Page 1

Installation Instructions for:

Crank Angle Sensor replacement for EMS P/N 30-6620

1990-1995 Nissan 300ZX VG30DE, VG30DETT

1989-1998 Nissan Skyline RB26DETT,

1993-1998 Skyline RB25DET,

1989-1994 Skyline RB20DET,

1988-1990 S13 180SX, 200SX and Silvia CA18DET

WARNING:

This installation is not for the tuning novice nor the PC illiterate!

Use this system with EXTREME caution! The AEM EMS System

allows for total flexibility in engine tuning. Misuse of this

product can destroy your engine! If you are not well versed in

,!

This product is legal in California for racing vehicles only and should never

engine dynamics and the tuning of management systems or are

not PC literate, please do not attempt the installation. Refer the

installation to a AEM trained tuning shop or call 800-423-0046

for technical assistance. You should also visit the AEM EMS

Tech Forum at http://www.aempower.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

be used on public highways.

© 2010 ADVANCED ENGINE MANAGEMENT INC.

2205 126

Instruction Part Number: 10-6620-A supplement

th

Street Unit A Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aempower.com

Page 1 of 25

Page 2

**Cam / Crank Angle Sensor: AEM trigger disc MUST be used

Discrepancies have been observed in the OEM cam/crank signals between model years

and/or trim levels; to avoid confusion the Series 2 EMS does not support the OEM Nissan

trigger pattern. A replacement trigger disc is now included with every Nissan EMS and

must be installed before attempting to start the engine. The following installation was

performed on a stock 300ZX. Installation in a Skyline or modified 300ZX may require

removal of different components to access the CAS sensor, but the procedure for the CAS

disc change should be identical.

Tools/parts required:

• Replacement trigger disc for Nissan RB/VG/VE cam angle sensor

(AEM P/N 35-8761, supplied with 30-6620 EMS)

• ¼” ratchet

• 4-6” extension

• 8mm socket

• 10 mm socket

• Sharpie

• Pick

• Small needle-nose pliers

• ¼ ” flat screwdriver

• No. 1 Phillips screwdriver

• No. 2 Phillips screwdriver

• Small mallet or dead blow hammer

• Medium-sized hammer

• Small prybar (or wide flat screwdriver)

• 3 M4x45mm cap screws (available at McMaster-Carr in pack of 25 for $1.47; p/n:

91280A149)

• Medium-sized pliers

• 3/8” pin punch

• 1/8” pin punch

• Vise or area to place sensor assembly on

• Red threadlocker

WARNING:

Failure to perform the following procedure correctly could result in permanent damage to

mechanical and electrical sensor components, which could result in engine damage.

Please read all instructions carefully before attempting this procedure, and do not attempt

the install if you feel you may not be able to perform all operations safely without

damaging components. AEM will not be held liable for any damage that occurs as a result

of these instructions.

Page 2 of 25

Page 3

Instructions:

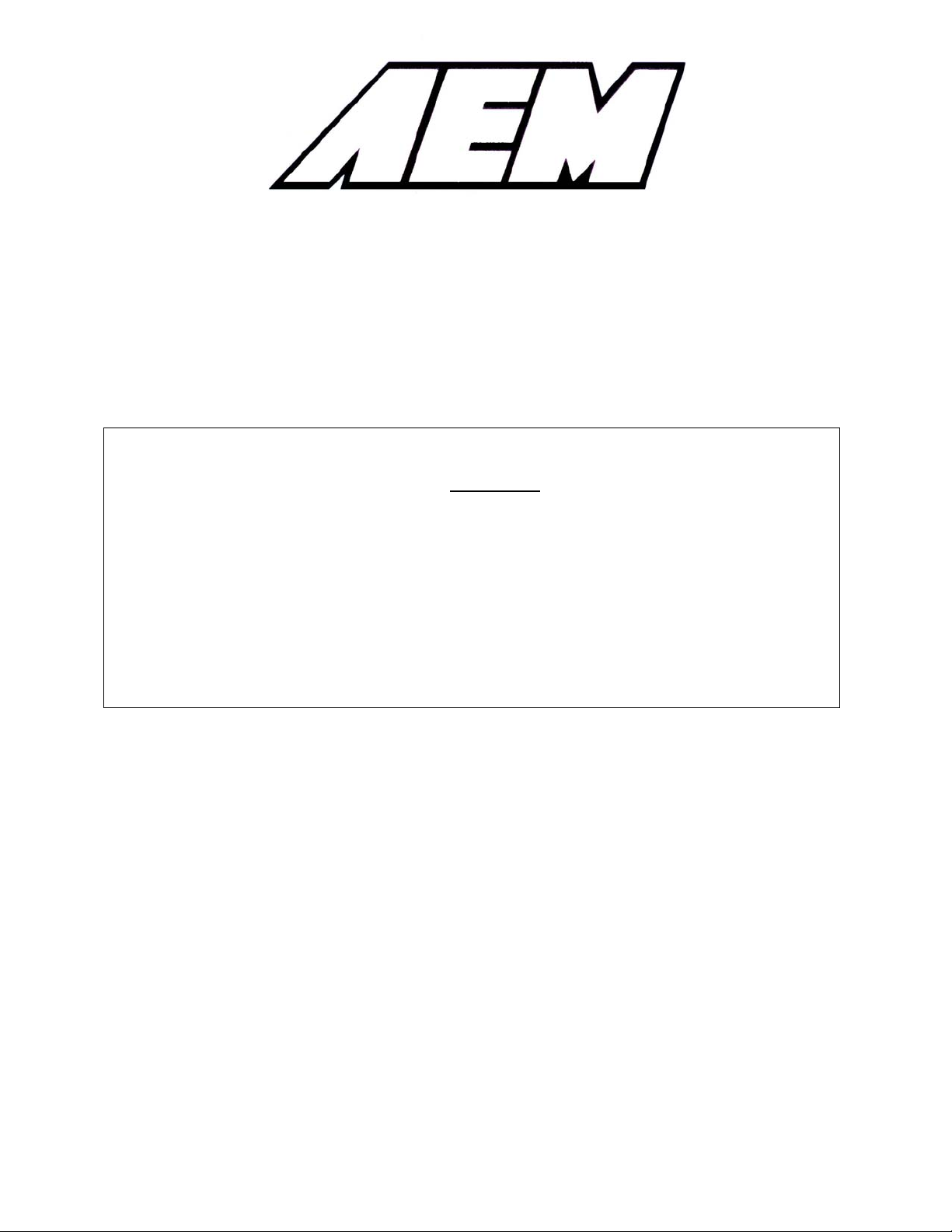

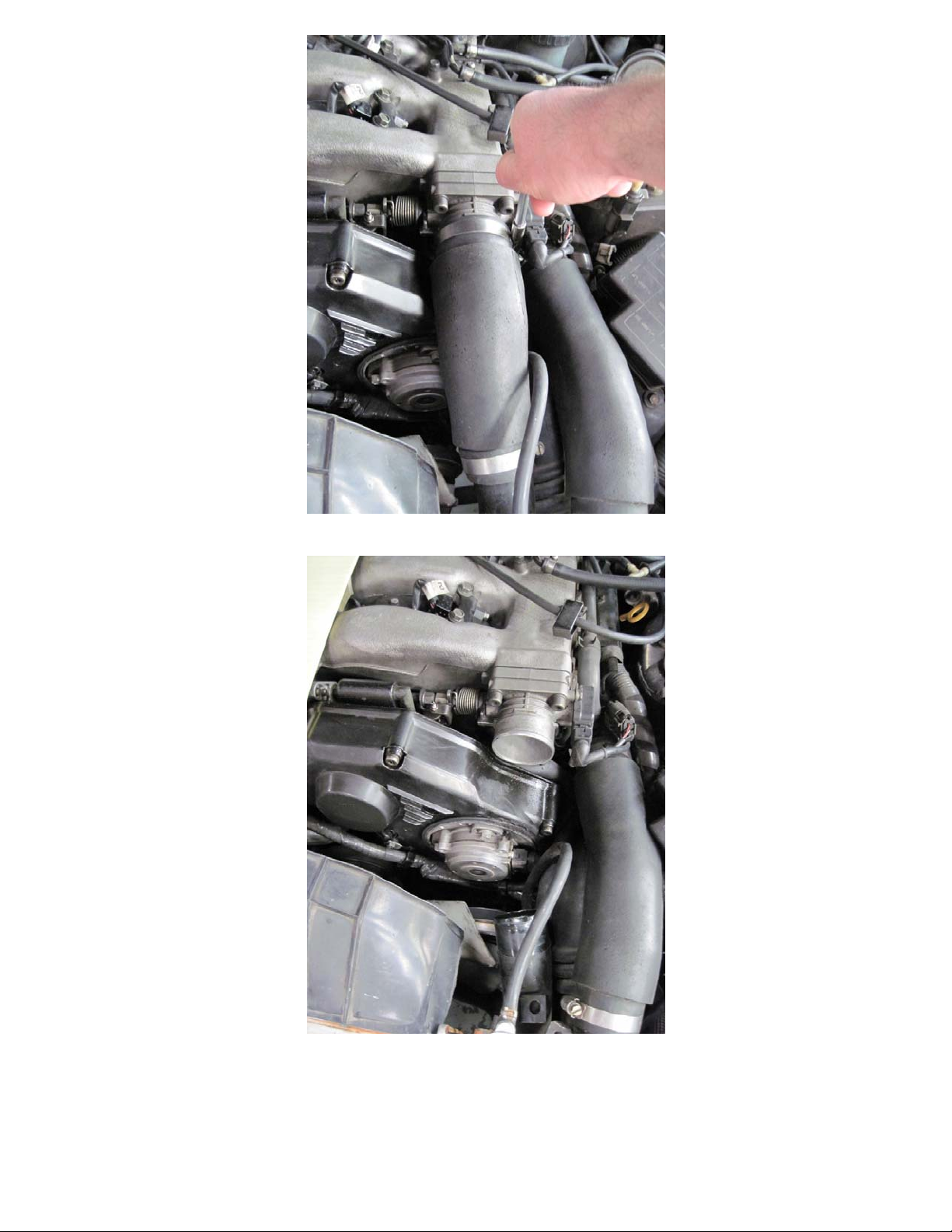

Locate the CAS sensor on your vehicle as shown in figures 1, 2, and 3.

Figure 1: Location of the CAS sensor

Figure 2: Location of the CAS sensor

Page 3 of 25

Page 4

Figure 3: Close-up of CAS sensor

Remove intake tube obstructing access to the CAS sensor using an 8mm socket as shown

in figures 4 and 5. Figure 6 shows how access to the CAS sensor looks once the tube is

removed.

Figure 4: Removal of intake tube using 8mm socket

Page 4 of 25

Page 5

Figure 5: Removal of intake tube using 8mm socket

Figure 6: Intake tube removed to access CAS sensor

Page 5 of 25

Page 6

Mark the three bolts on the CAS sensor with your Sharpie as shown in figures 7 and

8 so that the sensor will go back into its original position upon reinstallation.

Figure 7: Marking position of CAS sensor

Figure 8: Marking position of CAS sensor

Page 6 of 25

Page 7

Remove clip that holds the harness to the CAS sensor using a pick and a pair of

needle-nose pliers as shown in figures 9 and 10. This may be done after removing

the CAS assembly, but is best done now.

Figure 9: Pry here to remove this clip

Figure 10: Remove clip with needle-nose pliers

Page 7 of 25

Page 8

Remove the three bolts on the CAS sensor using a 10mm socket as shown in figure 11.

Take care not to turn the sensor. Mark with your Sharpie so that the sensor can be

reinstalled correctly as shown in figure 12. Figure 13 shows the cam with the CAS

assembly removed. (If you turn the sensor by accident, make sure to align it with cam and

mark it)

Figure 11: Removal of 3 CAS sensor bolts using 10mm socket

Figure 12: Mark shaft relative to housing for correct reinstallation onto cam

Page 8 of 25

Page 9

Figure 13: CAS sensor removed

Remove the three screws holding the CAS assembly together using a ¼” flat

screwdriver (use the flat screwdriver since these screws are tightly installed, but soft)

as shown in figure 14.

Figure 14: Taking apart CAS assembly using number 2 Phillips screwdriver

Page 9 of 25

Page 10

Remove screws holding the seal cover onto the assembly using a ¼” flat screwdriver

as shown in figure 15.

Figure 15: Removing seal cover on CAS assembly using ¼” screwdriver

Screw in the M4x45mm cap screws so that plenty of threads are engaged and lightly

tap the three bolts evenly using a mallet so that the assembly will separate as shown

in figure 16. If prying between the two halves is necessary as shown in figure 17, be

extremely careful not to damage the sensor inside or the rubber seal.

Figure 16: Using cap screws and mallet to loosen/remove cover

Page 10 of 25

Page 11

Figure 17: Using prybar to remove cover

Remove the 3 screws holding the CAS sensor onto the assembly as shown in figure

18 as well as the rubber seal shown in figure 19. Make sure that you do not remove

the screws in figure 20 because this may render the CAS sensor useless.

Figure 18: Remove 3 screws holding sensor using ¼” flat screwdriver

Page 11 of 25

Page 12

Figure 19: Remove seal from CAS assembly

Figure 20: DO NOT REMOVE THESE SCREWS!

Page 12 of 25

Page 13

Mount the assembly in a vise placing the two ears that stick out of the cover shown in

figure 21 on the jaws being mindful of the plastic connector to the CAS sensor as

shown in figure 22.

Figure 21: Mounting CAS assembly in vise to separate from shaft

Figure 22: Mounting CAS assembly in vise to separate from shaft

Page 13 of 25

Page 14

Remove the shaft from the remaining half of the housing using a 3/8” pin punch as

shown in figure 23. Figure 24 shows the sensor separated from the housing.

Figure 23: Separation of shaft from housing using 3/8” pin punch and hammer

Figure 24: CAS sensor removed from housing

Page 14 of 25

Page 15

This step requires a lot of finesse or help from a friend to hold the shaft from falling

off the vise. Mark the star socket relative to the shaft and remove the pin holding the

star socket onto the shaft using a 1/8” pin punch as shown in figure 25.

Figure 25: Removal of pin using 1/8” pin punch

Remove the star socket with a ¼” flat screwdriver as shown in figure 26. Figure 27

shows the star socket removed with the small rubber seal that is inside it.

Figure 26: Removal of star socket using ¼” flat screwdriver

Page 15 of 25

Page 16

Figure 27: Star socket removed from CAS sensor

This is another step that requires a little finesse or a friend. Remove the remaining

bearing using a pair of pliers with flat jaws to have a firm grip on the shaft but be

narrow enough to fit in between the collar on the shaft and the bearing. Hit the pliers

with a mallet. Note how the shaft is placed into the vise in figure 28. Figure 29 shows

the bearing removed from the shaft.

Figure 28: Removal of bearing from shaft using pliers

Page 16 of 25

Page 17

Figure 29: Bearing removed from shaft

Using the number 2 Phillips screwdriver remove the screws holding the CAS disc

onto the shaft as shown in figure 30.

Figure 30: Removal of 2 screws on CAS disc using number 2 Phillips screwdriver

Page 17 of 25

Page 18

Figure 31 shows the shaft removed once the screws are removed. Mark the disc so

that you can identify how it was mounted for future reference. Carefully remove the

CAS disc from the sensor by rotating the disc in the direction of the large arrow

relative to the locating pin so that it will pull directly up over the pin in the direction of

the small arrow.

Figure 31: CAS disc screws and shaft removed

The original and AEM trigger discs must be aligned in the correct orientation since the

locating pin is slightly offset as shown in figure 32.

Figure 32: Comparison of original and AEM trigger discs

Page 18 of 25

Page 19

Install the AEM CAS sensor disc (AEM PN 35-8761) as shown in figure 33.

Figure 33: AEM trigger disc being installed

Reinstall the shaft onto the CAS sensor as shown in figure 34 and replace the screws on

the shaft with some thread locker as shown in figure 35.

Figure 34: CAS sensor shaft reinstallation

Page 19 of 25

Page 20

Figure 35: Screws for CAS shaft replaced

Reinstall bearing as shown in figure 36. Next add some grease or spray lube onto the oring that came off of the star socket that goes over the bearing and lightly hammer the star

socket on a flat surface so that you are only hammering the shaft until the hole for the pin

that holds the star socket lines up as shown in figure 37. A pin punch can be used to align

the hole for the pin if it is slightly off.

Figure 36: Bearing placement on CAS shaft

Page 20 of 25

Page 21

Figure 37: Hammering star socket to press on socket and bearing

Similar to the removal of the pin, the reinstallation of the pin requires hammering the pin

back into the hole on the star socket as shown in figure 38 Note: The socket must be

aligned relative to the shaft before performing this step.

Figure 38: Aligning the star socket retaining pin

Page 21 of 25

Page 22

Reinstall the screws that hold on the plastic CAS sensor with some threadlocker to the

metal housing taking extreme care not to bend the trigger disc. This can be accomplished

by lightly pulling the shaft as shown in figure 39.

Figure 39: Reinstallation of CAS sensor screws

Reinstall rubber seal for housing as shown in figure 40.

Figure 40: CAS rubber seal reinstalled

Page 22 of 25

Page 23

Reinstall 2nd CAS housing half making sure that the plastic connector and rubber seal are

aligned properly to avoid CAS sensor and disc damage. The housing should be able to be

pressed on by hand with even pressure around the whole assembly. Once together,

reinstall screws with threadlocker. See figure 41.

Figure 41: Housing cover reinstalled

Reinstall the plastic connector cover as shown in figure 42.

Figure 42: Connector cover reinstalled

Page 23 of 25

Page 24

Align the CAS sensor with the mark you made at the beginning of the instructions or

alternatively, look at the cam and align the sensor with the groove in the cam. Make sure

that the sensor is seated properly before reinstalling the bolts. See figure 43.

Figure 43: Reinstalling the CAS sensor

Align bolts with previously made markings and tighten as shown in figure 44.

Figure 44: Reinstalling CAS sensor bolts

Page 24 of 25

Page 25

Reattach the plastic connector to the CAS sensor after making sure the metal retaining

clip is present and installed correctly. See figure 45.

Figure 45: Replacing CAS sensor connector

Reinstall the intake tube in the reverse of removal.

Page 25 of 25

Loading...

Loading...