INSTALLATION TESTERS

C.A 6116N

C.A 6117

ENGLISH

User's manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Thank you for purchasing a C.A 6116N or C.A 6117 installation tester. To obtain the best service from your unit:

read this user manual carefully,

comply with the precautions for use.

WARNING, risk of DANGER! The operator must refer to these instructions whenever this danger symbol appears.

Useful information or tip. Current clamp.

USB socket. Auxiliary rod.

The voltage on the terminals must not exceed 550 V. Equipment protected by double insulation.

The product is declared recyclable following a life cycle analysis in accordance with standard ISO 14040.

The CE marking indicates conformity with European LVD and EMC directives.

Chauvin Arnoux has adopted an Eco-Design approach in order to design this appliance. Analysis of the complete

lifecycle has enabled us to control and optimize the effects of the product on the environment. In particular this appliance exceeds regulation requirements with respect to recycling and reuse.

The rubbish bin with a line through it means that in the European Union, the product must undergo selective disposal

in compliance with Directive WEEE 2002/96/EC.

Definition of measurement categories:

Measurement category IV corresponds to measurements taken at the source of low-voltage installations.

Example: power feeders, counters and protection devices.

Measurement category III corresponds to measurements on building installations.

Example: distribution panel, circuit-breakers, machines or fixed industrial devices.

Measurement category II corresponds to measurements taken on circuits directly connected to low-voltage installations.

Example: power supply to electro-domestic devices and portable tools.

PRECAUTIONS FOR USE

This device is protected against accidental voltages of not more than 600V with respect to earth in measurement category III or

300V with respect to earth in measurement category IV (under shelter). The protection provided by the device may be compromised if it is used other than as specified by the manufacturer.

Do not exceed the maximum rated voltage and current and the measurement category.

Never exceed the protection limits indicated in the specifications.

Comply with the conditions of use, namely the temperature, the humidity, the altitude, the degree of pollution, and the place

of use.

Do not use the device or its accessories if they seem damaged.

Do not use the device if the battery compartment cover is missing or incorrectly installed.

To recharge the battery, use only the mains adapter unit provided with the device.

To replace the battery, disconnect everything connected to the device and set the switch to OFF.

Do not use a battery with a damaged jacket.

Use connection accessories of which the overvoltage category and service voltage are greater than or equal to those of the

measuring device (600 V Cat. III or 300 V Cat. IV).

Troubleshooting and metrological checks must be done only by accredited skilled personnel.

Wear the appropriate protective gear.

2

CONTENTS

1. FIRST START-UP .............................................................. 4

1.1. Unpacking ..............................................................4

1.2. Charging the battery

1.3. Carrying the device

............................................... 5

................................................5

1.4. Use on a desktop ................................................... 6

1.5. Brightness of the display ........................................ 6

1.6. Choice of language

................................................7

2. PRESENTATION OF THE DEVICES ................................8

2.1. Functions of the devices

.......................................9

2.2. Keypad ...................................................................9

2.3. Display unit ........................................................... 10

2.4. USB port

...............................................................10

3. USE ................................................................................. 11

3.1. General

................................................................. 11

3.2. Voltage measurement ...........................................11

3.3. Resistance and continuity measurement .............13

3.4. Insulation resistance measurement

...................... 17

3.5. 3P earth resistance measurement ........................ 20

3.6. Loop impedance measurement (Z

3.7. Earth measurement on live circuit (Za, Ra) ............27

) ..................... 24

S

3.8. Selective earth measurement on live circuit ......... 32

3.9. Measurement of the line impedance (Z

3.10. Measurement of the voltage drop in the

cables (

DV) .......................................................... 38

)...............35

i

3.11. Test of residual current device ............................41

3.12. Current and leakage current measurement ........49

3.13. Direction of phase rotation ................................. 51

3.14. Power measurement ..........................................53

3.15. Harmonics .......................................................... 56

3.16. Compensation for the resistance of the

measurement leads ............................................ 59

3.17. Adjustment of the alarm threshold ..................... 61

4. ERROR INDICATION ...................................................... 62

4.1. No connection ...................................................... 63

4.2. Out of measurement range ...................................63

4.3. Presence of dangerous voltage ............................ 63

4.4. Invalid measurement ............................................63

4.5. Device too hot ...................................................... 63

4.6. Check of internal protection devices ....................64

5. SET-UP ............................................................................ 65

6. MEMORY FUNCTION ....................................................68

6.1. Organization of the memory and navigation ........68

6.2. Entering the storage function ............................... 68

6.3. Create a tree ......................................................... 69

6.4. Record the measurement ..................................... 70

6.5. Read the records .................................................. 71

6.6. Erasure .................................................................73

6.7. Errors

7. DATA EXPORT SOFTWARE

.................................................................... 73

..........................................74

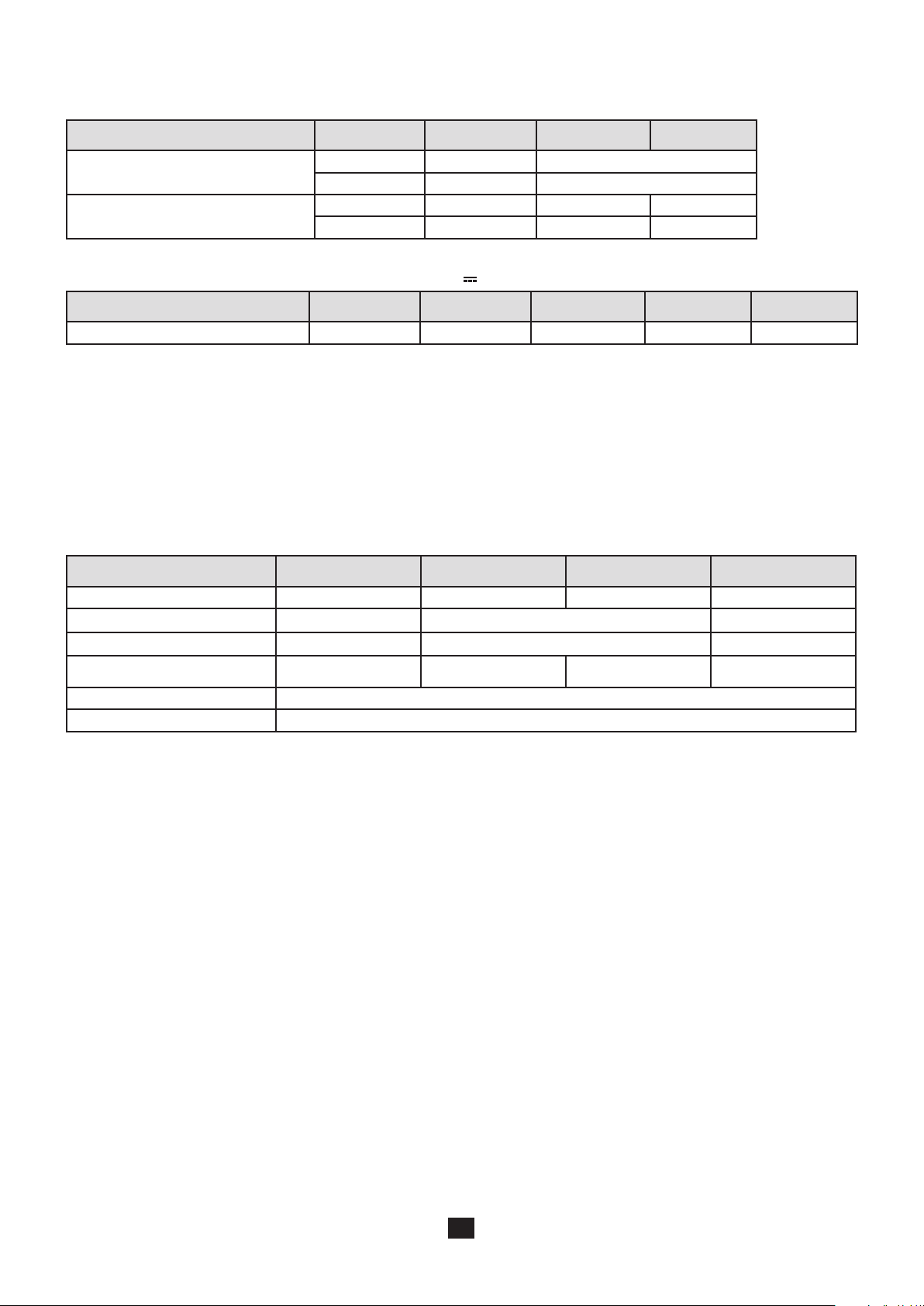

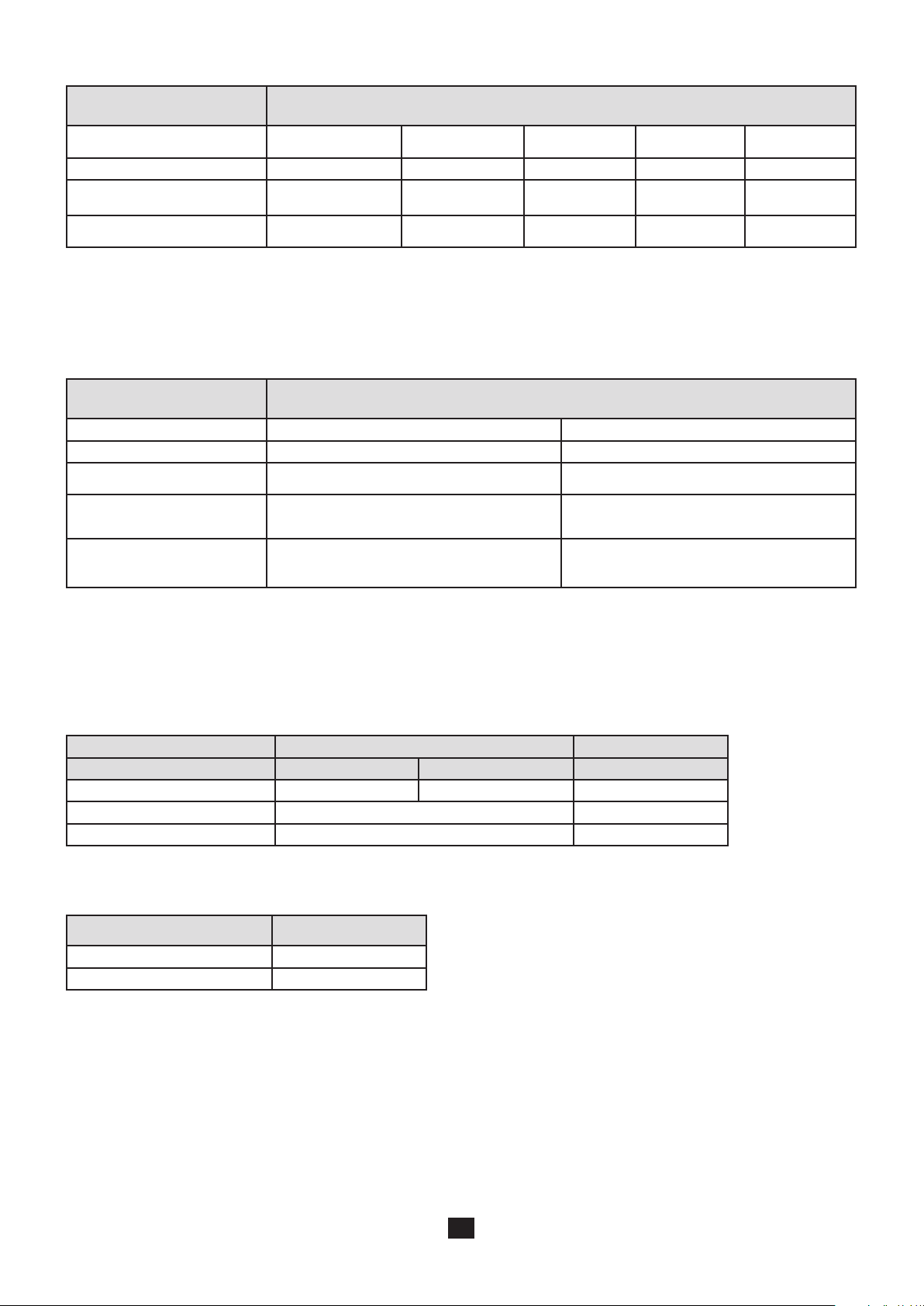

8. TECHNICAL CHARACTERISTICS ................................75

8.1. General reference conditions ...............................75

8.2. Electrical characteristics.......................................75

8.3. Variations in the range of use

8.4. Intrinsic uncertainty and operating uncertainty

............................... 86

.... 89

8.5. Power supply ........................................................89

8.6. Environmental conditions ..................................... 91

8.7. Mechanical characteristics .................................. 91

8.8. Conformity to international standards

8.9. Electromagnetic compatibility (EMC)

.................. 91

...................91

9. DEFINITIONS OF SYMBOLS ......................................... 92

10. MAINTENANCE ............................................................ 94

10.1. Cleaning .............................................................94

10.2. Replacing the battery

10.3. Resetting the device

......................................... 94

........................................... 95

10.4. Metrological check ............................................. 95

10.5. Repair ................................................................. 95

10.6. Updating of the internal software

....................... 95

11. WARRANTY ................................................................. 96

12. TO ORDER

....................................................................97

12.1. Accessories ........................................................ 97

12.2. Replacement parts ............................................. 97

13. APPENDIX

.................................................................... 99

13.1. Table of fuses managed by the C.A 6117 ..........99

3

1.1. UNPACKING

1. FIRST START-UP

➀

➂

➈

➃

➁

One C.A 6116N or C.A 6117.

1

One mains charger with cable for the battery.

2

Data export software on CD-ROM and a USB A/B cord.

3

➆

➅

➇

14

➄

12

➉

11

13

One tripod cable with mains plug (adapted to the country of sale.

4

One tripod cable, 3 safety leads.

5

Three probe tips (red, blue, and green).

6

Three crocodile clips (red, blue, and green).

7

Two elbowed-straight safety leads (red and black).

8

One 4-point hands-free strap.

9

One hand strap.

10

One remote probe.

11

One carrying bag.

12

One user manuals on CD-ROM (1 file per language).

13

One multilingual safety sheet.

14

4

50 / 60 Hz

1.2. CHARGING THE BATTERY

Before the first use, start by fully charging the battery. The charging must be done between 0 and 45°C.

> 90 VAC

< 264 VAC

Battery

loading...

Remove the cover from the mains connector on

the device.

Loading

The indicator of the

device lights.

completed.

Charging time:

approximately 5h.

Set the switch to OFF, but charging is possible when the device is not off.

1.3. CARRYING THE DEVICE

The 4-point hands-free strap will let you use the device while leaving your

hands free. Snap the four fasteners of the strap onto the four lugs on the

device.

Pass the strap around your neck.

Adjust the length of the strap, then the tilt of the device.

The indicator goes

off.

5

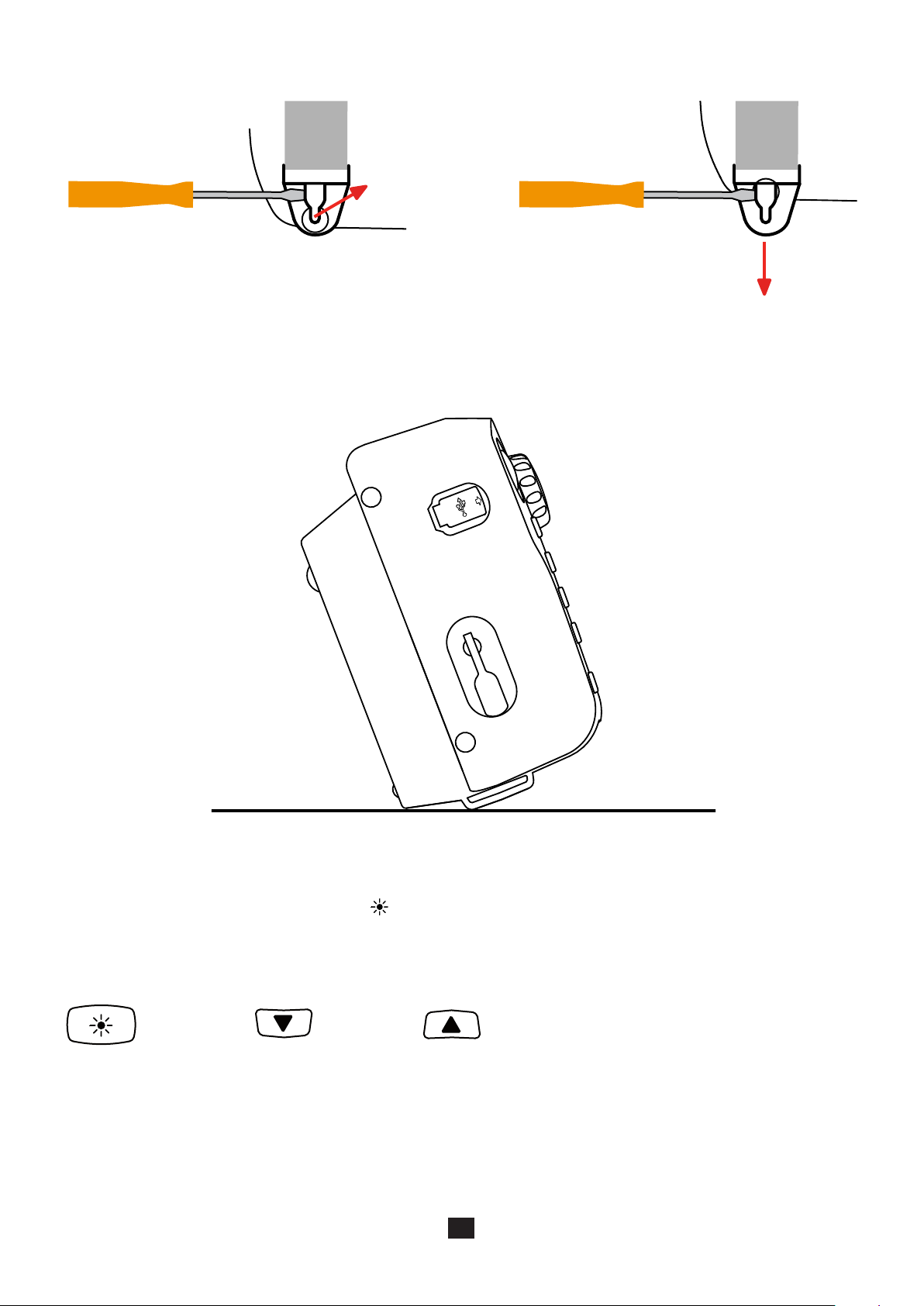

To withdraw the strap, slide a flat screwdriver under the tab of the fastener to lift it, then slide the fastener down.

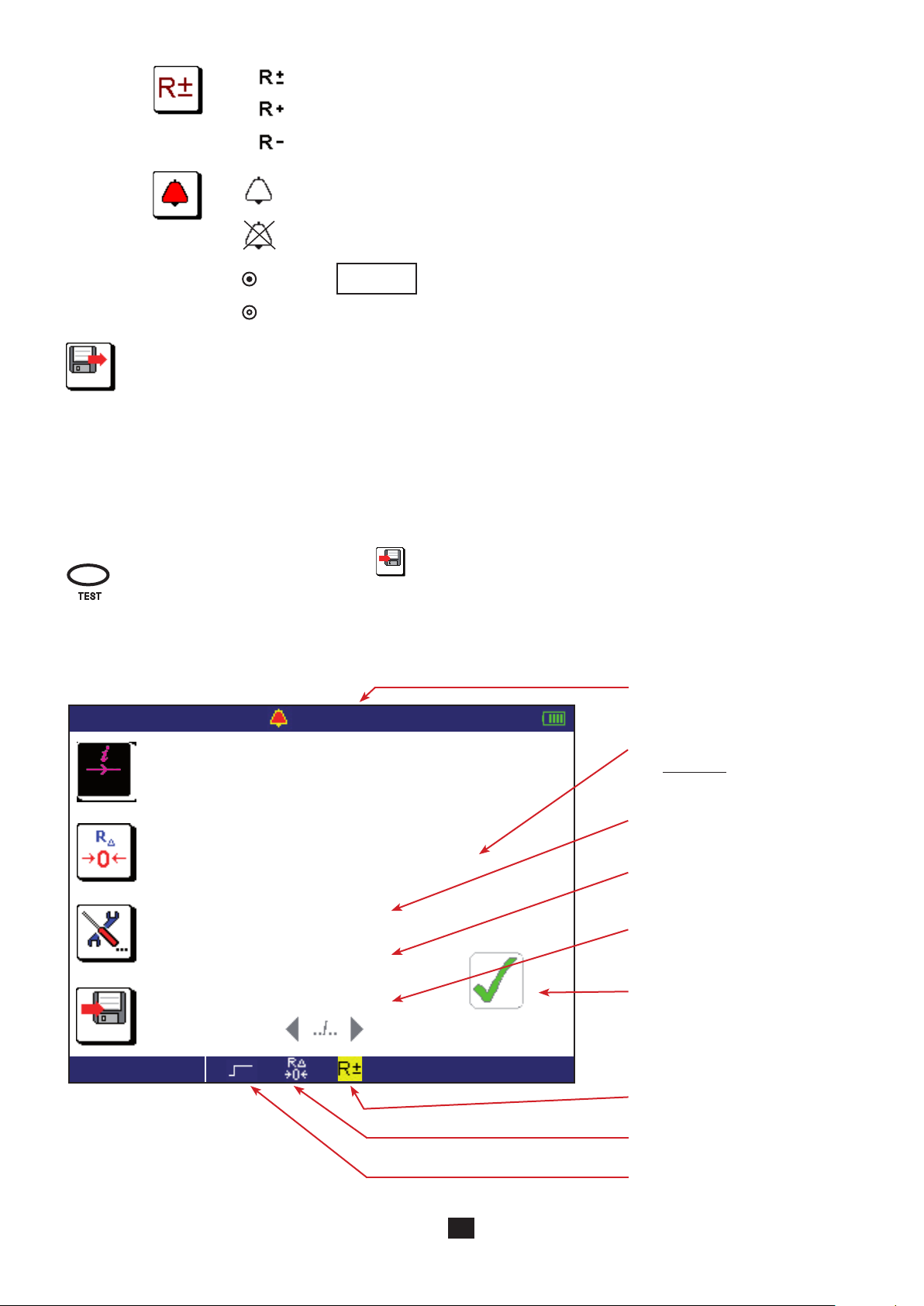

1.4. USE ON A DESKTOP

For use on a desktop, have the device rest on the fasteners of the hand strap and on the housing.

This lets the display unit be read directly.

1.5. BRIGHTNESS OF THE DISPLAY

To adjust the brightness of the display, press the key and one of the arrow keys simultaneously.

+

sustained

press

or

6

1.6. CHOICE OF LANGUAGE

Before using the device, first choose the language in which you want the device to display messages.

Set the switch to SET-UP.

SET UP

11-21-2013 11:17

Use the directional keypad to select the languages icon:

OK

OFF

OK

Press the OK key to validate your

choice.

SET-UP

Select your language, from among those proposed, using the keys and validate by pressing the OK key again.

You can download other languages from our site’s support space (see §10.6).

7

2. PRESENTATION OF THE DEVICES

TEST

TEST button to start

the measurements.

Four function

keys.

Connection terminals.

/

OK

Switch for selection

of the measurement

function or SETUP.

SET UP

OFF

Indicator light.

Stud for fixing on the

4-point hands-free

strap.

USB port for data

transfer to a PC.

Help key.

Brightness adjustment key.

Battery charging

connector.

Directional keypad:

four navigation keys

and one validation

key.

Fasteners for the hand

strap, also used to tilt

the device.

8

2.1. FUNCTIONS OF THE DEVICES

C.A 6116N and C.A 6117 installation testers are portable measuring devices with a colour graphic display. They are powered by

a rechargeable battery with a built-in charger and external power supply unit.

These instruments are intended to check the safety of electrical installations. It can be used to test a new installation before it is

powered up, to check an existing installation, whether in operation or not, or to diagnose a malfunction in an installation.

Measurement

functions

Controls one thirteen-position switch, one five-key navigator, one keypad with four function keys, one context-

voltage measurement

continuity and resistance measurement

insulation resistance measurement

earth resistance measurement (with 3 rods)

loop impedance measurement (Zs)

earth resistance on live circuit measurement (with an auxiliary probe)

selective earth resistance measurement (with an auxiliary probe and an optional current clamp)

calculation of the short-circuit current and of the fault voltages

line impedance measurement (Zi)

measurement of the voltage drop in the cables (for the C.A 6117 only)

test of type AC, A, and B residual current devices, in ramp mode, in pulse mode, or in non-tripping

mode (type B with the C.A 6117 only)

current measurement (with an optional current clamp)

detection of direction of phase rotation

active power and power factor measurement (single-phase or balanced three-phase network) with

display of the voltage and/or current curves

voltage and current harmonic analysis (with an optional clamp)

sensitive help key, one brightness key, and one TEST button.

Display 5.7” (115 x 86mm) colour graphic display unit, 1/4 VGA (320 x 240 points).

The only difference between the C.A 6116N and the C.A 6117 is that the C.A 6117 can test type B RCDs.

2.2. KEYPAD

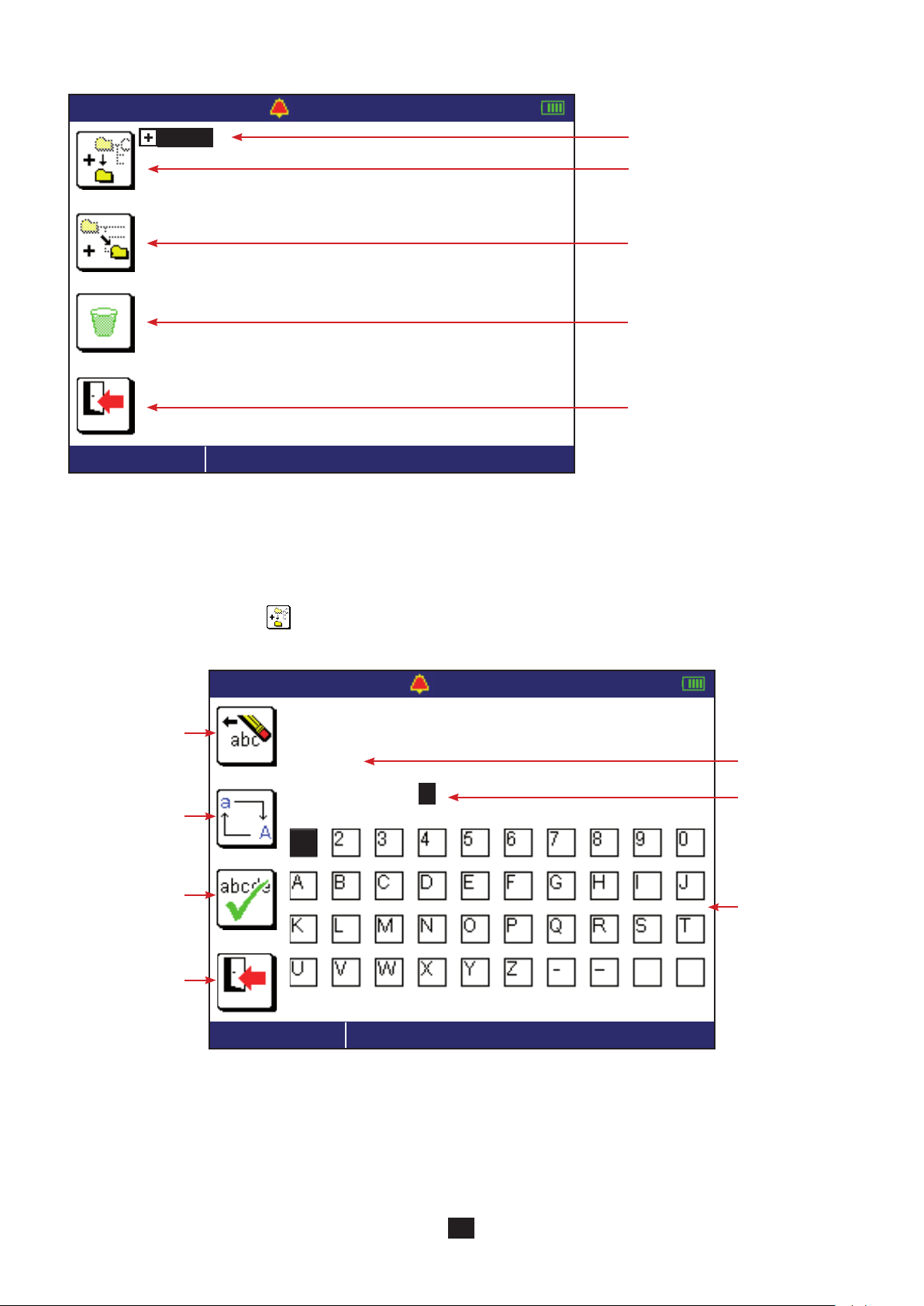

The actions of the 4 function keys are indicated on the display unit by adjacent icons. They depend on the context.

The help key can be used in all functions. The help function is context-sensitive: it depends on the function.

The key is used to adjust the brightness of the display.

The directional keypad comprises four navigation keys and one validation key.

9

2.3. DISPLAY UNIT

➀

➅

➈

➁

11-21-2013 10:47

6 mA

L-PE 230.3 V

L-N

N-PE

6 %

LOOP ZS

➂

50 . 0 Ω 50 . 1 Hz

230.4 V

0.8 V

➃

➄

L

➆

➇

➉

Top strip

1

Date and time

2

Alarm threshold

3

Frequency measured

4

Condition of the battery

5

Icons representing the functions of the keys

6

7

8

9

10

11

11

Position of the phase on the socket outlet

Display of measurement results

Bottom strip

Name of function

Information about the measurement in progress

2.4. USB PORT

The USB port of the device is used to transfer the stored data to a PC (see §7). This operation requires the prior installation of a

specific peripheral driver and other software.

The USB port can also be used to update the device’s internal software (see §10.6).

The USB cord and the associated software are supplied with the device.

10

3. USE

3.1. GENERAL

When it leaves the plant, the device is configured so that it can be used without changing the parameters. For most measurements, simply select the measurement function by turning the switch and press the TEST button.

However, you can also parameterize:

the measurements, using the function keys,

or the device itself, using SET-UP.

The device is not designed to operate when the charger is connected. The measurements must be made using battery

power.

3.1.1. CONFIGURATION

When configuring the measurements, you can always choose between:

validating by pressing the OK key,

or exiting without saving by pressing the key.

3.1.2. HELP

In addition to an intuitive interface, the instrument provides complete help in use and analyses and appraisals. Three types of

help function are available:

Help before the measurement can be accessed using the key. It indicates the connections to be made for each function

and important recommendations.

Error messages appear, as soon as the TEST button is pressed, to report connection errors, measurement parameterizing

errors, out-of-range values, defective installations tested, etc.

Help associated with the error messages. Messages containing the icon invite you to look up the help for ways to

eliminate the error found.

3.1.3. REFERENCE POTENTIAL

The user is assumed to be at the reference earth potential. He/she must therefore not be insulated from earth: must not

wear insulating shoes or insulating gloves and must not use a plastic object to press the TEST button.

3.2. VOLTAGE MEASUREMENT

Whichever function is chosen, except for SET-UP, the device always starts by measuring the voltage present on its terminals.

3.2.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

The device separates the alternating voltage from the direct voltage and compares the amplitudes to decide whether the signal

is AC or DC. In the case of an AC signal, the frequency is measured and the device calculates the RMS value of the AC part and

displays it. In the case of a DC signal, the device does not measure its frequency, but calculates its mean value and displays it.

For measurements made at the mains voltage, the device checks that the connection is correct and displays the position of the

phase on the socket outlet. It also checks the presence of a protective conductor on the PE terminal by means of the contact the

user makes with his/her finger by touching the TEST button.

11

3.2.2. MAKING A MEASUREMENT

Connect the lead to the device to be tested. As soon as the device is powered up, it measures the voltages present on its terminals

and displays them, whatever the setting of the switch.

/

In the ZS (RA/SEL.) and RCD, settings, the device also indicates the position of the phase on the display unit using the symbol.

The mains socket outlet of the measuring cable is marked with a white reference spot.

: the phase is on the right-hand contact of the mains plug when the white spot is up.

: the phase is on the left-hand contact of the mains plug when the white spot is up.

: the device cannot determine where the position of the phase, probably because the PE is not connected or the L and

PE conductors are interchanged.

The L symbol is displayed as soon as the voltage is high enough (> UL programmable in SET-UP). The terminal identified

as L is the one that has the highest voltage with respect to PE.

3.2.3. ERROR INDICATION

The only errors reported in voltage measurement are values outside the voltage measurement range. These errors are reported

in clear language on screen.

12

3.3. RESISTANCE AND CONTINUITY MEASUREMENT

3.3.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

For continuity measurements, the device generates a DC current of 200 or 12 mA, at the user’s discretion, between the W and

COM terminals. It then measures the voltage present between these two terminals and from it deduces the value of R = V/I.

For resistance measurements (current chosen = kW), the device generates a DC voltage between the W and COM terminals. It

then measures the current between these two terminals and from it deduces the value of R = V/I.

In the case of a measurement at high current (200 mA), at the end of one second, the device reverses the direction of the current

and makes another measurement for one second. The result displayed is the mean of these two measurements. It is possible to

make measurements with either the positive or the negative polarity of the current disabled.

For measurements at low current (12 mA or kW), the polarity is positive only.

3.3.2. MAKING A MEASUREMENT

To comply with standard IEC-61557, the measurements must be made at 200 mA. The reversal of the current serves to compensate for any residual electromotive forces and, more important, to check that the continuity is in fact duplex.

When you make continuity measurements that are not contractual, prefer a current of 12 mA. Even though the results cannot be

regarded as those of a normative test, this significantly increases the life of the device between charges and forestalls untimely

tripping of the installations if there is a connection error.

The permanent mode is used to chain measurements without having to press the TEST button each time.

If the object to be measured is inductive, it is better to switch to pulse mode at 200 mA and make a measurement at positive

polarity, then a measurement at negative polarity, manually, in order to leave time for the measurement to settle.

The alarm, if activated, serves to inform the user, by an audible signal, that the measurement is below threshold, making it unnecessary to look at the display unit to check this point.

Set the switch to W .

Use the leads to connect the device to be tested between the W and COM terminals of the device. The object to be tested must not be live.

SET UP

R

/

OFF

3.3.3. CONFIGURING THE MEASUREMENT

Before starting the measurement, you can configure it by modifying the parameters displayed:

Choice of measurement current: kW, 12 mA or 200 mA.

200mA

The high current (200 mA) can be used only to measure low resistances, up to 40 W.

The low current (12 mA) is used to make measurements up to 400 W.

The choice kW is used to make resistance measurements up to 400 kW.

To correct for the resistance of the measurement leads (leads and probe tips or crocodile clips), for measurements

at 12 and 200 mA (see §3.16).

Pressing the TEST button starts only one measurement (pulse mode).

Pressing the TEST button starts the continuous measurement (permanent mode). To

stop it, you must press the TEST button again.

13

Automatic reversal of polarity for a measurement at 200 mA.

TEST

k Ω

Ω

Measurement at positive polarity only.

Measurement at negative polarity only.

To activate the alarm.

To deactivate the alarm.

002.00

Before the measurement: to display the measurements already recorded.

6 %

Once the parameters have been defined, you can start the measurement.

3.3.4. READING OF THE RESULT

In the case of a 200 mA current:

11-22-2013 10:47

After the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

If you selected the pulse mode, press the TEST button once and the measurement stops automatically when it is over.

If you selected the permanent mode, press the TEST button once to start the measurement and a second time to

stop it, or else press the record key

2.00 Ω - - .- Hz

6 %

directly.

To set the alarm threshold (see §3.17). The default threshold is 2W.

Value of the alarm threshold.

200 mA

1 %

CONTINUITY

0 . 8 3 Ω

I 2 0 7 . 4 m A

R + 0 . 5 9 Ω

R - 1 . 0 8 Ω

Measurement result:

(R+) + (R-)

R =

2

Measurement current.

Measurement with a positive current (R+).

Measurement with a negative current (R-).

Case where the measurement is

below the alarm threshold.

Measurement with reversal of polarity.

Compensation for the resistance of

the measurement leads is activated.

Permanent mode.

14

To see the next display page.

22/07/2014 10:47

200 mA

2.00 Ω - - .- Hz

U Ω 0 . 0 V

L - PE 0 . 00 V

L - N X V

N - PE

1 %

CIAGLOSC

In the case of a 12 mA current, there is no current reversal.

X V

External voltage present on the

terminals just before the start of the

measurement.

11-22-2013 10:47

12 mA

I 1 2 . 3 m A

1 %

CONTINUITY

2.00 Ω - - .- Hz

1 8 . 4 Ω

Value of the alarm threshold.

Measurement result.

Current measurement.

Case where the measurement is

above the alarm threshold.

The polarity of the current is positive.

Compensation for the resistance of

the measurement leads is activated.

Pulse mode.

15

In the case of a resistance measurement (kW), there is no current reversal and no compensation for the measurement leads.

11-22-2013 10:47

kΩ

1 %

RESISTANCE

- - .- Hz

1 . 5 8 k Ω

Measurement result.

Case where the measurement is

below the alarm threshold.

Permanent mode.

3.3.5. ERROR INDICATION

The commonest error in the case of a continuity or resistance measurement is the presence of a voltage on the terminals. An error

message is displayed if a voltage greater than 0.5 VRMS is detected and you press the TEST button.

In this case, the measurement is not enabled. Eliminate the cause of the interference voltage and start the measurement over.

Another possible error is measurement of an overly inductive load that prevents the measurement current from stabilizing. In this

case, start the measurement in permanent mode with only one polarity and wait for the measurement to stabilize.

For help with connections or any other information, use the help function.

16

3.4. INSULATION RESISTANCE MEASUREMENT

3.4.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

The device generates a DC test voltage between the COM and MW terminals. The value of this voltage depends on the resistance

to be measured: it is greater than or equal to UN when R ≥ RN = UN /1 mA, and less otherwise. The device measures the voltage

and current present between the two terminals and from them deduces the value of R = V / I.

The COM terminal is the voltage reference point. The MW terminal therefore provides a negative voltage.

3.4.2. MAKING A MEASUREMENT

The alarm, if activated, serves to inform the user, by an audible signal, that the measurement is below threshold, making it unnecessary to look at the display unit to check this point.

Set the switch to MW.

Use the leads to connect the device to be tested between the COM and MW

terminals of the device. The object to be tested must not be live.

SET UP

OFF

R

To avoid leakage during the insulation measurement, which would

throw off the measurement, do not use the measuring cable when

/

you make this type of measurement, but two simple leads.

Generally, an insulation measurement on an installation is made between the interconnected phase(s) and neutral, on the one

hand, and earth, on the other.

L1

L2

L3

N

PE

/

If the insulation is not sufficient, you must then make the measurement between each of the pairs to locate the fault. It is for this

reason possible to index the recorded value with one of the following values:

L-N, L-PE, N-PE, L1-PE, L2-PE, L3-PE, L1-N, L2-N, L3-N, L1-L2, L2-L3 or L1-L3

The remoted TEST button of the optional remote control probe makes it easier to trigger the measurement. To use the remote

control probe, refer to its user’s manual.

C.A 6113/16/17

with

Operation only

L1

L2

L3

PE

17

TEST

M Ω

Ω

3.4.3. CONFIGURING THE MEASUREMENT

Before starting the measurement, you can configure it by modifying the parameters displayed:

To choose the nominal test voltage UN: 50, 100, 250, 500 or 1000 V.

To activate the alarm.

To deactivate the alarm.

k

Before the measurement: to display the measurements already recorded.

6 %

3.4.4. READING OF THE RESULT

11-22-2013 10:47

During or after the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

Once the parameters have been defined, you can start the measurement.

Keep the TEST button pressed until the measurement is stable. The measurement stops when the TEST button

is released.

Before disconnecting the leads or starting another measurement, wait a few seconds for the UN voltage to be zéro.

0500.0

500 kΩ - - .- Hz

To set the alarm threshold (see §3.17). As default, the threshold is set to

R (kW) = UN / 1 mA.

Value of the alarm threshold.

2 %

INSULATION

3 1 . 0 6 M Ω

V

577

7 s

Press TEST until the measurement

is stable

The bargraph provides a rapid quantitative indication of the insulation.

Measurement result.

The test voltage UN is present and

dangerous.

Duration of the measurement.

Case where the measurement is

above the alarm threshold.

To change display pages.

18

To see the next display page.

11-22-2013 10:47

500 kΩ - - .- Hz

U M Ω 0 . 3 V

External voltage present on the

L - PE X V

L - N X V

N - PE

Press TEST until the measurement

2 %

INSULATION

3.4.5. ERROR INDICATION

The commonest error in the case of an insulation measurement is the presence of a voltage on the terminals. If it is greater than

10 V (the exact value depends on UN, see § 8.2.5), the insulation measurement is not enabled. Eliminate the voltage and start the

measurement over.

is stable

X V

terminals just before the start of the

measurement.

To change display pages.

The measurement may be unstable, probably because of an overly capacitive load or an insulation fault. In this case, read the

measurement on the bargraph.

For help with connections or any other information, use the help function.

19

3.5. 3P EARTH RESISTANCE MEASUREMENT

This function is the only one that can measure an earth resistance when the electrical installation to be tested is not live (new installation, for example). It uses two auxiliary rods, with the third rod being constituted by the earth electrode to be tested (whence

the name “3P”).

It can be used on an existing electrical installation, but the power must be cut off (main RCD). In all cases (new or existing installation), the earthing strip of the installation must be open during the measurement.

It is possible to make a rapid measurement and measure only RE or else to make a more detailed measurement by also measuring the resistances of the rods.

3.5.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

The device generates between the H and E terminals a square wave at a frequency of 128 Hz and an amplitude of 35 V. It measures the resulting current, IHE , along with the voltage present between the S and E terminals, USE. It then calculates the value of

RE = USE/IHE.

To measure the resistances of the RS and RH rods, the device internally reverses the E and S terminals and makes a measurement.

It then does likewise with the E and H terminals.

3.5.2. MAKING A MEASUREMENT

There are several measurement methods. We recommend the «62%» method.

Set the switch to RE 3P.

Plant the H and S rods in line with the earth electrode. The distance between the S rod

and the earth electrode must be approximately 62% of the distance between the H rod

and the earth electrode.

In order to avoid electromagnetic interference, we recommend paying out the full length of

SET UP

the cables, placing them as far apart as possible, and not making loops.

earth

strap

/

OFF

H

S

62% d

d

Connect the cables to the H and S terminals. Power down the installation and disconnect the earth strap. Then connect the E

terminal to the earth electrode to be checked.

The alarm, if activated, serves to inform the user, by an audible signal, that the measurement is above threshold, making it unnecessary to look at the display unit to check this point.

3.5.3. CONFIGURING THE MEASUREMENT

Before starting the measurement, you can configure it by modifying the parameters displayed:

Choice of type of measurement: rapid, to measure RE only (icon crossed out), or detailed, to measure also rod

resistances RS and RH. This last case is useful if the ground is dry, making the resistance of the rods high.

To compensate for the resistance of the lead connected to the E terminal, for measurements of low values (see §3.16).

20

k Ω

Ω

To activate the alarm.

TEST

To deactivate the alarm.

050.00

Before the measurement: to display the measurements already recorded.

6 %

During or after the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

If the measurement must be made in a damp environment, remember to change the value of maximum contact voltage

UL in SET-UP (see §5) and set it to 25 V.

Press the TEST button to start the measurement. The measurement stops automatically.

This symbol invites you to wait while the measurement is in progress.

Do not forget to reconnect the earth strap at the end of the measurement before powering the installation back up.

To set the alarm threshold (see §3.17). As default, the threshold is set to 50W.

3.5.4. READING OF THE RESULT

In the case of a detailed measurement:

11-22-2013 10:47

R E 3 2 . 0 8 Ω

R s 1 . 5 8 k Ω

R h 1 . 3 2 k Ω

3 %

EARTH 3P

50.0 kΩ - - .- Hz

Value of the alarm threshold.

Measurement result.

Resistance of the S rod.

Resistance of the H rod.

Case where the measurement is

below the alarm threshold.

To see the voltages before the beginning of the test.

Compensation for the resistance of

the measurement leads is activated.

21

H

d

S

3.5.5. VALIDATION OF THE MEASUREMENT

To validate your measurement, move the S rod towards the H rod by 10% of d and make another measurement. Then move the

S rod, again by 10% of d, but towards the earth electrode.

H

S

52% d

62% d

72% d

/

d

The 3 measurement results must be the same to within a few percent. If this is the case, the measurement is valid. If not, it is

because the S rod is in the zone of influence of the earth electrode.

If the resistivity of the ground is homogeneous, it is necessary to increase distance d and repeat the measurements. If the resistivity of the ground is inhomogeneous, the measurement point must be moved either towards the H rod or towards the earth

terminal until the measurement is valid.

3.5.6. POSITIONING OF THE AUXILIARY RODS

To make sure that your earth measurements are not distorted by interference, we recommend repeating the measurement with

the auxiliary rods placed at a different distance and in another direction (for example rotated 90° from the first alignment).

2

S

H

S

E

d1

If you find the same values, your measurement is reliable. If the measured values are substantially different, it is probable that

they were influenced by earth currents or a groundwater artery. It may be useful to drive the rods deeper.

If the in-line configuration is not possible, you can plant the rods in a triangle. To validate the measurement, move the S rod on

either side of the line HE.

S

H

E

Avoid routing the connecting cables of the earth rods near or parallel to other cables (transmission or power supply), metal pipes,

rails, or fences, this in order to avoid the risk of cross-talk with the measurement current.

22

3.5.7. ERROR INDICATION

The commonest errors in the case of an earth measurement are the presence of an interference voltage or rod resistances that

are too high.

If the device detects:

a rod resistance greater than 15 kW,

a voltage greater than 25 V on H or on S when the TEST button is pressed.

In these two cases, the earth measurement is not enabled. Move the rods and start the measurement over.

To reduce the resistance of the rods RH (RS), you can add one or more rods, two metres apart, in the H (S) branch of the circuit.

You can also drive them deeper and pack the earth around them, or wet it with a little water.

For help with connections or any other information, use the help function.

23

3.6. LOOP IMPEDANCE MEASUREMENT (ZS)

R

R

In a TN or TT type installation, the loop impedance measurement is used to calculate the short-circuit current and to size the

protections of the installation (fuses or RCDs), especially their breaking capacity.

In a TT type installation, the loop impedance measurement makes it easy to determine the earth resistance without planting any

rods and without cutting off power to the installation. The result obtained, ZS, is the loop impedance of the installation between

the L and PE conductors. It is barely greater than the earth resistance.

From this value and the conventional touch voltage limit (UL), it is then possible to choose the rated differential operating current

of the RCD: IDN < UL / ZS.

This measurement cannot be made in an IT type installation because of the high earthing impedance of the supply transformer,

which may even be completely isolated from earth.

3.6.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

The device starts by generating pulses having a duration of 1.1 ms and an amplitude of at most 7 A between the L and N terminals. This first measurement is used to determine ZL.

It then applies a low current, 6, 9 or 12 mA at the user’s discretion, between the L and PE terminals. This low current serves to

avoid tripping residual current devices of which the nominal current is greater than or equal to 30 mA. This second measurement

is used to determine ZPE.

The device then calculates loop resistance ZS = Z

= ZL+ZPE , and short-circuit current Ik = U

L-PE

LPE/ZS

.

The value of Ik serves to check the proper sizing of the protections of the installation (fuses or RCDs).

For greater accuracy, it is possible to measure ZS with a high current (TRIP mode), but this measurement may trip the RCD of

the installation.

3.6.2. MAKING A MEASUREMENT

Set the switch to ZS (RA/SEL.).

Connect the measuring cable to the device, then to the socket outlet of the installation to be tested.

SET UP

At the time of connection, the device first checks that the voltages present

on its terminals are correct, then determines the position of the phase (L) and

of the neutral (N) with respect to the protective conductor (PE) and displays

it. If necessary, it then automatically switches the L and N terminals so that

the loop measurement can be made without modifying the connections of

the device.

OFF

If possible, first disconnect all loads from the network on which you make the loop

measurement.

It is possible to eliminate this step if you use a measurement current of 6 mA, which

allows a leakage current of up to 9 mA for an installation protected by a 30 mA

residual current device.

Case of a TT installation

L

L

RN

N

PE

Rb

In trip mode, it is not necessary to connect the N terminal.

Ra

/

RN

RE

Rb

Case of a TN installation

L

L

N

PE

/

24

k Ω

Ω

k A

For a more accurate measurement, you can choose a high current (TRIP mode), but the RCD that protects the installation may trip.

TEST

The alarm, if activated, serves to inform the user, by an audible signal, that the measurement is above threshold, making it unnecessary to look at the display unit to check this point.

The signal can be smoothed to produce a mean of several values. But the measurement then takes longer.

3.6.3. CONFIGURING THE MEASUREMENT

Before starting the measurement, you can configure it by modifying the parameters displayed:

6 mA

Choice of measurement current in non-tripping mode: 6, 9, 12 mA

or TRIP mode to use a high current that will give a more accurate measurement.

To compensate for the resistance of the measurement leads, for measurements of low values (see §3.16).

To activate or deactivate the smoothing of the signal.

The device proposes choosing the voltage for the Ik calculation from among the following values:

(Ik)

ULN (the measured voltage value),

the voltage of the old standard (for example 220 V),

the voltage of the current standard (for example 230 V).

Depending on the voltage ULN measured, the device proposes the following choices:

if 170<ULN<270 V: ULN, 220 V, or 230 V.

if 90<ULN<150 V: ULN, 110 V or 127 V.

if 300<ULN<500 V: ULN, 380 V or 400 V.

To deactivate the alarm.

Z-R

To activate the alarm on Z

(in TRIP mode) or on R

LPE

(in non-tripping mode).

LPE

6 %

050.00

Ik

Before the measurement: to display the measurements already recorded.

During or after the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

Press the TEST button to start the measurement. The measurement stops automatically.

When the TEST button is pressed, the device checks that the contact voltage is less than UL. If not, it does not

make the loop impedance measurement.

This symbol invites you to wait while the measurement is in progress.

To activate the alarm on Ik.

010.00

A

To set the alarm threshold (see §3.17). As default,

the threshold is set to 50 W.

To set the alarm threshold (see §3.17). As default,

the threshold is set to 10 kA.

25

3.6.4. READING OF THE RESULT

In the case of a non-tripping measurement, with smoothing:

Value of the alarm threshold.

11-22-2013 10:47

6 mA

I k 1 5 2.0 A

Z s 1 . 5 2 Ω

R s 1 . 3 6 Ω

L s 2 . 2 m H

4 %

LOOP Zs

50 .0 Ω 50 . 1 Hz

L

Value of the short-circuit current.

Value of the impedance.

Value of the resistance.

Value of the inductance.

Case in which the measurement is

below the alarm threshold.

To change display pages.

Value of the reference voltage for the

calculation of Ik.

Programmed maximum contact

voltage.

Compensation for the resistance of

the measurement leads is activated.

In the case of a measurement with tripping (TRIP) and without smoothing:

11-22-2013 10:47

10.0 Ω 50 . 1 Hz

I k 1 1.8 A

Z s 1 9 . 3 1 Ω

R s 1 9 . 0 8 Ω

L s 9 . 6 m H

4 %

LOOP Zs

L

Value of the short-circuit current.

Value of the impedance.

Value of the resistance.

Case where the measurement is

above the alarm threshold.

Value of the inductance.

3.6.5. ERROR INDICATION

See §3.8.5.

26

3.7. EARTH MEASUREMENT ON LIVE CIRCUIT (ZA, RA)

R

R

This function is used to make an earth resistance measurement in a place where it is impossible to make a 3P earth measurement

or to disconnect the earth connection strap, often the case in an urban environment.

This measurement is made without disconnecting the earth, with only one additional rod, saving time with respect to a conventional earth measurement with two auxiliary rods.

In the case of a TT type installation, this measurement is a very simple way to measure the earth of frame grounds.

In the case of a TN type installation, to determine the value of each of the earths put in parallel, it is necessary to perform a selective earth measurement on live circuit using a current clamp (see §3.8). Without this clamp, what you find is the value of the

global earth connected to the network, which is rather meaningless.

It is then more useful to measure the loop impedance to size the fuses and RCDs, and to measure the fault voltage to check the

protection of persons.

3.7.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

The device starts by making a loop measurement ZS (see §3.6) with a low current or a high current, at the user’s discretion. It

then measures the potential between the PE conductor and the auxiliary rod and from it deduces RA = U

chosen by the user.

For greater accuracy, it is possible to make the measurement with a high current (TRIP mode), but this measurement may trip

the RCD of the installation.

3.7.2. MAKING A MEASUREMENT

/I, I being the current

PI-PE

Set the switch to ZS (RA/SEL.).

SET UP

OFF

Case of a TT installation

L

L

RN

N

PE

Connect the measuring cable to the device, then to the socket outlet of the installation to be tested.

At the time of connection, the device detects the positions of the phase (L)

and of neutral (N) with respect to the protective conductor (PE) and displays

them. If necessary, it then automatically switches the L and N terminals so

that the loop measurement can be made without modifying the connections

of the terminals of the device.

If possible, first disconnect all loads from the network on which you make the earth

measurement on line circuit.

It is possible to eliminate this step if you use a measurement current of 6 mA, which

allows a leakage current of up to 9 mA for an installation protected by a 30 mA residual current device.

Plant the auxiliary rod at a distance of more than 25 metres from the earth electrode and

connect it to the (RA SEL) terminal of the device. The symbol is then displayed.

Case of a TN installation

L

L

RN

N

RE

PE

PE

Rb

Ra

> 25 m

/

Rb

Ra

> 25 m

/

27

To make this measurement, you can choose:

k Ω

Ω

k A

either a low current which avoids any untimely tripping out of the installation but gives only the earth resistance (RA).

or a high current (TRIP mode), which yields a more accurate earth impedance (ZA) with good measurement stability and can

also be used to calculate the short-circuit fault voltage, U

The alarm, if activated, serves to inform the user, by an audible signal, that the measurement is above threshold, making it unnecessary to look at the display unit to check this point.

The signal can be smoothed to produce a mean of values. But the measurement then takes longer.

3.7.3. CONFIGURING THE MEASUREMENT

Before starting the measurement, you can configure it by modifying the parameters displayed:

in accordance with standard SEV 3569.

FK,

6 mA

Choice of measurement current: 6 (default), 9, 12 mA,

or TRIP to use a high current that will yield a more accurate measurement.

To compensate for the resistance of the measurement leads, for measurements of low values (see §3.16).

To activate or deactivate the smoothing of the signal.

The device proposes choosing the voltage for the Ik calculation from among the following values:

(Ik)

ULN (the measured voltage value),

the voltage of the old standard (for example 220 V),

the voltage of the current standard (for example 230 V).

Depending on the voltage ULN measured, the device proposes the following choices:

if 170<ULN<270 V: ULN, 220 V or 230 V.

if 90<ULN<150 V: ULN, 110 V or 127 V.

if 300<ULN<500 V: ULN, 380 V or 400 V.

To deactivate the alarm.

Z-R

To activate the alarm on ZA (in TRIP mode) or on RA (in non-tripping mode).

6 %

050.00

Ik

Before the measurement: to display the measurements already recorded.

During or after the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

To activate the alarm on Ik (in TRIP mode only).

010.00

A

28

To set the alarm threshold (see §3.17). As default,

the threshold is set to 50 W.

To set the alarm threshold (see §3.17). As default,

the threshold is set to 10 kA.

TEST

Press the TEST button to start the measurement. The measurement stops automatically.

This symbol invites you to wait while the measurement is in progress.

3.7.4. READING OF THE RESULT

In the case of a measurement with a high current (TRIP mode), without smoothing:

Value of the alarm threshold.

11-25-2013 10:47

UFk

I K 4 6 8 A

U

6 %

EARTH 1P (Ra)

50 . 0 Ω 50 . 1 Hz

L

Value of the short-circuit current.

Earth electrode fault voltage in the

event of a short-circuit.

Case where the measurement is

above the alarm threshold.

FK 0.6 V

To change display pages.

Value of the reference voltage for the

calculation of Ik.

The rod is connected.

Programmed maximum contact

voltage.

Compensation for the resistance of

the measurement leads is activated.

UFk is calculated only in earth measurement on live circuit with a high current (TRIP mode). UFk = Ik x ZA.

29

To see the next display page.

11-25-2013 10:47

50 . 0 Ω 50 . 1 Hz

L

UFk

Z A 2 5.1 0 Ω

R a 2 4 . 8 Ω

L

a 5 . 6 m H

6 %

EARTH 1P (Ra)

The third page displays the values of ZS, RS, LS. The fourth page displays the voltages ULN, U

the measurement.

Value of the impedance.

Value of the resistance.

Value of the inductance.

To change display pages.

, U

LPE

and on the rod ( ) before

NPE

In the case of a measurement with a low current and smoothing, the first display screen is the following:

Value of the alarm threshold.

11-25-2013 10:47

6 mA

R A 2 5.1 0 Ω

6 %

EARTH 1P (Ra)

50 . 0 Ω 50 . 1 Hz

L

Measurement result.

Case where the measurement is

below the alarm threshold.

To change display pages.

Value of the reference voltage for the

calculation of Ik.

The rod is connected.

Programmed maximum contact

voltage.

Compensation for the resistance of

the measurement leads is activated.

30

3.7.5. VALIDATION OF THE MEASUREMENT

Move the rod ± 10% of the distance from the earth electrode and make two more measurements. The 3 measurement results

must be the same to within a few percent. In this case the measurement is valid.

If this is not the case, this means that the rod is in the zone of influence of the earth electrode. You must then move the rod away

from the earth electrode and redo the measurements.

3.7.6. ERROR INDICATION

See §3.8.5.

31

3.8. SELECTIVE EARTH MEASUREMENT ON LIVE CIRCUIT

R

R

This function is used to make an earth measurement and to select one earth from among others, in parallel, and measure it. It

requires the use of an optional current clamp.

3.8.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

The device starts by making a loop measurement ZS between L and PE (see §3.6) with a high current, and therefore with a risk of

tripping out the installation. This high current must be used to ensure that the current flowing in the clamp is large enough to be

measured. The device then measures the current flowing in the circuit surrounded by the clamp. Finally, it measures the potential

of the PE conductor with respect to the auxiliary rod and from it deduces R

the clamp.

3.8.2. MAKING A MEASUREMENT

ASEL

= U

PI-PE

/ I

, I

being the current measured by

SEL

SEL

Set the switch to ZS (RA/SEL.).

SET UP

OFF

RN

RE

Rb

Connect the measuring cable to the device, then to the socket outlet of the installation to be tested.

At the time of connection, the device detects the positions of the phase (L)

and of neutral (N) with respect to the protective conductor (PE) and displays

them. If necessary, it then automatically switches the L and N terminals so

that the measurement can be made without modifying the connections of

the terminals of the device.

Plant the auxiliary rod at a distance of more than 25 metres from the earth electrode

and connect it to the (RA SEL) terminal of the device. The symbol is then displayed.

Connect the clamp to the device; the symbol is displayed. Then place it on the

earth circuit to be measured.

Case of a TN installation

L

L

N

PE

PE

Ra1

Ra2

Ra3

> 25 m

/

Case of a TT installation

L

L

RN

N

PE

Rb

Ra1

Ra2

Ra3

> 25 m

/

For a more accurate measurement, you can choose a high current (TRIP mode), but the RCD that protects the installation may trip.

The alarm, if activated, serves to inform the user, by an audible signal, that the measurement is above threshold, making it unnecessary to look at the display unit to check this point.

The signal can be smoothed to produce a mean of several values. But the measurement then takes longer.

32

k Ω

Ω

In the selective earth measurement on live circuit, it is essential to do a compensation of the measurement leads and to

k A

TEST

redo it if it has not been done recently or if you have changed leads.

3.8.3. CONFIGURING THE MEASUREMENT

Before starting the measurement, you can configure it by modifying the parameters displayed:

The measurement current must be a high current (TRIP mode).

To compensate for the resistance of the measurement leads (see §3.16). It is essential for the selective earth measurement on live circuit.

To activate or deactivate the smoothing of the signal.

The device proposes choosing the voltage for the Ik calculation from among the following values:

(Ik)

ULN (the measured voltage value),

the voltage of the old standard (for example 220 V),

the voltage of the current standard (for example 230 V).

Depending on the voltage ULN measured, the device proposes the following choices:

if 170<ULN<270 V: ULN, 220 V or 230 V.

if 90<ULN<150 V: ULN, 110 V or 127 V.

if 300<ULN<500 V: ULN, 380 V or 400 V.

6 %

To deactivate the alarm.

Z-R

To activate the alarm on R

050.00

Ik

Before the measurement: to display the measurements already recorded.

During or after the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

Press the TEST button to start the measurement. The measurement stops automatically.

To activate the alarm on Ik (in TRIP mode only).

010.00

A

ASEL

.

To set the alarm threshold (see §3.17). As default,

the threshold is set to 50 W.

To set the alarm threshold (see §3.17). As default,

the threshold is set to 10 kA.

This symbol invites you to wait while the measurement is in progress.

33

3.8.4. READING OF THE RESULT

Value of the alarm threshold.

11-25-2013 10:47

R Asel 3 8.4 2 Ω

I s e l 1 6 3 . 5 m A

Z a 3 . 8 4 0 Ω

R a 3 . 8 3 8 Ω

7 %

EARTH Ra Sel.

L a 2 . 6 m H

50 . 0 Ω 50 . 1 Hz

Measurement result.

Value of the current measured by

the clamp.

Value of the impedance.

Value of the resistance.

Value of the inductance.

Case where the measurement is

above the alarm threshold.

To change display pages.

Value of the reference voltage for the

calculation of Ik.

The rod is connected.

Programmed maximum contact

voltage.

Compensation for the resistance of

the measurement leads is activated.

The clamp is connected.

The second page is used to see the value of short-circuit current Ik, f loop impedance ZS, of loop resistance RS nd of loop inductance LS.

The third page is used to see the value of the voltages ULN, U

3.8.5. ERROR INDICATION ((LOOP, EARTH ON LIVE CIRCUIT, AND SELECTIVE EARTH ON LIVE CIRCUIT)

The commonest errors in the case of a loop impedance measurement or earth measurement on live circuit are:

A connection error.

An earth rod resistance that is too high (>15 kW): reduce it by packing the earth around the rod and moistening it.

A voltage on the protective conductor that is too high.

A voltage on the rod that is too high: move the rod out of the influence of the earth electrode.

Tripping in the non-tripping mode: reduce the test current.

A current measured by the clamp in selective earth on live circuit that is too low: the measurement is not possible.

The user may have picked up a charge of static electricity, for example by walking on a carpet. In this case, when he/she

presses the TEST button, the device displays the error message «earth potential too high». The user must then be discharged by touching an earth before making the measurement.

LPE

, U

and on the rod ( ) before the measurement.

NPE

For help with connections or any other information, use the help function.

34

3.9. MEASUREMENT OF THE LINE IMPEDANCE (Zi)

R

R

R

The loop impedance measurement Zi (L-N, L1-L2, or L2-L3 or L1-L3) is used to calculate the short-circuit current and size the protections of the installation (fuse or RCD), whatever type of neutral the installation uses.

3.9.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

The device generates pulses having a duration of 1.1 ms and an amplitude of at most 7 A between the L and N terminals. It then

measures the voltages UL and UN and from them deduces Zi.

The device then calculates the short-circuit current Ik = ULN/Zi the value of which serves to check the proper sizing of the protections of the installation.

3.9.2. MAKING A MEASUREMENT

Set the switch to Zi.

SET UP

Case of a TT installation Case of a TN installation

L

L

RN

N

Rb

OFF

Ra

PE

Connect the measuring cable to the device, then to the socket outlet of the installation to be tested.

At the time of connection, the device first checks that the voltages present

on its terminals are correct, then determines the position of the phase (L) and

of the neutral (N) with respect to the protective conductor (PE) and displays

it. If necessary, it then automatically switches the L and N terminals so that

the line impedance measurement can be made without modifying the connections of the terminals of the device.

If you use the measuring cable that is terminated by three leads, you can connect

the PE lead (green) to the N lead (blue). Otherwise, the device cannot display the

position of the phase. But this does not prevent making the measurement.

L

L

RN

N

RE

PE

Rb

/

/

Case of an IT installation

L

L

RN

N

PE

Z

Ra

/

The alarm, if activated, serves to inform the user, by an audible signal, that the measurement is above threshold, making it unnecessary to look at the display unit to check this point.

The signal can be smoothed to produce a mean of values. But the measurement then takes longer.

35

k Ω

Ω

3.9.3. CONFIGURING THE MEASUREMENT

k A

k A

Before starting the measurement, you can configure it by modifying the parameters displayed:

To select measurement of Zi (line impedance measurement) or of DV (measurement of the voltage drop in the cables,

for the C.A. 6117 only). Here, you must select Zi.

To compensate for the resistance of the measurement leads, for measurements of low values (see §3.16).

To activate or deactivate the smoothing of the signal.

The device proposes choosing the voltage for the Ik calculation from among the following values:

(Ik)

ULN (the measured voltage value),

the voltage of the old standard (for example 220 V),

the voltage of the current standard (for example 230 V).

Depending on the voltage ULN measured, the device proposes the following choices:

if 170<ULN<270 V: ULN, 220 V, or 230 V.

if 90<ULN<150 V: ULN, 110 V or 127 V.

if 300<ULN<500 V: ULN, 380 V or 400 V.

To deactivate the alarm.

Z-R

Ik

ISC

To activate the alarm on Zi.

050.00

To activate the alarm on Ik.

010.00

A

To activate the alarm on Isc (for the C.A. 6117 only).

023.00

A

If there is an alarm on Isc, the fuse characteristics menu is displayed.

Choice of type of fuse: gG, B, C, or D.

Choice of rated current, IN: all standardized values between

2 and 1250 A.

The delay (the duration of application of IN before the fuse

blows): 0.1 s, 0.2 s, 0.4 s, 5 s and 35 minutes.

To set the alarm threshold (see § 3.17). As default,

the threshold is set to 50 W.

To set the alarm threshold (see §3.17). As default,

the threshold is set to 10 kA.

To adjust the alarm threshold (see § 3.17). The

default threshold is 23 A.

6 %

The device then deduces Isc from this and displays it.

Before the measurement: to display the measurements already recorded.

During or after the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

36

TEST

Press the TEST button to start the measurement. The measurement stops automatically.

When the TEST button is pressed, the device checks that the contact voltage is less than UL. If not, it does not

make the loop impedance measurement.

This symbol invites you to wait while the measurement is in progress.

If Ik is less than Isc, the fuse is not suited to the installation it protects and must be replaced.

3.9.4. READING OF THE RESULT

Value of the alarm threshold.

11-25-2013 10:47

I k 1 3 1 6 A

Z i 0 . 2 9 Ω

R i 0 . 1 5 Ω

L i 0 . 8 m H

5 %

LOOP Zi

50 . 0 Ω 50 . 1 Hz

L

Value of the short-circuit current.

Value of the impedance.

Value of the resistance.

Value of the inductance.

Case where the measurement is

below the alarm threshold.

To change display pages.

Value of the reference voltage for the

calculation of Ik.

Programmed maximum contact

voltage.

Compensation for the resistance of

the measurement leads is activated.

3.9.5. ERROR INDICATION

See §3.8.5.

37

R

F

R

F

3.10. MEASUREMENT OF THE VOLTAGE DROP IN THE CABLES (DV)

For the C.A. 6117 only. The voltage drop in the cables is measured to check that the cross section of the cables is sufficient for the

installation. A voltage drop that is too large (> 5%) means that the cross section of the cables is too small.

This measurement can be made whatever the type of neutral used in the installation.

3.10.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

The device makes a first measurement of Zi at a reference point, then a second measurement of Zi at the measurement point.

The voltage drop is then calculated: DV = 100 (Zi - Zi ref ) x IN / U

The result is expressed in %.

3.10.2. MAKING A MEASUREMENT

. IN is the rated current of the fuse that protects the installation.

REF

Set the switch to Zi.

You must make two measurements.

For the first, connect the tripod cable/3 safety leads to the instrument. Operate just

after the fuse that protects the installation. Connect the L cord (red) to the phase and

SET UP

the N cord (blue) to the neutral. Connect the PE cord (green) to the N cord (blue).

At the time of connection, the device first checks that the voltages present on

its terminals are correct, then determines the position of the phase (L) and of

the neutral (N) with respect to the protective conductor (PE) and displays it.

If necessary, it then automatically switches the L and N terminals so that the line

OFF

impedance measurement can be made without modifying the connections of the

terminals of the device.

L

L

N

RN

PE

Rb

Ra

/

For the second measurement, connect the tripod cable to the instrument and to one of the outlets of the installation.

L

L

N

RN

PE

Rb

Ra

/

The alarm, if activated, serves to inform the user, by an audible signal, that the measurement is above threshold, making it unnecessary to look at the display unit to check this point.

The signal can be smoothed to produce a mean of values. But the measurement then takes longer.

For this measurement, it is not necessary to connect the PE terminal.

38

TEST

3.10.3. CONFIGURING THE MEASUREMENT

Before starting the measurement, you can configure it by modifying the parameters displayed:

To select the measurement of Zi (line measurement impedance) or of V (measurement of the voltage drop in the

cables). Here, you must select DV.

To compensate for the resistance of the measurement leads, for measurements of low values (see §3.16).

Can be used to specify the characteristics of the fuse.

Choice of type of fuse: gG, B, C, or D.

2A

(Ik)

Choice of rated current, IN: all standardized values between 2 and 1250 A.

The delay (the duration of application of IN before the fuse blows): 0.1 s, 0.2 s, 0.4 s, 5 s and 35

minutes.

The device then deduces Isc from this and displays it.

The device proposes choosing the voltage for the Ik calculation from among the following values:

ULN (the measured voltage value),

the voltage of the old standard (for example 220 V),

the voltage of the current standard (for example 230 V).

Depending on the voltage ULN measured, the device proposes the following choices:

if 170<ULN<270 V: ULN, 220 V, or 230 V.

if 90<ULN<150 V: ULN, 110 V or 127 V.

if 300<ULN<500 V: ULN, 380 V or 400 V.

To deactivate the alarm.

DV

Before the measurement: to display the measurements already recorded.

6 %

During or after the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

Press the TEST button to start the measurement. The measurement stops automatically.

When the TEST button is pressed, the device checks that the contact voltage is less than UL. If not, it does not

make the loop impedance measurement.

This symbol invites you to wait while the measurement is in progress.

If Ik is greater than Isc, the fuse is unsuited to the installation it protects and must be replaced.

To activate the alarm on DV.

5.00%

To adjust the alarm threshold (see § 3.17). The default

threshold is 5%.

39

3.10.4. READING OF THE RESULT

After the first measurement:

Value of the alarm threshold.

11-25-2013 10:47

1.00%

I k 1 3 1 6 A

Z r e f 0 . 2 9 Ω

R i 0 . 1 5 Ω

L i 0 . 8 m H

5 %

LOOP dV

50 . 0 Ω 50 . 1 Hz

L

Value of the short-circuit current.

Value of the reference impedance.

Value of the resistance.

Value of the inductance.

Once the first measurement has

been made, change the connection as explained above and press

the TEST button again to make the

second measurement.

Value of the reference voltage for the

calculation of Ik.

Programmed maximum contact

voltage.

Compensation for the resistance of

the measurement leads is activated.

After the second measurement:

11-25-2013 10:47

1.00%

V - 0 . 3 3 %

Z r e f 0 . 8 3 6 Ω

Z l i n e 0 . 7 8 8 Ω

I n 1 6 . 0 0 A

5 %

LOOP dV

50 . 0 Ω 50 . 1 Hz

L

Result of the calculation of DV.

Value of the reference impedance.

Value of the 2nd impedance.

Value of the rated current of the fuse.

Case where the measurement is

below the alarm threshold.

3.10.5. ERROR INDICATION

See §3.8.5.

40

3.11. TEST OF RESIDUAL CURRENT DEVICE

The device can be used to perform three types of test on RCDs:

a tripping test in ramp mode,

a tripping test in pulse mode,

a non-tripping test.

The test in ramp mode serves to determine the exact value of the tripping current of the RCD.

The test in pulse mode serves to determine the tripping time of the RCD.

The non-tripping test serves to check that the RCD does not trip at a current of 0.5 IDN. For the test to be valid, the leakage current

must be negligible with respect to 0.5 IDN and, to ensure this, all loads connected to the installation protected by the RCD that is

being tested must be disconnected.

3.11.1. DESCRIPTION OF THE MEASUREMENT PRINCIPLE

For each of the three types of test, the device starts by checking that the RCD can be tested without compromising the user’s

safety, i.e. without causing the fault voltage, UF , to exceed 50 V (or 25 V or 65 V according to what is defined in the SET-UP for

UL ). The device therefore starts by generating a low current (<0.3 IDN) in order to measure ZS, as it would for a loop impedance

measurement.

It then calculates UF = ZS x IDN (or UF = ZS x 2 IDN or UF = ZS x 5 I

depending on the type of test requested), which will be the

DN

maximum voltage produced during the test. If this voltage is greater than UL, the device does not perform the test. The user can

then reduce the measurement current (to 0.2 IDN) so that the test current combined with the leakage current present in the installation will not lead to a voltage greater than UL.

For a more accurate measurement of the fault voltage, we recommend planting an auxiliary rod, as for earth measurements on

live circuits. The device then measures RA and calculates UF = RA x IDN (or UF = RA x 2 IDN or UF = ZS x 5 I

depending on the type

DN

of test requested).

Once this first part of the measurement has been made, the device goes on to the second part, which depends on the type of test.

For the ramp mode test, the device generates a sinusoidal current of which the amplitude increases gradually from 0.3 to 1.06

IDN between the L and PE terminals for type AC and A RCDs and from 0,2 to 2,2 IDN for type B RCDs. When the RCD opens

the circuit, the device displays the exact value of the tripping current and the tripping time. This time is an indication and may

differ from the trip time in pulse mode, which is closer to the operational reality.

For the pulse mode test, the device generates a sinusoidal current at the mains frequency, having an amplitude of IDN, 2 IDNor

5 IDN between the L and PE terminals for type AC and A RCDs and 2 IDN or 4 IDN for type B RCDs, lasting at most 500 ms. And

it measures the time the RCD takes to open the circuit. This time must be less than 500 ms.

For the non-tripping test, the device generates a current of 0.5 IDN for one or two seconds, depending on what the user has

programmed. Normally, the tripping must not trip.

In the ramp and pulse mode tests, if the RCD does not trip, the device sends a current pulse between the L and N terminals. If

the RCD trips, it is because it was incorrectly installed (N and PE reversed).

3.11.2. PERFORMING A TEST IN RAMP MODE

Set the switch to RCD .

SET UP

Connect the measuring cable to the device, then to a socket outlet included in the circuit

protected by the RCD to be tested.

At the time of connection, the device detects the positions of the phase (L) and

of neutral (N) with respect to the protective conductor (PE) and displays them. If

necessary, it then automatically switches the L and N terminals so that the test

can be done without modifying the connections of the terminals.

OFF

41

RL

RN

RCD

L

N

PE

Rb

Ra

/

If possible, first disconnect all loads from the network on which you test the RCD. This prevents interference with the test

by any leakage currents due to these loads.

If you have a current clamp, you can measure the leakage current (see §3.12) at the RCD and so make allowance for it during

the test.

To make a more accurate measurement of the fault voltage, plant the auxiliary rod at a distance of more than 25 metres

from the earth electrode and connect it to the (RA SEL) terminal of the device. The symbol is then displayed.

RCD

RL

L

N

RN

PE

Rb

Ra

> 25 m

/

Particular case:

To test a residual current device located downstream of another residual current device having a smaller nominal current, you

must use the measuring cable terminated by 3 leads and make the connections shown opposite (upstream-downstream method).

RCD RCD

RL

L

N

Rb

RN

Ra

PE

30 mA

blue

300 mA

green

/

red

42

3.11.3. CONFIGURING THE MEASUREMENT

TEST

Before starting the measurement, you can configure it by modifying the parameters displayed:

Choice of the nominal current of the residual current device IDN: VAR. (variable: the user programs a value be-

30 mA

tween 6 and 999 mA; this choice does not exist for type B RCDs), 10 mA, 30 mA, 100 mA, 300 mA, 500 mA,

650 mA, or 1000 mA.

Choice of type of residual current device: STD (standard), S or G (the S type is tested with a current of 2 IDN

as default).

Choice of the form of the test signal:

signal that starts with a positive alternation (type AC RCDs),

signal that starts with a negative alternation (type AC RCDs),

signal containing only positive alternations (type A RCDs),

signal containing only negative alternations (type A RCDs),

continuous positive DC signal (type B RCDs),

continuous negative DC (type B RCDs).

6 %

To restore the factory adjustment parameters: IDN = 30 mA, STD and signal

To perform a prior check of voltage UF, choose a test current: 0.2, 0.3, 0.4, or 0.5 IDN .

0.3 I∆N

Before the measurement: to display the measurements already recorded.

During or after the measurement: to record it.

The direction of the arrow indicates whether you can make a reading (arrow pointing out) or a recording (arrow

pointing in).

The percentage indicates the quantity of memory already used.

Press the TEST button to start the measurement. The measurement stops automatically.

In the case of type S or G circuit-breakers, the device counts 30 seconds between the prior test of UF and the test of

the RCD itself, in order to allow its demagnetization. This wait can be cut short by pressing the TEST button again.

To make a faster measurement by eliminating the prior check of voltage UF, choose: --x--.

To activate or deactivate the audible voltage alarm (the threshold being equal to UL).

This function makes it possible to locate, on the distribution panel, using the audible signal, the RCD

protecting a remote current socket outlet (typical case of a panel at a distance from the socket outlet)

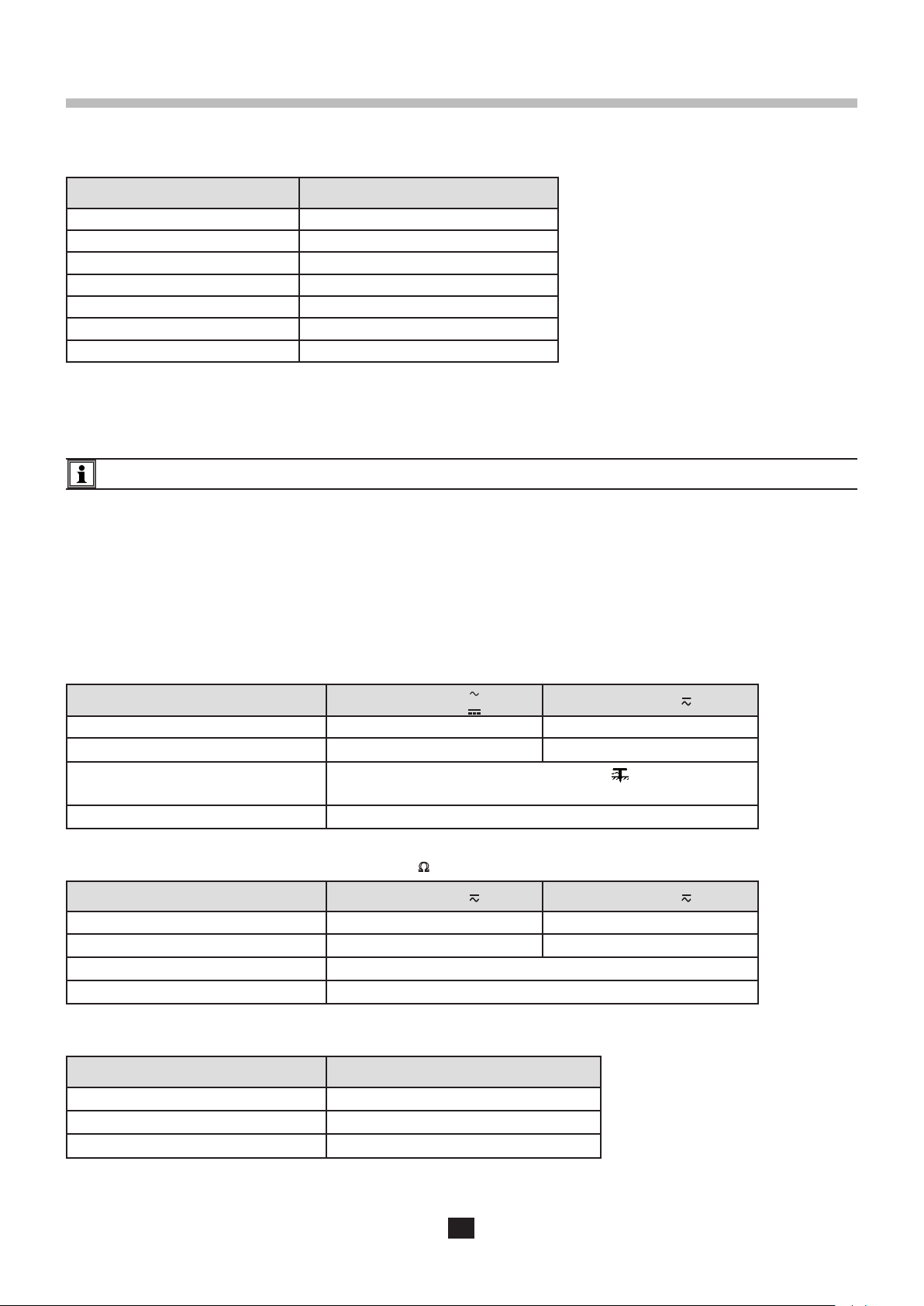

without being in the immediate vicinity of the device.