Gas ovens

INSTRUCTION BOOKLET

Please read this instruction booklet before using the appliance

35674-3501

Mod. EOG 621

GB

Important Safety Information

You MUST read these warnings carefully before installing or using the oven. If you need

assistance, contact our Customer Care Department on 08705 950950

Installation

This oven must be installed by qualified personnel to the

relevant British Standards.

Always use oven gloves to remove and replace food in the

oven.

This oven is heavy. Take care when moving it.

Remove all packaging, both inside and outside the oven,

before using the oven.

Do not attempt to modify the oven in any way.

The use of a gas cooking appliance results in the

production of heat and moisture in the room in which

it is installed. Ensure that the kitchen is well

ventilated: keep natural ventilation holes open or

install a mechanical ventilation device (mechanical

extractor hood).

Prolonged intensive use of the appliance may call for

additional ventilation, for example opening a window,

or more effective ventilation, for example increasing

the level of mechanical ventilation where present.

Child Safety

This oven is designed to be operated by adults. Do not

allow children to play near or with the oven.

The oven gets hot when it is in use. Children should be

kept away until it has cooled.

During Use

This oven is intended for domestic cooking only. It is not

designed for commercial or industrial purposes.

Do not block any of the oven vents. Never line any part

of the oven with aluminium foil.

Do not allow heatproof cooking material, e.g. roasting

bags, to come into contact with oven elements.

Ensure that all control knobs are in the OFF position

when not in use.

Do not leave cookware containing foodstuffs, e.g. fat or

oil in or on the oven in case it is inadvertently switched

ON.

When using other electrical appliances, ensure the

cable does not come into contact with the hot surfaces

of the oven.

Maintenance and Cleaning

Only clean this oven in accordance with the instructions.

The oven should be kept clean at all times. A build-up of

fats or other foodstuffs could result in a fire, especially in

the grill pan.

Always allow the oven to cool down and switch off the

electrical supply before carrying out any cleaning or

maintenance work.

Service

This oven should only be repaired or serviced by an

authorised Service Engineer and only genuine approved

spare parts should be used.

Environmental Information

After installation, please dispose of the packaging with

due regard to safety and the environment.

When disposing of an old appliance, make it unusable,

by cutting off the cable. Remove any door catches, to

prevent small children being trapped inside.

Never place plastic or any other material which may melt

in or on the oven.

Do not place sealed cans or aerosols inside the oven.

They may explode if they are heated.

Do not hang towels, dishcloths or clothes from the oven

or its handle.

Do not use this oven if it is in contact with water and never

operate it with wet hands.

Take great care when heating fats and oils as they will

ignite if they become too hot.

2

Keep this instruction book for future reference

and ensure it is passed on to any new owner.

Contents

For the User

Important Safety Information 2

Description of the Appliance 4

Controls 4

Before the First Use 5

24 hour Clock and Timer 6

Grilling with the turnspit 8

Using the Oven 8

Gas Oven Cooking Charts 9

Cleaning the Oven 10

Something Not Working 11

Service and Spare Parts 11

Guarantee Conditions 12

Guide to Use the instructions

For the Installer

Building in 16

Electrical Connection 17

Gas Connection 18

Conversion from Natural to LPG Gas 19

The following symbols will be found in the text to guide

you throughout the Instructions:

Safety Instructions

Step by step instructions for an

operation

F

Hints and Tips

Environmental information

This appliance complies with the following

E.E.C. Directives:

* 73/23 - 90/683 (Low Voltage Directive);

* 93/68 (General Directives);

* 89/336 (Electromagnetical

Compatibility Directive) .

and subsequent modifications

3

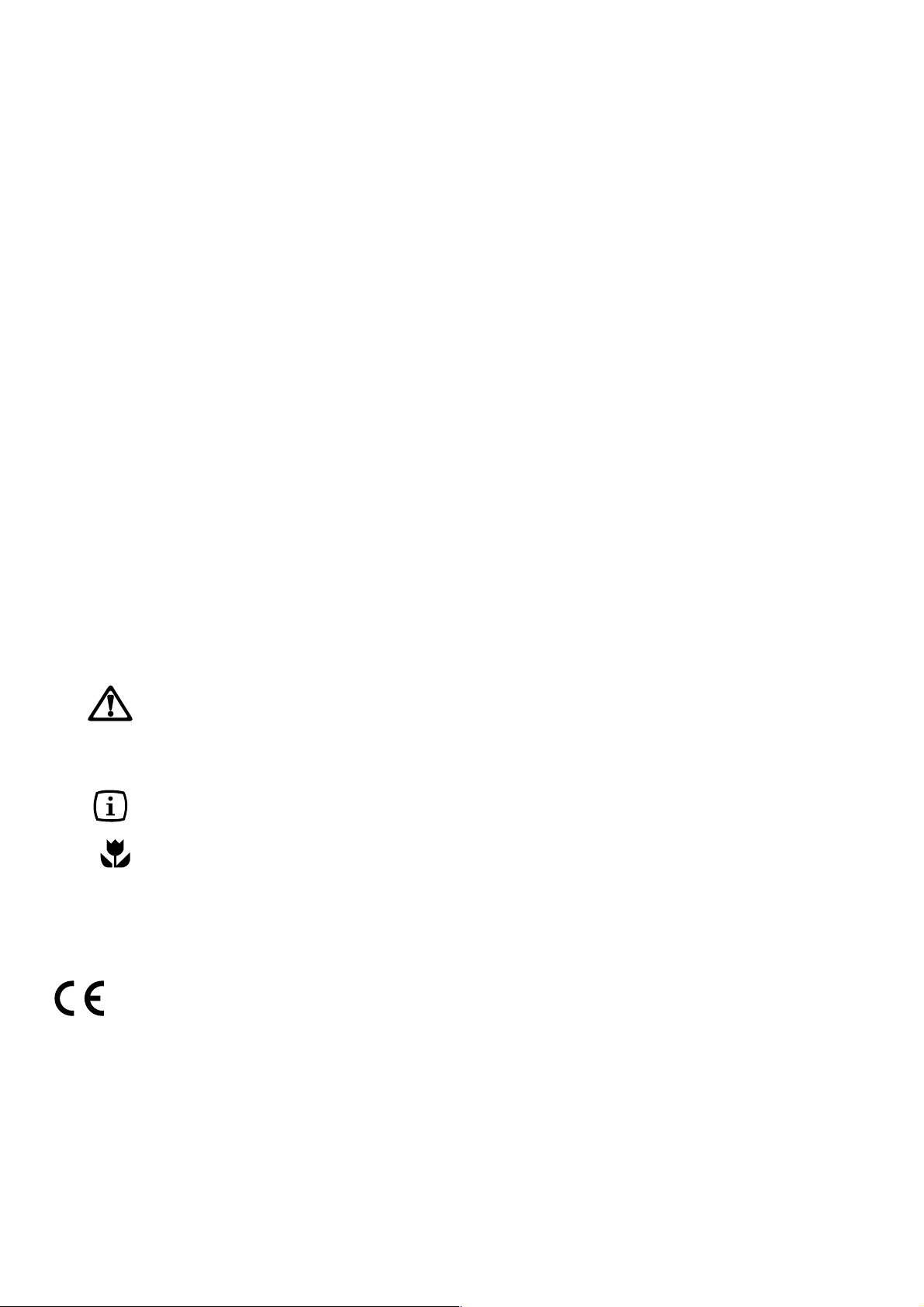

Description of the Appliance

2

3

7

56

4

1. Control panel

Controls

Oven Function Control Knob

1

8

9

10

2. Thermostat control knob

3. Gas stop Control Light

4. Oven function control knob

5. Thermostat control light

6. Mains on light

7. Electronic programmer

8. Grill

9. Oven lamp

10. Turnspit hole

Oven Light - The oven light will be on without

any cooking function.

Grill - The heat comes from the top element

only

Grill and Rotisserie - The turnspit can be

used for either spit roasting meat or for

kebabs and smaller pieces of meat.

Bottom heating element - The heat comes

from the bottom of the oven only

Gas oven operation

The oven cannot be switched on with the use of

flames.

To switch on the oven:

F

- Turn the oven function control knob to (the oven

lamp and the yellow light on the control panel will

come on)

- Turn the thermostat control knob to the required

temperature (the red light on the control panel will

come on).

- After 5 seconds, the oven will ignite. If the oven

does not switch on, the gas stop control light on

the control panel will come on.

To try to switch the oven again:

F

- turn the oven function and the thermostat control

knobs to l (zero) and wait some seconds before

trying to ignite the oven again.

FO 2478

When using the oven for the first time, it may be

necessary to try the ignition several times: this is

due to the air inside the gas pipes.

If there is a black out during the operation of the

oven, this will automatically switch on as soon as

power is restored.

Electric grill

- Turn the oven function control knob to and the

thermostat control knob to MAX;

To use the rotisserie and the electric grill:

F

- Turn the oven function control knob to and the

thermostat control knob to 200°.

4

Thermostat Control Knob

Turn the thermostat control knob clockwise to select

temperatures between 50°C and 250°C (MAX).

Mains on Light

The oven function control light will come on when the oven

function control knob is set.

Thermostat Control Light

The thermostat control light will come on when the

thermostat control knob is turned. The light will remain on

until the correct temperature is reached. It will then cycle

on and off to show the temperature is being maintained.

Gas stop Control Light

The gas stop control light will come on when the oven

burner switches off. To switch on, turn the control knob to

zero and wait some seconds, then ignite again.

Cooling fan

The cooling fan operates during cooking. Air is expelled

through vents between the oven door and the control

panel, as shown in the diagram.

The cooling fan may run on after the oven is switched off

to keep the controls cool. This is quite normal.

50

MAX

100

200

150

FO 2482

The Safety Thermostat (Electric

Grill)

This oven is provided with a safety thermostat. In case of

malfunctioning of the main thermostat, and consequent

over-heating, the safety device will stop the power supply

to the appliance. If this happens, call your local Service

Force Centre. Under no circumstances should you

attempt to repair the appliance yourself.

Before the First Use

Remove all packaging, both inside and outside

the oven, before using the appliance.

Before first use, the oven should be heated without food.

During this time, an unpleasant odour may be emitted.

This is quite normal.

1. Switch the gas oven function control

F

knob to and the thermostat control knob

to maximum position.

2. Open a window for ventilation.

3. Allow the oven to run empty for

approximately 45 minutes.

5

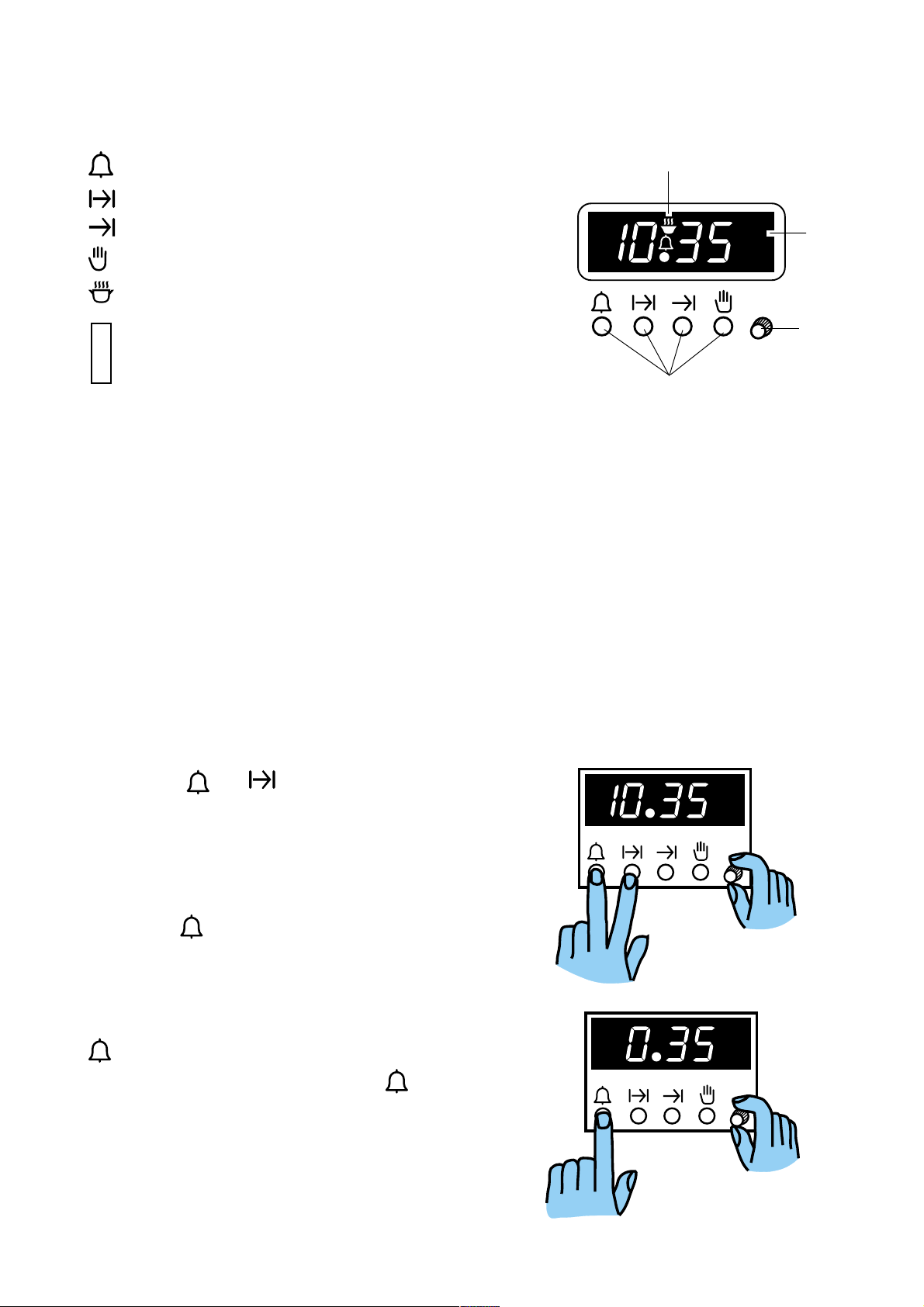

24 hour Clock and Timer

Minute minder

Cooking duration

End of cooking time

Manual function

Cookpot

symbol

A

A

U

U

T

T

O

O

Auto

symbol

Cookpot symbol - This will be displayed when a

program is in operation.

A

Auto symbol - This will be displayed when the

U

oven has been programmed for automatic

T

operation.

O

- + Time setting knob

The electronic timer can indicate the time of day, operate as a minute minder and automatically operate the oven.

Before the oven can be operated, the time of day must

be set on the electronic timer.

Please note that this is a 24 hour clock. For example,

2pm is shown as 14:00.

In case of loss of power, all the settings (time of day, set

program or program in operation), will be cancelled. When

the power is restored, the numbers on the display will

flash, and the timer has to be reset.

Programming

controls

- +

Time

setting

TO SET THE TIME OF DAY

F

Press buttons and , and at the same time turn

the time setting knob until the correct time of day is

displayed.

TO SET THE MINUTE MINDER

F

Press button and at the same time turn the setting

time knob until the duration time is displayed (maximum

23 hours, 59 minutes).

Our diagram shows the timer set for 35 minutes. After a

few seconds the time of day will show in the display.

To check the number of minutes remaining, press the

button. At the end of the timed period an alarm will

sound. To switch off the alarm press button .

- +

- +

6

MANUAL FUNCTION

F

Press button to set the oven for manual function.

TO SET THE TIMER TO

F

SWITCH OFF ONLY

This is useful if you want to begin cooking immediately

but have the oven switch off automatically.

1. Set the oven function control knob and the thermostat

control knob on the required settings.

2. Place food in the oven.

3. Press button and, at the same time, turn the

time setting knob until the required cooking duration

is displayed.

Our diagram shows the timer set for 1 hour 10 minutes.

At the end of the cooking time the oven will switch off, an

alarm will sound. Turn the oven function and thermostat

control knob to zero. To switch off the alarm press button

.

TO SET THE TIMER TO SWITCH

F

THE OVEN ON AND OFF

- +

A

A

U

U

T

T

O

O

- +

1. Ensure the clock is showing the right time of day.

2. Carry out steps 1, 2 and 3 as explained in "To set the

timer to switch off only".

3. Press button and at the same time turn the time

setting knob until the end cooking time is displayed.

Our diagram shows the end cooking time set for 7:35

pm.

At the end of the cooking time turn the oven function and

thermostat control knob to zero.

TO CANCEL A PROGRAMME

F

1. Press button and, at the same time, turn the

time setting knob until the cooking duration is set on

"zero".

2. If the end cooking time has been set too, press button

and at the same time turn the time setting knob

until the end cooking time is set on "zero".

A

A

U

U

T

T

O

O

- +

7

Using the Oven

4

Always cook with the oven door closed.

Stand clear when opening the drop down oven

door. Do not allow it to fall open - support the

door using the door handle, until it is fully open.

The oven has four shelf levels, and is supplied

with two shelves. The shelf positions are counted

from the bottom of the oven as shown in the

diagram.

It is important that these shelves are correctly

positioned as shown in the diagram.

Do not place cookware directly on the oven

base.

The anti-tip shelf has four small metal tabs on its frame

to prevent it from sliding out from the shelf supports.

Hints and Tips

Condensation and steam

When food is heated it produces steam in the same way as

a boiling kettle. The oven vents allow some of this steam to

escape. However, always stand back from the oven when

opening the oven door to allow any build up of steam or

heat to release.

If the steam comes into contact with a cool surface on the

outside of the oven, e.g. a trim, it will condense and produce

water droplets. This is quite normal and is not a fault with the

oven.

To prevent discouloration, regularly wipe away condensation

and also soilage from surfaces.

Cookware

Use any oven proof cookware which will withstand

temperatures of 250°C.

Baking trays, oven dishes, etc. should not be placed

on the oven base.

Do not use baking trays larger than 30 cm x 35 cm

(12 in x 14 in) as they will restrict the circulation of

heat and may affect performance.

3

2

1

FO 0336

ANTI-TIP SHELF

metal tabs

The effects of dishes

on cooking results

Dishes and tins vary in their thickness, conductivity,

colour, etc. which affects the way they transmit heat to

the food inside them.

A Aluminium, earthenware, oven glassware and bright

shiny utensils reduce cooking and base browning.

B Enamelled cast iron, anodized aluminium, aluminium

with non-stick interior and coloured exterior and dark,

heavy utensils increase cooking and base browning.

Grilling with the turnspit

1. Place the proper spit support in the oven.

2. Place the food in the spit and fix the forks by means

of the screws.

3. Insert the point of the spit in the motor drive hole,

which can be found in the back panel of the oven.

4. Place the outside edge of the spit on the spit

support and unscrew the handle.

5. Insert the dripping pan in the lowest level, after

pouring a little water in it.

6. Turn the thermostat control knob to 200.

Maximum cooking time: 60 minutes.

8

FO 0537

Gas Oven Cooking Charts

TEMPERATURE °C FOOD

PUDDINGS

Milk puddings 170 2 1½ - 2 hours

Baked sponge pudding 210 2 45-60 minutes

Baked custard 190 2 50-60 minutes

CAKES

Rich Fruit Cake 170 3 2

Christmas Cake 170 3 3

Victoria Sandwich 210 2 or 3 20-30 minutes

Madeira Cake 210 2 or 3 1 hour

Small Cakes 225 3 15-25 minutes

Plate tart 240 2 50 minutes

Fruit pie 240 2 50 minutes

Mince pies 225 2 or 3 15-25 mins

Profiteroles 210 2 25 minutes

YEAST MIXTURES

Bread

1lb Loaves MAX 2 or 3 30-40 minutes

Bread

2lb Loaves MAX 2 or 3 30-40 minutes

Rolls and Buns MAX 2 or 3 10-20 minutes

ROASTING MEAT

Beef 225 4 20-30 minutes

Lamb 225 4 25-30 minutes

Pork and veal 225 4 30-35 minutes

Chicken 225 4 20 minutes

Turkey 210 5 15-25 minutes

Duck and duckling 225 4 25 minutes

Stuffed poultry 225 4 25 minutes

SHELF COOKING

POSITION TIME

¼

hours

½

- 4½ hours

This chart is intended as a guide only.

It may be necessary to increase or

decrease the temperature to suit your

individual requirements. Only

experience will enable you to

determine the correct setting for your

personal requirements.

Grilling

Quantity

FOOD

Number

of pieces

Steaks

Sausages 8 500 4 MAX 10 6

Chicken joints 6 800 3 MAX 3 0 20

Kebabs 4 700 4 MAX 12 10

Tomatoes 8 500 4 MAX 12 —

Fish filets 4 400 4 MAX 8 6

Toasts 4 — 4 MAX 8 —

Bread 4 — 4 MAX 2~3 1

Gramms

4 800 4 MAX 10 8

Shelf

position

Grilling

4

3

2

1

temperature

°C

Minutes

upper

side

Cooking with the turnspit

FOOD Gr am ms Shelf position Temp. °C minutes

Chicken 1000 3 200 50/60

Roasts 800 3 200 50/60

lower

side

9

Cleaning the Oven

The oven should be kept clean at all times. A build-up of fats or other foodstuffs could result in a fire,

especially in the grill pan.

Cleaning materials

Before using any cleaning materials on your oven, check

that they are suitable and that their use is recommended

by the manufacturer.

Cleaners that contain bleach should NOT be used as

they may dull the surface finishes. Harsh abrasives

should also be avoided.

External cleaning

Regularly wipe over the control panel, oven door and door

seal using a soft cloth well wrung out in warm water to

which a little washing up liquid has been added.

To prevent damaging or weakening the door glass

panels avoid the use of the following:

Household detergent and bleaches

Impregnated pads unsuitable for non-stick

saucepans

Brillo/Ajax pads or steel wool pads

Chemical oven pads or aerosols

Rust removers

Bath/Sink stain removers

Oven Shelves

To clean the oven shelves, soak in warm soapy water

and remove stubborn marks with a well wetted soap

impregnated pad. Rinse well and dry with a soft cloth.

Oven lamp replacement

Disconnect the appliance.

Unscrew the lamp and replace it with another suitable

for higher temperatures (300°C) having the following

characteristics:

Voltage: 230-240V (50Hz)

Power: 25W

Connection: E14

Clean the outer and inner door glass using warm soapy

water. Should the inner door glass become heavily soiled

it is recommended that a cleaning product such as Hob

Brite, or Bar Keepers Friend is used.

DO NOT clean the oven door while the glass

panels are warm. If this precaution is not observed

the glass panel may shatter.

If the door glass panel becomes chipped or has

deep scratches, the glass will be weakened and

must be replaced to prevent the possibility of the

panel shattering. Contact your local Service Centre

who will be pleased to advise further.

Oven Cavity

The enamelled oven cavity is best cleaned whilst the

oven is still warm.

Wipe the oven over with a soft cloth soaked in warm

soapy water after each use. From time to time it will be

necessary to do a more thorough cleaning, using a

proprietary oven cleaner.

FO 0424

10

Something Not Working

If the appliance is not working correctly, please carry out the following checks, before contacting your local Service

Force Centre.

IMPORTANT:

installation, a charge will be made even if the appliance is under guarantee.

If you call out an engineer to a fault listed below, or to repair a fault caused by incorrect use or

SYMPTOM

n The oven or grill will not light

n Food is cooking too quickly or too slowly

n

The oven is not cooking evenly

n The oven light does not work

n Steam and condensation settle on the food and the

oven cavity.

SOLUTION

u Check that the oven is switched on at the wall

u Check that the power supply has not been

interrupted before the cooling fan has had time to cool

the oven down

u Check that there is not a problem with your gas

supply

u Check that you are using the recommended gas

marks and shelf positions

u Check that the oven is installed properly and is

level.

u Check that you are using the recommended gas

marks and shelf positions

u Check the light bulb, and replace it if necessary

(see "Oven lamp replacement")

u Refer to the contents of this booklet, especially to

the chapter Using the Oven.

u Leave dishes inside the oven no longer than 15-20

minutes after the cooking is completed.

If after these checks, the appliance still does not work,

contact your local Service Force Centre.

When you contact the Service Force Centre, they will

need the following information:

1. Your name, address and post code.

2. Your telephone number

3. Clear and concise details of the fault

4. The model and the serial number (see rating label)

5. Date of purchase

Service and Spare Parts

If you require spare parts or an engineer contact your local

Service Force Centre by telephoning:

08705 929 929

Your call will be routed to the Service Centre covering your

post code area. The addresses of Electrolux Service

Force Centres are detailed on the following pages.

CUSTOMER CARE

For general enquiries concerning your appliance and for

further information on Electrolux products, contact our

Customer Care Department by letter or telephone as

follows:

Customer Care Department

Electrolux

55-77 High Street

Slough

Berkshire SL1 1DZ

Tel : 08705 950 950*

* calls to this number may be recorded for training purposes

11

Guarantee Conditions

Electrolux Standard Guarantee

Conditions

We, Electrolux, undertake that if, within 12 months of the

date of the purchase, this Electrolux appliance or any part

thereof is proved to be defective by any reason only of

faulty workmanship or materials, we will, at our option,

repair or replace the same FREE OF ANY CHARGE for

labour, materials or carriage on condition that:

* The appliance has been correctly installed and used

only on the gas and electricity supply stated on the

rating plate.

* The appliance has been used for normal domestic

purposes only, and in accordance with the

manufacturer's instructions.

* The appliance has not been serviced, maintained,

repaired, taken apart or tampered with by any person

not authorised by us.

* All service work under this guarantee must be

undertaken by an Electrolux Service Force Centre.

* Any appliance or defective part replaced shall

become the Company's property.

* This guarantee is in addition to your statutory and

other legal rights.

Home visits are made between 8.30am and 5.30pm

Monday to Friday. Visits may be available outside these

hours, in which case a premium will be charged.

Exclusions

This guarantee does not cover:

* Damage or calls resulting from transportation,

improper use or neglect, the replacement of any light

bulbs or removable parts of glass or plastic.

* Costs incurred for calls to put right an appliance

which is improperly installed or calls to appliance

outside the United Kingdom.

* Appliances found to be in use within a commercial

or similar environment, plus those which are the

subject to rental agreements.

* Products of Electrolux manufacture which are not

marketed by Electrolux.

European Guarantee

If you should move to another country within Europe then

your guarantee moves with you to your new home

subject to the following qualifications:

* The guarantee starts from the date you first

purchased your product.

* The guarantee is for the same period and to the same

extent for labour and parts as exist in the new contry

of use for this brand or range of products.

* This guarantee relates to you and cannot be

transferred to another user.

* Your new home is within the European Community

(EC) or European Free Trade Area.

* The product is installed and used in accordance with

our instructions and is only used domestically, i.e. a

normal household

The electrical supply complies with the specification

given in the rating label.

* The product is installed taking into account

regulations in your new country.

Before you move, please contact your nearest Customer

Care centre, listed below, to give them details of your

new home. They will then ensure that the local Service

Organisation is aware of your move and able to look after

you and your appliances.

France Senlis +33 (0)3 44 62 22 22

Germany Nürnberg +49 (0)911 323 2600

Italy Pordenone +39 (0)1678 47053

Sweden Stockholm +46 (0)20 78 77 50

UK Slough +44 (0)1753 219 898

12

ELECTROLUX SERVICE FORCE

To contact your local Electrolux Service Force Centre telephone 08705 929 929

CHANNEL ISLANDS

GUERNSEY Gu ernsey Electricity

PO Box 4

Vale, Guernsey

Channel Islands

JERSEY Jersey Electricity

Company

PO Box 45

Queens Road

St Helier

Jersey

Channel Islands

JE4 8NY

SCOTLAND

ABERDEEN 54 Claremont Street

(M05) Aberdeen

AB10 6RA

AUCHTERMUCHY 33A Burnside

(M03) Auchtermuchy

Fife

KY14 7AJ

BLANTYRE Unit 5

(M07) Block 2

Auchenraith Industrial

Estate

Rosendale Way

Blantyre

G72 0NJ

DUMFRIES 9 3 Irish Street

(M01) Dumfries

Scotland

DG1 2PQ

DUNOON Briar Hill

7 Hill Street

(M 67) Dunoon

Argyll

PA23 7AL

GLASGOW 20 Cunningham Road

(M04) Clyde Estate

Rutherglen,

Glasgow,

G73 1PP

INVERNESS Unit 3B

(M06) Smithton Indust. Est.

Smithton

Inverness

IV1 2PD

ISLE OF ARRAN Arran Domestics

(OWN SALES) Unit 4 The Douglas

Centre

Brodick

Isle of Arran

KA27 8AJ

ISLE OF BARRA J Zerfah

(OWN SALES) 244 Bruernish

Isle of Barra

Western Islands

HS9 5QY

ISLE OF BUTE Walker Engineering

(M66) Glenmhor

Upper Serpentine

Road

Rothesay

Isle of Bute

PA20 9EH

ISLE OF LEWIS ND Macleod

(M69) 16 James Street

Stornoway

Isle of Lewis

PA872QW

KELSO 2-8 Wood Market

(M08) Kelso

Borders TD5 7AX

ORKNEY Cors ie Domestics

(M65) 7 King Street

Kirkwall

Orkney KW15 1RE

PERTH Hydro Electrical

Inveralmond House

Ruthervenfield Road

Perth PH1 3AQ

PERTH Graham Begg Unit 4

(OWN SALES) Airport Ind Estate

Wick KW1 4QS

SHETLAND Tait Electronic

(OWN SALES) Systems Ltd.

Holmsgarth Road

Lerwick

Shetland ZE1 0PW

SHETLAND Bolts Shetland Ltd

(OWN SALES) 26 North Road

Lerwick

Shetland ZE1 0PE

WHALSAY Leask Electrical

Harlsdale

Symbister, Whalsay

(OWN SALES) Shetland ZE2 9AA

NORTHERN IRELAND

BELFAST Owenmore House

(M27) Kilwee Industrial

Estate

Upper Dunmury Lane

Belfast

BT17 0HD

WALES

CARDIFF Guardian Industrial

(M28) Estate

Clydesmuir Road

Tremorfa, Cardiff

CF2 2QS

CLYWD Unit 6-7 Coed - Parc

(M14) Abergele Road

Rhuddlan

Clwyd

Wales

LL18 5UG

OSWESTRY Plas Funnon

Warehouse

(M17) Middleton Road

Oswestry

SY11 2PP

HAVERFORDWEST Cromlech Lodge

(M75) Ambleston

Haverfordwest

Pembrokeshire

SA62 5DS

DYFED Maes Y Coed

(M77) High Mead

Llanybydder

Carmarthenshire

SA40 9UL

NORTH EAST

GATESHEAD U nit 356a

(M39) Dukesway Court

Dukesway

Team Valley

Gateshead

NE11 0BH

GRIMSBY 15 Hainton Avenue

(M42) Grimsby

South Humberside

DN32 9AS

HULL Unit 1

(M41) Boulevard Industrial

Estate

Hull

HU3 4AY

LEEDS 64-66 Cross Gates

(M37) Road

Leeds

LS15 7NN

NEWTON AYCLIFFE Unit 16

(M45) Gurney Way

Aycliffe Ind Estate

Newton Aycliffe

DL5 6UJ

SHEFFIELD Pennine House

(M38) Roman Ridge Ind.

Roman Ridge Road

Sheffield

S9 1GB

NORTH WEST

BIRKENHEAD 1 Ke lvin Park

(M11) Dock Road

Birkenhead

L41 1LT

CARLISLE Unit 7

(M10) James Street

Workshops

James Street

Carlisle

Cumbria CA2 5AH

ISLE OF MAN South Quay Ind.

(M64) Estate

Douglas

Isle of Man IM1 5AT

LIVERPOOL Unit 1

(M15) Honeys Green

Precinct

Honeys Green Lane

Liverpool

L12 9JH

MANCHESTER Unit B

(M09) Central Industrial

Estate

St Marks Street

Bolton

BL3 6NR

PRESTON Un it 25 0

(M13) Dawson Place

Walton Summit

Bamber Bridge

Preston

Lancashire

PR5 8AL

STOCKPORT Un it 20 Ha igh Park

(M16) Haigh Avenue

Stockport

SK4 1QR

13

ELECTROLUX SERVICE FORCE

To contact your local Electrolux Service Force Centre telephone 08705 929 929

MIDLANDS

BIRMINGHAM 66 B irch Road East,

(M18) Wyrley Road

Industrial

Estate

Witton

Birmingham

B67DB

BOURNE M anning Road Ind

(M44) Estate

Pinfold Road

Bourne

PE10 9HT

BRIDGNORTH 6 5 St.Marys Street

(M72) Bridgnorth

Shropshire

WV16 4DR

GLOUCESTER 101 Rycroft Street

(M23) Gloucester

GL1 4NB

HEREFORD Unit 3

(M31) Bank Buildings

Cattle Market

Hereford

HE4 9HX

HIGHAM FERRERS 30 High Street

(M51) Higham Ferrers

Northants

NN10 8BB

ILKESTON Unit 2

(M43) Furnace Road

Ilkeston

DE7 5EP

LEICESTER Unit 7

(M22) Oaks Industrial Estate

Coventry Road

Narborough

Leicestershire

LE0 5GF

LINCOLN Unit 8 Stonefield Park

(M40) Clifton Street

Lincoln

LN5 8AA

NEWCASTLE 18- 21 Cro ft Road

UNDER LYME Brampton Industrial

(M12) Estate

Newcastle under

Lyme

Staffordshire

ST5 0TW

REDDITCH 13 Thornhill Road

(M20) North Moons Moat

Redditch

Worcestershire

B98 9ND

TAMWORTH Unit 3

(M19) Sterling Park

Claymore

Tamworth

B77 5DO

WORCESTER Unit 1&2

(M73) Northbrook Close

Gregorys Mill Ind

Estate

Worcester

WR3 8BP

14

LONDON & EAST ANGLIA

BECKENHAM 11a Gardener Ind

(M79) Estate

CHELMSFORD Hanbury Road

(M47) Widford Ind Estate

COLINDALE Unit 14

(M53) Capital Park

ELTHAM 194 Court Road

(M78) Mottingham - Eltham

ENFIELD 284 Alma Road

(M49) Enfield

GRAVESEND Unit B4,

(M57)

HARPENDEN Unit 4

(M46) Riverside Estate

LETCHWORTH 16-17 Woodsite Ind

(M50) Est.

LONDON 2/4 Ro yal Lane

(M76) Yie wsley

MAIDENHEAD Reform Road

(M60) Maidenhead -

MOLESEY 10 Island Farm

(M61) Avenue

NEWBURY 9 P ipers Court

(M24) Berkshire Drive

IPSWICH Unit 6C

(M48) Elton Park Business

NORWICH 2b Trafalgar Street

(M52) Norwich

SUNBURY Unit 1a

(M63) The Summit

Kent House Lane

Beckenham

Kent BR3 1QZ

Chelmsford

Essex

CM12 3AE

Capital Way

Colindale

London NW9 0EQ

London SE9 4EW

London

EN3 7BB

Imperial Business

Estate

Gravesend

Kent

DA11 0DL

Coldharbour Lane

Harpenden

AL5 4UN

Works Road

Letchworth

Herts

SG6 1LA

West Drayton

Middlesex

UB7 8DL

Berkshire

SL6 8BY

West Molesey

Surrey

KT8 2UZ

Thatcham

Berkshire

RG19 4ER

Centre

Hadleigh Road

Ipswich

IP2 0DD

NR1 3HN

Hanworth Road

Hanworth Ind Estate

Sunbury on Thames

TW16 5D

SOUTH EAST

ASHFORD Unit 2

(M58) Bridge Road

FLEET Unit 1

(M59) Redfields Industrial

HAYWARDS HEATH 21-25 Bridge Road

(M55) Haywards Heath

Business

Estate

Bridge Road

Ashford

Kent

TN2 1BB

Estate

Church Crookham

Fleet

Hampshire

GU13 0RD

Sussex

RH16 1UA

SOUTH WEST

BARNSTAPLE Main Road

(M30) Fremington

BOURNEMOUTH 63-65 Curzon Road

(M26) Bournemouth

BRIDGEWATER

(M35)

BRISTOL 11 Eldon Way

(M25) Eldonwall Trading

EMSWORTH 266 Main Road

(M33) Southboure

ISLE OF WIGHT Unit 8

(M34) Enterprise Court

NEWTON ABBOT Unit 2

(M29)

PLYMOUTH 16 Faraday Mill

(M32) Cattledown

REDRUTH Unit 7D Pool Industrial

(M36) Estate

Barnstaple

North Devon

EX31 2NT

Dorset

BH1 4PW

6 Hamp Industrial

Estate

Bridgewater

Somerset

Bristol

Avon

BS4 3QQ

Emsworth

PO10 8JL

Ryde Business Park

Ryde

Isle of Wight

PO33 1DB

Zealley Industrial

Estate

Kingsteignton

Newton Abbot

S. Devon

TQ12 3TD

Plymouth

PL4 0ST

Wilson Way, Redruth,

Cornwall

TR15 3QW

Instructions for the Installer

Technical Data

Oven

Model Number: EOG 621

APPLIANCE GAS SUPPLY: Natural Gas G20 20mbar

APPLIANCE CATEGORY

:II 2H3+

Cabinet Dimensions

Minimum aperture height 580 mm

Minimum aperture depth 550 mm

Minimum aperture width 560 mm

Grill Element 1,830 W

Oven burner 2,700 W (Natural gas)

Oven light 25 W

Cooling fan 25 W

Turnspit motor 4 W

Total rating 1,880 W

Supply voltage (50 Hz) 230-240 V

Important Safety Requirements

2,500 W (LPG)

This appliance must be installed in accordance with the

Gas Safety (Installation and Use) Regulations (current

addition) and the I.E.E. Wiring Regulations. Detailed

recommendations are contained in the following British

Standard Codes of Practice - B.S. 6172, B.S. 5440: Part

2 and B.S. 6891: Current Editions.

Provision for Ventilation

This appliance is not connected to a combustion

products evacuation device. It shall be installed and

connected in accordance with the current installation

regulations. Particular attention shall be given to the

relevant requirements regarding ventilation.

The room containing the appliance should have an air

supply in accordance with BS. 5440: Part 2 Current

Edition. All rooms require an openable window or

equivalent and some rooms will require a permanent vent

as well. For room volumes up to 5m3 an air vent 100cm

is required; for room volumes between 5m3 and 10m3,

an air vent with a minimum area of 50cm2 is required. If

the room has a door which opens directly to the outside,

no air vent is required. For room volumes that exceed

11m3 no air vent is required.

If there are other fuel burning appliances in the same

room, B.S. 5440: Part. 2: Current Editions should be

consulted to determine the requisite air vent

requirements.

2

Prolonged intensive use of the appliance may call for

additional ventilation, for example opening a window, or

more effective ventilation, for example increasing the

level of mechanical ventilation where present.

15

Building in

min 550

140 240

591

min. 4

560÷570

110

Location of appliance

The appliance may be located in a kitchen, a kitchen/

diner or bedsitting room but not in a bathroom, shower

room or bedroom.

It is essential that there is a minimum clearance of 3mm

between the top surface of the appliance and the inside

top of the cabinet. The unit must be fitted into a cabinet

conforming to Fig.2.

This oven unit may be used in a Built-in or a Built-under

situation (see relevant diagrams). If the appliance is to

be built-under a hob, it is recommended thet the hob be

installed before the oven unit.

Please ensure that when the oven is installed it is

easily accessible for the engineer in the event of

a breakdown.

BUILDING IN

The surround or cabinet into which the oven will be built

must comply with these specifications:

l the dimensions must be as shown in the relevant

diagrams;

l the materials must withstand a temperature increase

of at least 60°C above the ambient temperature;

l proper arrangements must be made of a continuous

supply of air to the oven to prevent the oven overheating.

Dimensions of the oven and recess required are given

in the relevant diagrams (in millimetres).

Fig.1

Fig.2

FO 0374

FO 0290

550

580

0

4

4

560-570

min 550

m

in

110

Fig.3

Fig.4

min. 4

591

560÷570

110

FO 2128

FO 2129

16

Securing the oven to the cabinet

1. Fit the oven into the cabinet recess,

2. Open the oven door

3. Secure the oven to the kitchen cabinet with four wood

screws, which fit the holes provided in the oven frame.

Electrical Connection

The oven is designed to be connected to 230-240V (50Hz)

electricity supply.

The oven has an easily accessible terminal block which

is marked as follows:

Letter L - Live terminal

Letter N - Neutral terminal

or E - Earth terminal

THIS OVEN MUST BE EARTHED

The cable used to connect the oven to the electrical

supply must comply to the specifications given below.

For Uk use only

It is necessary that you install a double pole switch

between the oven and the electricity supply (mains), with

a minimum gap of 3mm between the switch contacts and

of a type suitable for the required load in compliance with

the current rules.

The switch must not break the yellow and green earth

cable at any point.

Important

After installation and connecting, the cable must be

placed so that it cannot at any point reach a temperature

of more than 60°C above the ambient temperature.

Before the oven is connected, check that the main fuse

and the domestic installation can support the load; and

that the power supply is properly earthed.

Fig.5

FO 0039

Connection Min. size Cable / flex Fuse

via Cable/flex type

13 A socket 2.5 mm

outlet butyl min.

13 A insulated

spur box

Cooker 2.5 mm

Control twin and

Circuit earth

For Europe use only

Min. size Cable/flex Cable / flex type Fuse

1.5 mm

2

2

3 core 13 A

2

PVC/PVC

H05 RR-F 13 A

13 A

The manufacturer disclaims any responsibility should

these safety measures not be carried out.

17

Gas connection

Fitting the appliance and cabinet

The gas supply connection ramp is positioned in the front

upper side of the oven, behind the control panel.

To carry out the gas connection, partially insert the oven

in the recess (about 30 cm.) and operate on the

connection ramp from the top. The gas connection can

be carried out in both the following systems:

1) Fig. 6 flexible metallic pipes (with maximum length

up to 2 metres only) screw the feed pipe to the

1/2 connection ramp, inserting the gasket provided

between the pipe and the ramp;

2) Fig. 7 rigid metallic pipe (soft copper - minimum

diameter: 8 mm) insert the copper pipe into the

connection ramp after fitting the correct nut and olive

onto the copper pipe using a male / female adapter

(not supplied).

To carry out the connection:

- tighten (fig.8) the nuts by means of a 22 mm. spanner,

in order to keep the ramp in position and not to cause

any distortion to the gas supply circuit.

- completely insert the oven in the recess and secure it

as indicated in the relevant paragraph.

Check the gas supply ramp and the gas

connection pipe are not squeezed while the

oven is positioned into the recess.

Fig.6

FO 0671

nut

flexible

metallic pipe

gasket

rigid

metallic pipe

olive

male / female

adapter

The use of rubber flexible hoses is not

permitted.

WARNINGS

• Using a gas cooking appliance will produce heat

and moisture in the room which it has been

installed in. Ensure a continuous air supply,

keeping the air vents in good conditions or

installing a cooker hood with discharge tube.

• In case of intensive or long time use of the

appliance, make the ventilation more efficient,

by opening a window or increasing the electric

exhaust fan power.

Check the perfect sealing of the connection using

leak detection fluid.

Fig.7

Fig.8

FO 0672

gas supply

ramp

FO 0673

nut

18

Conversion from Natural to LPG Gas

IMPORTANT

The replacement/conversion of the gas hob

should only be undertaken by a CORGI registered

engineer.

It is important to note that this model is designed for

use with natural gas but can be converted for use with

butane or propane gas providing the correct injectors

are fitted. The gas rate is adjusted to suit. The oven

burner does not need any primary air regulation.

Replacement of gas oven

burner nozzle

To replace the gas oven nozzle, follow this procedure:

a) remove the bottom of the oven;

b) undo screw a and b and take the oven burner out;

c) with a socket spanner 7 unscrew and remove the

nozzle, situated in the bottom of the oven, and replace

it with the correct one (see Table on this page);

d) reassemble the burner following the same procedure

backwards.

TYPE OF GAS NOZZLES NOMINAL POWER IN GAS NOMINAL MIN MAX

1/100 MM POWER PRESSURE PRESSURE PRESSURE

KW m3/h g/h (mbar) mbar mbar

Fig. 9

a

b

Natural gas

(G20)

Butane

(G30)

Propane

(G31)

114 2,7 257 - 20 17 25

78 2,5 - 180 30 20 35

78 2,5 - 180 37 25 45

19

CUSTOMER CARE

Electrolux

55-77 High Street

Slough

Berkshire, SL1 1DZ

Tel: 08705-950950

© Electrolux Household Appliances Limited 2000

The Electrolux Group. The worlds No.1 choice.

The Electrolux Group is the worlds largest producer of powered appliances for kitchen, cleaning and outdoor use. More than

55 Group products (such as refrigerators, cookers, washing machines, vacuum cleaners, chain saws and lawn mowers) are

sold each year to a value of approx. USD 14 billion in more than 150 countries around the world.

Grafiche MDM - Forlì

Loading...

Loading...