.

1. Set the switch to

2. Connect the resistance to all 4 terminals.

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

.

R

31

Page 34

3. Start the measurement by pressing the START/STOP button.

H

S

ES

E

ALARM

AUTO

±

±

DC

DC

Ω

Ω

Ω

4. To display the measurement parameters, press DISPLAY several times.

The device displays the following parameters:

R+, R-, +U

H-E

, +I

H-E

, -U

H-E

, -I

H-E

, U-Act (U

and its frequency)

H-E

5.4 Earth/Ground Measurement (3-Pole)

This function is used to measure an earth (ground) resistance with 2 auxiliary

electrodes.

There are several measurement methods, the full and simplied (62% method) will

be discussed in this section.

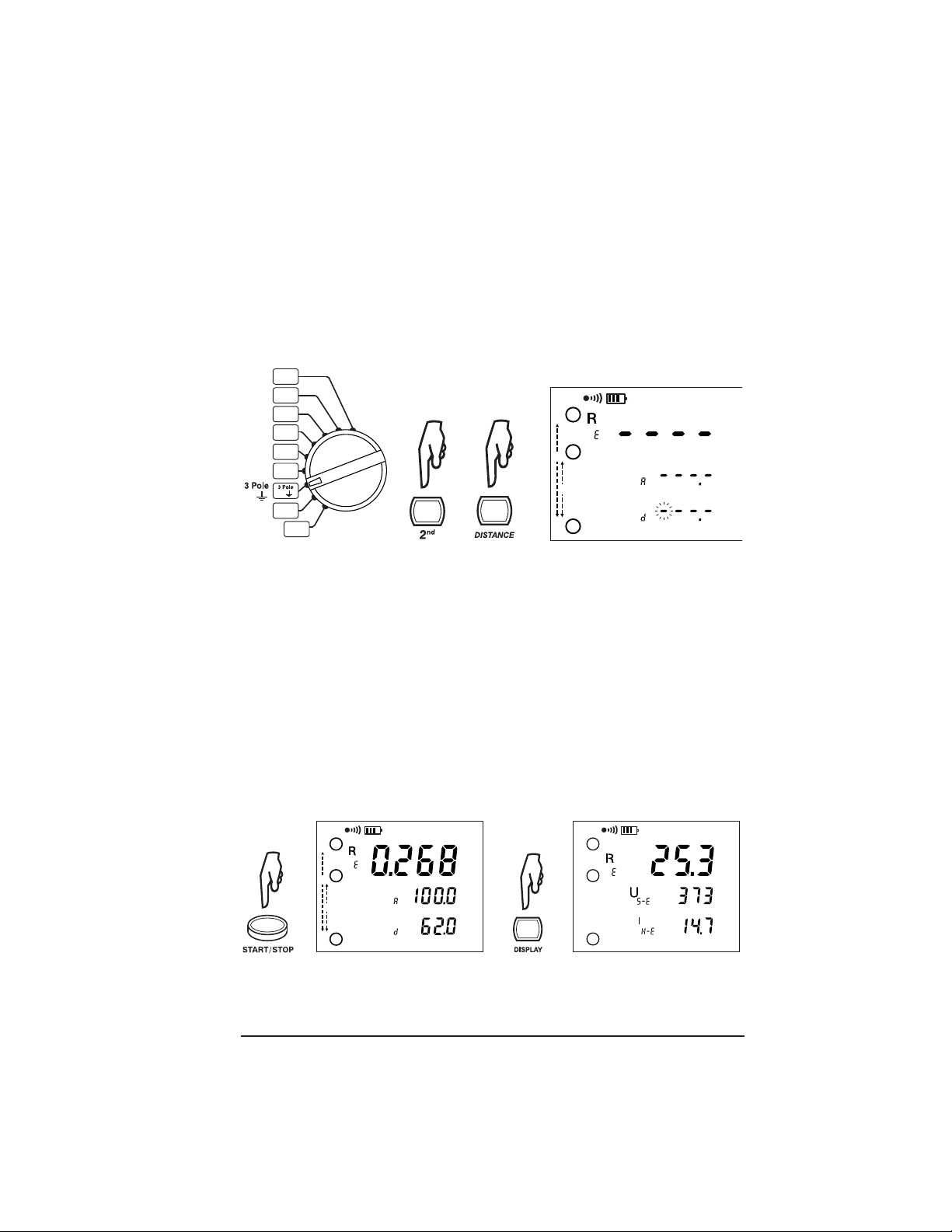

5.4.1 62% Method

1. Set the switch to

2. Place electrodes H (Z) and S (Y) to form a straight line with the earth electrode

under test.

The distance between electrode S (Y) and the earth electrode is 62% of

the distance between electrode H (Z) and the earth electrode; the distance

between the electrodes H (Z) and E (X) should be 8 to 10 times the depth of

the rod you are testing.

Ω

.

Ω

Ω

H (Z)

S (Y)

distance d - 62% d

distance A > 80 m

32

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 35

In order to avoid electromagnetic interference, it is best to unwind the full length of

each cable from the reel, to keep the cables as far apart as possible on the ground,

taking care not to form loops, and to avoid placing the cables near or parallel to

metallic conductors (cables, rails, fences, etc.).

Connect the cables to terminals H (Z) and S (Y) (red and blue respectively); dis-

connect the earth strap from the rod under test, then connect terminal E (green) to

the rod or electrode system to be tested.

3.

Press the 2nd button, then the DISTANCE button. The "hundredths" will blink.

H

S

A

AUTO

m

m

Ω

Ω

d

E

=

DISTANCE

=

4. To modify the hundredths (of meters or feet), press the ▲ button until the

desired digit is displayed (0-9).

5. To select and modify the tens, press the ► button and then the ▲ button until

the desired digit is displayed (0-9).

6. To select and modify the units and tenths of a unit, press the ► button and

then the ▲ button until the desired digits are displayed (0.0- 9.9).

7. To terminate the programming of distance, press the 2nd button and then the

DISTANCE button.

It is also necessary to program distance A. This is done in the same way as for

distance d.

8. Start the measurement by pressing the START/STOP button.

EARTH

H

S

A

d

E

=

=

AUTO

m

m

H

S

E

AUTO

Ω

mV

mA

9. To display the measurement parameters, press DISPLAY several times.

Ground Resistance Tester Model 6472

33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

The device displays the following parameters:

RE, U

S-E

, I

H-E

, U-Act (U

and its frequency, U

H-E

and its frequency).

S-E

To measure the resistances of auxiliary electrodes H (Z) and S (Y), or if the resistance of the electrodes is too high (see § 10.1), start the measurement with a long

press of the START/STOP button.

R

, RS will be displayed.

H

EARTH

H

S

Ω

AUTO

kΩ

Ω

k

> 2s

E

NOTE: Repeat the process at 52% and at 72% for the S electrode.

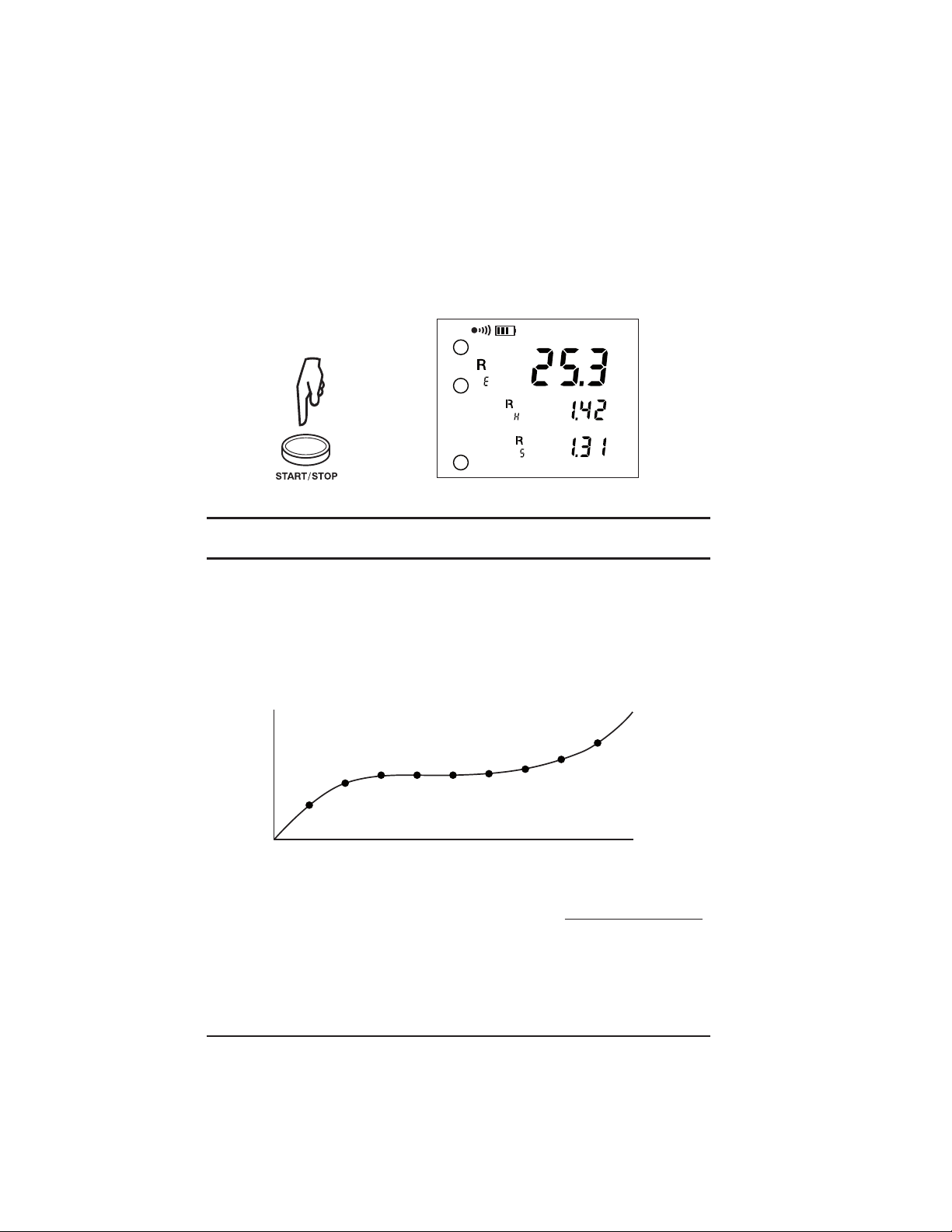

5.4.2 Full Method

A more thorough measurement can be obtained by taking measurement by mov-

ing the S (Y) auxiliary electrode every 10% between H (Z) and E (X) and plotting

the results. A distinct plateau should result as shown below.

R90

R80

R60

R70

R10

0 10

R30 R40 R50

R20

20 30 40 50 60 70 80 90 100

% H - E

Take the average of the 3 or 4 readings on the

plateau to obtain the earth electrode resistance.

34

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

R40 + R50 + R60 + R70

R =

4

Page 37

5.4.3 Recommendations for a Reliable Measurement

d2

Moving the Auxiliary Electrodes

Move electrode S (Y) towards electrode H (Z) by a distance equal to 10% of d and

make another measurement. Then move electrode S (Y) again by a distance equal

to 10% of d, but towards the earth electrode.

H (Z)

S (Y)

52% d

62% d

72% d

d

The 3 measurement results should be the same to within a few percent. If this is

the case, the measurement is valid.

If not, electrode S (Y) is in the zone of inuence of the earth electrode. It will be

necessary to increase distance d for the H (Z) auxiliary electrode and repeat the

measurements.

Positioning of the Auxiliary Electrodes

To make sure that your earth measurements are not distorted by interference, we

recommend repeating the measurement with the auxiliary electrodes placed at a

dierent distance and in another direction (for example, rotated 90° from the rst

alignment).

H (Z)

S (Y)

H (Z)

S (Y)

E (X)

d1

If you nd the same values, your measurement is reliable. If the measured values

are substantially dierent, it is likely that they were inuenced by earth currents or

a groundwater source. It may be useful to drive the electrodes deeper and/or wet

the ground near them to reduce their contact resistance with the soil.

Avoid routing the connecting cables of the earth electrodes near or parallel to other

cables (transmission or supply), metallic conductors, rails, or fences: high test frequencies may cause cross-talk and aect the measurements.

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

35

Page 38

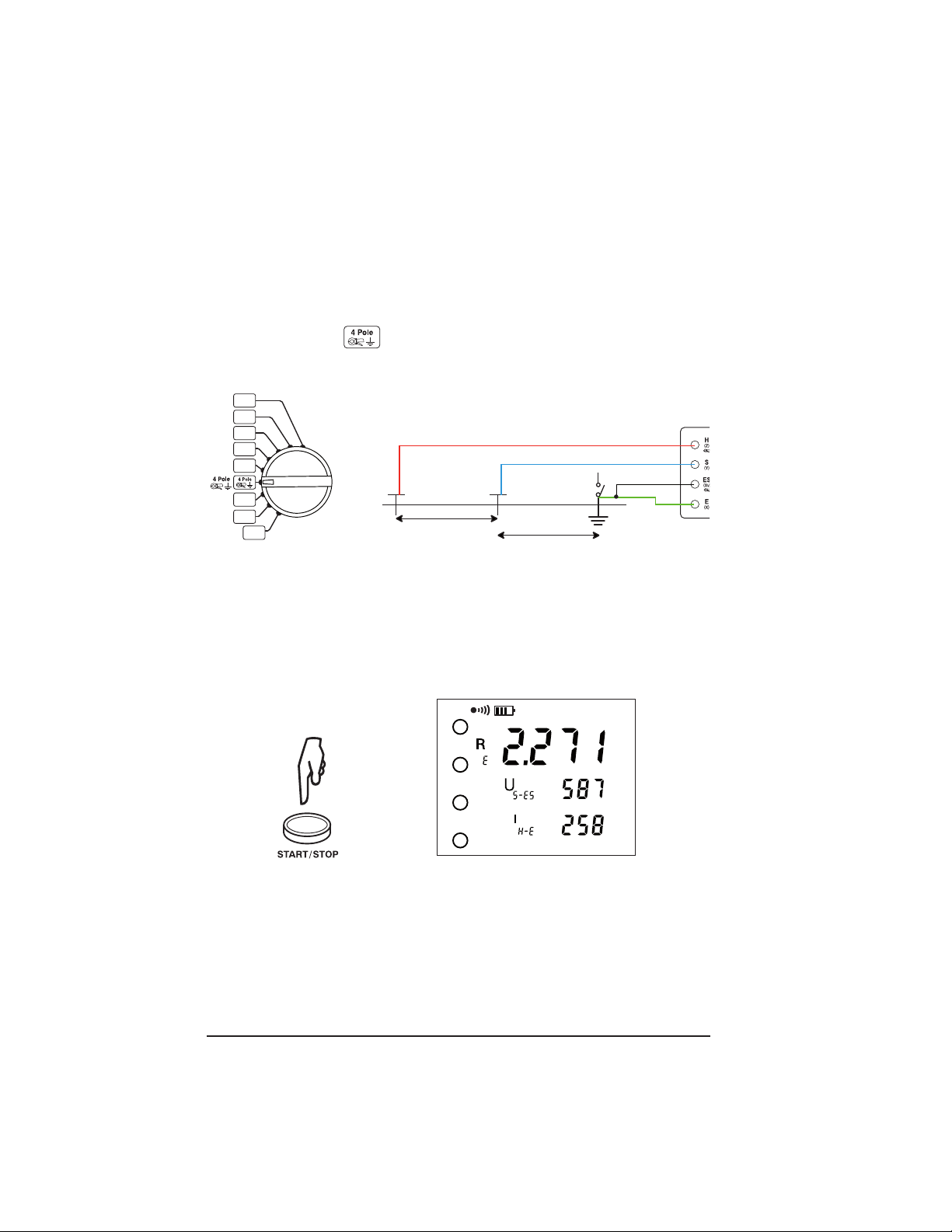

5.5 Earth/Ground Measurement (4-Pole)

H (Z)

5.5.1 Measurement without a Clamp

This function is suited to the measurement of very low earth resistances. It

provides better resolution (10x better than 3P measurement) and there is no need

to compensate for the resistance of the measurement leads.

1. Set the switch to .

2. Place electrodes H (Z) and S (Y) at least 30m apart.

S (Y)

> 30 m

> 30 m

In order to avoid electromagnetic interference, it is best to unwind the full length of

each cable from the reel, to keep the cables as far apart as possible on the ground,

taking care not to form loops, and to avoid placing the cables near or parallel to

metallic conductors (cables, rails, fences, etc.). Connect the cables to terminals

H (Z) and S (Y); disconnect the earth strap from the rod under test, then connect

terminals E (X) and ES (Xv) to the earth electrode to be tested.

3. Start the measurement by pressing the START/STOP button.

H

S

ES

E

AUTO

Ω

mV

mA

4. To display the measurement parameters, press DISPLAY several times.

The device displays the following parameters:

RE, U

S-E

, I

H-E

, U-Act (U

and its frequency, U

H-E

and its frequency).

S-E

To measure the resistances of auxiliary electrodes H (Z) and S (Y), or if the resistance of the electrodes is too large (see § 10.1), start the measurement with a long

press of the START/STOP button.

RH, RS, U

will be displayed.

H-E

36

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 39

> 2s

R

E4

H

S

ES

E

AUTO

Ω

kΩ

kΩ

We recommend repeating the measurement with the auxiliary electrodes placed at

a dierent distance and in another direction (see § 5.4.3).

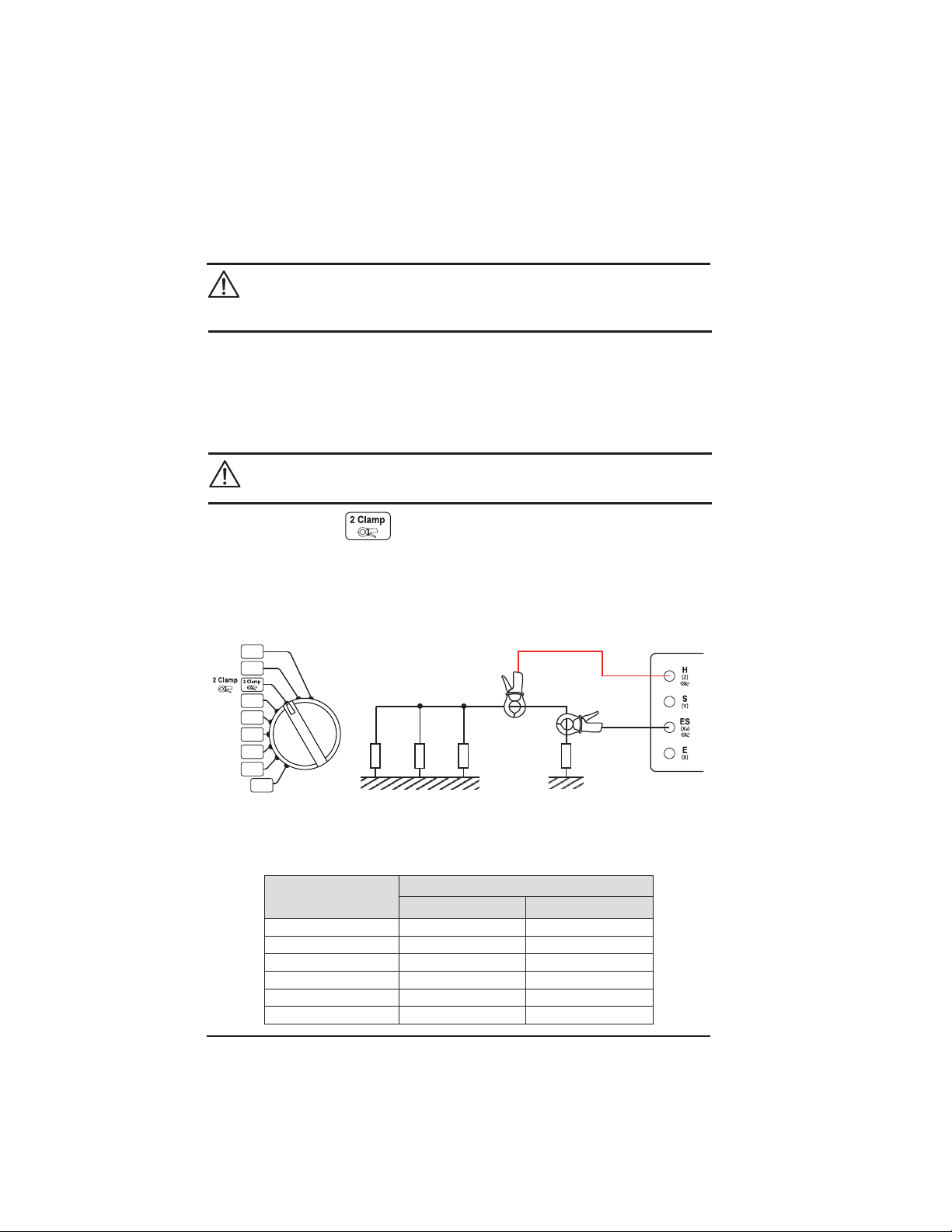

5.5.2 Measurements with a Clamp

For this selective earth measurement you need a current clamp, either a Model

SR182 or Model MN82 (both available as an accessory). These two types of

current clamps are specially designed to work with the 6472 ground tester.

The SR182 is more precise, suited to the measurement of higher currents (up to

40Arms) and for use on thicker conductors, while the MN82 (which is easier to

handle) accepts currents up to 10Arms and can be placed on conductors up to

3/4" (20mm) in diameter.

1. Set the switch to .

2. Place electrodes H (Z) and S (Y) at least 30m (98 ft) apart so that there is no

interference between them.

H (Z)

> 30 m (98 ft)

S (Y)

> 30 m (98 ft)

R

R

R

E3

E1

E2

In order to avoid electromagnetic interference, it is best to unwind the full length of

each cable from the reel, to keep the cables as far apart as possible on the ground,

taking care not to form loops, and to avoid placing the cables near or parallel to

metallic conductors (cables, rails, fences, etc).

3. Connect the cables to terminals H (Z) and S (Y), connect a cable between

terminal E (X) and the earth electrode under test, then connect the clamp to

terminal ES (Xv). The device recognizes it automatically.

Ground Resistance Tester Model 6472

37

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

4. Clamp to the path of the earth electrode to be checked, then connect a lead

from the current clamp to this same point [connection to terminal ES (XV) ].

Take care not to place the cable of electrode H (Z) too close to the current

clamp in order to avoid any transmission of the AC signal to the clamp (espe-

cially when using an MN82 clamp).

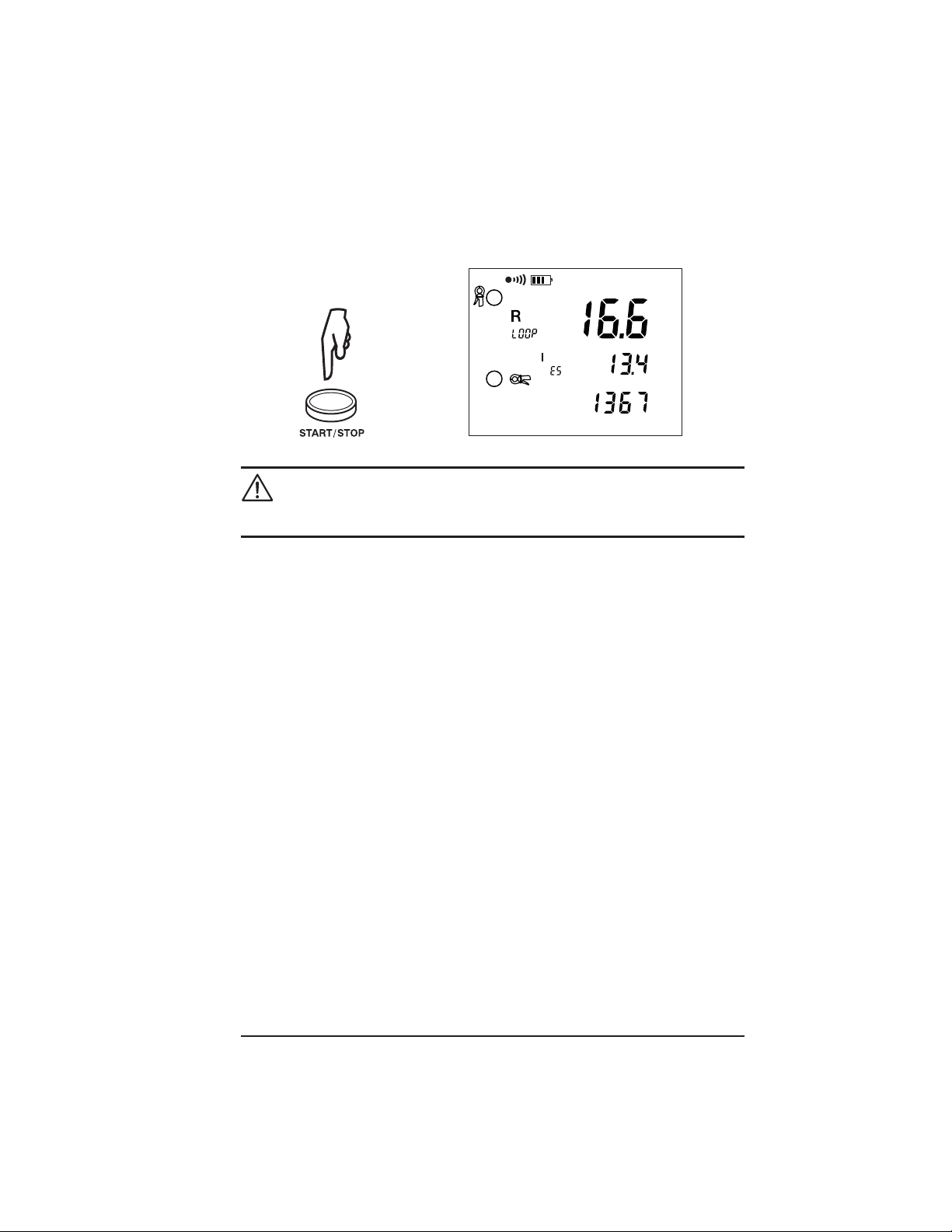

5. Start the measurement by pressing the START/STOP button.

H

S

ES

E

AUTO

Ω

mV

R

= RE1

SEL

mA

6. You can now move the clamp and its lead to measure the other earth resist-

ances, RE2, RE3, etc.

7. To display the measurement parameters, press DISPLAY several times.

The device displays the following parameters:

R

, U

SEL

S-ES

frequency).

, I

H-E

, R-Act (R

), U-Act (U

PASS

and its frequency), I-Act (IES and its

H-E

To measure the resistances of auxiliary electrodes H (Z) and S (Y), or if the resistance of the electrodes is too large (see § 10.1), start the measurement with a long

press of the START/STOP button.

RE, RH, RS, U

will be displayed.

E-S

> 2s

H

S

ES

E

AUTO

Ω

kΩ

kΩ

38

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Ground Resistance Tester Model 6472

Page 41

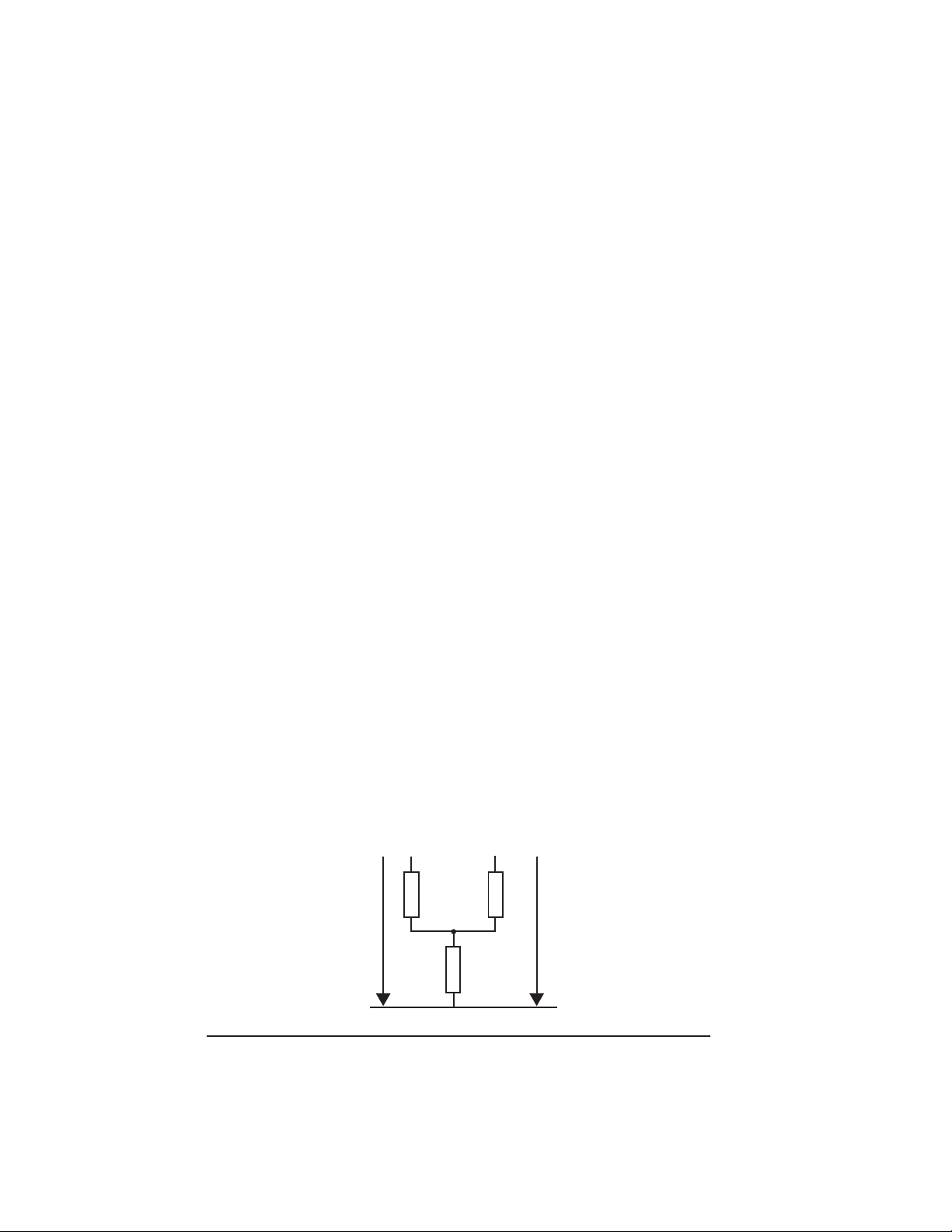

5.6 Soil Resistivity Measurements (ρ Position)

To measure the resistivity of the soil, two measurement methods are possible:

Wenner and Schlumberger

The dierence between the two methods lies in the positioning of the electrodes.

By default, the device selects the Wenner method. The Schlumberger method,

which allows you to move only 2 measurement electrodes rather than 3, is better

suited for measuring soil resistivity at multiple depths.

The soil resistivity measurement with dierent distances d, and therefore in different layers (in depth) of the soil, can be used to establish resistivity proles of

the soil in question, which can be useful for geological analysis, the exploration

of deposits, hydrological studies, etc., and to determine the location of an earth

electrode.

5.6.1 Advantages and Disadvantages of Wenner and Schlumberger

Schlumberger Wenner

Advantage Disadvantage Advantage Disadvantage

Need to move the two

potential electrodes ES

(Xv) and S (Y) only for

most readings. This can

significantly decrease the

time required to acquire

a sounding

Because the potential

electrode spacing is

small compared to

the current electrode

soakings, higher meter

sensitivity is required.

Because the potential

electrodes remain in

fixed locations, the effects of the near surface

lateral variations in

resistivity are reduced.

In general, interpretations

based on DC soundings

will be limited to simple,

horizontal; layered

structures

Ground Resistance Tester Model 6472

Potential electrode

spacing increases

as current electrode

spacing increases. Less

sensitive meters may

be used.

All four electrodes, the two

current E (X) and H (Z) and

the two potential ES (Xv)

and S (Y) must be moved

equally to acquire each

reading.

Because all electrodes

are moved for each

reading, this method can

be more susceptible to

near-surface, lateral, and

variations in resistivity.

These near surface lateral

variations could potentially

be misinterpreted in terms

of depth variations in

resistivity.

In general, interpretations

based on DC soundings

will be limited to simple,

horizontal; layered

structures.

Source: DC Resistivity - T. Boyd

39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

5.6.2 Changing the Measurement Method

x 2

1. Set the switch to .

2. Press the Hz/OPTIONS button. "AUTO" will blink.

W

H

ρ

d

S

d

ES

d

E

CONFIG

3. Press the Hz/OPTIONS button again. "W" will blink.

4. Press the ► button to change to the Schlumberger method.

5. To confirm and exit, press the Hz/OPTIONS button twice.

W

H

ρ

d

S

d

ES

d

E

CONFIG

AUTO

V

Hz

H

ρ

S

d

S

A

ES

d

E

CONFIG

AUTO

V

Hz

AUTO

V

Hz

To switch back to the Wenner method, simply repeat this procedure.

The last measurement method selected (Wenner or Schlumberger) is stored in

memory when the device is switched o.

5.6.3 Programming the Distance for Electrode Placement

The distance can be programmed before or after the measurement. If it is not

programmed, only the value of R

indeterminate.

1. Set the switch to .

2.

Press the 2nd button, then the DISTANCE button. The "hundredths" will blink.

40

will be displayed, since the value of ρ remains

S-ES

Ground Resistance Tester Model 6472

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

H

W

H

ρ

d

S

d

ES

d

E

DISTANCE

=

AUTO

Ωm

Ω

m