Page 1

WARNING:

!

This installation is not for the tuning novice nor the PC illiterate!

Use this system with EXTREME caution! The AEM EMS System

allows for total flexibility in engine tuning. Misuse of this

product can destroy your engine! If you are not well versed in

engine dynamics and the tuning of management systems or are

not PC literate, please do not attempt the installation. Refer the

installation to a AEM trained tuning shop or call 800-423-0046

for technical assistance. You should also visit the AEM EMS

Tech Forum at http://www.aempower.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

Installation Instructions for:

Crank Angle Sensor replacement for EMS P/N 30-6600

89-94 Nissan 240SX S13 KA24DE

91-94 Nissan Sentra B13 GA16DE

90-94 Nissan Pulsar GTi-R N14 SR20DET

91-93 Nissan NX B13 GA16DE

93-94 Nissan Altima U13 KA24DE

89-95 Nissan Bluebird U13 SR20DET

91-93 Infiniti G20 P10 SR20DE

This product is legal in California for racing vehicles only and should never

be used on public highways.

2010 ADVANCED ENGINE MANAGEMENT INC.

2205 126th Street Unit A Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aempower.com

Instruction Part Number: 10-6600-A supplement

Page 1 of 9

Page 2

**Cam / Crank Angle Sensor: AEM trigger disc MUST be used

Discrepancies have been observed in the OEM cam/crank angle trigger discs between

model years and/or trim levels; to avoid confusion the Series 2 EMS does not support the

OEM Nissan trigger pattern. A replacement trigger disc is now included with every Nissan

EMS and must be installed before attempting to start the engine. The following installation

was performed on a stock Nissan S13 240SX so your installation may require more or less

removal of parts, but the procedure for the CAS disc change should be identical.

Tools/parts required:

Replacement trigger disc for Nissan GA/KA/SR cam angle sensor

(AEM P/N 35-8760, supplied with 30-6600, 30-6601, 30-6602, 30-6610, 30-6611,

30-6620, and 30-6623 EMS)

8mm and 10mm socket with ratchet and extension

10mm combination wrench

Medium pry bar

¼” flat screwdriver

No. 2 Phillips screwdriver

No. 1 Phillips screwdriver

Red threadlocker

WARNING:

Failure to perform the following procedure correctly could result in permanent damage to

mechanical and electrical sensor components, which could result in engine damage.

Please read all instructions carefully before attempting this procedure, and do not attempt

the install if you feel you may not be able to perform all operations safely without

damaging components. AEM will not be held liable for any damage that occurs as a result

of these instructions.

Page 2 of 9

Page 3

Instructions with photos on the following pages:

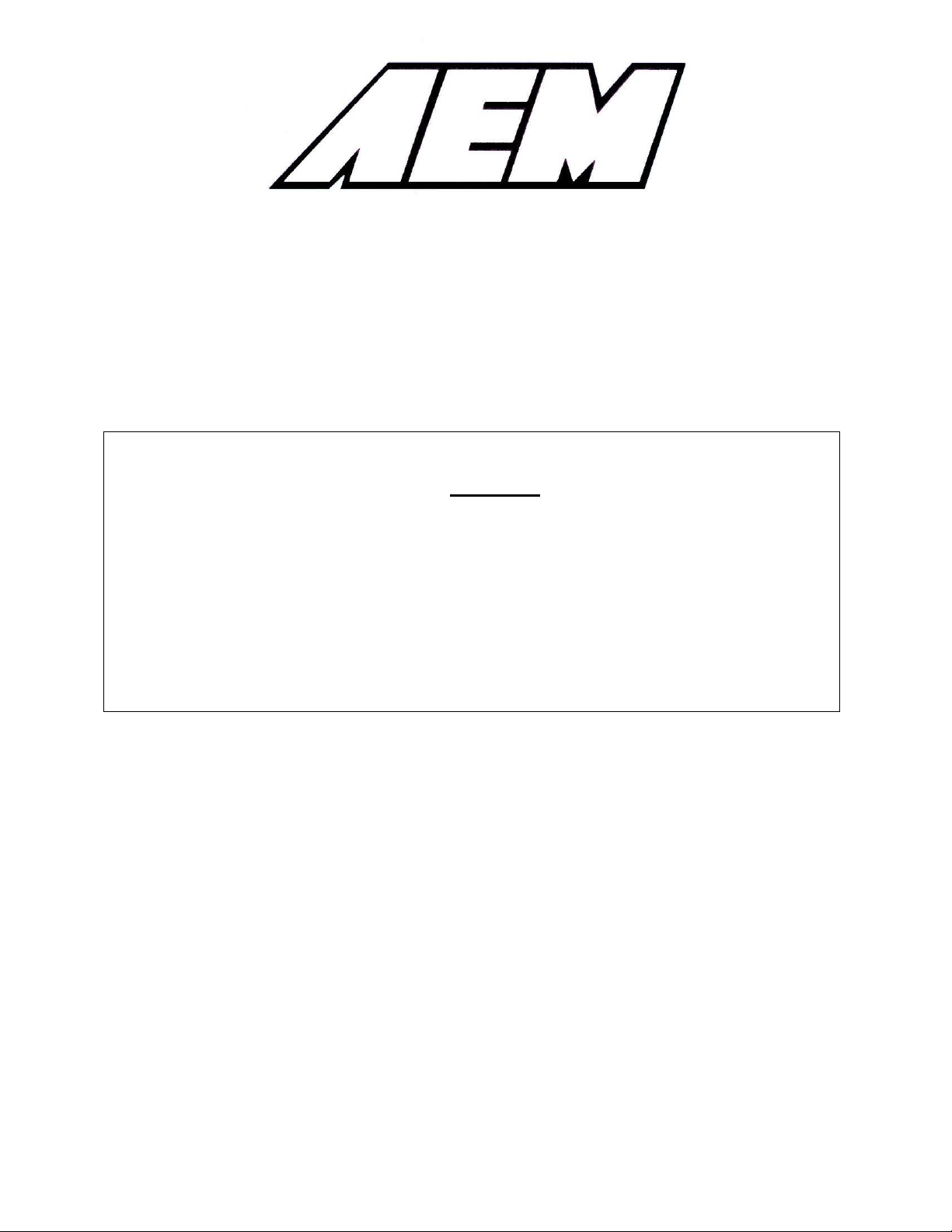

Remove the MAF sensor assembly as shown in figure 1. The arrow points to a mount that

may or may not be present on your vehicle which was removed using a 10mm

combination wrench and 10mm socket. The hose clamp is removed with the ¼” flat

screwdriver.

Figure 1: MAF assembly removal

Figure 2 shows the location of the CAS sensor (inside the distributor assembly).

Figure 2: Location of CAS sensor (underneath distributor cap)

Page 3 of 9

Page 4

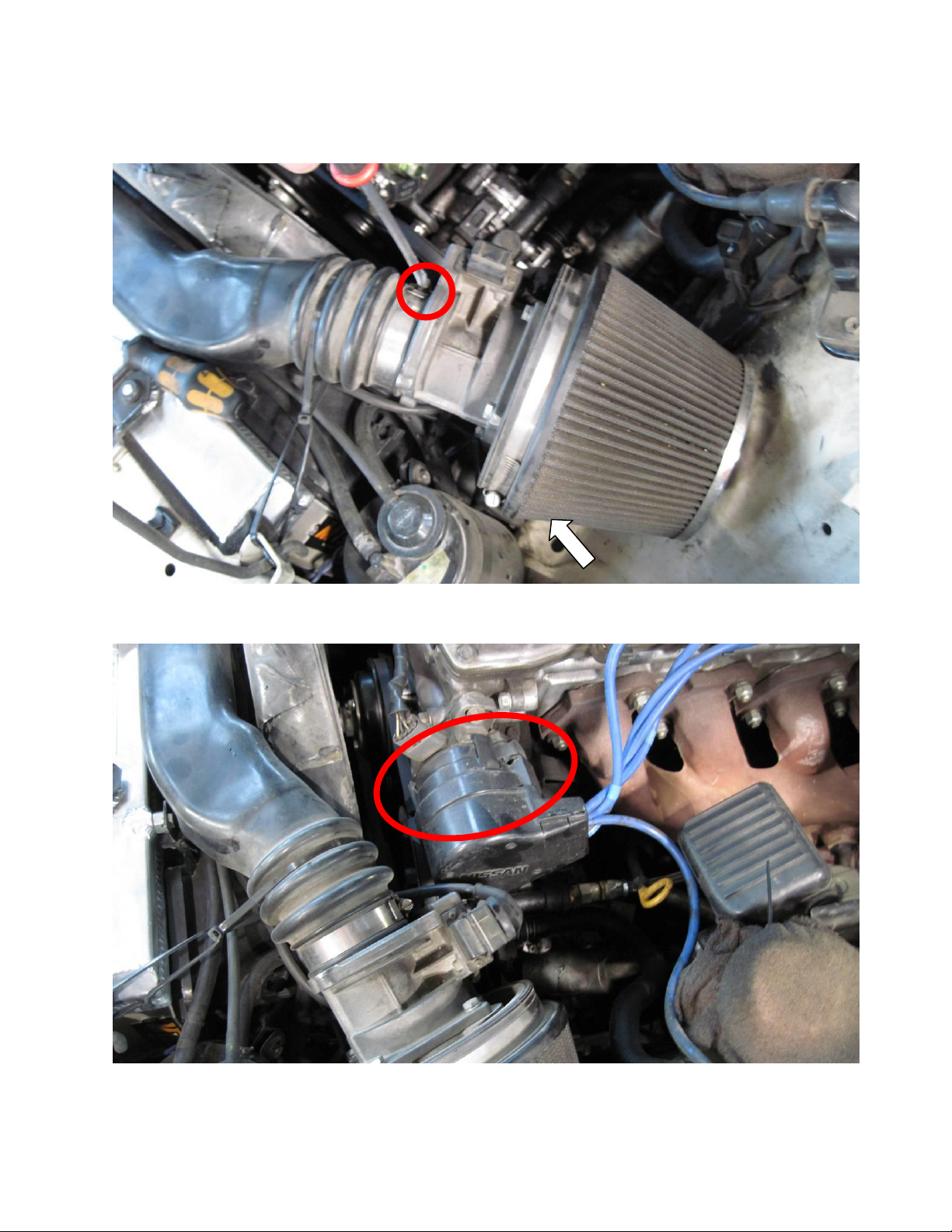

Remove the plastic cover as shown in figure 3.

Figure 3: Plastic wire cover removed

Remove the back part of the outer plastic cover on the distributor and remove the

distributor cap as shown in figure 4.

Figure 4: Plastic wire cover removed and distributor cap removed

Page 4 of 9

Page 5

Remove the distributor rotor with carefully with the pry bar as shown in figure 5, taking

note of how the rotor was oriented on the shaft. (The photo shows a different distributor

that has the same type of rotor installation)

Figure 5: Distributor rotor removed with pry bar

Remove the internal plastic cover shown in figure 6.

Figure 6: Internal plastic cover to be removed

Page 5 of 9

Page 6

Remove the internal CAS disc cover shown in figure 7 with a #2 Phillips screwdriver.

Figure 7: Removal of internal CAS disc cover

Remove the screw holding the CAS disc and collar as shown in figure 8 with the #2

Phillips screwdriver (Make sure screwdriver is firmly planted since this screw will be very

tight).

Figure 8: Original CAS disc removal

Page 6 of 9

Page 7

Figure 9 shows the original CAS disc with the collar that holds it in place removed. The

original disc can be removed now. For future use, the original disc should be marked UP

to remember what the original orientation of the disc is.

Figure 9: Original CAS disc with collar removed

The new AEM trigger disc is installed as shown in figure 10, orientation up or down is not

important, only the D-shaped mounting on the shaft.

Figure 10: AEM CAS trigger disc installed

Page 7 of 9

Page 8

The collar and screw can be reinstalled as shown in figure 11.

Figure 11: Trigger disc and collar reinstalled

The internal CAS disc cover can be reinstalled with two screws that held it in place as

shown in figure 12.

Figure 12: Trigger disc cover reinstalled

Page 8 of 9

Page 9

The internal plastic cover is reinstalled as shown in figure 13.

Figure 13: Internal plastic cover reinstalled

Reassemble the rest of the items in the reverse order of disassembly.

Page 9 of 9

Page 10

WARNING:

!

This installation is not for the tuning novice nor the PC illiterate!

Use this system with EXTREME caution! The AEM EMS System

allows for total flexibility in engine tuning. Misuse of this

product can destroy your engine! If you are not well versed in

engine dynamics and the tuning of management systems or are

not PC literate, please do not attempt the installation. Refer the

installation to a AEM trained tuning shop or call 800-423-0046

for technical assistance. You should also visit the AEM EMS

Tech Forum at http://www.aempower.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

Installation Instructions for:

Crank Angle Sensor replacement for EMS P/N 30-6601,

30-6602, 30-6620, and 30-6623

1991-1993 S13 180SX & Silvia SR20DET, 1994-1997 S14 180SX

& Silvia SR20DET, 1998 S14 Silvia SR20DET, 1993-1998 S13

200SX SR20DET, and 1999-2003 Skyline GTR RB26DETT

This product is legal in California for racing vehicles only and should never

be used on public highways.

2010 ADVANCED ENGINE MANAGEMENT INC.

2205 126th Street Unit A Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aempower.com

Instruction Part Number: 10-6600-B supplement

Page 1 of 9

Page 11

**Cam / Crank Angle Sensor: AEM trigger disc MUST be used

Discrepancies have been observed in the OEM cam/crank angle trigger discs between

model years and/or trim levels; to avoid confusion the Series 2 EMS does not support the

OEM Nissan trigger pattern. A replacement trigger disc is now included with every Nissan

EMS and must be installed before attempting to start the engine. The following installation

was performed on a modified Nissan S13 240SX with an SR20DET swap so your

installation may require more or less removal of parts, but the procedure for the CAS disc

change should be identical.

Tools/parts required:

Replacement trigger disc for Nissan RB/VG/VE cam angle sensor

(AEM P/N 35-8760, supplied with 30-6601, 30-6602, and 30-6620 EMS)

8mm socket with ratchet

¼ ” flat screwdriver

No. 1 Phillips screwdriver

Red threadlocker

WARNING:

Failure to perform the following procedure correctly could result in permanent damage to

mechanical and electrical sensor components, which could result in engine damage.

Please read all instructions carefully before attempting this procedure, and do not attempt

the install if you feel you may not be able to perform all operations safely without

damaging components. AEM will not be held liable for any damage that occurs as a result

of these instructions.

Instructions (figures on the following pages):

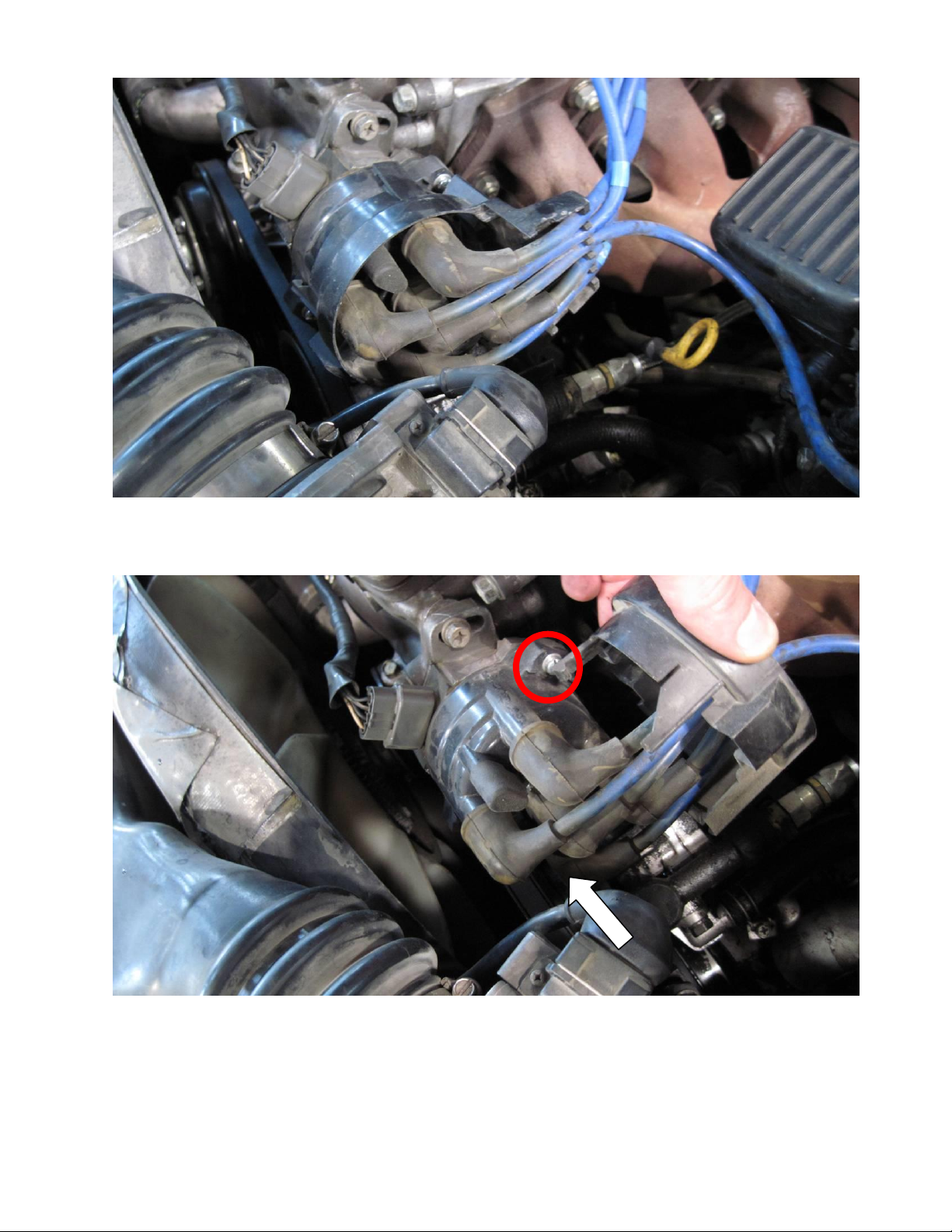

1. Figures 1 & 2 show the location of the CAS sensor disc cover

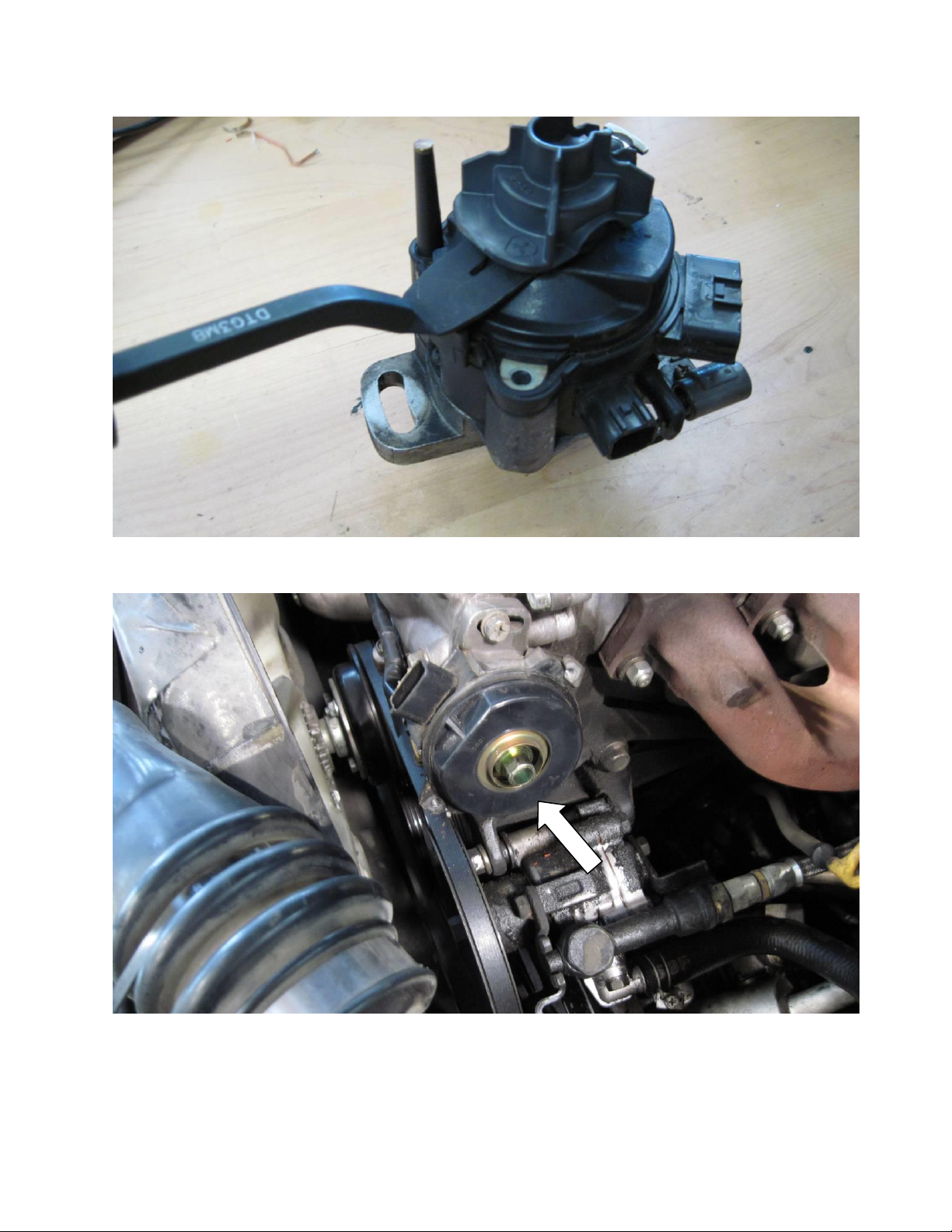

2. Figure 3 shows the removal of the vacuum line that goes to the blow-off valve for

this custom vehicle

3. Using the 8mm socket, the intake tube with blow-off valve are removed. Figures 4 &

5 show the removal of the intake tube which makes for easy access to the CAS disc

cover for this custom vehicle.

4. Figure 6 shows the uncovered CAS disc cover and figure 7 shows the CAS disc

cover being removed with the No. 1 Phillips screwdriver.

5. Figure 8 shows the uncovered CAS disc which is removed with the ¼” flat

screwdriver as shown in figure 9. Before complete removal, be sure to mark to

original disc to ensure correct installation if required. Figure 10 shows the screw

removed, figure 11 shows the washer removed, and figure 12 shows the original

CAS disc removed.

6. Carefully install the provided AEM CAS disc as shown in figure 13 and 14. When

replacing screw that holds CAS disc, apply threadlocker to it.

7. Reassemble all items in the reverse order of disassembly.

Page 12

Figure 1: Location of CAS

Figure 2: Location of CAS

Page 13

Figure 3: Removal of vacuum line from blow-off valve

Figure 4: Removal of intake tube

Page 14

Figure 5: Removal of intake tube

Figure 6: CAS cover

Page 15

Figure 7: Removal of CAS cover

Figure 8: Cover removed

Page 16

Figure 9: Removal of original CAS disc

Figure 10: Original CAS screw removed

Page 17

Figure 11: Washer removed

Figure 12: Original CAS disc removed

Page 18

Figure 13: Installation of AEM CAS disc

Figure 14: AEM CAS disc installed

Page 19

Installation Instructions 10-6610-A supplement for:

Crank Angle Sensor replacement for EMS P/N 30-6610/6611

95 Nissan 240SX S14 KA24DE

95-97 Nissan Sentra B14 SR20DE & GA16DE

95-96 Nissan Altima U13 KA24DE

94-96 Infiniti G20 P10 SR20DE

WARNING:

This installation is not for the tuning novice nor the PC illiterate!

Use this system with EXTREME caution! The AEM EMS System

allows for total flexibility in engine tuning. Misuse of this

product can destroy your engine! If you are not well versed in

,!

This product is legal in California for racing vehicles only and should never

engine dynamics and the tuning of management systems or are

not PC literate, please do not attempt the installation. Refer the

installation to a AEM trained tuning shop or call 800-423-0046

for technical assistance. You should also visit the AEM EMS

Tech Forum at http://www.aempower.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

be used on public highways.

© 2010 ADVANCED ENGINE MANAGEMENT INC.

2205 126

Instruction Part Number: 10-6610-A supplement

th

Street Unit A Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aempower.com

1

Page 20

**Cam / Crank Angle Sensor: AEM trigger disc MUST be used

Discrepancies have been observed in the OEM cam/crank angle trigger discs between

model years and/or trim levels; to avoid confusion the Series 2 EMS does not support the

OEM Nissan trigger pattern. A replacement trigger disc is now included with every Nissan

EMS and must be installed before attempting to start the engine. The following installation

was performed on a stock Nissan S14 240SX so your installation may require removal of

more parts, but the procedure for the CAS disc change should be identical.

Tools/parts required:

• Replacement trigger disc for Nissan GA/KA/SR cam angle sensor

(AEM P/N 35-8760, supplied with 30-6600, 30-6601, 30-6602, 30-6610, 30-6611,

30-6620, and 30-6623 EMS)

• 8mm and 10mm socket with ratchet and extension

• 10mm combination wrench

• Medium pry bar

• ¼” flat screwdriver

• No. 2 Phillips screwdriver

• No. 1 Phillips screwdriver

• Red threadlocker

WARNING:

Failure to perform the following procedure correctly could result in permanent damage to

mechanical and electrical sensor components which could result in engine damage.

Please read all instructions carefully before attempting this procedure, and do not attempt

the install if you feel you may not be able to perform all operations safely without

damaging components. AEM will not be held liable for any damage that occurs as a result

of these instructions.

2

Page 21

Instructions with photos on the following pages:

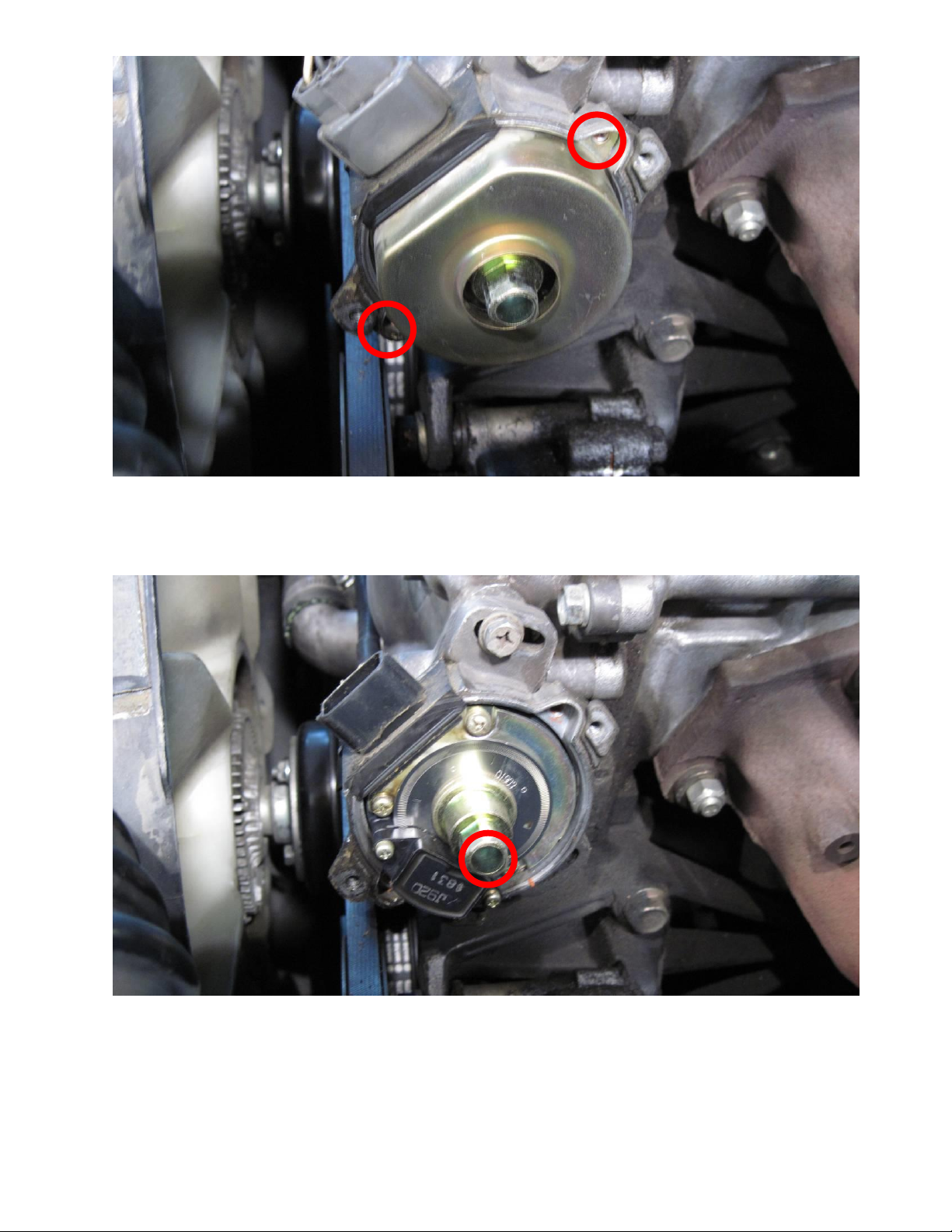

Remove the distributor cap with the #1 Phillips screwdriver as shown in figure 1 by

removing the two screws holding it in place (Note: these instructions were performed with

the distributor removed, but it is not necessary)

Figure 1: Distributor cap removal

Remove the distributor rotor with carefully with the pry bar as shown in figure 2, taking

note of how the rotor was oriented on the shaft.

Figure 2: Distributor rotor removed with pry bar

3

Page 22

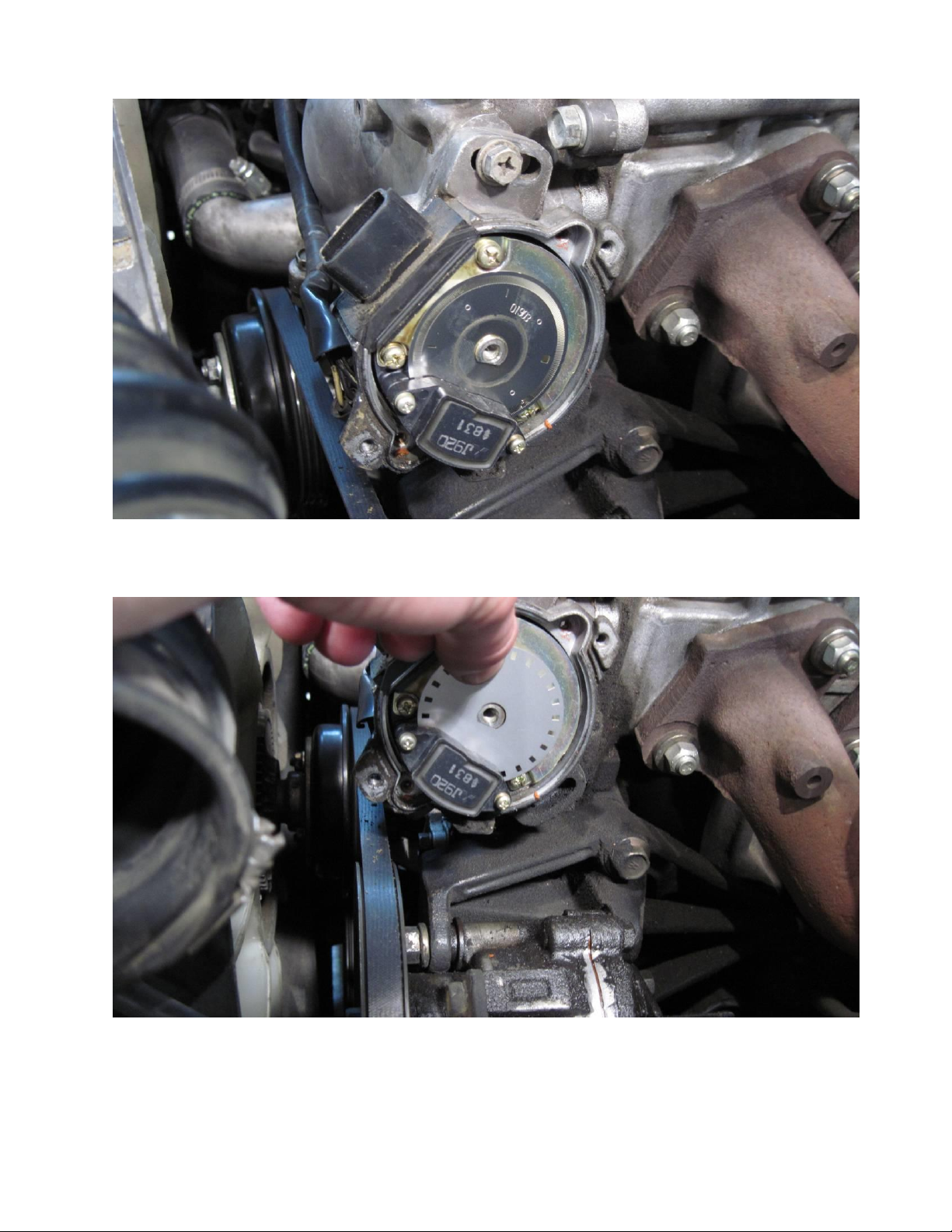

Remove the internal cover over the CAS disc as shown in figure 3.

Figure 3: Removal of internal cover over CAS disc

Remove the screw holding the CAS disc and collar as shown in figure 4 with the #2

Phillips screwdriver (Make sure screwdriver is firmly planted since this screw will be very

tight).

Figure 4: Removal of screw holding on CAS disc

4

Page 23

When collar and screw are removed, the assembly will look like figure 5.

Figure 5: Original CAS screw and collar removed

Install the AEM CAS disc as shown below in figure 6, with the D-shaped shaft aligned as

shown.

Figure 6: AEM CAS disc installed

5

Page 24

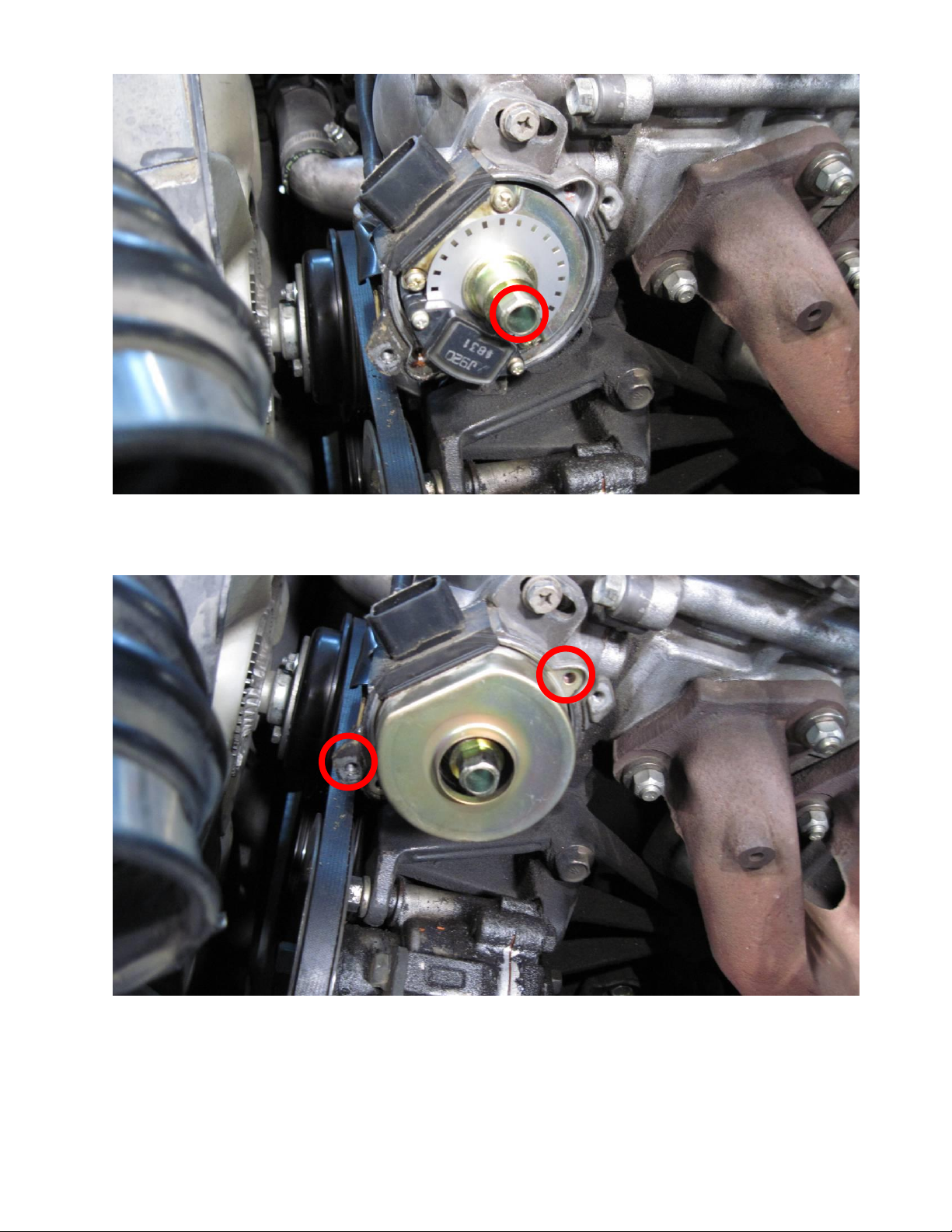

Reinstall the screw that holds the CAS disc with some red threadlocker with the #2 Phillips

screwdriver as shown in figure 7.

Figure 7: Screw and collar to hold CAS reinstalled with red threadlocker

Reassemble the rest of the items in the reverse order of disassembly.

Also note that the base calibrations were created with the distributor mounted in the

central adjustment position (two screws shown below) on our test vehicle. See figure 8

below:

Figure 8: Adjustment screws set to central position

6

Loading...

Loading...