Page 1

TIMELINE

1894 Orville Gibson of Kalamazoo, MI, invents the

archtop guitar and mandolin

1902 The Gibson company formed

1921 Gibson invents the adjustable truss rod –

still the industry standard – and the height

adjustable bridge

1935 Gibson’s first electric model, the E-150 Hawaiian

lap steel

1936 First standard Gibson electric, the ES-150

(“ES” stands for Electric Spanish)

1939 First cutaway Gibsons – Super 400 Premier and

L-5 Premier

1946 The P-90 single-coil pickup debuts

1949 First three-pickup guitar, the Gibson ES-5

1949 First guitar with a “Florentine” pointed cutaway,

the Gibson ES-175

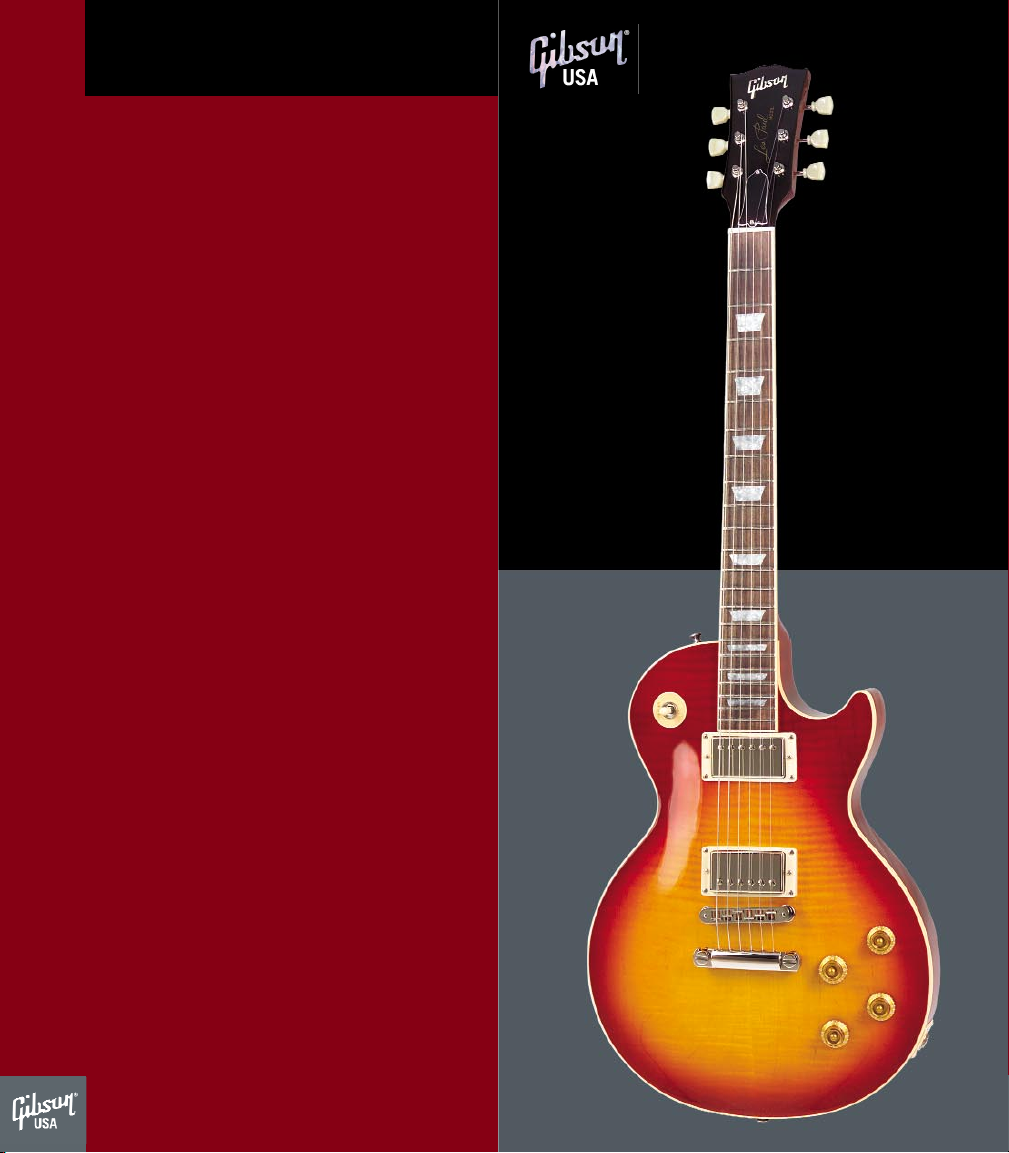

1952 Gibson’s first solidbody electric, the Les Paul Model

1954 Les Paul Custom “Black Beauty” and Les Paul

Junior officially introduced

1954 Tune-o-matic bridge, designed by Gibson president

Ted McCarty, introduced on Les Paul Custom

1955 Les Paul Special introduced

1957 Double-coil “humbucking” pickup debuts, invented

by Gibson’s Seth Lover

1958 First cherry sunburst finish on Les Paul Model,

name changed to Les Paul Standard

1958 Explorer, Flying V and Moderne introduced,

designed by Ted McCarty

1958 First semi-hollowbody electric guitar, the ES-335,

invented by Ted McCarty

1959 Les Paul Special gets double-cutaway body

1961 Les Paul line changes to SG body shape

1963 SG model name is official, Les Paul name dropped

1963 Firebird guitars and Thunderbird basses introduced

1968 Les Paul Standard and Custom reintroduced

1974 Gibson opens a plant in Nashville to make Les Pauls

1982 First solidbody acoustic, the Gibson Chet Atkins CE

1984 Gibson closes Kalamazoo plant, moves headquarters

to Nashville

1986 Current owners Henry Juszkiewicz and

Dave Berryman acquire Gibson

2002 Gibson introduces world’s first digital guitar

FEATURES

FACTS

ADVANTAGES

A RETAIL SALES GUIDE FOR

GIBSON

SOLIDBODY

GUITARS

ELECTRIC

A RETAIL SALES GUIDE FOR

GIBSON

SOLIDBODY

GUITARS

ELECTRIC

Page 2

PICKUPS

★ Gibson invented the double-coil humbucking

pickup

AD

Still setting the standard followed by other makers

★ Many choices of magnets and coil-winding

configurations

AD

Smooth to edgy tone, and everything in between

★ 2-wire or 4-wire

AD

Vintage wiring or modern (with coil-split capability)

★ Tight fit between polepieces and hand-machined

baseplate

AD

No lost vibrations, minimizes feedback

WELCOME TO GIBSON USA’S RETAIL

SALES GUIDE, A QUICK AND CONCISE

REFERENCE OF SALES TIPS.

Sales tips are organized by feature.

Under each feature are the facts or

specs of that feature, designated by ★.

Under each fact, designated by AD,

is the advantage to the player.

FEATURE

★ Fact

AD

Advantage

24.75" SCALE

★ Less string tension required to tune up

AD

Smooth, slinky feel

★ Allows for heavier-gauge strings

AD

Beefier tone

★ Frets spaced slightly closer together

AD

Easier to do the Chuck Berry rhythm part

(on E chord)

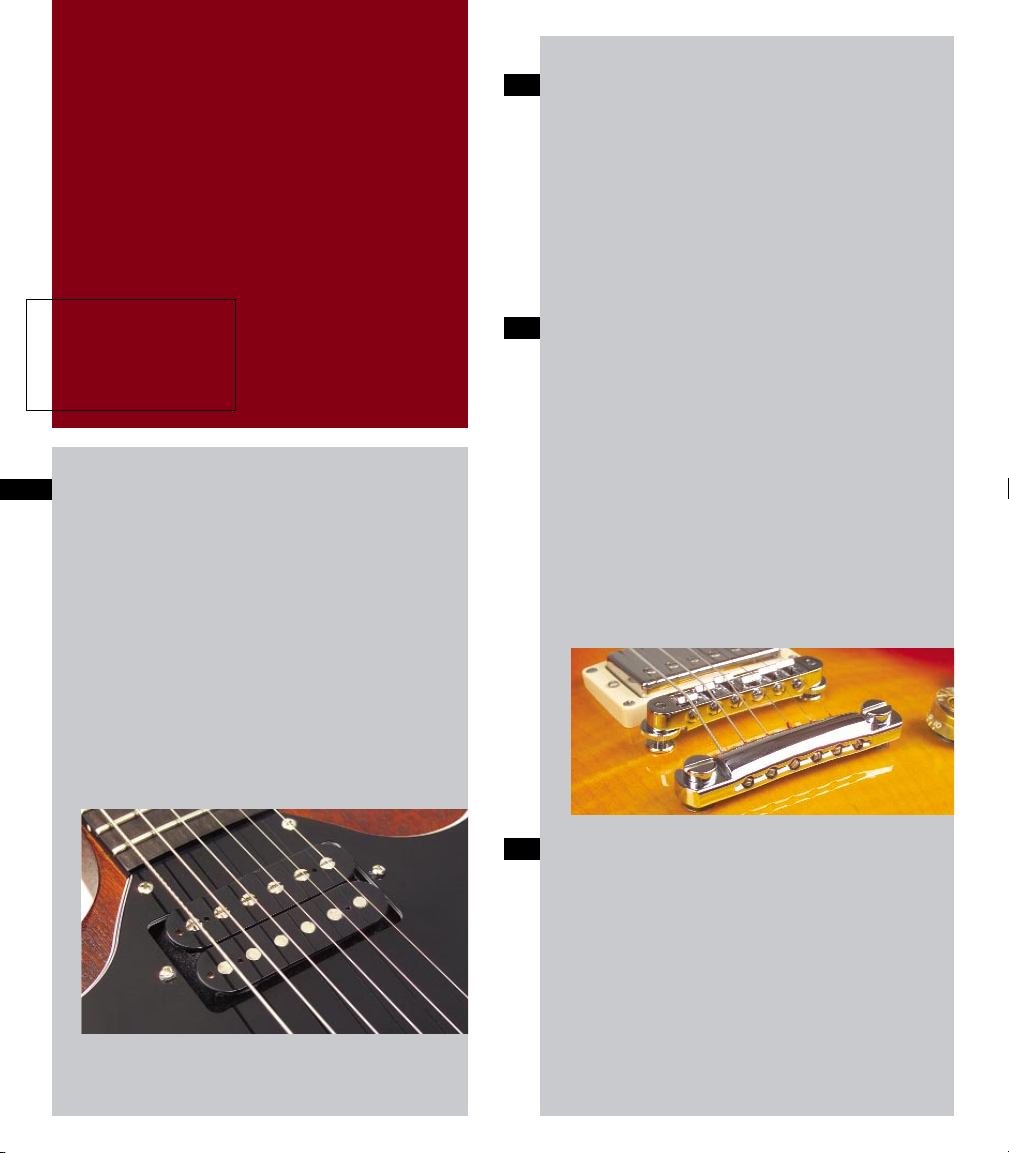

TUNE-O-MATIC BRIDGE

INVENTED BY LEGENDARY GIBSON PRESIDENT

TED MCCARTY IN 1954

★ Adjustable saddles

AD

Fine-tune intonation for each individual string,

for any string gauge or action height

★ Overall height-adjustable

AD

Easy adjustment to raise or lower action

AD No individual string adjustment necessary to

conform to fingerboard radius

★ Industry standard

AD

Copied by other makers, never equaled

STOPBAR TAILPIECE

INVENTED BY GIBSON IN 1953

★ Separate from bridge

AD

Does not transfer bridge vibrations to body,

better sustain

★ Height-adjustable

AD

Adjust downward to increase string pressure on

saddles = less slippage, more sustain

AD Adjust upward for less string pressure = “slinky”

or “spongy” feel when bending strings

Page 3

SET NECK

(EXCEPT “NECK-THRU” FIREBIRD MODELS)

★ Glued neck joint – not bolted or screwed – for

maximum contact between neck and body

AD

Neck and body function as single unit = better

tone, better sustain

★ No air space in neck cavity

AD

No loose or misaligned neck = no “shimmy” or

tuning problems

ANGLED HEADSTOCK

★ Strings cross nut at an angle of up to

17 degrees, increasing string pressure

AD

No loss of vibration of strings between nut and

tuners = better sustain

AD Strings stay in nut slots (no buzz)

AD No need for “string trees” or “string guides” to

compensate for bad headstock design

BINDING

VERY LABOR INTENSIVE, BUT MAKES

A GUITAR LOOK BETTER. AND…

★ Protects edges

AD

Fewer dings in areas most susceptible to damage

★ Neck binding installed over fret ends (most makers

install frets after binding, exposing fret ends)

AD

Smooth neck, no cut hands

LACQUER FINISH

NITROCELLULOSE LACQUER (MULTIPLE COATS

ON MOST MODELS) INSTEAD OF POLYURETHANE

USED BY MOST GUITAR MANUFACTURERS, USED

BY GIBSON ON ALL MODELS SINCE 1894

★ Repairable

AD

Scratches and dings can be touched up. A poly

finish can NOT be touched up.

★ Porous nature

AD

Does not “seal” wood in an airtight shell as poly

does, lets wood breathe = better tone

★ Dries to a thinner coat than poly

AD

Less interference with natural vibration of

instrument = purer tone

EQUILIBRIUM MOISTURE CONTENT

★ Wood is dried to a point of “equilibrium”–

determined by the temperature and humidity of

the factory – where the moisture content does

not change during the manufacturing process

AD

Tight-fitting joints, no expansion, shrinkage or

warping

★ All wood has same moisture content

AD

After leaving plant, guitar responds evenly to

temperature and humidity changes

Page 4

PICKUPS

PICKUPS MAGNET DESCRIPTION

490 Alnico II classic design, upper-mid boost

498 Alnico V classic design, hotter magnet

496 ceramic hot sound, neck position

500 ceramic super hot, USA’s highest output

Angus Young Alnico V high output

’57 Classic Alnico II vintage specs, matched bobbin windings

’BurstBucker 1 Alnico II “unmatched” bobbin windings,

slightly underwound

’BurstBucker 2 Alnico II “unmatched” bobbin windings,

same range as ’57 Classic

’BurstBucker Pro Alnico V neck and bridge, like BB 1 and

2 with hotter magnet

Mini humbucker Alnico II cutting sound

’BURSTBUCKER PRO (NECK)

’BURSTBUCKER PRO (BRIDGE)

’BURSTBUCKER TYPE 1

’BURSTBUCKER TYPE 2

’BURSTBUCKER TYPE 3

’57 CLASSIC

’57 CLASSIC PLUS

TONY IOMMI

ANGUS YOUNG

DIRTY FINGERS

490R

490T

498T

500T

496R

MINI HUMBUCKER

P-90

P-94R

P-94T

RELATIVE OUTPUT

“We dry wood to below 7% moisture content,”

as some guitarmakers claim, is a meaningless

statement. Wood should be dried to a level of

“equilibrium” – where it neither gains nor loses

moisture content – and that level depends on

the temperature and humidity of the facility.

GREEN – At Gibson USA, we maintain humidity at

45%. At a temperature of 70 degrees, wood reaches

the equilibrium level at 8.5% moisture content. Any

lower or higher, and the wood will not be stable.

YELLOW – “We dry below 7%.” If “below 7%” gets

down to 6.5%, then this guitarmaker needs to

keep his plant at 35% humidity with a temperature

of 100 degrees.

RED – A guitar maker in a dry climate, with a

humidity level of 25%, needs to dry wood even

farther – below 6% – to reach equilibrium.

EQUILIBRIUM MOISTURE CONTENT TABLE

30˚ F 40˚ F 50˚ F 60˚ F 70˚ F 80˚ F 90˚ F 100˚ F 110˚ F 120˚ F

1.1˚ C 4.4˚ C 10.0˚ C 15.5˚ C 21.1˚ C 26.6˚ C 32.2˚ C 37.7˚ C 43.3˚ C 48.8˚ C

5% 1.4 1.4 1.4 1.3 1.3 1.3 1.2 1.2 1.1 1.1

10% 2.6 2.6 2.6 2.5 2.5 2.4 2.3 2.3 2.2 2.1

15% 3.7 3.7 3.7 3.6 3.5 3.5 3.4 3.3 3.2 3

20% 4.6 4.6 4.6 4.6 4.5 4.4 4.3 4.2 4 3.9

25% 5.5 5.5 5.5 5.4 5.4 5.3 5.1 5 4.9 4.7

30% 6.3 6.3 6.3 6.2 6.2 6.1 5.9 5.8 5.6 5.4

35% 7.1 7.1 7.1 7 6.9 6.8 6.7 6.5 6.3 6.1

40% 7.9 7.9 7.9 7.8 7.7 7.6 7.4 7.2 7 6.8

45% 8.7 8.7 8.7 8.6 8.5 8.3 8.1 7.9 7.7 7.5

50% 9.5 9.5 9.5 9.4 9.2 9.1 8.9 8.7 8.4 8.2

55% 10.4 10.4 10.3 10.2 10.1 9.9 9.7 9.5 9.2 8.9

60% 11.3 11.3 11.2 11.1 11 10.8 10.5 10.3 10 9.7

65% 12.4 12.3 12.3 12.1 12 11.7 11.5 11.2 11 10.6

70% 13.5 13.5 13.4 13.3 13.1 12.9 12.6 12.3 12 11.7

75% 14.9 14.9 14.8 14.6 14.4 14.2 13.9 13.6 13.2 12.9

80% 16.5 16.5 16.4 16.2 16 15.7 15.4 15.1 14.7 14.4

85% 18.5 18.5 18.4 18.2 17.9 17.7 17.3 17 16.6 16.2

90% 21 21 20.9 20.7 20.5 20.2 19.8 19.5 19.1 18.6

95% 24.3 24.3 24.3 24.1 23.9 23.6 23.3 22.9 22.4 22

98% 26.9 26.9 26.9 26.8 26.6 26.3 26 25.6 25.2 24.7

RH (RH= RELATIVE HUMIDITY %)

Loading...

Loading...