AEMC Instruments 400D-10 w/6' Lead, 400D-60 w/6' Lead, 400D-6 w/6' Lead, 4000D-14 w/6' Lead User manual

Page 1

DIGITAL FLEXPROBE

®

400D-6

400D-10

400D-60

400D-120

4000D-14

ENGLISH

User Manual

www.GlobalTestSupply.com

Page 2

www.GlobalTestSupply.com

Page 3

Table of Contents

1. INTRODUCTION ............................................................................... 4

1.1 International Electrical Symbols ................................................5

1.2 DenitionofMeasurementCategories .....................................5

1.3 ReceivingYourShipment ..........................................................6

1.4 OrderingInformation .................................................................6

1.4.1 AccessoriesandReplacementParts ............................6

2. PRODUCT FEATURES ...................................................................... 7

2.1 Description ................................................................................7

2.2 ControlFeatures .......................................................................8

3. OPERATION .................................................................................. 10

3.1 MeasurementPrinciple ...........................................................10

3.2 Use .........................................................................................10

3.2.1 Connection ..................................................................10

3.2.2 Measurement ............................................................. 11

3.2.3 FreezingtheMeasurement ......................................... 11

3.2.4 SearchforMaximum ..................................................12

3.2.5 AutoPowerOFF .........................................................12

3.2.6 LowBattery .................................................................12

3.2.7 Disconnecting .............................................................12

4. SPECIFICATIONS........................................................................... 13

4.1 ReferenceConditions .............................................................13

4.2 Electrical .................................................................................13

4.3 VariationsinRangeofUse .....................................................14

4.4 TypicalFrequencyResponseCurves .....................................15

4.5 PowerSupply ..........................................................................15

4.6 Environmental .........................................................................16

4.7 Mechanical ..............................................................................16

4.8 Safety ......................................................................................16

4.9 ElectromagneticCompatibility ................................................16

2

www.GlobalTestSupply.com

Digital Flexprobe® Models 400D & 4000D

Page 4

5. MAINTENANCE ............................................................................. 17

5.1 Cleaning ..................................................................................17

5.2 ReplacingtheBatteries ...........................................................17

5.3 RepairandCalibration ............................................................18

5.4 TechnicalandSalesAssistance ..............................................18

5.5 Limited Warranty .....................................................................19

5.6 WarrantyRepairs ....................................................................19

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

3

Page 5

CHAPTER 1

INTRODUCTION

Thank you for purchasing an AEMC® Digital Flexbprobe.

For best results and for your safety, read the enclosed operating

instructions carefully and comply with the precautions for use.

PRECAUTIONS BEFORE USE

This instrument is protected against voltages of not more than

1000V with respect to ground in measurement CAT III or 600V in

CAT IV between the sensor and the conductor that measures the

current.

The protection provided by the instrument may be impaired if the

instrument is used other than as specified by the manufacturer.

• Do not exceed the rated maximum voltage and current or the

measurement category.

• Observe the conditions of use; temperature, relative humidity,

altitude, level of pollution, and location.

• Before each use, check the integrity of the insulation on the

sensor, cable and housing. Do not use the instrument if it is

open, damaged, poorly assembled, or if its accessories appear

damaged.

• The sensor must not be applied to or removed from uninsulated

conductors at dangerous voltages.

• Use personal protection equipment systematically.

• All troubleshooting and metrological checks must be

performed by competent and accredited personnel.

4

www.GlobalTestSupply.com

Digital Flexprobe® Models 400D & 4000D

Page 6

1.1 International Electrical Symbols

Signifies that the instrument is protected by double or reinforced insulation.

CAUTION - Risk of Danger! Indicates a WARNING and that the operator must

refer to the user manual for instructions before operating the instrument in all

cases where this symbol is marked.

Must not be applied to or removed from bare conductors at dangerous voltages.

Type B current sensor as per IEC 61010‑2‑032.

Important instructions to read and understand completely.

Important information to acknowledge.

Battery

Compliance with the Low Voltage & Electromagnetic Compatibility European

directives (73/23/CEE & 89/336/CEE)

In the European Union, this product is subject to a separate collection system

for recycling electrical and electronic components In accordance with directive

WEEE 2002/96/EC

1.2 Definition of Measurement Categories

CAT II: For measurements performed on circuits directly connected to

the electrical distribution system. Examples are measurements

on household appliances or portable tools.

CAT III: For measurements performed in the building installation at the

distribution level such as on hardwired equipment in fixed installation and circuit breakers.

CAT IV: For measurements performed at the primary electrical supply

(<1000V) such as on primary overcurrent protection devices,

ripple control units, or meters.

1.3 Receiving Your Shipment

Upon receiving your shipment, make sure that the contents are consistent with the packing list. Notify your distributor of any missing items. If

the equipment appears to be damaged, file a claim immediately with the

carrier and notify your distributor at once, giving a detailed description of

any damage. Save the damaged packing container to substantiate your

claim.

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

5

Page 7

1.4 Ordering Information

Digital FlexProbe® Model 400D-6 w/6 ft Lead

(TRMS, 4AAC, 40AAC, 400AAC) ............................................Cat. #2153.30

®

Digital FlexProbe

(TRMS, 4A

AC, 40AAC, 400AAC) ............................................Cat. #2153.31

Digital FlexProbe® Model 4000D-14 w/6 ft Lead

(TRMS, 40AAC, 400AAC, 4000AAC) ......................................Cat. #2153.32

Digital FlexProbe® Model 400D-60 w/6 ft Lead

(TRMS, 4AAC, 40AAC, 400AAC) ............................................Cat. #2153.33

Digital FlexProbe® Model 400D-120 w/6 ft Lead

(TRMS, 4AAC, 40AAC, 400AAC) ............................................Cat. #2153.34

All models include one Digital FlexProbe®, two AAA batteries and a product user manual.

1.4.1 Accessories

Multifix Multi-Position Magnetic Mounting Accessory ........Cat. #5000.44

Soft Carrying Case ..............................................................Cat. #2118.65

Model 400D-10 w/6 ft Lead

Replacement Parts

Small Classic Tool Bag (Cat. #2153.33 & 2154.34 only) .....Cat. #2133.72

6

www.GlobalTestSupply.com

Digital Flexprobe® Models 400D & 4000D

Page 8

CHAPTER 2

PRODUCT FEATURES

2.1 Description

An ideal addition to the electrician’s tool kit, the Digital FlexProbe® series

can be used for TRMS AC current measurements from 20mA to 4000A,

and are rated 600V CAT IV. They provide a welcomed solution when

accessing electrical conductors is difficult and in tight places.

Three models are available. The Model 400D, available with either a 6",

10", 60" or 120" sensor, has a measurement range starting at 20mA,

and is designed for work in residential, commercial and light industrial

applications. It can be used to check electrical distribution systems up

to 400 Amps.

The Model 4000D, available with a 14" sensor, has a measurement range

starting at 100mA and can be used on higher-power industrial installations,

as well as electrical utilities for measurements up to 4000 Amps.

Although they are high-performance instruments, the Digital FlexProbe®

series remain very simple to use: two buttons are all it takes to start the

instrument, deactivate the auto power-off, HOLD the value on the display

or store the maximum value (MAX HOLD). The values are read directly on

the built-in 4000-count display.

They are ergonomically designed for comfortable handheld use even

when bulky gloves are required. The optional articulating, magnetic

Multifix mounting system accessory makes it simple to hang on a wall,

door, table edge or clip onto a belt.

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

7

Page 9

2.2 Control Features

1

6

0

V

I

0

V

T

A

C

1

I

0

I

I

0

0

T

V

A

C

4000 A

2

HOLD

MODEL 400

TRMS CURRENT METER

M

AX

D

P

4

5

A

6

3

1. Flexiblesensor

-Model400D(6", 10", 60", 120")

-Model4000D(14")

2. Sensoropening/closinglever

3. Shieldedlead

4. Protectivehousing

5. LCDdisplay

HOLD

Digital

FlexProbe

MAX

(>2s)

7

®

6. ON/OFFbutton

7. HOLDbutton

8

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

Page 10

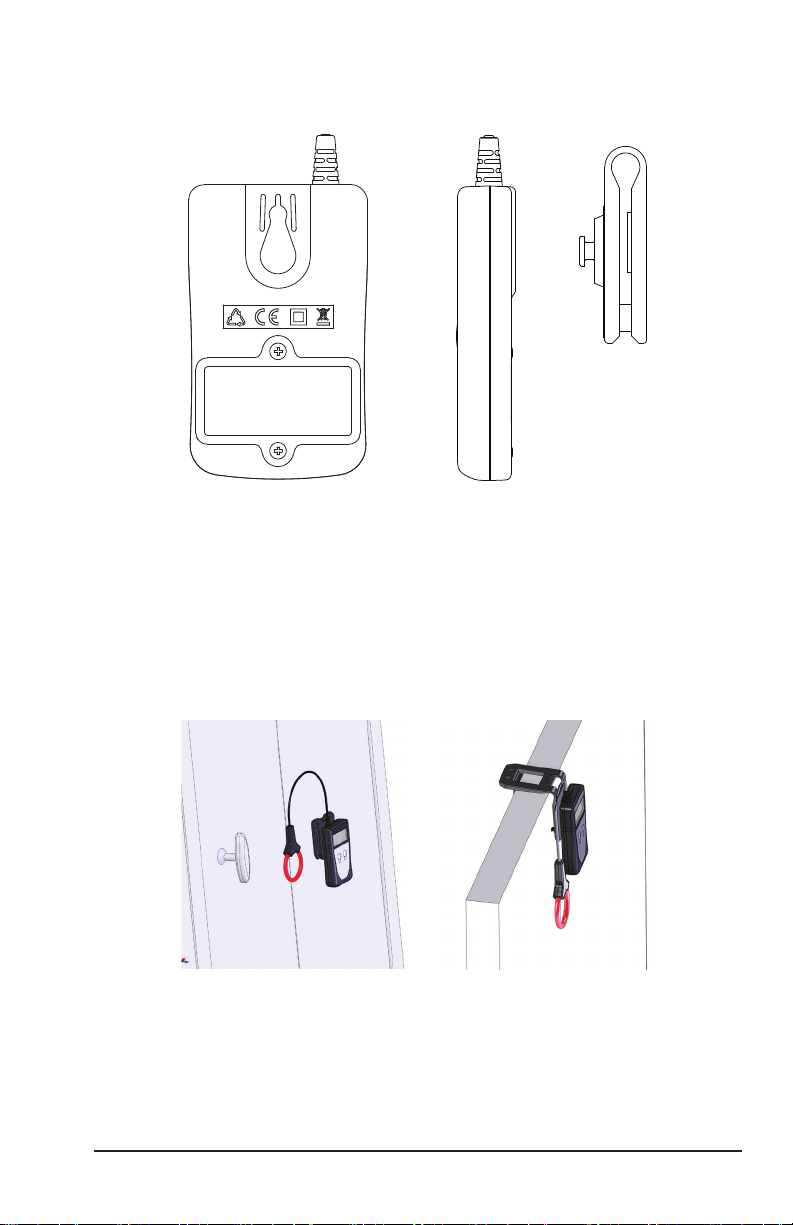

On the back of the protective housing is a notch for the attachment of a

belt clip (optional).

With the Multifix magnetic mounting accessory, you can position your

Digital FlexProbe® anywhere, leaving both hands free. The Multifix can

be used to:

• Carry the Digital Flexprobe® on a belt

• Attach it to a metal surface using the built-in magnet

• Attach it to a door top or the edge of a table

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

9

Page 11

CHAPTER 3

OPERATION

3.1 Measurement Principle

The flexible sensor is based on the Rogowski coil.

This principle combines:

• Excellent linearity with no saturation effect (therefore no heating)

• Light-weight (no magnetic circuit)

3.2 Use

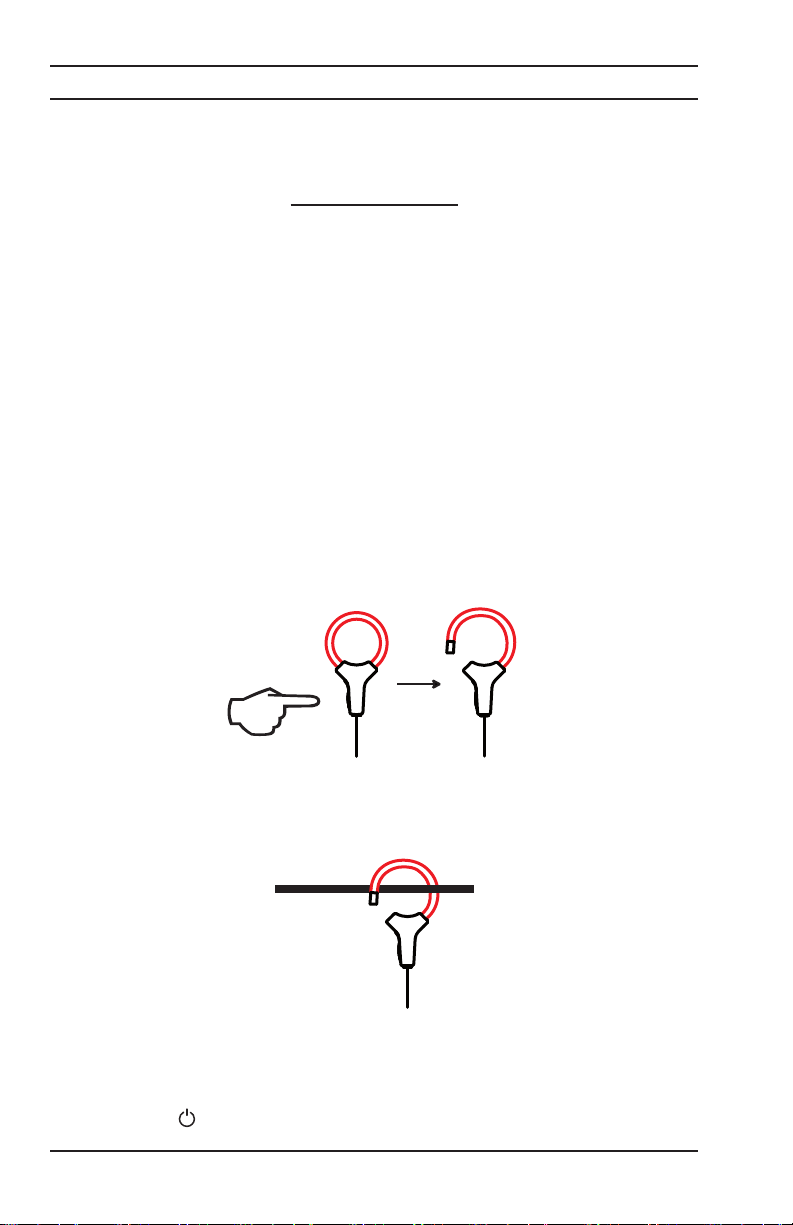

3.2.1 Connection

• Press the yellow opening lever to open the flexible coil.

• Place the sensor around the conductor through which the current

to be measured flows (only one conductor in the sensor), then close

the sensor.

• In order to optimize measurement quality, it is best to center the

conductor in the coil and make the shape of the coil as nearly circular as possible.

• Press the

10

button to turn the instrument on.

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

Page 12

3.2.2 Measurement

Read the measurement on the display. The current is given in Arms.

A

If the measurement exceeds the display capacity (4000A), the device displays 3999, blinking.

A

If the measurement is too low (see § 3.2), the device displays dashes.

A

If the edges of the signal are too steep, or its peak factor is too large, the

device displays OL.

A

3.2.3 Freezing the Measurement

If you want to freeze the display of a measurement, press the HOLD

button. The HOLD symbol is displayed.

HOLD

A

The device continues to make measurements, but the display is frozen.

To release it, press the HOLD button again.

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

11

Page 13

3.2.4 Search for Maximum

To search for a maximum, for example a spike lasting at least 100 ms,

press the HOLD (MAX > 2s) button for more than two seconds.

The Max symbol will display and the instrument will begin measuring.

M

AX

A

The Digital Flexprobe® compares each new measurement to the one

displayed. If the new measurement is greater than the old, it replaces it

in the display.

To return to the real-time display mode, press the HOLD (MAX > 2s)

button again.

3.2.5 Auto Power OFF

If there is no activity after 10 minutes, the Digital Flexprobe® turns off

automatically (unless the MAX function is active) to preserve battery life.

To deactivate the Auto Power OFF feature, press the

buttons simultaneously when turning the instrument on.

To reactivate automatic switching off, switch the device off, then back on.

and HOLD

3.2.6 Low Battery

When the battery voltage drops and the remaining battery life of the

instrument is approximately one hour, the symbol blinks on the

display.

When the battery voltage is too low to guarantee the accuracy of a

measurement, the symbol lights steadily. The batteries must then be

replaced (see § 5.2).

3.2.7 Disconnecting

Turn off the device by pressing the button. Press the yellow opening

lever to open the flexible sensor. Remove the sensor from the conductor.

12

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

Page 14

CHAPTER 4

SPECIFICATIONS

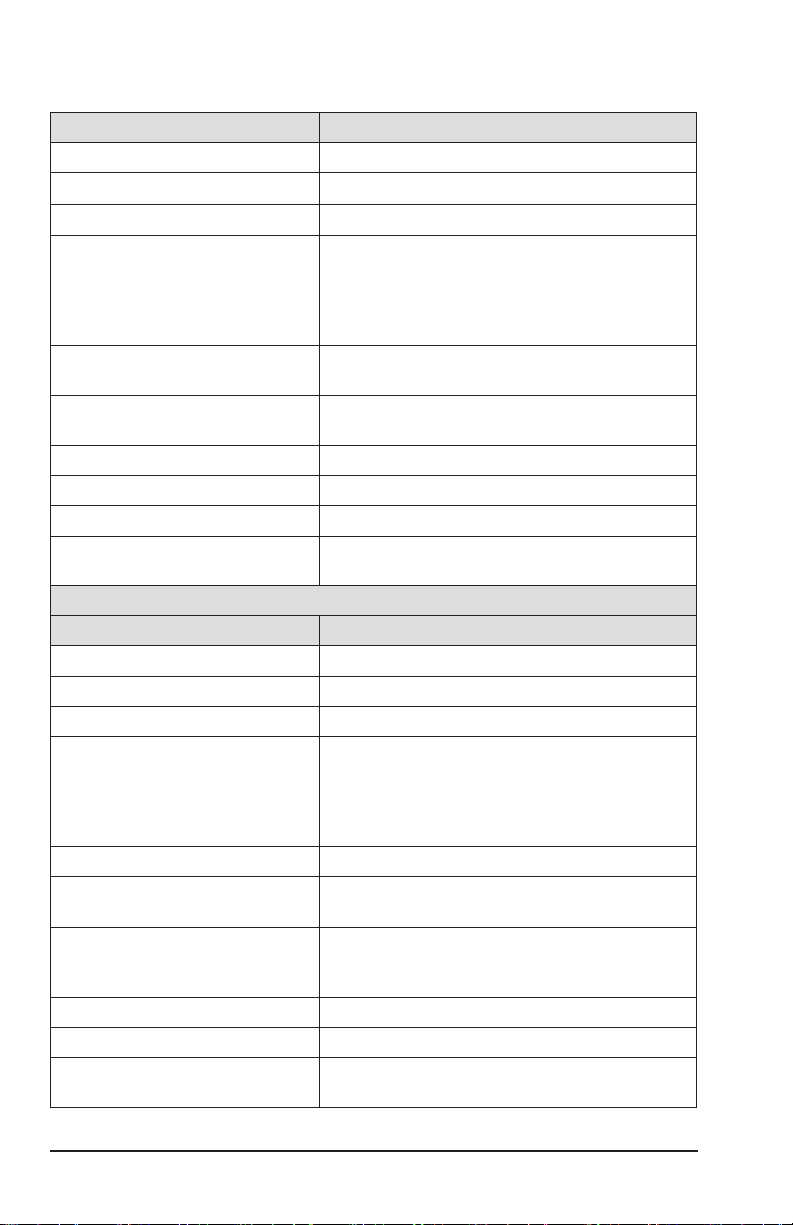

4.1 Reference Conditions

Quantity of influence Reference values

Temperature

Relative humidity

Frequency of the signal measured

Peak factor of the signal measured

Conductor diameter

Battery voltage

External electric field

External DC magnetic field (earth field)

External AC magnetic field

Position of the conductor

Shape of the measurement coil

centered in the measurement coil

23 ± 3°C

45 to 75% RH

40 to 65Hz

√2

≤5mm

2.8 to 3.2V

none

<40 A/m

none

nearly circular

4.2 Electrical

Model 400D-6 / 400D-10 / 400D-60 / 4000D-120

Display Range 4A 40A 400A

Measurement Range

Measurement Range (max)

Resolution

Accuracy

0.020 to 3.999A 4.00 to 39.99A 40.0 to 399.9A

0.100 to 3.999A 4.00 to 39.99A 40.0 to 399.9A

1mA 10mA 100mA

±(2% + 10ct) ±(1.5% + 2ct) ±(1.5% + 2ct)

Model 4000D-14

Display Range 40A 400A 4000A

Measurement Range

Measurement Range (max)

Resolution

Accuracy

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

0.20 to 39.99A 40.0 to 399.9A 400 to 3999A

1.00 to 39.99A 40.0 to 399.9A 400 to 3999A

10mA 100mA 1A

±(2% + 10ct) ±(1.5% + 2ct) ±(1.5% + 2ct)

13

Page 15

4.3 Variations in Range of Use

Quantity of influence Range of influence

Battery voltage

Temperature

Relative humidity

Frequency response

Position of the conductor in the

sensor (f<400 Hz)

Adjacent conductor

carrying alternating current

Peak factor

Serial mode rejection ratio in AC

Common mode rejection, 50/60 Hz

Influence of a 50/60Hz external

magnetic field

Typical Maximum

< 1ct

± 0.25% / 10°C

0.2%

See § 3.4

± 0.5 %

Away from opening: 55 dB

At opening: 55 dB

at 16.66Hz: ± (2 % + 1ct)

at 50Hz: ± (0.5 % + 1ct)

at 440Hz: ± (30 % + 1ct)

< 1ct

< 1ct

Housing: 43 dB

Sensor: 50 dB

Any position on the interior perimeter of the sensor

Accuracy

1.8 to 2V

0°C to 50°C

10 to 90% RH

10 to 20Hz

20 to 30Hz

30 to 400Hz

400 to 1000Hz

1000 to 3000Hz

Conductor touching the exterior

perimeter of the sensor

1.4 to 3.5 limited to 6000Apeak

0 to 400A

0 to 600Vrms

0 to 400A/m

±(2% + 1ct)

±( 0.5% / 10°C + 2cts)

± (0.3% + 2cts)

± (5% + 1ct)

± (1% + 1ct)

± (0.5% + 1ct)

± (6% + 1ct)

‑ 3 dB typical

± (1.5% ± 1ct)

Away from opening: ≥ 45 dB

At opening: ≥ 45 dB

± (6% + 1ct)

± (3% + 1ct)

Housing: ≥ 30 dB

Sensor: ≥ 40 dB

DC

—

≥50 dB

≥60 dB

14

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

Page 16

4.4 Typical Frequency Response Curves

(at 39AAC)

10 %

0 %

-10 %

-20 %

-30 %

-40 %

-50 %

zH 00001zH 0001zH 001zH 01

4.5 Power Supply

The device can be powered by either:

• Two 1.5V (AAA) alkaline batteries

• Two NiMH storage batteries of the same size

The nominal operating voltage is between 1.8V and 3.2V.

The battery life in continuous operation is:

• 70 hours with super-alkaline batteries

• 50 hours with NiMH storage batteries having a capacity

of 1200 mAh

The low battery condition is acknowledged by a blinking symbol on

the display. When lit steadily, the batteries must be replaced (see § 5.2).

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

15

Page 17

4.6 Environmental

Operating Temperature: 32° to 122°F (0° to 50°C)

Storage Temperature (without batteries): -4° to 158°F (-20° to +70°C)

Operating Relative Humidity: 80% RH to 122°F (50°C)

Storage Relative Humidity: 90% RH up to 113°F (45°C)

The sensor can withstand a temperature of 194°F (90°C)

Indoor use / Level of pollution: 2 / Altitude: < 2000m

4.7 Mechanical

Dimensions: 3.94 x 2.36 x 0.79" (100 x 60 x 20mm)

Cable Length: 6 ft (1.83m)

Sensor Length: 400D-6: 6" (170mm)

400D-10: 10" (250mm)

400D-60: 60" (1524mm)

400D-120: 120" (3048mm)

4000D-14: 14" (350mm)

Sensor Diameter: 400D-6: Ø 1.77" (45mm)

400D-10: Ø 2.75" (70mm)

400D-60: Ø 19" (483mm)

400D-120: Ø 38" (965mm)

4000D-14 : Ø 3.94" (100mm)

Weight: 0.29 lbs (130g) approx

Index of protection: IP 40 per IEC 60529

IK 04 per IEC 50102

V0 (per UL 94)

The flexible coil is resistant to oils and aliphatic hydrocarbons.

4.8 Safety

Electrical safety per IEC 61010-2-032 for type B sensors.

Rated 600V CAT IV.

4.9 Electromagnetic Compatibility

Emissions and immunity in an industrial setting compliant with IEC

61326-1 for portable devices.

16

www.GlobalTestSupply.com

Digital Flexprobe® Models 400D & 4000D

Page 18

CHAPTER 5

MAINTENANCE

Use only factory specified replacement parts. AEMC

responsible for any accident, incident, or malfunction following a repair

®

will not be held

done other than by its service center or by an approved repair center.

5.1 Cleaning

Disconnect the instrument from any source of electricity.

• Use a soft cloth lightly moistened with soapy water.

• Wipe with a moist cloth and then dry with a dry cloth.

• Do not allow water or other foreign substances into the case.

• Never use alcohol, solvents or hydrocarbons.

5.2 Replacing the Batteries

Disconnect the instrument from any source of electricity.

The battery must be replaced when the symbol flashes or remains

steady on the display.

• Use a screwdriver to unscrew the two closing screws on the back of

the housing.

• Replace the old battery with a new battery

(1.5V or AAA super-alkaline batteries).

• Close the housing; make sure that it is completely and correctly

closed.

• Screw both screws back in.

Used batteries must not be treated as ordinary household waste.

Take them to the appropriate recycling collection point.

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

17

Page 19

5.5 Limited Warranty

The Digital FlexProbe® Models 400D and 4000D are warranted to the owner

for a period of one year from the date of original purchase against defects in

manufacture. This limited warranty is given by AEMC

®

Instruments, not by

the distributor from whom it was purchased. This warranty is void if the unit

has been tampered with, abused or if the defect is related to service not performed by AEMC

®

Instruments.

Full warranty coverage and product registration is available on our

website at www.aemc.com/warranty.html.

Please print the online Warranty Coverage Information for your records.

What AEMC

®

Instruments will do:

If a malfunction occurs within the one-year period, you may return the

instrument to us for repair, provided we have your warranty registration

information on file or a proof of purchase. AEMC

®

Instruments will, at its

option, repair or replace the faulty material.

REGISTER ONLINE AT:

www.aemc.com

5.6 Warranty Repairs

What you must do to return an Instrument for Warranty Repair:

First, request a Customer Service Authorization Number (CSA#) by phone

or by fax from our Service Department (see address below), then return the

instrument along with the signed CSA Form. Please write the CSA# on the

outside of the shipping container. Return the instrument, postage or shipment

pre-paid to:

Ship To: Chauvin Arnoux

15 Faraday Drive • Dover, NH 03820 USA

Phone: (800) 945-2362 (Ext. 360)

(603) 749-6434 (Ext. 360)

Fax: (603) 742-2346 or (603) 749-6309

E-mail: repair@aemc.com

Caution: To protect yourself against in-transit loss, we highly recommend

you insure your returned material.

NOTE: You must obtain a CSA# before returning any instrument.

Digital Flexprobe® Models 400D & 4000D

www.GlobalTestSupply.com

®

, Inc. d.b.a. AEMC® Instruments

19

Page 20

Notes:

20

www.GlobalTestSupply.com

Digital Flexprobe® Models 400D & 4000D

Page 21

www.GlobalTestSupply.com

Loading...

Loading...