Page 1

ÖKO-LAVAMAT 60300

The environmentally friendly washing machine

Instruction book

Page 2

Dear customer,

f

Please read these user instructions carefully.

Above all, observe the "Safety" section in the first pages. Keep these

user instructions in a safe place for future reference. Please pass them

along to future owners of the appliance.

Important information concerning your safety and proper functioning

1

of the appliance is highlighted with the warning triangle or the signal

words (Warning!, Caution!, Attention!). Please observe carefully.

0 1. This symbol guides you step by step when operating the appliance.

2. ...

Next to this symbol you receive additional information and practical

3

tips on using the appliance.

Tips and information about the economical and environmentally

2

friendly use of the machine are marked with the clover.

These user instructions include tips for the correction of possible mal-

functions by the user. See the section "What to do when...".

Our customer service department is at your disposal should technical

problems occur. See also the "Service" section.

Printed on paper manu

He who thinks ecologically acts accordingly ...

2

actured with environmentally sound processes.

Page 3

Contents

CONTENTS

Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environmental protection tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Description of the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Drawer for Detergent and Conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

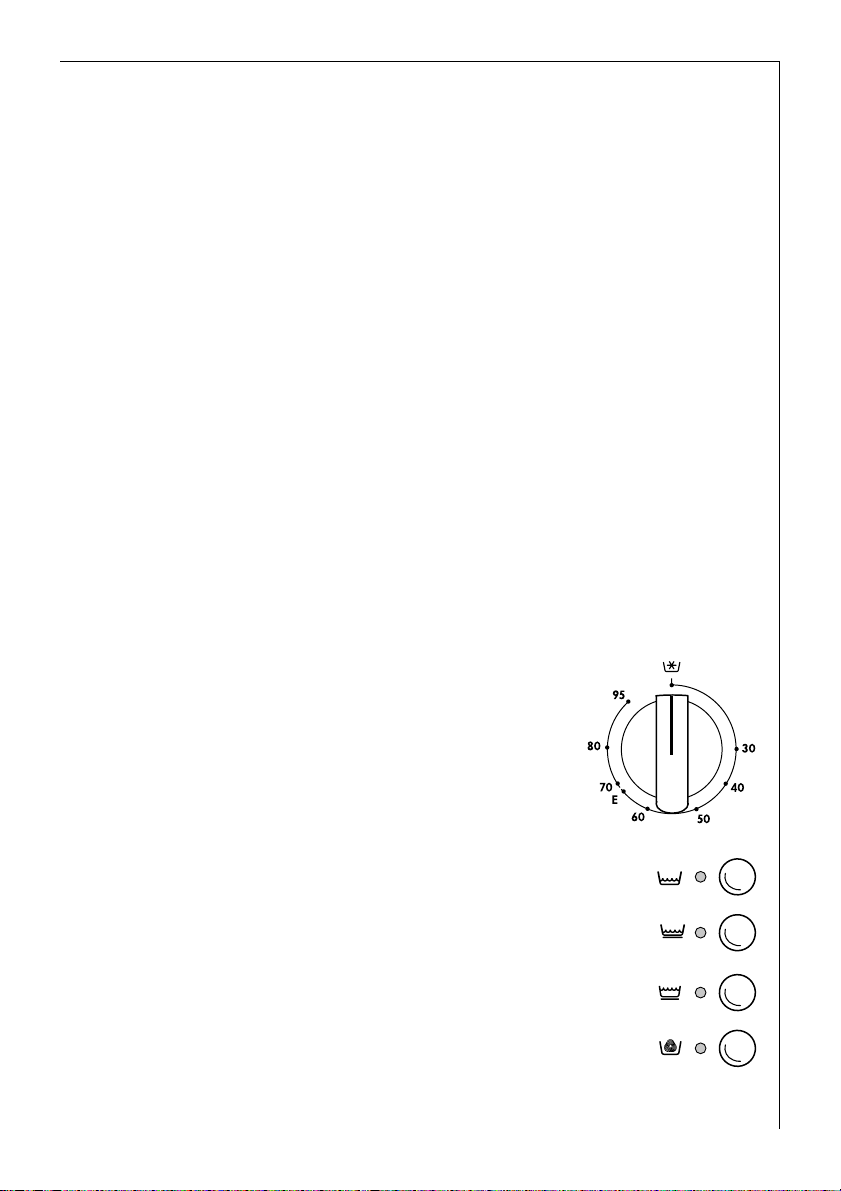

Program Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Temperature Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Washing Type Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

M (ON/OFF) Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Consumption Data and Time Required . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before Washing for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Prepare washing cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Sort washing and prepare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Washing Types and Care Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Detergent and conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Which detergent and conditioner? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

How much detergent and conditioner? . . . . . . . . . . . . . . . . . . . . . . . . . 16

Using Water Softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Performing A Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Brief Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Loading the Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adding Detergent/Conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Washing Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starting the Washing Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Changing the Spin Speed/Selecting Rinse Hold . . . . . . . . . . . . . . . . . . . . . . 20

During the Washing Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wash Complete/Removing the Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3

Page 4

Contents

Program Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Separate Soaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Separate Conditioning/Starching/Treatment . . . . . . . . . . . . . . . . . . . . . . . 24

Separate Rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Separate Spinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cleaning and Caring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Detergent drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Washing drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fill-in door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

What to do when… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

If the washing results are not satisfactory . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Perform emergency drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Clean the circulating pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Additional Rinse/Water Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation and Connection Instructions . . . . . . . . . . . . . . . . 34

Installation Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Dimensions of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Front and Side Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Transporting the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remove transportation protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Prepare the installation place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installation on a concrete base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installation on vibrating floors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Levelling on uneven floors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4

Page 5

Contents

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Permissible water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Water feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Water drain-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Delivery head above 1m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Service Departments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Guarantee Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5

Page 6

OPERATING INSTRUCTIONS

1 Safety

The safety standards of AEG electric appliances are in keeping with the

recognised rules of technology and the law governing the safety of

appliances. Nevertheless as a manufacturer we are committed to familiarise you with the following safety instructions:

Prior to initial start-up

• Observe the "Installation and Connection Instructions" below in

these user instructions.

• If the appliance is delivered during the winter and temperatures are

below freezing, allow the appliance to stand at room temperatur e for

24 hours before operation

Intended use

• The washing machine is intended exclusively for the washing of nor-

mal household washing in the home. If the appliance is used for purposes other than those intended, or if it is improperly operated, the

manufacturer can assume no liability for damages which may occur.

• Additions or modifications to the washing machine are strictly for-

bidden due to safety reasons.

• Use only those detergents which are suitable for the washing

machine. Observe instructions provided by the detergent manufacturer.

• Laundry to be washed may not contain any flammable solvents. This

must also be taken into consideration when washing pre-washed

laundry.

• Do not use the washing machine for dry-cleaning.

• Dyes and bleaches may only be used in the washing machine if such

use has been expressly endorsed by the manufacturer of these products. We can assume no liability for damages which may occur.

• Use tap water only. Rain water and industrial water may only be used

if they fulfil requirements in accordance with DIN1986 and DIN1988.

• Damage due to frost is not covered by the guarantee! If the washing

machine is located in a room in which below freezing temperatures

might occur, emergency draining must be carried out if danger of

freezing occurs (see "Emergency Draining"). Furthermore, the inlet

hose must be disconnected from the tap and laid on the floor.

6

Page 7

Operating instructions

Safety of children

• Packaging materials (e.g. sheet and Styrofoam) can be dangerous for

children. Danger of asphyxiation! Keep packaging materials at a safe

distance from children.

• Children are often unable to recognise the dangers involved with

electrical appliances. Provide for proper supervision during operation,

and do not allow children to play with the washing machine – the

danger exists that a child might lock itself into the appliance.

• Make certain that children or small animals do not climb into the

drum of the washing machine.

• If the washing machine needs to be disposed of, remove the mains

plug, destroy the door lock, cut off the electrical cable and dispose of

the plug and remaining cable separately. In this way children are prevented from locking themselves in and are not exposed life threatening danger.

General Safety

• Repairs to the washing machine may only be carried out by trained

personnel. Improper repairs can give rise to significant hazards. If

repairs are required, contact customer service or your dealer.

• Never use the washing machine if the mains cable is damaged or the

control panel, the work surface, or the plinth are damaged to such an

extent that components inside the machine are openly accessible.

• Switch off the washing machine before cleaning, maintenance and

servicing. In addition, unplug from the mains or – in the case of permanent connection – pull the circuit breaker, or completely remove

screw type fuses.

• Never remove the mains plug by pulling on the cable. Always grip the

plug.

• Multi-way plugs / connectors and extension cables must not be used!

• Do not clean the washing machine with a jet of water. There is a risk

of electric shock!

• When high temperature washing programs are selected, the glass in

the door becomes hot. Do not touch!

• Leave the water in the machine to cool down before performing an

emergency drain or cleaning the circulation pump.

• Small animals may gnaw at electrical power cables and water hoses.

There is a risk of electric shock and damage from water leaks! Keep

small animals away from the washing machine.

7

Page 8

Operating instructions

2 Disposal

Dispose of the packaging!

Dispose of washing machine packaging materials properly. All packaging materials are environmentally sound and can be safely disposed of,

or burned in a refuse incineration plant.

The plastic parts can be reused:

• The external plastic cover and the bags inside are made of polyethyl-

ene (marking >PE<).

• The padding is made of CFC free expanded polystyrene

(marking >PS<).

Corrugated components are made from recycled paper and should be

disposed of at a paper recycling station.

Dispose of your old appliance!

If, at some point in time, the service life of the appliance has expired,

please take it to your nearest recycling centre, or to your appliance

dealer, who will accept the old appliance for a minimal fee.

2 Environmental protection tips

• No pre-wash is required for normally soiled washing. This saves you

detergent, water and time (and is good for the environment!).

• If the indicated load capacities are taken full advantage of, the wash-

ing machine is especially efficient.

• For small loads, use only one half to one third of the recommended

detergent quantity.

• Stains and soiling confined to given areas can be removed by means

of appropriate pre-treatment. You can then wash at lower temperatures.

• Wash lightly to medium soiled cottons with the energy saving pro-

gram.

• Softeners are often not required. Try it! If you use a dryer, your wash-

ing will be soft and fluffy, even without softeners.

• A water softener should be used for water within a hardness range of

mid to high (as of hardness level II, see "Detergents and Conditioners"). Detergent can then always be dosed for water hardness level I

(= soft).

8

Page 9

Description of the Appliance

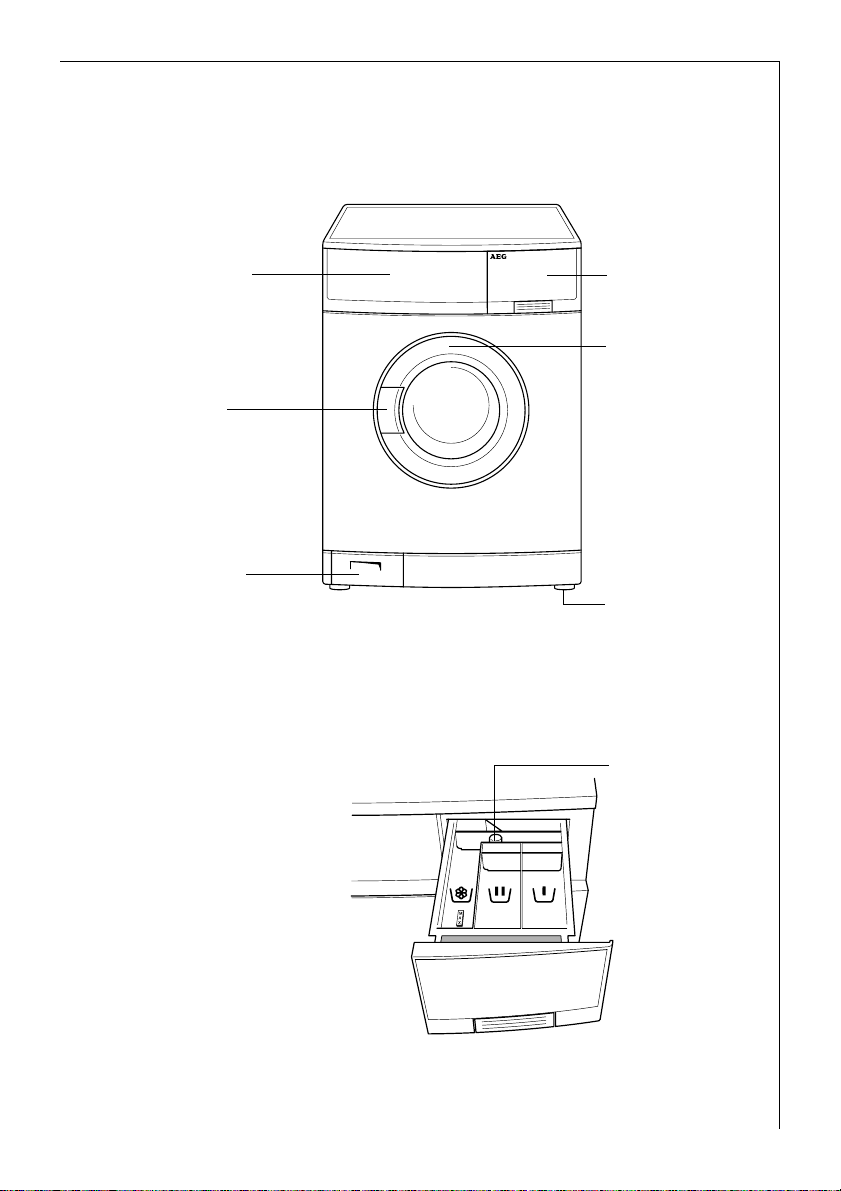

Front View

Control Panel

Door with

handle

Operating instructions

Drawer for

detergent and

softener

Rating plate

(behind door)

Flap in front of

the circulation

pump

Drawer for Detergent and Conditioner

k Pre Wash Detergent/

Detergent for

Soaking or

Stain Remover

l Main Wash Deter-

gent (powder) and,

if necessary, Water

Softener

w Liquid Conditioner

(Softener, Finisher,

Starch)

Threaded feet

(height adjustable)

Suction Cap

(must be securely

fitted)

9

Page 10

Operating instructions

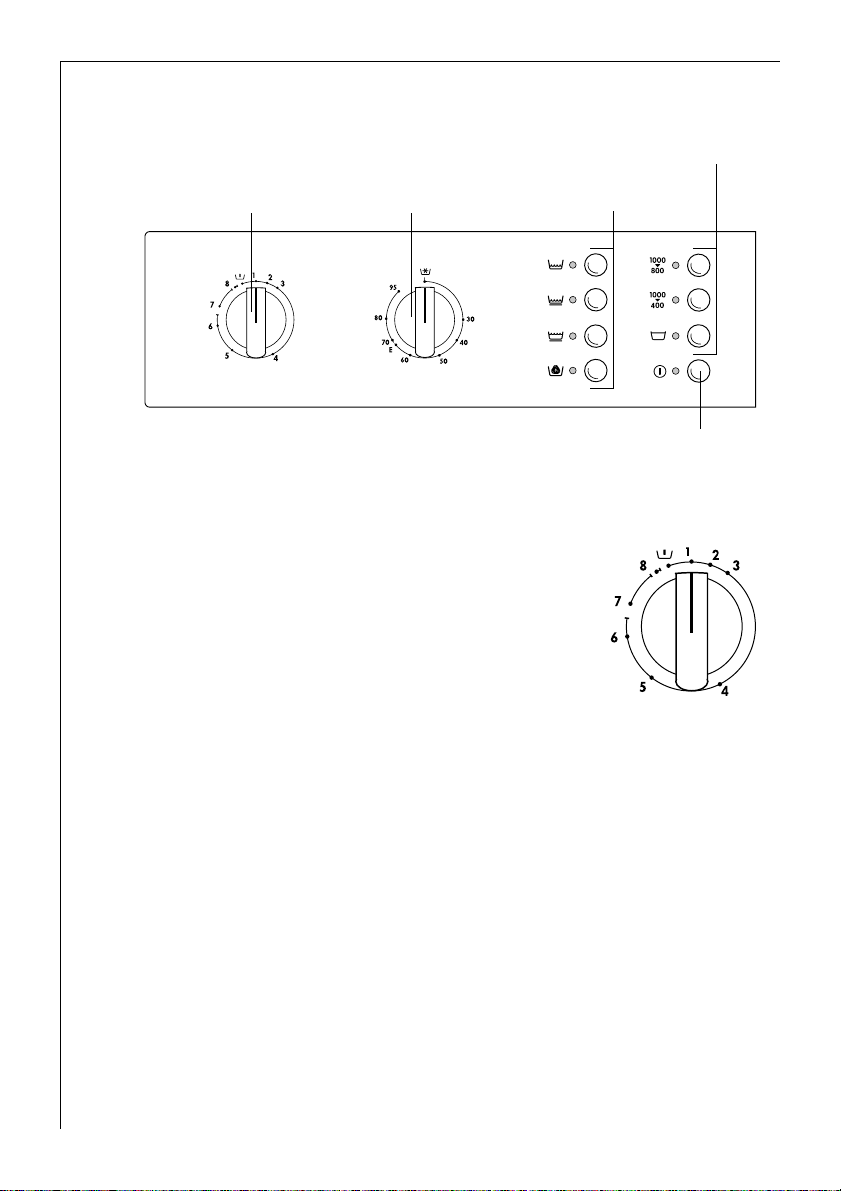

Control Panel

Spin Speed/RINSE HOLD Buttons

Program Selector

Temperature Selector

Washing Type Buttons

ON/OFF

Button

Program Selector

You define the type of wash using the

program selector.

Attention! Program selector may only

be rotated clockwise!

The various positions have the following effect:

Position k (PRE WASH)

Cold pre wash prior to the main wash, the main wash follows automatically. (Not for washing type s/WOOLLENS.)

10

Position 1 (STAIN)

For treating heavily soiled or stained washing. Lengthened main wash,

stain remover is washed in at the optimal point in the program cycle.

(Not for washing type s/WOOLLENS.)

Position 2 (MAIN WASH)

Main wash for normally soiled washing.

Position 3 (QUICK WASH)

Shortened main wash for lightly soiled washing.

Position 4 (RINSE)

Separate rinse, e.g. for rinsing hand washed fabrics (spinning in accordance with the selected washing type or rinse hold).

Page 11

Operating instructions

3 Rinse hold (o) means: the washing is left in the last rinse water, it is

not spun.

Position 5 (CONDITIONER)

Separate conditioning, separate starching, separate treatment of wet

cotton/linen or easy-care washing (1 rinse, liquid conditioner is washed

in from the w compartment, spinning in accordance with the selected

washing type or rinse hold).

Position 6 (SPIN)

Spinning after a rinse hold or separate spinning of hand washed fabrics

in accordance with the selected washing type.

Position 7 (SOAKING)

Separate soaking (temperature automatically limited to a maximum of

40°C), the washing is left in the water at the end of the program

(Not for washing type s/WOOLLENS).

3 After soaking the required main wash must be set, the program does

automatically continue.

Position 8 (PUMP OUT)

Pumps out the water after a rinse hold (without spinning).

Temperature Selector

You can set the following temperature

levels on the temperature selector:

r (COLD), 30, 40, 50, 60, E, 70, 80, 95

2 The E setting (Energy Saving Program) is

suitable for lightly to normally soiled cottons; temperature reduced to appr ox. 67°C.

Washing Type Button

The program sequence (e.g. max. possible temperature, water level, drum movement, number of

rinses, spin speed) is altered to suit the type of

washing using the washing type buttons.

t (COTTONS/LINEN)

For cottons and linen.

} (EASY-CARES)

For easy-care washing (mixed fabrics). Temperature automatically limited to a maximum of

60°C.

11

Page 12

Operating instructions

à (DELICATES)

For delicate washing (temperature automatically limited to a maximum

of 40°C).

s (WOOLLENS)

For machine washable woollens and particularly delicate fabrics (temperature automatically limited to a maximum of 40°C).

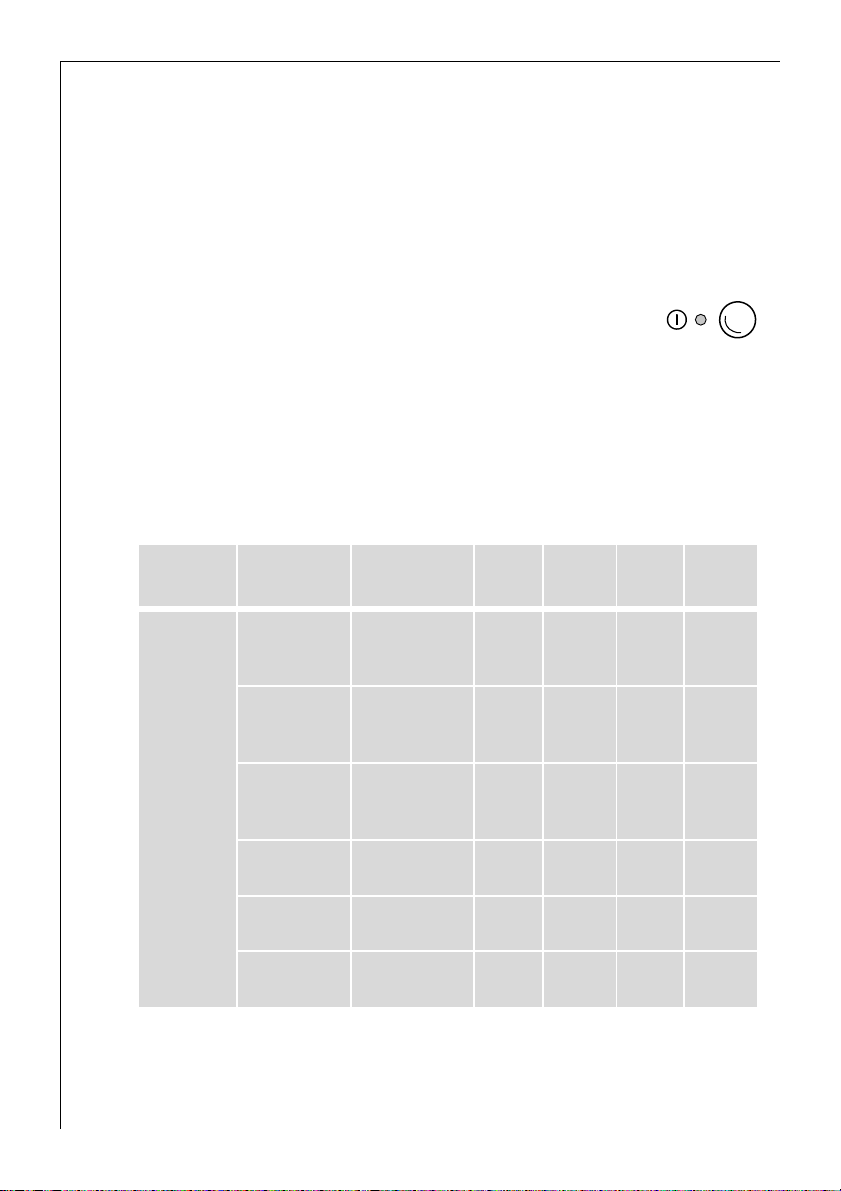

M (ON/OFF) Button

This button is used to switch on the washing

machine and start the selected program, or to

switch off the washing machine.

Consumption Data and Time Required

The values given in the following table for selected programs were calculated under standard conditions. They provide a useful guide for operation in the home.

Program

Selector

Position 2

(MAIN

WASH)

1)Note: program setting for testing in accordance with EN 60 456

Temperature

Selector

95

1)

60

40

40

30

30

Washing Type

Button

t

(COTTONS/

LINEN)

t

(COTTONS/

LINEN)

t

(COTTONS/

LINEN)

}

(EASY CARES)

Ã

(DELICATES)

s

(WOOLLENS)

Load

in kg

2.5 50 0.43 93

2.5 52 0.43 83

Water

in Litres

5 54 1.70 143

5 54 1.05 129

5 54 0.63 129

2 51 0.32 58

Energy

in kWh

Time in

minutes

12

Page 13

Operating instructions

Before Washing for the First Time

0 1.Pull the detergent drawer out from the control panel a little.

2. Pour around 1 litre of water into the washing machine via the detergent drawer . This will ensure when the washing machine is started that

the water container is closed and that the ECO valve can function correctly.

3. Perform a washing cycle without any washing, position 2 (MAIN WASH)

95, with half the normal dose of detergent.

This serves to remove residues resulting from production of the

appliance from the drum and the water container.

13

Page 14

Operating instructions

Prepare washing cycle

Sort washing and prepare

• Sort washing according to care symbol and type (see "Washing types

and care symbols").

• Empty all pockets.

• Remove metal objects (paper clips, safety pins etc.).

• In order to prevent bunching up of washing and damage to washing,

close zippers, button up duvets and pillow cases, and tie up loose

ends from, for example, aprons.

• Turn articles with double layered textiles inside out (sleeping bags,

anoraks etc.).

• Coloured, knitted fabrics, as well as wool and textiles with appliqués

should be turned inside out.

• Place small and delicate articles (baby booties, stockings, bras etc.)

into a washing net, a pillow case with zipper, or in large socks before

washing.

• Treat net curtains particularly carefully. Remove metal curtain rail

rollers or burred plastic rollers, or wrap these in a net or bag.

We cannot accept any liability for damage.

• Do not wash coloured and white washing together. White washing

will otherwise turn grey.

• New, coloured washing often contains excessive dye. Wash these

items separately the first time.

• Mix small and large articles of washing! This improves washing effi-

ciency, and the washing is more favourably distributed during the

spin cycle.

• Fluff washing before placing into the washing machine.

• Do not place folded washing into the drum.

• Observe tips for proper care such as "wash separately" and "wash

separately several times"!.

14

Page 15

Operating instructions

Washing Types and Care Symbols

Care symbols assist in the selection of the correct washing prog ram.

Washing should be sorted according to type and care symbol. The temperatures indicated in the care symbols are maximum temperatures.

Cottons ç

Cotton and linen fabrics with this care symbol are resistant to the

mechanical action of the washing machine and high temperatures. The

t (COTTONS/LINEN) program is suitable for this type of washing.

Linen èë

Cotton and linen fabrics with this care symbol are resistant to the

mechanical action of the washing machine. The t (COTTONS/LINEN)

program is suitable for this type of washing.

Easy-care washing êíî

Fabrics such as treated cottons, cotton mixtures and synthetics with

this care symbol need careful handling. The } (EASY-CARES) pr ogram

is suitable for this type of washing.

Delicates ì

Fabrics such as those with layered fibres, micro-fibres, as well as synthetics and net curtains with this care symbol need particularly careful

handling. The à (DELICATES) program is suitable for this type of

washing.

Woollens and particularly delicate washing 9 ì

Fabrics such as woollens, wool mixtures and silk with this care symbol

are particularly delicate in respect of the mechanical action of the

washing machine. The s (WOOLLENS) program is suitable for this type

of fabrics.

Important! Fabrics with the

ï (hand washing) or ñ (do not wash!)

care symbols must not be washed in the washing machine!

15

Page 16

Operating instructions

Detergent and conditioner

Which detergent and conditioner?

Use only detergents and conditioners which are suitable for use in

washing machines. Always observe the manufacturer’s instructions.

How much detergent and conditioner?

The required quantity depends upon:

• the amount of washing

2 If the detergent manufacturer does not include dosing instructions for

reduced loads, use one third less for half loads and only half of the full

load detergent quantity for very small loads.

• extent of soiling of the washing

• hardness of tap water

Observe instructions for use and dosing provided by the detergent and

conditioner manufacturer.

Using Water Softener

In the case of medium to very hard water (from har dness band II) water

softener should be used. Observe the manufacturer’s instructions! Then

always use detergent dosing for hardness band I (= soft). Information

on the hardness of the water in your area is provided by your local

water board.

16

Information on Water Hardness

Hardness Band

I – soft 0 – 7 to 1.3

II – medium-hard 7 – 14 1.3 – 2.5

III – hard 14 – 21 2.5 – 3.8

IV – very hard greater than 21 greater than 3.8

Water hardness in °dH

(German hardness scale)

Water hardness in mmol/l

(millimol per litre)

Page 17

Operating instructions

Performing A Wash

Brief Instructions

A wash is performed in the following steps:

0 1.Open the door, load the washing.

2. Close the door.

3. Add detergent/conditioner.

4. Set the correct washing program:

– Set the program on the program selector;

– Set the temperature on the temperature selector;

– Select the washing type using the washing type buttons.

5. Press the M (ON/OFF) button.

The washing machine is switched on. The washing program starts.

6. If necessary, change the spin speed or select rinse hold.

You can alter this setting and the temperature at any time during the

wash.

At the end of the washing program:

The washing program is finished when the M (ON/OFF) button indicator extinguishes.

Important! If the washing cycle ends with rinse hold, perform either

PUMP OUT (position 8) or SPIN (position 6) before opening the door.

7. Open the door, remove the washing.

8. Press the M (ON/OFF) button.

The washing machine is switched off.

17

Page 18

Operating instructions

Loading the Washing

3 For maximum loads see the "Program Tables". For notes on the correct

preparation of the washing, see "Washing Types and Care Symbols".

0 1.Sort the washing by type and prepare.

2. Open the door: pull the handle on the door.

3. Load the washing.

Important! Do not trap any washing when closing

the door! The fabrics and the machine could be

damaged!

4. Close the door firmly.

Adding Detergent/Conditioner

3 For information on detergents and conditioners see

"Detergents and Conditioners".

0 1.Open the drawer: press in the flap on the

drawer so as to be able to grasp the handle

(1), pull out the drawer (2).

2. Add detergent/conditioner.

k

l

w

18

Pre wash detergent/detergent for soaking

or stain remover

(only for k/PRE WASH, position 7/

SOAKING or position 8/STAIN programs.)

Powdered main wash detergent and water

softener, if necessary.

(If you use water softener, add the water

softener on top of the main wash detergent.)

Liquid conditioner

(softener, finisher, starch, other treatments)

Important! Do not fill the compartment beyond the MAX mark. Thick

liquid detergents can be diluted up to the MAX mark, powdered starch

can be dissolved.

3. Push the drawer fully home.

When using liquid detergents:

Add liquid detergent using the dosing containers provided by the

detergent manufacturer. Observe the instructions on detergent pack.

Page 19

Operating instructions

Setting the Washing Program

3 For suitable programs and the right temperature for the relevant type

of washing, see "Program Tables".

Important! Only turn the pro-

gram selector clockwise!

0 1.Set the program selector to the

desired washing program.

2. Set the temperature selector to the

required temperature.

3. Select the washing type.

– The display for the chosen washing type illumi-

nates.

– To change the selection, press another button.

Starting the Washing Program

0 1.Check whether the water tap is open.

2. Switch on the washing machine: Press the M (ON/OFF)

button.

– The washing program starts.

– The door is locked at the latest 15 seconds after

program start. The M (ON/OFF) indicator illuminates.

19

Page 20

Operating instructions

Changing the Spin Speed/Selecting Rinse Hold

0 If desired, reduce the spin speed for the final spin or

select rinse hold:

– Press the button for the required spin speed

– press the o (RINSE HOLD) button.

The indicator for the required spin speed (or o )

illuminates.

If o (RINSE HOLD) is selected, the washing is left in

the last rinse water, it is not spun.

3 If you do not reduce the spin speed, the final spin for all washing

programs is automatically performed at 1000 revolutions per minute.

The speed for the intermediate spin is dependent on the program

selected and cannot be changed.

During the Washing Program

Program Progress Indicator

The program selector serves as a progr am pr ogress indicator by r otating

in a clockwise direction to the end of the program.

3 In the case of the STAIN (position 1), MAIN WASH (position 2) and

QUICK WASH (position 3) programs, immediately after program start

the program selector moves to a position directly behind QUICK WASH

(position 3). The program selector then indicates the progress of the

program as usual.

Changing Settings

During the washing program you can:

– Change the spin speed

– Select o (RINSE HOLD)

– Change the temperature setting

Other settings cannot be altered.

Stopping the Program Early

0 1.Press the M (ON/OFF) button.

2. Turn the program selector clockwise to position 8 (PUMP OUT).

3. Press the M (ON/OFF) button again.

The water is pumped out.

20

Page 21

Operating instructions

Wash Complete/Removing the Washing

The washing program is finished when the M (ON/OFF) button

indicator lamp extinguishes.

After a Rinse Hold:

After a rinse hold the water must be pumped out first, or the washing

spun:

0 Either press one of the buttons to change the final spin speed/ (the

indicator lamp for the required spin speed illuminates)

or

turn the program selector clockwise to position 6 (SPIN),

(washing is spun in accordance with the program just completed),

or

turn the program selector clockwise to position 8 (PUMP OUT)

(water is pumped out).

Once the Program is Finished:

0 1.Open the door.

2. Remove the washing.

Important! The washing machine still needs to be switched off.

3. Press the M (ON/OFF) button.

4. Close the water tap.

5. Pull out the detergent drawer a little so that it can dry out. Leave the

door ajar so that air can circulate in the washing machine.

Important! If the washing machine is not to be used for a long period:

close the tap and isolate the washing machine from the mains.

21

Page 22

Operating instructions

Progr am Tables

Washing

Not all possible settings are listed in the following, but only those that

are useful and meaningful in everyday use.

Washing Type,

Care Symbol

Cottons

ç

Energy Saving

Program:

Cottons

ç

Linen

èë

Easy-Cares

êíî

Max. Load

(weight dry)

5kg

5kg

5kg

2.5kg

Program

1)

Selector

Position 2

(MAIN WASH)

Position k

(PRE WASH)

Position 1

(STAIN)

Position 3

(QUICK WASH)

Position 2

(MAIN WASH)

Position k

(PRE-WASH)

Position 2

(MAIN WASH)

Position k

(PRE-WASH)

Position 1

(STAIN)

Position 3

(QUICK WASH)

Position 2

(MAIN WASH)

Position k

(PRE WASH)

Position 1

(STAIN)

Position 3

(QUICK WASH)

Temperature

Selector

70 to 95

E

30 to 60

30 to 60

Washing Type

Button

t

(COTTONS/

LINEN)

t

(COTTONS/

LINEN)

t

(COTTONS/

LINEN)

}

(EASY CARES)

22

Page 23

Operating instructions

Washing Type,

Care Symbol

Max. Load

(weight dry)

Program

1)

Selector

Temperature

Selector

Washing Type

Button

Position 2

(MAIN WASH)

Position k

(PRE-WASH)

2

Position 1

(STAIN)

r (COLD)

to 40 Ã(DELICATES)

Delicates

ì

2.5kg

(or 15-20m

net curtains)

Position 3

(QUICK WASH)

Position 2

Woollens

9 ì

2)

2kg

(MAIN WASH)

Position 3

r (COLD)

to 40 s(WOOLLENS)

(QUICK WASH)

1)A 10-litre bucket contains about 2.5kg of dry washing (cotton).

2)Only wash woollen garments with the woolmark in the machine if they are also

marked with "does not produce fluff", "non-fluffing" or "washing machine-safe".

23

Page 24

Operating instructions

Separate Soaking

Type of

Washing

Cottons/Linen 5kg

Easy-Cares 2.5kg } (EASY-CARES)

Delicates 2.5kg à (DELICATES)

Max. Load

(weight dry)

Program

Selector

Position 7

(SOAKING)

Temperature

Selector

r (COLD) to

40

Washing Type Button

t (COTTONS/LINEN)

Separate Conditioning/Starching/Treatment

Type of

Washing

Cottons/Linen 5kg

Easy-Cares 2.5kg } (EASY-CARES)

Delicates 2.5kg à (DELICATES)

Woollens 2kg s (WOOLLENS)

Max. Load

(weight dry)

Program Selector Washing Type Button

t (COTTONS/LINEN)

Position 5

(CONDITIONER)

Separate Rinsing

Type of

Washing

Cottons/Linen 5kg

Easy-Cares 2.5kg } (EASY-CARES)

Delicates 2.5kg à (DELICATES)

Woollens 2kg s (WOOLLENS)

Max. Load

(weight dry)

Program Selector Washing Type Button

t (COTTONS/LINEN)

Position 4

(RINSE)

Separate Spinning

Type of

Washing

Cottons/Linen 5kg

Easy-Cares 2.5kg } (EASY-CARES)

Delicates 2.5kg à (DELICATES)

Woollens 2kg s (WOOLLENS)

24

Max. Load

(weight dry)

Program Selector Washing Type Button

t (COTTONS/LINEN)

Position 6

(SPIN)

Page 25

Operating instructions

Cleaning and Caring

Control panel

Attention! Do not use furniture care products or aggressive cleansers

for cleaning control panels and control elements.

0 Wipe control panels with a moist cloth. Use warm water.

Detergent drawer

The detergent drawer should be cleaned from time to time.

0 1.Pull the detergent drawer out as far as it will go.

2. Remove the detergent drawer by pulling sharply.

3. Remove siphon cap.

4. Clean the siphon cap under running

water.

5. Clean compartments with warm

water from the rear. For best results

use a bottle brush.

6. Push the siphon cap all the way on so

that it is securely seated.

7. Clean the entire compartment area of

the washing machine with a brush.

8. Set the detergent drawer into the guide tracks and push in.

25

Page 26

Operating instructions

Washing drum

The washing drum is made of rust-free stainless steel. Rusty objects in

the washing drum may lead to rust deposits on the drum.

Attention! Do not clean the stainless steel drum with acid containing

decalcifying age nts, abr asives containing chlorine or iron, or steel wool.

Appropriate cleansers are available from our customer service department.

0 Remove rust deposits at the drum with a stainless steel cleanser.

Fill-in door

0 Check on a regular basis to see if deposits or foreign objects are pr esent

in or at the rubber sleeve behind the door, and remove.

26

Page 27

Operating instructions

What to do when…

3

The somewhat different, in comparison to older washing machines, whistling noise during spinning is due to

the modern drive system.

A rattling sound on startup – in particular when using

for the first time – is caused by the circulation pump

and is due to the design.

Trouble Shooting

In the case of a malfunction try to solve the problem with the aid of

the notes given here. If you call in customer service to resolve one of

the malfunctions listed here, or rectify an error made in the operation

of the appliance, the customer service engineer’s visit is not free of

charge, even during the period of guarantee.

Malfunction Possible Cause Remedy

Washing machine does

not work.

The machine does not

take in water.

Mains plug is not plugged in. Insert mains plug.

House fuse in defective.

Door is not closed properly.

Tap is closed.

Sieve in the threaded fitting

on the water inlet hose is

blocked.

Replace fuse or switch on

trip.

Close door, lock must e ngage

audibly

Press the M (ON/OFF) button;

Open tap;

Reselect program;

Press the M (ON/OFF) button

again.

Unscrew the hose from the

tap, remove the sieve and

clean under running water

27

Page 28

Operating instructions

Malfunction Possible Cause Remedy

Washing machine

vibrates during operation or is unstable.

Excessive foaming

during the main wash.

Water runs out from

under the washing

machine.

Softener is not washed

in, w compartment

for conditioner is full

with water.

Appliance does not

spin, water in the

drum.

The height adjustable threaded feet are not correctly

adjusted.

There is only very little

washing in the drum (e.g.

only a towelling dressing

gown).

Water cannot be completely

pumped out because the

drain hose is kinked

or

the circulation pump is blocked.

Probably too much detergen t

was used

Threaded fitting on the

water inlet hose is leaking.

Drain hose is leaking.

Circulation pump cover is

not closed properly.

Washing is trapped in the

door.

Suction cap in the compartment for conditioner is not

correctly positioned or is

blocked.

o (RINSE HOLD) selected. Deselect o (RINSE HOLD).

Soaking program is finished.

Adjust threaded feet as per

the installation instructions.

Function is not impaired.

Check the drain hose and if

necessary remove any kink or

clean the circulation pump

and remove any foreign

bodies from the pump housing.

Dose detergent exactly in

accordance with the manufacturer’s instructions.

Tighten the water inlet hose

Check drain hose and if

necessary replace.

Close cover properly.

Stop program, remove

washing from the door, start

a new program.

Clean detergent drawer,

place suction cap firmly in

position.

Pump out the water and set

the main wash cycle as

desired.

28

Page 29

Operating instructions

Malfunction Possible Cause Remedy

Drain hose is kinked. Remove kink.

Washing is not spun

properly, water is still

visible in the drum.

It is not possible to

open the door.

Rinse water is cloudy.

Remnants of detergent

are building up in the

detergent drawer.

Program selector skips

k (PRE WASH).

Program selector

remains stationary at

position 7 (SOAKING).

Stain remover is not

washed in.

Maximum pumping height

(drain height 1m above the

floor on which the machine

is standing) exceeded.

Circulation pump is blocked.

In the case of siphon connection: siphon is blocked.

Program is not yet finished;

M (ON/OFF) indicator lamp is

illuminated.

This is probably due to using

a detergent with a high silicate content.

Tap is not fully open. Open tap fully.

The sieve in the threaded fit-

ting on the water inlet hose

at the tap is blocked.

Sieve on threaded fitting for

the water inlet hose on the

machine is blocked.

k (PRE WASH) combined

with s (WOOLLENS).

Position 7 (SOAKING) is combined with s (WOOLLENS).

Position 1 (STAIN) is combined with s (WOOLLENS).

Please contact customer service who have a retrofit kit

for pumping to heights of

greater than 1m.

Switch off the machine and

unplug from the mains, clean

the circulation pump.

Clean siphon.

Wait until the M (ON/OFF)

indicator lamp extinguishes.

No negative impact on the

rinsing results, possibly use

liquid detergent.

Clean sieve.

Clean sieve.

k (PRE WASH) cannot be

combined with s

(WOOLLENS).

Position 7 (SOAKING) ca nnot

be combined with

s (WOOLLENS).

Position 1 (STAIN) cannot be

combined with s

(WOOLLENS).

29

Page 30

Operating instructions

If the washing results are not satisfactory

If the washing is grey and there are calcium deposits in the drum

• Too little detergent was used.

• The wrong detergent was used.

• Special soiling was not pre-treated.

• Program or temperature not set correctly.

• When using component detergents, the individual components were

not used in the correct proportions.

If there are still gray stains on the washing

• Washing soiled with ointments, grease or oils was washed with too

little detergent.

• Too lower temperature was used for washing.

• A common cause is that softener – particularly that in concentrated

form – has got onto the washing. Wash out any such spots as quickly

as possible and use that particular softener carefully.

If at the end of the last rinse foam is still visible

• Modern detergents can cause foam also in the last rinse. The washing

is however sufficiently rinsed.

30

If there are white remnants on the washing

• This is an insoluble material contained in modern detergents.

This is not the result of unsatisfactory rinsing.

Shake or brush the washing. Perhaps you should turn the washing

inside out before washing in future. Reconsider choice of detergent,

possibly use liquid detergent.

Page 31

Operating instructions

Perform emergency drain

• If the washing machine no longer pumps out the water then an

emergency drain must be performed.

• If the washing machine is located in a room in which below freezing

temperatures might occur, emergency draining must be carried out if

danger of freezing occurs.

Furthermore, the inlet hose must be disconnected from the tap and

laid on the floor.

Warning! Switch the washing machine off and pull the mains plug

1

prior to emergency draining.

Attention! The water which runs out of the emergency draining hose

can be hot. There is a danger of scolding! Before an emergency drain

first allow the water to cool down!

0 1. Have a flat container on hand to catch the water running out.

2. Open the flap on the left of the pedestal

cover downwards and remove.

3. Remove the emergency drain hose from

the bracket.

4. Pull the emergency drain hose out a little.

5. Place the container under the hose.

6. Undo and remove the plug in the end of

the emergency drain hose by turning it in

an anti-clockwise direction.

The wash-water runs out. Depending

upon the amount of water, it may be

necessary to empty the container several

times. Temporarily close the emergency

drain hose with the plug to this end.

31

Page 32

Operating instructions

When the water is completely drained:

7. Press the end stop firmly back into the emergency drain hose.

8. Push the emergency drain hose back in a little and allow it to snap into

the mounting.

9. Put on the flap and close.

The ECO valve does not function when the machine has been fully

3

emptied. Therefore add approx. 1liter of water before the next wash

(pour in through the detergent drawer).

Clean the circulating pump

Warning! Switch off the washing machine and pull the mains plug

1

before cleaning the circulation pump!

0 1. First perform emergency draining (see above: "Perform Emergency

Drain").

2. Lay a cloth on the floor in front of the circulation pump cover. Some

water may run out.

3. Unscrew the circulation pump cover in an

anti-clockwise direction and remove.

4. Remove foreign body from the pump

housing.

5. Check whether it is possible to turn the

pump impeller. (Jerky pump movement is

normal.) If it is not possible to turn the

impeller, contact customer service.

6. Replace cover (insert stud on the cover

into the guide slot) and tighten in a

clockwise direction.

7. Close emergency drain hose, push in and

fix in place.

8. Close the flap.

32

Page 33

Operating instructions

Additional Rinse/Water Cooling

The washing machine is set up for extremely low water consumption.

• For people who suffer from an allergy to detergents, it can be useful

to rinse with more water (additional rinse).

• It may be necessary to cool the water before it is pumped out in order

to prevent damage to plastic waste pipes (water cooling).

You can activate these functions using the More Water Switch.

3 The program duration and water consumption are increased by water

cooling and/or the additional rinse.

Position "1": Water Cooling

At the end of the main wash, the water is cooled (by adding cold water)

prior to pumping out.

This setting is only effective for t (COTTONS/LINEN) with a temperature above 40 °C.

Position "2": Water Cooling and Additional Rinse

The water is cooled as in position 1, and an additional

rinse is also performed during the t (COTTONS/LINEN),

} (EASY-CARES) and à (DELICATES) programs.

3 As supplied the More Water Switch is set to position 0.

Make the Adjustment:

0 1.Pull out the detergent drawer until the More

Water Switch is accessible in the frame on the left.

2. Set the More Water Switch to

"1" (water cooling) or

"2" (water cooling and additional rinse).

33

Page 34

Installation and Connection Instructions

INSTALLATION AND CONNECTION

INSTRUCTIONS

Installation Safety Precautions

• Do not tip the washing machine over the front or the left side (seen

from the front). Electrical components could become wet!

• Check the washing machine for transport damages. You should never

connect a damaged appliance. In the event of a damage consult your

dealer.

• Make certain that all shipping braces have been removed and that

the splash guard is attached to the appliance, see "Shipping Brace

Removal". Otherwise damage may occur to the machine or close by

furniture during the spin cycle.

• The plug may only be inserted into a properly installed earthing con-

tact safety socket. Extension cables, octopus plugs or adapters may

not be used.

• For permanent connection a current interruption device must be pro-

vided for in the electrical circuit (fuse, circuit breaker, ground fault

circuit interrupter or the like) with a contact opening of at least

3 mm which allows for disconnection of the appliance at all poles.

Permanent connection may only be carried out by an authorised

electrician.

• Before starting your appliance please ensure that the nominal volt-

age and type of current specified on the rating plate are the same as

those used at the place of installation. Please also refer to the rating

plate for the type of fuse to be used.

• Prior to carrying out modifications on the appliance (on the worktop

or front door) pull out the mains plug.

• The mains feed-line may only be replaced by the customer service or

by an authorised electrician.

34

Page 35

Installation and Connection Instructions

Dimensions of the appliance

Front and Side Views

Rear View

35

Page 36

Installation and Connection Instructions

Installation of the appliance

Washing machines with arched covers are not suited for installation

3

beneath countertops.

Transporting the appliance

• Do not lay the washing machine on the front or on the left side (seen

from the front); otherwise the electrical components could become

wet!

• Never transport the appliance without transportation protection.

Remove the protection only at the place of installation! Transportation without protection can lead to damages to the appliance.

• Neither lift the appliance by an open door nor by the base.

• The appliance weighs approx. 85kg.

• By transportation with a trolley: Place the trolley only sidewise.

36

Page 37

Installation and Connection Instructions

Remove transportation protection

Attention! Be absolutely certain that all shipping braces have been

removed before installing the appliance.

Store all shipping braces in a safe place in case they are required for

future transport (moving).

Special spanner H and cover caps E (2 off) and G (1 off) are supplied

3

with the appliance.

0 1. Remove flexible tubing holder A.

2. Remove the two screws B with special spanner H.

3. Remove the four screws C.

4. Detach transportation rail D.

5. Close the two large openings with the cover caps E.

Attention! Press cover caps forcefully in, so that they snap into the

rear wall (protecting the interior of the appliance against sprayed

water).

6. Drive in the screws C into the four small holes again.

7. Remove the screw and compression spring F with special spanner H,

cover the hole with caps G.

Attention! Press cover caps forcefully in, so that they snap into the

rear wall (protecting the interior of the appliance against sprayed

water).

37

Page 38

Installation and Connection Instructions

Prepare the installation place

• The installation surface must be clean and dry, free of floor wax and

other smearing substances, so that the appliance does not slip off. Do

not use any lubricant as sliding aid.

• Installation on a high-veil carpet or floor tiles with soft sponge backs

is not recommended because the standing safety of the appliance is

then no longer ensured.

• By installation surfaces with small-format tiles, lay a conventional

rubber mat underneath.

• Small unevenness of the floor surface should never be levelled out by

laying pieces of wood, carton or similar elements, but rather basically

compensated by adjusting the screw feet.

• When it is unavoidable to install the appliance besides a gas or a

coal-fuelled cooker, due to spatial reasons: insert a piece of heatinsulating board (85 x 57 cm) between the cooker and the washing

machine; the board side facing the cooker must be provided with an

aluminium foil.

• The washing machine may not be installed in a frost-endangered

room. Frost-caused damages!

Flexible feed and drain tubings may not be crinkled or squeezed..

38

Installation on a concrete base

When installing on a concrete base,

for safety reasons it is imperative

that steel plates are installed, the

washing machine is then installed in

these plates. The steel plates are

available from customer service

under ET-No. 645 425 058.

Installation on vibrating

floors

In the case of floors that vibrate, especially wooden floors with floorboards that flex, a water-proof wooden panel of at least 15 mm thickness must be firmly screwed to at least 2 floor beams. If possible, install

the appliance in a corner of the room: the wooden floor is more firmly

supported in the corners and thus has less tendency to resonant vibration.

Page 39

Installation and Connection Instructions

Levelling on uneven floors

Using the four adjustable threaded feet, compensation can be made for

unevenness in the floor and the height of the appliance adjusted. The

height can be adjusted over the range +10... -5mm.

To adjust the feet use the special spanner supplied for removing the

transport braces.

0 1.Slide the special key firmly onto the hexagon head of the threaded foot

all the way to the stop.

2. Adjust the threaded feet so that the appliance is level and sits stably.

The appliance must not rock across the corners when operating under

load.

3. If necessary, check positioning with a spirit level.

Important! Never compensate for small areas of unevenness in the

floor through the use of wooden wedges, cardboard or the like. Levelling should only ever be performed by adjusting the feet.

Power supply

Details on the mains voltage,

type of current and the necessary fuse protection are to be

found on the rating plate. The

rating plate is above and

behind the door.

For permanent electrical connection within the electrical

circuit, provisions must be made which allow for electrical disconnection of the appliance from the mains with a contact opening of at least

3 mm at all poles. Suitable devices include circuit breakers, fuses

(threaded fuses must be entirely removed from the socket), ground

fault circuit interrupters and contactors. Permanent connection may

only be carried out by an authorised electrician.

;

This appliance conforms to the following EC directives

– "Low-Voltage Directive" 73/23/EWG dated 19 February 1973

and Directive amendment 93/68/EWG

– "EMC Directive" 89/336/EWG dated 3 May 1989

and Directive amendment 93/68/EWG

39

Page 40

Installation and Connection Instructions

Water connection

The washing machine is provided with safety devices which prevent

3

reverse pollution of drinking water and conform to the State regulations issued by water supply authorities (e.g. in Germany: DVGW Directives). Further protective measures in the installation are hence

unnecessary.

Attention! Appliances for cold water connection may not be connected to warm water!

Permissible water pressure

Water pressure must be equal to a least 1 bar (= 10N/cm2 = 0.1 MPa),

and no more than 10 bar (= 100N/cm

• By more than 10 bar: connect a pressure reduction valve upstream.

• By less than 1 bar: Unscrew the flexible inlet tubing on the magnetic

inlet valve on one side of the appliance and remove the flow meter

(thereby remove the sieve by means of a pair of pointed pliers and

then remove the rubber washer behind it). Remount the sieve.

2

= 1 MPa).

40

Page 41

Installation and Connection Instructions

Water feed

A flexible pressure tubing of 1.3m length is supplied.

If a longer feed tubing is needed, a complete VDE-approved tubing set

with mounted screw connections, supplied by our customer service,

should be used exclusively.

– For washing machines without Aqua-Control, tubing sets are

available in lengths of 2.2m, 3.5m and 5m.

– For washing machines with Aqua-Control, tubing sets are available

in lengths of 2.0m, 2.9m and 3.9m.

Attention! Under no circumstances may tubing be pieced together for

the purpose of lengthening!

Sealing rings are either inserted in plastic nuts of the tubing screw con-

3

nection or contained in an accompanying packet. Do not use other

seals.

0 1. Connect the angled hose connector to the

machine.

Attention! Plastic nut at the tube coupling

may only be hand tightened.

2. Connect the straight hose connector to a water tap

with an R 3/4 (inch) thread.

Attention! Only tighten the plastic nuts on the

hose connectors by hand.

3. By opening the water tap slowly prior to the initial

operation, check whether the connection is tight.

41

Page 42

Installation and Connection Instructions

Water drain-off

The drain-off tubing can be connected either to a siphon or be hanged

in a washing or sink basin or in a bathtub.

For extension (max. 3 m floor length and up to 80 cm high) only original tubing may be used. The customer service supplies drain-off tubing

of 2.7 and 4m lengths.

Water drain-off inside a siphon

The spout at the end of the tubing fits all common siphon types.

0 Make the connection spout/siphon secure with a tubing clip.

Water drain-off inside a basin

For hanging in a wash basin, sink or bath,

the drain hose must be prevented from

moving using the detachable elbow supplied.

The tube could otherwise be pushed out of

the basin by the reactive force imparted by

draining water.

Small sink basins are not suitable!

0 Fasten the elbow on the water tap or on

the wall by means of the hole.

Delivery heights above 1m

Every washing machine is provided with a suds pump for draining the

washing/rinsing suds, which can deliver liquids via the drain-off tubing

up to a height of 1m, measured from the standing level of the machine.

For delivery heights above 1m please establish contact with the AEG

customer service.

42

Page 43

Installation and Connection Instructions

Technical data

Height x Width x Depth 85x60x60cm

Depth with open door 95cm

Height adjustment approx. +10/-5mm

Weight when empty approx. 85kg

Load (depending on the program) max. 5kg

Area of use Household

Wash cycle drum speed max. 53min

Spin cycle drum speed see type plate

Water pressure 1-10bar

(=10–100N/cm

2

= 0.1 – 1.0MPa)

-1

r.p.m.

43

Page 44

Service Departments

SERVICE DEPARTMENTS

ELECTROLUX s.r.o.

divize AEG Domácí spotøebièe

Servis

Hanusova ulice

140 21 Praha 4

Tel.: 02/61 12 26 21/26 22

Telefax: 02/61 12 29 47

tø. Gen. Piky 3

613 00 Brno

Tel.: 05/45 24 51 13

Telefax: 05/45 24 51 03

44

Page 45

Guarantee Conditions

GUARANTEE CONDITIONS

Záruka, servis a náhradní díly

Pøeètìte si tento návod k obsluze a dodr¤ujte v nìm uvedené rady a pokyny. V mnoha

pøípadech si budete moci vyjasnit jakékoli pochybnosti sami a tudí¤ vyhnout se zbyteèným voláním do servisu. Pøedchozí èásti nazvané „Co dìlat, kdy¤...“ a „Servis“ obsahuje doporuèení, co by se mìlo zkontrolova døíve, ne¤ zavoláte servisního technika.

Jestli¤e po tìchto kontrolách závada stále existuje, zavolejte vaše nejbli¤ší autorizované servisní støedisko AEG. Ujistìte se, ¤e mù¤ete sdìlit model a seriové èíslo spotøebièe. Tyto informace naleznete na datovém štítku pøístroje. Originální náhradní díly lze

koupit od autorizovaných støedisek servisu AEG.

Podmínky záruky

My, výrobce, zaruèujeme, ¤e jestli¤e bìhem 12 mìsícù od data zakoupení tohoto

spotøebièe AEG se tento spotøebiè nebo jakákoli jeho èást uká¤ou jako vadné pouze z

dùvodu vadného zpracování nebo vadného materiálu, provedeme podle našeho uvá¤ení

bud’ opravu nebo výmìnu tého¤ bez placení za prací, materiál nebo pøepravu za pøedpokladu, ¤e

– spotøebiè byl správnì instalován a pou¤íván pouze na napìtí na štítku jmenovitých

hodnot

– spotøebiè byl pou¤íván pouze pro normální domácí úèely a v souladu s pokyny

výrobce pro provoz a údr¤bu na spotøebièi neprovádìla servis, údr¤bu ani opravu jiná

ne¤ námi autorizovaná osoba

– všechny servisní práce podle této záruky musí provádìt servis AEG nebo jím autorizo-

vané støedisko

– ka¤dý vymìnìný spotøebiè nebo vymìnìná vadná souèást se stanou naším vlastnict-

vím

– tato záruka platí vedle vašich zákonných nebo jinak právnì podlo¤ených práv

Výjimky – tato záruka se nevztahuje na:

– poškození nebo po¤adavky vzniklé v dùsledku pøepravy, nesprávného pou¤ití nebo

nedbalosti, výmìny ¤árovek a snímatelných èástí ze skla nebo plastických hmot

– náklady spojené s po¤adavky na odstranìní závad spotøebièe, který je nesprávnì

instalován

– spotøebièe, které jsou pou¤ívány v komerèním prostøedí vèetnì pronajímaných

– zemì Evropského spoleèenství. Lze pou¤ít standarní záruku, ale zajištìní, ¤e spotøebiè

splòuje normy platné v pøíslušné zemi, kam byl spotøebiè dopraven, je na zodpovìdnosti a na náklady vlastníka. Mù¤e být vy¤adován doklad o koupi.

Model............................................................................................

Èíslo výrobku (Prod. No.)......................................................

Seriové èíslo (Serial. No.)......................................................

eventuelnì KD . . . . . . . . . / . . .

Bezpeènost

Pøeètìte si tento návod a varovná upozornìní na zaèátku tohoto návodu.

Výrobce nezodpovídá za vady zpùsobené nesprávnì pou¤ívaným výrobkem nebo

výrobkem pou¤ívaným pro jiné úèely ne¤ jsou úèely specifikované v tomto

návodu.

Technické zmìny výrobku vyhra¤eny.

V pøípadì problému volejte zdarma 0800/16 00 16

45

Page 46

Index

INDEX

C

Calcium . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Conditioner . . . . . . . . . . . . . . . 9

liquid . . . . . . . . . . . . . . . . . . . . . . . . . .9

Conditioning . . . . . . . . . . . . . . . . . . . . . . . . 24

Cotton Mixtures . . . . . . . . . . . . . . . . . . . . . 15

Cottons . . . . . . . . . . . . . . . . . . 11

Customer Service . . . . . . . . . . . . . . . . . . . . 27

Customer service . . . . . . . . . . . . . .26

, 11, 16, 18

, 18

, 15, 22, 24

, 44, 47

D

Danger of freezing . . . . . . . . . . . . . . . . . . . 31

Danger of Frost . . . . . . . . . . . . . . . . . . . . . . . 6

Delicates . . . . . . . . . . . . . . . . . 12

Detergent . . . . . . . . . . . . . . . . . . . . .9

Detergent for Soaking . . . . . . . . . . . . . .9

, 15, 23, 24

, 16, 18

, 18

E

Easy-Cares . . . . . . . . . . . . . . . 11, 15, 22, 24

ECO Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ECO valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

G

Guarantee . . . . . . . . . . . . . . . . . . . . . . . .6, 27

L

Linen . . . . . . . . . . . . . . . . . . . . 11, 15, 22, 24

Liquid detergent . . . . . . . . . . . . . . . . . . . . . 18

M

Main Wash . . . . . . . . . . . . . . . . . . . . . . .10, 22

Main Wash Detergent . . . . . . . . . . . . . . .9

, 18

N

Net Curtains . . . . . . . . . . . . . . . . . .14, 15, 23

O

Open Door . . . . . . . . . . . . . . . 17, 18, 21, 29

P

Pre Wash . . . . . . . . . . . . . . . . . . . . . . . .10, 22

Pre Wash Detergent . . . . . . . . . . . . . . . .9

Program Progress . . . . . . . . . . . . . . . . . . . . 20

Pump Out . . . . . . . . . . . . . . . . . . . . . . . .11

, 18

, 21

Q

Quick Wash . . . . . . . . . . . . . . . . . . . . . .10, 22

R

Rating Plate . . . . . . . . . . . . . . . . . . . . . . 9, 39

Rating plate . . . . . . . . . . . . . . . . . . . . . . . . .47

Rinse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

additional rinse . . . . . . . . . . . . . . . . . . . .33

Rinse Hold . . . . . . . . . . . . . . . .10

, 11, 20, 21

S

Saving Energy . . . . . . . . . . . . . . . . . . . . 11, 22

Silk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Soaking . . . . . . . . . . . . . . . . . . . . . . . . . 11

Softener . . . . . . . . . . . . . . . . . . . . . . .8

Spin . . . . . . . . . . . . . . . . . . . . .10

Stain . . . . . . . . . . . . . . . . . . . . . . . 10

Stain Remover . . . . . . . . . . . . . . . . .9

Stains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Starch . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Starching . . . . . . . . . . . . . . . . . . . . . . . . 11

Stopping the Program . . . . . . . . . . . . . . . . .20

, 24

, 9, 18

, 11, 20, 24

, 18, 22

, 10, 18

, 30

, 18

, 24

W

Washing

coloured . . . . . . . . . . . . . . . . . . . . . . . . . .14

delicate . . . . . . . . . . . . . . . . . . . . . . .14

easy-care . . . . . . . . . . . . . . . . . . . . . . . . . .15

lightly soiled . . . . . . . . . . . . . . . . . . . . . . . .8

normally soiled . . . . . . . . . . . . . . . . . . . . . .8

Water

circulation pump . . . . . . . . . . . . . . . . 9

emergency drain . . . . . . . . . . . . . . . . . . .31

hardness . . . . . . . . . . . . . . . . . . . . . . . 8

pump out . . . . . . . . . . . . . . . . . . . . . 11

softener . . . . . . . . . . . . . . . . . . 8

water cooling . . . . . . . . . . . . . . . . . . . . . .33

Water Softener . . . . . . . . . . . . . . . . . . . . . . .18

Woollens . . . . . . . . . . . . . . . . . 12

, 15

, 32

, 16

, 21

, 9, 16, 18

, 15, 23, 24

46

Page 47

SERVICE

If a malfunction should occur at the appliance, refer first to the section

"What to do when ..." in these user instructions. If you do not find any

applicable instructions there, contact your customer service centre.

(Addresses and telephone number can be found in the "Service Departments" section.)

Be well prepared before you phone. This facilitates the diagnosis and

the decision as to whether a customer service visit is necessary. With

our checklist you can gather important information before making

your call:

Make a note of the PNC number and

the S-number.

Both of these number can be found

on the rating plate on the inside of

the door of your washing machine.

......................................................

PNC

......................................................

S-No.

In addition to this please establish if possible:

• How is the malfunction noticeable ?

• Under what circumstances does the malfunction occur?

Service

You will be charged even during the warranty period

– if you could have corrected the malfunction yourself with the help of

the malfunctions table (see "What to do when ..." section),

– if the customer service technician is required to make several trips

because he had not received all relevant information before his visit,

and must return, for example, to pick up replacement parts. This

additional driving can be avoided if your telephone call is well prepared, as described above.

47

Page 48

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

http://www.aeg.hausgeraete.de

© Copyright by AEG

H 243 288 540 - 01 - 1099

Loading...

Loading...