Page 1

Do-It-

Yourself

Planning &

Installation

Manual

for your new

AFUERA

TM

Central

Cleaning

System

Page 2

Before you start, read these instructions

thoroughly.You will be pleased to learn that a

central cleaning system is surprisingly easy

to install, and will provide you with years of

trouble-free enjoyment. All central cleaning

systems may be installed in either existing

or new construction. In either case, the number of inlets required and their locations

must be determined before starting the

installation.

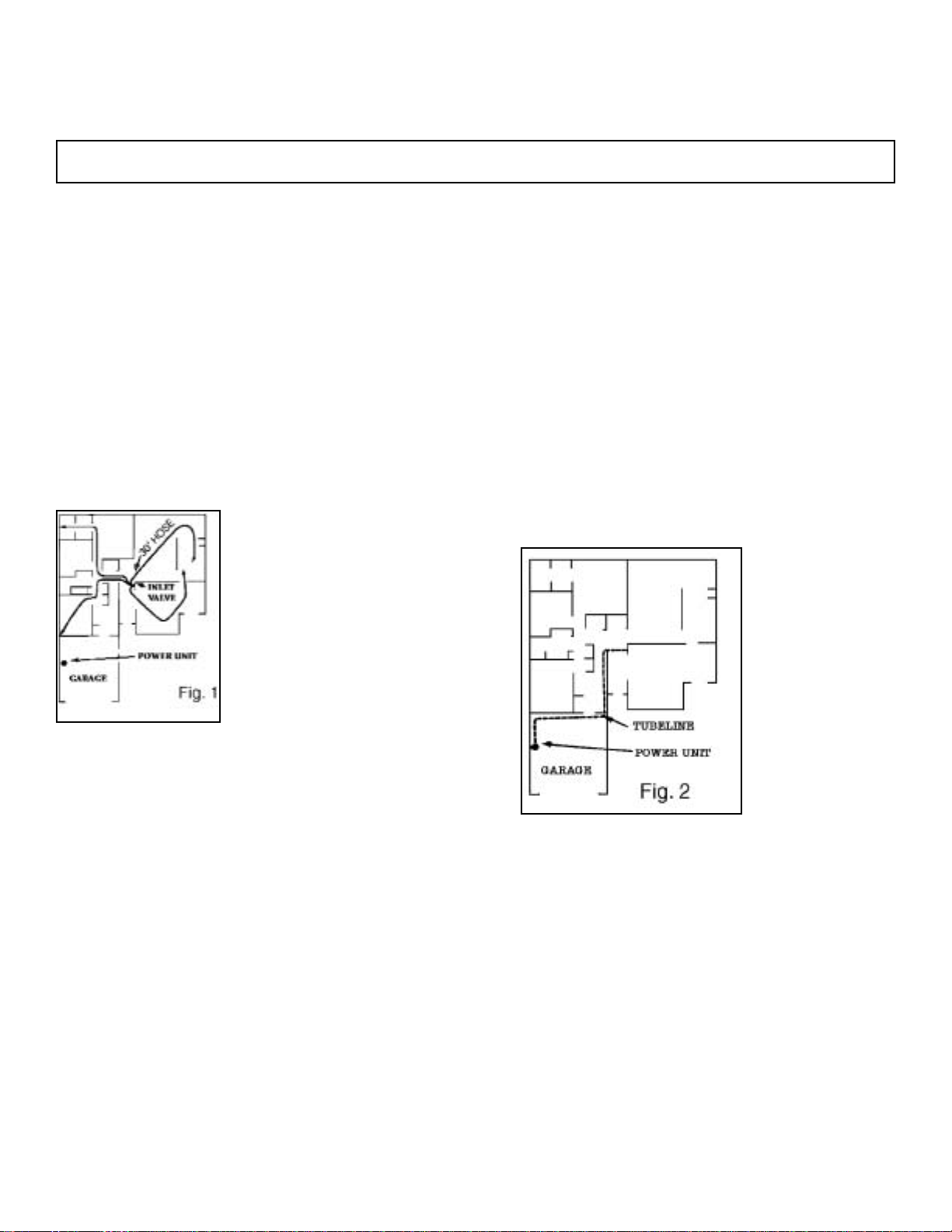

STEP 1: Choose the Valve Locations

Choose central locations for inlet valves in order to

cover the maximum area with the deluxe 30 foot

(9m) length hose. Usually several rooms (or The

Entire Main Floor) can be

serviced from a single inlet

valve (Fig. 1). There is an

inlet valve on the power unit

itself, and this feature often

reduces, by one, the number of inlets required. Since

floor plans are normally

drawn to 1/4" scale (1 to

50cm), a 7-inch (18cm)

piece of string or beaded

chain will help to determine

inlet valve locations and hose coverage using the

floor plans of the construction. If the building is existing or under construction, use a 30 foot (9m) tape or

rope. Be sure every inch of floor, wall, closet, and

ceiling can be reached, bearing in mind the hose

may have to reach around large pieces of furniture.

Good locations are centrally located in hallways or

closet walls near doorways. Inlets should be

installed near an electrical outlet (no more than 6 ft.

(1.82m) away). This would allow the use of an electric hose without using a drop cord. Caution—Do

not place inlet valves where a door slides in the

wall,behind possible furniture, or behind open

doors. In existing homes, consider whether you will

want floor inlets or wall inlets. Floor valves are more

easily installed than wall valves and sometimes are

the only practical installation. They have some disadvantages as the hose must be inserted at the floor

level rather than at a more convenient wall height.

Wall height is a matter of individual preference.

Some homeowners prefer the inlet at a convenient

fingertip height (about 30 inches (76cm)), while others want it to match the electric outlet height.

STEP 2: Choose Power Unit Location

The power unit can be mounted on almost any wall.

It should be out of the way , yet accessible, so the dirt

receptacle may be emptied. If you plan to exhaust

the power unit, locate it so piping can be run outside

conveniently. Venting over 10 ft. (3m) is not recommended. You will need to plug your power unit into

an electric outlet with no other loads on the circuit or

you may want to run a separate 15 amp. circuit.

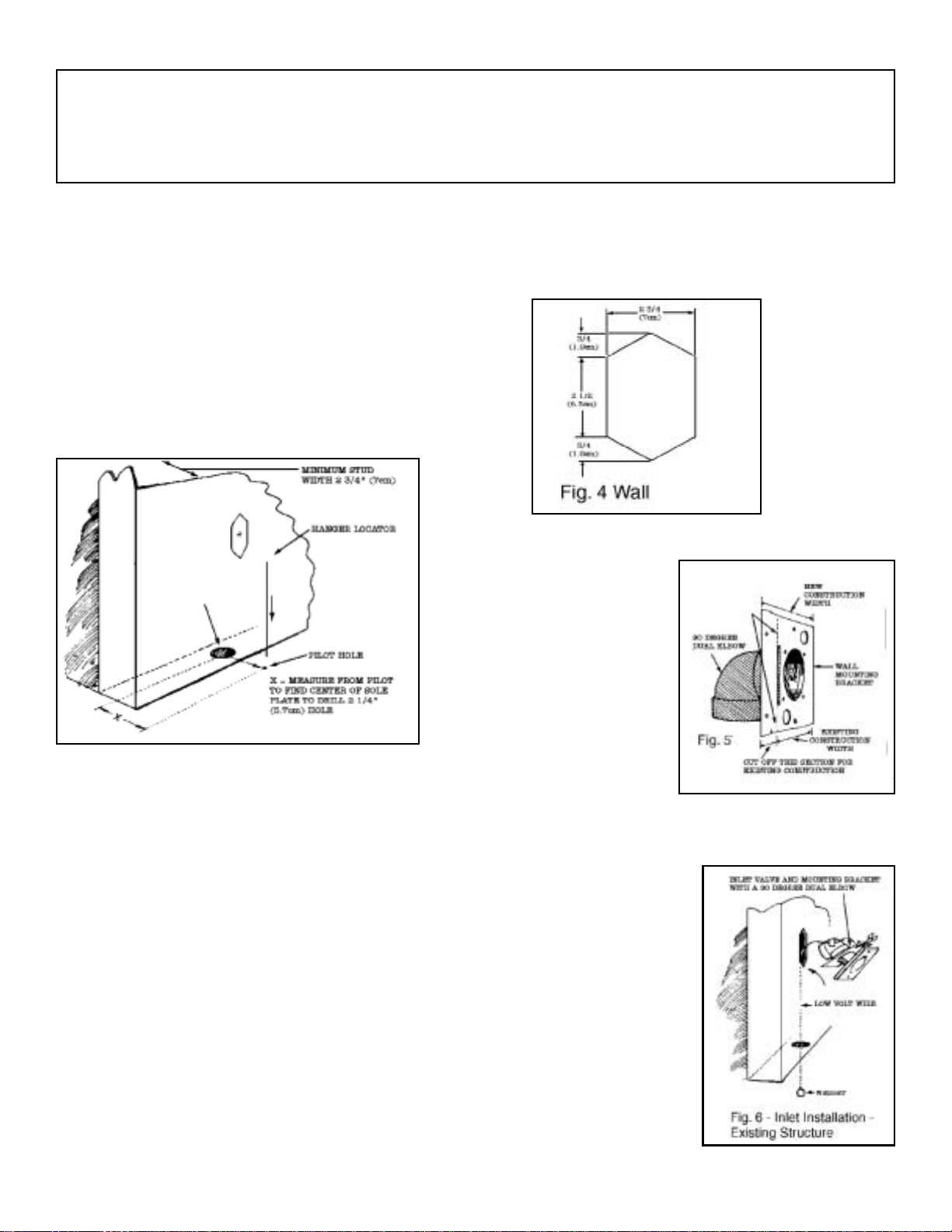

STEP 3: Plan the Tube System

Plan the entire tubing installation from the power unit

to the desired location of the valve(s) (Fig. 2). It is

best to run tubing under the floor in structures with

basements or adequate crawl space. In locations

with no under-floor access, tubing may be run “up”

to the attic and over

to the power unit

using the same precautions and basic

procedures as with a

“down” system. In 2or 3-story existing

structures, tubing

can be run to upper

levels, through

clothes chutes, back

corners of closets,

under stairways,

beside soil

pipes, beside chimneys, or in partition walls before

the drywall goes on. The system that uses the least

amount of bends and tubing should be used.

STEP 4: Tools Required

a) 1/2" (1.3cm) Electric Drill

b) 2-1/4" (5.7cm) Hole Saw or Cutter

c) Steel Tape Measure

d) Screwdriver (Phillips)

e) Screwdriver (Common Blade)

f) Wire Cutters

g) Common Hacksaw or Small Handsaw

h) Hammer i) Masonry Drill Bit

j) Chisel k)Pocket Knife

l) Metal Coat Hanger m)Electrical Tape

n) Razor Knife

A. How to Plan Your New Central Cleaning System

Page 3

STEP 1: Installing Inlet Valves

a) Wall Valves in Existing Structure

Determine as closely as possible desired location

of inlet valve. Drill a small pilot hole in the floor

directly below the proposed valve location. A

straight length of coat hanger wire, cut at an

angle, makes a good pilot hole drill bit, but, be

careful not to snag carpeting. Leave straightened

length of coat hanger wire through this pilot hole

to serve as locator and guide point (Fig. 3).

From beneath floor, measure over from pilot hole

to

locate the center of the sole plate.

NOTE: You may want to drill a 3/4" (1.9cm)

inspection hole to avoid drilling into the bottom of

a stud or other “inner-wall” obstruction. Drill a 21/4" (5.7cm) diameter hole through the center of

the sole plate. Using a flashlight or probe, inspect

the interior of the wall to be sure there are no

obstructions.

NOTE: The opening you are going to cut in the

wall for the inlet valve should be located between

studs, clear of obstructions such as plumbing,

wiring, heat ducts, etc. Minimum stud width for

sufficient clearance for inner-wall mountingbracket assembly is 2-3/4" (7cm). (See Fig. 3

above.)

b) Using METAL Stud-Mounting Bracket

Centered at the desired height above floor level,

cut an almost square opening 2-3/4" (7cm) wide

by 2-1/2" (6.35cm) high in the wall directly above

the 2-1/4" (5.7cm) sole plate hole. Cut or file two

3/4" (1.9cm) high triangular pieces above and

below the almost square opening so that your wall

opening exactly resembles (Fig. 4). Insert top

screw only through inlet valve and gently squeeze

inlet valve stem

into bracket

assembly until

you are able to

just start top

screw threads in

bracket assembly hole.

Now cut or break

off “New

Construction”

section from

metal wall mounting bracket and glue a 90 degree

dual elbow to the

pre-riveted

adapter ring

(Fig. 5). Strip the

low-volt wire and

tape it to the 90

degree dual elbow

with approximately

6 inches (15.3cm)

sticking through

wire guide hole.

Join two inlet valve

wires with wire

connectors supplied. Attach a

small weight to the

other end of the

low-volt wire and drop

the weighted wire

through the opening

in wall. Allow wire and

weight to hang

through sole plate

(Fig. 6).

B. How to Install Your New Central Cleaning

System

Page 4

insert assembled 90 degree dual elbow and

wall-bracket assembly through wall cutout hole

as illustrated (Fig. 7).

Once metal mounting bracket is completely inside wall

cavity, slide the

entire assembly

upwards so metal

plate is flush with

inner wall surface

and inlet valve is

flush with outer wall

surface. You can

insert index finger

through inlet valve opening and gently squeeze

inlet valve stem further into inner wall assembly

(Fig. 8).

NOTE: Mount inlet

valve so lid pulls

down to open.

Now, insert and

partially tighten

bottom\Inlet valve

screw. Tuck lowvoltage wires and

connectors under

sides of wall inlet

valve. Adjust inlet

valve for perfect

vertical alignment

and tighten both

inlet valve mounting screws. Be sure the inlet

valve lid operates freely. Apply glue to an adequate length of tubing and aim it upwards

through the hole and into the 90 degree dual

elbow fitting on the back of the mounting plate.

Join this branch line to the trunk line using a 90

degree sweep tee.

If the inlet valve is to be serviced from the attic,

shorter pieces of tubing joined by couplings

may be required due to overhead space restrictions. Precut these pieces and work quickly to

prevent the cement on the end of the tubing

from drying before it reaches the fitting at the

valve below.

c) Using PLASTIC Stud-Mounting

Bracket

Having determined the location is suitable, cut

a 2- 1/2" (6.35cm) x 4-3/8" (11cm) hole in the

wall at the

desired inlet

valve location (See Fig.

9).

Now cut or

break off

“new construction”

section from

plastic wall

mounting

bracket.

Tape low-

voltage wire

to the end of a sufficiently long piece of tubing

and pass it up from beneath. If the trunk line is

in the attic, tie a weight to the end of the lowvoltage wire and lower it through the opening.

Remove the wire and pass it through the upper

hole in the trimmed mounting plate. Bare an

inch of both wire leads and wrap them around

the lugs on the back of the valve in a clockwise

direction. Tighten the lugs with a Phillips screwdriver.

Apply cement to the flange on the back of the

mounting plate

and attach a

90 degree

dual elbow fitting oriented in

the appropriate direction.

Tilt the mounting plate forward and

angle it into

the hole in the

wall. Center

the mounting

plate in the

hole and pull

outward (See Fig. 10).

Page 5

Hold the mounting plate in place with a bent

coat hanger. Open the valve lid and slide the

valve flange first over the end of the coat hang-

er. Keep tension on the coat

hanger while

inserting the

valve into the

mounting plate

with a twisting

motion (See

Fig. 11). Do not

use glue; the

built in mounting plate gasket

will provide a

positive seal.

Align the screw

holes in the valve with those in the mounting

plate. Using the screws provided, secure the

valve in place. Use the extra short screw if the

longer is going to interfere with the tubing

behind. Do not over tighten.

Apply glue to an adequate length of tubing and

aim it upwards through the hole and into the 90

degree dual elbow fitting on the back of the

mounting plate. Join this branch line to the trunk

line using a 90 degree sweep tee.

If the inlet valve is to be serviced from the attic,

shorter pieces of tubing joined by couplings

may be required due to overhead space restrictions. Precut these pieces and work quickly to

prevent the on the end of the tubing from drying

before it reaches the fitting at the valve below.

d) Floor Valves

To install a floor inlet, drill a pilot hole with a coat

hanger and check the location as previously

described. When you are sure that the proposed location will not be blocked by a joist or

other obstruction, cut a hole in the carpet slightly larger than your 2-1/4" (5.7cm) drill bit. Drill a

2-1/4" (5.7cm) hole in the floor. Chisel or saw

this hole larger to accommodate the inlet valve

low-volt connections (Fig. 12).

Assemble an adapter reducer bushing and

some low-volt wire to an inlet valve. Screw the

valve to the floor. Repeat until all inlets are

installed (Fig. 13).

e) Closet Wall Installation—Existing

Structure

Often it is only practical to install your system

with the line coming up through the floor inside

a closet and

then through

both sides of

the wall. To use

this method,

select suitable

inlet valve

location, exercising same

precautions as

for normal wall

installation.

Using a length

of coat hanger,

pierce a hole

through both

walls (Fig. 14).

Page 6

Be sure to hold wire perfectly horizontal so that

both interior and exterior holes line up with one

another. Check for inner wall obstructions by

bending short length of coat hanger wire at a

right angle and twirling this right angle piece

inside the wall.

Drill a 2 1/4" (5.7cm) hole horizontally through

both sides of wall.

Make the hole in the exterior wall surface into

the same shape opening as described previously in

STEP 1 - (Installing Inlet Valves) (Fig. 4).

From inside closet, cut 2-1/4" (5.7cm) hole

through floor, either directly below opening in

wall or at convenient spot. (Caution: - Make

pilot hole as in STEP 1 previously.) Run lowvoltage wire through 2-1/4" (5.7cm) hole in

floor, and through wall to exterior of closet.

Pass low-voltage wire through the wire guide

hole of the inner wall closet assembly (Fig.

15) and tape low-voltage wire to this assembly

immediately behind the metal bracket.

Attach wires to low-voltage terminals at rear of

inlet

valve.

Place inner wall assembly lengthwise through

wall opening and arrange assembly so that

metal bracket is flush with inside surface of

wall. Screw inlet to wall as described previously in STEP 1, then complete as per (Fig. 16).

f) Wall V alve Installation—New Construction

Select a probable location for inlet valve and

drill a pilot hole in the floor. Go below to check

that tubing path is clear of present, or future,

obstructions such as floor joists, heating ducts,

plumbing, wires, etc.

At intended inlet valve location, drill a 2-1/4"

(5.7cm) diameter hole through sole plate. To

pinpoint center of hole, measure over 2"

(5.1cm) from side of stud and 2" (5.1cm) from

front of sole plate (Fig. 17).

Glue a length of tubing into a stud-mounting

bracket assembly. Cut a length of low-voltage

wiring, bring approximately 6" (15.24cm)

through top wire guide hole in stud bracket

assembly and double it back into elbow hole.

Tape wire to tubing at assembly elbow and

again close to end, and tuck remaining wire

into bottom of tubing.

Page 7

Screw plaster guard onto face of assembly

(See Fig. 18).

Drop bottom of tubing through 2-1/4" (5.7cm)

hole and nail stud mounting bracket assembly

to stud. Make sure center of inlet hole is at the

correct height above floor level and tubing

extends below sub-flooring.

Be sure to install a nail guard when holes are

drilled through the sole or top plates. This is to

prevent a nail or screw from penetrating the

vacuum tubing. Go to STEP 2 “Installation of

Tube System” and complete tubing system as

much as possible.

After the walls are finished and painted, the

plaster guards will be removed and inlet valves

installed. The tubing system may be completed

at that time and the power unit installed.

STEP 2: Installation of Tube System

(New or Existing Structure)

Starting at the inlet furthest from the power unit,

temporarily fasten the main line in position.

(Good idea: - From a nail or overhead pipe,

etc., make two loops of string or low-voltage

wire to pass PVC tubing through, to hold it in

position while you work.)

Push a length of PVC tubing up into bottom of

inlet valve assembly. Bear in mind, tube enters

all fittings approximately 3/4" (1.9cm). Measure,

cut, and slip-fit this vertical line to main horizontal line with a 90 degree sweep elbow.

To avoid potential clogging problems when

installing tubing and fittings, here are some recommendations:

• Always make straight cuts on tubing

• Always remove burrs from end of tubing.

• Be sure tubing fits against shoulder of fitting

with no gaps.

• Glue tubing side only before assembly into

fittings.

Connect additional inlet valves to main trunk

line with the 90 degree sweep tee (Fig. 19).

Be sure to install sweep tee fittings so sweep

is towards power unit (Fig. 20).

Always run branch lines, from sides or top of

main trunk line, never out of the bottom, as this

will create a trap for dirt to fall into.

Bring low-voltage wire along as you assemble

tubing.

Join or splice wire with wire connectors at each

branch or junction in the tubing. Neatly tape

wire to tube. Proceed until the tubing system is

complete.

Page 8

STEP 3: Installation of Power Unit

The power unit is screwed to the wall with the

bottom screws of the mounting bracket located

48" (1.2m) up from the floor to allow convenient

removal of the dirt canister. For proper motor

cooling, there must be at least 12" (30.5cm)

between the unit and the ceiling.

If mounting on plaster or panel walls, be sure

mounting bolts enter studs.

If mounting on concrete wall, drill the wall with a

masonry bit and insert plastic or lead anchors.

As an alternate mounting on concrete walls, 2"

x 4" (5.1 x 10.16cm) studs or plywood may be

suspended from overhead.

With the power unit mounted, strip the low-voltage wire and crimp into the two “slip-on” terminals provided. Connect main tube line to left

side of power unit, with connector and clamp

provided. Do not cement this connection to the

power unit in case you wish to remove at some

future date. Do not install power unit where the

ambient temperature exceeds 120 degrees

Fahrenheit (48.9 degrees C).

NOTE: For top-loading units, follow directions

provided with unit.

This unit may be exhausted to exterior to expel

fumes, germs, and some noise. Use the same

tubing and fittings as before. If vented, the

exhaust air should not be vented into a wall,

ceiling, or concealed

space of a building. Venting over 10 ft. (3m) is

not recommended.

NOTE: On/Off switch on power unit is for the

inlet on power unit only. All other inlets operate

automatically when the hose end is inserted into

the inlet valve or when the switch, which is

located on the hose handle, is turned on.

WIRING

Check local codes but use not less than #14-3

wire. Plug power unit cord into appropriate

120/220/230/ 240V - 50/60 cycle electrical outlet. Be sure line voltage is sufficient to handle a

15 amp. load.

Page 9

WARNING: ELECTRIC SHOCK COULD OCCUR IF USED ON WET SURFACES.

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. This appliance is equipped with a cord having an equipment grounding conductor and grounding plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with

a qualified electrician or service person if you are in doubt as to whether

the outlet is properly grounded. Do not modify the plug provided with the

appliance—if it will not fit the outlet, have a proper outlet installed by a

qualified electrician.

This appliance is for use on a nominal 120-volt circuit and has a ground

plug that looks like the plug illustrated in figure 21 for North American

units. For 220/230/240 volt units, consult your local building code/electrician.

Make sure that the appliance is connected to an outlet having the same

configuration as the plug. No adapter should be used with this appliance.

Check power unit On/Off switch and all inlet valves for operation. This

power unit is intended for household and commercial use.

Important Safety Instructions

When using electrical appliances, basic safety precautions should always be followed, including the following:

Read all instructions before using this vacuum.

NOTE: Your Central Cleaning System is U.L. listed and C.U.L. listed for dry pick-up only. To reduce the risk of

electric shock,DO NOT USE outdoors or on wet surfaces.

DANGER—

Always unplug power unit from the electrical outlet before servicing and cleaning.

WARNING— To reduce the risk of bur ns, fire, electric shock, or injury to persons:

1. Keep cord away from heated surfaces.

2. Do not allow to be used as a toy. Close supervision is necessary when this vacuum is used by or near

children.

Page 10

INLET VALVE EXTENSION

(for thick walls metal)

PLASTIC PLASTER

GUARD

(for new structure)

AUTOMATIC INLET VALVE

(plastic or optional metal)

ADAPTER & BRACKET

ASSEMBLY

(new or old structure)

3. Use this vacuum only for its intended use as described in this manual. (Use of attachments not recommended

by the manufacturer may cause fire, electric shock, or injury.)

4. Never operate this vacuum if it has a damaged cord or plug, if it is not working properly, if it has been dropped,

or damaged. Return to service center or have service person examine and repair.

5. Do not pull or carry this power unit by supply cord, use cord as a handle, close a door on cord, or pull cord

around sharp edges or corners.

6. Never disconnect plug by pulling on cord. To disconnect from outlet, grasp the plug, not the cord.

7 Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and

anything that may reduce air flow.

8. Keep hair, face, fingers, and loose clothing away from any openings.

9. Do not pick up cigarettes, live hot ashes, matches or similar materials.

10. Never operate vacuum without dust bag and/or filter in place.

11. To disconnect, turn all controls to the OFF position; then remove plug from outlet.

12. Never handle plug, cord, or power unit with wet hands.

13. Electric shock could occur if used on wet surfaces.

14. Use extra care when cleaning on stairs.

15. Do not use to pick up flammable or combustible liquids such as gasoline or use in areas where they may be

present.

16. For a grounded appliance: “Connect to a properly grounded outlet only. See grounding instructions.”

SA VE THESE INSTRUCTIONS

QUICK CHECK TABLE OF COMMON AND SPECIAL USE PARTS

90 DEGREE DUAL ELBOW

(Use w/above assembly or

as first bend in line. Never

elsewhere.)

COUPLINGS

(joins PVC tubing)

45 DEGREE Y

90 DEGREE SWEEP

ELBOW

45 DEGREE ELBOW

PLASTIC EXHAUST MUF-

FLER

90 DEGREE SWEEP

ELBOW

45 DEGREE ELBOW

with extension

ADAPTER, REDUCER

BUSHING

(for pipe to floor

mounted inlet valve)

T-ADAPTER

(for two story) (for two inlets in

same wall) Use only

w/adapter and bracket

assemblies.

NAIL GUARD

Loading...

Loading...