Page 1

SERVICE MANUAL

HOBS

© Electrolux Distriparts

Muggenhofer Straße 135

D-90429 Nürnberg

Germany

Fax +49 (0)911 323 1022

DGS-TDS-N

Ausgabe: 04.08

Publ.-Nr.

599 519 523

685

EN

Repair-Instruction

for induction hobs

DGS-TDS-N

21.04.08

Page 2

2 599 519 523 EN

1 General Information

These instructions serve the repairing of autarkic cooking hobs and cooking hobs in combination with

an oven with 3 or 4 inductions cooking zones respectively of the type E.G.O.. Also includes hobs with

2 induction zones (Domino, Mixed, Mixed gas) and the Frontline appliance series.

Please search for the corresponding alarm

symptom and then go through the alarm remedy measures from top to bottom.

Information concerning the replacement of parts is to be found in the corresponding replacement

instructions or are included with the spare parts.

All work is only to be carried out on the induction modules and the heating elements are only to be

carried out after they have been disconnected.

1.1 Leak current

A leak current of 5mA is normal and is therefore much higher than with other appliances.

1.2 Standby

The Standby power consumption amounts to < 1W (Induction plus user interface in the autonomous,

exception Frontline up to 2W).

The µprocessor for the measuring of the coil temperature is deactivated in standby, i.e. should the

cooking hob be heated up to hot pan being on the zone, no heating display "H“ is displayed when

switched off.

In this condition, the ventilator is also not switched on by external heating.

DGS-TDS

21.04.08

Page 3

3 599 519 523 EN

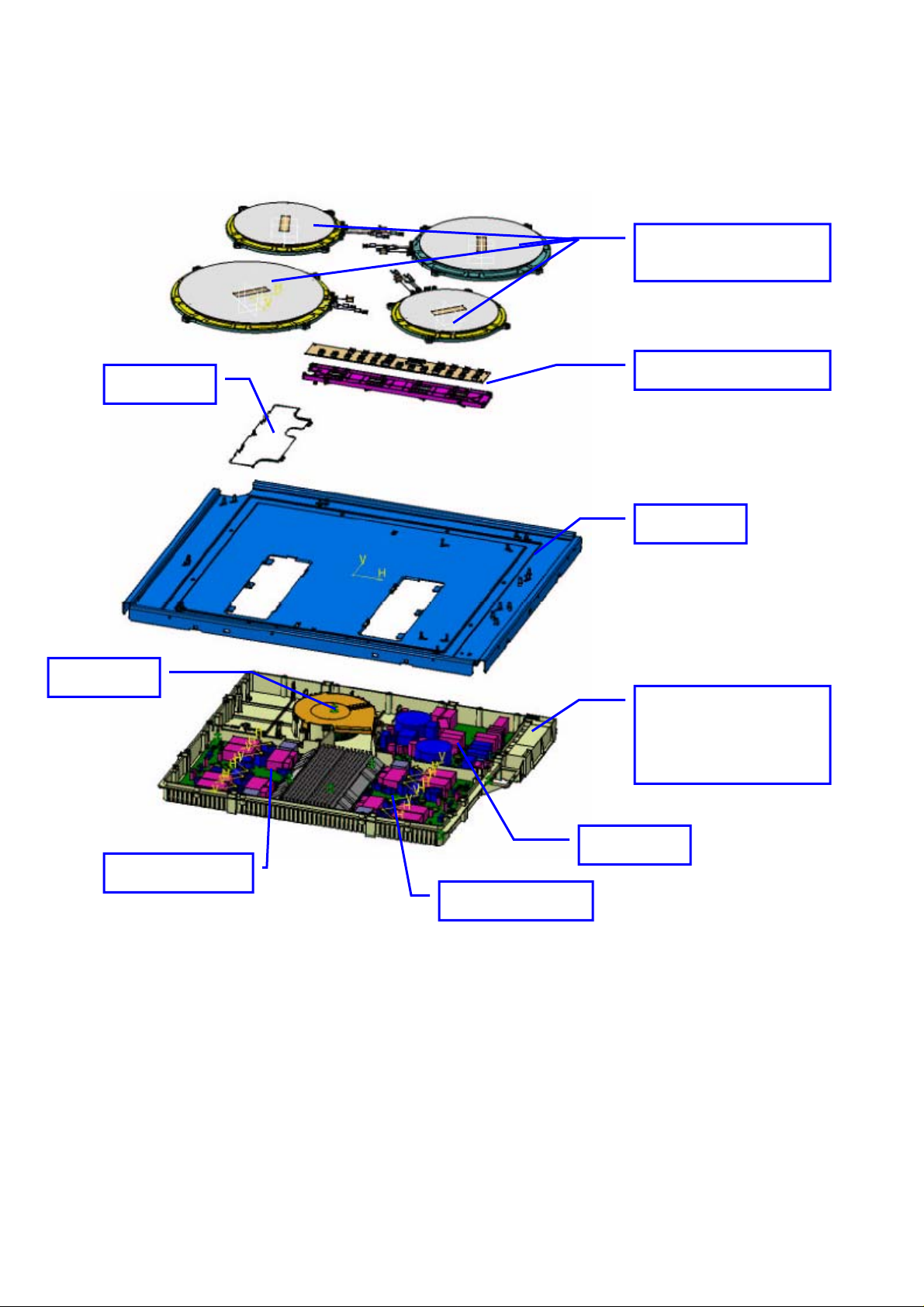

1.3 Block Diagram/Hob elements

Coils incl. Temperature

sensors.

Cover plate

Cooling fan

Touch control w. carrier

Coil carrier

Induction module w.

plastic housing incl.

mains terminal

Power mod. Left

DGS-TDS

21.04.08

Filter pcb

PowerMod. Right

Page 4

4 599 519 523 EN

2 Alarm Symptoms

2.1 Appliance not functioning at all, cannot be switched on

References e.g. (1) refer to the illustrations in Chapter 2.8

Alarm Symptom Cooking

Hob

Display

House fuse triggered None Incorrect connection at

Final induction phase

Cooking field cannot

be switched on.

Normally no "pips"

approx. 4 sec. after

mains voltage is

applied

respectively no quick

flashing up of the

display in the cooking

zone with not selfsufficient cooking

zones or front line

appliances.

No 5VDC betw. Pin 1 +

Connector of the cable

Touch control/display

Every 5-10 sec "beep"

of touch control

Only Frontline

appliances: cooking

zone can not be

activated. Display fully

on for more than 5 sec.

None Electronic system no

No mains voltage or

None N not connected to

All

indications

ON

Possible Alarm

Cause

the power connection

terminal

defect.

longer reacts

incorrect connection

(1 phase missing ->no

control voltage; N not

connected to terminal 4

and 5 not connected)

3 of the Bus for the

Touch Control

to the Touch Control

Display not inserted.

Fuse strip conductor burnt

out and/or final induction

phase defect

defect.

terminal 4 or 5.

Flat band cable

between user interface

and glass (touch

keyboard) not plugged

correctly.

.

/

Alarm Remedying

(1) Test the pin assignment and

230VAC between N and the phases on

the supply line.

See chapter 3 Testing Power Component

Disconnect the appliance from the mains

using the house fuse, reactivate after

approx. 10 sec..

(1) Test the pin assignment and

230VAC between 4 N and the 2 phases

on supply line terminals 1 and 2.

Both of the "N“s should be connected to

terminals 4 + 5, if appr. jumper.

(2) Test 1+3 5VDC on the underside of

the cooking field

(corresponds with the external lines of

the bus between filter and Touch

Control), if not applied, replace the

Filterboard.

Caution: this is difficult to test from

underneath using normal test probes!

(3) Test connector at the filter and Touch

Control.

Reapply the mains voltage.

See chapter 3 "Check power section'"

If 5VDC exist and power component already

replaced: replace

that the Touch Control is applied to the

glass

.

(1) Test the pin assignment and

230VAC between 4 N and the 2 phases

on supply line terminals 1 and 2.

Both of the "N“s should be connected to

terminals 4 + 5, if appr. jumper.

Check line for seat and correct position

(contact direction), see capter

"References Frontline"

Touch Control, ensure

DGS-TDS

21.04.08

Page 5

5 599 519 523 EN

2.2 Individual cooking zones do not work (partially) or work incorrectly or

cannot be used

Alarm Symptom Cooking

Hob

Possible Alarm

Cause

Alarm Remedying

Display

Pan does not heat

up.

Flashing

Coil not correctly

Distance between coil

Display "F" with 2

hobs with all pots

(also 1 hob with 3

hob models)

Should the above not succeed, replace the

No power on all hobs Normal

Individual buttons

cannot be used or

cannot always be

used.

Cooking hob power

too low or not

provided for a longer

duration.

Unsuitable pots

Induction coil is not

Fan does not start. 1) When setting a cooking phase >0, the

"H" in display when

cooking hob and

oven cold and

switched off.

Normal

cooking

phase

"F“

Flashing

"F“

cooking

phase

Touch Control defect. 1) See Chapter 5. Touch Control Autarkic

Normal

cooking

phase

"H“ Temperature sensor

Pan in the border

area of the pan

detection and only

works with low power

Pan not detected. Check whether the pots or pans are

connected.

and glass ceramic too

large.

1 phase missing ; only

possible with

induction SW.Ver.

0.50.

Demo mode

activated.

Incorrectly installed,

exhaust not possible

to the front.

(bottom bent)

applied to the glass

ceramic

defect.

Use different pot or this pot on a smaller

hob. See Chapter 4 Pot Detection

Information

suitable for induction. See 4 Pot Detection

Information

Check whether the coil lines are connected

and the torque has been adhered to.

Check whether the coil is applied to the

glass ceramic and whether the glass was

pushed was pushed down when screwing

in position.

(1) Test the pin assignment and

230VAC between 4 N and the 2 phases on

supply line terminals 1 and 2.

Both of the "N“s should be connected to

terminals 4 + 5, if appr. jumper.

affected power component..

See Chapter 5.2

Cooking Hobs Information..

2) Should this not help, replace Touch

Control.

(4) Change installation situation.

See Chapter 4 Pot Detection Information

Check whether the glass ceramic w as

pushed down when being screwed in

position and the coil has been correctly

positioned.

fan runs at a slow speed. If not, check the

fan for foreign bodies, remove these where

appropriate.

2) If necessary, replace fan.

3) Should this not succeed, replace power

component.

Replace corresponding coil with

temperature sensor. Also see Instructions

"E4“.

DGS-TDS

21.04.08

Page 6

6 599 519 523 EN

E

5

E

2.3 Alarm message "E“

When the appliance is switched on, "E“ / „xx“ Alarm Number is displayed in the timer display. With

Frontline the display of the front zone indicates the error number when switching on. The affected

zones are subsequently displayed with an "E" in the cooking phase display and are thereby disabled.

The other zones can still be used.

example (left touch control / right indication in the cooking zone):

1) Display alarm number after switching on for 10 sec.

Alarm number

2) 2 zones are disabled.

E0

0

Alarm

Symptom

Alarm display in the

Touch Control

display.

"E3“ Under voltage or over

"E4“ Coil temperature sensor

Display in

the

Cooking

Hob Timer

"E0“

Possible Alarm

Cause

Incorrect configuration on

the Filterboard.

voltage, is only displayed

for 10 sec. after voltage

has been applied.

defect or not correctly

connected.

Alarm Remedying

Disconnect cooking hob from mains,

wait 10 sec and reconnect the mains

supply.

Should alarm still be displayed,

replace filterboard..

1) Disconnect cooking hobs from the

mains, wait 10 sec. and reconnect the

mains.

2) Should alarm still be displayed,

test L1 against N (4),

test L2 against N (5) at the mains

connection

3) If OK, see

See Chapter 3 Testing Power

Component

1)

(5)Inspecting the contacts on the

power component.

Is the connector inserted?

2) The resistance at room

temperature (25°C) amounts to 1000

Ohm. This corresponds to approx. 3.3

Ohm per +1°C deviation.

If not in this range, replace affected

coil including temperature sensor.

3) Should above not succeed, replace

power component concerned.

(1).

DGS-TDS

21.04.08

Page 7

7 599 519 523 EN

A

Alarm

Symptom

Display

in the

Possible Alarm

Causes

Alarm Remedying

Cooking

Field

Timer

larm display in the

Touch Control

"E6“ Communication

"E7“ Alarm Temperature

"E8“ Communication

"E9“ Incorrect

"E5“ 1 phase missing 1) Check the house fuse.

2) Check the pin assignment, (1)

test L1 against N (4),

test L2 against N (5)

3) If ok, see Chapter 3.

1) (5)Checking of the contact with the power

interference

between filter and

power component.

or temp. Sensor is

defective/missing

Note: a norm

requirement with

regard to new

powerboards results

in the power supply

for the electronics

on the powerboard

being deactivated in

the case of a

missing or incorrect

temp. sensor value.

sensor heat sink

power component

interference betw.

filter and Touch

Control.

Central line at

RAST2.5 connector

/ line defect.

configuration for the

Touch Control on

the Filter board.

element.

Is the temp. Sensor connector locked in place

or the dummy connector (3 zone appliances,

no coil connected) inserted?

2) The resistance at room temperature (25°C)

is 1000 Ohm.A deviation of +1°C

corresponds to approx. +3.3 Ohm

Replace the corresponding coil incl.

Temperature sensor if not in this zone.

1) Check the cables between the two boards.

(6), Reinsert connector.

Or replace cable.

2) Should all of the zones on the cooking hob

be affected (Display "E" in the cooking phase

display), replace filter board .

3) Should the above not succeed, replace

power component.

Replace affected power component.

1) (3) Inspect connector at filter and the

Touch Control. Replace cable or filter and

Touch Control.

Reconnect mains voltage.

2) Should above not succeed, replace Touch

Control.

3) Should above not succeed, replace Filter

board.

Disconnect cooking field from the mains. Wait

10 sec. and reconnect to the mains voltage.

Should alarm still be displayed, replace Filter

board.

DGS-TDS

21.04.08

Page 8

8 599 519 523 EN

2.4 Other alarm symptoms

Alarm

symptoms

Buzzer defect Touch control

Individual display

elements do not

illuminate or do not

do so continuously.

Penetrating aromas

from the hob when

warm.

Pots cause noises Unsuitable pots. See Chapter 4 Pot Detection Information.

Normal sound level Interference noises result from the high

Display Possible Alarm

Alarm Remedying

Cause

Replace Touch Control.

defect.

Defective display

elements

Coils subjected to a

manufacturing

defect.

Replace Touch Control.

The aroma is non-toxic. Replace the affected

coils. These also have a slight arom when

cold. Clean the glass and aluminium sheet.

working frequency of the induction. This can

vary from pan to pan.

When measured in operation pursuant to

EN60335 §11-3 pursuant to EN60704 with 4

pots <47dBA.

A pot with boiling water has approx. 6062dBA.

2.5 Cooking zone with electric heating element not functioningt

Alarm symptoms Possible Alarm Cause Alarm Remedying

Cooking zone not

functioning.

Electric heating element

Relay defective 8) Check whether the rely is defective

If the above should not

No phase 2 power voltage

or wrong connection

defect

succeed.

(1) Check the pin configuration and

230V AC between N (4) and the phases

at terminals 1 and 2.

(7) Check whether the electric heating

element is open between the connections

or whther it has short-circuited. Replace

the heating element if defective.

and whether no voltage is applied to the

electric heating element. Also refer to the

circuit diagram.

Replace the filter module with the relay

DGS-TDS

21.04.08

Page 9

9 599 519 523 EN

(1)

(7)

(8)

2.5.1 Electric heating element relay instructions

• Refer to the wiring diagram xxx.

The electric heating element is pulsed on relay board HOC2000 in the cooker.

• Phase commutation with the cooker/hob combination, refer to Chapter 2.6, special error

images for the cooker/hob combination.

2.6 Special error images for the cooker/hob combination

Peculiarities:

• Output

L2 is not continuous and is only connected through when the right zone is switched through

(D37 / D39, Details, refer to the wiring diagram).

• The display in the hob is supplied with 5V DC from the induction module.

• The electronic hob control in the cooker is supplied with 5V DC from the HOC2000

powerboard in the cooker.

• Mixed with the electric heating element:

with the cooker/hob combination, the phases are normally connected to the

L1 left cooking zone

L2 right cooking zone

The induction module (front left and right cooking zones) are however connected to the

continuous phase L1.

Therear right electric heating element zone is always connected to L2.

L2 is only available however of one of the right cooking zones is switched on.

In order to avoid an overloading of L1, the rear left zone is therefore operated with L1 (D29) or

L2 (D37) if the front right zone is switched on.

The phase commutation is executed with the assistance of relays K501 and K504

A safety conductor strip (9) conductor strip of the K501 which can trigger a relay in case of an

error occurring (e.g. contact stuck together).

The output of the 210mm induction cooking zone is set to "P" if none of the right zones are

switched on and the rear left zone is fully switched on, without this display being released.

DGS-TDS

21.04.08

Page 10

10 599 519 523 EN

(9)

2.6.1 No display or error display on the cooking zone display on the cooker

Alarm symptoms Display Possible Alarm Cause Alarm Remedying

Error display "E". "E" if the

display

exists.

When voltage is applied, the

hob control in the cooker

hob display illuminates

briefly.

But: no display at the cooker,

no display at the hob, no

output at the induction zones.

defective.

Errors in the cooking zone display in

the cooker concern the hob. I.e. the

same error number is displayed as in

the hob display. For error displays,

refer to Chapter 2.3. Error display "E".

Additional instructions and tips

concerning cooker problems are to be

found in the Competence Service

Manual Doc. No. xxx.

DGS-TDS

21.04.08

Page 11

11 599 519 523 EN

2.6.2 Cooking zone at the cooker okay, no display at the hob or no output.

Alarm symptoms Display Possible Alarm Cause Alarm Remedying

The diplay in the hob does

not illuminate when voltage is

connected.

Cooker display okay.

But: no cooking stage display

at the hob, no output at the

induction zones.

No cooker output. Check pin D35 at the output

Communication connector

No 5V DC betweem Pin 1+3

Display defect Replace display

When voltage is applied, the

hob display illuminates

briefly. Display at cooker is

okay.

But: no output at the

induction zones

None. Output connector not

inserted..

not inserted or line

damaged.

of the display bus

See normal diagnosis chapter

Check the connector (10) and

the cable, check that it is

correctly engaged.

connector to determine

whether 230V AC voltage is

connected.

1) Checking the connection

between cooker / hob (11).

2) Hereby also explicitly check

the entrance point of the cable

at the hob for damage (14).

3) Check the seat of the

connector at the display in the

hob (12) to the induction

module or (13) to the cooker /

external user interface, ditto

induction module.

(2) check 5V DC Pin 1+3 on

the underside of the hob.

(corresponds to the our lines

of the bus line from the filter

to the display), if not

connected, replace the

filterboard. Caution: it is

difficult to measure this from

below with normal test probe!

2.2, individual induction

cooking zones do not

(temporarily) work or

incorrectly or cannot be

operated or see 2.3 chapter

error display "E"

DGS-TDS

21.04.08

Page 12

12 599 519 523 EN

(11)

(12)

(10)

(13)

(14)

Display in the hob 4 hobs dep. In comb. With cooker

external user Interface

(14)

2.7 Unknown display

For details, refer to the cooking field instruction manual

Symbol Comment

„.“

„-“

„A“ Fast heating up function („Ankochstoss“)

„E“ Alarm display siehe 2.3 Alarm message "E“

„F“ Pot detection – no pot detected

„H“ Residual heat indication

„L“ Lock – Function or key lock

„P“ Power (booster) function for induction

„∪“

Intermediate cooking levels („4.“)

Induction – zone switched off because of over temperature at the coil sensor (empty

pot)

Keeping warm

DGS-TDS

21.04.08

Page 13

13 599 519 523 EN

A

2.8 Control Point Illustrations

Terminal

1

2

(1)

3

4

(2) Pin 1, 3

5

Min. 5 mm

(3)

(5)

(4)

ir -

inlet

Min. 20mm

Remark: if there is no ventilation gap in the front it’s still possible to operate the hob. Only with longer useage ( >15 min. ) the

performance will drop. For Mixed hob this is e.g. – 20%, for full induction hobs it’s higher.

DGS-TDS

21.04.08

Oven

Page 14

14 599 519 523 EN

2.9 Images control point for 2 zones / Mixed Induction

(1)

(5)

(7)

(6)

(3)

Attention: mains connection for Domino is directly on filter pcb.

(1) Domino

(3)

DGS-TDS

21.04.08

(2)

Page 15

15 599 519 523 EN

3 Testing Power Component

1. When alarm messages and disabled zones exist ("E“ in cooking phase display), please make

a note of the power component which is affected.

2. (7) Check whether the lead from the filter board is connected, also check the bus lines (6)

µprocessors filter to power component.

3. If (8) IGBT has become shorted, this normally means that the IGBT housing is damaged.

Replace power component

4. (8) Measure resistance at the IGBTs

Pin1-Pin2 or Pin2-Pin3 >50kOhm Æ Okay

<50Ohm Æ power component defect & replace

Only replace the affected power component and (9) insert 20A fuse, completely separate the

fuse strip conductor.

S12 = right power component

S11 = left power component

5. By a short-circuit and destroyed power component, it is imperative that the coil lines be

inspected for signs of damage.

6. Also replace the filterboard should the replacement of the power component not succeed.

(6)

(9)

(7)

(7)

(6)

(8) 8 St. IGBT

Pin 1 2 3

DGS-TDS

21.04.08

Page 16

16 599 519 523 EN

4 Pot Detection Information

Suitable pot materials:

• Steel enamel

• Stainless steel (with magnet. bottom)

• Aluminium (with magnet. bottom)

• Cast iron

Unsuitable materials:

• Aluminium (Æ too much power)

• Copper

• Stainless steel (not magnetic)

• Glass

• Ceramic

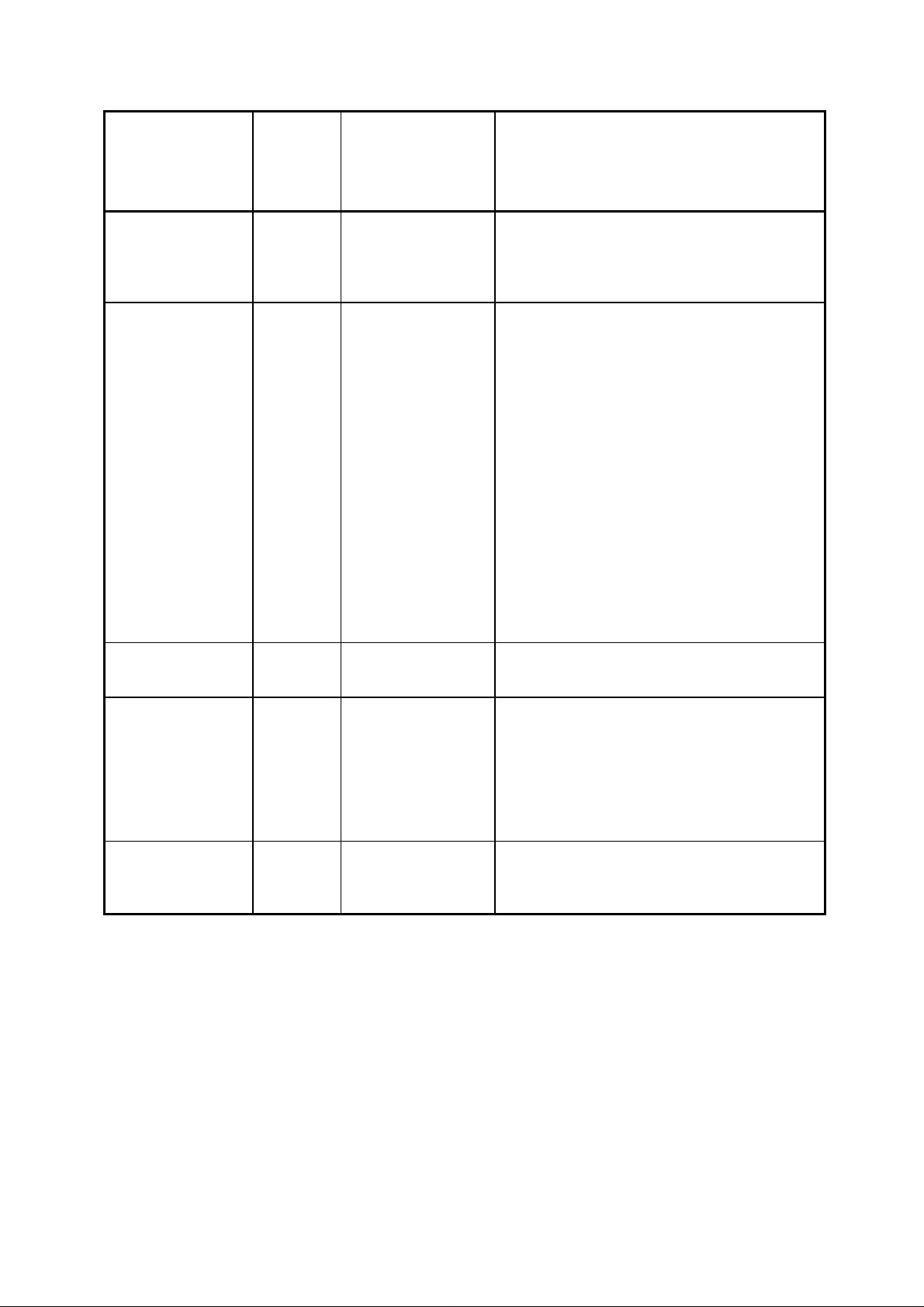

The pot detection is designed for the following diameters:

Nominal burner ∅ [mm] Minimum pot bottom ∅

instruction manual [mm]

145 125 100

180 145 120

210 180 140

260 180 180

With regard to Ind. G4, the same diameter is stipulated in the instruction manuals as for the previous

model. However, the real diameter which still functions is much smaller.

The performance for different pots can very by as much as +/- 10-15%.

• As reference pots, we recommend enamelled steel pots (e.g. Silit).

• 2-3 mm thick round steel plates in various diameters are very suitab l e for testing the pot detection

function.

• Sandwich bottoms can cause very unpleasant noises if they are not correctly pressed. The same

is the case with regard to handles which are a little loose.

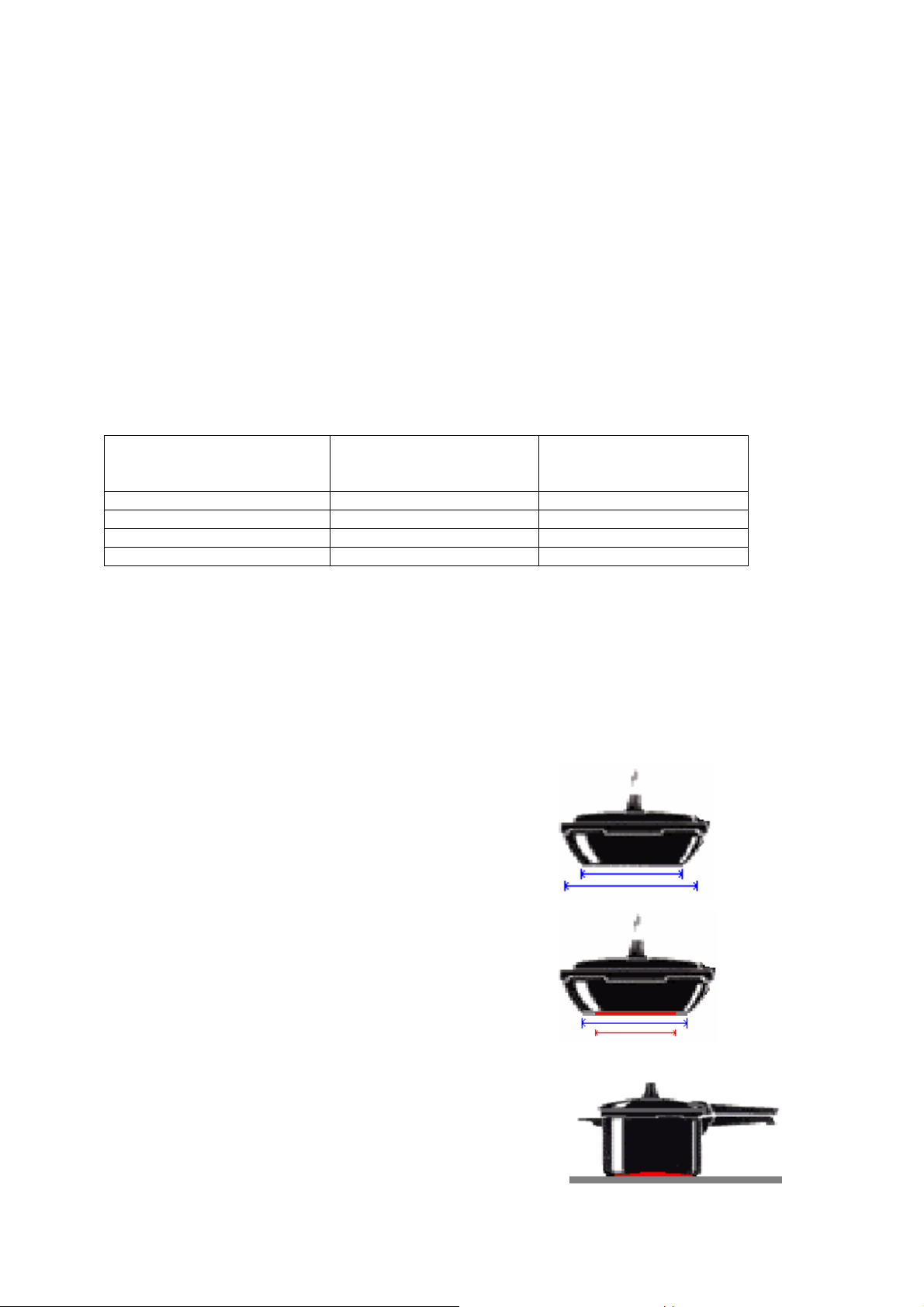

• The bottom diameter of the pot is decisive and not the

exterior diameter.

• With regard to stainless steel pots with sandwich bottoms,

the diameter of the magnetic part of the pot bottom is

decisive.

• an additional influencing factor is the vertical distance from

the coil, i.e. an uneven sandwich bottom has a negative

effect on the power consumption. The effect is exactly the

same if the induction coil is not pressed on the glass

ceramic.

Minimum pot bottom ∅

adjusted with steel plate

[mm]

DGS-TDS

21.04.08

Page 17

17 599 519 523 EN

5 Touch Control Autarkic Cooking Hobs Information

• The Touch Control works on the basis of the infrared principle, i.e. a signal is transmitted wi th a

transmitter which is then reflected by the finger and received once more.

5.1 Instructions on the operation / possible operation errors if the buttons do

not function:

• Do not use with the flat finger. Hold the finger relatively upright.

Otherwise 2 buttons can be activated, this is not signalled.

• Please do not approach slowly, especially not from the side, it is better to approach the button

faster.

A signal change is above all evaluated.

• Applying excessive pressure to the cooking hob will not make a difference.

It is better to release it for 5 sec. and then press the button again.

• If the adjustment of the cooking stage/timer does not continue after the button has been released,

this is due to the fact that the Touch Control receives a "Button Pressed" signal even from a

distance of some mm.

If the user interface is not adjacent to the glass ceramic, the signal for the key evaluation is very

much smaller and the keys can not be operated any more, i.e. pay always attention to intact

plastic carriers.

• If the appliance switches off without that the glass ceramic has been touched, is this becau se a

key in the extreme case.is switching even in a distance / height of 10 mm. This is the function

principle of the touch control and is a normal behaviour. I.e. do not replace the touch control!

DGS-TDS

21.04.08

Page 18

18 599 519 523 EN

5.2 Demo mode / Self test (Service mode) / Alarm Menu

To enter the self-test/Demo mode, the following sequence of buttons must be pressed:

1. Hob is off. Press main switch continuously until display is going off (without beep).

2. Press the "+" and " -" buttons of the front zones together (->short beep) for about 3 seconds (->

again short beep)

3. Press the timer selection key

Step 1

Step 3

d.

Step 2

4. The display shows a "d" for demo mode.

If you press the timer select key again you switch to “S” for Service mode,

another press gets you to “E” the alarm menu.

5. By pressing the button "+" of a cooking zone you activate the menu.

For example, status like above shown in the graphic – hob is in demo mode,

press ‘+’ key of zone to deactivate the demo mode.

Demo Mode:

If demo mode is activated the display with the „d“ shows additionally a dot.

After selecting the demo mode, the electronic goes to off. Now it can be used like usual but only

without heater activation. The deactivation of the demo mode is done in the same procedure as

activating. After deactivating the demo mode the electronic must go off. Now the hob can be used in

normal mode.

Service Mode “s”

Routine:

1. Test all LEDs / Displays for 10 Sec.

2. Show Software version Touch control for 10 Sec. in timer display

In the 7-Segment Display for zone right front (zone 4) an “0” is displayed as an indication that it is

step 0 – HUI.

3. Software display version power board.

Alarm Mode “E”

The last 5 stored alarm codes (if >o) are displayed like an actual alarm, each for 5 sec., starting with

the oldest (read request ‘5’ Alarm code message) to the newest (read request ‘1’).

5.3 Product history

5.3.1 Change from automatic boost to manual boost

This change was done due to customer complaints. It was introduced in seri es production July2004.

The change is implemented with a modified configuration on the filter board of the induction.

DGS-TDS

21.04.08

Page 19

19 599 519 523 EN

5.3.2 Error appliance can not be operated, display indicates "0"

This error has been disappeared after a reset.

For that there were 2 fault reasons in the hardware and software, this was removed by SW Vers. 4.2

from Dec. 2004.

6 Frontline self-sufficient hobs

6.1 Special references disassembly/assembly in case of a service:

1. Disassemble appliance

Î Remove tension clips

2. Open appliance

Î Attention! Before disassembling the glass draw off the connecting line between the user interface at the glass and

induction.

3. Replacement of display units

Î By means of a coin loosen plastic carriers by pressing and turning (29)

Î Shift back the plastic carrier until the front edge can be seen.

Î Lay plastic carrier to the bottom side

Î Remove locking bars like (30)

Î Draw off flat band cable

Î Replace electronic board

Î Assemble in the same way. Pay absolute attention to the correct putting and locking of the

band cable.

User interface and connection of two electronics at the glass ceramic (58 and 72 cm appliances)

(29) (33)

(33) clamp bradings into the locking clips of the right carrier.

DGS-TDS

21.04.08

Page 20

20 599 519 523 EN

Assembly of band cable

(30) (31)

Open locking (black bar) Put band cable (silver contacts visible)

Close locking in arrow direction

(32)

Turn down the electronic with displays onto the glass side, press the carrier flatly to the glass lower side

and let it lock in. For assembly press the locking slightly to the bottom.

6.2 Demo mode / Self test

To enter the self-test/Demo mode, the following sequence of buttons must be pressed:

1. Hob is off. Press main switch continuously until display is going off.

2. Press the "+" and " -" buttons of the zones together (short beep) for about 3 seconds

DGS-TDS

21.04.08

Page 21

21 599 519 523 EN

3. Then automatically the software version of the user interface is displayed,

for example „2“ „8“ = version 28 and all LEDs / Displays are ON for 10 Sec.

There is no alarm history mode available.

4. Demo mode

By pressing the button "A" / „P“ of one of the rear cooking zone you activate the demo mode, the

LED for Power function active is ON.

With activation of the demo mode the hob can be used like usual but without heater activation.

The deactivation of the demo mode is done in the same procedure as activating. The Led has to

be off.

New Demo Mode/ Service Mode/ Alarm menu control philosophy starting with

October 2007 production

To access the self-test/demo mode, press the buttons in the following order:

1. The cooking zone is switched off. Press the main switch until the display goes dark.

2. Press the "+" and "-" buttons of the zones (short beep) simultaneously for about 3 seconds.

3. After 3 seconds, a "d" for demo mode appears in the timer display or in the hot plate display

(depending on the model).

You can change between demo mode "d", service mode "S" and alarm menu "E" using the timer

button or "A" button (depending on the model). if you do not select anything, the unit will switch off.

Demo Mode „d“

Activation: Press the "+" button of the left-hand cooking zone

Indication in the timer display or in the cooking zones display (depending on the model): "do"

You can use the unit as usual, but without heater activation.

To be able to use the unit normally, you have to carry out the following steps:

- Repeat 1. to 3.; after 3 seconds, the timer display or the cooking zones display (depending on

the model) indicates a "do".

- Deactivation: press the "+" button of the left-hand cooking zone

- Indication in the timer display or in the cooking zones display (depending on the model): "d"

DGS-TDS

21.04.08

Loading...

Loading...