Page 1

DD 8793

Cooker Hood

Cappa aspirante

Campana extractora

Exaustor

Operating and Installation Instructions

Istruzioni di montaggio ed uso

Instrucciones de montaje y manejo

Manual de Instruções

Page 2

Contents

Safety warnings 4

for the user 4

for the installer 4

Description of the Appliance 6

Extractor version 6

Filter Version 6

Hood Operation 8

Switching on the hood 8

Switching on the light 8

Control device for grease or charcoal filter 8

Led signal for grease filter 8

Led signal for charcoal filter 8

Resetting the saturation indicator 8

Using the Remote Control 9

Remote Control Maintenance 9

Maintenance and care 10

Metal grease filter 10

Open the metal grease filter 10

Charcoal filter 11

Changing the light bulb 12

Cleaning 13

Special accessories 13

Technical assistance service 13

Guarantee conditions 14

Technic Details 15

Mounting accessories included 15

Electrical connection 16

Safety warnings for the electrician 16

Wall unit mounting 17

2

Page 3

Safety warnings

For the user

The cooker hood is designed to extract unpleasant odours from the

kitchen, it will not extract steam.

Always cover lighted elements, to prevent excess heat from

damaging the appliance. In the case of oil, gas and coal fired

cookers it is essential to avoid open flames.

Also, when frying, keep the deep frying pan on the cooker top/cooker

under careful control.

The hot oil in the frying pan might ignite due to overheating.

The risk of self-ignition increases when the oil being used is dirty.

It is extremely important to note that overheating can cause a fire.

Never carry out any flambé cooking under the hood.

Always disconnect the unit from the power supply before

carrying out any work on the hood, including replacing the

light bulb (take the cartridge fuse out of the fuse holder or switch off

the automatic circuit breaker).

It is very important to clean the hood and replace the filter at

the recommended intervals. Failure to do so could cause

grease deposits to build up, resulting in a fire hazard.

The appliance is not intended for use by young children or infirm

persons without supervision.

Older children must be supervised if using the appliance.

Young children should be supervised to ensure that they do not play

with the appliance.

WARNING - Ensure that the appliance is switched off before

replacing the lamp to avoid the possibility of electric shock.

This appliance is marked according to the European directive 2002/96/

EC on Waste Electrical and Electronic Equipment (WEEE).

By ensuring this product is disposed of correctly, you will help prevent

potential negative consequences for the environment and human health,

which could otherwise be caused by inappropriate waste handling of

this product.

The symbol on the product, or on the documents accompanying

the product, indicates that this appliance may not be treated as

household waste. Instead it shall be handed over to the applicable

collection point for the recycling of electrical and electronic equipment.

Disposal must be carried out in accordance with local environmental

regulations for waste disposal.

For more detailed information about treatment, recovery and recycling

of this product, please contact your local city office, your household

waste disposal service or the shop where you purchased the product.

3

Page 4

For the installer

When used as an extractor unit, the hood must be fitted with a hose

having preferably the same diameter as the outlet hole.

Attention: The hose is not supplied and must be purchased

separately.

Should there already be a pipe of diameter 125 mm that ducts to the

outside through the walls or roof, it is possible to use the 150/125

mm reduction flange provided. In this case the hood will be slightly

more noisy.

When installing the hood, make sure you observe the following

minimum distance from the top edge of the cooking hob/ring

surfaces:

electric cookers 600 mm

gas cookers 650 mm

If the instructions for installation for the gas hob specify a greater

distance, this must be adhered to.

The national Standard on fuel-burning systems specifies a maximum

depression of 0.04 mbar in such rooms.

The air outlet must not be connected to chimney flues or combustion

gas ducts. The air outlet must under no circumstances be connected

to ventilation ducts for rooms in which fuel-burning appliances are

installed.

The air outlet installation must comply with the regulations laid down

by the relevant local authorities.

When the unit is used in extraction mode, a sufficiently large

ventilation hole must be provided, with dimensions that are approximately the same as the outlet hole.

National and regional building regulations impose a number of

restrictions on using hoods and fuel-burning appliances connected to

a chimney, such as coal or oil room-heaters and gas fires, in the

same room.

Hoods can only be used safely with appliances connected to a

chimney if the room and/or flat (air/environment combination) is

ventilated from outside using a suitable ventilation hole approximately

500-600 cm2 large to avoid the possibility of a depression being

created during operation of the hood.

If you have any doubts, contact the relevant controlling authority or

building inspectors office.

Since the rule for rooms with fuel burning appliances is outlet hole of

the same size as the ventilation hole, a hole of 500-600 cm2, which

is to say a larger hole, could reduce the performance of the extractor

hood.

If the hood is used in its recirculation mode, it will operate simply and

safely in the above conditions without the need for any of the

aforementioned measures.

4

Page 5

When the hood is used in its extraction mode, the following rules

must be followed to obtain optimal operation:

- short and straight outlet hose

- keep bends in outlet hose to a minimum

- never install the hoses with an acute angle, they must always

follow a gentle curve.

- keep the hose as large as possible (preferably the same diameter

as the outlet hole).

- the length should be no more than:

3 metres with one 90° bend

2 metres with two 90° bends

Bends of more than 90° will reduce the efficiency of the hood and

reduce the airflow.

Failure to observe these basic instructions will drastically reduce the

performance and increase the noise levels of the extractor hood.

5

Page 6

Description of the Appliance

=

=

The cooker hood is designed to extract

unpleasant odours from the kitchen, it

will not extract steam.

The hood is supplied as an extractor unit

and can also be used with a recirculation

mode by fitting a charcoal filter.

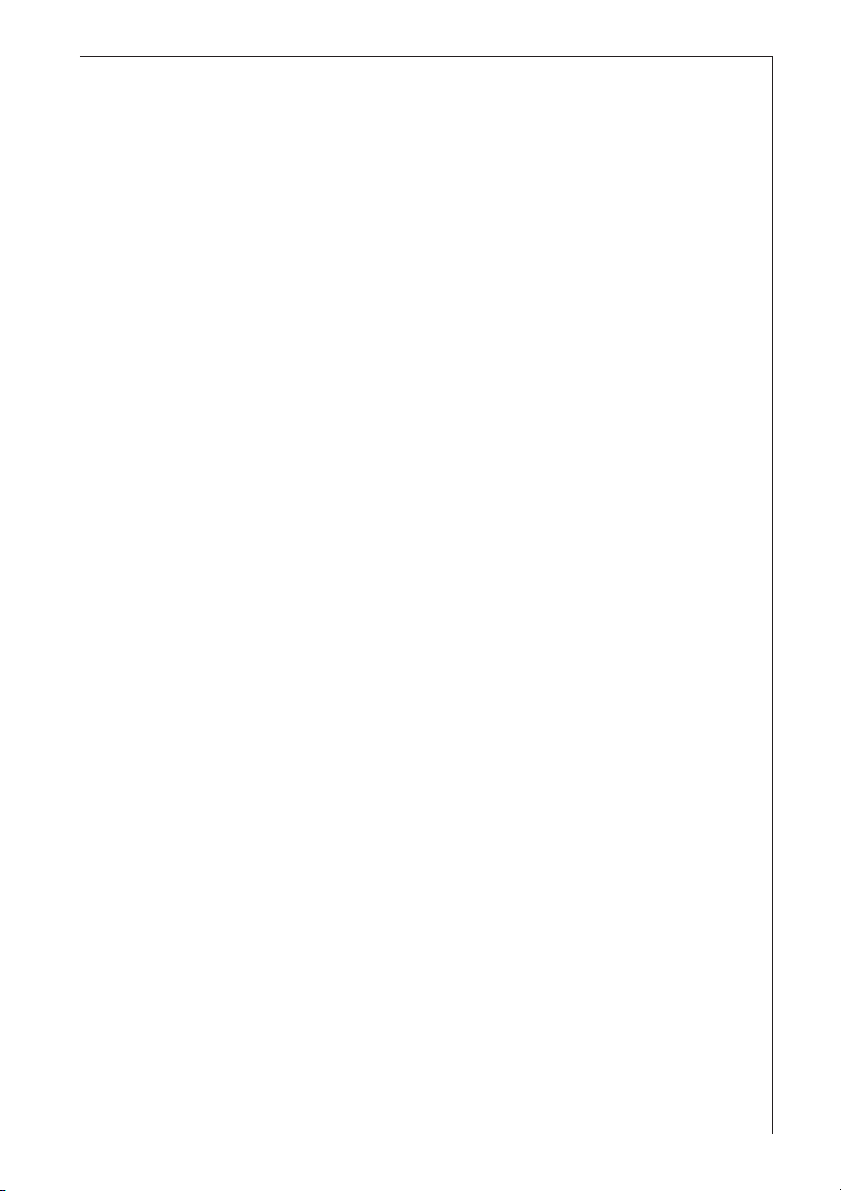

Extraction mode

In this mode fumes are extracted to the

outside via a hose connected to the

coupling ring D. Fig. 1.

In order to obtain the best performance the

hose should have a diameter equal to the

outlet hole.

Should there already be a pipe of diameter

125 mm that ducts to the outside through

the walls or roof, it is possible to use the

150/125 mm reduction flange provided. In

this case the hood will be slightly more noisy.

Recirculation mode

The air is filtered through a charcoal filter

and returned to the kitchen.

You will need an original charcoal filter for the

recirculation mode. (See Special

Accessories).

Assemble the deflector (3 parts): the three

parts must be fixed with 2 screws Ø 3.5 13

mm, the extension of the deflector is

adjustable and must correspond to the width

of the chimney flue support, to which it must

be fixed.

Fix the deflector using 4 screws Ø 2,9x6.5

mm. Fig. 2.

Optionally, the position of the chimney

elements can be changed.

When using the hood in the filter version the

chimney must be fixed at the top, with the air

outlet grill at the side.

Fig. 1

D

Fig. 2

6

Page 7

Control Panel

Best results are obtained by using a low speed for normal conditions

and a high speed when odours are more concentrated.

Turn the hood on a few minutes before you start cooking.

The hood should be left on after cooking for about 15 minutes or until

all the odours have disappeared.

The hood operation may be controlled via the control ball or with the

remote control.

Every status change (changing speed, switching on the lights, etc.)

and is recognizable from the variation of light emitted by the control

ball and by an acoustic signal.

The control ball serves also as a light signal :

No signal :

The hood is switched off.

Static green light :

Hood is switched on at power level 1 (minimum).

Static orange light :

Hood is switched on at power level 2 (medium).

Static red light :

Hood is switched on at power level 3 (maximum).

Alternating red light :

Hood is switched on at intensive power level (timed at 5 minutes)

Alternating green light :

Indicates the grease filter saturation - clean the grease filter

Alternating orange light :

Indicates the charcoal filter saturation - clean or replace the

charcoal filter

Attention!

The control Ball flashes orange to indicate the saturation of the odor

filter even when the charcoal filter is not installed inside the cooker

hood.

However perform the signal reset operation as follows: select the

intensive speed (the control ball lights up with a red flashing light),

depress again and hold depressed for about 3 seconds until a bip

sound indicates the reset.

7

Page 8

Switching on the hood - Fig. 3

The control ball is a balancer switch.

Depressing the control ball

repeatedly towards the right

switches on the hood and you may

select the suction level desired,

depressing once again on the right

the hood switches off.

Fig. 3

Switching on the light Fig. 3

Depress the control ball towards the

left :

once for submersed lighting,

once again for full lighting,

depress again to switch off the light.

depress

towards the

right to switch

on the hood

left to switch

Control device for grease or charcoal filter

The air duct, in this hood, is provided with a device that signals when

the filter requires cleaning or changing .

Led signal for grease filter

The LED signal flickers (flickering green light) when the grease filter

requires cleaning, occurs at about 40 operating hours.

Carefully note the device for grease filter maintenance!

Led signal for charcoal filter

The LED signal flickers (flickering orange light) when the charcoal filter

requires cleaning or replacing, occurs at about 160 operating hours.

Carefully note the device for charcoal filter maintenance!

depress

towards the

on the light.

Resetting the saturation indicator

After cleaning or replacing the filter, select the intensive speed (the

control ball lights up with a red flashing light), depress again and hold

depressed for about 3 seconds until a bip sound indicates the reset.

8

Page 9

Using the Remote Control

The remote control may operate in humid

environments, but not when placed on wet

surfaces.

Selecting the Suction Speed position the

remote control vertically near the cook top area

and rotate clockwise to increase the suction

speed, and anticlockwise to decrease the suction

speed.

Turning on the Light, press the remote control

from the top downwards once for suffused lighting,

again for full lighting, and again to turn off the light.

Fig. 4

Remote Control

Maintenance

Clean the remote control using non

abrasive detergents.

Follow the instructions below in order

to replace the batteries for the remote

control :

- Using a small screwdriver, raise the

cover on the base of the remote

control, in order to access the battery

compartment.

Remove the battery holder, and

replace 4 new batteries type ..394 of

1.5V.

Place the batteries in order in the battery holder (see Fig. 5) taking care

to respect the polarities indicated on the base of the upper section of

the remote control.

Warning!

If the remote control doesnt work after installation (yet the control ball

works correctly), do the following:

1. Place the remote control on the work surface near the hood.

2. Disconnect the hood from the mains.

3. Reconnect the hood to the mains.

Follow this procedure whenever the remote control doesnt work for no

apparent reason (e.g.: dead battery).

Fig. 5

9

Page 10

Maintenance and Care

The hood must always be disconnected from the electricity

supply before beginning any maintenance work.

Metal grease filter

The purpose of the grease filters is to absorb grease particles which

form during cooking and it must always be used, either in the

external extraction or internal re-circulation function.

Attention: the metal grease filters must be removed and washed,

either by hand or in the dishwasher, every four weeks.

Removing the metal grease filter

First, push the metal grease filter stop backwards, then extract the

filter, pulling downwards. Fig. 6.

Hand washing

Soak grease filters for about one hour

in hot water with a grease-loosening

cleaner, then rinse off thoroughly with

hot water. Repeat the process if

necessary. Refit the grease filters

when they are dry.

Dishwasher

Place grease filters in the dishwasher.

Select most powerful washing

programme and highest temperature,

at least 65°C. Repeat the process.

Refit the grease filters when they are

dry.

When washing the metal grease filter

in the dishwasher a slight

discolouration of the filter can occur,

this does not have any impact on its

performance.

Clean the inner housing using a hand

hot solution only(never use caustic

detergents, abrasive powders or brushes).

Fig. 6

10

Page 11

i

g

h

g

g

g

Charcoal filter

The charcoal filter should only be used if you want to use the hood in

recirculation mode.

To do this you will need an original charcoal filter (available from your

local Service Force Centre).

Cleaning/replacing the charcoal filter

Unlike other charcoal filters, the LONGLIFE charcoal filter can be

cleaned and reactivated. With normal use the filter should be cleaned

every second month (when using the hood 2,5 hours per day,on

avarage). The best way to clean the filter is in the dishwasher. Use

normal detergent and choose the highest temperature (65º C). Wash

the filter separately so that no food parts gets stuck on the filter and

later causes bad odours. To reactivate the charcoal, the filter should

be dried in an oven for 10 minutes with a maximum temperature of

100º C.

After approximately three years of use, the charcoal filter should be

replaced with a new, as the odour reduction capacity will be reduced.

Fitting

Remove the frame i which supports the filter h by turning 90° the two

knobs g.

Insert the charcoal filter inside the frame and put all parts back in

their place. Fig. 7.

To remove proceed in the reverse order.

Always specify the hood model code number and serial number when

ordering replacement filters. This information is shown on the rating

plate located on the inside of the unit.

The charcoal filter can be ordered from your local Service Force

Centre.

Fig. 7

11

Page 12

Warning

Failure to observe the instructions on cleaning the unit and changing

the filters will cause a fire hazard. You are therefore strongly

recommended to follow these instructions.

The manufacturer declines all responsibility for any damage to the

motor or any fire damage linked to inappropriate maintenance or

failure to observe the above safety recommendations.

Changing the light upper and lower bulbs

Disconnect the cooker hood from the mains supply.

Remove the lamp cover carefully, use a screw driver as a lever.

Fig. 8.

Replace the old bulb with a new one of the same type.

Refit the lamp cover.

If the light does not come on, make sure the bulb has been inserted

in correctly before contacting your local Service Force Centre.

12

Fig. 8

Page 13

Cleaning the hood

Clean the outside of the hood using a damp cloth and a solution of

water and mild washing up liquid.

Never use corrosive, abrasive or flammable cleaning products or

products containing bleach. .

Never insert pointed objects in the motors protective grid.

Only ever clean the switch panel and filter grill using a damp cloth

and mild washing up liquid.

It is extremely important to clean the unit and change the filters at the

recommended intervals. Failure to do so will cause grease deposits

to build up that could constitute a fire hazard.

Special accessories

Charcoal filter Type 20

Technical assistance service (not for UK)

You are welcome to telephone our technical assistance service (see list of technical

assistance centres) whenever you need information or in the unlikely event of a fault.

For service in Australia call 1300 650 020.

When calling, please be ready to specify:

1. The model code number

2. The serial number (E-Nr.)

3. The manufacturing number (F-Nr.)

This information is shown on the registration plate inside the unit behind the

grease filter.

We reserve the right to change specifications and colours as a result of our policy of

continuing technological development.

13

Page 14

Service and Spare Parts

In the event of your appliance requiring service, or if you wish to purchase spare parts,

contact your local Service Force Centre by telephoning: 08705 929 929

Your call will be automatically routed to the Service Centre covering your post code

area. For the address of your local Service Force Centre and further information about

Service Force, please visit the website at www.serviceforce.co.uk

Please ensure that you have read the section What to do if.... as the engineer will make

a charge if the fault is not a mechanical or electrical breakdown even the appliance is

under warranty. Please note that proof of purchase is required for in-guarantee

service calls.

Help us to help you

Please determine your type of enquiry before writing or telephoning.

When you contact us we need to know:

Your name Clear and concise details of the fault

Address and post code Name and model of the appliance*

Telephone number E number*

Serial number*

* This information can be found on the rating plate, which can be seen when the grease

filters are removed.

If you require Customer Service in the Republic of Ireland please contact us at

the address below:

AEG

Electrolux Group (Ire) Ltd

Long Mile Road

Dublin 12

Republic of Ireland

Tel: + 353 (0) 1 4090751

Email: service.eid@electrolux.ie

CUSTOMER CARE DEPARTMENT

For general enquiries concerning your AEG appliance or for further information on AEG

products, please contact our Customer Care Department by letter or telephone at the

address below or visit our website at www.aeg.co.uk

Customer Services Department

Major Appliances

AEGElectrolux

Addington Way

Luton

Bedfordshire

LU4 9QQ

08705 350 350 (*)

14

* calls to this number may be recorded for training purposes.

Page 15

Technical Details

Dimensions - extractor version (in cm):

Height 70-113

Width 89,8

Depht 50

Dimensions - filter version (in cm):

Height 78-122

Width 89,8

Depht 50

Maximum absorbed power: 210 W

Motor absorption: 1 x 170 W

Lighting: 2 x 20W

Lenght of the cable: 150 cm

Mounting accessories included

1 deflector (3 pieces to assemble)

2 metal screws 3,5 x 13 (to assemble the deflector)

1 chimney support (3 pieces to assemble)

4 metal screws 4 x 8 (to assemble the chimney support)

4 metal screws 3,5 x 9,5 (to affix the deflector to the support)

1 reduction flange Ø 125-120 mm

1 support bracket

5 wood-screws 5 x 45 mm (for wall mounting)

5 wall plugs Ø 8 mm (for wall mounting)

4 metal screws 2,9 x 6,5 (for chimney flue mounting)

4 metal screws 4 x 20 (to affix the screen to the cooker hood)

2 metal screws 3 x 9 (to affix the frame to the cooker hood)

1 allen spanner (for TORX screws)

15

Page 16

Electrical connection (not for UK)

Safety warnings for the electrician

Before connecting the appliance to the power supply, check that the

voltage indicated on the rating plate corresponds to the mains power

supply available. Appliances fitted with a plug can be connected to any

standard power socket within easy access.

Should it be necessary to provide a fixed connection, the hood must

only be installed by an electrician authorised by the local electricity

board. When installing, an omnipolar disconnector with a distance of at

least 3 mm between contacts must be provided.

Fixed connection of the appliance must only be carried out by an

authorised electrician.

Electrical connection for UK only

Safety warnings for the electrician

Connect the hood to the mains supply via a double pole switch which

has 3 mm minimum separation between the contacts.

The switch must be accessible at all times.

The following is valid in the United Kingdom only:

- the wire which is coloured green and yellow must be connected to

the terminal which is marked with the letter E or by the earth symbol

( ), or coloured green or green and yellow;

- the wire which is coloured blue must be connected to the terminal

which is marked with the letter N or coloured black, -

- the wire which is coloured brown must be connected to the terminal

which is marked with the letter L or coloured red.

16

Page 17

Wall unit mounting - Fig. 9

First decide which functioning version is better for you.

If you decide to use the hood in exhausting version we suggest to position

the upper section of the chimney so that the oulet slots are not visible

once installation has ended, on the contrary if is decided to use the hood

in recycling version BE SURE that the side with slots is up (see also A-BC sequence on on Fig. 9).

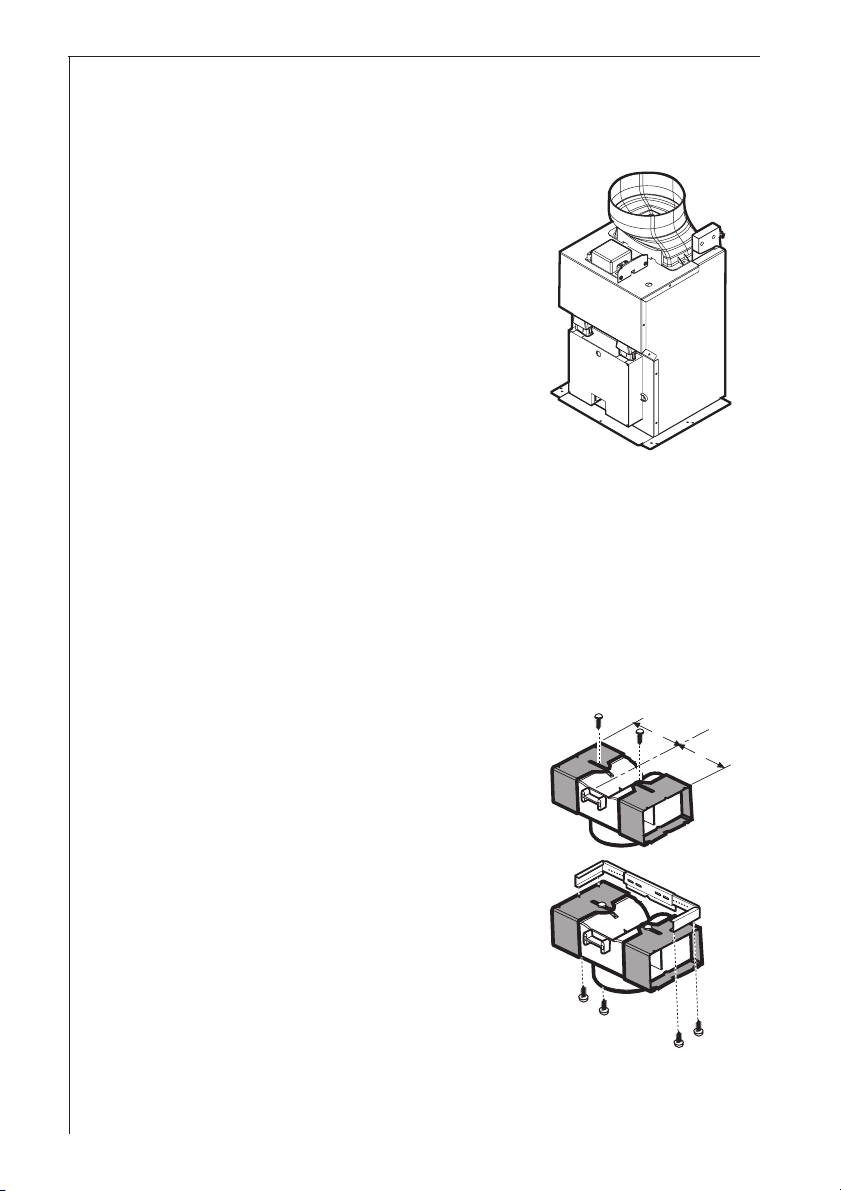

Assembling the chimney flue support/bracket (3 parts):

The three parts should be fixed with 4 screws, the support

extension is adjustable and should correspond to the internal width

of the telescopic chimney flue.

Assembling the deflector (3 parts only for filter version):

The three parts should be fixed with 2 screws, the deflector

extension is adjustable and should correspond to the width of the

chimney flue support, to which it is then fixed.

=

B

180°

=

=

X

G

F

X

=

X

G

A

C - OK!

H

F

Fig. 9

17

Page 18

Wall unit mounting - Fig. 10

Assemble the frame to the motor group (1).

Carry out the connection to the control ball and to the lamps (2) -

Note: the connectors contain an obliged mounting direction,

the connector for the control ball should be fixed in order that the

small dent corresponds to the housing perforation on the side of the

connection socket at the back of the control ball.

Fix the frame to the motor group using two screws (3).

Sign the wall with a center line, this will aid mounting procedure (4),

position the template so that the mid line printed on the template

matches with the center line previously signed, the lower side of the

template corresponds to the lower side of the hood once mounted

(5).

Drill two holes Ø 8mm and fix the support bracket with two wall

plugs and screws (6).

Hang the hood (7) adjust its position (8-9) and from the inside of the

hood sign one point for definitive fixing (10), remove the hood and

drill an hole Ø 8mm (11), fit a wall plugs, hang the hood again and

fix it definitively with a screw (12).

Drill two holes Ø 8mm on the upper side close to the ceilling (13), fit

two wall plugs and fix the chimney support with two screws (14).

In case the hood is to be used in filter version, mount the deflector

F on the chimney support with four screws and fit an exhausting

pipe (15) to connect deflector to the outlet hole D of the hood.

In case the hood is to be used in exhausting version, then the

deflector must not be mounted and fit an exhausting pipe (15) to

connect outlet hole D of the hood to the outside.

Make electrical connection (16), but leave the hood disconnected

from the home general electric panel.

Insert the vapour screen on the motor housing and fix it with four

screws (17).

Fix the chimney first up (18a) to the chimney support (18b), then on

the bottom (19a) to the upper side of the frame (19b) using four

screws.

Connect the hood the the home general electric panel and check if

the hood work properly.

18

Page 19

13

18b

14

18b

G

18a

18a

H

F

8-9

19a

1

16

2

3

4

7

19a

6

5

11

9

D

8

8-9

15

Fig. 10

10

17

19b

19b

17

12

19

Page 20

From the Electrolux Group. The world´s No.1 choice.

The Electrolux Group is the world´s largest producer of powered appliances for kitchen,

cleaning and outdoor use. More than 55 million Electrolux Group products (such as refrigerators,

cookers, washing machines,vacuum cleaners, chain saws and lawn mowers) are sold each

year to a value of approx. USD 14 billion in more than 150 countries around the world.

AEGElectrolux

Addington Way

Luton

Bedfordshire

LU4 9QQ

http://www.aeg.co.uk

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

http://www.aeg.hausgeraete.de

© Copyright by AEG

LI1Z1D Ed. 11/05

Loading...

Loading...