Page 1

Megohmmeters

Model 6522 & 6524

User Manual

ENGLISH

www.aemc.com

®

CHAUVIN ARNOUX GROUP

Page 2

Statement of Compliance

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

certifies that this instrument has been calibrated using

standards and instruments traceable to international

standards.

We guarantee that at the time of shipping your

instrument has met its published specifications.

An NIST traceable certificate may be requested at

the time of purchase, or obtained by returning the

instrument to our repair and calibration facility, for a

nominal charge.

The recommended calibration interval for this

instrument is 12 months and begins on the date of

receipt by the customer. For recalibration, please

use our calibration services. Refer to our repair and

calibration section at www.aemc.com.

Serial #: ________________________________

Catalog #: 2155.51 / 2155.52

Model #: 6522 / 6524

Please fill in the appropriate date as indicated:

Date Received: _________________________________

Date Calibration Due:

_______________________

Chauvin Arnoux®, Inc.

d.b.a AEMC® Instruments

www.aemc.com

Page 3

Copyright © Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments. All rights reserved.

No part of this documentation may be reproduced in any form or by any means (including electronic storage and retrieval

or translation into any other language) without prior agreement and written consent from Chauvin Arnoux®, Inc., as

governed by United States and International copyright laws.

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

15 Faraday Drive • Dover, NH 03820 USA

Tel: (800) 945-2362 or (603) 749-6434 • Fax: (603) 742-2346

This documentation is provided “as is,” without warranty of any kind, express, implied, or otherwise. Chauvin Arnoux®,

Inc. has made every reasonable eort to ensure that this documentation is accurate; but does not warrant the accuracy or

completeness of the text, graphics, or other information contained in this documentation. Chauvin Arnoux®, Inc. shall not

be liable for any damages, special, indirect, incidental, or inconsequential; including (but not limited to) physical, emotional

or monetary damages due to lost revenues or lost prots that may result from the use of this documentation, whether or

not the user of the documentation has been advised of the possibility of such damages.

Chauvin Arnoux®, Inc and AEMC® are registered trademarks of AEMC® Instruments.

Page 4

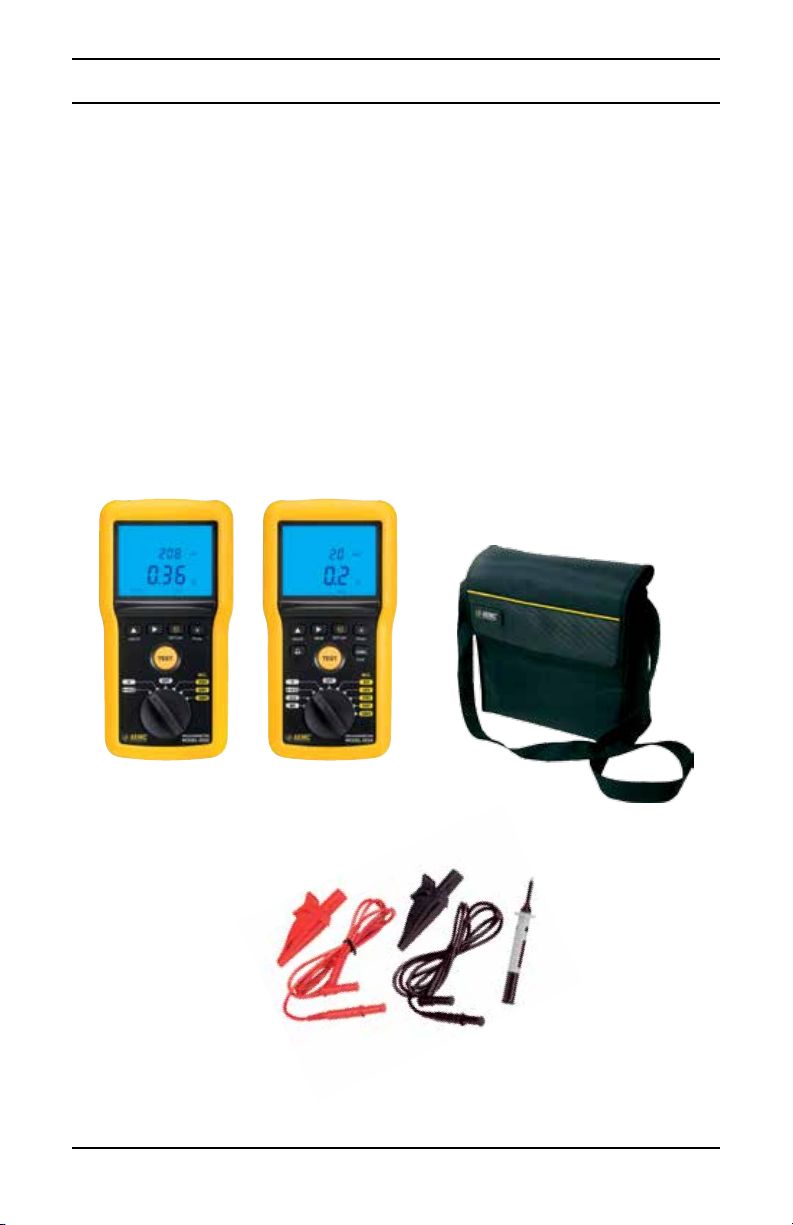

Thank you for purchasing the Megohmmeter Model 6522 or 6524.

For best results from your instrument:

■ Read these operating instructions carefully

■ Comply with the precautions for use

WARNING, risk of DANGER! The operator must refer to these

instructions whenever this danger symbol appears

WARNING, risk of electric shock. The voltage applied to parts

marked with this symbol may be hazardous

Equipment is protected by double insulation

> 700V

The voltage on the terminals must not exceed 700V

Ground/Earth

Battery

Information or useful tip

Remote test probe

The product is recyclable in accordance with standard ISO14040

This instrument exceeds regulatory requirements with respect to

recycling and reuse

Indicates conformity with European directives, in particular LVD and

EMC

Indicates that, in the European Union, the instrument must undergo

selective disposal in compliance with Directive WEEE 2002/96/EC.

This instrument must not be treated as household waste

Denition of Measurement Categories (CAT)

■ CAT II corresponds to measurements taken on circuits directly connected to

low-voltage installations.

Example: power supply to electro-domestic devices and portable tools.

■ CAT III corresponds to measurements on building installations.

Example: distribution panel, circuit-breakers, machines or xed industrial

devices.

■ CAT IV corresponds to measurements taken at the source of low-voltage

installations.

Example: power feeders and protection devices.

Page 5

PRECAUTIONS FOR USE

This instrument is compliant with safety standard IEC 61010-2-030, and the leads

are compliant with IEC 61010-031, for voltages up to 600V in CAT IV or 1000V in

CAT III.

Failure to observe the following safety instructions may result in electric shock,

re, explosion, and damage to the instrument and installation.

■ Carefully read and understand all precautions for use.

■ Be aware of all electrical hazards when using this instrument.

■ Using this instrument other than as specied may compromise its user

protection features.

■ The safety of any system in which this instrument is incorporated is the

responsibility of the integrator of the system.

■ This instrument can be used on CAT IV installations, for voltages

not exceeding 600V

RMS

with respect to ground or 700V

between terminals.

■ Do not use the instrument on networks whose voltage or category

exceeds those specied in this manual.

■ Observe all environmental conditions of use (see § 3).

■ Except for voltage measurements, take no measurements on

electrically “live” systems.

■ Do not use the instrument if it appears damaged, incomplete, or poorly

closed.

■ Before each use, check the condition of the insulation on the leads,

housing, and accessories. Any part on which the insulation is

deteriorated (even partially) must be set aside for repair or scrapping.

■ Using the instrument without its battery compartment cover may result

in electric shock to the user.

■ Before using your instrument, ensure it is completely dry.

■ Use only the leads and accessories supplied. The use of leads (or

other accessories) of a lower voltage rating or category limits the use

of the instrument/leads (or accessories) combination to the lowest

category and service voltage.

■ When handling the leads, test probes, and alligator clips, keep your

ngers behind the physical guards.

■ Before removing the battery compartment cover, ensure all

measurement leads and accessories are disconnected. Replace all

batteries at once. Use alkaline batteries.

■ Use personal protection equipment where appropriate.

■ All troubleshooting and metrological checks must be done by

competent, accredited personnel.

RMS

maximum

Page 6

Table of Contents

1. INTRODUCTION .....................................................................4

1.1 Receiving Your Shipment......................................................................4

1.2 Accessories...........................................................................................5

1.3 Replacement Parts ...............................................................................5

1.4 Description ............................................................................................5

1.4.1 Model 6522 (Front) ...................................................................6

1.4.2 Model 6524 (Front) ...................................................................7

1.5 Back of Instrument ................................................................................8

1.6 Terminals ..............................................................................................9

1.7 Function Buttons ...................................................................................9

1.8 LCD Display .......................................................................................10

2. OPERATION .......................................................................... 11

2.1 Setting Up the Instrument ...................................................................11

2.1.1 Conguration Settings ...........................................................11

2.1.2 Alarms.....................................................................................12

2.1.2.1 Activating/Deactivating the Alarm Function ....................12

2.1.2.2 Setting an Alarm Threshold ............................................13

2.1.2.3 Viewing Alarms ..............................................................14

2.1.3 ∆REL Function (Model 6524) .................................................15

2.1.4 HOLD Function.......................................................................16

2.1.5 Backlighting ............................................................................16

2.1.6 Standby Mode ........................................................................16

2.2 Taking Measurements .........................................................................17

2.2.1 Voltage Measurement.............................................................17

2.2.2 Insulation Measurement .........................................................18

2.2.2.1 TEST Button Operation ..................................................20

2.2.2.2 Timed Tests ...................................................................21

2.2.2.3 Remote Control Probe (Optional) ..................................22

2.2.3 Continuity Measurement.........................................................23

2.2.3.1 Lead Compensation .......................................................23

2.2.3.2 Continuity Measuring .....................................................24

2.2.4 Resistance Measurement (Model 6524).................................25

2.3 Recording Data (Model 6524).............................................................26

2.3.1 Recording a Measurement .....................................................26

2.3.2 Viewing Stored Recordings ....................................................27

2

Megohmmeter Model 6522/6524

Page 7

2.3.3 Deleting Recordings ...............................................................28

2.3.3.1 Deleting a Single Recording ..........................................28

2.3.3.2 Deleting All Recordings ..................................................28

3. SPECIFICATIONS ................................................................. 29

3.1 General Reference Conditions ...........................................................29

3.2 Electrical Specications ......................................................................29

3.2.1 Voltage Measurement.............................................................29

3.2.2 Frequency Measurement........................................................30

3.2.3 Insulation Measurement .........................................................30

3.2.4 Continuity Measurement.........................................................32

3.2.5 Resistance Measurement (Model 6524).................................32

3.2.6 Timer.......................................................................................32

3.2.7 Storage Memory (Model 6524) ...............................................33

3.3 Operating Environment .......................................................................33

3.3.1 Voltage Measurement.............................................................33

3.3.2 Insulation Measurement .........................................................34

3.3.3 Resistance and Continuity Measurement ...............................35

3.3.4 Intrinsic Uncertainty and Operating Uncertainty .....................36

3.4 Power Supply......................................................................................36

3.5 Environmental Conditions ...................................................................36

3.6 Mechanical Specications .................................................................37

3.7 Safety Standards ................................................................................37

4. MAINTENANCE & TROUBLESHOOTING ...............................38

4.1 Maintenance .......................................................................................38

4.1.1 Cleaning .................................................................................38

4.1.2 Replacing the Batteries ..........................................................38

4.2 Troubleshooting ..................................................................................40

4.2.1 Errors ......................................................................................40

4.2.1.1 Voltage present before an insulation measurement.......40

4.2.1.2 Range exceeded during an insulation measurement.....40

4.2.1.3 Voltage during continuity/resistance/measurement .......41

4.2.1.4 Memory full (Model 6524) ..............................................41

4.2.2 Resetting the Instrument ........................................................41

4.3 Repair and Calibration ........................................................................42

4.4 Technical and Sales Assistance ..........................................................42

4.5 Limited Warranty .................................................................................43

4.6 Warranty Repairs ................................................................................43

Megohmmeter Model 6522/6524

3

Page 8

1. INTRODUCTION

1.1 Receiving Your Shipment

Upon receiving your megohmmeter product package, ensure the contents are

consistent with the packing list. Notify your distributor of any missing items. If

the equipment appears to be damaged, le a claim immediately with the carrier

and notify your distributor at once, providing a detailed description. Save the

damaged packing container to substantiate your claim.

Ordering Information:

Megohmmeter Model 6522.............................................................. Cat. #2155.51

Megohmmeter Model 6524.............................................................. Cat. #2155.52

Shipping Contents:

One of the following:

Megohmmeter Model 6522

Megohmmeter Model 6524

Both models also include 6 AA batteries and a user manual.

4

or

Soft Carrying Case

Two 1.5m test leads (red/black), two alligator clips

(red/black), 1 test probe (black)

Megohmmeter Model 6522/6524

Page 9

1.2 Accessories

Megohmmeter Test Probe ................................................................ Cat. #2155.75

Case - Field Case (Waterproof) ........................................................ Cat. #2118.98

Case - Hands Free Carrying Case ................................................... Cat. #2118.99

Continuity Pole .................................................................................Cat. #2138.54

Probe - Set of 2, Color-coded (Red/Black) Grip Probes ................... Cat. #2152.26

1.3 Replacement Parts

Lead - Set of 2, Color-coded 5 ft (Red/Black) Silicone Leads, Test Probes &

Alligator Clips {Rated 1000V CAT IV} ............................................... Cat. #2152.05

For accessories and replacement parts, visit our store at www.aemc.com.

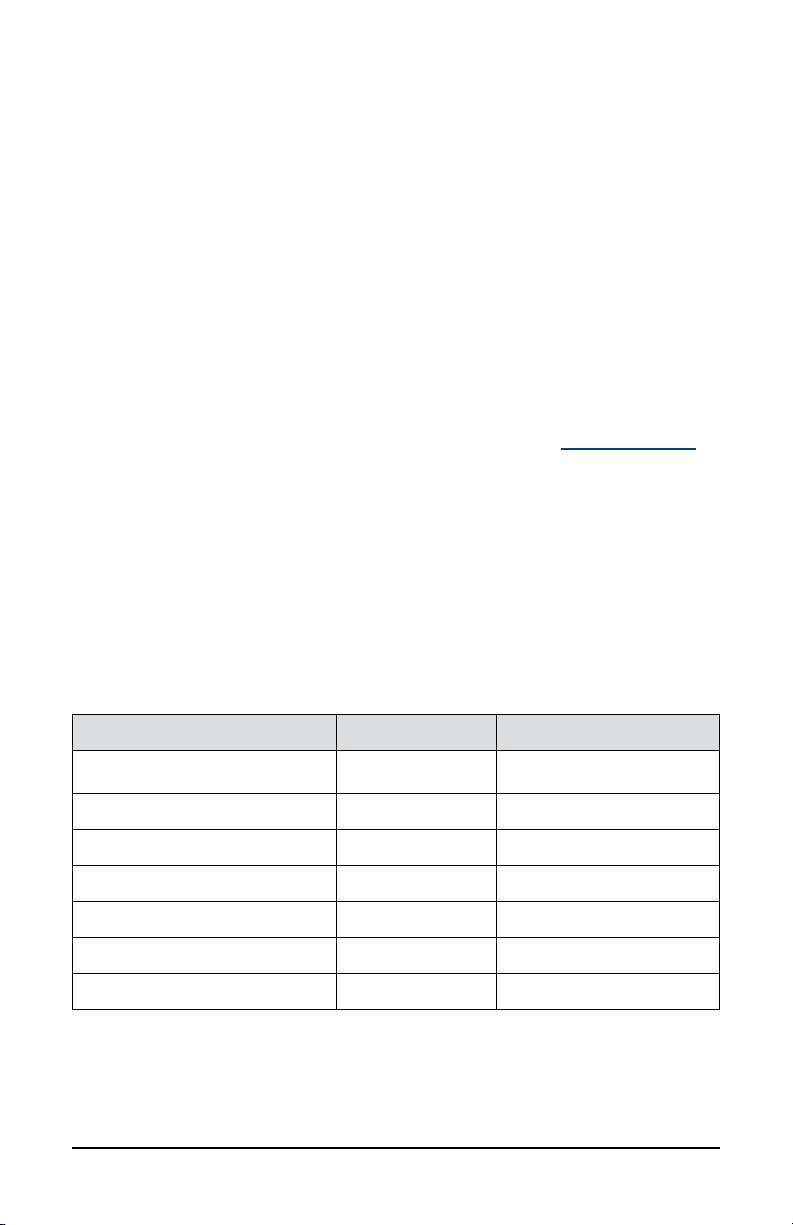

1.4 Description

The Megohmmeters Models 6522 and 6524 are portable measuring instruments

with digital displays. They are powered by batteries. These instruments can

check the safety of electrical installations. For example, they can be used to test

new installations before they are powered up, check an existing installation in a

power-o condition, or troubleshoot an installation.

Features Include:

Model 6522 Model 6524

Insulation test voltages 250, 500, and

1000V

PI and DAR ratios calculation

Continuity measurement

Resistance measurement

Programmable alarms

Frequency measurement

Storage of the measurements

Megohmmeter Model 6522/6524

50, 100, 250, 500, and

1000V

5

Page 10

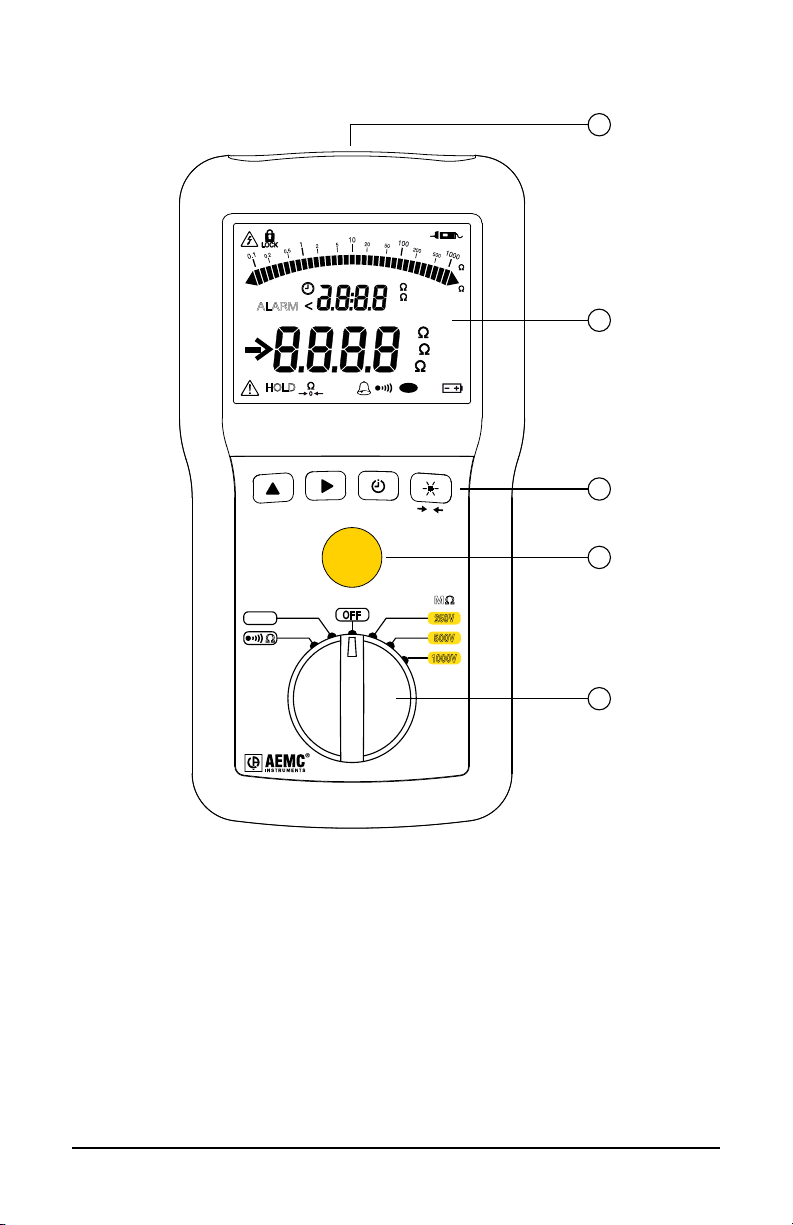

1.4.1 Model 6522 (Front)

<

ALARM

HOLD

G VHz

M mAµA

G

M

k

P

1

M

%

G

2

DC

AC

V

HOLD

SET-UP

0

TEST

MΩ

V

Ω

OFF

MEGOHMMETER

MODEL 6522

250V

500V

1000V

Figure 1

1. Input terminals

2. Blue backlit LCD

3. Four function buttons (see § 1.7)

4. TEST button to start insulation measurements (see § 2.2.2.1)

3

4

5

5. Six-position rotary switch to choose the function or to turn the instrument

OFF

6

Megohmmeter Model 6522/6524

Page 11

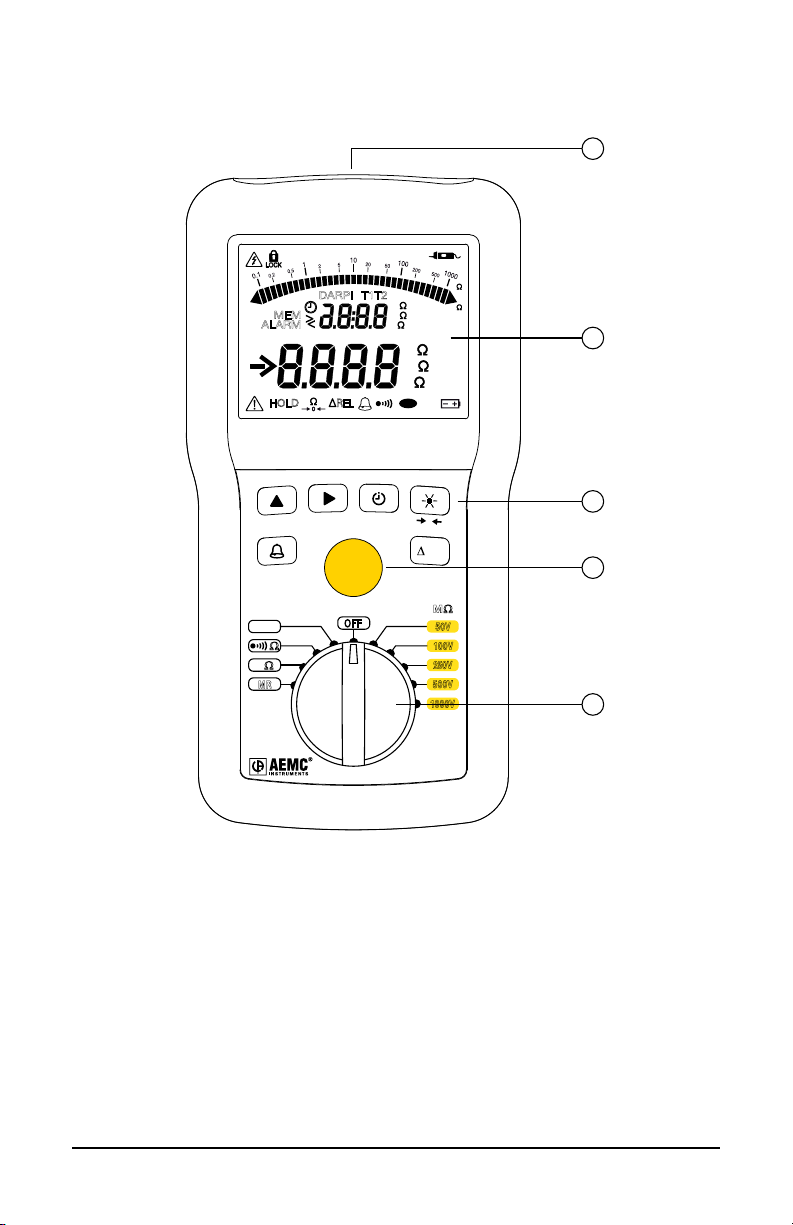

1.4.2 Model 6524 (Front)

1

ALARM

HOLD

HOLD

V

Ω

Ω

k

MR

MEM

>

<

DARPI

MEM

REL

TEST

OFF

T1T2

SET-UP

%

G VHz

M mAµA

k

G

M

DC

AC

V

k

P

0

REL

CLR

MΩ

50V

100V

250V

500V

1000V

MEGOHMMETER

MODEL 6524

M

G

2

3

4

5

Figure 2

1. Input terminals

2. Blue backlit LCD

3. Six function buttons (see § 1.7)

4. TEST button to start insulation measurements (see § 2.2.2.1)

5. Ten-position rotary switch to choose the function or to turn the instrument

OFF

Megohmmeter Model 6522/6524

7

Page 12

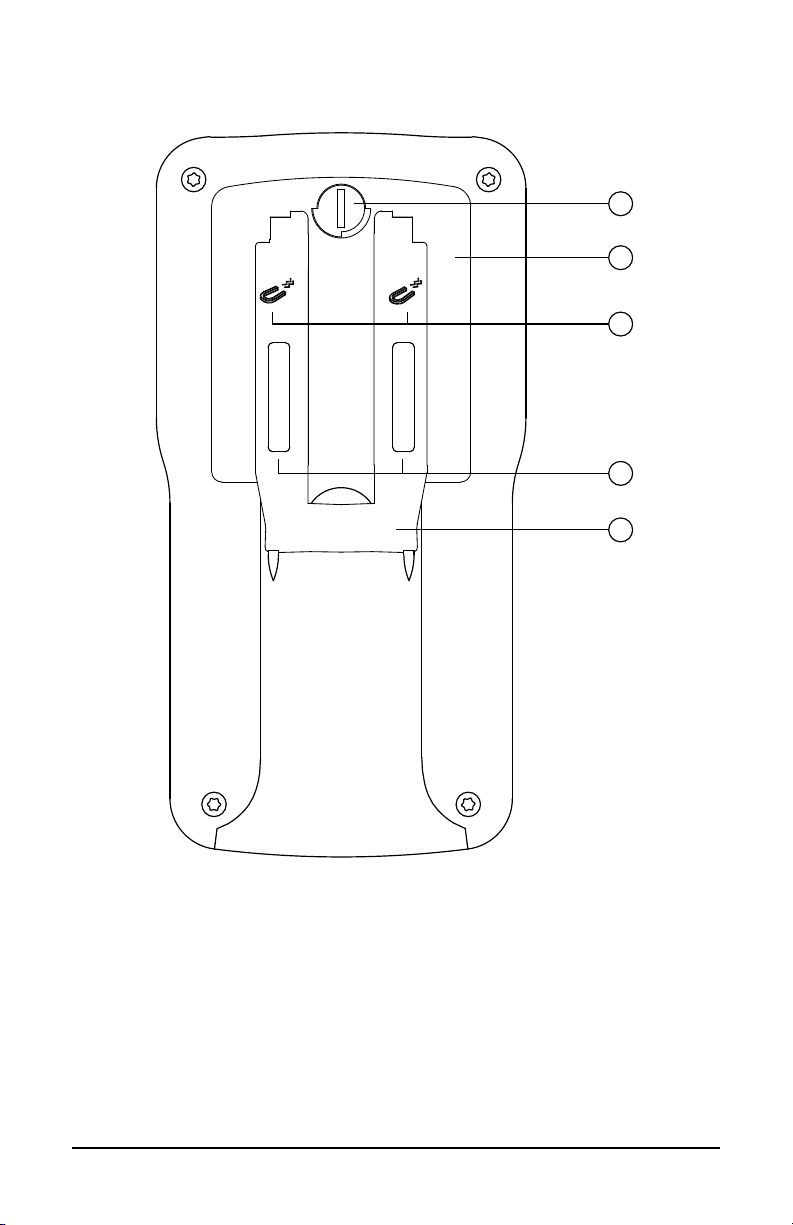

1.5 Back of Instrument

1

2

3

4

5

Figure 3

1. Captive quarter-turn screw

2. Battery compartment cover

3. Mounting magnets, molded into instrument case (Model 6524)

4. Non-skid pads

5. Stand

8

Megohmmeter Model 6522/6524

Page 13

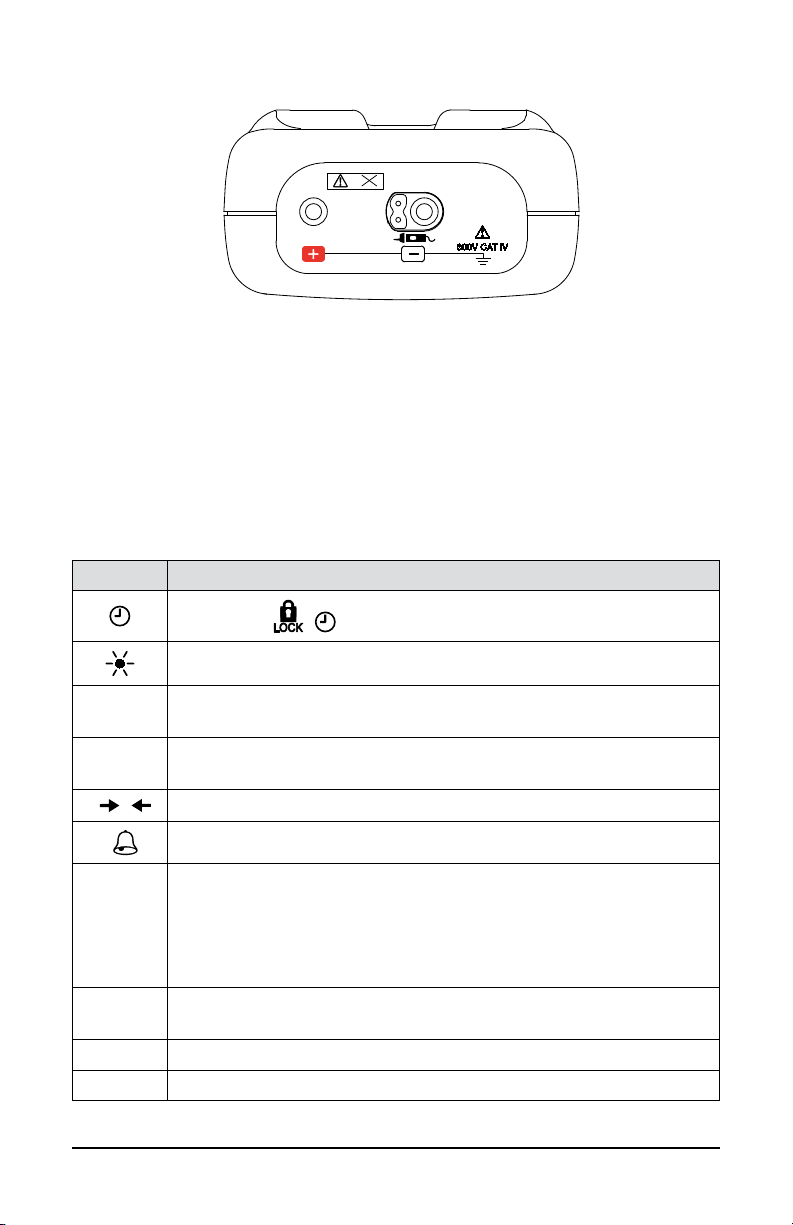

1.6 Terminals

0

> 700V

600V CAT IV

Figure 4

The instrument has one positive ( + ) terminal and one negative ( - ) terminal. The

negative terminal also supports the remote probe accessory (see § 2.2.2.3).

1.7 Function Buttons

In general, each button has two functions. One is marked on the button, and is

enabled via a short press. The second function is marked under the button, and

is enabled by a long (>2 seconds) press.

BUTTON

DESCRIPTION

Selects the , , PI, and DAR functions (§ 2.2.2).

Toggles backlighting ON and OFF (§ 2.1.5).

HOLD

SET-UP

Freezes/unfreezes the displayed measurement on the LCD (§

2.1.4).

Accesses the instrument’s setup parameters and information (§

2.1.1).

Applies lead compensation in continuity testing (§ 2.2.3.1).

(Model 6524) Activates/deactivates alarms (§ 2.1.2).

Modify the display and program the durations of insulation

measurements (§ 2.2.2.2).

Choose the continuity test current (§ 2.2.3).

Program the alarm thresholds on the Model 6524 (§ 2.1.2).

∆Rel

(Model 6524) Displays the dierence between the present

measurement and a stored reference measurement (§ 2.1.3).

MEM (Model 6524) Records measurements (§ 2.3).

CLR (Model 6524) Erase recorded measurements (§ 2.3.3).

Megohmmeter Model 6522/6524

9

Page 14

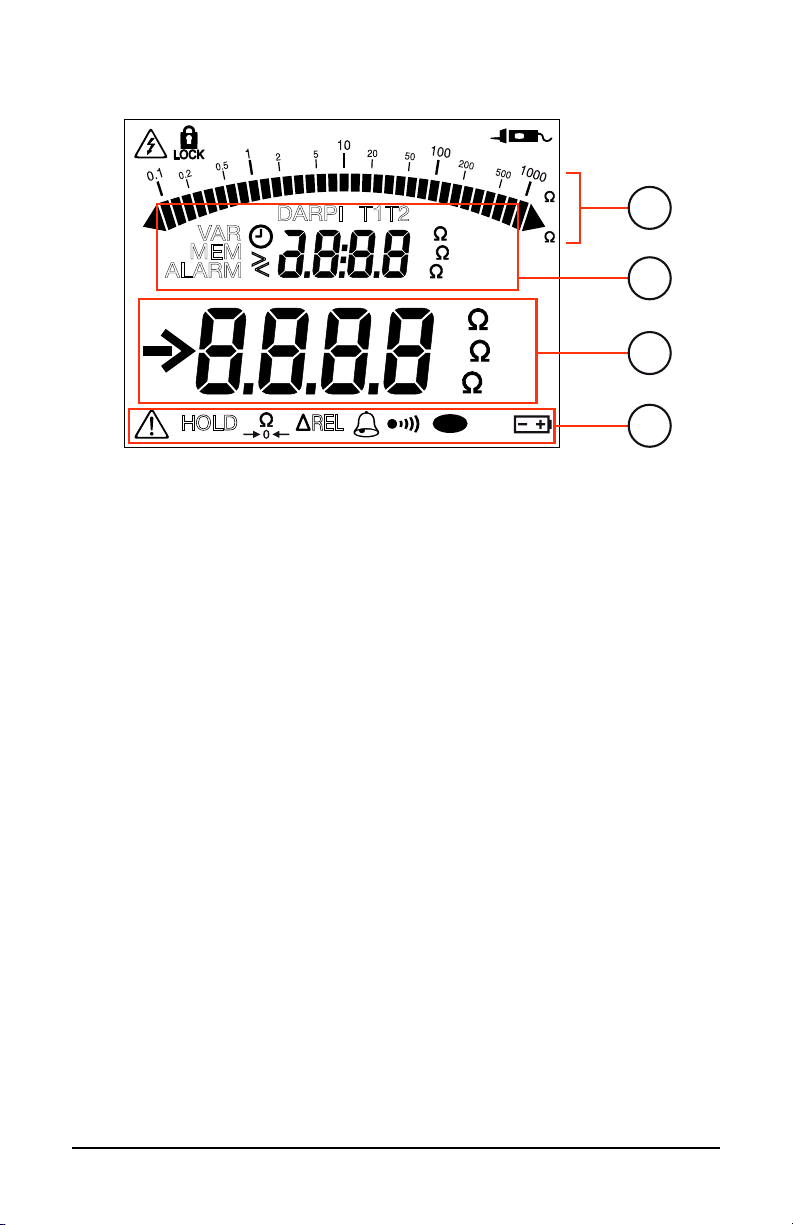

1.8 LCD Display

V

%

nF

µF

DC

AC

M

1

G

2

3

4

VAR

MEM

ALARM

>

<

DARPI

T1T2

G VHz

M mAµA

k nF/ km

G

M

k

HOLD

1. Logarithmic bar graph displays insulation measurements

2. Secondary display area

3. Main display area

4. Icons/indicators

When the measured value is below the minimum, the instrument displays - - - - .

When measuring voltage, if the reading falls outside the range dened by the

positive and negative limits, the instrument displays OL or – OL.

REL

Figure 5

P

10

Megohmmeter Model 6522/6524

Page 15

2. OPERATION

SET-UP

Except when measuring voltage, all measurements must be made on poweredoff systems. Therefore check to ensure there is no voltage on the system under

test before making a non-voltage measurement. When the rotary switch is set

to the voltage or an insulation testing position, the instrument measures and

displays any voltage present at the input terminals prior to the user pressing the

test button.

2.1 Setting Up the Instrument

2.1.1 Configuration Settings

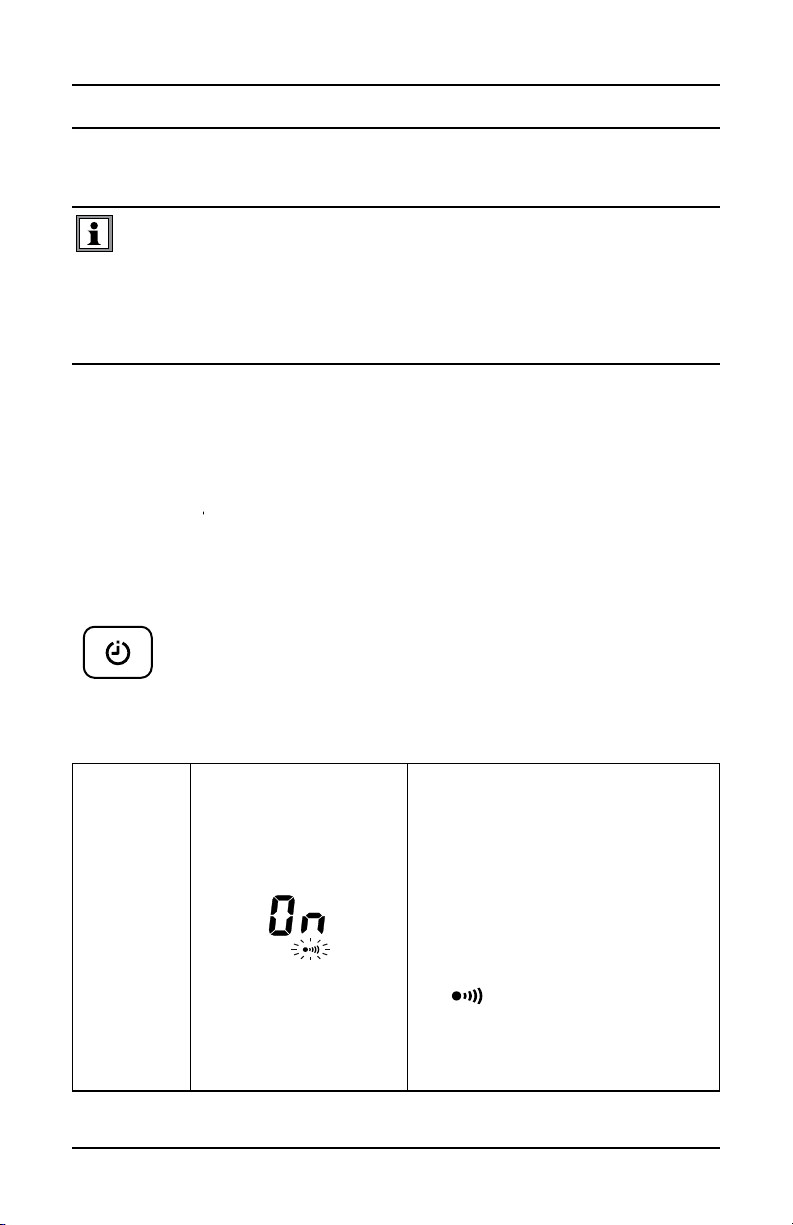

A >2 second press of the SET-UP button enables you to

change conguration settings on the instrument. You can

then use the ▲ and ► buttons to scroll through and modify

> 2s

parameters.

In Set-Up mode, the ▲ button performs the following functions:

1st press

on

Megohmmeter Model 6522/6524

The alarm buzzer is active. To

deactivate it:

1. Press . On will blink to

indicate it is selected.

2. Press to change the

setting to OFF.

3. Press to validate the

change.

The symbol disappears from the

display when you exit Set-Up.

Note that this setting reverts to On

when you turn OFF the instrument.

11

Page 16

2nd press

P

P

on

Automatic switching to standby

mode is activated. To deactivate it:

1. Press to select OFF (the

setting blinks).

2. Press to change the

setting to On.

3. Press to validate the

change.

rd

press

3

on

th

press

4

on

5th press

on

6th press

on

The

display when you exit Set-Up.

Note that this setting reverts to OFF

when you turn OFF the instrument.

Displays the instrument model

number.

Displays the instrument rmware

version.

Displays the instrument hardware

version.

Return to the rst press.

symbol appears on the

2.1.2 Alarms

The instrument includes an alarm function that sounds an audible buzzer when a

dened alarm condition is measured. Alarm features are model-dependent (see

below).

2.1.2.1 Activating/Deactivating the Alarm Function

Model 6522:

The alarm is available in continuity testing mode. Pressing

the TEST button activates the alarm. The

on the LCD, along with the threshold value (2Ω). If the

measurement is below this threshold and the buzzer is active,

the instrument emits an audible signal.

Megohmmeter Model 6522/6524

12

TEST

symbol appears

Page 17

Model 6524:

The alarm is available in insulation, resistance, and continuity

measurement modes. Pressing the

alarm. The

value.

symbol is displayed, along with the threshold

button activates the

ALARM

To turn OFF the alarm buzzer while it is sounding, press the HOLD button. To

deactivate an active alarm function, press the

2.1.2.2 Setting an Alarm Threshold

While

the alarm threshold by pressing the button (except during insulation

measurements). For each testing mode, there are three pre-dened threshold

values:

is displayed indicating the alarm function is active, you can change

■ Continuity: < 2Ω, <1Ω and <0.5Ω

■ Resistance: >50kΩ, >100kΩ and >200kΩ

■ Insulation:

50V : <50kΩ, <100kΩ and <20kΩ

100V : <100kΩ, <200kΩ and <400kΩ

250V : <250kΩ, <500kΩ and <1MΩ

500V : <500kΩ, <1MΩ and <2MΩ

1000V : <1MΩ, <2MΩ and <4MΩ

<

button.

Megohmmeter Model 6522/6524

13

Page 18

In each measurement mode, the third threshold can be replaced by a user-

ALARM

<

M

ALARM

k

M

>

dened value. To do this:

1. Press the ► button while the threshold value is displayed.

2. The > symbol starts blinking; you can change it to < by pressing the

button. This symbol indicates the direction of the alarm threshold: < for a

low threshold and > for a high threshold.

3. To change the threshold setting, press the ► button to navigate to the

rst digit, and then use the button to change its value.

4. Use the ► and buttons to select and change the other digits in the

threshold value, as well as the units of measurement.

5. When nished setting the threshold, press the ► button to validate the

setting.

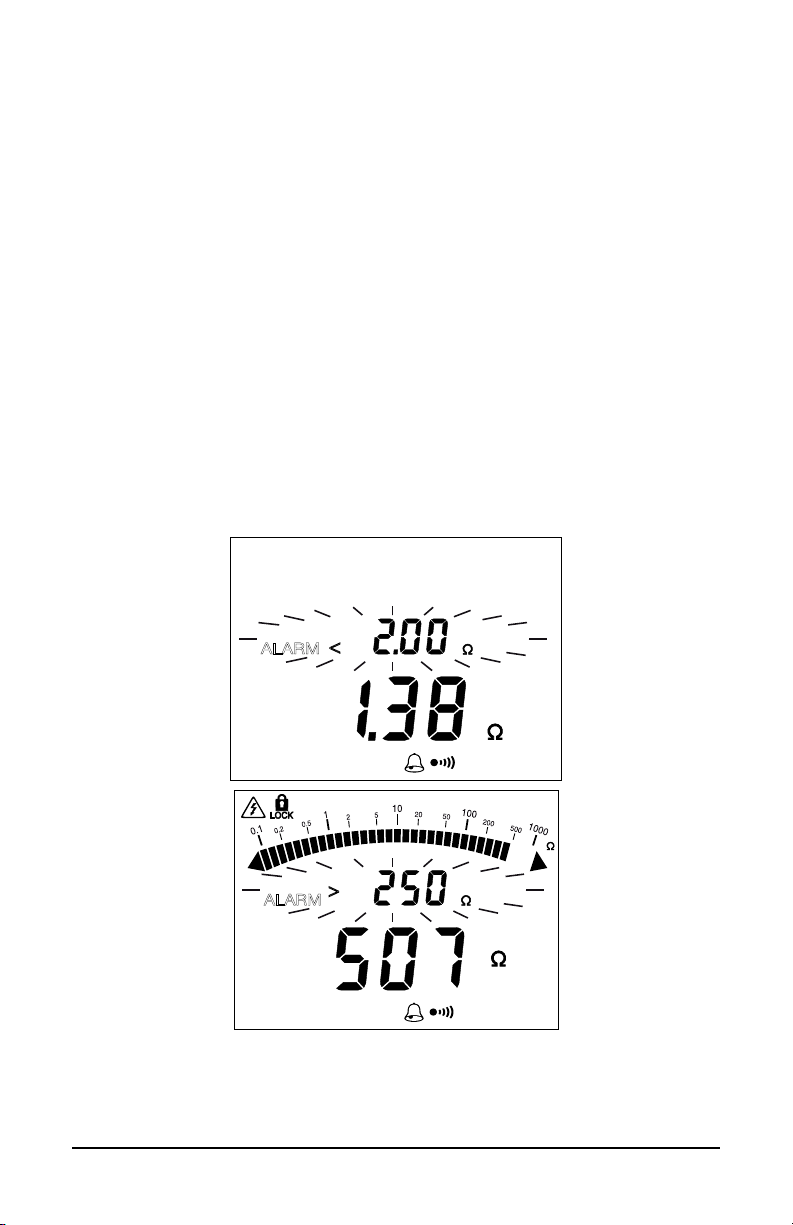

2.1.2.3 Viewing Alarms

When the measurement is below a low alarm threshold or above a high alarm

threshold, the instrument emits a continuous audible signal and the LCD

indicates the threshold crossed:

When checking continuity, this enables you to determine whether or not the

continuity measurement is less than 2Ω simply by listening, without looking at the

display. You can similarly check insulation quality.

14

Megohmmeter Model 6522/6524

Page 19

2.1.3 ∆REL Function (Model 6524)

CLR

M

REL

V

G

For an insulation, resistance, or capacitance measurement,

you can congure the instrument to subtract a reference value

from the measured value and display the dierence.

To activate this function, take a measurement, and then press

REL

If the measured value is less than the stored value, the display becomes

negative.

the ∆REL button. This measurement becomes the reference

(R

ref) and will be stored and subtracted from subsequent

measurement values (R

the LCD while this function is activated.

meas). The ∆REL symbol appears on

You can display the dierence as a percentage of the reference (

by pressing the button until the % sign appears:

%

G

M

REL

For insulation measurements, only the digital display is modified by ∆REL. The

bar graph continues to display the true measured value.

To deactivate the ∆REL function, press the ∆REL button or turn the rotary switch

to another setting.

Megohmmeter Model 6522/6524

15

)

Page 20

2.1.4 HOLD Function

HOLD

0

Pressing the HOLD button freezes the display of the

measurement. This can be done in all functions except the MΩ

settings, or during a timed measurement (

To unfreeze the display, press the HOLD button again.

2.1.5 Backlighting

Pressing the button turns ON backlighting for the LCD.

, DAR, PI).

To switch it OFF, press the

backlighting goes OFF automatically at the end of one

minute.

2.1.6 Standby Mode

After 5 minutes of operation with no user activity, the instrument automatically

switches to standby mode. To restore normal operation, simply press any button.

The instrument returns to the state it was in prior to entering standby mode, with

no loss of information (value of the last measurement, compensation of the leads,

∆Rel, timed mode, alarm, etc.).

Automatic switching to standby mode is disabled during:

■ insulation measurements in

DAR).

■ continuity measurements, for as long as measurements are made.

Automatic switching to standby is disabled via the SET-UP button (see § 2.1.1).

mode and in timed mode ( , PI, or

button again. Otherwise,

16

Megohmmeter Model 6522/6524

Page 21

2.2 Taking Measurements

100V

V

k

Ω

MR

OFF

Ω

250V

500V

1000V

50V

MΩ

2.2.1 Voltage Measurement

To ensure proper and accurate operation of the instrument, we recommend

measuring a known voltage (such as an electrical outlet) before measuring

unknown voltages.

1. Set the switch to V or to one of the MΩ positions.

2. Using the leads, connect the system to be tested to the instrument’s

terminals.

The instrument displays the voltage on the terminals. It detects whether the

voltage is AC or DC; and (for the Model 6524) if it is AC, displays its frequency.

Megohmmeter Model 6522/6524

G VHz

DC

AC

V

17

Page 22

V

DC

AC

G VHz

In the MΩ settings, the symbol indicates that the voltage is too high (>25V)

V

DC

AC

G VHz

and that insulation measurements are prohibited:

If the voltage is >15V, continuity, resistance, and capacitance measurements are

prohibited.

2.2.2 Insulation Measurement

Insulation measurement results can be affected by the impedances of

additional circuits connected in parallel or by transient currents.

Do not start any measurement while the symbol

is displayed.

1. Set the rotary switch to one of the MΩ positions. The test voltage

depends on the voltage of the installation to be tested.

18

Megohmmeter Model 6522/6524

Page 23

100V

V

k

Ω

MR

OFF

Ω

250V

500V

1000V

50V

MΩ

2. Use the leads to connect the system to be tested to the instrument’s

terminals. The system under test must be powered down and

discharged. When testing insulation, the typical connection is negative

(black) lead to conductor and positive (red) lead to ground or the outer

insulation of the device under test.

DC

V

3. (Optional) Press the button to display the current or the elapsed time.

(You can also do this during the measurement.)

4. Press the TEST button and hold it down until the displayed

measurement is stable. Note that if the instrument detects a voltage

greater than 25V in the system under test, pressing the TEST button

has no eect because the test will be prohibited. (An error screen will

appear.)

5. The resistance measurement is displayed on the LCD’s main display

area and on the bar graph. The secondary display area indicates the test

voltage generated by the instrument.

Megohmmeter Model 6522/6524

19

Page 24

M

G V

> 1s

TEST

The symbol indicates that the instrument is generating a hazardous

voltage (>70V).

6. At the end of the measurement, release the TEST button. The

instrument stops generating the test voltage and discharges the device

being tested. The

system under test has fallen below 70V.

NOTE: Do not disconnect the leads and do not start any measure-

ment while the symbol

When you release the TEST button, the measurement results remain displayed

until the next measurement, or the HOLD button is pressed, or the instrument is

turned OFF.

symbol is displayed until the voltage on the

is displayed.

M

2.2.2.1 TEST Button Operation

Pressing the TEST button starts an insulation measurement. In normal mode, the

test voltage is generated for as long as the button is pressed. When the button is

released, the measurement stops.

mode, press the test button once to start the measurement, then press it a

In

second time to stop; there is no need to keep the button pressed. However, if you

do not stop the measurement, it will stop automatically after 15 minutes.

In timed test mode (

measurement. The test will stop automatically at the end of the dened test

duration time.

20

, DAR, or PI) press the TEST button once to start the

Megohmmeter Model 6522/6524

Page 25

2.2.2.2 Timed Tests

PI

T1T2

DARPI

T1T2

The TIMER button activates timed test mode. This button is active only for

insulation measurements.

1st press This locks the TEST button. After you start the

measurement, it continues to run without requiring you to keep the TEST button pressed. The

test will run until you stop it, or when 15 minutes

have passed.

nd

press This activates timed test mode. You can set a test

2

duration between 1 and 39:59 minutes. Use the

and buttons to modify the value displayed.

When the time duration is displayed, press the

button to enter edit mode. When the rst digit

blinks, you can change it using the button.

Press to go to the next digit and to change

it. Then press to validate.

rd

press

3

th

press

4

th

press Exits timed test mode.

5

(Model 6524) This enables the PI function. This

is used to calculate the polarization index (the

ratio of the measurement at 10 minutes to the

measurement at 1 minute).

(Model 6524) This enables the DAR function. This

is used to calculate the dielectric absorption ratio

(the ratio of the measurement at 1 minute to the

measurement at 30 seconds).

When

, DAR, or PI is activated, pressing the TEST button starts the test. The

LCD displays the measurement, along with a “countdown” timer showing the time

remaining in the test. The test automatically stops when the duration end time is

reached and the result is displayed.

DAR

M

M

DAR

Megohmmeter Model 6522/6524

21

Page 26

HOLD

Successive presses on the button display intermediate

TEST

values. These include:

For

:

■ Programmed time, voltage, and current at the end of

the measurement

For PI and DAR:

■ T1 time and the voltage, current, and insulation

resistance at that time

■ T2 time and the voltage, current, and insulation

resistance at that time

Use the following table as a guide for interpreting the results of a DAR or PI test:

DAR PI Condition of insulation

DAR < 1.25 PI < 2 Poor or even dangerous

1.25 ≤ DAR < 1.6 2 ≤ PI < 4 Good

1.6 ≤ DAR 4 ≤ PI Excellent

Press the TEST button to return to voltage measurement.

2.2.2.3 Remote Control Probe (Optional)

The optional remote control probe is used to trigger the measurement using the

TEST button on the probe. To use this accessory, refer to its separate operating

instructions.

22

Megohmmeter Model 6522/6524

DC

V

Page 27

When the probe is connected, the symbol is displayed on the

0

> 2s

0

instrument’s LCD.

NOTE: The remote probe can also be used as a passive probe by simply

touching the probe tip to the test point. It is not necessary to press the test

button.

2.2.3 Continuity Measurement

Continuity measurement measures a low resistance (<10 or 100Ω depending on

the current) at a high current (200 or 20mA).

NOTE: A current of 20mA reduces the power consumption of the instrument,

increasing its battery life. However, the standard IEC 61557 requires 200mA

current for continuity testing.

The Model 6522 can take measurements only at 200mA.

If an external voltage >15V is detected in the system under test during the

continuity measurement, the instrument is protected without a fuse. The

continuity measurement is stopped and the instrument reports an error until the

voltage disappears.

2.2.3.1 Lead Compensation

Before checking continuity, you should compensate for the

resistance of the measurement leads. This ensures that the

resistance measurement excludes the resistance in the leads.

To do this, set the rotary switch to Ω. Then short-circuit the

measurement leads and press the

button for >2 seconds.

Megohmmeter Model 6522/6524

M mA

23

Page 28

The display changes to zero and the symbol is displayed. The resistance

0

100V

V

k

Ω

MR

OFF

Ω

250V

500V

1000V

50V

MΩ

OFF

of the leads will be systematically subtracted from all continuity measurements. If

the resistance of the leads is >10Ω, there is no compensation. The compensation

remains in memory until the instrument is turned OFF.

If the leads are changed with no change of compensation, the display may

become negative. The instrument reports that the compensation must be redone

by displaying a blinking

symbol.

To remove the compensation of the leads, leave the leads open and press the

button for >2 seconds. The LCD displays the resistance of the leads and

the

symbol goes o.

2.2.3.2 Continuity Measuring

1. Set the rotary switch to Ω.

2. (Model 6524) Press the ► button to display the measurement current.

The measurement current appears blinking on the LCD. You can change

the current by pressing the ► button.

3. Use the leads to connect the instrument to the system to be tested. The

system to be tested must be powered down.

24

Megohmmeter Model 6522/6524

Page 29

M mA

M mA

100V

V

k

Ω

MR

OFF

Ω

250V

500V

1000V

50V

MΩ

R

The instrument displays the

resistance and the current used in

the test.

To obtain a continuity value per

standard IEC 61557:

1. Take a measurement at

200 mA and note its value,

R1.

2. Reverse the leads and

note the value R2.

3. Calculate the mean:

2.2.4 Resistance Measurement (Model 6524)

Resistance measurements up to 1000kΩ are made with a low current.

1. Set the rotary switch to kΩ.

Megohmmeter Model 6522/6524

25

Page 30

2. Connect the system to be tested to the instrument. The device to be

k

MEM

tested must be powered down.

3. The instrument displays the results.

2.3 Recording Data (Model 6524)

2.3.1 Recording a Measurement

A measurement can be stored in the instrument’s memory if the measurement is:

■ “Frozen” on the LCD via the HOLD button (§ 2.1.4)

■ The result of a timed test (§ 2.2.2.2)

To save the

measurement, press

the MEM button for

>2 seconds. The

> 2s

measurement is stored

in the rst available

record in the instrument’s

memory.

The saved recording

includes all information

associated with the

measurement, including

voltage, current, duration

of tests, T1 and T2 (for

PI and DAR), and other

data. The recording

also includes a bar

graph indicating how

much available memory

remains in the instrument.

26

Megohmmeter Model 6522/6524

Page 31

2.3.2 Viewing Stored Recordings

100V

V

k

Ω

MR

OFF

Ω

250V

500V

1000V

50V

MΩ

M

MEM

1. Set the rotary switch to MR.

2. The instrument displays the last recording stored in the instrument. The

secondary (top) display indicates the memory location; while the main

display indicates the measured value.

To see the other measurements, press the button. The record number

is decremented and the corresponding measurement is displayed.

3. To scroll rapidly through the recorded measurements, keep the button

pressed.

4. To select a specic recording, use the button to change the recording

number.

5. Once you select the recording number, you can see all information

associated with the measurement. Press the MEM button for >2

seconds, then use the button to scroll the information.

6. When nished viewing recordings, press MEM for >2 seconds.

Megohmmeter Model 6522/6524

27

Page 32

2.3.3 Deleting Recordings

2.3.3.1 Deleting a Single Recording

1. Set the rotary switch to MR.

2. Use the and buttons to select the number of the recording to be

deleted.

3. Press the CLR button for >2 seconds. The record number blinks and the

LCD displays the letters CLR.

4. Press the MEM button for >2 seconds to conrm the deletion. To cancel,

press the CLR button for >2 seconds.

2.3.3.2 Deleting All Recordings

1. Set the rotary switch to MR.

2. Press the CLR button for >2 seconds.

3. Press the button; the record number is replaced by ALL.

4. To cancel, press the CLR button for >2 seconds. Otherwise, press the

MEM button for >2 seconds to conrm the deletion.

5. The instrument displays a message indicating the memory is empty.

28

Megohmmeter Model 6522/6524

Page 33

3. SPECIFICATIONS

3.1 General Reference Conditions

Quantity of Inuence Reference Values

Temperature 73.4° ± 5.4°F (23° ± 3°C)

Relative humidity 45 to 55% RH

Frequency DC and 45 to 65Hz

Supply voltage

Electric eld 0V/m

Magnetic eld < 40A/m

■ The intrinsic uncertainty is the error specied for the reference

conditions.

■ The operating uncertainty includes the intrinsic uncertainty plus

variations of the quantities of inuence (position, supply voltage,

temperature, etc.) as dened in standard IEC 61557.

In this section, uncertainties are typically expressed as % of the reading (R) plus

number of display counts (ct).

8 ± 0.2V

battery life indication 58% ± 8%

3.2 Electrical Specifications

3.2.1 Voltage Measurement

Specic reference conditions: Peak factor = 1.414 in AC, sinusoidal signal.

Measurement Range 0.3 to 399.9V 400 to 700V

Resolution 0.1V (AC and DC) 1V (AC and DC)

Intrinsic uncertainty ± (3% R + 2 ct)

Input impedance 400kΩ

Frequency ranges DC and 15.3 to 800Hz

Megohmmeter Model 6522/6524

29

Page 34

3.2.2 Frequency Measurement

Measurement Range 15.3 to 399.9Hz 400 to 800Hz

Resolution 0.1Hz 1Hz

Intrinsic uncertainty ± (1% R + 2 ct) ± (1.5% R + 1 ct)

3.2.3 Insulation Measurement

Specic reference condition: Capacitance in parallel on resistance = null

Measurement Range

Test Voltage Model 6522 Model 6524

50V 10kΩ to 10GΩ

100V 20kΩ to 20GΩ

250V 50kΩ to 10GΩ 50kΩ to 50GΩ

500V 100kΩ to 20GΩ 100kΩ to 100GΩ

1000V 200kΩ to 40GΩ 200kΩ to 200GΩ

Accuracy

Test Voltage

(VT)

Measurement

Range

Resolution 1kΩ 10kΩ 100kΩ 1MΩ 10MΩ 100MΩ

Accuracy

For all test voltages, when the insulation resistance is ≤ 2GΩ the intrinsic

uncertainty is ± (3% R + 2 ct).

Bar Graph

Measurement Range 0.1MΩ - 200GΩ*

Resolution 9 segments per decade

Intrinsic uncertainty ± (5% R + 1 segment)

*When the measurement range is exceeded, the whole bar graph is displayed.

30

10 to 999kΩ

and 1.000 to

3.999 MΩ

50V - 100V - 250V - 500V - 1000V

4.00 to

39.99MΩ

VT = 50V: ± (3% R + 2 ct + 2%/GΩ)

VT = 100V: ± (3% R + 2 ct + 1%/GΩ)

VT = 250V: ± (3% R + 2 ct + 0.4%/GΩ)

VT = 500V: ± (3% R + 2 ct + 0.2%/GΩ)

VT = 1000V: ± (3% R + 2 ct + 0.1%/GΩ)

40.0 to

399.9MΩ

Megohmmeter Model 6522/6524

400 to

3999MΩ

4.00 to

39.99GΩ

40.0 to

200.0GΩ

Page 35

Test Voltage

Measurement Range 0.0 to 399.9V 400 to 1250V

Resolution 0.1V 1V

Accuracy ± (3% R + 3 ct)

Typical Discharge Time after Test

To go from V

to 25V, the discharge time is < 2s/µF.

T

Test Current

Maximum test current: 2mA

Measurement

Range

0.01 to

39.99µA

40.0 to

399.9µA

0.400 to

2.000mA

Resolution 10nA 100nA 1µA

Accuracy ± (10% R + 3 ct)

Typical Test Voltage vs Load Curve

The voltage as a function of the measured resistance is illustrated below:

The range of operation per IEC 61557 is from 100kΩ to 2GΩ (see § 3.3.4).

Megohmmeter Model 6522/6524

31

Page 36

3.2.4 Continuity Measurement

Specic reference condition: Inductance in series with the resistance = zero.

Model Range

Measurement Range (without

compensation of the leads)

Resolution 10mΩ 100mΩ

Accuracy ± (2% + 2 ct)

Test Current 200mA 20mA

Open Voltage ≥ 6V

*In the case of incorrect compensation of the leads, the instrument allows display

of negative values, down to -0.05Ω at 200mA and -0.5Ω at 20mA.

Test Current

200mA range: 200mA (0mA + 20mA)

20mA range: 20mA ± 5mA

Measurement Range 0 to 250mA

Resolution 1mA

Accuracy ± (2% + 2 ct)

6522

0.00* to 10.00Ω 0.0 * to 100.0Ω

6524

Lead Compensation: 0 to 9.99Ω.

3.2.5 Resistance Measurement (Model 6524)

Measurement Range

Resolution 1Ω 10Ω 100Ω 1kΩ

Accuracy ± (3% + 2 ct)

Open voltage approximately 4.5V

32

0 to

3999Ω

4.00 to

39.99kΩ

Megohmmeter Model 6522/6524

40.0 to

399.9kΩ

400 to

1000kΩ

Page 37

3.2.6 Timer

Measurement Range 0:00 to 39:59

Resolution 1s

Accuracy ± 1s

3.2.7 Storage Memory (Model 6524)

Maximum number of recordings stored in memory: 300

3.3 Operating Environment

3.3.1 Voltage Measurement

Inuencing

Parameter

Temperature

Relative

Humidity

Frequency 15.3 to 800Hz V 1% 2% R + 1 ct

Supply

Voltage

Common

Mode

Rejection in

AC 50/60 Hz

Range of

inuence

-4 to 131°F

(20 to + 55°C)

20 to 80% RH V, F 1% R + 2 ct

6.6 to 9.6V V, F 0.1% R + 2 ct

0 to 600V

AC

Quantity

inuenced

V, F

V 50dB 40dB

Typical Maximum

Inuence

0.3% R/18°F

+ 1 ct

(0.3% R/10°C

+ 1 ct)

Megohmmeter Model 6522/6524

33

Page 38

3.3.2 Insulation Measurement

Inuencing

Parameter

Temperature

Relative

Humidity

Supply

Voltage

50/60Hz

AC voltage

superposed

on the test

voltage (VT)

Capacitance

in parallel on

resistance to

be measured

Range of

Inuence

-4 to 131°F

(-20 to + 55°C)

20 to 80% RH

6.6 to 9.6V MΩ 0.1% R + 2 ct

0 to 5µF at

1mA

0 to 2µF

0 to 1µF

Quantity

Inuenced

MΩ

R ≤ 3GΩ

3GΩ < R < 10GΩ

10GΩ ≤ R

VT: 50 to 500V

VT: 1000V

Measurement

current

MΩ 2% R + 1 ct 3% R + 2 ct

VT: 50 to 1000V 1% R + 2 ct

Measurement

current

R ≤ 0.1GΩ : 4V

from 0.1 to 1GΩ : 0.2V

100 and 250V:

from 100kΩ to 10MΩ : 20V

from 10MΩ to 1 GΩ : 0.3V

500 and 1000V:

from 500kΩ to 50MΩ : 20V

from 50MΩ to 3 GΩ : 0.3V

MΩ 1% R + 1 ct

50, 100 and 250V:

from 10kΩ to 3GΩ

500 and 1000V:

from 100kΩ to

10GΩ

50V: ≤5GΩ

250V: ≤15GΩ

1000V: ≤100GΩ

1% R/10°C

1% R/10°C +

50V:

6% R + 2 ct 10% R + 2 ct

6% R + 2 ct 10% R + 2 ct

6% R + 2 ct 10% R + 2 ct

Inuence

Typical Maximum

2% R/10°C +

2 ct

3% R/10°C +

+ 1pt

1 ct

2 ct

4% R/10°C +

2 ct

0.5% R/10°C +

1 ct

1% R/10 °C +

1 ct

2% R/10°C +

2 ct

1% R + 2 ct

5% R + 2 ct

34

Megohmmeter Model 6522/6524

Page 39

Common

mode

rejection in

AC 50/60 Hz

0 to 600Vac V 50dB 40dB

3.3.3 Resistance and Continuity Measurement

Inuencing

parameter

Temperature

Relative

Humidity

Supply Voltage 6.6 to 9.6V

50/60Hz

AC voltage

superposed on

the test voltage

(VT)

Common mode

rejection in AC

50/60 Hz

Range of

inuence

-4 to 131°F

(-20 to + 55°C)

20 to 80% RH

0.5Vac at 200mA

For R ≥ 10Ω:

0.4Vac

Accepts no

perturbations

0 to 600Vac

Quantity

inuenced

at 200mA

at 20mA

R

at 200mA 2% R + 1 ct 4% R + 2 ct

at 20mA 4% R + 2 ct

R 3% R + 2 ct

at 200mA

at 20mA

R

at 20mA

R

at 200mA

at 20mA

R

Inuence

Typical Maximum

2% R/10°C +

2 ct

2% R/10°C +

2 ct

1% R/10°C +

2 ct

0.1% R + 2 ct

5% R + 10 ct

50dB 40dB

Megohmmeter Model 6522/6524

35

Page 40

3.3.4 Intrinsic Uncertainty and Operating Uncertainty

These megohmmeters comply with standard IEC 61557, which requires that the

operating uncertainty (called B) must be less than 30%.

In insulation and continuity measurements:

where:

A = intrinsic uncertainty

E1 = inuence of the reference position ± 90°

E2 = inuence of the supply voltage within the limits indicated by the

manufacturer

E3 = inuence of the temperature between 32 and 95°F (0 and 35°C)

3.4 Power Supply

The instrument is powered by six 1.5V alkaline AA (LR6) batteries.

The voltage range ensuring correct operation is from 6.6 to 9.6V.

Typical life between charges:

■ 1500 5-second insulation measurements at 1000V for R = 1 MΩ, at the

rate of one measurement per minute.

■ 3000 5-second continuity measurements, at the rate of one

measurement per minute.

3.5 Environmental Conditions

Indoor use

Range of operation: -4 to 131°F (-20 to +55°C) and 20 to 80% RH

Range of storage (without batteries): -22 to 176°F (-30 to +80°C) and 10 to 90%

RH without condensation

Altitude: <6562 ft (2000m)

Degree of pollution: 2

36

Megohmmeter Model 6522/6524

Page 41

3.6 Mechanical Specifications

Dimensions (L x W x H): 8.31 x 4.25 x 2.36” (211 x 108 x 60mm)

Weight: approximately 1.87lb (850g)

Ingress protection:

■ IP 54 per IEC 60529, not in operation

■ IK 04 per IEC 50102

Drop test: per IEC 610

3.7 Safety Standards

Safety according to: EN 61010-2-30 : 2010

Insulation Class: 2

Pollution Degree: 2

Overvoltage Category: 600V CAT IV

Immunity according to: EN 61326-1 : 2013

Emission according to: EN 61326-1 : 2013

Specications are subject to change without notice.

Megohmmeter Model 6522/6524

37

Page 42

4. MAINTENANCE & TROUBLESHOOTING

G VHz %

Except for the batteries, the instrument contains no parts that can

be replaced by personnel who have not been specially trained and

accredited. Any unauthorized repair or replacement of a part by an

“equivalent” may impair safety.

4.1 Maintenance

4.1.1 Cleaning

Disconnect the unit completely and turn the rotary switch to OFF.

Use a soft cloth, dampened with soapy water. Rinse with a damp cloth and

dry rapidly with a dry cloth or forced air. Do not use alcohol, solvents, or

hydrocarbons.

Do not use the instrument again until it is completely dry.

4.1.2 Replacing the Batteries

At start-up, the instrument displays the remaining battery life:

If the battery voltage is too low to ensure correct operation of the instrument, a

“low battery” message appears on the LCD and the

38

Megohmmeter Model 6522/6524

symbol blinks:

Page 43

This indicates the batteries must be replaced. All batteries must be replaced at

the same time. To do this:

1. Disconnect any attached leads or accessories from the instrument and

turn the rotary switch to OFF.

2. Use a tool or a coin to turn the quarter-turn screw of the battery

compartment cover.

3. Remove the battery compartment cover.

4. Remove the batteries from the compartment.

Do not treat spent batteries as ordinary household waste. Take them to the

appropriate collection facility for recycling.

Megohmmeter Model 6522/6524

39

Page 44

5. Place the new batteries in the compartment, ensuring that each battery’s

G

<

M mAµA

G

polarity is correct.

6. Put the battery compartment cover in place and screw the quarter-turn

screw back in.

4.2 Troubleshooting

4.2.1 Errors

During instrument operation, errors may be displayed on the LCD. The causes

of any errors must be corrected before the instrument can resume normal

operation.

4.2.1.1 Voltage present before an insulation measurement

Before taking an insulation

measurement, the instrument

measures voltage on the system under

test. If it detects voltage in excess

of 25V and you attempt to take a

measurement, the instrument displays

the message shown to the left, and no

measurement is taken.

You must eliminate the voltage to

resume taking the measurement.

4.2.1.2 Range exceeded during an insulation measurement

If during an insulation measurement

the value to be measured exceeds the

measurement range (which depends

on the instrument and the test voltage),

the instrument reports this condition.

For example, the screen to the left is

displayed when the range is exceeded

on the Model 6524 while measuring in

the 100V range.

Megohmmeter Model 6522/6524

40

Page 45

G

DAR

With the Model 6524, if this

MEM

condition occurs during a DAR or PI

measurement, the instrument interrupts

the measurement and displays the

screen shown to the left.

4.2.1.3 Voltage present during a continuity, resistance, or capacitance measurement

If during a continuity, resistance,

or capacitance measurement the

instrument detects an external

voltage in excess of 15V (AC or DC),

it interrupts the measurement and

displays the screen show to the left.

You must eliminate the voltage to

resume the measurement.

4.2.1.4 Memory full (Model 6524)

When the memory is full (300

recordings), the instrument displays

the screen shown to the left. You must

remove one or more recordings before

new recordings can be saved (see §

2.3.3).

4.2.2 Resetting the Instrument

You can reset your instrument at any time. To do this:

1. Press the ▲ and

2. Turn the rotary switch to any setting other than OFF.

3. The instrument reboots.

Megohmmeter Model 6522/6524

buttons simultaneously.

41

Page 46

4.3 Repair and Calibration

To ensure that your instrument meets factory specications, we recommend

that it be scheduled to be sent back to our factory Service Center at one-

year intervals for recalibration, or as required by other standards or internal

procedures.

For instrument repair and calibration:

You must contact our Service Center for a Customer Service Authorization

Number (CSA#). This will ensure that when your instrument arrives, it will be

tracked and processed promptly. Please write the CSA# on the outside of the

shipping container. If the instrument is returned for calibration, we need to know

if you want a standard calibration, or a calibration traceable to N.I.S.T. (Includes

calibration certicate plus recorded calibration data.)

Ship To: Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

15 Faraday Drive • Dover, NH 03820 USA

Phone: (800) 945-2362 (Ext. 360) • (603) 749-6434 (Ext. 360)

Fax: (603) 742-2346 or (603) 749-6309

E-mail: repair@aemc.com

(Or contact your authorized distributor.)

Costs for repair, standard calibration, and calibration traceable to N.I.S.T. are

available.

NOTE: You must obtain a CSA# before returning any instrument.

4.4 Technical and Sales Assistance

If you are experiencing any technical problems, or require any assistance with

the proper operation or application of your instrument, please call, fax, or e-mail

our technical support team:

Phone: (800) 343-1391 • (508) 698-2115

E-mail: techsupport@aemc.com

42

Megohmmeter Model 6522/6524

Page 47

4.5 Limited Warranty

The Model 6522 and 6524 are warranted to the owner for a period of one year

from the date of original purchase against defects in manufacture. This limited

warranty is given by AEMC® Instruments, not by the distributor from whom it was

purchased. This warranty is void if the unit has been tampered with or abused, or

if the defect is related to service not performed by AEMC® Instruments.

Full warranty coverage and product registration is available on our website at:

www.aemc.com/warranty.html.

Please print the online Warranty Coverage Information for your records.

What AEMC® Instruments will do: If a malfunction occurs within the one-

year period, you may return the instrument to us for repair, provided we have

your warranty registration information on le or a proof of purchase. AEMC®

Instruments will, at its option, repair or replace the faulty material.

4.6 Warranty Repairs

What you must do to return an Instrument for Warranty Repair:

First, request a Customer Service Authorization Number (CSA#) by phone or by

fax from our Service Department (see address below), then return the instrument

along with the signed CSA Form. Please write the CSA# on the outside of the

shipping container. Return the instrument, postage or shipment pre-paid to:

Ship To: Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

15 Faraday Drive • Dover, NH 03820 USA

Phone: (800) 945-2362 (Ext. 360) • (603) 749-6434 (Ext. 360)

E-mail: repair@aemc.com

Caution: To protect yourself against in-transit loss, we recommend you insure

your returned material.

NOTE: You must obtain a CSA# before returning any instrument.

Megohmmeter Model 6522/6524

43

Page 48

CHAUVIN ARNOUX GROUP

12/16

99-MAN 100429 v3

®

Chauvin Arnoux

15 Faraday Drive • Dover, NH 03820 USA

Phone: (603) 749-6434 • Fax: (603) 742-2346

, Inc. d.b.a. AEMC® Instruments

www.aemc.com

®

Loading...

Loading...