Page 1

09/2 3/2013

AIR CONDITIONER & HEAT PUMP

DIGITAL CONTROL FOR DUCTED SYSTEM

INSTALLATION AND OPERATING IN STRUCTI ONS

FOR ACM1 35 , ACM 135SP,A CM150 ,A CM150SP,A CRG15 ,A CTH12

RECOR D TH IS U NIT INF OR MATI ON F OR FUTU RE R EF ERENC E:

Model N um be r:

Seria l Nu mb er:

Date Pu rc ha sed:

This ma nu al m ust be re ad a nd unde rs tood befo re i nstal la tion, adj us tment , se rvice, or m ai ntena nc e

is perf or me d. Th is u nit mus t be i nstalle d by a q ualif ie d service t ec hnici an . Modif ic ation of th is

product c an b e extre me ly haza rd ous and cou ld r esult i n pe rsonal in ju ry or pro pe rty damag e.

ROOM AIR

CONDITIONER

3TY1

Page 2

INSTALLATION & OPERATING INSTRUCTIONS

These instructions must stay with the unit

Safety Instructions

This manual h as s af et y information a nd i ns tructions to he lp u se rs eliminate or r ed uc e th e risk of

accidents a nd i nj ur ies.

Read and foll ow a ll s af ety informati on , in stallation gu id es , re commended p re ca ut ions, and safe

operating i ns tr uc tions.

GENERAL INFORMATION

A. Thi s air conditi oner / heat p ump is design ed for:

1. Ins tallation o n a recreat ional vehic le.

2. Mou nting on the ro of of a recre ational veh icle.

3. Roo f construct ion with ra fters/joi sts on 16 inc h centers.

4. 2.5 " to 5.5" inch th ick roofs .

B. The e ffic iency of th e air conditi oner / heat p ump will be affec ted by the

cond itions insi de and outs ide of the RV. Redu cing the he at gain of the RV wil l

allo w the air condi tioner / he at pump to func tion with g reater effici ency. Here

are so me suggesti ons to redu ce heat gain in y our RV.

1. Sel ect a shaded ar ea to park yo ur RV

2. Clo se windows an d utilize t he blinds and / o r curtain s.

3. Kee p doors shut.

4. Avoid us ing applian ces that prod uce heat.

Beginning the cooling / heating process early in the day will greatly improve the heat pump’s

ability to maintain the desired temperature.

In high temperature and high humidity environments, the air conditioner / heat pump should be

set in Cool mode with the Fan Speed in the high position, This will allow for optimal cooling

efficiency.

C. Con densation

The ma nufacture r of this air c onditione r / heat pump w ill not be resp onsible f or

dama ge caused by co ndensed m oisture on ce ilings or o ther surfac es, Air cont ains

mois ture and this m oisture t ends to conde nse on cold s urfaces, Wh en air enters

the RV, co ndensed m oisture may a ppear on the ce iling, wi ndows, meta l parts, et c.

The ai r condition er / heat pum p removes thi s moistur e from the air du ring cool ing

oper ation, Keep ing doors a nd windows cl osed when t his air condi tioner /h eat

pump i s operating w ill minim ize condens ation.

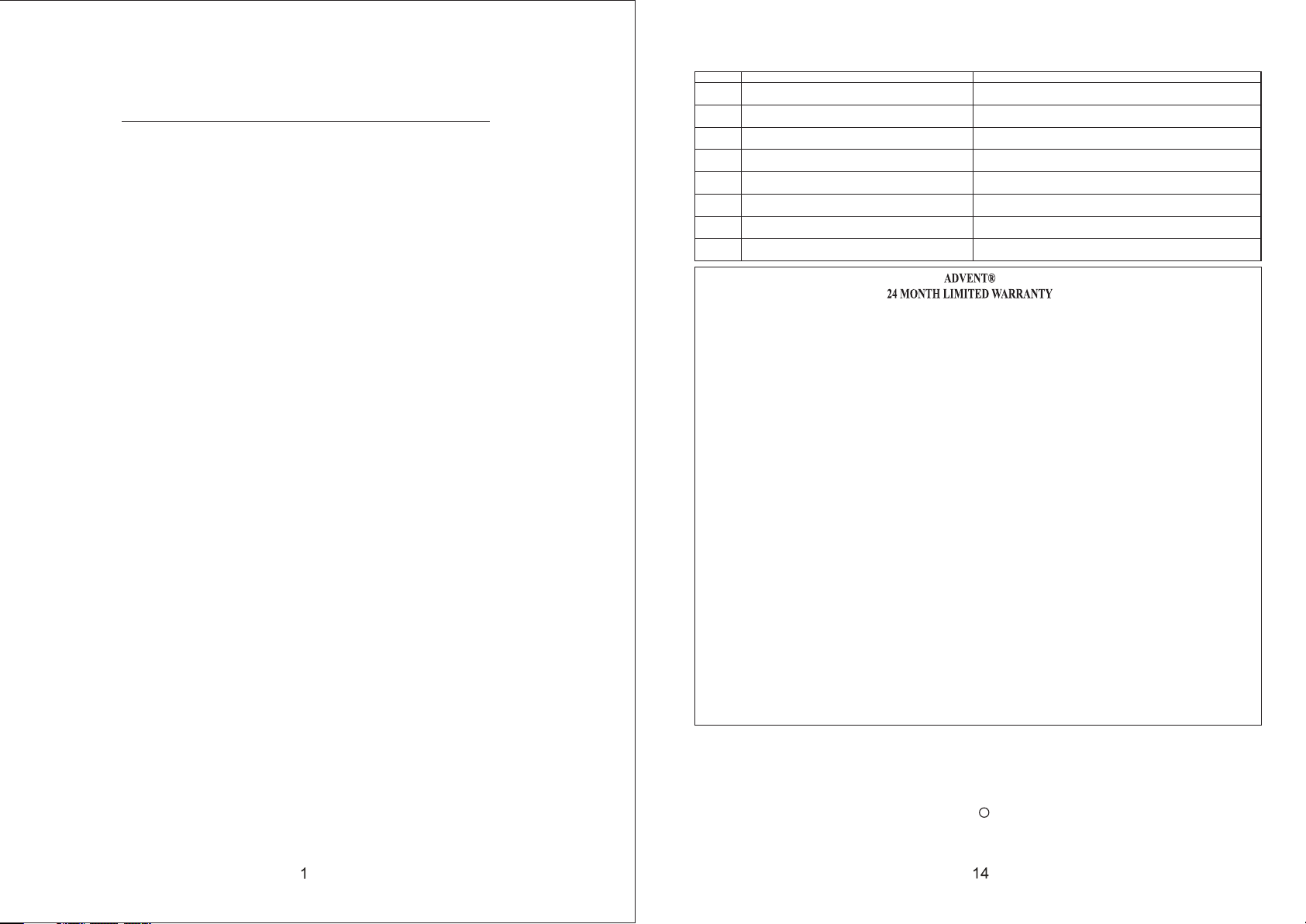

THERMOS TAT ERROR CODE TAB LE

CAU SE SOL UTION

DIS PLAY

Er

Dip S witch p ositi on inco rrect

E1

Roo m Temp Sen sor Def ect

E2

Ind oor Coi l Temp Sen sor Def ect

Out door Co il Temp Se nsor De fect

E3

E4

Out door Amb ient Tem p Senso r Defec t

E5

Com munic ation D efect w ith T-St at and Re lay Kit

DC vo ltage i s below 1 0 Volts( +/-0. 5V)

Lo

dF

Ind oor or Ou tdoor c oil is fr ozen

Set D ip swit hces to c orrec t posit ion on ba ck of The rmost at

Rep lace Th ermos tat

Che ck wire c onnec tions a nd ensu re sens or is pro perly i nstal led.

Rep lace Se nsor

Che ck wire c onnec tions a nd ensu re sens or is pro perly i nstal led.

Rep lace Se nsor

Che ck wire c onnec tions a nd ensu re sens or is pro perly i nstal led.

Rep lace Se nsor

Che ck wire c onnec tions a t T-Stat a nd rela y kit

Che ck wire c onnec tions a nd ensu re DC vol tage is a bove 10 v olts

Sys tem is de icing a nd can no t be used f or 35 min utes an d will re start

aut omati cally

ASA Electronics (ASA) warrants to the original retail purchaser of this Advent product that should this product or any

part thereof, proven defective in material or workmanship within 24 months from under normal use and conditions, be

the date of original purchase, such defect(s) will be repaired or replaced (at ASA'S option) without charge

for parts and repair labor.

The intended use of this Advent product is on recreational vehicles, also known as motorhomes and travel trailers.

Any installa be considered normal use and warranty coverage will not tion outside of this intended use is not to

be expressed warranty condition of improper installation. extended under the

To obtain repair or replacement within the terms of this warranty, contact ASA at (888) 283-7374. The product is

to be delivered with proof of warranty coverage (dated bill of sale), specification of defect(s) with purchaser’s

name and return address, transportation prepaid to ASA at the address shown provided at the time of return

authorization.

This warranty does not extend to the effects of this device on other devices, to costs incurred for removal or

reinstallation accessories, or electrical system(s). This warranty does of the product, or to damage of any product,

not part thereof which, in the opinion of the company, has been damaged through apply to any product or

alteration, i ndling, misuse, neglect, or accident. mproper installation, misha

THE EXTENT OF ASAS LIABILITY UNDER THIS WARRANTY IS LIMITED TO THE REPAIR OR

REPLAC NO EVENT, SHALL ASAS LIABILITY EXCEED THE EMENT PROVIDED ABOVE, AND, IN

PURCHASE PRICE PAID BY THE PURCHASER FOR THE PRODUCT.

This warranty is in lieu of all other express warranties or liabilities. ANY IMPLIED WARRANTIES, INCLUDING

ANY MERCHANTABILITY, SHALL BE LIMITED TO THE DURATION OF THIS IMPLIED WARRANTY OF

WARRANTY. ANY ACTION FOR BREECH OF ANY WARRANTY HEREUNDER INCLUDING

WARRANTY BROUGHT WITHIN A PERIOD OF 30 DAYS FROM OF MERCHANTABILITY MUST BE

THE DATE OF PURCHASE. IN NO CASE SHALL ASA BE LIABLE FOR ANY ORIGINAL

CONSEQUENTIAL OR INCIDENTAL ANY OTHER WARRANTY, DAMAGES FOR BREECH OF THIS OR

EXPRESS OR IMPLIED, WHATSOEVER. or representative is authorized to assume for the No person

company any liability other than expressed herein in connection with the sale of this product.

ASA Electronic 37000008s

(888) 283-7374 Rev B

IMPORTANT WARRANTY INFORMATION

DO NOT RETURN D EFECTIVE PRODU CT

TO YOUR PLAC E OF PURCHASE

CONTACT ADVEN T @ 1-888-283-73 74

Please place th is War ra nty Agreement and a co py o f yo ur sales receipt in a saf e an d secure location,

along with your o th er v aluable documents .

R

Page 3

CONNECT ING 115VAC WIRING

1. WA RNING - SHO CK HAZARD: To preve nt the possib ility of se vere person al injury or

equi pment damag e due to elec trical shoc k, always b e sure the elec trical po wer is

disc onnected or o ff b efore begin ning inst allatiom.

2. Rou te the 115VAC supply wiri ng previo usly routed i nto the fra me of the roof op ening,

thro ugh the strai n relief of t he electric al box and in to the high vol tage wiring a rea.

TO PREVENT THE POSSIBILITY OF SHOCK INJURY FROM APP LIANCE

OPERATION: THE WHITE WIR E MUST BE CONN ECTED TO NEUTRAL IN THE

SERVICE BOX ENTRANCE AND THE GREEN G ROUND WIRE M UST BE

CONNECT ED TO A GROUNDING SCREW.

ATTACH CEI LING GRILL

1. Pos ition the gri ll next to th e interior fr ame and att ach it with the p rovided scr ews.

2. Ins tall the filt er on the air i ntake grill s ection.

3. Sna p the intake gr ill secti on onto the mai n grille.

4. Ins tall the scre w covers.

MAINTENANCE

1. AI R FILTER:

Remo ve the return a ir filter ( after every 3 0 days of use ) located abo ve the remova ble

air in take grill. Wash the fi lter with s oap and warm wa ter, let dry a nd then reins tall.

Note : Never run the a ir condit ioner / heat pu mp withou t putting the a ir filter bac k in

plac e. Thi s may plug th e indoor coil w ith dirt an d may substan tially affect t he

perf ormance of th e unit.

2. Ai r Return Gr ill:

Clea n panel and con trol pane l with a soft clo th dampen ed with a mild de tergent . Never

use fu rniture pol ish or hars h chemicals .

3. FAN MO TOR:

Fact ory lubrica ted and req uires no serv ice.

4. FRO ST FORMATION ON CO OLING COIL:

Unde r certain con ditions , frost may for m on the indo or coil. If thi s should occu r, inspect

the fi lter and clea n if dirty. Make sur e air louve rs are not obst ructed. Air co ndition ers /

heat p umps have a gre ater tend ency to frost w hen the out side temper ature is rela tively

low. This may b e prevent ed by adjusti ng the ther mostat cont rol to a warm er setting.

SERVICE

If the u nit does not op erate:

1. If RV is conn ected to a ge nerator, che ck to be sure g enerator is r unning an d producing

the pr oper power.

2. If RV is conn ected to sh ore power, che ck to be sure s upply break er is sized p roperly to

run ai r condition er / heat pum p load and it is pl ugged int o power suppl y.

3. Che ck your fuse or c ircuit br eaker to see if i t is off.

4. Afte r the above che cks, call y our local ser vice cent er for furthe r help. This unit m ust be

serv iced by quali fied serv ice personn el only.

Model

ACM135

ACM135S P

ACM150

ACM150S P

Rated

BTU

Output

13500

15000

Electri ca l

Rating

115VAC

60Hz

1PH

Compres so r

Rated

Amperag e

9.9

12.4

Locked

Rotor

Amperag e

50.5

61

Fan

Amperag e

2.6

2.6 5.8

Locked

Fan Rotor

Amperag e

5.8 500

Air Flow

Refrige ra nt

(High

Speed)

(cfm)

500 16.9

(R410a)

(oz)

16.9

Min. wire

size

12AWG

copper

up to

24'

AC circui t

protect io n

(User

supplie d)

20 Amp

20 Amp

Unit

dimensi on s

(in)

31x24.9 x1 2. 9

31x24.9 x1 2. 9

Notes:

1. Con sult the Nati onal Elec tric Code for p roper siz ing for wire le ngths ove r 24 ft.

2. Whe n sizing the ge nerator, t he total powe r usage of yo ur recreati onal vehi cle

must b e considere d. Keep in mi nd generato rs lose pow er at high alti tudes and

from l ack of mainte nance.

3. CIR CUIT PROTECTI ON: Time Delay F use or HACR C ircuit Brea kers Requ ired.

INSTALLATION INSTRUCTIONS

1. PRECAU TIONS

A. Rea d installat ion and ope rating inst ruction s carefully b efore att empting to st art

your a ir conditio ner / heat pu mp installa tion.

B. The m anufactur er will not b e liable for an y damages o r injury incu rred due to f ailure

to fol low these ins tructio ns.

C. Ins tallation m ust compl y with the Nati onal Elec trical Code a nd any Stat e or Local

Code s or regulati ons.

D. DO NO T add any devic es or acces sories to thi s air condi tioner / heat p ump except

thos e specifica lly autho rized by manu facture r.

E. This equi pment mus t be serviced b y qualifi ed personne l and some st ates requir e

lice nsed person nel.

2. CHOOSI NG A LOCATION FOR THE AIR CONDITIONER / HE AT PUMP

This p roduct is des igned for u se as a RV r oof top air c onditione r / heat pump . The us e

of thi s product in ot her appli cations wil l void the ma nufacture s warrant y.

A. NOR MAL LO CATIONS:

The un it is designe d to fit over a n existing ro of vent ope ning. When th e vent is

remo ved, it norma lly creat es a 14-1/4" x1 4-1/4"±1/ 8" opening.

B. OTH ER LOCATIONS:

When a r oof vent is not a vailabl e or another lo cation is d esired, the f ollowin g is

reco mmended:

Weigh t

(Ibs)

68

68

Page 4

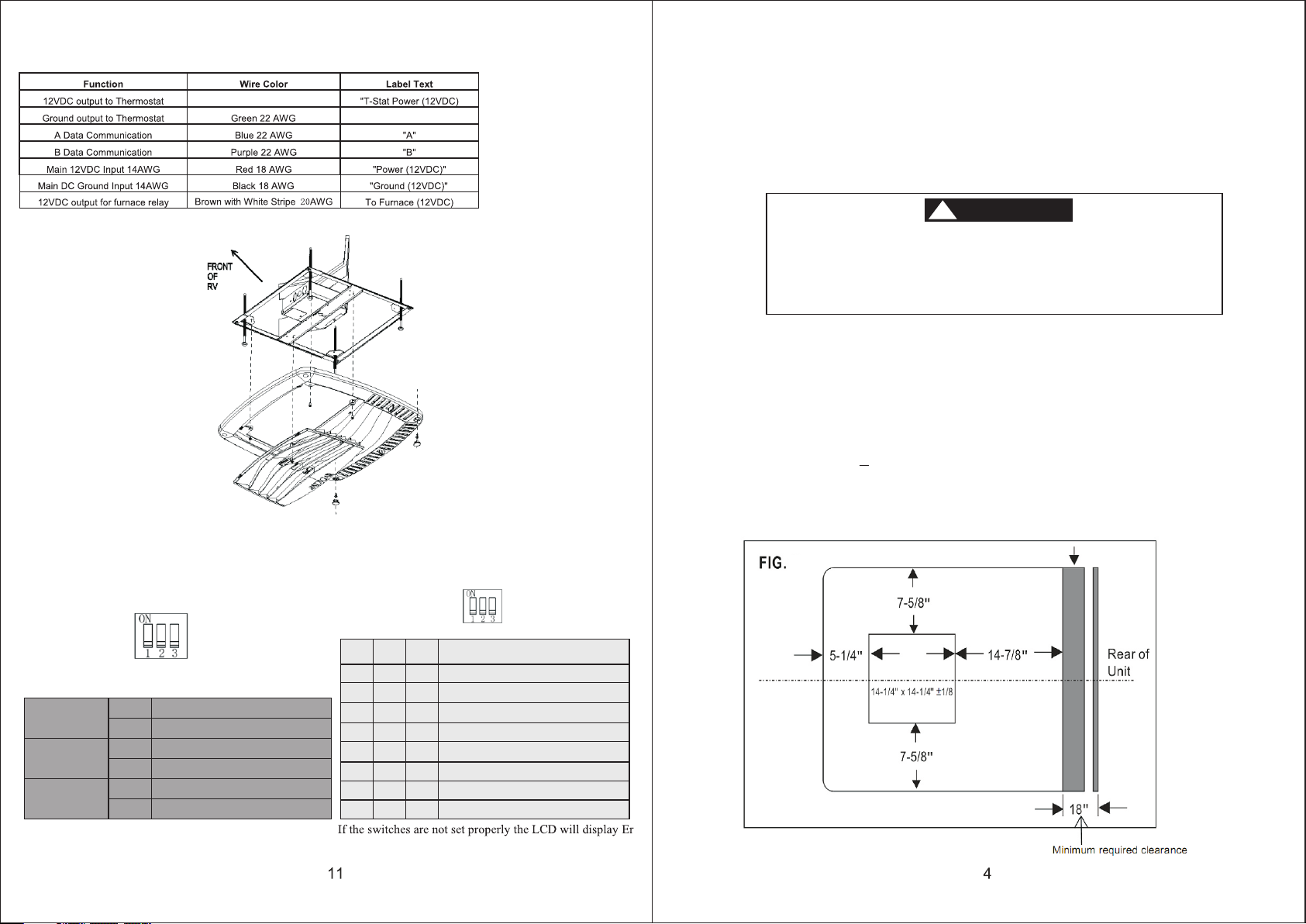

1. For o ne unit insta llation : The ai r conditi oner / heat pum p should be m ounted slig htly

forw ard of center ( front to ba ck) and cente red from si de to side. See F IG.1.

FIGU RE 1

ACTH12 TH ERMOSTAT INSTALLATION:

2. For t wo unit insta llation : Install one a ir condit ioner / heat pu mp 1/3 distan ce and the

othe r air conditi oner / heat p ump 2/3's fro m front of RV and cen tered fro m si de to side.

See FI G.2.

FIGU RE 2

It is pr eferred tha t this air co nditioner / h eat pump be i nstalled in a r elatively f lat and

leve l roof sectio n measure d with the RV parke d on a level surf ace; howe ver, up to 15

degr ee slant to eit her side, o r front-to- back is acc eptable.

ACTH12 TH ERMOSTAT WIRING

12V+

T O U P P E R U N I T

R E L A Y B O X

B

A

C O M

1 2 V +

IMPORTANT: When connecting the wires:

1. Mak e any adjustm ents requ ired to relie ve pinche d or stressed w iring.

2. Rem ove 1/4"ins ulation f rom the 4 wires . Use a small F Iat-head sc rew driver to l oosen

the wi re terminal s crews. Pu sh each corre spondin g wire into the p roper termi nal

hole a nd tighten ea ch screw.

Page 5

MAIN RELAY KIT WIRING

Red wit h Whi te St ri pe 22 AWG

COM

FIG. 7

C. POST LOC ATION SELECTI ON:

1. Che ck for obstru ctions in t he area where a ir condit ioner / heat pu mp will be

inst alled. A minimu m clearance o f 18" is requir ed for the re ar section of t he air

cond itioner / hea t pump to any o ther roof mou nted obje ct.

2. The roof mu st be capab le of support ing 100 Ibs w hile the RV is in mot ion. Normal ly,

a 200 Ib . static load d esign wil l meet this req uiremen t.

3. ROOF PREPARATION

There may b e electric al wiring be tween the roof and

the ceili ng. Discon nect 120 vol t AC power cord and th e

positiv e (+) 12 volt DC t erminal at t he supply battery.

Failure t o follow thi s instruction may create a shock

hazard ca using deat h or severe pe rsonal injury.

A. EXISTI NG ROOF VENT R EMOVAL:

1.Un screw and rem ove the roo f vent.

2. Rem ove all caulk ing compo und around op ening.

3. Sea l all screw hol es and seam s where the roo f gasket wi ll be located . Use a good

grad e of all weathe r sealant .

B. NEW OPEN ING:

1.A 14- 1/4" x 14-1/4 "+1/8" op ening must be c ut throug h the roof and ce iling of th e RV.

It is re commended t his openi ng be located b etween ro of framewor k.

2. Mar k a 14-1/4" x 14- 1/4" squa re on the roof an d careful ly cut the open ing.

3. Usi ng the roof ope ning as a gui de, cut the mat ching hol e in the ceilin g. See FIG.3.

WARNING

!

THERMOS TAT DIP SWITCH SE TTINGS:

Dip swi tc h

As shown ALL OFF

Heat St rip f un cti on disa ble

Dip Swi tch 1

Dip Swi tch 2

Dip Swi tch 3

Default S et ting is 1 OFF, 2 OFF, 3 ON

Off

Heat St rip f un cti on enab le

On

Heat Pu mp fu nc tio n disab le

Off

Heat Pu mp fu nc tio n enabl e

On

Off

Furna ce fu nc tio n disab le

On

Furna ce fu nc tio n enabl e

SW1 SW2 SW 3

OFF OFF OFF

ON

OFF OFF

OFF OF F

ON

OFF OFF

ON

ON O N

OFF

ONON

OFF ON

ON

ONONOFF

ON

Dip s witch

.3

Mod e Cycle

FAN - COO L

FAN - COO L - HEAT STRIP

FAN - COO L - HEAT PUMP

FAN - COO L - FURNA CE

Con figur ation n ot poss ible

FAN - COO L - HEAT PUMP - FUR NACE

FAN - COO L - HEAT STRIP - FU RNACE

Con figur ation n ot poss ible

Page 6

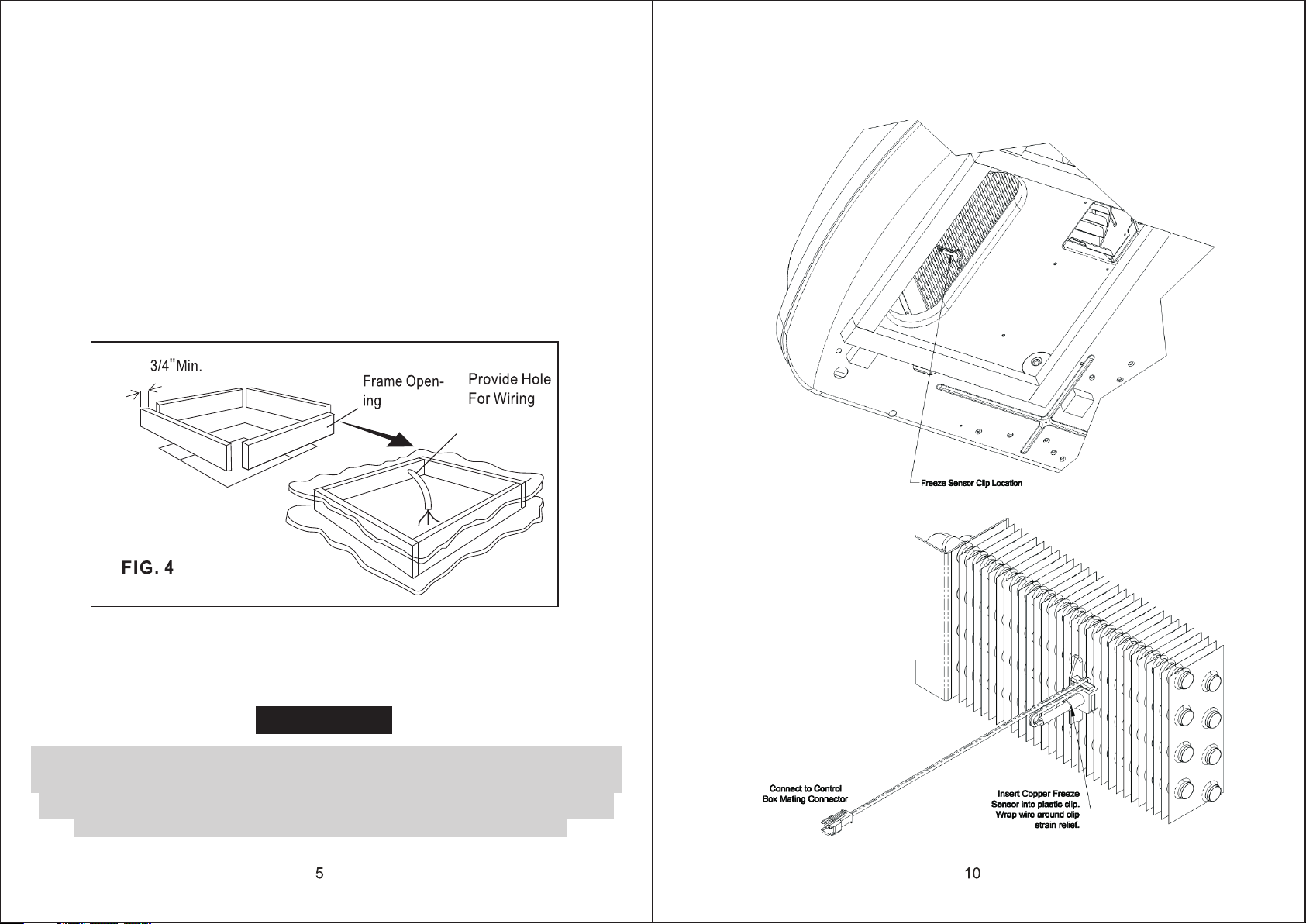

C. OPENIN G PREPARATION:

1. If th e opening exc eeds 14-3 /8" x 14-3/8" , it will be ne cessary to in stall space rs.

2. If th e opening is le ss than 14- 1/8" x 14-1/8 ", it must be e nlarged.

3. Rou te a 12/3 Rmoex t ype suppl y line from the c ircuit br eaker box to th e Front of

the ro of opening.

a. The power s upply mus t be on a separat e 20 amp Time De lay Fuse or HAC R

Circ uit Breaker.

b. Wir ing must comp ly with all N ational, St ate and Loc al wiring cod es.

c. Mak e sure at least 1 5" of wire ex tend into the r oof openi ng to ensure ea sy

conn ections.

4. The ope ni ng must be fr amed to provi de adequa te support an d prevent a ir from

bein g drawn from th e roof cavi ty. Lum ber 3/4" th ick or more and l ong enoug h to

brid ge the openin g must be use d. Remember t o provide a n entrance ho le in the

fron t of the openin g for 110v, 12 v, an d thermosta t wires. See FI G.4.

ALTERNATIVE FREEZE SENSOR INSTALL ATI ON

Chec k Upper Unit to s ee if freez e sensor clip i s preinst alled in evap orator fi ns. If so,

inse rt the copper s ensor fro m the Ducted Ce iling kit i nto the clip as s how below.

5. The 14-1/ 4" x14-1/ 4"(+1/8) ro of openin g is part of the re turn air du ct and must be

fini shed in accor dance wit h NFPA sta ndard 501 C, Standard f or Recrea tional

Vehic les, Sectio n 2-7.

CAUTION

It is the res ponsibil ity of the installer of this system to ensure structural

integri ty of the RV roof. Never create a low spot on th e roof where w ater

will coll ect. Water standing around the air condi tioner/h eat pump may

leak into t he interio r causing damage to the product and RV

Page 7

AIR RETUR N GRILL INSTALLATION (ACR G15)

The Air R eturn Grill i s designe d for applica tion in sys tems that uti lize fiel d fabricate d (OEM

supp lied)air du cting. The duct ing must be r outed throu gh the ceil ing cavity (b etween the

inte rior ceilin g and roof) . Ducting spe cificat ions are give n in the sect ion labeled S upply

Duct ing and Regis ters.

INSTALLATION REQUIREMENTS

(ROOF THI CKNESS MUS T BE AT LEAST 2.5" )

1. The ACRG mus t be instal led under the r oof openi ng. Th e ACRG bolts t o the

unde rside of the ro of unit. Co mpression o f the frame d ceiling cav ity between t he roof

unit a nd the ACRG is wha t holds bot h component s in place.

2. Cei ling cavity d epth (the m easuremen t from the ce iling to the ro of): 5.5" - Max imum,

2.5" - M inimum

3. The 115 VAC service for t he air cond itioner / hea t pump must b e routed into t he ACRG

(ref er to Fig.5 A & B below ). 12VDC sh ould be route d to the digi tal control b ox. If a LP

furn ace is being us ed, a contr ol wire must be c onnecte d from the furn ace to the digi tal

cont rol box for pro per opera tion.

FIGU RE 5A WIRING DIA GRAM FOR HE AT PUMP

COM

12VAB

BLU

GRN

PURPLE

RED/WH T

COM

12VAB

4WAY VALVE

Page 8

FIGU RE 5B WIRING DI AGRAM FOR AI R CONDITION ER ONLY

RED/WH T

4.Th e ACRG has a 6pin, t wo 3 pin & two 2 pi n connector s extendi ng from the fro nt of

the re lay kit. These co nnectors ma te with the a ir conditio ner / heat pump . When

maki ng this conne ction, ve rify that the p lugs are pr operly alig ned and hav e sn apped

toge ther secure ly.

5.Pr ovided with t he ACRG,is a d ivider plat e which is us ed to separat e the warm re turn

air fr om the cold sup ply air. If th e roof thickn ess is grea ter than 2.5" , you MUST use the

addi tional divi der provi ded.

SUPPLY DUCTING AND REG ISTERS

A. Duc ting

1. The field f abricat ed supply duc ting must a ttach to both s ides of the ACRG . A

mini mum of two duct s are requi red, with one d uct attac he d to each sid e of the plenum .

2. Eac h duct must hav e a minimum h eight of 1-1/ 2". Maxim um height can not exceed 4" .

Tot al free are a inside each d uct must be no le ss than 10 sq uare inches .

NOTE : To decrease res trictio n and increas e airflow, t he ducting sh ould make a s fe w bends

and tu rns as possib le. When co rners or turn s are require d, we recom mend that you

add ra dii to the corn ers to keep a irflow at a air flow and syst em perfor mance.

3. All fi eld fabrica ted air sup ply ducting m ust be insu lated to avoi d condens ation and

prev ent cooling / h eating lo ss.

B. Reg isters

Air re gisters sho uld have a mi nimum disch arge area o f 48 square inc hes per sys tem, or 24

squa re inches per d uct run.

War nings abo ut wiring:

1. U.L . approval re quires th e power suppl y to be coppe r conductor s with mini mu m #12AWG .

2. To prevent vo ltage dro ps greater th an 10% duri ng starting l oads, adh ere to the foll owing

guid eline: For le ngths gre ater than 50 fe et, use #10 AWG.

TEMPLATE MOUNTING

Fram e Mounting

1. Pla ce the air cond itioner / h eat pump over t he roof ope ning.

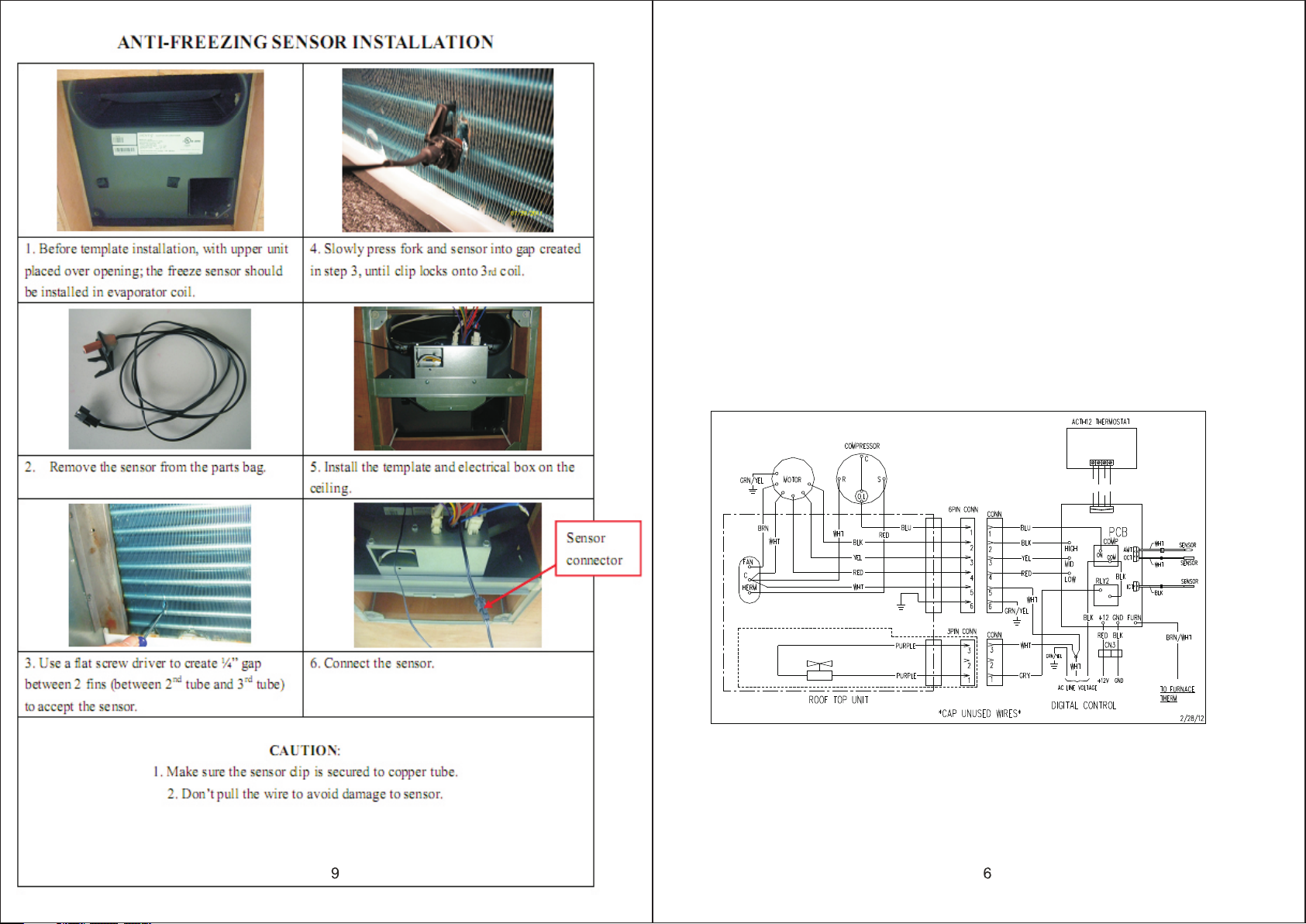

2. Ins tall freeze s ensor(s ee below Fig. 6). Some ai r condition ers / heat pump s may conta in

a prei nstalled, p lastic, r etaining cl ip for the fr eeze sensor. I f the clip is pre sent in the

evap orator coil , please us e this clip and d iscard th e clip that cam e with the free ze sensor.

Inse rt the freeze s ensor int o the plastic c lip and ens ure the freez e sensor is sec ured

prop erly in the cli p. Connec t the freeze se nsor harn ess to the rela y box mating ha rness.

3. Pos ition the mou nt frame in to the ceilin g opening . See Figure 7.

4. Usi ng the four bol ts provid ed, hold up the m ount temp late to the cei ling. The four mo unting

bolt s are to be inser ted up thro ugh the botto m of the moun t te mplate an d into the bott om

of the a ir conditio ner / heat pu mp. Tighten al l 4 boles equ ally to compr ess gasket 33 -35

inch p ounds. When m oving the a ir conditio ner / heat pu mp be sure not to d amage the

gask et by sliding i t across th e roof. If the ga sket is damag ed and need s replaced, p lease

cont act ASA Electro nics and pu rchase an aut horized Ad vent gasket f or replac em ent.

Usin g other gaske t materia l is not recomm ended and c ould result i n warrant y de nial.

5. Ins tall divide r with foam s eal against b ase pan of up per unit. On th inner roofs , the divid er

may be t oo high, so bre ak away add itional por tion. Rem ove paper cov er on fixed d ivider,

inse rt loose divi der again st base pan and s tick to fix ed divider.

6. Cut t he insulati on to the hei ght of the divi der, cente r insulatio n on divide r before remo ving

pape r backing and a pply to div ider. Excess i nsulati on will help en sure the se al at the end

of the d ivider/fr ame.

7. Con nect 115VAC and 12VDC wir es, Freez e Sensor Thermi stor, Heat Pum p specifi c

(Out door Coil Therm istor, Outdo or Ambient Therm istor), a nd thermost at cable acco rding

to the w iring diagr am. Insta ll the cover ov er the elec trical box us ing the small s crew

prov ided as shown i n Figure 7.

8. Sea l all seams bet ween outp ut airside an d return ai rside with in sulatio n and foil tape .

Loading...

Loading...