Page 1

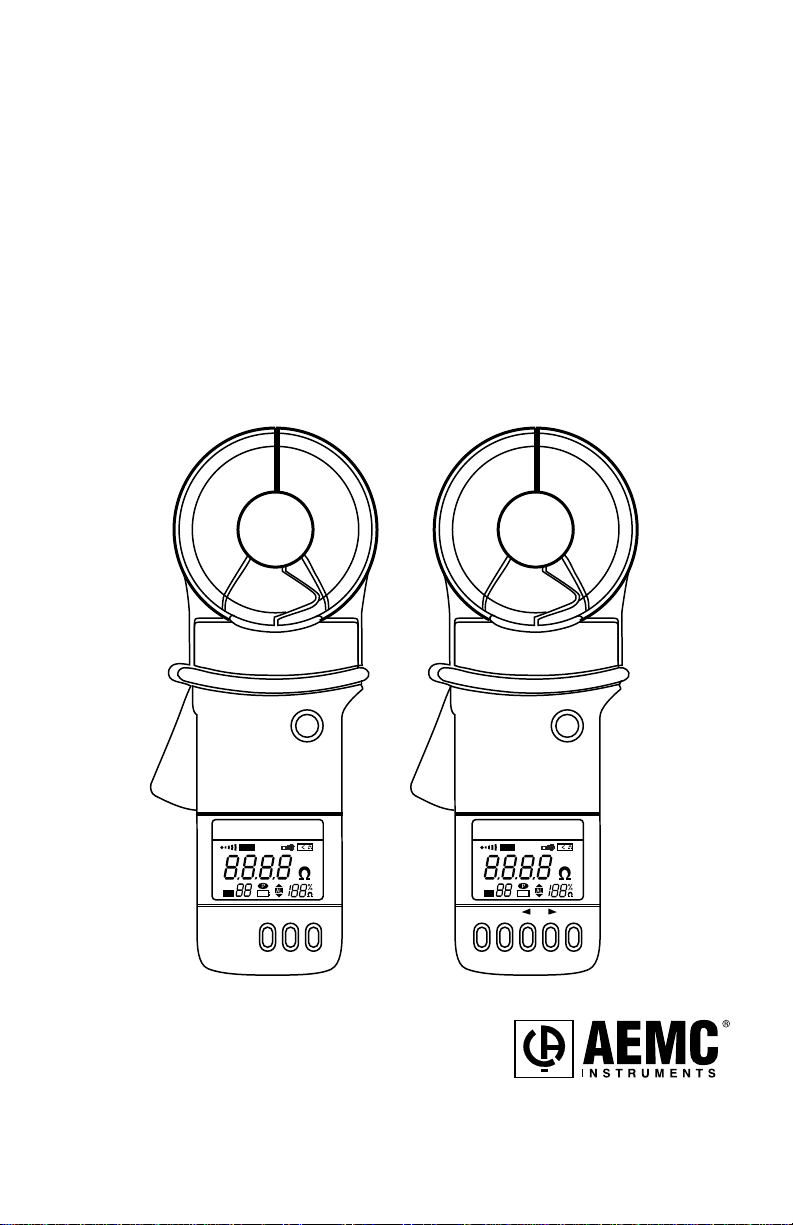

Clamp-On

HOLD

+

—

m

A

R

1

HOLD

MEM

MR

NOISE

Model 3710

GROUN D TES TER

AEMC

I NS T R U M E NT S

A Ω

ON

OFF

HOLD

+

—

m

A

R

1

HOLD

MEM

MR

NOISE

Model 3730

GROUN D TES TER

AEMC

I NS T R U M E NT S

MEM AL A Ω

ON

OFF

Ground Resistance Testers

Models 3710 and 3730

USER MANUAL

Page 2

Owner’s Record

The serial number for the Model 3710 or Model 3730 is located inside

the battery compartment of the instrument. Please record this number

and purchase date for your records.

CLAMP-ON GROUND RESISTANCE TESTER MODEL 3710

CATALOG #1221.01

SERIAL #:

PURCHASE DATE:

DISTRIBUTOR:

CLAMP-ON GROUND RESISTANCE TESTER MODEL 3730

CATALOG #1221.02

SERIAL #:

PURCHASE DATE:

DISTRIBUTOR:

99-MAN-100061

5th Revision

Printed 03/98

AEMC®Instruments

by Chauvin Arnoux, Inc.

Page 3

Table of Contents

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Receiving Your Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Government Orders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safety Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Model 3710 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Model 3730 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Digital Display Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Additional Features of the Model 3730 . . . . . . . . . . . . . . . . . . .12

Function Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Programming the Alarm Setpoint . . . . . . . . . . . . . . . . . . . . . . .17

Changing the Alarm Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Memory Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Clear Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Function Access Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Programming Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Field Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Operating Reference Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Calibration Check Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Commonly Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Page 4

Table of Contents (cont.)

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Repair and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Technical and Sales Assistance . . . . . . . . . . . . . . . . . . . . . . . . . .36

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . .Inside back cover

Page 5

Warning

These safety warnings are provided to ensure the safety of personnel and the proper operation of the instrument.

• The instrument must not be operated beyond its specified operating range.

• Safety is the responsibility of the operator.

• All metal objects or wires connected to the electrical system

should be assumed to be lethal until tested. Grounding systems

are no exception.

• Use extreme caution when using the instrument around energized electrical equipment.

• Never attempt to use the instrument to twist or pry the ground

electrode or ground wire away from the equipment being

grounded.

• Open and close the clamp-on jaws slowly ensuring proper

alignment.

• AEMC®Instruments considers the use of rubber gloves to be an

excellent safety practice even if the equipment is properly operated and correctly grounded.

Ground Resistance Tester Models 3710/3730

3

Page 6

Receiving Your Shipment

Upon receiving your shipment, be sure that the contents are consistent

with the packing list. Notify your distributor of any missing items. If the

equipment appears to be damaged, file a claim immediately with the

carrier and notify your distributor at once, giving a detailed description

of any damage. Save the damaged packing container to substantiate

your claim.

Packaging

The Clamp-On Ground Resistance Testers Model 3710 (Cat. #1221.01)

and Model 3730 (Cat. #1221.02) are shipped with a hard carrying case,

one 9 V battery (not installed), an instruction manual with warranty

registration and a calibration loop. The manual, warranty card, and calibration loop are located behind the “egg crate” foam on the inside of the

carrying case cover.

Government Orders

The Clamp-On Ground Resistance Tester Model 3710 (Cat. #1221.01)

has been issued a National Stock Number. Orders for the Model 3710

should reference NSN 6625-01-377-8030.

Accessories

One multiple calibration loop, Cat. #1223.01

4

Ground Resistance Tester Models 3710/3730

Page 7

Description

Outline

The ground resistance tester Models 3710 and 3730 measure ground rod

and small grid resistance through any season, without the use of auxiliary

ground rods. Clamp-on ground resistance testers are used in multigrounded systems without disconnecting the ground under test. The

Models 3710 and 3730 simply clamp around the ground conductor or rod

and measure the resistance to ground. By performing measurements on

intact ground systems, the user also verifies the quality of the grounding

connections and bonds. Resistance and continuity of grounding loops

around pads and buildings may also be measured.

Both models include a current measurement function. The probe’s high

sensitivity enables measurement of leakage current flowing to ground or

circulating in ground loops down to 1 mA and neutral currents to 30 A

rms. This feature provides additional information which is becoming vital

as distribution ground networks carry higher levels of noise and

harmonics which affect power quality.

Both models offer battery life information at power-up and Auto-Off

for power management. Additional features are also displayed on the

large LCD to ensure precise measurements. The Buzzer and Auto-Off

features may be disabled from the push-buttons at any time.

The Model 3730 offers an Alarm function and a Memory (logging) function. In the Alarm mode, the probe will audibly and visually indicate if the

reading is beyond an input set point. The user may also have the Alarm

initiated above or below the set point. This Alarm feature permits quick

field checks where only “pass” or “fail” readings will suffice.

The Memory function logs up to 99 measurements (Ohms or Amperes).

This enables the user to conduct field surveys, and to retrieve and

analyze the readings at a later time. The alarm settings and stored

memory information are saved when the ground tester is turned off.

Product Construction

The Models 3710 and 3730 body cases are built of Lexan®for rugged

use. The probe heads are encapsulated in a double-walled Lexan®shell

Ground Resistance Tester Models 3710/3730

5

Page 8

for extra strength and are reinforced at the body interfaces for enhanced

field reliability. Overall construction and mechanical design ratings such

as drop test, shock and vibration, weatherproofing against water

projections or dust, meet or exceed IEC (International Electrotechnical

Commission) standards. The products have also been designed to

meet IEC 1010, UL 1244, CSA and GS safety approvals .

Jaw Design

The probe head, or jaw, is a key component in the measurement and

overall product performance. Considerable research and development

were dedicated to ensuring its performance, reliability and versatility.

The large jaw has an inner opening diameter of 1.25" (32 mm) - double

its predecessor’s diameter - while retaining the same overall jaw

thickness, permitting use on tight ground conductors on poles and in

manholes. The large opening accommodates not only ground rods, but

larger ground conductors (up to 1000 MCM) typically found in telecommunication or railroad applications.

The inner jaw is composed of two independent and individually shielded

magnetic cores permitting the injection of a test signal and accurate

return signal measurement without noise interference or cross talk

common to separate probe instruments.

Thorough mechanical design, including small winglets, ensures repetitive

jaw alignment for accuracy and prevents undesirable insertions into the

jaw spring assembly.

Body Design

The ergonomic body design permits one-handed operation. The guard

provides additional strength, and prevents the hand from slipping or

coming into contact with conductors under test. The Lexan®body construction provides strength. The LCD lens cover may be easily replaced

if scratched. The sealed push-buttons directly access all test functions

and are easily operated even with gloved hands.

Lexan®is a registered trademark of General Electric Corporation.

6

Ground Resistance Tester Models 3710/3730

Page 9

Electrical Specifications

Ground Resistance

Measurement Range

Autoranging

1.0 to 1200 Ω

Range

1.0 to 50.0 Ω

50.0 to 100.0 Ω

100 to 200 Ω

200 to 400 Ω

400 to 600 Ω

600 to 1200 Ω

Ground or Leakage Current

Autoranging

1 mA to 30.00 A rms

* Reference conditions: 23°C ± 3K, 50% RH ± 10%, battery at 8 V ± 0.2V,

external magnetic field < 40 A/m, external electrical field < 1 V/m, conductor

centered, loop resistance noninductive. Accuracy % of reading.

1 to 300 mA

0.300 A to 3.000 A

3.00 A to 30.00 A

Resistance Measurement Frequency: 1689 Hz

Resistance Overload: OL displayed above 1200 Ω

Current Measurement Frequency: 47 to 800 Hz

Current Overload: OL displayed above 30 A rms

Resolution

0.1 Ω

0.5 Ω

1 Ω

5 Ω

10 Ω

50 Ω

1 mA

0.001 A

0.01 A

Accuracy*

± (1.5% + 0.1 Ω)

± (2.0% + 0.5 Ω)

± (3.0% + 1 Ω)

± (6.0% + 5 Ω)

± (10% + 10 Ω)

Approx. 25%

± (2.5% + 2 mA)

± (2.5% + 2 mA)

± (2.5% + 20 mA)

MECHANICAL SPECIFICATIONS

Dimensions: 9.25 x 3.94 x 2.17" (235 x 100 x 55 mm)

Weight: 2.2 lbs. (1 kg)

Case Material: Lexan®920A (UL94V2)

Ground Resistance Tester Models 3710/3730

7

Page 10

Jaw Cover Material:

Lexan®500R with 10% fiberglass charge (UL94V0)

LCD Cover Material: Lexan®920A (UL94V1)

Color: Gray body, red jaws

Jaw Window Diameter: 1.25” (32 mm)

Jaw Opening: 1.38” (35 mm)

Operating Temperature: -10 ° to 55 °C

Operating Humidity: 0 to 90% RH @ -10 ° to 40 °C, 75% RH @ 55 °C

Storage Temperature: -40 ° to 70 °C

Power Supply: 9 V alkaline (IEC 6LF22 or NEDA 1604A)

Battery Life:

typical: 8 hours or approximately 1000 measurements of 30 seconds

LCD: 3-3/4 digit, 1.73 x 1.10” (44 x 28 mm)

US Design Patent: #362,639

SAFETY SPECIFICATIONS

UL, CSA approvals pending

IEC 1010-1 Double Insulation

Environmental: IP30, IEC 359 Group III

Vibration Test: IEC 68-2-6

Shock Test: IEC 68-2-27

Drop Test (1m): IEC 68-2-32

Dielectric Test: 2500 V AC

Working Voltage: 150 V, Cat. III - Pollution Degree 2

300 V, Cat. III - Pollution Degree 1

Max A Overload: 100 A continuous, 200 A (< 5s) 50/60 Hz

OL displayed above 30 A rms

Calibration Cycle: Calibration once a year is recommended

8

Ground Resistance Tester Models 3710/3730

Page 11

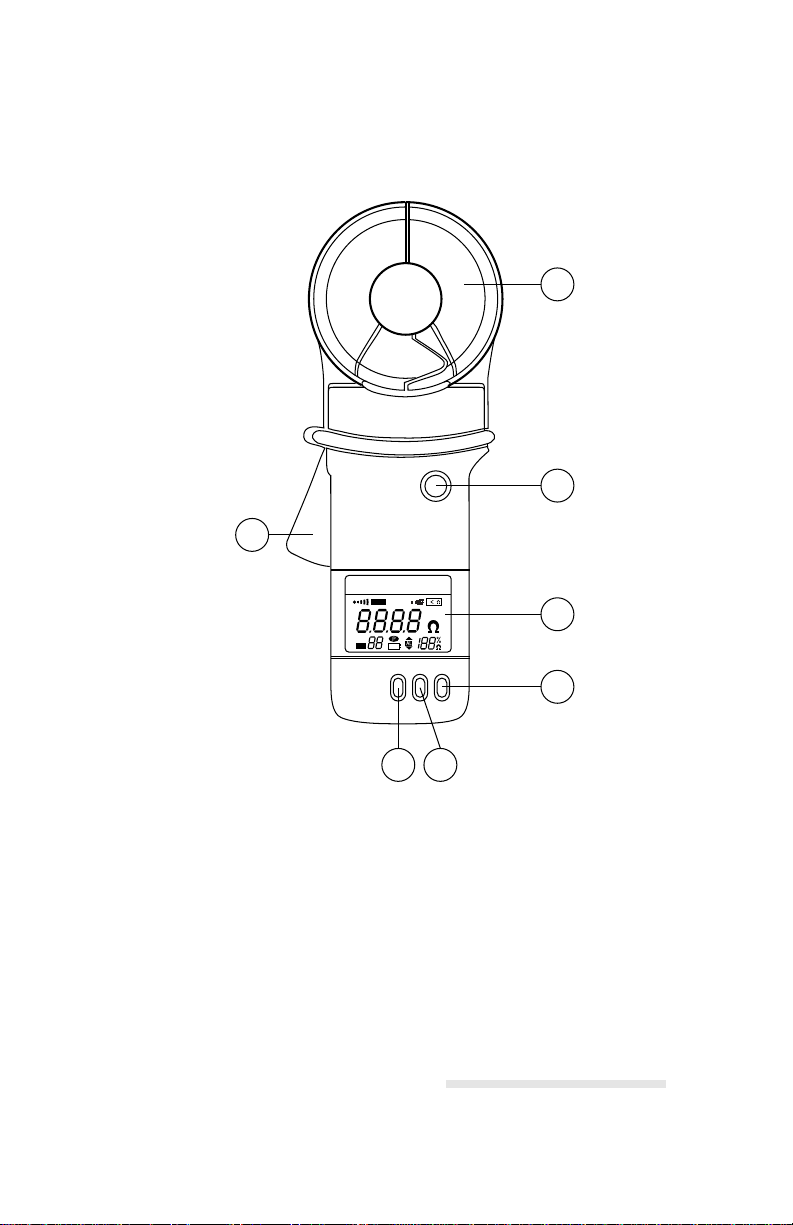

Model 3710 Controls

HOLD

+

—

m

A

R

1

HOLD

MEM

MR

NOISE

Model 3710

GROUN D TES TER

AEMC

IN S T R U ME N T S

A Ω

ON

OFF

1

2

3

4

7

56

1. Head Assembly: Consists of

two individually shielded

magnetic cores

2. Hold: Freezes last measured

value on the display

3. Display: 3000 count LCD,

Ground Resistance Tester Models 3710/3730

function indicators

4. ON/OFF: Power ON or OFF,

activates display self-test at

power-up

5. Ω: Resistance measurement

6. A: Current measurement

7. Lever: Opens or closes jaws

9

Page 12

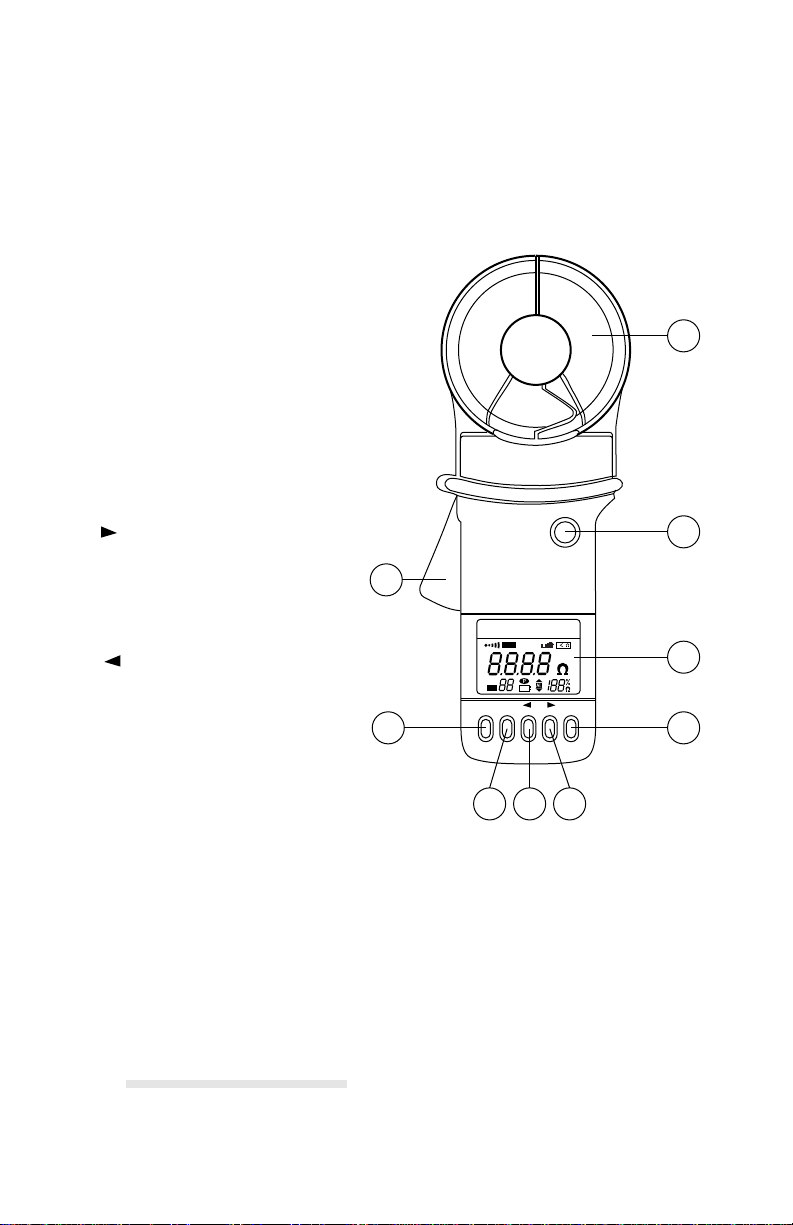

Model 3730 Controls

HOLD

+

—

m

A

R

1

HOLD

MEM

MR

NOISE

Model 3730

GROUN D TES TER

AEMC

IN S T R UM E N T S

MEM AL A Ω

ON

OFF

1

2

3

49

7

568

1. Head Assembly: Consists

of two individually shielded

magnetic cores

2. Hold: Freezes last measured value on the display

3. Display: 3000 count LCD,

function indicators

4. ON/OFF: Power ON or

OFF, activates display self

test at power-up

5. Ω: Resistance Measurement

Increment the Alarm set-

point, increment Memory

position in program mode

6. A: Current Measurement

Decrement the Alarm

setpoint, decrement the

Memory in program mode

7. Lever: Opens or closes jaws

8. AL: Activates/deactivates

the Alarm function, access

the value of the Alarm

setpoint in program mode

9. MEM: Stores the reading into memory, reads Memory Recall (MR)

values and clears the memory in recall mode

10

Ground Resistance Tester Models 3710/3730

Page 13

Digital Display Features

mA, A

R

1

NOISE

HOLD

+

—

m

A

R

1

HOLD

MEM

MR

NOISE

Figure 3

Displayed when the beeper is active. To turn the beeper On/Off,

push ON & Ω together at power-up. The beeper is active when

displayed.

Displayed when the HOLD function is activated. This function

locks the present displayed value. During HOLD: A, Ω, and

Alarm functions are deactivated. The Memory function may still

be used.

Indicates that the jaws of the instrument are not properly

closed. The Open Jaw indication is present only in the Ω Mode.

Check for foreign matter in the jaw mating surface.

In the Ω function, this symbol indicates the presence of excessive stray noise in the ground electrode under test. This symbol

will be present if noise signals reach an amplitude of approx. 5

A or 50 V. Resistance measurement values are no longer valid.

The beeper is also activated.

Displayed when measured resistance is below 1 Ω. This may

indicate that grounding electrode you are clamped onto is

continuous with itself (the instrument is measuring a metallic

loop and not the ground electrode resistance). In this situation,

electrode resistance measurements may not be valid.

Current measurement mode.

Ground resistance measurement mode.

Ground Resistance Tester Models 3710/3730

11

Page 14

Indicates the Auto-Off feature is deactivated and the instrument

MR

MEM

+

–

stays on permanently (until turned off by the user). With no

symbol displayed, after 5 minutes of non-use the instrument will

automatically shut itself off. The Auto-Off feature is turned

On/Off by pressing Hold at power-up.

Display flashes this symbol (1/second) during a low battery

condition. Measurements are still possible. When this symbol is

displayed continuously, measurements are no longer possible.

Battery replacement is necessary.

Indicates the approximate percentage of useful battery life

remaining (0-100%). This function is displayed only upon initial

power-up when the ON push-button is held down for more than

3 seconds.

The overload symbol will illuminate when the measurement

reading is beyond the limits of the instrument:

Resistance > 1200Ω

Current > 30.00 A rms

The beeper is activated in current overload.

Additional Features of the Model 3730

Indicates that an alarm set point is set in memory. Alarm set

points may be set from 1 to 199Ω.

Arrows indicate whether the measured value is above or below

alarm setpoint.

Memory function is activated. Ninety-nine (99) separate values

may be logged for either resistance (Ω), current (A) or a combination thereof. At the 99th value, display number will blink

indicating that memory is full.

Memory recall register. Displays the numbered value being

recalled from memory (1-99).

Note: Models 3710 and 3730 share the same LCD and display all

segments at power-up. Functions not available on the 3710 are

displayed at power-up.

12

Ground Resistance Tester Models 3710/3730

Page 15

Function Controls

+

–

m

A

R

1

HOLD

MEM

MR

NOISE

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

A Ω

ON

OFF

+

–

m

A

R

1

HOLD

NOISE

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

A Ω

ON

OFF

Model 3710 and 3730 share common functions (On/Off, A, Ω, Auto-off,

Buzzer disable, Hold). Even though the Model 3710 is shown in the

examples for these functions, the controls will respond identically for the

Model 3730.

On/Off

The ON/OFF push-button, when pushed actuates power on or power off

with an audible control tone. Upon initial power-up, the instrument will

be in the Ohms function (Ω) and will go to OL until clamped on. When

the ON push-button is pushed and held down, after three seconds the

instrument will beep and provide a self test featuring a full function display (Fig. 4) followed by status indications for:

a. Status of remaining battery life (battery symbol blinks, 0-100%) (Fig. 5)

b. Number of stored values in memory (MEM blinks, 0-99) (Model 3730

only)

Release the ON/OFF push-button to initialize the instrument.

A light chirping sound may be heard in the Ω mode. This is a normal

condition generated by the instruments power management system.

Figure 4

Ground Resistance Tester Models 3710/3730

Figure 5

13

Page 16

Auto-Off

HOLD

MR

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

A Ω

ON

OFF

MR

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

A Ω

ON

OFF

HOLD

A Ω

ON

OFF

HOLD

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

The instrument will shut off automatically after five minutes of non-use.

The instrument will issue a short beep 15 seconds prior to shutting

down and the LCD flashes once per

second. The Auto-Off may be disabled

by turning on the meter while holding

down the HOLD push-button. The

indicator will appear on the display to

indicate the Auto-Off feature has been

disabled. (Fig. 6)

Hold

The HOLD push-button freezes the

last measured value onto the display.

Figure 6

When the HOLD function is enabled,

is displayed on the LCD. (Fig. 7)

When the HOLD function is enabled, other control functions are disabled (except the memory function).

To exit HOLD, press the HOLD

push-button and normal operation

is resumed.

Note: When HOLD is pressed during power-up, the auto-off feature

is disabled and is displayed

on the LCD. See Auto-Off.

Figure 7

Beeper Disable

To disable the beeper, press the ON

and Ω together at power-up. The

indicator will disappear from the LCD.

(Fig. 8)

14

Ground Resistance Tester Models 3710/3730

Figure 8

Page 17

Resistance

R

1

HOLD

MR

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

A Ω

ON

OFF

R

1

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

A Ω

ON

OFF

MR

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

A Ω

ON

OFF

The Ωfunction provides resistance measurements from 1.0 to 1200Ω in

six autoranges. (Fig. 9)

Range Resolution

1.0 to 50.0 Ω 0.1 Ω

50.0 to 100.0 Ω 0.5 Ω

100 to 200 Ω 1 Ω

200 to 400 Ω 5 Ω

400 to 600 Ω 10 Ω

600 to 1200 Ω 50 Ω

Figure 9

Upon initial power-on, the Ω function is chosen by default.

The Models 3710 and 3730 will track

down to 0.7 Ω and indicate below

1 Ω (Fig. 10). Below 0.7 Ω the display

stays locked on 0.7 Ω. Accuracy is not

defined below 1 Ω. Measurements

below 1 Ω typically indicate the ground

tester is clamped onto a closed loop

and that the signal is not flowing

through the ground under test.

Figure 10

If the resistance readings are above

1200 Ω, OL will be displayed on the LCD

(Fig. 11). This may indicate high ground

resistance but may also be caused by a

disconnected or poorly bonded ground.

Figure 11

Ground Resistance Tester Models 3710/3730

15

Page 18

Current

m

A

HOLD

MR

Model 3710

GROUND TESTER

AEMC

INSTRUMENTS

A Ω

ON

OFF

Press A to enter the current function. True RMS current measurements

are possible up to 30.00 A.(Fig. 12)

Above 30 Arms, OL will be displayed and the test must be discontinued.

The beeper is also activated during OL.

Range Resolution

1 to 300 mA 1 mA

0.300 to 3.000 A 0.001 A (1 mA)

3.00 A to 30.00 A 0.01 A (10 mA)

Figure 12

16

Ground Resistance Tester Models 3710/3730

Page 19

Alarm

Model 3730

GROUND TESTER

AEMC

INSTRUMENTS

MEM AL A Ω

ON

OFF

Model 3730

GROUND TESTER

AEMC

INSTRUMENTS

MEM AL A Ω

ON

OFF

Turn the Alarm on/off by pressing the

AL button. The alarm feature provides a continuous audible warning

(when beeper is active) and visual

indications when a setpoint has been

reached (Fig. 13, 14) (e.g. alarm indication when ground electrode resistance is above the NEC limit of 25 Ω.)

If the alarm is not triggered, only

will be displayed indicating that the

alarm is active.

Figure 13

Programming the Alarm Setpoint

To program the alarm setpoint, push ON and AL together at power-up.

The alarm setpoint value will blink. To program the proper setpoint value

(1 to 199 Ω), use the curser arrows

( down, up).

When the setpoint is reached, turn

the instrument off. This will put the

setpoint into memory. Turn the

instrument back on (you may need

to press AL to activate the alarm feature).

Note: The alarm setpoint is preset at

Figure 14

25 Ω. The alarm will be triggered

when the setpoint is

exceeded

.

The user has the option of having the alarm triggered when a reading is

below

the programmed setpoint. This is accomplished with an internal

switch and outlined in the following section.

Ground Resistance Tester Models 3710/3730

17

Page 20

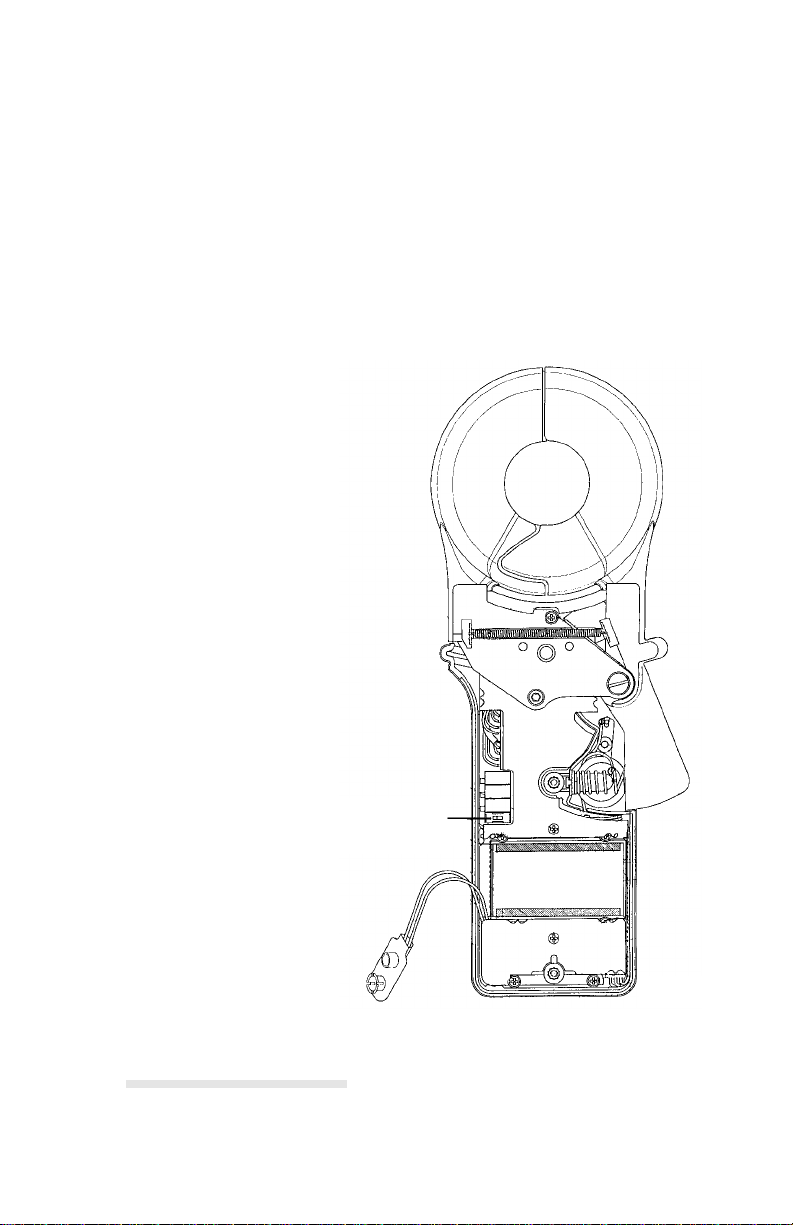

Changing the Alarm Trigger

The Model 3730 alarm may be set to trigger above or below a setpoint.

Follow the procedure below for setting the alarm trigger.

1. The instrument must be OFF and disconnected from any

conductor.

2. Place the meter face down and remove the two phillips screws on

the back of the instrument.

3. Remove the back cover by

pulling down and away

from the instrument.

4. To set the alarm to trigger

above a setpoint, slide the

alarm setpoint switch to

the right. To set the alarm

to trigger below a setpoint,

slide the alarm setpoint

switch to the left.

5. Replace the back cover

while ensuring that it slips

beneath the hold-down lip

and fits securely into position. Use caution not to

pinch the battery leads.

6. Install and tighten screws.

18

Alarm Setpoint Switch

Right - Alarm above the setpoint

Left - Alarm below the setpoint

Ground Resistance Tester Models 3710/3730

Battery

Compartment

Figure 15

Page 21

Memory

MEM

Model 3730

GROUND TESTER

AEMC

INSTRUMENTS

MEM AL A Ω

ON

OFF

MR

Model 3730

GROUND TESTER

AEMC

INSTRUMENTS

MEM AL A Ω

ON

OFF

To activate the Memory feature, press

the A and ON buttons together at powerup (Fig. 16). MEM will be displayed.

The Memory feature allows the user to

log into memory 1 to 99 measured values

(including OL). Measured values can

now be logged for both resistance (Ω)

and amps (A) by pushing the MEM button

during measurement and during “HOLD”.

Figure 16

A long beep indicates the measurement

was stored. After the 99th value is entered (MEM 99) will blink indicating

memory is now full. Measurements may still be made but no longer

logged. Stored values are retained when the instrument is turned off.

Pressing the A and ON buttons again at power-up will de-activate the

Memory feature.

Memory Recall

To recall memory values, push ON and

MEM together at power-up. MR will be displayed with the memory number (Fig. 17).

Memorized value will be displayed. To

select stored values use the cursor arrows

( down, up). For rapid access of

memory recall values, press the cursor

push-button continuously.

Turn the instrument off to exit the Memory

Figure 17

Recall mode.

Clear Memory

To clear the memory, push ON & MEM together at power-up and hold

them down. After a three second interval the “clear” message will be

displayed (Fig. 18) along with four repetitive beeps and a fifth long tone.

The memory is now cleared (Fig. 19).

Once cleared, releasing the ON & MEM buttons returns the instrument

to Resistance measurement mode.

Ground Resistance Tester Models 3710/3730

19

Page 22

MEM

Model 3730

GROUND TESTER

AEMC

INSTRUMENTS

MEM AL A Ω

ON

OFF

Model 3730

AEMC

INSTRUMENTS

GROUND TESTER

MEM AL A Ω

OFF

ON

Figure 18

Figure 19

Function Access Summary

Push Button(s) Function Setting

Function Used Saved @ Power Down

On/Off ON/OFF

Ω Function Ω Default Setting

A Function A No

Alarm Function (Ω) AL Yes

Display Hold HOLD No

Auto-Off On/Off ON + HOLD No

Beeper On/Off ON + Ω No (3710), Yes (3730)

Programming Summary

Push Buttons Function Setting

Function Used Saved @ Power Down

Memory On/Off ON + A Yes

Memory Recall (MR) ON + MEM (< 2 sec) No

Clear Memory ON + MEM (> 6 sec) No

Program Alarm ON + AL No

Setpoint

20

Ground Resistance Tester Models 3710/3730

Page 23

Principle of Operation

Rx »

1

Σ

n

i=1

1

Ri

V

I

= Rx +

1

Σ

n

i=1

1

Ri

Typically grounded distribution system may be simulated by the basic

circuit shown in Fig. 20 or an equivalent circuit, shown in Fig. 21. If voltage (V) is applied to any measured grounding electrode Rx through a

special transformer, current (I) flows through the circuit, thereby

establishing the following equation:

where, usually

Therefore, V/I = Rx is established. If I is detected and measured with V

kept constant, the measured grounding electrode resistance Rx can be

obtained. A signal is fed to a special transformer via a power amplifier

from a 1.689 kHz constant voltage oscillator. The resulting current is

then sensed by a detection CT. An active filter is used to dampen earth

current at commercial frequency and high-frequency noise.

Example: If we clamp around any grounding electrode in a multi-grounded

system, the measured value of the electrode under test will be the resistance of that particular rod in series with the equivalent parallel resistance

value that the rest of the multi-grounded system represents. If we had an

electrical system that had 101 grounding electrodes and each had a

resistance value of 25 Ω, and we were to clamp around any electrode in

the system, the measured value would be 25 Ω in series with the equivalent parallel resistance or 0.25 Ω. The displayed value would be 25.2 Ω

(instrument resolution to 0.1 Ω).

V/I = 25 Ω + 0.25 Ω

Rx = 25.2 Ω

In most field applications, the number of electrodes that make up a

multi-grounded system would be higher, therefore the equivalent

parallel resistance is negligible with respect to the rod under test.

Ground Resistance Tester Models 3710/3730

21

Page 24

I

V

Rx R1 R2 Rn-1 Rn

Rx R1 RnRn-1

RX

R1

R2

Figure 20

Rn-1

Rn

RX

22

R1

Figure 21

Ground Resistance Tester Models 3710/3730

Rn-1

Rn

Page 25

Field Applications

Grounding

conductor

Ground level

Ground

rod

Butt plate

Utility

pole

Pole Ground Rods

Remove any molding covering the ground conductor, and provide sufficient room for the jaws of the clamp-on. The jaws must be able to close

easily around the conductor. The jaws can be placed around the ground

rod itself.

Note: The instrument must be placed so that the jaws close around an

electrical path from the system neutral or ground wire to the ground rod

or rods as the circuit provides.

Select the current range “A.” Clamp onto the ground conductor and measure the ground current. The maximum range is 30.00 A Trms. However,

if the ground current exceeds 5 A or noise exceeds 50 V, ground resistance measurements are not possible.

measurement.

Remove the instrument from the circuit noting the location

for maintenance and continue to the next test location.

After noting the ground current, select the ground resistance range (Ω)

and measure the resistance directly. The reading you measure with the

clamp-on tester indicates not just the resistance of the rod, but of the

connection to the system neutral and all bonding connections between

the neutral and the rod.

Note that in Fig. 22 there

is both a butt plate and a

ground rod. In this type

of circuit, it is necessary

to place the instrument

above the bond so that

both grounds are included in the test. For future

reference, note the date,

ohms reading, current

reading and pole number.

Replace any molding you

may have removed from

the conductor.

Figure 22

Do not proceed further with the

Ground Resistance Tester Models 3710/3730

23

Page 26

Note: A high reading or OL indicates one or more of the following:

Service box

Service meter

Pole-mounted

transformer

Building wall

Ground

rods

Ground level

Water pipe

Service box

Service meter

Pole-mounted

transformer

Building wall

A. Poor ground rod

B. Open ground conductor

C. High resistance bonds on the rod or splices on the conductor;

watch for buried split butts, clamps, and hammer-on connections.

Service Entrance or Meter

Follow the same procedure as for Pole Ground Rods. Notice that

Fig. 24 shows multiple ground rods and in Fig. 23 the ground rods have

been replaced with a water

pipe ground. You may also

have both types acting as a

ground. In these cases, it is

necessary to make the mea-

Ground

Level

Building Wall

Pole-mounted

Transformer

Service Meter

Service

Box

surements between the service neutral and both

grounded points.

Figure 23

24

Ground

Rods

Building Wall

Pole-mounted

Transformer

Service Meter

Figure 24

Service

Box

Water Pipe

Ground Resistance Tester Models 3710/3730

Page 27

Pad Mounted Transformer

R

1

Ground rod(s)

Enclosure

Underground service

Concentric

Neutral

Service

Buss

Open Door

Open Door

Ground

rods

Enclosure

Underground service

Observe all safety requirements — High voltage may be present!

Locate and number all rods (usually only a single rod is present). If the

ground rods are inside the enclosure, refer to Fig. 25 and if they are

outside the enclosure, refer to Fig. 26. If a single rod is found within

the enclosure, the

measurement should

be taken on the conductor just before the

bond on the ground

rod. Often, more than

one ground conductor

is tied to this clamp,

looping back to the

enclosure or neutral.

In many cases, the

best reading can be

obtained by clamping the instrument onto the ground rod itself, below

the point when the ground conductors are attached to the rod, so that

you are measuring the ground circuit. Care must be taken to find the

conductor with only one return path to the neutral.

Generally 0.7 Ω indicates that you are on a closed loop. In

Fig. 26, the ground rod is located outside the enclosure. Clamp at the

indicated measuring

point to obtain the correct reading. If more

than one rod exists at

different corners of the

enclosure, it is necessary to determine how

they are connected to

properly measure the

ground resistance.

Ground Resistance Tester Models 3710/3730

Underground

Service

Enclosure

Figure 25

Figure 26

Ground

Rods

25

Page 28

Transmission Towers

Ground Rod

Support

Concrete

Pad

Observe all safety requirements — Dangerously high voltage may be

present!

Locate the ground conductor at the base of the tower. Many different

configurations exist. Care should be taken when searching for the

ground conductor. Fig. 27 shows a single leg mounted on a concrete

pad with an external ground conductor. The point at which you clamp

the instrument should be above all splices and connections which allow

for multiple rods, butt

wraps, or butt plates.

Note: Current flowing

to ground may be high.

Central Office

Locations

The main ground conductor from a ground

window or a ground

plane is usually the

location to clamp the

Support

Concrete Pad

tester. Due to the

wiring practices within

the central office,

Ground Rod

Figure 27

there are many locations at which you can look at the water pipe or counterpoise from within the building. An effective location is usually at the ground buss in the

power room, or near the backup generator.

By measuring current and resistance at several points and comparing

the readings, you will be able to identify neutral loops, utility grounds

and central office grounds. The test is effective and accurate when the

ground window is connected to the utility ground at only one point.

26

Ground Resistance Tester Models 3710/3730

Page 29

Service Panel

GROUND BUS

NEUTRAL BUS

SERVICE

PANEL

PHONE

CATV

GROUND

ELECTRODE

A B NEUTRAL

ELECTRIC

UTILITY

240 VAC

Bare

WH

BK

120 VAC

If we clamp-on the grounding electrode conductor in Fig. 28, the multigrounded system required to complete the circuit may be from different

sources. These sources may include the following: Electric Neutral,

Phone, CATV, and Water.

The Electric Utility Neutral should be the principle conductor of the lowimpedance signal return path required to test the resistance of this ground

electrode with the Model 3710/3730. This can be verified by removing

other ground connections, noting if any changes appear in the readings.

If by removing one of these signal return paths a much higher reading is

noted, it could mean that the primary signal return path (the Electric

Neutral) is defective

or open.

Note: For safety

reasons do not remove any ground

source without first

de-energizing the

service panel.

Ground Resistance Tester Models 3710/3730

Figure 28

27

Page 30

Phone Pedestal

Provide sufficient room for the Model 3710/3730 jaws, which must be

able to close easily around the conductor (Fig. 29). The jaws can be

placed around the ground rod itself.

Note: If not enough room is available for this task refer to Fig. 30 and

continue with this example. The clamp must be placed so that the jaws

are in an electrical path from the sheath bond(s) or ground bar to the

ground rod(s) as the circuit provides.

Select the current range “A.” Clamp onto the ground conductor and

measure the ground current. The maximum current range is 30 Amps.

If the ground current exceeds 5 Amps, ground resistance measurements are not possible. Do not proceed further with the measurement.

Remove the clamp-on tester from the circuit, noting the location for

maintenance, and continue to the next test location.

After noting the ground current, select the ground resistance range “Ω”

and measure the resistance directly. The reading you measure with the

3710/3730 indicates the resistance of not just the rod, but also the connection to the sheath ground and all bonding connections between the

sheath bond and the rod.

A high reading indicates one or more of the following:

A. Poor ground rod

B. Open ground conductor

C. High resistance bonds on the rod or splices on the conductor. Also

look for bad connections on the ground bar to the sheath(s).

Note: This same test can be done using the TIP instead of the sheath

ground. However keep in mind that this is intended to be grounded only

back at the central office.

28

Ground Resistance Tester Models 3710/3730

Page 31

Above Telephone Space

Ground level

Sheath Connection

Ground

rod

Phone

Pedestal

Ground Bar

Ground level

Sheath Connection

Ground

rod

Phone

Pedestal

Ground Bar

1. Remove ground bar

connection to pedestal rod

2. Extend pedestal rod

lead to the ground

bar using a

temporary jumper

Select the current range “A.” Clamp onto the ground wire and measure

the current (Fig. 31). The maximum current range is 30 Amps. If the

ground current exceeds 5 Amps, resistance measurements are not

possible. Do not proceed further with the measurement. Remove the

clamp-on tester from the circuit, noting the location for attention, and

continue to the next test location.

Ground Resistance Tester Models 3710/3730

Figure 30

Figure 29

29

Page 32

After noting the current, select the ground resistance range “Ω” and

R

1

R

1

Staples

Ground wire doubled

under ground clamp

measure the resistance directly. The reading you measure with the

3710/3730 indicates the bonding connections between the Telephone

ground and the Power company ground. One of the following two

scenarios should be observed:

A. If “OL” or a high resistance reading is displayed this would indicate

no bond has been established or a poor connection exists between

the Telephone and Power grounds.

B. If and/or a very low reading is displayed then the bond between

these two grounds has been verified.

General Measurement Notes

A reading of OL is most likely a cable which is not connected to the

ground at both ends. It may be there is no ground rod at all, or that there

is no path back to the system neutral.

A reading which is 0.7 Ω generally indicates that the cable where

you are clamped is continuous with itself. You may have located a ground

loop, which can usually be confirmed by comparatively high current

readings also obtained when readings are taken at multiple locations. A

good low resistance ground may also have very high AC current flowing,

depending upon the type of equipment being grounded.

30

Figure 31

Ground Resistance Tester Models 3710/3730

Page 33

Operating Reference Card

AEMC

I N S T R U M E N T S

Clamp-on Ground

Resistance Tester

Model 3710/3730

Operating Reference

!

ON/OFF

Ω

A

HOLD

Ω

HOLDONON

+

+

ON/OFF

Measure

ground resistance [Ω]

Measure AC current [mA, A]

Freeze (hold) the display

Toggle the buzzer [ ] on/off

Toggle auto power on/off

A ON

+

Toggle memory display on/off

AL

MEM

MEM

ON

ON

ON

+

+

+

AL

Turn alarm [ AL ] on/off

MEM

Store the reading in memory

Program alarm mode.

Use to adjust

Short beep:

On/off memory recall [MR]

Long beep (6s):

Clear memory [CLR]

Up

Model 3730

Additional Features

Down

Included with the Model 3710 and 3730 you will find an operating reference card like the one shown here.

This card summarizes all the features of the Model 3710 and 3730.

Ground Resistance Tester Models 3710/3730

Figure 32

31

Page 34

Calibration Check Loop

®

INST R U M E N T S

CALIBRATION LOOP 25Ω

The multiple calibration loop is now replaced by a single point 25 Ω loop

(Fig. 33). It is provided to perform a quick check of the instruments.

Check the clamp-on ground resistance tester by clamping around the

loop; the 3710 or 3730 should read between 24.2 Ω and 25.8 Ω.

* Value is for ambient temperature between 68° and 78°F. Value may differ a

few counts under or above this temperature.

32

Figure 33

Ground Resistance Tester Models 3710/3730

Page 35

Commonly Asked Questions for Clamp-on Ground Resistance Measurements

Q. Can the Clamp-on method be used effectively on high tension towers despite the distance or spacing between them?

A. Yes. Extended distances will not adversely effect the measurement

results. The important factor is that it be a multiple electrode system.

Q. Does the grounding electrode have to be disconnected and isolated as

is required when using the “Fall-Of-Potential” test with auxiliary electrodes?

A. No. Actually the electrode must be connected to the system to provide

the path for test signal injection as well as to provide the background

impedance necessary as the reference. Additionally, if the tested rod is

poorly bonded to the ground connector, a high reading will be present.

Q. Does this mean I am not able to test an independent electrode?

A. No, however as soon as the connection is made to a multiple electrode system, usually provided by the connection to the system neutral,

you can clamp on and make a measurement.

Q. Must the instrument be clamped directly on the electrode?

A. No, the instrument will provide valid measurement results when

clamped on to the electrode or the conductor leading to the grounding

electrode. The reading through the conductor will also verify not only the

grounding electrode resistance, but connections of the ground wire to

the rest of the system.

Q. Does the system under test have to be energized or de-energized to

perform the test?

A We are measuring the grounding network. The only requirements are

that ground connections be made to the system under test and that the

voltage-to-ground at the tested point not exceed the instrument rating.

Ground Resistance Tester Models 3710/3730

33

Page 36

Q. Can the clamp-on method be used for substation grid resistance

testing?

A. It depends. It can be used as long as the instrument can be clamped

onto a point on the grounding system at a common point where it ties

to the system neutral. Testing a grid must be treated as if it were a

single electrode. Often, clamping on to points within the grid system will

yield a closed loop reading.

Q. How does clamp-on ground testing compare with the standard

“Fall-Of-Potential” test?

A. Empirical testing has validated that when performed correctly, both

methods will provide accurate and repeatable readings for ground electrode resistance.

Q. How large a conductor can the jaw accommodate?

A. The inner diameter of the jaw is 1.25" and can accommodate cables

up to 1000 MCM.

Battery Replacement Procedure

The Clamp-On Ground Resistance Testers are powered by a single 9

volt battery. The battery replacement indicator will display continuously

when battery replacement is required.

Recommended replacement type is Alkaline (IEC 6LF22, 6LR61 or

NEDA 1604A). Ni-Cad batteries may also be used. To change the battery refer to figure 15, page 17 and follow this procedure.

1. The instrument must be OFF and disconnected from any conductor.

2. Place the meter face down and remove the two Phillips screws on

the back of the instrument.

3. Remove back cover by pulling it down and away from the instrument.

4. Lift the battery away from the case and disconnect the battery.

5. Connect the new battery and position the leads so that they won’t get

pinched when the cover is replaced.

34

Ground Resistance Tester Models 3710/3730

Page 37

6. Replace the back cover noting that it slips beneath the hold down lip

and fits securely into position.

7. Install and tighten screws.

Typical battery life is approximately 8 hours of use or about 1000 separate

30-second measurements.

Troubleshooting

Symptom Indication/

Instrument will not turn ON Low Battery

Recommended Action

Replacement required

Continuous audible tone Alarm setpoint tripped

Deactivate Alarm or

Change Setpoint Trigger mode

Display is erratic Foreign matter in jaws

Clean jaw mating surfaces

Function controls inoperative Hold button on

Turn HOLD off

Light pulsing audible beep Normal operation

Battery power management feature

Ground Resistance Tester Models 3710/3730

35

Page 38

Repair and Calibration

To guarantee that your instrument complies with the factory specifications, we recommend that the Models 3710 & 3730 be submitted to our

factory service center at one-year intervals for recalibration, or as

required by other standards.

For instrument repair and/or calibration, please call our factory, toll-free,

at (800) 945-AEMC (800-945-2362):

CHAUVIN ARNOUX, Inc.

d.b.a. AEMC®Instruments

15 Faraday Drive

Dover, NH 03820 USA

Tel: (800) 954-2362

(603) 749-6434

Fax: (603) 742-2346

(Or contact your authorized distributor.)

Estimates for repairs, normal recalibration, and calibration traceable to

N.I.S.T. are available upon request. Overseas customers must receive

written authorization before returning any instrument.

Technical and Sales Assistance

If you are experiencing any technical problems, or require any assistance with the proper use or application of this instrument, please call

our technical hotline:

CHAUVIN ARNOUX, Inc.

d.b.a. AEMC® Instruments

200 Foxborough Blvd.

Foxborough, MA 02035 USA

Tel: (800) 343-1391

(508) 698-2115

Fax: (508) 698-2118

www.aemc.com

36

Ground Resistance Tester Models 3710/3730

Page 39

Limited Warranty

These Ground Resistance Testers Models 3710 & 3730 are warrantied

to the owner for a period of 1 year from the date of original purchase

against defects in manufacture. This limited warranty is given by

AEMC®Instruments, not by the distributor from whom it was purchased.

This warranty is void if the Ground Resistance Testers Models 3710 &

3730 have been tampered with, abused, or if the defect is related to service not performed by AEMC®Instruments.

What AEMC®Instruments Will Do:

year period, you may return the Ground Resistance Testers Models

3710 & 3730 to us for repair or replacement free of charge, provided we

have your REGISTRATION CARD on file. AEMC®Instruments will, at

its option, repair or replace the faulty material.

Note: If a card is not on file, we will require a dated proof of purchase

as well as your REGISTRATION CARD accompanied by the defective

material.

What You Must Do:

from AEMC®Instruments, then return the Ground Resistance Testers

Models 3710 & 3730, indicating place and date of purchase, with a written explanation of the reason for return. Return material, postage prepaid to:

Chauvin Arnoux, Inc.

d.b.a. AEMC®Instruments

Service Department

15 Faraday Drive

Dover, NH 03820 USA

Tel: (800) 945-2362

Fax: (603) 742-2346

Caution: To protect against in-transit loss, we recommend that you

insure your returned material.

For full warranty coverage, please read the Warranty Card which is

affixed to the Warranty Registration Card. Please keep the Warranty

Card with your records.

First obtain a return authorization by phone or by fax

(603) 749-6434

If a malfunction occurs within the 1

Page 40

Clamp-On

Ground Resistance Testers

Models 3710 and 3730

USER MANUAL

Chauvin Arnoux, Inc. d.b.a. AEMC® Instruments

99-MAN-100061 Rev 05 03/98

Loading...

Loading...