Page 1

ÖKO−FAVORIT 55750

Dishwasher

Instructions for use

Page 2

Dear Customer

Please read these operating instructions carefully.

Please make sure you read the safety instructions on

the first pages of these operating instructions! Keep

the operating instructions for future reference. Pass

them on to any future owners.

With the warning triangle and/or by means of

key words (Caution!, Important!), informa−

tion is emphasized which is important for your

safety or the correct functioning of the ap−

pliance. It is essential that this information is

observed.

1. This symbol guides you step by step when operating

the appliance.

2. . . .

3. . . .

Next to this symbol you receive additional in−

formation and practical tips on using the ap−

pliance.

Tips and information about the economical

and environmentally friendly use of the ma−

chine are marked with the clover.

These operating instructions contain information ab−

out how to independently solve any problems which

may arise. See "Remedying faults".

Please also take note of the contents of the «Service»

section.

2

Page 3

Content

Safety Instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of the Appliance 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Hints & Tips 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prior to Using for the first Time 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filling with rinse 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the rinse dosage 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filling the salt dispenser 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Water Softener 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The first wash cycle 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crockery Basket 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cutlery basket 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower basket 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper basket 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filling with detergent 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting and starting the program 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program display 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remaining running time 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End of the program 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety lock 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delay start 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Correcting or Deleting the Program Selection / Pre−selected Start Time 17. . . . . . . . . . . . . . . . . . . . . .

ECO button 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Chart 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mains power loss 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error message 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading the crockery basket 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and care 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Cleaning 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re−filling the salt dispenser 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refilling the rinse aid 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the large strainer 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the fine strainer 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the spray arm nozzles 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the appliance 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appliances with stainless steel outer surfaces 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remedying faults 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service & Spare Parts 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Care 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Directives 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Instructions UK 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Supply Connections 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water outlet hose connection 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connection 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly Instructions for the Side Rail Assembly Kit 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Information for Test Institutes 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Page 4

Safety Instructions

The safety aspects of this appliance comply with the accepted technical standards and the applicable safety regula−

tions. Nevertheless, we consider it our obligation to make you aware of the following safety information:

Installation

• Any electrical work required to install this appliance

should be carried out by a qualified electrician or

competent person.

• Any plumbing work required to install this ap−

pliance should be carried out by a qualified plumber

or competent person.

• This appliance is heavy. Care should be taken when

moving it.

• It is dangerous to alter the specifications or attempt

to modify this product in any way.

• Care must be taken to ensure that the appliance

does not stand on the electrical supply cable.

Child Safety

• This appliance is designed to be operated by adults.

Children should not be allowed to tamper with the

controls or play with the product.

• Keep all packaging well away from children.

• Keep all detergents in a safe place out of children’s

reach.

• Keep children away from the appliance when the

door is open, and take care when closing the door

not to trap childrens fingers.

Before Use

• Check your dishwasher for any transport damage.

Never connect a damaged appliance. If your ap−

pliance is damaged contact your retailer.

• Before using your dishwasher for the first time, en−

sure the voltage and current rating in your home is

the same as indicated on the rating plate.

During use

• Items that are contaminated by petrol paint, steel

or iron debris, corrosive, acidic or alkaline chemicals

must not be washed in this dishwasher.

• Under no circumstances should you open the door

whilst the appliance is in operation. Always turn off

the appliance before opening the door.

• Only use detergent specifically designed for use in

dishwashers.

• Long bladed knives stored in an upright position are

a potential hazard.

• Long and/or sharp items of cutlery such as carving

knives must be positioned horizontally in the upper

basket.

• When finished loading or unloading close the door,

as an open door can be a hazard.

• Isolate the appliance from the power supply and

turn off the water supply after use.

• Care should be taken when cleaning the bottom

door seal and hinge area as any exposed metal ed−

ges may cut if care is not taken.

• This product should be serviced by an authorised

Service Engineer, and only genuine spare parts

should be used.

• Under no circumstances should you attempt to re−

pair the machine yourself. Repairs carried out by in−

experienced persons may cause injury or serious

malfunctioning. Contact your local Service Force

Centre.

• In the case of a fault, turn off the appliance, discon−

nect the appliance from the water supply and con−

tact your local Service Force Centre.

• Never sit or stand on the open door.

• If the power supply cable of your dishwasher is da−

maged, it must be replaced by a cable available from

your local Service Force Centre.

• The water protection system prevents any water da−

maged providing:

− The dishwasher is connected to the mains sup−

ply.

− The dishwasher is correctly installed.

4

Page 5

Environmental Information

Packaging: All packing materials used are environmen−

tally friendly and reusable. The cardboard parts are

made from recycled paper, and the wood parts are un−

treated. The plastics are marked as follows:

"PE" for polyethylene − e.g. packaging foil

"PS" for polystyrene

"POM" for polyoxymenthylene

Old appliances: When disposing of an old appliance,

cut off the power supply cable and remove any door

catches, to prevent young children being trapped in

side.

Contact your local Council or Environmental Health

Office to see if there are cycling facilities in your area.

Keep this instruction book for

future reference and ensure it is

passed on to any new owner.

5

Page 6

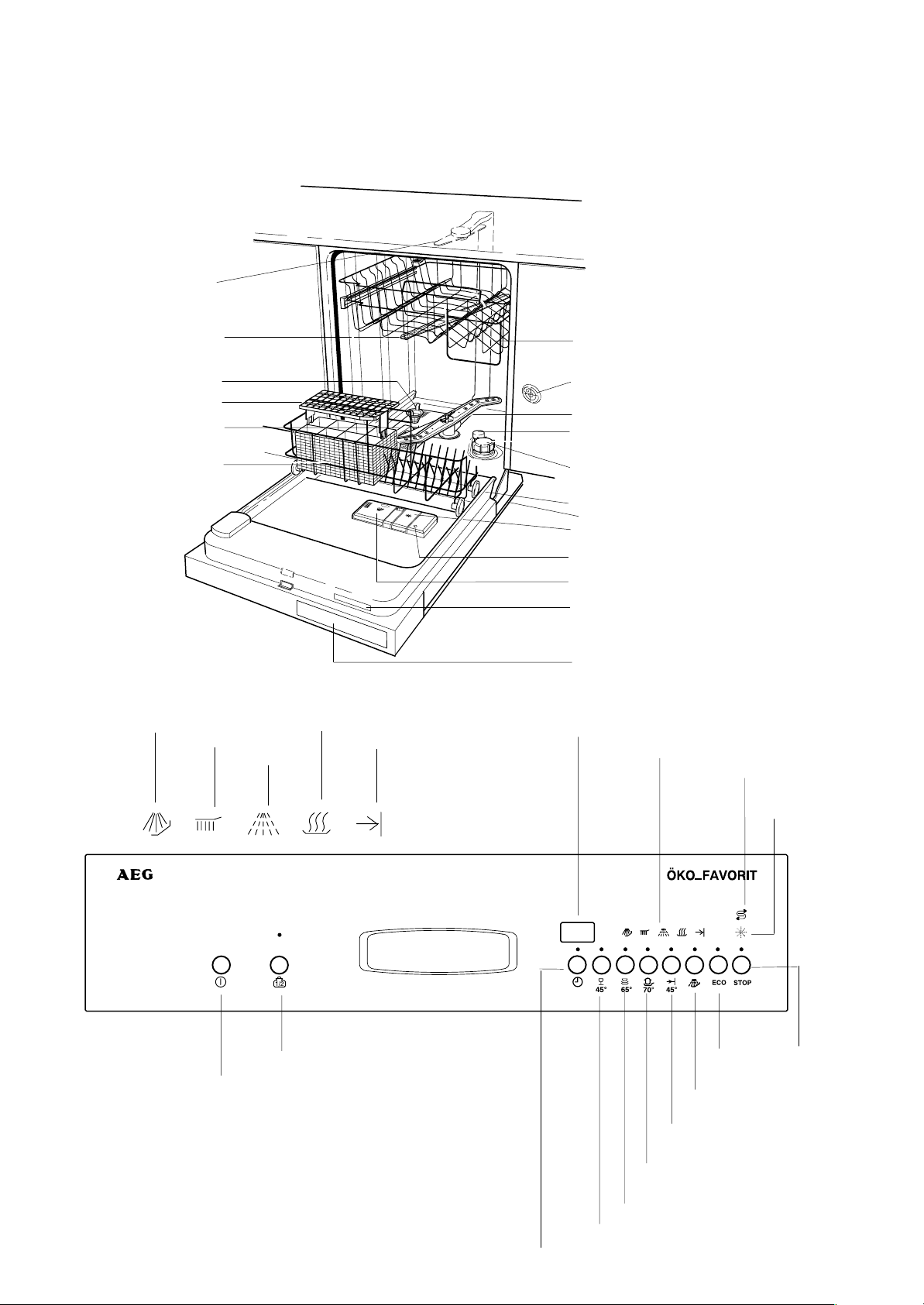

Description of the Appliance

t

Dishwasher

Cover for spray arm

Centre spray arm

Coarse strainer

Cutlery basket top

Fine strainer with

micro−strainer

Curtlery basket

Control Panel

Pre−rinse

Clean

Rinse

Dry

Programme end

Upper dish basket

(height−adjustable)

Setting switch for water softener

Lower spray arm

Water inlet valve: do not open,

do not fill with water

Salt container

Lower basket

Tank for rinse

Dosage orifice for rinse

Detergent container

Rating plate

Programme guide

Start time / Remaining time display

Programme sequence display

Regenerating salt

control lamp

Clear rinse agen

control lamp

Half load

Mains switch

Program button Intensive,

with control lamp

Program button Normal,

with control lamp

Program button Gentle, with control lamp

Delay start button

6

Economy

Program button Pre−rinse,

with control lamp

Program button Quick,

with control lamp

Stop

Page 7

General Hints & Tips

To save energy:

• Do not prewash dishes under running water.

• Wait until the dishwasher is full before washing a

load. If necessary use the rinse and hold button.

• If washing a reduced quantity of dishes up to maxi−

mum of 50% of the capacity, use the half load but−

ton (1/2).

• Always select a wash programme suitable for the

type of crockery being washed and to the level of

soiling (See Programme Chart).

• Follow the detergent dosage recommendations in

this instruction book and the detergent manufac−

turers instructions. Never over dose or under dose.

• Ensure the water softener is correctly set.

For best washing and drying results

• Before loading remove all scraps of food and soak

very heavily soiled pots and pans.

• Arrange saucepans, cups and glasses etc. upside

down.

• Tilt items with convex or concave surfaces so the

water drains off easily.

• Avoid contact between the dishes as far as possible.

• Wait a few minutes before removing the dishes; in

this way they will be cooler and the drying will be

improved.

• Empty the lower basket first and then the upper

basket; this will avoid water dripping from the up−

per basket onto the dishes in the lower one.

• You will improve drying results by leaving the dish−

washer door ajar for at least 15−30 minutes as soon

as the programme finishes.

Items not suitable for dishwashers.

The following items should not be washed in the

dishwasher (unless they are sold as dishwasher

proof).

• Cutlery with wooden or horn handles or glued parts

• Bronze cutlery

• Saucepans with wooden handles

• Aluminium ware

• Crystal ware

• Leaded glass

• Plastic items

• Antique or fine decorated china

• Tin and copper items

• Artistic objects

• Wooden board

Crockery that may be suitable:

• Earthenware crockery can be washed in the dish−

washer if the manufacturer has indicated that it is

suitable.

• Some glazed finishes may fade after frequent ma−

chine washing.

• Silver and aluminium parts tend to discolour during

machine washing.

• Copper, pewter and brass tend to stain.

• A chemical reaction can occur between silver cut−

lery and stainless steel cutlery. As a precaution do

not wash together.

• Iron and cast iron objects can rust and stain other

items.

• Certain types of decoration can discolour when

washed in a dishwasher.

If in doubt check with the manufacturer of the item.

When buying new dishes, ensure that they are dishwas−

her proof.

For best results we recommend the use of Finish detergents, rinse aid and salt.

7

Page 8

Prior to Using for the first Time

Do the following steps before using your dishwasher

for the first time.

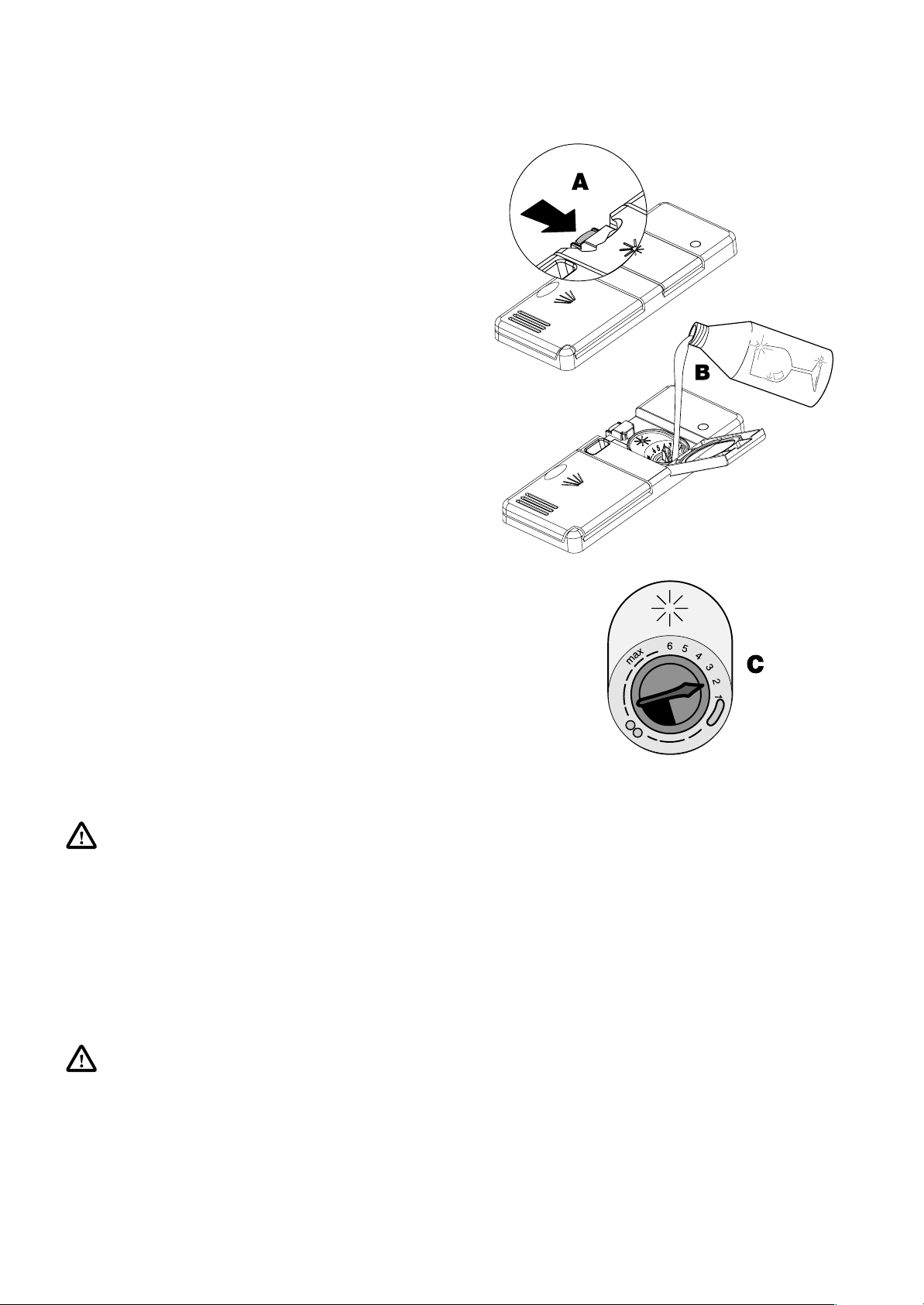

Fill with rins

1. Open the store tank by pressing the locking key if

the pilot light of the rinse is on (A).

2. Pour in rinse up to the "max." marking (B).

Do not fill up too much.

3. Close the store tank until it locks audibly.

4. Remove immediately any run out rinse otherwise

foam development may occur.

The pilot light for the rinse switches off.

Setting the rinse dosage

1. Open the store tank by pressing the locking key (A).

2. Turn the dosage arrow (C) to the left by hand or by

a coin or screwdriver in order to increase the quan−

tity. Setting ex works is step 2 (Perfect setting are

steps 2 − 4).

3. Close the store tank.

Please follow chapter "Remedying faults " about it on

page 24.

Filling the salt dispenser

Warning! Only use special salt for dishwashers.

Other types of salt (e.g., cooking salt) often

contain water−insoluble components which

can block the water softener and may render

it unserviceable.

Salt and detergent packages often look very similar.

Detergent accidentally poured into the salt dispenser

will damage the water softener. Each time you fill with

special salt, ensure that you are really holding a salt

package in your hand.

Never fill the salt dispenser with rinse aid or

detergent!

8

Page 9

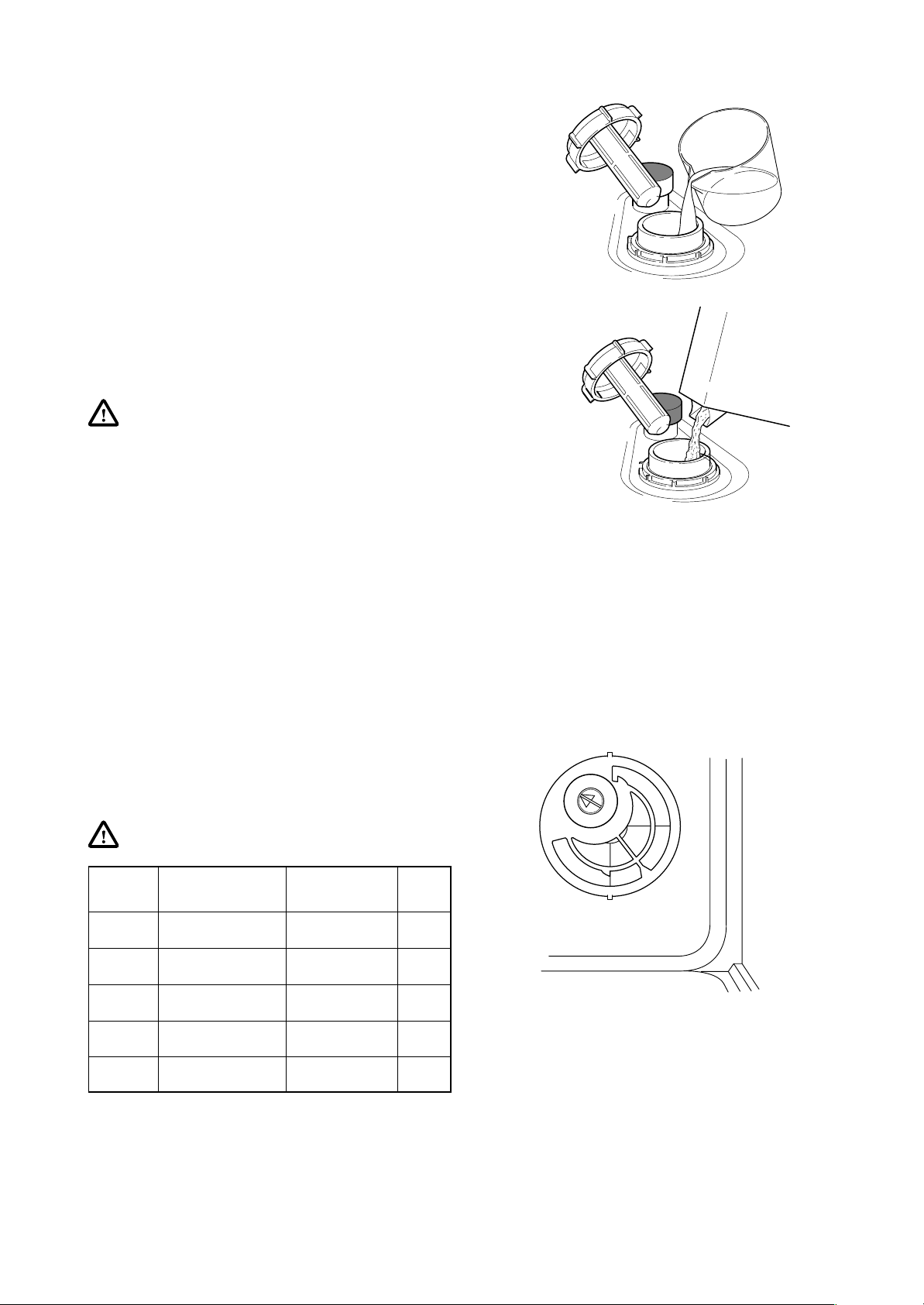

Fill with salt as follows:

1. Open the cap (A) of the salt dispenser.

2. Fill the dispenser with water (B)

A

3. Fill with 1 kg of special salt (C). As a result, approx.

1 litre of water will be displaced.

4. Remove salt from around the opening of the dis−

penser.

5. Close the salt dispenser by turning the cap until the

stop is reached.

6. Immediately run the "Pre−rinse"program to

wash away any salt residues.

The salt display will go out after 1 or 2 rinse cycles.

Do not remove the water feed valve, and do not

fill with detergent for any reason.

Setting the Water Softener

The dishwasher is equipped with a water softener de−

signed to remove minerals and salts from the water

supply, which would have a detrimental or adverse ef−

fect on the operation of the appliance.

The higher the content of these salts, the harder your

water is.

The softener should be adjusted according to the hard−

ness of the water in your area. Your local Water author−

ity can advise you on the hardness of the water in your

area.

B

C

Adjust the dosage as follows:

Turn the setting button using a coin or a screwdriver

until the arrow on the knob points to the desired num−

ber.

The arrow must point to a number and the po−

sition must be engaged positively.

Clarke

degrees

0 − 9 0 − 12,5 0 − 125 1

9 − 18 12,5 − 25 125 − 250 2

18 − 26 25 − 37,5 250 − 375 3

26 − 35 37,5 − 50 375 − 500 4

> 35 > 50 > 500 5

French degrees

(°TH)

PPM (Parts

per Million)

Level

The first wash cycle

− When using for the first time, use the Intensive pro−

gram.

4

3

2

5

1

9

Page 10

Crockery Basket

− Cutlery basket with top

− Lower basket

− Upper basket

The illustration gives you some tips for the op−

timal loading of your dishwasher.

Before loading, remove any food scraps. Do not

rinse with warm water or use a manual deter−

gent.

Cutlery basket

Place cutlery in the cutlery basket with the handles

downward.

Except for cutlery very narrow handles, which

could penetrate through the cutlery basket

and could block the spray arm.

without

cutlery basket

top

Make sure that cutlery and tall articles near the

basket handle do not prevent the lid of the de−

tergent dispenser from opening.

Important:

Long bladed knives stored in an upright

position are a potential hazard.

Long and / or sharp items of cutlery such as

carving knives must be positioned horizon−

tally in the upper basket.

Take care when loading or unloading sharp

items such as knives.

Cutlery basket top

With the top fitted to the cutlery basket, the cutlery no

longer touches. All parts are accessible for the water

jet. In this way, cleaning and drying of the cutlery is im−

proved.

Removing the cutlery basket top

− Press in the clips slightly (A) and remove the cutlery

basket top upwards (B).

with cutlery

basket top

10

Page 11

Lower basket

Heavily soiled, large pieces of crockery will be tho−

roughly cleaned in the lower basket.

1. Pull out the lower basket to its full extent.

2. Arrange large and heavy pieces of crockery, such as

plates, bowls, pots etc., in the lower basket.

Do not change the position of the basket

handle, as malfunctions may occur when the

detergent container opens.

Adjustable plate rail, right, 10 piece

In order to make optimal use of the space in the lower

basket, the plate rails can be set in two positions, in the

longitudinal and transverse directions.

1. To take out the plate rails, the plate rail grip must

be pulled away upwards (A).

A

2. The plate rails are then put into the transverse posi−

tion by fitting them into the longitudinal struts (D)

on the lower basket, and then pressing down the

plate rail (B) until it snaps into place.

The plate rail can be varied sideways (C). Positioning as

described above.

B

D

C

11

Page 12

Adjustable plate rail insert, 5 piece

For deep plates or bowls, a part of the left plate rail can

be removed.

− To remove the plate rail insert, the plate rail grip

is pulled away upwards (A).

The plate rail insert can also be used instead of the

10−piece plate rail, right (B).

A

B

B

Hinged plate rail, left

For large bowls and pots, the plate rail can be unhin−

ged.

1. Remove the 5 piece plate rail inserts and cutlery

basket.

2. Pull the plate rail slightly upwards, and fold down

onto the basket base to the right.

The crosswise plate rack on the front right is optimally

suited to small, flat plates with a diameter of

170−210 mm.

Do not place any hollow articles in the front

right of the lower basket as the detergent dis−

penser should not be prevented from opening.

D

1

2

12

Page 13

Upper basket

Delicate, smaller pieces of crockery are gently washed

in the upper basket.

1. Pull out the upper basket to the stop.

2. Arrange the small, light and delicate pieces of crok−

kery such as saucers, cup’s, glasses and tempera−

ture−resistant plastic parts in the upper basket.

Adjustable glass holder

For stem glasses, suspend the glass holder in the right−

hand position (Fig. A) and fold it up.

For high, cylindrical glasses, suspend the glass holder

in the let−hand position (Fig. B) and fold it up.

Glasses can also be placed over the protruding rods

(Fig. C).

To unload the glass holder, or if it is not being used, fold

it back to the right.

Adjustable Cup Support

Arrange crockery offset on and below the hinged cup

support, so that the spray jet can reach all parts.

Fig. A

Fig. B

Fig. C

Stem glasses can be suspended from the cut−outs in

the cup support.

The cup support can be positioned at two dif−

ferent heights.

13

Page 14

The upper basket is adjustable to the

right

Set the upper basket to the desired height, correspon−

ding to your crockery.

Even possible with the upper basket loaded.

Raising:

1. Pull out the upper basket.

2. Lift up the right side.

3. Pull forward to the stop, and latch into the upper

position.

Lowering:

1. Pull out the upper basket

2. Lift the right side, and lower into the lower position.

Before washing, check that the spray arm

can rotate freely.

Maximum plate size

Upper basket: top position

∅ 19

∅ 30

Large plates placed at an angle

Lower basket

∅ 27

Maximum plate size

Upper basket: bottom position

∅ 21

∅ 28

∅ 25

14

Lower Basket:

Place only flat plates up to Ø 210 mm

in the front at the right.

Page 15

Filling with detergent

y

Never use hand detergent or industrial clea−

ning agents.

Do not use anything else than commercial de−

tergents that are suitable for domestic dish−

washers.

The detergent dispenser is normally open.

If it is closed:

1. Open the detergent container by pressing the lok−

king key (A).

2. Fill the dry tank up with detergent according to de−

tergent manufacturer’s indications (B). Do place

tabs in the detergent container or cutlery basket

according to manufacturer’s directions only.

3. You can pour extra detergent into the second hol−

low in case of washing programmes with warm pre−

rinsing (C).

4. Press shut detergent container

Selecting and starting the program

1. Push the crockery basket completely in.

2. Fold up the door, and press it shut.

The door lock must latch, otherwise the ma−

chine will not start.

3. Press the mains switch.

4. Press the Half Load button if only half the amount

of dishes are loaded.

5. Select one of the programs 1 − 5. Refer to the Pro−

gram Table.

The indicator lamp for the selected programme flashes

for 5 seconds before the wash programme starts.

6. For a period of 5 seconds it is possible to change to

another programme, and also to select the Eco but−

ton or the Half Load button.

After each press of a button, there is a period

of 5 seconds during which any corrections can

be made.

Half load

Mains switch

Econom

Do not open the door after the program has started!

To prevent scolding and damage to units by escap−

ing steam.

15

Page 16

Program display

The illuminated symbols in the display indicate which

phase of the program is currently running.

Remaining running time

As soon as a program starts, the time remaining lights

up in the display field in minutes. This time varies de−

pending on the loading and temperature of the incom−

ing water. The display may remain at one time for sevral

minutes. It may also jump in time this quite normal,

and does not indicate a fault.

End of the program

The illumination of a "0" in the start delay display and

the program end symbol in the program display indi−

cate the end of the washing program.

Pre−rinse

Cleaning

Rinsing

Drying

Program end

Safety lock

The safety lock prevents an accidental restart after the

end of the program. In order to be able to enter a new

program, the dishwasher must either be switched off

and then on again, or the door must be opened and

then closed again.

The safety lock is released as soon as only the

Programme End symbol is illuminated in the

programme display.

Delay start

The start of the selected program can be delayed bet−

ween 1 and 9 hours in steps of 1 hour using the Start

Time Pre−selection button.

− By repeatedly pressing the button, the delay time

can be programmed in hours, and will be displayed

in the display field.

Display: Hours and a small "h".

16

Page 17

A washing program can be selected first, and

y

then the pre−selected start time can be pro−

grammed, or vice versa.

If a pre−selected start time is programmed without a

washing program, the programmed time goes out after

5 seconds. After selecting a program, the selection of

the start delay must take place within 5 seconds.

An activated pre−selected start time will be indicated

in the display field by a blinking dot.

After the pre−selected start time has expired, the

machine starts up the selected program automati−

cally.

Correcting or Deleting the

Program Selection /

Pre−se−

lected Start Time

Using the Stop button, a running program or the pre−

selected start time can be interrupted or cancelled.

Interruption:

− Briefly activating the Stop button causes an inter−

ruption of all programs, and the Stop control lamp

blinks.

− Activating the Stop button again makes the pro−

gramming active once again.

Cancelling:

− Holding down the Stop button longer than 2 se−

conds deletes the program and the pre−selected

start time, and any water present will be pumped

out. The Program End symbol in the display lights up

as soon as all the water has been pumped out.

ECO button

The wash temperature is reduced using the ECO button,

as a result less energy is consumed during heating up.

The economy button can be selected for all wash pro−

grams.

The ECO button should be used in particular when

using low−alkali compact cleaners with enzymes. The

enzymes produce their full dirt−releasing effect in a

temperature range between 40 and 50 °C.

Using the Half Load button, energy is saved if the dish−

washer is only half full. Nevertheless optimal washing

results are achieved (see Program Chart).

In the case of the simultaneous selection of

ECO and Half Load, the Half Load program is

run.

Half load

Mains switch

Econom

17

Page 18

Program Chart

ÇÇÇÇ

Gentle

Pre−rinse

Clean

Rinse

Rinsing

Intermediate

Drying

Duration of

programm

Light to normally soiled crockery

+ ECO Lightly soiled crockery

+ Lightly soiled crockery with half load

Normal

Heavily−soiled crockery

+ ECO The most economical programme for

stubborn dirt. Using this programme, AAA

performance in accordance with the

EN 50242 "Energy Label" is achieved *)

+ Normally soiled crockery with half load

Intensive

Very heavily−soiled crockery

+ ECO Heavily to very heavily−soiled crockery

+ Heavily to very heavily−soiled crockery

with half load

47°C

40°C

40°C

45°C

40°C

40°C

50°C

50°C

50°C

68°C

63°C

63°C

65°C

60°C

60°C

68°C

68°C

65°C

73°C

68°C

68°C

59 min.

48 min.

45 min.

70 min.

2.5 h

64 min.

86 min.

81 min.

75 min.

Quick

Very light to lightly soiled crockery

+ ECO very lightly soiled crockery

+ very lightly soiled crockery with half load

45°C

40°C

40°C

65°C

60°C

60°C

44 min.

38 min.

34 min.

Pre−rinse

Wash off cold

The programme times and temperatures are intended as a guide only. The actual programme times will de−

pend an incoming water temperature an pressure

*) A = Best energy efficiency

A = Best cleaning result

A = Best drying result

Programme with significantly extended drying

For the test washes in accordance with the test standard EN 50 242 (see page 31) extremely stubborn soiling is used

that only rarely occurs in day to day use.

We therefore recommend the selection of a program appropriate for the level of soiling in accordance with this

chart. Dried−on residues mostly requires a powerful program.

5

18

Page 19

Mains power loss

In case of a power failure, or a deliberate disconnection

to the power supply, all the set values are retained.

Error message

The electronics of the dishwasher can independently

recognise and display faults. If a fault occurs, an error

code in the display, one of the program control lamps

and the Program End symbol in the display will blink.

Please note down this error code before making con−

tact your Service Centre.

The error message is deleted by switching off the main

switch.

Error codes and possible causes

A = Water tap closed, inlet hose filter blocked

C = Drain hose, coarse or fine strainer or sink trap

blocked

E = Water pressure too low, water tap not comple−

tely opened, inlet hose or inlet hose filter is

blocked, machine losing water.

E2 = Call AEG Service force

H = Call AEG Service force

Start time /

Remaining time

display

Programme

sequence display

Mains switch

L = Call AEG Service force

Unloading the crockery basket

After the washing program is complete:

1. First unload the lower basket.

2. Then unload the upper basket, so that no drops of

water fall onto the dry crockery in the lower basket.

Inspect the coarse strainer after every washing

sequence. Clean as necessary.

19

Page 20

Cleaning and care

Internal Cleaning

Ensure that the seals around the door, the detergent

and rinse aid dispensers are cleaned regularly with a

damp cloth.

We recommend the use of Finish Dishwasher Cleaner,

every 3 months or run a 65oC wash without dishes

using detergent. Regular use of Finish Dishwasher

Cleaner cleans inaccessible parts, eliminates unplea−

sant food odours and helps prevent the build−up of li−

mescale.

Re−filling the salt dispenser

Never fill the salt dispenser with rinsing aids or

detergents!

When the salt replenishment lamp lights up, you must

refill the special salt for the water softener.

Proceed as described in the "Using for the First Time"

chapter on page 8, however you do not need to add any

water during this process.

Immediately after refilling, run the "Pre−rinse"

program to wash away any salt residues.

Refilling the rinse aid

Upon lighting up of the rinse indication you should re−

fill rinse.

Proceed as described in chapter "Prior to Using for the

first Time" page 8.

Remove immediately any run out liquid rinse

otherwise foam development may occur.

Cleaning the large strainer

Check the large strainer after every cleaning run. Clean

as necessary.

− The large strainer can be simply pulled out and be

re−installed.

− Clean the strainer under running water.

Large strainer

Fine strainer

20

Page 21

Cleaning the fine strainer

The fine strainer must be cleaned from time to time:

1. Unlock the strainer by turning right.

2. Lift out the fine strainer and clean it under running

water with a brush.

3. Place the strainer in its holder.

4. Secure it by turning left until it locks (arrows).

Do not press the handle downwards.

If the strainer does not lock, the spray arm

nozzles may become blocked.

1.

3.

2.

4.

Cleaning the spray arm

nozzles

Regularly check the nozzles on the three spray arms for

blockages. If necessary, clean out the nozzles with a

fine wire or a fine pin and a strong jet of water.

Take care not damage the nozzle openings.

Roof spray arm

Remove the roof spray arm:

1. Loosen the securing screw (A) by turning to the left.

2. Pull the spray arm from the shaft.

3. Clean the spray arm and the securing screw.

4. Refix the spray arm with the securing screw (A) by

turning to the right.

A

21

Page 22

Central spray arm

1. Remove the central spray arm by turning it to the

side, and hoisting off.

The two−part spray arm bearing is held together by

a clamping spring (B).

2. To re−install, press the central spray arm upwards

until you can feel it locking into place.

Lower spray arm

Remove the lower spray arm:

1. Loosen the nut (C) by turning it to the left

2. Pull the spray arm from the shaft

3. Clean the nozzles

4. Refix the spray arm with the nut (C) by turning to

the right.

Shake stubborn waste out of the spray arm af−

ter allowing it to dry completely.

B

C

Cleaning the appliance

Clean the outer surfaces of the machine, and in parti−

cular the control panel, regularly using a soft, damp

cloth.

Only use neutral detergents (e.g., hand washing liquid),

but not scouring agents or solvents such as acetone,

paintbrush cleaner or thinners etc.

Appliances with stainless steel

outer surfaces

For the stainless steel front, we recommend thorough

and regular care and cleaning with suitable stainless

steel cleaners.

Pay attention to the instructions regarding detergents

and care products. Do not use abrasive or scouring

agents.

Before wiping, apply the detergent to a damp cloth,

clean the surfaces with it, and dry with a clean cloth.

When cleaning, ensure that the stainless steel surface

finish (the fine diagonal lines) is not worked against

the grain: no circular movements!

22

Page 23

Remedying faults

Certain problems are due to lack of simple maintenance or oversights, which can be solved easily without calling out

an engineer. Before contacting your local Service Force Centre, please carryout the checks listed below.

Important: If you call out an engineer to a fault listed below or to repair a fault caused by incorrect use or

installation a charge will be made even if the appliance is in guarantee.

The drain pump runs continually even when the ap−

pliance is switched off.

− The water protection system has been triggered.

First close the water taps, and then pull out the

mains plug or switch off or turn out the fuses. Call

AEG Service Force.

The program does not start.

− Are the fuses of the fixed installation in order? Is the

appliance connected to the electrical supply?

− Has the door been properly closed? Press the door

shut until the door lock latches in.

− Has the pre−select start time been set?

The machine does not fill with water.

− Is the water tap completely open?

− Is the water tap blocked? Open and close the water

tap several times.

− Is the strainer in the hose fitting to the water tap

blocked? Clean the strainer if necessary.

− Is the inlet hose kinked? Check the hose run.

− Is a minimum water flow pressure of 1 bar availa−

ble?

The program sequence display remains static at the

start of the cleaning

− Is the water tap completely open?

− Is the strainer in the hose fitting at the water tap

blocked? Clean if necessary.

The water is not pumped away

− Is the drain hose kinked? Check the run of the hose

(see the "Water Drainage" section).

− Is the sink drain blocked? Clear any blockages.

The crockery is not clean

− Have you selected a program that is suitable for the

type and degree of soiling of your crockery? (see

Program Chart)

− Was the spray arm blocked by crockery or pieces of

cutlery?

− Are the spray arm nozzles clean?

− Are all the filters in the base of your dishwasher

clean? Have the filters been installed correctly?

− Have you used the correct amount of detergent?

− Is the drain hose correctly filted.

− Is the on−site sink drain blocked?

− Is there salt in the salt dispenser? Without it, the

water will not be softened. Lime deposits can form

on your crockery and in the machine.

− Has the water softener system been set to the local

water hardness?

The crockery is not dry, and has no sparkle.

− Is there rinse aid in the dispenser?

− Has the salt dosage been correctly set?

Glasses and dishes have streaks, stripes, milky blot−

ches or blue−coloured bloom.

− The rinse aid is being overdosed. Set a lower rinse

aid dosage

Glasses and dishes have dried−on "water drops".

− The rinse aid is being underdosed. Set the rinse aid

dosage higher.

− Is the lid of the salt container properly closed?

Rust marks can be seen in the washing area.

− The dishwasher interior is made of stainless steel.

Rust marks inside the dishwasher are caused by ex−

ternal rust (rust particles from the water piping,

from pans, cutlery etc.). Remove such marks using

a commercially−available stainless steel cleaner.

− Was the "Pre−rinse" program started immediately

after refilling the salt?

− Have you arranged the crockery so that the sprayed

water has access to all surfaces, both internal and

external? The crockery baskets must not be overfil−

led.

23

Page 24

Error codes and possible causes

A = Water tap closed, inlet hose filter blocked

C = Drain hose, coarse or fine strainer or sink trap

blocked

E = Water pressure too low, water tap not comple−

tely opened, inlet hose or inlet new filter is

blocked, machine losing water.

E2 = Call AEG Service force

H = Call AEG Service force

L = Call AEG Service force

24

Page 25

Service & Spare Parts

If you wish to purchase spare parts or require an engi−

neer, contact your local AEG Service Force Centre by

telephoning:

08705 929929

Your telephone call will be automatically routed to the

Service Centre covering your post code area.

When you contact the Service Centre they will need

the following information:

1. Your name & address, including post code.

2. Your telephone number.

3. Clear and concise details of the fault.

4. The model, serial and production number.

(This information can be found the rating plate). In

order that you have this information to hand when

you call, we recommend you write the information

below.

Product No: .........................................................................

Serial No: .............................................................................

Model No: ............................................................................

5. Date of purchase.

Please note that it will be necessary to provide proof

of purchase for any in guarantee service call.

In–guarantee customers should ensure that the chap−

ter headed ‘Remedying Faults’ has been read, as the en−

gineer will make a charge if the fault is not a mechani−

cal or electrical breakdown.

Customer Care

For general enquiries concerning your AEG appliance

or for further information on AEG products please con−

tact our Customer Care Department by letter or tele−

phone as follows:

Customer Care Department

AEG Domestic Appliances

55−77 High Street

Slough

Berkshire SL1 1DZ

Serial Number

Prod-Nr.:

Serie-Nr.:

Mod:

Modell

Tel: 08705 350350

25

Page 26

Technical Data

Dimensions

Operational voltage

Frequency

Power consumption Circulation pump 150 W

Power consumption Heating elements 2000 W

Total power 2150 W 10 A

Mains water pressure

Cold or hot water up to

max. 65 °C

Capacity

Half load (1/2)

Width

Height

Max. depth

Max. depth with open door

min.

max.

*Standard place settings IEC

*Standard place settings IEC

54.6 cm

75.9 cm

57.0 cm

114.5 cm

230 V

50 Hz

1 bar (flow pressure)

10 bar

11

6

Consumption

Intensieve

Intensieve + Eco

Intensieve + 1/2

Normal

Normal + Eco

Normal + 1/2

Quick

Quick + Eco

Quick + 1/2

Gentle

Gentle + Eco

Gentle + 1/2

* A standard place setting consists of: 1 soup bowl, 1 flat plate, 1 dessert plate, 1 saucer, 1 cup, 1 glass, 1 knife, 1

fork, 1 soup spoon, 1 dessert spoon, 1 tea spoon.

Energy (kWh)

1,6

1,3

1,13

1,0

1,0

0,9

1,0

0,8

0,7

1,0

0,8

0,7

Water (l)

16

16

15

16

15

15

14

14

12

14

14

12

Directives

This appliance conforms with EC−Directives

Low Voltage Directive 73/23/EEC and the amendment to LVD 90/683/EEC

EMC Directive 89/336/EEC and the amendment to EMC 92/31/EEC

CE Marking Directive 93/68/EEC

26

Page 27

Installation Instructions UK

Any electrical work required to install this

appliance should be carried out by a quali−

fied electrician or competent person.

Any plumbing work required to install this

appliance should be carried out by a quali−

fied plumber or competent person.

• The dishwasher is delivered ready for connection,

i.e. with power supply cable, drain hose and inlet

hose with fitted filter and seal.

• The installation should be carried out to connec−

tions provided in a neighboring cupboard (not di−

rectly behind the unit).

• The regulations of the local water and electricity

companies must be complied with.

Water Supply Connections

• The dishwasher must be plumbed into a cold water

supply.

• The water pressure must be within the limits given

in the technical specifications. Your local Water Au−

thority will advise you on the average mains pres−

sure in your area.

• A shut−off device with a ¾" connection must be

provided on site.

• The inlet hose has a filter to remove any impurities

from the water supply and a rubber seal. When fit−

ting ensure that the filter and seal are correctly po−

sitioned.

No water must escape from the fitting after

the shut−off device has been opened.

Water outlet hose connection

• Ensure the drain hose is not bent or squashed as the

could prevent or slow down the discharge of water.

• The outlet hose should be connected to a water

outlet provided in a neighboring cupboard (not di−

rectly behind the unit).

550

762

600

510

546

574

759

570

• The dishwasher is fitted with a device to prevent the

back flow of water, which allows the installation

height of the unit to be above the outlet height.

• The highest point of the drain hose should never ex−

ceed the unit height.

AEG

153 0409 25 / 09.99

27

Page 28

Electrical Connection

This appliance must be earthed.

The manufacturer declines any responsibil−

ity should this safety measure not be ob−

served.

Before switching on make sure the electricity supply

voltage is the same as that indicated on the appliance

rating plate.

Changing a fuse

Your appliance is supplied with a 13 amp plug fitted.

In the event of having to change the fuse in the plug

supplied, a 13amp ASTA approved (BS1363A) fuse must

be used,

Should the plug need to be replaced for any reason,

proceed as described below.

The wires on the mains lead are coloured in accordance

with the following code.

Green and Yellow −Earth

Blue −Neutral

Brown −Live

The wired coloured green and yellow must be connec−

ted to the terminal marked with the letter "E" or by the

earth symbol

or coloured green and yellow.

The wired coloured blue must be connected to the ter−

minal "N" or coloured black.

The wire cooured brown must be connected to the ter−

minal marked "L" or coloured red.

Upon completion there must be no cut, or stray strands

of wire present and the cord clamp must be secure over

the outer sheath.

A cut off plug inserted into a 13amp socket

is a serious safety (shock) hazard.

Ensure that the cut of plug is disposed of sa−

fely.

Permanent connection

In the case of permanent connection it is necessary

that you install a double pole switch between the ap−

pliance and the electricity supply (mains), with a mini−

mum gap of 3mm between the switch contacts and a

type suitable for the required load in compliance with

the current electrical regulations.

The switch must not break the yellow and green earth

cable at any point.

AEG

28

153 0409 25 / 09.99

Page 29

Assembly Instructions for the Side Rail Assembly

Kit

Components:

1 off Side rail, right SL R

1 off Side rail, left SL L

4 off Spacer 4 mm DS 1

4 off Spacer 3mm DS 2

4 off Spax screw 4.0 x 20 galvanised SCHR

600

A+B

510min.

Detail B

DS 1

DS 2

546

Detail A

SL L

neighbouring

edge

SL L

SCHR

100

19

21

16

759

19

574

562−

762

16−

19

550

Procedure:

Frame side panel thickness 19 mm:

− Remove the protective tape of the two spacing washers (DS 1) mounted on the side rails (SL R + SL L).

− Position the side rail (SL L): > Lower side (open) lying on the floor of the niche

− Press on and fix the side rail (SL L), and secure with the supplied screws (2x SCHR

− Repeat this procedure for side rail SL R.

Frame side panel thickness 16 mm:

− Remove the protective tape of the two spacing washers (DS 1) mounted on the side rails (SL R + SL L).

− Stick the separately−supplied 3 mm spacing washers (SL R + SL L) over the pre−mounted 4 mm spacing washers

(DS 1) as shown in Detail B.

The adhesive tape of the 3mm spacing washer (DS 2) must be on the outer side.

− Continue as described for the 19 mm thick frame side panel.

568

SL L

> Edge lying against the side panel of the frame (see Detail A).

SL R

570

759

153 0771 03 / 03.98

29

Page 30

Installation

• Stick on the damp protection film as described in

the instructions on the rear side of the film (shorten

where necessary).

• Attach the side rails to the side panels of the furni−

ture as described in the separate assembly instruc−

tions.

• Place the appliance in front of the high cupboard,

and run the cable and hoses through the high cup−

board’s bay so that they are neither kinked or squas−

hed.

• Align the dishwasher in the centre of the bay and

flush with the side panels, and where necessary, ad−

just to be flush at the front surface using shims.

• Carefully open the door of the appliance without

changing the settings of the appliance.

• Using the pre−drilled holes, screw the appliance to

the side panels of the furniture on both sides in the

upper inner area (see Detail A).

Detail A

Detail B

• Before screwing the appliance diagonally through

the base plate using two additional screws (always

pre−drill), it is advisable to protect the appliance

door from damage using suitable materials (e.g. the

cardboard packaging). In order to tighten these

screws, the door must be opened by approx. 45 de−

grees (see Detail B).

Technical Data

Dimensions

Height 75.9 cm

Depth 57.0 cm

Width 54.6 cm

Capacity 12 place settings

Electrical connection 230−240V – 50Hz

Motor rating during wash 140 W

Power of heating element 2000 W

Overall power 2150 W

Water supply pressure Minimum 1bar

Maximum 10 bar

AEG

30

153 0409 25 / 09.99

Page 31

Information for Test Institutes

Prior to the tests, the salt container for the

water softener and the rinse aid container

must be completely full.

Test standard: EN 50 242

Comparison program: Normal + Eco

Capacity: 11 standard place settings

Detergent dosing: 27,5 g in the detergent

container

Rinse aid dosing: setting 6

Loading example:

Noise measurement

− Measurement of the acoustic power level according

to EN60704−2−3

− The measurement is to be made directly after the

completion of a short program.

Oval plates

Flat plates

Dessert plates

Soup plates

Upper basket in lower (lowered) position

1−10 Soup spoons

11 Serving fork

12 Soup spoon

13−23 Forks

24 Sauce ladle

Soup plates

25−35 Knives

36−37 Serving spoons

38−48 Dessert spoons

49−59 Tea spoons

Dessert plates

31

Page 32

AEG Hausgeräte GmbH

Postfach 1036

D−90327 Nürnberg

http://www.aeg.hausgeraete.de

ECopyright by AEG

153 1081 01 / 06.02

From the Electrolux Group. The world’s No.1 choice

The Electrolux Group is the world’s largest producer of powered appliances for kitchen, cleaning and outdoor use. More than 55 million Electrolux

Group products (such as refrigerations, cookers, washing machines, vaccum cleaners, chain saws and lawn mowers) are sold each year for a value of

32

approx. USD 14 billion in more than 150 countries around the world.

Loading...

Loading...