Advantech PCL-722 (Rev. B1), PCL-722 (Rev. A2) PCL-722 144-ch Digital I/O ISA Card User Manual

PCL-722

144-ch Digital I/O ISA Card

User Manual

Copyright

The documentation and the software included with this product are copyrighted 2011 by Advantech Co., Ltd. All rights are reserved. Advantech

Co., Ltd. reserves the right to make improvements in the products

described in this manual at any time without notice. No part of this manual may be reproduced, copied, translated or transmitted in any form or

by any means without the prior written permission of Advantech Co., Ltd.

Information provided in this manual is intended to be accurate and reliable. However, Advantech Co., Ltd. assumes no responsibility for its use,

nor for any infringements of the rights of third parties, which may result

from its use.

Acknowledgements

PC-LabCard is a trademark of Advantech Co., Ltd.

IBM, PC are trademarks of International Business Machines Corporation.

MS-DOS, Windows, Microsoft Visual C++ and Visual BASIC are

trademarks of Microsoft Corporation.

Intel and Pentium are trademarks of Intel Corporation.

Delphi and C++ Builder are trademarks of Borland Corporation.

Part No. 2003722010 1st Edition

Printed in Taiwan November 2011

PCL-722 User Manual ii

Product Warranty (2 years)

Advantech warrants to you, the original purchaser, that each of its products will be free from defects in materials and workmanship for two years

from the date of purchase.

This warranty does not apply to any products which have been repaired or

altered by persons other than repair personnel authorized by Advantech,

or which have been subject to misuse, abuse, accident or improper installation. Advantech assumes no liability under the terms of this warranty as

a consequence of such events.

Because of Advantech’s high quality-control standards and rigorous testing, most of our customers never need to use our repair service. If an

Advantech product is defective, it will be repaired or replaced at no

charge during the warranty period. For out-of-warranty repairs, you will

be billed according to the cost of replacement materials, service time and

freight. Please consult your dealer for more details.

If you think you have a defective product, follow these steps:

1. Collect all the information about the problem encountered. (For

example, CPU speed, Advantech products used, other hardware

and software used, etc.) Note anything abnormal and list any

onscreen messages you get when the problem occurs.

2. Call your dealer and describe the problem. Please have your manual, product, and any helpful information readily available.

3. If your product is diagnosed as defective, obtain an RMA (return

merchandize authorization) number from your dealer. This allows

us to process your return more quickly.

4. Carefully pack the defective product, a fully-completed Repair and

Replacement Order Card and a photocopy proof of purchase date

(such as your sales receipt) in a shippable container. A product

returned without proof of the purchase date is not eligible for warranty service.

5. Write the RMA number visibly on the outside of the package and

ship it prepaid to your dealer.

iii

Declaration of Conformity

CE

This product has passed the CE test for environmental specifications

when shielded cables are used for external wiring. We recommend the use

of shielded cables. This kind of cable is available from Advantech. Please

contact your local supplier for ordering information.

FCC Class A

Note: This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

Technical Support and Assistance

Step 1. Visit the Advantech web site at www.advantech.com/support

where you can find the latest information about the product.

Step 2. Contact your distributor, sales representative, or Advantech's cus-

tomer service center for technical support if you need additional

assistance. Please have the following information ready before

you call:

- Product name and serial number

- Description of your peripheral attachments

- Description of your software (operating system, version, application software, etc.)

- A complete description of the problem

- The exact wording of any error messages

PCL-722 User Manual iv

Safety Instructions

1. Read these safety instructions carefully.

2. Keep this User's Manual for later reference.

3. Disconnect this equipment from any AC outlet before cleaning.

Use a damp cloth. Do not use liquid detergents for cleaning.

4. For plug-in equipment, the power outlet socket must be located

near the equipment and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a reliable surface during installation. Dropping it or letting it fall may cause damage.

7. The openings on the enclosure are for air convection. Protect the

equipment from overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source is correct before connecting the equipment to the power outlet.

9. Position the power cord so that people cannot step on it. Do not

place anything over the power cord.

10. All cautions and warnings on the equipment should be noted.

11. If the equipment is not used for a long time, disconnect it from the

power source to avoid damage by transient overvoltage.

12. Never pour any liquid into an opening. This may cause fire or electrical shock.

13. Never open the equipment. For safety reasons, the equipment

should be opened only by qualified service personnel.

14. If one of the following situations arises, get the equipment checked

by service personnel:

a. The power cord or plug is damaged.

b. Liquid has penetrated into the equipment.

c. The equipment has been exposed to moisture.

d. The equipment does not work well, or you cannot get it to work

according to the user's manual.

e. The equipment has been dropped and damaged.

f. The equipment has obvious signs of breakage.

15. DO NOT LEAVE THIS EQUIPMENT IN AN ENVIRONMENT

WHERE THE STORAGE TEMPERATURE MAY GO BELOW 20° C (-4° F) OR ABOVE 60° C (140° F). THIS COULD DAM-

v

AGE THE EQUIPMENT. THE EQUIPMENT SHOULD BE IN A

CONTROLLED ENVIRONMENT.

16. CAUTION: DANGER OF EXPLOSION IF BATTERY IS

INCORRECTLY REPLACED. REPLACE ONLY WITH THE

SAME OR EQUIVALENT TYPE RECOMMENDED BY THE

MANUFACTURER, DISCARD USED BATTERIES ACCORDING TO THE MANUFACTURER'S INSTRUCTIONS.

The sound pressure level at the operator's position according to IEC 7041:1982 is no more than 70 dB (A).

DISCLAIMER: This set of instructions is given according to IEC 704-1.

Advantech disclaims all responsibility for the accuracy of any statements

contained herein.

Safety Precaution - Static Electricity

Follow these simple precautions to protect yourself from harm and the

products from damage.

1. To avoid electrical shock, always disconnect the power from your

PC chassis before you work on it. Don't touch any components on

the CPU card or other cards while the PC is on.

2. Disconnect power before making any configuration changes. The

sudden rush of power as you connect a jumper or install a card may

damage sensitive electronic components.

PCL-722 User Manual vi

Contents

Chapter 1 Introduction .................................................... 2

1.1 Features ............................................................................. 2

1.2 Specifications .................................................................... 2

1.2.1 Digital Input ................................................................... 2

1.2.2 Digital Output ................................................................ 3

1.2.3 General Specifications ................................................... 3

1.3 Applications ...................................................................... 3

1.4 Installation Guide .............................................................. 4

1.5 Software Overview............................................................ 5

Chapter 2 Installation ....................................................... 8

2.1 Unpacking ......................................................................... 8

2.2 Driver Installation ............................................................. 9

2.3 Hardware Installation ...................................................... 11

Chapter 3 Signal Connections ........................................ 14

3.1 Overview ......................................................................... 14

3.2 Switch & Jumper Settings .............................................. 14

3.3 Signal Connections.......................................................... 18

3.4 Interrupt Handling ........................................................... 21

Appendix A Programming Examples .............................. 24

Appendix B Block Diagram............................................... 30

Appendix C PC I/O Port Address Map ............................ 32

Figure 1.1:Installation Flow Chart ................................. 4

Figure 2.1: Advantech Automation Software Setup ...... 9

Figure 2.2:Different Options for Driver Setup ............ 10

Figure 3.1:Card Connectors, Jumpers & Switches ...... 14

3.2.1 Base Address Selection ................................................ 15

Table 3.1:Switch Position Summary ........................... 15

3.2.2 96/144-bit Mode Setting .............................................. 16

Figure 3.2:Select 144 or 96 I/O ................................... 16

3.2.3 Interrupt Settings .......................................................... 17

Figure 3.3:Interrupt Enable Selection .......................... 17

3.3.1 Configuration .............................................................. 18

Table 3.3:CFG register format (mode 0) ..................... 19

Table 3.2:8255 Address Map ....................................... 19

Table 3.4:8255 Mode 0 Configuration Table .............. 20

vii Table of Contents

PCL-722 User Manual viii

2

1

CHAPTER

Introduction

This chapter contains information on the

PCL-722 and instruction on card configuration in order to match your application and prepare it for installation on

your system.

Sections include:

• Features

• Specifications

• Applications

• Installation Guide

• Software Overview

Chapter 1 Introduction

The PCL-722 144 bit DIO card is a generalized 144 line parallel digital I/

O board that has six channels. Each channel emulates mode 0 of a 8255

programmable peripheral interface chip, and has 24 lines of digital input

and/or output. Every channel has an individual connector with OPTO-22

compatible pin assignment. Two lines of each connector can be used to

generate a hardware interrupt. These inputs are buffered and can be connected to IRQ 2, 3, 4, 5, 6 and 7. The PCL-722 is a full-size PC add-on

card and can fit any full-length expansion slot in the IBM PC XT/AT or

compatible computer running at any clock rate.

1.1 Features

• 144 TTL digital I/O lines, (6 connectors, each with 24 I/O lines)

• The 24 I/O lines of each connector are configured to port PA (8 bit), PB

(8 bit), PC Upper (4 bit) and PC Lower (4 bit). Each port can be programmed to digital input or digital output

• Emulates mode 0 of 8255 PPI

• Programmable interrupt handling

• OPTO-22 compatible 50-pin connector

• Direct interface to wide range of peripherals

1.2 Specifications

1.2.1 Digital Input

Channels: 144 (24 channels x 6 ports) shared with output

Compatibility: 5V/TTL

Input Voltage: Logic 0: 0.0 V ~ 0.80 V @ -0.2 mA

Logic 1: 2.0 V ~ 5.25 V @ 20 uA

Interrupt Capable Ch.: Bits 0 and 3 of Port C can generate an interrupt to

IRQ 2, 3, 4, 5, 6 or 7

Interrupt Bandwidth: 800Hz @ 0.5 Duty cycle

PCL-722 User Manual 2

1.2.2 Digital Output

Channels: 144 (24 channels x 6 ports) shared with input

Compatibility: 5V/TTL

Output Voltage: Port A, B, C

Logic 0: 0.4 V max. @ 24 mA

Logic 1: 2.4 V min. @ -15 mA

1.2.3 General Specifications

Power Consumption: Typical: +5 V @ 1.3 A

Max.: +5 V @ 1.8 A

Operating Temperature: 0 ~ 60°C (32 ~ 140°F)

Storage Temperature: -20 ~ 70°C (-4 ~ 158°F)

Operating Humidity: 5 ~ 95% RH, non-condensing (refer to IEC 68-2-3)

I/O Connectors: 6 x 50-pin male ribbon-cable connectors. Pin assignment

are fully compatible with Opto-22 I/O modules racks

Dimensions (L x H): 334 x 100 mm (13.2" x 3.9)

1.3 Applications

• Industrial AC/DC I/O module monitoring and control

• Relay and switch monitoring and control

• Parallel data transfer

• Sensing the signals of TTL, DTL, CMOS logic

• Driving indicator LED's

3 Chapter 1

1.4 Installation Guide

Before you install your PCL-722 card, please make sure you have the following necessary components:

• PCL-722 DA&C card

• PCL-722 User Manual

• Driver software Advantech DLL drivers (in the companion CD-ROM)

• PC or workstation with a ISA-bus slot

Some other optional components are also available for enhanced operation: ActiveDAQ, ActiveDAQ Pro, LabView or other 3rd-party software

packages.

After you get the necessary components and maybe some of the accessories for enhanced operation of your multifunction card, you can then

begin the installation procedure. Figure 1.1 gives users an overview of the

software and hardware installation procedure:

Figure 1.1: Installation Flow Chart

PCL-722 User Manual 4

1.5 Software Overview

Advantech offers a rich set of DLL drivers, third-party driver support and

application software to help fully exploit the functions of your

PCL-722 card:

• Device Drivers (on the companion CD-ROM)

• LabVIEW driver

• Advantech ActiveDAQ Pro

Programming Choices for DA&C Cards

You may use Advantech application software such as Advantech Device

Drivers. On the other hand, advanced users can use register-level programming, although this is not recommended due to its laborious and

time-consuming nature.

Device Drivers

Advantech Device Driver software is included on the companion

CD-ROM at no extra charge. It also comes with all Advantech DA&C

cards. Advantech’s Device Drivers features a complete I/O function

library to help boost your application performance. Advantech Device

Drivers for Win 2000/XP works seamlessly with development tools such

as Visual C++, Visual Basic, Borland C++ Builder and Borland Delphi.

Register-level Programming

Register-level programming is available for experienced programmers

who find it necessary to write code directly at the level of the device register. But since register-level programming requires much effort and time,

it is strongly recommend to use the Advantech Device Drivers instead.

5 Chapter 1

PCL-722 User Manual 6

2

2

CHAPTER

Installation

This chapter contains a package item

checklist, proper instructions for

unpacking and step-by-step procedures

for card installation.

Sections include:

• Unpacking

• Driver Installation

• Hardware Installation

• Device Configuration

Chapter 2 Installation

2.1 Unpacking

After receiving your PCL-722 package, please inspect its contents first.

The package should contain the following items:

• PCL-722 card

• Companion CD-ROM (Device Drivers included)

• User Manual

The PCL-722 cards harbor certain electronic components vulnerable to

electrostatic discharge (ESD). ESD can easily damage the integrated circuits and certain components if preventive measures are ignored.

Before removing the card from the antistatic plastic bag, you should take

the following precautions to ward off possible ESD damage:

Touch the metal part of your computer chassis with your hand to discharge the static electricity accumulated on your body. Alternatively, one

can also use a grounding strap.

Touch the anti-static bag to a metal part of your computer chassis before

opening the bag.

Take hold of the card only by the metal bracket when removing it out of

the bag.

After taking out the card, you should first:

Inspect the card for any possible signs of external damage (loose or damaged components, etc.). If the card is visibly damaged, please notify our

service department or our local sales representative immediately. Do not

install a damaged card into your system.

Also, pay extra caution to the following aspects during installation:

Avoid physical contact with materials that could hold static electricity

such as plastic, vinyl and Styrofoam.Whenever you handle the card, grasp

it only by its edges. DO NOT TOUCH the exposed metal pins of the connector or the electronic components.

Note: Keep the anti-static bag for future use. You might

need the original bag to store the card I you have to

remove the card from a PC or transport it elsewhere.

PCL-722 User Manual 8

2.2 Driver Installation

We recommend you install the driver before you plug the PCL-722 into

your system, since this will guarantee a smooth installation process.

The Advantech Device Drivers Setup program for the PCL-722 card is

included in the companion CD-ROM that is shipped with your DA&C

card package. Please follow the steps below to install the driver software:

1. Insert the companion CD-ROM into your CD-ROM drive.

2. The Setup program will be launched automatically if you have the

autoplay function enabled on your system. When the Setup Program is

launched, the Setup Screen will appear.

Note: If the autoplay function is not enabled on your computer,

use Windows Explorer or Windows Run command to execute AUTORUN.EXE on the companion CD-ROM.

Figure 2.1: Advantech Automation Software Setup

3. First, install the Advantech Device Manager.

4. Select the “Individual Drivers” to install the specific device driver then

just follow the installation instructions step by step to complete your

device driver installation and setup.

9 Chapter 2

Figure 2.2: Different Options for Driver Setup

For further information on driver-related issues, an online version of the

Device Drivers Manual is available by accessing the following path:

Start/Advantech Automation/Device Manager/Device Driver’s Manual

PCL-722 User Manual 10

2.3 Hardware Installation

Note: Make sure you have installed the driver and Advantech

Device Manager before you install the card (please refer

to chapter 2.2 Driver Installation)

After the Device Drivers installation is completed you can install the

PCL-722 card into any ISA slot on your computer. A complete device

installation procedure should include device setup, configuration and testing. The following sections will guide you through the Setup, Configuration and Testing of your device. However, it is suggested that you refer to

the computer’s user manual or related documentation if you have any

doubts. Please follow the steps below to install the card.

1. Turn off your computer and unplug the power cord and cables.

2. Remove the cover of your computer.

3. Remove the slot cover on the back panel of your computer.

4. Touch the metal part on the surface of your computer to neutralize the

static electricity that might be on your body.

5. Insert the PCL-722 card into a ISA slot. Hold the card only by its edges

and carefully align it with the slot. Insert the card firmly into place.

6. Fasten the bracket of the ISA card on the back panel rail of the com-

puter with screws.

7. Connect appropriate accessories (50-pin flat cable, wiring terminals,

etc. if necessary) to the ISA card.

8. Replace the cover of your computer chassis. Re-connect the cables you

removed in step 2.

9. Plug in the power cord and turn on the computer.

After your card is properly installed on your system, you can now configure your device using the Advantech Device Manager Program that has

itself already been installed on your system during driver setup.

11 Chapter 2

PCL-722 User Manual 12

2

3

CHAPTER

Signal Connections

This chapter provides useful information about how to connect input and

output signals to the PCL-722 via the

I/O connector.

Sections include:

• Overview

• Switch & Jumper Settings

• Signal Connections

Chapter 3 Signal Connections

3.1 Overview

Maintaining signal connections is one of the most important factors in

ensuring that your application system is sending and receiving data correctly. A good signal connection can avoid unnecessary and costly damage to your PC and other hardware devices. This chapter provides useful

information on how to connect input and output signals to the PCL-722

via the I/O connector.

3.2 Switch & Jumper Settings

The PCL-722 card has two function jumper settings.

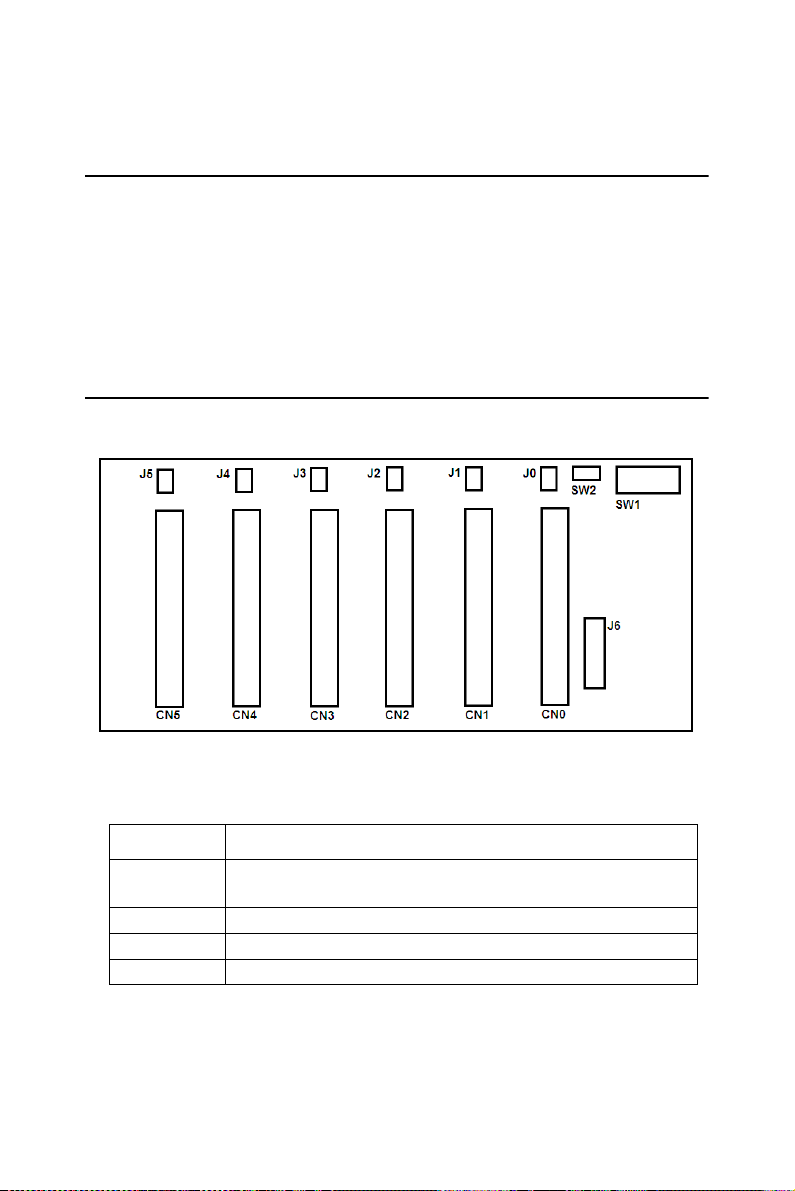

Figure 3.1: Card Connectors, Jumpers & Switches

Location Descriptions

CN0 ~ CN5 OPTO-22 50 pin connector for digital input or output chan-

nels (Port 0 ~ Port 5)

J0 ~ J5 & J6 Interrupt setting

SW1 Base address setting

SW2 96/144-bit mode setting

PCL-722 User Manual 14

3.2.1 Base Address Selection

The PCL-722 requires 32 consecutive address locations

within the I/O space. Some I/O address locations will be

occupied by internal I/O and your peripherals. In order to

avoid conflict with these devices, the PCL-722 address can

be set by a 6 position DIP switch and placed anywhere in the

IBM PC decoded external UO space.

The 200-3FF hex (512-1023 decimal) address range provides

extensive unused areas of I/O space, though you should

check with the IBM Standard Technical Reference Manual

for possible conflicts with commonly installed peripherals.

Table 3.1: Switch Position Summary

I/O Address Range (Hex)

------------------------------------(Fixed)-------------------------------------------------

200-20F 1 0 0 0 0 0

210-21F 1 0 0 0 0 1

220-22F 1 0 0 0 0 0

......

2C0-2CF* 1 0 1 1 0 0

......

300-30F 1 1 0 0 0 0

......

3F0-3FF 1 1 1 1 1 1

Switch Position

12345

A9 A8 A7 A6 A5 A4

Note:

- ON=0, OFF=1

- A4...A9 corresponds to PC bus address lines

- * means factory setting

- Switch position 6 is not used

15 Chapter 3

3.2.2 96/144-bit Mode Setting

The PCL-722 can limit the 32 required addresses to 16, therefore, the digital I/O is limited to 96 bits. SW2 (see Fig. 3.2

below) sets the number of usable I/O. The PCL-722 card

should be left in the 144 bit mode unless this address conflicts with the addresses of other peripherals already installed

or those to be installed in neighbouring slots.

Figure 3.2: Select 144 or 96 I/O

By selecting 96 bit mode, two or more boards can be mapped

consecutively on adjacent addresses. By selecting 144 bit

mode, a minimum gap of 8 addresses will exist between each

board. The following address list provides examples of multiple board addressing with consecutive addresses. Note that

these are not the only addresses available because other combinations can be used.

Board 1 Board 2

200-20F 210-21F

230-23F 240-24F

250-25F 260-26F

Note: In 144 bit mode, base address line A4 is not in functional

status, therefore, A4 of SW1 does not need to be set.

The following base addresses are available:

200,220,240,260,280,2A0,2C0,2E0

300,320,340,360,380,3A0,3C0,3E0

The following base addresses are illegal:

210,230,250,270,290,2B0,2D0,2F0

310,330,350,370,390,3B0,3D0,3F0

PCL-722 User Manual 16

You can set the address according to the information given in

Table 3.1.

3.2.3 Interrupt Settings

Pins PC-0 and PC-3 of each channel of the PCL-722 generate

hardware interrupts and can be set to any of the interrupt

request lines IRQ2, 3, 4, 5, 6 and 7.

The IRQ signal is TRI-STATED allowing multiple PCL-722

boards to share the same interrupt line. For example, two

PCL-722 boards in a system can have IRQ2 selected.

The following diagram shows the locations of interrupt

enable selection jumpers (J0 ~ J5).

Figure 3.3: Interrupt Enable Selection

The interrupt channels setting (J6):

17 Chapter 3

3.3 Signal Connections

The PCL-722 card emulates MODE 0 of 8255 PPI, and is pin

compatible with popular industrial solid state I/O racks and

modules such as those manufactured by OPTO-22, Potter

Brumfield, Gordos, and others.

The PCL-722 has six 50-pin male IDC connectors that interface with position OPTO-22 racks 8, 16 and 24.

Two of the I/O lines (PC-0, PC-3) of each channel can be

used to generate a hardware interrupt.

Note: The PCL-722 emulates MODE 0 of 8255 PPI, therefore, it

is in effect the same as a 8255 controller card and all

packages or programs that support the 8255 in MODE 0

can be used on PCL-722 without reconfiguring software.

3.3.1 Configuration

Mode 0 of 8255 provides simple input and output for each of

the three ports and no handshaking is required as data is written directly to or read from a specified port (see 8255 MODE

0 Function Definitions).

Read-back is another useful function of the PCL-722 and this

allows the user to monitor each output port of each channel.

8255 MODE 0 FUNCTION DEFINITIONS

- Two 8-bit ports (Port A, Port B)

- Two 4-bit ports (Port C upper, Port C lower)

- Any port can be used for input or output

- Outputs are latched whereas inputs are not latched

- 16 different input/output configurations are available in this

mode.

PCL-722 User Manual 18

Table 3.2: 8255 Address Map

Register Address Function

Port A BASE ADDRESS +0 Read/Write

Port B BASE ADDRESS +1 Read/Write

Port C BASE ADDRESS +2 Read/Write

CFG REG BASE ADDRESS +3 Write Only

Example” Base address set at 300

Table 3.3: CFG register format (mode 0)

CH0 CH1 CH2 CH3 CH4 CH5

Port A 300 304 308 30C 310 314

Port B 301 305 309 30D 311 315

Port C 302 306 30A 30E 312 316

CFG Port 303 307 30B 30F 313 317

D7 D6 D5 D4 D3 D2 D1 D0

1 00??0??

1: input 0: output Port C low

nibble

1:input 0:output for Port B

1: input 0: output Port C low

nibble

1:input 0:output for Port A

19 Chapter 3

The following table lists all possible configured “commands”

to configure 8255 in mode 0.

Table 3.4: 8255 Mode 0 Configuration Table

D4 D3 D1 D0

Config. PA0-PA7 PC4-PC7 PB0-PB7 PC0-PC3

80H output output output output

81H output output output input

82H output output input output

83H output output input input

88H output input output output

89H output input output input

8AH output input input output

8BH output input input input

90H input output output output

91H input output output input

92H input output input output

93H input output input input

98H input input output output

99H input input output input

9AH input input input output

9BH input input input input

PC 7 1 2 GND

PC 6 3 4 GND

PC 5 5 6 GND

PC 4 7 8 GND

PC 3 9 10 GND

PC 2 11 12 GND

PC 1 13 14 GND

PC 0 15 16 GND

PB 7 17 18 GND

PB 6 19 20 GND

PB 5 21 22 GND

PB 4 23 24 GND

PB 3 25 26 GND

PB 2 27 28 GND

PB 1 29 30 GND

PB 0 31 32 GND

PA 7 33 34 G ND

PA 6 35 36 G ND

PA 5 37 38 G ND

PA 4 39 40 G ND

PA 3 41 42 G ND

PA 2 43 44 G ND

PA 1 45 46 G ND

PA 0 47 48 G ND

+5V 49 50 GND

PCL-722 User Manual 20

3.4 Interrupt Handling

D

P

E

J2

Interruptdisabled

D

P

E

J2

Interruptenabled

D

P

E

J2

*ifPC‐4‘Low’,

Interruptenabled

*ifPC‐4‘High’,

Interruptdisabled

The PCL-722 has two lines (PC-0, PC-3) for each channel to generate

hardware interrupt.

The interrupts are edge-triggered. PC-0 traps a rising edge signal, while

PC-3 traps a falling edge signal. To use the interrupts, simply insert the

appropriate IRQ jumper to select the desired interrupt level (IRQ 2-7).

To determine which input generated the interrupt, read Port C lower, bits

0 and 3, to locate the current state of inputs. Note that the inputs are not

latched and no “first event” trapping is provided to determine which input

was active first.

The user can select which channel is to be interrupt enable by setting

interrupt enable jumpers J0, J1, J2, J3, J4 and J5. Refer to the table below:

NO INTERRUPT REQUEST

BUS STATUS

PC-0 PC-3

H X NO INTERRUPT REQUEST

L H->L INTERRUPT REQUEST

X L NO INTERRUPT REQUEST

L->H H INTERRUPT REQUEST

RESPONSE

21 Chapter 3

Note: In the event that an interrupt signal is generated from a

rising-edge or a falling-edge change, and if additional

interrupt signals are still to be inputted, the bit-status must

be reset to its original station, i.e. PC-0 should be set at 0

and PC-3 should be set at 1 before such signals can be

inputted. For example, lxx0 (1000, 1010, 1100, 1110)

Although interrupt signals are normally received from

external peripherals, the PCL-722 can also execute a

(test) output signal to simulate an interrupt being inputted

from an external device. See the example in Appendix.

PCL-722 User Manual 22

2

A

APPENDIX

Programming

Examples

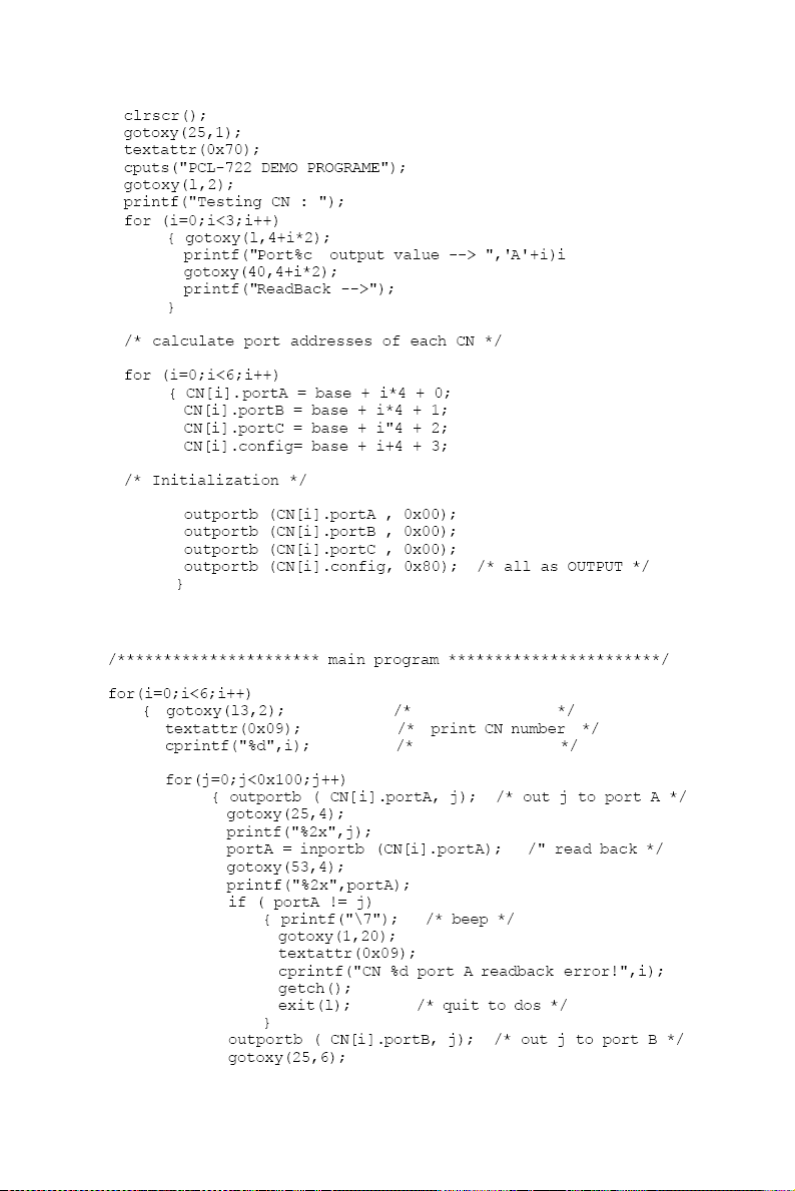

Appendix A Programming Examples

The PCL-722 is easily programmed and the following section lists some

program examples. All the program examples below have been fully

tested on PC-XT/AT or compatible computers.

Note: The following programs should be run under Turbo C version 1.5

or 2.0.

PCL-722 User Manual 24

25 Appendix A

PCL-722 User Manual 26

27 Appendix A

PCL-722 User Manual 28

2

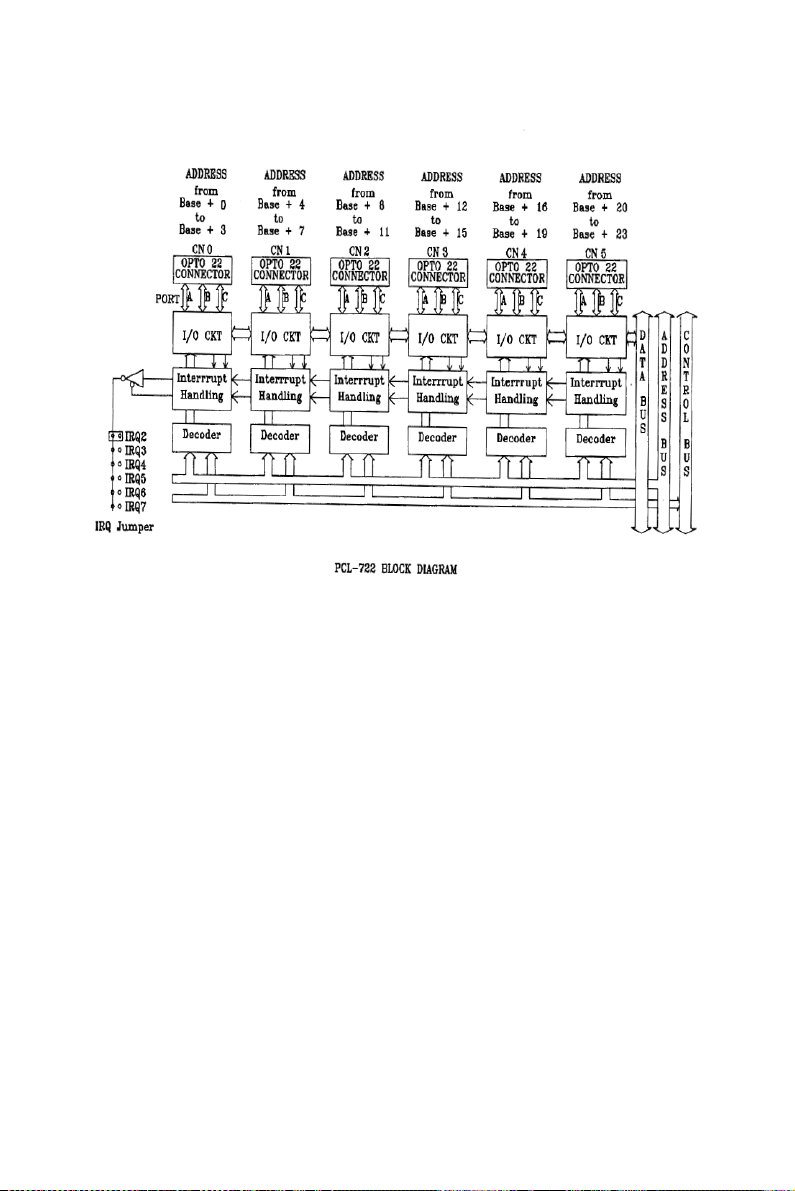

B

APPENDIX

Block Diagram

Appendix B Block Diagram

PCL-722 User Manual 30

2

C

APPENDIX

PC I/O PORT

ADDRESS MAP

Appendix C PC I/O Port Address Map

I/O Address Range (Hex) Function

000-1FF Base system

200 Reserved

201 Came control

202-277 Reserved

278-27F Second printer port

280-2F7 Reserved

2F8-2FF COM2

300-377 Reserved

3713-37F First printer port

380-3AF Reserved

3B0-3BF Mono Disp/Print adapter

3C0-3CF Reserved

3D0-3DF Color/Graphics

3E0-3EF Reserved

3F0-3F7 Floppy disk drive

3F8-3FF COM1

PCL-726 User Manual 32

Loading...

Loading...