Page 1

ARCTIS U

66050i

Built-in freezer

Operating and Installation Instructions

Page 2

Dear customer,

Before placing your new refrigerator/freezer into operation please read

these operating instructions carefully. They contain important

information for safe use, for installation and for care of the appliance.

Please keep these operating instructions for future reference. Pass them

on to possible new owners of the appliance.

These operating instructions are for use with several technically comparable models with varying accessories. Please observe the notes which

apply to your model.

Notes which are important for your safety or for the proper functioning of the appliance are stressed with a warning triangle and/ or with

signal words (

Warning!, Caution!, Important!). Please observe the

following carefully.

This symbol guides you step by step in the operation of the appliance.

Supplementary information regarding operation and practical applications of the appliance appear after this symbol.

Tips and notes concerning economical and environmentally sound use

of the appliance are marked with the cloverleaf.

The operating instructions contain instructions for the correction of

possible malfunctions by the user in the section "What to do if ...". If

these instructions should not be sufficient, please contact your local

Service Force Centre.

Printed on paper manufactured with environmentally sound proceses

he who thinks ecologically acts accordingly...

☞

2

Page 3

3

Contents

Important Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Appliance Packaging Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Disposal of old Appliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Remove transport packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grid preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reversing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Building the appliance in under a worktop . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fitting the plinth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Description of the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

View of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Prior to Initial Start–Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating and indicator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warning system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starting up and temperature regulation . . . . . . . . . . . . . . . . . . . . . . 20

Ice pack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Freezing and storing frozen food . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Storage Goods Symbol/Freezing Calendar . . . . . . . . . . . . . . . . . . . . . 22

Preparation of Ice Cubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Defrosting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Switching off the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Magnetic door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Energy Saving Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Correcting Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Service & Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Help us to Help You . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Customer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Noises during operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Regulations, Standards, Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Technical terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 4

4

Important Safety Instructions

These warnings are provided in the interests of your safety. Ensure

you fully understand them before installing or using the appliance.

Your safety is of paramount importance. If you are unsure about the

meaning of these warnings contact the Customer Care Department

for assistance.

Intended use

• The freezer is intended for use in the home. It is suitable for the freezing of fresh food and storing frozen food, as well as for making

ice. If the appliance is used for purposes other than those intended

or used incorrectly, no liability can be accepted by the manufacturer

for any damage that may be caused.

• Alterations or changes to the freezer are not permitted for reasons

of safety.

• If you use the freezer in a commercial application or for purposes

other than the freezing or frozen storage of foods, the manufacturer

accepts no liability for any damages which may occur.

Prior to initial start–up

• Check the appliance for transport damage. Under no circumstance

should a damaged appliance be plugged in. In the event of damage,

please contact your supplier.

• Ensure that the appliance does not stand on the electrical supply

cable.

Important: if the supply cable is damaged, it must be replaced

by authorised service or qualified personnel using a special cable of

the same type.

Refrigerant

The refrigerant isobutane (R600a) is contained within the refrigerant

circuit of the appliance, a natural gas with a high level of environmental compatibility, which is nevertheless flammable.

• During transportation and installation of the appliance, be certain

that none of the components of the refrigerant circuit become

damaged.

• If the refrigerant circuit should become damaged:

– avoid open flames and sources of ignition;

– thoroughly ventilate the room in which the appliance is situated.

Safety of children

• Packaging (e.g. wraps, polystyrene) can be dangerous for children.

There is a risk of suffocation! Keep packaging material away from

children!

Page 5

5

• Please make old appliances unusable prior to disposal. Pull out the

mains plug, cut off the mains cable, break or remove spring or bolt

catches, if fitted. By doing this you ensure that children cannot lock

themselves in the appliance when playing (there is risk of

suffocation!) or get themselves into other dangerous situations.

• Often children cannot recognise the hazards present in household

appliances. It is therefore important that you ensure adequate

supervision and never let children play with the appliance!

Daily Operation

• Containers with flammable gases or liquids can leak at low

temperatures. There is a risk of an explosion! Do not store any

containers with flammable materials such as spray cans, fire extinguisher refill cartridges etc in the refrigerator/freezer.

• Bottles and cans must not be placed in the freezer. They can burst

when the contents freeze, high carbonate content drinks can even

explode! Never store lemonade, juices, beer, wine, sparkling wine

etc. in the freezer. Exception: high alcohol content spirits can be

stored in the freezer.

• Do not put ice creams or ice cubes in the mouth immediately after

removal from the freezer. Very cold ice can freeze to the lips or tongue and cause injury.

• Do not touch frozen food with wet hands. Your hands could stick

to the food causing skin abrasions.

• Do not operate any electrical appliances in the refrigerator/freezer

(e.g. electric ice cream makers, mixers etc.).

• Before cleaning the appliance, always switch off the appliance and

unplug it, or disconnect from the electricity supply.

• When unplugging always pull the plug from the mains socket, do

not pull on the cable.

In case of malfunction

• If a malfunction occurs on the appliance, please look first in the

"What to do if ..." section of these instructions. If the information

given there does not help, please do not perform any further repairs

yourself.

• This product should be serviced by an authorised engineer and only

genuine spare parts should be used.

• Under no circumstances should you attempt to repair the appliance

yourself. Repairs carried out by inexperienced persons may cause

injury or serious malfunctioning. Contact your local AEG Service

Force Centre.

Page 6

6

Disposal

Appliance Packaging Information

All materials are environmentally friendly. They can be dumped or

burned at an incinerating plant without danger.

About the materials: The plastics can be recycled and are identified as

follows:

>PE< for polyethylene, e.g. the outer covering and the bags in the

interior.

>PS< for polystyrene foam, e.g. the pads, which are all free of chlorofluorocarbon.

The carton parts are made from recycled paper and should be disposed

of at a waste-paper recycling collection location.

Disposal of old Appliances

For environmental reasons, refrigeration appliances must be disposed

of properly. This applies to your old appliance, and - at the end of its

service life - for your new appliance as well.

Warning! Before disposing of old appliances make them inoperable.

Remove plug from mains, sever the power cable, remove or destroy

any snap or latch closures. This eliminates the danger that playing

children lock themselves into the appliance (danger of suffocation!) or

place themselves into other life-endangering situations.

Disposal:

• The appliance may not be disposed of with domestic waste or bulky

refuse.

• The refrigerant circuit, especially the heat exchanger at the back of

the appliance, must not be damaged.

• Information concerning collection schedules or locations can be

obtained from your local Council or Environmental Health Office.

Remove transport packaging

The appliance and the interior fittings are protected for transport.

Pull off the adhesive tape on the left and right side of the door.

You can remove any remnants of adhesive using white spirit.

Remove all adhesive tape and packing pieces from the interior of the

appliance.

☞

☞

Page 7

7

Installation

Installation Location

The appliance should be set up in a well ventilated, dry room.

Energy use is affected by the ambient temperature.

The appliance should therefore

– not be exposed to direct sunlight;

– not be installed next to radiators, cookers or other sources of heat;

– only be installed at a location whose ambient temperature

corresponds to the climate classification, for which the appliance is

designed.

The climate classification can be found on the rating plate, which is

located at the left on the inside of the appliance.

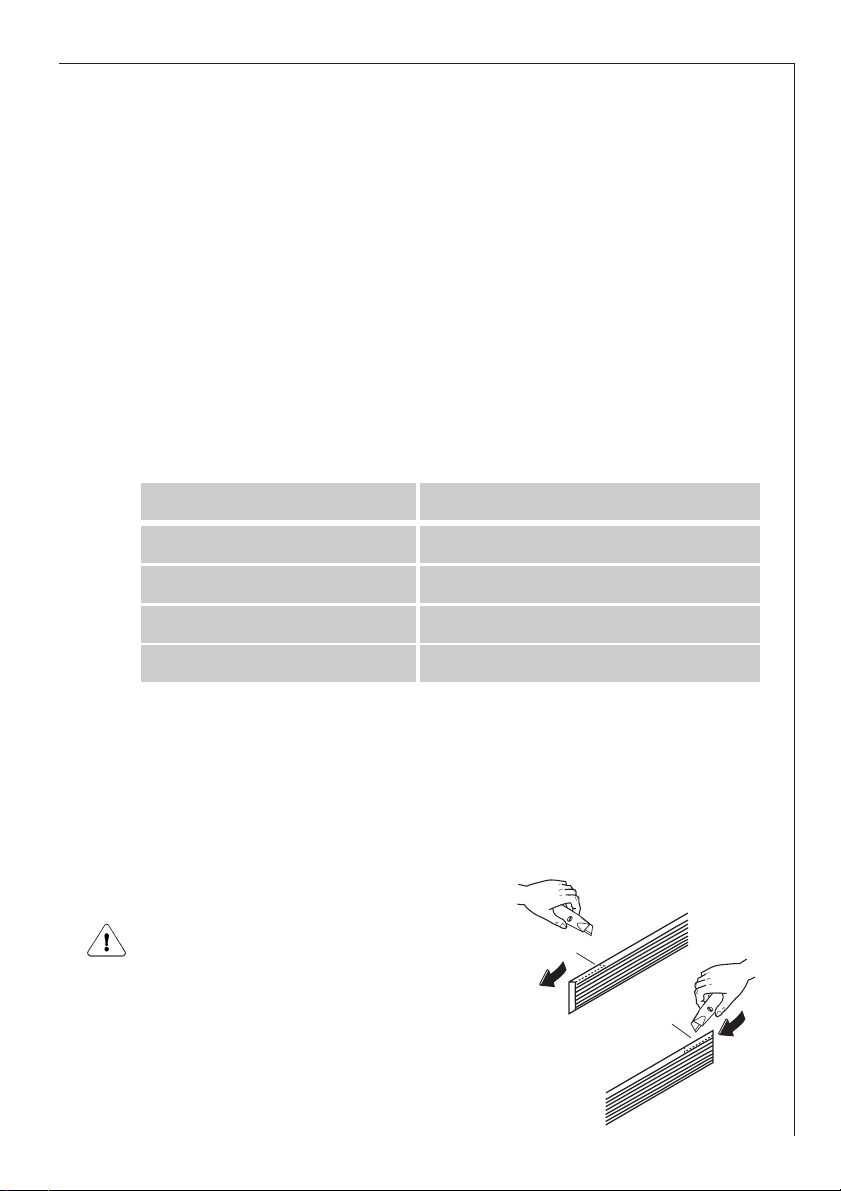

The following table shows which ambient temperature is correct for

each climate classification:

If the refrigeration appliance is installed next to another refrigerator or

freezer a clearance of 5 cm at the sides is required, in order to prevent

the formation of condensation on the outside of the appliance.

Grid preparation

The side at which the door opens can be changed from the right side

(as supplied) to the left side, if the installation site requires.

Warning! When changing the side at

which the door opens, remove

plug from the mains.

Left door opening:

Remove the left side (A) of the grid

cutting it from the rear (see figure).

Remove the right side (B) of the grid

cutting it from the rear (see figure).

☞

☞

Climate classification for an ambient temperature of

SN +10 to +32 °C

N +16 to +32 °C

ST +18 to +38 °C

T +18 to +43 °C

A

O002/2

B

Page 8

8

1

1

2

3

4

5

Re-install the grid to the base of the

appliance by pushing on to the clasps (a)

until they click.

☞

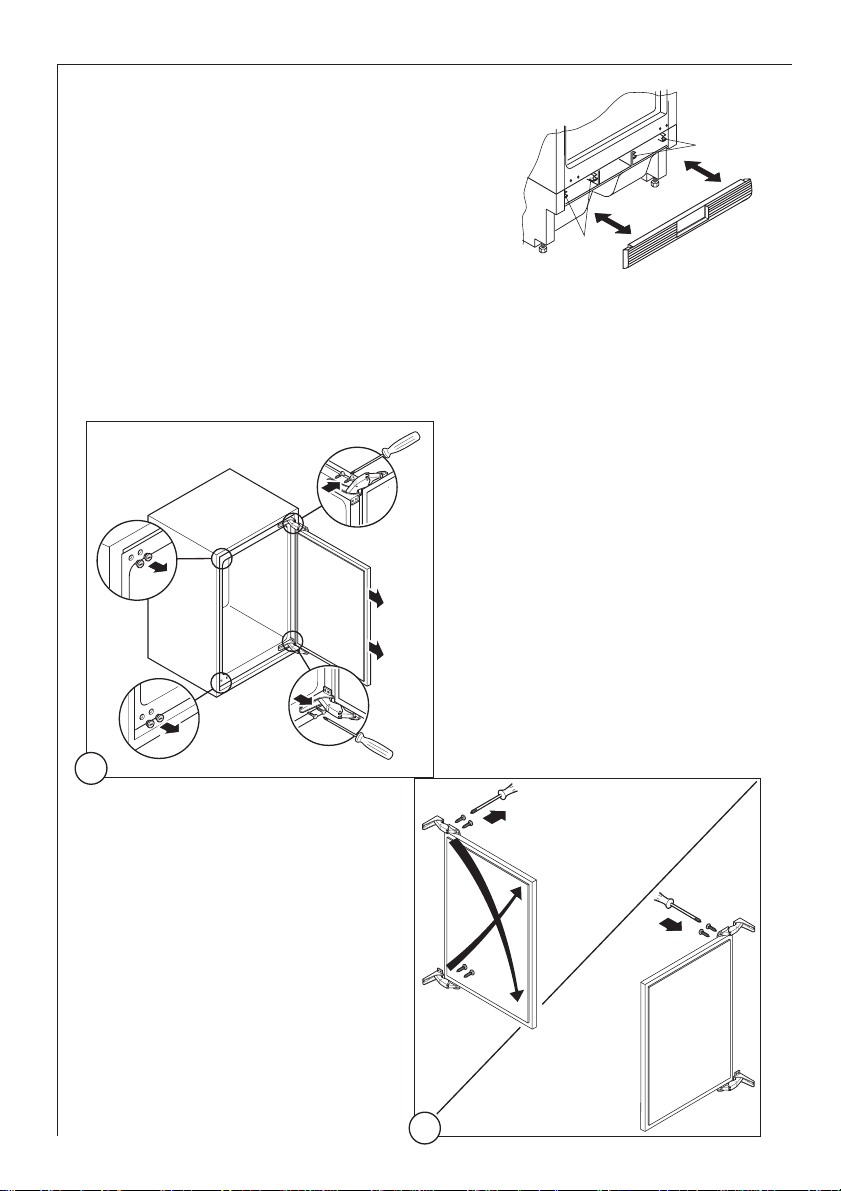

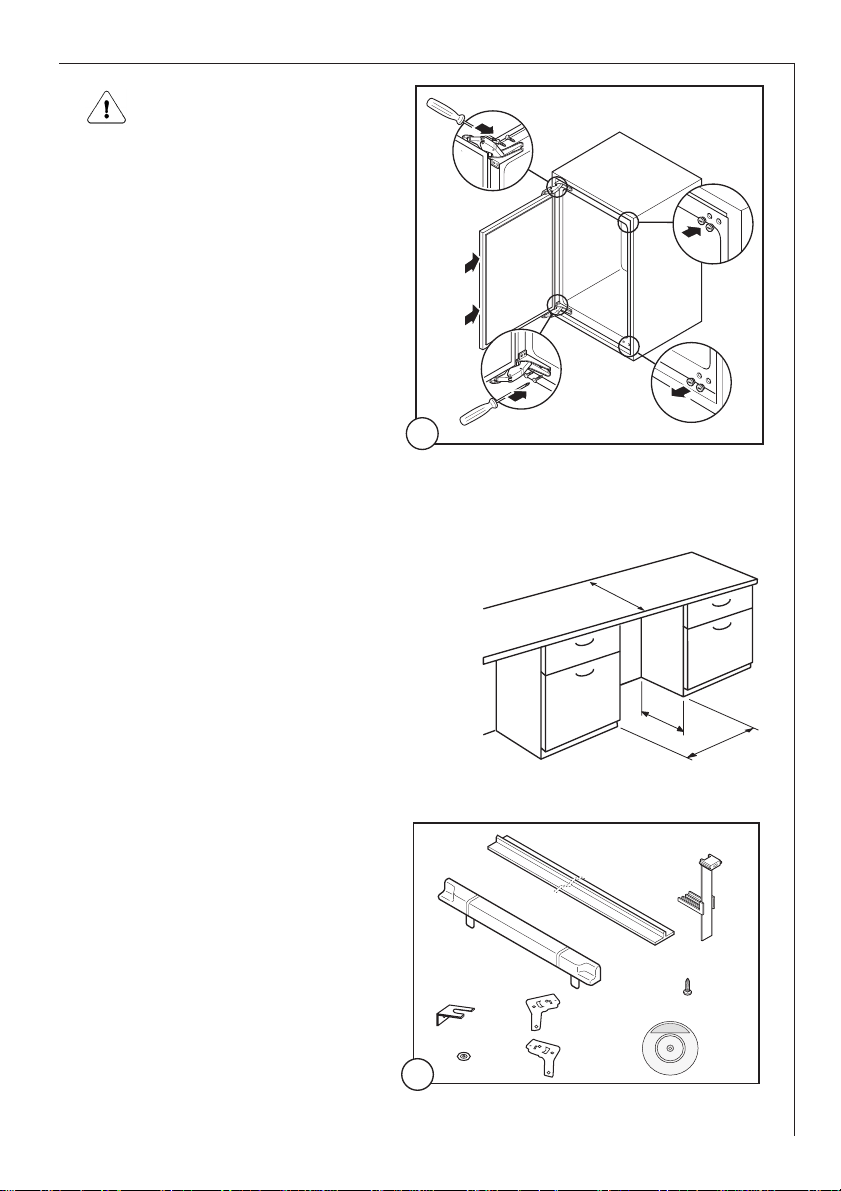

Reversing the door

The side at which the door opens can be changed from the right side

(as supplied) to the left side, if the installation site requires.

To reverse the opening direction of the door, proceed as shown in the

figures:

6

8

7

2

a

a

Page 9

9

Warning! After completion

of the door reversing operation, check that the door

gasket adheres to the cabinet. If the ambient temperature is cold (i.e. in Winter),

the gasket may not fit perfectly to the cabinet. In that

case, wait for the natural

fitting of the gasket or

accelerate this process by

heating up the part involved

with a normal hairdryer on

a low setting.

Installation kit

☞

Building the appliance in under a worktop

The dimensions of the recessed

installation area must correspond

with those indicated in the figure.

☞

10

9

3

11

13

12

600

550

min.

600

1xB

1xA

2

2

1

1

1

2xC

12

2

Page 10

10

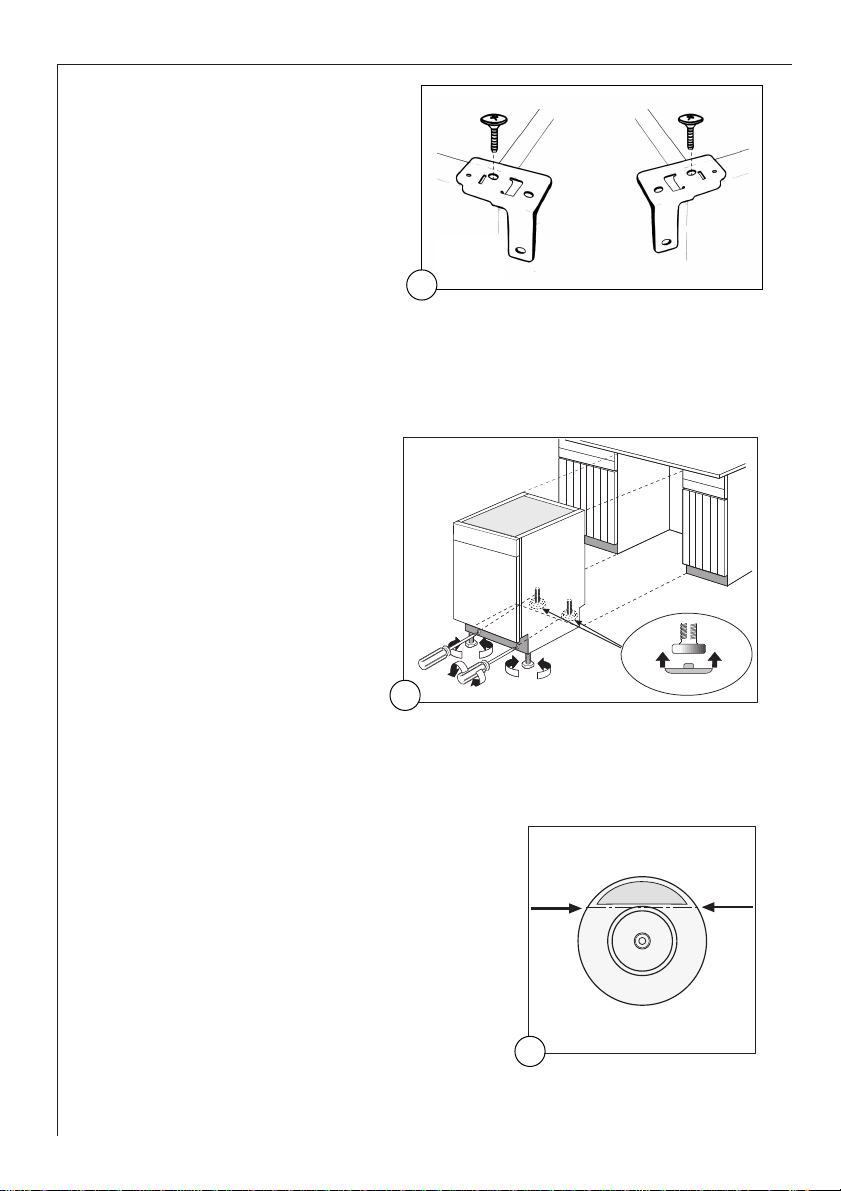

To fit these brackets remove the two screws at the top left and right

hand front corners of the cabinet.

Position the two brackets as shown in the figure and replace the two

securing screws.

☞

☞

Push the appliance into

place. The plug socket necessary for connection of

the appliance to the electricity supply should be

positioned, so that the plug

is not placed in the recess.

To adjust the height proceed as follows:

Loosen or tighten the two

front feet.

☞

☞

2

The rear feet are adjusted by turning the screw in the front kick plate

to the left or right.

☞

Two cabinet securing brackets

are supplied with the installation pack. They need to be

assembled onto the cabinet

prior to cabinet being pushed

into the Kitchen aperture.

☞

Left hand

bracket

Right hand

bracket

1/a

If necessary, pads are supplied for the

rear feet to make sliding the appliance

in and out of the recess easier. To fit the

pads, press them onto the rear feet.

If required, the dimensions of these

pads can be reduced by breaking them

where marked.

☞

2/a

596

555

max

-

Li89

+

II52

Page 11

11

N.B. The joint cover (B) is to be

assembled after having

installed the appliance in the

recess.

Push the appliance into

place and retain the cabinet with screws through

the securing brackets

into the worktop or

adjacent woodwork as

necessary.

☞

5

2

B

3

4

1

115°

Page 12

12

To mount the furniture door

proceed as shown in the figures:

☞

7

8

ab

clic

clic

c

C

C

6

a

b

10

1

2

3

4

C

Page 13

Upper part of kitchen furniture panel

Lower part of kitchen

furniture panel

9/a

275 275

max 100

11

=

=

10

9

b

a

=

=

1

2

10

1

2

3

45

°

13

Page 14

14

Refit the covering strip.

☞

12

A

13

Page 15

15

Fitting the plinth

Important!

For the efficient operation of the appliance, it is important that the

original ventilation grid is used.

• For an opening height dimension

A=820 mm and a plinth height

dimension a=100 mm, the plinth

may be fitted without adjustments.

The same applies to an opening

height dimension B=870 mm and a

plinth height dimension b=150 mm.

• For plinth heights greater than

a=100 mm, b=150 mm, a cut should

be made in the plinth, 580 mm wide,

in the centre of the appliance

position, leaving a remaining height

of a=100 mm, b=150 mm.

• Attach plinth to the kitchen units.

Important!

The plinth must be positioned at a minimum distance of 25 mm from

the door.

Please check whether, after installing your appliance and especially

after reversing the door, the door seal seals right round. A badly fitting

door seal may lead to heavy frosting and result in a higher power consumption (see also “What to do if ...”).

Power supply

A correctly installed, earthed socket is required for the electrical supply. The supply must have a fuse rating of at least 10 Amps. If the

socket is not accessible once the appliance is built in, the electrical

installation must include suitable means of isolating the appliance

from the mains (e.g. a fused spur).

Before initial start-up, refer to the appliance rating plate to ascertain

if supply voltage and current values correspond with those of the

mains at the installation location.

e.g.: AC 220 ... 240 V 50 Hz or

220 ... 240 V ~50 Hz

(i.e. 220 to 240 volts alternating current, 50 Hertz)

The rating plate is inside the appliance on the left.

☞

A = 820

B = 870

25

25 - 80

580

a = 100

b = 150

Page 16

16

The mains cable may only be changed by a qualified electrician or

competent person. If your appliance needs repairing, please contact

your local AEG Service Force Centre.

Electrical Connection

Any electrical work required to install this appliance should be carried

out by a qualified electrician or competent person.

WARNING – THIS APPLIANCE MUST BE EARTHED

The manufacturer declines any liability should these safety measures not be observed.

Before switching on, make sure the electricity supply voltage is the

same as that indicated on the appliance rating plate. The rating plate

is inside, on the left.

The appliance is supplied with a 13 amp plug fitted. In the event of

having to change the fuse in the plug supplied, a 13 amp ASTA

approved (BS 1362) fuse must be used.

Important

The wires in the mains lead are coloured in

accordance with the

following code:

Green and Yellow Earth

Blue Neutral

Brown Live

As the colours of the wires in the mains lead

of this appliance may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows:

1.The wire coloured green and yellow must be connected to the terminal marked with the letter “E” or by the earth symbol or coloured

green and yellow.

2.The wire coloured blue must be connected to the terminal marked

“N” or coloured black.

3.The wire coloured brown must be connected to the terminal marked

“L” or coloured red.

4.Upon completion there must be no cut, or stray strands of wire present and the cord clamp must be secure over the outer sheath.

Warning! A cut-off plug inserted into a 13 amp socket is a serious

safety (shock) hazard. Ensure that the cut-off plug is disposed of

safety.

GREEN & YELLOW

BLUE

13 AMP. FUSE

13 AMP

BROWN

CORD CLAMP

Page 17

17

Description of the appliance

View of the appliance

➁

➂

➃

➀

Freezer calendar

➁

Control panel

➂

Drawer (only for storage)

➃

Drawer (for storing frozen food and freezing fresh produce)

➄

Temperature display

➅

Magnet holder for door alarm

Prior to Initial Start–Up

Please clean the appliance interior and all accessories prior to initial

start-up (see section: “Cleaning and Care”).

Remove the ice pack from the appliance.

Only put the ice pack to freeze in the top drawer after the optimum

storage temperature of –18 °C has been reached.

Re-freeze thawed ice packs in the same way, e. g. after cleaning the

appliance.

☞

☞

☞

☞

➂

➃

➄

➅

➀

➀

➀

Page 18

Operating and indicator panel

Important! Only use the appliance when built-in!

1 Thermostat control knob

2 ON/OFF switch

3 Pilot light (green)

4 Warning light (red)

5 Fast freeze light (yellow)

6 Fast freeze button and used to switch off the warning tone

The appliance can be activated/deactivated by pressing the

ON/OFF

switch (2)

. When the green pilot light (3) is illuminated this shows

that the appliance is on.

A coin in needed to turn the

thermostat control knob (1). This makes

it is more difficult to change the temperature setting accidentally

(child protection).

The

green pilot light (3), which comes on when the panel is switched

on and the mains voltage is available. In this switch position, the

refrigerating unit operates automatically.

The

thermostat control knob (1) can be used for variable setting of

the storage temperature for your frozen food.

The optimum storage conditions occur at

-18°C and can be checked at the

ther-

mometer (fig.).

The fast-freeze button (6) with its yellow

pilot light (5)

. The yellow pilot light comes

on when the switch (6) has been operated. The refrigerating unit then

operates continuously.

The

red temperature warning light (4) comes on when:

– the appliance has been started up but the storage temperature has

not yet been attained;

18

123456

Page 19

19

– the minimum storage temperature is no longer being maintained

(fault);

– excessive amounts of fresh food are placed inside; or

– if the appliance door is open for too long.

Turn the thermostat control knob to the desired setting with the aid

of a coin.

The compressor starts and then runs automatically. The green pilot

light illuminates.

Important! Wait until the freezer compartment has reached a temperature of -18°C, or the red warning light has gone out, before storing

frozen food.

Warning system

The warning system comprises of an optical warning light (red) and an

acoustic warning tone. The red warning light and the warning tone

signal an alarm

- if the appliance door is left open too long;

- if the temperature in the freezer compartment is too warm.

"Open Door" warning

The warning tone sounds if the door is left open for more than 60

seconds.

You can switch off the warning tone by closing the door.

Temperature Warning

The red warning light illuminates and the warning tone sounds if the

temperature in the freezer compartment is warmer than -12°C.

An increase in the temperature in the freezer compartment may be

caused by

- frequent or extended opening of the door;

- storing large quantities of warm food;

- a high ambient temperature;

- a malfunction in the cooling system.

Switch off the warning tone by pressing the fast freeze button. The

yellow fast freeze light illuminates. The red warning light remains illuminated until the required temperature has been reached again.

After the storage temperature has been reached, press the fast freeze

button again to switch off the fast freeze function. The yellow light

goes out.

Note: when the appliance is switched on for the first time, the warning light and the warning tone signal an alarm because the necessary

storage temperature in the freezer compartment has not yet been

reached.

☞

☞

☞

☞

Page 20

Starting up and temperature regulation

Turn the thermostat control knob (1) in the direction of “1”.

The green light (3) and the red light (4) come on, the audible warning

sounds (if fitted), and the refrigeration motor starts up.

Additionally operate the fast-freeze switch (6).

The yellow pilot light (5) comes on, the audible warning switches off,

and the freezer motor runs continuously.

Only when the red light (4) has gone out should you reset the fastfreeze switch (6) the yellow light (5) goes out and the audible warning

is activated again.

The temperature regulator (1) can be used to set the required storage

temperature, -18°C or colder.

Setting “1” means:

highest, warmest internal temperature

Setting “4” means:

lowest, coldest internal temperature

Recommended regulator setting:

1.5 to 2.

Important: Regularly check on the red temperature pilot light (4) and

the thermometer that the required storage temperature is being maintained.

Ice pack

There is an ice pack in one drawer of the freezer.

Refer to the section “Prior to Initial Start–Up” concerning freezing of

the ice pack.

In the event of a power failure or malfunction, the ice pack will

lengthen the amount of time it takes for the frozen food to defrost by

several hours.

The ice pack can only fulfil this task if it is placed in the uppermost

drawer, at the front, above the frozen food.

You can use the ice pack for cooling cold bags.

Freezing and storing frozen food

You can use your freezer for freezing fresh food yourself.

Important!

• The temperature in the freezer compartment must be –18°C or

colder before freezing food.

☞

☞

☞

20

Page 21

21

• Please observe the freezing capacity given on the rating plate. The

freezing capacity is the maximum quantity of fresh food that can be

frozen within a period of 24 hours. If you wish to freeze food several days in a row, please observe a maximum capacity of only 2/3 to

3/4 of that on the rating plate. The quality of the food is best preserved when it is frozen right through to the core as quickly as possible.

• Allow warm food to cool down before freezing. The warmth will

cause increased ice formation and increase the power consumption.

• Please note the maximum storage times specified by the manufacturer.

• Thawed foods which have not been processed further (cooked into

meals) may not under any circumstances be frozen a second time.

• Containers with flammable gases or liquids can leak at low temperatures. There is a risk of an explosion! Do not store any containers

with flammable materials such as, for example, spray cans, fire

extinguisher refill cartridges etc in the refrigerator/freezer.

• Bottles and cans must not be placed in the freezer. They can burst

when the contents freeze, high carbonate content drinks can even

explode! Never store lemonade, juices, beer, wine, sparkling wine

etc. in the freezer.

Press the fast freeze button for the freezing of fresh food. The yellow

light illuminates.

To utilise the maximum rated freezing capacity, switch on the fast

freeze switch 24 hours before freezing is due to start (the yellow light

illuminates). For smaller amounts the fast freeze switch should be

switched on 4 - 6 hours in advance.

All foods must be packed air tight prior to freezing, so that they do

not dry out or lose their flavour, and so that no flavour contamination of other frozen goods occurs.

Caution! Do not touch frozen food with wet hands. Your hands could

stick to the food and cause skin abrasions.

Place the packed food in the drawers. Place food to be frozen in the

appliance´s two top drawers (4) equipped with its own refrigerated

shelves. Unfrozen food must not touch items already frozen, otherwise

the frozen food could begin to defrost. Freezer drawers (3) should only

be used for storage of frozen food.

Place frozen foods in the drawers sorted by type, as far as possible.

Index tabs are supplied for placing on drawers. To mark the contents

of the individual drawers, press the index tab over the corresponding

symbol (see "Frozen Food Symbols/Freezer Calendar" section). This will

give you a better overview of the contents, avoid extended door

opening and therefore save electricity.

☞

☞

☞

Page 22

22

Once the required storage temperate has been reached, press the fast

freeze button again. The yellow light goes out.

Tips:

• The following are suited for the packaging of frozen goods:

– freezer bags and polyethylene wraps;

– special containers for frozen goods;

– extra–thick aluminium foil.

• The following are suitable for sealing bags and wrap: plastic clips,

rubber bands or tape.

• Smooth the air out of the bag before sealing; air makes it easier for

the frozen food to dry out.

• Make flat packages, because these freeze more quickly.

• Do not fill containers for frozen goods to the brim with liquid or

paste–like goods, because liquids expand during freezing.

Storage Goods Symbols/Freezing Calendar

• The symbols on the drawers show

different types of frozen goods.

• The numbers indicate storage times

in months for the appropriate types

of frozen goods. Whether the upper

or lower value of the indicated storage time is valid depends on the quality of the foods and pre-treating before freezing. The lower value applies to foods with high fat

content.

• By attaching the included indextabs to the drawers, they can be

marked according to which type of

foods the individual compartments

contain.

Preparation of Ice Cubes

Fill the ice cube tray 3/4 full with cold water, place it in the freezer

compartment and leave to freeze.

To loosen the frozen cubes, either bend the ice cube tray or hold it

under running water for a few seconds.

Important! Never try to free an ice tray that is frozen to the freezer

compartment using pointed or sharp edged objects. Use the ice scraper

supplied.

☞

☞

☞

Page 23

Defrosting

During use and when the door is opened, moisture is deposited as

frost inside the appliance, particularly on the evaporator melts. This

frost must be removed from time to time using the soft plastic scraper

supplied. Under no circumstances use hard or pointed objects for this

purpose.

The freezer should always be defrosted when the layer of frost has

reached a thickness of approx. 4 millimetres. Defrost should be carried

out once a year regardless of the amount of frost that has built up. A

good time for defrosting is when the appliance is empty or contains

only little food.

Each temperature rise reduces the keeping qualities of your frozen

food. Around 12 hours before defrosting your freezer, switch over to

fast freeze to build up a low temperature reserve in the frozen food.

Warning!

• Do not use electrical heating appliances or any other mechanical or

artificial devices to speed up the defrosting process.

• Do not use defrosting sprays, they can be hazardous to your health

and/or contain substances that damage plastics.

Caution! Do not touch frozen food with wet hands. Your hands could

stick to the food and can cause skin abrasions.

Remove frozen food, wrap it in several layers of newspaper and store

it, covered, in a cool place.

Switch off the appliance and unplug it, or pull the fuse or switch off

the circuit breaker.

Remove all drawers except the bottom one. The bottom drawer serves

as a practical container to collect the water from the thawing ice.

Tip: To speed up the defrosting process, place a pan with warm water

in the appliance and close the door. Remove pieces of ice that have

fallen before they completely defrost.

Remove the bottom drawer and dry the interior of the bottom compartment thoroughly.

After defrosting, thoroughly clean the freezer compartment and interior fittings ( see "Cleaning and Care" section).

☞

☞

☞

☞

☞

☞

23

Page 24

Switching off the appliance

To switch off the appliance, turn the thermostat control knob to position "0".

If the appliance is not going to be used for an extended period:

Remove all deep-frozen packages as well as ice-trays.

Switch off the appliance by turning the temperature regulator to

position "0".

Remove the mains plug or switch off or disconnect from the

electricity supply.

Defrost freezer and clean thoroughly (see section: “Defrosting and

Cleaning”).

Leave the door open to avoid the build up of odours.

Cleaning and Care

For hygienic reasons the appliance interior, including interior accessories, should be cleaned regularly.

Warning!

• The appliance must not be connected to the mains during cleaning.

Danger of electrical shock! Before cleaning switch the appliance off

and remove the plug from the mains, or switch off or turn out the

circuit breaker or fuse.

• Never clean the appliance with a steam cleaner. Moisture could

accumulate in electrical components and there is a danger of an

electric shock. Hot vapours can lead to the damage of plastic parts.

• The appliance must be dry before it is placed back into service.

Important!

• Ethereal oils and organic solvents can attack plastic parts, e.g.

– lemon juice or the juice from orange peel;

– butyric acid;

– cleansers which contain acetic acid.

Do not allow such substances to come into contact with appliance

parts.

• Do not use any abrasive cleansers.

Remove frozen food and wrap it in several layers of newspaper. Store

it in a cool place, well covered.

Defrost the appliance prior to cleaning (see “Defrosting” section).

☞

☞

☞

☞

☞

☞

☞

☞

24

Page 25

Switch off the appliance and unplug it.

Clean the appliance and the interior accessories with a cloth and

lukewarm water. Commercially available dish washing detergents may

also be used.

After cleaning wipe with fresh water and rub dry.

After everything is dry, switch to fast freeze. After running the appli-

ance for two or three hours, it is ready again for storing frozen food.

An accumulation of dust will affect

the performance of the appliance and

cause excessive electricity consumption. The structure of the appliance

permits you to clean the rear zone

close to the wall, using a vacuum

cleaner.

☞

Remove the plinth (1), then the ventilation grid (2);

☞

Carefully pull the air deflector out (3).

Magnetic door seal

After opening and closing the door of your freezer you will not be

able to open the door again immediately. This is because a vacuum

will have developed inside, keeping the door closed until the pressures

inside and outside the door have equalised. After a few minutes you

can easily reopen the door.

☞

☞

☞

☞

25

3

21

Page 26

26

Energy Saving Tips

• Do not install the appliance near boilers, radiators or other sources

of heat. High ambient temperatures cause longer, more frequent

operation of the compressor.

• Ensure sufficient air circulation and exhaust at the appliance base

and at the back wall of the appliance. Never cover air vent

openings.

• Do not place warm foods into the appliance. Allow warm foods to

cool first.

• Do not leave the door open any longer than necessary.

• Do not set temperature any colder than necessary.

• Check the storage temperature in the freezer on the thermometer.

• Put frozen food in the fridge to defrost. The cold in the frozen food

will then be used to cool the fridge.

What to do if ...

Correcting Malfunctions

Spare parts:

The following spare parts can be ordered from the Service Force

Centre. You can fit these yourself without any special skill or training,

e.g.:

– freezer drawers

A malfunction may be caused by only a minor fault that you can rec-

tify yourself using the following instructions.

Please check whether the pilot lights come on, the refrigerating unit

operates, and the internal temperature is being maintained. Do not

perform any other work on the appliance if the following information

does not provide assistance in your specific case.

Warning! Repairs to refrigerators/freezers may only be performed by

competent service engineers. Improper repairs can give rise to significant hazards for the user. If your appliance needs repairing, please

contact your specialist dealer or your Local Service Force Centre.

Page 27

27

Symptoms

Appliance does not work,

no pilot light is

illuminated.

Possible Cause

Appliance is not switched

on.

Mains plug is not plugged

in or is loose.

Fuse has blown or is

defective

Socket is defective.

Mains malfunctions are to

be corrected by an

electrician.

Remedy

Switch on the appliance.

Insert mains plug.

Check fuse, replace if

necessary.

The compressor runs

continuously

Green light does not light

up, yellow light lights up

when the fast freeze function is activated.

If the freezer system has stopped working and the freezer is full, the

reserve in the cold accumulator and in the deep frozen food itself will

give the food a hold over time of about 29 hours. If the freezer is

without a cold accumulator the hold over time will be reduced to

about 20 hours.

Green light faulty.

Please inform your local

Service Force Centre.

Yellow light does not light

up, when the fast freeze

function is activated,

appliance is on.

Yellow light faulty.

Please inform your local

Service Force Centre.

Temperature is set too

cold.

Turn the thermostat control knob to a warmer setting temporarily.

Heavy build up of frost,

possibly also on the door

seal.

Door seal is not airtight

(possibly after reversing

the door).

Carefully warm the leaking

sections of the door seal

with a hair dryer (on a

cool setting). At the same

time shape the warmed

door seal by hand such

that it sits correctly.

Page 28

28

Symptoms Possible Cause Remedy

The compressor starts after

a period of time.

This is normal, no error has

occurred.

The compressor does not

start immediately after

changing the temperature

setting.

Important: regularly check on the red temperature pilot light and

thermometer to establish that the storage temperature is being maintained.

The freezer temperature is

not sufficient, red light

illuminates, temperature

alarm signal sounds.

Temperature is not

properly adjusted.

A large quantity of warm

food placed in the appliance within the last 24

hours.

Please look in the “Initial

Start Up” section.

Press the fast freeze

switch.

Do not leave the door

open any longer than necessary. Press the fast freeze

switch.

Door was open for an

extended period.

The appliance is near a

heat source.

Please look in the

“Installation Location”

section.

Page 29

Service & Spare Parts

In the event of your appliance requiring service, or if you wish to purchase spare parts, contact your local AEG Service Force Centre by telephoning:

08705 929 929

Your call will be automatically routed to the Service Centre covering

your post code area.

In guarantee customers should ensure that the above checks have been

made as the engineer will make a charge if the fault is not a mechanical or electrical breakdown.

Please note that proof of purchase is required for in-guarantee service

calls.

Help us to Help You

Please determine your type of enquiry before writing or telephoning.

When you contact us we need to know:

1. Your name, address and post code.

2. Your telephone number.

3. Clear and concise details of the fault.

4. The model number and serial number (see rating plate).

5. Date of purchase.

Customer Care

For general enquiries concerning your AEG appliance and for further

information on AEG products, please contact our Customer Care

Department at the address below or visit our website at

www

.aeghome.co.uk

Customer Care Department

AEG Domestic Appliance Limited

55-77 High Street

Slough

Berkshire

SL1 1DZ

Tel: 08705 350350

(*)

(*)

calls to this number may be recorded for training purposes.

29

Page 30

30

Noises during Operation

The following noises are characteristic of refrigeration appliances:

•

Clicks Whenever the compressor switches on or off, a click can

be heard.

•

Humming As soon as the compressor is in operation, you can hear

it humming.

•

Bubbling/ When refrigerant flows into thin tubes, you can hear

Splashing bubbling or splashing noises. Even after the compressor

has been switched off, this noise can be heard for a

short time.

Regulations, Standards, Guidelines

This appliance was designed for household use and was manufactured

in accordance with the appropriate standards. The necessary measures

in accordance with appliance safety legislation regulations (GSG), accident prevention regulations for refrigeration appliances (VBG 20) and

the regulations of the German Society of Electrical Engineers (VDE)

were observed in the manufacture of this appliance.

The refrigerant circuit has been checked for leaks.

This appliance is in accordance with the following EU

guidelines:

– 73/23/EWG dated 19 February 1973 - low voltage guidelines.

– 89/336/EWG dated 3 May 1989

(including guideline change notice 92/31/EWG) - EMV guideline

Page 31

31

Technical terminology

• Refrigerant

• Refrigerant

Circuit

• Evaporator

• Compressor

• Condenser

Liquids that can be used to a generate a cooling

effect are known as refrigerants. They have a relatively low boiling-point, indeed so low, that the

warmth from the food stored in the fridge or freezer

can cause the refrigerant to boil and vaporise.

Closed circulation system that contains the refrigerant. The refrigerant circuit comprises primarily of an

evaporator, a compressor, a condenser and pipe

work.

The refrigerant is evaporated in the evaporator.

Similar to all other liquids, refrigerant requires heat

to evaporate. This heat is removed from the interior

of the appliance, as a result the interior is cooled.

The evaporator is therefore located inside the appliance or placed in foam immediately behind the

inner wall and thus not visible.

The compressor looks like a small drum. It is driven

by a built-in electric motor and is mounted on the

base of the appliance at the rear. The task of the

compressor is to draw in vaporised refrigerant from

the evaporator, to compress it, and to pass it on to

the condenser.

The condenser normally has the form of a grid. The

refrigerant compressed in the compressor is liquefied

in the condenser. During this process, heat is

released to the surrounding air at the surface of the

condenser. The condenser is mounted on the base of

the appliance.

Page 32

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

http://www.aeg.hausgeraete.de

© Copyright by AEG

03-0301

2222 740-24

Page 33

documentation manual, user maintenance, brochure, user reference, pdf manual

This file has been downloaded from:

User Manual and User Guide for many equipments like mobile phones, photo cameras, monther board, monitors, software, tv, dvd, and othes..

Manual users, user manuals, user guide manual, owners manual, instruction manual, manual owner, manual owner's, manual guide,

manual operation, operating manual, user's manual, operating instructions, manual operators, manual operator, manual product,

Loading...

Loading...