Page 1

SERVICE SERVICE

MANUALMANUAL

Page 2

CONTENTS

1. INSTRUCTION………………………………………………………………………………1

2. ALIGNMENT PROCEDURE………………………………………………………………..2

3. FOR FACTORY MENU ADJUSTMENT SEE CHART5~CHART11…………………….5

4. GENERAL DESCRIPTION OF THE SDA 9380-B21……………………………………10

5. INTRODUCTION OF THE VPC 3230D………………………………………………..12

6. INTRODUCTION OF THE MSP 3425G…………………………………………………14

7. GENERAL DESCRIPTION OF THE PW1235…………………………………………15

8. GENERAL DESCRIPTION OF THE TDA6111Q………………………………………18

WIRING DIAGRAM……………………………………………………………………….20

BLOCK DIAGRAM………………………………………………………………………...21

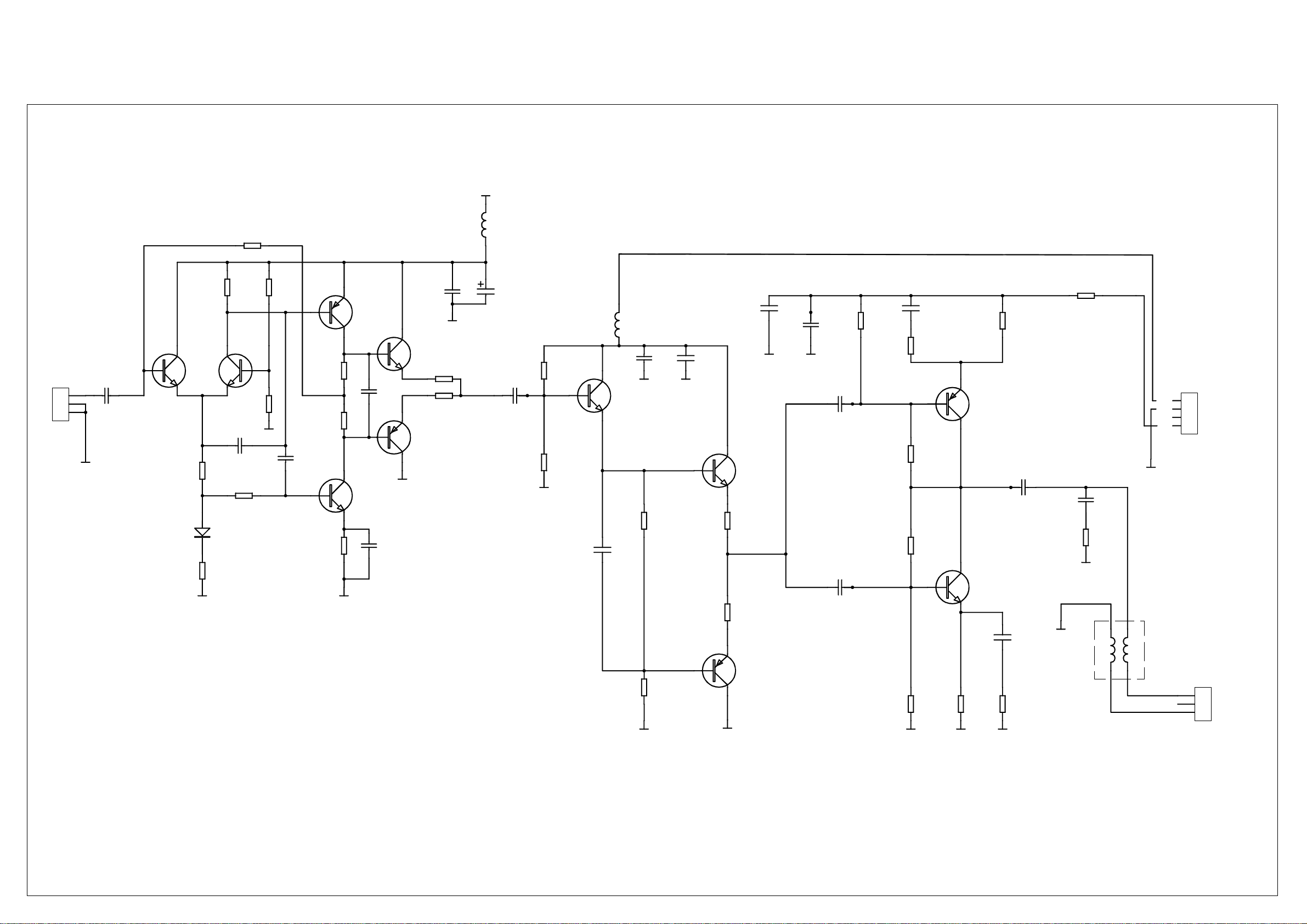

SCHEMATIC DIAGRAM………………………………………………………………….22

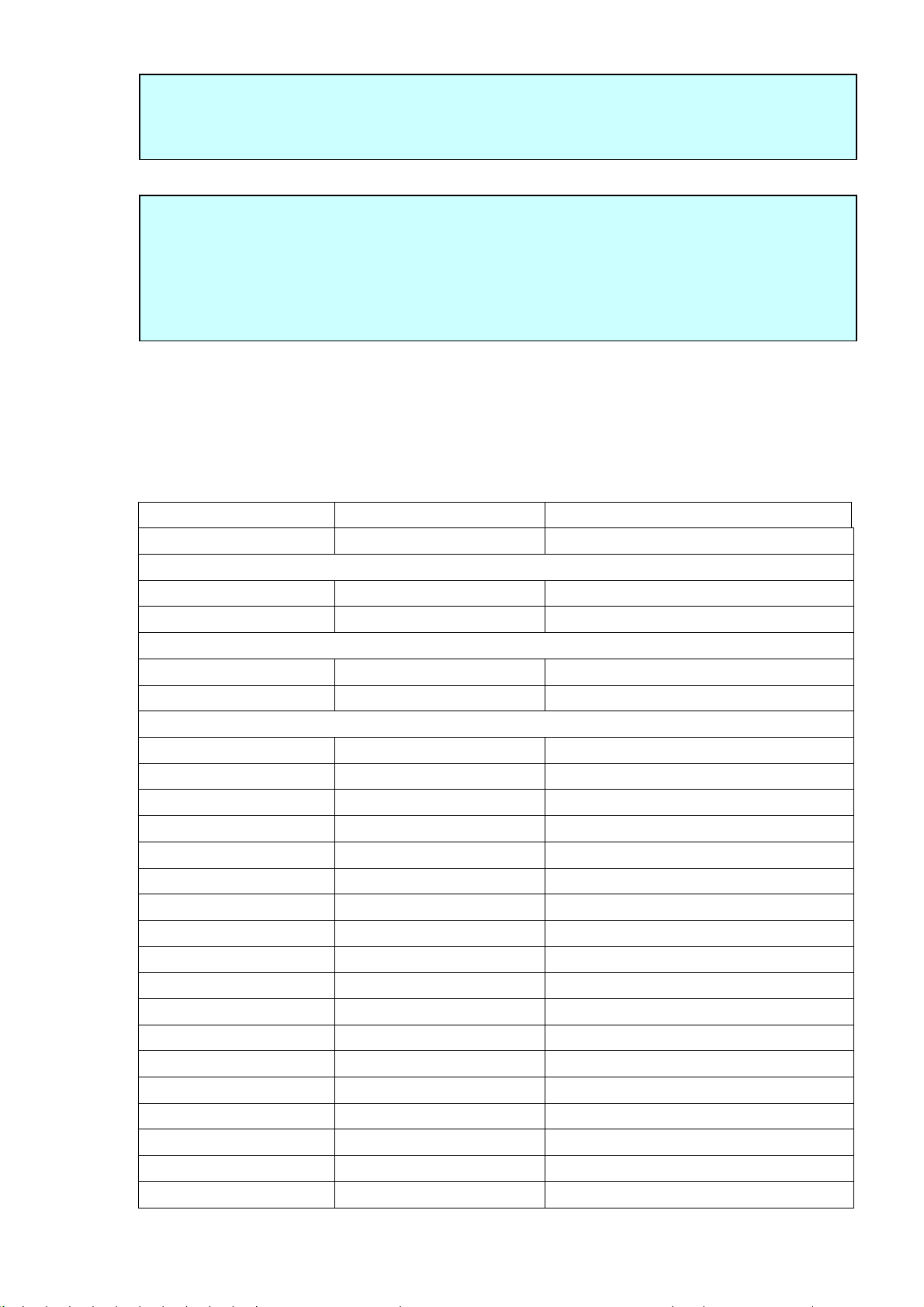

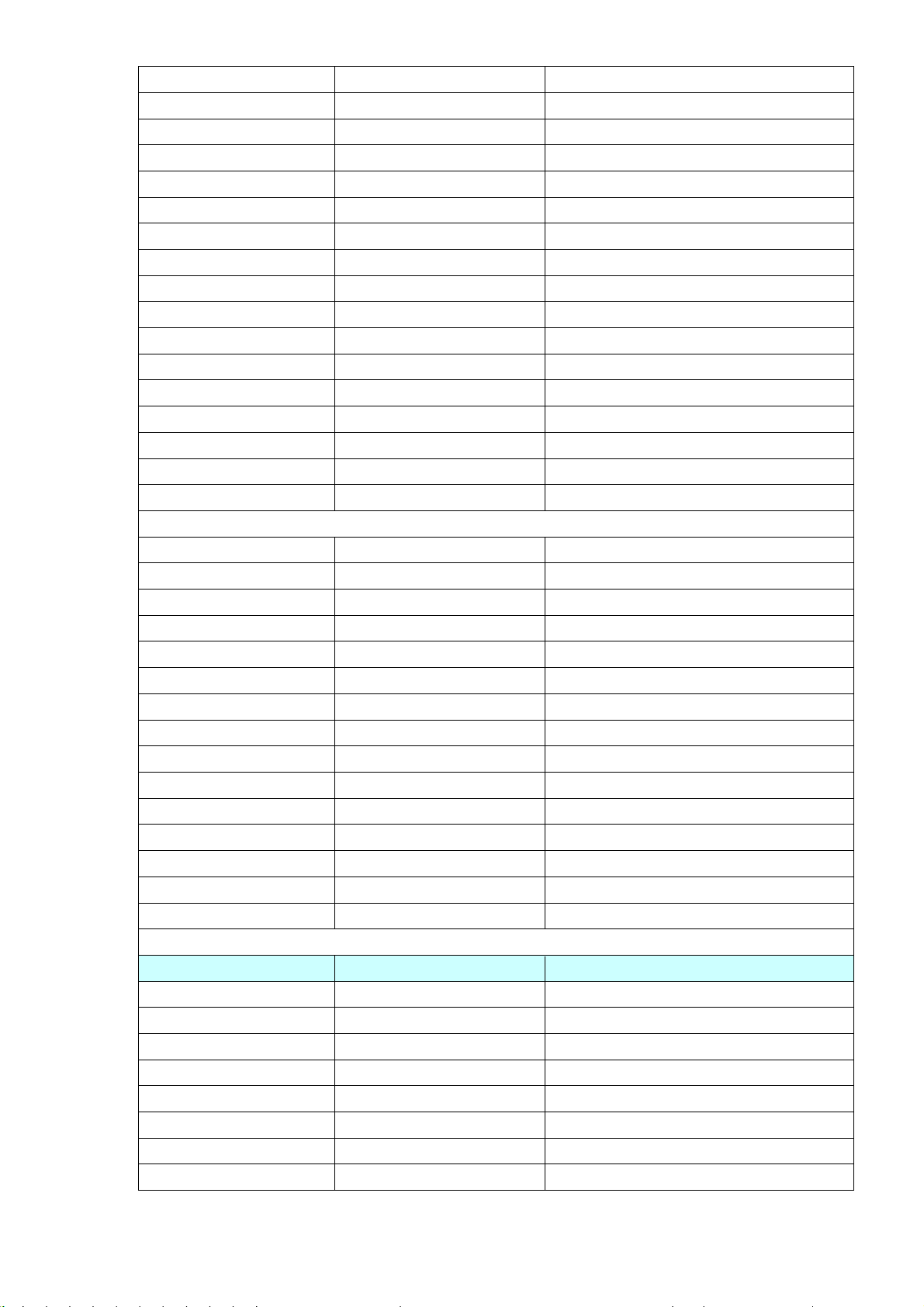

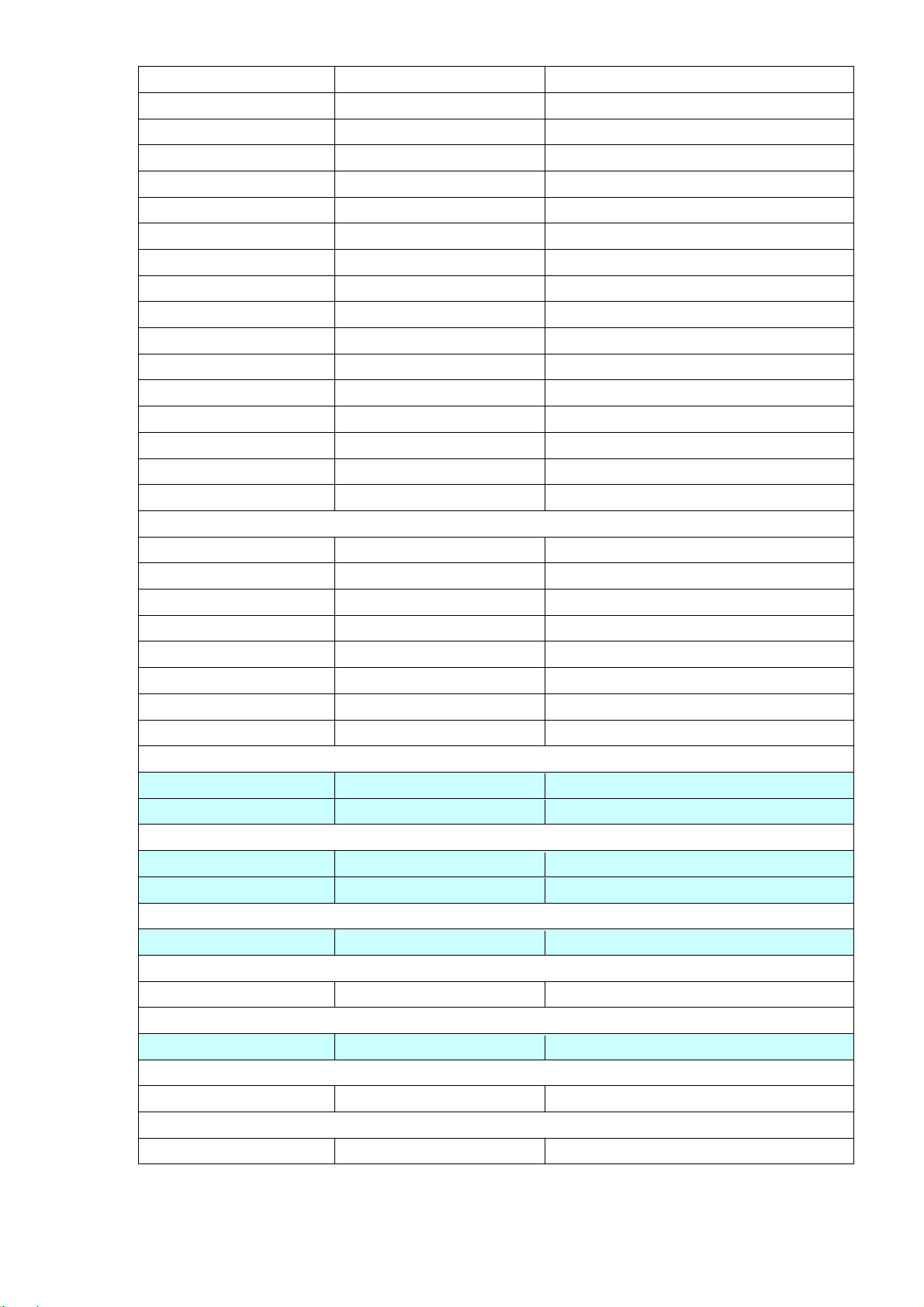

ELECTRICAL PARTS LIST………………………………………………………………27

0

Page 3

CAUTION: THIS SERVICE MANUAL IS ONLY FOR PROFESSIONAL SERVICE PERSONNEL’S

REFERENCE. BEFORE SERVICING THIS CHASSIS, PLEASE READ THE

FOLLOWING NOTICE ITEMS.

1. INSTRUCTION

Before servicing and aligning this equipment, please read the following “X-RAY RADIATION

PRECAUTION” ,“SAFETY PRECAUTION” and “PRODUCT SAFETY NOTICE”.

1.1 X-RAY RADIATION PRECAUTION

Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such

1

hazards, the high voltage must not be above the specified limit. The normal value of the high

voltage of this receiver see below chart:

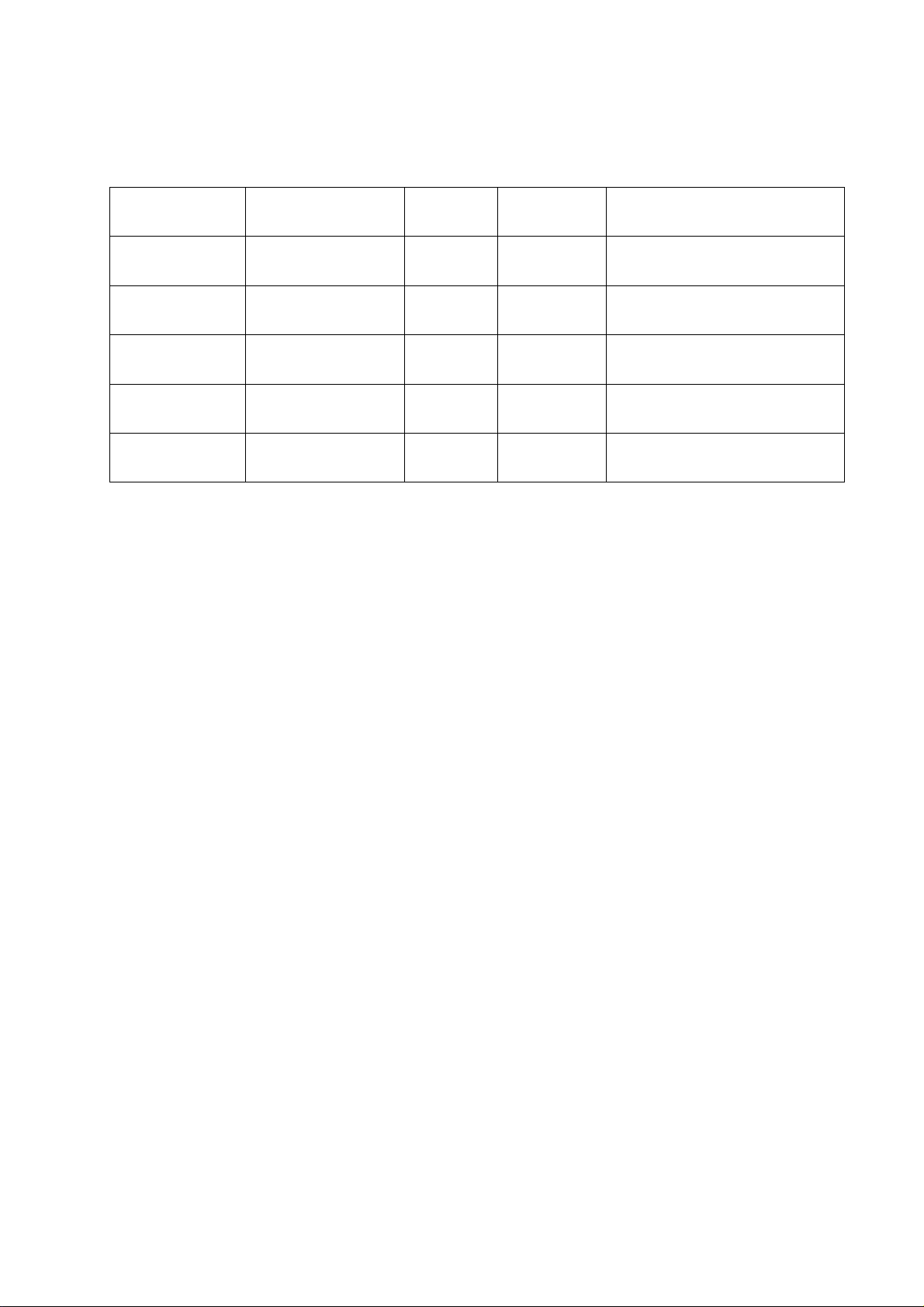

Chart 1 High voltage requirement

T2751

T3251

Model

High voltage normal

value

30 kV

30 kV

1 kV

1 kV

Utmost value Beam current

35 kV 1.6 mA

35 kV 1.6 mA

Each time a receiver requires servicing, the high voltage should be checked following the HIGH

2

VOLTAGE CHECK procedure in this manual. It is recommended the reading of the high voltage

be recorded as a part of service record. It is important to use an accurate and reliable high voltage

meter.

* When checking, main power (B+) should be kept at 135 V (for Toshiba pure flat CRT).

The primary source of X-RAY RADIATION in this TV receiver is the picture tube. For continuous

3

X-RAY RADIATION protection, the replacement tube must be exactly the same type tube as

specified in the parts list.

Some parts in this receiver have special safety-related characteristics for X-RAY RADIATION

4

protection. For continuous safety, parts replacement should be undertaken only after referring to

the PRODUCT SAFETY NOTICE below.

1.2 SAFETY PRECAUTION

WARNING:

Service should not be attempted by anyone unfamiliar with the necessary precaution on this receiver.

The following are the necessary precautions to be observed before servicing this chassis.

1) Since the power supply circuit of this receiver is directly connected to the AC power line, an

isolation transformer should be used during any dynamic service to avoid possible shock hazard.

2) Always discharge the picture tube anode to the CRT conductive coating before handling the

picture tube. The picture tube is highly evacuated and if broken, glass fragments will be violently

expelled. Use shatter proof goggles and keep picture tube away from the unprotected body while

handling.

1

Page 4

3) When replacing a chassis in the cabinet, always be certain that all the protective devices are put

back in place, such as: non-metallic control knobs, insulating covers, shields, isolation

resistor-capacitor network etc.

4) When replacing parts or circuit boards, disconnect the power cord.

5) When replacing a high wattage resistor (oxiode metal film resistor) on the circuit board, keep the

resistor 10mm (1/2in) away from circuit board.

6) Connection wires must be kept away from components with high voltage or high temperature.

7) If any fuse in this TV receiver is blown, replace it with the FUSE specified in the chassis parts list.

1.3 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the chassis have special safety-related characteristics.

These characteristics are often passed unnoticed by a visual inspection and the X-RAY RADIATION

protection afforded by them cannot necessarily be obtained by using replacement components rated

for higher wattage, etc. Replacement parts which have these special safety characteristics are

identified in this manual and its supplement electrical components having such features are shaded

on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of

substitute replacement parts which do not have the same characteristics as specified in the parts list

may create shock, fire, X-RAY RADIATION or other hazards.

1.4 Testing equipment

HDTV signal generator: VG853 or other same type, 1 set.

Signal generator: PM5515 or the same type, 1 set.

Voltameter: FULK805A or the same type, 1 set.

White balance alignment equipment: 1 set

Standard testing jigs: 1 set.

Geometry alignment equipment: 1 set.

Alignment stick: 1 set.

Degaussor: 1 set.

2 Alignment procedure

2.1 Instruction

a) In this chassis since there are a great amount of data needed to be set, these setting all are stored

2

PROM. To reduce the alignment working, use the aligne d E2PROM as a female parent to

in E

copy and then use them. Or refer to appendix chart and preset E

b) To conduct the alignment, the power supply should be AC120 V,60 Hz. The whole unit should be

preheated for 30 minutes.

c) To conduct with color purity, conver gence, white balance alignment or other alignment relative to

color, the CRT should be degaussed thoroughly.

d) Since this chassis adopts modulization structure, before mounting, every module should be

conducted with alignment.

e

The factory menu’s alignment should use XOCECO RC-T03-0A remote control. Press power

switch to turn on the set, in turn press button “SLP-MUTE-AV-MENU” to enter into factory menu.

2

2

PROM value and then use.

Page 5

Press SLP or 0 button to exit. Press MUTE button to preset before Out-factory.

f) For the supporting mode in this set see below chart 2.

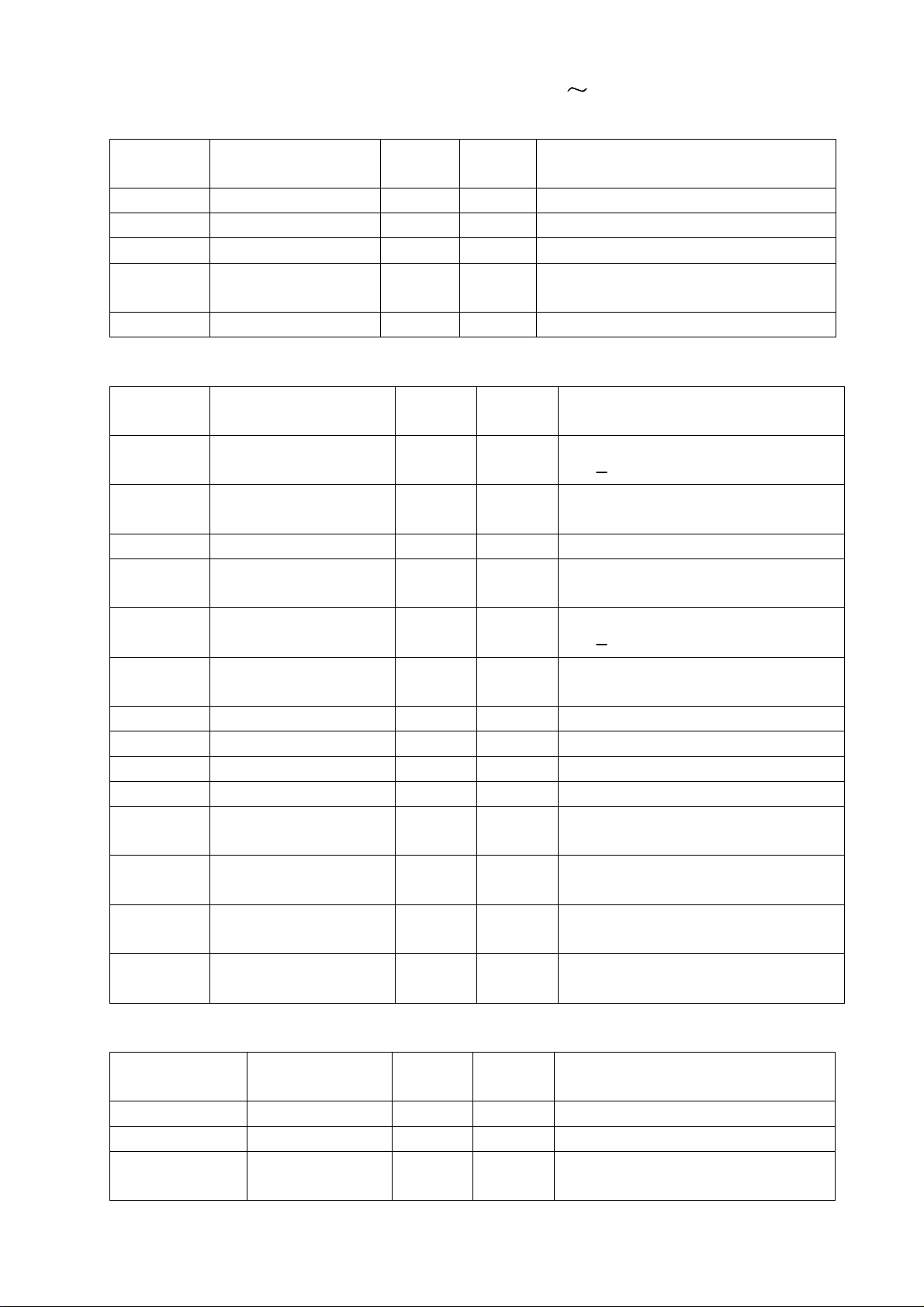

Chart 2 The supporting mode in this set

Working mode Mode instruction H-frequency

Hz

TV TV mode 33.75k 60 Adjust firstly, every item should

1920*1080i/33.75K American HDTV mode 33.75k 60 Horizontal and vertical parameter,

720P*576/45.125K American HDTV mode 33.75k 60 Horizontal and vertical parameter,

640*480i(YCrCb) YcbCr(15.7K,59.97HZ) 33.75k 60 Horizontal and vertical parameter,

640*480p(YPrPb) Progressive

DVD(31.5K,60HZ)

33.75k 60 Horizontal and vertical parameter,

V-frequencyHz Alignment instruction

adjust

white balance

white balance

white balance

white balance

2.2 Alignment procedure

2.2.1 Module alignment

In all the module alignment, use a normal working TV set as an alignment frock, pull the set’s

corresponding module and keep it as an example. Insert the module wanted to be check,

then apply power to alignment.

a) AV board module

AV interface function check: check all the AV input/outputs function, it should meet the Product

Standard requirements.

b) Digital processing board module

No alignment point, apply the power and check whether S-VIDEO, YCbCr, YpbPr input is normal.

c) Main board

No alignment point. Apply the power and measure “B+” voltage, the reading should be 105V,

check there are no assemble error, the OSD,SVM is normal, and it is OK.

2.2.2 Chassis adjustment

Correctly insert all modules and parts, connect CRT board parts to CRT, apply power and

check B+ voltage, the reading should be 105V. (on J332/J305)

2.2.3 The whole unit adjustment

Be sure the whole unit has been preheated for 30 minutes.

a) Focus adjustment

1) In TV mode receive crosshatch signal, at the same time set SVM to OFF.

2) Adjust FOCUS inductance L306 on Dynamic Power Board to make R323 dynamic focus

voltage be 1KV+/-50V.

3) Adjust FOCUS potentiometer on FBT and CRT to make horizontal and vertical grid both

thinnest, and consider horizontal grid mainly.

4) Set SVM to ON, check the whole effect.

b) Dark current (SCREEN voltage) adjustment

In TV mode receive gray scale signal, after entering into factory menu status, press “1” button to

enter into “FACTORY MENU 1” factory menu, first preset WHITE-R, WHITE-G, WHITE-B’s

value all to 0, adjust SCREEN potentiometer to make SCREEN LOCK on the screen lower part

3

Page 6

display OK and it is OK, at this time, if changing channel, it should not appear flyback line. This

state should also be OK after finish adjusting the white balance. .

c) White balance adjustment

Adjust on the basis of the above step, at standard status use gray scale signal to adjust.

1

Press “1”button to firstly adjust TV input white balance: fix the testing point at about 40 nits gray

scale, then by adjusting WHITE-R,WHITE-G and WHITE-B to make the value meet chart 3’s

requirement.

2

Press “5” button to adjust YpbPr input white balance: use oscilloscope to measure Y signal

output on Digital Processing Board. Adjust G-0 gray scale to make blanking level be even with

black level, adjust G-G to make signal amplitude to be 0.7V and eight level gray scale be even,

then adjust R-G, B-G, R-0, B-0’s value to make white balance meet chart 3’s requirement.

Chart 3: chroma coordinates requirements

Colour temperature 12000K

X coordinate

Y coordinate

0.270

0.283

0.008 MPDC

0.008 MPDC

d) Picture size position and high voltage adjustment

In component mode input 1080I signal

Use crosshatch and electrical circle signal, after entering into factory menu status, press “2”

button to enter into “FACTORY MENU 2” factory menu to adjust picture’s linearity. Adjust

R339 joint point to make the V-center deflection range be within ±5MM(T3251), or

±3MM(T2751).

Change the signal to white background, or gre atly change contrast and brightness, or press

PIC button to switch among several kinds of analogue amount to make corresponding beam

current changes, adjust V-EHT-COM, H-EHT-COM to make raster’s size basicly not change

when at different beam current status.

3) According to chart 2 in turn apply every testing signal (firstly apply YpbPr signal, then TV or AV

signal), then press “5” button to enter into “FACT ORY MENU 5”, adjust H-S, V-S, H-SIZE, V-SIZE to

make picture normal.

e) Sub-brightness adjustment

Receive split field signal, set colour/contrast/brightness to 0, check whether screen second gray is

slightly bright, otherwise press “6” button, in factory menu select CONTRAST MAX and BRIGHT

MAX to adjust.

f) Filament/beam current/high voltage check and adjustment

1) Filament voltage: receive a TV program signal, set picture mode to “STANDARD”,th e filament

voltage effective value should be 6.3

0.2 Vrms.

2) Beam current check: receive all white field signal, set picture mode to “SPORTS”, measure

R360 two terminals’ voltage and the reading should be less than or be equal to 1.6V. If not,

after entering into factory menu status, press “4” button to enter into “RGB MENU” factory

menu, adjust AV BEAM LIMIT item to make beam current meet requirements.

3) High voltage check: receive D8 signal, set picture mode to “STANDARD”, measure CRT high

voltage and the reading should be A value in chart 3. When brightness, contrast is set to

minimum (zero beam current), measure the high voltage, the reading should not exceed B

value in chart 4.

4

Page 7

Chart 4 High voltage check requirements

Parameters

A

B

74 cm

30 kV

34+ kV

0.5 kV

2751

CRT Size

86 cm

30 kV 0.5 kV

34 kV

3251

4) High voltage protection: receive a picture signal, adjust until picture and sound are normal,

short R340 and the circuit should immediately enter into power-off protection state and the

state should keep. Turn off the power switch and then turn on, the picture and sound should

restore to before-testing state.

g) Peak value adjustment

On the condition of SCREEN and beam current has been adjusted properly, in order to show

picture’s contrast well and control picture’s colour tail, apply a little beam current picture (for

example, black and white crosshatch) and set picture’s contrast and brightness to maximum, then

after entering into factory menu status, press “4” button to enter into “RGB MENU” factory menu,

by adjusting PEAK DRIVE LIMIT item to make the whole unit’s picture colour just without colour tail

on the condition of maximum contrast and it is OK.

h) Every control buttons’ check

Check according to Instruction manual.

i) Check all the input/output terminals’ function, please check according to “PRODUCTION

STANDARD”

i) Out-factory setting

Set picture to “Standard”.

Set sound to “Music”.

Set Blue back to ON.

Set OSD language to English.

Set DNR to SOFT.

Set SVM to ON.

Set Volume to 30.

Set Loudness to OFF.

Set AVC to ON.

Set CCD to OFF.

Set child lock password, V-chip password to 0000.

Set V-chip all rating to no rating .

Set the channel to Cable 3. .

5

Page 8

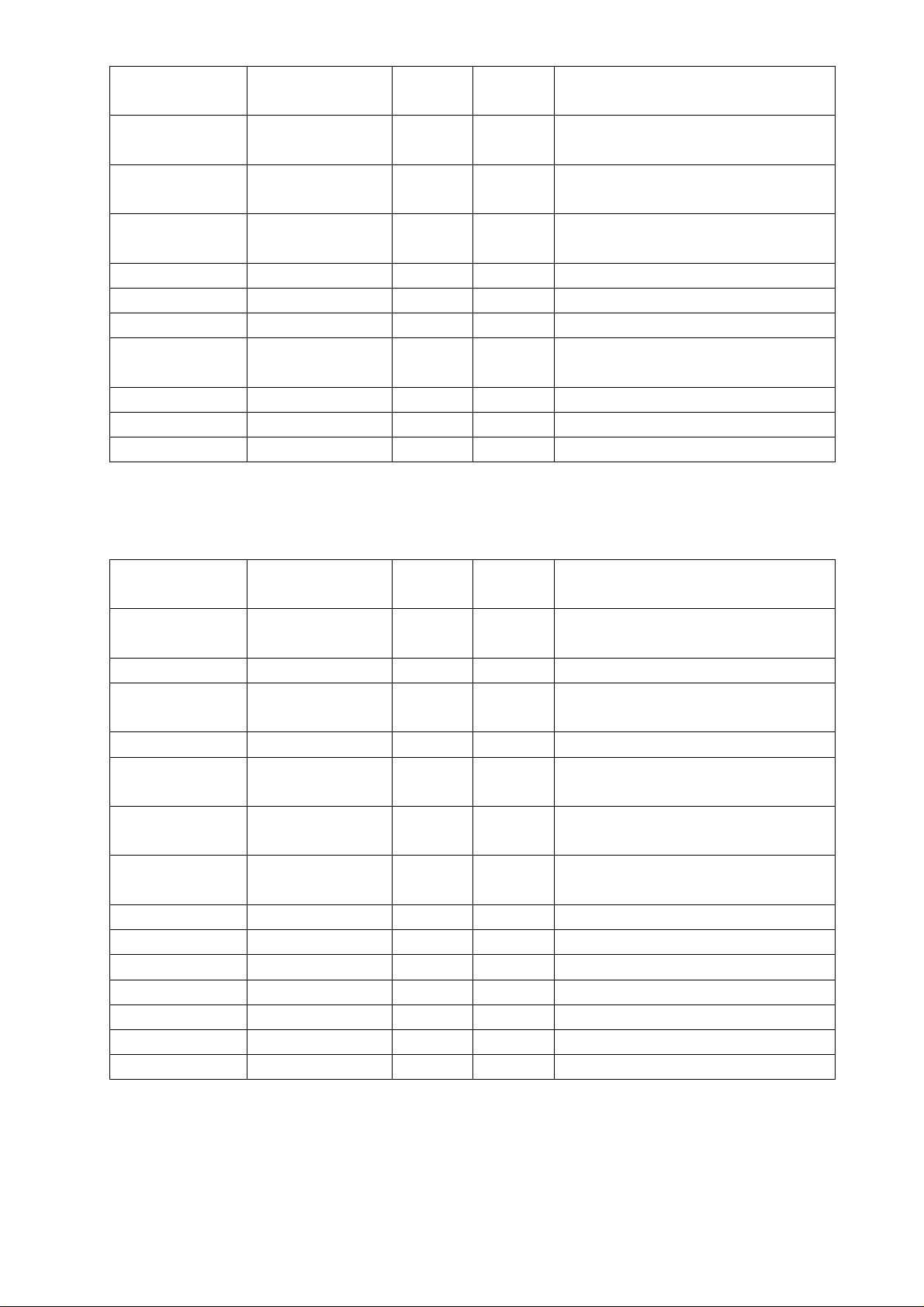

3 For factory menu adjustment see Chart 5 Chart 11.

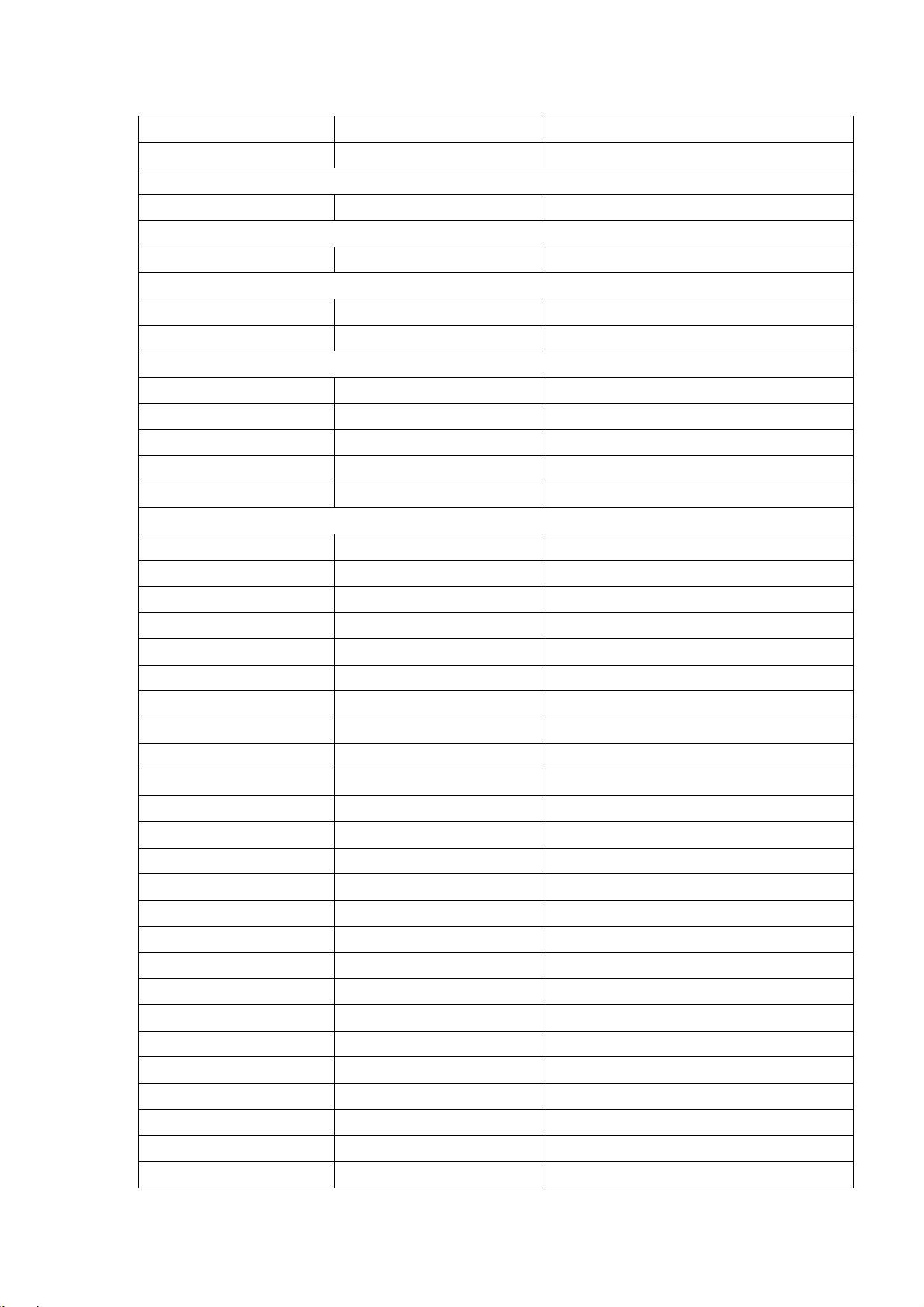

Chart 5 Factory menu (1)WRITE

Item name Item instruction Range

WRITE R Bright balance R BF-3F Refer to white balance adjustment part 1

WRITE G Bright balance G BF-3F Refer to white balance adjustment part 1

WRITE B Bright balance B BF-3F Refer to white balance adjustment part 1

SCREEN

LOCK

2003-XX-XX Version date fix

Dark current

adjustment

OK/OFF OK

Default

value

Adjust SCREEN potentiometer until OK

Chart 6 factory menu (2)

Item Item instruction Range

V SIZE V-size 80-7F 39 To make vertical reproduction rate reach

V SHIFT V-center 80-7F 17 To make picture center and CRT center be

V LINEAR V-linearity 80-7F 41 To make V-linearity distortion minimum.

V S CORR Vertical S-correction 80-7F F7 To make vertical S-correction distortion

H SIZE H-size 80-7F 08 To make horizontal reproduction rate reach

H SHIFT H-center 80-7F 43 To make picture horizontal center be in

V ANGLE Parallelogram correction 80-7F 05 To correct parallelogram distortion

V BOW Arch correction 80-7F 0E To correct arch distortion

PIN AMP Pincushion correction 80-7F 60 To make pincushion distortion minimum

PIN PHASE Trapezoid correction 80-7F AE To make trapezoid distortion minimum

UP

CORNER

LOWER

CORNER

EXT

CORNER

V SYNC

CONT

Upper edge corner

correction

Lower edge corner

correction

Edge and corner

correction

80-7F 20

80-7F 11 To correct upper two corners distortion

80-7F C5 To correct lower tow corners distortion

80-7F C5 Corner edge correction

Default

value

90% 92%

in accordance

minimum.

90% 92%

accordance with CRT center.

Chart 7: factory menu (3)

Item Item instruction Range

V SCROLL Vertical scroll 0-FF 00 Not adjust, set default value

V ASPECT V-size 0-FF 00 Not adjust, set default value

V EHT Vertical high

voltage correction

80-7F BD To make vertical raster size not change

Default

value

when beam current changes greatly.

Adjusting method

Adjustment method

Adjustment method

6

Page 9

H EHT Horizontal high

voltage correction

AFC EHT COM High voltage auto

frequency control

H BLANK TIME Horizontal

blanking width

H BLANK PHASE Horizontal

blanking phase

V BLANK START V-sync phase 80-7F FB Not adjust, set default value

V BLANK END V-sync phase 80-7F 11 Not adjust, set default value

MIN NO.OF LINE H-blanking phase 80-1F 00 Not adjust, set default value

MAX NO.OF LINE H-blanking end

position

PWM CONTROL H-blanking width 80-7F 02 Not adjust, set default value

PLL CONTROL 0 H-blanking width 80-7F 0B Not adjust, set default value

PLL CONTROL 1 H-blanking width 80-7F 62 Not adjust, set default value

80-7F 9D To make horizontal raster size not change

when beam current changes greatly.

20-1F 08 Not adjust, set default value

80-7F E4 Not adjust, set default value

80-7F F9 Not adjust, set default value

80-7F FF Not adjust, set default value

Chart 8 Factory menu (4)RGB MENU

Item Item instruction Range

INT H-SYNC

PHASE

AV BEAM LIMIT Beam current limit 80-7F 1A Refer to beam current adjustment part

AV BEAM LIMIT

CHA

PEA DRIVE LIMIT Peak value limit 80-7F 00 Refer to peak value adjustment part

PEAK DRIVE TOP Top peak value

PEA DRIVE

BOTTOM

PEA DRIVE L-R Left/right edge

DEFLECT 0 80-7F 03 Can not adjust, set default value

DEFLECT 1 80-7F 05 Not adjust, set default value

RGB CONTROL 0 80-7F 84 Not adjust, set default value

RGB CONTROL 1 80-7F 18 Not adjust, set default value

RGB CONTROL 2 80-7F 20 Not adjust, set default value

RGB CONTROL 3 80-7F 03 Not adjust, set default value

V INPUT MODE 80-7F 85 Not adjust, set default value

H-sync phase 80-7F 12 Not adjust, set default value

Beam current limit 80-7F 81 Refer to beam current adjustment part

80-7F 10 Not adjust, set default value

limit

Bottom peak

value limit

peak value limit

80-7F 47 Not adjust, set default value

80-7F 88 Not adjust, set default value

Default

value

Adjustment method

7

Page 10

Chart 8 factory menu FACTORY 5(HDTV mode)

Item Item insturction Range

R-G Red gun gain 00-FF 80 Refer to white balance adjustment part2

G-G Green gun gain 00-FF 80 Refer to white balance adjustment part2

B-G Blue gun gain 00-FF 80 Refer to white balance adjustment part2

R-O Red gun bias value 00-FF 80 Refer to white balance adjustment part2

G-O Green gun bias value 00-FF 80 Refer to white balance adjustment part2

B-O Blue gun bias value 00-FF 80 Refer to white balance adjustment part2

H-S H-phase 00-FF Geometrical adjustment

V-S V-phase 00-FF Geometrical adjustment

H-SIZE H-size 00-FF Geometrical adjustment

V-SIZE V-size 00-FF Geometrical adjustment

Default

value

Adjustment method

Chart 9: factory menu 6

Item Item instruction Range

CONTRAST

MAX

CONTRAST

CEN

CONTRAST

MIN

BRIGHT

MAX

BRIGHT

CEN

BRIGHT

MIN

COLOR

MAX

COLOR

CEN

COLOR MIN Colour minimum value 00-7F 00 Not adjust, set to default value

SHARP

MAX

TINT CEN Tint center value 00-7F 00 Not adjust, set to default value

Contrast maximum 00-7F 7F Not adjust, set to default value

Contrast center value 00-7F 3F Not adjust, set to default value

Contrast minimum value 00-7F 00 Not adjust, set to default value

Brightness maximum value 00-7F 7F Not adjust, set to default value

Brightness center value 00-7F 3F Not adjust, set to default value

Brightness minimum value 00-7F 00 Not adjust, set to default value

Colour maximum value 00-7F 3F Not adjust, set to default value

Colour center value 00-7F 20 Not adjust, set to default value

Sharpness maximum

value

00-7F 7F Not adjust, set to default value

Default

value

Adjustment method

Chart 10 Factory menu 7

Item Item instruction Range

VOLUME-1 Sound curve 00-7F 0F Not adjust, set to default value

VOLUME-25 Sound curve 00-7F 1F Not adjust, set to default value

VOLUME-50 Sound curve 00-7F 3F Not adjust, set to default value

VOLUME-100 Sound curve 00-7F 7F Not adjust, set to default value

Default

value

Adjustment value

8

Page 11

BASS MAX Bass maximum value 00-7F 7F Not adjust, set to default value

BASS MIN Bass minimum value 00-7F 00 Not adjust, set to default value

TREBLE MAX Treble maximum value 00-7F 7F Not adjust, set to default value

TREBLE MIN Treble minimum value 00-7F 00 Not adjust, set to default value

SURROUND

MAX

SURROUND

MIN

BLANCE CEN Balance center value 00-7F 20 Not adjust, set to default value

LOUDNESS

ON

LOUDNESS

OFF

Surround sound

maximum value

Surround sound

minimum value

Setting value when

loudness is on

Setting value when

loudness is off

00-7F 7F Not adjust, set to default value

00-7F 00 Not adjust, set to default value

00-7F 7F Not adjust, set to default value

00-7F 00 Not adjust, set to default value

Chart 11 Factory menu 8

Item Item insruction Range

OSD-HP

MENU

OSD-HP AV

SEL

OSD-HP

NORMAL

SVM DELAY SVM delay phase 00-7F 03 Not adjust, set to default value (after

ZOOM DATA

OPTION

DATA1

H-MUTE

DELAY

MENU phase 00-7F 00 Not adjust, set to default value (after

AV menu phase 00-7F 00 Not adjust, set to default value(after

Other menu phase 00-7F 00 Not adjust, set to default value (after

9 picture zoom

16

OPTION 00-FF 01 Not adjust, set to default value

Horizontal failure of

oscillations time delay

amount

80-7F 20 Not adjust, set to default value(after

00-FF 5A Not adjust, set to default value. If less than

Default

value

adjustment, open the menu again and it

is effective)

adjustment, open the AV selection menu

again and it is effective)

adjustment, open the OSD again and it is

effective)

adjustment, turn on the set again and it is

effective)

adjustment, turn on the set again and it is

effective)

10, the screen will light and burn the tube.

Adjustment method

9

Page 12

Chart 12 Factory menu 9 DESIGN MENU

Item Item instruction Range

IC XXX Relative IC chip

ADD H Address high 8 byte 00-FF Press VOL+/- button to change

ADD L Address high 8 byte 00-FF Press VOL+/- button to change

DATA H Data high 8 byte 00-FF Press VOL+/- button to change

DATA L Data lower 8 byte 00-FF Press VOL+/- button to change

READ Reading current data YES/NO

REFRESH Reflesh changed data YES/NO

SAVE Save changed data YES/NO

Default

value

Adjustment method

10

Page 13

4.General description of the SDA 9380-B21.

The SDA 9380 is a highly integrated deflection controller and RGB video processor for CTV

receivers with 15 to 19kHz or 31 to 38kHz line frequencies. The deflection component controls

among others a horizontal driver circuit for a flyback line output stage, a DC coupled vertical

saw-tooth output stage and an East-West raster correction circuit. All adjustable output

parameters are I2C-Bus con-trolled. Inputs are HSYNC and VSYNC. The HSYNC signal is the

reference for the internal clock system which includes the ¦µ1 and ¦µ2 control loops.

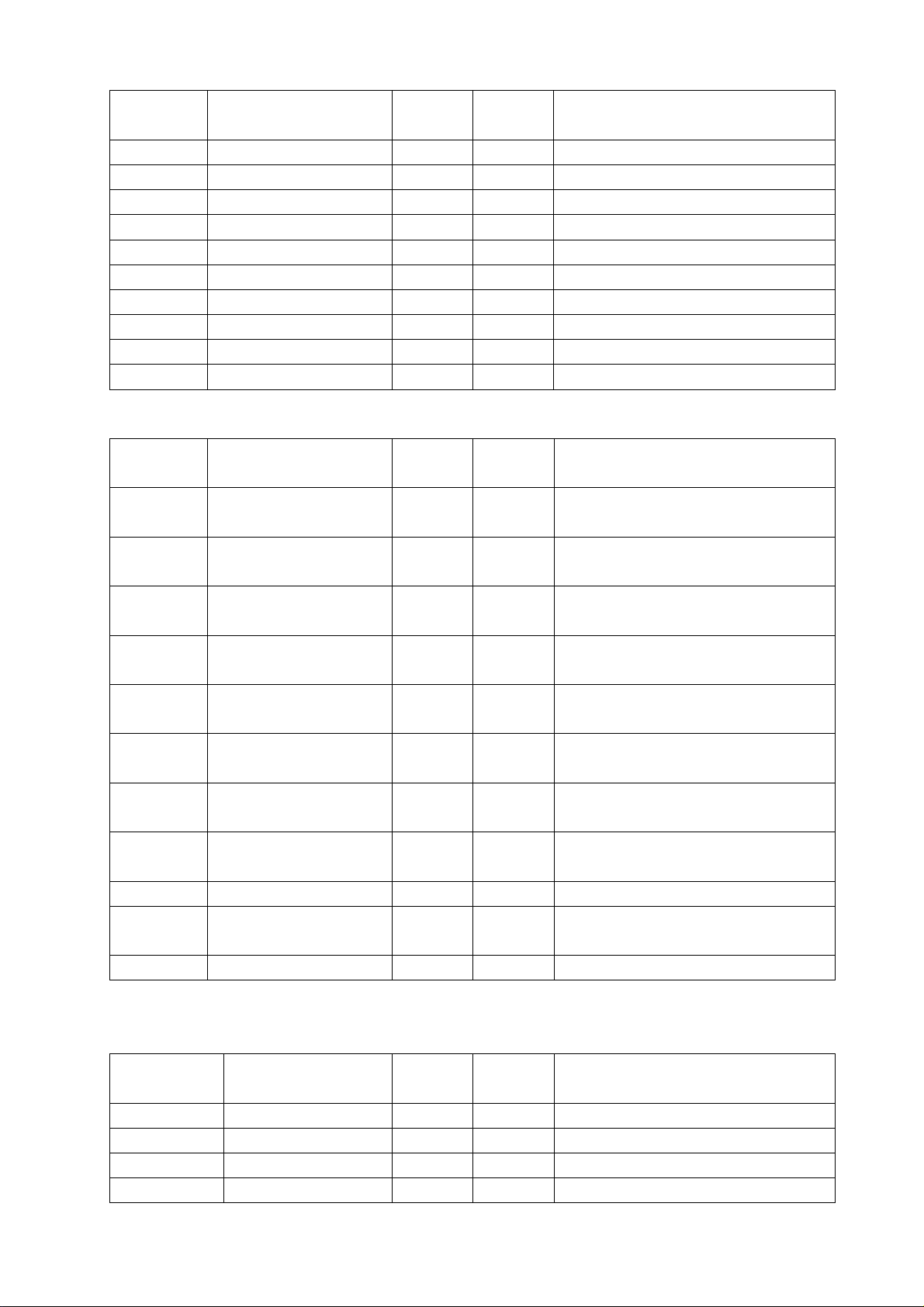

Block diagram of the SDA 9380-B21:

SCL

SDA

BSOIN

RESN

TEST

FH1_2

VSYNC

HSYNC

CLEXT

CLKI

HSAFE

H35K

H38K

RGB 2

FBL 2

FBL 1

RGB

/

YUV

YUV/RGB

X1

X2

SWITCH D/A

I²C

CONTROL

VBLO

SCP

HPROT

VPROTSSD

PROTECTION

START UP

PROTON

H-OUT

V-OUT

EW-OUT

HD

VD+

VD-

E/W

CLL

PWM

PLL

CLAMP

3

1

0

CLAMP

3

CLAMP

3

MATRIX

3

MATRIX

3

MATRIX

3

YUV

3

SWITCH

YUV

3

YUV

Y

UV

2

3

PW/PH- CORR

AVERAGE

BEAM LIMITER

BLACK

STRETCH

SATURATION

CONTROL

UV

RGB

MATRIX

Y

PWM

IBEAM

SVM

VDD(A1..4)

VSS(A1..4)

VDD(D1..2)

VSS(D1..2)

VDD(MC)

VSS(MC)

SUBST

BRIGHTNESS

CONTROL

3

DELAY

3

BLUE STRETCH

3

CONTRAST

CONTROL

3

PEAK DRIVE

3

LIMITER

3

3

VREFC

MEASURE

PULSES

CUT OFF +

WHITE POINT

OUTPUT

BUFFER

VREFH

VREFN

DCI

ROUT

GOUT

BOUT

11

Page 14

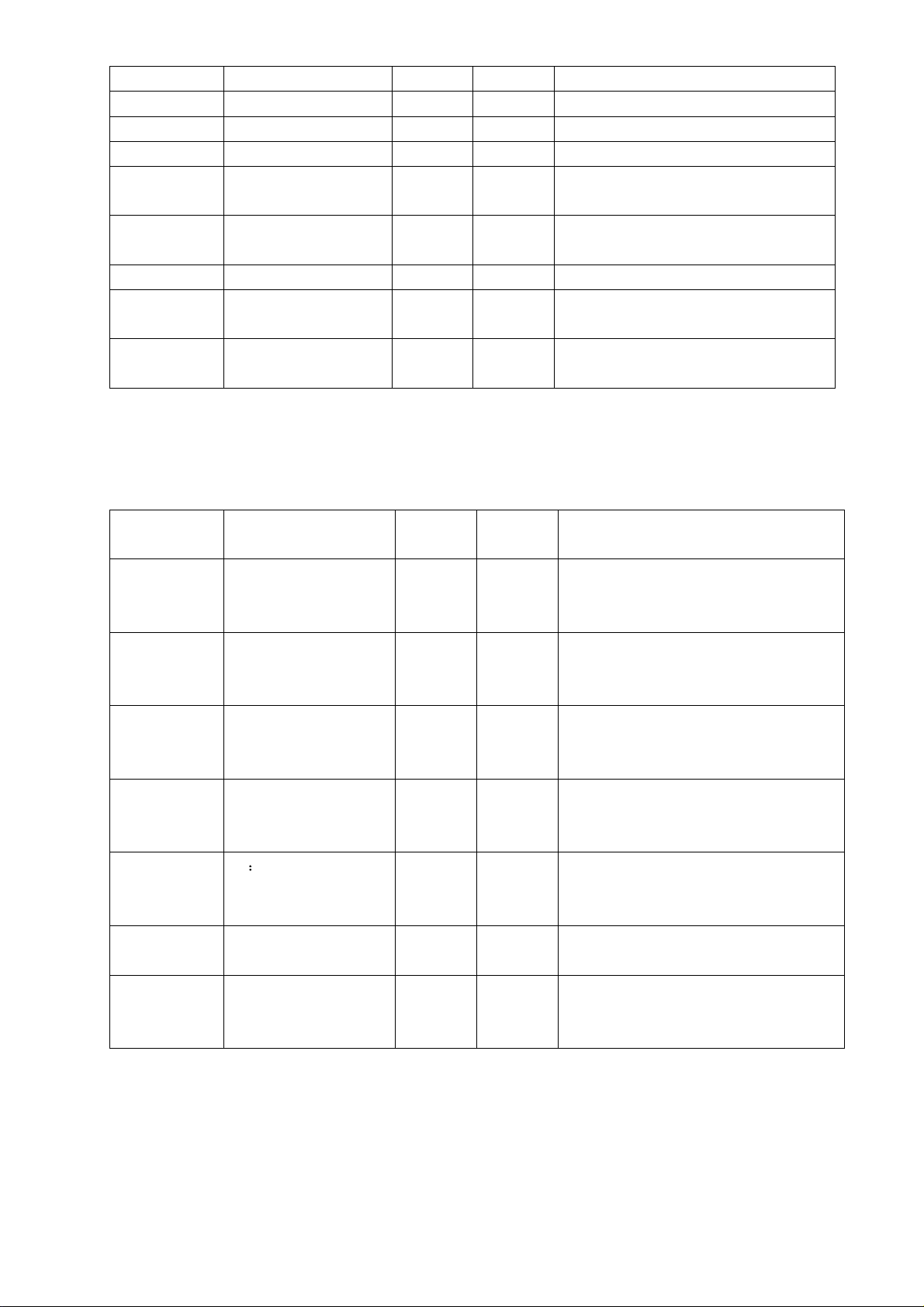

PIN CONFIGURATION:

CLKI

X2

X1

CLEXT

TEST

SUBST

RESN

SCL

SDA

VDD(D)

VSS(D)

HD

H35K

H38K

PWM

VSS(D)

VDD(D)

SSD

SWITCH

64 63 62 61 60 59 58 57 56 55 54 53 5152 50 49

1

SVM

BOUT

SCP

VSS(MC)

VDD(MC)

ROUT

GOUT

R2

G2

B2

2

3

4

5

6

7

8

9

SDA 9380

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 3029 31 32

D/A

FH1_2

=

HSYNC

VSS(A1)

VDD(A1)

E/W

VSS(A2)

VDD(A2)

VD-

VD+

VPROT

VSS(A3)

VDD(A3)

FBL2

FBL1

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

HSAFE

HPROT

B/V 1

G/U 1

R/Y 1

VSS(A4)

V/B 0

U/G 0

Y/R 0

VDD(A4)

DCI

VREFC

VREFN

VBLO

VREFH

PROTON

IBEAM

BSOINVSYNC

12

Page 15

5.Introdution of the VPC 3230D.

The VPC 3230D is a high-quality, single-chip video front-end, which is targeted

for 4:3 and 16:9, 50/ 60 and 100/120 Hz TV sets. It can be combined with other

members of the DIGIT3000 IC family (such as DDP 33x0A/B, TPU 3040) and/or

k

c

T

b

U

Y O

T

C

C r

OE

OU

Y C

6

1

tter

tput

u

O

er

l

S c a

2D

Y

IT U-R 65

F o rma

IT U-R 60

a

de

ram

P IP

Mo

P ano

C r

L

T

F IF O

C N

l

ry

mo

C ontro

Me

s

t

g

s

es

n

ra

tn

t

h

n

a ki

C o

P e

B rig

C b

c

lo

C

L L

S ync

s

C B u

2

I

c

n

n

y

H S

k

O

V S y

AV

ion

+

nerat

C loc

e

G

k

.

n

C loc

G e

s

u

C B

2

I

z

.25 MH

20

r

e

Mix

Y

lor

C o

tiv e

ap

d

A

alog

An

r

e

d

o

c

De

b

C om

nd

e

-

t

on

F r

C r

C b

n

tio

L

P A

NT S C

S E C AM

C

lter

F i

S

NT

C

AG

t

n

T i

tura

S a

Y

C r

C b

F B

s

ing

L

es s

P A

P roc

G

Y /

ADC

×

2

alog

An

t

on

ix

r

ras

t

ont

Ma

C

R

V/

U/B

ent

n

t

nes

n

rati

u

T i

ght

S at

B ri

F B

ADC

on t-E nd

mpo

r

o

F

C

4 x

C IN

VIN1

VIN2

VIN3

it can be used with 3rd-party products.

Block diagram of the VPC 3230D:

T

U

VIN4

V O

B /

R G

Y C rC b

B /

F B

R G

Y C rC b

13

Page 16

PIN CONFIGURATION:

XT AL1

XT AL2

AS G F

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41

65

G NDF

66

VR T

67

I2C S E L

68

IS G ND

69

VS U P F

70

VO UT

71

C IN

72

VI N1

73

VI N2

74

VI N3

75

VI N4

76

VS U P AI

77

G NDA I

78

VR E F

79

F B1 IN

AIS G ND

80

1 2 3 4 5 6 7 8 9 10 1112 13141516 17181920 2122 2324

NC

VS T BY

C LK 5

F PDA T

F S Y/HC

MS Y /HS

VS

IN TL C V S UP S Y

AV O

VP C 323X D

G NDS Y

C 0

C 1

C 2

C 3

G NDC

VS UP C

C 4

C 5

C 6

C 7

40

Y 0

39

Y 1

38

Y 2

37

Y 3

36

VS U P Y

35

G NDY

34

Y 4

33

Y 5

32

Y 6

31

Y 7

30

G NDL LC

29

VS U PL LC

28

LL C1

27

LL C2

26

VS U P PA

25

G NDP A

B 1/CB 1IN

G 1/Y1IN

R 1/CR 1 IN

B 2/CB 2IN

G 2/Y2 IN

R 2/CR 2 IN

AS G F

NC

VS UP C AP

VS UP D

G NDD

G NDC AP S CL

C LK 20

F FOE

F FR E

F FR S TW

F FWE

F FIE

Y CO EQ

VG A V

T E ST

R E S Q

S DA

14

Page 17

6.Introdution of the MSP 3425G.

The MSP 3425G family of single-chip Multistandard Sound Processors covers the sound

processing of all analog TV standards worldwide, as well as the NICAM digital sound standards.

The full TV sound processing, starting with analog sound IF signal-in, down to processed analog

AF-out, is performed in a single chip.

Simplified functional block diagram of the MSP 3425G:

r

e

k

S

Loud-

spea

C

DA

er

es sing

ound

Loud-

S

spea k

P roc

e-

es sing

P r

proc

2

I

C

DA

ct

e

ce S el

S our

e

ca l

P res

1

T

AR

S C

t

T

c

R

put

e

t

l

A

u

S e

O

S C

e

l

ca

s

e

P r

PIN CONFIG

or

De-

modulat

C

AD

1

F

ound I

S

S 1

S 2

2

2

I

I

1

T

AR

S C

C

AD

t

T

c

P

e

l

AR

nput

DS

I

S e

S C

2

T

AR

S C

NO

MO

15

Page 18

I2

DAC M

DAC

M

NC

_

L

26

25

VE R F

_

R

24

NC

2

23

22

R E

S E T

NC

Q

21

20

S _

DA_

I

NC

N2

19

18

DV S U P

DV S S

17

16

M

27

28

29

30

31

32

33

34

35

36

37

NC

NC

VR E F

S

S

NC

AH V S

C

AH V S

AG NDC

C

C

1_OU

1_OU

1

T

T

_R

_L

A

P

L_M

UP

S

NC

ADR _

C L

15

S P

38

NC

ADR _

WS

14

34

39

S

C

2_IN

_

L

ADR

_

DA

13

x5G

40

S

C

2_IN

_

R

I2

S _

DA_

I

N1

12

41

S

C

1_IN

_

L

7.General description of the PW1235.

D_C

I2

S _

DA_

I2S

_

O

W

UT

S

11

10

42

43

S

VR E F

C

1_IN

T

O

_

R

P

I2

I2S

C

_

_

DA

C L

9

8

44

45

MO

AV S

N

S

O

_

I

N

S T

ADR _

AN DB Y

I2

C _

C L

7

46

AV S

UP

S

E

Q

L

6

5

47

48

AN A_

AN A_

I

I

N

N

1

D_C

T

T

R _

R _

I/O_ 0

I/O_ 1

NC

TP

4

3

2

1

49

50

51

52

NC

TE

XT

XT

AL

S T

E

N

AL

_

_

IN

O

UT

The PW1235 Video Signal Processor is a high quality, digital video signal processor that

incorporates Pixelworks' patented, state-of-the-art video deinterlacer and scaler. Using

sophisticated algorithms, the PW1235 is able to effectively deinterlace video input by creating

motion vectors that follow frame-to-frame movement, and provide clear, progressive output in

both analog and digital formats.

With support for NTSC and PAL video formats, the PW1235 can be designed into any TV,

monitor, or projector application. Support for 3:2 and 2:2 film mode detection enables the

PW1235 to provide the best quality display for existing film and video standards. The PW1235

can dynamically enter or exit film mode (with flexible programming) to display mixed content

with the best possible quality.

As a single device, the PW1235 integrates many functions onto one chip. It has embedded a

scaler, an advanced deinterlacer, memory controller, color space converter, and Digital-toAnalog Converter (DAC) onto one chip. There are two video input ports-a primary video port

and a secondary input port-that are used to accept YUV video in the ITU-R601 and ITU-R656

formats respectively. Video content is analyzed on a single-pixel granularity to detect

presence or absence of noise and compute the amount of motion. Motion video is processed

using a highly intelligent algorithm that simultaneously eliminates noise and interpolates pixels

along any angle to produce a noise-free picture without jagged-edge artifacts.

As part of a Pixelworks solution, combining the PW1235 with a Pixelworks ImageProcessor

(such as the PW113, PW166 or PW181) offers the world's best combination of

16

Page 19

deinterlacing and scaling of video or graphics. This combination of high quality deinterlacing

and scaling is essential for higher resolution outputs such as XGA, SXGA, and UXGA that

need to display NTSC and PAL video.

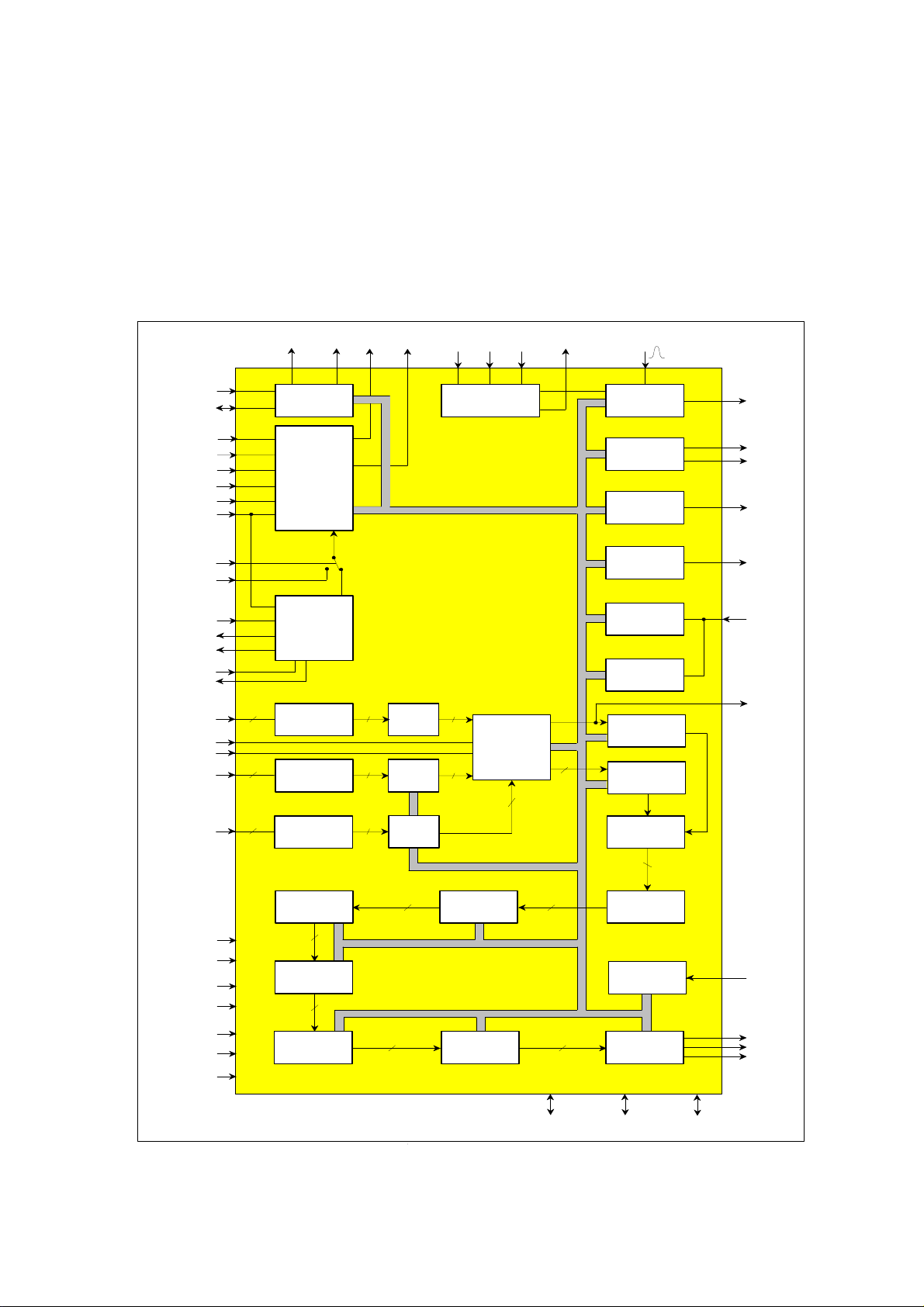

Internal block diagram of the PW1235:

Digita l

Output

Ti mi n g

Ti mi n g

Display

Up

Scaler

P-Channel

Deinterlacer

YU V

CSC

(YUV )

Video

Video

Enhancements

RGB

Merge

CSC

CSC

Analog

Output

DACs

HSync

Timi ng

VSync /

Blue

Screen

LUT

Color

Data

Digita l

Output

Dis play Unit

I-Channel

(I/P)

Picture

Detecti on

(3:2 & 2:2)

Film-Mode

Memory Unit

Primary

Video

Previ ou s

I-Channel

P-Channel

B-Channel

Progra mming Unit

Noise

Moti on

Reduction

Input Unit

Detect and

Down

Scaler

PW1235

Input

Video

Internal Block Diagram

601

ITU-R BT

Primary

Video Port

656

ITU-R BT

Secondary

Video Port

24-Bi t

Port

Digital

Grap hi cs

Interface

Tw o -W i re

17

Page 20

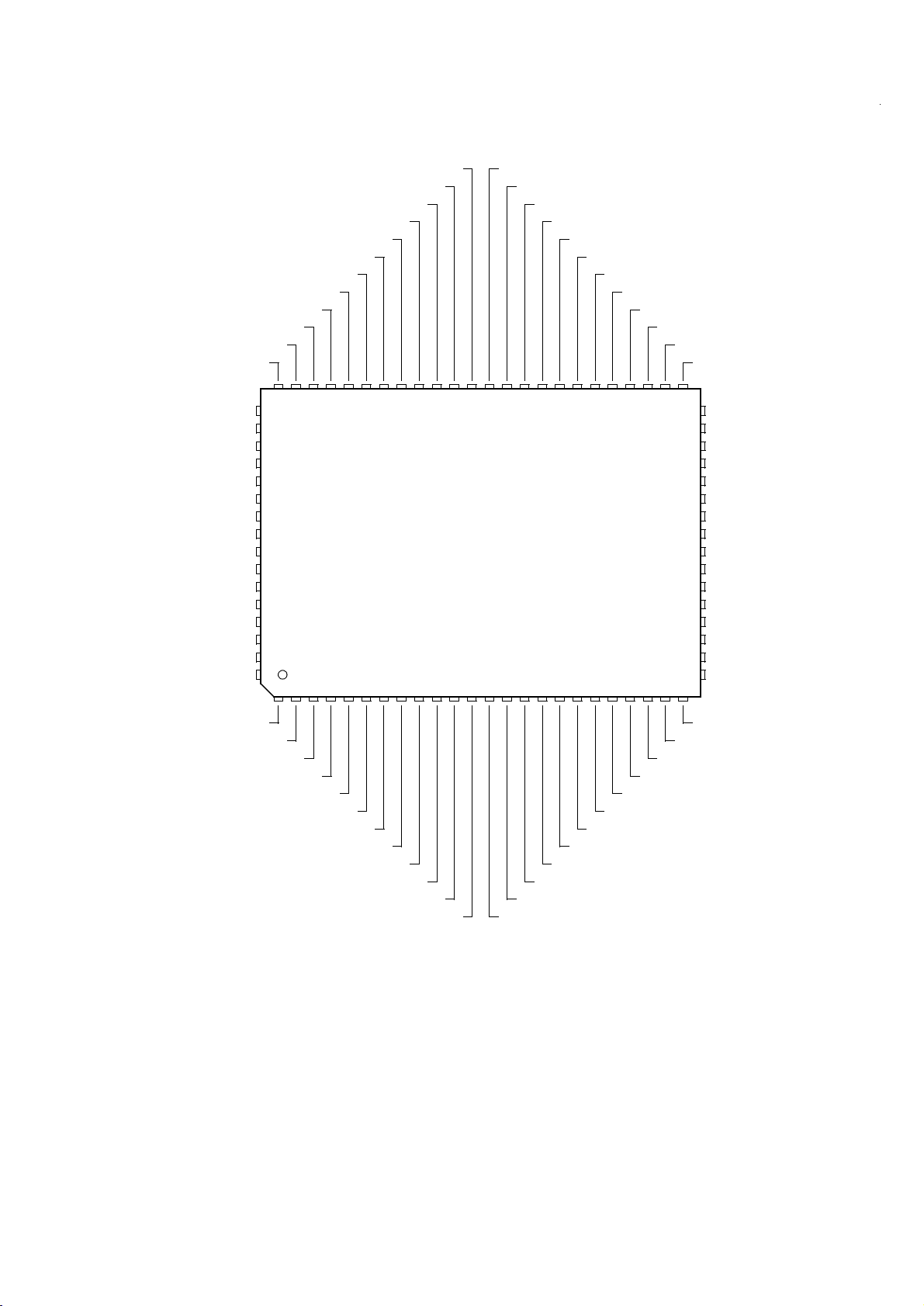

PIN CONFIGURATION:

MCU C M D

MCUWR

MCUCS

PV SS

MCURDY

VSS

MCUD7

MCUD6

MCU D 5

MCU D 4

MCU D 3

192

191

190

189

188

187

186

185

18 4

18 3

PVSS

DPAVSS

DP AVD D

DPDVS S

DPDVDD

PVDD

MV E

PVSS

MA4

MA3

VDD

MA5

MA2

PVDD

MA6

MA1

MA7

PVSS

MA0

MA8

MA 10

PVDD

MA9

MA 13

VS S

MA 11

MA 12

PVSS

MCL K F B

PVDD

MRA S

MCA S

MWE

PVSS

MCL K

PVDD

MD8

MD7

PVSS

MD9

VDD

MD6

PVDD

MD10

MD5

PVSS

MD11

MD4

PVDD

MD12

MD3

PVSS

MD13

MD2

PVDD

MD14

VS S

MD1

PVSS

MD15

MD0

PVDD

193

194

NC

195

NC

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

123456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051525354555657585960616263

VB 0

VB 1

VB 2

VB 3

VB4

VDD

18 2

VB5

VB6

VB7

PVS S

MCU D 2

PV DD

MCUD1

MCUD0

MCUA7

MCUA6

VDD

MCUA5

MCU A4

MCU A3

PV SS

MCU A 2

MCUA1

MCUA0

ADGVSS

ADGVDD

PVDD

A DAV SS

ADAVDD

VREF O UT

VREF I N

COMP

RSET

AV S33 R

AV D3 3R

ADR

AVS33G

AVD33G

ADG

AVS 33B

AVD33B

ADB

ADDVDD

ADD V SS

PV SS

CGMS

DEN

TEST CL K

PVDD

DR7

DR 6

VDD

DR5

DR4

PV SS

DR3

DR2

VSS

DR1

DR0

PVDD

DG 7

DG6

181

180

179

178

177

176

175

174

17 3

17 2

171

170

169

168

167

166

165

164

163

16 2

16 1

160

159

158

157

156

155

154

153

15 2

15 1

15 0

149

148

147

146

145

144

143

142

14 1

14 0

139

138

137

136

135

134

133

132

131

13 0

12 9

128

DG5

127

DG4

126

PVSS

125

DG3

124

DG2

123

VDD

122

DG1

121

DG0

120

PVDD

119

DB7

118

DB6

117

DB5

116

DB4

115

PVSS

114

DB3

113

DB2

112

VSS

111

DB1

110

DB0

109

PVDD

108

DENR

107

DENB

106

DENG

105

PVSS

104

DHS

103

DVS

102

DCLK

101

PVDD

100

DGR7

99

DGR6

98

DGR5

97

DGR4

96

PW1235

TDI

VSS

VG 0

VG1

VG2

VG3

VSS

VG4

VG5

VG6

SV HS

SV VS

PVD D

SV CLK

VG7

PV SS

VR0

VR1

VR2

VR3

VR4

VR5

VR6

VR7

CREF

PVVS

PVHS

PVDD

PV CLK

VDD

PVSS

XTALI

PVDD

2WA1

2WA2

XTALO

TCK

TDO

TMS

PV SS

2WCLK

2WDAT

TEST

PV SS

PVDD

TRSTN

RESETn

MPDV SS

MPAVSS

MPDVDD

MPAVDD

PVSS

95

DGR3

94

DGR2

93

VDD

92

DGR1

91

DGR0

90

PVDD

89

DGG7

88

DGG6

87

DGG5

86

DGG4

85

PVSS

84

DGG3

83

DGG2

82

DGG1

81

DGG0

80

PVDD

79

DGB7

78

DGB6

77

VSS

76

DGB5

75

DGB4

74

PVSS

73

DGB3

72

DGB2

71

DGB1

70

DGB0

69

PVDD

68

DGCLK

67

DGVS

66

DGHS

65

PVSS

64

NC

NC

PVDD

18

Page 21

8.General description of the TDA6111Q.

The TDA6111Q is a video output amplifier with 16 MHz bandwidth. The device is contained

in a single in-line 9-pin medium power (DBS9MPF) package, using high-voltage DMOS

technology, intended to drive the cathode of a colour CRT.

Block diagram of the TDA6111Q:

PIN CONFIGURATION:

rr ent

ent

cath ode

tra ns i

ou tput

u

o utput

C

cath ode

D

bla ck c

meas ur ement

ou tput

7

R OR

MIR

F OL LO WE R S

9

ou tput

feedbac k

tag e

s uppl y v ol

6

HIG H

input

7 V

R OR

MIR

8

bia s

V

par

C

5

R

O

R

MIR

T

E

C

E N

R

R

R

U

S OU

TDA 6111Q

L

TIA

E

G

E N

E R

S TA

IF F

D

C

R

O

R

MIR

8

5

MG A0

input L OW

s uppl y v olta ge

nd

42

grou

(s ubs trate )

h

gew idt

ndb ook , fu ll pa

ha

3

1

i

input

input

inve rting

no n-inv ert

19

Page 22

P INNING

S YMB OL P IN DE S CR IP TIO N

V

V

V

ip

DDL

in

1 non-inver ting v oltage input

2 s upply voltage L OW

3 inverting v o ltage input

G N D 4 g round, s ubs trate

I

om

5 black c urr ent me a s urement

ou tput

V

V

V

V

DDH

cn

oc

fb

6 s upply voltage H IG H

7 cathode trans ient volta ge ou tput

8 cathode DC voltage o utput

9 feedbac k v oltage outpu t

ndb ook , h alfp age

V

1

ip

V

2

DDL

V

3

in

G ND

4

V

I

om

DDH

V

V

V

cn

oc

TDA 6111Q

5

6

7

8

9

fb

MG A05 7

F ig.2 P in c onfiguratio n.

20

Page 23

Wiring Di agram

491-752J0-02

AC POWER

665-89501-02

SWITCH BOARD

782-13Y90-050A

X1

DEGAUSS COIL

X501

KEY BOARD

782-T3251-0500 782-T32511-2900

665-21201-05

MAIN BOARD

782-T3251-0100

X502 X101 X503

X203 X201 X202

X901

X902 XA01

665-51201-66

665-41201-188

665-81201-40

AV BOARD

FRONT AV BOARD

782-T3251-2900

XAA4 XAA5 XAA6

665-4E301-49

SPEAKER

X401

CRT BOARD

782-T3251-0200

X205

X402 X403

665-64301-06

GND FOCUS

X302

C330

665-3E301-15

X204

VM BOARD

782-T3251-6400

XV03

665-31201-107

VM COIL

XV01 XV02

665-41201-258

Page 24

BLOCK DIAGRAM

22

Page 25

Page 26

AV1IN

AV2IN

AV1OUT

XA01

C

Y

V

R

L

C

Y

V

R

L

V

R

L

AV BOARD

RA63

100

RA69

100

RA74

1n

1n

RA64

100

CA111

1n

CA110

1n

RA72

100

RA59

100

4K7

RA75

4K7

RA67

RA70

100

RA79

4K7

RA78

4K7

LA20

10uH

LA21

10uH

100

CA106

10n

CA88

100u/10V

CA90

100u/10V

CA93

10u/16V

CA94

10u/16V

CA107

10n

CA87

100u/10V

CA89

100u/10V

CA92

10u/16V

CA91

10u/16V

CA97

100u/10V

RA42

5K6

RA43

5K6

RA83

100K

RA82

LA17

10uH

LA18

10uH

LA19

10uH

100K

LA16

10uH

RA76

100K

RA77

100K

CA105

1n

CA152

CA113

1n

1n

RA65

75

RA71

75

RA81

100K

RA80

100K

RA73

100K

RA84

1K

RA85

1K

CA112

1n

RA60

82

75

RA61

75

RA68

CA108

CA109

RA66

82

+9V

LIM

RIM

CI1

10U

VIM

LA15

CA86

LA09

100U

104

VA19

BC843

COM

YOM

+

CA82

104

VA18

BC843

CA72

0.1u

CA74

220u/16V

R2

+9V

10U

LA38

CA143102

RA143

4.7K

RA149

100K

CA138

10U

CA95 1U

SI1

+

YI1

+

VI1

VI1

1

LI1

+

RI1

+

LI1

CI2

SI2

+

YI2

2

YI1

3

RI1

4

CI1

5

6

SI1

7

VI2

8

LI2

9

YI2

10

RI2

11

CI2

12

+

RA58

CA81

1U

48

RTV

V1

220

RA56

1U

470

CA80

47

44

45

46

TV

LTV

COUT1

LV1

Y1

RV1

C1

S2-1

S-1

V2

CXA2089Q

LV2

Y2

RV2

C2

S2-213S-214V315LV316Y317RV318C319S2-320S-321LV422V423RV4

SI2

+

CA69

10u/16V

1N

RA28 100K

RA26

RA31

VCC

S1D

S2D

S1C

S2C

CA67

10u/16V

+

+

4K7

RA30

82

100K

YI3

LI3

16

15

EN

14

13

12

DD

11

10

9

DC

DA06

1N4148

+

VI2

+

RI2

CA63

+

LI2

CA64 1N

+

VO

DCOUT

RO

LO

DA09

DA12

1N4148

DA05

1N4148

1N4148

DA08

1N4148

DA04

1N4148

CA203

104

NA04

1

IN

2

S1A

3

S2A

4

DA

5

S1B

6

S2B

7

DB

8

GND

PI5V330

DA13

1N4148

GND

+

CA68 10u/16V

100

RA27

RA55

470

43

42

YOUT1

NA02

CA66

10u/16V

4K7

RA29

CI3

RI3

DA07

1N4148

TRAP1

CA71

10N

RA41

100

CA701N

104

CA201

DA10

41

RA57

220

82

1N4148

RA40

10U

CA202

CA75

+

100u/10V

CA131

100U

+

104

CA132

R134 15K

37

38

39

CIN1

BIAS

YIN1

LOUT1

VOUT140ROUT1

MUTE

Vcc

VOUT2

ROUT2

YOUT2

LOUT2

COUT2

DC OUT

SDA

SCL

ADR

24

+

+

CA96

CA98

10u/16V

1u/16V

RA395K6

RA130 1K

MONO

TV2

SI3

Y

LA40

VA28

10K

BC847

RA207

75

LA39

10K

DA14

DA15

1N4148

DA11

1N4148

RA201

1N4148

36

35

34

33

32

31

30

29

28

27

26

25

27K

RA161 100

RA162 100

Pb

27K

RA202

CA205

10U

CA204

104

CA73 103

LA41

VA29

10K

BC847

RA208

75

RA44

RA46

1K

VA17

BC847

RA491KRA471KRA48

Pr

27K

27K

RA203

RA206

27K

RA205

LA4210K

VA30

BC847

CA20610U

RA209

75

RA45

1K

470

VA16

VA15

BC843

BC847

CA99

10u/16V

+

CA10010u/16V

+

220

SIF

+5V

SC1R

SC1L

RO

LO

DA03

+9V

1N4148

RIM

LIM

CA159

+

10U

VS1

LA32

22U

47U

CA166

CA165

CA170

10U

104

CA169

104

+

LA23

10U

10U

LA22

CA158

LA29

100U

CA153

1.5P

LO

RO

VO

DCOUT

SDA

SCL

LA13

22

22

100

CA209

CA220

RA204 27K

CA218

CA208 22

CA20710U

10U

RA214

100

NA05

1

2

VA27

BC847

75

RA210

CA210

CA212

CA211

RA213

10u

104

10U

75

3

4

75

5

RA211

6

M52347

7

8

9

RA212

0

+5V

LA43

10uH

100

10U

CA214

CA213

20

0

19

100

18

17

16

15

14

13

12

1110

RA215

CA216

104

HS1

100

RA216

CA217

104

CA215

L0

LA34 10U

CA140

102

100K

15K

RA133

CA141102

RA139

4.7K

RA146

16

VDD

100K

CA134

10U

13

NA07

12

X

X114X2

TC4052BP

15

Y01Y22Y3Y34Y15INH6VEE7GND

CA133

10U

4.7K

RA137

100K

CA139

RA145

102

LA33

10U

NA06

ZA03

52

XOUT

18.432M

51

XIN

50

CA187

TEST

1.5P

49

NC

48

CA177

103

CA176

56P

1.5N

CA174

+

102

CA173

CA163 1U

+

CA164 1U

+

CA161 1U

+

CA162 1U

+

104

470P

CA175

CA172

IF-

47

IF+

46

AVSU

45

AVSS

44

43

VTOP

42

SC1R

41

SC1L

40

SC2R

39

SC2L

38

37

CA171

104

CA160

10U

+

102

36

3.3U

AGND

35

AHV

+

34

CAPM

33

AHVS

32

NC

31

SCLO

30

SCRO

29

REF1

CA168

CA167

28

102

27

MSP3445

L3

10U

LA36

RA141

4.7K

RA147

CA136

10U

10

B9A

X311X0

RA136

8

CA137

10U

4.7K

100K

RA142

RA150

LA37

10U

CA135

10U

4.7K

CA144

RA148

RA140

102

LA35

10U

1

TP

2

3

IO1

4

IO0

5

SLA

6

STB

7

SCL

8

SDA

9

10

11

100K

100K

RA156

RA155

RA154

DA02

DA01

CA142

102

RA158

RA157

10K

100K

VA23

BC847

VA24

BC847

100

100

100

5C2

5C2

RA131

15K

10K

+

CA154

220U

SC1R

RA13215K

RA135

IO1

IO0

SC1L

R3

L2

R0

IO1

IO0

+5V

SCL

SDA

YI3

LI3

RI3

CI3

SI3

M_L

RST

SCL

SIF

TV2

L2

L3

L0

R0

R3

R2

VIM

SDA

MONO

M_R

XA01

1

V/Y

2

GND

3

L

4

R

5

GND

6

C

7

GND

8

S

9

GND

10

R

11

L

V/Y-G-L-R-G-C-G-S-G-R-L

XA05

M_L

1

STB

2

RST

3

SCL

4

SIF

5

TV2

6

GND

7

L

8

L

9

L

10

GND

11

R

12

R

13

R

14

TV1

15

GND

16

SDA

17

VOL

18

MONO

19

M_R

20

12

DVSU

DVSS

REF2

DACR

DACL

GND

RST

13

14

15

16

1.5N

17

470P

220P

47U

+

LA31

+5V

22U

CA183

CA186

CA182

CA181

18

19

20

21

22

23

24

25

26

RA153

RST

100

CA180

103

CA179

CA178

102

102

CA185

M_R

+

1U

CA184

M_L

+

1U

+9V

+5V

Pb

VS1

COM

YOM

HS1

Y

Pr

XA04

1

+9V

2

+5V

3

Pb

4

GND

5

VS1

6

GND

7

C

8

B

9

R

10

VS2

11

HS2

12

GND

13

G

14

FB

15

Y

16

17

HS1

18

Y

19

Pr

20

GND

RA116

75

Y

Cb

RA120

RA11875

75

Cr

XA03

RA117

75

Y

RA11975

Pb

RA121

75

Pr

Page 27

X401

12V

GND

R

G

B

GND

D

SP

TO MAIN

EHT

N401 TDA6110Q

CRT BOARD

C413

22N

R411

750

C409

104

R413

100

D401

1

2

3

4

5

6

7

8

HZ12B1

R414

10K

R409

2K

V401

C1815

C414

22N

R412

750

R410

1.8K

Vip1Vddl2Vin3GND4Iom5Vddh6Vcn7Von8Vfb

C412

C408

100N

C411

100U

C410

100N

N402

Vip1Vddl2Vin3GND4Iom5Vddh6Vcn7Von8Vfb

C416

100N

C407

100N/250V

R407

51K/1W

TDA6110Q

C419

C415

100N/250V

R416

51K/1W

9

560P/500V

9

560P/500V

L404

L405

L403

R418

2.2/2W

1UH

1UH

1UH

R421

2.2/2W

R417 560/C

R419 560/C

R408 560/C

SG401 300V

R

G

B

SG404 300V

SG402 300V

CRT

H1 H2 G1G2 G4

SG404 2KV

103/2KV

G3

C421

CRT SCREEN

R420

2.2M

L407

22UH

VR401

20M

L409

22UH

Focus

G2

L408

22UH

X403

X402

TO MAIN

200V

6.3V

R415

1.8K

C418

100U

100N

C417

TO CRT GRAND

CAUTION:

All the parts in the sc hmatic diagram marke d

N403 TDA6120Q

Vip1Vddl2Vin3GND4Iom5Vddh6Vcn7Von8Vfb

9

L402

22UH

6

5

4

3

2

1

L406

0.27UH

C420

33UF/250V

L401

10UH

C401

22N

R401

750

R403

1.8K

R405

1K

C404

100U

C402

100N

C403

100N

C405

R404

51K/1W

C406

100N/250V

560P/500V

with the sign of

are extremely important

for safety.

The schmatic diagram is repre se ntative only .

The value of the parts will be changed w ith the

improvement of the c ircuit.

1. The unit of resistance is ohm.

K=1,000 ohm M=1,000,000 ohm

2. The unit of induc tance is H.

mH=1/1,000H uH=1/1,000mH

3. The unit of capacitance is F.

uF=1/1,000,000F pF=1/1,000,000uF

4. The meaning of the sy mbols is below:

small signal ground

large signal ground

Page 28

RV10

1K5

LV01

100uH

12V

XV02

SVM

1

2

3

GND

CV01

100P

VV01

2SC1959

GND

RV06

1K

DV01

IN4148

RV12

68

RV05

8K2

VV02

2SC1959

CV04

220P

RV08

4K7

GND

RV07

10K

RV11

10K

CV06

10N

VV05

2SA562

RV04

180

RV09

180

VV03

2SC1959

RV1368CV25

GND

CV05

10N

47N

GND

VV04

2SC1959

VV16

2SA562

RV02

47

RV03

47

GND

CV03

100N

CV02

100U

CV21

100P

RV35

3.9K

RV34

12K

LV02

100uH

+

VV06

2SC1959

CV22

100u/16v

CV24

RV33

300

RV36

820

0.1u

CV3

+

CV23

100u/16V

VV17

2SC1959

RV31

10

RV32

10

VV18

2SA562

+

CV07

22u/100V

CV08

100n

CV09

1n

CV12

1n

RV16

270

+

47u/16V

RV15

2.2

RV17

15K

RV18

15K

RV21

270

CV10

VV07

2SA1964

2SC5248

RV20

10

VV08

RV01

330/1W

RV14

10

XV01

1

12V

2

GND

3

4

105V

TO CRT BOARD X404

CV13

22n

+

CV11

47u/16v

RV19

2.2

222

RV22

120

CV14

TV01

1

2

3

XV03

VM BOARD

VM-OUT

Page 29

Page 30

XAA3

XAA2

L

R

CY

XAA1

XAA6

123

16789

4

XAA5

10

234

11

123

5

RAA6

560

4

RAA5

560

CAA3

1N

RAA3

82

V

RAA1

100KCAA1

1N

R

LAA2

10UH

L

RAA2

100K

CAA2

1N

LAA1

10UH

1

2

3

4

5

6

7

8

XAA4

U/Y

GND

L

R

GND

C

GND

S

L_O

GND

R_O

GND

L_SP

R_SP

GND

GND

FRONT AV BOARD

RAA4

82

Page 31

CB_VPC

CY_VPC

CR_VPC

CD4

22P

CD5

22P

RST

CD189

CD190

CD192

SCL

SDA

RST

R/Pr

G/Y

B/Pb

DBUSY4

DBUSY5

DBUSY6

DBUSY7

DBUSC4

DBUSC5

DBUSC6

DBUSC7

RD1

2.2M

SCL

SDA

220n

220n

220n

RD18

100

SCL

SDA

R9

75

R10

75

R11

75

RP3

100x4

RP10

100x4

SCL

SDA

CD143

220n

RD39 100

RD40 100

RD38

100

+3.3VD

DBUSY0

DBUSY1

DBUSY2

DBUSY3

LLA0

VS3

HS3

DBUSC0

DBUSC1

DBUSC2

DBUSC3

XD1

10.0MHz

10uF/16V

CD144

1n5

CD155

0.1UF

RP4

100x4

RP5

100x4

RD2

RD3

CD8

0.IUF

CD146

CD145

+

CD147

SCL3

SDA3

47n

390p

+3.3VD

100

100

3230D_VREF

11

12

13

15

16

17

18

20

21

22

23

25

26

27

28

30

31

32

33

35

36

37

38

40

41

43

44

45

47

48

50

51

52

53

55

56

1

2

3

4

6

7

8

9

RD42

100*

CLK20

UD1A

VB0

VB1

VB2

VB3

VB4

VB5

VB6

VB7

SVHS

SVVS

SVCLK

VG0

VG1

VG2

VG3

VG4

VG5

VG6

VG7

PVCLK

CREF

PVVS

PVHS

VR0

VR1

VR2

VR3

VR4

VR5

VR6

VR7

XTALI

XTALO

I2CA1

I2CA2

SCL

SDA

TDO

TCK

TDI

TMS

TRSTn

RESETn

TEST

PW1235

CD130

220n

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

CD133 1n

Cin

CD134 680n

Yin

CD212 680nG/Y

CD132

CD131

390p

1n5

77

78

80

79

VREF

B1/CB1 IN

G1/Y1 IN

R1/CR1 IN

B2/CB2 IN

G2/Y2 IN

R2/CR2 IN

ASGF

NC

VSUPCAP

VSPD

GNDD

GNDCAP

SCL

SDA

RESQ

TEST

VGAV

YCOEQ

FFIE

FFWE

FFRSTW

FFRE

FFOE

CLK20

CD156

CD162

330p

FB1IN

GNDAI

AISGND

GDNPA25VSUPPA26LLC227LLC128VSUPLLC29GNDLLC30Y731Y632Y533Y434GNDY35VSUPY36Y337Y238Y139Y0

47n

LD13

10uH

CD163

68n

76

75

VSUPAI

UD8

VPC3230D

DBUSY6

DBUSY7

MCUCMD

MCUWR

MCUCS

MCURDY

MCUD7

MCUD6

MCUD5

MCUD4

MCUD3

MCUD2

MCUD1

MCUD0

MCUA7

MCUA6

MCUA5

MCUA4

MCUA3

MCUA2

MCUA1

MCUA0

VREFOUT

VREFIN

COMP

RSET

CGMS

TESTCLK

ADR

ADG

ADB

DEN

DR7

DR6

DR5

DR4

DR3

DR2

DR1

DR0

DG6

DG7

5VA

+2.5VD

CD50

0.1uF

5VA

CD107

0.1uF

CD106

+

10uF

LD4

4.7uH

CD105

0.1uF

CD104

+

10uF

1

4

2

UD6

AMS117

OUT

ADJ/GND

TAB/OUT

IN

3

CD103

0.1uF

CD102

+

10uF

CD127

+

100pF

LD3

4.7uH

5

34

93

123

140

175

205

235

14

29

42

54

69

80

90

101

109

120

131

143

180

208

216

224

230

237

243

249

256

194

197

199

200

58

60

63

64

151

154

157

165

149

163

166

3

CD118

+

10uF

UD1C

VDD

VDD

VDD

VDD

VDD

VDD

VDD

VDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

PVDD

NC

DPAVDD

DPDVDD

PVDD

MPDVDD

MPAVDD

NC

PVDD

AVD33B

AVD33G

AVD33R

PVDD

ADDVDD

ADAVDD

ADGVDD

PW1235

GVS

GHS

SOG

GHS_PW

+5V1 5VD

CD108

47uF/10V

+5V2

CD109

47uF/10V

UD4

TAB/OUT

IN

ADJ/GND

AMS117

CD97

CD98

+

10uF

LD8

4.7uH

CD120

0.1uF

LD9

4.7uH

LD11

+5V1

AVU3

CD135

390p

VRT

CD148

47n

67

65

66

69

70

71

CIN

VIN172VIN273VIN374VIN4

DBUSY5

VRT

GNDF

VOUT

DBUSY3

DBUSY4

192

191

190

188

186

185

184

183

182

181

179

178

177

176

174

173

172

170

169

168

162

161

160

159

156

153

150

146

145

144

142

141

139

138

136

135

133

132

129

130

ASGF

ISGND68VSUPF

I2CSEL

XTAL2

XTAL1

CLK5

VSTBY

FPDAT

MSY/HS

FSY/HC

INTLC

VSUPSY

GNDSY

GNDC

VSUPC

40

3LLC1

CD164

DBUSY0

DBUSY1

DBUSY2

DBUSY[0..7]

CD2

0.1uF

CD1

0.1uF

RD4

1K

RD6

75

RD5

10K

+3.3VD

CD136

1n5

NC

VS

AVO

C0

C1

C2

C3

C4

C5

C6

C7

68n

RD7

0*

CD137

220n

CD149

+

10uF/16V

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

RD43

100

+3.3VA

ROUT

GOUT

BOUT

RD8

75

RD9

10K

CD3

+

10uF/16V

RD10

75

CD138

0.1uF

Yin

Cin

RD11

0*

10uH

CD140

+

10uF

CD139

+

10uF

XD2

20.25MHz

CD150

CD151

15p

15p

RD36 100

V1-OUT

H1-OUT

RD37

DBUSC0

DBUSC1

DBUSC2

DBUSC3

DBUSC4

DBUSC5

DBUSC6

DBUSC7

LLA0

R7

75

R8

75

GCLK

GADU[7:0]

AD9883 YUV 4:4:4 INPUT

GADY[7:0]

GADV[7:0]

VS2

HS2

CD152

0.1uF

CD153

0.1uF

100

CD157

1n5

CD158

220n

GHS_PW

GVS

GCLK

RD12

CD141

+

10uF

CD159

1n5

GADU[7:0]

GADY[7:0]

GADV[7:0]

RD13 100

CD154

+

10uF

CD161

47n

CD160

68n

RP1

100x4

GADU0

GADU1

GADU2

GADU3

GADU4

GADU5

GADU6

GADU7

RP6

GADY0

GADY1

GADY2

GADY3

GADY4

GADY5

GADY6

GADY7

RP7 100x4

GADV0

GADV1

GADV2

GADV3

GADV4

GADV5

GADV6

GADV7

RP11

100x4

100

RD14

10K

LD12

10uH

CD142

0.1uF

VS3

HS3

RP2

RD15

10K

+3.3VA

+3.3VD

CD61

0.1uF

CD75

0.1uF

CD51

0.1uF

CD6

22pF

R/Pr

G/Y

B/Pb

+3.3VA

+3.3VD

100x4

100x4

RP8

100x4

RP9

100x4

CD7

22pF

CD62

0.1uF

CD76

0.1uF

CD52

0.1uF

R1

75

R2

75

R6

75

+3.3VA

+3.3VD

CD63

0.1uF

CD77

0.1uF

100

102

103

104

106

107

108

110

111

113

114

116

117

118

119

121

122

124

125

127

128

L1

3.3UH

L2

3.3UH

L3

3.3UH

CD53

0.1uF

66

67

68

70

71

72

73

75

76

78

79

81

82

83

84

86

87

88

89

91

92

94

95

97

98

99

+3.3VA

CD64

0.1uF

+3.3VD

CD78

0.1uF

UD1B

DGHS

DGVS

DGCLK

DGB0

DGB1

DGB2

DGB3

DGB4

DGB5

DGB6

DGB7

DGG0

DGG1

DGG2

DGG3

DGG4

DGG5

DGG6

DGG7

DGR0

DGR1

DGR2

DGR3

DGR4

DGR5

DGR6

DGR7

DCLK

DVS

DHS

DENG

DENB

DENR

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DG0

DG1

DG2

DG3

DG4

DG5

PW1235

R3

75

R4

75

R5

75

+3.3VA

+3.3VA

+3.3VA

CD65

CD66

CD67

0.1uF

0.1uF

0.1uF

+3.3VD

+3.3Vpll

+3.3Vpll

CD79

CD81

0.1uF

0.1uF

+3.3VD+3.3VD+3.3VD+3.3VD

CD54

CD55

CD56

0.1uF

0.1uF

0.1uF

C1

330p

C2

330p

C3

330p

CD82

0.1uF

CR_VPC

CY_VPC

CB_VPC

+3.3VA

CD68

0.1uF

CD57

0.1uF

JD2

CON15

JD1

CON15

+3.3VA

CD69

0.1uF

+3.3VD+3.3VD+3.3VD+3.3VD

CD58

0.1uF

MD10

MD11

MD12

MD13

MD14

MD15

MCLK

MWE

MCAS

MRAS

MCLKFB

MA10

MA11

MA12

MA13

MUE

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

+3.3VA

CD70

0.1uF

+3.3VD

255

252

248

245

242

239

236

232

231

234

238

241

244

247

250

254

229

227

226

225

223

213

210

207

204

203

206

209

211

214

217

215

220

221

218

201

CD80

0.1uF

+3.3VD

+3.3VD

+2.5VD

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

MA12

MA13

RD16

10K

CD9

0.1uF

CD10

0.1uF

CD11

0.1uF

GOUT

BOUT

ROUT

VS2

HS2

+5V2

RST

SCL

SDA

VS_CPU

HS_CPU

+5V1

R/Pr

B/Pb

G/Y

HS_VGA

VS_VGA

Yin

Cin

+3.3VD

CD12

0.1uF

+3.3VD

CD13

0.1uF

+2.5VD

CD14

0.1uF

MD[15:0]

MCLK

MWE

MCAS

MRAS

MCLKFB

MA[13:0]

RD17

0*

+3.3VD

+2.5VD

+3.3VD

R/Pr

G/Y

B/Pb

HS_VGA

VS_VGA

CD15

0.1uF

CD16

0.1uF

CD17

0.1uF

MD[15:0]

MCLKFB

SDA

SCL

CD71 47nF

CD72 47nF

CD73 1nF

CD74 47nF

CD83

0.1uF

+3.3VD

CD18

0.1uF

+3.3VD

CD19

0.1uF

+2.5VD

CD20

0.1uF

MCLK

MWE

MCAS

MRAS

MCLKFB

MA[13:0]

MCLK

+3.3Vpll

RD24

RD25

RD26

RD22

RD23

+3.3VD

CD21

0.1uF

+3.3VD

CD22

0.1uF

+2.5VD

CD23

0.1uF

CD59

3.9nF

680

680

CD84

0.1uF

+3.3VD

+3.3VD

+2.5VD

MA[13:0]

MCLK

MCLKFB

CD60

39nF

100

100

10K

CD24

0.1uF

CD25

0.1uF

CD26

0.1uF

MWE

MCAS

MRAS

+3.3VA +3.3VD +3.3Vpll

59

62

RD21

3.3K

+3.3VD

+3.3VD

+2.5VD

AVD126AVD227AVD339AVD442AVD545AVD646AVD751AVD852AVD9

33

FILT

57

SDA

56

SCL

55

A0

38

CLAMP

29

COAST

RD20

54

48

49

43

30

31

58

37

CD27

0.1uF

CD28

0.1uF

CD29

0.1uF

+3.3VD

+3.3VD

+2.5VD

MWE

MCAS

MRAS

RAIN

GAIN

SOGIN

BAIN

HSYNC

VSYNC

REFBYP

MIDSCV

CD30

0.1uF

CD31

0.1uF

CD32

0.1uF

100

AD9883 KST -110

GND11GND210GND320GND421GND524GND625GND728GND832GND936GND1040GND1141GND1244GND1347GND1450GND1553GND1660GND1761GND1863GND1968GND20

+3.3VD

+3.3VD

+3.3VD

CD33

CD36

0.1uF

0.1uF

+3.3VD

+3.3VD

+3.3VD

CD34

CD37

0.1uF

0.1uF

+2.5VD

+2.5VD

+2.5VA

CD35

CD38

0.1uF

0.1uF

MA0

23

MA1

24

MA2

25

MA3

26

29

MA4

30

MA5

MA6

31

32

MA7

33

MA8

34

MA9

22

MA10

35

MA11

20

MA12

21

MA13

16

17

18

19

15

39

38

37

+3.3VD

UD3

CD39

0.1uF

CD40

0.1uF

CD43

0.1uF

UD2

+3.3VD

+2.5VA

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

BA0

BA1

WE

CAS

RAS

CS

LDQM

UDQM

CLK

CKE

AVD10

VDD111VDD222VDD323VDD578VDD469VDD6

+3.3VD+3.3VD

+3.3VD

CD41

CD42

0.1uF

0.1uF

CD45

0.1uF

+3.3VD

9

27

VDD1VDD14VDD

VDDQ3VDDQ

HY57V641620HG

VSSQ6VSSQ12VSS28VSS41VSSQ46VSSQ52VSS

79

CD44

0.1uF

VDDQ43VDDQ

35

PVD134PVD2

GREEN0

GREEN1

GREEN2

GREEN3

GREEN4

GREEN5

GREEN6

GREEN7

BLUE0

BLUE1

BLUE2

BLUE3

BLUE4

BLUE5

BLUE6

BLUE7

DATACK

HSOUT

SOGOUT

VSOUT

80

49

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

NC

NC

54

RED0

RED1

RED2

RED3

RED4

RED5

RED6

RED7

2

4

5

7

8

10

11

13

42

44

45

47

48

50

51

53