Page 1

SERVICE SERVICE

MANUALMANUAL

Page 2

CONTENTS

X-RAY RADIATION PRECAUTION………………………………………………………1

SAFETY PRECAUTION

…………………………………………………………………..

1

PRODUCT SAFETY NOTICE…………………………………………………………….2

INSTALLATION AND SERVICE ADJUSTMENTS………………………………………3

GENERAL INSTRUCTION…………………………………………………………………4

ALIGNMENT ITEMS AND PROCEDURE

………………………………………………..

4

FACTORY ADJUSTMENT MODE…………………………………………………………5

CHECKING POINT……………………………………………………………………………6

PRESET THE FOLLOWING IN FACTORY…………………………………………………7

FACTORY MENU

………………………………………………………………………………

CONVERGENCE MAGNET ASSEMBLY POSITIONING

……………………………..

7

11

COLOR PURITY ADJUSTMENT…………………………………………………………..11

CONVERGENCE ADJUSTMENT…………………………….……………………………..12

CENTER CONVERGENCE ADJUSTMENT …………………………………………..12

CIRCUMFERENCE CONVERGENCE ADJUSTMENT

……………………………..

12

USA CHANNEL FREQUENCY TABLE (181 CH)………………………………………14

WIRING DIAGRAM……………………………………………………………………….16

BLOCK DIAGRAM………………………………………………………………………...17

IC BLOCK DIAGRAM

……………………………………………………………………..

18

SCHEMATIC DIAGRAM………………………………………………………………….26

ELECTRICAL PARTS LIST………………………………………………………………27

CAUTION:

THIS SERVICE MANUAL IS ONLY FOR PROFESSIONAL SERVICE PERSONNEL’S

REFERENCE. BEFORE SERVICING THIS CHASSIS, PLEASE READ THE FOLLOWING

NOTICE ITEMS.

0

Page 3

SAFETY INSTRUCTION

Before servicing and aligning this equipment, please read the following “X-RAY RADIATION

PRECAUTION” ,“SAFETY PRECAUTION” and “PRODUCT SAFETY NOTICE”.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such hazards,

the high voltage must not be above the specified limit. The normal value of the high voltage of this receiver is

29 or 26.5kV(20”) at zero beam current (minimum brightness) under 120V AC power source. the high voltage

must not, under any circumstances, exceed 32kV.

2. Each time a receiver requires servicing, the high voltage should be checked following the HIGH

VOLTAGE CHECK procedure in this manual. It is recommended the reading of the high voltage be recorded as

a part of service record. It is important to use an accurate and reliable high voltage meter.

3. This receiver is equipped with a Fail Safe (FS) circuit which prevents the receiver from producing an

excessively high voltage even if the B+ voltage increases abnormally. Each time the receiver is serviced, the FS

circuit must be checked to determine that the circuit is properly functioning, following the FS CIRCUIT

CHECK procedure in this manual.

4. The primary source of X-RAY RADIATION in this TV receiver is the picture tube. For continuous X-RAY

RADIATION protection, the replacement tube must be exactly the same type tube as specified in the parts list.

5. Some parts in this receiver have special safety-related characteristics for X-RAY RADIATION protection.

For continuous safety, parts replacement should be undertaken only after referring to the PRODUCT SAFETY

NOTICE below.

SAFETY PRECAUTION

WA RN I N G:

Service should not be attempted by anyone unfamiliar with the necessary precaution on this receiver. The

following are the necessary precautions to be observed before servicing this chassis.

1) Since the power supply circuit of this receiver is directly connected to the AC power line, an isolation

transformer should be used during any dynamic service to avoid possible shock hazard.

2) Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube.

The picture tube is highly evacuated and if broken, glass fragments will be violently expelled. Use shatter

proof goggles and keep picture tube away from the unprotected body while handling.

3) When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in

place, such as: non-metallic control knobs, insulating covers, shields, isolation resistor-capacitor network

etc.

4) When replacing parts or circuit boards, disconnect the power cord.

5) When replacing a high wattage resistor (oxiode metal film resistor) on the circuit board, keep the resistor

10mm (1/2in) away from circuit board.

6) Connection wires must be kept away from components with high voltage or high temperature.

7) If any fuse in this TV receiver is blown, replace it with the FUSE specified in the chassis parts list.

8) Before returning the set to your customer, always perform an AC leakage current check on the exposed

1

Page 4

metallic parts of the cabinet, such as antennas, terminals, screwheads, metal overlays, control shafts etc. to

A

be sure the set is safe to operate without danger of electrical shock. Plug the AC line cord directly into a

120V AC outlet (do not use a line isolation transformer during this check). Use an AC voltmeter having

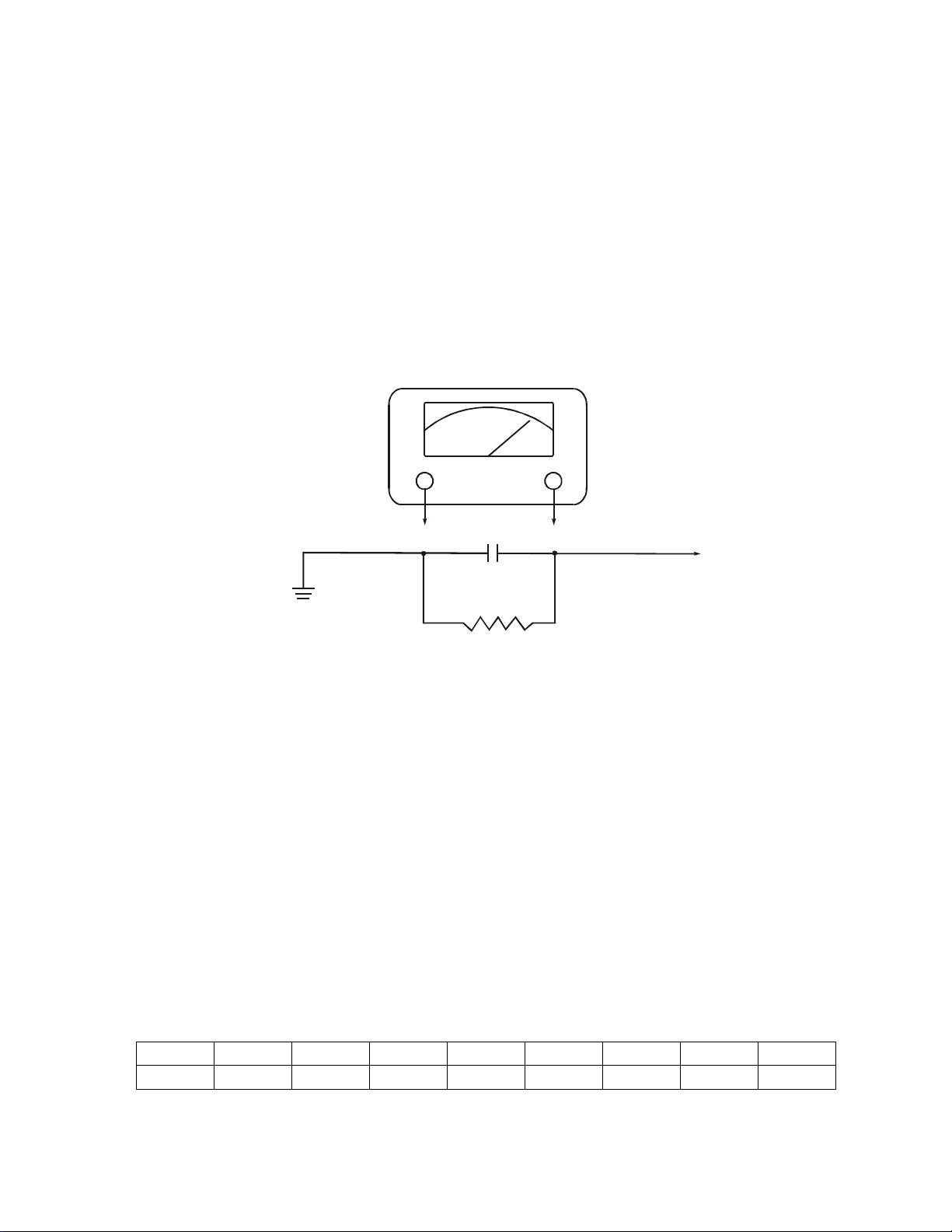

5000 ohms per volt or more sensitivity in the following manner:

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15µF, AC type capacitor, between a known good

earth ground (water pipe, conduit, etc.) and the exposed metallic parts, one at a time. Measure the AC

voltage across the combination of 1500 ohm resistor and 0. 15µF capacitor. Reverse the AC plug at the AC

outlet and repeat AC voltage measurements for each exposed metallic part. Voltage measured must not

exceed 0.3 volts RMS. This corresponds to o.2 milliamp. AC. Any value exceeding this limit constitutes a

potential shock hazard and must be corrected immediately.

C VOLTMETER

¦Ì

0.15 FD

Good earth ground

such as a water

pipe, conduit, etc.

1500ohm

10watt

Place this probe on

each exposed

metallic part.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the chassis have special safety-related characteristics. These

characteristics are often passed unnoticed by a visual inspection and the X-RAY RADIATION protection

afforded by them cannot necessarily be obtained by using replacement components rated for higher wattage, etc.

Replacement parts which have these special safety characteristics are identified in this manual and its

supplement electrical components having such features are shaded on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute

replacement parts which do not have the same characteristics as specified in the parts list may create shock, fire,

X-RAY RADIATION or other hazards.

B+ CHECK

1) Prepare the test equipment.

2) Use the DC voltameter at DC 200V position to test B+ test point, i.e. B+.

3) Connect the power plug to AC 120V/60Hz, turn on the power switch, wait for normal raster, Check B

100V±0.2V.

Test point B+ B1-5V B2-9V B3-10V B4-32V TH-12V TH-20V TH-200V

DC(V) 100 5 9 12 32 12 20(22) 200

+

=

2

Page 5

j

r

N

N

INSTALLATION AND SERVICE ADJUSTMENTS

GENERAL

In the majority of cases, a color television receiver will need only slight touch – up adjustment upon installation.

Check the basic characteristics such as FS,EHV,and focus. Observe the picture for good black and white details

without objectionable color shading. If color shading is evident, demagnetize the receiver.

If color shading still persists, perform purity and convergence adjustments. This should be all that is necessary

to achieve optimum receiver perfomance.

FOCUS ADJUSTMENT

Adjust the FOCUS control (on T302) for well defined scanning lines on the picture screen.

HIGH VOLTAGE CHECK

CAUTION: These is no HIGH VOLTAGE ADJUSTMENT on this chassis. Checking should be done following

the steps below.

1. Connect an accurate high voltage meter to the second anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST controls to minimum (zero beam current).

3. High voltage will be measured below 9 (20”)KV.

4. Vary the BRIGHINESS control to both extremes to be sure the high voltage does not exceed the limit under

any conditions.

FS CIRCUIT CHECK

The Fail Safe (FS) circuit check is indispensable for the final check in the servicing. Checking should be done

following the steps below.

1. Turn the power switch on and adjust customer controls for normal operation.

2. Temporarily short TP501 and TP502 on the Main Board with a jumper wire. Raster and sound will

disappear.

3. The receiver must remain in this state even after removing the jumper wire. This is the evidence that the FS

circuit is functioning properly.

4. To obtain a picture again, temporarily turn the receiver off and allow the FS circuit more than 30 seconds to

reset. Then turn the power switch on to produce a normal picture.

Troubleshooting Guide for Fail Safe Circuit

3

Check that the set returns to normal operation when

pin 64 of N201 on the Main Board is grounded with

umper wire.

YES

Check if the voltage

across capacitor C551 is

approximately 17.2V

YES

Defective Fail Safe Circuit

O

Faulty

Power Circuit o

Horizontal Circuit

O

Page 6

General instruction

1. This chassis’ EEPROMN801 M24C08 should copy standard data, if necessary, deal it with “factory

adjustment”. If directly use blank EEPROM, should first preset I

For factory adjustment method, refer to The appendix: factory menu.

2. If without special indication, the alignment is conducted on the below condition:

a) AC power supply 120 V/60 Hz.

b) The whole unit is preheated for more than 30 min.

3. There is built-in auto degaussing circuit, it will degauss automatically within 1second after turning on.

4. If CRT is with magnetism and affects color purity and convergence, the internal degaussing can not degauss

completely, can use degaussor to degauss externally. If color purity and convergence is still poor, then do

color purity and convergence adjustment.

2

C data, then go on other common alignment.

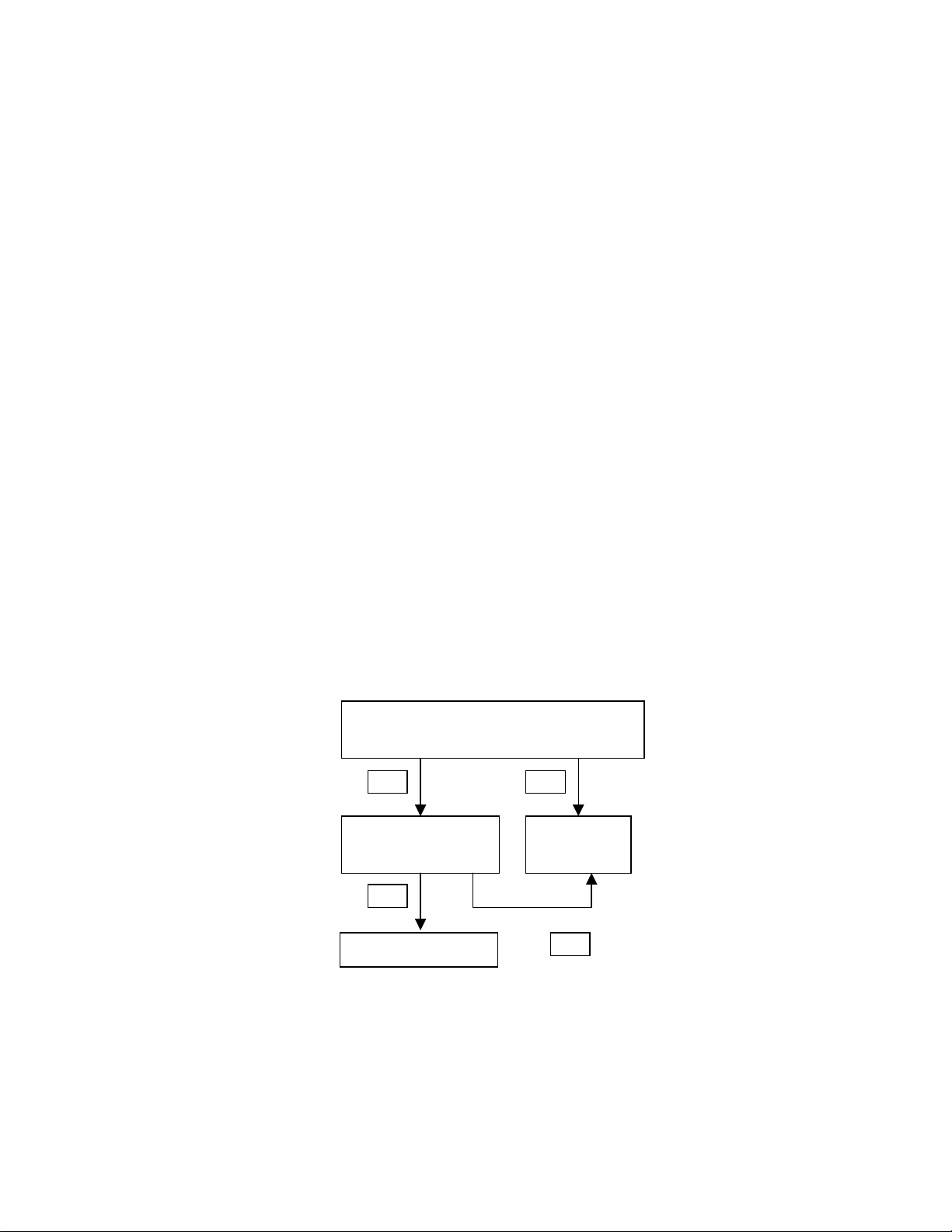

Alignment items and procedure

1. B+ voltage check

2. RF AGC voltage adjustment

3. Focus adjustment

4. Screen-grid voltage and white balance adjustment

5. Horizontal,vertical scan center adjustment

6. Horizontal,vertical scan amplitude adjustment

7. Pattern correction adjustment

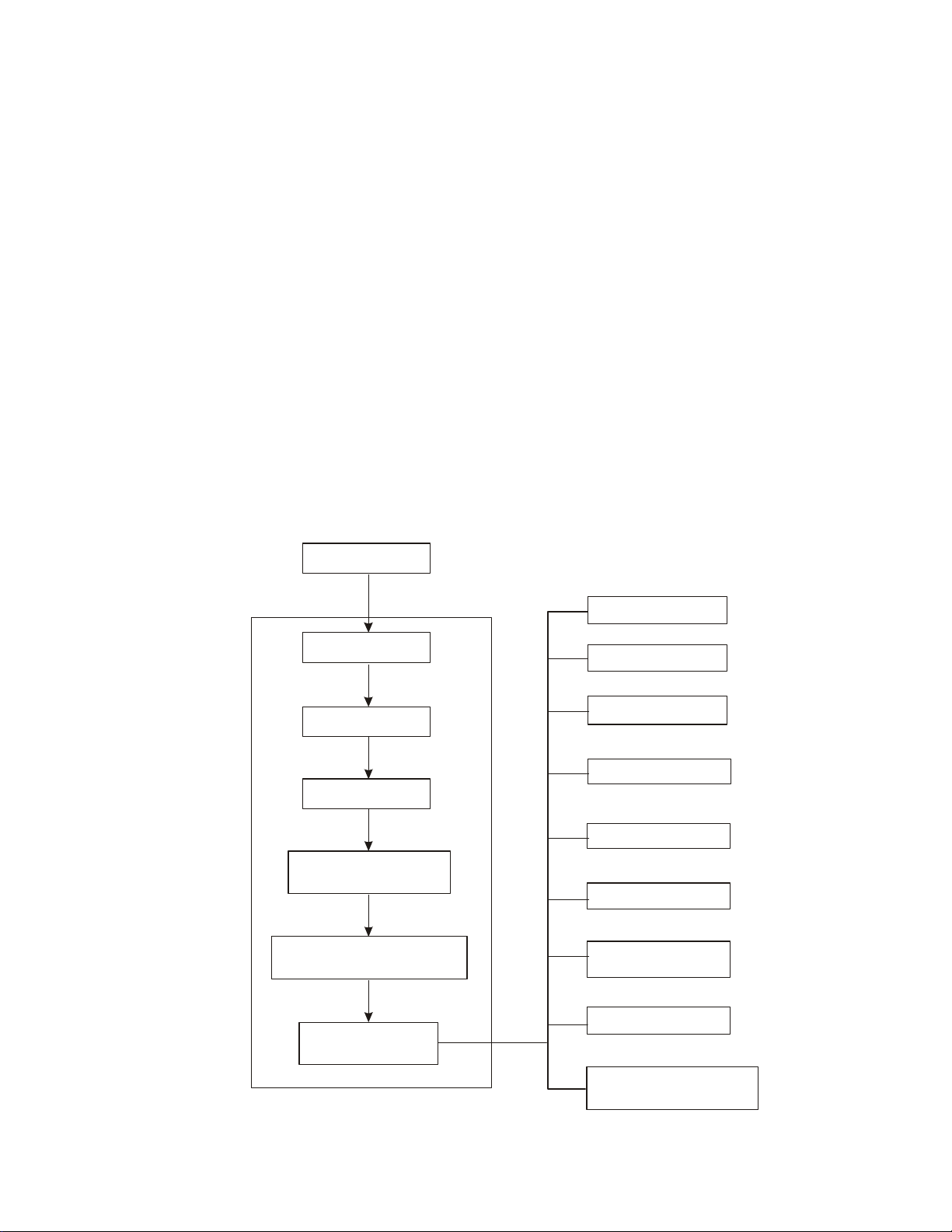

8. The alignment flow chart see figure below.

EEPROM copy

B+ check

RFAGC adjustment

FOCUS

Screen-grid voltage

White balance adjustment

Scanning amplitude center &

raster correction adjustment

High voltage check

X-ray protection check

Filament voltage check

Picture and sound check

Sub-brightness check

White balance check

Color purity

convergence check

¡¢

AV term inal c heck

Check

The TV set & remote

controller's function check

Figure 1: Alignment flow chart

4

Page 7

Factory adjustment mode

1. B+ voltage test

a) Make sure the AC power is 120 V/60 Hz

b) Connect digital voltmeter to B+ test point, receive A-7 signal, set picture control to“MEMORY 2” state,

test B+, the test voltage should be 100 V±0.3 V.

2. AGC adjustment

a) Receive 60 dB split field A-7 signal.

b) Use oscilloscope or digital voltmeter to monitor test N201 pin 43 voltage(AGC output).

c) Press R-AGC button, by making use of [←][→] button, increase the value from low to high until the

voltage just reach 4.0 V, at this time picture noisy spot should basically disappear, otherwise continue

fine tune R-AGC button.

3. Focus adjustment

3. 1 Receive A-12 signal, set user control to “MEMORY 2” state.

3. 2 Adjust FBT’s focus potentiometer, to make the screen’s B area’s focus optimum.

4. Acelerating electrode adjustment method (use A-7 signal)

4.1 Roughly adjust white balance, fix RCUT value, adjust GCUT,BCUT,GDRV,BDRV’s value to make white

balance basically normal.

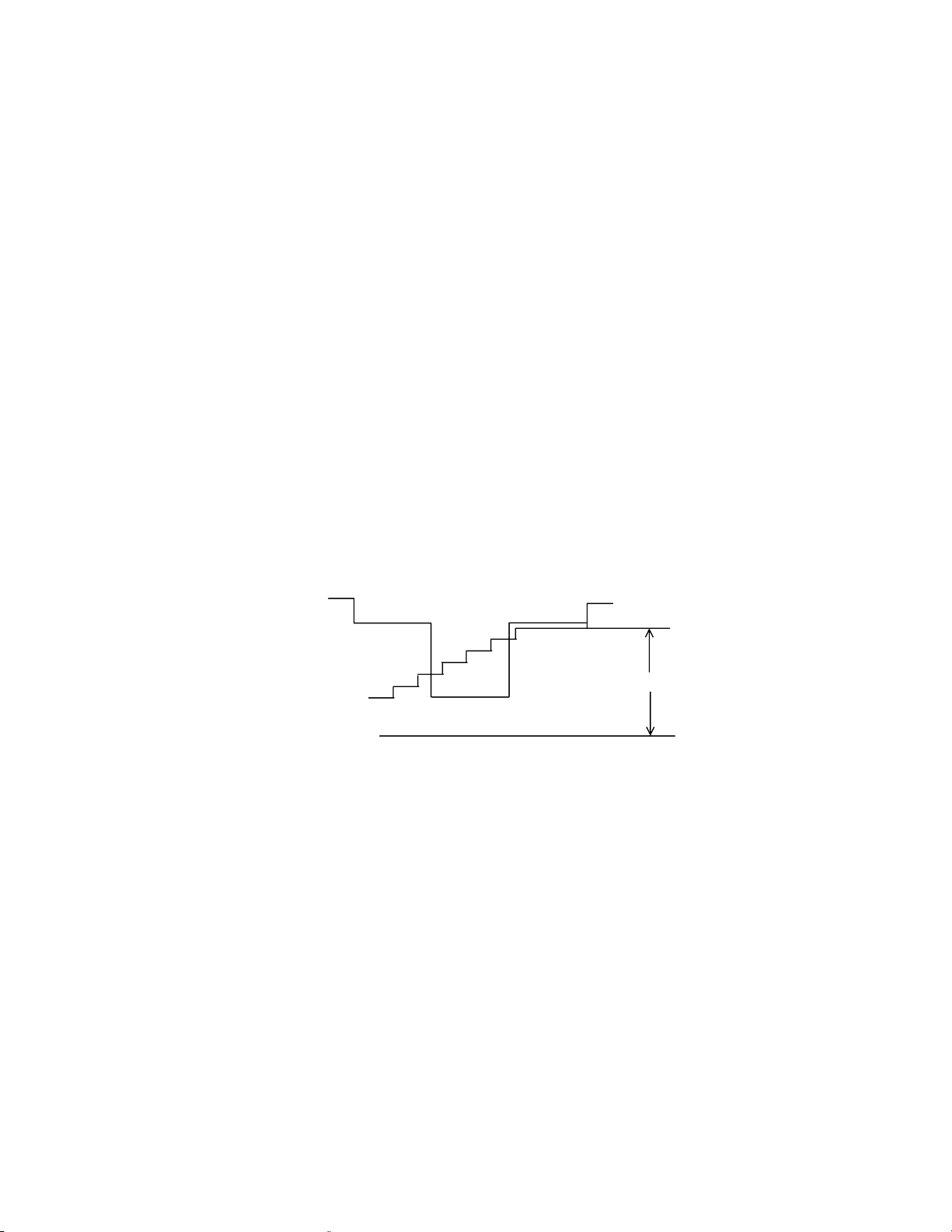

4.2 Set the color to 0, contrast to 30, use oscilloscope to adjust CRT’s red gun’s waveform (see below figure),

adjust brightness to make the seventh step’s (the darkest) DC level be 180V, adjust accelerating electrode to

make the seventh step slightly light up (just can separate the seventh step and below dark field).

0V

Fig 2: red gun waveform

4.3 Fine adjust white balance (color temperature: 12000K±8MPCD X=0.270±0.008 Y=0.283±0.008 )

4.4 Set contrast,brightness,color all to 0, adjust BRTN to make A-7’s upper left 2 lattice slightly light up.

5. Horizontal,vertical scan center adjustment

5.1 Item adjustment

VLIN 50Hz V-linearity adjustment

VSC 50Hz Vertical S-correction

VLIS 60Hz V-linearity adjustment

VSS 60Hz Vertical S-correction

5.2 PAL(50 Hz) H-center,V-center adjustment

Receive D35 signal, set user control to “MEMORY 2” state, fine tune V-center VP50, H-center HPOS,

to make picture’s center be in accordance with screen’s center.

5.3 NTSC(60Hz)H-center,V-center adjustment

Receive A6 signal, set user control to “MEMORY 2” state, adjust V-center VP60, H-center HPS to make

picture’s center be in accordance with screen’s center.

180V

5

Page 8

6. Vertical scan amplitude adjustment

6.1 PAL(50 Hz)V-amplitude adjustment

Receive D35 signal, set user control to “MEMORY 2” state, adjust V-amplitude HIT, make picture’s upper

and lower overscanning be screen size’s 8%.

6.2 NTSC(60 Hz)V-amplitude adjustment

Receive A 12 signal, set user control to “MEMORY 2” state, adjust V-amplitude HITS to make picture’s

upper and lower overscanning be screen size’s 8%.

Checking point

1. High voltage check

1.1 Connect high voltage meter to CRT’s second anode and GND.

1.2 Receive A-7 signal, set user control to “MEMORY 1” state, the high voltage should be 29.0 kV±1 kV.

1.3 When brightness and contrast be set to minimum (zero beam current), the high voltage should not exceed

32 kV.

2. CRT filament voltage check

Receive A-7 signal, set picture control to “MEMORY 2” state, use effective value voltmeter to test CRT

filament voltage, the reading should be (6.3±0.3)Vrms.

3. X-ray protection check

3.1 Receive A-7 signal, set user control to “MEMORY 2” state.

3.2 Short R554(TP501,TP502), X-ray protection circuit should effect.

4. Picture and sound check

4.1 Receive standard TV signal.

4.2 Making use of picture control buttons to check color,contrast,brightness,sharpness,tint’s control function.

4.3 Making use of sound control buttons to check volume control function.

5. Sub-brightness check

Receive A-7 signal, set color ,contrast,brightness all to 0, picture’s left side first grid slightly lights.

6. This set can produce 28 kinds of testing signal by itself. Press “SLEEP PIC DSP MENU AV” button,

every time you press the buttons, one kind of testing signal will be produced. The first fourteen signals

are NTSC signal and the other fourteen signals are PAL signal. After these signals are cycled for one

time, it will return to original screen.

7. Color purity and convergence check(Use common regulation)

8 . AV t e r m in als ( AV I N /OUT c h e c k )

9. Other control buttons (on the set and on the remote controller) function check.

6

Page 9

Preset the following in factory

1. Picture menu:

CONTRAST 100

BRIGHTNESS 50

COLOR 50

SHARPNESS 50

TINT ±00

PICTURE

MEMORY 4

MODE

▼MORE

2. Volume preset to 30.

3. Set OSD language to English.

4. Color system preset to AUTO.

5. TV mode:channel position number 2.

6. Firstly press SHOP OUT D/K SPOUT out-factory button on the factory remote controller,

“ready” will appear, wait for 8-10 seconds, the preset will be stored.

Factory menu

1. Enter into factory menu to operate.

1.1 Press “SLEEP PIC DSP MENU” button(The period of two-press should be within 5 seconds), enter into

factory menu.

1.2 Use MENU button to scroll the pages(P1,P2,P3).

1.3 In factory menu status, press SLEEP button to exit.

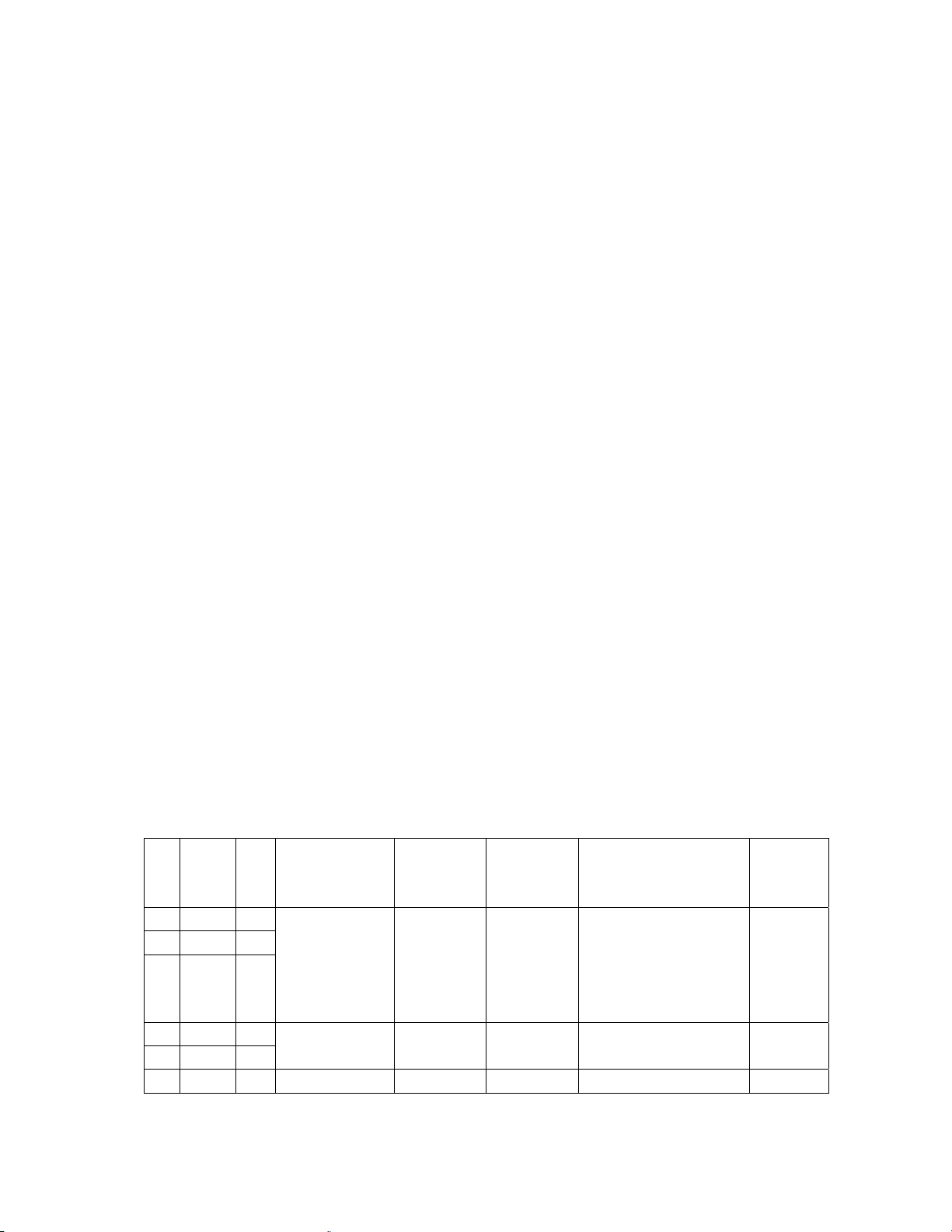

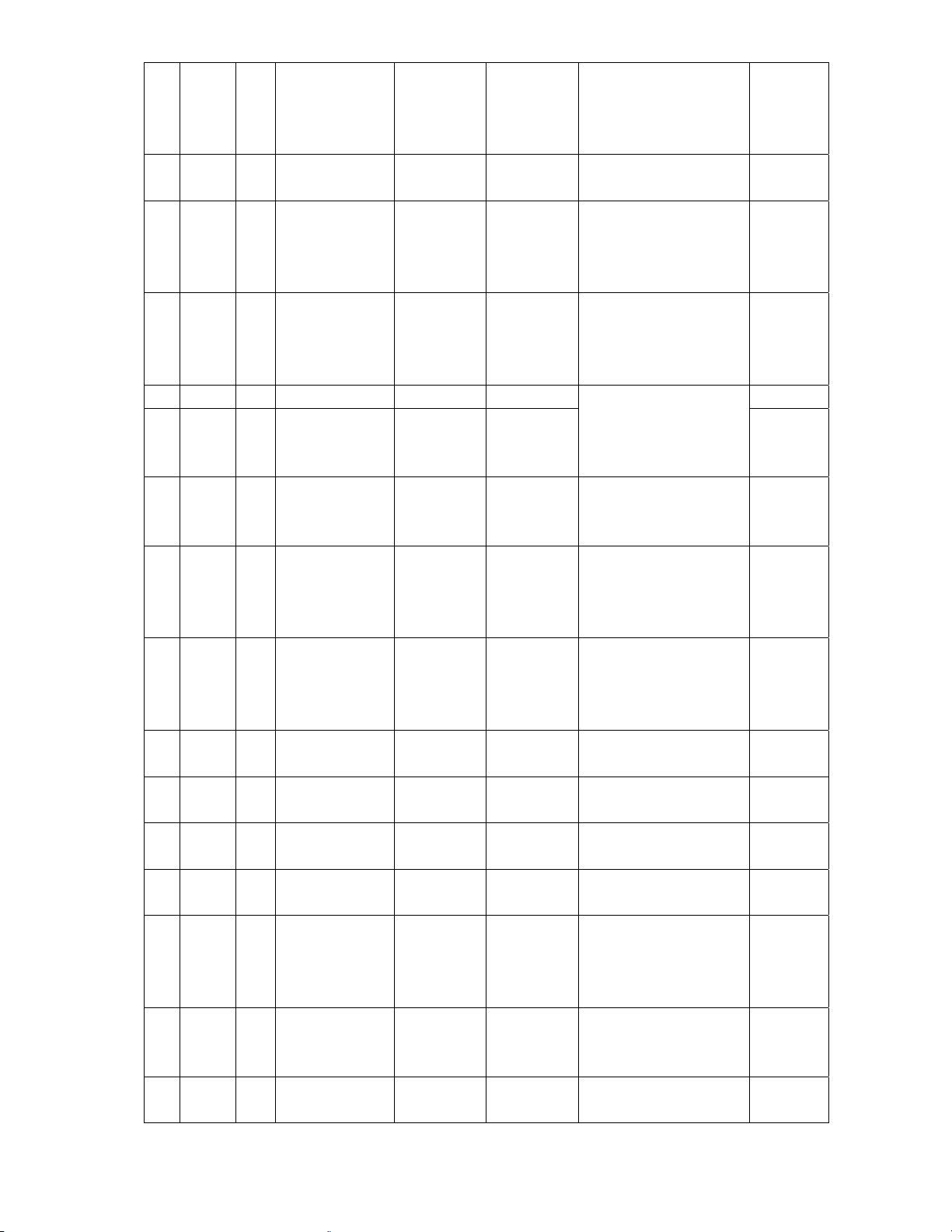

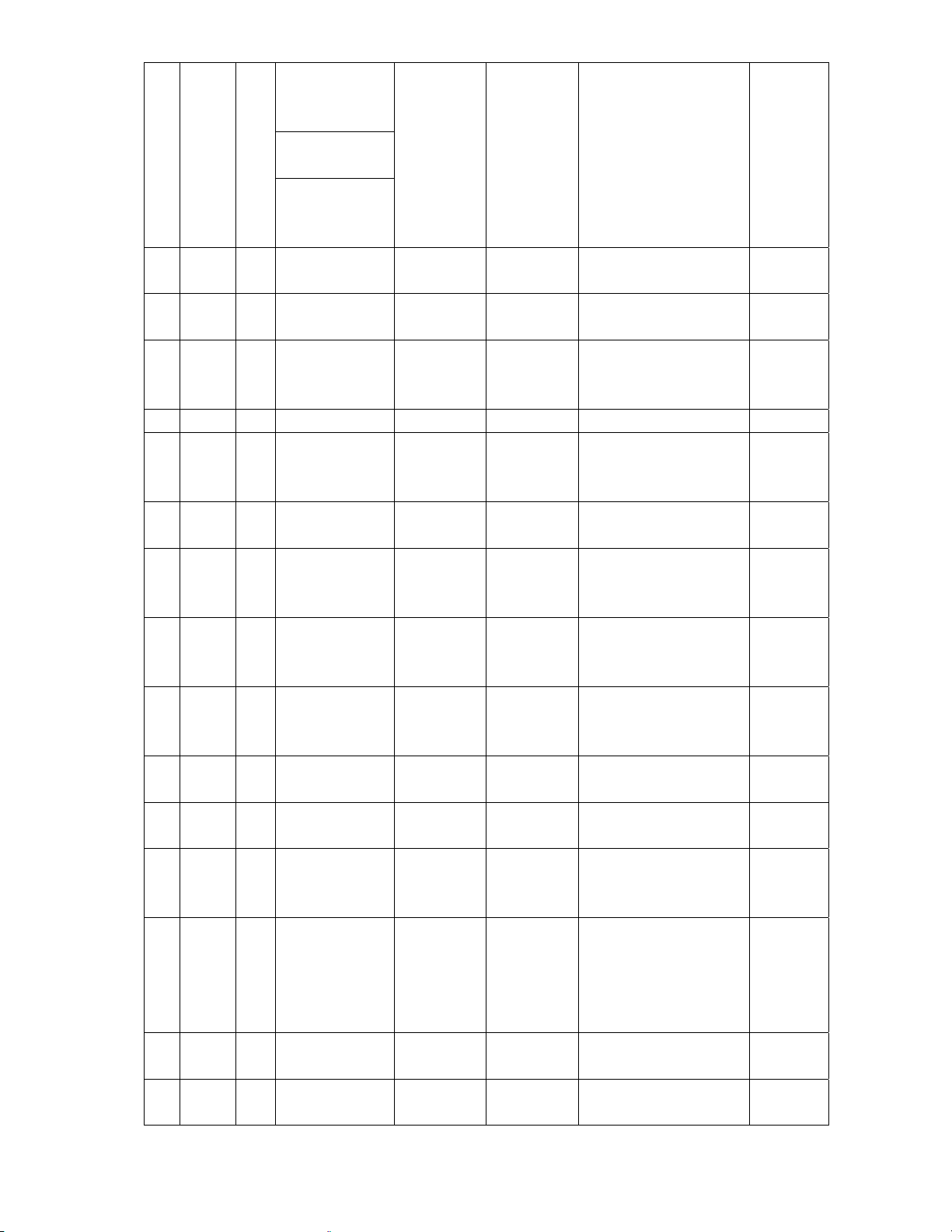

2. Factory menu contents(

OSD

No

.

01

02

03

04

05

charac

ter

RCUT

GCUT

BCUT

GDRV

BDRV

Pre

set

2F

4D

4B

41

45

06 HPOS 11 50Hz H-center MEMORY2 D35 screen

See below appendix 1.)

Appendix 1 Factory menu

Adjustment

Analogue

item

Dark area white

balance

Bright area

white balance

Contrast 0

Color 0

Bright 50

MEMORY1

setting

Input signal Adjustment methods Test point

Black/white

signal

Or

horizontal

Make dark area obtain

correct “white color”

screen

bright line.

Black/white

signal

Make dark area obtain

correct “white color”

screen

7

Page 10

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

VP50

HIT

VLIN

VSC

HPS

VP60

HITS

VLIS

VSS

RAGC

HAFC

V25

V50

TXCX

RGCN

ABL

06 50Hz V-center MEMORY2 D35

Adjust to make picture’s

vertical and horizontal

center be in accordance

with CRT center.

50Hz

25

V-amplitude

MEMORY2 D35

Cross-hatch

0B V-linearity MEMORY2

signal

(PAL)

Cross-hatch

signal

(PAL)

05

Vertical

S-correction

MEMORY2

03 60Hz H-center MEMORY2 A6 screen

Make V-amplitude meet

checking standard

screen

Adjust to make

screen’s upper and lower

cross-hatch height be

screen

equal.

Adjust to make screen’s

upper and middle and

lower cross-hatch

screen

height be equal.

Adjust to make picture’s

vertical and horizontal

03 60Hz V-center MEMORY2 A6

center be in accordance

screen

with CRT center.

60Hz

02

V-amplitude

60Hz V-linearity

00

02

29

03

42

4E

3F

16

23

fine tune

60Hz Vertical

S-correction

RF AGC

adjustment

1/2 AFC data

adjustment

25% volume

adjustment

50% volume

adjustment

YUV sub-color

maximum value

YUV sub-color

minimum value

Auto brightness

limitation

MEMORY2 A12

Cross-hatch

MEMORY2

signal

(NTSC)

Cross-hatch

MEMORY2

signal

NTSC

MEMORY2 A7

A12 Fix

A21 Fix

A21 Fix

Bright 50

Color 100

Contrast 50

Bright 50

Color 0

Contrast 50

In any

signal will

display

MENU

Let picture

without

color

MEMORY1 A7 fix Screen

To make V-amplitude

meet checking

screen

standard.

Adjust to make screen’s

upper and lower

cross-hatch height be

screen

equal.

Adjust to make screen’s

upper and middle and

lower cross-hatch

Screen

height be equal.

Adjust to make picture

without noise

Let character not

defocusing

N20143

Screen

Let character clear Screen

8

Page 11

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

DCBS

CNTX

CNTC

CNTN

SCNT

BRTX

BRTC

BRTN

BRTS

COLX

COLC

COLP

COLN

TNTX

TNTC

TNTN

BIT4, 5 OSD

character

brightness level

BIT2, 3

42

Ygamma value

BIT 0,1 black

level stretch

value

Sub-contrast

50

maximum value

Sub-contrast

3F

middle value

Sub-contrast

0F

minimum value

MEMORY1 Gray scale Fix Screen

Contrast 50 Gray scale Fix Screen

Contrast 0

Color 0

Gray scale Fix Screen

Bright 50

0F Sub-contrast Natural Gray scale Fix Screen

Sub-bright

1A

maximum value

Bright middle

2D

value

Sub-bright

20

minimum value

Contrast 50

Bright 100

A7 Fix Screen

Color 0

MEMORY2 A7 Fix Screen

Contrast 50

Bright 0

A7 Fix Screen

Color 0

Contrast 0

1C Sub-bright

Bright 50

A7 Fix Screen

Color 0

Sub-color

7F

maximum value

Sub-color

40

00

00

middle value

PAL sub-color

middle value

Sub-color

minimum value

Contrast 50

Bright 50

Color 100

Natural A7 Fix Screen

Natural D8 Fix Screen

Contrast 50

Bright 50

Color 0

D8

A7

Fix Screen

A7 Let picture without color Screen

Contrast

50

Sub-tint

maximum

value

100

Bright 50

Color 50

A7 Fix Screen

Tint 100

Sub-tint middle

50

50

value

Sub-tint

minimum

Natural A7 Fix Screen

Contrast

100

A7 Fix Screen

9

Page 12

39

40

41

42

43

44

45

46

47

48

49

50

TNCD

SHPX

SHPN

ST3

SV3

ST4

SV4

SVD

DEF

STBY

ASSH

VBLK

value Bright 50

Color 50

Tint 0

Contrast

DVD Tint

40

middle value

100

bright 50

Color 50

Tint 0

Sub-sharpness

3F

maximum value

Sub-sharpness

10

minimum value

Sharpness

100

Sharpness 0 A12 Fix Screen

NTSC3.58 TV

input signal’s

2E

sharpness

MEMORY1

middle value

NTSC3.58 AV

input signal’s

2E

sharpness

MEMORY1

middle value.

Non NTSC3.58

TV input

2E

signal’s

MEMORY1 A12, B12 Fix Screen

sharpness

middle value

Non NTSC 3.58

AV input

2E

signal’s

MEMORY1

sharpness

middle value.

DVD sharpness

19

middle value

Fix Screen

0:picture

parallel

01

1:picture

non-parallel

Decoder

intermediate

00

amplifier

STANDBY

Single side

00

sharpness

Vertical

blanking

00

beginning point,

ending point.

DVD Fix Screen

A12 Fix Screen

Video input

NTSC3.5

Fix Screen

signal

Video input

NTSC3.5

Fix Screen

signal

Video input

PAL sign al

Cross-hatch

signal

Fix Screen

Fix

10

Page 13

MOD

51

03 Mode data

Chroma

UCOM

52

00

auto-phase

control setting

NOIS

53

54

55

SYCT

TUNR

01 Noise check

Sync signal

08

check

02 Tuner selection

CCD(concealed

56

CCD_

OSD

caption) OSD

50

beginning

position

57

58

59

60

61

62

CCD_

OSDF

OSDF

OSD

OPT

OPTM1

OPTM2

CCD character

50

size

OSD character

4F

size

15 OSD position

07

A3

13

Note 1:The original password CHILD LOCK MENU 0000,

VCHIP PASSWORD 0000.

CONVERGENCE MAGNET ASSEMBLY POSITIONING

Convergence magnet assembly and rubber wedges need mechanical positioning. Refer to below figure 1.

COLOR PURITY ADJUSTMENT

NOTE: Before attempting any purity adjustment, the receiver should be operated for at least fifteen minutes.

1. Demagnetize the picture tube and cabinet using a degaussing coil.

2. Set the CONTRAST and BRIGHTNESS controls to the maximum.

3. Receive PM5515 monochromatic signal (such as G) to provide a green raster on the screen.

4. Loosen the clamp screw holding the yoke, and slide the yoke backward to provide vertical green belt

(zone) in the picture screen.

5. Remove the Rubber Wedges.

6. Rotate and spread the tabs of the purity magnet around the neck of the picture tube until the green belt

is in the center of the screen. At the same time, center the raster vertically by adjusting the magnet.

7. Move the yoke slowly forward or backward until a uniform green screen is obtained. Tighten the

clamp screw of the yoke temporarily.

8. Check the purity of the red and blue raster.

9. Obtain a white raster, referring to “CRT WHITE BALANCE ADJUSTMENT”.

10. Proceed with convergence adjustment.

11

Page 14

FIG.3

CONVERGENCE ADJUSTMENT

NOTE: Before attempting any convergence adjustments, the receiver should be operated for at least fifteen

minutes.

CENTER CONVERGENCE ADJUSTMENT

1. Receive crosshatch pattern with a color bar signal generator.

2. Adjust the BRIGHTNESS and CONTRAST controls for well defined pattern.

3. Adjust two tabs of the 4-Pole Magnets to change the angle between them (see figure 4) and superimpose red

and blue vertical lines in the center area of the picture screen. (see figure 5)

4. Turn the both tabs at the same time keeping the constant angle to superimpose red and blue horizontal lines at

the center of the screen.(see figure 5)

5. Adjust two tabs of 6-Pole Magnets to superimpose red/blue line with green one. Adjusting the angle affects

the vertical lines and rotating both magnets affects the horizontal lines.

6. Repeat adjustments 3,4,5, keeping in mind red, green and blue movement, because 4-Pole Magnets and

6-Pole Magnets interact and make dot movement complex.

CIRCUMFERENCE CONVERGENCE ADJUSTMENT

1. Loosen the clamping screw of deflection yoke to allow the yoke to tilt.

2. Put a wedge as shown in figure 1 temporarily. (Do not remove cover paper on adhesive part of the wedge.)

3.Tilt front of the deflection yoke up or down to obtain better convergence in circumference. (See figure 5).

Push the mounted wedge into the space between the picture tube and the yoke to hold the yoke temporarily.

4. Put other wedge into bottom space and remove cover paper to stick.

5. Tilt front of the yoke right or left to obtain better convergence in circumference (see figure 5)

6. Keep the yoke position and put another wedge in either upper space. Remove cover paper and stick the wedge

on the picture tube to fix the yoke.

7. Detach the temporarily mounted wedge and put it in another upper space. Stick it on the picture tube to fix the

yoke.

8. After fixing three wedges, recheck overall convergence. Tighten the screw firmly to fix the yoke tightly in

place.

12

Page 15

9. Stick three adhesive tapes on wedges as shown in figure 3.

Fig5. Dot Movement Pattern

13

Page 16

BAN

D

VHF

Low

VHF

High

USA CHANNEL FREQUENCY TABLE (181 CH)

P IF=45.75 MHz

C IF=42.17MHz

S IF=41.25MHz

UNIT: MHz

CHANNE

L

W+1

W+2

W+3

W+4

W+5

W+6

W+7

W+8

W+9

W+10

P

CARRIER

2 55.25 59.75 101

3 61.25 65.75 107

4 67.25 71.75 113

5 77.25 81.75 123

6 83.25 87.75 129

A-6

A-5

A-4

A-3

A-2

A-1

A

B

C

D

E

F

G

H

I

7 175.25 179.75 221 15 477.25 481.75 523

8 181.25 185.75 227 16 483.25 487.75 529

9 187.25 191.75 233 17 489.25 493.75 535

10 193.25 197.75 239 18 495.25 499.75 541

11 199.25 203.75 245 19 501.25 505.75 547

12 205.25 209.75 251 20 507.25 511.75 553

13 211.25 215.75 257 21 513.25 517.75 559

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

S

CARRIER

85.25 89.75 131

91.25 95.75 137

97.25 101.75 143

103.25 107.75 149

109.25 113.75 155

115.25 119.75 161

121.25 125.75 167

127.25 131.75 173

133.25 137.75 179

139.25 143.75 185

145.25 149.75 191

151.25 155.75 197

157.25 161.75 203

163.25 167.75 209

169.25 173.75 215 14 471.25 475.75 517

217.25 221.75 263 22 519.25 523.75 565

223.25 227.75 269 23 525.25 529.75 571

229.25 233.75 275 24 531.25 535.75 577

235.25 239.75 281 25 537.25 541.75 583

241.25 245.75 287 26 543.25 547.75 589

247.25 251.75 293 27 549.25 553.75 595

253.25 257.75 299 28 555.25 559.75 601

259.25 263.75 305 29 561.25 565.75 607

265.25 269.75 311 30 567.25 571.75 613

271.25 275.75 317 31 573.25 577.75 619

277.25 281.75 323 32 579.25 583.75 625

283.25 287.75 329 33 585.25 589.75 631

289.25 293.75 335 34 591.25 595.75 637

295.25 299.75 341 35 597.25 601.75 643

301.25 305.75 347 36 603.25 607.75 649

307.25 311.75 353 37 609.25 613.75 655

313.25 317.75 359 38 615.25 619.75 661

319.25 323.75 365 39 621.25 625.75 667

325.25 329.75 371 40 627.25 631.75 673

331.25 335.75 377 41 633.25 637.75 679

337.25 341.75 383 42 639.25 643.75 685

343.25 347.75 389 43 645.25 649.75 691

349.25 353.75 395 44 651.25 655.75 697

355.25 359.75 401

LOCAL BAND CHANN

EL

W+11

UHF

W+12

W+13

W+14

W+15

W+16

W+17

W+18 403.25

W+19

W+20

W+21

W+22

W+23

W+24

W+25

W+26

W+27

W+28

W+29

45 657.25 661.75 703

P

CARRIER

S

CARRIER

361.25 365.75 407

367.25 371.75 413

373.25 377.75 419

379.25 383.75 425

385.25 389.75 431

391.25 395.75 437

397.25 401.75 443

409.25 413.75 455

415.25 419.75 461

421.25 425.75 467

427.25 431.75 473

433.25 437.75 479

439.25 443.75 485

445.25 449.75 491

451.25 455.75 497

457.25 461.75 503

463.25 467.75 509

469.25 473.75 515

LOC

AL

407.75 449

14

Page 17

USA CHANNEL FREQUENCY TABLE (181 CH)

P IF=45.75 MHz

C IF=42.17MHz

S IF=41.25MHz

UNIT: MHz

BAND CHANNEL P CARRIER S CARRIER LOCAL

UHF

46 663.25 667.75 709

47 669.25 673.75 715

48 675.25 679.75 721

49 681.25 685.75 727

50 687.25 691.75 733

51 693.25 697.75 739

52 699.25 703.75 745

53 705.25 709.75 751

54 711.25 715.75 757

55 717.25 721.75 763

56 723.25 727.75 769

57 729.25 733.75 775

58 735.25 739.75 781

59 741.25 745.75 787

60 747.25 751.75 793

61 753.25 757.75 799

62 759.25 763.75 805

63 765.25 769.75 811

64 771.25 775.75 817

65 777.25 781.75 823

66 783.25 787.75 829

67 789.25 793.75 835

68 795.25 799.75 841

69 801.25 805.75 847

15

Page 18

WIRING DIAGRAM

X302

782-13Y00-05

S501

782-K2035-01

FBT

782-K2035-05

X90-1

X301

X202

N201

Xv02

X601

X201

Xv11

X90-1

X302

782-K2035-02

X401

16

Xv11

782-K2035-29

Xv02

Page 19

A

A

BLOCK DIAGRAM

AC 120V

ROUT

B+100V

B+ 100V

B29V-1

BSC24-3031

DB501

B15V-1

FBT

POWER

B432V

AUDIO OUT

N601

AN7522N

RIN

ON/OFF

X-R

D

LIN

TC4052

N5832

RMIN

POWER

EEPROM

M24C08BN6

N801

N501

B312V

TH-12V

TH-20V

TH-200V

VOUT

17

V323

HOUT

TEA8172

R

G

B

TUNER

CRT

Page 20

IC BLOCK DIAGRAM

P61/LED1/ADC8bit

P60/ADC8bit

P53/ADC8bit/TC1/Int2

uP Dvss

Reset

8MHz

TEST

uP DVDD 5V

uP VVss

TV AGND

FBP

SCP

HAFC1

Vsaw

Vout

H.Vcc 9v

TV DGND

EXT CVBS/Y

Dvcc

TV IN 1Vpp

TRAP

IF Vcc 9V

TVout 2.2Vpp

SIF out

TMPA8801PSN(PN)

8-bit int.timer 2

Watchdog timer

interrupt

Ext. 5 Int. 11

IIC bus interfece

XO

Ext. 1 Int. 1

¡Á¡Á

¡Á¡Á

¡Á

STOP/IDLE mo de

Hor.Proc.

Sync.sepa

Hor.VCO HAFC-1

RGB Matrix

Vert.Proc.

V.C /D

V.r am p

Y gamma

Sharpness

ATT

1

2

3

4

5

6

7

8

+

9

10

11

HAFC-2 H-shift

12

13

Hout

14

+

V.geometry

V.D ri ve

15

16

17

++

18

19

Cb input

20

Y input

21

Cr input

22

23

Cin

24

+

25

26

27

ABCL

28

AU out

29

+

30

31

32

+

EXT AU

16-bit int.timer 2

¡Á

870

¡Á

CPU core

Color Uni-color

Black stretch

Romote preprocessor

CCD

C-Trap

8-bit ADC Ext 3

I/O

10 I/O port

14-bit PWM 1

7-bit

¡Á

PWM 1

Int. 1

¡Á

¡Á

¡Á

ROM:64kB

RAM:2KB

ROM correction

OSD R/G/B/Ys/I

Font:16

Display:32C 12L

Color:8

Character:384

Half-tone Test signal

Transparent

¡Á

18

¡Á

Base Band Pr c.

1H DL Int/Ext switch

o

Chroma Proc.

C-BPF

PAL/ NTSC

TINT

Y Proc.

AGC

AGC

DET

Reg.

PIF Proc.

PAL/NTSC demod

Auto.VCO

alignment

AFT

64

63

62

61

60

59

58

57

56

55

54

53

52

Cut-off Drive

AKB

51

50

49

48

47

46

45

44

43

42

IF

41

40

39

38

37

FM

DEMO

36

35

34

BPF

33

P63/LED2

P30/Int3/RXIN

P31/Int4/TC3

P20/Int5/Stop

P40/PWM14bit

P50/PWM7bit/TC2/Int0

P51/SCL

P52/SDA

P56

uP AVdd 5V

+

uP MPAGND

TV AGND

Bout

Gout

Rout

+ +

RGB Vcc 9V

IKin

APC Fil

+

Black Det

Monitor out

+

YC Vcc 5V

F AGC

R

IF IN

SAW

IF GND

++

IF AGC

Deemph

S-Reg.F

IF Vcc 5V

+

PIF PLL

+

DC NF

H.correc/SIF in

18

Page 21

10K

10K

£©

(Ta

10

3.3

£©

(Ta

3.3

0.1

¡À£©

(10%

0.022

AN5832SA

180K

PE

26

2.2

24

+

32

SDA/SAPID

SCL/STID

27

Wide Band

2

IC

Decoder

+

+

2

3

Spectral

Filter

Filter

+

5

6

4

10% Tantalum capacitor

(Ta)

28293015251917182321

Spectral

Wide Band

Wide Band

RMS Det

Expand

2.2

Lout Rout

2.2

+

GND

AGC

Matrix

& Mode SW

Offset

Cancel

Offset

Cancel

L-R

L+R

Filter

75 s

Filter

De-Emph

SAP out

5V

VCC

Pilot Det

+

0.33

PLL

Pilot

Cancel

SAP

RMS Det

Spectral

Expand

Dbx

De-Emph

(L-R)/SAP

Switch

Filter

0.1

Demod

Noise

Det

13

SIF

Base Band

0.22

Input

Input

0.1

2.2 2.2 2.22.2

4.7

3.3K

+++++

1000P

+

SIF

22

Demod

Input

Offset

Cancel

VCA

4.7

19

SIF/BB

Stereo

Filter

SAP

SW

7

8

AGC

2

IC/PARA

Mode Control SW

SAP

Det

Filter

9

MODE

10

FOMO

Noise

Filter

11

MUTE

14

0.033

12

SIF/BB

Page 22

1D

S

2

VIN1

+

-

O.C.P/F.B

5

VIN2

GND

3

-

+

STR-G5653

O.S.C

Vin

4

START O.V.P LATCH DRIVE

REG

+

-

T. S . D

ERROR AMP

20

Page 23

TEA8172

Amplifier

1

-

Power

7

+

4

Flyback

Thermal

Protection

Generator

362

5

21

Page 24

AN7522N

11 12

10

22

3 4 5 6 7 8 9

2

1

Vcc GND

Page 25

THE IC PIN’S VOLTAGE IN NORMAL/STAND BY WORKING MODE (120V, PRESENT

MODE)

1. TMPS8801(N201)

PIN Vlotage(V)

Normal

Voltage (V)

Stand by

PIN Voltage(V)

Normal

Voltage(V)

Stand by

1 5.69 5.63 33 3.04

2 5.69 5.62 34 2.55

3 5.68 5.61 35 2.48

4 0 0 36 5.20

5 5.69 5.62 37 2.25

6 2.52 5.60 38 4.5

7 2.29 2.49 39 1.77

8 0 2.26 40 0

9 5.69 5.60 41 0.10

10 0 0 42 0.10

11 0 43 2.11

12 1.06 44 5.19

13 1.81 45 1.84

14 6.81 46 2.46

15 4.21 47 2.66

16 5.03 48 1.37

17 9.19 49 1.37

18 0 50 9.23

19 2.56 51 2.41

20 2.57 52 2.48

21 2.56 53 2.59

22 0 54 0 0

23 0 55 5.70 5.60

24 2.55 56 0.06 5.56

25 3.52 57 5.33 5.54

26 2.77 58 5.23 5.50

27 4.71 59 0.01 0

28 3.60 60 2.20 5.56

29 9.24 61 0 0.04

30 3.73 62 5.04 5.50

31 1.91 63 5.64 5.55

32 0 64 0 1.04

23

Page 26

2. AN5832(NS01)

4. TEA8172(N301)

PIN Voltage(V) PIN Voltage(V)

1 Empty 17 3.23

2 0.73 18 3.58

3 2.76 19 5.20

4 0.60 20 Empty

5 2.45 21 3.67

6 2.03 22 3.48

7 5.20 23 2.25

8 Empty 24 5.14

9 Empty 25 0

10 Empty 26 Empty

11 Empty 27 4.90

12 Empty 28 1.89

13 3.45 29 2.22

14 3.46 30 2.22

15 2.28 31 Empty

16 Empty 32 2.12

PIN Voltage

1 3.75

2 20.6

3 1.53

4 0.01

5 12.86

6 20.9

7 3.76

5. STR-G5653(N501)Voltage(V)

PIN 1 2 3 4 5

Standby 135 0 0 20 0

Voltage 18 0 0 32 5

3. AN7522N(N601)

PIN Voltage(V)

1 10.52

2 4.66

3 0

4 4.68

5 8.18 0.44

6 1.49

7 0

8 1.48

9 0.43

10 4.62

11 0

12 4.61

6. TC4052(TV)

PIN Voltage PIN Voltage

1 4.30 9 0.05

2 0.27 10 0.01

3 0.75 11 0

4 Empty 12 0.74

5 0.22 13 0.74

6 0 14 0.6

7 0 15 0.13

8 0 16 9.23

7. TDQ-3B8GN(A101)

1 3 4 5 6/7 9 11

AGC AS SCL SDA BM1/2 BT IF

2.1 5.0 5.7 5.3 5.03 32 0

24

Page 27

The triode pin’s voltage in normal working mode (120V, PRESENT Mode. Parenthesis

means stand by)

Symbol Type

Voltage

C E B

V101 2SC2717 7.38 0.24 1

V206 C1815Y 9.23 1.97 2.59

V207 C1815Y 9.23 1.85 2.48

V208 C1815Y 9.23 1.79 2.41

V401 2SC2688 164.6 1.46 1.77

V402 2SC2688 161.4 1.53 1.84

V403 2SC2688 156.4 1.64 1.95

V404 2SC1815Y 2.81 0.01 0.01

V801 2SA1015 0 2.52 1.84

V802 2SA1015 2 9.16 9.18

V803 C1815 4.95 0 0.24

V810 A562TM-0 5.7 5.71 5.03

V601 C1815-Y 0.55 0 0

V509 2SA1015 0 13.06 13.13

V508 SFORIB42 0.01 0.03 0.01

V201 C1815Y 9.24 3.02 3.72

V205 2SA1015Y 0 3.75 3.07

VV01 2SA1015 0 0.7 0.03

V203 C1815Y 9.24 3.68 4.34

V501 2SA1015 9.89(7.41) 13.14(7.56) 12.56(6.77)

V502 2SC1815-Y 12.56(0) 0.01(0) 0.03(0.68)

V505 2SC3807 13.14(7.5) 9.21(0) 9.77(0.13)

V507 2SC3807 9.89(7.3) 5.72(5.5) 6.26(6.0)

V506 2SC1815-BL 9.77(0.2) 0.01(0) 0.03(0.7)

V324 C3807 7.03 5.33 5.89

V322 C2383-0 21.2 0.01 0.4

N303 78M09 13(1 Pin) 0(2Pin) 9(3Pin)

25

Page 28

CAUTION: All the parts in the schematic

diagram marked with red frame and the signs

of are extremely important a safety. In case of

replacement of any part of the components. Be

sure to consult the service manual carefully.

1. The schematic diagram is characteristic. The

various values in the electric circuits are

basic data, which are changeable

according to the various basic circuits.

2. Testing waves are obtained by inputting the

standard color bar of the signed.

3. Resistance unit is in Ohm, namely:

K=1000 M=1000K

Capacitance unit is in F.

P= F( =10

-6)

4. Unless otherwise noted inside, all resistors

are 1/6W, the withstand voltage of all

capacitor are 50V.

5. Inductance unit is in H.

6. The mark in the diagram means Ferrite

ring.

7. The symbols of various types of resistors and

capacitors are listed as follows:

Carbon Film

Metal Film

M

Potentiometer

1/2W

1W

2W

3W

1

2

3

Ceramic

AC Ceramic

AC

Ployester

Ploypropylene

Metal Polyester

Aluminium

Tantalum

+

+

T

Page 29

16151413121110987654321

NTSC

2001.11.26

9V-2

GND

KILL

SPOT KILL

D

X901

1 5

REMO IN

GND

+5V

12V-2

KEY

C

XV11

GND

1 5

*

1

2

10

XV10

11

3

2200U

V IN

4

XV09

GND

A IN R

A IN L

1

GND

XV08

Y

XV07

XV06

X601

B

A

+

_

_

+

X501

LN

AC

N

L

R

W

4

1

N

L

L OUT +

L OUT -

R OUT -

R OUT +

C610

100P

LV06

10uH

LV05

10uH

GND GND GND GND

C611

100P

100n400V

CV1610uF

5698

4

CV15

16V 10uF

CV10

100P

GND

CV09

GND

C611

100P

C508

4n7 250V

2

C506

4n7 250V

C505

V801

2SA1015

R815

R814

560K

680

C809

50V F1u

LED901

*

RC901

3

2

1

RECEIVER

GND

S906

MENU

RV23150

GND

7

RV22

150

10K

RV20

GND

RV19

100P

10K

GND

C613

100P

DB501

T2SB60

1

4

R502

5D2-14LC

1

3

2

t

C504

RT501

470P

9

C502

AC250V 0.1u

T501

LF210-65

C501

AC250V 0.22uF

R501

2M2

R811

2.2K

R812

100

R816

68K

R901

270

GND

C901

R907

120K

S905

TV/AV

L OUT +

4n7 250V

4n7 250V

FU501

T2.5A/AC250V

R810

470

R813

3.3K

GNDGND

C808

CH180

V802

2SA1015

R817

12K

GND GND GND

GND

16V 47uF

R906

30K

S904

VOL-

R OUT +

C509

3

C507

C503

470P

GND

R818

3.9K

12V-2

5V-1

R905

18K

680P 2K

B. G. R.

C807

16V 33uF

GND

C810

B1500

C522

0.01 1KV

C513

R902

47

S903

VOL+

2SA966

RBG

MONITOR

C811

B1800

REMO IN

R904

12K

V509

RL501

JQX-115F

2

1 5

LF21065

1N4148

T502

1 6

X201

V803

C1815

R819

3.9K

KEY

R903

5.6K

S902

CH-

R610

12K

VD601

C549

4.7uF

GND

C548

470uF16V

4

220uF/250V

D

S

2 1

R508

0.15 2W

GND

X903

1

S901

CH+

MUTE

SPOT KILL

GND

VD509

1N4148

R549

10K

VD506

IN4148

GND

C510

C511

100n 400v

N501

STR-G5653

Cont

Block

VD505

IN4148

R507

680

10

GND

VD602

IN4148

R609

12K

R511

10 1/4W

FB/OCP

GND

16V 10uF

C240

100

GND GND

TV/AV

8M

Gnd in

7

GND

C606

10uF

*R606

GND GND

C826

100P

SCL

C239

100

SCL1

X-TAL

6

47

VD803

HZ4B1

R860

220

2K7

SDA

GND

C824

16V 10u

GND

Ch.2 in

8

L601

1mH

GND

C827

100P

SDA1

TEST

GND

C604

GND

R808

10K

R809

10K

5V-1

R820

10K

R867

10K

C802

C825

L802

12uH

Vol10Ch.2 out-11Gnd12Ch.2 out+

9

C605

10uF

C603

10uF

N801

45

SDAGND

3

6

SCL

A2

TEST

A1

A0

M24C08BN6

C804

1K

RMT IN

POWER

PW

STAND-BY

R850

R851

100

100

R854

R853

10K

10K

2

1

A/B

33V

Ch.1out+

23

L OUT +

27P

GND

WP

7

8VCC

R805

27K

R804

10K

GND

TV SYNC

KEY

R852

1K

R855

33K

GND

A562TM-0

Gnd

4

R604

L OUT -

R807

GND GND

47

C806

0.01

C607

A

16v47uF

R801

1K

GND

VOL

AV SW

GND

RESET5VX-TAL

10n

C821

C82247C823

R856

470

RESET

V810

Stand by

Ch.1out-

5

R601

C602

100K

10uF

GND

GND

47K

C805

B

G801

R861 4K7

R859

1K5

Ch.1 in

6

2

1

GND

5V-1

R822

10K

R803

2

12345678910111213141516171819202122232425262728

C820

0.01

GND

5V-1

R866

10K

GND

X202

VOL

V601

C1815-Y

GND

R548

220

12V-2

R607

10K

N601

AN7522

C601

25V 2200uF

VOL

Vcc

1

GND

12V

N502

TLP621GP

1 2

3

4

R505

1/2W-1M

4

5

C514

47uF/50V

R504

C515

470P

220K 1W

5K6

VD501

S5295J

IN4148

HZ16-1

VD502

VD503

VD504

IN4148

R503

Vin

3

POWER

R510

1K8

T503

1

9

2

R518

5M6

C521

2200 AC250V

8

12

11

10

13

14

GND

18

4

3

R512

47

6

RP501

100

R506

1K

5

C516

1200P

7

VD530

TRU3A

C530

330P 2KV

GND

VD532

TFR155

C532

330P 500V

VD533

TFR155

C536

330P 500V

GND

VD534

TFR155

C540

330P 500V

GND

180V 470uF

XITP

R536

1/2W 1

C542

R537

1/2W 1

C543

.1

R538

1W 0.47

C544

.1

VD531

HZ6C2

C531

GND GND

1

GND

2

.1

GND

C537

1000uF/16V

C541

2200uF25V

SCHEMATIC DIAGRAM

B.WPG. R.

789

R212

200

V208

C1815Y

R208

150

51

G OUT

H-AFC

C221

0.47uF 50V

Ch.2 in (R)

C609

10n

R532

4.7 1W

V501

22K

C534

1000uF 16V

GND

B1-5V

C539

.01

200

R213

M

C222

GND

Ch.1 in (L)

2SA1015

B2-9V

10V

1K

GND

C214

R207

150

R OUT

V-SAW

0.47

C535

GND

16V 100u

C223

VOUT

H SYN

.01

L202

12uH

C215

0.01

GND

C213

C212

0.22uF

B2200

GND

GND

30K

33K

R206

R246

1KIN

APC FIL

RGB VCC(9V)

V-OUT

H-VCCNCCb

C224

C2251uC2261uC227

.01

1000uF

GND GND

L203

R222

12uH

1K

GND

R309

15K

3

B4-32V

R545

15K 2W

H VCC

9V

X-RAD

B+

R542

4K7

GND

V506

2SC1815-BL

GND

C211

1u

R205

220K

BLACK DET

R223

CbYCr

100

2

5V-1

110V

R541

4K7

L209

12uH

C210

R224

100

SFORIB42

R868

M1962M

GND

C209

100uF

0.01

GNDGND

RF AGC

YC VCC

MONITOR OUT

Y-INCrTV-GND

R256

100

1u

GND

R225

100

C256

B2200

IDENT

R552

V508

2K7

GND GND GND

C550

1K

0.01

R311

R310

GND

0.01

MUTE

0.01

10n

R OUT -

R530

GND

C533

100uF

8V

GND

12uH

5V

GND

GND

5V-1

R602

GND

15K2W

8V

R547

C547

16V10uF

L801

R531

220

R214

1K

1K

R215

GNDGND

C1815Y

C801

16V 10u

GND

GND

GND

R220

10K

10K

R OUT +

GND

L501

75uH

V502

2SC1815-Y

R546

7501W

C546

GND

V507 2SC3807

1K

GND

L502

100uH

R210

R211

200

V206

V207

C1815Y

R209

150

GND

52535455565758596061626364

GND

B OUT

N201

TMPS8801PSAN

FBP-IN

SCP-OUT

H-OUT

C220

B8200

R221

8.2K

SDA/SCL

Y/C

H SYN

4

H OUT

10K

R603

C608

10n

GND GND

R533

6K8

GND

R534

V505

2SC3807

VD507

HZ9C3

GND

25V47uF

VD508

HZ6B1

C538

330uF16V

B3-10V

Z201

3215

4

R204

820

IF IN

C-IN

R226

100

C228

C IN

VD561

HZ18-3

10K

3K9

GND

C310

47uF/16V

L201

12uH

IF IN

EXT-IN

GND

C229

0.47uF

10uF

1/2W 270

Y IN

TP502 TP501

R553

30K

C305

1000p

IF GND

DVCC 5V

C230

0.01

C231

0.47u

R227

R554

10K

input

Non inv

GND

GND

GND

C232

C208

0.01

C205

C233

0.1

R228

390K

1

0.1

Vcc

Out Stage

C207

16V 470u

GNDGND

4.7uF 50V

M

1uF

IF-AGC

TV IN

M

M

GND

17.2V

N301

V out

C302 10P

220uF 35V

R305

33K

R302

12K

R108

220

C204

M

C206

0.01uF

DEEMPH

ABCL-IN

C234

10u

GND

C235

VD204

1N4148

11

GND

ABL

TEA8172

Gnd

GND

VD301

TVR-1B

C303

R307

200

R306

10K

C306

4.7uF/50V

GND

C109

0.01

L103

0.68uH

GND

C108

0.01

R202

C203

100

1000P

C202

R203

1.5M

S-REG

IF-VCC

PIF PLL

AUDIO-OUT

IF-VCC(9V)

TV-OUT

29 30 31 32

GND GND

GND

C236

0.01

10u

R230

100

GND

L208

12uH

R229

3.3K

TV IN

Y CB CR

H-OUT

EXT IN

9V-2

R243

1K

R244

1K

J079

Vcc 1

Flyback

20V

C301

1n

C308

0.1

M

C307

1000u 35V

R303

*1.2 1W

GND

2SC2717

R201

330K

0.47u

R242

3K3

V201

C1815Y

Inv in

1234567

GND

M

GND

R106

270

V101

R107

33

C201

16V 10u

333435363738394041424344454647484950

DC-NF

SIF-OUT

9V-2

GND

C351 0.1

GND GND

R308

1

C309

0.1

X301

R104

5.6K

R105

1K

GND

SIF-IN

EXT-AUDIO

C238

R231

0.01

100

R240

R241

390

330

2SA1015Y

R237

100

L204 10uH

R236

220

C350

220uF 35V

11

C107

0.01

L102

0.56uH

C246

0.01

Z203

LT4.5M

GND

GND

R233

27K

TV/AV/L/R

V205

GND

XT4.5MB

GND

12V-2

R312

R316/R317

GND

R314

R315

GND

3456 12

5V-2

9V-2

VT

A101

R103

100

C560

1000

GNDGNDGND

GND

C243

V203

0.01uF

C1815Y

R232

27K

GND

R235

R234

1K

1K

GND

GND

R239

2K2

R238

1K

Z202

C311

GND

220uF25V

TH-20V

5V-2

1W 150

GND

C344

0.01

1000uF 35V

1W 150

18K

1K

R320

330

R322

330

C2383-0

GND GND GND

IF

C561

50V 10u

GND GND

33V

C3807

C341

GND

V322

IF

1011

N505

uPC574JL

C244

16V 47uF

GND

RV01

LV07

100uH

CV13

0.1

C551

50V10u

GND

C557

.01

GND

V324

GND

C343

470uF 16V

C346

0.01

GND

C322

1n 500V

782-K2035-0100

M

CS08

1

SIF IN

XS01

GND

GND

5V-2

R216

SDA

100

SCL

R217

GND

RV16

C349

GND

C329

4u7 160V

S5295J

C330

390n 200V

GND

75

RV05

GND

RV04

GND

IDENT

LV04

10uH

LV03

10uH

100P

R328

1W10K

CKX5-2K-2

GND

RV21

Y

Cb

Cr

CV12

100P

10K

GND

CV11

10K

GND

HEATER

8

7 6 5

75

A IN L

A IN R

LV02

10uH

LV01

10uH

200V

100

GND

L IN

L IN

R IN

R IN

8

GND

Y

2 1

9 10

XV05

4 3

C

3

XV03

1

*

GND

XV02

1

L IN

R IN

GND

V IN

4

V-IN

XV01

6

L1

A-IN L

7

1

R1

A IN R

3

18

V1

V-IN Y

19

15

Y

17

75

RV13

GND

8

Cb

75

RV12

GND 9

4

Cr

75

RV11

GND

5

10

L2

11

12

R2

13

14

GND

4

667-K2035-0200

GND

1

X302

1 6

X401

R

G

B

9V

GND

GND

AS

SCL

SDA

C106

0.01

89

GND

16V 470uF

7

C105

GND

BM2

6

BM1

L101

68uH

AGC

AGC

3

R109

100

R102

15K

R101

62K

12

C102

50V 4.7u

GNDGND

4

5

R110

100

SCL

SDA

BT

5V-2

9V-2

RV17

2.2K

RV18

1K

GND

VV01

2SA1015

SIF IN

5

SIF IN

CV08

100P

10K

RV15

GND

GND

CV07

100P

10K

RV14

GND

GND

SDA/SCL

5V-2

R IN

L IN

9V-2

L IN

CV03

CV04

10uF

1000u/16V

C324

CV05

100uF

GND

C556

GND

VD342

TFR155

1n

GND

NV01TC4052

10

A

11

3X

0X

12

XC

13

1X

14

2X

15

16 0Y

VDD

C333

VD302

5600

5.1V

GND

TH-12V

C347

330P 500V

V323

D1651

C325

4n7 1K6V

VSSB

VEE

INH

1Y

3Y

YC

2Y

GND

C348

33uF 160V

C326

*6n81K6V

GND

89

7

6

5

4

3

2

1

R333

6.8K

330P 500V

C352

GND GNDGNDGND

GND

R IN

R313

6.8K

VD343

R350

1W 1

R351

1W 1

R343

1W 10

GND

C327

*820P 2KV

TFR155

12

13

TH-200V

100V

CV01

10uF

CV02

10uF

Ch.2 in (R)

10K

RV10

RV07

RV08

CV06

5K6

16V 10u

100K

RV09

5K6

GND GND

RV06

100K

10uF/250V

R555

T302

1 1W

5

HV

3

8

GND

4

2

1

6

10

L333

*HL1830H

R326

1W 1K

R325

1K

C331

56n 200V

L322

600J3R0

R327

1W 1K

FOCUS

SCREEN

7

GND

VD321

GND

10K

J076

R345

2W 12

C332

3300

Ch.1 in (L)

GND

9V-2

GND

GND

VD346

HZ6B1

R323

GND

B

A

C555

1000u/16V

C345

10uF 16V

330P 500V

1W 2K

C323

1uF 160V

RV02

100

RV03

100

GND

VD341

TFR155

C342

R324

5W 3K3

T301

14

16V 10u

VD562

S5295G

N303

78M09

GND

R342

1W 1K

2.2uF

CS07

L+R REF

PLL

M

CS10

0.1uF

M

0.033uF

SAP DET

VCC

M

CS21

0.1uF

GND

CS06

M

0.1uF

SIF/BB

NOISE DET

NC

INPUT

CS12

1000P

CS14

4.7uF

SIF IN

MUTE

SIFREF

CS15

GND

CS19

100uF

FOMO

STEREO

REF

2.2uF

GND

GND

1

GND GND

NC

PILOT

DET

17 18 19 20 21 222324 252627 28 29 30 31 32

3K3

RS01

CS09

M

0.33uF

CS11

0.22uF

782-Q2735-3100

XS01

XV06

R1

L1

1

5

2

4

3

GND

X601

V1

7

1

6

A IN L

A IN R

782-K2035-2900

S501

782-K20351-0500

V401

2SC2688

L402

68uH

R425

2K7

C411

100uF 16V

VD404

IN4148

220uF 16V

R424

R417

1K2

VD405

IN4148

C410

R401

100

R407

4K7

R402

100

R408

4K7

R403

100

R409

4K7

SPOT KILL

R427

1K

GND

GND

V402

2SC2688

R405

300

C406

0.01

V405

2SA1015Y

GND

GND

GND

V403

2SC2688

GND

GND

R404

300

R406

300

R422

VD401

1N4148

R410

330

C401

390P

GND

VD402

1N4148

R411

330

C402

390

GND

VD403

1N4148

R412

330

C403

470

GND

22K

R423

1K8

GND

MODE

SDA/

RS06

100

LS01

0.68uH

GND

V404

2SC1815Y

GND

CS20

0.01uF

SAPID

GND

V IN

CV15

10uF

RV22

X202

R416

*

*R426

2.7 1W

AGC SW

GND

5V-2

SDA

4

220

R413

1K2

15

CS05

0.022uF

I2C/PARA

PE

RS07

100

GND

SCL

XV10

11

4569

7

R414

1K2

16

17

4

CS04

0.1uF

M

M

SPE FIL

SPE DET

SCL/STID

AGC DET

CS16

GND

RS02

180K

16

15

GND

10

GND

8

R419

15K 2W

R420

15K 2W

R421

15K 2W

R415

1K2

GND

X402

1

CS02

CS03

0.33uF

3.3uF

WB DET

SPE TIME

Lout

Rout

RS03

RS08

1K

1K

2.2uF

5v-2

VS01

C1815-Y

RS09

CS20

100

2.2uF

RS10

680

R out

GND GND

L out

8

XV11

15

L OUT +

132

CV16

10uF

RV23

220

200V

200V

GND

L401

C409

100uH

10uF 250V

GND

CS01

10uF

CS17

2.2uF

X403

*

6

8

2

4

3

12345678910111213141516

WB TIME

NC

GND

GND

NC

L-R DEF

CS18

2.2uF

VS02

C1815-Y

RS04

100

R OUT +

NS01

AN5832

RS05

680

57

GND

C407

2n2 2KV

SCREEN

FOCUS

D

C

B

A

HV

2002.04.22

Title

782-K2035-01DL

Number RevisionSize

A0

Date: 13-Jun-2002 Sheet of

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

File: \\..\UOC NTSC 020108 TEXT.sch Drawn By:

Page 30

Page 31

N

f

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION

PERCAUTION”, “SAFETY PRECAUTION” AND “RPODUCT SAFETY NOTICE” O

PAGE 1&2 OF THIS MANUAL.

CAUTION: 1. The shaded areas makes in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with type

identical to those in the original circuit or specified in the parts list. Before replacing any o

these components, read carefully the PRODUCT SAFETY NOTICE on page 2.

2. Do not degrade the safety of the receiver through improper servicing.

ELECTRICAL PARTS LIST

MAIN BOARD

SYMBOL PART NO.

782-K2035-0100 MAIN PCB

CRYSTAL

G801 329-58001-00 8MHZ

DIODE

VD204 340-00001-003 1N4148

VD504 340-00001-003 1N4148

VD505 340-00001-003 1N4148

VD506 340-00001-003 1N4148

VD502 340-00001-003 1N4148

VD601 340-00001-003 1N4148

VD602 340-00001-003 1N4148

VD509 340-00001-003 1N4148

VD321 340-00005-003 S5295J

VD501 340-00005-003 S5295J

VD301 340-00086-003 TVR-1B

VD343 340-00288-003 TFR155

VD562 340-00005-00 S5295J

VD342 340-00288-00 TFR155

VD341 340-00288-00 TFR155

VD532 340-00288-00 TFR155

VD533 340-00288-00 TFR155

VD530 340-00292-00 TRU3A

VD534 340-00291-00 TEU2YX

DESCRIPTION

27

Page 32

SYMBOL PART NO.

DESCRIPTION

REGULATED DIODE

VD510 340-51180-00 HZ12A1

VD803 340-50380-003 HZ4B1

VD302 340-50910-003 HZ9C1

VD531 340-50610-003 HZ6C2

VD507 340-50950-003 HZ9C3

VD503 340-51560-003 * HZ16-1

VD561 340-51850-003 HZ18-3

VD346 340-50560-003 HZ6B1

VD508 340-50560-003 HZ6B1

REDTIFIER

DB501 340-80022-00 T2SB60

TRANSISTOR

V508 343-00420-404 SFORIB42

V810 343-05620-604 2SA562TM-O

V205 343-10150-104 2SA1015Y Pr2.5

V501 343-10150-104 2SA1015Y Pr2.5

V801 343-10150-104 2SA1015Y Pr2.5

V802 343-10150-104 2SA1015Y Pr2.5

VV01 343-10150-104 2SA1015Y Pr2.5

V509 343-10150-104 2SA1015Y Pr2.5

V201 343-18150-104 2SC1815-Y

V203 343-18150-104 2SC1815-Y

V502 343-18150-104 2SC1815-Y

V601 343-18150-104 2SC1815-Y

V803 343-18150-104 2SC1815-Y

V206 343-18150-104 2SC1815-Y

V207 343-18150-104 2SC1815-Y

V208 343-18150-104 2SC1815-Y

V506 343-18150-204 2SC 1815-BL

V323 343-18030-80 ST1803DHI

V322 343-23830-60 2SC2383-0

V101 343-27170-00 2SC2717

V505 343-38070-00 2SC3807

V507 343-38070-00 2SC3807

V324 343-38070-00 2SC3807

IC

N505 352-05740-00 uPC574 (D)

N502 352-06210-7Q TLP621-GB(UL) (O)

N801 352-24080-50 M24C08BN6 (M)

28

Page 33

SYMBOL PART NO.

DESCRIPTION

NV01 352-40520-60 TC4052BP (M)

N501 352-56530-00 STR-G5653 (M)

N601 352-75220-00 AN7522N (M)

N303 352-78009-10 TA78L009AP (D)

N301 352-81720-10 TDA8172 (M)

N201 352-88030-00 TMPA8803CSBNG-3VJ0

S-VIDEO

XV05 364-91202-00 CKX5-2K-2

AV SOCKET

XV01 364-98205-00 AV901-6

RELAY

RL501 457-12019-90 JQX-14FF-012-1HS

SAW FILTER

Z201 458-07008-00 M1962M

CERAMIC CAPACITOR

C503 459-B147M-20 ECK-DNS471MBX

C504 459-B147M-20 ECK-DNS471MBX

C521 459-B222M-20 ECK-DNS222MEX

C506 459-B247R-00 DE0807F472ZAC250V

C507 459-B247R-00 DE0807F472ZAC250V

C508 459-B247R-00 DE0807F472ZAC250V

C509 459-B247R-00 DE0807F472ZAC250V

THIN-FILM CAPACITOR

C502 462-2B410-M0V 250VAC-0.1uF-M

C501 462-2B422-M0V 250VAC-0.22uF-M

METAL RESISTOR

R313 467-2E268-H0 1/2W-6.8kΩ-JL

R532 467-2FA47-H0 1W-4.7Ω-JL

R546 467-2F175-H0 1W-750Ω-JL

R326 467-2F210-H0 1W-1KΩ-JL

R323 467-2F220-H0 1W-2KΩ-JL

R328 467-2F310-H0 1W-10kΩ-JL

R504 467-2F422-H0 1W-220K-JL

R508 467-2GB15-H0 2W-0.15Ω-JL

R345 467-2G012-H0 2W-12Ω-JL

R530 467-2G315-H0 2W-15kΩ-JL

R545 467-2G315-H0 2W-15kΩ-JL

R307 467-2E120-H0 1/2W-200Ω-JL

R227 467-2E127-H0 1/2W-270Ω-JL

R507 467-2E168-H0 1/2W-680Ω-JL

29

Page 34

SYMBOL PART NO.

DESCRIPTION

R342 467-2E210-H0 1/2W-1kΩ-JL

MELTABLE RESISTOR

R536 467-4E001-H0 1/2W-1Ω-JL

R537 467-4E001-H0 1/2W-1Ω-JL

R350 467-4FB33-H0 1W-0.33Ω-JL

R351 467-4FB33-H0 1W-0.33Ω-JL

R538 467-4FB33-H0 1W-0.33Ω-JL

R555 467-4F001-H0 1W-1Ω-JL

R343 467-4F010-H0 1W-10Ω-JL

WIRE-ROUND RESISTOR

R303 467-6FA12-H0 RX21-1-1.2Ω-J

CEMENT RESISTOR

R324 467-50233-H8 RY27-3Z-5W-3.3K-J

CARBON RESISTOR

R503 467-8E510-H0A 1/2W-1MΩ-J

R501 467-8E522-H0A 1/2W-2.2M-J

R518 467-8E556-H0A 1/2W-5.6MΩ-J

THERMISTOR

RT501 469-10023-00 96708 (9Ω)

R502 469-40004-00 5D2-14LC

SWITCH TRANSFORMER

T503 470-00272-00 SR3601B

POTENTIOMETER

RP501 468-01108-00 GVA061-100Ω±20%

INDUCTANCE WITH COLOUR CODES

LV01 471-2010K-003 SPT0305-100K-5

LV02 471-2010K-003 SPT0305-100K-5

LV03 471-2010K-003 SPT0305-100K-5

LV04 471-2010K-003 SPT0305-100K-5

L801 471-2012K-003 SPT0305-120K-5

L201 471-2012K-003 SPT0305-120K-5

L202 471-2012K-003 SPT0305-120K-5

L208 471-2012K-003 SPT0305-120K-5

L209 471-2012K-003 SPT0305-120K-5

L101 471-2068K-003 SPT0305-680K-5

LV07 471-2110K-003 SPT0305-101K-5

L102 471-2B56K-00 SPT0305-R56K-5

L103 471-2B68K-00 SPT0305-R68K-5

L204 471-2010K-00 SPT0305-100K-5

L601 471-2210K-10 LGA0410-1000uH-K

30

Page 35

SYMBOL PART NO.

L802 471-2012K-00 SPT0305-120K-5

L203 471-2012K-00 SPT0305-120K-5

H-DRIVE TRANSFORMER

T301 472-10038-00 DE1939

FBT

T302 472-2411B-00 BSC25-3368

CERAMIC FILTER

Z203 475-15451-00 LT4.5MH

CERAMIC TRAP FILTER

Z202 475-25451-00 XT4.5MB

H-LINEARITY COIL

L333 477-00083-00 LX221

POWER FILTER

T501 477-20028-00 LF21065

T502 477-20028-00 LF21065

FIXED INDUCTANCE

L501 477-40031-00 LG750

L502 477-40164-00 LGB1012-L100

FBT

T302 472-24206-00 BSC24-3031!

OTHER

TUNER(A101) 590-40707-00 115-B-8035AZ

POWER CORD 491-702D0-02 UL

FUSE(FU501) 569-16101-90 51S 2.5A/250V

CRT 335-2112K-00U CRT54SX503Y22-DC01

DEGAUSSING COIL 477-12102-00 BD-204A

CRT SOCKET(X403) 364-58204-00 GZS8-17(UL)

DESCRIPTION

FRONT AV BOARD

SYMBOL PART NO.

782-K2025-2900 FRONT AV PCB

AV SOCKET

XV06 364-93202-00 AV306-2

ELECTROLYTIC CAPACITOR

CV15 464-6D610-M0 CD110-16V-10uF-M

CV16 464-6D610-M0 CD110-16V-10uF-M

CARBON RESISTOR

RV22 467-1D115-H0 RT14-1/4W-150Ω-J

RV23 467-1D115-H0 RT14-1/4W-150Ω-J

31

DESCRIPTION

Page 36

CRT BOARD

SYMBOL PART NO.

782-J2130-0200 CRT PCB

DIODE

VD401 340-00001-00 1N4148

VD402 340-00001-00 1N4148

VD403 340-00001-00 1N4148

TRANSISTOR

V404 343-18150-10 2SC1815-Y

V401 343-26880-60 2SC2688M

V402 343-26880-60 2SC2688M

V403 343-26880-60 2SC2688M

METAL RESISTOR

R419 467-2G315-H0 2W-15kΩ-JL

R420 467-2G315-H0 2W-15kΩ-JL

R421 467-2G315-H0 2W-15kΩ-JL

MELTABLE RESISTOR

R426 467-4F003-H0 1W-3Ω-JL

INDUCTANCE WITH COLOUR CODES

L401 471-1110K-00 EL0606SKI-101K

L402 471-2068K-10 LGA0410-68uH-K

DESCRIPTION

STEREO BOARD

SYMBOL PART NO.

782-Q2735-310A STEREO PCB

IC

NS01 352-58320-50 AN5832SA (D)

TRANSISTOR

VS01 343-18150-104 2SC1815-Y

VS02 343-18150-104 2SC1815-Y

INDUCTANCE WITH COLOUR CODES

LS01 471-2068K-103 LGA0410-68uH-K

DESCRIPTION

32

Loading...

Loading...