Page 1

INTRAC-305 PREFACE

INTRAC™-305

INTELLIGENT TRACKING ANTENNA CONTROL UNIT

INSTALLATION & USER MANUAL

ISSUE 3.2

10 June 2008

Advantech AMT Ltd

39 Edison Road

St Ives

Huntingdon

Cambs PE27 3LF

England

Tel UK General Enquiries 01480 357600

International General Enquiries + 44 1480 357600

Fax UK 01480 357601 International + 44 1480 357601

e-mail info.europe@advantechwireless.com

Website http://www.advantechwireless.com

The copyright of this document is vested in Advantech AMT Ltd and the document is issued in confidence

for the purpose only for which it is supplied. It must not be reproduced, in whole or in part, or used for

tendering or manufacturing purposes or disclosed to a third party except with the written consent of

Advantech AMT Ltd. Advantech AMT is a wholly owned operating company of Advantech Wireless Inc.

© 2011 Advantech Wireless. INTRAC-305 MANUAL - ISSUE 3.2 Page i

Page 2

PREFACE INTRAC-305

PREFACE

This equipment manual provides user/operational and

installation information on the Advantech AMT Limited

INTRAC-305 Satellite Tracking Antenna Controller.

MANUAL SECTIONS :-

Introducing the INTRAC-305 An overview of the INTRAC-305.

Safety Safe usage of the INTRAC-305.

Specification & Options The supplied specification, the fitted options and the available

options.

Operating the INTRAC-305 How to use and operate the INTRAC-305.

Alarms A description of the alarm conditions which can occur.

Technical Description A technical description of the operation of the INTRAC-305.

Installation How to install and set-up an INTRAC-305 system, includes

information on the external connections to the INTRAC-305.

Fault Finding Assistance in finding any faults which may arise.

Warranty and Repair Warranty and repair service provided by Advantech AMT

Information Ltd.

Page ii INTRAC-305 MANUAL - ISSUE 3.2 © 2011 Advantech Wireless

Page 3

INTRAC-305 PREFACE

© 2011 Advantech Wireless. INTRAC-305 MANUAL - ISSUE 3.2 Page iii

Page 4

CONTENTS INTRAC-305

SUBJECT PAGE

Preface ................................................................................................................... i

Contents .................................................................................................................. ii

Introducing the INTRAC-305 .................................................................................... iv

Quick Start Guide …………… ………......................................................................... vii

1. SAFETY ................................................................................................................. 1

Electrical ................................................................................................. 1

Fusing ...................................................................................... 1

Earthing .................................................................................... 1

Battery Disposal ....................................................................... 1

RF I/P Connector Voltage ......................................................... 1

Emergency Stop ....................................................................... 1

Mechanical .............................................................................................. 2

EMC ........................................................................................................ 2

2. SPECIFICATIONS & OPTIONS ............................................................................ 3

Requirements of Antenna System .......................................................... 3

Specification ........................................................................................... 4

Options ................................................................................................... 6

3. OPERATING THE INTRAC-305 ............................................................................ 9

Front Panel ............................................................................................. 9

The Menu Structure ............................................................................... 10

The Menu Screen ................................................................................... 11

Alphabetical Index of the Menus ............................................................ 12

The Menus ............................................................................................. 14

Normal Operation ................................................................................... 50

4. ALARMS & ERRORS ............................................................................................ 51

Primary Alarms ...................................................................................... 51

Secondary Alarms .................................................................................. 52

Alarm Outputs ........................................................................................ 52

Recovering from Alarms ........................................................................ 52

Power Failure ......................................................................................... 53

Errors ..................................................................................................... 53

IESS-412 Data ....................................................................................... 53

5. TECHNICAL DESCRIPTION ................................................................................. 55

The Tracking Algorithm ......................................................................... 55

The Modes ............................................................................................. 58

Standby ................................................................................... 58

Auto .......................................................................................... 58

Manual ..................................................................................... 59

Goto ......................................................................................... 59 Sleep 7

Remote .................................................................................... 61

Using IESS-412 or NORAD Data .......................................................... 61

The IESS-412 Data ................................................................. 61

NORAD Data ............................................................................ 63

Rapid Model Generation ........................................................................ 63

Program Track ....................................................................................... 64

Reserve Model ........................................................................................ 64

Clear Models ........................................................................................... 64

Antenna Motion Limits ............................................................................ 65

Axes Position .......................................................................................... 65

Tracking Signal ....................................................................................... 65

Page iv INTRAC-305 MANUAL - ISSUE 3.2 © 2011 Advantech Wireless

Page 5

INTRAC-305 CONTENTS

SUBJECT PAGE

6. INSTALLATION .................................................................................................….. 67

Introduction ..........................................................................................…. 67

Connections (general) ............................................................................ 68

Rear Panel Layout .................................................................................. 69

Connector Pin Allocations :-

Resolvers ...................................................................………….. 70

Motor Control ............................................................................ 71

Stp-Trk / Alarms ......................................................................... 72

Communication Ports ................................................................. 72

Remote Port …………………………………………… 72

Test Ports ………………………………………………. 73

Serial Port RS422/423 Setting .............................…. 74

Serial Port Usage .................................................…. 74

Tracking Signal Connections ..................................................…. 75

Resolvers (pointing angles) ....................................................................... 75

Southern Hemisphere ............................................................................… 76

Tracking Signal Input ...........................................................................…. 76

With IBR-L .............................................................................…. 76

Without IBR-L ........................................................................…. 76

Operational Checks ..............................................................................…. 77

7. FAULT FINDING .................................................................................................... 79

Introduction ............................................................................................ 79

Fault Symptoms :-

INTRAC doesn’t appear to power up ....................................... 80

Replacing display back-light ..................................................... 80

Front panel keys do not function .............................................. 82

Emergency Stop does not function .......................................... 82

Pointing angles incorrect ......................................................... 82

No antenna drive ...................................................................... 83

No tracking signal ..................................................................... 84

8. WARRANTY & REPAIR ........................................................................................ 85

Warranty ................................................................................................. 85

Repair Service ....................................................................................... 85

Repairs not under Warranty ................................................................... 86

APPENDICES ........................ See separate appendices index ............................. 87

© 2011 Advantech Wireless. INTRAC-305 MANUAL - ISSUE 3.2 Page v

Page 6

INTRODUCTION INTRAC-305

INTRODUCING THE INTRAC-305

The INTRAC-305 INtelligent TRacking Antenna Controller is a

microprocessor based controller for tracking any nominally

geostationary satellite including those at low elevation or with

high angles of inclination. It has been designed as a direct

physical replacement for the Andrew APC300 Steptrack

Controller. For information on replacing an Andrew APC300

with the INTRAC-305 see section 6 - Installation.

The INTRAC-305 builds a model of the satellite’s orbit using a

mathematical algorithm. To build the orbit model the INTRAC

makes measurements by perturbing the antenna pointing

angle very slightly and monitoring the change in received

beacon signal strength. These small movements enable the

INTRAC to estimate the position of the satellite and this

estimate is used by the modelling algorithm.

The system always tracks the satellite from the orbit model.

The small movements of antenna pointing are only used to

maintain and update the model.

By using the model to point the antenna the INTRAC system

ensures that the antenna is always pointed accurately at the

satellite. This is in contrast to Step Track systems where the

antenna spends most of the time not actually pointing directly

at the satellite.

The regular measurements made by the INTRAC ensure that

changes in the apparent orbit, due to station keeping

manoeuvres or other causes, are identified. The model is

modified and refined to incorporate these changes and

accurate tracking is automatically maintained. The INTRAC

will automatically increase the measuring rate if necessary in

order to obtain sufficient information on the changing orbit.

As the INTRAC tracks using its orbit model it will continue to

track the satellite if the tracking signal is degraded or lost.

The satellite position may be accurately predicted from the

model for up to 72hrs without a tracking signal.

The INTRAC system provides this exceptional tracking

performance and robustness for satellites with any inclination,

at any look angle, even in the presence of severe beacon

signal degradation entirely automatically. No operator

intervention or parameter setting is required when conditions

or satellites are changed.

Page vi INTRAC-305 MANUAL - ISSUE 3.2 © 2011 Advantech Wireless

Page 7

INTRAC-305 INTRODUCTION

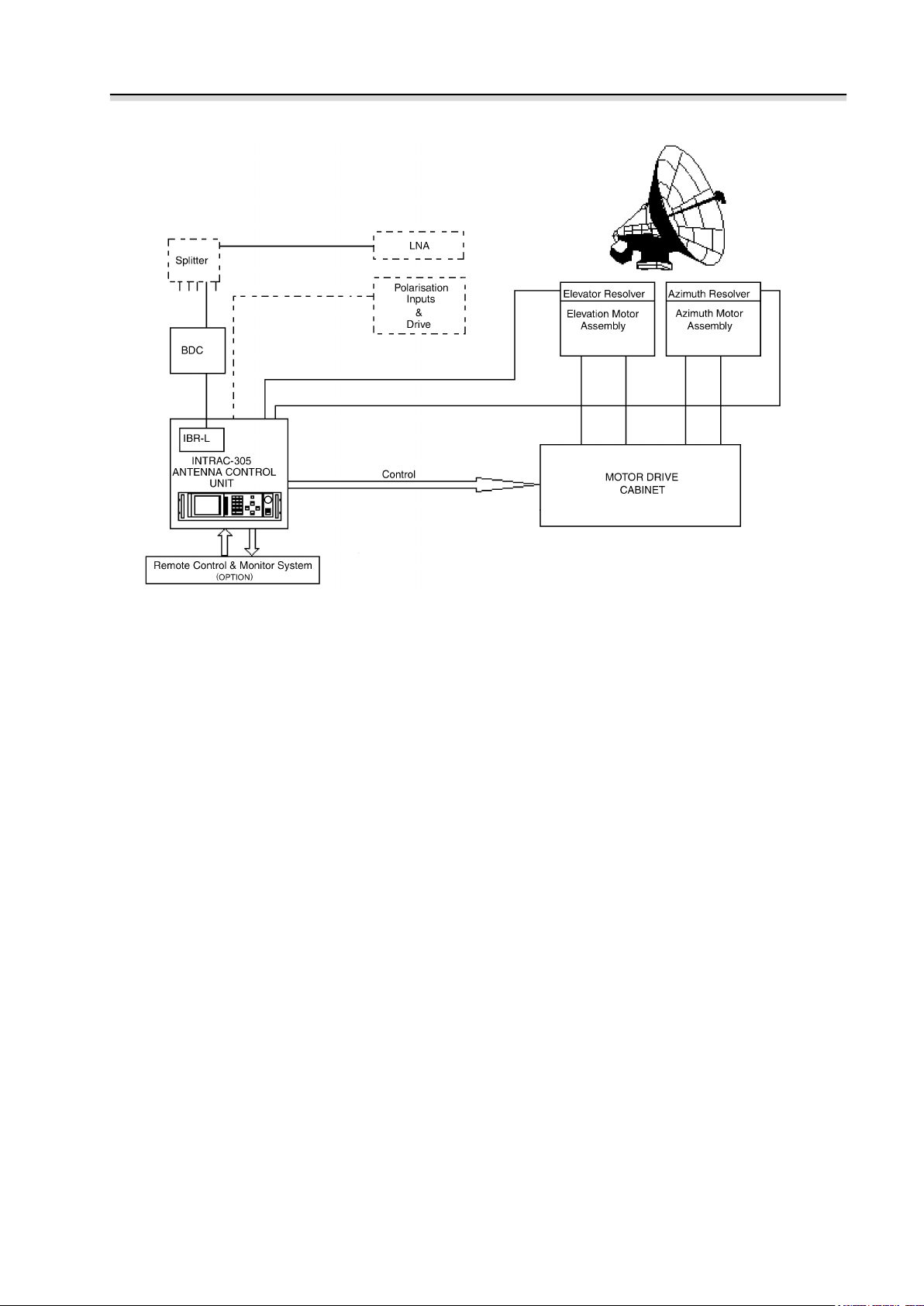

A Typical System

The antenna position resolvers provide direction information

to the INTRAC. The IBR-L (beacon receiver) provides

tracking signal strength. (A signal strength derived dc voltage

from an external receiver may be used in place of the

Advantech AMT IBR-L)

The Motor Drive Cabinet receives the antenna drive

commands from the INTRAC and drives the azimuth,

elevation and polarisation (option) motors and brake

assemblies.

Limit switches on the antenna prevent it from being moved

beyond mechanically defined positions.

The INTRAC-305 may be controlled from its front panel or

from an optional PC based Remote Control and Monitoring

Terminal.

Retro Fitting Existing Step Track or Program Track installations may be

updated to INTRAC systems. Advantech AMT Ltd. have

considerable experience of retro fitting INTRAC systems.

© 2011 Advantech Wireless. INTRAC-305 MANUAL - ISSUE 3.2 Page vii

Page 8

IQUICK START GUIDE INTRAC-305

A suggested quick start procedure is given below:

1/ Before modifying system make a note the antenna pointing angles from the old tracking

system.

2/ Perform any recommended resolver mounting bracket modifications.

3/ Connect INTRAC-305 in place of Andrew APC300 and check that the Fitted Options

(Home>Function>System Setup>Fitted Options) (Manual page 39) are set correctly. Note

that the resolvers used with the APC300 system were normally x2 resolvers which would

require the x2 setting in the fitted options.

4/ Select Station Coordinates (Home>Function>System Setup>Station Coordinates) and

ensure that latitude is in correct hemisphere (North or South). You only need to enter the

correct station co-ordinates if you intend to use IESS-412 or Norad ephemeris data.

5/ Select Date and Time (Home>Function>System Setup>Date & Time) and enter the correct

time and date (in UT (GMT)). This is only strictly necessary if you intend to use IESS-412 or

Norad ephemeris data, but most users prefer to set the time correctly anyway.

6/ Select beamwidth (Home>Function>System Setup>Az & El Beamwidth) and set the receive

3 dB beamwidths of your antenna.

7/ Now ensure drive direction feedback is correct.

Select Manual on INTRAC . (Home>New Mode>Manual/Stow) Note displayed Az angle.

Command drive Right. Check if displayed angle increases or decreases.

Command drive left. Check if displayed angle increase or decreases.

Continue driving left until displayed angle has returned to the previously noted angle.

The angle should have increased while driving right and decreased while driving left. If it did

the opposite then the resolver sense is not correct and will need correcting. By bringing the

antenna back to the original displayed angle we have maintained the angle reference.

Note the displayed Elevation angle and repeat the operation for Elevation. Commanding Up

should give an increasing angle, Down a decreasing angle. If you found the opposite then

you will need to change the elevation resolver sense. Make sure you return the antenna to

the same elevation position (reading).

8/ If either resolver senses required changing then Select Fine Tune (Home>Function>System

Setup>Fine Tune) and change the required senses on the first screen. Then press EN to

continue and adjust the fine tune offsets so that the angle display reads the correct angles (

the ones you noted in step 1).

9/ Now check that Manual drive drives the angles in the expected direction. At this point you

can also check that the physical direction on motion of the antenna is also correct, but this

will be correct if the original installation was correct.

10/ Connect the beacon signal.

If an IBR-L is fitted and an L-band beacon is available connect this to the RF input on the

rear panel of the INTRAC. Select the correct frequency and check that a valid beacon level

is displayed. Manually peak the antenna to maximize the beacon level and check that the

beacon does not overload (24.9 dB displayed).

Page viii INTRAC-305 MANUAL - ISSUE 3.2 © 2011 Advantech Wireless

Page 9

INTRAC-305 QUICK START GUIDE

If an IBR-L is not fitted then provide a voltage signal to the beacon 1 input. You will need to

adjust the potentiometers (See manual page 76) to set the gain and offset to the correct

values. Manually peak the antenna to maximize the beacon level and check that the

beacon does not overload (24.9 dB displayed).

11/ Set any other parameters, such as Soft Limits.

12/ Select Auto-New Model (Home>New Mode>Auto New Model) and press enter. Monitor

system over 24 hours and check that system is maintaining track with displayed mode

“Learning”. Soon after the 24 hour learning period the mode should change to “Tracking”,

indicating that the system has successfully computed a full INTRAC model.

© 2011 Advantech Wireless. INTRAC-305 MANUAL - ISSUE 3.2 Page ix

Page 10

WARNING

POSSIBLE LETHAL POTENTIALS EXIST WITHIN THIS EQUIPMENT

THE COVERS SHOULD NOT BE REMOVED EXCEPT BY QUALIFIED PERSONNEL.

SWITCH OFF POWER AND ISOLATE SUPPLY BEFORE REMOVING COVERS.

IF IT IS NECESSARY TO OPERATE THE EQUIPMENT WITH THE COVERS

REMOVED FOR SERVICING PURPOSES ALL NECESSARY PRECAUTIONS

SHOULD BE TAKEN TO PROTECT AGAINST ELECTRIC SHOCKS

SAFETY INTRAC-305

1. SAFETY

ELECTRICAL

Fusing The standard unit is protected by a user replacable fuse in the

live/phase power supply line.

Care should be taken to ensure that the power cable is

correctly connected to the power source such that the

live/phase connection of the INTRAC is connected to the

live/phase terminal of the supply.

When replacing the fuse be sure to do so with one of the

correct value and type.

The Dual Redundant power supply version is protected by

separate board mounted fuses on each power supply. These

are not user replaceable.

Earthing It is important that the electrical supply has a good and proper

earth and that earth is connected through to the INTRAC-305

via the power cable.

Battery Disposal The processor board contains a Nickel Cadmium (NiCd) or

Lithium battery. These elements are toxic. The battery

should be disposed of according to national requirements.

DO NOT PLACE IN NORMAL GARBAGE OR IN A FIRE.

RF I/P Connector for IBR-L 18Vdc may be present on the inner of the N-Type connector

to power the LNB/BDC. This voltage can be removed by

unplugging connector J41.

Emergency Stop There is a latching emergency stop switch on the INTRAC

front panel. Pressing this switch will remove power from the

antenna drive motors and the INTRAC will enter Standby

Page 10 INTRAC-305 MANUAL - Issue 3.2 © Advantech AMT Ltd

mode. To restore drive the switch should be rotated

clockwise (CW) and Auto Continue selected.

Page 11

1

INTRAC-305 SAFETY

Facilities exist at the Motor Drive Cabinet for the connection

of external emergency stop switches. It is highly

recommended that those fitted be of the latching type.

MECHANICAL

Mounting The INTRAC-305 must not be mounted so that it is supported

only by the front panel. A proper rack mounting kit must be

used. This may be either of the fixed mounting type or the

sliding rail type.

EMC

The unit is designed to meet the requirements of the EC EMC

Directive and conforms to the relevant standards for EMC

emissions and immunity.

Important To ensure that an INTRAC installation also complies with the

EMC Directive it is important to make all interconnections

between the INTRAC-305 and associated equipment using

good quality screened cables as recommended in the

appropriate sections of this manual.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 11

Page 12

Page 13

2

INTRAC-305 SPECIFICATION & OPTIONS

2. SPECIFICATION & OPTIONS

The following pages contain the specification of the INTRAC-

305, a list and description of the available options and a chart

of the delivered configuration.

Required Mechanical Characteristics of the Antenna System

To enable the full tracking performance of the INTRAC-305

the antenna system must conform to certain overrun and

tracking constraints.

The tracking drive speed must be less than 1/10 of the

antenna beamwidth per second and the overrun (drift) when

power is removed from the motors must be less than 1/

the beamwidth.

If the system does not conform to these requirements please

consult with Advantech AMT Limited.

20

of

© 2011 Advantech Wireless. INTRAC-305 MANUAL - Issue 3.2 Page 1

Page 14

SPECIFICATION & OPTIONS INTRAC-305

SPECIFICATION

Tracking Accuracy Typically <0.1dB RMS signal degradation after tracking for

30minutes (with tracking signal).

Prediction Accuracy Typically <0.1dB RMS signal degradation over 72hrs (after

loss of tracking signal).

Tracking Signal May be derived from an external tracking receiver or from the

(optional) Integral Beacon Receiver (IBR-L).

External DC voltage varying directly with received signal strength

(in dB). Scale factors between 0.1V/dB and 1.0V/dB can be

preset with up to 10V offset.

Internal Internal IBR-L requires an L-band signal with a level in the

range -80dBm to -45dBm and C/No >40dB. Stability better

than 150KHz. The received frequency is selected from the

INTRAC front panel.

The signal voltage and lock lost indicators are generated

internally.

Antenna Position Encoders Single resolver units. Operating frequency is 800Hz nominal.

Az & El The INTRAC-305 is designed to operate directly with

standard Andrew resolvers. Antennas used with the APC300

controller, for which the INTRAC-305 is a replacement, are

normally fitted with x2 resolvers. The part numbers of the two

(alternative manufacturers) 2x resolvers known to have been

used by Andrew are:

Harowe 11BRCX-310-M-85V

Clifton 11-BHM-19F/F776

The INTRAC-305 can be configured (by the user in “Fitted

Options”) to operate with the lower resolution (x1) resolver

that may be fitted to antennas intended for APC100 control.

The part numbers of the two (alternative manufacturers) 1x

resolvers known to have been used by Andrew are:

Harrowe 11_BRCX-310-R-85V

Clifton 11-BHW-46TK/F561 or F817

Pol The standard version of the INTRAC-305 is firmware

configured for x1 resolvers. Firmware to enable the use of a

x2 resolver for can be provided on request.

Page 2 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 15

2

INTRAC-305 SPECIFICATION & OPTIONS

Position Offset The indicated pointing angles can be electrically offset in all

axes to an accuracy of 0.01 to compensate for angular

mounting offset in the position encoders.

Back-up Time is maintained by a battery backed clock. Operating

parameters, data and orbital models are held in EEPROM.

Outputs Antenna drive.

Emergency Stop contacts.

Alarm contacts.

Dimensions 483mm Wide x 132mm High x 406mm Deep.

(19” rack x 3U).

Mounting Standard 19” rack mounts or rails.

DO NOT MOUNT BY FRONT PANEL LUGS ALONE

THE UNIT MUST BE SUPPORTED ALONG ITS SIDES.

Weight 12kg (without IRB-L).

15kg (with IRB-L).

Operating Temperature 0C - 40C.

Relative Humidity 10% - 90% non-condensing.

Power 220V - 240V 50Hz 50W.

110V - 120V 60Hz 50W.

Power supplies are auto-switching

Country of Origin United Kingdom.

© 2011 Advantech Wireless. INTRAC-305 MANUAL - Issue 3.2 Page 3

Page 16

RS423

RS422

Ribbon

Cable

Position

Link

Position

Ribbon

Cable

Position

Link

Position

Test Port 1

Test Port 2

J12

J11

J44 Front

J46 Front

J15

J14

J44 Rear

J46 Rear

Serial Port Configuration - Connector and Link Positions

Port Designation

SPECIFICATION & OPTIONS INTRAC-305

OPTIONS A number of options are available for the INTRAC-305.

The options are described in the following pages. Some of

these options require changes to the firmware or hardware

and some are only available when ordered at the time of

initial order.

Serial Interfaces only need a change to switch and / or

connector positions within the INTRAC.

Voltage The power supply unit (or units for Dual Redundant PSU

option) of the INTRAC-305 auto switch for nominal mains

voltages of 110Vac or 220Vac.

Tracking Signal The INTRAC-305 can be supplied with an integral L-band

beacon receiver (IBRL). Alternatively a voltage, from an

external receiver, which varies directly with the received

signal strength in dB may be used. The IBRL option should

be specified at time of initial order.

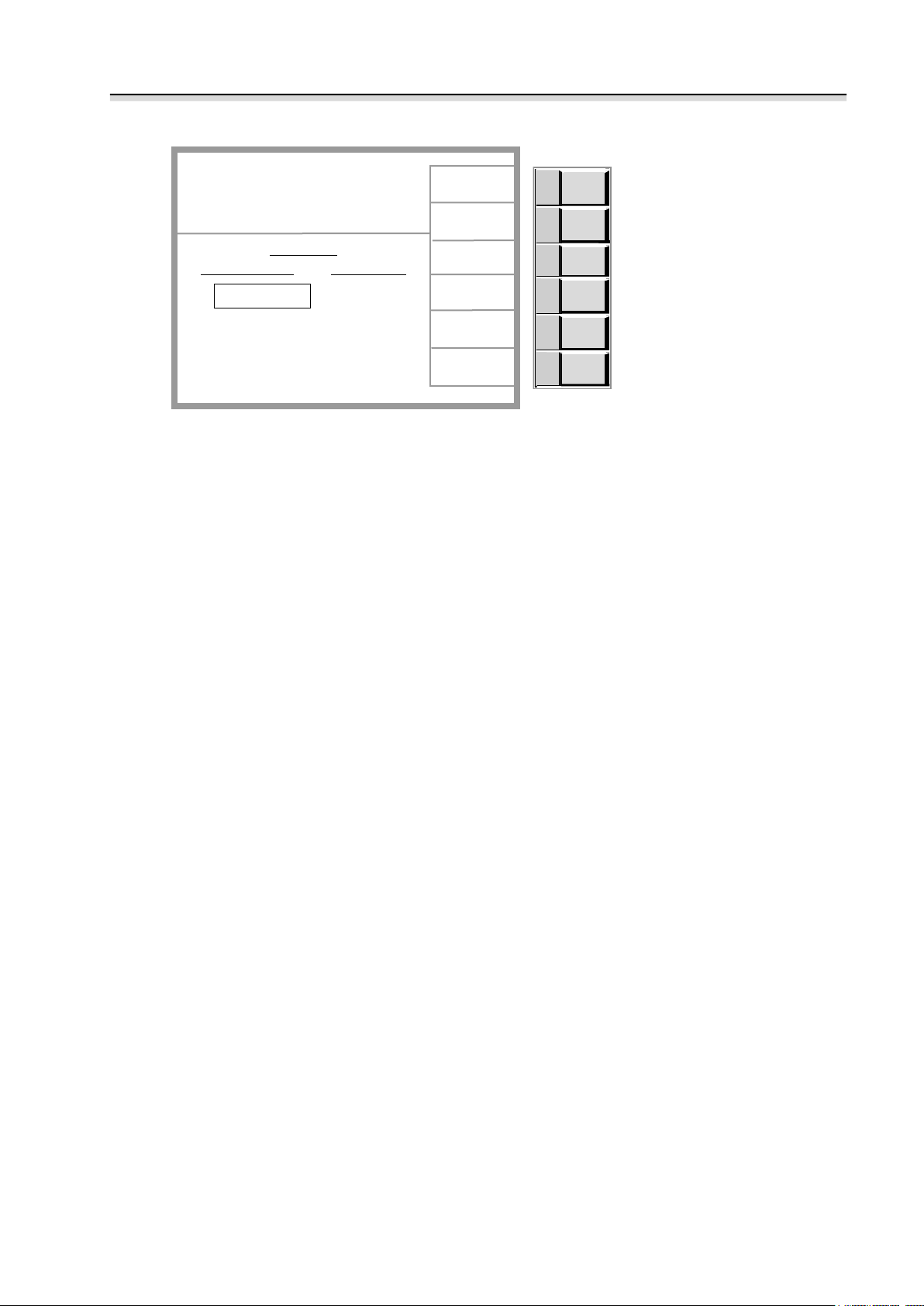

Serial Interfaces There are three communication ports on the INTRAC-305,

“Remote Port”, “Test Port 1” and “Test Port 2”. The Remote

Port is configured for RS232/RS423. Test Ports 1& 2 can be

independently configured as either RS423 or RS422.

This involves connecting the rear panel connectors to the

appropriate connectors on the main board and setting the

option links as shown below.

Polarisation If the antenna has motorised polarisation the INTRAC can be

user configured to control the polarisation angle. Polarisation

uses the standard Andrew polarisation resolver.

Note The standard version of the INTRAC-305 is firmware

configured for a Pol resolver geared 1:1 to the polarisation

tube. Firmware for a Pol resolver geared 2:1 to the

polarisation tube is available if required. Note this is a

Page 4 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 17

2

INTRAC-305 SPECIFICATION & OPTIONS

firmware change and required the EPROM on the interface

card to be changed.

Mount Type Two types of antenna mount may be used with the INTRAC.

An Az/El mount or a Polar mount. The appropriate one is

selected in “Fitted Options” as AZ/El or Hr-Ang/Declination.

Resolver Type The INTRAC-305 is intended for use with standard Andrew

resolvers, either x2 or x1 versions. Normally the INTRAC-305

is to replace an Andrew APC300 and the antenna will have

been fitted with x2 resolvers. Refer to the earlier specification

section. This is a user configuration option.

Stow Option There is provision in the INTRAC-305 configuration for Az/El

preliminary and final stow positions to be set.

The “Stow” command causes the antenna to be driven to the

preliminary position in both axes. Once at this position the

antenna is driven to the final position.

The “Unstow” command causes the pin(s) to be removed

(where appropriate) and the antenna driven to the preliminary

position.

The preliminary and/or final positions can be set to “not-

used” for one or both axes.

Dual Redundant PSU The INTRAC-305 can be supplied with dual redundant power

supplies. In this option the single PSU is replaced by two

indepenent PSUs and associated combining hardware.

Independent switched power inlets are provided and the

front panel power switch is replaced by status LEDs. The

INTRAC-305 will operate normally when either or both PSUs

are operational. This option must be requiested at time of

initial order

© 2011 Advantech Wireless. INTRAC-305 MANUAL - Issue 3.2 Page 5

Page 18

Deliberately blank

SPECIFICATION & OPTIONS INTRAC-305

Page 6 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 19

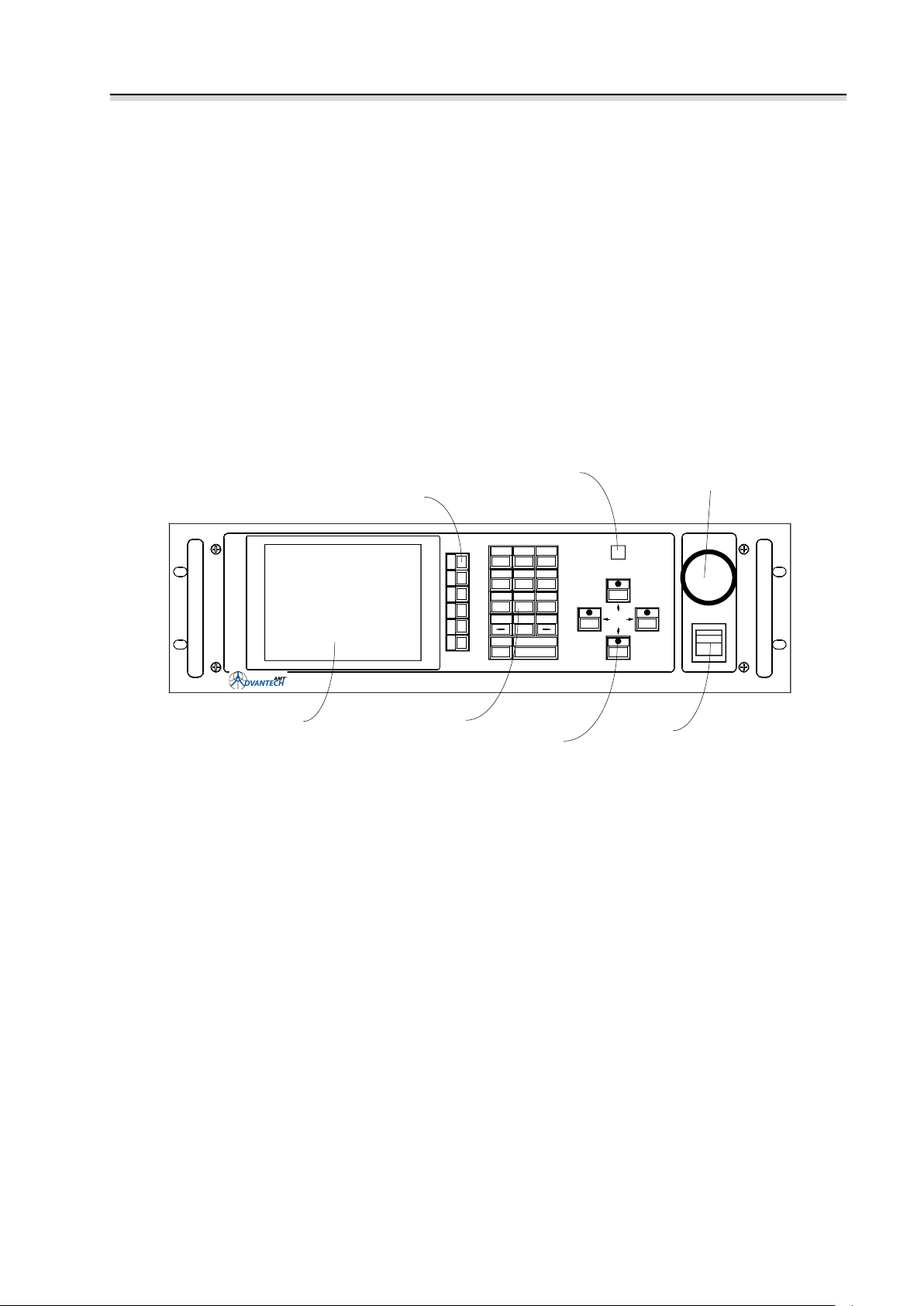

3

POWER

CONTROL

SYSTEM ALARM

MANUAL +ENTER

0

4

7

1 5 8 2 3 6 9

Intrac Antenna Controller

INTRAC 305

EMERGENCY

STOP

LCD DISPLAY PANEL

ON/OFF

SWITCH

NUMERIC KEYPAD

EMERGENCY STOP

BUTTON

SYSTEM ALARM

INDICATOR

MENU KEYS

MANUAL CONTROL KEYS

(STATUS LEDS on

DUAL PSU unit)

INTRAC-305 OPERATION

3. OPERATING THE INTRAC-305

The INTRAC-305 may be operated directly from the front

panel or from the (optional) Remote Control and Monitoring

Terminal.

For both methods of operating a series of menus enables a

user to program the INTRAC and to invoke its modes of

operation.

Operation from the front panel is described in this section of

the manual. The (optional) remote terminal (the RCM-4) is

described in the appendices.

FRONT PANEL

LCD Display Panel This displays the current status of the INTRAC-305 and the

selected menu which includes the labels for the menu keys.

Menu Keys These six keys have functions dependant on the selected

menu. The right side of the menu display indicates the

function of each key for that menu.

Numeric Keypad The keypad is used to enter or edit data into the INTRAC.

The & keys move the cursor left and right.

The +/- key is used to change the sign or, in some cases to

insert a space character.

Manual Control Keys For manual control of the antenna pointing when the INTRAC

is in manual mode.

System Alarm Indicator Illuminates when a primary alarm occurs and remains on until

the cause of the alarm is cleared.

Note. An active primary alarm disables antenna drive.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 7

Page 20

MODELS

RAPID MODEL GENERATE

PROGRAM TRACK

RESERVE MODEL

EDIT IESS-412

EDIT NORAD

EDIT STAR TRACK

EDIT SATELLITE

CONFIGURATION

EDIT SATELLITE

BEACON FREQUENCY

SYSTEM SETUP

FINE TUNE

STATION COORDINATES

DATE & TIME

AZ& EL BEAMWIDTH

CONTRAST & BRIGHTNESS

STOW SETUP

FITTED OPTIONS

selected by menu list

SOFT LIMITS

EXTENDED AZ not avail

DIAGNOSTICS OFF

BEACON THRESHOLD

DIAGNOSTICS ON

CLEAR MODELS

HOME

NEW MODE

FUNCTION

ALARMS

MANUAL/

GOTO

AUTO CONTINUE

AUTO NEW MODEL

STANDBY

STOW

SEARCH

GOTO SATELLITE

GOTO POSITION

BEACON POL not avail

REMOTE LOCAL

OPERATION INTRAC-305

Emergency Stop Button Pressing the button removes all drive from the antenna. The

button locks in the safe position when pressed. To enable

drive to return to the antenna the button must be rotated

clockwise until it releases.

On/Off Switch Illuminated rocker switch to apply power to the INTRAC-305.

Illuminated when the INTRAC is on. On Dual Redundant

PSU units the rocker switch is replaced by status LEDs.

Dual Redundant Status Leds On Dual Redundant PSU units there is a green and red status

LED for each PSU. Green indicates that the PSU is powered

and working normally. Red indicates thjat the PSU is

powered but faulty. When the PSU is unpowered both LEDs

will be off. The INTRAC will operate correctly when at least 1

green LED is illuminated.

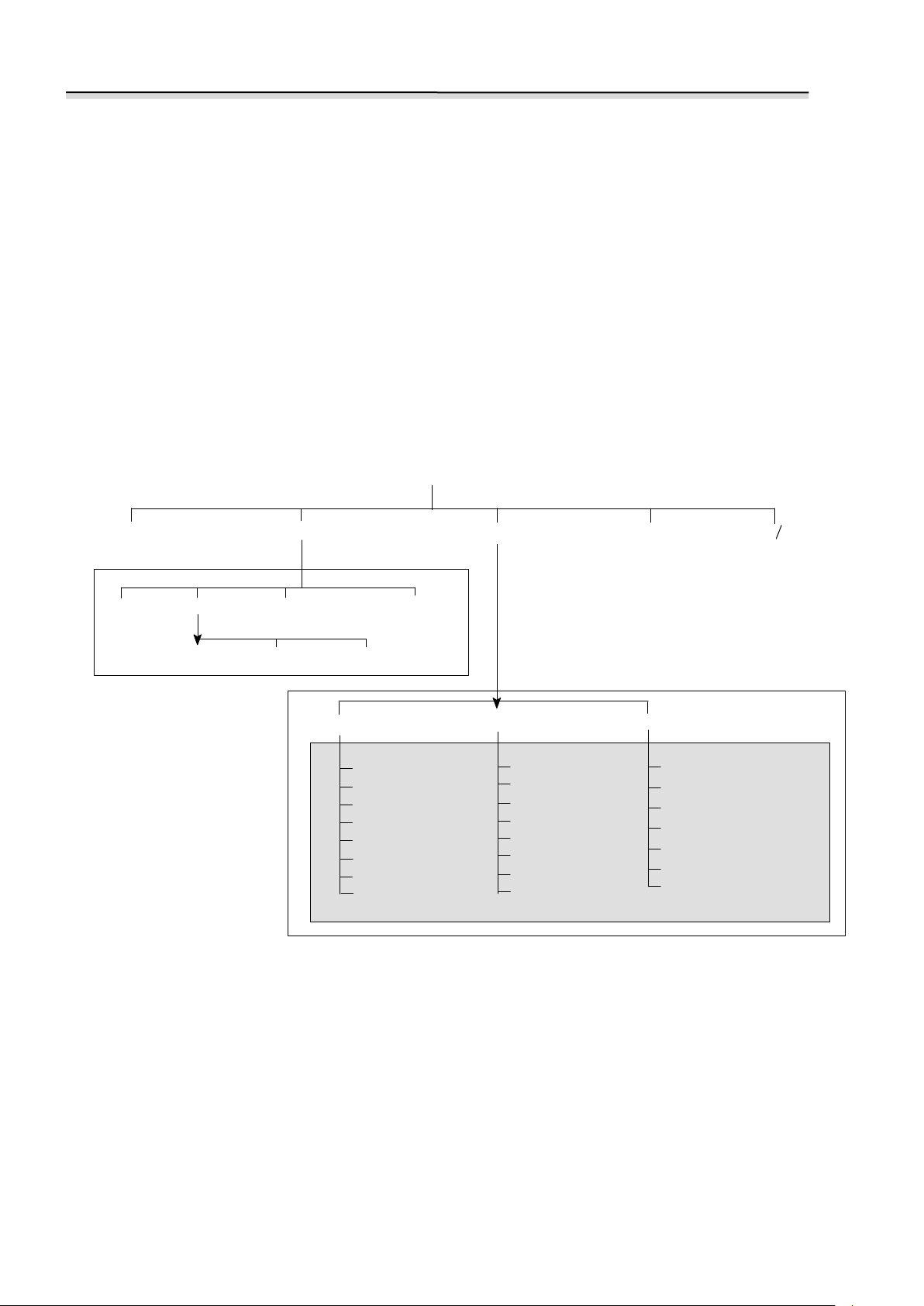

THE MENU STRUCTURE

The diagram above shows the various menus in a “tree”

The menu headings in heavy type are selected by the six

Page 8 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

structure.

menu keys from the “HOME” menu. The headings in the box

below “NEW MODE” are selected by the menu keys in NEW

MODE. The shaded area headings are sub menus of the

MODELS, CONFIGURATION and SYSTEM SETUP menus.

They are accessed by using the “Next Field” menu key from

the appropriate menu followed by the “ENTER” key on the

numeric keypad.

Page 21

3

INTRAC-305 OPERATION

Example To select “STOW SETUP” from the HOME menu :-

FUNCTION (menu key)

SYSTEM SETUP (menu key)

NEXT FIELD (menu key) press five times.

ENTER (numeric keypad)

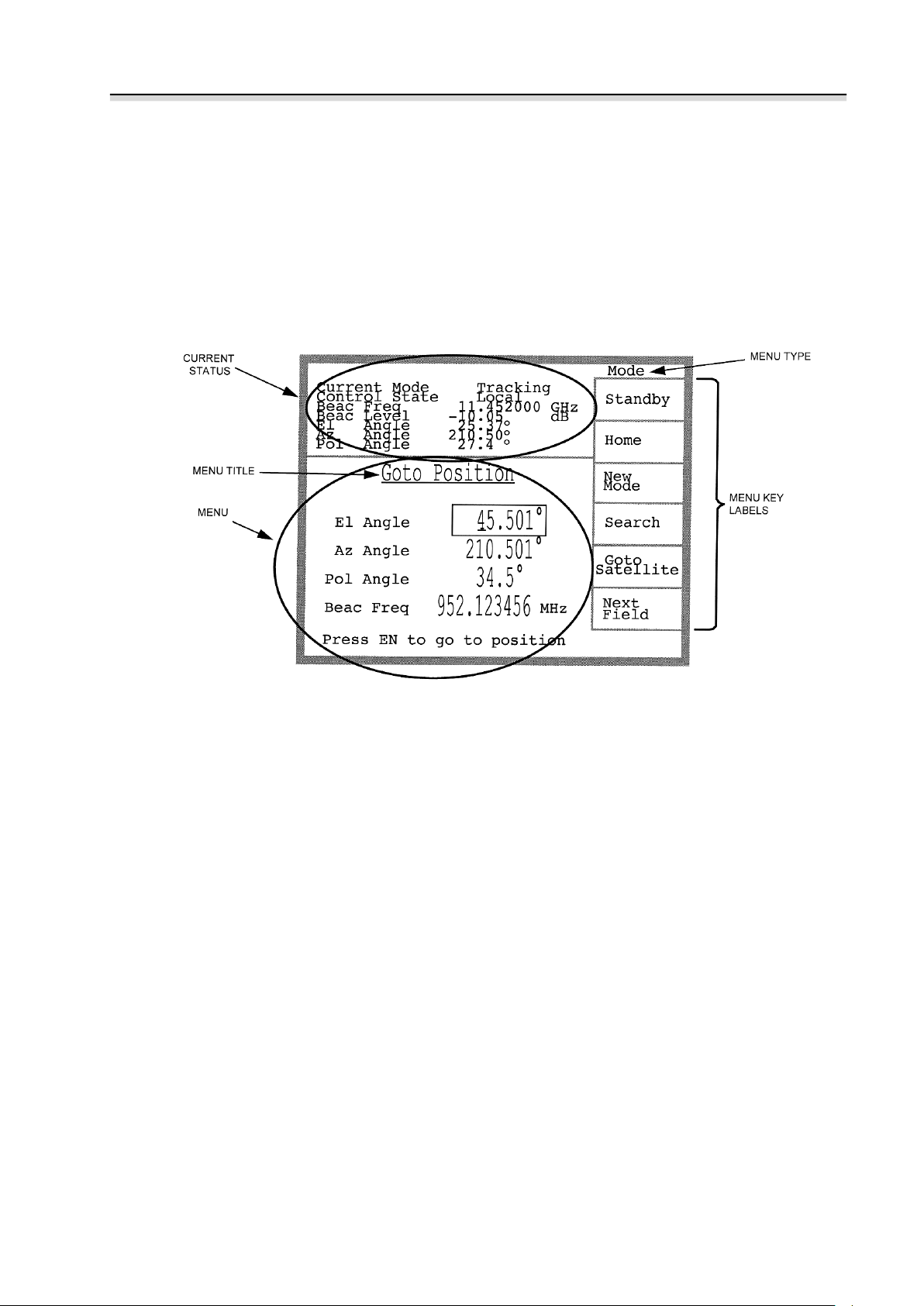

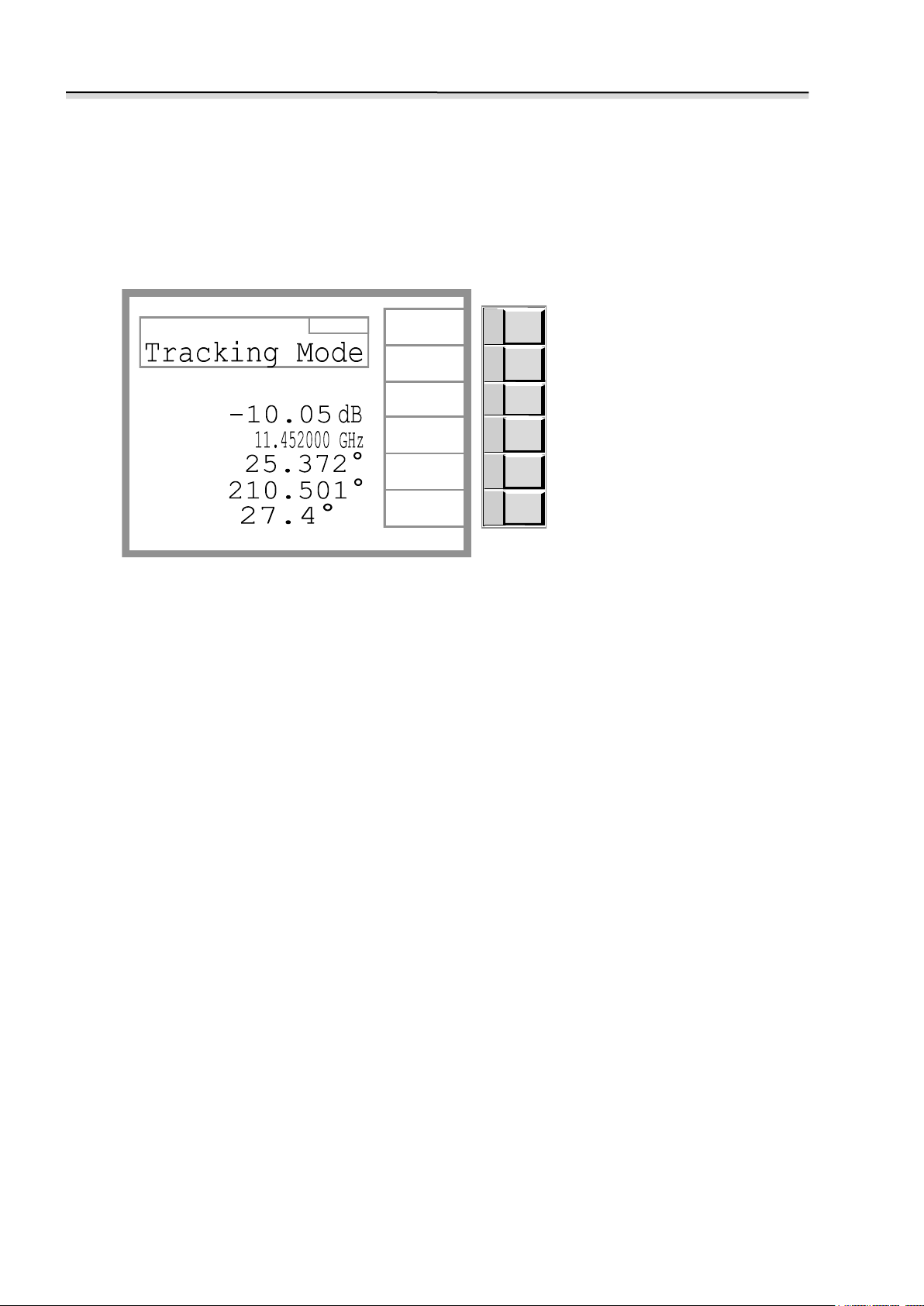

THE MENU SCREEN

A typical menu display screen is shown above. In this

example it is the “Goto Position” used to drive the antenna to

a particular pointing angle.

The top section shows the current mode of the INTRAC,

whether the control is remote or local and the various pointing

angles of the antenna.

Note On some screens (e.g., HOME) the current status display

expands to fill the lower part of the screen.

Down the right side of the screen are the current functions of

the six menu keys.

Above the key labels is the menu type designator, i.e., one of

the six main menu headings.

The main part of the display relates to the selected menu.

The individual menus are described on the following pages in

order of the menu tree shown above. The order is from left to

right and taking the branches as they come.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 9

Page 22

OPERATION INTRAC-305

On the next page is an alphabetical index of the menus to

assist in the quick location of a specific function.

ALPHABETICAL INDEX OF MENUS

Alarms ...................................................................... 48

Auto Continue ...................................................................... 21

Auto New Model ...................................................................... 22

Az & El Beamwidth ...................................................................... 36

Beacon Frequency ...................................................................... 24

Beacon Threshold ...................................................................... 29

Beamwidth Az & El ...................................................................... 36

Brightness & Contrast ...................................................................... 30

Clear Models ...................................................................... 47

Configuration ...................................................................... 23

Contrast & Brightness ...................................................................... 30

Date & Time Setting ...................................................................... 34

Diagnostics On/Off ...................................................................... 28

Edit IESS-412 ...................................................................... 43

Edit NORAD ...................................................................... 44

Edit Satellite Table ...................................................................... 25

Edit Star Track ...................................................................... 45

Fine Tune Offsets ...................................................................... 32

Fine Tune Sense ...................................................................... 31

Fitted Options ...................................................................... 39

Function ...................................................................... 23

Goto Position ...................................................................... 18

Page 10 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 23

3

INTRAC-305 OPERATION

Goto Satellite ...................................................................... 20

Home ...................................................................... 14

IESS-412 Edit ...................................................................... 43

Local/Remote ...................................................................... 49

Manual/Stow ...................................................................... 17

Models ......................................................................40 to 47

New Mode ...................................................................... 16

NORAD Edit ...................................................................... 44

Program Track ...................................................................... 41

Rapid Model Generate ...................................................................... 40

Remote/Local ...................................................................... 49

Reserve Model ...................................................................... 42

Satellite Table Edit ...................................................................... 25

Search ...................................................................... 19

Select Stow Use ...................................................................... 38

Show Alarms ...................................................................... 48

Standby ...................................................................... 15

Star Track Edit ...................................................................... 45

Station Co-ordinates ...................................................................... 33

Soft Limits ...................................................................... 26

Stow ...................................................................... 17

Stow Set-up ...................................................................... 37

System Set-up ......................................................................30 to 39

Time Rate Correction ...................................................................... 35

Time Setting ...................................................................... 34

X2 Setup …………………………………………………… 27

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 11

Page 24

1

2

3

4

5

6

moves to the New Mode menu (not

available when in remote Control Mode)

moves to the 1st ‘Function’ menu(not

available when in remote Control Mode)

shows the Alarms menu ie the currently

active alarms

toggles the INTRAC between Remote

and Local control modes

Home

Function

Standby

(not used)

Show

Alarms

New

Mode

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

Beac Level

Beac Freq

El Angle

Az Angle

Pol Angle

Local

Current Mode

Select

Remote

OPERATION INTRAC-305

HOME

Path HOME

Note This menu can be reached directly from almost every menu

by pressing Menu Key 2.

Description This is the root Menu as shown in the menu structure diagram

on page 10.

It is from here that the five main menus are accessed directly

by use of the Menu Keys.

Page 12 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 25

3

1

2

3

4

5

6

moves to the New Mode menu (not

available when in remote Control Mode)

Standby

New

Mode

puts the antenna control system into

STANDBY mode

Local

Current Mode

Beac Level

Beac Freq

El Angle

Az Angle

Pol Angle

Select

Remote

(Local)

Function

Show

Alarms

moves to the 1st ‘Function’ menu(not

available when in remote Control Mode)

shows the Alarms menu ie the currently

active alarms

toggles the INTRAC between Remote

and Local control modes

Home

INTRAC-305 OPERATION

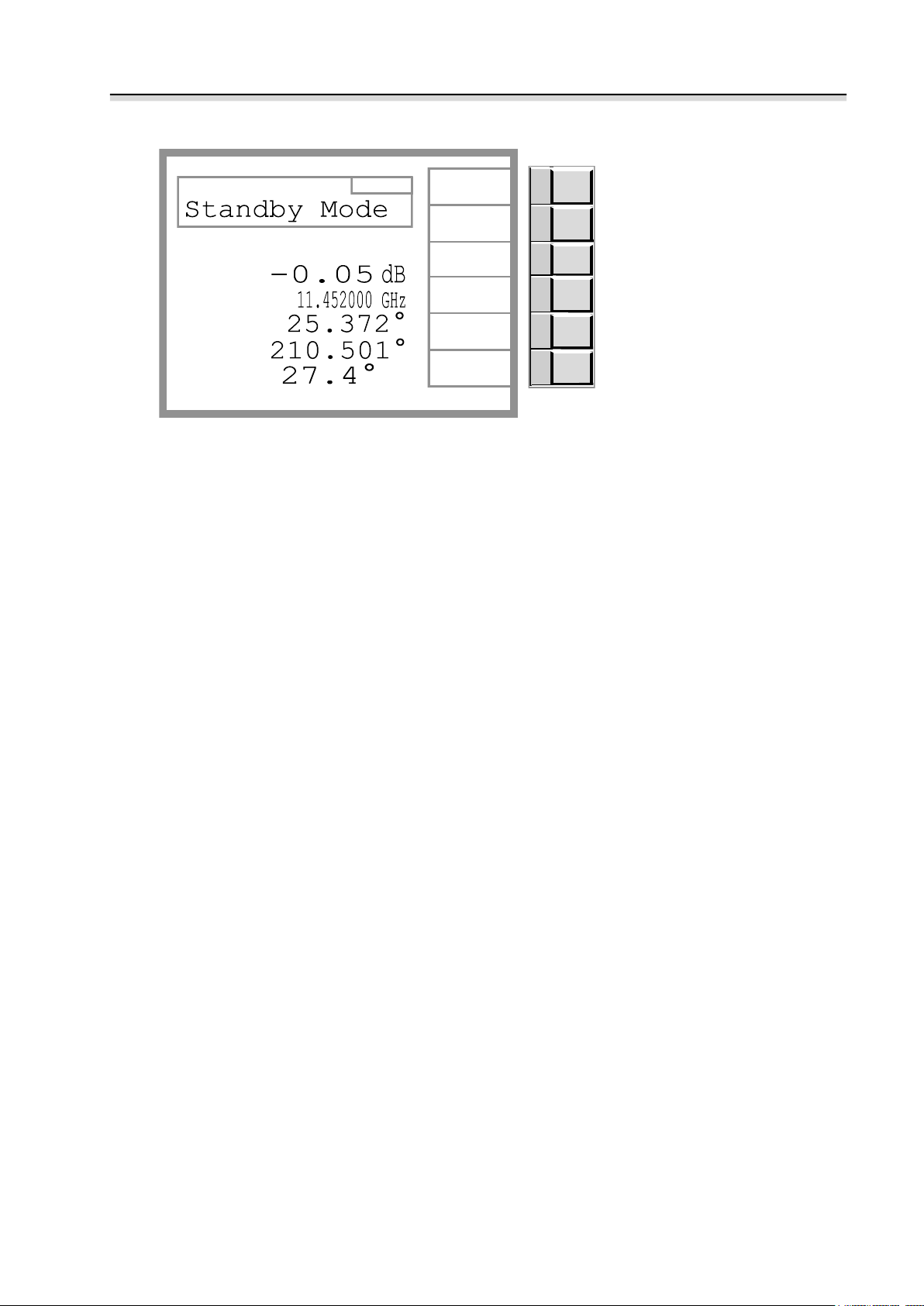

STANDBY

Path STANDBY

Note This menu can be reached directly from almost every menu

by pressing Menu Key 1.

Description Standby is a monitoring but no movement mode.

The antenna is not driven in this mode but its position and the

beacon signal strength are monitored and displayed.

External inputs are also monitored and any appropriate

alarm(s) become active. The System Alarm indicator will

illuminate and the alarms may be viewed by pressing “Show

Alarms”.

Standby mode is entered in one of three ways : by being selected by the operator using Menu Key 1.

by a primary alarm becoming active.

at the end of a Goto move or at the end of a search.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 13

Page 26

1

2

3

4

5

6

moves to the Manual/Stow menu

moves to the 1st ‘Goto’ menu ie Goto

Position

resumes tracking using the INTRAC’S

current model

clears the INTRAC’S current model and

starts learning a new model

New Mode

Auto

New

Model

Goto

Standby

Auto

Continue

Manual

/Stow

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

Beac Level

Beac Freq

El Angle

Az Angle

Pol Angle

Local

Current Mode

Home

skips to the Home (root) menu

OPERATION INTRAC-305

NEW MODE

Path Menu key 3 from the “HOME” or “STANDBY” menus.

Description Displays the current mode and antenna pointing angles on

the full screen.

This is the entry menu for moving the antenna.

Menu key 3 leads to the Manual antenna control and antenna

stow menu.

Menu key 4 leads to the “Goto” menu for “Goto Position”,

“Goto Satellite” and “Search”.

Menu key 5 resumes tracking using the current model.

(Assuming that there is a valid model).

Menu key 6 clears the existing model and starts learning a

new model for the satellite at the current pointing.

Page 14 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 27

3

1

2

3

4

5

6

moves to the New Mode menu (not

available when in remote Control Mode)

Stows or Unstows (toggle) the antenna

depending on its current state

(toggle) selects whether manual control

buttons drive Az/El or Pol axes

latches the currently operated Manual

Drive button until pressed a second time

Manual

Latch

Drive

Stow/

Unstow

Standby

skips to the Home (root) menu

Select

Az&El

or Pol

New

Mode

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

Beac Level

Beac Freq

El Angle

Az Angle

Pol Angle

Local

Current Mode

Home

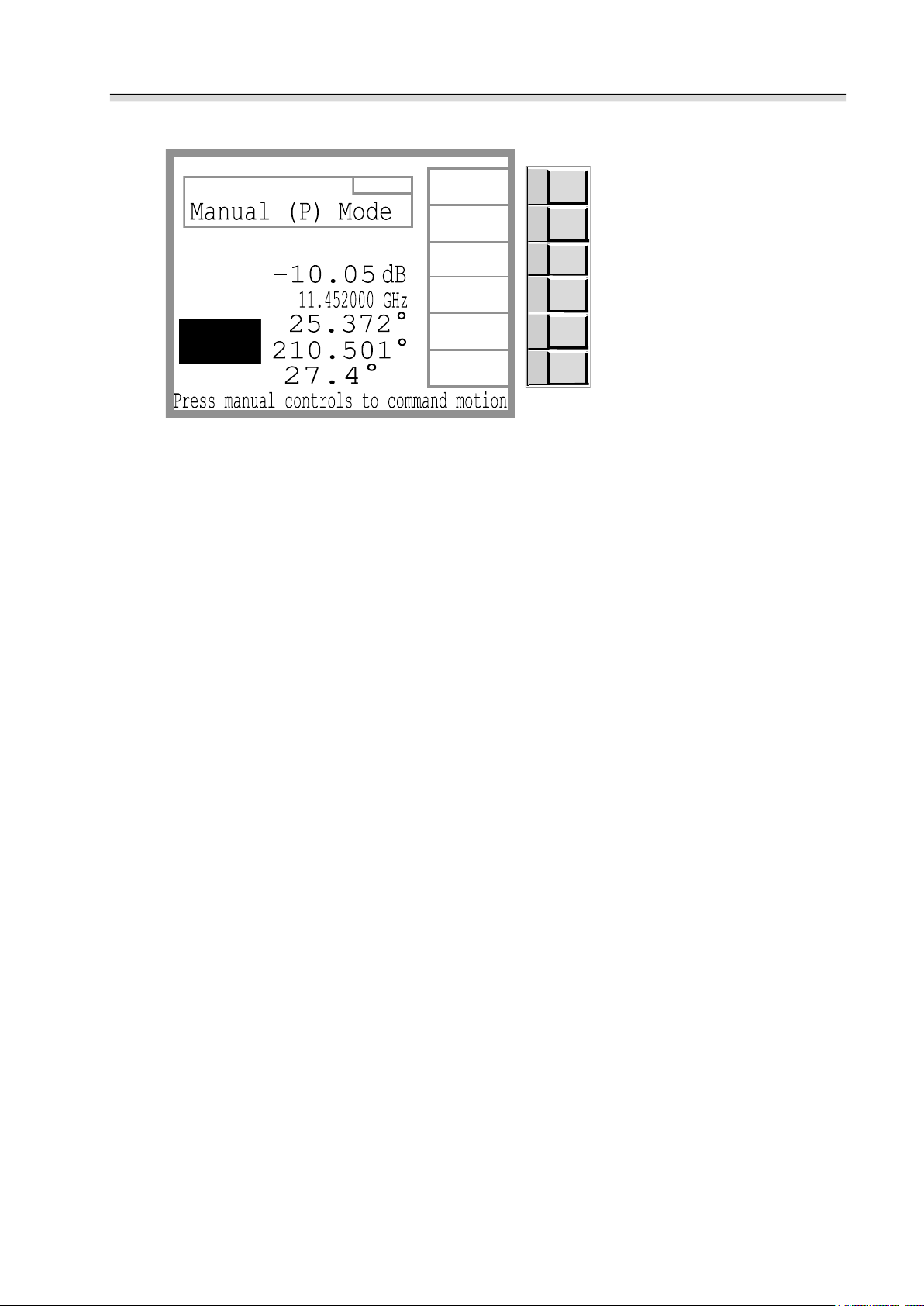

INTRAC-305 OPERATION

MANUAL/STOW

Path HOME - NEW MODE - MENU KEY 3

Description

Manual This menu screen enables the antenna pointing direction to

be changed manually by use of the Manual Control Keys on

the front panel. Menu key 5 enables either azimuth &

elevation or the polarisation motors to be driven.

Azimuth is driven by the left and right manual keys.

Elevation is driven by the upper and lower manual keys.

Polarisation is driven by the left (ccw) and right (cw) manual

keys.

Menu key 6 latches which ever manual key is pressed and

drives at an increased speed. (useful for large distance

moves) Pressing key 6 again releases the latching effect.

Stow Menu key 4 (alternate functions) causes the antenna to be

driven to the pre-set stow position (via the preliminary stow

position) and, where appropriate, the stow pins to be driven

into locking position.

If the antenna is “stowed” key 4 causes the stow pins to be

withdrawn, where appropriate, and the antenna to drive to the

preliminary stow position. (see Stow Setup)

Notes The Drive Fail alarm does not work in Manual (P) mode.

The antenna may be driven through azimuth 0 (North) in

Manual (P) mode is local (front panel) control as opposed to

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 15

Manual (P) mode (azimuth 180 [South] in Southern

Hemisphere).

remote manual control which is Manual (A) Mode.

Page 28

El Angle

Az Angle

Pol Angle

Beac Freq MHz

1

2

3

4

5

6

skips to the New Mode menu

skips to the Search menu

skips to the Goto Satellite menu

moves the highlight box to the next field

in the current menu

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

Az Angle 210.50

Pol Angle 27.4

Mode

Press EN to go to position

Next

Field

Search

Home

Standby

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

Goto

Satellite

New

Mode

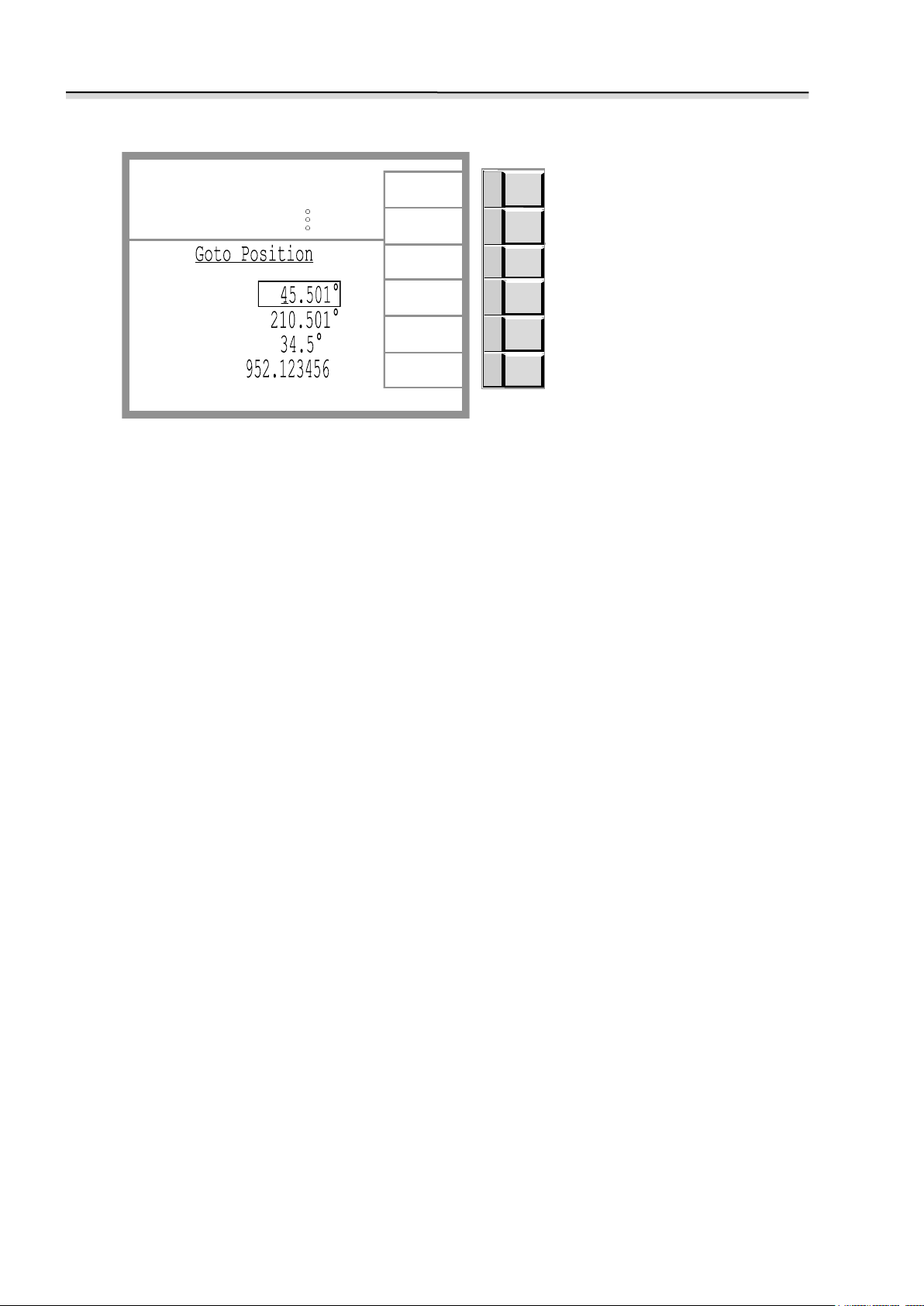

OPERATION INTRAC-305

GOTO (Position)

Path HOME - NEW MODE - MENU KEY 4

Note Pressing menu key 4 (Goto) on the New Mode menu leads to

the Goto Position (as opposed to Goto Satellite) menu. Goto

Satellite and Search are accessed from this (Goto Position)

menu by Menu Keys 5 and 4 respectively.

Description Used to drive the antenna to the co-ordinates displayed.

The co-ordinates can be set by using menu key 6 (Next Field)

to step through the three angles and the Beacon Frequency.

The co-ordinate enclosed in the box can be edited from the

numeric keypad. The & keys are used to move the

cursor to the desired character.

Pressing the ENTER key causes the antenna to commence

driving to the set co-ordinates. When the antenna reaches

the position the INTRAC enters STANDBY Mode.

Page 16 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 29

3

1

2

3

4

5

6

skips to the Goto Position menu

(not used)

skips to the Goto Satellite menu

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

moves the highlight box to the next field

in the current menu

SEARCH

Nom. Angle Box Size

El -027.334 2.0

Az 178.550 2.0

Dwell Time 25secs

Beac Freq 12.250500GHz

Press EN to begin search

Mode

Current Mode Tracking

Control State Local

Beac Freq 11.500000GHz

El Angle 25.55

Az Angle 235.45

Pol Angle 25.63

Next

Field

Goto

Satellite

Goto

Position

Standby

Home

INTRAC-305 OPERATION

SEARCH

Path HOME - NEW MODE - GOTO (Position) - MENU KEY 4

Description Used to search a specific area of sky for the strongest signal

on the beacon frequency.

The antenna may be driven to the nominal co-ordinates of the

required satellite by either the Goto Position or Goto Satellite

commands or manually. Alternatively the Az & El co-

ordinates can be entered on this screen.

Using Menu Key 6 (Next Field) and the numeric keys the

satellite's position and beacon frequency may be entered.

The search box size and the antenna dwell time are also

entered in the same manner.

The box size parameters are either side of the nominal angle

thus entering 2 will cause a 4 scan.

The dwell time is the time that the antenna will remain at each

step. It is the lock time of the beacon receiver. For the IBR-L

(The Signal Processors supplied Integrated Beacon Receiver)

the default dwell time of 25 seconds is correct.

Once all the co-ordinates are set pressing ENTER will start

the search. The antenna will drive to the nearest corner of

the search box before commencing the search pattern.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 17

Page 30

El Angle 145.50

o

Az Angle 210.50

o

Pol Angle -134.5

o

Band 1

Beac Freq 950.000000 MHz

1

2

3

4

5

6

skips to the Goto Position menu

skips to the Search menu

skips to the Edit Satellite Table menu

recalls and displays the satellite table

data of the satellite whose number is

indicated in the highlight box

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

o

Az Angle 210.50

o

Pol Angle 27.4 o

Mode

Press EN to go to Satellite

Recall

Satellite

Data

Search

Home

Standby

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

Edit

Satellite

Table

Goto

Position

OPERATION INTRAC-305

GOTO SATELLITE

Path HOME - NEW MODE - GOTO (Position) - MENU KEY 5

Description The INTRAC-305 can store the co-ordinates, polarisation

angle and beacon frequency of 40 satellites. With this screen

the antenna can be driven to any satellite whose parameters

have been stored.

When this screen is accessed the displayed parameters refer

to the current satellite.

To move to a new satellite key in the required satellite’s

number using the numeric keypad. (Press Menu Key 6 to

view the stored parameters if required)

Press ENTER and the antenna will drive to the new satellites

co-ordinates. Select Home (Menu key 2) to leave this menu

without moving to a new satellite.

If the satellite’s parameters need to be changed Menu Key 5

switches to the Edit Satellite screen. For an explanation of

that facility see “Edit Satellite Table”.

Menu key 6 is used to view the data of a satellite after

entering the “Number”.

Page 18 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 31

3

1

2

3

4

5

6

moves to the Manual/Stow menu

moves to the 1st ‘Goto’ menu ie Goto

Position

resumes tracking using the INTRAC’S

current model

clears the INTRAC’S current model and

starts learning a new model

New Mode

Auto

New

Model

Goto

Standby

Auto

Continue

Manual

/Stow

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

Beac Level

Beac Freq

El Angle

Az Angle

Pol Angle

Local

Current Mode

Home

skips to the Home (root) menu

INTRAC-305 OPERATION

AUTO CONTINUE

Path HOME - NEW MODE - MENU KEY 5

Description This facility does not have a screen of its own. It is a function

If the INTRAC had been in Learning or Tracking mode and

The antenna may have been stowed or moved off satellite for

If the INTRAC had been Tracking but the time off satellite was

Note Until and unless the orbit model is cleared pressing Auto

(see Auto New Model on the next page)

enabled by a menu key on the New Mode menu.

had been taken out of that mode, and the model was still

valid, pressing Auto Continue will return the INTRAC to that

mode.

some other reason. Alternatively the INTRAC may have gone

into Standby due to an alarm. In either case (once the

antenna has been unstowed) pressing Auto Continue will

cause the antenna to drive back to the satellite and continue

Learning or Tracking.

too long for the model to be relied on it will restart in Learning

mode to build a new model.

Continue will cause the antenna to be driven to the satellite of

that model. Thus if a new satellite is required to be tracked

the antenna must be driven to that satellite’s location and

“Auto New Model” used to cause the INTRAC clear the

existing model and start to build a new one.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 19

Page 32

1

2

3

4

5

6

moves to the Manual/Stow menu

moves to the 1st ‘Goto’ menu ie Goto

Position

resumes tracking using the INTRAC’S

current model

clears the INTRAC’S current model and

starts learning a new model

New Mode

Auto

New

Model

Goto

Standby

Auto

Continue

Manual

/Stow

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

Beac Level

Beac Freq

El Angle

Az Angle

Pol Angle

Local

Current Mode

Home

skips to the Home (root) menu

OPERATION INTRAC-305

AUTO NEW MODEL

Path HOME - NEW MODE - MENU KEY 6

Description This facility does not have a screen of its own. It is a function

enabled by a menu key on the New Mode menu.

Auto New Model is used when it is required to track a new

satellite. It causes the INTRAC to clear the existing model (if

there is one) and start to build a new model of the orbit of the

satellite whose beacon signal it is receiving.

Thus before pressing the Auto New Model key the antenna

must be peaked on the required satellite’s main transmission

lobe. The peaking may be done in manual mode or

automatically using Search Mode.

On pressing Auto New Model the INTRAC will enter Learning

mode. After 24hrs of learning the orbit and building the model

the INTRAC will enter Tracking mode.

Page 20 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 33

3

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the

HOME menu

skips to the Home (root) menu

skips to the Models menu

controls whether ‘Angles’ or

‘Diagnostics’ appear on Test Port 1

skips to the System Setup menu

moves the highlight box to the next field

in the current menu

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

Az Angle 210.50

Pol Angle 27.4

Standby

Home

Models

Test

Port-1

Diags

System

Setup

Function

Press EN to accept selection

Next

Field

> Beacon Pol not avail <

Beacon Frequency

Edit Satellite Table

Soft Limits

x2 Setup

Diagnostics On

Diagnostics Off

Beacon Threshold

INTRAC-305 OPERATION

FUNCTION (Configuration)

Path HOME - MENU KEY 4

Note There are three separate menus under the FUNCTION

This Configuration menu can also be reached by Menu Keys

Description The Configuration menu contains seven sub menus plus

The sub menus are described on the following pages.

The Diagnostics On & Off keys are used to route the INTRAC

WHEN IT IS REQUIRED TO CONTROL THE INTRAC FROM

Menu Key 4 Test Port - 1 Diags (Angles)

The data available at Test Port - 1 is either INTRAC

heading. Pressing Menu Key 4 (FUNCTION) on the “Home“

menu leads to the CONFIGURATION menu from which the

MODELS menu and the SYSTEM SETUP menu are reached

via Menu Keys 3 & 5 respectively.

from the MODELS & SYSTEM SETUP menus

Diagnostics On & Off.

diagnostic data to the Remote Control port. This facility

enables one PC to be used as both the remote control

terminal and the diagnostics receiving terminal. However it

cannot do both at the same time.

THE REMOTE TERMINAL DIAGNOSTICS MUST BE

SWITCHED OFF.

diagnostic data (the same diagnostic data as mentioned

above) or angles data. Selection between these two is by

Menu Key 4 whose label toggles between “Diags” & “Angles”

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 21

Page 34

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

skips to the Models menu

skips to the Config menu

skips to the System Setup menu

moves the highlight box to the next field

in the current menu

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

o

Az Angle 210.50

o

Pol Angle 27.4 o

Standby

Home

Models

Config

System

Setup

Function

Press EN to accept selection

Next

Field

Frequency: MHz

Band No : 4

1 L 945 to 1750 MHz

2 C 3.7 to 4.2 GHz

3 X 7.07 to 7.87 GHz

4 Ku1 10.95 to 11.70 GHz

5 Ku2 11.70 to 12.20 GHz

6 Ku3 12.55 to 12.75 GHz

7 Ku4 12.25 to 12.75 GHz

OPERATION INTRAC-305

BEACON FREQUENCY

Path HOME - FUNCTION - MENU KEY 6 - ENTER

Description This function effects the tuning of the IBR-L (if fitted) to the

beacon frequency of the satellite to be tracked.

The IBR-L operates over the frequency range 945MHz to

1.75GHz (L-band). A block down converter is required to

convert the actual beacon frequency to the L-band range.

Note The conversion from the operating frequency to the L-band

frequency for the IBR-L is performed automatically for BDCs

with standard local oscillator frequencies.

Setting Frequency Menu Key 6 (Next Field) selects either the Frequency or Band

No. for editing. The Band No. must be set first otherwise the

frequency cannot be entered.

Use the numeric keypad to overwrite the band number and/or

frequency as required.

The down conversions assumed by the INTRAC-305 are : Band No. Conversion

1 none

2 5.15GHz - C band

3 X band - 6.3GHz

4 Ku1 band - 10GHz

5 Ku2 band - 10.75GHz

6 Ku3 band - 11.475GHZ

7 Ku4 band - 11.3GHZ

Notes Whilst bands 6 & 7 cover, in part, the same frequency range

To use an X-band frequency below 7.25GHz an IBR-L with an

Page 22 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

the down conversion frequency is different.

extended low frequency range is required.

Page 35

3

Satellite Number 01

Elevation 33.74

o

Azimuth 162.83

o

Polarization - 90.0

o

Band 1

Frequency 950.000000 MHz

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

skips to the Models menu

skips to the Config menu

skips to the System Setup menu

moves the highlight box to the next field

in the current menu

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

o

Az Angle 210.50

o

Pol Angle 27.4 o

Standby

Home

Models

Config

System

Setup

Function

Press EN to accept selection

Next

Field

INTRAC-305 OPERATION

EDIT SATELLITE TABLE

Path HOME - FUNCTION - MENU KEY 6 (X2) - ENTER

or From Models or System Setup:-

CONFIG - MENU KEY 6 (X2) - ENTER

Description The INTRAC-305 can store bearing parameters for 40

satellites.

This function allows the editing of previously stored data

and/or the addition of new data.

Menu Key 6 steps the edit box through the six fields. Using

the numeric keypad enter the satellite’s parameters and the

number it is to be stored under.

Pressing ENTER sets the new values.

Note 1 The Satellite Number must be between 1 and 40 inclusive.

Note 2 If the frequency is between 12.55GHZ and 12.75GHZ ensure

that the correct band number is set for the down converter

frequency, i.e., band 6 or band 7.

(see previous page - Beacon Frequency)

To view the data relating to a satellite number use the Goto

Satellite menu, page 22.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 23

Page 36

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

o

Az Angle 210.50

o

Pol Angle 27.4 o

Standby

Home

Function

Press EN to accept all fields

Azimuth left(CCW) 95.00

O

Azimuth right(CW) 160.00

O

Elevation Lower -5.00

O

Elevation Upper 99.99

O

Polarization(CCW) -110.00

O

Polarization(CW) 6.00

O

skips to the Home (root) menu

skips to the Config menu

skips to the System Setup menu

Config

System

Setup

moves the highlight box to the next field

in the current menu

skips to the Models menu

Models

Next

Field

OPERATION INTRAC-305

SOFT LIMITS

Path HOME - FUNCTION - MENU KEY 6 (x3) - ENTER

or From Models or System Setup :-

CONFIG - MENU KEY 6 (x3) - ENTER

Description Antenna movement limits may be programmed which will stop

the antenna drive (and raise a primary alarm) if any one of

them is reached.

Note 1 These are software limits they do not physically break

the drive circuits to the antenna motors.

Note 2 DRIVE IN MANUAL MODE IS NOT INHIBITED BY THE

SOFT LIMITS.

Setting Menu Key 6 (Next Field) steps the edit box through the six

fields. Data is overwritten with the numeric keypad. Pressing

ENTER accepts all the fields.

Page 24 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 37

3

X2 resolvers have a 1:2

gearbox on the input shaft

to provide extra resolution.

This screen allows the user

to resolve a +/- 180º

ambiguity in the displayed

main axes angles.

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

sets the offset for the X2 resolver

clears the offset for the X2 resolver

(not used)

(not used)

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

Az Angle 210.50

Pol Angle 27.4

Standby

Home

Set

Offset

Function

Press EN to accept selection

Clear

Offset

X2 RESOLVER SETUP

INTRAC-305 OPERATION

X2 SETUP

Path HOME - FUNCTION - MENU KEY 6 (x4) - ENTER

or From Models or System Setup :-

CONFIG - MENU KEY 6 (x4) - ENTER

Note This function is only available if the “Resolver Type” in

System Setup - Fitted Options has been set to “EG-01 Fitted”.

If the “Extended Az” in System Setup - Fitted Options has

been set to “Fitted” this line of the Configuration menu reads

“Extended Azimuth Setup”. (see previous page)

Description The EG-01 resolvers have a 1:2 gear ratio between the input

shaft and the angle data output. This is in order to achieve

higher resolution. However it means that the output moves

through 720 for 360 of input rotation. Thus in Azimuth the

INTRAC seeks to initially resolve this 180 ambiguity.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 25

Page 38

1

2

3

4

5

6

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

Az Angle 210.50

Pol Angle 27.4

Standby

Home

Models

Test

Port-1

Diags

System

Setup

Function

Press EN to accept selection

Next

Field

Beacon Frequncy

Edit Satellite Table

Soft Limits

Extended Azimuth Setup

> Diagnostics On <

Diagnostics Off

Beacon Threshold

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

skips to the Models menu

selects whether ‘Angles’ or ‘Diagnostics’

appear on Test Port 1

skips to the System Setup menu

moves the highlight box to the next field

in the current menu

OPERATION INTRAC-305

DIAGNOSTICS ON / DIAGNOSTICS OFF

Path HOME - FUNCTION - MENU KEY 6 (x5 for ON)

(x6 for OFF) - ENTER

or From Models or System Setup

CONFIG - MENU KEY 6 (x5 or 6) - ENTER

Description Diagnostics On & Off are used to route the INTRAC

diagnostic data to the Remote Control port.

Use Menu Key 6 to step the highlight bar to the ON or OFF

line and press ENTER to set.

Note This facility enables one PC to be used as both the remote

control terminal and the diagnostics receiving terminal.

However it cannot do both at the same time.

WHEN IT IS REQUIRED TO CONTROL THE INTRAC FROM

THE REMOTE TERMINAL DIAGNOSTICS MUST BE

SWITCHED OFF.

Page 26 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 39

3

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

skips to the Models menu

skips to the Config menu

skips to the System Setup menu

(not used)

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

o

Az Angle 210.50

o

Pol Angle 27.4 o

Standby

Home

Models

Config

System

Setup

Function

Set Level: -14.12 dB

Press EN to accept selection

INTRAC-305 OPERATION

BEACON THRESHOLD

Path HOME - FUNCTION - MENU KEY 6 (x8) - ENTER

or From Models or System Setup

CONFIG - MENU KEY 6 (x8) - ENTER

Description On this screen the beacon signal strength at which the

beacon level alarm trips is set.

If the tracking signal level falls below the value set here the

INTRAC-305 considers the tracking signal receiver to have

lost lock on the beacon.

Edit the value in the “Set Level” box using the numeric

keypad. The & move the cursor.

Note The only function of the beacon level alarm is to operate a

relay for external use. It is not used by the INTRAC algorithm

and, when it occurs in isolation without an alarm from the

IBR-L, has no effect on the INTRAC operation or mode.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 27

Page 40

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

adjusts contrast of LCD display panel

adjusts brightness of LCD display panel

restores factory defined baseline

settings

moves the highlight box to the next field

in the current menu

Standby

Home

Contrast

adjust

Bright

adjust

Normal

Function

Press Enter to store values

Next

Field

OPERATION INTRAC-305

CONTRAST & BRIGHTNESS

Path HOME - FUNCTION - SYSTEM SETUP - ENTER

or From Models or Configuration

SYSTEM SETUP - ENTER

Description The screen Contrast and Brightness can be adjusted in this

menu.

The Contrast range is from 0 to 15 and the Brightness range

is from 0 to 8.

The levels are set using Menu Key 3 for contrast and Menu

Key 4 for brightness.

Each press of a key increases the displayed number by one

and the screen brightness or contrast changes.

When the display is at its most visible press ENTER to store

the values.

Menu Key 5 (Normal) sets the Brightness and Contrast to the

default values which are 8 in both cases.

Note The Flicker setting is not an operator controllable parameter.

Page 28 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 41

3

Resolver Sense:

Azimuth >true<

Elevation inv

Pol Angle inv

1

2

3

4

5

6

(not used)

toggles the highlighted parameter

between ‘true’ and ‘inv’

(not used)

moves the highlight box to the next field

in the current menu

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

o

Az Angle 210.50

o

Pol Angle 27.4 o

Function

Press EN to accept sense settings

Next

Field

Change

Resolver

Sense

Home

Standby

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

INTRAC-305 OPERATION

FINE TUNE - sense

Path HOME - FUNCTION - SYSTEM SETUP -

MENU KEY 6 (x2) - ENTER

or From Models or Configuration

SYSTEM SETUP - MENU KEY 6 (x2) - ENTER

Description This menu allows the “sense” of the Azimuth, Elevation and

Polarisation resolvers to be inverted. This is necessary to

allow for different mounting arrangements for the resolvers.

Use Menu Key 6 to step the edit highlight through the three

angles. Use Menu Key 4 (Change Resolver Sense) to toggle

between “true” and “inv.”

Pressing ENTER accepts the settings and moves on to the

“FINE TUNE - Offsets” menu. (see next page)

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 29

Page 42

Resolver Sense:

Azimuth >true<

Elevation inv

Pol Angle inv

To change offsets:

Press the manual drive keys

(with FAST key if reqd) to

adjust the displayed angle

1

2

3

4

5

6

(not used)

(not used)

(not used)

(not used)

Toggles between ‘Select Pol Axis’ &

Select Az/El Axes’ moving the highlight

box to the labeled parameter

speeds up the effect of the currently

pressed manual Drive Key

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

o

Az Angle 210.50

o

Pol Angle 27.4 o

Select

Pol

Axis

Function

Press EN to EXIT Fine Tune

FAST

OPERATION INTRAC-305

FINE TUNE - Offsets

Path See “FINE TUNE - Sense” on previous page.

Description This menu allows an offset to be inserted between the “angle”

from the resolver and the displayed angle in order to calibrate

the system for any difference between the actual antenna

angle and the resolver angle.

The actual pointing angles of the antenna are accurately

established and the displayed angles are set to those angles

using this facility.

Azimuth & Elevation or Polarisation are selected using menu

key 5.

The setting of the offset is done using the manual drive keys.

For Az & El the right and left keys offset the Az and the upper

and lower keys offset the El. For Pol the right and left keys

are used.

The angles displayed in the upper section of the menu screen

change in real time. Menu Key 6 may be used together with

the direction key to increase the rate of change.

The actual amount of offset is not displayed.

The offset can be returned to zero for any angle by pressing

the opposite keys at the same time.

Care should be taken to release both keys at the same time

otherwise another offset will be inserted.

Note This should only be carried out at commissioning or on the

Caution Inserting any offset will reset the orbit model.

Page 30 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

installation of a new resolver or if the relationship between the

antenna and a resolver has changed.

Page 43

3

1

2

3

4

5

6

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

Az Angle 210.50

Pol Angle 27.4

Function

Press EN to accept selection

Home

Standby

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

Lat : -123.1234 o+North

Long : 123.1234 o East

Height: +10.0000 km

Offsets Az : -180.1234

o

El : -180.1234

o

skips to the Config menu

skips to the System Setup menu

Config

System

Setup

moves the highlight box to the next field

in the current menu

skips to the Models menu

Models

Next

Field

INTRAC-305 OPERATION

STATION CO-ORDINATES

Path HOME - FUNCTION - SYSTEM SETUP -

MENU KEY 6 (x2) - ENTER

or From Models or Configuration

SYSTEM SETUP - MENU KEY 6 (x2)

Description The co-ordinates of the earth station are entered in this menu.

Also any offsets required if the antenna base is not

perpendicular.

The five edit fields are stepped through using Menu Key 6

(Next Field). The values are entered using the Numeric

Keypad.

Pressing ENTER accepts the values.

Note These parameters are not required by the INTRAC-305 for its

orbit modelling. However they are required if IESS-412 or

NORAD Ephemeris data is to be used and for Star Track

Mode.

© 2011 Advantech Wireless INTRAC-305 MANUAL - Issue 3.2 Page 31

Page 44

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Home (root) menu

moves to the Time Rate Correction

menu

skips to the Config menu

skips to the System Setup menu

moves the highlight box to the next field

in the current menu

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB

El Angle 25.37

Az Angle 210.50

Pol Angle 27.4

Standby

Home

Time

Rate

Corr.

Config

System

Setup

Function

Press EN to accept all fields

Next

Field

Year : 97

Month : 12

Day : 25

Hour : 11

Minute: 35

Second: 10

OPERATION INTRAC-305

DATE & TIME

Path HOME - FUNCTION - SYSTEM SETUP -

MENU KEY 6 (x3) - ENTER

or From Models or Configuration

SYSTEM SETUP - MENU KEY 6 (x3) - ENTER

Description The date and time are entered in this menu.

The edit box is stepped through the six fields using Menu Key

6 (Next Field). The values are entered using the Numeric

Keypad. The clock uses the 24hr system.

Pressing ENTER accepts the values displayed.

Note 1 The clock is battery backed.

Note 2 The clock frequency can be adjusted by up to +/- 180

seconds per day in the “Time Rate Correction” menu which is

accessed by Menu Key 3. (see next page)

Page 32 INTRAC-305 MANUAL - Issue 3.2 ©2011 Advantech Wireless

Page 45

3

1

2

3

4

5

6

puts the antenna control system into

STANDBY mode and skips to the HOME

menu

skips to the Models menu

skips to the Config menu

skips to the System Setup menu

Current Mode Tracking

Control State Local

Beac Freq 11.452000 GHz

Beac Level -10.05 dB