Page 1

User Manual

WISE-1510

M2.COM LoRa IoT Node

Page 2

Copyright

The documentation and the software included with this product are copyrighted 2016

by Advantech Co., Ltd. All rights are reserved. Advantech Co., Ltd. reserves the right

to make improvements in the products described in this manual at any time without

notice. No part of this manual may be reproduced, copied, translated or transmitted

in any form or by any means without the prior written permission of Advantech Co.,

Ltd. Information provided in this manual is intended to be accurate and reliable. However,

Advantech Co., Ltd. assumes no responsibility for its use, nor for any infringements

of the rights of third parties, which may result from its use.

Acknowledgements

ARM is trademarks of ARM Corporation.

Freescale is trademarks of Freescale Corporation.

Microsoft Windows are registered trademarks of Microsoft Corp.

All other product names or trademarks are properties of their respective owners.

Product Warranty (2 years)

Advantech warrants to you, the original purchaser, that each of its products will be

free from defects in materials and workmanship for two years from the date of purchase.

This warranty does not apply to any products which have been repaired or altered by

persons other than repair personnel authorized by Advantech, or which have been

subject to misuse, abuse, accident or improper installation. Advantech assumes no

liability under the terms of this warranty as a consequence of such events.

Because of Advantech’s high quality-control standards and rigorous testing, most of

our customers never need to use our repair service. If an Advantech product is defective,

it will be repaired or replaced at no charge during the warranty period. For out-of-

warranty repairs, you will be billed according to the cost of replacement materials,

service time and freight. Please consult your dealer for more details.

If you think you have a defective product, follow these steps:

1. Collect all the information about the problem encountered. (For example, CPU speed,

Advantech products used, other hardware and software used, etc.) Note anything

abnormal and list any onscreen messages you get when the problem occurs.

2. Call your dealer and describe the problem. Please have your manual, product, and any

helpful information readily available.

3. If your product is diagnosed as defective, obtain an RMA (return merchandize

authorization) number from your dealer. This allows us to process your return more

quickly.

4. Carefully pack the defective product, a fully-completed Repair and Replacement Order

Card and a photocopy proof of purchase date (such as your sales receipt) in a

WISE-1510 User Manual 1

Page 3

shippable container. A product returned without proof of the purchase date is not

eligible for warranty service.

5. Write the RMA number visibly on the outside of the package and ship it prepaid to your

dealer.

Declaration of Conformity

FCC Class B

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: Any changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate this equipmt.t.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

IMPORTANT NOTE:

FCC Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20cm

between the radiator & your body.

This module is intended for OEM integrator. The OEM integrator is responsible for the compliance

to all the rules that apply to the product into which this certified RF module is integrated.

Additional testing and certification may be necessary when multiple modules are used.

WISE-1510 User Manual 2

Page 4

USERS MANUAL OF THE END PRODUCT:

In the users manual of the end product, the end user has to be informed to keep at least 20cm

separation with the antenna while this end product is installed and operated. The end user has to be

informed that the FCC radio-frequency exposure guidelines for an uncontrolled environment can be

satisfied.

The end user has to also be informed that any changes or modifications not expressly approved by

the manufacturer could void the user's authority to operate this equipment.

If the labelling area is small than the palm of the hand, then additional FCC part 15.19 statement is

required to be available in the users manual: This device complies with Part 15 of FCC rules.

Operation is subject to the following two conditions: (1) this device may not cause harmful

interference and (2) this device must accept any interference received, including interference that

may cause undesired operation.

LABEL OF THE END PRODUCT:

The final end product must be labeled in a visible area with the following " Contains TX FCC ID:

M82-WISE1510 ".

If the labelling area is larger than the palm of the hand, then the following FCC part 15.19 statement

has to also be available on the label: This device complies with Part 15 of FCC rules. Operation is

subject to the following two conditions: (1) this device may not cause harmful interference and (2)

this device must accept any interference received, including interference that may cause undesired

operation.

IC

This radio transmitter has been approved by Industry Canada to operate with the antenna types

listed below with the maximum permissible gain indicated. Antenna types not included in this list,

having a gain greater than the maximum gain indicated for that type, are strictly prohibited for use

with this device.

Le présent émetteur radio a été approuvé par Industrie Canada pour fonctionner avec les types d'antenne

énumérés ci-dessous et ayant un gain admissible maximal d'antenne. Les types d'antenne non inclus dans

cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour

l'exploitation de l'émetteur.

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to

the following two conditions: (1) this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de

licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de

WISE-1510 User Manual 3

Page 5

brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

Part No.

MPN

Description

1750008625-01

TH-915i

Dipole Ant. SUB-1G 1.8dBi SMA/M BLK 902-928 IPX6

brouillage est susceptible d'en compromettre le fonctionnement.

This radio transmitter (9404A-WISE1510) has been approved by Industry Canada to operate with

the antenna types listed below with the maximum permissible gain indicated. Antenna types not

included in this list, having a gain greater than the maximum gain indicated for that type, are strictly

prohibited for use with this device.

Le présent émetteur radio (9404A-WISE1510) a été approuvé par Industrie Canada pour fonctionner avec

les types d'antenne énumérés ci-dessous et ayant un gain admissible maximal d'antenne. Les types

d'antenne non inclus dans cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont

strictement interdits pour l'exploitation de l'émetteur.

Antenna list:

IMPORTANT NOTE:

IC Radiation Exposure Statement:

This equipment complies with IC RSS-102 radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20cm

between the radiator & your body.

Cet équipement est conforme aux limites d'exposition aux rayonnements IC établies pour un environnement

non contrôlé. Cet équipement doit être installé et utilisé avec un minimum de 20 cm de distance entre la

source de rayonnement et votre corps.

This module is intended for OEM integrator. The OEM integrator is responsible for the compliance

to all the rules that apply to the product into which this certified RF module is integrated.

Additional testing and certification may be necessary when multiple modules are used.

Any changes or modifications not expressly approved by the manufacturer could void the user's

authority to operate this equipment.

USERS MANUAL OF THE END PRODUCT:

In the users manual of the end product, the end user has to be informed to keep at least 20cm

separation with the antenna while this end product is installed and operated. The end user has to be

informed that the IC radio-frequency exposure guidelines for an uncontrolled environment can be

satisfied.

The end user has to also be informed that any changes or modifications not expressly approved by

WISE-1510 User Manual 4

Page 6

the manufacturer could void the user's authority to operate this equipment. Operation is subject to

the following two conditions: (1) this device may not cause harmful interference and (2) this device

must accept any interference received, including interference that may cause undesired operation.

LABEL OF THE END PRODUCT:

The final end product must be labeled in a visible area with the following " Contains IC:

9404A-WISE1510 ".

The Host Model Number (HMN) must be indicated at any location on the exterior of the end product

or product packaging or product literature which shall be available with the end product or online.

WISE-1510 User Manual 5

Page 7

Packing List

Part No.

Description

1750008598-01

Sub G antenna Dipole L=195mm, 1dBi 902~928 MHz

1750008599-01

Sub G antenna Dipole L=195mm, 1dBi 863~870 MHz

1750008569-01

Antenna Cable SMA to MHF4 L=300mm

1700015038

FPC Cable 10P-0.5mm 7.9cm for DCU2.0

9696WED200E

ASS'Y WISE-ED20 A101-1 M2.COM Daughter

1931000590

Screw M2.5x5L F/S D=5.3 H=0.8 (1+) ST Ni

1700023619-01

A cable USB-A 4P(M)/micro USB 5P(M) 1m ADAM-T212

1700025876-01

M cable USB-A 4P(M)/Plug-in 2P-5.0 90CM

XRISC-ADP-10HW-AG

ADP A/D 100-240V 10W 5V WM

193A231540

POST F=M3*6L M=M3*6L D=5 d=2.88 B=5 H=15 Cu

Part No.

Description

9696150000E

ASS'Y WISE-DB1500 A101-1 M2.COM CARRIER

Part No.

WISE-1510WMB-SDA1N

Frequency Band

902-928MHz for North America (LoRaWAN)

Part No.

WISE-1510WMB-SDA1E

Frequency Band

863-870MHz for Europe (LoRaWAN)

Before setting up the system, check that the items listed below are included and in good condition. If

any item does not accord with the table, please contact your dealer immediately.

1 WISE-1510

1 Screw for WISE-1510

1 China RoHs Notice

Optional Accessories

Development Board

Ordering Information

WISE-1510 User Manual 6

Page 8

WISE-1510 User Manual 7

Page 9

Safety Instructions

1. Read these safety instructions carefully.

2. Keep this User Manual for later reference.

3. Disconnect this equipment from any AC outlet before cleaning. Use a damp cloth. Do

not use liquid or spray detergents for cleaning.

4. For plug-in equipment, the power outlet socket must be located near the equipment

and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a reliable surface during installation. Dropping it or letting it fall

may cause damage.

7. The openings on the enclosure are for air convection. Protect the equipment from

overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source is correct before connecting the equipment

to the power outlet.

9. Position the power cord so that people cannot step on it. Do not place anything over the

power cord.

10. All cautions and warnings on the equipment should be noted.

11. If the equipment is not used for a long time, disconnect it from the power source to

avoid damage by transient overvoltage.

12. Never pour any liquid into an opening. This may cause fire or electrical shock.

13. Never open the equipment. For safety reasons, the equipment should be opened only

by qualified service personnel.

14. If one of the following situations arises, get the equipment checked by service

personnel:

The power cord or plug is damaged.

Liquid has penetrated into the equipment.

The equipment has been exposed to moisture.

The equipment does not work well, or you cannot get it to work according to the

user's manual.

The equipment has been dropped and damaged.

The equipment has obvious signs of breakage.

DISCLAIMER: This set of instructions is given according to IEC 704-1. Advantech

disclaims all responsibility for the accuracy of any statements contained herein.

WISE-1510 User Manual 8

Page 10

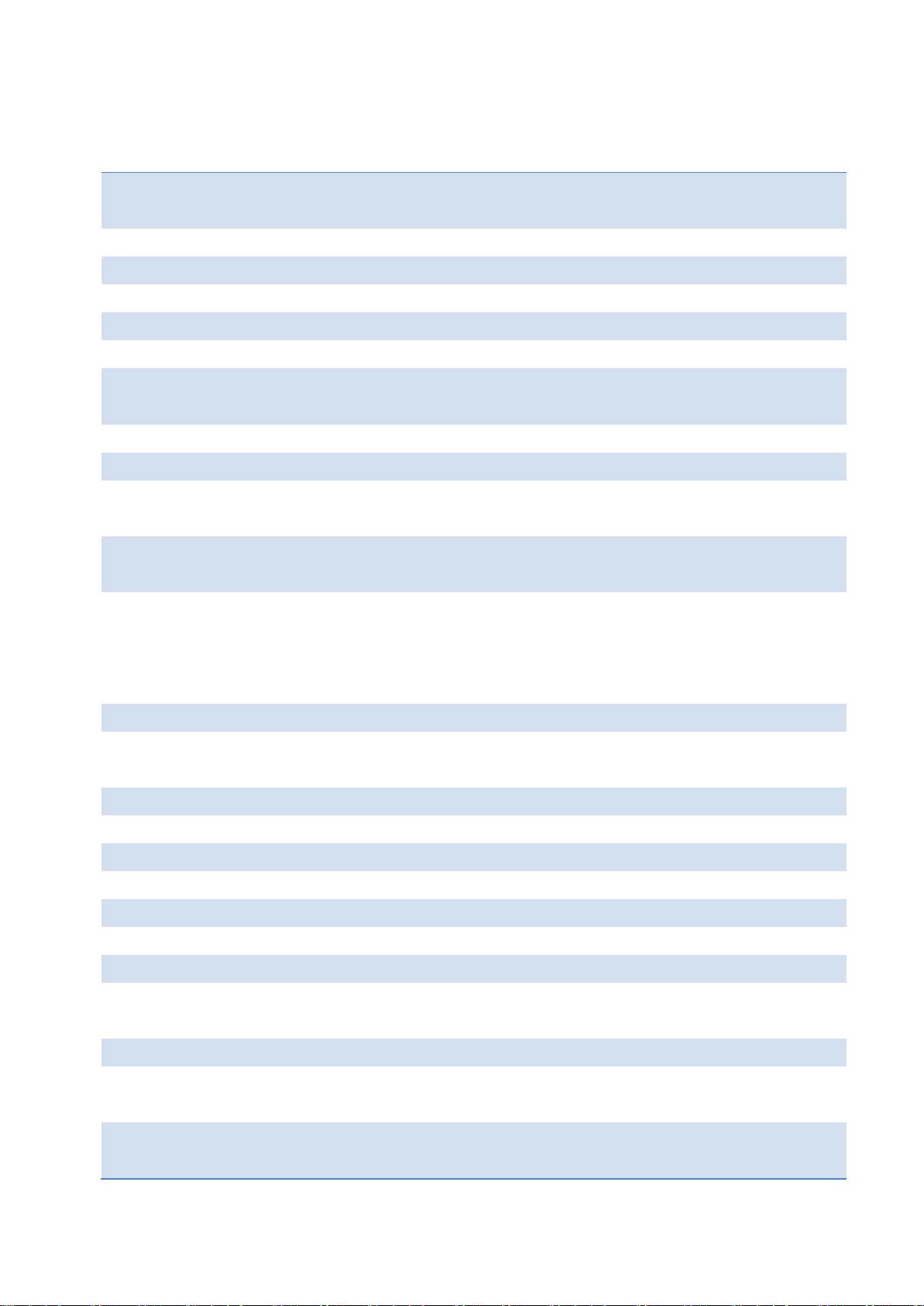

Change Log:

Date

Version

Description / Major change

2017/01/05

V0.1

Draft version

2017/02/03

V0.2

Modify chapter 3.2 & 3.3 and add Figure. 10

2017/02/13

V0.3

Update optional accessory with Sub G antenna

Chapter 5 is added for the instruction to enable LoRaWAN

2017/03/14

V0.4

Modify chapter 3.5~3.7 and 4.

2017/04/10

V0.5

Add chapter 3.5 Memory Layout and update 3.6~3.7

2017/04/12

V0.6

Remove Chapter 1.3, update page 2~3 Declaration of

Conformity, Chapter 3.6 and add appendix I and II

2017/04/19

V0.7

Update page 2~5 Declaration of Conformity

WISE-1510 User Manual 9

Page 11

Table of Content

1. PRODUCT OVERVIEW ............................................................................................. 11

1.1. INTRODUCTION ..................................................................................................... 11

1.2. SPECIFICATIONS ..................................................................................................... 12

2. H/W INSTALLATION ................................................................................................ 13

2.1. BOARD CONNECTOR .............................................................................................. 13

2.2. MODULE OUTLINE ................................................................................................. 15

2.3. CONNECTOR SPECIFICATIONS ................................................................................. 15

2.3.1. TOP SIDE CONNECTOR PHYSICAL DIMENSIONS ..................................................... 15

2.3.2. CARRIER BOARD CONNECTION LENGTH ................................................................ 16

2.3.3. CARRIER BOARD CONNECTOR HEIGHT .................................................................. 17

2.4. WISE-1510 PIN-OUT MAP ....................................................................................... 18

2.5. QUICK STARTER OF WISE-1510 ............................................................................... 19

2.5.1. DEBUG PORT CONNECTION .................................................................................. 19

3. DEVELOPMENT ENVIRONMENT SETUP ................................................................... 22

3.1. OVERVIEW ............................................................................................................. 22

3.2. INSTALLATION ........................................................................................................ 22

3.3. CONFIGURATION ................................................................................................... 23

3.4. COMPILATION ........................................................................................................ 24

3.5. MEMORY LAYOUT .................................................................................................. 25

3.6. PARTITIONING ....................................................................................................... 27

3.7. FLASHING APPLICATION (RUNTIME IMAGE) ............................................................ 28

3.8. TESTING ................................................................................................................. 32

4. APPLICATION DEVELOPMENT ................................................................................. 33

4.1. NODE API............................................................................................................... 33

4.2. SAMPLE CODE FOR API ........................................................................................... 35

APPENDIX I: NODE SETUP PARAMETERS ........................................................................ 38

APPENDIX II: SENSOR DATA FORMAT ............................................................................. 40

WISE-1510 User Manual 10

Page 12

1. Product Overview

1.1. Introduction

WISE-1510 is a wireless module integrated with ARM Cortex-M4 Processor and LoRa

/ LoRaWAN connectivity. This technology is the best solution for Low-Power

Wide-Area Network (LPWAN) Applications. LoRaWAN is defined to optimize the

power consumption and wide range. Your sensors or applications with low data rate

requirement can be achieved years battery lifetime and kilometers long distance

connection. Advantech WISE-1510 also provides multi-interfaces for sensor and I/O

control. With ARM mbed embedded microprocessor operating system and add-on

software stacks, it's convenient to build the application software or sensor algorithm

over mbed OS. Data can be quickly and easily acquired and transformed into a

different format to communicate with WISE-PaaS or other cloud services. Developer

can build their application backbone faster and focus on their applications,

value-added services.

The main features of WISE-1510 are:

ARM Cortex-M4 Core Processor

Built-in LoRa / LoRaWAN connectivity

Great for Low Power Wide Range application

Rich interfaces for sensor and I/O control

Support mbed OS 5.2

Support wide temperature -40 ~ 85 °C

WISE-1510 User Manual 11

Page 13

1.2. Specifications

Processor System

MCU

ARM Cortex-M4 Core Processor 80MHz

STM – STM32L443RC

Memory

RAM

64KB

Flash

256KB

Form Factor

M2.COM Type A 2230

Spec. Standard

M2 COM Technical SPEC_v1.1

Wireless Network

Standard

LoRa Proprietary (Harmony Link) / LoRaWAN

Frequency

Band

863-870MHz for Europe (LoRaWAN)

902-928MHz* for North America (LoRaWAN)

Channels

Spreading Factor: 7 ~ 12

Topology

Star network

Transmit

Power

Up to +18dBm

Receiver

Sensitivity

Up to -136dBm at SF = 12 / 125KHz

RF Data

Rate

50 kbps at FSK mode EU868

(Based on LoRaWAN spec 1R0 version)

21.9 kbps at SF7 mode US915

(Based on LoRaWAN spec 1R0 version)

Function

End node

Antenna

connector

MHF4 connector

I/O

UART

1 (4-wire, support RTC/CTS)

I2C

1 GPIO

8 PWM

1 SPI

1 ADC

4 USB

1 (device only)

Programming / Debug

Port

1 via WISE-ED20 (CN1)

Power

3.3V

Environment

Operational

Temperature

-40 ~ 85° C

Operating

Humidity

5% ~ 95% Relative Humidity, non-condensing

WISE-1510 User Manual 12

Page 14

Physical

Characteristics

Dimensions

(WxD)

22 x 30 mm

OS

mbed 5.2

* Note: Frequency Band can be configurable for Japan or Korea by request.

2. H/W Installation

2.1. Board Connector

M2.COM Type A Module

Module size: 22 mm x 30 mm

PCB thickness: 0.8 mm ± 10%

Pin count: 75 pins

Module input voltage: 3.3V DC-in

Connector mating force: 30N Maximum

Connector current rating: 0.5A / Power contact

Connector operation temperature range: -45 °C to +85 °C

WISE-1510 User Manual 13

Figure 1 Card Edge Bevel

Page 15

Figure 2 Card Edge Outline-Topside

Figure 3 Card Edge Outline-Backside

Reference from PCI Express M.2 Specification Rev 1.0 (Nov 1, 2013) Section 2.3.5 Card PCB Details

WISE-1510 User Manual 14

Page 16

2.2. Module Outline

The mechanical dimension information of M2.COM form factor follows the Type A 2230

module size: 22 x 30 mm. Both module types use a 75-position host interface

connector and have room to support up to four RF connectors in the upper section.

Figure 4 Type A 2230

2.3. Connector Specifications

2.3.1. Top Side Connector Physical Dimensions

The top-side scheme has two connectors that share a common footprint but have

different stack-up requirements.

Length – 22 mm maximum including land pattern

Width – 9.1 mm maximum including land pattern

WISE-1510 User Manual 15

Page 17

Figure 5 Top Side Connector Physical Dimensions

Reference from PCI Express M.2 Specification, Revision 1.0, November 1, 2013

2.3.2. Carrier Board Connection Length

The carrier board connector of M2.COM follows the Type 2230 M.2 module connector:

The additional increase in length is 7.05mm maximum for top-side connector to

the module length.

The retention screw adds 2.75 mm maximum.

The maximum extension, including land pattern, beyond the module leading

edge is 4.3 mm.

M2.COM module lengths are 30 mm and 42 mm.

WISE-1510 User Manual 16

Page 18

Figure 6 Carrier Board Connection Length

Reference from PCI Express M.2 Specification, Revision 1.0, November 1, 2013

2.3.3. Carrier Board Connector Height

The dimensions of M2.COM form factor follow the Type A 2230 -D3 M.2 module size.

Hence, the carrier board connectors must choose H3.2-D3 or H4.2-D5 connector as in

the following diagrams.

Figure 7 H3.2-D3

Reference from PCI Express M.2 Specification, Revision 1.0, November 1, 2013

WISE-1510 User Manual 17

Page 19

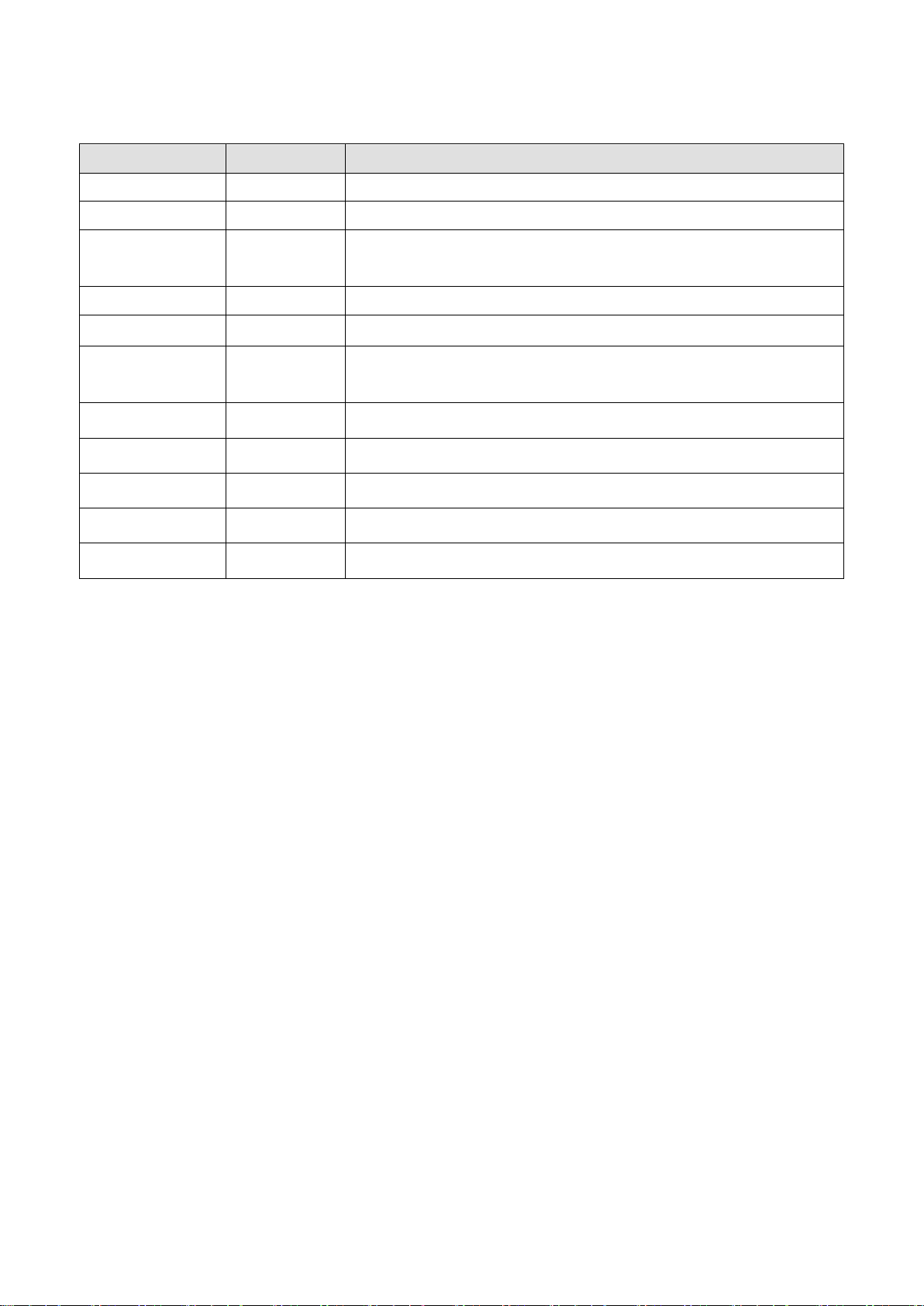

2.4. WISE-1510 Pin-Out Map

PIN

M2.COM

Signal name

STM32L443RCI6

MCU Pin Name

M2.COM

Signal name

PIN

1

GND

GND

3.3V

VCC

2 3 USB_DP

PA12

3.3V

VCC

4 5 USB_DM

PA11

N.C.

6 7 GND

GND

N.C.

8 9 N.C.

N.C.

10

11

N.C.

N.C.

12

13

N.C.

N.C.

14

15

N.C.

PC6

CB_RESET_OUT#

16

17

N.C.

GND

GND

18

19

N.C.

PC9

CB_PWR_ON

20

21

N.C.

PC4

UART TX (O)

22

23

N.C.

Connector Key

Connector Key

Connector Key

Connector Key

Connector Key

Connector Key

Connector Key

Connector Key

PB11

UART RX (I)

32

33

GND

GND

PB1

UART RTS (O)

34

35

N.C.

PB13

UART CTS (I)

36

37

N.C.

PA8

GPIO0

38

39

GND

GND

PC8

GPIO1

40

41

PWM0

PA5

PC7

GPIO2

42

43

N.C.

PC5

GPIO3

44

45

GND

GND

PB0

GPIO4

46

47

ADC0

PA7

PA3

GPIO5

48

49

N.C.

PA2

GPIO6

50

51

GND

GND

PB6

GPIO7

52

53

ADC2

PA6

N.C.

54

55

ADC3

PA4

PC2

W_DISABLE#

56

57

GND

GND

PC1

I2C_DATA

58

59

ADC4

PA0

PC0

I2C_CLK

60

61

N.C.

PB15

SPI_MOSI

62

63

GND

GND

PB14

SPI_MISO

64

65

VDD_RTC

VBAT(3.3V)

PB10

SPI_CLK

66

67

Backup#

PA1

PB12

SPI_CS0#

68

WISE-1510 User Manual 18

Page 20

69

GND

GND

PB9

SPI_CS1#

70

71

RESET_IN#

NRST

3.3V

VCC

72

73

Wake#

PC3

3.3V

VCC

74

75

GND

GND

Figure 8 M.2 Connector

2.5. Quick Starter of WISE-1510

2.5.1. Debug Port Connection

1. Connect debug port FPC cable to WISE-1510 debug port (CN1; on the back of

PCB)

2. Connect WISE-ED20 debug board to the FPC debug cable.

3. Connect USB-to-microUSB cable from WISE-ED20 to the USB port on your PC.

WISE-1510 User Manual 19

Page 21

2.5.2. Debug Port Setting

WISE-1510 can communicate with a host server (Windows or Linux) by using serial

cables. Common serial communication programs such as Hyper Terminal, Tera Term

or PuTTY can be used in this case. The example below describes the serial terminal

setup using Hyper Terminal on a Windows host:

1. Connect WISE-ED20 with your Windows PC by using a serial cable.

2. Open Hyper Terminal on your Windows PC, and select the settings as shown in

Figure 9.

3. Terminal will show the image version as Figure 10.

WISE-1510 User Manual 20

Page 22

Figure 9 Hyper Terminal Settings for Terminal Setup

Figure 10 Image version is shown on terminal

WISE-1510 User Manual 21

Page 23

3. Development Environment Setup

3.1. Overview

ARM mbed is used for you to create applications running on WISE-1510. Your

application code is written in C++. It uses the application programming interfaces

(APIs) that mbed OS provides. These APIs allow your code to work on different

microcontrollers in a uniform way. This reduces a lot of the challenges in getting

started with microcontrollers and integrating large amounts of software. Besides, we

also provide you node APIs which facilitates LoRa node development. Our offline

development tool is the mbed CLI, a command-line tool. This requires having a

toolchain installed on your computer. mbed CLI is the name of the ARM mbed

command-line tool, packaged as mbed-cli, which enables the full mbed workflow:

repositories version control, maintaining dependencies, publishing code, updating

from remotely hosted repositories and invoking ARM mbed’s own build system and

export functions, among other operations. The basic workflow for mbed CLI is to:

1. Initialize a new repository, for either a new application (or library) or an imported

one.

2. Build the application code.

3. Test your build.

4. Publish your application.

3.2. Installation

To install mbed CLI, related tools are required to be installed first. Please refer to the

video tutorial. ( https://www.youtube.com/watch?v=cM0dFoTuU14 )

Please follow the steps described in the tutorial video to install mbed CLI.

1. Install Python

mbed CLI supports Windows, Linux and Mac OS X operating systems. You can select

the OS you prefer to work with. mbed CLI is a Python script, so you’ll need Python to

use it. The version 2.7.11 of Python has been verified with mbed CLI.

https://www.python.org/downloads/release/python-2711/

Note: mbed CLI is incompatible with Python 3.

2. (Optional) Install Git or Mercurial

If you would like to maintain your source code in repositories, you can continue

with the next step. mbed CLI supports both Git and Mercurial repositories, you can

install which one you prefer:

WISE-1510 User Manual 22

Page 24

Git - version 1.9.5 or later ( https://git-scm.com/ ).

Mercurial - version 2.2.2 or later ( https://www.mercurial-scm.org/ ).

If you don’t want to use repositories, you can just skip it.

3. Install gcc

mbed CLI invokes the mbed OS 5 tools for various features, such as compiling,

testing and exporting to industry standard toolchains. To compile your code, you will

need either a compiler or an IDE:

Compilers: GCC ARM, ARM Compiler 5, IAR.

IDE: Keil uVision, DS-5, IAR Workbench.

We select GCC ARM Embedded, so you can install version 4.9 of GCC ARM

Embedded ( https://launchpad.net/gcc-arm-embedded ).

Note: Version 5.0 or any other versions above may be incompatible with the tools.

4. Install mbed CLI

You can get the latest stable version of mbed CLI from PyPI

$ pip install mbed-cli

Note: On Linux or Mac, you may need to run with sudo.

Finally, you’ve to extract the source code to the working directory from the SDK we

released. The structure of the working directory is as below:

docs/ <-- Documents for SDK

loranode_L443_sdk_R1_0_02/mbed-os/ <-- mbed os

loranode_L443_sdk_R1_0_02/libHLLoraNode.a <-- Harmony Link Lora

Node library

loranode_L443_sdk_R1_0_02/node_api.h <-- Node API header file

loranode_L443_sdk_R1_0_02/main.cpp <-- Sample code

3.3. Configuration

After the installation of required tool chains, please set up the directory of mbed CLI to

link the folder of toolchains which you want to use for compiling the source tree.

You can set the GCC ARM Embedded location via the command as below:

$ mbed config --global GCC_ARM_PATH "C:\Program Files\GCC_ARM"

[mbed] C:\Program Files\GCC_ARM now set as global GCC_ARM_PATH

WISE-1510 User Manual 23

Page 25

Next, you can select the tool chain and target platform which mbed CLI uses to build

applications. Change directory to target mbed program.

$ mbed config target NUCLEO_L443RC

[mbed] NUCLEO_L443RC now set as default target in program "xxxxx"

$ mbed config toolchain GCC_ARM

[mbed] GCC_ARM now set as default toolchain in program "xxxx"

You can see the active mbed CLI configuration via:

$ mbed config --list

[mbed] Global config:

GCC_ARM_PATH =C:\Program Files\GCC_ARM

[mbed] Local config (xxxx):

TOOLCHAIN=GCC_ARM

TARGET=NUCLEO_L443RC

3.4. Compilation

mbed CLI uses the current directory as a working context. This means that before

calling any mbed CLI command, you must first change to the working directory

containing the code. Then, Use the mbed compile command to compile your code:

$ mbed compile -c

Building project xxxxx (NUCLEO_L443RC, GCC_ARM)

Scan: .

Scan: mbed

Scan: env

Compile [ 0.5%]: base64.cpp

Compile [ 1.0%]: oslmic.cpp

…

Compile [100.0%]: node_sapi.cpp

Link: xxxxx

Elf2Bin: xxxxx

+--------------------+--------+-------+-------+

| Module | .text | .data | .bss |

+--------------------+--------+-------+-------+

| Fill | 223 | 16 | 41 |

| Misc | 104316 | 7804 | 5017 |

| drivers | 3592 | 4 | 224 |

WISE-1510 User Manual 24

Page 26

| hal | 802 | 0 | 8 |

| platform | 1782 | 4 | 297 |

| rtos | 910 | 4 | 4 |

| rtos/rtx | 7369 | 20 | 6870 |

| targets/TARGET_STM | 19944 | 4 | 1719 |

| Subtotals | 138938 | 7856 | 14180 |

+--------------------+--------+-------+-------+

Allocated Heap: unknown

Allocated Stack: unknown

Total Static RAM memory (data + bss): 22036 bytes

Total RAM memory (data + bss + heap + stack): 22036 bytes

Total Flash memory (text + data + misc): 146794 bytes

Image: ./BUILD/NUCLEO_L443RC/GCC_ARM/xxxxx.bin

Now, you have your application in binary format ready for flashing.

3.5. Memory Layout

A basic overview of mbed memory model is as below:

Each thread of execution in the RTOS has a separate stack. When you use the RTOS,

before explicitly initializing any additional thread, you will have four separate stacks:

• The stack of the main thread (executing the main function).

• The idle thread executed each time all the other threads are waiting for external

or scheduled events. This is particularly useful for implementing energy saving

strategies (like sleep).

• The timer thread that executes all the time-scheduled tasks (periodic and

nonperiodic).

• The stack of OS scheduler itself (also used by the ISRs).

Stack checking is turned on for all threads, and the kernel will error if an overflow

condition is detected.

WISE-1510 User Manual 25

Page 27

WISE-1510 User Manual 26

Page 28

3.6. Partitioning

The content of flash is portioned by boot loader as below:

Boot Loader occupies the first 16 kilo-bytes starting at 0x8000000. LoRa Config

partition is used to store LoRa parameters, which occupies no more than 4 kilo-bytes.

All user own parameters should be written into User Config partition, for which another

4 kilo-bytes are reserved. Application (Runtime image) partition is where users’

application is stored, up to 224 kilo-bytes can be used.

WISE-1510 User Manual 27

Page 29

3.7. Flashing Application (Runtime Image)

To flash runtime image, your terminal program needs to support “Y-Modem”.

Tera Term is used for demonstration here.

Step 1: UART port connect via debug board

Connect USB-to-microUSB cable from WISE-ED20 to the USB port on your Windows

PC. (Red frame is reset button.)

Open the corresponding COM port in serial program, ex: Tera Term.

Set baud rate to 115200.

WISE-1510 User Manual 28

Page 30

Step 2: Runtime image upgrade mode

Press ‘u’ on the PC keyboard and press reset button on ED-20 debug board.

The terminal will show messages as below.

Press "1" to “Download image to the internal Flash”.

WISE-1510 User Manual 29

Page 31

Step 3: Start upgrading via Y modem

Select the run-time image ".bin" file via Y-Modem.

Waiting for run-time image transmission is complete.

WISE-1510 User Manual 30

Page 32

After downloading completed, the terminal will show as below.

Step 4: Reset device

Press reset button on ED-20 debug board to reset device.

WISE-1510 User Manual 31

Page 33

3.8. Testing

Now, you’re ready to test your WISE-1510. The sample application we created is to

send sensor data every 5 seconds via LoRa if values are changed. To observe it, you

can connect the debug port as described earlier. After reset WISE-1510, the result is

shown on your Terminal as below:

WISE-1510 User Manual 32

Page 34

4. Application Development

Node APIs were provided to assist user develop applications. There are 2 UART

interfaces in WISE-1510. “debug_serial” is used for user development and debug.

User can see debug information of sample code via debug_serial. “m2_serial” is the

UART interface of M2.com.

4.1. Node API

Following show the architecture of the layer of LoRa Node and user application. User

can send request to LoRa node via API and got response. Besides, application can

also be notified by callback function if some event occurs from LoRa node.

Node APIs were listed as below:

System Start/reboot

nodeApiInitCarrierBoard

nodeApiStartLora

nodeApiReboot

Configuration get/set/save/factory reset

WISE-1510 User Manual 33

Page 35

nodeApiGetDevEui

nodeApiGetAppEui

nodeApiGetAppKey

nodeApiGetDevAddr

nodeApiGetNwkSKey

nodeApiGetAppSKey

nodeApiGetDevActMode

nodeApiGetDevOpMode

nodeApiGetDevAdvwiseFreq

nodeApiGetDevAdvwiseDataRate

nodeApiGetDevAdvwiseTxPwr

nodeApiSetDevEui

nodeApiSetAppEui

nodeApiSetAppKey

nodeApiSetDevAddr

nodeApiSetNwkSKey

nodeApiSetAppSKey

nodeApiSetDevActMode

nodeApiSetDevOpMode

nodeApiSetDevAdvwiseFreq

nodeApiSetDevAdvwiseDataRate

nodeApiSetDevAdvwiseTxPwr

nodeApiSaveCfg

nodeApiLoadCfg

nodeApiApplyCfg

nodeApiFactoryReset

LoRa callback function register/status check/send data

nodeApiSetTxDoneCb

nodeApiSetRxDoneCb

nodeApiJoinState

nodeApiSendData

System deep sleep (low power) mode

WISE-1510 User Manual 34

Page 36

nodeApiSetDevSleepRTCWakeup

The detailed description of APIs can be found in /docs/html/index.html in the released

SDK.

4.2. Sample Code for API

If WISE-1510 was plugged in M2.com carrier board (WISE-DB1500), do below action

to enable M2.com carrier board.

Set boud rate of debug_serial and m2_serial.

Create sensor thread.

Set and apply node configuration.

Start LoRa.

Start LoRa State loop to start rx/tx data.

Deep sleep mode is supported but disabled in default, please enable

NODE_DEEP_SLEEP_MODE_SUPPORT if you want to try low power mode.

WISE-1510 User Manual 35

Page 37

2 API were used to notify user application that LoRa finished transmit or receive

action. What you should do is Register callback function in the beginning.

Make sure node successfully joined LoRa gateway.

Then, start to run the state machine. If no data need to send, enter deep sleep

mode and wait for waking up NODE_ACTIVE_PERIOD_IN_SEC seconds.

This example send sensor (Temperature, Humidity) data periodically, user should

modify node_get_sensor_data() to implement read sensor data.

If Tx complete, node_tx_done_cb() will transfer to NODE_STATE_LOWPOWER

and prepare to read/send sensor data again.

If LoRa node got downlink data, node_rx_done_cb() will be invoked to get data.

Then transfer to NODE_STATE_LOWPOWER.

WISE-1510 User Manual 36

Page 38

The detailed description of Sample code can be found in /docs/html/index.html in the

released SDK.

WISE-1510 User Manual 37

Page 39

Appendix I: Node Setup Parameters

In the sample application, there is a function node_set_config() as below:

This function is used to configure all parameters of nodes. Let’s go through them

briefly.

1. Device EUI (DevEUI) is read from eFuse, and set without any change.

2. Two application dependent parameters, application EUI (AppEUI) and application

key (APPKey), are set respectively (line 218 and 219).

3. Device address (DevAddr) is derived from DevEUI by extracting the last 8 bytes

(line 220), and set (line 221). It’s up to users to define the format as long as it

matches with gateway’s setting.

4. Two session keys: network session key (NwkSKey) and application session key

(AppSKey) are set (line 222 and 223).

5. So far, all required parameters for node activation are set properly. Then, you can

decide to activate the node by either ABP (Activation By Provisioning) or OTAA

(Over-The-Air Activation). Here, we set it to ABP (line 224). Please be noted that,

only three of the above parameters are used for ABP, including DevAddr,

NwkSKey and AppSKey. If you’d like to use OTAA, then change the input

parameter of nodeApiSetDevActMode() from 2 to 1. The other three parameters

are used for OTAA, including DevEUI, AppEUI, and APPKey are set.

6. Select nodes to work with LoRaWAN or Harmony Link by setting the device

WISE-1510 User Manual 38

Page 40

operating mode (DevOpMode): 1 for Harmony Link* and 2 for LoRaWAN. Here,

Harmony Link is selected as the default. (line 225) If you’d like to use LoRaWAN,

change it from 1 to 2.

* Harmony Link is Advantech’s proprietary LoRa MAC.

7. You can select which class of Node: 1 for Class A, and 3 for Class C. (2 for Class B

is reserved for future use.) Here, Class C is selected (line 226).

8. The remaining part are used to set radio related parameters, including data rate

(DevAdvwiseDataRate), frequency (DevAdvwiseFreq) and transmission power

(DevAdvwiseTxPwr) (line 227~229). Please be noted all of RF parameters are

region dependent, so you’ve to set their values accordingly. Make sure you DO

NOT violate the regional regulation.

After all parameters are configured, be reminded to apply them by nodeApiApplyCfg().

WISE-1510 User Manual 39

Page 41

Appendix II: Sensor Data Format

In the sample application, node_get_sensor_data() encodes sensor data according to

the following format:

,where

Length: Total TLV length

MsgType: Fixed as 0xc

Multiple TLVs are one or more Tag-Length-Values: tag matches with gateway’s setting,

length is sensor data length, and value is sensor data. All octets are in hexadecimal.

For example, LoRa Payload Field setting on WISE-3610 is as below:

If temperature is 25.55 Celsius degree, translate decimal 2555 to hexadecimal 9FB.

Similarly, if humidity is 60.55%, translate from decimal 6055 to hexadecimal 17A7.

The encoded data will be

0x9 | 0xc | 0x1 | 0x3 | 0x1 | 0x9 | 0xFB | 0x2 | 0x2 | 0x17 | 0xA7

, where

0x9: the Total TLV length, included two TLVs

0xc: the fixed MsgType

0x1 | 0x3 | 0x1 | 0x9 | 0xFB: the first TLV with tag id (0x1), value length (0x3), and

positive (0x1) value (0x9FB)

0x2 | 0x2 | 0x17 | 0xA7: the second TLV with tag id (0x2), value length (0x2), and

unsigned value (0x17A7)

Be reminded temperature “Sign” setting is On, 1 extra byte is required to indicate (0

means negative, and 1 means positive) , but humidity "Sign" setting on gateway is Off,

so no extra 1 byte is required.

Users are free to define their own payload field format, but only sensor data encoded

according to the above format can be decoded successfully, and displayed on LoRa

Dashboard on WISE-3610.

WISE-1510 User Manual 40

Loading...

Loading...