Page 1

HMI-640S

486-based panel PC with 6.0" LCD

flat panel display

User's Manual

Page 2

Copyright notice

This document is copyrighted 2000 by Advantech Co., Ltd. All rights

are reserved. Advantech Co., Ltd. reserves the right to make improvements to the products described in this manual at any time without

notice.

No part of this manual may be reproduced, copied, translated or

transmitted in any form or by any means without the prior written

permission of Advantech Co., Ltd. Information provided in this manual

is intended to be accurate and reliable. However,

Advantech Co., Ltd assumes no responsibility for its use, nor for any

infringements upon the rights of third parties which may result from its

use.

Acknowledgments

HMI-640S, CPC-2245N, CPC-2430, CPC-2520 and CPC-2900 are all

trademarks of Advantech Co., Ltd. IBM, PC/A T, and PS/2 are trademarks of International Business Machines Corporation. MS-DOS and

Windows CE are trademarks of Microsoft Corporation. All other brand

and product names mentioned herein are trademarks or registered

trademarks of their respective holders.

Part No. 2008064000

1st Edition Printed in T aiwan Feb 2000

Page 3

FCC Class A notes

This equipment has been tested with a class A computing device and

has been found to comply with part 15 of FCC Rules. Operation in a

residential area may cause unacceptable interference to radio and TV

receptions requiring the operator to take whatever steps are necessary

to correct the interference.

Page 4

Safety Instructions

1. Read these safety instructions carefully.

2. Keep this installation reference guide for later reference.

3. Disconnect this equipment from any AC outlet before cleaning. Do not use

liquid or spray detergents for cleaning. Use a damp cloth.

4. For pluggable equipment, the power outlet must be installed near the

equipment and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a reliable surface during installation. Dropping it or

letting it fall could cause damage.

7. The openings on the enclosure are for air convection. Protect the equipment from overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source is correct before connecting the

equipment to the power outlet.

9. Position the power cord so that people cannot step on it. Do not place

anything over the power cord.

10 . All cautions and warnings on the equipment should be noted.

11 . If the equipment is not used for a long time, disconnect it from the power

source to avoid damage by transient over-voltage.

12 . Never pour any liquid into an opening. This could cause fire or electrical

shock.

13 . Never open the equipment. For safety reasons, the equipment should be

opened only by qualified service personnel.

14 . If any of the following situations arises, get the equipment checked by

service personnel:

a. The power cord or plug is damaged.

b. Liquid has penetrated into the equipment.

c. The equipment has been exposed to moisture.

d. The equipment does not work well, or you cannot get it to work

according to the installation reference guide.

e. The equipment has been dropped and damaged.

f. The equipment has obvious signs of breakage.

15 . DO NOT LEAVE THIS EQUIPMENT IN AN UNCONTROLLED

ENVIRONMENT WHERE THE STORAGE TEMPERATURE IS BELOW 20° C (-4° F) OR ABOVE 60° C (140° F). IT MAY DAMAGE THE

EQUIPMENT.

The sound pressure level at the operator's position according to IEC 704-1:1982

is equal to or less than 70 dB(A).

DISCLAIMER: This set of instructions is given according to IEC 704-1.

Advantech disclaims all responsibility for the accuracy of any statements

contained herein.

Page 5

Wichtige Sicherheishinweise

1 . Bitte lesen sie Sich diese Hinweise sorgfältig durch.

2 . Heben Sie diese Anleitung für den späteren Gebrauch auf.

3. Vor jedem Reinigen ist das Gerät vom Stromnetz zu trennen. Verwenden Sie

Keine Flüssig-oder Aerosolreiniger. Am besten dient ein angefeuchtetes Tuch

zur Reinigung.

4. Die NetzanschluBsteckdose soll nahe dem Gerät angebracht und leicht

zugänglich sein.

5. Das Gerät ist vor Feuchtigkeit zu schützen.

6 . Bei der Aufstellung des Gerätes ist auf sicheren Stand zu achten. Ein Kippen

oder Fallen könnte Verletzungen hervorrufen.

7. Die Belüftungsöffnungen dienen zur Luftzirkulation die das Gerät vor

überhitzung schützt. Sorgen Sie dafür, daB diese Öffnungen nicht abgedeckt

werden.

8 . Beachten Sie beim AnschluB an das Stromnetz die AnschluBwerte.

9 . Verlegen Sie die NetzanschluBleitung so, daB niemand darüber fallen kann. Es

sollte auch nichts auf der Leitung abgestellt werden.

10 . Alle Hinweise und Warnungen die sich am Geräten befinden sind zu beachten.

11 . Wird das Gerät über einen längeren Zeitraum nicht benutzt, sollten Sie es

vom Stromnetz trennen. Somit wird im Falle einer Überspannung eine

Beschädigung vermieden.

12 . Durch die Lüftungsöffnungen dürfen niemals Gegenstände oder Flüssigkeiten

in das Gerät gelangen. Dies könnte einen Brand bzw. elektrischen Schlag

auslösen.

13 . Öffnen Sie niemals das Gerät. Das Gerät darf aus Gründen der elektrischen

Sicherheit nur von authorisiertem Servicepersonal geöffnet werden.

14 . Wenn folgende Situationen auftreten ist das Gerät vom Stromnetz zu trennen

und von einer qualifizierten Servicestelle zu überprüfen:

a. Netzkabel oder Netzstecker sind beschädigt.

b. Flüssigkeit ist in das Gerät eingedrungen.

c. Das Gerät war Feuchtigkeit ausgesetzt.

d. Wenn das Gerät nicht der Bedienungsanleitung entsprechend

funktioniert oder Sie mit Hilfe dieser Anleitung keine Verbesserung

erzielen.

e. Das Gerät ist gefallen und/oder das Gehäuse ist beschädigt.

f. Wenn das Gerät deutliche Anzeichen eines Defektes aufweist.

15 . Bitte lassen Sie das Gerät nicht unbehehrt hinten unter -20° C (-4° F) oder

oben 60° C (140° F), weil diesen Temperaturen das Gerät zerstören könten.

Der arbeitsplatzbezogene Schalldruckpegel nach DIN 45 635 Teil 1000 beträgt

70dB(A) oder weiger.

DISCLAIMER: This set of instructions is provided according to IEC704-1.

Advantech disclaims all responsibility for the accuracy of any statements

contained therein.

Page 6

Contents

Chapter 1 General Information ..................................... 1

1.1 Introduction....................................................................... 2

1.2 Specifications .................................................................... 2

General .................................................................................2

Standard functions (CPC-2245N) ........................................2

Ethernet interface................................................................. 4

SVGA/Flat panel interface (CPC-2520) ..............................4

Power supply........................................................................4

Environmental specifications ................................................4

T ouchscreen .........................................................................5

1. 3 LCD Specifications ........................................................... 5

1. 4 I/O Arrangement .............................................................. 6

1. 5 Total Solution .................................................................... 7

1.6 Dimensions ........................................................................ 8

1.7 Mounting ........................................................................... 9

Chapter 2 System Setup ............................................. 11

2.1 General ............................................................................ 12

2. 2 Packing List .................................................................... 1 2

2. 3 Initial Setup ..................................................................... 1 3

2. 3 Installing a CompactFlash Memory Card .................. 1 4

Installing a CompactFlash adapter .....................................1 4

Installing a 2.5" HDD .........................................................15

HMI-640S is designed as a HDD-less platform of a high

reliability . However, if a HDD should be used, its installation

procedure is described as follows:......................................15

2. 4 Connecting the Power Adapter .................................... 1 6

2. 5 Installing a PC/104 Module .......................................... 1 7

2. 6 First System Boot .......................................................... 1 9

Power up for the first time .................................................19

Assign the Device Name ...................................................19

2. 7 Exploded Diagram .......................................................... 2 0

Page 7

Chapter 3 Maintenance ................................................ 21

3. 1 Removing the Front/Rear Panel .................................. 2 2

3. 2 LCD Display .................................................................... 2 4

3. 3 LCD Backlight ................................................................ 2 5

3.4 Power Supply................................................................... 26

3. 5 I/O Adapter (CPC-2900) ............................................... 2 7

3. 6 Core of HMI-640S

(CPC-2520/CPC-2245N/CPC-2430) ........................... 2 8

Chapter 4 CPC-2245N Main Board.............................. 29

4.1 Introduction..................................................................... 30

4. 2 Specifications .................................................................. 31

ISA/IDE/FDD/parallel port (144-pin SODIMM socket) ...31

VGA/LAN/serial port/keyboard/mouse

(40-pin FPC connector)...................................................... 32

Mechanical and environmental........................................... 32

4. 3 Board layout: dimensions ............................................. 3 3

4. 4 Jumpers and connectors ............................................... 3 4

4. 5 Board layout: jumper/connector locations ................. 3 5

4. 6 Safety precautions .......................................................... 3 6

4. 7 Setting jumpers ............................................................... 3 7

4.7.1 Clear CMOS (J2) ......................................................38

4. 8 CompactFlash interface (CN2) ..................................... 3 8

4. 9 ISA/IDE/floppy drive/parallel port (CN3) ................... 3 9

4.9.1 ISA bus......................................................................42

4.9.2 IDE interface ............................................................. 46

4.9.3 Floppy drive ...............................................................48

4.9.4 Parallel port ...............................................................49

4.10 VGA/LAN/serial ports/keyboard/mouse (CN4) ........ 5 0

4.10.1 VGA interface......................................................... 51

4.10.2 Ethernet configuration .............................................52

4.10.3 Keyboard and PS/2 mouse connector .....................52

Table 4-15: PS/2 mouse connector .....................................53

4.10.4 Serial ports............................................................... 5 3

4. 11 Power supply connector (CN5) .................................... 5 5

Page 8

4.12 Card installation ............................................................. 56

4.13 Card removal .................................................................. 5 7

4.14 FPC cable installation .................................................... 5 8

Chapter 5 CPC-2520 VGA/LCD Control Board........... 59

5.1 Introduction..................................................................... 60

5.2 Specifications .................................................................. 61

General ............................................................................... 61

Mechanical and environmental........................................... 61

5. 3 Board layout: dimensions ............................................. 6 2

5. 4 Jumpers and connectors ............................................... 6 3

5. 5 Board layout: jumper/connector locations ................. 6 4

5. 6 Safety precautions .......................................................... 6 5

5.7 Jumper settings .............................................................. 6 6

5. 8 LCD panel select (SW1) ................................................ 6 7

5. 9 Display connectors (CN2, CN3) .................................. 6 7

5.10 LCD display connector (CN2) ...................................... 6 8

5. 11 VGA display connector (CN3) ...................................... 6 9

5.12 FPC cable installation .................................................... 7 1

Chapter 6 Networking Communication ...................... 73

6.1 Introduction..................................................................... 74

6. 2 Networking via LAN ...................................................... 7 4

6. 2 Networking via RS-232 ................................................. 7 6

6. 3 Simple Networking via a Hub ....................................... 7 7

Chapter A Cabling for RS-232 Port ............................. 79

Chapter B DIP Switch Settings ................................... 83

B. 1 Touchscreen Specifications .......................................... 8 4

Page 9

Figures

Figure 4-1: Board layout: jumper/connector locations ................................. 3 5

Figure 4-2: Damping resistor ....................................................................... 47

Tables

Table 4-1: Jumpers and connectors ........................................................... 34

Table 4-2: Clear CMOS (J2) ........................................................................38

Table 4-3: ISA/IDE/floppy drive/parallel port connector (CN3) ....................4 0

Table 4-4: ISA bus - CN3 cross reference table (ISA pin A) .......................4 2

Table 4-5: ISA bus - CN3 cross reference table (ISA bus pin B) ................4 3

Table 4-6: ISA bus - CN3 cross reference table (ISA bus pin C) ................44

Table 4-7: ISA bus - CN3 cross reference table (IDE pin D) ......................4 5

Table 4-8: IDE hard drive connector ............................................................46

Table 4-9: Floppy drive connector ............................................................... 48

Table 4-10: Parallel port connector ...............................................................4 9

Table 4-11: FPC connector (CN4) ................................................................. 5 0

Table 4-12: VGA interface .............................................................................. 51

Table 4-13: Ethernet configuration ................................................................ 52

Table 4-14: PS/2 keyboard connector ...........................................................5 3

Table 4-15: PS/2 mouse connector .............................................................. 53

Table 4-16: Serial port default settings .........................................................5 4

Table 4-17: COM1 RS-232 serial port connector.......................................... 54

Table 4-18: COM2 RS-232 serial port connector.......................................... 54

Table 4-19: Power supply connector (CN5) .................................................. 5 5

Table 5-1: Jumpers and connectors ........................................................... 63

Table 5-2: LCD display connector (CN2) .................................................... 6 8

Table 5-3: VGA display connector (CN3).....................................................69

Table 5-4: VGA display connector (CN3).....................................................70

Page 10

Page 11

General Information

This chapter gives background

information on the HMI-640S.

Sections include:

• Introduction

• Specifications

• LCD Specifications

• I/O Arrangement

• Total Solution

• Dimensions

• Mounting

CHAPTER

1

Page 12

1.1 Introduction

The HMI-640S meets all of the requirements necessary to serve as

an industrial operator interface. This panel PC provides an all-in-one

486 PC platform with 6.0" STN color LCD display, on-board VGA,

two COM ports (one RS-232, one RS-232/422/485), one removable

CompactFlash adapter, an external 16-bit PC/104 expansion slot and a

touchscreen. The heart of the HMI-640S is a general-purpose miniature

computer that is suitable for a variety of applications.

The HMI-640S is suitable for various industry applications, including

factory automation, automated production lines, precision machinery ,

production process control, environmental control, terminal information system and entertainment management system. HMI-640S is a

reliable, cost-effective solution to your application's processing

requirements.

The HMI-640S offers optional HMI software package, which is preinstalled on the CompactFlash card. All that user has to do is insert the

CompactFlash card into the adapter box on the machine, and turn on

the power. For more details, please contact your local Advantech

distributors or our branch office.

1.2 Specifications

General

• Construction: Plastic molding with an optional PC/104 metal

cover

• Dimensions (W x H x D): 197.5 x 142.8 x 63.4 mm

(7.76" x 5.61" x 2.49")

• Weight: 1.5 kg (3.3 lb)

Standard functions (CPC-2245N)

• CPU with core logic: STPC Client 66MHz, which is equivalent to 66

MHz 80486 CPU

• BIOS: Award 256 KB Flash BIOS

2

HMI-640S User's Manual

Page 13

• RAM: 16MB EDO RAM on board

• IDE hard disk drive interface: Supports up to two Enhanced IDE

devices, auto-detect BIOS

• Multi-mode parallel port: Configured to LPT1, LPT2, LPT3 or

disabled. Supports SPP/EPP/ECP; D-SUB 25-pin connector (on I/O

module)

• Serial ports: One serial RS-232 port, one serial RS-232/422/485 port

(configurable by DIP switches; please refer to Appendix B).

• PS/2 keyboard/mouse connector : Mini-DIN keyboard connector

• Watchdog timer: Generates a system reset at a fixed 1.6-second

interval. Watchdog timer can be enabled/disabled through software.

The Watchdog timer is disabled by default factory setting.

• External expansion slot: 104-pin connector , supports up to two

cascaded 16-bit PC/104 cards with +5 V and +12 V

• Battery: 3 V @ 195 mA Lithium battery for CMOS backup

Chapter 1 General Information

3

Page 14

Ethernet interface

• Chipset: Realtek RTL8139A 10/100 Base-T controller

• Network (LAN): Novell NE1000/2000 compatible. Supports both

boot ROM function and software drivers

SVGA/Flat panel interface (CPC-2520)

• Chipset: C&T 69000

• Display memory: 2 MB SDRAM embedded

• Hardware Windows acceleration: 32-bit graphic engine. Hardware

line drawing and 64 x 64 x 2 hardware cursor

• Resolution: 640 x 480 @ 16M colors

800 x 600 @ 16M colors

1024 x 768 @ 64K colors

Note: The resolution and hardware Windows acceleration

function of the flat panel interface is partially dependent on the resolution of the flat panel.

Power supply

• Output rating: 25 W

• Input voltage: 18 ~ 30 V

DC

• Output voltage: +5 V @ 4 A, +12 V @ 0.5 A

Environmental specifications

• Operating temperature: 0 ~ 45° C (32° ~ 113° F)

• Relative humidity: 0 ~ 95% RH (non-condensing), 40° C

• Safety: Meets UL/CSA

• FCC Class A, CE certified

• Vibration: 10 ~ 18 Hz, 1.5 mm peak-to-peak displacement

18 ~ 500 Hz, 1 G acceleration

4

HMI-640S User's Manual

Page 15

Touchscreen

• Type: Resistive

• Resolution: 1024 x 1024

• Light transmission: 75%

• Software driver:HMI-640S supports both DOS and Windows CE

• Lifetime: More than 3 million touches

1.3 LCD Specifications

M odel HM I-640S

Display type

M ax. colors or

grayscales

Size

LCD model

Resolution

Brightness

Dot size (W x H)

Viewing angle

O perating

Tem perature

LCD M TBF

Backlight M TBF

STN color LCD

256 colors

6.0"

KCB060VG 1CA-A21

or com patible

640 x 480

(V G A )

70cd/m²

0.043 x 0.169

90°

0 ~ 50° C

62,000 hours

10,000 hours

Chapter 1 General Information

5

Page 16

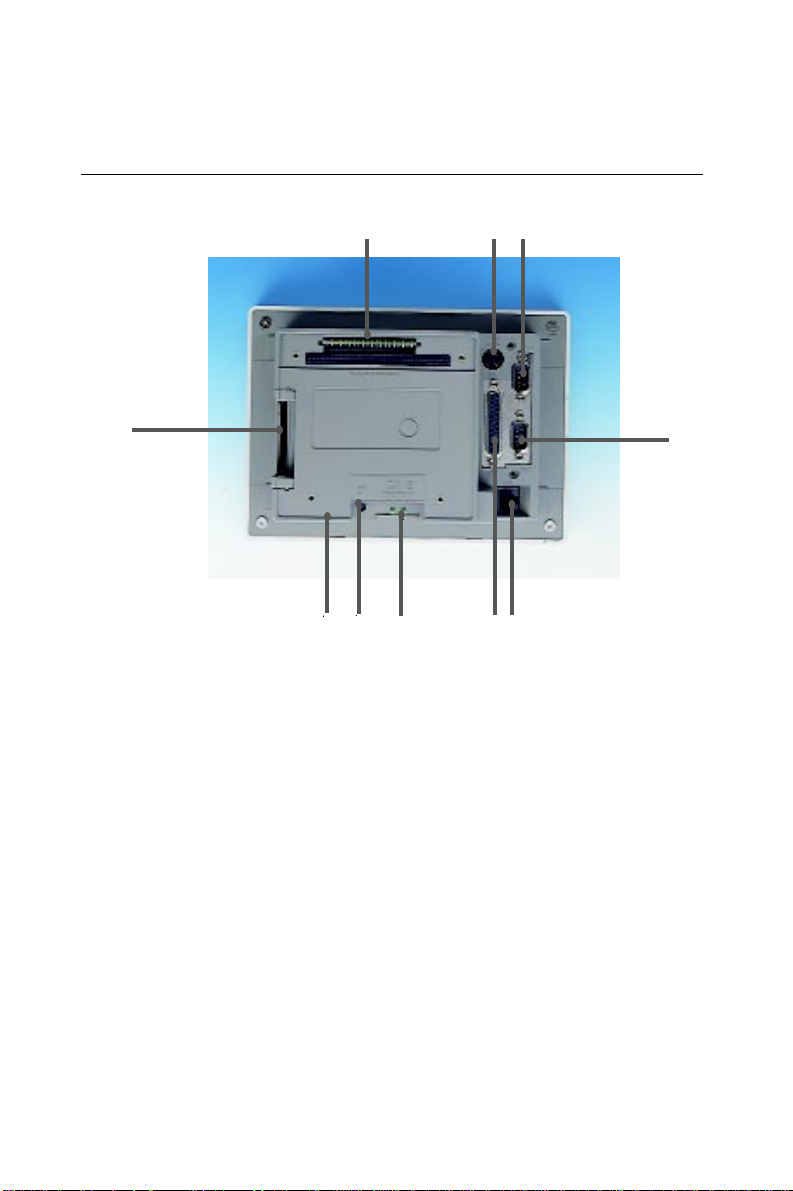

1.4 I/O Arrangement

The I/O arrangement of the HMI-640S is shown below:

b

d

c

a

i h g f

j

a. IDE connector

b. PC/104 slot

c. PS/2 keyboard and

mouse connector

d. Serial COM2 port

e. Serial COM1 port

f. Ethernet port

g. Parallel port

h. 24 VDC input connector

& chassis GND

i. LCD contrast

j. Slide power switch

Note: Serial port COM2 can be configured to operate in

RS-232, RS-422 or RS-485 mode. This is set by DIP

switches on the upper side of the back cover. Before

attaching connectors, please make sure the DIP

switch settings are correct. (See Appendix B for

COM2 port settings.)

e

6

HMI-640S User's Manual

Page 17

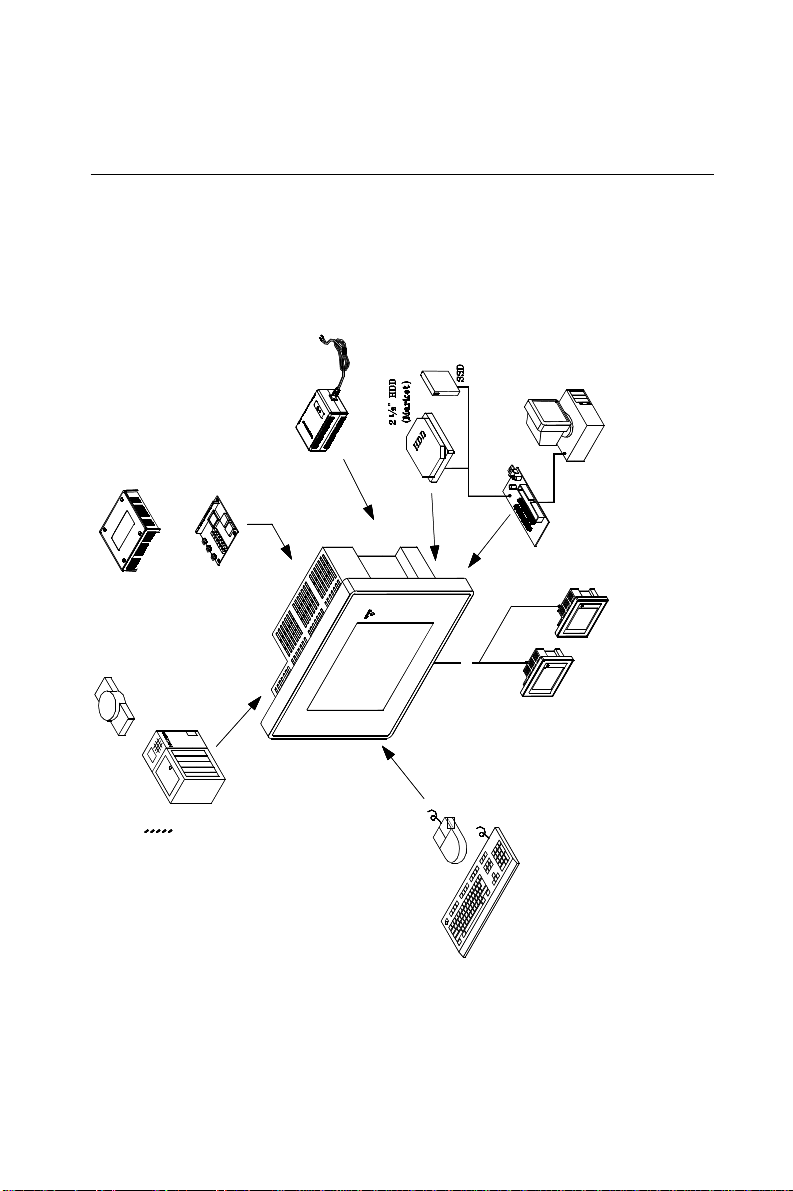

1.5 Total Solution

DC

Power Supply

Adapter

(24 V )

(Advantech)

(Advantech)

PC/104 + Cover

COM Port

(Advantech)

(Advantech)

SSD Adapter (IDE)

HMI-640S

(Advantech)

Ethernet

HMI-640S

Data Acquisition Module

(Advantech)

Industrial PC

PS/2

Mouse

(Market)

PS/2

Keyboard

Chapter 1 General Information

7

Page 18

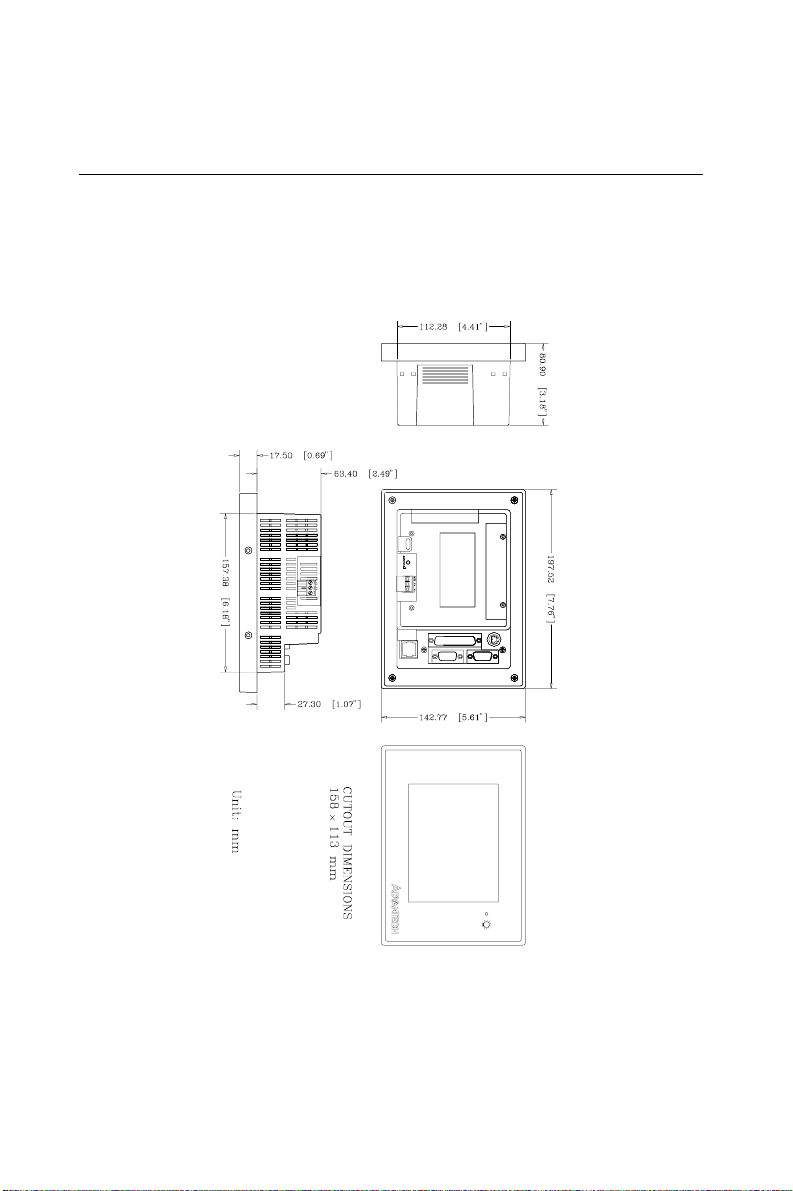

1.6 Dimensions

The HMI-640S can be placed on a shelf or a table, or mounted onto a

panel. Cutout panel dimensions are as follows:

8

HMI-640S User's Manual

Page 19

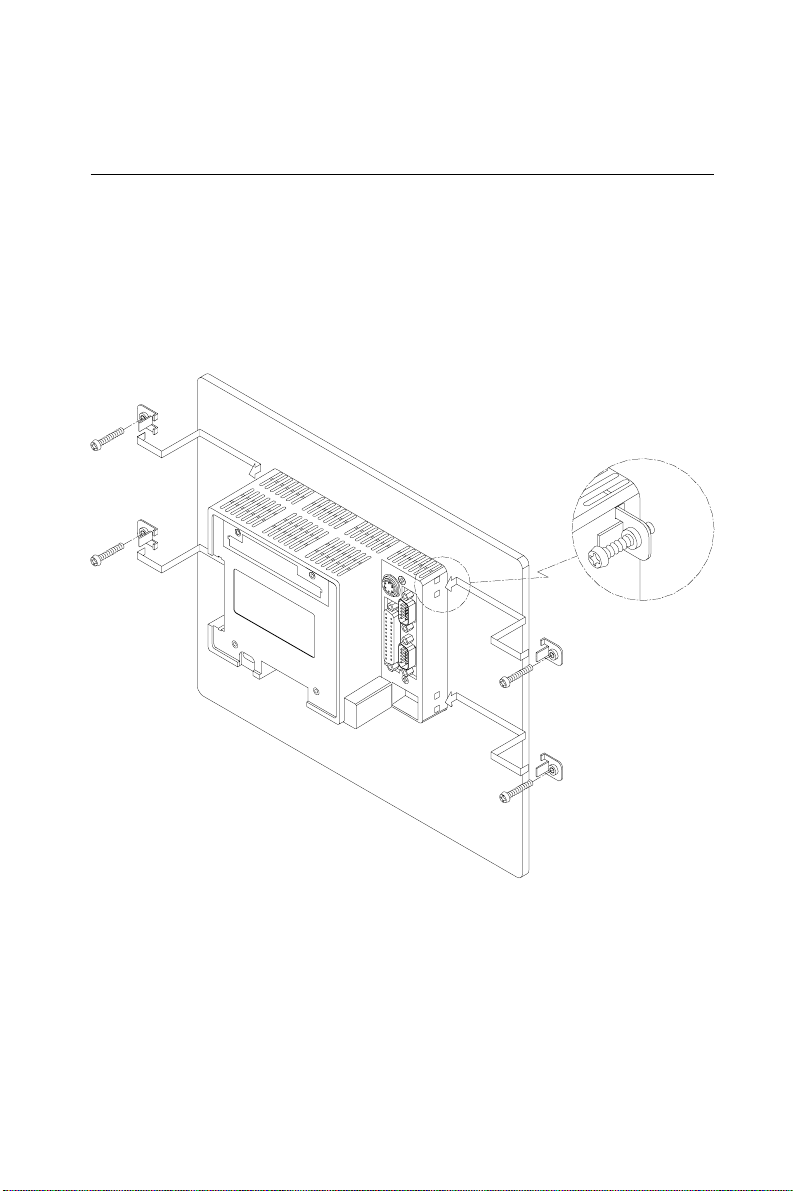

1.7 Mounting

If you want to panel mount your HMI-640S, use the four brackets that

are included within your package. First, fit the HMI-640S body onto

the cutout panel and hold it temporarily in place with your hands.

Then, insert each bracket into the four keyholes on both sides of the

HMI-640S rear case, and use appropriate screws to fix the HMI-640S

body on the cutout panel.

Chapter 1 General Information

9

Page 20

10

HMI-640S User's Manual

Page 21

CHAPTER

2

System Setup

This chapter explains how to set up the HMI640S hardware.

Sections include:

• General

• Packing List

• Initial Setup

• Installing a CompactFlash memory card

• Connecting the Power Adapter

• Installing a PC/104 Module

• First System Boot

• Exploded Diagram

Page 22

2.1 General

The HMI-640S compact profile panel PC can simultaneously monitor

and sample the data from several traditional PLC controllers. It takes

full advantage of a wide range of available software programs, and its

upgrade can be performed both quickly and easily with the replacement of various optional modules.

The HMI-640S is easily customizable to fulfill your needs. The power

supply and I/O adapter are all readily accessible by removing the front

or rear panel.

Warning! Verify that power source has been disconnected

from the HMI-640S before you install any of its

components or accessories. Note that no power

source should be attached to the HMI-640S during

any hardware installation or servicing.

2.2 Packing List

When you first receive your HMI-640S package, please check the

packing list below to make sure you have all the necessary items that

should come with your package:

q HMI-640S compact panel PC

q CompactFlash adapter box

q Power adapter

q User's Manual

q Service CD

q DB-9 null modem cable

q Accessory pack

If you have purchased additional software options, you should have

optional items such as:

q 16 MB CompactFlash card pre-installed with specific software

q End User License Agreement (EULA) for W indows CE

12

HMI-640S User's Manual

Page 23

2.3 Initial Setup

The HMI-640S offers an easy setup feature: It takes merely 3 easy

steps for your initial setup before use. Simply take out the HMI-640S

from it's package and follow the steps below for a quick initial setup:

Step 1: Insert CompactFlash memory card (with Windows CE and/or

specific application software inside) into the appropriate bus

slot.

Step 2: Connect the power adapter cord to HMI-640S and plug the

other end of the cord into the power outlet.

Step 3: Turn the sytem power on for the first boot.

Warning! Before installing the serial por t mouse driver, you

must remove the PS/2 mouse driver from your

system.

Note: The PS/2 mouse driver cannot be simultaneously

installed with a serial/COM port mouse driver.

Note: It might be possible that you may see several light or

dark dots on the LCD panel while system powers up.

These minor imperfections actually originate from the

LCD panel manufacturing process and will not affect

the normal operation of your system in any way.

Chapter 2 System Setup

13

Page 24

2.3 Installing a CompactFlash Memory Card

Installing a CompactFlash adapter

1 . V erify that the power source to the HMI-640S has been properly

disconnected.

2 . Insert the CompactFlash adapter frimly but gently into the IDE-

compatible slot as shown in the picture below .

3 . Make sure your CompactFlash memory card is inserted properly

into place.

14

HMI-640S User's Manual

Page 25

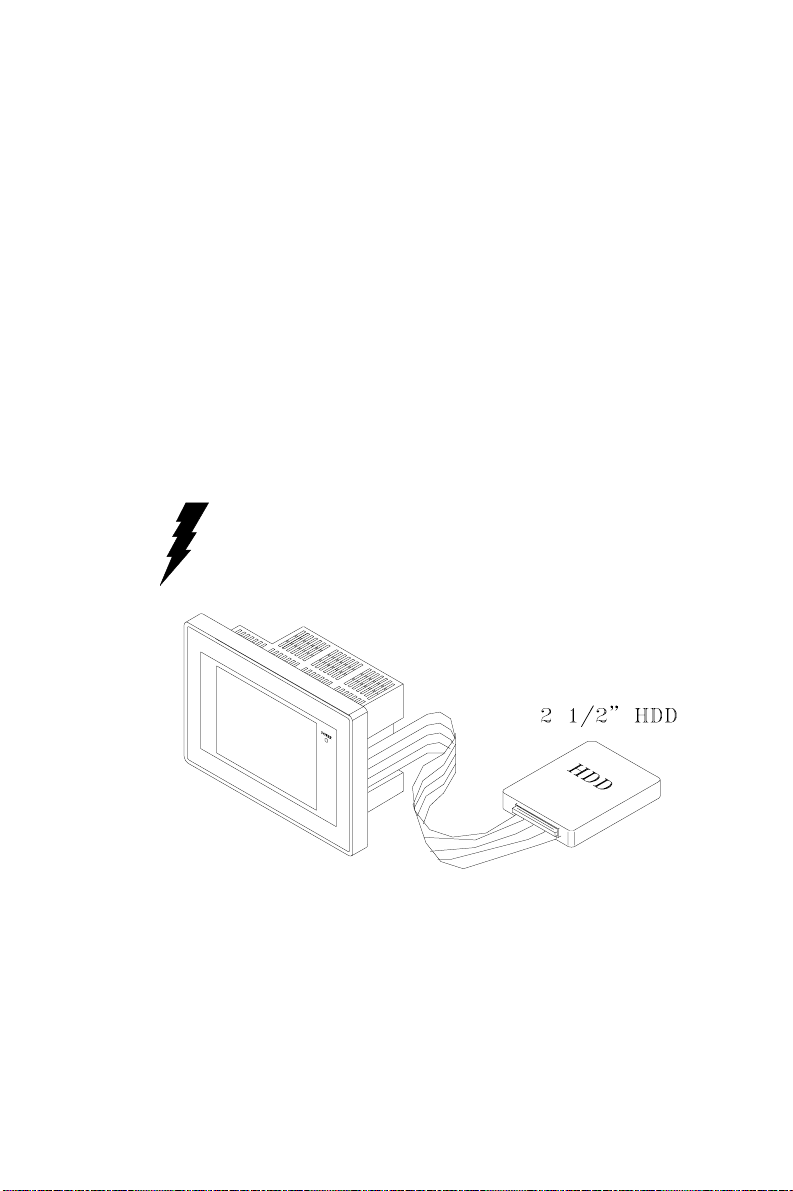

Installing a 2.5" HDD

HMI-640S is designed as a HDD-less platform of a high reliability .

However, if a HDD should be used, its installation procedure is

described as follows:

1 . V erify that the power source to the HMI-640S has been properly

disconnected.

2 . Connect the HDD via a cable to the IDE-compatible slot on the

HMI-640S. Make sure that you have inserted the cable connector

properly into the slot.

Warning! When connecting the cable to the HDD, make sure

that pin 1 on the cable is connected to pin 1 on the

connector of the HDD. Faulty or wrong connection

might damage your HDD.

Chapter 2 System Setup

15

Page 26

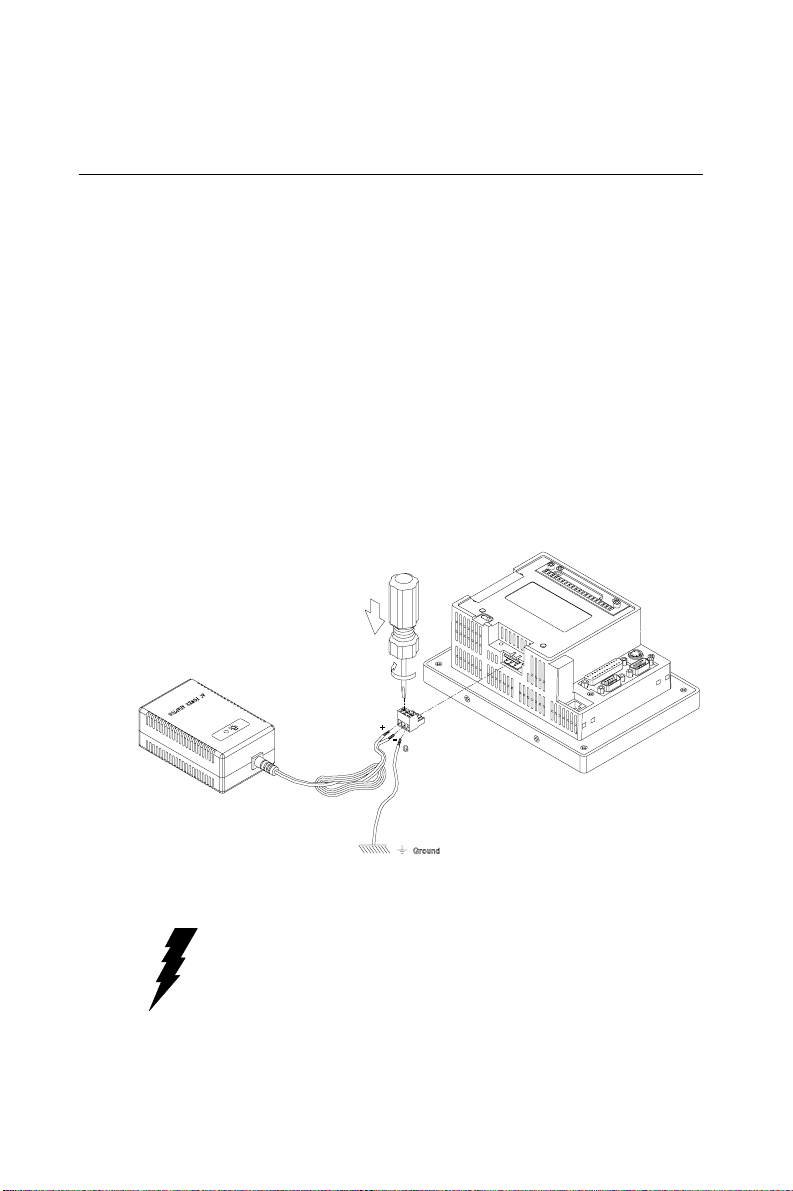

2.4 Connecting the Power Adapter

Before connecting the power adapter to your HMI-640S, you must first

attach the Power T erminal Block onto the 24 VDC power receptable

located beneath the HMI-640S. After the Power T erminal Block has

been attached, you can then connect the power adapter to the Power

T erminal Block to provide power supplies to your HMI-640S.

To connect the power adapter:

1 . Identify each wire of the power adapter cord (you must first make

sure which is +, - or GND specifically).

2 . Unscrew the screws on the power terminal. Insert each wire of the

power adapter cord specifically into its designated connector hole

(+, - and GND) on the Power T erminal Block. Fasten the screws to

secure wires in the connector holes.

Warning! Avoid shorting any bare wires since it may cause

damages to your system or device.

16

HMI-640S User's Manual

Page 27

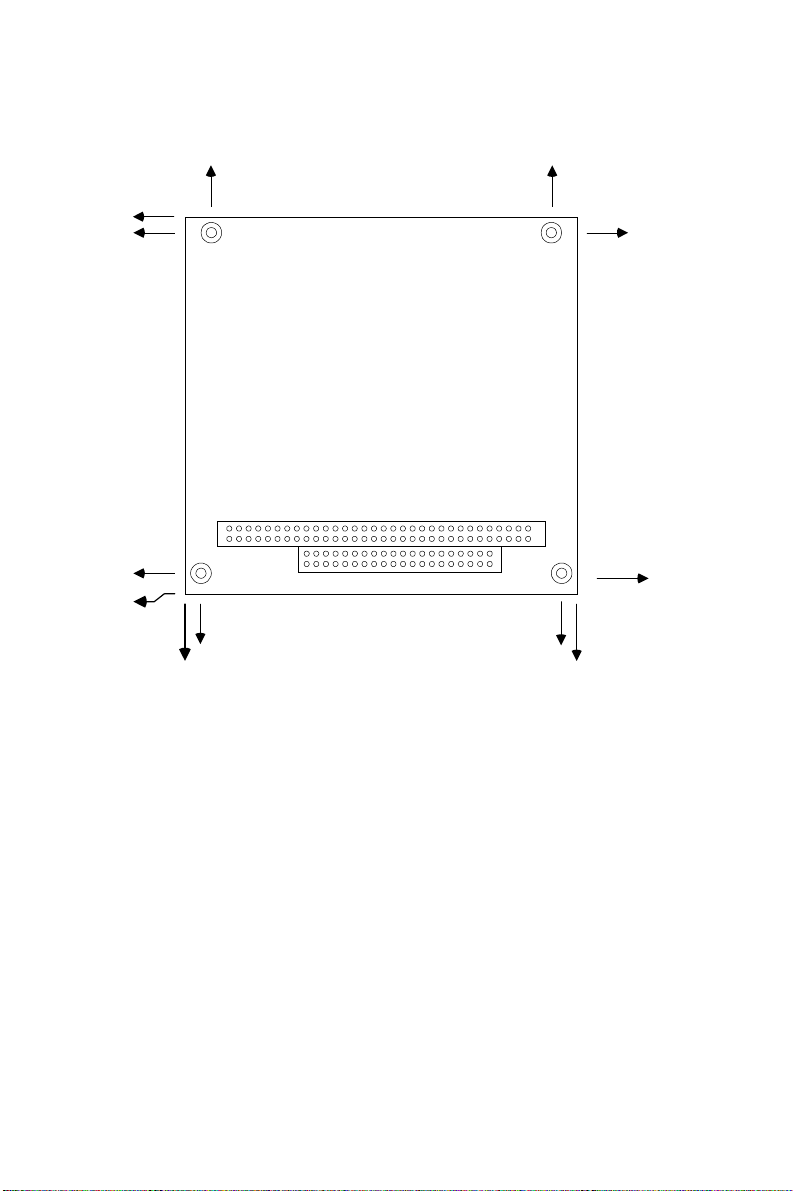

2.5 Installing a PC/104 Module

The HMI-640S's PC/104 connector gives you the flexibility to attach to

the PC/104 expansion modules, which perform same functions as

traditional plug-in expansion cards. Using these modules might save

you space and valuable slots.

T o install a PC/104 module:

1 . V erify that the power source to the HMI-640S has been properly

disconnected.

2 . Detach the metal cover on the rear panel.

3 . Plug the PC/104 module's male connectors into ISA expansion slot's

female connectors by pressing the module firmly with caution.

4 . Secure the two PC/104 modules onto the HMI-640S.

5 . Replace the PC/104 cover.

Chapter 2 System Setup

17

Page 28

88.9

82.6

95.9

90.8

5.1

90.8

5.1

0

5.1

0

85.1

90.2

PC/104 module dimensions (mm ±5 %)

18

HMI-640S User's Manual

Page 29

2.6 First System Boot

After you have properly installed the CompactFlash memory card preinstalled with Windows CE or even with specific application software ,

all you have to do is simply plug in the power and the system is ready

for the first boot.

Power up for the first time

Please follow the steps below to perform your first system boot :

1. Turn on the power switch. Meanwhile, the Power LED on the front

panel will light up.

2. The Windows CE operating system starts to boot from the CompactFlash memory .

3. W ait for a while for Windows CE to complete its fist startup.

Assign the Device Name

After you have successfully booted for the first time, you can now

assign a Device Name to your HMI-640S for network identification.

Follow the instructions below to assign the Device Name:

1. First Click Start/Settings/Control Panel/Communication Proper-

ties to access the Communication Properties page.

2. Select the Device Name tab on the properties page, and assign a

Device Name to your HMI-640S. The Device Name is what comes to

distinguishe your HMI-640S within the network environment.

3. Click Ok to accept the Device Name setting.

4. Reboot your system to make your Device Name effective on the

network.

After you have assigned a Device Name to your HMI-640S on the

network, you can proceed futher with other configurations or installation procedures if need be.

Chapter 2 System Setup

19

Page 30

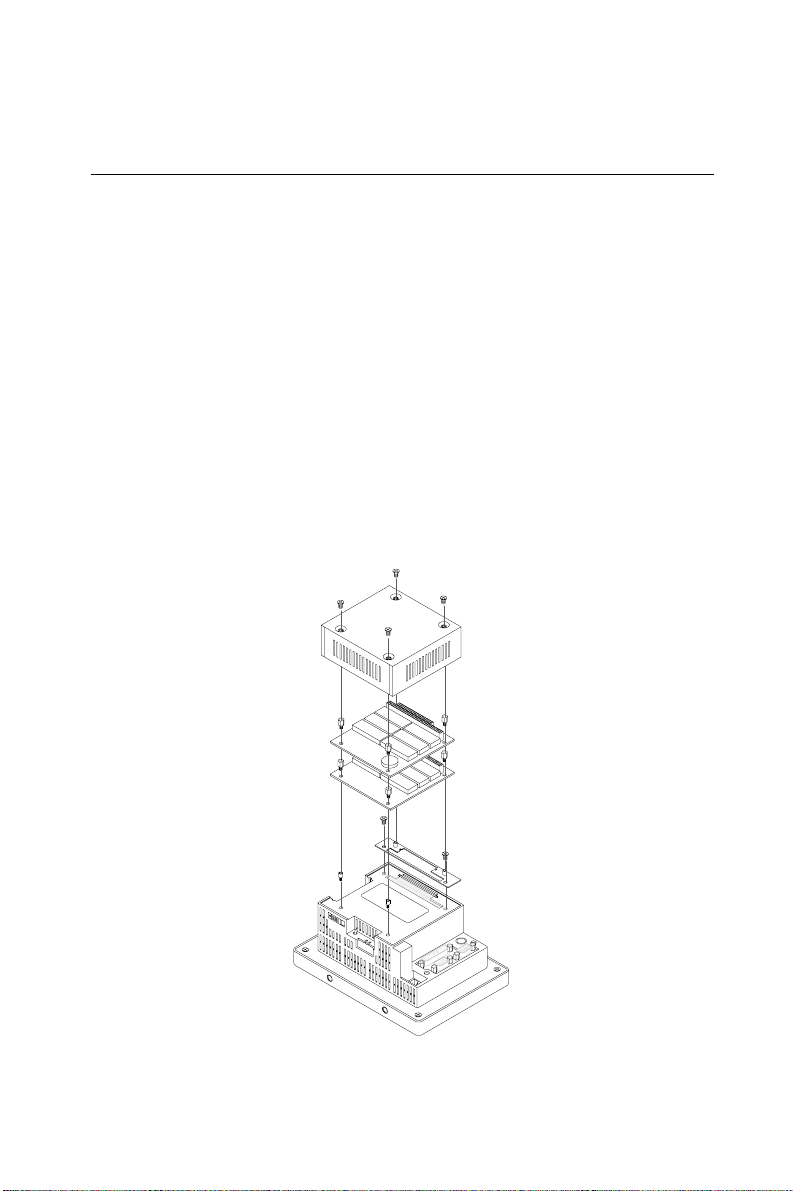

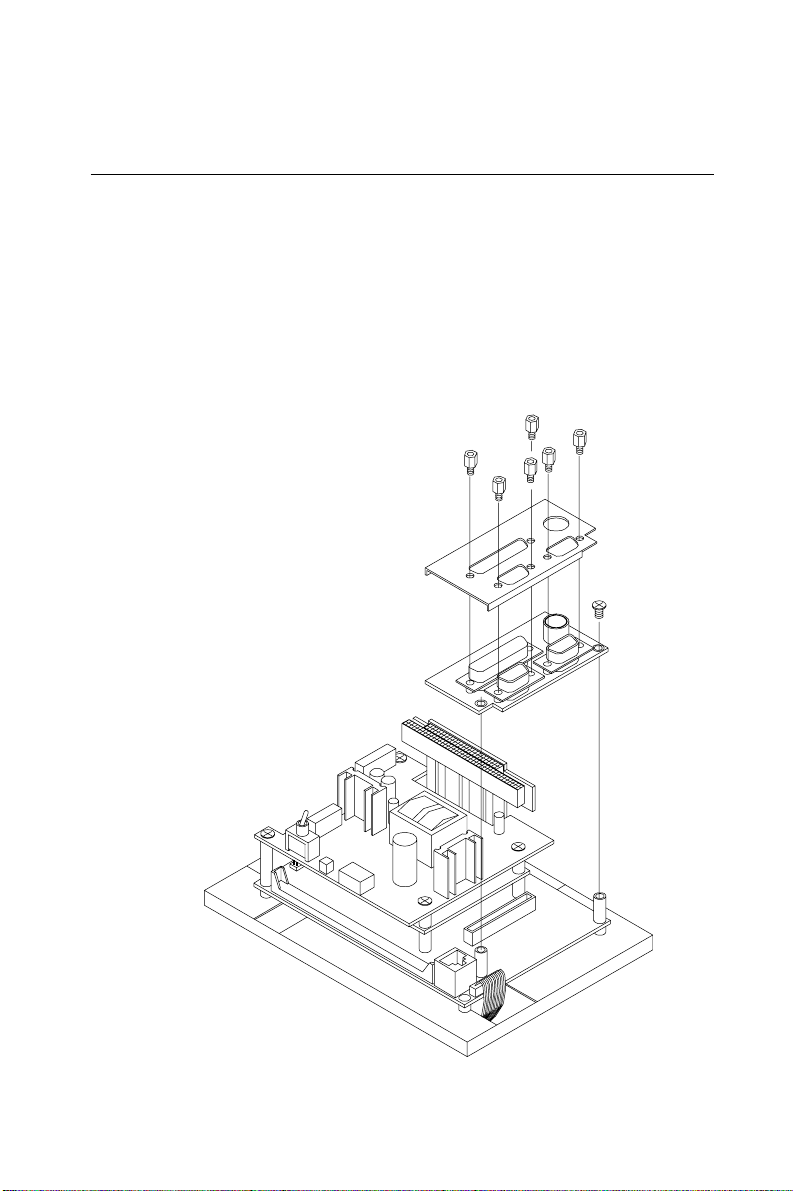

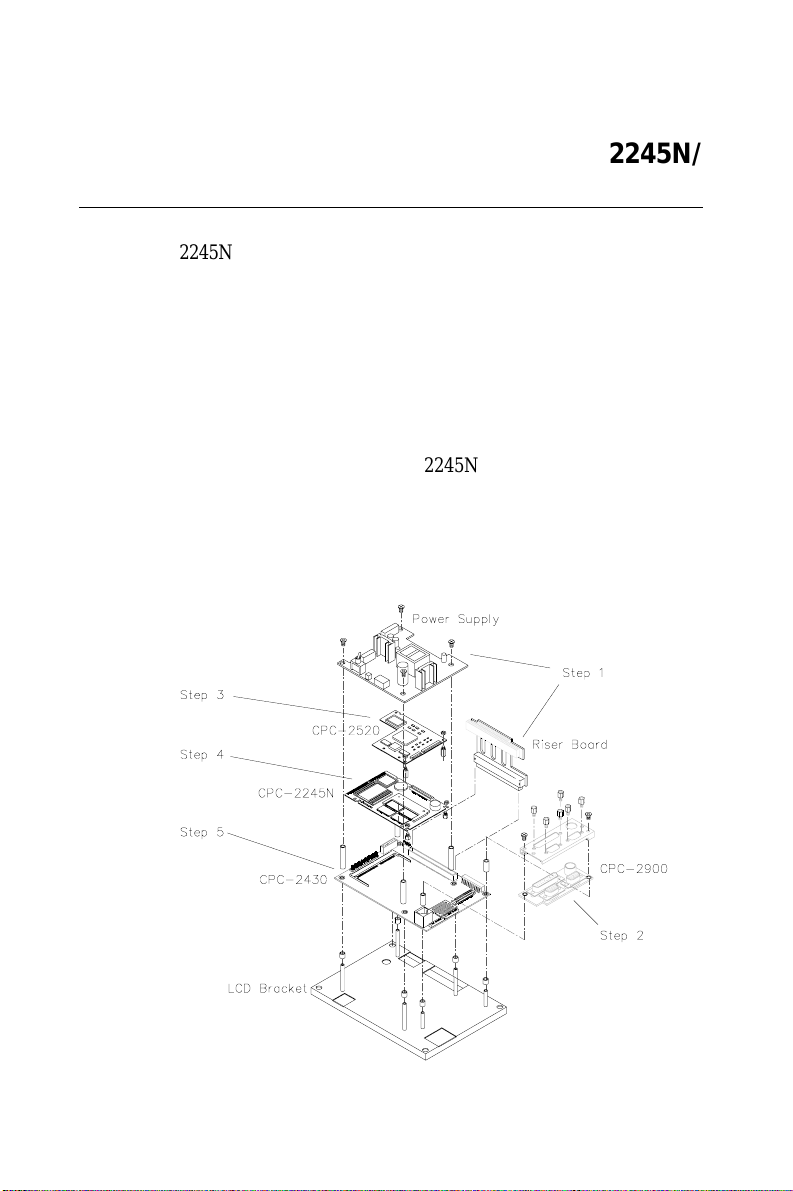

2.7 Exploded Diagram

The following exploded diagram is provided to help with assembly or

disassembly of the HMI-640S.

20

HMI-640S User's Manual

Page 31

CHAPTER

3

Maintenance

The HMI-640S is of a modular design so

that it is convenient for users to maintain

or service its internal components. This

chapter will describe the disassembling

process for the machine.

Sections include:

• Removing the Front/Rear Panel

• LCD Display

• LCD Backlight

• Power Supply

• I/O Adapter (CPC-2900)

• Core of HMI-640S (CPC-2520/-2245N/-2430)

Page 32

The HMI-640S is of a modular design so that it is convenient for users

to maintain or service its internal components. This chapter will

describe the disassembling process for the machine. The Service CD

bundled in the HMI-640S package provides even more details for your

reference.

3.1 Removing the Front/Rear Panel

Y ou need only to remove the front panel of your HMI-640S to replace

its LCD or backlight. To remove the front panel, first verify the power

source to the HMI-640S has been disconnected. Next, remove the two

screws found on the underside of the front panel. Pinch a corner of the

front panel up with one hand, and then pull the other corner of the

front panel firmly outward to remove the front panel.

22

HMI-640S User's Manual

Page 33

You need only to remove the rear panel to replace the DRAM, power

supply, I/O adapter, and certain components. To remove the rear panel,

first verify that the power source to the HMI-640S has been disconnected. Then remove the six screws on the rear panel and pull it away

from the HMI-640S main body.

Chapter 3 Maintenance

23

Page 34

3.2 LCD Display

The LCD display rarely needs replacing during normal life span of the

HMI-640S.

Howerver, if you should need to replace the LCD display , please follow

the procedure below:

1 . Verify that the power source to the HMI-640S has been disconnect-

ed.

2 . Open the front panel. (See Section 3.1.)

3 . Remove the LCD from the steel chassis by first removing the four

screws.

4 . Disconnect the cable from the LCD (marked "A" in the diagram

below) and the LCD inverter (marked "B").

24

HMI-640S User's Manual

Page 35

3.3 LCD Backlight

T o replace the backlight:

1 . Verify that the power source to the HMI-640S has been disconnect-

ed.

2 . Open the front panel. (See Section 3.1.)

3 . Remove the LCD from the steel chassis.

4 . Disconnect the cables from the LCD and the LCD inverter.

5 . Remove the screw that attaches the LCD backlight to the LCD

display . Pull the backlight out horizontally .

6. To insert the backlight and reassemble the unit, just reverse the

steps of the above procedure.

Warning: The backlight is fragile. Use caution when handling

or replacing it. It is recommended that the backlight

repair or replacement should be done by qualified

service personnel only.

Chapter 3 Maintenance

25

Page 36

3.4 Power Supply

T o repair or replace the power supply:

1 . Verify that the power source to the HMI-640S has been disconnect-

ed.

2 . Open the rear cover. (See Section 3.1)

3. Remove the four screws attaching the power supply to the CPU

board.

4. Disconnect the cable from the power supply.

5. Replace the power supply and reassemble.

Warning: Shut off power to the HMI-640S before attempting to

repair the power supply. Simply switch off the power

and unplug the unit.

26

HMI-640S User's Manual

Page 37

3.5 I/O Adapter (CPC-2900)

T o replace or service the I/O adapter, follow these steps:

1 . Verify that the power source to the HMI-640S has been disconnect-

ed.

2 . Remove the rear cover. (See Section 3.1.)

3 . Remove the screw which attaches the I/O adapter to the Carrier

Board.

4 . Replace the I/O adapter and reassemble the HMI-640S.

Chapter 3 Maintenance

27

Page 38

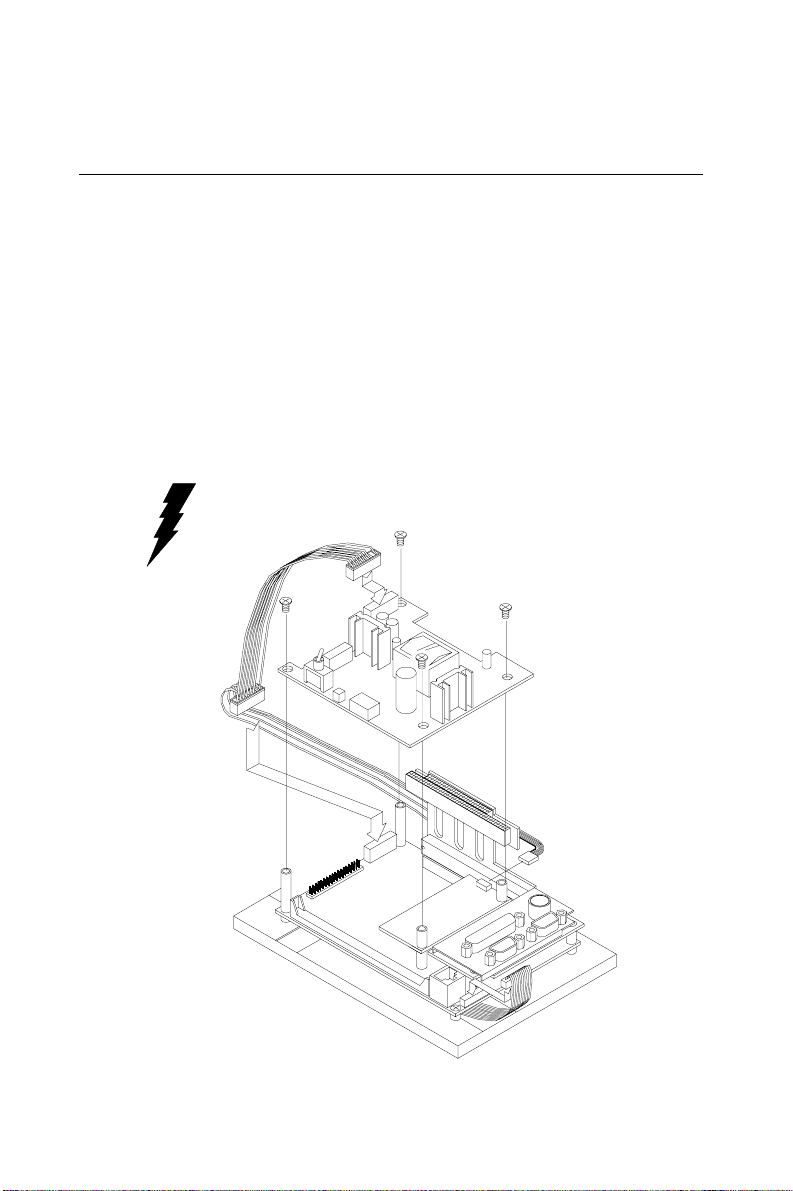

3.6 Core of HMI-640S (CPC-2520/CPC-2245N/

CPC-2430)

The core of HMI-640S consists of CPC-2520 VGA/LCD control board,

CPC-2245N main board and CPC-2430 carrier board. After removing

power supply and I/O board as mentioned in previous sections, you

can disassemble the other boards by the following steps:

1 . T ake off the riser board as you remove the power supply.

2 . Take off the CPC-2900 I/O board as mentioned in last section.

3 . Loosen the two nuts on the CPC-2520 VGA/LCD control board, and

remove it from the main board beneath.

4 . Loosen the two nuts on the CPC-2245N main board. Pull the two

SO-DIMM latches outward, then the main board can be released

from the SO-DIMM connector.

5 . When all the boards above are removed, you can take off the CPC-

2430 carrier board with ease.

28

HMI-640S User's Manual

Page 39

4

CHAPTER

CPC-2245N Main Board

This chapter provides:

• Background information such as card

specification and board layout of CPC-

2245N.

• The installation procedures for CPC-

2245N hardware, including instructions on

setting jumpers and connecting peripherals, switches and indicators. Be sure to

read all safety precautions before you

begin the installation procedure.

Page 40

4.1 Introduction

Advantech’s new mini biscuit PC, the CPC-2245N, is truly an all-in

one 486 processor-based single board computer. It comes equipped

with 16 MB DRAM on board, an SVGA interface which supports

CRT monitors with up to 4 MB display memory , a 10/100Base-T

Ethernet interface, and a CompactFlash solid state-disk socket. In

addition, it is equipped with two RS-232 serial ports, one bidirectional printer port which supports SPP , ECP and EPP modes, an IDE

HDD interface, a floppy disk controller, as well as one ISA interface

for functional expansion. With its industrial grade reliability , the

CPC-2245N can operate continuously at temperatures up to 60º C

(140º F). This compact unit offers all these functions within the

space of a 2.5" hard disk drive (68 x 100 mm). All these numerous

features provide an ideal price/performance solution for commercial

and industrial applications where stability and reliability are

essential.

The CPC-2245N mini biscuit PC’s power can be supplied through a

SODIMM socket or an on-board power connector. Thus, the

CPC-2245N can be embedded into the user’s system board, or used

as a single board application. The ISA bus, HDD, FDD and parallel

interface are connected to the user’s system board via a SODIMM

socket. This form factor has the benefits of easy maintenance. A

damaged card can be replaced within 30 seconds. Furthermore, the

mini biscuit PC is easily upgraded from 486 to Pentium® without the

need to change the user’s system board.

The CPC-2245N provides many useful functions in a tiny card. It

reserves a small PCI connector for other extension modules, such

as the CPC-2520 VGA/LCD module. It provides more flexible

functions to satisfy all users' different application requirements.

The CPC-2245N is small-sized, highly integrated, easy to maintain,

easy to upgrade, and easy to install. These features make it ideal for

applications such as small industrial controllers, panel PCs,

security systems, Internet gateways, instruments, medical

equipment, building automation, and so on.

30 HMI-640S User's Manual

Page 41

4.2 Specifications

• CPU: STPC Client, 66 MHz

• On-card cache: 8 KB

• BIOS: 256 KB Flash BIOS

• Chipset: STPC Client

• Super I/O chipset: Winbond W83977F

• RAM memory: 16 MB EDO RAM on board

• Solid state disk: Supports one CompactFlash card as an

emulated HDD

• Watchdog timer: 1.6 sec. intervals

ISA/IDE/FDD/parallel port (144-pin SODIMM

socket)

• I/O expansion: 16-bit A T-bus

• Enhanced IDE hard disk drive interface: Supports up to two

hard disk drives. BIOS auto-detect

• Floppy disk drive interface/multi-mode parallel port: FDD

interface and parallel port share the same connector. The FDD

and/or parallel port can be switched in BIOS setup

-FDD interface supports up to two floppy disk drives, 5.25"

(360 KB and 1.2 MB) and/or 3.5" (720 KB, 1.44 MB and 2.88

MB)

-Parallel supports SPP , ECP and EPP

Chapter 4 CPC-2245N Main Borad 31

Page 42

VGA/LAN/serial port/keyboard/mouse (40-pin FPC

connector)

• VGA with 64-bit windows accelerator

-Display memory: 4 MB share memory architecture (UMA

structure)

-Display resolution: 1280 x 1024 @ 64 K colors, 1024 x 768 @

16 M colors

-Automatically disables internal VGA if an external add-in VGA

is plugged into the system

• 10/100Base-T Ethernet interface

-Chipset: RTL-8139A PCI local bus Ethernet controller

-Ethernet interface: IEEE 802.3U compatible 100/10Base-T

interface

• Serial ports: T wo RS-232 serial ports

• Keyboard and PS/2 mouse: Supports standard PC/AT keyboard

and PS/2 mouse

• Power connector: 4-pin mini power connector

Mechanical and environmental

• Power supply voltage: +5 V (4.75 ~ 5.25 V)

• Max. power requirements: +5 V @ 1.5 A

• Operating temperature: 0 ~ 60° C (32 ~ 140° F)

• Board size: 68 x 100 mm

• Weight: 0.05 kg (0.1 1 lb)

32 HMI-640S User's Manual

Page 43

4.3 Board layout: dimensions

Chapter 4 CPC-2245N Main Borad 33

Page 44

4.4 Jumpers and connectors

On-board connectors link to external devices such as hard disk

drives, keyboards, floppy drives, and so on. In addition, the board

has jumpers for configuring your board for specific applications.

The table below lists the function of each of the board’s jumpers

and connectors. Later sections in this chapter give detailed

information on each jumper setting, and instructions for connecting

external devices to your card.

T able 4-1: Jumpers and connectors

Name Function

CN1 PCI connector

CN2 CompactFlash socket

CN3 SODIMM gold finger (ISA/HDD/FDD/parallel/power)

CN4 I/O connector (LAN/VGA/RS-232/KB/mouse)

CN5 Power connector

J 2 Clear CMOS

J 3 Fan connector (reserved)

34 HMI-640S User's Manual

Page 45

4.5 Board layout: jumper/connector

locations

Figure 4-1: Board layout: jumper/connector locations

Chapter 4 CPC-2245N Main Borad 35

Page 46

4.6 Safety precautions

Warning! Always completely disconnect the power cord from

your chassis whenever you are working on it. Do

not make connections while the power is on

because sensitive electronic components can be

damaged by the sudden rush of power. Only

experienced electronics personnel should open

the PC chassis.

Caution! Always ground yourself to remove any static

charge before touching the CPU card. Modern

electronic devices are very sensitive to static

electric charges. Use a grounding wrist strap at all

times. Place all electronic components on a

static-dissipative surface or in a static-shielded

bag when they are not in the chassis.

36 HMI-640S User's Manual

Page 47

4.7 Setting jumpers

You may configure your card to match the needs of your application by setting jumpers. A jumper is the simplest kind of electrical

switch. It consists of two metal pins and a small metal clip (often

protected by a plastic cover) that slides over the pins to connect

them. T o "close" a jumper, you connect the pins with the clip. To

"open” a jumper, you remove the clip. Sometimes a jumper will have

three pins, labeled 1, 2 and 3. In this case you would connect either

pins 1 and 2, or 2 and 3.

1

Closed 2-3Open Closed

The jumper settings are schematically depicted in this manual as

follows:

1 2 3

Closed 2-3Open Closed

A pair of needle-nose pliers may be helpful when working with

jumpers.

3

2

If you have any doubts about the best hardware configuration for

your application, contact your local distributor or sales representative before you make any changes.

Generally, you simply need a standard cable to make most connections.

Chapter 4 CPC-2245N Main Borad 37

Page 48

4.7.1 Clear CMOS (J2)

This jumper is used to erase CMOS data and reset system BIOS

information.

The procedure for clearing CMOS is:

1. Turn off the system.

2 . Short pin 2 and pin 3.

3 . Turn on the system. The CMOS is now cleared.

4 . Turn off the system. Short pin 1 and pin 2.

5 . Turn on the system. The BIOS is now reset to its default

setting.

T able 4-2: Clear CMOS (J2)

Function 1-2 2-3

Protect* Closed Open

Clear CMOS Open Closed

* default setting

4.8 CompactFlash interface (CN2)

This socket accepts an IDE-compatible CompactFlash memory

card.

The CompactFlash interface uses a primary IDE channel, which

should be set as the master channel.

38 HMI-640S User's Manual

Page 49

4.9 ISA/IDE/floppy drive/parallel port

(CN3)

The CPC-2245N provides a +5 V 16-bit ISA bus, one IDE channel

(support two IDE devices), one parallel interface and one floppy

interface (support two floppy drives). All these are provided via a

144-pin SODIMM gold finger (CN3), which can be plugged into a

DODIMM socket on the user's system board. Users can choose

suitable positions on their system board for their HDD, FDD or

parallel connectors.

The floppy interface and parallel interface share the same pin

assignment, so they cannot be used simultaneously. Users can

select either an FDD or parallel port, by referring to their BIOS

setup manual.

Chapter 4 CPC-2245N Main Borad 39

Page 50

T able 4-3: ISA/IDE/floppy drive/parallel port connector (CN3)

Pin Signal Bus Pin Signal Bus

1 +5 V POWER 7 3 +5 V POWER

2 ZW IS A 7 4 RESET IDE

3 SA18 ISA 75 RSTDRV I S A

4 SA19 ISA 76 IRQ3 IS A

5 +5 V POWER 7 7 GND POWER

6 +5 V POWER 7 8 DACK7 IS A

7 +5 V POWER 7 9 DACK6 IS A

8 TC ISA 80 DACK5 ISA

9 GND POWER 8 1 DACK3 I SA

1 0 G ND POWER 82 DACK2 I S A

11 GN D POWER 83 DACK1 IS A

1 2 G ND POWER 84 DACK0 I S A

1 3 G ND POWER 85 HDCS0 IDE

1 4 G ND POWER 86 HDCS1 IDE

1 5 G ND POWER 87 GN D POWER

1 6 G ND POWER 88 IRQ7 ISA

17 IRQ6 IS A 89 IRQ9 ISA

18 IRQ5 IS A 90 IRQ10 IS A

19 IRQ4 IS A 91 IRQ11 IS A

20 SA10 IS A 92 SA1 1 ISA

21 SA9 ISA 93 SA8 ISA

22 SA14 IS A 94 SA13 I SA

23 SA17 IS A 95 SA16 I SA

24 SA12 IS A 96 SA15 I SA

25 IRQ12 IS A 97 IRQ15 I SA

26 SYSCLK ISA 98 IRQ14 IS A

2 7 DRQ3 IS A 99 DRQ2 I S A

28 OSC (14 MHz) ISA 100 DRQ5 I SA

2 9 DRQ1 IS A 101 DRQ6 I SA

3 0 DRQ0 IS A 102 DRQ7 I SA

31 HDACK IDE 103 HDDRQ IDE

32 HDIOW IDE 104 HDIRQ IDE

33 LA17 ISA 105 HDIOR IDE

34 LA19 ISA 106 LA20 ISA

35 LA22 ISA 107 LA18 ISA

40 HMI-640S User's Manual

Page 51

36 SA0 ISA 108 LA21 ISA

37 LA23 ISA 109 SA1 ISA

38 SA2 ISA 110 SA4 ISA

39 SA6 ISA 111 SA3 ISA

40 HDD0 IDE 112 SA7 ISA

41 HDD8 IDE 113 SA5 ISA

42 HDD2 IDE 114 HDD11 IDE

43 HDD1 IDE 115 HDD3 IDE

44 HDD6 IDE 116 HDD5 IDE

45 HDD10 IDE 117 HDD4 IDE

46 HDD7 IDE 118 HDD9 IDE

47 HDD14 IDE 119 HDD15 IDE

48 HDD13 IDE 120 HDD12 IDE

49 SD8 ISA 121 SD0 ISA

50 SD10 ISA 122 SD2 ISA

51 SD11 ISA 123 SD3 ISA

52 SD9 ISA 124 SD4 ISA

53 SD14 ISA 125 SD1 ISA

54 SD13 ISA 126 SD6 ISA

55 SD12 ISA 127 SD7 ISA

56 BALE ISA 128 SD5 ISA

57 SD15 ISA 129 IOCHRDY ISA

58 SMEMR ISA 130 MEMW ISA

59 SBHE ISA 131 IOR ISA

60 MEMR ISA 132 MASTER ISA

61 IOCS16 ISA 133 SMEMW ISA

62 IOCHCK ISA 134 MEMCS16 ISA

63 REFRESH ISA 135 IOW ISA

64 ACK PRT 136 AEN ISA

65 PE PRT 137 BUSY PRT

66 PD6 PRT 138 PD5 PRT

67 PD4 PRT 139 PD3 PRT

68 PD2 PRT 140 PD1 PRT

69 PD0 PRT 141 AUTOFD PRT

70 STROBE PRT 142 ERR PRT

71 INIT PRT 143 PD7 PRT

72 SLCTIN PRT 144 SLCT PRT

Chapter 4 CPC-2245N Main Borad 41

Page 52

4.9.1 ISA bus

T able 4-4: ISA bus - CN3 cross reference table (ISA pin A)

ISA bus CN3

Pin Signal Pin Signal

A 1 I/O CHCK 62 IOCHCK

A2 SD7 127 SD7

A3 SD6 126 SD6

A4 SD5 128 SD5

A5 SD4 124 SD4

A6 SD3 123 SD3

A7 SD2 122 SD2

A8 SD1 125 SD1

A9 SD0 121 SD0

A10 I/OCHRDY 129 IOCHRDY

A11 AEN 136 AEN

A12 SA19 4 SA19

A13 SA18 3 SA18

A14 SA17 23 SA17

A15 SA16 95 SA16

A16 SA15 96 SA15

A17 SA14 22 SA14

A18 SA13 94 SA13

A19 SA12 24 SA12

A20 SA11 92 SA1 1

A21 SA10 20 SA10

A22 SA9 21 SA9

A23 SA8 93 SA8

A24 SA7 112 SA7

A25 SA6 39 SA6

A26 SA5 113 SA5

A27 SA4 110 SA4

A28 SA3 111 SA3

A29 SA2 38 SA2

A30 SA1 109 SA1

A31 SA0 36 SA0

42 HMI-640S User's Manual

Page 53

T able 4-5: ISA bus - CN3 cross reference table (ISA bus pin B)

ISA bus CN3

Pin Signal Pin Signal

B1 GND 9 GND

B2 RSTDRV 75 RSTDRV

B3 +5 V 1 +5 V

B4 IRQ9 89 IRQ9

B5 -5 V - B6 DRQ2 99 DRQ2

B7 -12 V - B8 0 WS 2 ZW

B9 +12 V - B10 GND 10 GND

B11 SMEMW 133 SMEMW

B12 SMEMR 58 SMEMR

B13 IOW 135 IOW

B14 IOR 131 IOR

B15 DACK3 81 DACK3

B16 DRQ3 27 DRQ3

B17 DACK1 83 DACK1

B18 DRQ1 29 DRQ1

B19 REFRESH 63 REFRESH

B20 CLK 26 SYSCLK

B21 IRQ7 88 IRQ7

B22 IRQ6 17 IRQ6

B23 IRQ5 18 IRQ5

B24 IRQ4 19 IRQ4

B25 IRQ3 76 IRQ3

B26 DACK2 82 DACK2

B27 T/C 8 TC

B28 BALE 56 BALE

B29 +5 V 73 +5 V

B30 OSC 28 OSC (14 MHz)

B31 GND 11 GND

Chapter 4 CPC-2245N Main Borad 43

Page 54

T able 4-6: ISA bus - CN3 cross reference table (ISA bus pin C)

ISA bus CN3

Pin Signal Pin Signal

C1 SBHE 59 SBHE

C2 LA23 37 LA23

C3 LA22 35 LA22

C4 LA21 108 LA21

C5 LA20 106 LA20

C6 LA19 34 LA19

C7 LA18 107 LA18

C8 LA17 33 LA17

C9 MEMR 60 MEMR

C10 MEMW 130 MEMW

C11 SD8 49 SD8

C12 SD9 52 SD9

C13 SD10 50 SD10

C14 SD11 51 SD11

C15 SD12 55 SD12

C16 SD13 54 SD13

C17 SD14 53 SD14

C18 SD15 57 SD15

44 HMI-640S User's Manual

Page 55

T able 4-7: ISA bus - CN3 cross reference table (IDE pin D)

ISA bus CN3

Pin Signal Pin Signal

D1 MEMCS16 134 MEMCS16

D2 I/OCS16 61 IOCS16

D3 IRQ10 90 IRQ10

D4 IRQ11 91 IRQ11

D5 IRQ12 25 IRQ12

D6 IRQ15 97 IRQ15

D7 IRQ14 98 IRQ14

D8 DACK0 84 DACK0

D9 DRQ0 30 DRQ0

D10 DACK5 80 DACK5

D11 DRQ5 100 DRQ5

D12 DACK6 79 DACK6

D13 DRQ6 101 DRQ6

D14 DACK7 78 DACK7

D15 DRQ7 102 DRQ7

D16 +5 V 5 +5 V

D17 MASTER 132 MASTER

D18 GND 12 GND

Chapter 4 CPC-2245N Main Borad 45

Page 56

4.9.2 IDE interface

Users can attach two IDE devices to the IDE channel, one drive

must be set as the master and another as the slave. You may do this

by setting the jumpers on the drives. Refer to the documentation

that came with your drive for more information.

A jumper diagram usually appears on the top side of a hard disk

drive.

IDE hard drive connector

Table 4-8: IDE hard drive connector

IDE connector CN3 IDE connector CN3

Pin Signal P in Signal Pin Signal P in Signal

1 IDE RESET 74 RESET 2 GND 13 GND

3 DATA 7 (*2) 46 HDD7 4 DATA 8 (*2) 41 HDD8

5 DATA 6 (*2) 44 HDD6 6 DATA 9 (*2) 1 1 8 HDD9

7 DATA 5 (*2) 116 HDD5 8 DATA 10 (*2) 45 HDD10

9 DATA 4 (*2) 117 HDD4 1 0 DATA 1 1 (*2) 114 HDD11

11 DATA 3 (*2) 115 HDD3 12 DAT A 1 2 (*2) 120 HDD12

13 DATA 2 (*2) 42 HDD2 14 DAT A 1 3 (*2) 48 HDD13

15 DATA 1 (*2) 43 HDD1 16 DAT A 1 4 (*2) 47 HDD14

17 DATA 0 (*2) 40 HDD0 18 DAT A 1 5 (*2) 119 HDD15

19 SIGNAL GND 14 GND 20 N/ C - 21 DMA REQUEST 103 HDDRQ 22 GND 14 GND

23 IO WRITE (*2) 32 HDIOW 24 GND 14 GND

25 IO READ (*2) 105 HDIOR 26 GND 15 GND

27 IO CHANNEL 129 IOC HRDY 28 GND (*1) 15 GND

READY

29 HDACK 31 HDACK 30 GND 16 G ND

31 IRQ 104 HDIRQ 32 N /C - 33 ADDR 1 107 LA18 34 N/C - 35 ADDR 0 33 LA17 36 ADDR 2 - 37 HARD DISK 85 HDCS0 38 HARD DISK 86 HDCS1

SELECT 0 (*2) SELECT 1 (*2)

39 IDE ACTIVE 40 GN D 16 41 VCC 6 +5 V 42 VCC 6 +5 V

43 GND 1 6 GND 44 N/C --

46 HMI-640S User's Manual

Page 57

Note : IDE pin 28 must pull 470 ohms resistor to GND.

Note : 33 ohms damping resistors is recommended to

connect near IDE connector. Please refer to Fig.

2-2 below.

Note : We do not recommend connection to the following

IDE HDD models of Seagate: ST 31276A, ST

31720A, ST 32531A, ST 33240A or ST 34340A

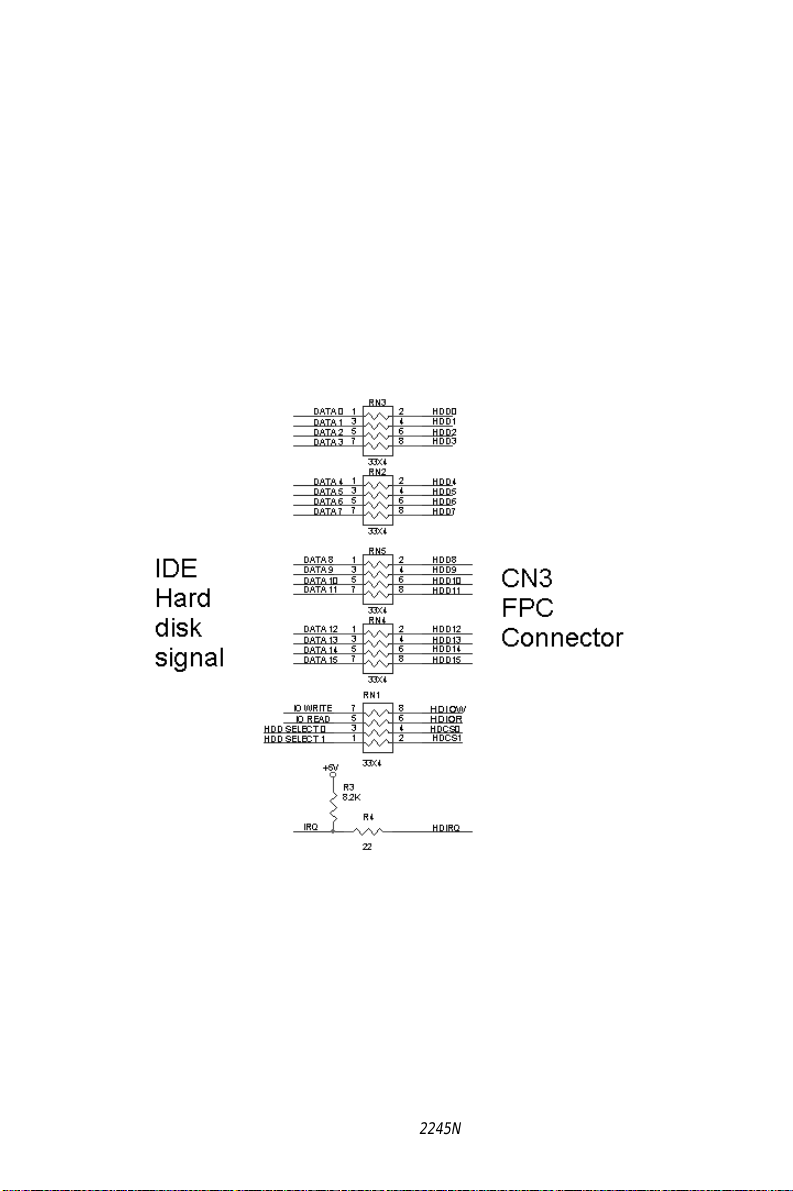

Figure 4-2: Damping resistor

Chapter 4 CPC-2245N Main Borad 47

Page 58

4.9.3 Floppy drive

Users can attach up to two floppy disk drives to the CPC-2245N via

a SODIMM socket. The CPC-2245N supports any combination of

5.25" (360 KB / 1.2 MB) and/or 3.5" (720 KB / 1.44/2.88 MB) drives.

The following table lists the pin assignments for the floppy disk

connector:

Table 4-9: Floppy drive connector

FDD connctr. CN3 FDD connector CN3

Pin Signal Pin Signal Pin Signal Pin Signal

1 GND 9 GND 2 High density 141 AUTOFD

3 GND 9 GND 4 N/C

5 GND 10 GND 6 N/C

7 G ND 1 0 G ND 8 Index 69 PD 0

9 GND 11 GND 10 Motor enable A 66 PD6

11 GN D 11 G ND 1 2 Driver select B 6 4 ACK

13 GN D 12 GN D 1 4 Driver select A 143 P D 7

15 GN D 12 GN D 16 Motor enable B 13 7 BUSY

17 G ND 13 GND 18 Direction 71 INIT

19 GND 13 GND 20 Step pulse 72 SLCTIN

21 GN D 1 4 G ND 22 Write data 65 PE

23 GND 14 GND 24 Write enable 144 SLCT

25 GN D 15 G N D 26 Track 0 140 PD1

27 GN D 15 GN D 28 Write protect 6 8 PD2

29 GND 16 G ND 30 Read data 1 39 P D3

31 GN D 1 6 GN D 32 Select head 14 2 E RR

33 GND 9 GND 34 Disk change 67 PD4

48 HMI-640S User's Manual

Page 59

4.9.4 Parallel port

The parallel port is normally used to connect the CPU card to a

printer through a DB25 connector. The CPC-2245N includes an onboard parallel port, accessed through a SO. DIMM golden finger.

The parallel port is designated as LPT1 and can be disabled or

changed to LPT2 or LPT3 in the BIOS setup manual.

Table 4-10: Parallel port connector

Printer port CN3 Printer port CN3

Pin Signal Pin Signal Pin Signal Pin Signal

1 /STROBE 70 STROBE 14 \AUTOFD 1 41 AUTOFD

2 DO 69 PD0 15 ERR 142 ERR

3 D1 140 PD1 16 \INIT 71 INIT

4 D2 68 PD2 17 \SLCTINI 72 SLCTIN

5 D3 13 9 PD3 18 GND 9 GND

6 D4 67 PD4 19 GND 9 GND

7 D5 13 8 PD5 20 GND 10 GND

8 D6 66 PD6 21 GND 10 GND

9 D7 14 3 PD7 22 GND 11 GND

10 \ACK 64 ACK 23 GND 11 GND

11 BUSY 1 37 BUSY 24 GND 12 GND

12 PE 65 PE 25 GN D 12 G ND

13 SLCT 1 4 4 SLCT

Chapter 4 CPC-2245N Main Borad 49

Page 60

4.10 VGA/LAN/serial ports/keyboard/

mouse (CN4)

The CPC-2245N provides a VGA interface, a 10/100 Base-T Ethernet, two RS-232 serial ports, one keyboard and one PS2 mouse

through a 40-pins FPC connector (CN4). User can design their FPC

cable for connecting CPC-2245N's FPC connector to user's system

board. User can choose suitable position to layout VGA, LAN,

COM port, Keyboard and mouse connector on user's system

board.

Table 4-11: FPC connector (CN4)

Pin Signal Pin Signal

1 GND 21 DSR2

2 KBVCC 2 2 R X2

3 EXT RESET 23 CD2

4 DDC1 24 TX2

5 DDC0 25 RI2

6 V SYNC 26 CTS2

7 H SYNC 27 RTS2

8 BLUE 28 DTR2

9 GREEN 29 KBVCC

10 RED 30 MSDT

11 KBVCC 31 KBDT

12 G N D 32 KBCK

13 RI1 33 MSCK

14 CTS1 34 GN D

15 RTS1 35 TPT16 DTR1 36 TPT+

17 TX1 37 GND

18 CD1 38 TPR19 RX1 39 TPR+

20 DSR1 40 GND

50 HMI-640S User's Manual

Page 61

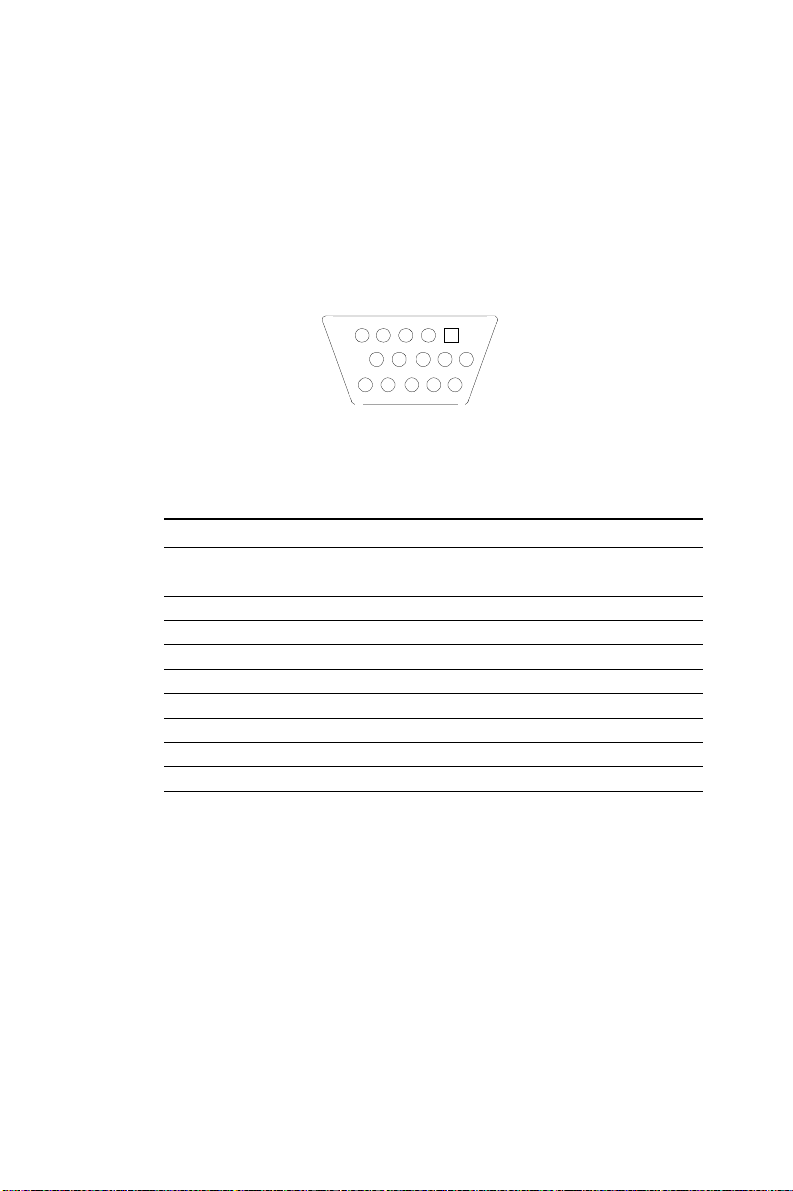

4.10.1 VGA interface

The VGA connector is a 15-pin D-SUB connector. Users can follow

a transfer table to layout these VGA signals to a standard 15-pin

D-SUB connector.

5

10

15 11

1

6

Table 4-12: VGA interface

VGA CN4 VGA CN4

Pin Signal Pin Signal Pin Signal Pin Signal

1 RED 10 RED 9 Vcc 2 KBVCC

2 GREEN 9 GREEN 10 GND 1 GND

3 BLUE 8 BLUE 11 N / C - 4 N/C - - 12 SDT 5 DDC0

5 GND 1 GND 13 H-SYNC 7 H SYNC

6 GND 1 GND 14 V-SYNC 6 V SYNC

7 GND 12 GND 15 SCK 4 DDC1

8 GND 12 GND

Chapter 4 CPC-2245N Main Borad 51

Page 62

4.10.2 Ethernet configuration

The CPC-2245N is equipped with a high performance 32-bit PCI-bus

Fast Ethernet interface that are fully compliant with IEEE 802.3u

10/100Base-T specifications. Ethernet connector is a RJ-45 jack.

User can follow a transfer table to connect Ethernet signals to a

standard RJ-45 connector.

Table 4-13: Ethernet configuration

RJ-45 CN4 RJ-45 CN4

Pin Signal Pin Signal Pin Signal Pin Signal

1 TD+ 36 TPT+ 2 TD - 35 TPT3 R D+ 39 TPR+ 4 NC - 5 N C - - 6 RD - 3 8 TPR7NC-- 8NC--

4.10.3 Keyboard and PS/2 mouse connector

The CPC-2245N provides a keyboard and PS2 mouse interface

through a 40-pin FPC connector (CN4) for connection of PS/2

keyboard and PS/2 mouse.

In most cases, especially in embedded applications, a keyboard is

not used. The standard PC/AT BIOS will report an error or fail

during power-on self-test (POST) after a reset if the keyboard is not

present. The CPC-2245N's BIOS "Standard CMOS Features" allows

you to select "Halt on" under the "All, but keyboard" or "All, but

disk/key" selection. This allows no-keyboard operation in embedded system applications without the system halting under POST

(power on self test).

52 HMI-640S User's Manual

Page 63

Table 4-14: PS/2 keyboard connector

PS/2 Keyboard CN4 PS/2 Keyboard CN4

Pin Signal Pin Signal Pin Signal Pin Signal

1 KB_Data 31 KBDT 4 Vcc 29 KBVCC

2 NC - - 5 KBCLK 32 KBCK

3 GND 34 GND 6 NC - -

Table 4-15: PS/2 mouse connector

PS/2 Mouse CN4 PS/2 Mouse CN4

Pin Signal Pin Signal Pin Signal Pin Signal

1 MD ATA 30 MSDT 4 Vcc 29 KBVCC

2 NC - - 5 MCLK 33 MSCK

3 GND 34 GND 6 NC - -

4.10.4 Serial ports

The CPC-2245N offers two serial ports: COM1 and COM2, both in

RS- 232. These ports let you connect to serial devices (a mouse,

printers, etc.) or a communication network.

Y ou can select the address for each port (For example, 3F8H

[COM1], 2F8H [COM2]) or disable it, using the BIOS Advanced

Setup program. Different devices implement the RS-232 standard in

different ways. If you are having problems with a serial device, be

sure to check the pin assignments for the connector.

The IRQ and address range for both ports are fixed. However, if

you wish to disable the port or change these parameters later, you

can do this in the system BIOS setup. The table below shows the

settings for the CPC-2245N board's ports:

Chapter 4 CPC-2245N Main Borad 53

Page 64

Table 4-16: Serial port default settings

Port Address Default

COM1 3F8, 2F8, 3E8, 2E8 3F8/IRQ4

COM2 3F8, 2F8, 3E8, 2E8 2F8/IRQ3

The following table shows the pin assignments for the card's

RS-232 port:

1

6

5

9

Table 4-17: COM1 RS-232 serial port connector

RS-232 CN4 RS-232 CN4

Pin Signal Pin Signal Pin Signal Pin Signal

1 DC D 18 CD 1 6 DS R 20 DSR1

2 RX 19 RX1 7 RTS 15 RTS1

3 TX 17 TX1 8 CTS 14 CTS1

4 DTR 16 DTR1 9 RI 13 RI1

5 GND 37 GND

Table 4-18: COM2 RS-232 serial port connector

RS-232 CN4 RS-232 CN4

Pin Signal Pin Signal Pin Signal Pin Signal

1 DC D 23 CD 2 6 DS R 21 DSR2

2 RX 22 RX2 7 RTS 27 RTS2

3 TX 24 TX2 8 CTS 26 CTS2

4 DTR 28 DTR2 9 RI 25 RI2

5 GND 40 GND

54 HMI-640S User's Manual

Page 65

4.11 Power supply connector (CN5)

In single board computer without carrier applications, user may

connect a power directly to the CPC-2245N board through CN5. See

the following table for its pin assignments:

Table 4-19: Power supply connector (CN5)

Pin Function

1NC

2 GND

3 GND

4 +5 V

Chapter 4 CPC-2245N Main Borad 55

Page 66

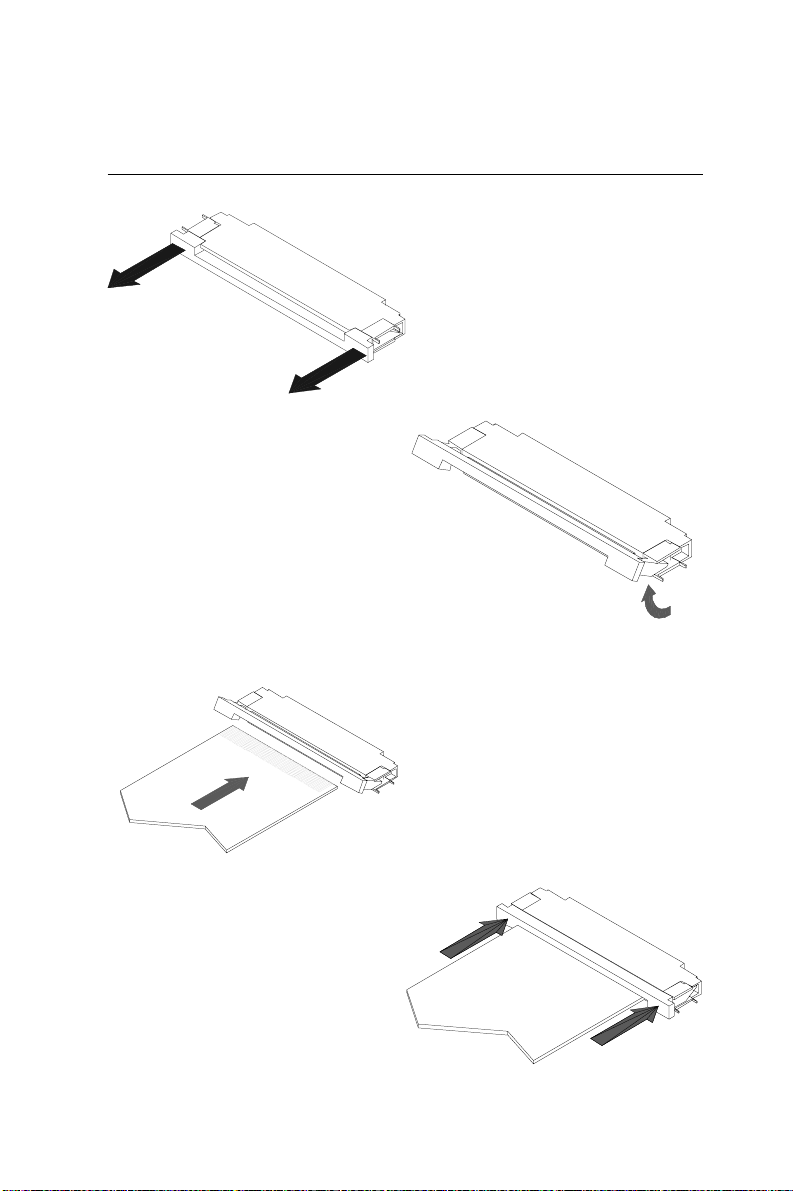

4.12 Card installation

56 HMI-640S User's Manual

Page 67

4.13 Card removal

Chapter 4 CPC-2245N Main Borad 57

Page 68

4.14 FPC cable installation

58 HMI-640S User's Manual

Page 69

5

CHAPTER

CPC-2520 VGA/LCD

Control Board

This chapter provides:

• Background information such as card

specification and board layout of CPC-

2520.

• The installation procedures for CPC2520 hardware, including instructions on

setting jumpers and connecting peripherals, switches and indicators. Be sure to

read all safety precautions before you

begin the installation procedure.

Page 70

5.1 Introduction

The CPC-2520 is an extension VGA/LCD module for the CPC-2245

mini biscuit PC. The CPC-2520 uses a C&T 69000 chipset for its

PCI/SVGA controller. It supports many popular LCD, EL, and gas

plasma flat panel displays and conventional analog CRT monitors.

The 69000 VGA BIOS supports monochrome LCD, EL, color TFT

and STN LCD flat panel displays. In addition, it also supports

interlaced and non-interlaced analog monitors (color and monochrome VGA) in high-resolution modes while maintaining complete

IBM VGA compatibility . Digital monitors (i.e. MDA, CGA, and

EGA) are NOT supported. Multiple frequency (multi-sync) monitors are handled as if they were analog monitors.

With on-board 2 MB display memory , the VGA controller can drive

CRT displays or color panel displays with resolutions up to 1024 x

768 at 64 K colors.

CRT and panel displays can be used simultaneously. The CPC-2520

can be set in one of three configurations: on a CRT, on a flat panel

display, or on both simultaneously. The system is initially set to

simultaneous display mode.

60 HMI-640S User's Manual

Page 71

5.2 Specifications

General

• Flat panel VGA interface

• Chipset: C&T 69000 VGA controller with Windows accelerator

• Display memory: 2 MB SDRAM in built-in chip

• Display output:

50-pin FPC connector for flat panel interface

12-pin FPC connector for VGA interface

• Display type: Supports CRT and flat panel (TFT , DSTN, and

mono) displays. Can display both CRT and flat panel simultaneously

• Resolution: 640 x 480 @ 16 M colors

800 x 600 @ 16 M colors

1024 x 768 @ 64 K colors

Mechanical and environmental

• Power supply voltage: +5 V (4.75 V ~ 5.25 V)

• Max. power requirements: +5 V @ 0.8 A

• Operating temperature: 0 ~ 60° C (32 ~ 140° F)

• Board size: 68 x 100 mm (2.7" x 3.9")

• Weight: 0.05 kg (0.1 1 lb)

Chapter 5 CPC-2520 VGA/LCD Control Board 61

Page 72

5.3 Board layout: dimensions

62 HMI-640S User's Manual

Page 73

5.4 Jumpers and connectors

On-board connectors link to external devices such as hard disk

drives, keyboards, or floppy drives, etc. In addition, the board has

jumpers for configuring your board for specific applications.

The table below lists the function of each of the board's jumpers

and connectors. Later sections in this chapter give detailed

information on each jumper setting, and gives instructions for

connecting external devices to your card.

T able 5-1: Jumpers and connectors

Number Function

SW1 LCD panel type setting

CN1 Reserved for VGA testing

CN2 LCD display connector

CN3 VGA display connector

CN4 PCI bus

Chapter 5 CPC-2520 VGA/LCD Control Board 63

Page 74

5.5 Board layout: jumper/connector

locations

64 HMI-640S User's Manual

Page 75

5.6 Safety precautions

Warning! Always completely disconnect the power cord from

your chassis whenever you are working on it. Do

not make connections while the power is on

because sensitive electronic components can be

damaged by the sudden rush of power. Only

experienced electronics personnel should open

the PC chassis.

Caution! Always ground yourself to remove any static

charge before touching the CPU card. Modern

electronic devices are very sensitive to static

electric charges. Use a grounding wrist strap at

all times. Place all electronic components on a

static-dissipative surface or in a static-shielded

bag when they are not in the chassis.

Chapter 5 CPC-2520 VGA/LCD Control Board 65

Page 76

5.7 Jumper settings

You configure your card to match the needs of your application by

setting jumpers. A jumper is the simplest kind of electric switch. It

consists of two metal pins and a small metal clip (often protected

by a plastic cover) that slides over the pins to connect them. To

close a jumper you connect the pins with the clip. To open a

jumper you remove the clip. Sometimes a jumper will have three

pins, labeled 1, 2 and 3. In this case you would connect either pins

1 and 2 or 2 and 3.

2

1

Closed 2-3Open Closed

A pair of needle-nose pliers may be helpful when working with

jumpers. If you have any doubts about the best hardware configuration for your application, contact your local distributor or sales

representatives before you make any changes.

66 HMI-640S User's Manual

Page 77

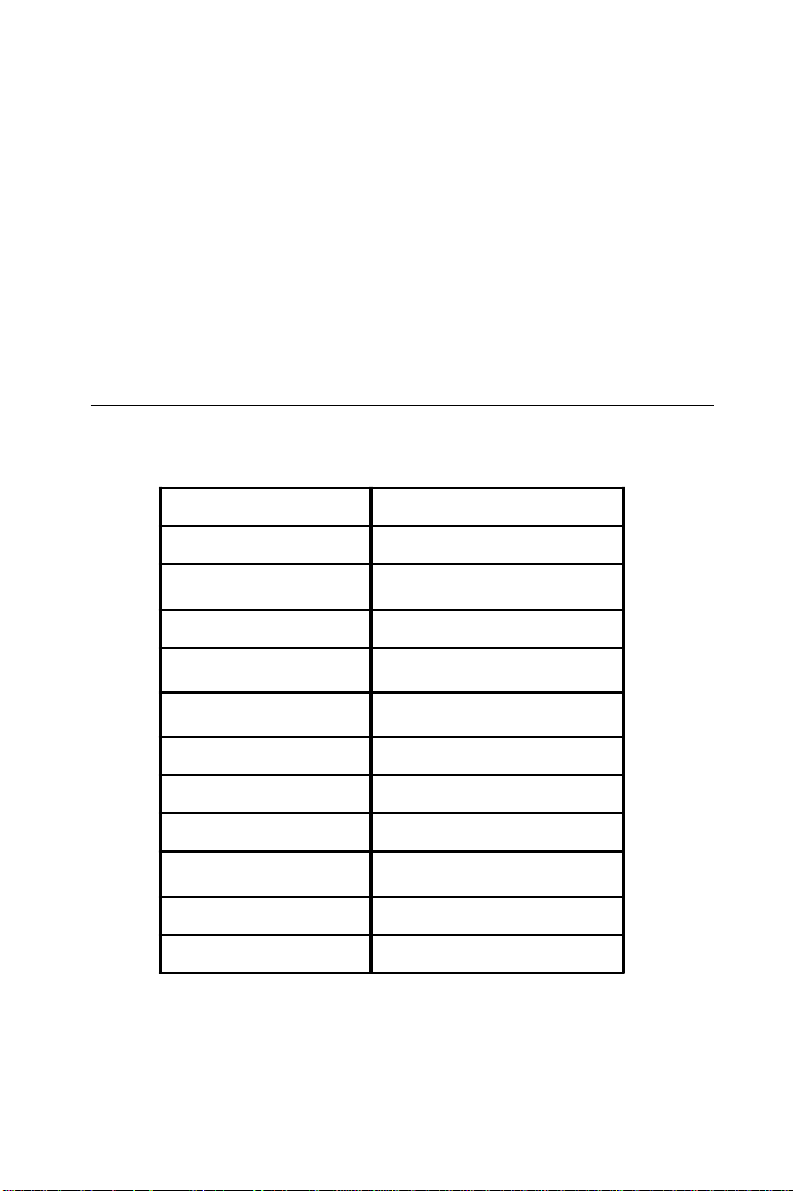

5. 8 LCD panel select (SW1)

Panel #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A B C D

ON ON ON ON 1024 x 768 DSTN

OFF ON ON O N 1280 x 1024 TFT

ON OFF ON ON 640 x 480 DSTN

OFF OFF ON ON 800 x 600 DST

ON ON OFF ON 640 x 480 Sharp TFT

OFF ON OFF ON 640 x 480 18-bit TFT

ON OFF OFF ON 1024 x 768 36-bit TFT

OFF OFF OFF ON 800 x 600 TFT

ON ON ON OFF 800 x 600 TFT (larg e BIOS only )

OFF ON ON O FF 800 x 600 TFT (large BIOS onl y)

ON OFF ON OFF 800 x 600 DSTN (l arge BIOS o nly )

OFF OFF ON OFF 800 x 600 DSTN (large BIOS o nly )

ON ON OFF OFF 1024 x 768 TFT (large BIOS o nly )

OFF ON OFF OFF 1280 x 1024 DSTN (large B IOS o nly )

ON OFF OFF OFF 1024 x 600 DSTN (large B IOS o nly)

OFF OFF OFF OFF 1024 x 600 TFT (larg e B IOS onl y)

SW1

Panel Type

5.9 Display connectors (CN2, CN3)

The CPC-2520 PCI SVGA interface can drive conventional CRT

display and is capable of driving a wide range of flat display,

including electroluminescent (EL), gas plasma, passive LCD, and

active LCD displays. The card has two connectors to support these

display , one for CR T VGA monitor and one for flat panel displays.

Chapter 5 CPC-2520 VGA/LCD Control Board 67

Page 78

5.10 LCD display connector (CN2)

LCD display connector on CPC-2520 is a 50-pin FPC connector.

The CPC-2520 supports up to 36 bits LCD panel.

T able 5-2: LCD display connector (CN2)

Pin Signal Pin Signal

1 ENAVEE 26 P15

2 LP 27 P16

3 ENAVDD 28 P17

4 FLM 29 P18

5 SHIFT CLK 30 P19

6 SHIFT CLK- 31 GN D

7 M 32 P20

8 ENABKL 33 P21

9 GND 34 P22

10 P0 35 P23

1 1 P1 36 P24

12 P2 37 P25

13 P3 38 P26

14 P4 39 P27

15 P5 40 GND

16 P6 41 P28

17 P7 42 P29

18 GND 43 P30

19 P8 44 P31

20 P9 45 P32

21 P10 46 P33

22 P1 1 47 P34

23 P12 48 P35

24 P13 49 GND

25 P14 50 GND

Note: The model number of the CN2 socket is

IL-FPR-50S-HF (JAE Co., Ltd.)

68 HMI-640S User's Manual

Page 79

5.11 VGA display connector (CN3)

VGA display connector on CPC-2520 is a 12-pin FPC connector,

these VGA signals can be connected to client's system board

through a FPC cable. Client can design this cable by referring to

Cable layout diagram in chapter of design guide.

T able 5-3: VGA display connector (CN3)

Pin Signal

1 GND

2 +5V

3 +5V

4 GND

5 H SYNC

6 DDC1

7 V SYNC

8 DDC0

9 BLUE

1 0 RED

1 1 GREEN

12 GND

Note: The model number of the CN3 socket is

IL-FPR-12S-HFC (JAE Co., Ltd.)

Chapter 5 CPC-2520 VGA/LCD Control Board 69

Page 80

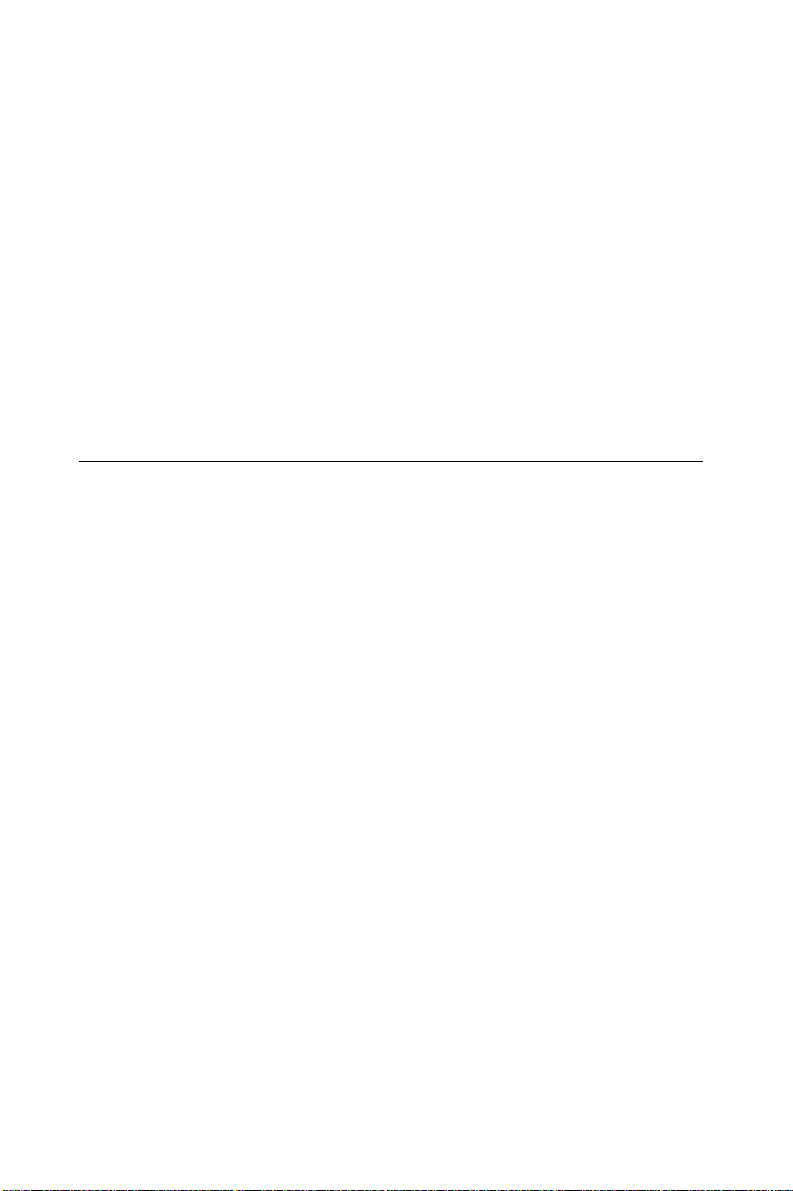

The VGA connector is a 15-pin D-SUB connector. User can

follow a transfer table to layout these VGA signals to a standard

15-pin D-SUB connector.

5

10

15 11

T able 5-4: VGA display connector (CN3)

1

6

VGA CN3 VGA CN3

Pin Signal Pin Signal Pin Signal Pin Signal

1 RED 10 RED 9 Vcc 2, 3 +V

2 GREEN 11 GREEN 10 GND 4 GND

3 BLUE 9 BLUE 11 N/C - 4 N/C - - 12 SDT 8 DDC0

5 GND 1 GND 13 H-SYNC 5 H SYNC

6 GND 1 GND 14 V-SYNC 7 V SYNC

7 GND 12 GND 15 SCK 6 DDC1

8 GND 12 GND

70 HMI-640S User's Manual

Page 81

5.12 FPC cable installation

Chapter 5 CPC-2520 VGA/LCD Control Board 71

Page 82

72 HMI-640S User's Manual

Page 83

CHAPTER

6

Networking Communication

This chapter describes the ways to get your

HMI-640S connected to the host PC.

Sections include:

• Introduction

• Networking via LAN

• Networking via RS-232

• Simple Networking via a Hub

Page 84

6.1 Introduction

The HMI-640S is designed as a networking gadget that readily

connect itself to the host PC either via existing LAN or a RS-232

interface. Its network capability makes it nothing less than a powerful

platform for any application that demands networking communication

or remote file transfer. The following sections will guide you through

the networking steps for HMI-640.

6.2 Networking via LAN

Ethernet has been so predominant in LANs that we come to regard it

as the de facto standard for network communication within LANs.

The HMI-640S takes advantage of Ethernet networking to connect to

a host PC for convenient network communication and file transfer.

Please follow the procedure described below to set up network

connection between HMI-640S and host PC via Ethernet network:

1. Before connecting to LAN, first make sure you have properly set

up your host PC on a Ethernet LAN running TCP/IP networking

protocol. If you have not installed the TCP/IP network protocol on

your host PC, you must install it first before joining the host PC to

Ethernet LAN.

2. Make sure your HMI-640S is running an OS that has its TCP/IP

network protocol enabled.

Note: If you use a CompactFlash drive which is prein-

stalled with Windows CE or other network-enabling

software, your HMI-640S is ready for TCP/IP

networking. You don't have to install other components to run TCP/IP networking.

3. Disconnect any power source from your HMI-640S.

Note: Be sure to power off the HMI-640S before you

connect or disconnect any cable.

74

HMI-640S User's Manual

Page 85

4. Use a twisted-pair UTP or STP cable (category 3, 4, 5) to connect

the HMI-640S through its RJ-45 port to a hub (or a switch) within the

Ethernet LAN, to which your host PC is also connected to.

5. Assign valid IP addresses for your HMI-640S and host PC. If you

are joining an existing Intranet, ask your network administrator for

valid IP addresses. If your are using a DHCP server on the network,

you have just no need to assign IP addresses yourself.

Note: To assign the IP addresses to your machines, just

access

Start/Settings/Control Panel/Network

properties sheet and enter valid IP addresses for

your machine.

Note: If your network are using a DHCP server for

dynamic IP address assignment, you have then no

need to assign by yourself since the IP addresses

will be assigned to each networking device once it

is connected to the network.

6. Enter the device name for your HMI-640S for network identification.

Note: To assign a

access

device name

to your HMI-640S, just

Start/Settings/Control Panel/Network

properties sheet and enter the device name for your

HMI-640S. You have to reboot your system to make

the device name viable on the network.

7. After properly establishing the IP status and the device name of

your machine on the network, You must reboot to make it viable on

the network.

8. After rebooting is complete, verify that your HMI-640S is

functionable within the network.

Chapter 6 Networking Communication

75

Page 86

Note: To verify that your HMI-640S has joined the net-

work and is properly connected with your host PC,

just try to access your host PC through the Windows CE Explorer by typing

//host_name_of_host_PC

the address bar. Press Enter to search for the host

PC. If the connection is successful, you can see

the network shares that is available from the host

PC. Or you can simply "ping" your HMI-640S from

your host PC to make sure TCP/IP is working. (e.g.

c:\ping

_your_HMI-640S )

IP_address_of_your_HMI-640S or device_name_of

6.2 Networking via RS-232

RS-232 is a time-honored standard interface for industrial automation. It is very convenient to implement albeit much more limited in

its communication distance. The HMI-640S is provided with a RS232 port, from which it can be connected to your host PC via a

NULL modem cable.

Please follow the procedure described below to set up network

connection between HMI-640S and host PC via RS-232 interface:

1. Before connecting to RS-232, first make sure your COM port

service on the host PC has been enabled.

in

Note: If you are running Windows 95/98 on the host PC,

the Com port ser vice should be enabled on default

without extra installation of other component. On

the other hand, if you are running Windows NT on

the host PC, make sure the RAS (i.e.

Access Service

) service on your host PC system

is running properly. If you have not installed the

RAS service, you must install it on your system.

2. Use the DB-9 NULL modem cable (that accompanies your HMI640S) to connect the HMI-640S through its RS-232 port to the COM

port of your host PC.

76

HMI-640S User's Manual

Remote

Page 87

Note: Be sure to power off the HMI-640S before you

connect or disconnect any cable.

3. Power up your HMI-640S and after the system boot has completed, try access Start/Programs/Communication/Remote Networking

properties sheet.

4. Click Make New Connection to pop up a dialog box and choose

Direct Connection.

5. Double-click the New Connection icon to connect to the PC.

6. After you have successfully connected to the host PC, just verify

the validity of your RS-232 connection by typing the host name of

your host PC in the Address Bar of your Windows CE Explorer.

Press Enter to search for the host PC. If the connection is successful, you can see the network shares that is available from the host PC.

6.3 Simple Networking via a Hub

If you want only to connect your HMI-640S and the host PC through

RJ-45 ports, it is required that you use twisted-pair cables to connect

both to a central hub. Note that this network configuration is essentially the same with Ethernet despite a configuration of merely two

end nodes.

After you have established a proper connection, you can verify the

network communication according to the procedure described in the

previous section.

Chapter 6 Networking Communication

77

Page 88

78

HMI-640S User's Manual

Page 89

APPENDIX

A

Cabling for RS-232 Port

The HMI-640S is equipped with a watchdog

timer that resets the CPU if processing

comes to a standstill for any reason. This

feature ensures system reliability in industrial stand-alone or unmanned environments.

Page 90

HMI-640S is shipped together with a serial cable (NULL modem cable)

for customers to make a direct connection between it and the host PC.

Note that off-the-shelf NULL modem cables may not be wired correctly. The following list is the wiring table for this cable:

9-pin NULL Modem Cable:

Remoet host

serial port

connector

Calling syste m

serial port

connector

Signal

32Transmit Data

23Receive Data

7 8 Request to Send

87Clear to Send

6,1 4

Data S e t Rea dy

and Carrier Detect

80

HMI-640S User's Manual

5 5 Signa l Gr o und

4 6,1

Data Terminal

Rea d y

Page 91

25-pin NULL Modem Cable:

Re moet host

seri a l po rt

connector

Calling sy st em

seri a l po rt

connector

Signal

23Transmit Data

3 2 Receive Data

4 5 Request to Send

5 4 Clear to Send

6, 8 20

Data S e t Rea dy

and Carrier Detec

7 7 Signal Ground

20 6, 8

Data Terminal

Ready

Appendix A Cabling for RS-232 Port