AEG 860 D User Manual

860 D/8609 D

Einbau-Kamin-Dunstabzugshauben

Build-In Chimney Fume Extractor

Flood

Flottes aspirantes encastrables avec

évacuation de l’air par la cheminée

Inbouwafzuigkap voor schoorsteen

Inbyggnadsfiàktar for anslutning till

skorsten

Flormirakenteiset liesituulettimet

Montage- und Gebrauchsanweisung

Instructions for Installation and Use

Instructions de montage et mode

d’emploi

Montage- en gebruiksaanwijzing

Montering och anvandning

Asennus- ja käyttöohje

Contents

Safety instructions Page

For the electrical installer 28

For the kitchen furniture installer 28—29

Before installing

General 30

Appliance description 30

Technical data:

— Dimensions 30

— Electrical connection values 31

— Fan outputs 31

Air outlet-exhaust air 31

Accessohes/instaliation materials 32

Preparing to install

— Preparing forexhaust air operation 32

— Preparing the wall box (exhaust air operation) 33

— Position of exhaust air opening 33

— Special accessories Exhaust air hoses 34

— Preparing for return air operation 34

— Preparing forexhaust air operation 35

installation

— Wall mounting 36/37

— Additional installation work for return air operation 38

Safety instructions

For the user 40

Appliance description/operation 41 /42

— Instructions on pre- and after-running of fume extractor

hoods 43

— instructions on metal fat filter 43

— Instructions on active carbon filter 43

Maintenance and care

— Changing the metal fat filter (cleaning)

— Changing the active carbon filter

(during return air operation only)

— Changing the fluorescent lamp/starter

Cleaning

— General cleaning instructions

Special accessories

Customer service

— E- and F-No. indications in case of faults

44/45

148

44

46

47

48

49

27

Safety instructions

For the

electrical

installer

For the kitchen

furniture

installer

28

Arrangement of the protective contact plug socket inside the

chimney cover plate (Fig. EO/2) confers two advantages:

1. The plug socket is not visible.

2. You can easily de-energize the appliance where necessary

by unplugging it.

For the necessary fixed connection, the fume extractor hood

may be connected only by an electrical installer registered with

the electricity board covering your area. An isolating device is to

be provided on the fixed wiring side.

Switches with a contact opening of more than 3 mm also apply

as isolating devices. These include line protection switches,

fuses, and contactors (VDE 0730, s. 7, Part 1 ).

Connection

220 V~ via fixed supply lead with protective contact plug (Eu

ropa version).

240 V~ via fixed supply lead (UK).

(Fixed connection to be made only by an approved electrical

installer)

This appliance complies with the radio interference suppression

requirements of EC Directives 76/889 EC and 82/499 EC.

The exhaust air may not be introduced into a smoke flue or

exhaust gas chimney.

Introduction of the exhaust air into a shaft used for ventilation

of the installation spaces of firerooms is not permitted.

If the exhaust air is introduced into a non-operational smoke

flue or exhaust gas chimney, it is advisable to seek the con

sent of the competent chimney-sweep.

The official exhaust air guidance regulations are basically to

be complied with.

During operation as an exhaust air appliance, an adequate

supply air opening of approximately the same size as the ex

haust air opening is to be ensured.

According to the Provincial Building Regulations, the joint op

eration of fume extractor hoods and chimney-linked fire

places, such as coal- or oil-fired ovens and gas heaters, in the

same space is subject to specific restrictions.

In such spaces, the Fireplace Regulations only allow an under

pressure of max. 0.04 mbar.

The safe joint operation of chimney-linked appliances and

fume extractor hoods is only guaranteed if space and/or

dwelling (space/air interaction) are externally ventilated by a

suitable supply air opening of around 500—600 cm2 and an

underpressure thereby avoided when the fume extractor hood

is running.

In doubtful cases, please seek the advice and consent of the

competent area chimney-sweep or the local building auth

orities.

Since, in spaces without fireplace, the rule is; “Supply air

opening as large as exhaust air opening”, the efficiency of the

exhaust air device may be impaired by the greater opening of

500-600 cm^.

Operation of the hood as a return air hood in such circumstan

ces is safe and is not subject to the regulations noted above.

Operation of the fume extractor hood in return air mode is

optimum only when the following are ensured:

— short, straight exhaust air runs

— as few pipe bends as possible

— running of pipes in flat arcs, not in acute angles

— as large as possible pipe diameters (basically min. 120 mm

dia. for two-motor hoods).

Faiiure to observe these principles is inevitably associated

with power losses and increased operating noise.

During installation of the fume extractor hood, the following

minimum distances from the upper edge of the hob to the

lower edge of the fume extractor hood must be complied with:

For the kitchen

furniture

installer

Electric cookers

Gas cookers

Coal- and oil-fired cookers

650 mm

650 mm

min. 700 mm

29

General

The fume extractor hood is supplied as an exhaust air appliance

and may be used as a return air appliance through application

of an active carbon filtre (special accessory).

For this purpose, you need the AEG Original Active Carbon Filter (see special accessories).

Appliance

description

Technical

data

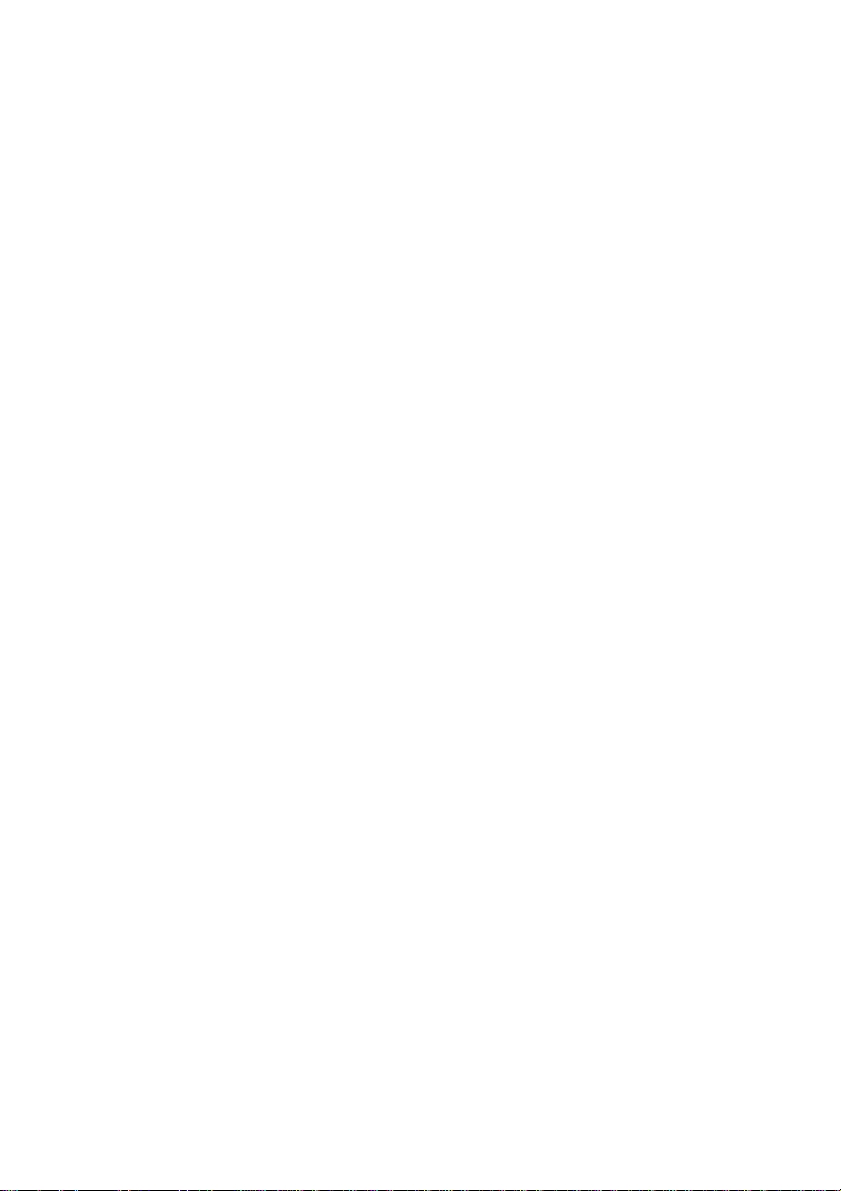

A = Light switch

B = Blower switch (On/Off)

C = Blower switch settings

D = Metal filter grille (fat filter)

The fume extractor hood is switched on and controlled via the

different controls

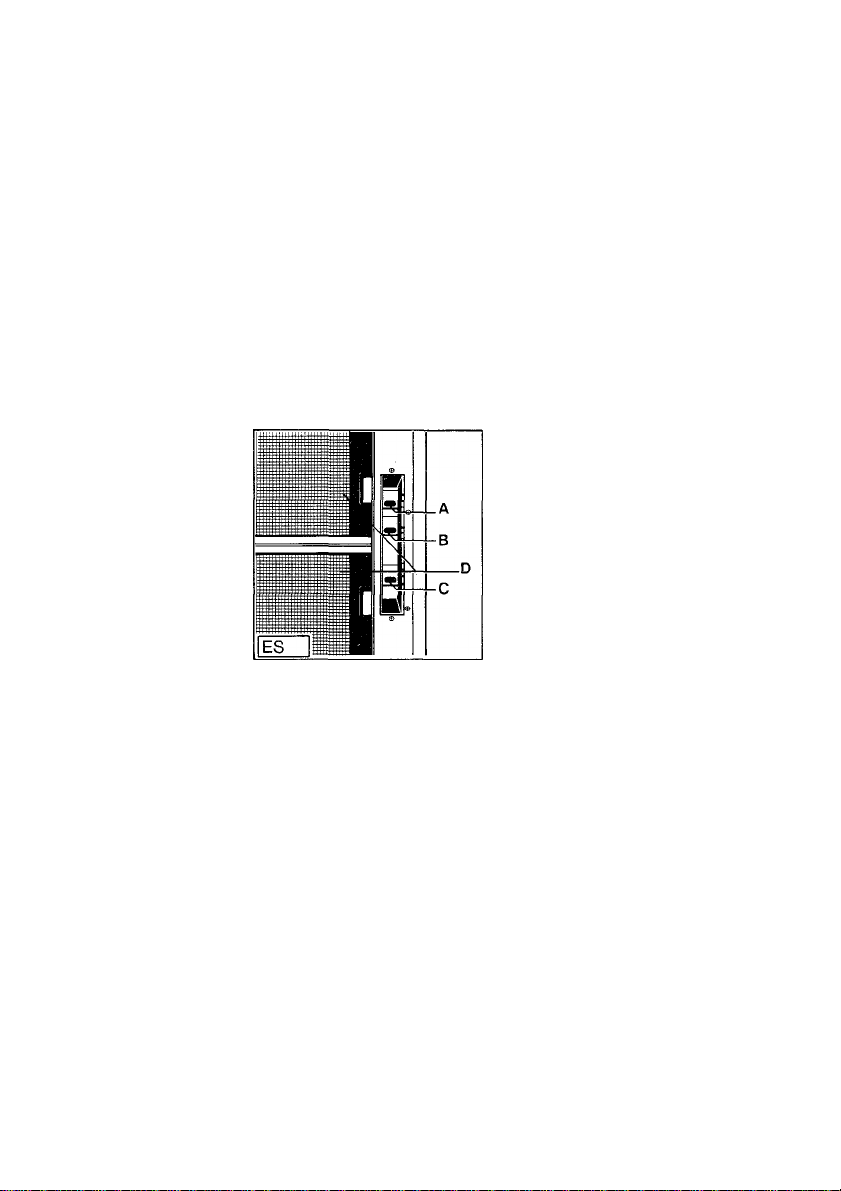

Dimensions:

860 D

Height Width

255 599

Depth

490

(in mm)

30

Weight:

Net:

8609 D

Height

255

Weight:

Net:

22 kg

Width

899

24.5 kg

Depth

497

(in mm)

Connection value:

860 D 8609 D

Total connected load: 179 W

Fan motor:

Lighting:

2x 82 W

1 X 15 W

(fluorescent lamp)

180 W

2x 82 W

1 X 16 W

(fl. lamp)

Fan outputs (settings) to DIN 44 971 860/8609 D Setting 1 Setting 2

Exhaust air: 200 mVh 320 mVh 400 nnVh 520 m^/h

Return air: 140 m^/h 240 m^/h 290 m^/h 360 m^/h

Setting 3 Setting 4

Exhaust air system 125 mm dia.

Air outlet arranged centrally above

Pipe connection of 125 mm dia. for exhaust air hoses of 125 mm

dia.

Air outlet

Draufsicht = Plan

31

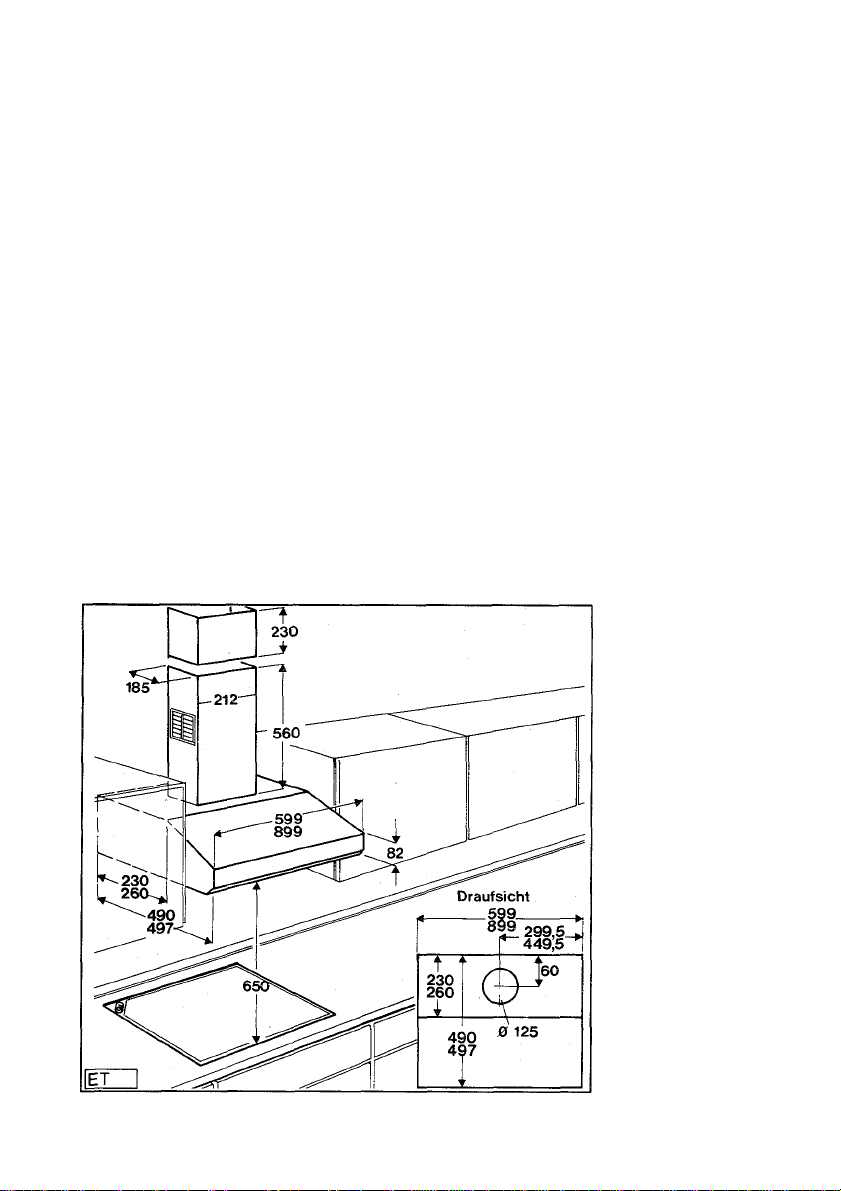

Accessories/installation materials

1 wall rail (for mounting of fume extractor hood)

4 wall plugs for 8 mm, 40 mm long wood screws (for mounting

of chimney retaining plate on wall and wall rail)

4 button-head wood screws, 5 x 40 to DIN 7996

2 wall plugs for 5 mm, 30 mm long wood screws (for mounting

of clamping piece)

2 button-head wood screws, 6 x 30 to DIN 85

1 drilling template for appliance mounting

1 125 mm dia., 800 mm long hose

2 125 mm dia. hose clips for above

1 chimney equalizer (230 mm high)

1 chimney cover plate with air outlet grille for return air

1 chimney retaining plate

1 guide piece (T-piece) for return air operation

4 button-head 2.9 mm x 6.5 mm long sheet metal screws (for

mounting of chimney retaining plate with chimney cover

plate)

3 5x 60 mm screws to DIN 7996 for mounting of wall rail

3 8 x 60 mm wall plugs for wall rail

Preparing for The fume extractor hood is factory-supplied for commissioning

exhaust air in upward exhaust air mode,

operation Prior to installation of the fume extractor hood, a hole should

be arranged in the outer wall for the wall box (return/supply

air) apart from mounting drillholes.

32

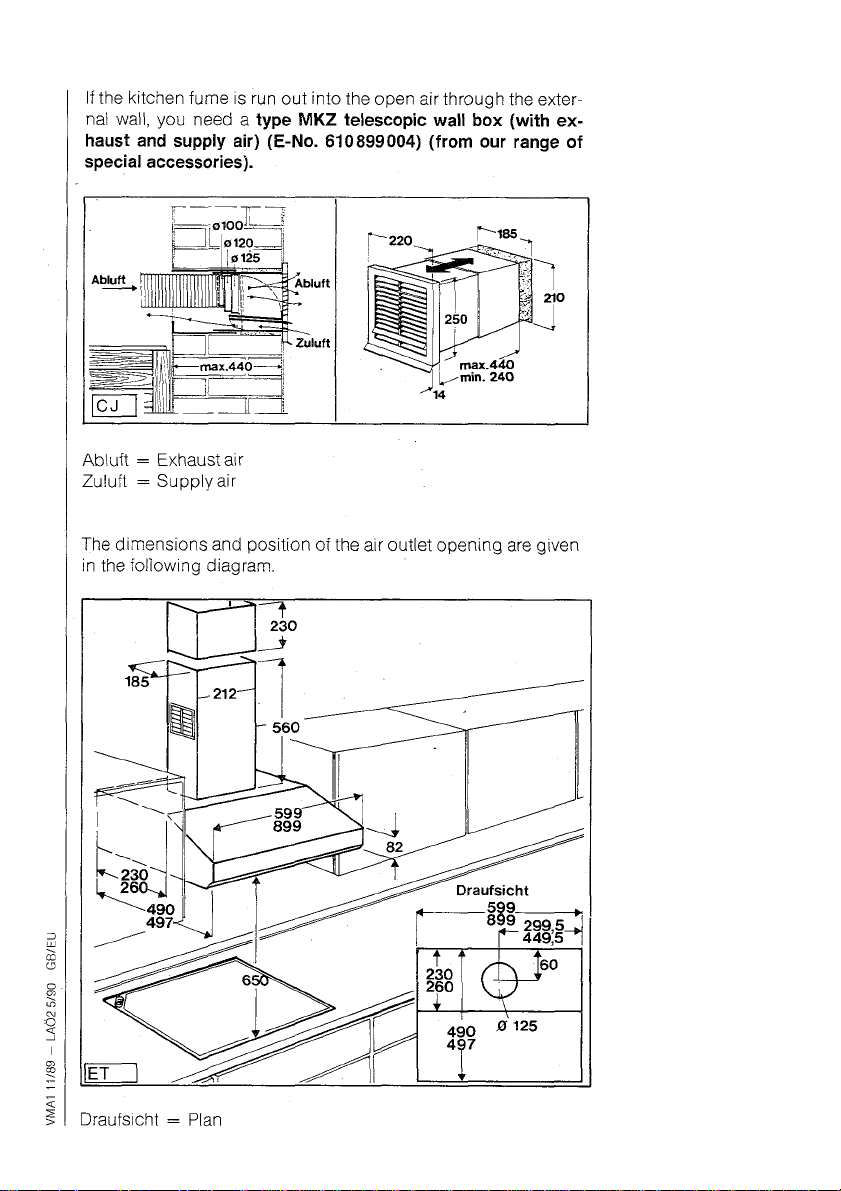

Preparing the

wall box

(exhaust air

operation)

Position of

exhaust air

opening

33

Loading...

Loading...