Page 1

!

WARNING:

This installation is not for the tuning novice nor the PC illiterate!

Use this system with EXTREME caution! The EMS-4 allows for

total flexibility in engine tuning. Misuse of this product WILL

destroy your engine!

Installation of the EMS-4 must be performed by a qualified EFI

technician familiar with EFI sensors, actuators and wiring.

You should also visit the AEM EMS Tech Forum at

http://www.aempower.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

INSTALLATION AND TUNING GUIDE FOR:

EMS P/N 30-6905

EMS-4

PROGRAMMABLE ENGINE MANAGEMENT SYSTEM

This product is legal in California for racing vehicles only and should never be used on public

highways.

2205 W. 126TH STREET, UNIT A HAWTHORNE CA 90250

AEM PERFORMANCE ELECTRONICS

PHONE: 310-484-2322 FAX: 310-484-0152

http://www.aemelectronics.com

Page 1 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 2

Revision History

Version

Date

Modified Sections

Description

Initial Release, 1.0

12/27/10

1.1

12/28/10

Typical Idle Setup

Tab

Injectors section

Added example calculations

for Idle Frequency Settings

Clarified a section reference

1.2

12/28/10

Injection Phasing

Coil Phasing

Added details on Injector

Advance table

Added details on alternative

firing order setups

1.3

12/30/10

EMS-4 GPIOs

Added additional details to

example setups

1.4

1/4/11

Timing Pattern

Basics

Corrected error in diagram

1.5

1/10/11

Various

Fixed several minor

typographical errors

1.6

2/10/11

Internal Logging

Clarifications

1.7

3/23/11

Advanced Tuning

Added Switched Ign

Retard/Cut documentation

Page 2 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 3

Table of Contents

General Information ...................................................................................................................... 6

Electronics Warranty ..................................................................................................................... 6

Part 1 – EMS-4 Installation ........................................................................................................... 7

EMS-4 Basic Specifications ...................................................................................................... 7

Wire Harness Options ............................................................................................................... 7

ECU Terminations with Mini Harness, P/N 30-2905-0 ......................................................... 10

Electronic Wiring Conventions ............................................................................................. 16

Grounding ............................................................................................................................ 17

Power Requirements of the AEM EMS ................................................................................ 17

Use of Relays to Control Ancillary Devices ......................................................................... 17

Installation with Full Harness, P/N 30-3905-96 ....................................................................... 18

USB Connector .................................................................................................................... 18

CAN Connector .................................................................................................................... 19

Injectors ............................................................................................................................... 19

Coils / Electronic Ignition System Basics ............................................................................. 21

TPS (Throttle Position Sensor) ............................................................................................ 26

MAP Sensor ......................................................................................................................... 26

Air Temp Sensor .................................................................................................................. 27

Water Temp Sensor ............................................................................................................. 28

Crank Sensor ....................................................................................................................... 29

Cam Sensor ......................................................................................................................... 33

Vehicle Speed Sensor (VSS) ............................................................................................... 34

Part 2 – AEM Tuner .................................................................................................................... 37

Software Installation ................................................................................................................ 37

AEM Tuner .............................................................................................................................. 39

Basic Terminology ............................................................................................................... 40

Menu Items .......................................................................................................................... 42

Editing EMS Calibration Files .................................................................................................. 77

Editing Options Displays ...................................................................................................... 77

Editing 2D Table Displays .................................................................................................... 81

Editing Channel Displays ..................................................................................................... 89

Editing 3D Map Displays ...................................................................................................... 90

Page 3 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 4

Part 3 – Tuning Guide ................................................................................................................. 98

Background ............................................................................................................................. 98

Fuel Tuning General Concepts ............................................................................................ 98

Spark Tuning General Concepts ......................................................................................... 99

Calibration Setup ................................................................................................................... 100

Base Calibrations ............................................................................................................... 100

Timing Pattern Basics ........................................................................................................ 101

Fuel Phasing and Injector Setup ........................................................................................ 104

A more complex example .................................................................................................. 106

Ignition Phasing and Coil Dwell Discussion ....................................................................... 107

Set up RPM and Load axes ............................................................................................... 114

EFI Sensors ........................................................................................................................... 115

TPS (Throttle Position Sensor) .......................................................................................... 115

MAP (Manifold Pressure Sensor) ...................................................................................... 116

Air Temperature Sensor .................................................................................................... 119

Water Temp Sensor ........................................................................................................... 120

O2 (Oxygen) Sensors ......................................................................................................... 120

Knock Sensor .................................................................................................................... 125

Sensor Calibration ............................................................................................................. 126

Fuel System Setup ................................................................................................................ 134

Fuel Pump Setup ............................................................................................................... 134

Fuel Pump Sizing ............................................................................................................... 135

Fuel Pump Location ........................................................................................................... 136

Fuel Hoses and Routing .................................................................................................... 136

Fuel Delivery Hose Sizes ................................................................................................... 137

Fuel Filter and Fuel Rail ..................................................................................................... 137

Fuel Pressure Regulator and Pulse Dampener ................................................................. 139

Basic Tuning .......................................................................................................................... 142

Timing Pickup Confirmation ............................................................................................... 142

Noise .................................................................................................................................. 145

Ignition Synchronization ..................................................................................................... 146

Crank Fuel & Engine Start ................................................................................................. 148

Idle Air Control ................................................................................................................... 150

Page 4 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 5

Fuel Tuning ........................................................................................................................ 158

Acceleration/Deceleration Modifiers for Engine Fueling .................................................... 176

Ignition Tuning Theory ....................................................................................................... 182

Ignition Map ....................................................................................................................... 193

Ignition Trims ..................................................................................................................... 193

Vehicle Speed .................................................................................................................... 197

EMS-4 GPIOs .................................................................................................................... 199

Data logging ....................................................................................................................... 209

Advanced Tuning .................................................................................................................. 216

Boost Control ..................................................................................................................... 216

Knock Control .................................................................................................................... 231

Traction Control ................................................................................................................. 233

2Step Rev Limiter .............................................................................................................. 242

O2 Feedback ..................................................................................................................... 245

Nitrous Control ................................................................................................................... 252

Anti-Lag ............................................................................................................................. 256

Analog Input Switch ........................................................................................................... 259

Staged Injection ................................................................................................................. 260

Switched Ignition Retard/Cut ............................................................................................. 266

Glossary of Terms ................................................................................................................. 269

Index ...................................................................................................................................... 278

Page 5 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 6

General Information

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE ATTEMPTING TO INSTALL THIS

PRODUCT. VISIT THE AEM PERFORMANCE ELECTRONICS TECH SUPPORT FORUM AT

http://forum.aempower.com/forum/index.php ALL CURRENT SOFTWARE AND DOCUMENTATION

IS AVAILABLE ON THIS FORUM.

YOU MAY ALSO CONTACT AEM PERFORMANCE ELECTRONICS TECH SUPPORT AT 1-800-423-

0046 IF YOU HAVE ANY QUESTIONS.

Electronics Warranty

Advanced Engine Management Inc. warrants to the consumer that all AEM Electronics products

will be free from defects in material and workmanship for a period of twelve months from date of

the original purchase. Products that fail within this 12-month warranty period will be repaired or

replaced when determined by AEM that the product failed due to defects in material or

workmanship. This warranty is limited to the repair or replacement of the AEM part. In no event

shall this warranty exceed the original purchase price of the AEM part nor shall AEM be

responsible for special, incidental or consequential damages or cost incurred due to the failure

of this product. Warranty claims to AEM must be transportation prepaid and accompanied with

dated proof of purchase. This warranty applies only to the original purchaser of product and is

non-transferable. All implied warranties shall be limited in duration to the said 12-month

warranty period. Improper use or installation, accident, abuse, unauthorized repairs or

alterations voids this warranty. AEM disclaims any liability for consequential damages due to

breach of any written or implied warranty on all products manufactured by AEM. Warranty

returns will only be accepted by AEM when accompanied by a valid Return Merchandise

Authorization (RMA) number. Product must be received by AEM within 30 days of the date the

RMA is issued.

Please note that before AEM can issue an RMA for any electronic product, it is first necessary

for the installer or end user to contact the tech line at 1-800-423-0046 to discuss the problem.

Most issues can be resolved over the phone. Under no circumstances should a system be

returned or a RMA requested before the above process transpires.

AEM will not be responsible for electronic products that are installed incorrectly, installed in a

non-approved application, misused, or tampered with.

Any AEM electronics product can be returned for repair if it is out of the warranty period. There

is a minimum charge of $50.00 for inspection and diagnosis of AEM electronic parts. Parts used

in the repair of AEM electronic components will be extra. AEM will provide an estimate of repairs

and receive written or electronic authorization before repairs are made to the product.

Page 6 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 7

Part 1 – EMS-4 Installation

CPU Core:

16 bit / 40 MHz

Injector Drivers:

4 x Saturated (8 ohm minimum, High Impedance Only)

Coil Drivers:

4 x 0-5V Falling Edge Fire (do not connect directly to coil

primary)

GPIO Pins:

4 x 1.5A Low Side Output / 0-5V Analog Input / Switch Input

4 x 1.5A Low Side Output / 0-5V Analog Input / PWM output

O2 Sensor Input:

1 x 0-5V analog

Timing Sensor Inputs:

1 x VR (mag) Cam Input

1 x VR (mag) Crank Input

1 x Hall VSS Input

1 x Hall Crank Input

1 x Hall Cam Input

Knock Sensor Input

1x Programmable

Throttle Position Input

1 x 0-5V

Manifold Pressure Sensor

1 x 0-5V

Coolant Temperature Sensor

1 x analog

Inlet Air Temperature Sensor

1 x analog

USB

1 x EMS / PC Communication

CAN

1 x Programmable Send / Receive

Sensor Ground

1 x

5 Volt Reference

1 x

EMS-4 Basic Specifications

EMS-4 Specifications

Wire Harness Options

EMS-4 with 30-2905-96 Full Harness EMS-4 with 30-2905-0 Mini Harness

Page 7 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 8

Page 8 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 9

Page 9 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 10

Two partially assembled harness options are available for the EMS-4:

1. P/N 30-2905-96 EMS-4 Full Harness

2. P/N 30-2905-0 EMS-4 Mini Harness

Photographs and schematics for each are shown above. The Full Harness option is best suited

to applications where no factory harness exists or where modifications are so extensive, it is

easier to build a custom harness. This harness includes a fused power distribution center with

main relay. All circuits are pre-terminated at the ECU connector. All sensor input and actuator

output leads are grouped and clearly labeled. All power and ground splices are pre-configured.

All sensitive communications and CAN data stream circuits are pre-configured.

The Mini Harness option is best suited to applications where the factory harness is suitable as a

starting point for modifications. Like the fully populated harness, the mini version includes preterminated CAN data stream and communications circuits. It also includes primary power and

ground inputs. This is the minimum required for powering up the EMS and enabling

communications. All other harness terminations are the responsibility of the installer. A bag of

Delphi/Packard female terminals is included for terminating all circuits at the main ECU

connector.

Installers choosing the Mini Harness option should refer to the Full Harness schematic

above and the EMS-4 System Diagram that shows an example of a complete system

design.

ECU Terminations with Mini Harness, P/N 30-2905-0

To following steps illustrate how to open the ECU connector backshell so additional circuits can

be added.

Begin by cutting the strain relief tie

wrap holding the terminal bag as

shown.

Page 10 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 11

Using a sharp pick or

probe, push in on the

locking tabs holding the

outer retainer.

Remove the retainer.

Page 11 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 12

Use pick to pry open the

retaining tabs holding the

backshell halves together.

Open the shell to expose

the cavities.

Page 12 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 13

To remove a terminal,

carefully pry up on the

retaining clip. Be careful

as the clips can break if

bent too far.

To add a new circuit,

insert the terminal from

the back as shown until it

clicks into place.

Page 13 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 14

Showing terminal fully

seated.

Following is the proper tool for use with the Delphi Micro Pack terminals used in the ECU main

connector.

Delphi Part No: 12070948

Application: Unsealed Micro-Pack 100, Female only

Core and Insulation

Cable Range (mm2): 2.0-0.35

Page 14 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 15

The tool is available in many places. One is shown below. Web address –

http://www.mouser.com AEM recommends using the proper tool for all ECU terminations.

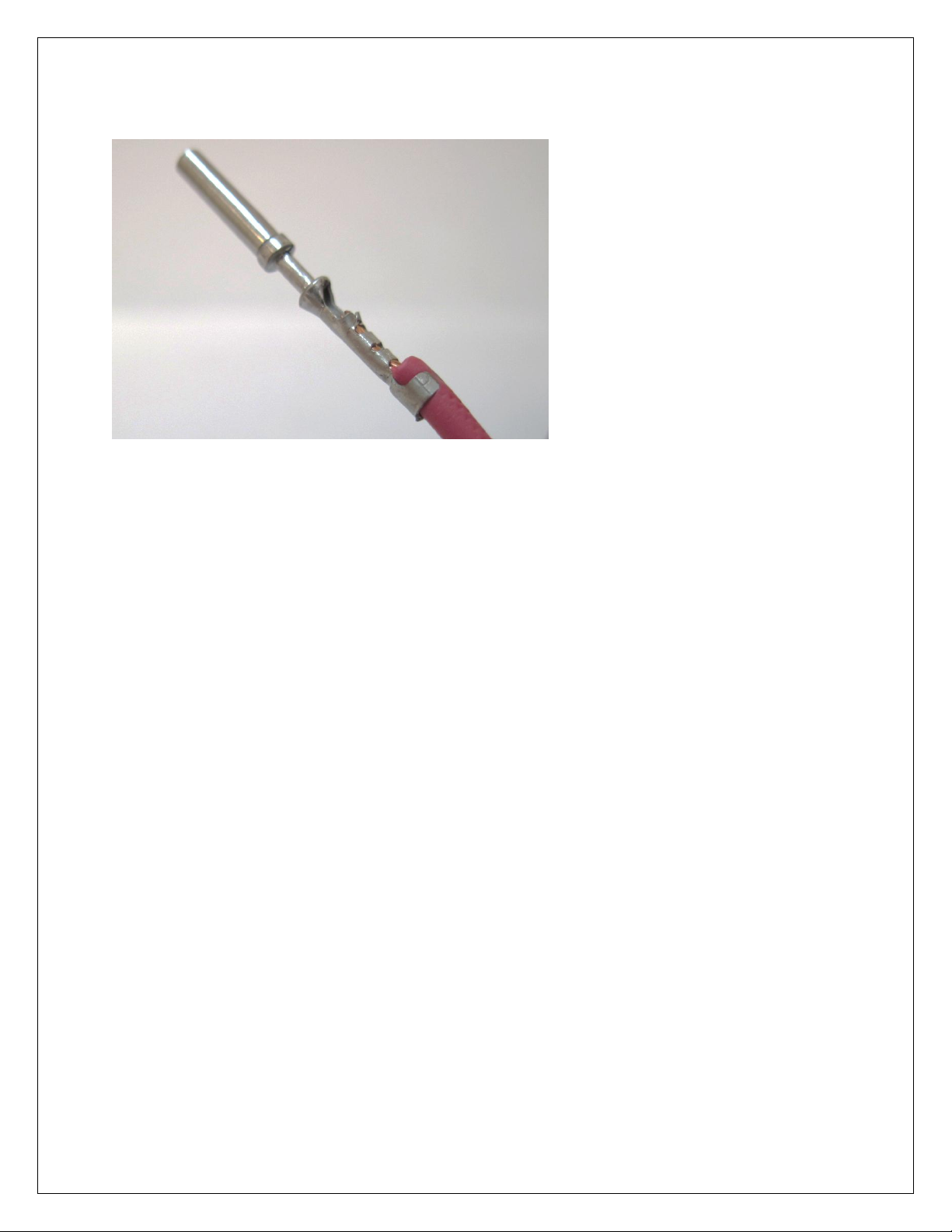

Image shows a properly crimped

terminal. Top View.

Page 15 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 16

Side View. After crimping, be sure

to do a pull test to make sure the

terminal is properly installed.

Electronic Wiring Conventions

A proper wiring job includes proper termination of the wire at the sensor. The wire terminal end

must be moisture tight where it plugs into the sensor and it must have strong, electrically sound

terminals. The preferred method of securing a wire to a terminal is to use a crimp terminal with

NO solder. It is important to use the proper crimping tool for sound terminal construction.

Plastic terminal plugs must have moisture tight seals. Inspect each plug to make sure the seals

are in place. Also, before the plug is installed on the sensor, apply a dab of di-electric grease in

the terminal slots to further aid in corrosion resistance.

If a splice into a wire must be made and no solder-less terminals are available, then you must

properly solder the splice.

Noise can be a serious problem and can cause intermittent misfiring of the engine. Every

precaution should be taken to prevent interference to the ECU‟s operation. Resistive plug leads

are REQUIRED, and shielded cables from the crank and cam angle sensor inputs are highly

recommended. All racing AEM EMS wire harnesses come with properly shielded cables and are

color coded for easy identification of circuits. They are also shrink wrapped for abrasion

protection. The crank and cam angle sensor wire has a bare wire running down the length of it.

It is NOT terminated at the sensor end of the cable because we ground it at the plug end of the

harness. DO NOT GROUND THIS WIRE! This will cause a condition called ground looping

and will remove any noise protection the cable has.

To eliminate or reduce the chance of EMI, wires that carry high current must run in twisted pairs.

An example of this would be the power leads from a multiple spark ignition system. These

ignition systems can carry up to 100 amps for a couple milliseconds at the time of discharge,

which induces a strong magnetic field in close proximity of the wires.

Page 16 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 17

The routing of the wire loom is critical to EFI system performance and safety. The following

safety considerations should be made when installing the wire loom:

Heat protection: the loom should be placed away from or insulated from sources of heat.

The obvious item(s) that should be avoided are the exhaust manifolds, EGR delivery

tubes, and turbochargers. If it is absolutely necessary to route a wire in close proximity

to any of these items, then a suitable insulator must be used.

Noise suppression: do not route wires near the HT leads. For coil- on-plug ignition

systems this is not as critical.

Moving component protection: route wires away from moving components such as fans,

the blower belt, or the throttle linkage. Also, make sure the wires are not under any

strain when the engine is at full deflection on the motor mounts (we have seen map

sensor wires disconnect while under full acceleration because the motor mounts were

bad).

Never have the wires in exposed bundles throughout the engine compartment. A

professional harness has shrink tube over it to resist abrasion and chemical damage to

the wire loom.

Grounding

The ECU must have an electrically secure ground connection, which means that the battery

negative must be properly grounded to the chassis AND engine. The ground wire, whether it is

from the battery or to the chassis and engine, must have perfect electrical conductivity. This

means that there must not be any paint or rust under the wire terminal. Make sure that when

you install the ground wire there is bare metal exposed where the wire contacts the vehicle

component. To prevent rust build up, we recommend applying a protective layer of dielectric

grease, such as Standard Ignition SL-4, to the bare metal surface. The ground wire must be at

least the same gauge as the power lead to the ECU. We also recommend that the ground wire

be as short as possible.

Power Requirements of the AEM EMS

The AEM EMS requires a minimum supply voltage of 10V or greater to run. We recommend

that the ECU be supplied with 13.8V nominal operating voltage. Ensure that the vehicle‟s

charging system is in perfect operating condition prior to installing the AEM EMS.

Use of Relays to Control Ancillary Devices

Relays are remote switching devices that are used to isolate a device from the ECU‟s circuitry to

reduce noise and power constraints on the ECU. Typical devices that are powered by a relay

are:

Fuel Pump

Variable Valve Control

Oxygen Sensor Heater

ECU power

Nitrous Oxide solenoids

Page 17 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 18

Noise can be caused by the electric motor in a fuel pump, which if connected directly to the

ECU, may feed back into the circuit board ground plane. In the case of a fuel pump, the typical

amperage required to run the pump is 10A or more depending on its size. The driver in the

ECU that sends the command to run the fuel pump is only capable of supplying 1.5A, and

clearly this type of load on the driver would cause it to burn out. There are drivers that can

handle larger currents but cost, size, heat dissipation, and noise problems prevent their use.

Typical relays in use today are capable of carrying 40A. A relay has an electromagnet

inside it that is used as a switch. This electromagnet, or switch, is used to position a

contact within the relay that is capable of carrying high current. There are typically four

or five terminals on the base of a relay. These terminals can be wired in several ways to

achieve different results. Refer to the EMS-4 System Schematic for common wiring

schemes used with relays.

Installation with Full Harness, P/N 30-3905-96

For the following section, please refer to the EMS-4 System Diagram for more

information. It shows a schematic representation of a properly designed system using

the fully populated harness.

NOTE: The columns in the connection tables below labeled “WIRE” refer to the wire

gauge recommended for the harness.

USB Connector

USB Connector

Page 18 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 19

A high quality over-molded termination is included for USB communications. Plug one end of a

standard USB extension cable (included) into the harness connector and the other end into an

open USB port on the PC. Communications is possible only when the EMS is powered up.

CAN Connector

CAN Connector

A compact pre-terminated connector is included for use with AEM CAN enabled devices.

Injectors

Injector Basics

A fuel injector is a valve that can be opened and closed very quickly. To open the valve, current

must flow through a solenoid contained in the upper part of the injector assembly. The EMS-4

triggers the injector by providing a ground path to the negative terminal. Fused power is

provided to the other terminal from the harness.

WARNING! – The EMS-4 is compatible with high impedance injectors only. For direct

drive operation, injector coil resistance must be greater than 8 ohms. Low impedance

injectors can be used if a suitable ballast resistor box or Peak and Hold Driver module is

used such as AEM P/N 30-2710.

To determine the size of the injectors, the total engine power must be estimated or known. The

fuel pump calculations and BSFC information mentioned in the Fuel Pump Sizing section on

page 135 provides a good understanding of the fuel requirements for an engine. The following

equation will allow you to determine the requirements of your injectors:

Page 19 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 20

((Power x BSFC) x (1 + Safety Margin))/Number of Injectors = pounds/hour

Name

Wire

Wire

Color

Stamping

Injector #1

22

Orange

INJ 1

Injector #2

22

Orange

INJ 2

Injector #3

22

Orange

INJ 3

Injector #4

22

Orange

INJ 4

Fused Injector Power

14

Red

INJ POWER

An example of this equation is:

6 CYL. engine rated at 500 hp on gasoline using moderate boost with a 15% safety margin on

the injector

500 x .625 = 313 lbs/6 = 52 lbs/hr/ injector. 52 x 1.15=60lbs/hr/ injector

If we take the flow of the injector (60 lbs/hr) and multiply it by the number of cylinders (6), we

arrive at a total of 360 lbs/hr of flow. As you can see, the fuel pump described in the fuel pump

sizing section referenced above has enough capacity to feed the engine with a little room to

spare.

It is a good idea to know the maximum operating pressure of the fuel injectors. In some cases

the fuel injector will not open if the fuel pressure exceeds the design limit of the injector. Also, at

the higher pressures the injector fuel flow may become non-linear and cause inconsistent fuel

delivery, usually creating a lean condition. Most injectors can withstand up to 70 psi. Many of

the pintle style injectors can withstand higher pressure.

In the fuel injector sizing, always use a safety margin between 15-20%.

Harness Connections

Injector Harness Connections

INJ1 – Connect to 1st injector to fire.

INJ2 – Connect to 2nd injector to fire.

INJ3 – Connect to 3rd injector to fire.

INJ4 – Connect to 4th injector to fire.

INJ POWER – Fused injector power. Splice required number of power leads and distribute to

each injector.

Page 20 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 21

AEM kit P/N 30-2020 (Optional) Bosch Style Injector Connector Kit contains the parts to

assemble 4 injector connectors. The kit contains Four Bosch style female injector connectors

and 10 contacts (2 extra contacts are included for spares).

IMPORTANT!

The contacts are “Pull to Seat” meaning you must feed the wire through the connector housing

BEFORE you crimp on the contacts. The wire is then pulled back into the housing and the

contact locks in place. The contact cannot be inserted or removed from the rear (wire side entry)

of the housing.

Contacts (10 Included)

Plating Tin Plated

Cable Range 1.00 - 0.05 mm2

Outside Cable Diameter 2.40 - 2.03 mm2

Temperature Range -40 to 125 C

Resistance in mOhms at 20 mV > 10.0 Ohms

Voltage Drop in mV per amp > 3.0 Ohms

Housing (4 Included)

Color Black

Cavities or Contacts 2

Gender Female

Temperature Range -40 to 125 C

Resistance at 20 mV > 10.0 mOhm

Voltage Drop per amp > 3.0 mV

Exterior Dimensions 27.8L X 29.6W X 20H

Seating Process Pull To Seat

Coils / Electronic Ignition System Basics

An ignition coil is charged when current flows through the primary side of the coil. A coil driver

is required to sink the current and dissipate the heat generated during operation. The coil

outputs from the EMS-4 are used to trigger the drivers. The drivers can either be contained

within the coils themselves or they can be contained within a stand-alone device installed

between the EMS-4 and the coils.

There are several different types of ignition systems in use on modern cars.

They are:

Distributed spark using a single coil and a distributor for all cylinders.

Wasted spark using one coil for two cylinders.

Direct Fire using one coil on plug of each cylinder.

Distributed Spark

Distributed spark systems have been around the longest. As the name implies, the spark is

distributed to the plugs via a coil output to a rotor, then through the distributor cap to the

appropriate plug via a high-tension (HT) lead. This is the most complex system because of the

relationship that has to be maintained between the firing point, rotor to cap terminal angle, and

Page 21 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 22

engine position. Distributed spark systems also rely on a mechanical link between the engine

Name

Wire

Wire

Color

Stamping

Coil 1 Output

22

Dk Blue

IGN 1

Coil 2 Output

22

Dk Blue

IGN 2

and ignition output, which adds another dimension of unreliability-and to a minor extentinaccuracy in timing. In addition to these problems, distributed spark systems typically produce

the least intense spark of all ignition systems. The time to achieve full charge diminishes as

engine speed increases; therefore the coil charge is reduced as a function of RPM. In spite of

the potential problems with distributed spark systems, they have been used successfully for

many years on high-performance engines. Distributed spark ignition systems respond well to

spark amplification within their design limits.

Wasted Spark

Wasted spark systems employ one coil for two cylinders. The term “wasted spark” comes from

the fact that each plug fires every engine revolution. On a 4-cycle engine, the piston is at Top

Dead Center (TDC) two times for every cycle; once for firing and again during the overlap

phase. The wasted spark coil fires one plug Before Top Dead center (BTDC) and another plug

just before the overlap phase (at the latest part of the exhaust stroke before the exhaust valve

closes). Wasted spark systems have a higher potential for spark intensity because the duty of

charging and discharging is split between the coils, which allows for more charge time per coil.

Additionally, wasted spark systems build up less heat in the coil, making it more reliable.

Wasted spark systems have been in use since the mid 80‟s on GM cars and on motorcycles for

considerably longer than that. There are no moving parts, no complicated relationships with a

cap and rotor to maintain, and they deliver very accurate spark timing. Furthermore, multichannel spark amplification systems to enhance spark duration or intensity are available for

wasted spark ignition systems.

Direct Fire

Direct fire systems employ one coil on each spark plug and is the most reliable system used

today, (this type of system is used on most modern cars). Each coil fires sequentially in the

cylinder firing order. The charge time for each coil is twice as long as those of a wasted spark

system, which allows direct-fire, coil manufacturers to build compact, lightweight coils that retain

sufficient spark energy. There are no moving parts to wear out and no HT leads that will

deteriorate. The lack of HT leads in direct fire systems is a major advantage for an EFIequipped car because there is a very low incidence of noise due to leaking or improperly routed

wires. There have been incidences of the terminal from a direct-fire coil (that attaches to the

spark plug) cracking and subsequently causing Radio Frequency Interference (RFI) or “noise” to

the ECU. This will cause engine operation problems, but it should be noted that these cases

are extremely rare.

Harness Connections

Coil Harness Connections

Page 22 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 23

Coil 3 Output

22

Dk Blue

IGN 3

Coil 4 Output

22

Dk Blue

IGN 4

Fused Coil Power

14

Red

COIL PWR

Coil Ground

14

Black

PWR GND

Warning! - The ignition outputs from the EMS-4 are not designed to trigger an ignition

coil directly. Connecting them to a coil that does not contain a built-in driver will damage

the EMS-4. Coils without built-in drivers typically have only two pins on the connector.

Coils with built-in drivers typically have 4 or more pins on the connector. If you are not

sure what kind of ignition coils you have, contact AEM tech support for help.

IGN 1 – Connect to 1st coil driver to fire.

IGN 2 – Connect to 2nd coil driver to fire.

IGN 3 – Connect to 3rd coil driver to fire.

IGN 4 – Connect to 4th coil driver to fire.

COIL PWR – Fused coil power. Splice required number of power leads and distribute to each

coil.

PWR GND – Ignition power ground.

AEM Kit P/N 30-2840 (Optional) Four Channel Coil Driver is custom manufactured to AEM‟s

specifications by HÜCO Electronic GmbH in their ISO 9001 facility in Germany. It has been

specially designed by AEM for driving the high power dwell controlled ignition coils commonly

found on performance engines.

The 30-2840 Kit contains:

Four Channel Coil Driver

Five Pin Mating Connector

Four Pin Mating Connector

10 Terminals & Wire seals (one extra of each as a precaution)

Mounting hardware

Thermal Grease

Page 23 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 24

Coil Driver

Connect to

ECU Coil 1 Output

EMS-4 harness, IGN 1

ECU Coil 2 Output

EMS-4 harness, IGN 2

ECU Coil 3 Output

EMS-4 harness, IGN 3

ECU Coil 4 Output

EMS-4 harness, IGN 4

Ground

EMS-4 harness, PWR GND

Coil 1 Negative Terminal

Coil 1 Negative Terminal

Coil 2 Negative Terminal

Coil 2 Negative Terminal

Coil 3 Negative Terminal

Coil 3 Negative Terminal

Coil 4 Negative Terminal

Coil 4 Negative Terminal

AEM Four Channel Coil Driver P/N 30-2840

Four Channel Coil Driver Connections

Coil Driver Connections

CDI Installations

The ignition outputs from the EMS-4 are considered a falling edge fire signal where signal high

is dwell time. A coil driver will invert the signal from the EMS-4 pulling the signal low (ground)

and allowing current to flow through the coil primary windings. Some CDI ignition boxes are

only capable of triggering on the “rising edge” or “Points Trigger” signal. These systems will still

require an in-line coil driver to invert the ignition output to fire on the correct edge. The AEM

Twin Fire CDI system P/N 2820 (8 channel) and 2821 (4 channel) can be configured to fire on

either a rising or falling edge. Applications using an AEM Twin Fire will not require an in-line coil

driver. Contact your CDI manufacturer for more information.

Page 24 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 25

Signal comparison – before and after coil driver

DWELL

DWELL

FALLING

5V

GND

IGNITION OUTPUT FROM EMS TO COIL DRIVER OR CDI

IGNITION OUTPUT AFTER COIL DRIVER

DWELL

DWELL

RISING EDGE

12V

GND

EDGE FIRE

FIRE

Page 25 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 26

Name

Wire

Wire

Color

Stamping

+5.0 volts, Vcc

22

Red

VCC

Throttle Position Sensor

22

White

THROTTLE

Sensor Ground

22

Black

SIG GND

Name

Wire

Wire

Color

Stamping

+5.0 volts, Vcc

22

Red

VCC

Manifold Pressure

Sensor

22

White

MAP

Sensor Ground

22

Black

SIG GND

TPS (Throttle Position Sensor)

Harness Connections

TPS Harness Connections

VCC – Connect to sensor 5 volt reference

THROTTLE – Connect to sensor signal

SIG GND – Connect to sensor ground

MAP Sensor

Harness Connections

MAP sensor harness connections

VCC – Connect to sensor 5 volt reference

MAP – Connect to sensor signal

SIG GND – Connect to sensor ground

Optional AEM MAP Sensor Listing:

AEM P/N 30-2130-30 “MAP Sensor Kit, 2 BAR”

Typically used to measure intake, air box and crankcase pressures.

AEM P/N 30-2130-50 “MAP Sensor Kit, 3.5 BAR”

Typically used to measure intake & exhaust back pressures.

Page 26 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 27

AEM P/N 30-2130-75 “MAP Sensor Kit, 5 BAR”

Name

Wire

Wire

Color

Stamping

Inlet Air Temp Sensor

22

White

AIR TEMP

Sensor Ground

22

Black

SIG GND

Typically used to measure intake & exhaust back pressures.

Air Temp Sensor

Harness Connections

Air Temperature Sensor Harness Connections

AIR TEMP – Connect to sensor signal

SIG GND – Connect to sensor ground

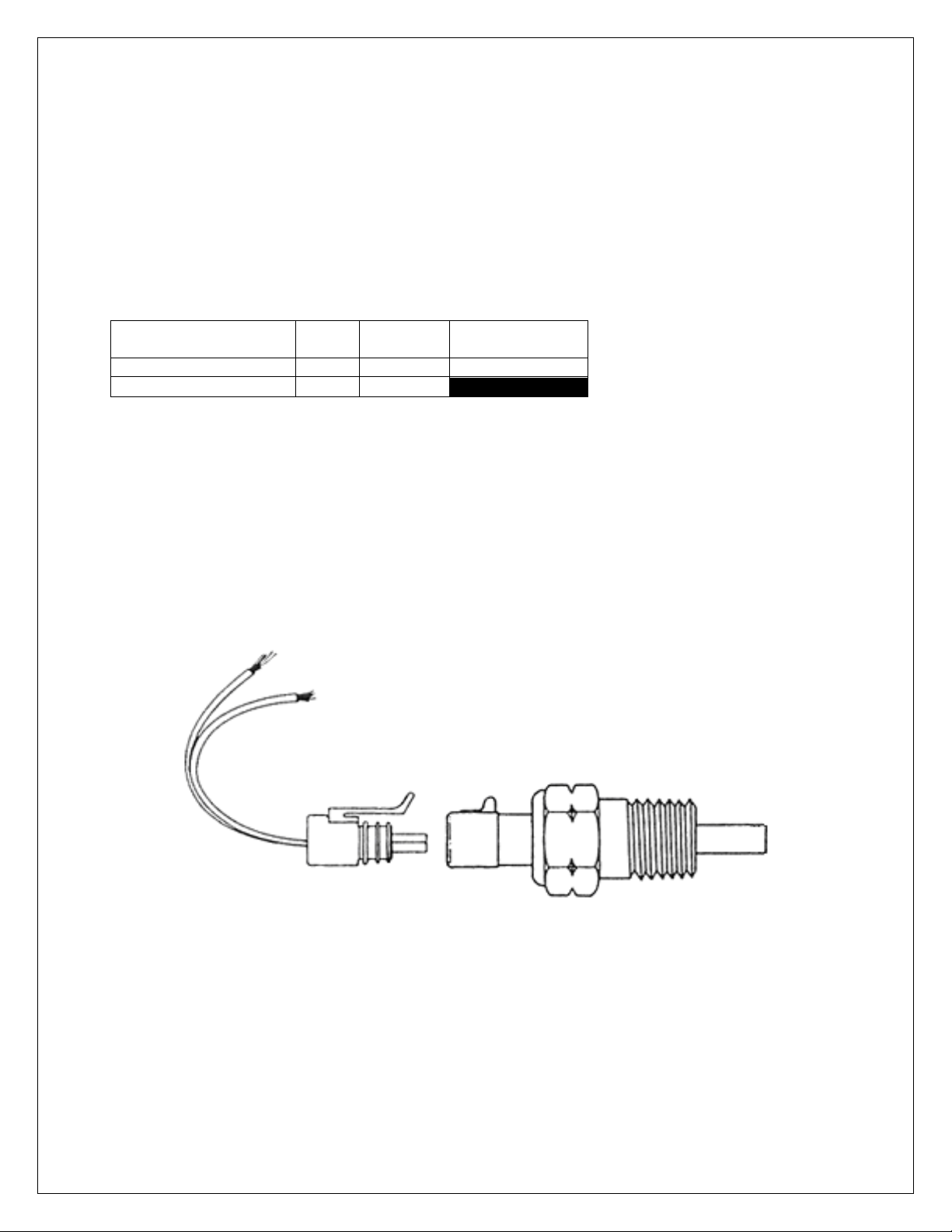

AEM P/N 30-2010 (Optional) Air Temp Sensor kit is specifically designed for temperature

measurements in automotive systems. The kit contains One GM style temperature sensor, one

“6” Flying Lead” mating connector assembly and a weld in aluminum bung.

Air Temperature Sensor Diagram

Housing Material: Brass with 3/8” NPT Thread (Torque to 25 Ft-Lbs)

Elec. Termination: Integral weatherproof connector, Includes mating connector with 6” leads,

18 AWG.

Wiring to your EMS: Polarity does not matter. Connect one wire to harness AIR TEMP lead

and the other to harness SIG GND lead.

Page 27 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 28

Name

Wire

Wire

Color

Stamping

Coolant Temp Sensor

22

White

COOLANT

Sensor Ground

22

Black

SIG GND

Water Temp Sensor

Harness Connections

Water Temperature Sensor Harness Connections

COOLANT – Connect to sensor signal

SIG GND – Connect to sensor ground

AEM P/N 30-2011 (Optional) Water Temp Sensor kit is specifically designed for temperature

measurements in automotive systems. The kit contains One GM style temperature sensor, one

“6” Flying Lead” mating connector assembly and a weld in aluminum bung.

Water Temperature Sensor Diagram

Housing Material: Brass with 3/8” NPT Thread (Torque to 25 Ft-Lbs)

Elec. Termination: Integral weatherproof connector, Includes mating connector with 6” leads,

18 AWG.

Wiring to your EMS: Polarity does not matter. Connect one wire to harness COOLANT lead

and the other to harness SIG GND lead.

Page 28 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 29

Crank Sensor

Crank Sensor Basics

The crank sensor is used to calculate engine speed, ignition timing and injection phasing

angles. It senses a toothed wheel (reluctor wheel, reluctor ring, etc.) and converts this pattern

into a voltage/frequency signal that the EMS uses for basic calculations. Either on its own, or

combined with the cam position sensor, it is the most important input to the system. There are

two basic types of crank sensors, variable reluctance (VR or “mag”) and hall-effect.

VR Sensor raw voltage signal

Page 29 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 30

Hall Effect voltage signal

The internal circuitry on the EMS is different depending on what type of sensor is being used.

Note that there are two different inputs on the EMS for crank and cam position. One for a Hall

Effect type pickup. The other for a VR or “mag” pickup.

The EMS-4 crank sensor VR inputs go through a signal conditioning chip on the circuit board

that converts the raw (zero crossing) signal into a clean 0-5V square wave signal as shown

below. The signal conditioning circuit will invert the significant edges of the raw signal. The

consistent edge of the raw signal in the example below is the rising edge. The conditioning

circuit inverts the signal and creates a falling significant edge.

Page 30 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 31

Internal Signal Conditioning Example

Shows signal conditioning with

edge invert on typical “missing

tooth” style VR crank sensor pattern

Page 31 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 32

Shows signal conditioning with edge

invert on typical evenly spaced VR

crank pattern.

Internal Signal Conditioning Detail

All VR Crank Sensor inputs to the EMS-4 must be connected such that the rising edge of the

raw sensor signal is the consistent zero crossing edge as shown in the examples above.

Failure to do this could result in misfires or ignition timing inaccuracies. Verify data with an

oscilloscope or contact your sensor manufacturer to verify polarity. The crank inputs to the

EMS-4 are contained within a black shielded cable assembly as shown below. Refer to the

EMS-4 System Diagram for more information.

Crank Sensor Input Cable End

Page 32 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 33

Harness Connections

Crank Sensor Ground

28

White

Crank Sensor Mag Input

28

Green

Crank Sensor Hall input

24

Black

+12 volts

24

Red

Cable Shield

---

Crank Sensor Harness Connections

Crank Sensor Mag Input, Green – Connect to VR (+) signal (rising edge zero cross). Not used

for Hall sensor configurations.

Crank Sensor Hall input, Black – Connect to Hall sensor signal. Not used for VR sensor

configurations.

+12 volts, Red – Connect to Hall sensor reference voltage. Not used for VR sensor

configurations. Insulate if not using (hot at key-on).

Crank Sensor Ground, White – Connect to Crank sensor VR (-) or Hall sensor signal ground

Cam Sensor

Cam Sensor Basics

The cam sensor is used to calculate engine position. It is necessary for sequential fuel

calculations. It senses a toothed wheel (reluctor wheel, reluctor ring, etc.) and converts this

pattern into a voltage/frequency signal that the EMS uses for basic calculations. Combined with

the crank position sensor, it is one of the most important inputs to the system. There are two

basic types of cam sensors, variable reluctance (VR or “mag”) and hall-effect.

All VR Cam Sensor inputs to the EMS-4 must be connected such that the rising edge of the raw

sensor signal is the consistent zero crossing edge as shown in the examples above. Failure to

do this could result in misfires or ignition timing inaccuracies. Verify data with an oscilloscope or

contact your sensor manufacturer to verify polarity. The crank inputs to the EMS-4 are

contained within a black shielded cable assembly as shown below. Refer to the EMS-4

System Diagram for more information.

Page 33 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 34

Cam Sensor Ground

28

White

Cam Sensor Mag Input

28

Green

Cam Sensor Hall

24

Black

+12 volts

24

Red

Cable Shield

---

Cam Sensor Input Cable End

Harness Connections

Cam Sensor Harness Connections

Cam Sensor Mag Input, Green – Connect to VR (+) signal (rising edge zero cross). Not used

for Hall sensor configurations.

Cam Sensor Hall, Black – Connect to Hall sensor signal. Not used for VR sensor

configurations.

+12 volts, Red – Connect to Hall sensor reference voltage. Not used for VR sensor

configurations. Insulate if not using (hot at key-on).

Cam Sensor Ground, White – Connect to Crank sensor VR (-) or Hall sensor signal ground

Vehicle Speed Sensor (VSS)

Vehicle Speed Sensor Basics

Page 34 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 35

The vehicle speed sensor must be a hall-effect device. It is used to detect wheel speed for use

Name

Wire

Wire

Color

Stamping

VSS Ground

22

Black

PWR GND

VSS Hall Input

22

White

VSS

+12.0 volts

22

Red

PWR

in various EMS-4 software functions.

Harness Connections

Vehicle Speed Sensor Harness Connections

PWR GND – Connect to vehicle speed sensor ground pin.

VSS – Connect to vehicle speed sensor signal pin.

PWR – Connect to vehicle speed reference voltage pin.

Page 35 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 36

DO NOT CONNECT

DIRECT TO BATTERY

Fuel Pump and Idle Air Control Example Circuits

The example above shows proper wiring design for inductive loads like fuel pump relays and

idle air control/boost control solenoids. Note that simple on/off type outputs from the EMS-4 can

be connected to any GPIO output but Pulse Width Modified (PWM) circuits such as those used

for idle control or boost control must be connected to GPIO 5 – 8, pins 14 – 17 on the 36 way

ECU connector. Note that the EMS-4 does not support Stepper Motor idle air control

valves. Do not connect the power side of any actuator (relay, solenoid, etc.) direct to the

battery. Only use switched, fused power as shown above. Refer to the EMS-4 System

Diagram for more information.

Page 36 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 37

Part 2 – AEM Tuner

Software Installation

All current AEM Tuner software installations are available for download from the AEM

Performance Electronics Forum at:

http://forum.aempower.com/forum/index.php

All Software Downloads Link

Click on the All Software & Firmware Downloads forum.

Software Downloads Link

Next click on the AEM Performance Electronics – All Software & Firmware Downloads forum

Software Downloads Link

Next click on the link shown above to reach the official download page. Note that you can

subscribe to this thread to be notified when software updates are released.

Page 37 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 38

Software Installation Revision Notes Example

All current software releases will include a set of revision notes describing feature changes or

additions since the last update.

Page 38 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 39

Software Installation Instructions

Follow the Installation Instructions as outlined above.

After the software installation is complete, click on the AEM Tuner icon to launch the application.

AEM Tuner Shortcut

AEM Tuner

When AEM Tuner launches, the application will begin with a window similar to the one below:

Page 39 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 40

AEM Tuner Environment

Basic Terminology

Calibration File – The calibration file is what the tuner modifies and will be specific to the engine

setup.

Options – Single values that are set by the user to change the operation of an EMS.

Channels - Channels are data for viewing and logging. They are a window to the engine. They

tell you everything the engine is doing and what all of the sensors are seeing. This window is

one of the most valuable tools in helping to tune the engine.

Tables – Tables are two dimensional data sets that define one value as a function of another.

Maps – Maps are three dimensional data sets that define one value as a function of two others.

Tabs – Tabs are screen templates that the user can create and edit to group sets of calibration

data as needed.

Workspace – User defined AEM Tuner configuration settings that include in part: Basic

application preferences, the display settings, the number of tabs displayed and the tab

configuration, color preferences, unit preferences, hot keys, etc.

Page 40 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 41

Item Explanations - Item Explanations provide a brief

description of what the currently selected in the currently

selected Display does, or is used for. So, for example, if the

selected Display was an Options Display, the Item

Explanation would describe the selected Option with that

selected Options Display. For Calibration items (Options

and Tables) this explains how the ECU uses that item to

accomplish a function. For Log items (Channels) this

explains what the value represents to the ECU.

Function Explanations - Function Explanations provide an

in depth explanation of the way Options, Tables and

Channels work together in the ECU to accomplish a

function. Here a function just means anything that the ECU

needs to control. So, for example, firing the fuel injectors is

a function, or controlling a boost control solenoid is a

function. Function explanations are associated with the

selected Display, so selecting a Display is the only way to

change the Function Explanation displayed.

Links - Function Explanations can contain links to the

Calibration and Log items they refer to (Options, Tables,

and Channels). Links are indicated with blue underlined

text, just as the standard hyperlinks in a web browser are.

When the user clicks on a link the item (either Calibration or

Log) the link references will be added to the appropriate

Display on the current Display Sheet and selected, giving it

focus. If that item already exists in a Display on the current

Display Sheet, then the item will just be selected. So, for

example, if the user clicks a link representing the "WG

Base Duty” map (as seen in example of the left) the 3D

Map Display containing that table would be opened (unless

it already existed on the Sheet) and that Display would

become selected.

Option links are treated differently from Table and Channel

links. Instead of just displaying the name of the Option in

the link, its current value from the loaded Calibration is

used, to provide an even more meaningful description of

how your particular car is setup. So if a link is simply a

number, it is an Option link. It can still be clicked just as

Table and Channel links are, and the referenced Option will

be displayed and selected.

Page 41 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 42

Menu Items

Following is a basic description of each menu function.

FILE

Open Calibration - Opens a previously saved calibration file

Open Last EMS Calibration – Opens the last calibration file saved in memory

Open Recent Calibration – Displays a list of recent opened calibrations files. Choose one to

open.

Save Calibration – Saves currently loaded calibration file with the same file name. Only active

when a calibration file is loaded.

Save Calibration As – Saves the currently loaded calibration with the option of changing the

file name.

New Calibration – Creates a new blank calibration file.

Page 42 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 43

Close Calibration – Closes the currently loaded calibration file.

Calibration Notes – Allows the user to enter text that describes the calibration file.

Calibration Notes

Workspace

File-Workspace

Page 43 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 44

Workspace – Open – Opens a previously saved workspace file.

Workspace – Open Recent – Displays a listing of recently opened workspace files.

Workspace – Save – Saves the current workspace file under the same filename.

Workspace – Save As – Saves the current workspace with the option of choosing a new

filename.

Workspace – New – Creates a new blank workspace.

Exit – Closes the AEM Tuner application.

EDIT

Edit Menu

Undo - Undoes the last change made to the loaded calibration. Does not undo changes made

to the workspace or Application Preferences, only the loaded calibration.

Redo - Redoes the last change Undone in the system. Does not redo changes made to the

workspace or Application Preferences, only the loaded calibration.

Copy - Copies the currently selected calibration value from the selected Display into the

system's clipboard. This can be used to copy multiple cells in a 2D or 3D table. In this case the

values are copied in a csv (Comma Separated) format that can be pasted into an Excel

spreadsheet.

Paste - Pastes the value in the system's clipboard to the selected item in the selected Display. It

can be either a number (for Options and Tables), or a set of numbers in csv (Comma

Separated) for tables. If pasting into a table, the number of values in the clipboard does not

need to match the number of cells selected to be pasted into. In this case the values from the

clipboard will be interpolated to fit into the selected cells of a table.

Page 44 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 45

DISPLAY

Display Menu

Display Explorer – Opens a separate window where the user can select options, channels,

tables or maps for use in the current tab. Browse through the list of available displays and

double click on one to add it to the current tab.

Display Explorer

Page 45 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 46

Show Options Full List Display – Opens a display that contains all available options for the

current calibration type. Used for internal AEM diagnostics only.

Show Coils Display – Opens a display that contains selections for activating and configuring

ignition coil outputs.

Coils Display

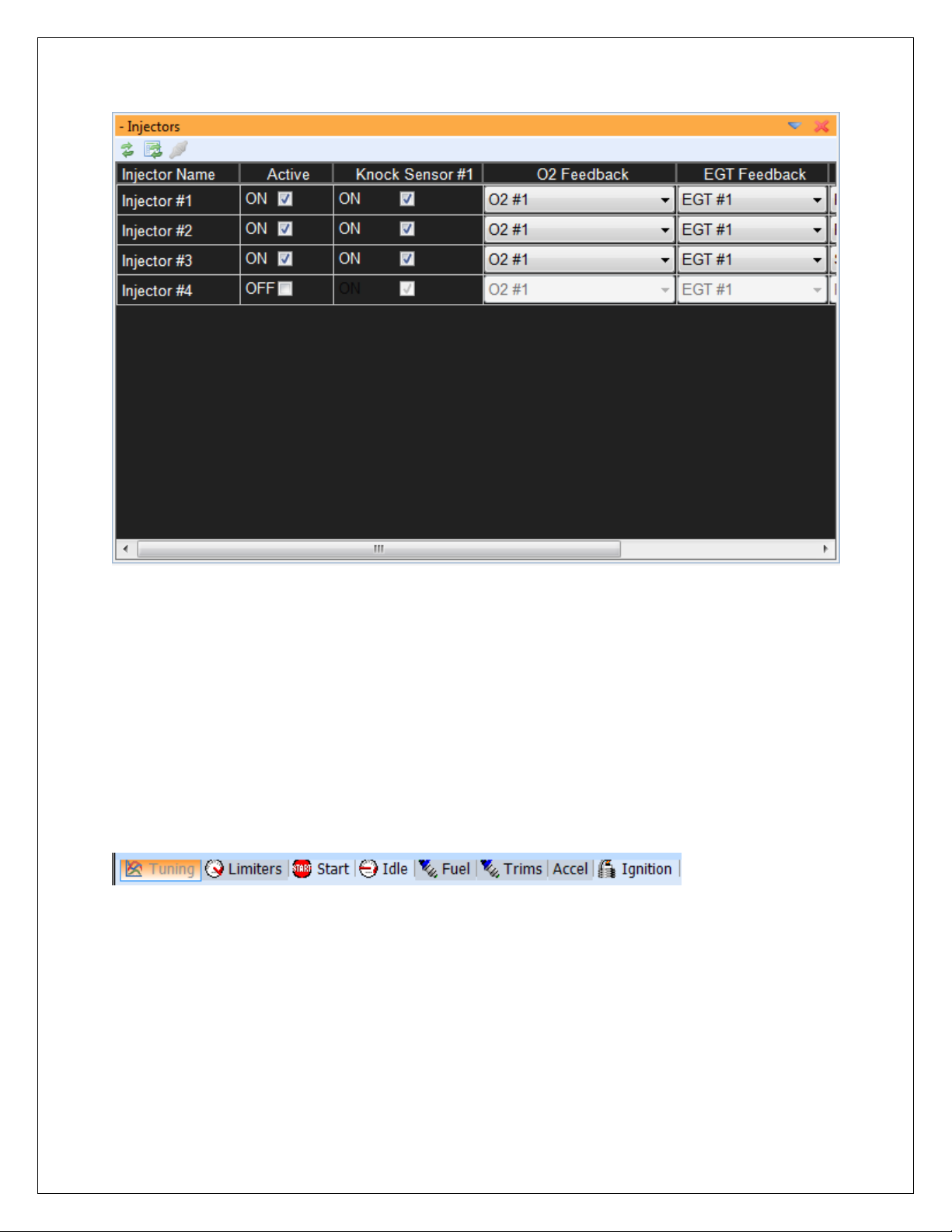

Show Injectors Display – Opens a display that contains selections for activating and

configuring injector outputs.

Page 46 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 47

Injectors Display

Auto Arrange Displays – Automatically organizes the displays within the current tab so that

none are overlapping.

Restore Displays – Restores the workspace settings back to the previously saved settings.

TABS

AEM Tuner Tabs

The Tabs menu item lists all currently saved tabs screen templates. Right clicking in the tab

area of the menu space shown above will bring up the following menu:

Page 47 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 48

Tabs Menu

New tabs can be created. Existing tabs can be renamed hidden or deleted. Currently hidden

tabs can be displayed for re-use and all tab properties can be modified by selecting the Property

item.

Tabs Menu Detail

Tabs are saved as part of the Workspace configuration. Remember to save the workspace to

retain your changes.

Page 48 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 49

ECU

EMS Menu

Connect to ECU – Instructs AEM Tuner to attempt a communications connection with the EMS

hardware.

Disconnect – If connected, instructs AEM Tuner to close the communications connection with

the EMS.

Upload Calibration – Loads a new calibration file into the EMS.

Page 49 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 50

Upload Calibration Dialog

Click the Browse button to select a calibration file. Note that the calibration firmware version

must match the EMS firmware version. The current EMS version is displayed at the top of this

window. An optional check box labeled Download EMS‟s Calibration First allows the currently

loaded calibration file to be saved prior to loading the new one. When the desired calibration file

is chosen, click on the Go button to load it into the EMS. Follow the on-screen instructions and

cycle power afterwards.

Set Password – Allows the user to define a password for the EMS calibration. Must be

connected to an EMS for this function to become available.

Page 50 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 51

Set Password Dialog

Clear EMS Calibration – Clears the currently loaded calibration from EMS memory.

Upload EMS Firmware – Allows the user to update the EMS firmware to the most current

revision. Follow the on-screen instructions to complete the upgrade. Note that a new

calibration compatible with the new firmware version is required to complete the process.

Clear EMS Firmware – Clears the currently loaded firmware version. Follow the on-screen

instructions to complete the process.

EMS Connection Preference – Allows the user to choose how AEM Tuner will connect with the

EMS. Note that EMS-4 systems do not have a serial port connection capability.

Page 51 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 52

EMS Connection Preference Dialog

LOGGING

Logging Menu

Start PC Logging – (F6 Hotkey) will log data from all channel displays in the active tab.

Cancel PC Logging – (F8 Hotkey) will stop logging and discard the file.

Stop and Save – (F7 Hotkey) will stop logging and prompt the user to save the logged file.

EMS Internal Logging Setup – Opens a dialog window that allows the user to configure the

internal logging settings of the EMS.

Page 52 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 53

EMS Internal Logging Setup Dialog

Logging Conditions

Logging Conditions – Defines the activation criteria for the internal logging function.

Logging is Off – Internal logging function is disabled.

Logging is Always On – When the EMS is powered up, the logger is logging.

Page 53 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 54

Logging is on when engine is running – When engine speed is greater than 0, data will be

logged.

Logging is on when the vehicle is moving – When the vehicle speed is greater than 0, data will

be logged. Note that this setting requires a properly configured vehicle speed sensor.

Logging is on at full throttle – Data will be logged at wide open throttle only.

Logging is on with custom conditions – Logging activation is determined by the following

settings:

Logging Custom Conditions

Log Switch Settings

Select Use Switched Input to define a log activation switch input from the drop down list.

Page 54 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 55

Internal Logging Memory Control

Select Loop Logging to continue logging after all memory is used. Only the oldest data will be

lost when the log loops.

Use the slider to select the logging rate. The rate, channels selected and EMS logging memory

capacity will be used to estimate the log run time.

Download EMS Log Menu Item

Download EMS Log – Select this item when connected to the EMS to download the current

logged data file.

Open AEMLog – Select this item to Open AEMLog data analysis software.

Page 55 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 56

TOOLS

Tools Menu

Configure Output Dialog – Used to define the activation criteria for EMS configurable outputs.

Configure Outputs Dialog

Page 56 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 57

GPIO General Purpose Activation

To activate an output for a General Purpose Function, double click on the output function

row/column cell adjacent to the output name as shown. Select General Purpose from the drop

down list then hit the ENTER key to confirm.

Output Activation Criteria

Under Pin Configuration, check the Enable Pin box to activate the output. The Switch Input

drop down selection allows the user to select a switch input to manually activate the output.

Note that the general pin conditions must also be met in addition to the switch input status for

Page 57 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 58

the output to activate. To control the output using only the pin conditions, select Ignore Switch

Input and set the activation conditions as needed. In the example above the following

conditions must be true for the output to turn on:

RPM greater than 0

Engine Load greater than -14.40 psig

Throttle Position greater than 0%

Road Speed (Vehicle Speed) greater than 0

Coolant Temperature greater than -198 deg F

Configure Telemetry Dialog – Allows the user to select custom settings for serial or CAN

telemetry output. Note that the EMS-4 systems do not support serial comms or telemetry.

EMS-4 systems communicate with the PC using USB only.

Telemetry Setup Menu Items

Calibration Compare Tool – Will compare two calibrations and allow the user to copy settings

from one to the other.

Compare With Calibration Menu Item

The calibration compare tool will compare the currently loaded calibration with a second one

chosen by the user. With a calibration opened in AEM Tuner, the first step is to select the

second calibration.

Page 58 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 59

Compare - Open File Window

Calibration Compare Dialog

The tool will allow the user to choose and copy selected options, tables or maps values from the

“Compared Calibration” to the currently opened calibration.

Compare Calibration Detail

Page 59 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 60

The tabs at the top of the window allow the user to select between different types of data,

options, tables or maps.

To copy a value, highlight it and click Copy Selection. Alternatively, all items can be copied at

once by clicking the Copy All button.

Convert Current Calibration Tool – Will convert a calibration created in one EMS version to

another EMS version. Calibration versions must match the version of software installed in the

EMS. Software installed in the EMS is also referred to as firmware. The EMS firmware is

constantly being upgraded and improved. When AEM releases a new version of firmware, the

convert calibration tool allows customers to convert a previously tuned calibration so it is

compatible with the new firmware revision.

Convert Calibration Menu Item

Page 60 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 61

Configure Conversion Dialog

The first step is to choose the EMS version to convert the current opened calibration into. There

are two different types of conversions, Auto and Manual. Manual conversions are usually for

internal AEM use but these can also be accomplished by experienced users as well. Auto

conversions employ a conversion script provided with the new firmware release. The

conversion script simplifies the process limiting the number of decisions the user must make

during the conversion process.

Preferences – The preferences tool is used to define many AEM Tuner application specific

preferences.

Page 61 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 62

Tools - Preferences Menu Item

Unit Preferences

The first preference category allows the user to select their preferred units. This selection

defines what units will be used in channel displays and logged data for each type.

Unit Preferences Detail

The right hand column in this dialog includes drop down selection lists. Left click to activate the

drop down then select from the list.

Page 62 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 63

Display Preferences

The display preferences dialog includes basic color and font preferences for use in AEM Tuner.

Experiment to find what works best. This dialog also includes preferences for Live Tracing.

Live Tracing is used in maps to graphically highlight the areas of the map the EMS is accessing

at any given point in time. This is only active when the EMS is powered up and connected to

the PC.

Page 63 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 64

Hotkey Preferences

Hotkeys are time saving tools and are extremely useful. The Hotkeys preference dialog allows

the user to have complete control over the Hotkeys defined for almost any action. Many

standard Hotkeys are pre-defined. All can be modified by the user. To add a new Hotkey to

one of the action items in the list or to modify an existing Hotkey, highlight the action item then

type the preferred Hotkey into the box below:

Hotkey Detail

To define a Hotkey using the Control + I combination, click inside the Hotkey box and type

Control + I then click the Modify button to activate the change.

Page 64 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 65

Logging Preferences

There are two types of logging, Internal Logging and PC Logging. The system can be

configured to always log to the PC when the PC is connected to the EMS by selecting the first

checkbox in the window above. The second checkbox allows the user to always delete the log

file saved internally to the EMS after downloading. Otherwise, a copy is downloaded and the

original is retained in EMS memory. Standard log file names for both types of logging can also

be configured in this window.

Page 65 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 66

Calibration Edit Preferences

When the first checkbox in the window above is selected, the ENTER key must always be

pressed to confirm calibrations changes. This is the default configuration.

The Auto-Rescale selection allows AEM Tuner to continuously optimize the resolution in the

main fuel map and crank injector time table. Default setting for this selection is ON.

Page 66 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 67

Quick Tune Preferences

The quick tune feature allows AEM Tuner to automatically calculate main fuel map changes

necessary to minimize the O2 correction value.

Page 67 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 68

Application Preferences

The application preferences dialog controls settings related to Workspace, Calibration Files and

Tabs loading. It also allows the user to enable or disable the application updates feature.

When the Check for Application Updates at Startup is selected, AEM Tuner will connect to the

internet and notify the user of software or calibration file updates from AEM.

Page 68 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 69

WIZARDS

Wizards Menu Item

Setup Wizard – Contains pre-defined options, tables and maps to configure a calibration file for

a certain purpose. Applying a Setup Wizard modifies the currently opened calibration file.

Setup Wizards can be used to apply the proper battery offsets for fuel injectors or select the

proper settings for a certain manifold pressure, air temperature or coolant temperature sensor.

AEM is constantly adding to the list of available Setup Wizards for each EMS type.

Page 69 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 70

Setup Wizards

To use a Setup Wizard, select a Wizard type then either double click on the desired settings or

click once and hit the Apply button.

In addition to the generic Setup Wizard shown above, there are several specific Wizards used to

accomplish certain tasks.

Set Throttle Range Wizard – The useable range for the TPS sensor must be defined in the

calibration file accurately. The Set Throttle Range Wizard automates this process.

Set Throttle Range Wizard

The PC must be connected to the EMS. With the throttle in the full closed position, monitor the

TPS Volts value in the window above. Minimum TPS voltage is usually 0.5 – 1.0 volts. Click

the Set TPS Volts Min button. Next push the throttle to the wide open position. Monitor the

TPS Volts value. Maximum TPS voltage is usually 4.0 to 4.5 volts. With the throttle held open,

Push the Set TPS Volts Max button. Close the window. The throttle is now calibrated.

Page 70 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 71

Ignition Timing Sync Wizard – The purpose of the Timing Sync Wizard is to synchronize the

actual ignition timing with the value commanded by the EMS.

Ignition Timing Sync Wizard

The PC must be connected to the EMS and the engine must be running. To minimize ignition

timing fluctuation, the timing from the EMS can be locked at a given setting. Select or type in a

value then click the Lock Ignition Timing at checkbox. Next measure the ignition timing at the

balancer with a timing light and compare the actual reading to the commanded “locked” value.

If they differ, use the Advance or Retard Timing buttons to adjust the actual value until it

matches the locked timing value.

Change Injector/Pressure Wizard – If the fuel pressure setpoint is adjusted or if different size

injectors are installed on an engine that was previously tuned, the injector/pressure wizard can

be used to automatically compensate for this change.

Page 71 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 72

Change Injector/Pressure Wizard

Enter the original (old) injector size and pressure setting and the new settings. AEM Tuner will

automatically adjust the calibration to account for these changes.

Configure Gear Ratio Wizard – The gear ratio can be calculated based on a ratio of engine

speed to vehicle speed. Once the gear ratio is calculated, the data can be used to define a gear

position table based on calculated gear ratio. This wizard automates the process.

Page 72 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 73

Configure Gear Ratio Wizard

The EMS must be powered up and the PC must be connected. WARNING! This procedure

should be completed on a chassis dynamometer to ensure safety. The driven wheels must be

rotating to generate a suitable vehicle speed signal. Follow the on-screen instructions. Select

Engine Speed for GearCal Spd 1 and Vehicle Speed for GearCal Spd 2. Note that certain plug

and play applications may have different settings but these will be pre-configured in the base

calibration. While driving in each gear, click the Gear 1 – 7 buttons to sample data. When all

gears are sampled, click the Set to Gear Ratio Table button to finalize the process.

Staged Injection Wizard – This wizard is used to determine the flow ratio between the primary

and secondary injectors and to account for differences in fuel type, fuel pressure or number of

injectors.

Page 73 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 74

To use the wizard, enter the number of primary and secondary injectors, the flow rate of each

(as measured in the same units) and the stoichiometric ratio of the fuel used for each. Click the

OK button to complete the process.

Note that there are still certain settings necessary to completely define a staged injection

setup. These will be covered later in this manual.

LIVE TRACING

Live Tracing Menu

Page 74 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 75

Main Fuel Map showing Live Tracing

Live Trace

The Live Trace features displays a brief “history” of where the EMS has been accessing tuning

data from a map.

Stop Live Tracing – Stops Live Tracing if currently running.

Clear Live Tracing – Clears the current Live Trace saved in Memory.

Show Live Tracing – Displays the currently saved Live Trace.

Toggle Live Tracing Mode – Toggles between the two available Live Tracing modes, auto

fading with trail length or no fading. See also Tools – Preferences – Display.

HELP

Help Menu

Tuning Explanation – Toggles On/Off the Item Explanation pane on the right hand side of the

AEM Tuner window.

Page 75 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 76

Program Guide – Opens the on-line help file.

Check Updates – If connected to the internet, AEM Tuner will contact the AEM servers and

download any available software or calibration file updates.

AEM Tuner Updates Feature

Click the Download and Install button to save the files. Calibration file updates are automatically

saved in the AEM Updates folder as shown below:

Page 76 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

Page 77

About AEM Tuner – Displays the installed version and build date:

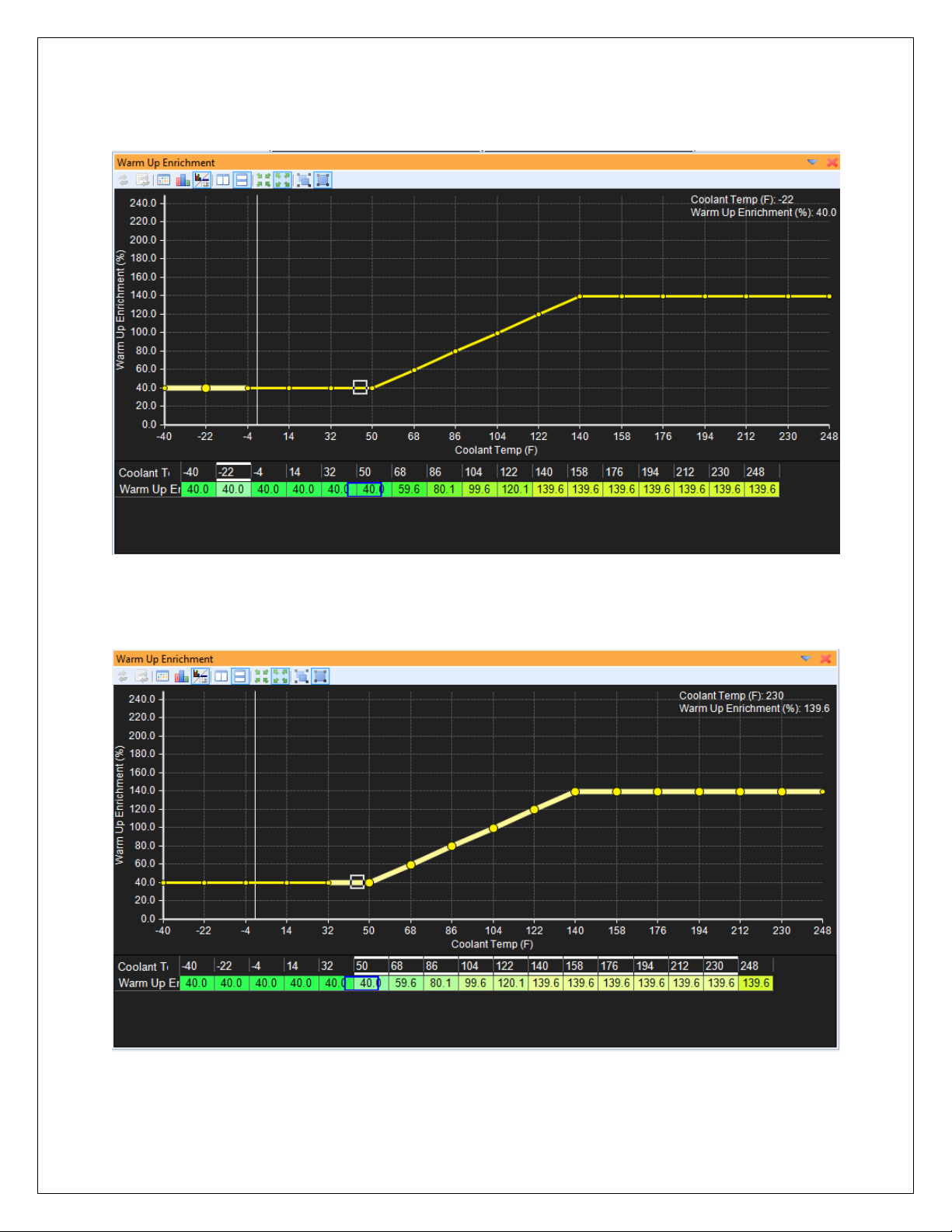

Editing EMS Calibration Files