Page 1

User Manual

EKI-1500 Series

1/2/4-port RS-232/422/485 Serial

Device Servers

Page 2

Copyright

Part No. 2009152102 Edition 3

Printed in Taiwan October 2016

The documentation and the software included with this product are copyrighted 2016

by Advantech Co., Ltd. All rights are reserved. Advantech Co., Ltd. reserves the right

to make improvements in the products described in this manual at any time without

notice. No part of this manual may be reproduced, copied, translated or transmitted

in any form or by any means without the prior written permission of Advantech Co.,

Ltd. Information provided in this manual is intended to be a ccurate and reliable. However, Advantech Co., Ltd. assumes no responsibility for its use, nor for any infringements of the rights of third parties, which may result from its use.

Acknowledgements

Intel and Pentium are trademarks of Intel Corporation.

Microsoft Windows and MS-DOS are registered trademarks of Microsoft Corp.

All other product names or trademarks are properties of their respective owners.

Product Warranty (5 years)

Advantech warrants to you, the original purchaser, that each of its products will be

free from defects in materials and workmanship for five years from the date of purchase.

This warranty does not apply to any products which have been repaired or altered by

persons other than repair personnel authorized by Advantech, or which have been

subject to misuse, abuse, accident or improper installation. Advantech assumes no

liability under the terms of this warranty as a consequence of such events.

Because of Advantech’s high quality-control standards and rigorous testing, most of

our customers never need to use our repair service. If an Advantech product is defective, it will be repaired or replaced at no charge during the warranty perio d. For out ofwarranty repairs, you will be billed according to the cost of replacement materials,

service time and freight. Please consult your dealer for more details.

If you think you have a defective product, follow these steps:

1. Collect all the information about the problem encountered. (For example, CPU

speed, Advantech products used, other hardware and software used, etc.) Note

anything abnormal and list any on screen messages you get when the problem

occurs.

2. Call your dealer and describe the problem. Please have your manual, product,

and any helpful information readily available.

3. If your product is diagnosed as defective, obtain an RMA (return merchandize

authorization) number from your dealer. This allows us to process your return

more quickly.

4. Carefully pack the defective product, a fully-completed Repair and Replacement

Order Card and a photocopy proof of purchase date (such as your sales receipt)

in a shippable container. A product returned without proof of the purchase date

is not eligible for warranty service.

5. Write the RMA number visibly on the outside of the p ackage and ship it prepaid

to your dealer.

ii EKI-1500 Series User Manual

Page 3

Declaration of Conformity

CE

This product has passed the CE test for environmental specifications when shielded

cables are used for external wiring. We recommend the use of shielded cables. This

kind of cable is available from Advantech. Please contact your local supplier for

ordering information.

This product has passed the CE test for environmental specifications. Test conditions

for passing included the equipment being operated within an industrial enclosure. In

order to protect the product from being damaged by ESD (Electrostatic Discharge)

and EMI leakage, we strongly recommend the use of CE-compliant industrial enclosure products.

FCC Class A

Note: This equipment has been tested and found to comply with the limit s for a Class

A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Technical Support and Assistance

1. Visit the Advantech web site at www .advante ch.com/support where you can find

the latest information about the product.

2. Contact your distributor, sales representative, or Advantech's customer service

center for technical support if you need additional assistance. Please have the

following information ready before you call:

– Product name and serial number

– Description of your peripheral attachments

– Description of your software (operating system, version, application software,

etc.)

– A complete description of the problem

– The exact wording of any error messages

iii EKI-1500 Series User Manual

Page 4

Warnings, Cautions and Notes

Warning! Warnings indicate conditions, which if not observed, can cause personal

injury!

Caution! Cautions are included to help you avoid damaging hardware or losing

data. e.g.

There is a danger of a new battery exploding if it is incorrectly installed.

Do not attempt to recharge, force open, or heat the battery. Replace the

battery only with the same or equivalent type recommended by the manufacturer. Discard used batteries according to the manufacturer's

instructions.

Note! Notes provide optional additional information.

Document Feedback

To assist us in making improvements to this manual, we would welcome comments

and constructive criticism. Please send all such - in writing to: support@advantech.com

Packing List

Before setting up the system, check that the items listed below are included and in

good condition. If any item does not accord with the table, please contact your dealer

immediately.

1 x EKI-1521 or EKI-1522 or EKI-1524 serial device server

1 x Terminal Block

1 x Document and software CD

2 x Wall/panel mount kit

1 x RS-232 loopback DB9 tester

EKI-1500 Series User Manual iv

Page 5

Safety Instructions

1. Read these safety instructions carefully.

2. Keep this User Manual for later reference.

3. Disconnect this equipment from any AC outlet before cleaning. Use a damp

cloth. Do not use liquid or spray detergents for cleaning.

4. For plug-in equipment, the power outlet socket must be located near the equip-

ment and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a reliable surface during installation. Dropping it or letting

it fall may cause damage.

7. The openings on the enclosure are for air convection. Protect the equipment

from overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source is correct before connecting the

equipment to the power outlet.

9. Position the power cord so that people cannot step on it. Do not place anything

over the power cord.

10. All cautions and warnings on the equipment should be noted.

11. If the equipment is not used for a long time, disconnect it from the power source

to avoid damage by transient overvoltage.

12. Never pour any liquid into an opening. This may cause fire or electrical shock.

13. Never open the equipment. For safety reasons, the equipment should be

opened only by qualified service personnel.

14. If one of the following situations arises, get the equipment checked by service

personnel:

15. The power cord or plug is damaged.

16. Liquid has penetrated into the equipment.

17. The equipment has been exposed to moisture.

18. The equipment does not work well, or you cannot get it to work according to the

user's manual.

19. The equipment has been dropped and damaged.

20. The equipment has obvious signs of breakage.

21. CAUTION: DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY

REPLACED. REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE

RECOMMENDED BY THE MANUFACTURER, DISCARD USED BATTERIES

ACCORDING TO THE MANUFACTURER'S INSTRUCTIONS.

22. DO NOT LEAVE THIS EQUIPMENT IN AN ENVIRONMENT WHERE THE

STORAGE TEMPERATURE MAY GO BELOW -40°C (-40°F) OR ABOVE 75°C

(167°F). THIS COULD DAMAGE THE EQUIPMENT. THE EQUIPMENT

SHOULD BE IN A CONTROLLED ENVIRONMENT.

23. This is building-in equipment and shall be installed in a suitable enclosure.

Warning!

Hot surface. Do not touch.

v EKI-1500 Series User Manual

Page 6

Safety Precaution - Static Electricity

Follow these simple precautions to protect yourself from harm and the products from

damage.

To avoid electrical shock, always disconnect the power from your PC chassis

before you work on it. Don't touch any components on the CPU card or other

cards while the PC is on.

Disconnect power before making any configuration changes. The sudden rush

of power as you connect a jumper or install a card may damage sensitive electronic components.

EKI-1500 Series User Manual vi

Page 7

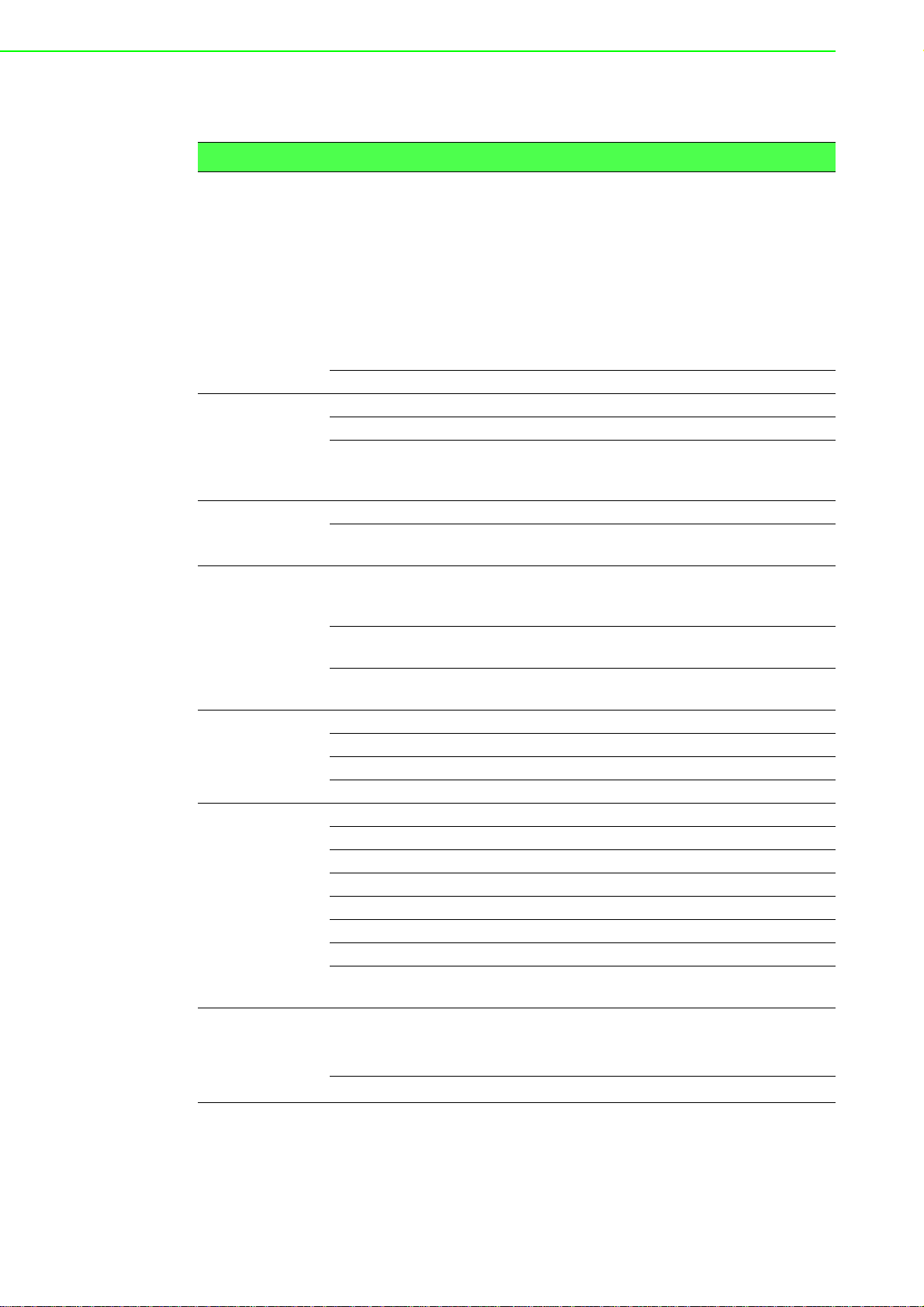

Contents

Chapter 1 Introduction..........................................1

1.1 Overview ................................................................................................... 2

1.2 Device Features........................................................................................2

Chapter 2 Getting Started.....................................3

2.1 Specifications............................................................................................ 4

2.2 Hardware...................................................................................................6

2.2.1 Front View . ...................................... .... ... ... ... ... .... ... ....................... 6

Figure 2.1 Front View ................................................................ 6

Figure 2.2 Front View ................................................................ 7

Figure 2.3 Front View ................................................................ 8

2.2.2 Rear View ..................................................................................... 9

Figure 2.4 Rear View.................................................................9

Figure 2.5 Rear View...............................................................10

2.2.3 Top View.....................................................................................10

Figure 2.6 Top View................................................................. 10

Figure 2.7 Top View................................................................. 11

2.2.4 LED Indicators ............................................................................ 11

Figure 2.8 System LED Panel .................................................11

2.2.5 Dimensions................................................................................. 12

Figure 2.9 Dimensions.............................................................12

Figure 2.10 Dimensions............................................................. 13

2.3 Connecting Hardware .... ... .... ... ... ....................................... ... ... .... ... ... ... .. 14

2.3.1 Choosing a Location.................................................... .... ... ... ... .. 14

Figure 2.11 Installing the Mounting Bracket ..............................14

Figure 2.12 Installing the DIN-Rail Mounting Kit........................ 15

Figure 2.13 Removing the DIN-Rail... ... ... ... ... .... ... ... ... .... ... ... ... .. 15

Figure 2.14 Installing Wall Mount Plates ...................................16

Figure 2.15 Securing Wall Mounting Screws............................. 17

Figure 2.16 Wall Mount Installation ........................................... 17

2.3.2 Serial Connection............................ .... ... ... ... ... .... ........................ 18

Figure 2.17 DB9 Pin Assignment...............................................18

2.3.3 Power Connection.......................................................................18

Figure 2.18 Power Wiring for EKI-1500 Series.......................... 19

Chapter 3 Utility Configuration..........................20

3.1 Installing the Configuration Utility............................................................21

Figure 3.1 InstallShield Wizard 1 of 4...................................... 21

Figure 3.2 InstallShield Wizard 2 of 4...................................... 22

Figure 3.3 InstallShield Wizard 3 of 4...................................... 22

Figure 3.4 InstallShield Wizard 4 of 4...................................... 23

3.2 Starting the Configuration Utility..............................................................24

Figure 3.5 Configuration Utility Overview ................................24

3.3 Discovering Your Device Server ............................................................. 25

3.3.1 Auto Searching ............... ... .... ... ... ....................................... ... .....25

Figure 3.6 Open View of Serial Device Configuration Utility....25

Figure 3.7 Selecting a Group...................................................26

Figure 3.8 Selecting a Device..................................................26

Figure 3.9 Viewing Basic Settings........................................... 26

3.3.2 Network Settings.........................................................................27

Figure 3.10 Utility Overview....................................................... 27

vii EKI-1500 Series User Manual

Page 8

Figure 3.11 Network Settings Overview .................................... 28

3.4 Administrator Settings................. ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... ......... 29

3.4.1 Locate the Serial Device Server ................................................. 29

Figure 3.12 Locate the Serial Device Server............................. 29

3.4.2 Securing the Serial Device Server.............................................. 30

Figure 3.13 Lock the Serial Device Server................................ 30

Figure 3.14 Enter a Password. ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... .. 30

Figure 3.15 Reset Device. ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... .. 31

Figure 3.16 Unlock the Serial Device Server............................. 31

3.4.3 Restore to Factory Default Settings ... ... .... ... ... ... .... ... ... ... ... .... ... .. 32

Figure 3.17 Restore to Factory Default Settings .................. ... .. 32

3.4.4 Resetting the Device................................................................... 33

Figure 3.18 Reset Device. ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... .. 33

3.4.5 Add to Favorite .................................. ... .... ... ... ... .... ... ... ... ... .... ..... 34

Figure 3.19 Add to Favorite........ ... ... ... .... ... ... ... ......................... 34

3.4.6 Auto Mapping.............................................................................. 34

3.4.7 Manual Mapping.......................... ... ... ... .... ... ... ... .... ... ... ............... 34

3.4.8 Update Firmware......................... ... ... ... .... ... ... ... .... ... ... ... ............ 35

Figure 3.20 Update Firmware .. ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... .. 35

Chapter 4 Selecting An Operating Mode.......... 36

4.1 Overview................................................................................................. 37

4.2 COM Port Redirector (Virtual COM Port)................................................ 37

Figure 4.1 Virtual COM Mode.................................................. 37

Figure 4.2 Configuring Virtual COM Mode.. ....... ... ... ... ... .... ... .. 38

4.2.1 Normal mode.............................................................................. 38

4.2.2 Round-Robin mode...................................... ... ... .... ... ... ... ... .... ... .. 38

4.3 USDG Data Mode.......................................... ... ...................................... 39

4.3.1 USDG TCP Client Mode............................................................. 39

Figure 4.3 USDG TCP Client Mode......................................... 39

Figure 4.4 Peers for Receiving Data ....................................... 39

4.3.2 USDG Data TCP Server mode................................................... 40

Figure 4.5 USDG TCP Server Mode........................ ... ... .... ... .. 40

Figure 4.6 USDG Data Mode ................................... ... ... .... ... .. 40

4.3.3 USDG UDP Server/Client mode.. ... ... ... .... ... ... ... .... ... ... ... ... .... ... .. 40

4.4 USDG Control Mode...................................... ... ...................................... 41

Figure 4.7 USDG Control Mode ......................................... ... .. 41

4.4.1 Hangup Character ...................................................................... 41

4.4.2 Guard Time................................................................................. 42

4.5 RFC2217 Mode....................................................................................... 42

Chapter 5 Setting up Virtual COM Port............. 43

5.1 Setting COM Port Redirector .................................................................. 44

5.2 Virtual COM Port Mapping... .... ... ... ......................................................... 44

5.2.1 Auto Mapping.............................................................................. 44

Figure 5.1 Selecting Auto Mapping ......................................... 44

Figure 5.2 Selecting Auto Mapping ......................................... 45

Figure 5.3 Mapping Selected Ports................................ .... ... .. 45

Figure 5.4 Viewing VCOM Mapping Results........................... 45

5.2.2 Manual Mapping.......................... ... ... ... .... ... ... ... .... ... ... ............... 46

Figure 5.5 Selecting Manual Mapping................... ... ... ... .... ... .. 46

Figure 5.6 Viewing Manual VCOM Mapping Results .............. 46

Figure 5.7 Viewing Manual VCOM Mapping Results .............. 47

5.2.3 Configuration Wizard.................................................................. 47

Figure 5.8 Selecting the Configuration Wizard............... .... ... .. 47

5.2.4 Confirming Virtual COM Settings................................................ 48

Figure 5.9 Serial Port Listing on EKI Device ........................... 48

EKI-1500 Series User Manual viii

Page 9

Figure 5.10 System Port VCOM Mapping Configuration...........49

Figure 5.11 Verifying VCOM Mapping Configuration................. 49

5.2.5 Removing VCOM Ports....................... ... ... .................................. 50

Figure 5.12 Remove VCOM Port...............................................50

5.2.6 Exporting and Importing VCOM Mapping................................... 50

5.3 Running a Diagnostic Test......................................................................51

Chapter 6 Web Interface.....................................52

6.1 Overview ................................................................................................. 53

6.2 Accessing the Web Page........................................................................53

6.2.1 Accessing the Web Page via Configuration Utility...................... 53

Figure 6.1 Accessing the Web Page via Configuration Utility..53

6.2.2 Accessing the Web Page via Web Browser................................ 54

6.3 System .................................................................................................... 54

Figure 6.2 System....................................................................54

6.4 Ethernet Configuration ............................................................................55

Figure 6.3 Ethernet Configuration............................................55

6.5 Port Configuration. ... ... ... ... .... ...................................... .... ... ... ... .... ... ... .....56

6.5.1 Basic...........................................................................................56

Figure 6.4 Port Configuration > Basic......................................56

6.5.2 Operation.................................................................................... 57

Figure 6.5 Port Configuration > Operation...............................57

6.5.3 Advanced....................................................................................58

Figure 6.6 Port Configuration > Operation...............................58

6.6 Monitor.................................................................................................... 59

6.6.1 Setting......................................................................................... 59

Figure 6.7 Monitor > Setting....................................................59

6.6.2 Statistic ....................................................................................... 60

Figure 6.8 Monitor > Statistic................................................... 60

6.6.3 Connected IP............ ... ... ....................................... ... ... ...............61

Figure 6.9 Monitor > Connected IP.......................................... 61

6.7 Auto Warning (Alarm)............... ... ... .... ... ... ... .... ... ... .................................. 61

6.7.1 Setting......................................................................................... 61

Figure 6.10 Alarm > Setting.......................................................62

6.7.2 Event........................................................................................... 63

Figure 6.11 Alarm > Event......................................................... 63

6.8 Syslogd ...................................................................................................64

6.8.1 Syslogd Setting......................................... ... ... ............................ 64

Figure 6.12 Syslogd > Syslogd Setting...................................... 64

6.8.2 Syslogd Message............................ .... ... ... ... ... .... ........................ 64

Figure 6.13 Syslogd > Syslogd Message .................................. 64

6.9 Tools ....................................................................................................... 65

6.9.1 Ping............................................................................................. 65

Figure 6.14 Tools > Ping ...........................................................65

6.9.2 Reboot ........................................................................................ 66

Figure 6.15 Tools > Reboot.......................................................66

6.10 Management........................................................................................... 66

6.10.1 Log File.......................................................................................66

Figure 6.16 Management > Log File.......................................... 66

6.10.2 Change Password....................................................................... 67

Figure 6.17 Management > Change Password.........................67

6.10.3 Export Device Settings................................................................ 67

Figure 6.18 Management > Export.......................................... .. 67

6.10.4 Import Device Settings................................................................67

Figure 6.19 Management > Import ............................................67

ix EKI-1500 Series User Manual

Page 10

Chapter 7 Telnet/Serial Console

Configuration .................................... 68

7.1 Overview................................................................................................. 69

7.2 Telnet Console........................................................................................ 69

7.2.1 Create a new connection............................................................ 69

Figure 7.1 Creating a Telnet Connection................................. 69

7.2.2 Input the IP address.................................. ... ... ... .... ... ... ... ... .... ... .. 70

Figure 7.2 Creating a Telnet Connection................................. 70

7.2.3 Connection Success................................................................... 70

Figure 7.3 Telnet Connection Console.................................... 70

7.3 Command List................................................................ .... ... ... ... ... .... ... .. 71

7.3.1 system ........................................................................................ 71

7.3.2 port.............................................................................................. 71

7.3.3 portadv........................................................................................ 72

7.3.4 mvcom........................................................................................ 72

7.3.5 mctrl............................................................................................ 73

7.3.6 mdata.......................................................................................... 73

7.3.7 net............................................................................................... 73

7.3.8 password .................................................................................... 74

7.3.9 alarm........................................................................................... 74

7.3.10 monitor........................................................................................ 74

7.3.11 time............................................................................................. 74

7.3.12 service ........................................................................................ 75

7.3.13 mrfc2217..................................................................................... 75

7.3.14 apply........................................................................................... 75

7.3.15 exit.............................................................................................. 75

7.3.16 help............................................................................................. 75

7.3.17 reboot.......................................................................................... 75

Chapter A TCP and UDP Port Numbers............ 76

A.1 List of Known TCP and UDP Port Numbers ........................................... 77

EKI-1500 Series User Manual x

Page 11

Chapter 1

1Introduction

Page 12

1.1 Overview

The EKI-1500 Series are network-based serial device servers that connect RS-232/

422/485 serial devices, such as PLC, meters, sensors, and barcode readers, directly

to a TCP/IP network.

Once connected through a EKI-1500 Series serial server, devices are able to send

and receive data through a network. This extends the traditional COM ports of a PC,

with access over a TCP/IP network. Through networking, you can control and monitor remote serial devices over either a LAN or WAN. Since the EKI-1500 Series is

connected through a TCP/IP network, you may need to know some basic facts about

networking in order to connect the server correctly.

The EKI-1500 Series features two independent Ethernet ports and MAC addresses

to provide a redundant network mechanism to avoid data loss. The EKI-1500 Series

provides various operations: COM port redirection mode (Virtual COM Port mode),

TCP Server/ Client mode, UDP mode, Control mode and RFC2217 mode. Detailed

descriptions of each operation are provided in a later chapter.

1.2 Device Features

Provides 2 x 10/100 Mbps Ethernet ports for LAN redundancy

Provides COM port redirection (Virtual COM), TCP and UDP operation modes

Supports up to 921.6 kbps, and any baud rate setting

Allows a max. of 5 hosts to access one serial port

Allows a max. of 16 hosts to be accessed as TCP client mode

Built-in 15 KV ESD protection for all serial signals

Provides rich configuration access, including: Windows utility, Telnet console,

and Web Browser

Supports 32-bit/64-bit Windows 2000/XP/Vista/7/8/8.1/10, Windows Server

2003/2008/2012, and Linux

Automatic RS-485 data flow control

Supports surge protection for D.C. power ports with line to line 2 KV, and line to

earth 4 KV; for signal ports with 4 KV.

Supports a wide operating temperature (I models only)

Supports isolation and wide operating temperature (CI models only)

EKI-1500 Series User Manual 2

Page 13

Chapter 2

2Getting Started

Page 14

2.1 Specifications

Specifications Description

Interface I/O Port

Power Connector Terminal block

Physical Enclosure Metal with solid mounting hardware

Installation DIN-Rail and Wall mount

Dimensions

(W x H x D)

LED Display System LED Power 1, Power 2, Status

Port LED LAN: Speed, Link/Active

Environment Operating

Temperature

Storage

Temperature

Ambient Relative

Humidity

Ethernet

Communications

Serial

Communications

Power Power

Compatibility IEEE 802.3, IEEE 802.3u

Speed 10/100 Mbps

Port Connector 8-pin RJ45

Protection Built- in 1.5 KV magnetic isolation

Port Type RS-232/422/485, software selectable

Port Connector DB9 male

Data Bits 5, 6, 7, 8

Stop Bits 1, 1.5, 2

Parity None, Odd, Even, Space, Mark

Flow Control XON/XOFF, RTS/CTS, DTR/DSR

Baud Rate 50 bps ~ 921.6 kb ps, any baud rat e se ttin g

Protection Built-in 15 KV ESD for all signals

Consumption

Power Input 12 ~ 48V

EKI-1521: 2 x RJ45 + 1 x RS-232/422/485

EKI-1521I: 2 x RJ45 + 1 x RS-232/422/485

EKI-1521CI: 2 x RJ45 + 1 x RS-422/485

EKI-1522: 2 x RJ45 + 2 x RS-232/422/485

EKI-1522I: 2 x RJ45 + 2 x RS-232/422/485

EKI-1522CI: 2 x RJ45 + 2 x RS-422/485

EKI-1524: 2 x RJ45 + 4 x RS-232/422/485

EKI-1524I: 2 x RJ45 + 4 x RS-232/422/485

EKI-1524CI: 2 x RJ45 + 4 x RS-422/485

EKI-1521/EKI-1522: 36.6 x 140 x 95mm (1.44" x

5.51" x 3.74")

EKI-1524: 48.6 x 140 x 95mm (1.91" x 5.51" x 3.74")

Serial: Tx, Rx

EKI-1521/EKI-1522/EKI-1524: -10°C ~ 60°C (14°F ~

140°F)

‘CI & I’ models: -40°C ~ 70°C (-40°F ~ 158°F)

-40°C ~ 85°C (-40°F ~ 185°F)

5 ~ 95% RH

'CI' models: 2KV Isolation for RS-422/485 signals

EKI-1521: 5.2W

EKI-1522: 5.2W

EKI-1524: 6.3W

, redundant dual inputs

DC

EKI-1500 Series User Manual 4

Page 15

Specifications Description

Software Driver Support 32-bit/64-bit Windows XP/Vista/7/8/8.1/10, Windows

Server 2003/2008/2008 R2/2012/2012 R2, and Linux

Utility Advantech EKI Device Configuration Utility

Operation Modes

COM port redirection mode (Virtual COM)

TCP/UDP server (polling) mode

TCP/UDP client (event handling) mode

Pair connection (peer to peer) mode

Configuration Windows utility , Telnet console, Web Browser

Management SNMP MIB-II

Regulatory

Approvals

EMC CE, FCC Part 15 Subpart B (Class A)

Safety UL (UL60950-1), Class 1, Div II, ATEX

5 EKI-1500 Series User Manual

Page 16

2.2 Hardware

1

2

3

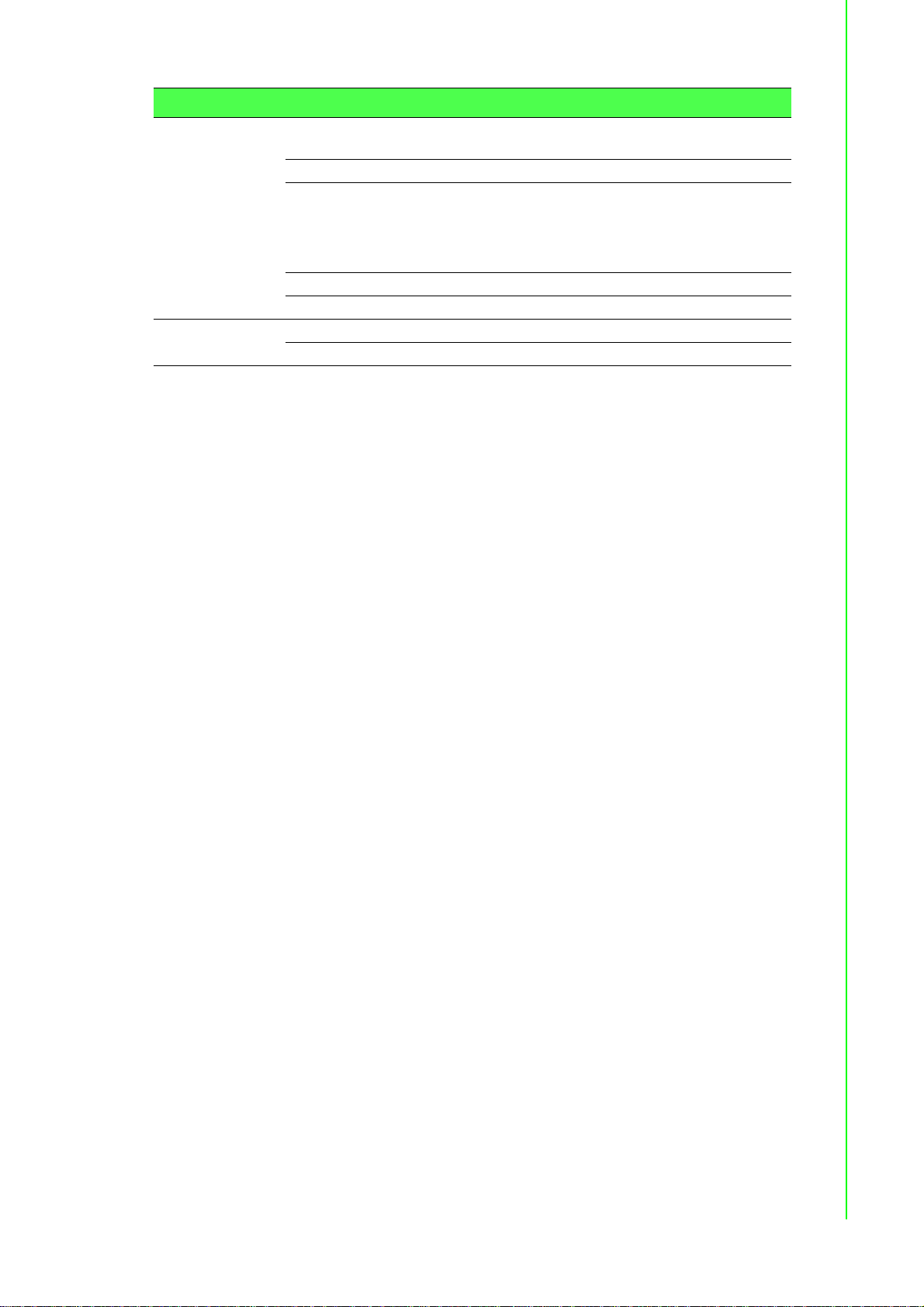

2.2.1 Front View

The following view shows the EKI-1521.

P1 P2 Status

Default

1

LAN

2

TxRx

Serial ports

1

EKI-1521

Figure 2.1 Front View

No. Item Description

1 System LED panel See “LED Indicators” on page 11 for further details.

2 ETH port RJ45 ports x 2

3 Serial port DB9 pinout, supports RS-232/422/485

EKI-1500 Series User Manual 6

Page 17

The following view shows the EKI-1522.

1

1

2

Default

LAN

TxRx

TxRx

P1 P2 Status

Serial ports

EKI-1522

1

2

3

Figure 2.2 Front View

No. Item Description

1 System LED panel See “LED Indicators” on page 11 for further details.

2 ETH port RJ45 ports x 2

3 Serial port DB9 pinout, supports RS-232/422/485

7 EKI-1500 Series User Manual

Page 18

The following view shows the EKI-1524.

1

2

3

P1 P2 Status

Default

1

LAN

2

TxRx

TxRx

Serial ports

TxRx

1

2

3

TxRx

4

EKI-1524

Figure 2.3 Front View

No. Item Description

1 System LED panel See “LED Indicators” on page 11 for further details.

2 ETH port RJ45 ports x 2

3 Serial port DB9 pinout, supports RS-232/422/485

EKI-1500 Series User Manual 8

Page 19

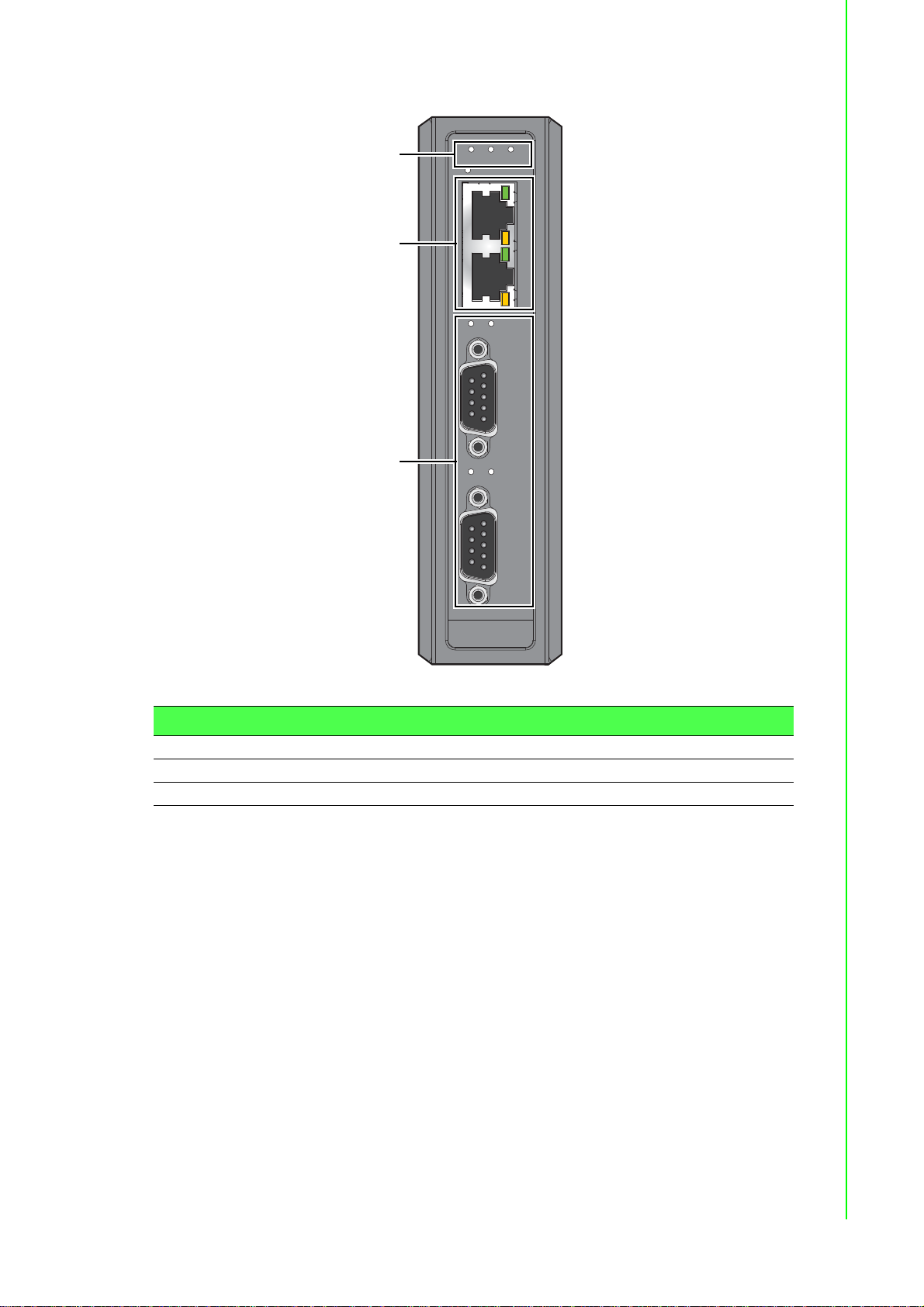

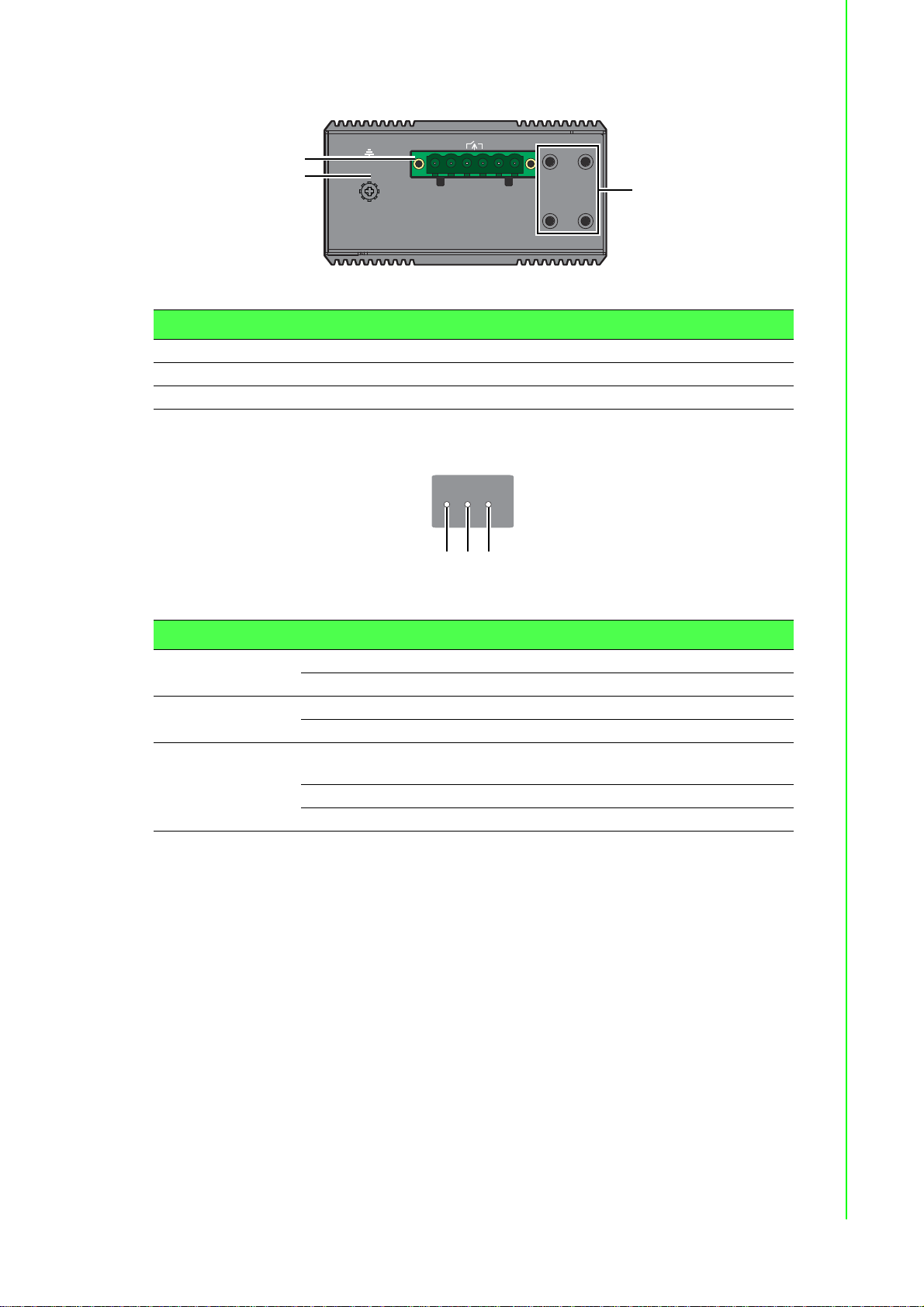

2.2.2 Rear View

1

The following view is valid for the EKI-1521 and EKI-1522.

Figure 2.4 Rear View

No. Item Description

1 DIN-Rail mounting

plate

Mounting plate used for the installation to a standar d DIN rail

9 EKI-1500 Series User Manual

Page 20

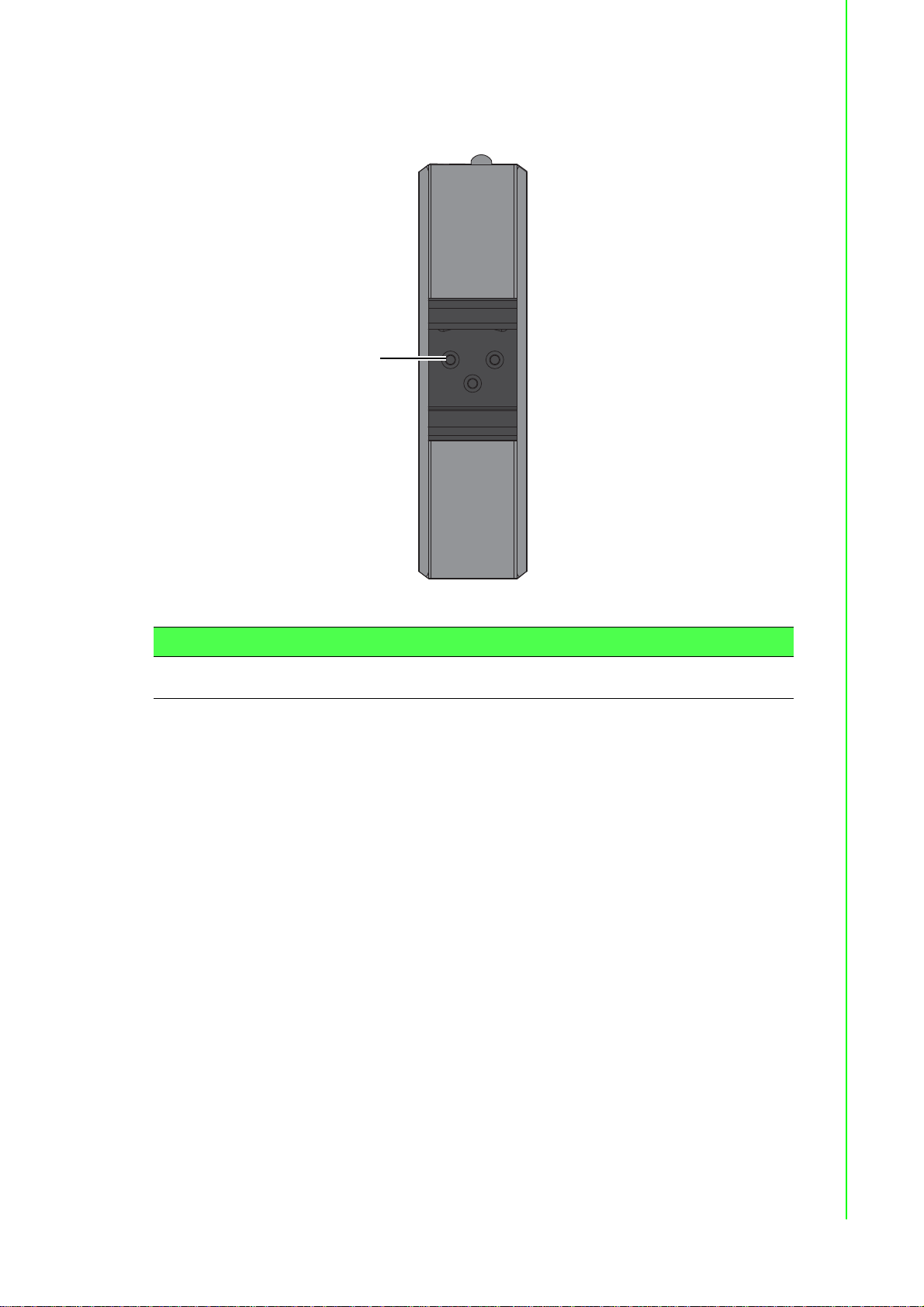

The following view shows the EKI-1524.

1

1

3

2

No. Item Description

1 DIN-Rail mounting

plate

2.2.3 Top View

The following view is valid for the EKI-1521 and EKI-1522.

No. Item Description

1 Terminal block Connect cabling for power and alarm wiring

2 Ground terminal Screw terminal used to ground chassis

3 Wall mounting holes Screw holes (x4) used in the installation of a wall mounting plate

Figure 2.5 Rear View

Mounting plate used for the installation to a standard DIN rail

P-Fail

V2- V2+ V1- V1+

1A@24V

DC12-48V

PWR1

PWR2

Figure 2.6 Top View

EKI-1500 Series User Manual 10

Page 21

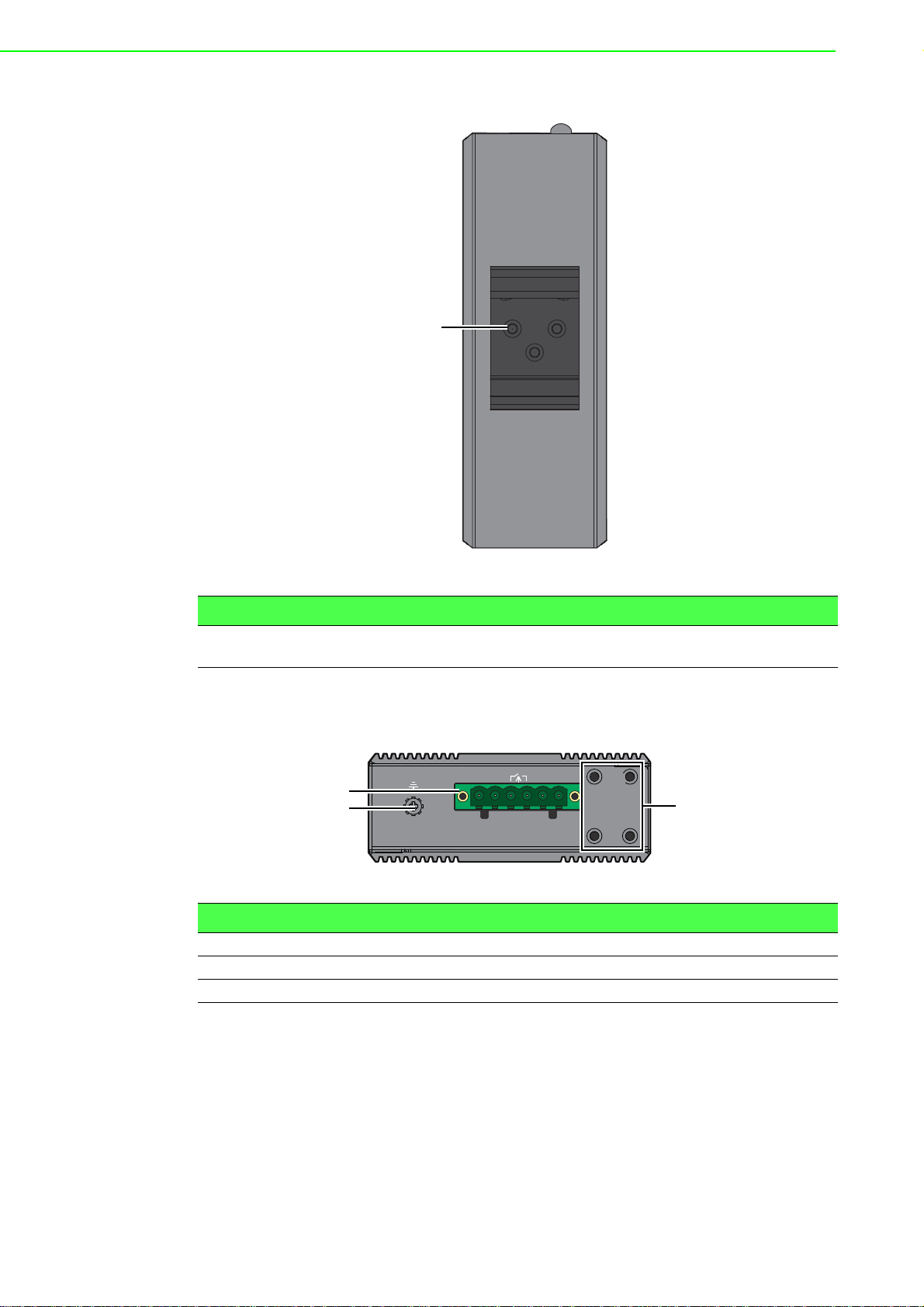

The following view is valid for the EKI-1524.

1

3

2

P1 P2 Status

12

3

No. Item Description

1 Terminal block Connect cabling for power and alarm wiring

2 Ground terminal Screw terminal used to ground chassis

3 Wall mounting holes Screw holes (x4) used in the installation of a wall mounting plate

2.2.4 LED Indicators

P-Fail

V2- V2+ V1- V1+

1A@24V

DC12-48V

PWR1

PWR2

Figure 2.7 Top View

Figure 2.8 System LED Panel

No. LED Name LED Color Description

1 P1 Green Power 1 is on

Off Power 1 is off, or power error condition exists

2 P2 Green Power 2 is on

Off Power 2 is off, or power error condition exists

3 Status Amber The device server has been located by utility’s loca-

tion function

Amber, blinking System is ready (1cycle/sec.)

Off System is not working

11 EKI-1500 Series User Manual

Page 22

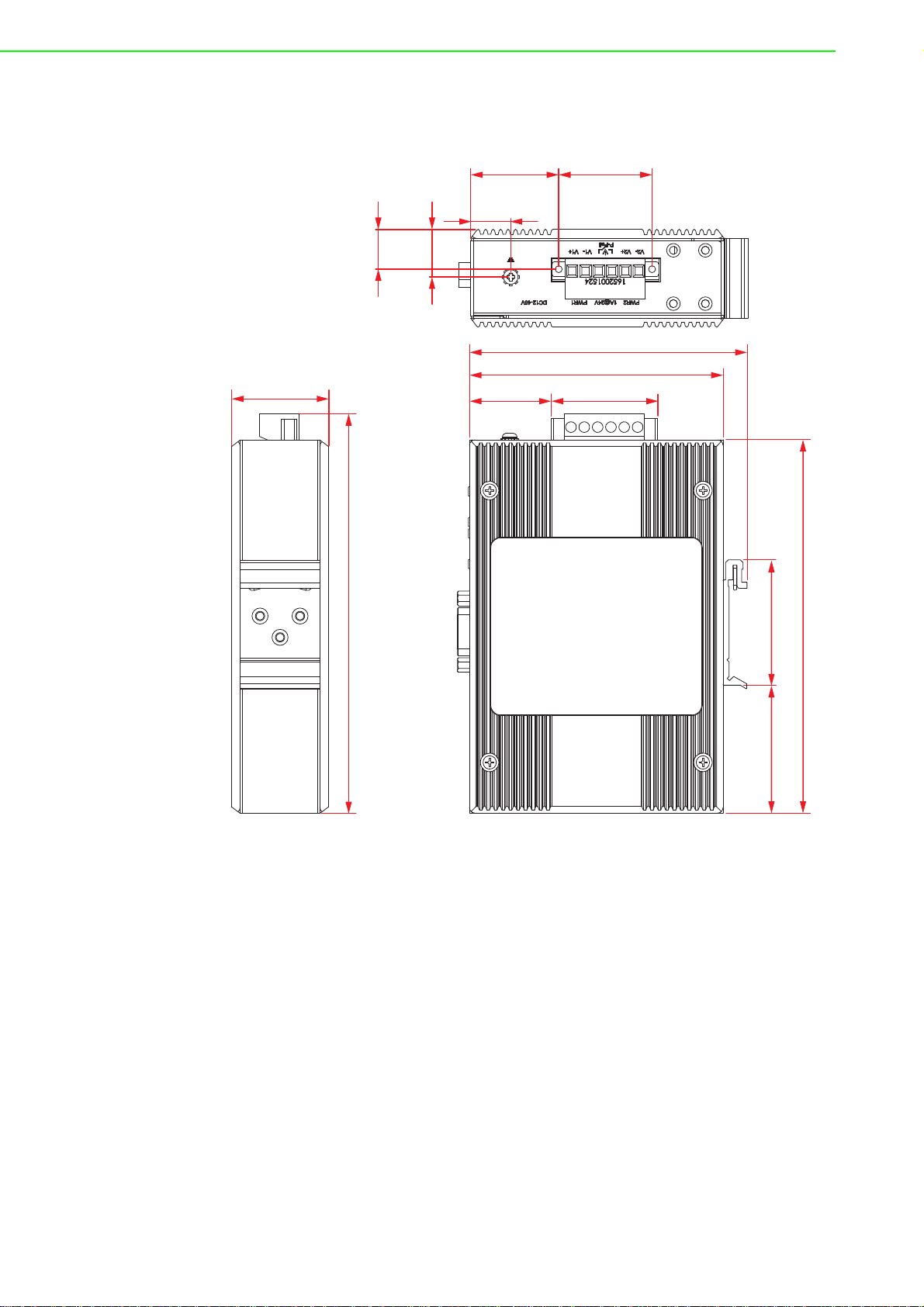

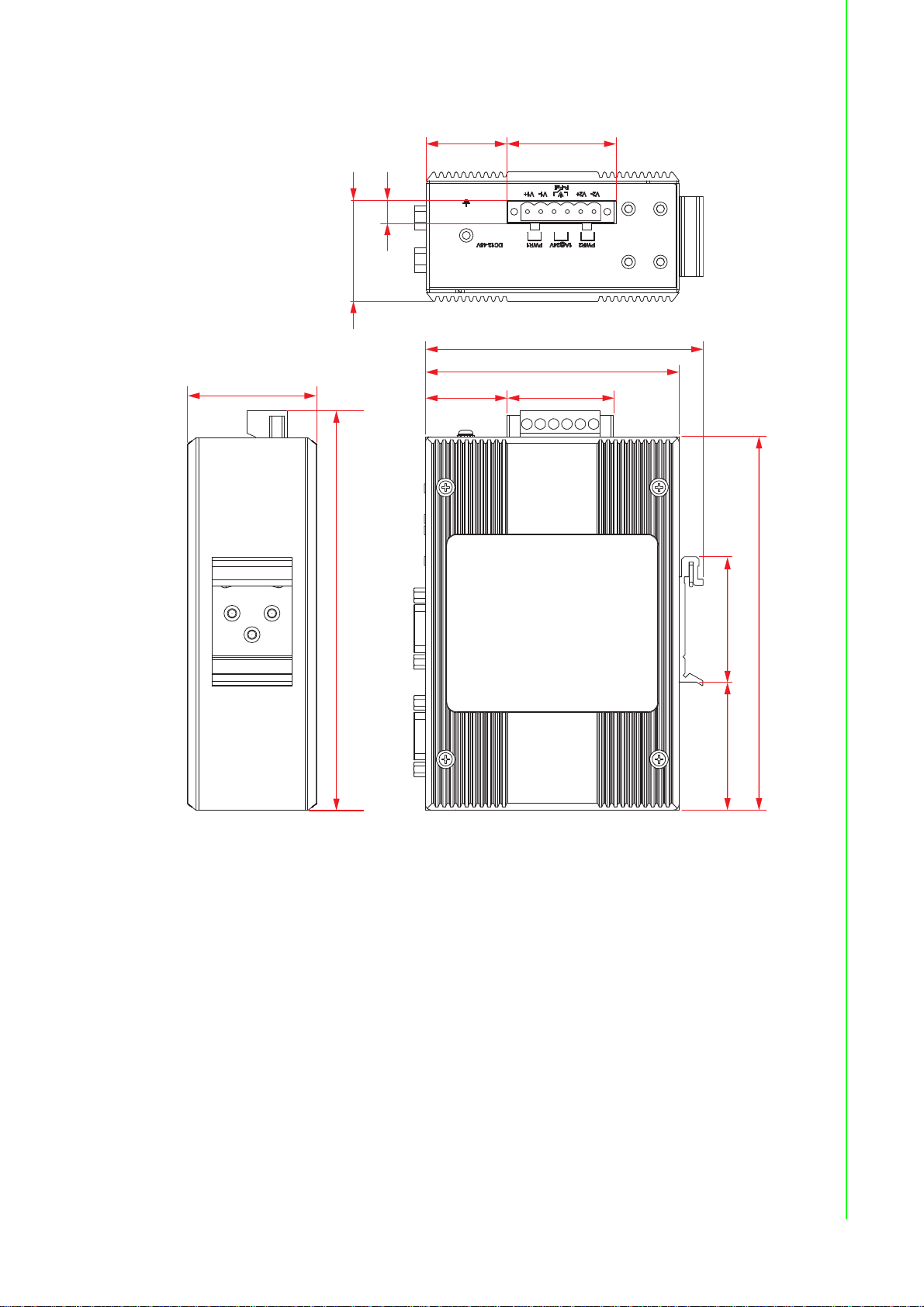

2.2.5 Dimensions

33

15

35

14.90

17.83

Unit: mm

The following view is valid for the EKI-1521 and EKI-1522.

36.60

104

95

30.50 40

149.80

Figure 2.9 Dimensions

47.0547.95

140

EKI-1500 Series User Manual 12

Page 23

The following view is valid for the EKI-1524.

104

95

30.50 40

140

47.0547.95

Unit: mm

30.5 40

8.32

37.70

48.60

149.80

Figure 2.10 Dimensions

13 EKI-1500 Series User Manual

Page 24

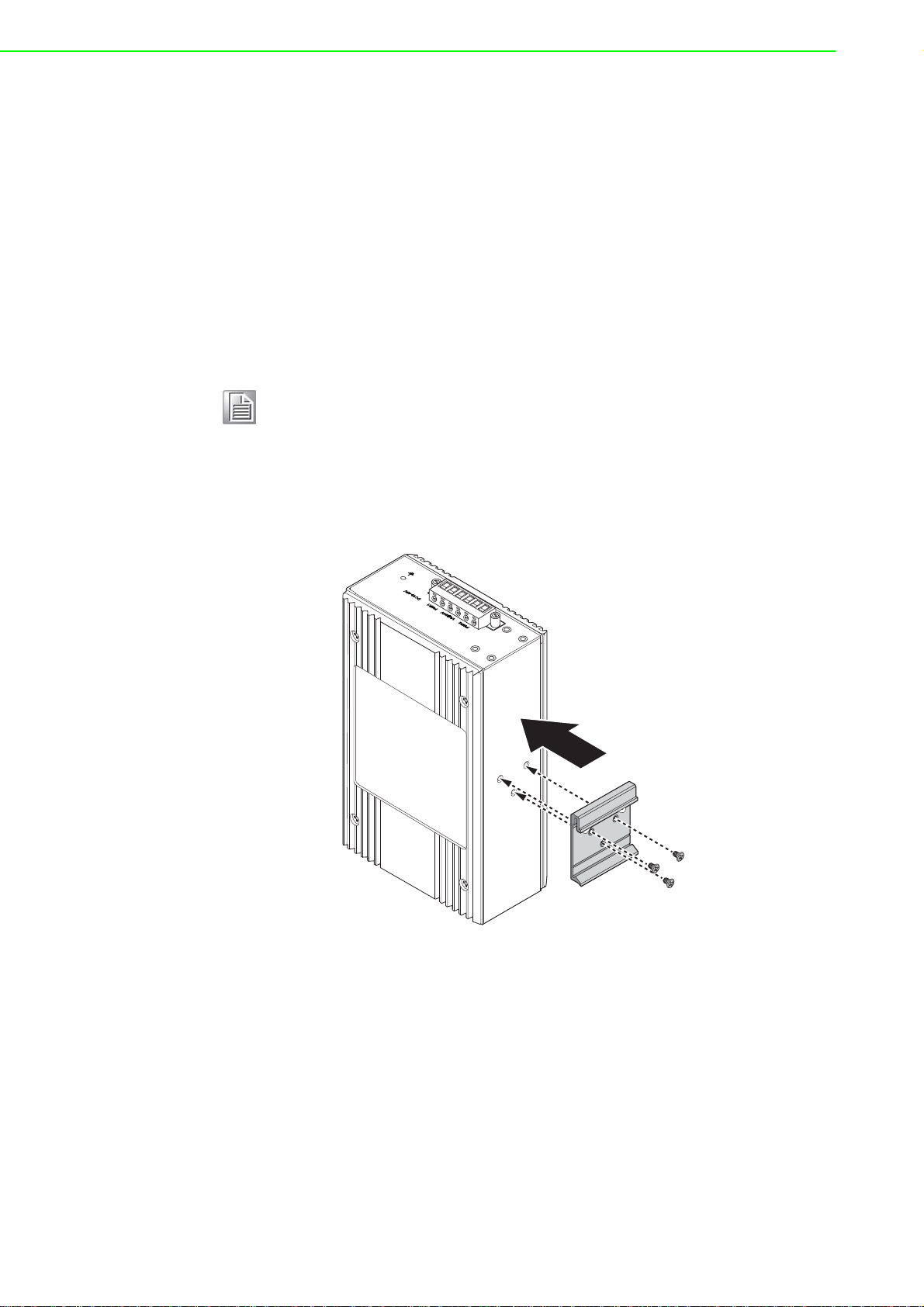

2.3 Connecting Hardware

2.3.1 Choosing a Location

2.3.1.1 DIN Rail Mounting

The DIN rail mount option is the quickest installation option. Additionally, it optimizes

the use of rail space.

The metal DIN rail kit is secured to the rear of the serial device server. The device

can be mounted onto a standard 35mm (1.37”) x 75mm (3”) height DIN rail. The

devices can be mounted vertically or horizontally. Refer to the following guidelines for

further information.

Note! A corrosion-free mounting rail is advisable.

When installing, make sure to allow for enough space to properly install

the cabling.

Installing the DIN-Rail Mounting Kit

1. Align the mounting bracket on the rear side. The screw holes on the device and

the mounting bracket must be aligned, see the following illustration.

2. Secure the mounting bracket with M3 screws, see the following figure.

\

Figure 2.11 Installing the Mounting Bracket

EKI-1500 Series User Manual 14

Page 25

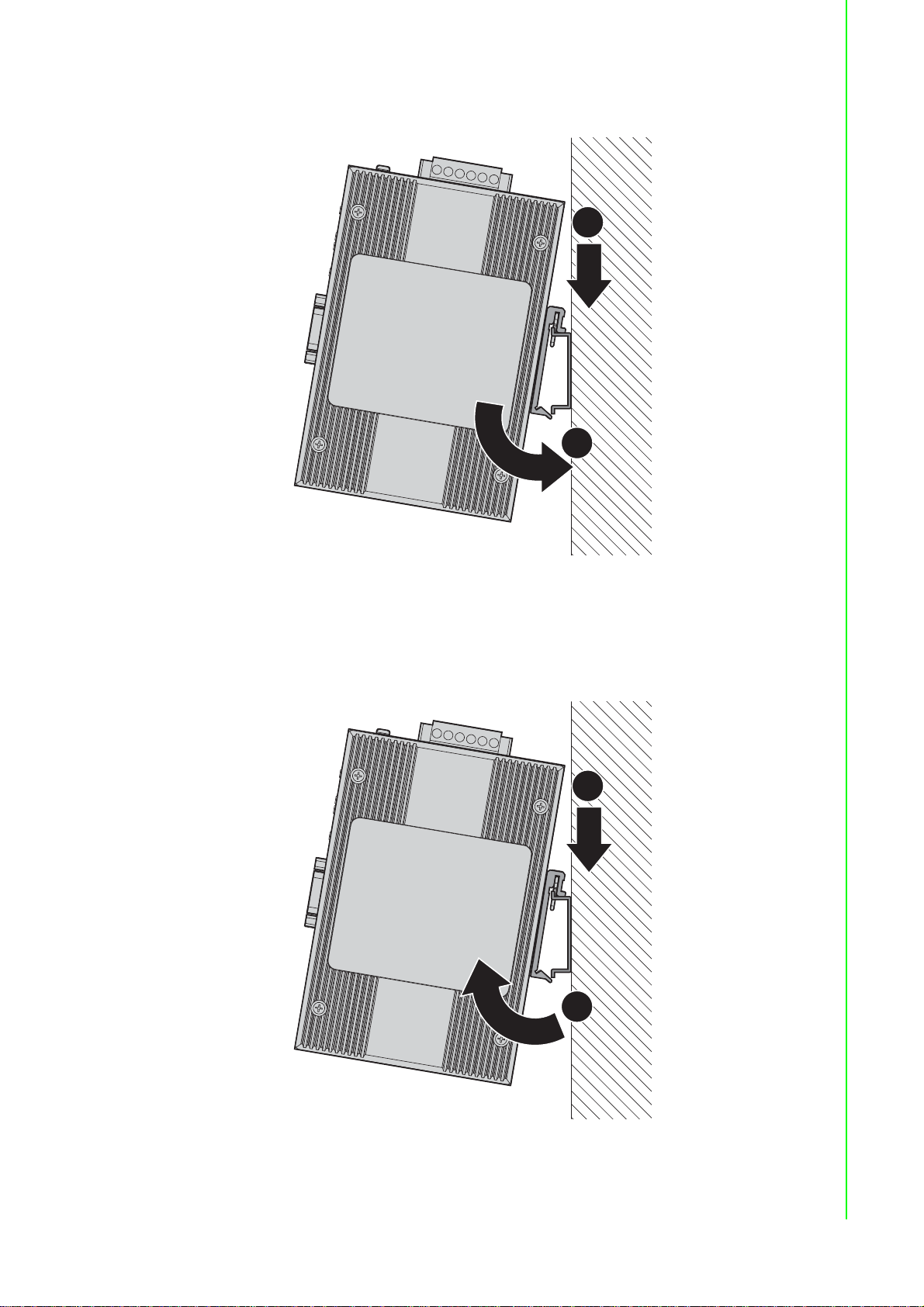

3. Insert the top back of the mounting bracket over the DIN rail.

DIN Rail

DIN Rail

4. Push the bottom of the server towards the DIN rail until it snaps into place.

\

1

2

Figure 2.12 Installing the DIN-Rail Mounting Kit

Removing the DIN-Rail Mounting Kit

1. Push the server down to free the bottom of the plate from the DIN rail.

2. Rotate the bottom of the device towards you and away from the DIN rail.

3. Once the bottom is clear of the DIN rail, lift the device straight up to unhook it

from the DIN rail.

\

1

2

Figure 2.13 Removing the DIN-Rail

15 EKI-1500 Series User Manual

Page 26

2.3.1.2 Wall-Mounting

The wall mounting option provides better shock and vibration resistance than the DIN

rail vertical mount.

Note! When installing, make sure to allow for enough space to properly install

the cabling.

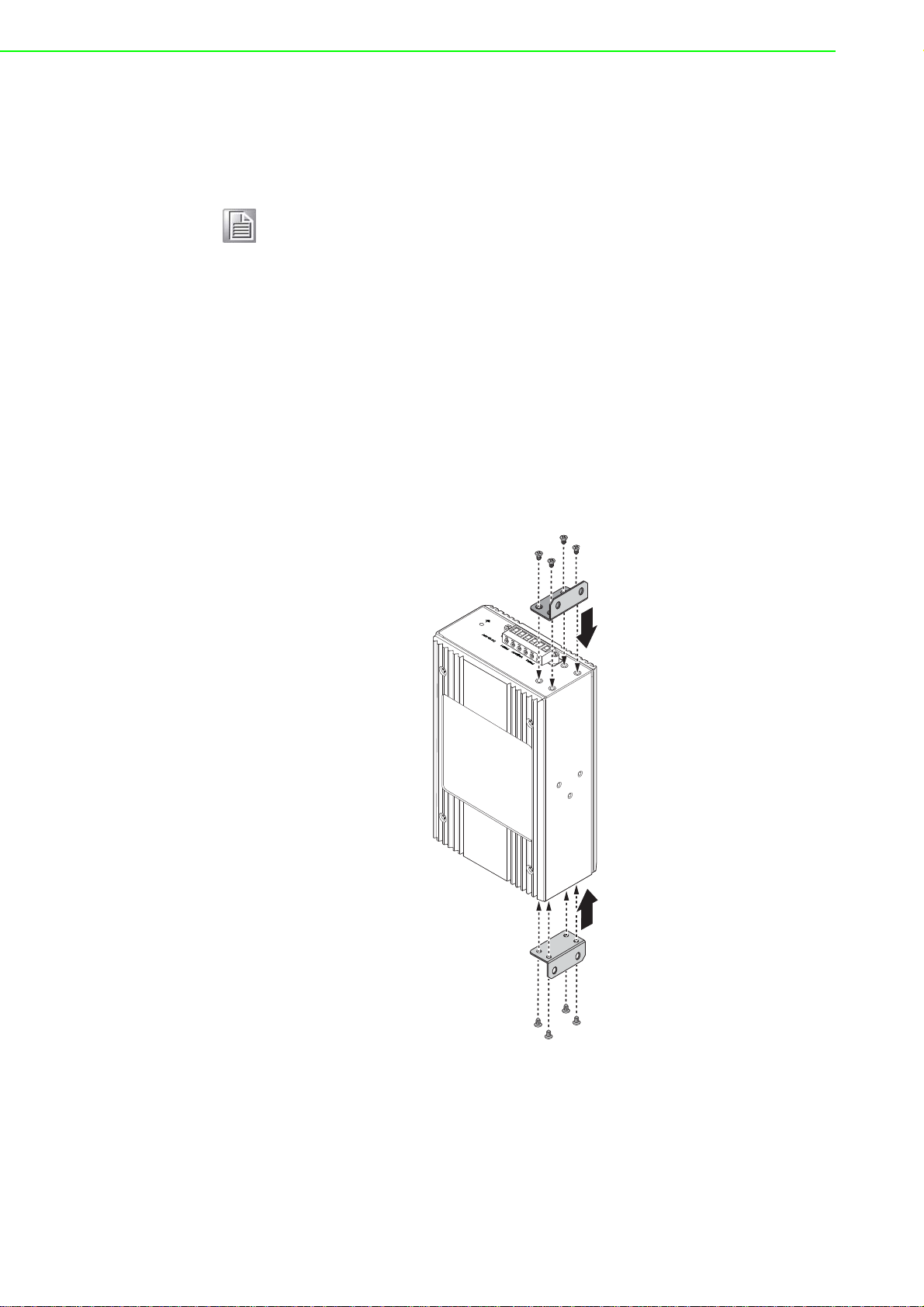

Before the device can be mounted on a wall, you will need to remove the DIN rail

plate.

1. Rotate the device to the rear side and locate the DIN mounting plate.

2. Remove the screws securing the DIN mounting plate to the rear panel of the

server.

3. Remove the DIN mounting plate. Store the DIN mounting plate and provided

screws for later use.

4. Align the wall mounting plates on the top and bottom side. The screw holes on

the device and the mounting plates must be aligned, see the following illustration.

5. Secure the wall mount plates with M3 screws, see the following figure.

Figure 2.14 Installing Wall Mount Plates

Once the wall mounting plates are secure on the device, you will need to attach

the wall screws (x8).

EKI-1500 Series User Manual 16

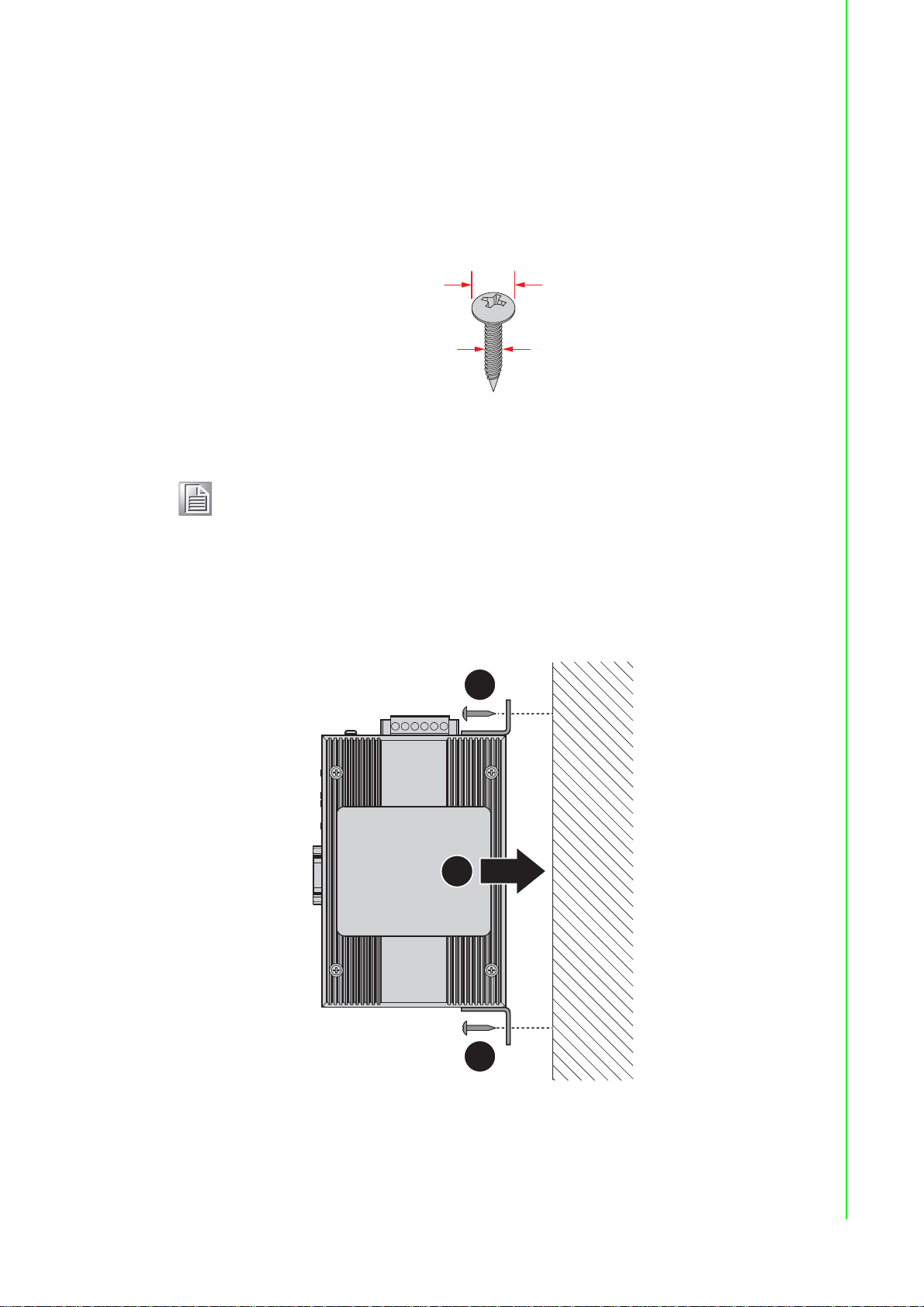

Page 27

6. Locate the installation site and place the server against the wall, making sure it

8 mm

4 mm

2

2

1

is the final installation location.

7. Use the wall mount plates as a guide to mark the locations of the screw holes.

8. Drill four holes over the four marked locations on the wall, keeping in mind that

the holes must accommodate wall sinks in addition to the screws.

9. Insert the wall sinks into the walls.

10. Insert the screws into the wall sinks.

Figure 2.15 Securing Wall Mounting Screws

Note! Make sure the screws dimensions are suitable for use with the wall

mounting plate.

Do not completely tighten the screws into the wall. A final adjust-

ment may be needed before fully securing the wall mounting plates

on the wall.

11. Align the wall mount plate over the screws on the wall.

12. Install the wall mount plate on the screws and slide it forward to lock in place,

see the following figure.

13. Once the device is installed on the wall, tighten the screws to secure the device.

Figure 2.16 Wall Mount Installation

17 EKI-1500 Series User Manual

Page 28

2.3.2 Serial Connection

1

9

6

5

EKI-1500 Series provides up to four ports DB9 (male) connectors. RS-232/422/485

pin assignments as below:

Pin 1 2 3 4 5 6 7 8 9

RS-232 DCD RX TX DTR GND DSR RTS CTS RI

RS-422 TX- TX+ GND RX+ RXRS-485 DATA- DATA+ GND

2.3.3 Power Connection

2.3.3.1 Overview

Figure 2.17 DB9 Pin Assignment

Warning! Power down and disconnect the power cord before servicing or wiring

the serial device server.

Caution! Do not disconnect modules or cabling unless the power is first switched

off.

The device only supports the voltage outlined in the type plate. Do not

use any other power components except those specifically designated

for the serial device server.

Caution! Disconnect the power cord before installation or cable wiring.

The EKI-1500 Series supports dual 12 to 48 VDC power inputs and power-fail relay

output.

EKI-1500 Series User Manual 18

Page 29

The following figure illustrates a P-Fail alarm application example. The P-Fail alarm

PWR2

P-Fail

DC12-48V

PWR1

V2- V2+ V1- V1+

1A@24V

Load

External

Power

contacts are visible on the front view of the terminal block.

Figure 2.18 Power Wiring for EKI-1500 Series

You can connect an alarm indicator, buzzer or other signaling equipment through the

relay output. The relay opens if power input 1 or 2 fails. In a wiring example where an

LED is connected to the relay output, the LED would be off in an Open state.

19 EKI-1500 Series User Manual

Page 30

Chapter 3

3Utility Configuration

Page 31

3.1 Installing the Configuration Utility

Note! Microsoft.NET Framework version 2.0 or greater is required for this

application.

1. Insert the Advantech EKI Device Configuration Utility CD-ROM into the CD-

ROM drive (whereas E:\ is the drive name of your CD-ROM) on the host PC.

2. Use Windows explorer or the Windows Run command to execute the setup pro-

gram, the path for the setup program on the CD-ROM is as follows:

E:\EKI_Device_Configuration_Utility_v2.01.exe

3. If there is an existing COM port mapping utility on the host PC, remove it at this

time. A system reboot may be necessary before continuing the installation.

4. Once the InstallShield Wizard screen displays, click Next to proceed with the

installation.

Figure 3.1 InstallShield Wizard 1 of 4

21 EKI-1500 Series User Manual

Page 32

5. The Software License Agreement displays, press I Agree to continue or Cancel

to stop the installation.

Figure 3.2 InstallShield Wizard 2 of 4

The InstallShield continues and a status screen displays. The default inst allation

path is C:\Program Files\EKI Device Configuration Utility.

Figure 3.3 InstallShield Wizard 3 of 4

EKI-1500 Series User Manual 22

Page 33

6. Once the installation of the package is finished a Configuration Utility Setup

screen displays. Click Finish to conclude the process and exit the InstallShield

Wizard.

Figure 3.4 InstallShield Wizard 4 of 4

23 EKI-1500 Series User Manual

Page 34

3.2 Starting the Configuration Utility

5

4

3

2

6

1

Advantech EKI series serial device servers provide an easy-to-use utility to configure

your serial device server through an Ethernet connection. For secure administration,

it can also restrict the access rights for configuration to only one host PC. With this

secure function enabled, other PCs will not have permission for configuration. After

the installation program on the Advantech IEDG Series Driver Utility CD-ROM is finished, the serial device servers are ready for use and configuration.

Advantech Serial Device Server Configuration Utility is an excellent device server

management tool. You can connect and configure the local and remote Advantech

serial device servers easily. The utility provides access to the following functions:

Configure the network settings (you can set the IP address, Gateway address,

and Subnet mask)

View and set the serial port parameters (configure operating mode, baud rate,

serial port settings and operating mode settings)

Perform diagnostic tests (virtual COM port testing, port status list)

Perform administrative functions (export and import the serial device server set-

ting, manage access IP, a descriptive name, upgrade firmware)

You can open the Configuration Utility fro m the Wind ows Start Menu by clicking Start

> All Programs > EKI Device Configuration Utility > EKI Device Configuration

Utility. The Configuration Utility displays as shown in the following figure.

Figure 3.5 Configuration Utility Overview

No Item Description

1 Menu Bar Displays File, View, Management, Tools and Help.

EKI-1500 Series User Manual 24

2 Quick Tool Bar Useful management functions shortcuts.

3 Serial Device Server

List Area

4 Information Panel Click on the devices or move cursor to the devices, the related

5 Status Bar Displays the current time.

6 Configuration Area Click on the item on the Device Server List Area, the configura-

Available devices are listed in this area. Devices and COM ports

can be organized or grouped in this area.

information is shown in this area.

tion page displays.

Page 35

3.3 Discovering Your Device Server

3.3.1 Auto Searching

Advantech Serial Device Server Configuration Utility will automatically search all the

EKI-1500 Series device servers on the network and show them on the Serial Device

Server List Area of the utility. The utility provides an auto-search function to show

your device (s) by simply executing the configuration utility program from the Start

Menu.

From here all device on the same network domain will be searched and displayed on

Device Server List Area. You can click on the device name to show the features of

the specific device.

Click on the “+” before the model name, and the utility will expand the tree structure

to show the individual device name. Click on the “-” before the model name, and the

utility will collapse the tree structure.

Figure 3.6 Open View of Serial Device Configuration Utility

In the previous figure, the EKI serial device server is listed as EKI-1524-BE-04FFAB.

Note! When you run the configuration utility for the first time, the default device

name is obtained from the serial device’s MAC identification number.

The name can be altered through the configuration utility.

Select the device in this sub-tree. The first tab on the Configuration Area shows the

summary of “Basic Information” included device type, version, and name, “Ethernet

25 EKI-1500 Series User Manual

Page 36

Information”, and “Serial Port Information”. The serial port information frame displays

the operation mode, status and connected host IP.

Figure 3.7 Selecting a Group

Click on the “+” before the device name, and the utility will expand the interfaces on

this device server.

Figure 3.8 Selecting a Device

Click on each item to enter the configuration page to change the setting. The configuration will be introduced on following sections.

Figure 3.9 Viewing Basic Settings

EKI-1500 Series User Manual 26

Page 37

3.3.2 Network Settings

Prior to setting up the server’s IP address determine the IP address mode.

There are four mode types available:

Static IP: mode to assign a specific assigned address

DHCP / AutoIP: mode to automatically assign IP addresses through a DHCP

server

BOOTP / AutoIP: mode to automatically assign an IP address through the con-

figuration server

DHCP/BOOTP/AutoIP: mode to automatically assign an IP address using a

Bootstrap Protocol or DHCP server.

The server is set with the following default IP configuration:

10.0.0.1 (Eth1)

10.0.0.2 (Eth2)

The EKI series includes a software utility option, which you can install on your system, for configuration through computer-based software. The EKI series also

includes a web interface option for configuration through a standard web browser.

Figure 3.10 Utility Overview

27 EKI-1500 Series User Manual

Page 38

You can choose from four possible IP Configuration modes --- Static, DHCP, BOOTP,

and DHCP/BOOTP.

Figure 3.11 Network Settings Overview

Item Description

Static IP Static IPUser defined IP address, Subnet Mask, and Default Gateway.

DHCP + Auto-IP DHCP Server assigned IP address, Subnet Mask, Default Gateway,

and DNS.

BOOTP + Auto-IP BOOTP Server assigned IP address.

DHCP + BOOTP +

Auto-IP

DNS Setting In order to use DNS feature, you need to set the IP address of the

DHCP Advanced

Setting

DHCP Server assigned IP address, Subnet Mask, Default Gateway,

and DNS, or BOOTP Server assigned IP address. (If the DHCP

Server does not respond)

DNS server to be able to access the host with the domain name. The

EKI serial device server provides Primary DNS Server and Seconda ry

DNS Server configuration items to set the IP address of the DNS

server. Secondary DNS Server is included for use when Primary DNS

server is unavailable.

When you enabling DHCP protocol to get IP address, it will be waited

DHCP server to give IP within DHCP time out. The default value is

180 seconds.

Note! When you have finished the configuration of these settings for each cat-

egory, please press the “Apply” button in order to make these settings

effective on the Serial Device Server.

EKI-1500 Series User Manual 28

Page 39

3.4 Administrator Settings

3.4.1 Locate the Serial Device Server

When several serial device servers are connected to the network, identification of a

specific serial device is possible through the Locate function.

To locate the serial device server:

1. From the device list frame, locate the desired device and right-click on it to dis-

play the settings menu.

2. Select Locate from the menu.

Figure 3.12 Locate the Serial Device Server

The unit’s Status LED will turn solid amber and the buzzer will sound until you click

Stop Locate.

29 EKI-1500 Series User Manual

Page 40

3.4.2 Securing the Serial Device Server

3.4.2.1 Lock the Serial Device Server

The configuration utility provides the “Lock Device” function to make it more secure.

To lock the serial device server:

1. Right-click a desired device to display the settings menu.

2. Select Lock Device.

Figure 3.13 Lock the Serial Device Server

3. Enter a password. Retype the password entry to confirm the profile password.

Figure 3.14 Enter a Password

EKI-1500 Series User Manual 30

Page 41

4. Right-click a desired device to display the settings menu. Select Reset Device

to restart the serial device server and store your setting p assword into th e memory.

Figure 3.15 Reset Device

3.4.2.2 Unlock the Serial Device Server

To unlock the serial device server:

1. Right-click a desired device to display the settings menu.

2. Select Unlock Device.

3. Enter the password as entered in the Lock Device procedure.

Figure 3.16 Unlock the Serial Device Server

If you forgot the password, you must restore the setting of the serial device server to

the factory defaults, which will be introduced in the next section.

31 EKI-1500 Series User Manual

Page 42

3.4.3 Restore to Factory Default Settings

The configuration utility provides the function to restore the serial device server to

factory default settings.

Figure 3.17 Restore to Factory Default Settings

The confirm message will display after clicking Restore to Factory Default Settings. If you really want to restore the serial device sever to factory default settings,

please click Yes button to continue.

Power off the serial device server within ten seconds. After reconnecting the power,

all settings will be reset to the factory default. If the power supply remains connected

for more than ten seconds, the serial device server will not be changed.

EKI-1500 Series User Manual 32

Page 43

3.4.4 Resetting the Device

The Reset Device is available to allow you to reset the serial device server . The fun ction disconnects both the ethernet and serial connections.

The function also allows the serial device server to save new configuration settings to

flash memory. Once a new setting is changed, you can use the Save function to

accept the changes. You will need to reset the device to save the settings to flash

memory.

From the To access this page, click Tools > Reboot.

Click Reboot to reboot the serial device server. Any configuration changes you have

made since the last time you saved will be lost.

To reset the device:

1. Right-click a desired device to display the settings menu.

2. Select Reset Device.

Figure 3.18 Reset Device

The device resets. Once the process is complete, the serial device server displays

under the Serial Device Server listing once again.

33 EKI-1500 Series User Manual

Page 44

3.4.5 Add to Favorite

The Add to Favorite function allows to easily map available devices to Favorite’s. By

bookmarking specific devices, you can create quickly accessible shortcuts for existing critical devices from the vast pool of locally or remotely networked EKI devices.

Figure 3.19 Add to Favorite

3.4.6 Auto Mapping

See “Auto Mapping” on page 44 for further details.

3.4.7 Manual Mapping

See “Manual Mapping” on page 46 for further details.

EKI-1500 Series User Manual 34

Page 45

3.4.8 Update Firmware

Advantech continually upgrades its firmware to keep up with the ever-expanding

world of computing. You can use the update firmware function in the utility to carry

out the upgrade procedure. Please access Advantech’s website: http://www.advantech.com to download the latest version of the firmware. Before updating the firmware, make sure that your host’s Network domain is as same as the serial device

server or the host can establish the TCP connection to the serial device server.

To update firmware:

1. Right-click a desired device to display the settings menu.

2. Select Update Firmware.

Figure 3.20 Update Firmware

3. Select the firmware file you want to update.

Wait for a few seconds for the firmware to finish updating. After the update has completed, click on the OK button. The serial device server will restart automatically.

Note! Be sure that the host PC Ethernet network domain is as same as the

EKI-1500 Series serial device server or the host PC can establish the

TCP connection with the serial device server while doing the updating

firmware process.

35 EKI-1500 Series User Manual

Page 46

Chapter 4

4Selecting An

Operating Mode

Page 47

4.1 Overview

P

W

R

2

P

-

F

a

i

l

D

C

1

2

4

8

V

P

W

R

1

V

2

V

2

+

V

1

V1

+

1

A@

2

4

V

1

2

4

LA

N

D

ef

au

lt

T

x

R

x

T

x

R

x

T

x

Rx

T

x

Rx

Rx

P1

P

2

S

t

a

t

u

s

S

e

r

i

a

l

P

o

r

t

s

E

K

I

1

5

2

8

C

I

EKI 1524

Ethernet

Ethe

r

Device A

SCADASCADA

S

S

C

C

A

A

A

D

D

A

A

S

C

C

A

A

D

D

A

SSS

C

C

C

A

A

A

D

D

S

S

C

C

A

A

D

D

SCADA

COM11 (Device F)

COM12 (Device G)

COM13 (Device H)

COM14 (Device I )

Port 1

Port 4

Port 2

Port 3

Device H

Device I

Device G

Device F

1

1

vi

vi

c

e

c

RS232/422/485

The EKI-1500 Series is designed to network-enable any RS-232/422/485 serial

device, an provides industry-grade hardware and easy-to-use software to make connecting serial devices to an Ethernet network a surprisingly simple process.

These units immediately upgrade your existing serial devices for integration into the

Internet world. The EKI-1500 Series features many powerful functions, such as high

speed data transfer, access-control, auto-detection of all EKI series products, and

more.

After the simple installation steps to attach your network and serial device to the

appropriate connectors on the serial device servers and driver installation, you will be

able to communicate with the serial devices via its own application software and wit

the EKI serial device server. COM port redirector, USDG TCP server mode, TCP client mode, UDP server mode, UDP client mode, RFC2217 mode are all different

methods of making a serial connection across using one or more serial device servers.

4.2 COM Port Redirector (Virtual COM Port)

Advantech EKI Device Configuration Utilityis a serial COM port redirector that creates virtual COM ports and provides access to serial device connected to Advantech

serial device server . You can configure the serial device server and enable the Virtual

COM port using one integrated utility. Advantech EKI Device Configuration Utilityallows you to configure Microsoft applications to communicate with network enabled

serial device servers as easily as if they were physically installed in or directly connected on the PC.

The Advantech redirector can create up to 255 virtual COM ports. Application to the

host can open a virtual COM port to access the serial device servers at the same

time. The redirector will handle each active virtual COM port as a separate TCP connection to Advantech serial device servers.

De

evic

e

evi

Figure 4.1 Virtual COM Mode

37 EKI-1500 Series User Manual

Page 48

The EKI-1500 Series provides Multi-access function through an Ethernet connection

path, allowing a maximum of five connections to open one serial port simultaneously.

In this mode all connections must use the same serial setting. If one serial setting

within this configuration is configured differently, the data communication will not

function correctly.

The Host Idle Timeout setting monitors the connection between the host and the

device. If the Host Idle Timeout setting time is reached, the device server will release

the resources allocated to the port mapping. This prevents a stalled host from affecting the connective device.

The Multi-access function has two modes. One is Normal mode and the other is

Round-Robin mode.

4.2.1 Normal mode

By disabling the Response Timeout parameter, the EKI-1500 Series will operate in

normal mode. When multiple hosts simultaneously open the serial port, only the first

connected host obtain management control, the remaining connections only have

data communication function. Each serial port supports up to five simultaneous connections, so multiple hosts can transmit/receive data to/from the same serial port

simultaneously. Every host can transmit data to the same serial port, and the EKI1500 Series will also transmit data to every hosts. When the multiple hosts transmit

data to the same serial port at the same time, the received data from Ethernet and

the outputs of serial port are mixed. When the EKI-1500 Series receives data from

serial port, the data will also be transmitted to the connected hosts simultaneously.

Figure 4.2 Configuring Virtual COM Mode

4.2.2 Round-Robin mode

By enabling the Response Timeout parameter, the EKI-1500 Series Series operates

in “Round-Robin mode”. Each serial port supports up to five simultaneous connections allowing hosts to simultaneously transmit/receive data to/from the same serial

port. Every host can simultaneously transmit data to the same serial port, EKI-1500

Series processes the data in the order arrived. The EKI-1500 Series processes the

first host’s request and replies. The serial device server determines the end of the

serial acknowledgement through a response timeout. When EKI-1500 Series serial

device server does not receive a response from the serial port after a response timeout query, the device replies with an acknowledgement and then processes the next

host request. With an increased number of hosts, response time may be lengthy,

increasing the period of the Response Timeout.

Frame Break is an important parameter for Round Robin mode. The parameter is a

smart method of reducing ineffective waiting periods and streamlining the transmission process.

If the Frame Break function is disabled, EKI-1500 Series devices will wait for a

“Response Timeout” period, whether or not the device has transmitted data. During

this period, the host commands are queued and processed in the order received.

If Frame Break is enabled, the serial port idle is longer than the Frame Break period.

The EKI-1500 Series assumes the communication is completed and continues with

the next query. This is an efficient way to reduce waiting time and improve performance.

EKI-1500 Series User Manual 38

Page 49

4.3 USDG Data Mode

P

W

R

2

P

-

F

ai

l

D

C

1

2

4

8

V

P

W

R

1

V

2

V

2

+

V1

-

V

1

+

1

A

@2

4

V

1

2

4

L

A

N

D

e

fa

u

lt

T

x

R

x

T

x

R

x

T

x

R

x

T

x

R

x

P

1

P

2

S

ta

tus

S

e

r

ial P

or

ts

E

K

I

1

5

2

4

Ethernet 1

RS232/422/485

Ethernet 2

The EKI-1500 Series can funciton as either a Data TCP server or a Data TCP client.

Both operations support TCP and UDP protocol. The EKI-1500 Series allows you to

treat your serial devices as if they were networking devices. You can issue commands or transmit data from serial devices, connected to a EKI-1500 Series device,

to any devices that are connected to the Internet.

4.3.1 USDG TCP Client Mode

In TCP Client mode, the TCP connection is established from the EKI serial device

server. This o peration mode supports a maxi mum of 16 simult aneous connections for

each serial port on EKI-152X series to one host or several hosts. You can configure

the IP address and TCP port number of the network hosts connected to the EKI serial

device server using the Advantech Serial Device Server Configuration Utility. After

configuring the devices, when the EKI serial device server receives the data from the

serial port, and the device server connects to the hosts which are configured.

Figure 4.3 USDG TCP Client Mode

In USDG Data TCP Client mode, you may need to enable the peer numbers you

would like to receive. You can set a maximum sixteen network devices to which you

may connect. You need to fill out the IP Address and Port (including local port and

peer port) of each network device to which you want to connect.

In the Peer for Receiving Data menu, entering “0” as the value for the Local Port will

assign a random TCP Port for an EKI device.

Figure 4.4 Peers for Receiving Data

39 EKI-1500 Series User Manual

Page 50

4.3.2 USDG Data TCP Server mode

P

W

R

2

P

-

F

a

i

l

D

C

1

2

4

8

V

P

W

R

1

V

2

V2

+

V1

-

V

1

+

1

A

@

2

4

V

1

2

4

L

A

N

D

e

fa

u

lt

T

x

R

x

T

x

R

x

T

x

R

x

T

x

R

x

P

1

P2

S

ta

tus

S

e

r

ial P

or

t

s

E

K

I

15

2

4

Ethernet 1

RS232/422/485

Ethernet 2

In TCP server mode, the TCP connection is initiated from the host to the EKI serial

device server. This operation mode supports a maximum of five simultaneous connections for each serial port on an EKI serial device server from a single or multiple

hosts. However a multi-host connection simult aneously tran smit s the data from a single serial port.

Figure 4.5 USDG TCP Server Mode

Figure 4.6 USDG Data Mode

4.3.3 USDG UDP Server/Client mode

The USDG UDP mode is primarily used for the broadcasting of messages over a network. In UDP server mode, data is transmitted from the Host connected to the EKI1500 Series USDG UDP Port (Default Port 5300). In the default UDP client mode,

EKI serial device servers simultaneously transmits UDP messages to a maximum of

16 peers.

USDG Data mode supports Data Idle Timeout, Data Listen Port, and Command Listen Port parameters.

4.3.3.1 Data Idle Timeout

The default is 60 seconds. If you want to keep connection continually, you can diasble the Data Idle T imeout. Dat a idle Time is the time period for which the device waits

for data. If the EKI-1500 Series does not receive data during established idle time,

the EKI-1500 Series will disconnect temporarily. When the data comes in, it will

reconnect automatically. Users do not need to reconnect.

EKI-1500 Series User Manual 40

Page 51

4.3.3.2 Data Listen Port

The TCP/UDP port number represents the source port number, and the number is

used to identify the channel for remote initiating connections. The port range is 1024-

65533. If an unknown caller wants to connect to the system and request services,

they must define the TCP/UDP port to carry a long-term conversation.

Each node on a TCP/IP network has an IP address, and each IP address can allow

connection on one or more TCP port. The well-known TCP ports are those that have

been defined; for example, port 23 is used for Telnet connections. There are also

custom sockets that users and developers define for their specific needs. The default

TCP/UDP port of the EKI-1500 Series Port1 is 5300, Port2 is 5301, etc. Users can

adjust them according to preference or application. Each port has its own data listen

port to accept the connection requests of other network device. The data listen port

cannot be set to the same value. You can transmit/receive data to/from devices via

the data listen port.

4.3.3.3 Command Listen Port

Each port has its own command listen port to accept connection requests from other

network devices, so the command listen port cannot be set to the same value. The

Command Listen Port is different from the Data Listen port. <Default Port is 5400>

4.4 USDG Control Mode

In controlling mode, the EKI serial device server presents a modem interface to the

attached serial device: it accepts AT-style modem commands to connect / disconnect

to other networking device.

If you want a serial device running application program to connect/disconnect to different devices on request, this function is available through the USDG Control mode.

Figure 4.7 USDG Control Mode

4.4.1 Hangup Character

The default character is “+”. After you have connected to another serial device an via

EKI device, you may need to disconnect, using the command “+++”. To do this, press

“+” three times and wait for the Guard timeout <default value is 1000ms>; the device

will disconnect. You can set “Guard Time” to define the idle time.

41 EKI-1500 Series User Manual

Page 52

4.4.2 Guard Time

The default value is 1000 ms.

Example: <Guard Time>+++<Guard Time>

Command Function

ATD <IP address><TCP port><CR> Forms a TCP connection to the specified host.

ATA <CR> Answering an incoming call

+++<CR> Returns the user to the command prompt when

<LF><CR> OK <LF><CR> Commands are executed correctly

<LF><CR> CONNECT <LF><CR> Connect to other device

<LF><CR> RING ddd.ddd.ddd

<LF>< CR>

<LF><CR> DISCONNECT

<LF><CR>

<LF><CR> ERROR <LF><CR> Incorrect commands

<LF><CR> FAIL <LF><CR> If you issue an ATDT command and can not connect

Ex: ATDT 192.0.55.22:5201

In above example, the EKI serial device server forms

a raw TCP connection to the networking device

(192.0.55.22). The TCP port is 5201.

entered from the serial port during a remote host connection.

Detect the connection request from other device,

which IP address is ddd.ddd.ddd.ddd.

Disconnect from other device

to the device, it will response “FAIL”.

4.5 RFC2217 Mode

RFC2217 mode is similar to virtual COM mode in that a driver is used to establish a

transparent connection between a host computer and a serial device by mapping the

serial port on EKI-1500 Series devices to a local COM port on a host computer.

RFC2217 defines general COM port control options based on the Telnet protocol.

Third party drivers supporting RFC2217 are widely available on the Internet and can

be used to implement virtual COM mapping to the serial port of your device.

EKI-1500 Series User Manual 42

Page 53

Chapter 5

5Setting up Virtual COM

Port

Page 54

5.1 Setting COM Port Redirector

Advantech COM port mapping software is a serial COM port redirector that creates

virtual COM ports and provides access to serial devices connected to an Advantech

serial device servers. Your serial device applications can communicate with serial

devices connected to the Advantech serial device servers without software ch anges.

Since the virtual COM ports work like standard Windows COM ports, your application

software sees no difference between a local serial device and one connected to an

Advantech serial device server.

The COM redirector utility and the virtual COM port management utility are integrated

into one utility with same GUI. The Advantech Serial Device Server Configuration

Utility can create all Virtual COM ports using the Auto Mapping function or by using

the manual mapping function.

5.2 Virtual COM Port Mapping

5.2.1 Auto Mapping

1. On your desktop, navigate to Start > All Programs > EKI Device Configura-

tion Utility and click Advantech EKI Device Configuration Utility to open the

utility.

2. Under Serial Device Servers, locate your server and click the icon to exp and

the listing.

3. Select the target device and right-click on it to open up the options menu win-

dow.

4. Locate Auto Mapping and select it.

Figure 5.1 Selecting Auto Mapping

The Batch Automatic Mapping Virtual COM Port window displays.

EKI-1500 Series User Manual 44

Page 55

5. Locate From System Port and click the drop-down menu to select the target

System Port

Device Port

Selected

Options

COM port.

6. From the network address list, select the address options to map.

The selected address displays the Device Port and (EKI serial device server

physical serial port) and the system port which will be the VCOM port for the PC.

Figure 5.2 Selecting Auto Mapping

7. From the network address list, select the address options to map.

8. Click Map Selected Ports to set the configuration.

Figure 5.3 Mapping Selected Ports

Once the mapping function is initialized, a successful mapping process results in the

virtual mapping of the designated physical serial port and VCOM PC port. See the

following figure.

Figure 5.4 Viewing VCOM Mapping Results

45 EKI-1500 Series User Manual

Page 56

5.2.2 Manual Mapping

VCOM

PC Port

EKI Physical

Serial Port

1. On your desktop, navigate to Start > All Programs > EKI Device Configura-

tion Utility and click Advantech EKI Device Configuration Utility to open the

utility.

2. Under Serial Device Servers, locate your server and click the icon to expand

the listing.

3. Select the target device and right-click on it to open up the options menu win-

dow.

4. Locate Manual Mapping and select it.

Figure 5.5 Selecting Manual Mapping

The Manual Mapping Virtual COM Port window displays.

5. In the Device > Serial Port drop-down menu, select the target port to map.

This is the physical serial port on the EKI device.

6. In the Host > COM Port drop-down menu, select the target COM port to map.

This is the virtual port on the target PC.

Figure 5.6 Viewing Manual VCOM Mapping Results

EKI-1500 Series User Manual 46

Page 57

7. Click Map it to continue the process. The mapping process may require a short

time. Once this step is completed, the Manual Mapping Virtual COM Port window displays again to map the VCOM port on the target PC.

Once the mapping function is initialized, a successful mapping process results

in the virtual mapping of the designated physical serial port and VCOM PC port.

See the following figure.

Figure 5.7 Viewing Manual VCOM Mapping Results

To allow for an automatic connection after a reboot or a power up, click the Auto

Reconnect option to enable this function.

5.2.3 Configuration Wizard

1. On your desktop, navigate to Start > All Programs > EKI Device Configura-

tion Utility and click Advantech EKI Device Configuration Utility to open the

utility.

2. Under Serial Device Servers, locate your server and click the icon to expand

the listing.

3. From the tool bar, select Configuration Wizard.

Figure 5.8 Selecting the Configuration Wizard

The Wizard screen displays and lists available devices.

4. Select the target device and click Next to continue.

The Wizard Device Settings window displays.

5. Under Serial Port Settings, click the Type drop-down menu and select the port

type.

Review the settings under the Ethernet fields and verify them.

6. Click Next to continue or Previous to return to the previous screen.

The selected settings are displayed in the following Wizard window.

47 EKI-1500 Series User Manual

Page 58

7. Locate the radio button correlating to the target port to modify and click on it to

select it.

Verify the Device Port (EKI device physical serial port) and System Port (virtual

COM port for PC) settings before continuing.

8. Click Finish to complete the process. A Wizard complete! screen displays indi-

cating the completion of a successful procedure.

5.2.4 Confirming Virtual COM Settings

1. On your desktop, navigate to Start > All Programs > EKI Device Configura-

tion Utility and click Advantech EKI Device Configuration Utility to open the

utility.

2. Locate Serial Ports menu in the menu pane and click on the Expand icon next

to Virtual COM Ports to view a list of the mapped ports.

3. Select a VCOM port to view its settings.

Figure 5.9 Serial Port Listing on EKI Device

For the next step, you will need to open the device manager on your system.

Using the Device Manager, you can both view and change the COM port settings.

Note! The following instructions were developed in a Windows 7 environment;

the Windows XP equivalent is displayed in parentheses (). Instructions

may vary according to the operating system used.

4. On your desktop, click on the Start button and then on Control Panel. A win-

dow displays showing all the available control panels.

5. Click on Hardware and Sound (Hardware). A list of all available hardware con-

figuration options displays.