Page 1

AWS-8248

Industrial Workstation

with 14.1" LCD Display

Users Manual

i

Page 2

Copyright

This document is copyrighted January, 2002, by Advantech Co., Ltd. All

rights are reserved. Advantech Co., Ltd. reserves the right to make

improvements to the products described in this manual at any time. Specifications are thus subject to change without notice.

No part of this manual may be reproduced, copied, translated, or transmitted in any form or by any means without the prior written permission of

Advantech Co., Ltd. Information provided in this manual is intended to

be accurate and reliable. However, Advantech Co., Ltd., assumes no

responsibility for its use, nor for any infringements upon the rights of

third parties which may result from its use.

Acknowledgements

AWS-8248T, AWS-8248TP, AWS-8248T-T, and AWS-8248TP-T are all

trademarks of Advantech Co., Ltd. IBM and PC are trademarks of International Business Machines Corporation. MS-DOS is a trademark of

Microsoft Corporation. All other brand and product names mentioned

herein are trademarks or registered trademarks of their respective owners.

Part No. 2002824800 1st Edition

Printed in Taiwan January 2002

AWS-8248 Users Manual ii

Page 3

FCC Class A

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy. If not

installed and used in accordance with this user's manual, it may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at his own

expense.

iii

Page 4

Packing List

Before you set up the AWS-8248, make sure that the following items

have been included in your package, and that this manual is in good condition. If anything is missing or damaged, contact your dealer immediately:

• One AWS-8248 industrial workstation with 14.1" flat panel display

• One accessory box, including:

- One power cord

- One keyboard transfer cable

- One HMI products drivers and utilities CD-ROM

- AWS-8248 User's Manual

- Flat gray cable for 3.5" HDD and slim CD-ROM

- RS-232 cable to link touchscreen to CPU card (for -T models only)

- TSCB-9516 drivers installation guide (for -T models only)

- Screw bag with screws If any of these items is missing or damaged, contact your distributor or sales

representative immediately.

Additional Information and Assistance

1.Visit the Advantech web site at www.advantech.com where you can

find the latest information about the product.

2.Contact your distributor, sales representative, or Advantech's customer

service center for technical support if you need

additional assistance. Please have the following information ready before

you call:

•Product name and serial number

•Description of your peripheral attachments

•Description of your software (operating system, version, application

software, etc.)

•A complete description of the problem

•The exact wording of any error messages

AWS-8248 Users Manual iv

Page 5

Safe ty In st ru ct ions

1. Read these safety instructions carefully.

2. Keep this User's Manual for later reference.

3. Disconnect this equipment from any AC outlet before cleaning. Use a damp

cloth. Do not use liquid or spray detergents for cleaning.

4. For plug-in equipment, the power outlet socket must be located near the

equipment and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a reliable surface during installation. Dropping it or letting it fall may cause damage.

7. The openings on the enclosure are for air convection. Protect the equipment

from overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source is correct before connecting the

equipment to the power outlet.

9. Position the power cord so that people cannot step on it. Do not place anything

over the power cord.

10. All cautions and warnings on the equipment should be noted.

11. If the equipment is not used for a long time, disconnect it from the power

source to avoid damage by transient overvoltage.

12. Never pour any liquid into an opening. This may cause fire or electrical shock.

13. Never open the equipment. For safety reasons, the equipment should be

opened only by qualified service personnel.

14. If one of the following situations arises, get the equipment checked by service

personnel:

a. The power cord or plug is damaged.

b. Liquid has penetrated into the equipment.

c. The equipment has been exposed to moisture.

d. The equipment does not work well, or you cannot get it to work according

to the user's manual.

e. The equipment has been dropped and damaged.

f. The equipment has obvious signs of breakage.

15. DO NOT LEAVE THIS EQUIPMENT IN AN ENVIRONMENT WHERE

THE STORAGE TEMPERATURE MAY GO BELOW -20° C (-4° F) OR

ABOVE 60° C (140° F). THIS COULD DAMAGE THE EQUIPMENT. THE

EQUIPMENT SHOULD BE IN A CONTROLLED ENVIRONMENT.

The sound pressure level at the operator's position according to IEC 704-1:1982 is

no more than 70dB (A).

DISCLAIMER: This set of instructions is given according to IEC 704-1. Advantech disclaims all responsibility for the accuracy of any statements contained

herein.

v

Page 6

W ic ht i ge Si ch e rh ei s hi nw e is e

1. Bitte lesen sie Sich diese Hinweise sorgfältig durch.

2. Heben Sie diese Anleitung für den späteren Gebrauch auf.

3. Vor jedem Reinigen ist das Gerät vom Stromnetz zu trennen. Verwenden Sie

Keine Flüssig-oder Aerosolreiniger. Am besten dient ein angefeuchtetes Tuch

zur Reinigung.

4. Die NetzanschluBsteckdose soll nahe dem Gerät angebracht und leicht

zugänglich sein.

5. Das Gerät ist vor Feuchtigkeit zu schützen.

6. Bei der Aufstellung des Gerätes ist auf sicheren Stand zu achten. Ein Kippen

oder Fallen könnte Verletzungen hervorrufen.

7. Die Belüftungsöffnungen dienen zur Luftzirkulation die das Gerät vor überhitzung schützt. Sorgen Sie dafür, daB diese Öffnungen nicht abgedeckt werden.

8. Beachten Sie beim. AnschluB an das Stromnetz die AnschluBwerte.

9. Verlegen Sie die NetzanschluBleitung so, daB niemand darüber fallen kann.

Es sollte auch nichts auf der Leitung abgestellt werden.

10. Alle Hinweise und Warnungen die sich am Geräten befinden sind zu

beachten.

11. Wird das Gerät über einen längeren Zeitraum nicht benutzt, sollten Sie es vom

Stromnetz trennen. Somit wird im Falle einer Überspannung eine Beschädigung vermieden.

12. Durch die Lüftungsöffnungen dürfen niemals Gegenstände oder Flüssigkeiten

in das Gerät gelangen. Dies könnte einen Brand bzw. elektrischen Schlag auslösen.

13. Öffnen Sie niemals das Gerät. Das Gerät darf aus Gründen der elektrischen

Sicherheit nur von authorisiertem Servicepersonal geöffnet werden.

14. Wenn folgende Situationen auftreten ist das Gerät vom Stromnetz zu trennen

und von einer qualifizierten Servicestelle zu überprüfen:

a - Netzkabel oder Netzstecker sind beschädigt.

b - Flüssigkeit ist in das Gerät eingedrungen.

c - Das Gerät war Feuchtigkeit ausgesetzt.

d - Wenn das Gerät nicht der Bedienungsanleitung entsprechend funktioniert

oder Sie mit Hilfe dieser Anleitung keine Verbesserung erzielen.

e - Das Gerät ist gefallen und/oder das Gehäuse ist beschädigt.

f - Wenn das Gerät deutliche Anzeichen eines Defektes aufweist.

Der arbeitsplatzbezogene Schalldruckpegel nach DIN 45 635 Teil 1000

beträgt 70dB(A) oder weiger.

DISCLAIMER: This set of instructions is given according to IEC704-1.

Advantech disclaims all responsibility for the accuracy of any statements

contained herein.

AWS-8248 Users Manual vi

Page 7

Table of Contents

Contents

Chapter 1 Introduction ......................................................1

1.1 Introduction....................................................................... 2

Figure 1.1: The PCA-6108C and PCA-6107P2 passive back-

planes.................................................................. 3

1.2 Specifications .................................................................... 4

1.3 Front and rear panel layout................................................ 7

Figure 1.2: Front panel layout...............................................7

Figure 1.3: Rear panel layout ................................................ 7

1.4 Dimensions........................................................................ 8

Figure 1.4: AWS-8248 dimensions....................................... 8

Chapter 2 System Setup.....................................................9

2.1 General ............................................................................ 10

2.2 Detaching the work drawer............................................. 10

Figure 2.1: Detaching the work drawer...............................11

2.3 Adding cards ................................................................... 12

Figure 2.2: Installing add-on cards...................................... 12

2.4 Installing optional drives................................................. 13

Figure 2.3: HDD installation............................................... 14

Figure 2.4: Slide CD-ROM installation ..............................14

Figure 2.5: Installing optional drives .................................. 14

2.5 Attaching cables.............................................................. 15

Figure 2.6: Connect the display power................................ 15

Figure 2.7: Cables on the rear panel.................................... 15

2.6 Rack mounting ................................................................ 16

Figure 2.8: Rack mounting the AWS-8248.........................16

2.7 Panel mounting................................................................ 17

Figure 2.9: Panel mounting the AWS-8248........................17

Chapter 3 Maintenance....................................................19

3.1 Passive backplane............................................................20

Figure 3.1: Removing the passive backplane......................20

3.2 Power supply................................................................... 21

Figure 3.2: Removing the power supply .............................21

3.3 LCD display module ....................................................... 22

Figure 3.3: Removing LCD display module (first steps).... 22

Figure 3.4: Removing LCD display module (final steps) ... 23

3.4 Keyboard translator......................................................... 24

Figure 3.5: Keyboard translator input/output (actual)......... 24

Figure 3.6: Keyboard translator input/output (schematic).. 25

Figure 3.7: Removing the keyboard translator....................26

vii

Page 8

3.5 LED board.......................................................................27

Figure 3.8: Removing the LED board................................. 27

3.6 Floppy disc drive (FDD)................................................. 28

Figure 3.9: Removing the FDD...........................................28

3.7 Membrane keypad........................................................... 29

Figure 3.10:Replacing the membrane keypad..................... 30

3.8 Touchscreen sensor (-T models) ..................................... 31

Figure 3.11:Replacing the touchscreen sensor .................... 32

Chapter 4 Macro Key Programming..............................33

4.1 Introduction..................................................................... 34

4.2 Macro Key Review.......................................................... 34

4.3 Syntax..............................................................................35

4.4 How to use SFED8248.COM.......................................... 37

Figure 4.1: The Macro Editor screen ..................................37

4.5 Example........................................................................... 38

Figure 4.2: Macro examples................................................ 38

Appendix A Display Timing Mode & OSD ......................41

A.1 Supported Input Timing Modes ...................................... 42

Table A.1: Supported Input Formats ................................. 42

A.2 OSD Operation Keypad .................................................. 43

Table A.2: Keypad functions............................................. 43

A.3 OSD function and operation............................................ 44

Figure A.1:OSD menu ........................................................ 44

Table A.3: OSD Functionality........................................... 44

Appendix B Power Supply Specification...........................45

B.1 Supported Input Timing Modes ...................................... 46

B.2 -48 V DC power supply .................................................. 47

Table B.1: -48 VDC power supply output characteristics. 48

Table B.2: -48 VDC power supply DC output wire list .... 51

B.3 24 VDC power supply..................................................... 52

Appendix C Touchscreen (optional) ..................................55

C.1 Specifications ..................................................................56

C.2 Installation of Touchscreen Driver.................................. 57

viii

Page 9

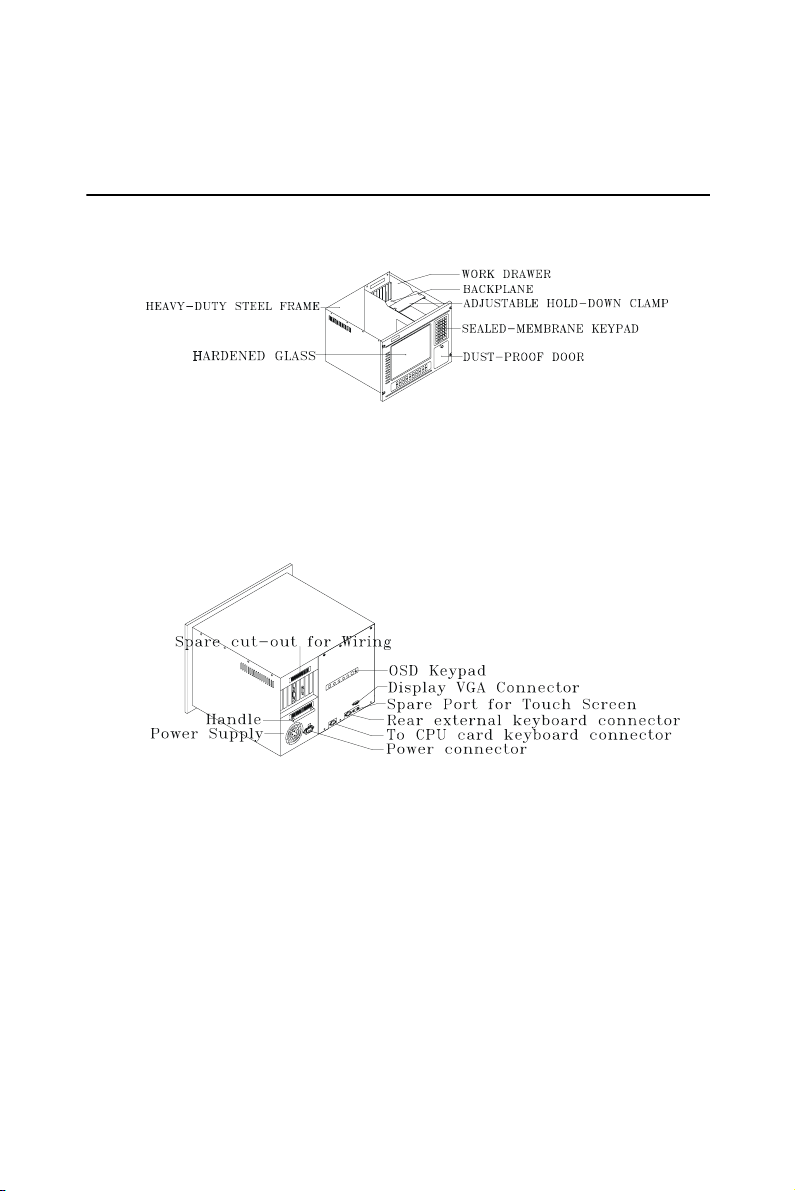

Introduction

• Introduction

• Specifications

• Front and rear panel layout

•Dimensions

CHAPTER

1

1 Chapter 1 Introduction

Page 10

Chapter 1 Introduction

1.1 Introduction

We designed the AWS-8248 specifically for the factory floor and other

harsh industrial environments. This 19" rack/panel-mount workstation

offers full state-of-the-art industrial computing technology packaged

within one compact unit. It includes a 14.1" color LCD monitor, 7-slot

passive backplane, slide-out "work drawer" card cage, 250-watt power

supply, 3½" floppy disk drive (slim CD-ROM and 3½" HDD optional),

front and rear 5-pin keyboard connectors and a sealed front panel that

conforms to NEMA 4 and NEMA 12 specifications. All of these features

are housed in a rugged workstation chassis which provides protection

from dust, vibration and moisture.

14.1" Color LCD

• Vertical and flat screen for better display quality

• High resolution display (1024 x 768)

• Anti-static treatment on the glass surface to minimize dust accumulation on the monitor

• Digital screen adjustment for accurate picture quality

39-key sealed-membrane operating keypad

You can enter numerical data using the workstation's convenient 39-key

sealed-membrane operating keypad. The keypad has excellent tactile

response. You can also attach an external keyboard through a connector

on the front panel.

Programmable macro function keys

An additional membrane keypad offers 10 ordinary function keys (F1 ~

F10) and 10 programmable macro keys (SF1 ~ SF10). Macro keys automate common key sequences, even inside application programs.

Front-accessible control panel

You can easily access the workstation's controls from the front of the unit

via a sturdy protective door. Controls include LEDs, and switches for

power and system reset. The front panel also holds a 3½" 1.44 MB FDD.

The aluminum door protects the controls from the environment outside.

The door has a waterproof foam-rubber seal and captive handscrew to

hold it closed. In addition, the door offers protection against accidental

operation of the unit's controls.

AWS-8248 User’s Manual 2

Page 11

Passive backplanes

The AWS-8248 offers two types of passive backplanes, the PCA-6108C

and the PCA-6107P2. They allow you to run your industrial applications

from a variety of full-featured CPU cards.

Figure 1.1: The PCA-6108C and PCA-6107P2 passive backplanes

The backplanes are formed from four-layer PCBs with ground and power

planes to reduce noise and power-supply impedance. They have LED

power indicators for +5 V, +12 V, -5 V and -12 V.

Advantech's PCA-6107P2 passive backplane can be installed into the

AWS-8248TP. It contains two PCI-compatible slots, four PC/AT-compatible (ISA-bus) slots and one dedicated slot for a CPU card. Three powerconnectors are also included in the PCA-6107P2.

Alternatively, Advantech's PCA-6108C passive backplane can be

installed into the AWS-8248T. It contains eight PC/AT-compatible (ISAbus) slots, termination resistors for high-speed signals and terminal block

connectors to supply power from the board.

Convenient work drawer

The AWS-8248's "work drawer" card cage slides out in a snap for

reduced MTTR. It makes adding or exchanging plug-in cards and changing power supplies quick and easy. Our standard PC/AT compatible passive backplane lets you run your industrial applications from a variety of

full-featured CPU cards. and easy overclocking of frequency and Vcore

voltages all through the BIOS Specifications.

3 Chapter 1 Introduction

Page 12

1.2 Specifications

General

• Construction: Heavy-duty aluminum and steel chassis

• Disk drive housing: Holds one 3½" FDD, one slim CD-ROM and

one 3½" HDD (slim CD-ROM and HDD optional)

• Cooling system:

- One 32 CFM fan (flow out) on rear panel for power supply

- One 29 CFM fan (flow in) for monitor on rear panel

- One 36 CFM fan in the chassis for plug-in cards

• Dimensions:

- Width: 482 mm (19.0")

- Depth: 450 mm (17.7")

- Height: 356 mm (14.0")

• Weight: 29 kg (63.9 lbs)

LCD Display

- Display type: 14.1" TFT LCD

- Max. resolution: 1024 x 768

- Maxi. colors: 262K

2

- Luminance (cd/m

- Viewing angle: 90°(H), 50°(H)

- Operating temperature: 0 ~ 50°C

- LCD MTBF: 50,000 hours

- Backlight lifetime: 50,000 hours

- Interface: Direct VGA

- LCD defect specification: refer to Advantech web site

Front Panel

• Keypads: One with 39 operating keys, one with 10 function keys

and 10 programmable macro function keys

): 200

AWS-8248 User’s Manual 4

Page 13

• Keyboard connector: Pre-wired 5-pin DIN connector with dustprotection cover on front and rear panel

• Switches: Reset and power on/off.

Passive backplane

• AWS-8248T & AWS-8248T-T:

8 ISA slot passive backplane

• AWS-8248TP & AWS-8248TP-T:

4 ISA / 2 PCI / 1 CPU slot passive backplane

Power supply

• AC input: 250 W (standard offer)

• Input voltage:

85 ~ 130 V

or 180 ~ 260 VAC , switchable

AC

• Output voltage:

+5 V @ 25 A; +12 V @ 9 A; -5 V @ 0.5 A; -12 V @ 2.0 A

• MTBF: 100,000 hours

• Safety: UL/CSA/TUV

-48 V

• Input voltage: -38 ~ -58 V

input 310 W (optional)

DC

DC

• Output voltage:

+5 V @ 30 A; +12 V @ 10 A; -5 V @ 1.0 A; -12 V @ 5 A

• MTBF: 100,000 hours

24 V

• Input voltage: 19 ~ 32 V

input 250 W (optional)

DC

DC

• Output voltage:

+5 V @ 25 A; +12 V @ 10 A; -5 V @ 1.0 A; -12 V @ 1.0 A

• MTBF: 100,000 hours

Compact CD-ROM kit (optional)

• 24x slim CD-ROM kit with support bracket

(model no. CDR-825-0024)

5 Chapter 1 Introduction

Page 14

Environmental specifications

• Operating temperature: 0 ~ 50° C (32 ~ 122° F)

• Relative humidity: 5 ~ 85% @ 40° C, non-condensing

• Vibration: 5 ~ 17 Hz, 0.1" double-amplitude displacement 17 ~

500 Hz, 1.0 G peak to peak.

AWS-8248 User’s Manual 6

Page 15

1.3 Front and rear panel layout

Figure 1.2: Front panel layout

Figure 1.3: Rear panel layout

7 Chapter 1 Introduction

Page 16

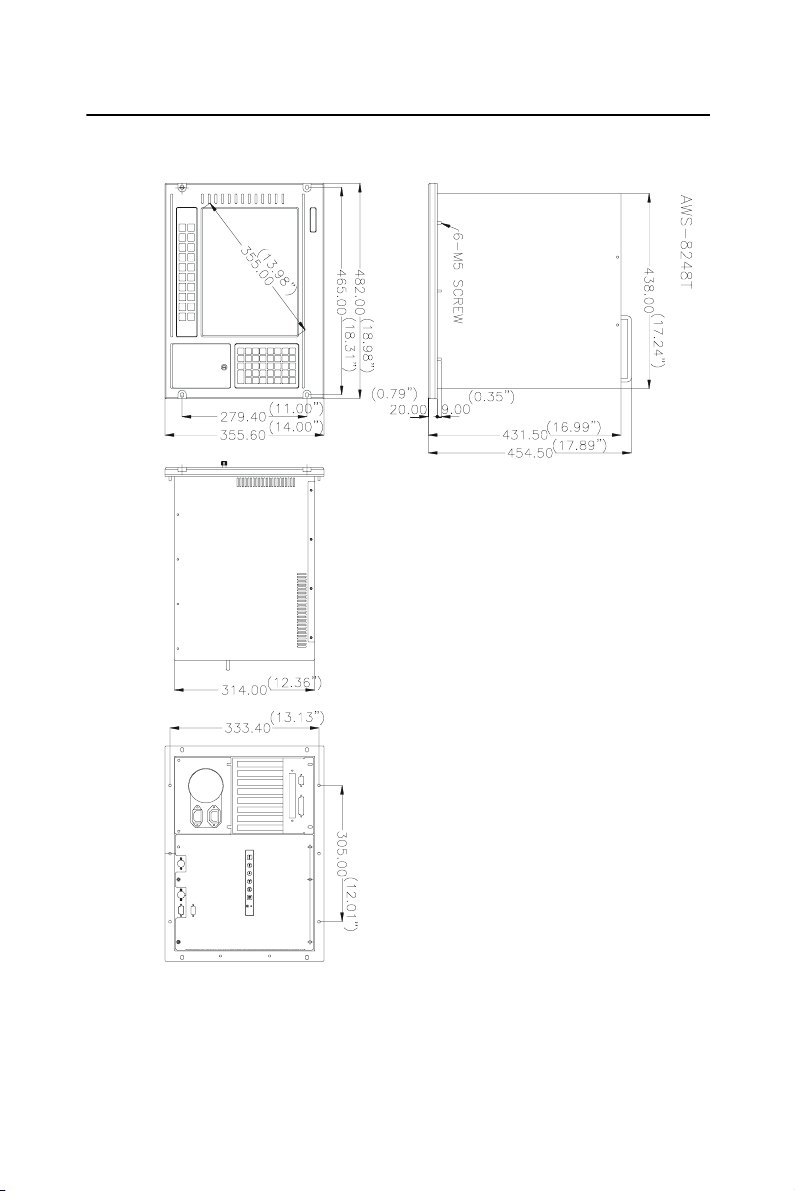

1.4 Dimensions

Figure 1.4: AWS-8248 dimensions

AWS-8248 User’s Manual 8

Page 17

System Setup

• General

• Detaching the work drawer

• Adding cards

• Installing optional drives

• Attaching cables

• Rack/Panel mounting

CHAPTER

2

9 Chapter 2 System Setup

Page 18

Chapter 2 System Setup

2.1 General

When you receive your workstation you will find a backplane, power

supply, and floppy disk drive already installed. Further setup of the AWS8248 is easy. All you have to do is slide out its work drawer module,

install a CPU card, optional hard disk drive and whatever additional I/O

cards your application requires. You can then mount your workstation

into a 19-inch rack or into a panel.

Warning!

1. Do not begin your installation until you are sure

there is no power flowing within the AWS-8248.

Power must be switched off and the main power

cord unplugged.

2. Every time you service the AWS-8248, you

should switch the power off and unplug the main

power cord.

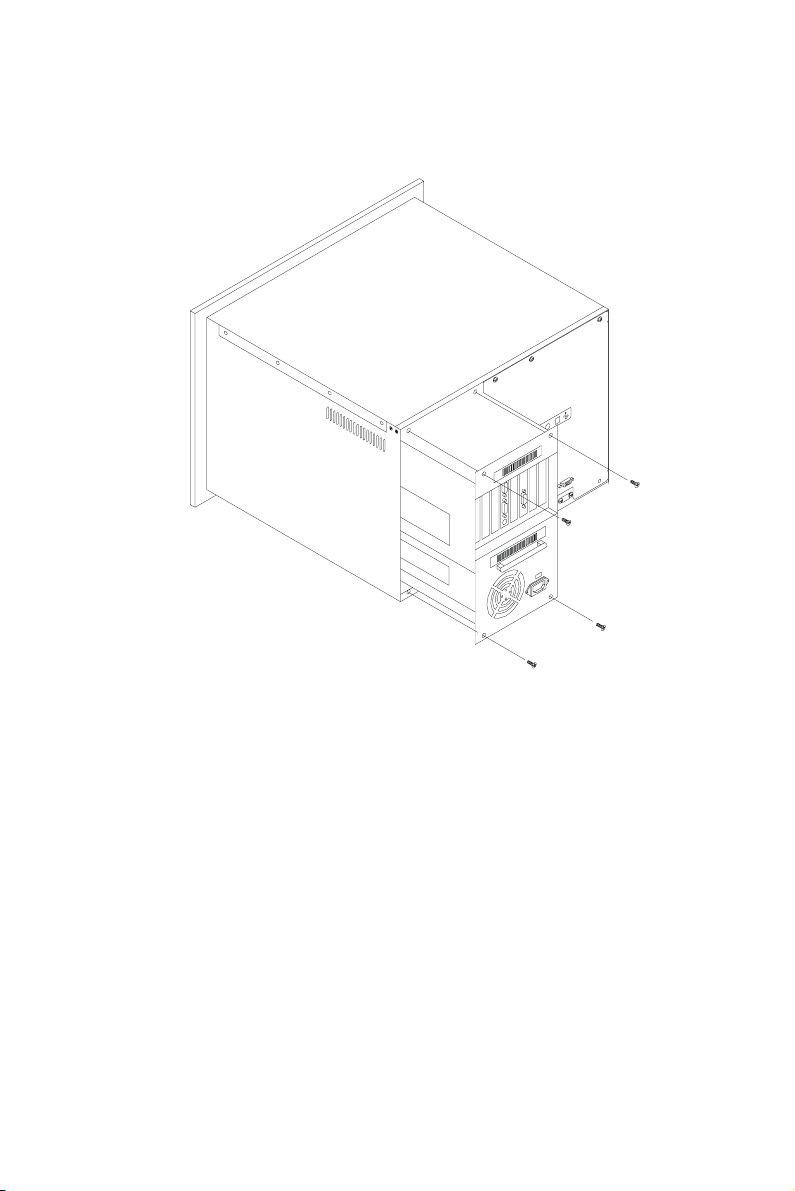

2.2 Detaching the work drawer

The work drawer is a card cage that slides in and out of the body of the

AWS-8248, providing easy access to your cards, drives and power supply.

1. Detach the cables that connect the work drawer to the main chassis.

2. Detach the main power cord, keyboard and video connectors from

the work drawer.

3. Four screws on the back of the AWS-8248 hold the drawer in the

chassis. Remove the screws, and the drawer can then slide out

freely.

AWS-8248 User’s Manual 10

Page 19

Figure 2.1: Detaching the work drawer

11 Chapter 2 System Setup

Page 20

2.3 Adding cards

Remove the cover of the work drawer by either removing the 10 screws

that attach it or by sliding it out. Remove the screw that fixes the card

hold-down clamp, and remove the clamp.

Slowly slide the card in and carefully press it into the backplane socket.

Secure it by screwing it into the top mounting bar. (See Fig. 2-2.) Connect

the card wiring. Add any additional cards or take out cards you need to

service. Reattach the hold-down clamp. When you have finished, reattach

the cover.

Figure 2.2: Installing add-on cards

AWS-8248 User’s Manual 12

Page 21

2.4 Installing optional drives

The AWS-8248 provides space for three disk drives underneath the work

drawer. That is, one floppy disk drive, one hard disk drive and one slim

CD-ROM drive. If you wish, you can add an extra hard disk drive and an

extra slim CD-ROM drive above the power supply. (See Figs. 2-1 and 2-

3.)

1. Remove the six screws at the rear of the work drawer and pull

down the power supply assembly using the handle. You will find a

drive bay for fixing an HDD and a slim CD-ROM drive.

2. Detach the four screws from the drive bay, and slide out the two

drive-support brackets.

3. Attach the HDD by fixing it to the drive support brackets with the

six screws.

4. Add the optional CD-ROM (CDR-825-0024) over the HDD, and

tighten it with the six screws.

5. Slide the assembled HDD and CD-ROM drive into the drive bay.

6. Attach a 40-pin ribbon cable with two connectors; one being a

power connector to the HDD, and the other being a power connector to the CD-ROM.

7. Secure the drive in the drive bay with the screws, and attach this

assembly to the work drawer.

13 Chapter 2 System Setup

Page 22

Figure 2.3: HDD installation

Figure 2.4: Slide CD-ROM installation

Figure 2.5: Installing optional drives

AWS-8248 User’s Manual 14

Page 23

2.5 Attaching cables

Once you have added your cards, drives and other equipment, connect the

display power (see Fig. 2-6, and reattach the cables on the rear panel (see

Fig. 2-7), you should switch on the AWS-8248 and confirm that it works.

Figure 2.6: Connect the display power

Figure 2.7: Cables on the rear panel

15 Chapter 2 System Setup

Page 24

2.6 Rack mounting

The AWS-8248 can be mounted in a 19" rack. Ensure that all addi-tional

equipment has been installed correctly and that the cabling has been reattached. (See Fig. 2-7) Remove the screw covers on the front panel. Attach

the case to the rack using screws on both sides.

Figure 2.8: Rack mounting the AWS-8248

AWS-8248 User’s Manual 16

Page 25

2.7 Panel mounting

Panel mounting the AWS-8248 is easy. Just line up the holes in the panel

aperture and the holes on the panel, and then secure the AWS-8248 to the

panel with the mounting bolts.

Figure 2.9: Panel mounting the AWS-8248

17 Chapter 2 System Setup

Page 26

AWS-8248 User’s Manual 18

Page 27

Maintenance

• Passive backplane

• Power supply

• CRT m onitor

• Keyboard translator

• LED board

• Floppy disk drive (FDD)

• Membrane keyboard

• Touchscreen sensor (optional)

CHAPTER

3

19 Chapter 3 Maintenance

Page 28

Chapter 3 Maintenance

3.1 Passive backplane

Before detaching the backplane, you must slide out the work drawer. Follow these steps:

1. Switch off the power, and detach the main power cord.

2. Detach the work drawer from the AWS-8248 unit. (See Fig. 2-1.)

3. Slide the work drawer out as far as it will go. Detach the holding

clamp, cables and all the installed cards.

4. Detach the P8 and P9 power connectors by pulling them down.

Unscrew the seven screws and detach the backplane.Our workstations are equipped with programmable function keys (macro keys)

that greatly enhance the operator interface. Macros, which are far

more powerful than batch files, automate the most commonly used

input sequences. They extended their functional reach to within

application programs.(See Fig. 3-1.)

Figure 3.1: Removing the passive backplane

AWS-8248 User’s Manual 20

Page 29

3.2 Power supply

The power supply provides 250 watts and meets UL, CSA and TUV standards. To repair it, you must slide out the work drawer.

1. Switch off the power, and detach the main power cord.

2. Detach the work drawer from the AWS-8248 unit.

(See Fig. 2-1.)

3. Slide the work drawer out as far as it will go.

4. Detach the P8 and P9 power connectors by pulling them down.

5. Remove the four screws at the rear of the work drawer. Pull down

the power supply assembly using the handle.

(See Fig. 3-2.)

6. Remove the four screws at the rear of the power supply holding

plate.

7. Detach the power supply and replace it.

Figure 3.2: Removing the power supply

21 Chapter 3 Maintenance

Page 30

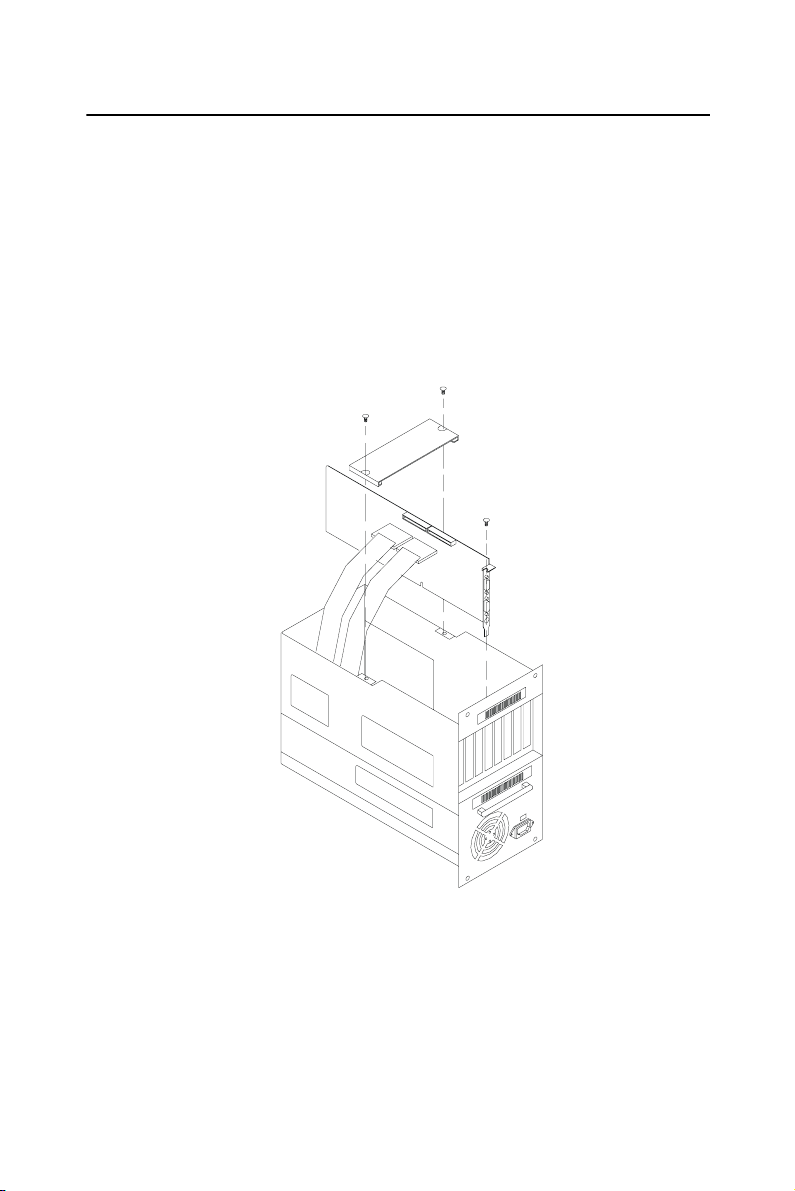

3.3 LCD display module

1. Switch off the power, and detach all the cables.

2. Detach and slide out the work drawer. (Refer Fig. 2-1.)

3. Unscrew and detach the upper and back cover. ( Refer Fig. 3-3)

4. Unscrew and detach the keyboard translator board. ( Refer Fig. 3-3)

5. Unscrew the 4 screws which hold the LCD display module.(Refer

Figs. 3-4.)

Figure 3.3: Removing LCD display module (first steps)

AWS-8248 User’s Manual 22

Page 31

Figure 3.4: Removing LCD display module (final steps)

23 Chapter 3 Maintenance

Page 32

3.4 Keyboard translator

The keyboard translator is an interface between a standard PC keyboard

layout and a specific keypad layout. The output side is connected to the

keyboard connector of the CPU card. The input side is connected to three

flat cables leading to the membrane keypad and two 5-pin external keyboard jacks.

Figure 3.5: Keyboard translator input/output (actual)

AWS-8248 User’s Manual 24

Page 33

Figure 3.6: Keyboard translator input/output (schematic)

25 Chapter 3 Maintenance

Page 34

To service the keyboard translator:

1. Switch off the power, and detach the main power cord.

2. Detach the work drawer and cover from the AWS-8248 unit. (See

Fig. 2-1.)

3. Slide the work drawer out as far as it will go.

4. Detach all cables connected to the keyboard translator. These

include cables to the keyboards, the cable to the CPU card, and the

cable to the function keypad.

5. Detach the cables which connect the keyboard translator to the

operating keypad. You should also detach these cables from the

operating keypad. To do so, remove the membrane keypad connector protective bracket, and carefully pull off the two membrane

keypad cables.

6. Unscrew the three screws, pull out the keyboard translator, and

replace it.

Figure 3.7: Removing the keyboard translator

AWS-8248 User’s Manual 26

Page 35

3.5 LED board

Before replacing the LED board, you must slide out the work drawer. Follow these steps:

1. Switch off the power, and detach the main power cord.

2. Detach the work drawer from the AWS-8248 unit.

(See Fig. 2-1).

3. Slide the work drawer out as far as it will go.

4. Pull off the LED cable.

5. Unscrew the two screws, and replace the LED board. (See Fig. 3-

8.)

Figure 3.8: Removing the LED board

27 Chapter 3 Maintenance

Page 36

3.6 Floppy disc drive (FDD)

Before replacing the FDD, you must slide out the work drawer. Follow

these steps:

1. Switch off the power, and detach the main power cord.

2. Detach the work drawer from the AWS-8248 unit. (See Fig. 2-1.)

3. Slide the work drawer out as far as it will go.

4. Pull off the flat cable and the power cable.

5. Unscrew the four screws on the outside of the side panel of the

AWS-8248 unit, and remove the FDD. (See Fig. 3-9.)

Figure 3.9: Removing the FDD

AWS-8248 User’s Manual 28

Page 37

3.7 Membrane keypad

This eventually wears out after exhaustive and prolonged use. The metal

dome switches lose their elasticity, the contact surfaces wear down, and

chemical corrosion sets in. The membrane keypad film can become torn.

If more than, say, three metal domes are broken, this may indicate that the

keypad tail series is broken, or that the single cable connecting the keypad

tail is defective.

Replacing the membrane keypad is now easier than before. You must,

however, slide out the work drawer.

To replace the operating membrane keypad:

1. Switch off the power, and detach the main power cord.

2. Detach the work drawer and cover from the AWS-8248 unit. (See

Fig. 2-1.)

3. Slide the work drawer out as far as it will go.

4. Remove the membrane keypad connector protective bracket, and

carefully pull off the two membrane keypad cables.

(See Fig. 3-10.)

5. Tear the operating membrane keypad from the aluminium panel,

and replace it.

To replace the function membrane keypad:

1. Tear the function membrane keypad from the aluminium panel

directly.

2. Carefully pull off the membrane keypad cables connecting the keypad tail. (See Fig. 3-10.)

3. Remove the function membrane keypad, and replace it.

29 Chapter 3 Maintenance

Page 38

Figure 3.10: Replacing the membrane keypad

AWS-8248 User’s Manual 30

Page 39

3.8 Touchscreen sensor (-T models)

The touchscreen sensor may eventually wear out after exhaustive and

prolonged use. Before you replace it, you must slide out the work drawer.

1. Switch off the power, and detach the main power cord.

2. Detach the work drawer and cover from the AWS-8248 unit. (See

Fig. 2-1.)

3. Slide the work drawer out as far as it will go.

4. Remove the operating membrane keypad connector protective

bracket, and carefully pull off the two operating membrane keypad

cables.

5. Detach the external keyboard cable from the keyboard translator.

6. Detach the four waterproof sponges.

7. Unscrew the 12 screws around the perimeter of the front panel

which hold the panel to the main chassis.

8. Separate the front panel from the chassis, the touchscreen cable

from the touchscreen sensor, and the function keypad cable from

the function keypad. (See Fig. 3-11.)

9. Detach the four shock-absorbing sponges, and detach the touchscreen sensor. Remove any residual adhesive from the aluminium

panel.

10. Apply new adhesive, and attach the touchscreen sensor to the aluminium panel. Make sure that the sensor is oriented correctly.

31 Chapter 3 Maintenance

Page 40

Figure 3.11: Replacing the touchscreen sensor

AWS-8248 User’s Manual 32

Page 41

CHAPTER

4

Macro Key Programming

• Introduction

• Macro key overview

•Syntax

• Using SFED8248.COM

•Examples

33 Chapter 4 Macro Key Programming

Page 42

Chapter 4 Macro Key Programming

4.1 Introduction

Our workstations are equipped with programmable function keys (macro

keys) that greatly enhance the operator interface. Macros, which are far

more powerful than batch files, automate the most commonly used input

sequences. They extended their functional reach to within application

programs.

4.2 Macro Key Review

The complete macro function consists of the following elements:

Macro keys (SF1 , SF2, ... SF10)

Ten programmable macro keys that are located on the dust-proof door on

the front panel of your workstation.

Macro EEPROM

Holds the key sequences that are activated when the corresponding macro

key is pushed.

Macro programming utility

In the sub-directory, AWS-8259&8124&8248/KBT-utility, of the HMI

utility CD-ROM, you will find a program called SFED8248.COM.. The

SFED8248 program provides an edit function to produce an ASCII file

that contains key stroke sequences for every macro key. After you have

finished editing the file, the program will ask you whether you want to

save the macro script and/or transmit it to the EEPROM. Macros consist

of keystroke sequences to automate the most common procedures in your

application. The way they function is much like batch files (.BAT) under

DOS, but there are some differences. In a Macro, you have to specify the

ENTER key explicitly. Also, macros give you the option of entering key

sequences in an application that was executed by the macro itself.

AWS-8248 User’s Manual 34

Page 43

4.3 Syntax

Macro definitions consist of ASCII characters or character codes for special characters (ALT, ENTER, SHIFT, F1, SF2, and so on). These codes

are predefined, and SFED8248.COM will display them on the screen for

you. They are easily recognizable,

appearing between the square brackets, "[" and "]".

For example:

ALT is represented by [26]

ENTER is represented by [33]

In your macro script, you can enter ordinary text (ASCII characters) or

the code(s) of the required special character(s).

For example:

CD\TOOLKIT[33] means CD\TOOLKIT [ENTER]

For combination keystrokes (ALT/SHIFT/CTRL + another key) enter the

codes of the special characters, followed by [90]

(RELEASE).

35 Chapter 4 Macro Key Programming

Page 44

For example:

ALT-F1 is represented by [26][44][90]

CRTL-C is represented by [28]C[90]

SHIFT-B is represented by [27]B[90]

ALT-X is represented by [26]X[90] or [26]x[90]

ALT-F1 is represented by [26][44][90]

SHIFT-X is represented by [27]X[90]

SHIFT-F1 is represented by [27][44][90]

CTRL-X is represented by [28]X[90]

CTRL-F is represented by [28][44][90]

CTRL-ALT-DEL is represented by [28][26][41][90] (reboot)

CTRL-ALT-A is represented by [28][26]A[90]

CTRL-SHIFT-1 is represented by [28][27]1[90]

Another useful function is the DELAY instruction. You can instruct the

macro program to wait before executing the next keystroke.

SFED8248.COM displays the codes that you can use for various delays.

For example:

[86] - wait for 10 seconds before executing next keystroke

[88] - wait for 1 minute before executing next keystroke

[26]A[90][86][26]B[90] means ALT-A, wait 10 seconds, ALT-B

AWS-8248 User’s Manual 36

Page 45

4.4 How to use SFED8248.COM

Advantech Workstation Special Function Key Edit Program Rev. 11/16/1995

Table of Control Codes : Example : SF5 =CD\WINDOWS[33]WIN[33]

3 Sec [84]

1 Hour [89]

HOME [3C]

END [3D]

PGUP [3E]

PGDN [3F]

INS [40]

DEL [41]

SF1 to SF10 = [70] to [79]

ESC [36]

→→→→

[3B]

F4 [47]

F8 [4B]

F12 [4F]

[ [30]

↑↑↑↑

[38]

F1 [44]

F5 [48]

F9 [4C]

RELEASE [90]

] [31]

↓↓↓↓

[39]

F2 [45]

F6 [49]

F10 [4D]

BS [35]

←←←←

[3A]

F3 [46]

F7 [4A]

F11 [4E]

Key delay Mode :

TAB [24]

ALT [26]

SHIFT [27]

CTRL [28]

ENTER[33]

PRTSC[7E]

PAUSE[7F]

0.1 Sec [80]

5 Sec [85]

0.5 Sec [81]

10 Sec [86]

1 Sec [82]

30 Sec [87]

2 Sec [83]

1 Min [88]

SF1 =

SF2 =

SF3 =

SF4 =

SF5 =

SF6 =

SF7 =

SF8 =

SF9 =

SF10 =

KBT ID:AD111695

ESC:Quit/Save/Transmit

First, boot your system under pure DOS mode (not DOS shell in windows) and copy all the files to your hard disk and/or make a backup disk.

Then start the macro editor. You will have to specify either an existing

macro script file or a new macro script file. Here we will create a new file

by typing SFED8248 NEWKEY.TXT [ENTER].

The following screen will appear:

When you have finished editing, press the ESC key. At the bottom line of

the screen you will be prompted to choose if you want to save the file

and/or if you want to transmit it to the EEPROM.

After confirmation with the Enter key, the tasks are carried out and you

return to DOS.

Figure 4.1: The Macro Editor screen

37 Chapter 4 Macro Key Programming

Page 46

4.5 Example

Ad

Edit P

11/16/199

We will explain all macro functions that you can find in the EXAMPLE.TXT We will explain all macro functions that you can find in the

EXAMPLE.TXT macro script file. When typing SFED8248 EXAMPLE.TXT the following editor screen will appear:

vantech Workstation Special Function Key

Table of Control Codes : Example : SF5 =CD\WINDOWS[33]WIN[33]

TAB [24]

ALT [26]

SHIFT [27]

CTRL [28]

ENTER[33]

PRTSC[7E]

PAU SE [7F ]

Key delay Mode :

0.1 Sec [80]

5 Sec [85]

SF1 =

CD\TOOL[33]SFED825 EXAMPLE.TXT[33]

COPY C:\CONFIG.EMM C:\CONFIG.SYS[33]Y[33][85][79]

SF2 =

SF3 =

C:\WP51\WP[33][86][27][4D][90]REPORT.WP5[33]

SF4 =

SF5 =

SF6 =

SF7 =

SF8 =

SF9 =

[28][26][41][90]

SF10 =

Save(Y/N)? Transmit(Y/N)?

HOME [3C]

END [3D]

PGUP [3E]

PGDN [3F]

INS [40]

DEL [41]

SF1 to SF10 = [70] to [79]

0.5 Sec [81]

10 Sec [86]

rogram Rev.

[30]

[

[38]

↑

F1 [44]

F5 [48]

F9 [4C]

RELEASE [90]

1 Sec [82]

30 Sec [87]

KBT ID:AD111695

[31]

]

[39]

↓

F2 [45]

F6 [49]

F10 [4D]

2 Sec [83]

1 Min [88]

5

BS [35]

[3A]

←

F3 [46]

F7 [4A]

F11 [4E]

ESC:Quit/Save/Transmit

3Sec [84]

1 Hour [89]

ESC[36]

[3B]

→

F4 [47]

F8 [4B]

F12 [4F]

Figure 4.2: Macro examples

AWS-8248 User’s Manual 38

Page 47

SF1 = CD\TOOL[33] SFED825 EXAMPLE.TXT[33]

This macro changes to the TOOL directory, then starts up

SFED8248.COM with EXAMPLE.TXT.

SF2 = COPY C:\CONFIG.EMM C:\CONFlG.SYS [33] Y [33] [85]

[79]

The configuration information is changed by copying CONFIG.EMM to

CONFIG.SYS. After a delay of 5 seconds, [85], the macro invokes macro

function key SF10, [79], which was defined to reset the system.

SF4 = C:\WP51\WP[33][86][27][4D][90]REPORT.WP5[33]

This example shows that after a macro executes, it is able to direct the

program to accomplish several tasks. WordPerfect is started. After a delay

of 10 seconds (time to load the program), the

command Shift-F10, [27][4D], is issued to import a text file. The name of

the text file (REPORT.WP5) is inserted; and finally ENTER, [33], causes

the text file to be loaded and displayed on the screen.

SF10 = [28][26][41][90]

Restarts the computer (CTRL-ALT-DEL).

39 Chapter 4 Macro Key Programming

Page 48

AWS-8248 User’s Manual 40

Page 49

Appendix

A

Display Timing Mode &

OSD

• Supported input timing modes

• OSD operation keypad

• OSD function and operation

41 Appx. A

Page 50

Appendix A Display Timing Mode and OSD

A.1 Supported Input Timing Modes

The nineteen kinds of timings below are already programmed in this

module. The input synchronous signals are automatically recognized.

Vertical Frequencies

Resolution

640x480

800x600

1024x768

Note 1: Even if the preset timing is entered, a little adjust-

56Hz 60Hz 70Hz 72Hz 75Hz

Yes

Yes Yes

Yes Yes Yes Yes

Yes Yes Yes

Table A.1: Supported Input Formats

ment of the functions such as Horizontal period,

CLK-delay and display position, are required. The

adjusted values are memorized in every preset number.

Note 2: This module recognizes the synchronous signals

with near preset timing of the frequency of the HS

and Vsync, even in the case that the signals other

than the preset timing that were entered.

Note 3: Because adjustments may not fit, such as differing

magnifying ratios or, in the case that you use it

except for the display timing that was preset.

AWS-8248 User’s Manual 42

Page 51

A.2 OSD Operation Keypad

The OSD keypad, including six keys and a two color indicator, is

designed as the OSD operation interface.

The six keypad functions are in Table A-2.

Auto

Sel

WX

WX

WXWX

Exit

On/OFF

Press this button to execute auto adjustment process

Press to show the OSD screen or select an item to

change its setting

To move between items or increase or decrease setting

To exit from the current setting in OSD function

Turns display backlight ON and OFF

Table A.2: Keypad functions

Note: The green light means that the COMMON board detects the input

signal and ends output signal to LCD panel.

43 Appx. A

Page 52

A.3 OSD function and operation

Auto-adjustment process or to adjust manually:

1. Press [Sel] button to display the OSD Menu shown below.

WWWW

XXXX

or

2. Press

3. Press [Sel] button to select the menu option.

4. Press

5. Press [Exit] button or wait until time out to save changes and exit

the menu or sub-menu.

button to scroll to the desired menu option.

WWWW

XXXX

or

button to adjust the setting.

Figure A.1: OSD menu

Table A-3 is the OSD menu hierarchy and function description.

Main Menu Sub Menu Sub Menu Functionality

Brightness Reset Brightness Adjust display brightness

Contrast

Infor matio n Display input mod e info rmation

All Res et Rese t all p ara mete rs t o fact ory d efault s ett ing

Contrast Reset Contrast Adjust RGB contrast simultaneously

R Sub Contrast Reset R Contrast Adjust R contrast

G Sub Contrast Reset G Contrast Adjust G contrast

B Sub Contrast Reset B Contrast Adjust B contrast

H. Size Reset H. Size Adjust clock number per line

Clock Phase Reset Clock Phase Adjust phase of ADC sample clock

Position

H. Position Reset H. Position Adjust display image left or right

V. Position Reset V. Position Adjust display image up or down

Table A.3: OSD Functionality

AWS-8248 User’s Manual 44

Page 53

Appendix

B

Power Supply Specification

• 250 watt power supply

•-48 V

• 24 V

power supply

DC

power supply

DC

45 Appx. B

Page 54

Appendix B Power Supply Specifications

B.1 Supported Input Timing Modes

The AWS-8248 off-line switching power supply is ideal for use in workstations. It has been designed to meet UL, CSA and TUV safety standards. It has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment.

Specifications

Input

• Input range: 90~135/180~265 V

• Input frequency:47 ~ 63 Hz

• Input current: 6 A @ 115 V

• Efficiency: >65% @ full load, nominal line

• EMI/RFI: FCC Part 15 Class B; VDE 243 Calss B & CISPR 22

Class B

Output load range:

Output Voltage Regulations Minimum load Maximum load Peak load Ripple & Noise

V1 +3.3 V +/-5 % 0 A 14 A - 50 mV

V2 +5 V +/-5 % 1 A 25 A - 50 mV

V3 +12 V +/-5 % 0.2 A 8 A 16 A 120 mV

V4 -12 V +/-10 % 0 A 0.8 A - 120 mV

V5 -5 V +/-5 % 0 A 0.5 A - 100 mV

V6 +5 VSB +/-5 % 0 A 1 A - 50 mV

AC

; 3 A @ 230 V

AC

AC

1. Maximum continuous DC output power shall not exceed 250 W

2. +3.3 V and +5 V total O/P power should not exceed 145 W

3. -12 V and -5 V max. total combined current is 0.8 A

4. M.T.B.F: 100K hours min. at max. load and 25° C ambient

conditions

AWS-8248 User’s Manual 46

Page 55

B.2 -48 V DC power supply

The following specifications describe the physical and electrical characteristics of a 310 W, four output, DC to DC switching power supply

housed in a standard size PS/2 casing.

Specifications

Input voltage: -38 ~ -58 VDC (continuous operation)

-48 VDC (normal operation)

Input current: 10 A max. @ -48 V

Inrush current: 5 A max. @ -48 V

Efficiency: 70% min. @ full load and normal line voltage

DC

DC

input

input

47 Appx. B

Page 56

Output characteristics:

Total regulation

tolerance

Output

voltage

+5 V

DC

+12 V

-5 V

DC

-12 V

DC

Min. Max. Surge Max. Min. Max.

2 A 25 A 30 A +3% -3%

DC

0 A 10 A 12 A +3% -3%

0.0 A 1.0 A - +5% -5%

0.0 A 5 A - +3% -3%

Table B.1: -48 V

Loading current

power supply output characteristics

DC

Note 1: Total regulation tolerance includes temperature

change, warmup drift and dynamic load.

Note 2: Ripple and noise were measured differentially at

the power supply using loads that were each

shunted by at least a 0.1 m F ceramic disc

capacitor and a 10 m F electrolytic capacitor, each

capacitor having a bandwidth up to 20 MHz.

Overshoot (resistive load):

Any output overshoot when the power is turned on does not exceed

10% of the nominal output voltage.

Output power: Maximum continuous: 310 W

Noise

plus

ripple

50 mV

p-p

120 mV

p-p

50 mV

p-p

120 mV

p-p

AWS-8248 User’s Manual 48

Page 57

Power good and power fail signals (optional):

When the power is turned on, the power good signal will activate 100 to

500 ms after all output DC voltages are operating within their respective

regulation limits.

The power fail signal will activate at least 1 ms before the +5 V output

voltage falls below its regulation limit.

Short circuit protection:

A short circuit placed on any output to ground is shut down. When the

short circuit conditions have ceased to exist, power will then be recycled

to restart the power supply.

Over-current protection:

The power supply will shut down all the DC outputs when any output is

overloaded beyond its current limit or beyond its nominal line voltage

limit. When the over-current conditions have ceased to exist, power will

then be recycled to restart the power supply.

Current limit ranges: 5 V: 32 ~ 45 A

12 V: 13 ~ 20 A

-12 V: 6 ~ 12 A

-5 V: 1.5 ~ 3 A

Over-voltage protection:

The power supply will shut down all the DC outputs when any output

maximum voltage limit is exceeded. When the over-voltage conditions

have ceased to exist, power will then be recycled to restart the power supply.

Voltage limit ranges: 5 V: 6.25 ±0.75 V

12 V: 14 ±1 V

-5 V: -6.25 ±0.75 V

-12 V: -14 ±1 V

49 Appx. B

Page 58

Reset time:

When the power supply has automatically shut down, and the short circuit, over-current and/or over-voltage conditions have ceased to exist,

power will be automatically recycled to restart the power supply within 3

seconds of such return to normal conditions.

No load start:

When the power supply is switched on but with no load connected, the

power supply does not get damaged, and it is still completely safe for

users.

Transient response:

Dynamic load change: ±50% of maximum rating load

Recovery time: 500 µs max.

Reliability:

Mean time between failures (MTBF):100,000 hours minimum

Operating temperature: 0 ~ 50° C

Storage temperature: -40 ~ 60° C

Operating and storage humidity:10 ~ 95% RH

Operating altitude: sea level ~ 15,000 ft

Storage altitude: sea level ~ 50,000 ft

International Standards Compliance

Safety: UL 1950

CSA 22.2 No. 234

TUV EN 60950

EMI: FCC Part 15 Subpart J Class B

AWS-8248 User’s Manual 50

Page 59

DC Output wire list

All DC output cables use UL 1007 type wires.

Wire

Connector Output Color

P8-1

P8-2

P8-3

P8-4

P8-5 COM Black 18

P8-6

P9-1

P9-2 COM Black 18

P9-3

P9-4

P9-5

P9-6

PE-1

PE-2

PE-3

PE-4

PF-1

PF-2

PF-3

PF-4

PA-1

PA-2

PA-3

PA-4

PB-1

PB-2

PB-3

PB-4

PG Orange 18

+5 V Red 18

+12 V Yellow 18

-12 V Blue 18

COM Black 18

COM Black 18

-5 V White 18

+5 V Red 18

+5 V Red 18

+5 V Red 18

+12 V Yellow 18

COM Black 18

COM Black 18

+5 V Red 18

+5 V Red 20

COM Black 20

COM Black 20

+12 V Yellow 20

+12 V Yellow 18

COM Black 18

COM Black 18

+5 V Red 18

+12 V Yellow 18

COM Black 18

COM Black 18

+5 V Red 18

#AWG

Length

(mm)

300

+30/-10

300

+30/-10

300

+30/-10

150

+30/-10

300

+30/-10

150

+30/-10

Housing Terminal

BURNDY

GTC 6P-1

or

equivalent

BURNDY

GTC 6P-1

or

equivalent

AMP

480424-0

or

equivalent

AMP

171822-4

or

equivalent

AMP

480424-0

or

equivalent

AMP

480424-0

or

equivalent

BURNDY

DCK 18-2TR9

or equivalent

BURNDY

DCK 18-2TR9

or equivalent

AMP

61314

or equivalent

AMP

170262-1 or

equivalent

AMP

61314

or equivalent

AMP

61314

or equivalent

Table B.2: -48 V

power supply DC output wire list

DC

51 Appx. B

Page 60

B.3 24 VDC power supply

This is a DC to DC switching mode power supply with a 24 VDC input.

Input voltage:+19 ~ +32 V

Input current:16 A max. @ +24 V

Inrush current:10 A max. @ +24 V

(normal operation)

DC

input

DC

input

DC

Output load range:

Table B.3: 24 VDC power supply output load range

Output No OutputMin. load Rated load Peak load Voltage accuracy

1 +5 V 1.0 A 25 A 30 A 4.90 ~ 5.10 V

2 +12 V 0 A 10 A 12 A 11.28 ~ 12.72 V

3 -12 V 0 A 1 A 2 A -11.40 ~ -12.60V

4 -5 V 0 A 1 A 2 A -4.75 ~ -5.25 V

At the factory, the +5 V output was set between 5.00 and 5.10 V, while

other outputs were simultaneously set at 60% of their respective rated

loads.

The -5 V and -12 V outputs can be used at their respective rated loads.

The +5 V output should carry a load of at least 4 A.

Output power:

Total DC continuous power does not exceed 250 W. Each output should

be able to operate continuously under its maximum load.

Ripple and noise:

Peak to peak ripple and noise for each output is less than 1% of

each output’s respective voltage. Measurements were performed

with a 15 MHz bandwidth limited oscilloscope, and each output

was terminated with a 0.47 µF capacitor.

V

AWS-8248 User’s Manual 52

Page 61

Line regulation:

The output line regulation for each output is less than ±1%, when measured at each output’s respective rated load and under ±10% changing

input voltage conditions.

Load regulation:

The values for each of the following output numbers were obtained by

changing each output load ±40% from the 60% rated load, whilst simultaneously keeping all other outputs at 60% of their respective rated loads.

Table B.4: 24 VDC power supply load regulation

Output No OutputMin. load Rated load Peak load Voltage accuracy

1 +5 V 1.0 A 25 A 30 A 4.90 ~ 5.10 V

2 +12 V 0 A 10 A 12 A 11.28 ~ 12.72 V

3 -12 V 0 A 1 A 2 A -11.40 ~ -12.60V

4 -5 V 0 A 1 A 2 A -4.75 ~ -5.25 V

Power good signal:

When the power is turned on, the power good signal will activate 100 to

500 ms after all output DC voltages are operating within their respective

regulation limits.

Power fail signal:

This will activate at least 0.5 ms before any of the output voltages fall

below their respective regulation limits.

53 Appx. B

Page 62

General features

Efficiency:

65% typical when measured at nominal input and rated load.

Input protection:

Protection against wrong polarity if the +24 V input voltage is mistakenly

reversed.

Output protection:

If for some reason the power supply fails to control itself, the built-in

over-voltage protection circuit will shut down the outputs to prevent damage to external circuits. The trip point of the

crowbar circuit is approximately 5.7 ~ 7.0 V. The power supply will go

into hiccup mode under short circuit or overload

conditions, and will recover automatically when such conditions cease to

exist.

Environmental specifications

Operating temperature: 0 ~ 45° C

Storage temperature: -40 ~ 75° C

International standards compliance

Safety: UL 1950 D3

CSA 234

TUV EN 60950

AWS-8248 User’s Manual 54

Page 63

Appendix

C

Touchscreen (optional)

• Installation of touchscreen driver

55 Appx. C

Page 64

Appendix C Optional Touchscreen

C.1 Specifications

Electrical

Operating Voltage: 3.3 to 5 VDC typical

Sheet Resistance: 220 ± 30% W/square

Linearity: +/- 1.5% full scale linearity error in either

direction.

Insulation Resistance: > 20

Optical

Total light Transmission: 68% typical (> 66% @ 550 nm test)

Environmental

Operating Temperature Range: -20°C to +50°C, ambient humidity

Storage Temperature High: +70°C, 500 hours at ambient humidity

Storage Temperature Low: -40°C, continuous at ambient humidity

Accelerated Aging: 100 hours continuous exposure at

Mechanical

Activation Method: Gloved or ungloved finger

Activation Force: < 70g average with non-metal stylus

ΜΩ

@ 25 VDC.

60°C/95% RH

Thermal Shock: 25 cycles (one cycle is

30 min. dwell alternating from -40°C

to +85°C with less than 10 min. trans

fer time).

Delrin or plastic stylus (no metal) with

1mm radius full hemispherical tip

< 90g average with 5/8” diameter sili

cone finger

AWS-8248 User’s Manual 56

Page 65

Durability

Point Activation Life: 1 Million activations on a single point

with a 5/8” diameter silicone finger

with a 350g load at 2 Hz

Character Activation Life: >100,000 characters written within a

20mm x 20mm

C.2 Installation of Touchscreen Driver

The touchscreen for the AWS-8248 Series provides drivers for use with

MS-DOS, Windows 3.1, 95, 98, NT, and 2000. For the detailed touchscreen driver installation procedure, please refer to the “TSCB-9516

Driver Installation Guide” in the accessory box.

57 Appx. C

Page 66

AWS-8248 User’s Manual 58

Loading...

Loading...