Page 1

Instruction

STOP!

THIS PRODUCT HAS LEGAL RESTRICTIONS.

READ THIS BEFORE INSTALLING/USING!

THIS PRODUCT MAY BE USED SOLELY ON VEHICLES USED IN SANCTIONED COMPETITION WHICH MAY

NEVER BE USED UPON A PUBLIC ROAD OR HIGHWAY, UNLESS PERMITTED BY SPECIFIC REGULATORY

EXEMPTION. (VISIT THE “EMISSIONS” PAGE AT HTTP://WWW.SEMASAN.COM/EMISSIONS FOR STATE BY

STATE DETAILS.)

IT IS THE RESPONSIBILITY OF THE INSTALLER AND/OR USER OF THIS PRODUCT TO ENSURE THAT IT IS

USED IN COMPLIANCE WITH ALL APPLICABLE LAWS AND REGULATIONS. IF YOU HAVE PURCHASED

THIS PRODUCT IN ERROR, DO NOT INSTALL AND/OR USE IT. PLEASE CONTACT THE RETAILER FROM

WHOM YOU PURCHASED THE PRODUCT TO ARRANGE A RETURN FOR A FULL REFUND OR VISIT

AEMELECTRONICS.COM/PRODUCT-LEGAL-RESTRICTIONS FOR FURTHER INSTRUCTIONS.

Manual

Infinity Supported Application

2005–2008 Hemi 5.7L, 6.1L

WARNING: This installation is not for the tuning novice! Use this system with EXTREME caution! The AEM

Infinity Programmable EMS allows for total flexibility in engine tuning. Misuse or improper tuning of this

product can destroy your engine! If you are not well versed in engine dynamics and the tuning of engine

management systems DO NOT attempt the installation. Refer the installation to an AEM-trained tuning

shop or call 800-423-0046 for technical assistance.

NOTE: All supplied AEM calibrations, Wizards and other tuning information are offered as potential

starting points only. IT IS THE RESPONSIBILITY OF THE ENGINE TUNER TO ULTIMATELY CONFIRM IF THE

CALIBRATION IS SAFE FOR ITS INTENDED USE. AEM holds no responsibility for any engine damage that

results from the misuse or mistuning of this product!

AEM Performance Electronics, 2205 126th Street Unit A, Hawthorne, CA 90250

AEM Performance Electronics

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number:

Document Build 8/25/2014

Page 2

2

OVERVIEW

The AEM Infinity EMS can be adapted to most fuel injected engines. The base configuration files

available for the Infinity ECU are starting points only and will need to be modified for your specific

application. This manual lists the files available and suggested changes for your engine. It is the

responsibility of the installer to assign pin locations, build a wiring harness, and to verify their information

before starting the engine.

MODELS

Chrysler

2005–2008 5.7 Hemi

2005–2008 6.1 Hemi

DOWNLOADABLE FILES

Files can be downloaded from www.aeminfinity.com. An experienced tuner must be available to configure

and manipulate the data before driving can commence. The Quick Start Guide and Full Manual describe

the steps for logging in and registering at www.aeminfinity.com. These documents are available for

download on the AEM Electronics website: http://www.aemelectronics.com/

FILES

Downloadable files for Hemi

7100-XXXX-62 Infinity-10 (XXXX = serial number)

7101-XXXX-63 Infinity-8 (XXXX = serial number)

In order to properly control a Hemi engine, the application specific settings described in this document

MUST be changed to the given settings. Failure to do so may result in improper function and possible

ECU damage.

ADAPTER HARNESS OPTIONS

30-3702 Harness, Mini Lead

This harness includes a fused power distribution center with main relay. Pre-terminated connectors are

available for the internal UEGO sensors and AEMNet. A bag of multi-color flying leads is included to

simplify custom harness builds.

30-3701 Connector Kit

This kit includes mating connectors and terminals for the Infinity. It also includes a main relay kit which

is necessary for proper power distribution. This kit is best suited for experienced installers who want to

build their own harness.

30-3600 O2 Sensor Extension Harness

30-3601 IP67 Comms Cable

30-3602 IP67 Logging Cable

© 2014 AEM Performance Electronics

Page 3

Infinity Supported Application

IMPORTANT APPLICATION SPECIFIC SETTINGS

Infinity Tuner Wizard Setup

Engine

In the Wizard Engine tab confirm the following settings:

Number of Cylinders = 8

Engine Cycle Type = 4 Stroke

Ignition Type = Sequential (Coil On Plug)

Firing Order = 1-8-4-3-6-5-7-2

Cam/Crank

In the Wizard Cam/Crank tab confirm the following setting:

Dodge Hemi V8 (2005–2008)

3

Injector Setup

In the Wizard Injector Setup tab confirm the following setting:

Number of Injectors = 8

Input Functions

In the Wizard Input Functions tab confirm the following setting:

AC Input Switch Setup = AC_Req_dig

Output Functions

In the Wizard Output Functions tab confirm the following setting:

LowSide 8 Setup = MILOutput or EngineProtectOut

Ignition Sync

** NOTE: These settings are applicable to firmware release v95 and greater only.**

Add a text grid control to your layout and select the following channels. Make sure their values match

the settings below for initial timing sync.

TrigOffset [degBTDC] = 24.00

CamSyncAdjustment = 18.00

See QuickStart Guide section Setup: Ignition Sync for instructions on timing sync.

© 2014 AEM Performance Electronics

Page 4

4

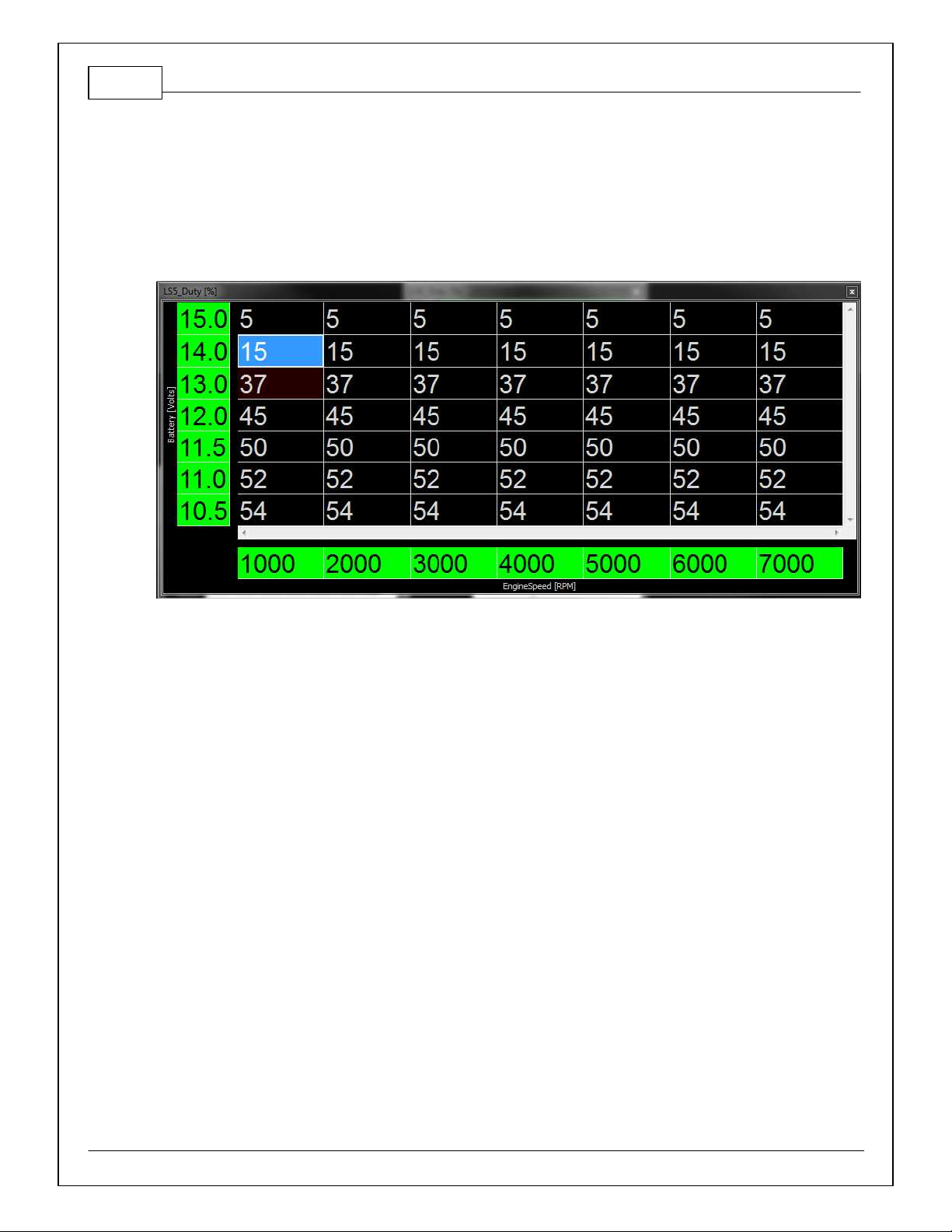

IMPORTANT ALTERNATOR CONTROL

In order to control the 5.7/6.1 Hemi alternator, Hemi pin 16 must be connected to Infinity pin C1-2 (LS5).

The user must then configure the 2D table named “LS5_Duty [%]” for proper alternator charging.

Below is a baseline table that will allow basic alternator behavior. Higher duty cycle yields higher

alternator output.

© 2014 AEM Performance Electronics

Page 5

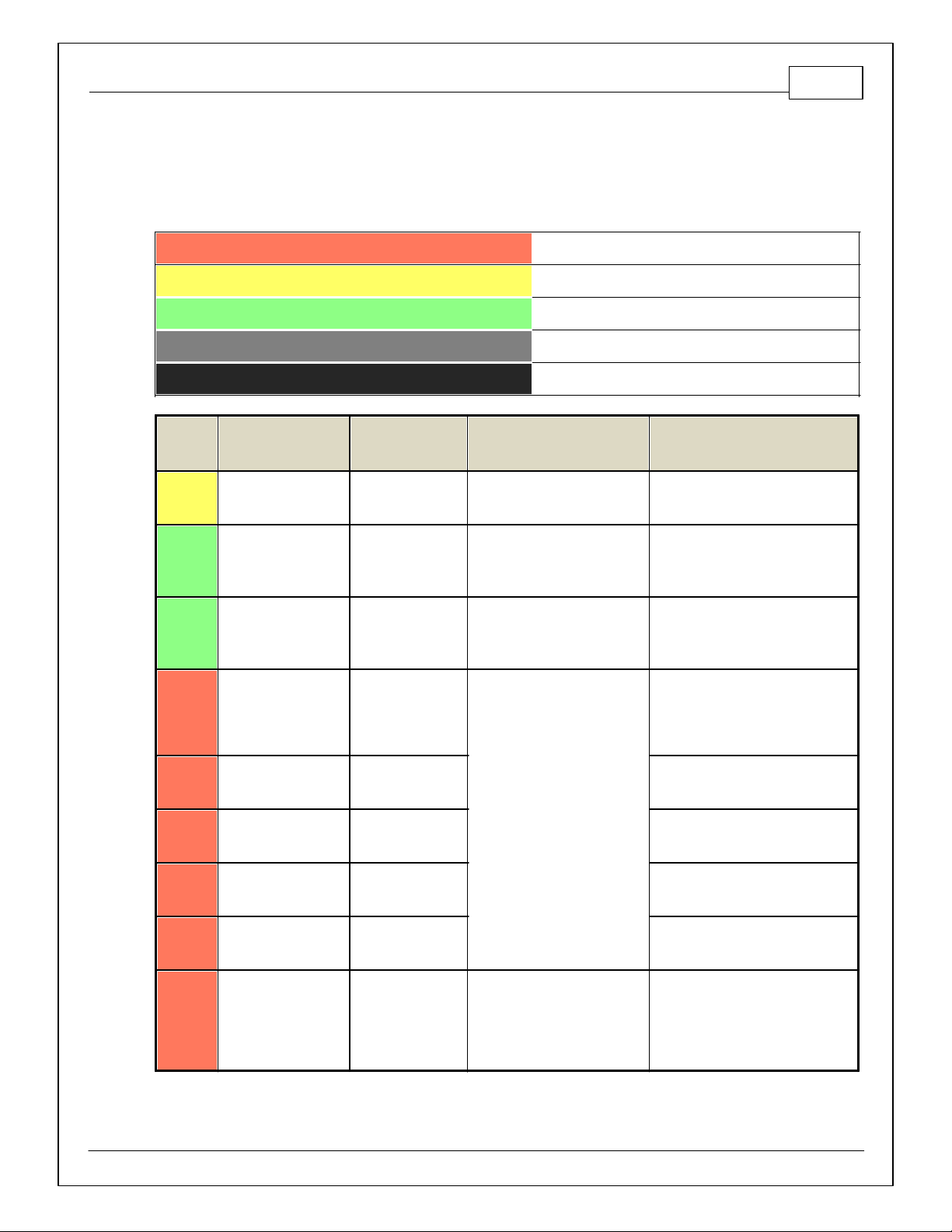

PINOUTS

Dedicated

Dedicated and not reconfigurable

Assigned

Assigned but reconfigurable

Available

Available for user setup

Not Applicable

Not used in this configuration

Required

Required for proper function

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C1-1

LowsideSwitch_4

A/C Relay Control

Lowside switch, 4A max, NO

internal fly back diode.

See "LowSide Assignment Tables" for

output assignment.

C1-2

LowsideSwitch_5

LS5

Lowside switch, 4A max with

internal fly back diode. Inductive

load should NOT have full time

power.

See Setup Wizard Page "LowSide

Assignment Tables" for output

assignment and 2D table "LS5_Duty

[%]" for activation.

C1-3

LowsideSwitch_6

LS6

Lowside switch, 4A max with

internal fly back diode. Inductive

load should NOT have full time

power.

See Setup Wizard Page "LowSide

Assignment Tables" for output

assignment and 2D table "LS6_Duty

[%]" for activation.

C1-4

UEGO 1 Heat

UEGO 1 Heat

Bosch UEGO controller

Lowside switch for UEGO heater control.

Connect to pin 4 of Bosch UEGO

sensor. NOTE that pin 3 of the Sensor

is heater (+) and must be power by a

fused/switched 12V supply .

C1-5

UEGO 1 IA

UEGO 1 IA

Trim Current signal. Connect to pin 2 of

Bosch UEGO sensor.

C1-6

UEGO 1 IP

UEGO 1 IP

Pumping Current signal. Connect to pin

6 of Bosch UEGO sensor.

C1-7

UEGO 1 UN

UEGO 1 UN

Nernst Voltage signal. Connect to pin 1

of Bosch UEGO sensor.

C1-8

UEGO 1 VM

UEGO 1 VM

Virtual Ground signal. Connect to pin 5

of Bosch UEGO sensor.

C1-9

Flash_Enable

Flash Enable

10K pulldown

Not usually needed f or automatic

firmware updates through Inf inity Tuner.

If connection errors occur during update,

connect 12 v olts to this pin before

proceeding with upgrade. Disconnect the

12 v olts signal af ter the update.

Infinity Pinouts

Infinity Supported Application

5

© 2014 AEM Performance Electronics

Page 6

6

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C1-10

+12V_R8C_CPU

Battery Perm Power

Dedicated power management

CPU

Full time battery power. MUST be

powered before the ignition switch input

is triggered. (See C1-65.)

C1-11

Coil 4

Coil 4

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C1-12

Coil 3

Coil 3

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C1-13

Coil 2

Coil 2

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C1-14

Coil 1

Coil 1

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C1-15

Coil 6

Coil 6

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C1-16

Coil 5

Coil 5

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C1-17

LowsideSwitch_2

Coolant Fan 1 Control

Lowside switch, 4A max, NO

internal fly back diode.

See "LowSide Assignment Tables" for

output assignment.

C1-18

LowsideSwitch_3

MIL Output

Lowside switch, 4A max with

internal fly back diode. Inductive

load should NOT have full time

power.

See Wizard page "LowSide Assignment

Tables" for output assignment.

MIL Activ ates when any of the following

flags are true: ErrorAirTemp, ErrorBaro,

ErrorCoolantTemp, ErrorEBP,

ErrorFuelPressure, UEGO_0_Diag_error,

UEGO_1_Diag_error, ErrorMAFAnalog,

ErrorMAFDigital, ErrorMAP,

ErrorOilPressure, ErrorThrottle.

C1-19

AGND_1

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

C1-20

AGND_1

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

C1-21

Crankshaf t Position

Sensor Hall

Crankshaf t Position

Sensor Hall

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Cam/Crank for

options.

C1-22

Camshaf t Position

Sensor 1 Hall

Camshaf t Position

Sensor 1 Hall

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Cam/Crank for

options.

© 2014 AEM Performance Electronics

Page 7

Infinity Supported Application

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C1-23

Digital_In_2

Camshaf t Position

Sensor 2 Hall

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Cam/Crank for

options.

C1-24

Digital_In_3

Turbo Speed Hz

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Input Function

Assignment f or calibration constant.

TurboSpeed [RPM] = Turbo [Hz] * Turbo

Speed Calibration.

C1-25

Digital_In_4

Vehicle Speed Sensor

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Input Function

Assignment f or calibration constant.

C1-26

Digital_In_5

Flex Fuel

10K pullup to 12V. Will work with

ground or floating switches.

See channel FlexDigitalIn [Hz] f or raw

frequency input data.

C1-27

Knock Sensor 1

Knock Sensor 1

Dedicated knock signal processor

See Setup Wizard page Knock Setup f or

options.

C1-28

Knock Sensor 2

Knock Sensor 2

Dedicated knock signal processor

See Setup Wizard page Knock Setup f or

options.

C1-29

+12V_Relay_Control

+12V Relay Control

0.7A max ground sink f or external

relay control

Will activate at key on and at key of f

according to the configuration settings.

C1-30

Power Ground

Ground

Power Ground

Connect directly to battery ground.

C1-31

CANL_Aout

AEMNet CANL

Dedicated High Speed CAN

Transceiv er

Recommend twisted pair (one twist per

2") with terminating resistor. Contact

AEM for additional information.

C1-32

CANH_Aout

AEMNet CANH

Dedicated High Speed CAN

Transceiv er

Recommend twisted pair (one twist per

2") with terminating resistor. Contact

AEM for additional information.

C1-33

LowsideSwitch_1

Boost Control

Lowside switch, 4A max with

internal fly back diode. Inductive

load should NOT have full time

power.

See Setup Wizard page Boost Control

for options. Monitor BoostControl [%]

channel for output state.

C1-34

Lowside Fuel Pump

drive

Fuel Pump

Lowside switch, 4A max, NO

internal fly back diode.

Switched ground. Will prime for 2

seconds at key on and activ ate if RPM

> 0.

C1-35

Analog_In_7

Throttle Position

Sensor

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See the Setup Wizard Set Throttle

Range page f or automatic min/max

calibration. Monitor the Throttle [%]

channel. Also DB1_TPSA [%] f or DBW

applications.

7

© 2014 AEM Performance Electronics

Page 8

8

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C1-36

Analog_In_8

MAP Sensor

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See the Setup Wizard Set Manifold

Pressure page for setup and calibration.

Monitor the MAP [kPa] channel.

C1-37

Analog_In_9

Fuel Pressure

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See the Setup Wizard Fuel Pressure

page f or setup and calibration. Monitor

the FuelPressure [psig] channel.

C1-38

Analog_In_10

Baro Sensor

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See the Setup Wizard Barometric

Pressure page for setup and calibration.

Monitor the BaroPress [kPa] channel.

C1-39

Analog_In_11

Shift Switch Input

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See the 1D lookup table 'ShiftSwitch' f or

setup. Also assignable to multiple

functions. See Setup Wizard f or details.

C1-40

Analog_In_12

Mode Switch

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See the 1D lookup table 'ModeSwitch'

for input state.

A multi-position rotary switch such as

AEM P/N 30-2056 is recommended.

Also assignable to multiple f unctions.

See Setup Wizard for details.

C1-41

+5V_Out_1

+5V Out

Regulated, fused +5V supply f or

sensor power

Analog sensor power

C1-42

+5V_Out_1

+5V Out

Regulated, fused +5V supply f or

sensor power

Analog sensor power

C1-43

HighsideSwitch_1

HS1 (switched 12V)

0.7A max, High Side Solid State

Relay

See Setup Wizard page 'HighSide

Assigment Tables' f or configuration

options.

See 2D lookup table 'HS1_Table' for

activation settings.

© 2014 AEM Performance Electronics

Page 9

Infinity Supported Application

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C1-44

HighsideSwitch_0

VTEC

0.7A max, High Side Solid State

Relay

See Setup Wizard page 'HighSide

Assigment Tables' f or configuration

options.

See 2D lookup table 'HS0_Table' for

activation settings.

See Setup Wizard page 'VTEC' f or

default activ ation criteria.

C1-45

Crankshaf t Position

Sensor VR+

Crankshaf t Position

Sensor VR+

Dif ferential Variable Reluctance

Zero Cross Detection

See Setup Wizard page Cam/Crank for

options.

C1-46

Crankshaf t Position

Sensor VR-

Crankshaf t Position

Sensor VR-

See Setup Wizard page Cam/Crank for

options.

C1-47

Camshaf t Position

Sensor 1 VR-

Camshaf t Position

Sensor 1 VR-

Dif ferential Variable Reluctance

Zero Cross Detection

See Setup Wizard page Cam/Crank for

options.

C1-48

Camshaf t Position

Sensor 1 VR+

Camshaf t Position

Sensor 1 VR+

See Setup Wizard page Cam/Crank for

options.

C1-49

VR+_In_2

Non Driv en Lef t

Wheel Speed Sensor

+

Dif ferential Variable Reluctance

Zero Cross Detection

See Non Driven Wheel Speed

Calibration in the Setup Wizard Input

Function Assignment page.

C1-50

VR-_In_2

Non Driv en Lef t

Wheel Speed Sensor

-

C1-51

VR-_In_3

Driv en Left Wheel

Speed Sensor -

Dif ferential Variable Reluctance

Zero Cross Detection

See Driven Wheel Speed Calibration in

the Setup Wizard Input Function

Assignment page.

C1-52

VR+_In_3

Driv en Left Wheel

Speed Sensor +

C1-53

DBW1 Motor -

DBW Motor Control

Close

5.0A max Throttle Control Hbridge

Driv e

+12V to close

C1-54

DBW1 Motor +

DBW Motor Control

Open

5.0A max Throttle Control Hbridge

Driv e

+12V to open

C1-55

Power Ground

Ground

Power Ground

Connect directly to battery ground.

C1-56

Injector 6

Injector 6

Saturated or peak and hold, 3A

max continuous

Injector 6

C1-57

Injector 5

Injector 5

Saturated or peak and hold, 3A

max continuous

Injector 5

C1-58

Injector 4

Injector 4

Saturated or peak and hold, 3A

max continuous

Injector 4

C1-59

Injector 3

Injector 3

Saturated or peak and hold, 3A

max continuous

Injector 3

9

© 2014 AEM Performance Electronics

Page 10

10

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C1-60

Power Ground

Ground

Power Ground

Connect directly to battery ground.

C1-61

+12V

+12V In

12 v olt power f rom relay

12 v olt power f rom relay. Relay must

be controlled by +12V Relay Control

signal, pin C1-29 above.

C1-62

Injector 2

Injector 2

Saturated or peak and hold, 3A

max continuous

Injector 2

C1-63

Injector 1

Injector 1

Saturated or peak and hold, 3A

max continuous

Injector 1

C1-64

+12V

+12V In

12 v olt power f rom relay

12 v olt power f rom relay. Relay must

be controlled by +12V Relay Control

signal pin C1-29 abov e.

C1-65

+12V_SW

Ignition Switch

10K pulldown

Full time battery power must be

available at C1-10 before this input is

triggered.

C1-66

Analog_In_Temp_1

Coolant Temp Sensor

12 bit A/D, 2.49K pullup to 5V

See "Coolant Temperature" Setup Wizard

for selection.

C1-67

Analog_In_Temp_2

Intake Air

Temperature

12 bit A/D, 2.49K pullup to 5V

See "Air Temperature" Setup Wizard for

selection.

C1-68

Harness_Analog_In_Tem

p_3

Oil Temperature

Sensor

12 bit A/D, 2.49K pullup to 5V

See 1D table OilTempCal table f or

calibration data and OilTemp [C] for

channel data.

C1-69

Stepper_2A

Stepper 2A

Automotiv e, Programmable

Stepper Driv er, up to 28V and

±1.4A

Be sure that each internal coil of the

stepper motor is properly paired with the

1A/1B and 2A/2B ECU outputs.

Supports Bi-Polar stepper motors only.

C1-70

Stepper_1A

Stepper 1A

Automotiv e, Programmable

Stepper Driv er, up to 28V and

±1.4A

Be sure that each internal coil of the

stepper motor is properly paired with the

1A/1B and 2A/2B ECU outputs.

Supports Bi-Polar stepper motors only.

C1-71

Stepper_2B

Stepper 2B

Automotiv e, Programmable

Stepper Driv er, up to 28V and

±1.4A

Be sure that each internal coil of the

stepper motor is properly paired with the

1A/1B and 2A/2B ECU outputs.

Supports Bi-Polar stepper motors only.

C1-72

Stepper_1B

Stepper 1B

Automotiv e, Programmable

Stepper Driv er, up to 28V and

±1.4A

Be sure that each internal coil of the

stepper motor is properly paired with the

1A/1B and 2A/2B ECU outputs.

Supports Bi-Polar stepper motors only.

C1-73

Power Ground

Ground

Power Ground

Connect directly to battery ground.

C2-1

DBW2 Motor +

DBW Motor Control

Open

5.0A max Throttle Control Hbridge

Driv e

+12V to open

© 2014 AEM Performance Electronics

Page 11

Infinity Supported Application

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C2-2

DBW2 Motor -

DBW Motor Control

Close

5.0A max Throttle Control Hbridge

Driv e

+12V to close

C2-3

Power Ground

Ground

Power Ground

Connect directly to battery ground.

C2-4

Injector 7

Injector 7

Saturated or peak and hold, 3A

max continuous

Injector 7

C2-5

Injector 8

Injector 8

Saturated or peak and hold, 3A

max continuous

Injector 8

C2-6

Injector 9

Injector 9

Saturated or peak and hold, 3A

max continuous

Injector 9

C2-7

Injector 10

Injector 10

Saturated or peak and hold, 3A

max continuous

Injector 10

C2-8

Power Ground

Ground

Power Ground

Connect directly to battery ground.

C2-9

+12V

+12V In

12 v olt power f rom relay

12 v olt power f rom relay. Relay must

be controlled by +12V Relay Control

signal, pin C1-29 above.

C2-10

Injector 11

Injector 11

Saturated or peak and hold, 3A

max continuous

Not used

C2-11

Injector 12

Injector 12

Saturated or peak and hold, 3A

max continuous

Not used

C2-12

Analog_In_17

A/C Analog Request

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See Setup Wizard Input Functions page

for input selection. See AC_Request_In

1-axis table f or activ ation logic.

C2-13

Analog_In_18

DBW_APP1 [%]

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

C2-14

Analog_In_19

DBW_APP2 [%]

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

C2-15

Analog_In_Temp_4

Charge Out

Temperature

12 bit A/D, 2.49K pullup to 5V

See ChargeOutTemp [C] table f or

calibration data and ChargeOutTemp [C]

for channel data.

11

© 2014 AEM Performance Electronics

Page 12

12

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C2-16

Analog_In_Temp_5

Airbox Temperature

12 bit A/D, 2.49K pullup to 5V

See AirboxTemp [C] table f or calibration

data and AirboxTemp [C] f or channel

data.

C2-17

Analog_In_Temp_6

Fuel Temperature

12 bit A/D, 2.49K pullup to 5V

See FuelTemp [C] table f or calibration

data and FuelTemp [C] f or channel data.

C2-18

Analog_In_13

Oil Pressure

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See Setup Wizard Oil Pressure page f or

setup options. See OilPressure [psig] for

channel data.

C2-19

Analog_In_14

Traction Control Mode

/ Sensitivity

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See the TC_SlipTrgtTrim [MPH] 1-axis

table. A multi-position rotary switch such

as AEM P/N 30-2056 is recommended.

C2-20

Analog_In_15

Exhaust Back

Pressure

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See Setup Wizard Exhaust Pressure

page f or setup options. See EBPress

[kPa] for channel data.

C2-21

Analog_In_16

DBW1_TPSB [%]

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

C2-22

+5V_Out_2

+5V Out

Regulated, fused +5V supply f or

sensor power

Analog sensor power

C2-23

+5V_Out_2

+5V Out

Regulated, fused +5V supply f or

sensor power

Analog sensor power

C2-24

+5V_Out_2

+5V Out

Regulated, fused +5V supply f or

sensor power

Analog sensor power

C2-25

VR+_In_5

Driv en Right Wheel

Speed Sensor +

Dif ferential Variable Reluctance

Zero Cross Detection

See Driven Wheel Speed Calibration in

the Setup Wizard Input Function

Assignment page.

C2-26

VR-_In_5

Driv en Right Wheel

Speed Sensor -

C2-27

VR-_In_4

Non Driv en Right

Wheel Speed Sensor

-

Dif ferential Variable Reluctance

Zero Cross Detection

See Non Driven Wheel Speed

Calibration in the Setup Wizard Input

Function Assignment page.

© 2014 AEM Performance Electronics

Page 13

Infinity Supported Application

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C2-28

V R+_In_4

Non Driv en Right

Wheel Speed Sensor

+

C2-29

LowsideSwitch_9

Tachometer

Lowside switch, 4A max with

internal fly back diode, 2.2K 12V

pullup. Inductiv e load should NOT

have full time power.

See Setup Wizard page Tacho for

conf iguration options.

C2-30

AGND_2

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

C2-31

AGND_2

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

C2-32

AGND_2

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

C2-33

Analog_In_20

Spare Analog Input

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

C2-34

Analog_In_21

3 Step Enable Switch

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See 3StepSwitch 1-axis table f or setup.

C2-35

Analog_In_22

USB Logging Activ ate

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See USBLoggingRequestIn channel f or

input state. See Setup Wizard page USB

Logging f or conf iguration options.

C2-36

Analog_In_23

Charge Out Pressure

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals ref erenced to +12V as

this can permanently damage the ECU.

See ChargeOutPress [kPa] channel f or

input state. See Setup Wizard page

Charge Out Pressure f or calibration

options.

C2-37

Digital_In_6

Spare Digital Input

No pullup. Will work with TTL

signals.

Input can be assigned to diff erent pins.

See Setup Wizard page Input Function

Assignments for input mapping options.

C2-38

Digital_In_7

Clutch Switch

No pullup. Will work with TTL

signals.

See ClutchSwitch 1-axis table for setup

options. Input can be assigned to

diff erent pins. See Setup Wizard page

Input Function Assignments for input

mapping options.

13

© 2014 AEM Performance Electronics

Page 14

14

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C2-39

Power Ground

Ground

Power Ground

Connect directly to battery ground.

C2-40

Power Ground

Ground

Power Ground

Connect directly to battery ground.

C2-41

CanH_Bout

CANH

Dedicated High Speed CAN

Transceiv er

Not used

C2-42

CanL_Bout

CANL

Dedicated High Speed CAN

Transceiv er

Not used

C2-43

LowsideSwitch_8

Engine Protect

Warning Out

Lowside switch, 4A max with

internal fly back diode. Inductive

load should NOT have full time

power.

Activates if any of the following flags

are true: OilPressProtectOut,

LeanProtectOut, CoolantProtect. Output

can be assigned to other f unctions. See

Setup Wizard page LowSide Assignment

Tables f or additional options.

C2-44

LowsideSwitch_7

Spare GPO1

Lowside switch, 4A max with

internal fly back diode. Inductive

load should NOT have full time

power.

See Spare GPO1 Basic Setup section of

User GPIOs and PWM Setup Wizard

page LowSide Assignment Tables f or

additional options.

C2-45

UEGO 2 VM

UEGO 2 VM

Bosch UEGO Controller

Virtual Ground signal. Connect to pin 5

of Bosch UEGO sensor.

C2-46

UEGO 2 UN

UEGO 2 UN

Nernst Voltage signal. Connect to pin 1

of Bosch UEGO sensor.

C2-47

UEGO 2 IP

UEGO 2 IP

Pumping Current signal. Connect to pin

6 of Bosch UEGO sensor.

C2-48

UEGO 2 IA

UEGO 2 IA

Trim Current signal. Connect to pin 2 of

Bosch UEGO sensor.

C2-49

UEGO 2 HEAT

UEGO 2 HEAT

Lowside switch for UEGO heater control.

Connect to pin 4 of Bosch UEGO

sensor. NOTE that pin 3 of the Sensor

is heater (+) and must be power by a

fused/switched 12V supply .

C2-50

+12V_R8C_CPU

Battery Perm Power

Dedicated power management

CPU

Optional full time battery power. MUST

be powered bef ore the ignition switch

input is triggered. (See C1-65.)

C2-51

Coil 7

Coil 7

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C2-52

Coil 8

Coil 8

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

© 2014 AEM Performance Electronics

Page 15

Infinity

Pin

Hardware Reference

7100-XXXX-62

7101-XXXX-63

Function

Hardware Specification

Notes

C2-53

Coil 9

Coil 9

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C2-54

Coil 10

Coil 10

25 mA max source current

0–5V Falling edge fire. DO NOT connect

directly to coil primary. Must use an

ignitor OR CDI that accepts a FALLING

edge f ire signal.

C2-55

Highside Fuel Pump

switch

Fuel Pump

Highside switch, 0.7A max, Solid

State Relay, NO internal fly back

diode.

+12V High Side Driv e. Will prime for 2

seconds at key on and activ ate if RPM

> 0.

C2-56

Not used

Not used

Not used

Not used

Infinity Pin Numbering

Infinity Supported Application

15

© 2014 AEM Performance Electronics

AEM Infinity Connectors Viewed from Wire Side

Page 16

16

12 MONTH LIMITED WARRANTY

Advanced Engine Management Inc. warrants to the consumer that all AEM High

Performance products will be free from defects in material and workmanship for a

period of twelve (12) months from date of the original purchase. Products that fail within

this 12-month warranty period will be repaired or replaced at AEM’s option, when

determined by AEM that the product failed due to defects in material or workmanship.

This warranty is limited to the repair or replacement of the AEM part. In no event shall

this warranty exceed the original purchase price of the AEM part nor shall AEM be

responsible for special, incidental or consequential damages or cost incurred due to the

failure of this product. Warranty claims to AEM must be transportation prepaid and

accompanied with dated proof of purchase. This warranty applies only to the original

purchaser of product and is non-transferable. All implied warranties shall be limited in

duration to the said 12-month warranty period. Improper use or installation, accident,

abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims any

liability for consequential damages due to breach of any written or implied warranty on

all products manufactured by AEM. Warranty returns will only be accepted by AEM when

accompanied by a valid Return Merchandise Authorization (RMA) number. Product

must be received by AEM within 30 days of the date the RMA is issued.

Please note that before AEM can issue an RMA for any electronic product, it is first

necessary for the installer or end user to contact the EMS tech line at 1-800-423-0046 to

discuss the problem. Most issues can be resolved over the phone. Under no

circumstances should a system be returned or a RMA requested before the above

process transpires.

AEM will not be responsible for electronic products that are installed incorrectly, installed

in a non-approved application, misused, or tampered with.

Any AEM electronics product can be returned for repair if it is out of the warranty period.

There is a minimum charge of $50.00 for inspection and diagnosis of AEM electronic

parts. Parts used in the repair of AEM electronic components will be extra. AEM will

provide an estimate of repairs and receive written or electronic authorization before

repairs are made to the product.

© 2014 AEM Performance Electronics

Loading...

Loading...