Page 1

HG60FXA

HG75FXA

HG90FXA

EN User manual

Page 2

Page 3

GENERAL NOTICE

We invite you to read this instruction booklet carefully, before installing and using the equipment.

It is very important that you keep this booklet together with the equipment for any future

If this equipment should be sold or transferred to another person, make sure that the new

user receives the booklet, so that they can learn how to operate the appliance and read the

This appliance complies with the following Directives:

EEC 2009/142/CE (Gas) EEC 2004/108/CE (Electromagnetic Compatibility)

EEC 2006/95/CE (Low Voltage) EEC 2004/1935/CE (Contact with foods)

WARNING

– The installation must be carried out by authorised personnel, in conformity with the regulations in force.

– CAUTION: The surface temperature of underbench components exceeds 95°C. To avoid a hazard,

underbench access must be restricted. Refer to the installation instructions.

– This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

– Children should be supervised to ensure that they do not play with the appliance.

– Before powering the equipment, check that it is properly adjusted for the type of gas at disposal (see the

“installation” paragraph).

– If the supply cord is damaged it must be replaced by a special cord or assembly available from the

manufacturer or its service agent.

– Before carrying out the maintenance or cleaning the equipment, cut off power supply and allow it cool

down.

– Make sure that air circulates around the gas equipment. Insufficient ventilation produces a lack of oxygen.

– In case of an intense or prolonged use of the equipment, it may be necessary to improve aeration, for

example by opening a window or increasing rangehood venting power, if it exists.

– The products of combustion must be discharged outside through a suction hood or an electric fan (see

the “installation” paragraph).

– For any possible operation or modification, apply to an authorized Technical Assistance Centre and

demand original spare parts.

– Where this appliance is installed in marine craft or in caravans, it shall not be used as a space heater.

– Not for use in marine craft, caravans or mobile homes unless each burner is fitted with a flame safeguard.

– Do not spray aerosols in the vicinity of the appliance while it is in operation.

– Do not store or use flammable materials or items in the vicinity of this appliance.

consultation.

corresponding notice.

This is a Class 3 appliance.

DO NOT MODIFY THIS APPLIANCE.

Servicing shall be carried out only by authorised personnel.

The product label, with the serial number, is fixed to the underside of hob.

An additional label should be adhered to adjacent cabinetry for easy access- refer installation

instructions.

The manufacturer refuses all responsibility for possible damages to things or people, resulting

from incorrect installation or from an improper, incorrect or unreasonable use of this equipment.

3

Page 4

INSTRUCTIONS FOR THE USER

It is necessary that all the operations regarding the installation, adjustment and

adaptation to the type of gas available are carried out by authorised personnel, in

conformity with the regulations in force. The specific instructions are described in the

booklet section intended for the installer.

Conditions of Use.

This appliance is intended to be used in household and similar applications such as:

- Staff kitchen areas in shops, ofces and other working environments

- Farm Houses

- By clients in hotels, motels and other residential type environments

- Bed and breakfast type environment

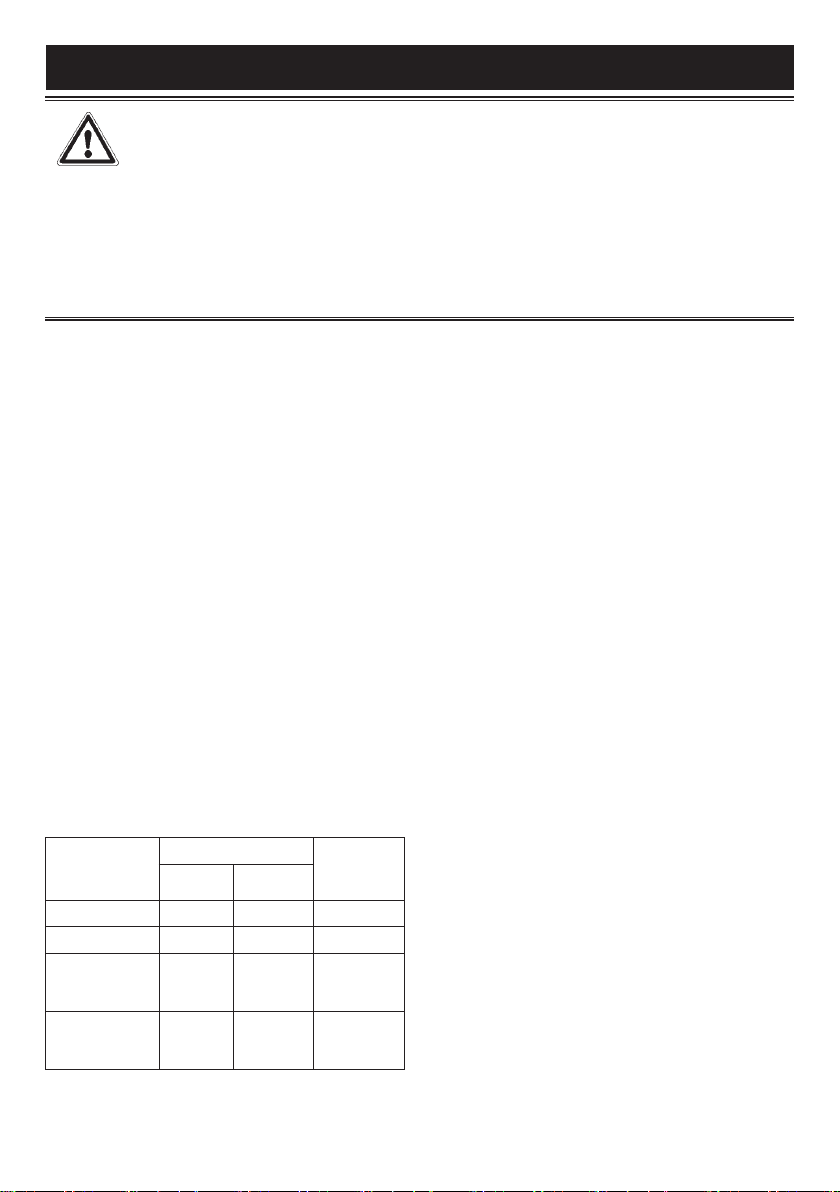

USING THE BURNERS

The symbols silk-screen printed on the side of the knob

indicate the correspondence between the knob and the

burner.

Automatic start-up with valves

Turn the corresponding knob anticlockwise up to the

maximum position (large flame, fig.1/1/A) and press the

knob.

Once the burner has been started up, keep the knob

pressed for about 6 seconds.

ATTENTION: the triple ring (wok) burner switches on

only in the maximum flame position

Using the burners

In order to obtain the maximum yield without waste of

gas, it is important that the diameter of the pot is suitable

for the burner potential (see the following table), so as to

avoid that the flame going out (fig. 2).

Use the maximum capacity to quickly make liquids reach

boiling temperature, and the reduced capacity to heat

food or maintain boiling. All of the operating positions

must be chosen between the maximum and the minimum

ones, never between the minimum position and the

closing point.

The gas supply can be interrupted by turning the knob

clockwise up to the closing position. If there is no power

supply, it is possible to light the burners with matches,

setting the knob to the start-up point (large flame, fig. 1).

Power (MJ/h) Ø of

BURNERS

Auxiliary 3,4 3,4 10 - 14 cm

Semi-rapid 6,3 5,6 16 - 18 cm

Triple crown

(wok on 5

burner models)

Double crown

(wok on 4

burner models)

NG LPG

18,0 15,0 24 - 26 cm

10,3 9,6 20 - 22 cm

cookware

(*)

It is important to use cookware with the sizes

specified and ensure the cookware is always

correctly centred over the burner. Using

oversize cookware can potentially cause heat

damage to your benchtop and/or control knobs

which will not be covered under warranty.

Notice

– When the equipment is not working, always check that

the knobs are in the closing position (see fig.1).

– If the flame should blow out accidentally, the safety

valve will automatically stop the gas supply, after a

few seconds. To restore operation, set the knob to the

lighting point (large flame, fig. 1) and press.

– While cooking with fat or oil, pay the utmost attention as

these substances can catch fire when overheated.

– Do not place unstable or deformed pots on the burner,

so as to prevent them from overturning or overflowing.

– Handles should be turned away from the front of the

bench to avoid accidents.

– When the burner is started up, check that the flame is

regular and, before taking pots away, always lower the

flame or put it out.

(*) For cookware with diameter 120mm or

below use mini-trivet supplied, refer fitment

instructions on page 15.

4

Page 5

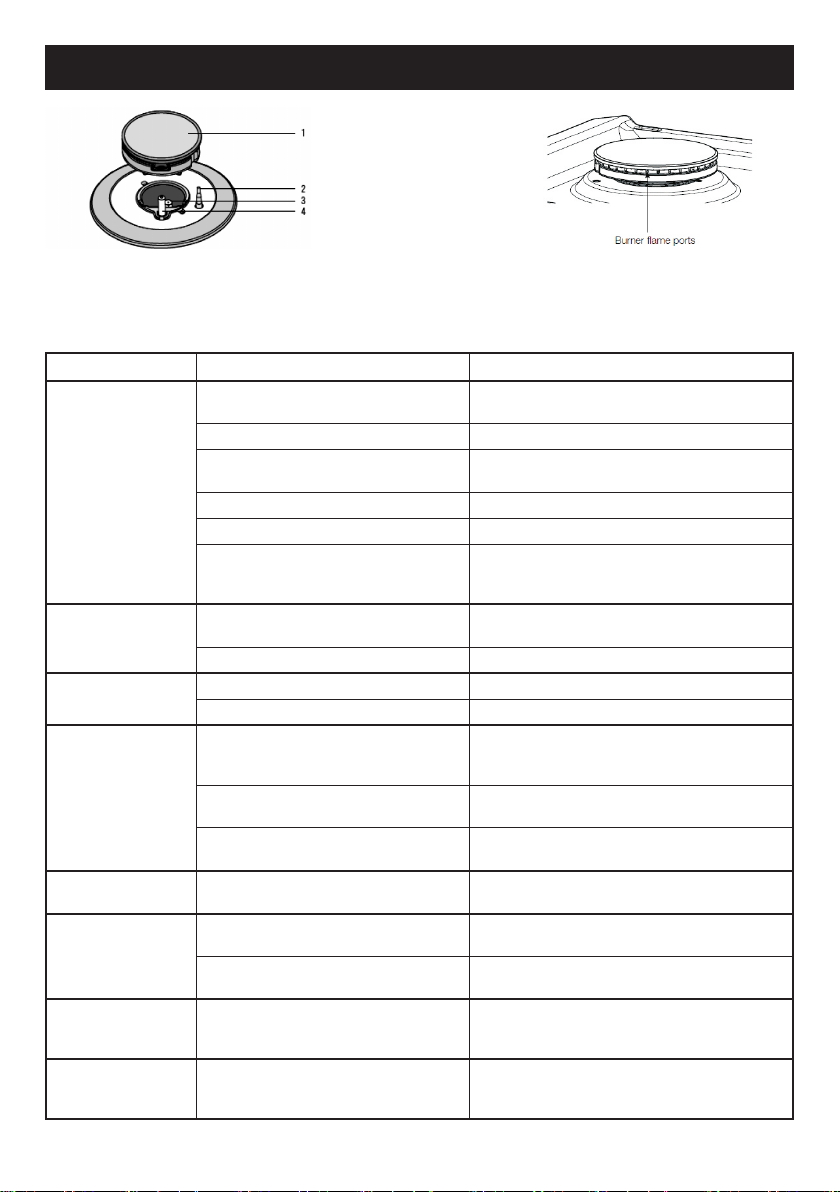

INSTRUCTIONS FOR THE USER

1 Burner 3 Injector

2 Flame safeguard sensor 4 Ignition spark plug

If you have a problem with the cooktop, check the table below. You may be able to solve the problem and this will save

you from paying for a service call. You will have to pay for a service call even in the warranty period if the problem is one

listed below

FAULT POSSIBLE CAUSES REMEDY

Burner will not light

even though the

sparker is working.

No spark is obtained

when control knob is

activated

Flames uneven or

tending to lift

Flames not staying on

when knob released

Low heat, slow

cooking

Benchtop or knobs

overheating

Cooktop stainless

steel discoloured

Outer ring of wok

burner goes out

when set to low

Knob not held down long enough in ‘High’

position for flame safeguard to engage

Gas supply valve turned off Turn on gas supply to appliance

Wrong knob turned Ensure the knob you are turning corresponds to the

Port blockage in ignition area Ensure that ports in ignition area are clean and dry

Ignition spark plugs wet or dirty Dry or clean ignition spark plugs

Injector blocked

Electricity supply is disconnected or

switched off"

Ignition spark plugs wet or dirty Dry or clean ignition spark plugs

Flame ports blocked or wet Clean or dry flame ports

Burner incorrectly fitted Ensure this component is fitted correctly

Knob not held down long enough

in ‘High’ position for flame safeguard

(where fitted) to engage

Knob not set between ‘High’ and

‘Low’

Dirt or spillage on flame safeguard

sensor (where fitted)

Incorrect cooking pot or pan being used Refer to table page 3

Incorrect cooking pot or pan used Check table on page 3 for correct pot or pan to be

Pot or pan not located on burner

properly

Pot or pan being is too large Ensure pot sizes used are as per user manual

This is not a failure. This is a function of the

dual wok burner to give a very low power

flame option

Repeat lighting procedure and hold knob down for 6

seconds in ‘High’ position (refer page 3)

burner you want to light

Ensure the injector remains free of any foreign

material. If necessary, use a thin piece of wire to

clear the orifice.

Switch on electricity or check fuses

Repeat lighting procedure and hold knob

down for 6 seconds in ‘High’ position

(refer page 3)

Knob MUST be set between these positions

Clean flame safe guard sensor tip

used

Ensure pot or pan is centrally located

on burner

requirements. Clean with STEEL POWER (available

through spare parts).

No remedy - burner is functioning as intended

If the above points have been checked and there is still a problem with the cooktop, please call the Service Centre.

5

Page 6

INSTRUCTIONS FOR THE USER

CLEANING

Before any operation, disconnect the appliance from

the electrical supply.

Don’t use a steam cleaner for the cleaning the hob.

It is advisable to clean the appliance when it is cold.

Enamelled parts

The enamelled parts must be washed with a sponge and

soapy water or with a light detergent.

Do not use abrasive or corrosive products.

Do not leave substances, such as lemon or tomato juice,

salt water, vinegar, coffee and milk on the enamelled

surfaces for a long time.

Stainless steel parts

Stainless steel can be stained if it remains in contact with

highly alkaline water or aggressive detergents for an

extended period of time.

All grades of stainless steel may stain, discolour or

attain an adhering layer of grime in normal operation.

To achieve optimum surface appearance stainless steel

must be kept clean regularly using the following cleaning

procedures, this ensuring good performance and long

service life.

INSTRUCTIONS FOR THE INSTALLER

Wash with warm soapy water and rinse with clean water.

Where the stainless steel has become extremely dirty

with signs of surface discolouration (due to periods of

neglect or misuse) use a stainless steel cleaner

DO NOT use abrasive scourers or steel wool. When

removing these stains be sure to follow the polish of

brushing lines.

Burners and racks

These parts can be removed to make cleaning easier.

The burners must be washed with a sponge and soapy

water or with a light detergent, wiped well and placed in

their housing perfectly. Make sure that the ame-dividing

ducts are not clogged. Check that the feeler of the safety

valve and the start-up electrode are always cleaned, so

as to ensure optimum operation.

Gas taps

The possible lubrication of the taps must be carried out by

authorised personnel, exclusively.

In case of malfunctions of the gas taps call customer

service

The operations indicated below must be followed by authorised personnel exclusively, in

Important notice:

conformity with the regulations in force.

The manufacturing firm refuses all responsibility for damages to people, animals or things,

resulting from the failure to comply with such provisions.

This appliance shall be installed only by authorised persons and in accordance with the

manufacturer’s installation instructions, local gas fitting regulations, municipal building codes,

electrical wiring regulations, and any other statutory regulations. For Australia and New Zealand

this appliance must be installed by an authorised person in compliance with AS/NZS 5601.1 Gas

installations part 1: general installations, and AS/NZS 5601.2 Gas installations part 2: LP GAS

installations in caravans and boats for nonpropulsive purposes. For outside of Australia/New

Zealand refer to the relevant installation code for gas appliances in your country.

INSTALLATION

– For conversion to LPG

– 1 Universal LPG sticker

The installation kit contains the following:

– 1 natural gas regulator

– 1 elbow

– 1 manifold

– 2 fibre sealing washers

– 4 brackets for assembly

– 4 bracket screws

– 1 pack of cooktop to benchtop seals

– 1 duplicate rating label

– 4 or 5 injectors

Additional accessory for cooking with vessels

diameter 120mm or below

– 1 mini trivet

– 1 wok trivet

Installing the top

The appliance is designed to be embedded into heatresistant benchtop capable of withstanding 85°C.

6

Page 7

INSTRUCTIONS FOR THE INSTALLER

Adjacent walls, cupboards and protection for

combustible materials.

Ensure that the appliance is installed in

accordance with clauses 6.2.5 and 6.10.1.1 of AS/

NZS 5601.1, or clauses 6.9.1 and 6.9.5 of

AS/NZS 5601.2 with regard to clearances

to combustible surfaces and materials, and

clearances to rangehoods and exhaust fans.

Clearance of 200mm from the periphery of burners

to vertical combustible surfaces is required.

Clearances to combustible surfaces may be

reduced only if combustible surfaces are protected

in accordance with clause 6.10.1.2 of AS/NZS

5601.1, or clause 6.9.2 of AS/NZS 5601.2.

The equipment must not be installed near

inflammable materials, such as curtains,

cloths,etc. Make a cut out in the benchtop, with

the dimensions indicated in fig.3, at a distance of

at least 50 mm from the appliance border to the

adjacent walls.

MODEL L (mm) P (mm) D (mm)

HG60FXA

HG75FXA

HG90FXA

Rangehoods and exhaust fans* shall be installed

in accordance with the manufacturer’s relevant

instructions. However, in no case shall the

clearance between the highest part of the hob

of the gas cooking appliance and a range hood

be less than 600mm or, for an overhead exhaust

fan, 750mm. (*An exhaust fan is defined as a

mechanical device other than a rangehood for

moving air from one interior space to another, or

to outside of the space)

IMPORTANT:

A separation panel at least 10mm from the

bottom of the cooktop must be included during

installation to prevent access to the underside

of the appliance. This panel can be made of any

non-combustible rigid material. Refer (fig. 4).

If the hob is going to be installed on the top of an

oven, precautions must be taken to guarantee an

installation in accordance with current accident

prevention standards. Pay particular attention to

the position of the electric cable and gas pipe: they

must not touch any hot parts of the oven.

Moreover, if the hob is going to be installed on

the top of a built in oven without forced cooling

ventilation, proper air vents must be installed to

guarantee an adequate ventilation, with the lower

air entering with a cross section of at least 200cm2,

560 480 60

720 480 60

860 480 60

and the higher air exiting with a cross section of at

least 60 cm2.

Fastening the top

Every cook-top is equipped with a special washer.

A set of hooks is also supplied for mounting the

cook-top.

Depending on the type of mounting surface, the

suitable type of mounting hook is supplied (hook A

or hook B).

For the installation proceed as follows:

– Remove all loose components from the top.

– Turn the appliance upside down lay it's edges on

foam packaging blocks to prevent damage to the

ignition spark plugs and lay the seal S along the

external border (fig. 5).

– Introduce and place the cook-top in the hole

made in the piece of furniture, then fasten it

with the screws and fastening brackets supplied

(fig.6).

WARNING: Failure to fix the cooktop to the bench

could result in loosening of the gas connection

through movement of the cooktop and a gas leak

may result.

A duplicate rating label is included with these

instructions. Ensure this is attached to a readily

accessible surface, so that the cooktop can be

easily identied in the case of a service call.

INSTALLATION ROOM

This appliance is not provided with a device for

exhausting the products of combustion.

Therefore, it is necessary to discharge these

outside.

The room where this appliance is installed

must have a natural air inflow, so as to ensure

a regular gas combustion and room ventilation:

the necessary air volume must not be lower than

20m3.

Air must come from permanent openings made on

the room walls that communicate with the outside.

The section of these openings shall correspond to

at least 200 cm2.

OPERATION ON N.G / S.N.G.

Regulator

An appliance regulator is provided. The regulator

must be positioned so that the pressure test nipple

is accessible when the appliance is installed.

Connect the gas supply to the 1/2" B.S.P. internal

thread inlet of the regulator. Refer to page 8 for

connection point position.

Regulators are supplied pre-adjusted and

configured by the component maker for use with

Natural Gas. The appliance installer is not required

7

Page 8

INSTRUCTIONS FOR THE INSTALLER

to make an adjustment to obtain the correct outlet

pressure setting.

An arrow on the base of the regulator indicates

the direction of gas flow when the inlet and outlet

of the regulator is orientated correctly. When the

regulator has been fitted check for leaks from the

connections with soapy water.

Gas Connection

This appliance is supplied for use with Natural

Gas. However, it can be converted for use with

LPG. Refer to LP conversion chapter.

Supply pipe sizing

The total hourly gas consumption for the appliance

is shown on the data label. The required supply

pressure (i.e. at inlet to appliance regulator) for

each gas type is shown on the data label, and

given in page "TECHNICAL CHARACTERISTIC

TABLES". Use this information in conjunction with

the length of run, number of elbows, tees and

bends, the available service pressure and the

supply requirements of other installed appliances

to determine a suitable pipe size. For assistance

in this matter refer to the appropriate section of the

Installation Code AS5601.

An AGA certified class B or D flexible connection

may be used to connect the cooktop in accordance

with the AS5601 and in particular section 4.8.

Where a hose assembly is used and the cooktop

is in the installed position, the hose assembly shall

be suitable for connection to a fixed consumer

piping outlet located at a point 800 - 850mm above

the floor and in the region outside the width of the

appliance to a distance of 250mm. The point of

connection to consumer piping must be accessible

with appliance installed.

Elbow positioning

It is possible to reposition the elbow if required by

loosening the locking nut and elbow by using two

spanners. Re-tighten the entire assembly after the

elbow has been repositioned. When fitting elbow to

appliance, ensure that the sealing washer is fitted.

Regulator

An appliance regulator is provided. The regulator

must be positioned so that the pressure test nipple is

accessible when the appliance is installed. Connect

the gas supply to the ½” B.S.P. internal thread inlet

of the regulator. Refer page 10 for connection point

position.

Assembly of Regulator

The assembly of the regulator to the cooktop

manifold is achieved via the elbow union and

sealing washersupplied.

The ½” parallel thread connects to the manifold, and

the sealing washer is placed between the manifold

end and the flat face on the elbow.

The ½” tapered thread connects to the outlet of the

regulator, and is sealed on the thread using

approved thread sealing tape or approved thread

sealing compound.

The inlet of the regulator is a ½” parallel thread and

is connected to consumer piping or hose assembly.

Regulators are supplied pre-adjusted and

configured by the component maker for use with

Natural Gas.

The appliance installer is not required to make an

adjustment to obtain the correct outlet pressure

setting.

An arrow on the base of the regulator indicates the

direction of gas flow when the inlet and outlet of the

regulator is orientated correctly. When the regulator

has been fitted check for leaks from the connections

with soapy water.

Checking the gas supply

1. Check the manometer zero point is correct.

2. Connect the manometer to the cooktop

pressure point. This is located on the

regulator.

3. Turn on the gas supply and electricity and try

to ignite the gas. NOTE! lt will take additional

time to light the gas for the first time as air

needs to be purged from the pipes.

4. With the appliance operating check the outlet

pressure

• when all burners of the appliance are

operating at maximum,

• when the smallest burner of the appliance is

operating at minimum.

Under these conditions the outlet pressure should

not vary from the nominal outlet pressure of

1.00kPa by more than ± 0.20kPa

If the regulator appears to not perform

satisfactorily, then check the following points:

1. If the outlet pressure is consistently too low

then the inlet pressure may be too low and

adjustment of an upstream regulator may be

needed, or an upstream regulator or valve

with insufficient flow capacity may be present

in the gas supply line. If this is suspected then

it may be necessary to repeat fhe checks

whilst measuring both the inlet and outlet

pressure to determine if the inlet pressure is

in the range 1.13 - 5kPa.

2. Check that the regulafor has been fitted to the

gas supply line in the correct orientation, the

arrow on the base of the body indicates the

direction of gas flow.

8

Page 9

INSTRUCTIONS FOR THE INSTALLER

Once these checks have been completed, if the

regulator still fails to perform in a satisfactory

manner it should be replaced.

Electrical connection

The appliance is supplied with a standard 10

Amp service cord terminated by a 3-pin plug for

connection to a standard household socket. The

electrical supply is required to power the electronic

ignition system.

NOTE: It will be necessary for servicing purposes

to disconnect the electrical power supply. The

power point should therefore be accessible after

the appliance is installed, as specified in the local

wiring regulations.

TESTING APPLIANCE OPERATION

After installation the installer must fully test the

appliance and ensure it operates correctly before

handing it over to the customer.

GAS CONVERSIONS AND ADJUSTMENTS

Data Label

This appliance is suitable for Natural Gas and

Universal LPG; ensure that the available gas supply

matches the Data Label.

When converting from Natural Gas to Universal

LPG ensure that the NG regulator is removed

and replaced with the Test Point Assembly. An

AGA Approved gas regulator suitable for a supply

pressure of 2.75kPa should be part of the gas

tank supply and the test point pressure should be

adjusted to 2.75kPa.

Replacing the injectors

If the equipment is adjusted for a type of gas that is

different from the one available, it is necessary to

replace the burner injectors.

The choice of the injectors to replace must be

made according to the table of the “technical

characteristics” as enclosed.

Act as follows:

– remove the racks and burners.

– by means of a straight spanner L, unscrew the

injectors U (fig.7 - 7/A) and substitute it with the

corresponding one. Please note the wok burner

on models HG75FX-M and HG90FX-M has

three injectors (refer U1 & U2 of Figure 7/A for

positions)

– tighten the injectors strongly.

After changing the injectors, it is necessary to

eliminate residual natural gas in the system.

To do this you have to turn to the maximum

position then press the knob of each burner and

wait few seconds.

Adjusting the burners

The lowest flame point must always be properly

adjusted and the flame must remain on even if

there is an abrupt shift from the maximum to the

minimum position.

If this is not so, it is necessary to adjust the lowest

flame point as follows:

– start the burner up

– turn the tap up to the minimum position (small

flame)

– remove the knob from the tap rod

– introduce a flat-tip screwdriver in the hole F of the

tap (fig.8) and turn the by-pass screw up to a

proper adjustment of the lowest flame point.

For the models with triple crown is possible

adjust the lowest flame point for the external

or internal ring. Is sufficient to turn the screws

indicated in fig. 8/A.

As regards U-LPG gas burners, the by-pass

screw must be tightened completely.

MAINTENANCE

Maintenance Schedule

No regular maintenance is required for the hotplates

except cleaning.

Replacing the power supply cable

If the power supply cable should be replaced,

it is necessary to use a cable with a section of

3x0.75mm2, type H05VV-F or H05RR-F, complying

with the regulations in force.

The connection to the terminal board must be

effected as shown in fig.9 - 9/A:

brown cable L (phase)

blue cable N (neutral)

green-yellow cable (ground)

9

Page 10

MAXIMUM

OFF

MINIMUM

OFF

MAXIMUM INNER

AND OUTER RING

MINIMUM INNER RING

CLOSED OUTER RING

MAXIMUM INNER RING

MAXIMUM INNER RING

1

MINIMUM OUTER RING

Note that the dotted line section shown above is

the transition between the operating zones. It is

recommended not to leave the knob in this position.

CLOSED OUTER RING

1/A

2

3

5

4

6

U1

U2

C

7

10

7/A

Page 11

F

For the external ring

8

9

For the internal ring

8/A

9/A

11

Page 12

22

Gas Connection

70

Electrical Supply

Cord

200

510

Gas Connection

70

4

510

Gas Connection

70

4

510

5

8

590

Electrical Supply Cord

520

2

3

Electrical Supply Cord

8

750

610

2

3

MODEL: HG60FXA

Depth of cooktop casing

from benchtop surface : 60 mm

2

2

MODEL: HG75FXA

Depth of cooktop casing

from benchtop surface : 60 mm

2

2

MODEL: HG90FXA

Depth of cooktop casing

3

NG Universal LPG

2 Semi-rapid burner 6.3 MJ/h 5.6 MJ/h

3 Auxiliary burner 3.4 MJ/h 3.4 MJ/h

4 Triple ring burner 18.0 MJ/h 15.0 MJ/h

5 Double ring burner 10.3 MJ/h 9.6 MJ/h

8 Control knob for burner

8

890

from benchtop surface : 60 mm

12

Page 13

Stainless steel can be stained if it remains in contact with highly alkaline water or aggressive detergents

for an extended period of time.

All grades of stainless steel may stain, discolour or attain an adhering layer of grime in normal operation.

To achieve optimum surface appearance stainless steel must be kept clean regularly using the following

cleaning procedures, this ensuring good performance and long service life.

Wash with warm soapy water and rinse with clean water. Where the stainless steel has become

extremely dirty with signs of surface discolouration (due to periods of neglect or misuse) use a stainless

steel cleaner DO NOT use abrasive scourers or steel wool. When removing these stains be sure to follow

the polish of brushing lines.

MODEL HG60FXA MODEL HG75FXA

Ø 180

Ø 220

Ø 180

Ø 140

MODEL HG90FXA

Ø 180

Ø 260

Ø 140

Ø 260

Ø 180

Ø 180

Ø 180

Ø 140

Ø 180

Ø 180

13

Page 14

TECHNICAL CHARACTERISTIC TABLES

BURNERS

GAS

NORMAL

PRESSURE

INJECTOR

DIAMETER

TAPE BY

PASS

DIAMETER

N° DESCRIPTION KPa 1/100 mm 1/100 mm

2 SEMI-RAPID

3 AUXILIARY

Universal LPG 2.75 65 31 5.6

Natural 1.00 110 1/2 turn 6.3

Universal LPG 2.75 52 27 3.4

Natural 1.00 80 1/4 turn 3.4

Universal LPG 2.75 50 / 68 (x2) 60 15.0

TRIPLE (WOK)

4

CROWN

Natural 1.00 75 / 130 (x2)

1/3 turn

inner / 1 turn

outer

DOUBLE (WOK)

5

CROWN

Universal LPG 2.75 85 60 9.6

Natural 1.00 145 Adjust. 10.3

WIRING DIAGRAM

MODEL: HG60FXA MODEL: HG75FXA / HG90FXA

IGNITION

GENERATOR

TRIPOLAR

TERMINAL

IGNITION

GENERATOR

NOMINAL

HEAT INPUT

(MJ/h)

18.0

TRIPOLAR

TERMINAL

MICRO-UNIT

MICRO-UNIT

14

Page 15

INSTRUCTIONS FOR USING THE MINI TRIVET

The mini-trivet included with this cooktop is to be

used for cooking vessels of diameter 120mm or

smaller

Correct fitment

Examples of positioning of mini-trivet

15

MODEL:

HG60FXA

MODEL:

HG75FXA

MODEL:

HG90FXA

Page 16

INSTRUCTIONS FOR USING THE WOK TRIVET

The cast iron wok trivet included with this cooktop

is to be used for cooking only the wok burner.

Correct fitment

Examples of positioning cast iron wok trivet

MODELS:

HG75FXA

HG90FXA

B

Please note the step of the trivet fingers on the wok burner main trivet. (applicable for models

HG75FXA and HG90FXA) To avoid spillages lift and move cooking receptacles to and from this burner

rather than sliding across the trivets

16

Page 17

FOR SALES IN AUSTRALIA AND NEW ZEALAND

Warranty

ALL AEG BRANDED APPLIANCES

This doc ument sets out t he terms and con ditions of th e product

warran ties for AEG App liances. It is a n importan t document. Pl ease

keep it wit h your proof of pur chase docume nts in a safe plac e for

future r eference shoul d you require se rvice for your A ppliance.

1. In t his warranty :

(a) ‘accepta ble quality’ as referred to in clause 10 of this warranty has

the same mea ning referred to in the ACL;

‘ACL’ m eans Schedule 2 to the C ompetition and Con sumer

(b)

Act 2 010;

(c) ‘Appliance’ me ans any AEG product p urchased by you and

accompan ied by this documen t;

(d) ‘ASC’ means AEG authorised service centres;

(e) AEG is the brand controlled by Electrolux Home Products Pt y Ltd

of 163 O’Riordan Stre et, Mascot NSW 2020, ABN 51 0 04 762 341 in

respec t of Appliances purchased in Australia a nd Electrolux (N Z)

Limited (coll ectively ‘Elec trolux’) of 3-5 Nia ll Burgess Road, Mount

Wellington, in re spect of Applian ces purchased in New Zealand;

(f) ‘major failure’ as refer red to in clause 10 of this warr anty has the

same meanin g referred to in the ACL and in cludes a situation w hen

an Applian ce cannot be repaire d or it is uneconomic for Electrolux,

at its dis cretion, to repair an A ppliance during th e Warranty Period;

(g) ‘Warranty Period ’ means the Appliance is warranted again st

manuf acturing defects in Austra lia and New Zealand for

60 mont hs, following the date of original purchase of the Appliance;

(h) ‘you’ means the purchas er of the Appliance not having purchased

the Applia nce for re-sale, and ‘your ’ has a correspondin g meaning.

2. This war ranty only applie s to Appliances purc hased and used in Aus tralia

or New Zealand in normal domestic applications and is in addition to

(and does not exc lude, restrict , or modify in any way) a ny non-excludable

statuto ry warranties in Australia or New Zeala nd.

3. During t he Warranty Period Electrolux or it s ASC will, at no extra

charge if you r Appliance is readily ac cessible for service, wit hout special

equipment and subject to the se terms and conditi ons, repair or replac e

any part s which it consider s to be defective. Elec trolux or its A SC may

use remanu factured par ts to repair your App liance. You agree that any

replaced A ppliances or part s become the proper ty of Electro lux. This

warrant y does not apply to ligh t globes, batter ies, filters or similar

perishable parts.

4. Part s and Appliances no t supplied by Elect rolux are not covered by

this warranty.

5. To the extent pe rmitted by law, you will be ar the cost of trans portation,

travel and d elivery of the Ap pliance to and from Elec trolux or its ASC. I f

you reside outside of the ser vice area, you will bear the c ost of:

(a) travel of an authorised r epresentative;

(b) transpor tation and deliver y of the Appliance to and f rom Electrolux

or its ASC .

In all insta nces, unless the A ppliance is transp orted by Electrol ux or

an AEG autho rised represent ative, the Applianc e is transpor ted at the

owner’s cos t and risk while in tran sit to and from Electrolux or its ASC.

6. Proof of purc hase is required before yo u can make a claim under

this warr anty.

7. You may not make a claim under this warran ty unless the de fect claimed

is due to faul ty or defecti ve parts or work manship. Electrolu x is not

liable in the fo llowing situation s (which are not exhaus tive):

(a) the A ppliance is damaged by :

(i) accident

(ii) mis use or abuse, includin g failure to properly mai ntain or service

(iii) normal wea r and tear

(iv) p ower surges, elec trical storm dam age or incorrect p ower supply

(v) incomplete or improper installation

(vi) incorrect, improper or inappropriate operation

(vii) insec t or vermin infestation

(viii) failure to c omply with any additional instruc tions supplied wi th

the Appliance;

(b) the Applianc e is modified without authority f rom Electrolux in

writing;

(c) the Ap pliance’s serial number or warranty sea l has been removed

or defaced;

(d) the Applianc e was serviced o r repaired by anyone other t han

Electro lux, an authoris ed repairer or ASC.

8. This war ranty, the contrac t to which it relates a nd the relationship be tween

you and Elec trolux are govern ed by the law applicabl e where the Applianc e

was purcha sed. Where the Ap pliance was purchas ed in New Zealand for

commercia l purposes the Con sumer Guarantee Ac t does not apply.

9. To the extent pe rmitted by law and su bject to your non- excludable

statuto ry rights and wa rranties, AEG exclud es all warranties a nd

liabilitie s (other than as contained in this documen t) including liabili ty

for any loss o r damage whether di rect or indirec t arising from your

purchase, u se or non use of the App liance.

10. For AEG Appl iances and serv ices in Australia, t he Appliances come w ith

a guarante e that cannot be exclud ed under the ACL. You are entitle d

to a replacem ent or refund for a major f ailure and for compen sation for

any other reasonably foreseea ble loss or damage. You are also e ntitled

to have the Appliance repaired or replaced if the Applia nce fails to

be of accept able quality and t he failure does not am ount to a major

failure. The b enefits to you given by t his warranty a re in addition to your

other righ ts and remedies und er a law in relation to the Appliances or

services to which the warr anty relates.

11. At a ll times during the Warr anty Period, Elec trolux shall, at it s discretion,

determin e whether repair, replacement or refund will ap ply if an

Applianc e has a valid warrant y claim applicable to it.

12. For App liances and serv ices provided in New Zeala nd, the Appliance s

come with a g uarantee pursuant to the provisions of th e Consumer

Guarantee s Act, the Sale of Good s Act and the Fair Trading Ac t.

13. To enquire ab out claiming under thi s warranty, please follow these steps:

(a) caref ully check the oper ating instruc tions, user manual an d the

terms of thi s warranty;

(b) have the model a nd serial number of th e Appliance availab le;

(c) have the proof of purchase (e.g. an i nvoice) available;

(d) telephone the numbers shown below.

14. You accept that i f you make a warrant y claim, Electrolu x and its ASC

may exchange i nformation in relation to you to enable Elect rolux to

meet its o bligations under t his warranty.

Before calling for service, please ensure that the steps listed in clause 13 above have been followed.

FOR SERVICE

or to find the address of your nearest

state service centre in Australia

PLEASE CALL 1300 363 664

customercare@aegaustralia.com.au

OR EMAIL

For the cost of a local call (Australia only)

FOR SERVICE

or to find the address of your nearest

authorised service centre in New Zealand

FREE CALL 0800 10 66 10

OR EMAIL customercare@electrolux.co.nz

AE G_Wa rr_A ug13

(New Zealand only)

Important Notice

SERVICE AUSTRALIA

www.aeg.com/au

SERVICE NEW ZEALAND

www.aeg.co.nz

17

FOR SPARE PARTS

or to find the address of your nearest

state spare parts centre in Australia

PLEASE CALL 13 13 50

customercare@aegaustralia.com.au

OR EMAIL

For the cost of a local call (Australia only)

FOR SPARE PARTS

or to find the address of your nearest

state spare parts centre in New Zealand

FREE CALL 0800 10 66 20

OR EMAIL customercare@electrolux.co.nz

(New Zealand only)

Page 18

18

Page 19

19

Page 20

www.aeg.com/shop

COD. 208685-00 - 09.09.2015

Loading...

Loading...