Page 1

35941 G

Gas hob

Operating Instructions

SA

Page 2

ENGLISH

SA

Important Safety Information

These warnings are provided in the interest of safety. You must read them

carefully before installing or using the appliance.

During Operation

• This appliance has been designed for non professional purpose in private houses

only. It is meant to cook edible foodstuff only and MUST NOT be used for any other

purposes.

• It is dangerous to alter the specification in any way.

• For hygiene and safety reasons, this appliance should be kept clean at all times. A

build-up of fats or other foodstuff could result in a fire.

• Under no circumstances should you attempt to repair the appliance yourself. Repairs

carried out by unexperienced persons may cause injury or serious malfunctioning.

Refer to your local Service Centre. Always insist on genuine spare parts.

• Ensure that all control knobs are in the OFF position when not in use.

• Should you connect any electrical tool to a plug near this cooking appliance, ensure

that electric cables are not in contact with it and keep them far enough from the

heated parts of this appliance.

• If the appliance is out of order, disconnect it from the electric supply.

Child Safety

• This appliance has been designed to be operated by adults and children under

supervision. Young children MUST NOT be allowed to tamper with the controls or play

near or with the oven.

• Accessible parts of this appliance may become hot when it is in use. Children should

be KEPT AWAY until it has cooled.

About Installation, Cleaning and Manteinance

• It is mandatory that all operations required for the installation are carried out by a

qualified or competent person, in accordance with existing rules and regulations.

• Disconnect the appliance from the electrical supply, before carrying out any cleaning

or manteinance work.

2

Page 3

• Ensure a good ventilation around the appliance. A poor air supply could cause lack

of oxygen.

• Ensure that the gas supply complies with the gas type stated on the identification

label, placed near the gas supply pipe.

• This appliance is not connected to a combustion products evacuation device. It must

be installed and connected in accordance with current installation regulations.

Particular attention shall be given to the relevant requirements regarding ventilation.

• The use of a gas cooking appliance results in the production of heat and moisture

in the room in which it is installed. Ensure that the kitchen is well ventilated: keep

natural ventilation holes open or install a mechanical ventilation device (mechanical

extractor hood).

• Prolonged intensive use of the appliance may call for additional ventilation, for

example opening of a window, or more effective ventilation, for example

increasing the level of mechanical ventilation where present.

• Once you removed all packaging from the appliance, ensure that it is not damaged

and the electric cable is in perfect conditions. Otherwise, contact your dealer before

proceeding with the installation.

• The manufacturer disclaims any responsability should all the safety measures not

be carried out.

Service

• Under no circumstances should you attempt to repair the appliance yourself. Repairs

carried out by unexperienced persons may cause injury or serious malfunctioning.

Refer to your local Service Centre. Always insist on genuine spare parts.

UU

U

Environmental Information

UU

• After installation, please dispose of the packaging with due regard to safety and the

environment.

• When disposing of an old appliance, make it unusable, by cutting off the cable.

• The symbol on the product or on its packaging indicates that this product may

not be treated as household waste. Instead it shall be handed over to the applicable

collection point for the recycling of electrical and electronic equipment. By ensuring

this product is disposed of correctly, you will help prevent potential negative

consequences for the environment and human health, which could otherwise be

caused by inappropriate waste handling of this product. For more detailed information

about recycling of this product, please contact your local city office, your household

waste disposal service or the shop where you purchased the product.

3

Page 4

Contents

Important Safety Information ............................................................................ 2

Guide to Use the instructions ............................................................................. 5

Description of the Hob .......................................................................................... 6

Operation................................................................................................................... 7

Maintenance and Cleaning .................................................................................. 8

The Hob Top................................................................................................... 8

Pan Supports ................................................................................................. 8

The Burners .................................................................................................... 8

Something Not Working? ..................................................................................... 9

Instructions for the Installer ............................................................................. 10

Engineers technical data ......................................................................... 10

Installation .............................................................................................................. 12

Gas connection ...................................................................................................... 13

Cut Out Size ............................................................................................................ 14

Building In ............................................................................................................... 14

Fitting the hob to the worktop ............................................................. 16

Electrical connections.......................................................................................... 17

Permanent Connection............................................................................ 18

Adaptation to different types of gas .............................................................. 19

4

Page 5

Guide to Use the instructions

The following symbols will be found in the text to guide you throughout the

Instructions:

Safety Instructions

Step by step instructions for an

))

)

))

operation

Hints and Tips

i

This appliance is manufactured according to

the following EEC directives:

73/23 EEC - 90/683 EEC - 93/68 EEC 89/336 EEC - 90/396 EEC,

current edition.

These instructions are only for the countries stated by the symbol printed on the

front cover of this instruction book.

5

Page 6

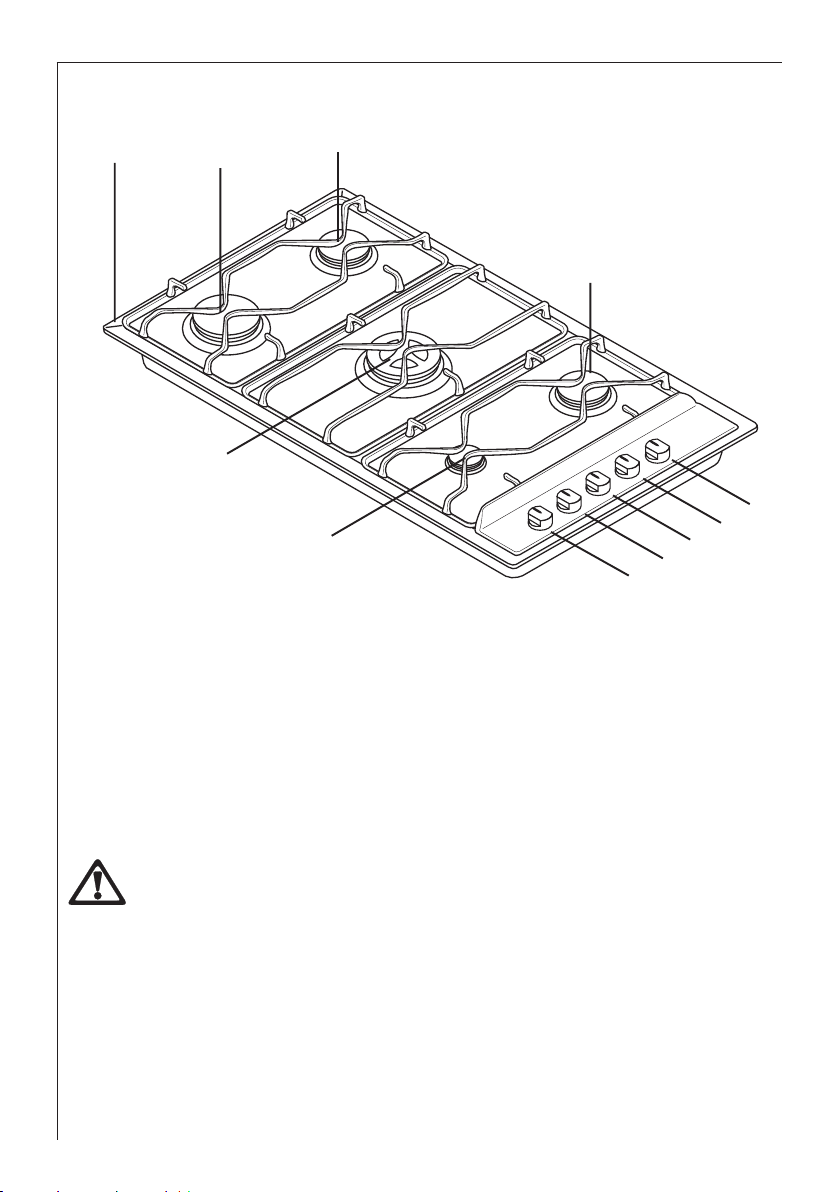

Description of the Hob

1

2

4

1. Hob Top

2. Rapid Burner

3. Semi-rapid Burners

4. Double-crown Burner

5. Auxiliary Burner

6. Control knob for back left burner (semi-rapid)

7. Control knob for back right burner (semi-rapid)

8. Control knob for front right burner (auxiliary)

9. Control knob for central burner (double-crown)

10.Control knob for front right burner (rapid)

3

5

3

6

7

8

9

10

INSTALLATION

Any gas installation must be carried out by a qualified installer, and

in accordance with existing rules and regulations.

The relevant instructions are to be found in the second section of this

manual.

Please, ensure that, once the hob is installed, it is easily accessible for

the engineer in the event of a breakdown.

WHEN THE HOB IS FIRST INSTALLED

Once the hob has been installed, it is important to remove any

protective materials, which were put on in the factory.

6

Page 7

Operation

HOB BURNERS

To light a burner, turn the relevant control knob anticlockwise to the

maximum position (

Upon ignition, keep the knob pushed down for about 5 seconds. This

will allow the "thermocouple" to be heated and the safety device to be

switched off, otherwise the gas supply would be interrupted. Then,

check the flame is regular and adjust it as required.

If the burner does not ignite, turn the control knob to zero, and try

i

again.

When switching on the mains, after installation or a power cut, it is

quite normal for the spark generator to be activated automatically.

To ensure maximum burner efficiency, you should only use pots and

pans with a flat bottom fitting the size of the burner used (see table).

Burner minimum maximum

), then push it down to ignite the burner.

diameter diameter

Double-crown (ultra-rapid)

Large (rapid) 180 mm. 260 mm.

Medium (semi-rapid) 120 mm. 220 mm.

Small (Auxiliary) 80 mm. 160 mm.

As soon as a liquid starts boiling, turn down the flame so that it will barely

i

keep the liquid simmering.

If you use a saucepan which is smaller than the recommended size, the

flame will spread beyond the bottom of the vessel, causing the handle to

overheat.

Take care when frying food in hot oil or fat, as the overheated splashes could

easily ignite

If the control knobs become difficult to turn, please contact your local AEG-

Electrolux Service Force Centre.

180 mm. 260 mm.

7

Page 8

Maintenance and Cleaning

Before any maintenance or cleaning can be carried out, you must

DISCONNECT

The hob is best cleaned whilst it is still warm, as spillage can be

removed more easily than if it is left to cool.

The Hob Top

Regularly wipe over the hob top using a soft cloth well wrung out in

warm water to which a little washing up liquid has been added. Avoid

the use of the following:

- household detergent and bleaches;

- impregnated pads unsuitable for non-stick saucepans;

- steel wool pads;

- bath/sink stain removers.

Pan Supports

the hob from the electricity supply.

When washing the pan supports by hand, take care when drying them

as the enamelling process occasionally leaves rough edges. If necessary,

remove stubborn stains using a paste cleaner.

The Burners

The burner caps and crowns can be removed for cleaning.

Wash the burner caps and crowns using hot soapy water, and remove

marks with a mild paste cleaner. A well moistened soap impregnated

steel wool pad can be used with caution, if the marks are particularly

difficult to remove.

After cleaning, be sure to wipe dry with a soft cloth.

8

Page 9

Something Not Working?

If the hob is not working correctly, please carry out the following checks before

contacting your local AEG-Electrolux Service Force Centre.

SYMPTOM

There is no spark when lighting

the gas.

SOLUTION

Check that the unit is plugged in

and the electrical supply is

switched on.

Check the mains fuse has not

blown.

Check the burner cap and crown

have been replaced correctly, e.g.

after cleaning.

The gas ring burns unevenly.

Check the main jet is not blocked

and the burner crown is clear of

food particles.

Check the burner cap and crown

have been replaced correctly, e.g.

after cleaning.

If after all these checks, your hob still does not operate correctly, contact your

local AEG-Electrolux Service Force Centre.

9

Page 10

Instructions for the Installer

Engineers technical data

OVERALL DIMENSIONS Width: 860 mm.

Depth: 500 mm.

Height: 88 mm.

CUT OUT DIMENSIONS Width: 830 mm.

Depth: 470 mm.

Thickness: 30 mm.

HEAT INPUT

Rear Left Burner (semi rapid) 2,0 kW

Front Left Burner (rapid) 3,0 kW Natural Gas

2,8 kW LPG

Central Burner (double-crown) 3,5 kW

Rear Right Burner (semi rapid) 2,0 kW

Front Right Burner

APPLIANCE CLASS 3

APPLIANCE CATEGORY II2E+3+

GAS SUPPLY LPG Gas 28-30/37 mbar

ELECTRICAL SUPPLY 230 V, 50 Hz - 220 V, 60 Hz

10

(auxiliary) 1,0 kW

Page 11

BURNER

NORMAL REDUCED

POWER POWER

NORMAL POWER

NATURAL GAS

kW kW m3/h g/h

inj.

1/100

Auxiliary

(Small) 1,0 0,33 70 0,095 0,111 50 72 71

Ø 55 mm.

Semi-rapid

(Medium) 2,0 0,45 96 0,190 0,221 71 144 143

Ø 71 mm.

Rapid Natural Gas:

(Big) 3,0 0,65 119 0,286 0,332 86 202 200

Ø 102 mm. LPG:2,8

DoubleCrown 3,5 1,20 136 0,333 0,386 93 252 250

Ø 129 mm.

G20 G25

20mbar 25mbar

LPG GAS

28-30/37 mbar

inj.

1/100

G30 G31

Burner Dia. Tap By-pass

1/100 mm

Auxiliary 28

Semi-rapid 32

Rapid 40

Double-Crown 56

Aeration adjustment none

11

Page 12

Installation

zz

z The following instructions about installation and maintenance must be

zz

carried out byqualified personnel in compliance with the regulation in

force.

zz

z The side walls of the unit in which the hob is going to be installed must

zz

not exceedthe height of the working top.

zz

z Avoid installing the appliance in the proximity of inflammable materials

zz

(e.g. curtains,tea towels etc.).

zz

z The appliance must be electrically disconnected before all interventions.

zz

If any electric supply to the appliance is required to carry out the work,

ensure all the necessary precautions are followed.

zz

z THE MANUFACTURER WILL NOT ACCEPT LIABILITY, SHOULD ANY

zz

OF THE OTHERSAFETY INSTRUCTIONS INCORPORATED IN THIS

BOOK OR THE REGULATION INFORCE BE IGNORED.

12

Page 13

Gas connection

Choose fixed connections or use a flexible pipe in stainless steel in compliance

with the regulation in force.If using flexible metallic pipes, be careful they do

not come in contact with mobile parts or they are not squeezed. Use the same

attention when the hob is combinated with an oven.

IMPORTANT - To ensure a correct operation, a saving of energy and the longlife of the appliance, the voltage pressure of the appliance must correspond to

the recommended values. The adjustable connection is fixed to the

comprehensiveramp by means of a threaded nut G 1/2".

Interpose the sealing between the components as shown in the diagram.

Screw the parts without forcing, adjust the connection in the required direction

and tighten everything. The adjustable connection allows the feeding pipe to be

situated in the site purposefully allocated on the side of the protection box of

the hob itself (see diagram). This connection allows the overall dimensions of the

hob plus the feeding to be contained into a depth of 30 mm.

The appliance, before leaving the factory, has been tested in order to give you

the best results.

IMPORTANT - When the final connection has been made, it is essential that a

thorough leak test is carried out on the hob and installation.

Use some soapy water, never a flame.

FO 0264

FO 0265

A) Ramp with ending nut

B) Seal

C) Adjustable connection

A) Ramp ending with nut

B) Adjustable connection

C) Rigid or flexible metallic

gas pipe

13

Page 14

Cut Out Size

The dimensions of the cut-out are given in the diagram.

500

470

FO 2407

Building In

Kitchen unit with door

860

830

55 min.

Proper arrangements must be taken in designing the forniture unit, in order

to avoid any contact with the bottom of the hob which can be heated when

it is operated. The recommended solution is shown in Fig. 1.

The panel fitted under the hob should be easily removable to allow an easy

access if a technical assistance intervention is needed.

Kitchen unit with oven

The hob recess dimensions must comply the indication given in Figs. 2 and 5

and must be provided with brackets to allow a continuous supply of air.

To avoid overhating, the building in should be carried out as shown in Figs. 3

and 4.

14

Page 15

The hob's electric connection and the

oven's one must be carried out

separately, both for safety reasons and

to allow the oven to be easily taken off

the unit.

Hanging forniture units or hoods must

be placed at 650 mm. minimum from

the hob (Fig. 5).

Fig. 2

Fig. 3

Fig. 1

FO 1013

a) Removable panel

b) Space possibly useful for

connections

FO 0947

FO 0198

15

Page 16

Fig. 4

FO 0938 FO 0939

Fig. 5

Fitting the hob to the worktop

Before fitting the hob into the

cut out, a sealing gasket

supplied with the hob must be

fitted to the edge of the cut

out. It is essential that no gaps

are left in this seal in order to

prevent spillage near the hob

seeping into the cabinet below.

1) Place the sealing

))

)

))

gasket all around the

edge of the cut out.

Seal

a

2) Place the hob into

the cut out and

secure it by means of

the relevant fixing

clamps and screws, as

shown in the diagram.

3) Remove the excess seal

The edge of the hob forms a double seal which prevents the ingress of

liquids.

16

FO 0199

Page 17

Electrical connections

The appliance is designed to be connected to 230 V monophase 50 Hz AC

220 V, 60 Hz electrical supply.

The connection must be carried out in compliance with the laws and

regulations in force.

Before the appliance is connected:

1) check that the main fuse and the domestic installation can support the load

(see the rating label);

2) check that the power supply is properly earthed in compliance with the

current rules;

3) check the socket or the double pole switch used for the electrical connection

can be easily reached with the appliance built in the forniture unit.

The appliance is supplied with a connection cable. This has to be provided with

a proper plug, able to support the load marked on the identification plate. The

plug has to be fitted in a proper socket.

If connecting the appliance directly to the electric system, it is necessary that

you install a double pole switch between the appliance and the electricity

supply, with a minimum gap of 3 mm. between the switch contacts and of a type

suitable for the required load in compliance with the current rules.

The connection cable has to be placed in order that, in each part, it cannot reach

a room temperature higher than 50°C.

The brown coloured phase cable (fitted in the terminal block contact marked

with "L") must always be connected to the network phase.

REPLACEMENT OF THE VOLTAGE CABLE

The connection of the voltage cable to the appliance's terminal block is of type

"Y". This means that its replacement requires the specific equipment of a

technician.

The connection of the voltage cable to the appliance's terminal block is of type

"Y". This means that its replacement requires the specific equipment of a

technician.

In this case, only cable type H05 V2V2-F T90 must be used. The cable section

must be suitable to the voltage and the working temperature.

The yellow/green earth wire must be approximately 2 cm. longer than the phase

wires.

17

Page 18

Permanent Connection

In the case of a permanent connection, it is necessary that you install

a double pole switch between the hob and the electricity supply

(mains), with a minimum gap of 3 mm. between the switch contacts

and of a type suitable for the required load in compliance with the

current electric regulations.

The switch must not break the yellow and green earth cable at any

point.

Ensure that the hob supply cord does not come into contact with

surfaces with temperatures higher than 50 deg. C.

18

Page 19

Adaptation to different types of gas

Injectors replacement

• Remove the pan supports.

• Remove the burner's caps and crowns.

• With a socket spanner 7 unscrew and

remove the injectors (see diagram),

and replace them with the ones

required for the type of gas in use.

• Reassemble the parts, following the

same procedure backwards.

• Replace the rating label (placed near

the gas supply pipe) with the relevant

one for the new type of gas supply.

You can find this label in the package

of the injectors supplied with the appliance.

Should the feeding gas pressure be different or variable compared with the

required pressure, an appropriate pressure adjuster must be fitted on the gas

supply pipe, in compliance with the rules in force.

Adjustment of minimum level

To adjust the minimum level of the

burners, proceed as follows:

• Light the burner.

• Turn the knob on the minimum

position.

• Remove the knob.

• With a thin screwdriver, adjust the

by-pass screw (see diagram). If

changing from LPG to natural gas

unscrew about 1/4 turn the by-pass

screw, until a small regular flame is obtained

If changing from natural gas to LPG, completely tighten clockwise the screw,

until a small regular flame is obtained.

• Finally check the flame does not go out when quickly turning the knob from

the maximum position to the minimum position.

This procedure can easily be carried out, anyhow the hob has been positioned

or built in the working top.

FO 0392

by-pass screw

19

Page 20

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

http://www.aeg.hausgeraete.de

Copyright by AEG

From the Electrolux Group.

The Electrolux Group is the world’s largest producer of powered appliances for kitchen,

cleaning and outdoor use. More than 55 million Electrolux Group products (such as

refrigerators, cookers, washing machines, vacuum cleaners, chain saws and lawn

mowers) are sold each year to a value of approx. USD 14 billion in more than 150

countries around the world.

The world’s No.1 choice.

35690-6001 04/05

Grafiche MDM - Forlì

Loading...

Loading...