Page 1

L 62699

LAVAMAT

95

E60

E40

40

30

60

50

40

40

30

40

30

40

E90

F

D

C

B

A

1200

900

700

400

LAVAMAT L 62699

La lavadora ecológica

The environmentally friendly washing machine

Instrucciones para el uso

Instruction booklet

PERFEKT IN FORM UND FUNKTION

Page 2

Dear customer,

Please read these operating instructions carefully and pay particular

attention to the safety notes indicated in the first pages. We recommend that you keep this instruction booklet for future reference and

pass it on to any future owners.

The warning triangle and/or the key words (Warning!, Caution!) emphasize information that is particularly important for your safety or correct

functioning of the appliance.

This symbol guides you, step by step, in the operation of the appliance.

The information marked with this symbol provides additional instruc-

tions and practical tips on the use of the appliance.

Tips and information about economical and ecological use of the

machine are marked with the clover symbol.

Should any problems arise, this booklet provides instructions on how to

solve them by yourself; see section “Something not working?”.

If this information is not sufficient, please contact our nearest SERVICE

CENTRE.

Printed on recycled paper.

People who think ecologically, act accordingly…

45

Page 3

Contents

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-49

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Tips for environmental protection

Main features of your washing machine . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Description of the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Programme selector dial. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

START/PAUSE button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

DELAYSTART button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Programme Option buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

STAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

QUICK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

SOAK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

PREWASH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

SPIN SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

RINSE HOLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Programme progress display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cancelling a programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Altering a programme which is running. . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Opening the door after the programme has started. . . . . . . . . . . . . . . . . 58

Detergent dispenser drawer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Before the first wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Preparing the wash cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Sorting out and preparing the laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Weight of laundry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Types of fabric and care labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61-62

Detergents and additives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Which detergent and additive? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

How much detergent?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Liquid detergent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Adding a water softener (descaling product) . . . . . . . . . . . . . . . . . . . . . . . . . 63

Information on water hardness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

46

Page 4

Contents

How to wash

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Load the laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Add detergent and additives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Select the desired wash programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Select the desired options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Select the SPIN SPEED or RINSE HOLD option . . . . . . . . . . . . . . . . . . . . . . . . 66

Select the EXTRA RINSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Select the DELAY START option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Starting the programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

At the end of the programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67-68

Programme charts: wash and special programmes . . . . . . . . . . . . . . . 69-71

Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

After each wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Periodical cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Detergent dispenser drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Door seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Drain pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Water inlet filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Emergency emptying out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Frost precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74-75

Something not working?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-77

Unsatisfactory washing results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Instructions for installation and electrical connection. . . . . . . . . . . . . . . 81

Safety instructions for the installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Dimensions of the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Front view and side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Levelling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Water inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Water drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Permanent connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

47

Page 5

Safety instructions

The safety of AEG appliances complies with the industry standards and

with legal requirements on the safety of appliances. However, as manufacturers, we feel it is our duty to provide the following safety notes.

General safety

• Repairs to the machine must be carried out only by qualified personnel. Repairs carried out by inexperienced persons could cause serious

danger. Contact your local AEGService Force Centre.

• Never start the machine if the electrical supply cable is damaged or

the control panel or worktop are so damaged that inner components

can be reached.

• Unplug the appliance before carrying out any cleaning or maintenance operations.

• Never pull the power supply cable to remove the plug from the socket; always take hold of the plug itself.

• Never spray the machine with a jet of water. Danger of electric shock!

• During high temperature wash programmes the door glass may get

hot. Do not touch it!

• Let the water cool down before carrying out emergency emptying or

before opening the door in an emergency.

• Small animals can gnaw electric wires and water hoses causing electrocution hazard and damage due to water leaks.

48

Positioning, connection, starting up

• Follow the instructions for positioning and connection.

• Carry out a first wash without laundry (COTTONS E60, with half the

amount of detergent) in order to remove any manufacturing residue

from the tub and the drum.

• Should the machine be purchased in winter, when temperatures can

be below 0°, leave the appliance for 24 hours at ambient temperature

before starting it.

Page 6

Safety instructions

Child safety

• Children are often not aware of how dangerous electrical appliances

can be. When the machine is working, children should be carefully

supervised and not be allowed to play with the appliance - there is a

risk that they could become trapped inside.

• The packaging components (e.g. plastic film, polystyrene) can be dangerous to children - danger of suffocation! Keep them out of children’s reach.

• Keep all detergents in a safe place out of children’s reach.

• Make sure that children or pets do not climb into the drum.

• When the appliance is to be scrapped, cut off the electrical supply

cable and destroy the plug with the remaining cable. Disable the door

catch in order to prevent children from becoming trapped inside

while playing.

Proper use

• This appliance is designed for domestic use only. If the machine is

used for any other purposes or is not used correctly, the manufacturer accepts no responsibility for any damage that might occur.

• For safety reasons, the appliance must not be modified.

• Use only detergents suitable for washing machines and follow the

manufacturer’s instructions.

• Garments which have been in contact with flammable solvents

should not be machine washed.

• Do not use your machine for dry cleaning.

• Dyes and bleaching agents may only be used if specifically permitted

by the manufacturer of these products. We cannot be held responsible for any damage.

• Always unplug the appliance and turn off the water tap after use.

49

Page 7

Disposal

Packaging materials

The materials marked with the symbol are recyclable.

>PE<=polyethylene

>PS<=polystyrene

>PP<=polypropylene

This means that they can be recycled by disposing of them properly in

appropriate collection containers.

Machine

Use authorised disposal sites for your old appliance. Help to keep your

country tidy!

Tips for environmental protection

To save water, energy and to help protect the environment, we recommend

that you follow these tips:

• Normally soiled laundry may be washed without prewashing or soak

in order to save detergent, water and time (the environment is protected too!).

• Use the energy saving programme when washing normally soiled garments.

• The machine works more economically if it is fully loaded.

• When small loads are washed, use only half to two thirds of the recommended amount of detergent.

• With adequate pre-treatment, stains and limited soiling can be

removed; the laundry can then be washed at a lower temperature.

• If the water has a medium or high degree of hardness (starting from

hardness degree II, see “Detergents and additives”) water softeners

must be added.

The amount of detergent can then be adjusted to hardness degree I (= soft).

50

Page 8

Main features of your washing machine

• Programme and temperature setting using the programme selector.

• Stain option for effectively treating stained washing.

• Energy saving programmes for normally soiled cotton items.

• Speed for the final spin can be reduced to 900, 700 or 400 rpm.

• RINSE HOLD: the laundry is left immersed in the final rinse water to

prevent creasing.

• Delay timer: programme start can be delayed up to 23 hours (e.g. to

times with a more economical power rate).

• Programme progress display showing the programme steps selected

and the programme phase which is running.

• Because of its gentle washing action, the special wool cycle washes

your garments with extreme care.

• 4-compartment drawer for detergent, fabric softener and bleaching

agent.

• Unbalance detection device: to prevent vibration during spinning.

• The ECO valve allows total use of detergent and reduces water con-

sumption so saving energy.

51

Page 9

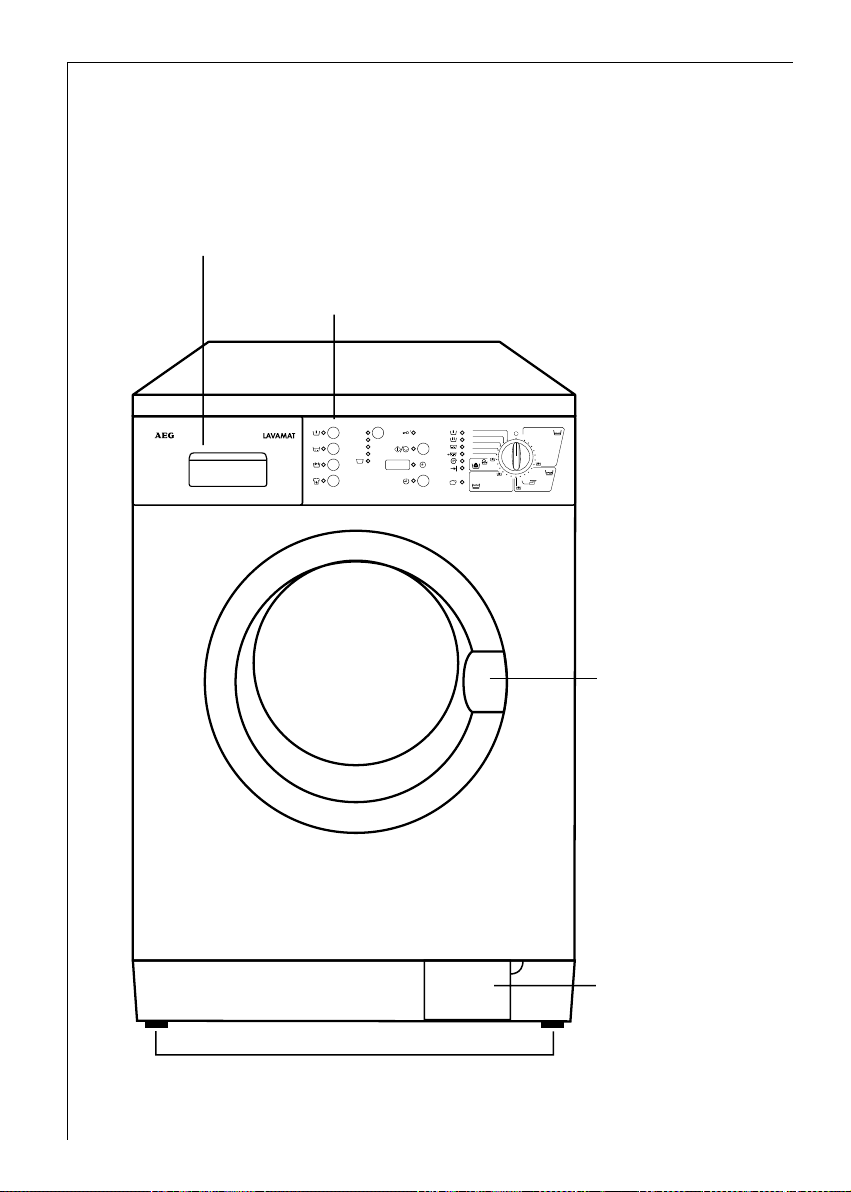

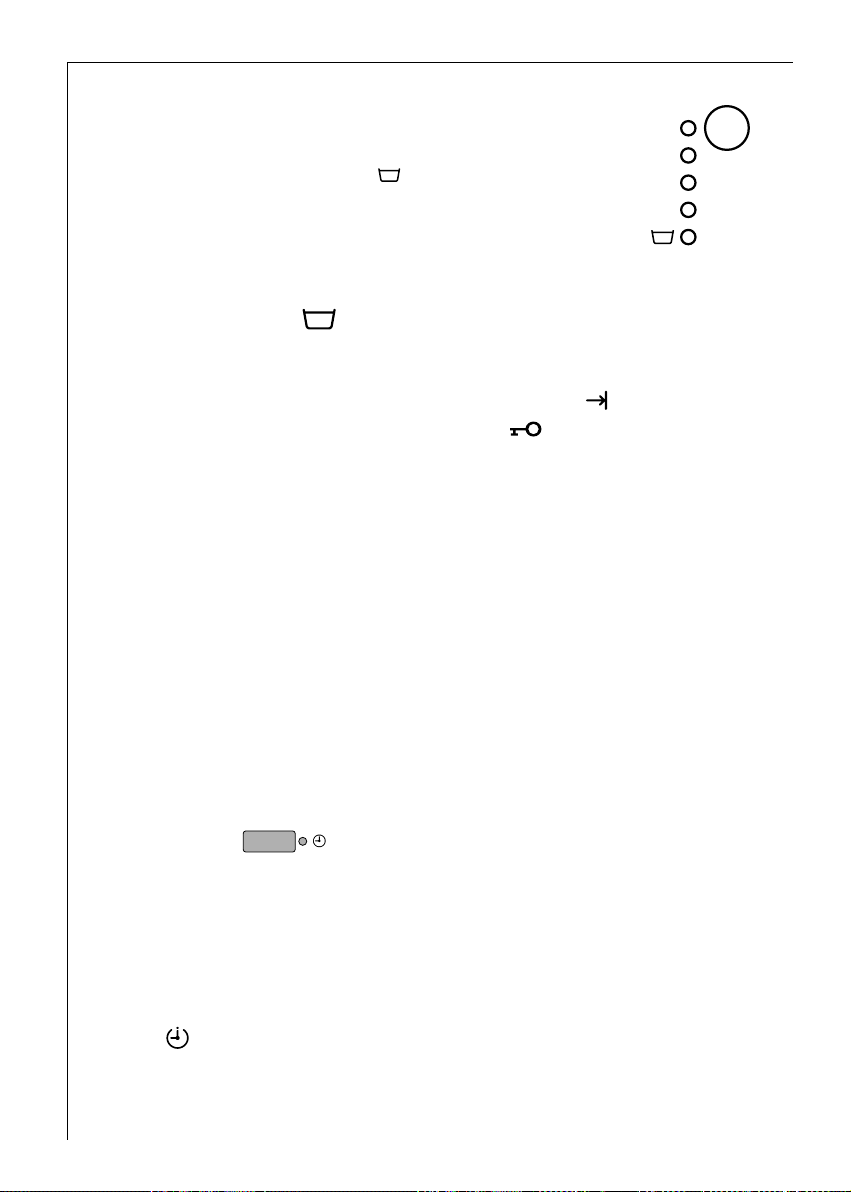

Description of the appliance

L 62699

95

E60

E40

40

30

60

50

40

40

30

40

30

40

E90

F

D

C

B

A

1200

900

700

400

Drain pump

Door

Control panel

Detergent drawer

Adjustable feet

Front view

52

Page 10

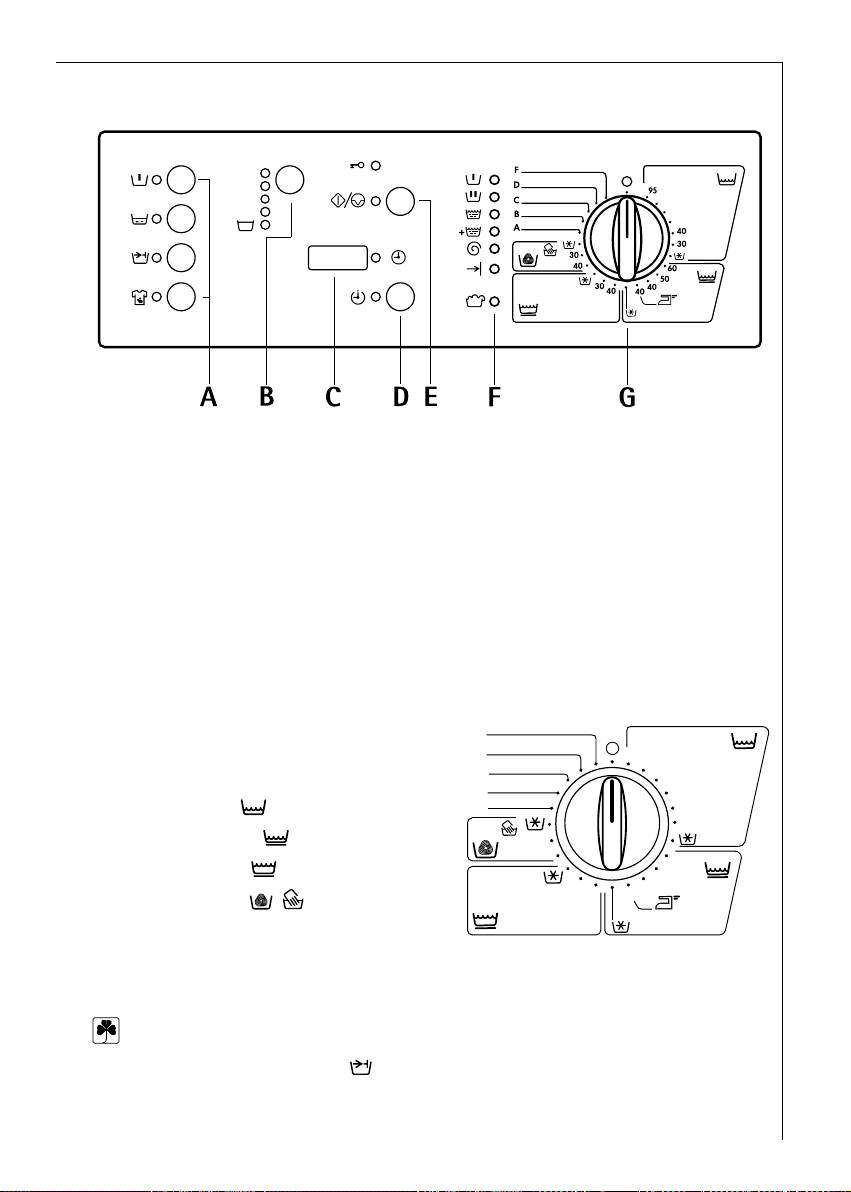

Control panel

700

1200

900

400

E60

E40

E90

95

40

60

50

40

40

30

40

30

40

A

D

F

C

B

30

E60

E40

E90

A = Option buttons

B = Spin speed button

C = Display

D = Delay start button

E = START/PAUSE button

F = Programme progress display

G = Programme selector dial

Description of the appliance

Programme selector dial

The programme selector determines the type of washing cycle (e.g. water

level, drum movement, number of rinses) and the washing temperature

according to the type of laundry.

The selector dial is divided into 5

sections:

• Cottons

• Synthetics

• Delicates

• Woollens (hand washing)

• Special programmes A...F

• Reset programme O/OFF

The selector dial can be turned either clockwise or anticlockwise.

Position E90, E60 and E40 corresponds to the ENERGY SAVING pro-

gramme for normally soiled laundry, extended washing time (cannot be

combined with QUICK ).

53

Page 11

Description of the appliance

Position at 40°C = Easy to iron.

In this position the laundry is gently washed and spun to avoid any

creasing. In this way ironing is easier.

Position = cold wash

START/PAUSE button

This button has two functions:

a) Start

After having selected the required progr amme, press this button to start

the machine. If you have selected the DELAY START option , the

machine starts its hourly countdown.

b) Pause

To interrupt a programme which is running, press the START/PAUSE

button: the relevant light starts to flash.

To restart the programme from the point at which it was interrupted,

press the START/PAUSE button again.

DELAY START button

The wash programme can be delayed from 30 min – 60 min – 90 min,

2 hours and then by 1 hour up to a maximum of 23 hours by means of

this button.

Selecting the delayed start

54

• Select the programme and the required options.

• Select the delay start.

• Depress START/PAUSE button: the machine starts its hourly count

down.

The programme will start after the selected delay has expired.

Cancelling the delayed start

• Depress START/PAUSE button .

• Depress DELAY START button until the symbol 0’ is displayed.

• Depress START/PAUSE button again to restart the programme.

To modify the delay time, after the programme has already started, set

the programme again and select the new desired delay time.

Page 12

Description of the appliance

Programme Option buttons

Depending on the programme, different functions can be combined.

These must be selected after choosing the desired programme and

before depressing the START/PAUSE button.

When these buttons are pressed, the corresponding pilot lights come on.

When they are pressed again, the pilot lights go out.

STAIN

To treat heavily soiled or stained laundry with stain remover (extended main

wash with time optimised stain action phase, not selectable for wool, handwash or programmes with temperatures lower than 40°C).

This function cannot be used with SOAK and PREWASH .

QUICK

By pressing this button the washing time is reduced. For use when

washing lightly soiled laundry.

This option is not available with programme wool, handwash and economy programmes.

SOAK

The machine performs a soak of about 30 minutes at 30°C. By pressing

the DELAY START button the soak time can be prolonged up to 10

hours max. After this time the wash cycle will automatically start.

This function cannot be used with WOOL programme, PREWASH or

STAIN options.

The soak programme ends with a short spin in programmes for Cotton

and Synthetics, and with emptying of the water without spinning for

Delicates.

PREWASH

The machine performs a prewash cycle before the main wash. The prewash cycle ends with a short spin in programmes for Cotton and Synthetics, and with emptying of the water without spinning for Delicates.

This option is not available with the wool programme and cannot be

used with SOAK and STAINS .

To be used for heavily soiled laundry.

Important: By depressing at the same time buttons and the

machine will perform an extra rinse (see page 66).

55

Page 13

Description of the appliance

1200

900

700

400

SPIN SPEED

Press this button to reduce the maximum speed of the final

speed proposed by the machine for the selected programme or to select option (RINSE HOLD).

The maximum spin speed for cotton and the programmes “B” and “D” is 1200 rpm, for the rest of the

programmes is 900 rpm.

RINSE HOLD

By selecting this option, the last rinse water is not emptied out, to

prevent the fabrics from creasing. When the programme has finished,

the START/PAUSE button goes off, the pilot light (END) on the programme progress display illuminates, the light remains off and the

display shows a static zero to indicate that the water must be emptied

out.

To empty out water there are two possibilities:

• Select programme “C” (draining):

The water is emptied out without spinning.

• Select programme “D” (spin) or “F” (delicate spin). Select the spin speed

by means of the relevant button and then depress the START/PAUSE

button. The water is emptied out and the laundry is spun at the selected spin speed.

Warning! The programme selector dial must be turned first to RESET

O and then to the DRAIN programme “C”, “D” or ”F”.

If the water is not emptied out, the machine automatically empties

itself after 18 hours.

Display

The display shows the following information:

• Duration of the selected programme (in minutes), calculated automatically on the basis of the maximum recommended load for each type

of fabric.

• When the programme has finished, a steadily lit zero is displayed.

• Delayed start, (23 hours max.) programmed using the special button

. The countdown is updated every hour till 2 hours and then every

30 minutes.

• Alarm code indicating a fault in the machine operation (see page 77).

56

Page 14

Description of the appliance

PREWASH

WASH

RINSES

EXTRA RINSE

SPIN

OVERDOSAGE

END

Programme progress display

By selecting the wash programme, the pilot lights

corresponding to the various phases making up the

programme come on.

After the machine has started, only the running

phase pilot light stays on. When the programme has

finished, the END pilot light comes on.

When the programme has finished, if the OVERDOSAGE light comes

on, it indicates that too much detergent has been used.

57

Page 15

Description of the appliance

Cancelling a programme

To cancel a programme which is running, turn the programme selector

dial to the RESET O position.

Warning! After a programme which ends with water in the drum

(RINSE HOLD option), turn the selector dial first to O and then to

the programme “C”, “D” or “F”.

Altering a programme which is running

To modify the selected programme turn the programme selector dial to

O and then choose a new programme.

The water is not emptied out and after pressing the START/PAUSE button again the machine restarts with the newly selected programme.

Opening the door after the programme has started

To open the door set the machine to PAUSE by pressing the ST ART/P AUSE

button.

The door can be opened if:

• the machine is not already heating;

• the water level is not above the bottom edge of the door;

• the drum is not turning.

The light on the control panel indicates if the door can be

opened:

• green light: the door can be opened;

• unlit light: the door cannot be opened;

• flashing red light: the door is open.

58

Page 16

Detergent dispenser drawer

Cl

Compartment for prewash or soak detergent and stain remover . The pr ewash

or soak detergent is added at the beginning of the wash programme. The

stain remover is added during the STAIN-Action phase in the main wash.

Compartment for powder or liquid detergent used for main wash.

It is emptied at the beginning of the wash cycle.

Compartment for liquid additives (fabric softener, starch).

It is emptied at the last rinse.

The quantity of additives must not exceed the “MAX” mark in the

drawer.

Compartment for bleaching agent.

It is emptied at the first rinse.

The quantity must not exceed the “MAX” mark in the drawer.

Before the first wash

Before your first wash, we recommend that you pour 2 litres of water

into the main wash compartment of the detergent drawer in

order to activate the ECO valve.

Then, run a cotton cycle at E60, without any laundry in the

machine, to remove any manufacturing residue from the drum and

tub.

Pour 1/2 a measure of deter gent into the dispenser dr awer and start the

machine.

59

Page 17

Preparing the wash cycle

Sorting out and preparing the laundry

• Sort out the laundry according to type of fabrics and care labels (see

“Types of fabric and care labels”).

• Empty pockets.

• Remove any metal parts (safety pins, clips, etc.).

• To prevent the laundry from getting damaged and forming bundles,

it is advisable to close zips, button up pillowcases and quilt covers and

tie up loose straps such as those of aprons.

• Turn double faced items inside out (sleeping bags, anoraks, etc.)

• Turn coloured knitted fabrics, woollens and fabrics with trim inside

out.

• Wash small and delicate items (baby socks, tights) inside a laundry net

or in a pillow case closed with a zip, or in larger socks.

• Treat curtains with special care. Remove all metal or plastic hooks or

put them in a net or a bag. We take no responsibility for any damage.

• Whites and coloureds must be washed separately: white items can

loose their whiteness.

• New coloured fabrics often have excess dyes; it is advisable to wash

them separately for the first time.

• Wash small and large items together; this improves the washing result

and the laundry is better distributed during spinning.

• Shake out garments before putting them into the machine.

• Insert each garment separately.

60

Page 18

Weight of laundry

60

40

30

40

50

60

95

Preparing the wash cycle

Sort of laundry

1200 gBathrobes

300-600 gWork shirts

700 gQuilt covers

500 gSheets

100 gBlouses

200 gHand towels

100 gTea towels

200 gShirts

200 gPillowcases

200-250 gNight-gowns/Pyjamas

200-300 gTablecloths

250 gUnderwear

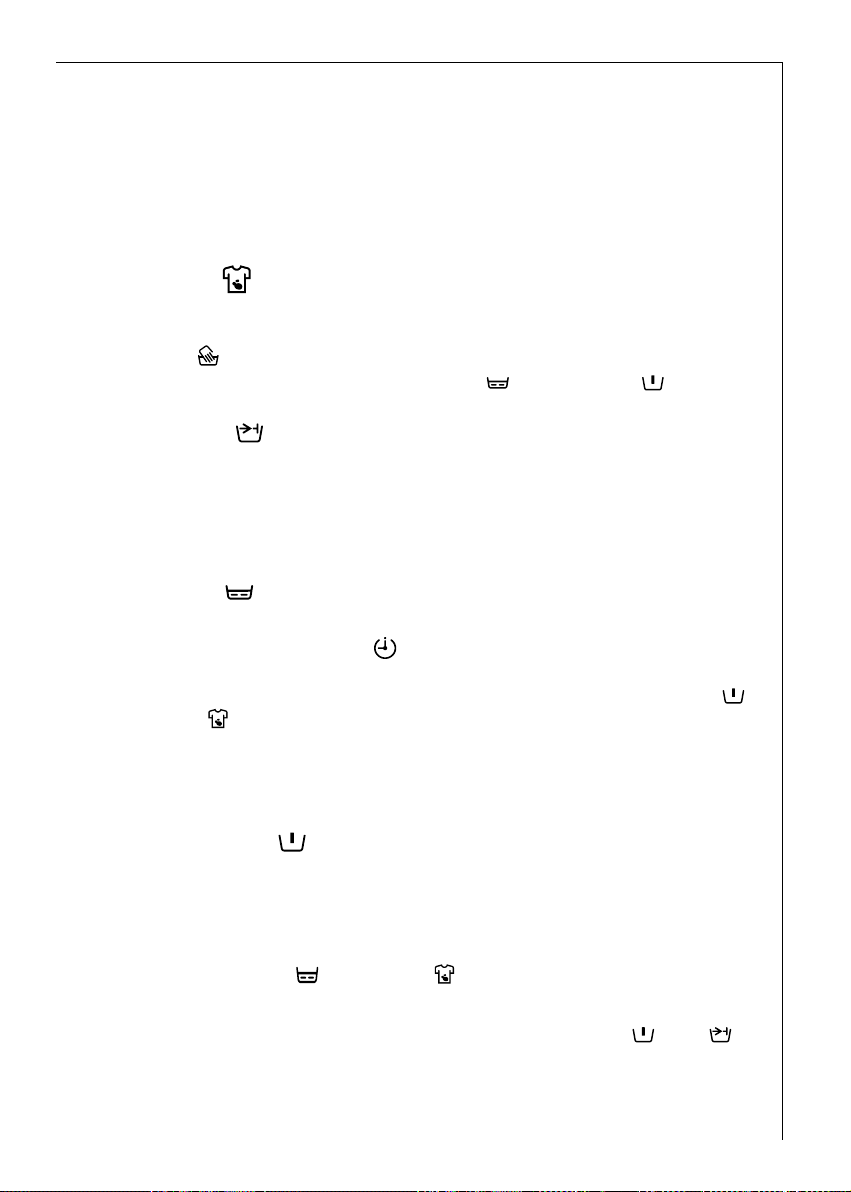

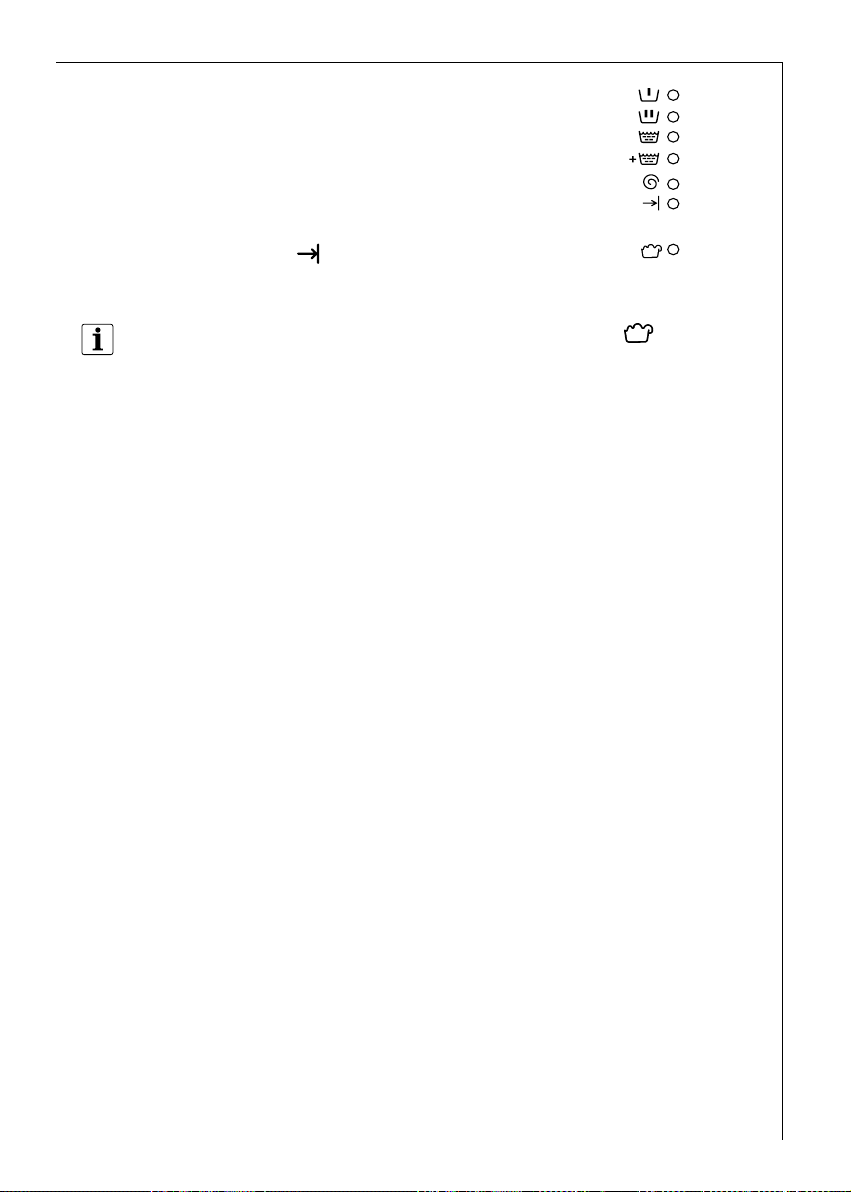

Types of fabric and care labels

The labels on garments help you to select the most suitable wash programme. The laundry should be sorted out according to the type of fabric and the instructions indicated on care labels.

Temperatures indicated on labels are always maximum temperatures.

Cotton

Linen and cottons marked with this symbol can be washed at high temperatures.

Cotton

Linen and cottons marked with this symbol are colourfast and can be

washed at 60°C.

Cotton

Garments marked with these symbols have delicate colours, therefore

the washing temperature must not exceed these values.

Synthetics

Mixed and synthetic fabrics marked with these symbols require a gentle

wash programme and they must therefore be washed using the specific

programme.

Approximate

dry weights

61

Page 19

30

40

30

40

Preparing the wash cycle

Delicates

Microfibres, synthetics or curtains marked with these symbols require a

very gentle treatment.

The DELICATES programme is suitable for this type of fabric.

Woollens and particularly delicate items

Fabrics such as wool, wool mix or silk marked with this symbol are particularly sensitive to machine washing.

The WOOL programme is suitable for this type of fabric.

If the label has the symbol (do not wash), the garments must not

be machine washed!

The wool wash cycle of this machine has been approved by Woolmark

for the washing of machine washable Woolmark products provided

that the garments are washed according to the instructions on the

garment label and those issued by the manufacturer of this washing

machine. M9604.

62

Page 20

Preparing the wash cycle

Detergents and additives

Which detergent and additive?

Use only detergents and additives for washing machines. Follow the

manufacturer’s instructions.

How much detergent?

The quantity depends on:

• the load:

if the manufacturer does not provide any indications on the amount of

detergent for small loads, use about one third less than the suggested

amount for half loads and half the amount for very small loads;

• the degree of soil:

use a small amount of detergent for lightly soiled garments. Judge

the amount according to the detergent manufacturer’s instructions

and size of the load;

• the water hardness:

the harder the water, the more detergent required. Instructions

according to water hardness are given on the detergent pack.

Liquid detergent

Liquid detergent can be poured directly into the main wash compartment

of the dispenser drawer immediately before starting the programme, or

a special dispenser can be used that is placed directly in the drum. Measure the detergent according to the manufacturer’s instructions.

Adding a water softener (descaling product)

A water softener must be added when water has a medium-high degree

of hardness (from degree of hardness II). Follow the manufacturer’s

instructions. The quantity of detergent can then always be adjusted to

degree of hardness I (= soft). Information on water hardness can be

obtained from your local water supply authority.

Information on water hardness

Degree of hardness French degrees °TH

German degrees °dH

0-7I=Soft

0-15

16-257-14II=Medium

26-3715-21III=Hard

more than 37more than 21IV=Very hard

63

Page 21

How to wash

Cl

Cl

Load the laundry

Open the door.

Place the laundry in the drum, one item at a time. Distribute laundry as

evenly as possible. Close the door.

Add detergent and additives

Pull the drawer

out till it stops.

Pour the main

wash detergent

into compartment

.

If you wish to perform a prewash, a

SOAK or a STAINAction programme, pour detergent or stain remover into compartment .

Important!

Do not use normal detergent for the STAIN-Action programme,

always use a STAIN remover.

64

Pour the fabric softener into compartment and the bleaching

agent into compartment without exceeding the “MAX” mark.

Close the drawer gently, pushing it fully in.

Page 22

Select the desired wash programme

95

E60

E40

40

60

50

40

40

30

40

30

40

E90

A

D

F

C

B

30

1200

900

700

400

Turn the programme selector

dial to the desired position:

the lights corresponding to

the different phases making

up the selected programme

light on.

The display shows the duration of the programme.

Select the desired options

depending on the degree of soil of the laundry.

The corresponding light comes on.

Select the spin speed or RINSE HOLD option

It is possible to select a lower spin speed by means of

the relevant button; the light corresponding to the

selected speed comes on.

Selecting the option (RINSE HOLD) the laundry is

left immersed in the final rinse water.

How to wash

If the spin speed is not reduced, the final spin speed will

be as follows:

- cottons 1200 r.p.m.

- synthetics 900 r.p.m.

- delicates 900 r.p.m.

- wool (hand washing) 900 r.p.m.

65

Page 23

How to wash

EXTRA RINSE

This appliance is designed for saving water. However, for people with

a very delicate skin (allergic to detergents) it may be necessary to

rinse the laundry using an extra quantity of water (extra rinse).

The extra rinse is available only with the cotton, synthetics or delicate

programme and with programme “A”.

Selection of the EXTRA RINSE option

Press simultaneously the buttons and for about 4 seconds: the

light comes on in the programme progress display.

This function stays permanently on. To remove it press the buttons

and again until the light comes off.

Select the DELAY START option

To delay starting of a programme, press the DELAY START button

before starting the machine. The figures corresponding to the

selected delay will be displayed for about 3 seconds, after which the

duration of the selected programme will appear on the display.

If the button (SOAK) has been pressed the selected delay will correspond to the soak time. If no delay time is selected the soak programme will last about 30 minutes.

When the START/PAUSE button is pressed, the selected delay will

appear again on the display and the machine starts its countdown.

66

Page 24

Starting the programme

PREWASH

WAS H

RINSES

EXTRA RINSE

SPIN

OVERDOSAGE

END

1. Check that the water tap is open.

2. Press START/PAUSE to start the programme.

If the Delay Start option has been selected the programme will start

at the end of the countdown.

If the door light is red and flashing at the start of the programme it indicates that the door is open. Close the door and press

the START/PAUSE button again.

If the delay start option has been selected, the machine starts its

countdown, in hours till 2 hours and then every 30 minutes, which

will appear on the display. During this period it is possible to load

other laundry, to cancel the delay time.

• Load other laundry: press the START/PAUSE button. Open the door.

Load the laundry. Close the door and press the START/PAUSE button

again.

• Cancel the delay time: press the START/PAUSE button. Press the

DELAY START button until 0’ appears on the display. Press the

START/ PAUSE button again.

Programme progress display

By selecting the wash programme, the pilot lights corresponding to the various phases making up the programme

come on. After the machine has started, only the running

phase pilot light stays on.

How to wash

Display

The time to the end of the programme decreases minute by minute and

appears on the display.

At the end of the programme

The machine stops automatically. A zero appears on the display. The

END light comes on in the programme progress display.

67

Page 25

How to wash

If the RINSE HOLD option has been selected, the START/PAUSE but-

ton goes off, the pilot light (END) on the programme progress display illuminates, the light remains off and the display shows a static zero to indicate that the water must be emptied out.

To empty out water there are two possibilities:

• Select programme “C” (draining):

The water is emptied out without spinning.

• Select programme “D” (spin) or “F” (delicate spin). Select the spin speed

by means of the relevant button and then depress the START/PAUSE

button. The water is emptied out and the laundry is spun at the selected spin speed.

Turn the selector dial to O to switch the machine off.

Remove the laundry from the drum.

Check that the drum is empty so as to avoid any forgotten items

being damaged in a subsequent wash (e.g. shrinking) or their colour

running into a load of whites.

Close the water tap.

Leave the door open to prevent the formation of mildew and unpleas-

ant smells.

68

Page 26

Programme chart

Wash programmes for cottons

Wash

programme

White

Cottons

E90

Whites

ECONOMY

E60

Cottons

ECONOMY

E40

Coloured

cottons

ECONOMY

Coloured

cottons

Temp.

95°

E90

(●)E60

E40 Non fast-coloureds.

40°-30°

Fabrics

Cotton and linen,

for example normally soiled work

garments, sheets,

household linen,

underwear, towels.

White cotton and

linen, for example

normally to lightly

soiled sheets and

household linen.

Whites and fastcoloureds.

Coloured cotton or

linen fabric, shirts,

underwear, towels.

Additional

functions

STAIN

SOAK

QUICK

PREWASH

EXTRA RINSE

RINSE HOLD

SPIN SPEED

STAIN

SOAK

PREWASH

EXTRA RINSE

RINSE HOLD

SPIN SPEED

STAIN

SOAK

PREWASH

EXTRA RINSE

RINSE HOLD

SPIN SPEED

STAIN

SOAK

PREWASH

EXTRA RINSE

RINSE HOLD

SPIN SPEED

STAIN**

SOAK

QUICK

PREWASH

EXTRA RINSE

RINSE HOLD

SPIN SPEED

Max.

load

5 kg

5 kg

5 kg

5 kg

5 kg

(●) In compliance with EC directive 92/75, the consumption figures indicated on

the energy label refer to the E60 wash programme for cotton.

* The consumption data shown on this chart is to be considered purely indicative, as it may vary depending on the quantity and type of laundry, on the inlet

water temperature and on the ambient temperatur e. It refers to the highest temperature for each wash programme.

** Only at 40°.

Consumption*

Energy

kWh

2.0

1.4

0.85

0.95

0.55

Water

lt.

53

49

42

49

49

Duration

min.

145

147

137

140

117

69

Page 27

Programme chart

Wash programmes for synthetics, delicates and wool

Wash

programme

Synthetics

Synthetics

Delicates 40°-30°

Wool

Hand wash

Temp.

60°-50°

40°

40°

40°-30°

/

Fabrics

Synthetic fabrics,

underwear,

coloured garments,

non-shrink shirts,

blouses.

Synthetics, easy

iron.

Delicate fabrics, for

example curtains.

Wool, wool mixtures, silk.

Additional

functions

STAIN**

SOAK

QUICK

PREWASH

EXTRA RINSE

RINSE HOLD

SPIN SPEED

STAIN/SOAK

QUICK

PREWASH

EXTRA RINSE

RINSE HOLD

SPIN SPEED

SOAK

QUICK

PREWASH

EXTRA RINSE

RINSE HOLD

SPIN SPEED

RINSE HOLD

SPIN SPEED

Max.

load

2.5 kg

1.5 kg

2.5 kg

2 kg

Consumption*

Energy

kWh

0.9

0.4

0.5

0.35

Water

lt.

54

51

55

55

Duration

min.

89

93

60

56

* The consumption data shown on this chart is to be considered purely indicative, as it may vary depending on the quantity and type of laundry, on the inlet

water temperature and on the ambient temperature. It refers to the highest

temperature for each wash programme.

** Not with the position .

70

Page 28

Programme chart

Special programmes

A

B

C

D

Descrip-

tion

This programme can

be used for

rinsing hand

washed garments.

Hand washed

garments to

be starched

or softened.

For emptying

out the last

rinse water in

programmes

with the Rinse

Hold option

Separate spin

for cottons.

Programme phases

3 rinses with liquid

additive.

Short spin.

1 rinse with liquid

additive.

Long spin.

The water is emptied

out.

Long spin.

Programme

Gentle

rinses

Softeners

Drain

Spin

Additional

functions

EXTRA RINSE

RINSE HOLD

SPIN SPEED

RINSE HOLD

SPIN SPEED

SPIN SPEED

Max.

load

5 kg

5 kg

/

5 kg

Consumption*

Energy

kWh

0.05

Water

lt.

52

18

/

Duration

min.

27

21

2

10

Separate spin

for synthetics

F

Short spin

O

(Reset/Off)

and delicate

fabrics.

Short spin.

For cancelling the

programme which

is running or to

switch the machine

off.

SPIN SPEED

2.5 kg

6

* The consumption data shown on this chart is to be considered purely

indicative, as it may vary depending on the quantity and type of laundry,

on the inlet water temperature and on the ambient temperature.

71

Page 29

Cleaning and maintenance

After each wash

At the end of the wash programme, pull the dispenser drawer out a little to let it dry.

Leave the door ajar to allow air to circulate.

If the machine is not used for a prolonged period:

Close the water tap and unplug the appliance.

Periodical cleaning

Exterior

Clean the outside of the cabinet with soap and water only. Rinse with

clean water and dry.

Important: do not use methylated spirits, solvents or similar products

to clean the cabinet.

Detergent dispenser drawer

After a while,

detergents and

fabric softeners

leave deposits in

the drawer.

Clean the drawer,

from time to

time, by rinsing it

under a running

tap. To remove

the drawer from the machine, press the button in the rear left-hand

corner.

To facilitate cleaning, the top part of the additive compartments can be

removed.

Detergent can also accumulate inside the

drawer recess: clean it with an old toothbrush.

Refit the drawer after cleaning.

72

Page 30

Cleaning and maintenance

Door seal

Check from time to time the door seal and

eliminate eventual possible objects that could

be trapped in the fold.

Drain pump

The pump should be inspected regularly and particularly if

the machine does not empty and/or spin

the machine makes an unusual noise during draining due to objects

such as safety pins, coins etc. blocking the pump.

Proceed as follows:

Disconnect the appliance.

If necessary wait until the water has cooled down.

Open the pump door.

Place a container

close to the

pump to collect

any spillage.

Release the

emergency emptying hose, place

it in the container and remove its

cap.

When no more water comes out, unscrew the pump and remove it.

Always keep a rag nearby to dry up spillage of water when removing

the pump.

Remove any

objects from the

pump impeller by

rotating it.

Put the cap back

on the emergency

emptying hose

and place the latter back in its

seat.

Screw the pump fully in.

Close the pump door.

73

Page 31

Cleaning and maintenance

Water inlet filter

If you notice that the machine is taking

longer to fill, check that the filter in the

water inlet hose is not blocked.

Turn off the water tap.

Unscrew the hose from the tap.

Clean the filter in the hose with a stiff brush.

Screw the hose back onto the tap.

Emergency emptying out

If the water is not discharged, proceed as follows to empty out the

machine:

pull out the plug from the power socket;

close the water tap;

if necessary, wait until the water has cooled down;

open the the pump door;

place a bowl on the floor and place the end of the emergency empty-

ing hose into the bowl. Remove its cap. The water should drain by gravity into the bowl. Whe the bowl is full, put the cap back on the hose.

Empty the bowl. Repeat the procedure until water stops flowing out;

clean the pump if necessary as previously described;

replace the emergency emptying hose in its seat after having plugged it;

screw the pump again and close the door.

74

Frost precautions

If the machine is installed in a place where the temperature could drop

below 0°C, proceed as follows:

Close the water tap and unscrew the water inlet hose from the tap.

Place the end of the emergency emptying hose and that of the inlet

hose in a bowl placed on the floor and let water drain out.

Screw the water inlet hose back on and reposition the emergency emp-

tying hose after having put the cap on again

By doing this, any water remaining in the machine is removed, avoiding

ice forming and consequently damage to the appliance.

When you use the machine again, make sure that the ambient temper-

ature is above 0°C.

.

Page 32

Something not working?

Important

!!

Every time you drain the water through the emergency emptying hose

you must pour 2 litres of water into the main wash compartment of the

detergent drawer and then run the drain programme “C”. This will activate the ECO valve avoiding that part of the detergent remains unused

at next washing.

Something not working?

If during the spin cycle the machine makes an unusual

whistling noise, different from the noise made by traditional washing machines, this is due to a

new type of motor.

If water is not visible in the drum, this is due

to the modern technology of new washing

machines that use less water than traditional

machines.

Troubleshooting

If a problem arises, you can try to solve it

yourself following the instructions below.

If you call out an engineer when one of the following problems arises,

or to repair a fault due to incorrect use, the call-out will be charged

even if requested within the guarantee period.

During machine operation it is possible that the END light flashes and

the following alarm codes may be displayed:

- E10: problem with the water supply

- E20: problem with water draining

- E40: door open

Once the problem has been eliminated, press the START/PAUSE button

to restart the programme. If after all checks, the problem persists, contact your local AEGService Force Centre.

Problem

The machine does not work

Possible cause

The main electrical fuse Replace the fuse.

has blown.

The door is not properly Close the door; the click

closed (E40). of the lock should be heard.

The plug is not connected. Insert the plug.

The START button has not Press the button.

been pressed.

The DELAY START Check the selected delay on

option has been selected. the display.

Solution

75

Page 33

Something not working?

Problem

The machine does not fill

The machine fills then

empties immediately

The machine does not

empty and/or does not spin

There is water on the floor

Possible cause

The water tap is closed (E10). Open the water tap.

The water inlet hose is Check the whole length of the

squashed or kinked (E10). hose and remove the kink.

The small filter of the water Clean the filter.

inlet hose is clogged (E10).

The door is not properly Close the door.

closed (E40).

The end of the drain hose Place the hose at the right

is too low. height (see Installation

section).

The drain hose is Check the whole length of

squashed or kinked (E20). the hose and remove the

kink.

The drain pump or the Clean the pump or check

drain hose are clogged (E20). the hose.

The RINSE HOLD option Empty out the water by

(stop with water in drum) pressing the START button

has been selected. or selecting the DRAIN

programme.

The laundry is not evenly Redistribute the laundry

distributed inside the drum. manually in the drum.

Too much detergent has Measure detergent

been used. according to the

manufacturer’s instructions.

An unsuitable detergent Use a suitable washing

has been used that machine detergent.

creates too much foam.

One of the connectors on Check that the hose is

the water inlet hose is firmly screwed on at both

leaking. ends.

The drain pump has not Fully screw the pump into

been properly screwed on place.

after cleaning.

The cap on the emergency Replace the cap on the

emptying hose has not been emergency emptying hose

replaced after cleaning the after cleaning the pump.

pump.

Solution

76

Page 34

Something not working?

Problem

The machine vibrates or is

noisy

The door will not open

Spinning starts late or the

machine does not spin

Possible cause

The transit bolts have Check that the machine

not been removed. has been unpacked as

described in the Installation

section.

The feet have not been Carefully level the machine.

adjusted.

There is little laundry in Correct operation of the

the drum. machine is not affected.

The programme is still Wait until the end of the

running and the drum programme before opening

is turning. the door.

The water level is above the Before opening the door,

bottom edge of the door. the water must be emptied

out.

The machine is heating the Wait until the end of the

water. heating phase.

The unbalance detection If the laundry is not evenly

device that prevents distributed inside the drum

excessive vibration during at the beginning of the

spinning has cut in. spin cycle, the machine

detects this and tries to

redistribute it more evenly

by means of a few drum

rotations.

Only when the laundry is

more evenly distributed

will the spin cycle be

performed, at a lower speed,

if the laundry is not evenly

distributed.

If, after about 10 minutes,

the laundry is still tangled,

the machine will not spin.

Therefore, if the laundry is

still wet at the end of the

cycle, it is advisable to

redistribute it manually

inside the drum and to

select the spin programme.

Solution

77

Page 35

Something not working?

Unsatisfactory washing results

If the laundry looks grey and lime scale is found in the drum

• Too little detergent has been used.

• An unsuitable detergent has been used.

• Stubborn stains have not been treated prior to washing.

• The programme/temperature has not been correctly selected.

If grey stains remain on the laundry

• Laundry stained with ointments, grease or oil has been washed with

an insufficient amount of detergent.

• The temperature selected for the wash programme was too low.

• Fabric softener - especially the concentrated type - has come into

direct contact with the laundry. Wash these stains immediately and

pour fabric softener carefully.

Foam is still visible even after the last rinse

• Modern detergents often produce foam, even in the last rinse. However the laundry has been completely rinsed.

White residue is left on the laundry

• This is due to insoluble components in modern detergents and is

therefore not the result of insufficient rinsing. Shake or brush the

laundry. In futur e, it may be better to turn garments inside out befor e

washing them. Check the choice of detergent; try using liquid detergents.

78

Page 36

Technical data

Height x Width x Depth 85x60x60 cm

Depth with door opened 100.5 cm

Height adjustment ± 10 mm approx.

Load (depending on programme) 5 kg max.

Use domestic

Drum speed during washing max. 55 rpm

Drum speed during spinning 1200/900/700/400 rpm

Water pressure 50-800 kPa

This appliance complies with the following EC directives:

- 73/23/EEC of 19.2.1973 “Low voltage directive”, including directive

93 / 68 / EEC

- 89/336/EEC of 3.5.1989 “Electromagnetic Compatibility Directive”.

79

Page 37

Service

IPX4

Mod. L62699 Type P6347647

Prod.No. 914515208 00

220-230V~50Hz 2200 W 10 A

Ser.No.

Made in EEC

In the section “Something not working?” some problems that can be

solved by yourself are listed. Read this section in the event of problems.

If you are not able to find a solution, contact the Service centre.

In all cases, explain your problem carefully, in order to facilitate troubleshooting: the engineer will be able to decide whether a service call

is necessary.

Take note of the serial number (Ser.No.) and the product number (Prod.

No.) indicated on the rating plate.

Ser. No. . . . . . . . . . . . . . . . . . . . . . . .

Prod. No. . . . . . . . . . . . . . . . . . . . . . .

Furthermore, try to specify, as precisely as possible:

- The symptoms of the fault

- When the fault occurs

- The alarm code displayed

When can a service visit be charged during the guarantee period?

- when it should have been possible to solve the problem by yourself,

with the help of the troubleshooting chart (see section “Something

not working?”)

- when the engineer has to come out several times because he has

not been given all the relevant information he needs and so, for

example, has to fetch spare parts. Repeated trips can be avoided if

you prepare your call to the Service centre as described above.

80

Page 38

Instructions for installation and electrical connection

Safety instructions for the installer

• This appliance is heavy, care should be taken when moving it.

• When unpacking the appliance, check that it is not damaged. If in

doubt, do not use it and contact the retailer.

• All internal packing must be removed before using the appliance.

Serious damage may be caused to the machine or adjacent furniture

if the protective transit devices are not completely removed. Refer to

the relevant paragraph.

• Any electrical work required to install this appliance must be carried

out by a qualified electrician.

• Any plumbing work required to install this appliance must be carried

out by a qualified plumber.

• After having installed the machine, check that it is not standing on

its electrical supply cable.

• If the appliance is placed on a carpeted floor, ensure that air can circulate freely between the adjustable feet and the floor.

• The installation should comply with local water authority and building regulations requirements.

• Should the appliance power supply cable need to be replaced, this

should be carried out by our Service Force Centre.

81

Page 39

Dimensions of the appliance

90

L 62699

95

E60

E40

40

30

60

50

40

40

30

40

30

40

E90

F

D

C

B

A

1200

900

700

400

565

605

1005

25

Cold water

335

170

70

40

45

85

Power cable

Drain

Front view and side view

Rear view

82

Page 40

Installation

P0001

P1124

2

3

1

Unpacking

All transit bolts and packing must be removed before using the appliance.

Using a spanner,

unscrew and

remove the 2 rear

bottom screws.

Slide out the 2

plastic pins. Lay

the machine on

its back, taking

care not to

squash the hoses. This can be avoided by

placing one of the corner packing pieces

between the machine and the floor.

Remove the polystyrene block from the

bottom of the machine and release the

two plastic bags.

Carefully slide out the left-hand bag removing

it towards the

right and then

downwards.

Slide out the righthand bag removing it towards the

left and then

upwards.

Set the machine

upright and

remove the

remaining rear

screw. Slide out

the relevant pin.

Plug the open

holes with the

plugs which you

will find in the plastic bag containing the instruction booklet.

You are advised to keep all transit devices so that they can be refitted if the

machine ever has to be transported again.

83

Page 41

Installation

Positioning

Install the machine on a flat hard floor.

Make sure that air circulation around the machine is not impeded by

carpets, rugs etc.

• Before placing it on small tiles, apply a rubber coating.

• Never try to correct any unevenness in the floor by putting pieces of

wood, cardboard or similar materials under the machine.

• If it is impossible to avoid positioning the machine next to a gas

cooker or coal-burning stove, an insulating panel (85x57 cm) covered

with aluminium foil on the side facing the cooker or stove, must be

inserted between the two appliances;

• The machine must not be installed in rooms where the temperature

can drop below 0.

• The water inlet hose and the drain hose must not be kinked.

• Please ensure that when the appliance is installed, it is easily accessible for the engineer in the event of a breakdown.

Levelling

Carefully level by screwing the adjustable

feet in or out. Never place cardboard, wood

or similar materials under the machine to

compensate for any unevenness in the

floor.

Water inlet

Connect the

water inlet hose

to a separate tap

with a 3/4"

thread.

The other end of

the inlet hose

which connects to

the machine can

be turned in any direction. Simply loosen the fitting, rotate the hose

and retighten the fitting, making sure there are no water leaks.

The inlet hose must not be lengthened. If it is too short and you do not

wish to move the tap, you will have to purchase a new , longer hose specially designed for this type of use.

84

Page 42

Water drainage

The end of the drain hose can be positioned

in three ways:

Hooked over the edge of a sink using the

plastic hose guide supplied with the

machine. In this case, make sure the end

cannot come unhooked when the machine

is emptying.

This could be done by tying it to the tap

with a piece of string or attaching it to the

wall.

In a sink drain pipe branch.This branch must be above the trap so that

the bend is at least 60 cm above the ground.

Directly into a

drain pipe at a

height of not less

than 60 cm and

not more than

90 cm.

The end of the

drain hose must always be ventilated, i.e. the inside diameter of the

drain pipe must be larger than the outside diameter of the drain hose.

The drain hose must not be kinked.

For a correct functioning of the machine the drain hose must

remain hooked on the proper support piece situated on the top

part of the back side of the appliance.

Installation

Electrical connection

This machine is designed to operate on a 220-230 V, single-phase,

50 Hz supply.

Check that your domestic electrical installation can take the maximum

load required (2.2 kW), also taking into account any other appliances in

use.

Connect the machine to an earthed socket.

The manufacturer does not accept any responsibility for damage or

injury through failure to comply with the above safety precaution.

85

Page 43

Installation

Permanent connection

In the case of a permanent connection it is necessary that you install a

double pole switch between the appliance and the electricity supply

(mains), with a minimum gap of 3 mm between the switch contacts and

of a type suitable for the required load in compliance with the current

electrical regulations.

The switch must not break the yellow and green earth cable at any

point.

This operation must be performed by a qualified electrician.

Important: The power supply cable must be easily accessible after

installing the machine.

86

Page 44

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

http://www.aeg.hausgeraete.de

© Copyright by AEG

132988040-06-04/01

Loading...

Loading...