Page 1

The Advanced®Osmometer

Model 3D3

User ’s Guide

3D35 Rev12 042508

Page 2

The Advanced®Model 3D3 User’s Guide

Copyright

This user’s guide is copyrighted by Advanced Instruments, Inc. with all

rights reserved. Under copyright laws, this guide may not be reproduced

in any form, in whole or part, without the prior written consent of

Advanced Instruments.

© 2003 Advanced Instruments, Inc.

Advanced Instruments has reviewed this guide thoroughly. All material

contained within is believed reliable, but the accuracy and completeness

are not guaranteed or warranted, and are not intended to be representations or warranties concerning the product described.

®

Windows

United States and other countries. All other trademarks are the property

of Advanced Instruments, Inc.

is a registered trademark of Microsoft Corporation in the

Hot-Line®Service

If you have any questions or problems regarding the proper operation of

your instrument, please contact our Hot-Line Service department by

calling one of the following numbers.

• 800-225-4034 (toll-free within the USA and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-0811 (fax)

ii

Page 3

Table of Contents

Safe Use vii

Parts & Accessories xi

Calibrators & Standards xiii

Foreword: Theory and Technique xv

Principles of Freezing-Point Osmometry xv

Instrumentation xvi

Freezing-Point Thermodynamics xvii

Definitions xviii

Figure 1: Standard Freezing Curve xvii

Chapter 1 — Installation & Setup 1

A. Things to do in advance 1

B. Storage of supplies 2

C. Installation 2

D. Power-up 6

Figure 2: Model 3D3 Osmometer and Acccessories 3

Figure 3: Back Panel 5

Table 1: Model 3D3 Osmometer Packing List 3

Chapter 2 — Instrument Operation 11

Hazardous material cautions 11

A. Function of major components 11

B. Fluid check and startup 18

C. Setup 19

D. Test 28

iii

Page 4

The Advanced®Model 3D3 User’s Guide

E. Sample preparation 28

F. Sample tubes and sample sizes 28

G. Sample test procedure 29

Repeatability tips 33

Figure 4: Model 3D3 Components and Controls 12

Table 2: Communications Port Connections 14

Table 3: Printer Power Connections 15

Table 4: Printer Port Connections 16

Table 5: Setup Menu Options 20

Table 6: Test Mode Options 28

Chapter 3 — Standards & Quality Control 35

A. Purpose of quality control 35

B. Repeatability and accuracy 35

C. Standards and controls 36

D. Maintenance of standards 36

E. Quality control implementation 37

Chapter 4 — Calibration 39

Chapter 5 — Troubleshooting & Service 43

A. Service & maintenance cautions 43

B. Obtaining service 44

C. Routine maintenance 45

D. Shutdown and storage 46

E. Troubleshooting 46

F. Test 48

G. Adjustment and replacement of parts and assemblies 55

Figure 5: Operating Head 57

Figure 6: Mandrel, Probe and Stir/Freeze Wire Adjustment 61

iv

Page 5

Table of Contents

Appendices 67

Appendix A — Troubleshooting table 67

Appendix B — Product specifications 79

Appendix C — Regulatory notices 81

Appendix D — Warranty and warranty duties 83

Appendix E — Supplemental RS-232 information 87

Appendix F — Symbol definitions 89

Appendix G — Service log 93

Figure 7: RS-232 External Cable 88

Index 95

v

Page 6

The Advanced®Model 3D3 User’s Guide

Notes:

vi

Page 7

Safe Use

To reduce the risk of bodily injury, electric shock, fire, and

damage to your instrument, please read and observe the precautions in this User’s Guide.

• If the product is used in a manner not in accordance with the

equipment design, operating instructions or manufacturer's

recommendations, the operation of the product may be

impaired to the extent that a safety hazard is created.

• Do not attempt to perform electrical work if you are not

fully qualified. This manual is not a substitute for electrical

training.

Symbol conventions

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important operating and maintenance (servicing) instructions in the literature accompanying this product.

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the user to the presence of

uninsulated dangerous voltage within the product's enclosure

that may be of sufficient magnitude to constitute risk of

electric shock to persons.

The static symbol within an equilateral triangle is intended

to alert the user to the presence of internal components that

could be damaged by static electricity.

This static symbol is intended to alert the user to the presence of a specific component that could be damaged by static electricity.

vii

Page 8

The Advanced®Model 3D3 User’s Guide

This symbol indicates the presence of alternating current (AC).

This symbol indicates the presence of a fuse.

This symbol indicates the presence of protective earth ground.

General cautions

• This product should be operated only with the type of power source

indicated on the product’s electrical ratings label. Refer to the installation instructions included with the product.

• If the power cord provided is replaced for any reason or if an alternate cord is used, the cord must be approved for use in the local

country. The power cord must be approved for the product’s listed

operating voltage and be rated at least 20% greater than the ampere

ratings marked on the product’s electrical ratings label. The cord

end that connects to the product must have an IEC 60320 connector.

• Plug the product into an approved grounded electrical outlet.

• Do not disable the power cord’s grounding plug.

• If an extension cord or power strip is used, make sure that the cord

or strip is rated for the product, and that the total ampere ratings of

all products plugged into the extension cord or strip do not exceed

80% of the cord’s or strip’s rating limit.

• Route power cords so that they will not be walked on, tripped on, or

pinched by items placed upon or against them. Pay particular attention to the plug, electrical outlet, and the point where the cord exits

the product.

• Do not pull on cords and cables. When unplugging cords or cables,

grasp the corresponding connector.

viii

Page 9

Safe Use

• Do not install or use this product in any area subject to extreme

short-term temperature variations, or locations that exceed the specified operating environment temperatures.

• Never use this product in a wet area.

• To avoid injury or fire hazard, do not operate this product in an

explosive atmosphere.

• Do not install or use the product on an unstable, non-level work surface.

• Do not operate this product with the covers removed or unsecured.

ix

Page 10

The Advanced®Model 3D3 User’s Guide

Notes:

x

Page 11

Parts & Accessories

To order parts and accessories, contact the Advanced

Instruments Customer Service Department by using one of the

following numbers.

• 800-225-4034 (toll-free within the USA and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-3669 (fax)

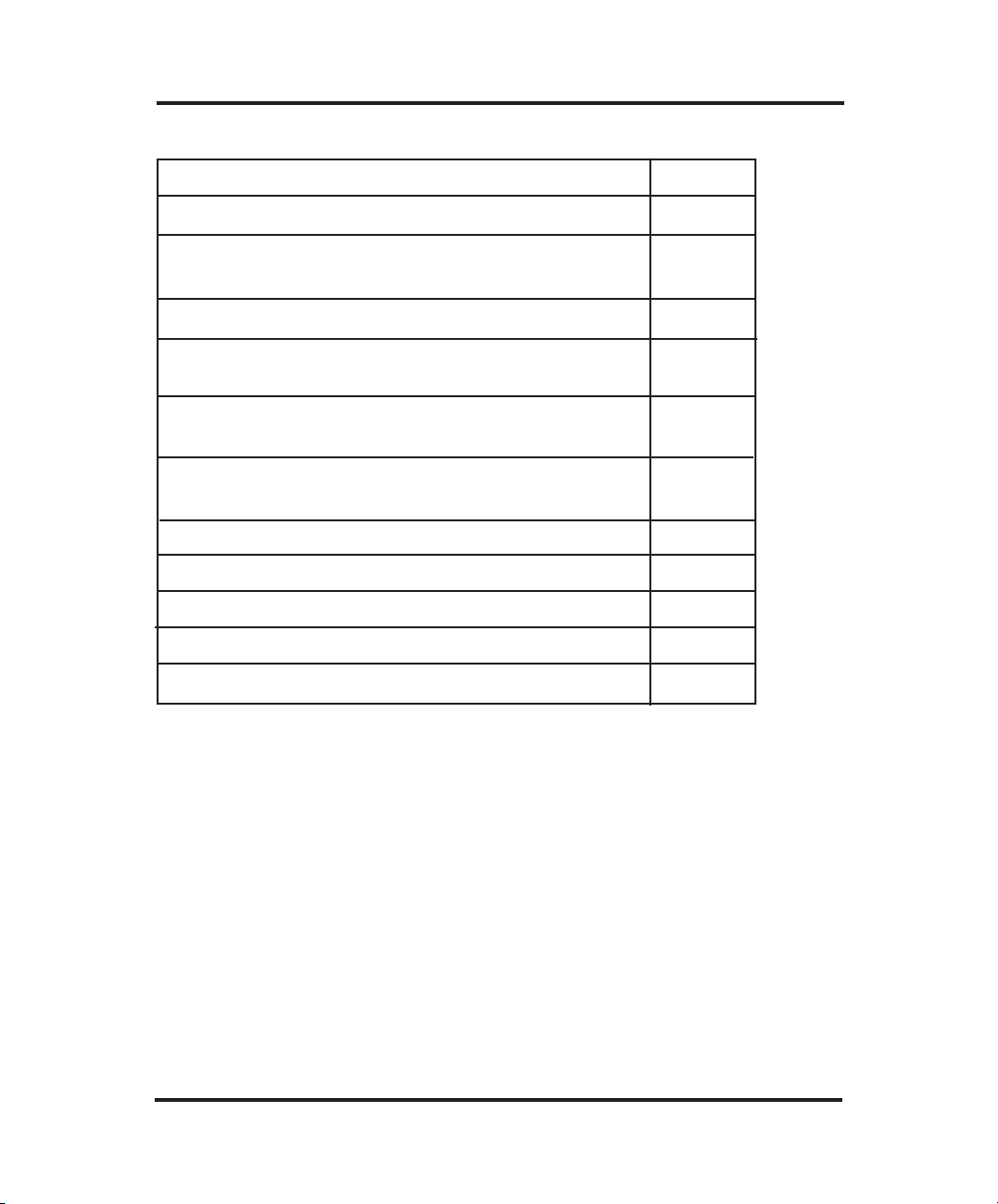

PART DESCRIPTION

1-Amp Time Delay (T) Fuse for 200-250V

2-Amp Time Delay (T) Fuse for 100-130V

Clapper

Disposable Air Filters

Disposable Sample Tubes, 0.2 or 0.25 mL

Thermal Printer with Interface Cable, Operation Manual,

Thermal Paper Roll, and Printer Power Supply (100-120

VAC)

Thermal Printer with Interface Cable, Operation Manual,

Thermal Paper Roll, and Printer Power Supply (230 VAC)

Heat Transfer Fluid

Heat Transfer Fluid Filter

Mandrel

Operator/Supervisor Keys

Power Cord (specify voltage and country)

Printer Paper (5 rolls)

PART NO.

7011

7022

3C2241

3D2340

3LA825

3D3555_NA

3D3555_EU

3DA811

4S0710

3LH500

3D3185

3D3835

xi

Page 12

The Advanced®Model 3D3 User’s Guide

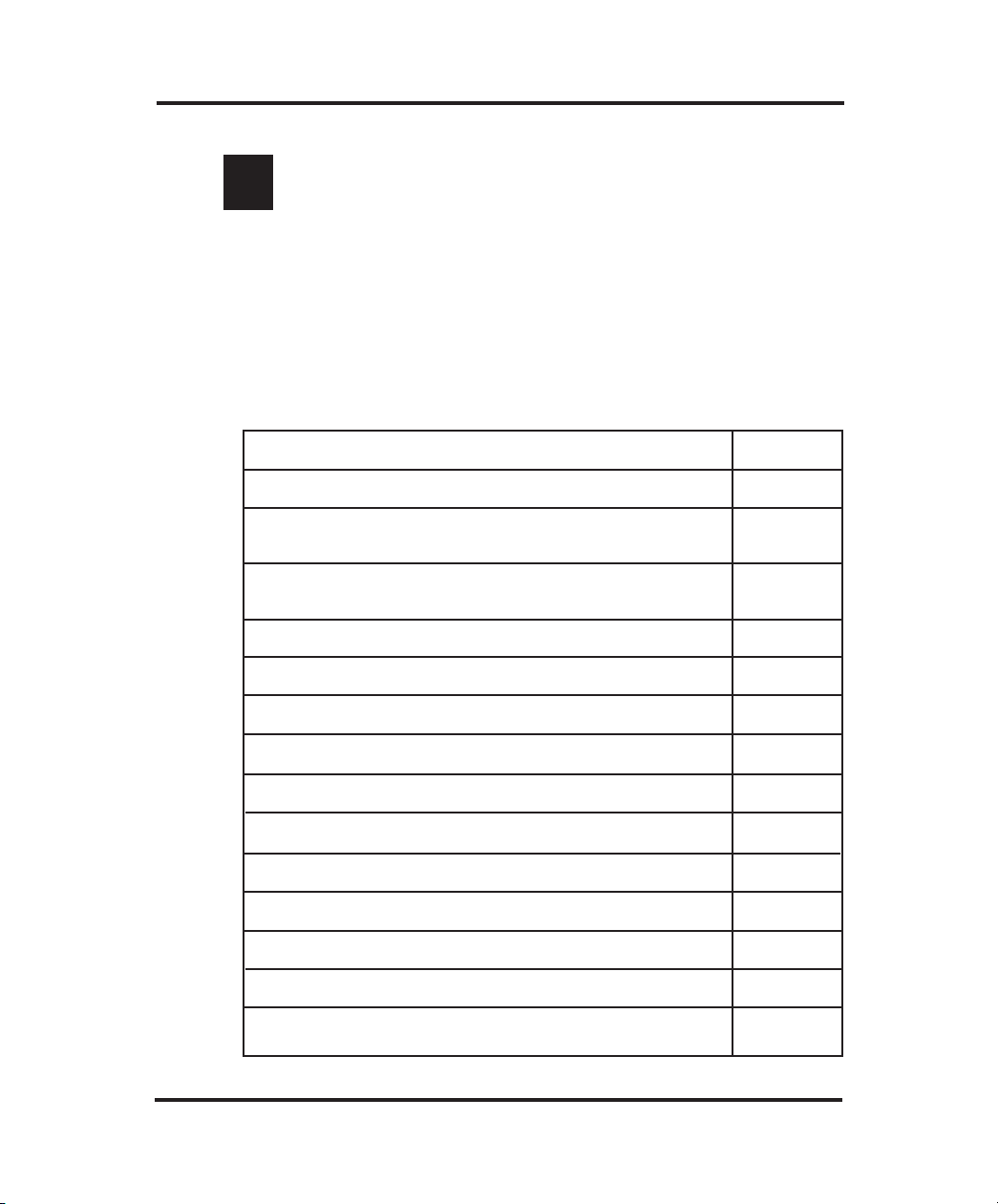

PART DESCRIPTION

Probe/Stir Wire Alignment Tool

Replacement Sample Probe with Mandrel and three 10-mL

ampules of Probe Bin Setting Fluid (Stainless Steel)

Sample Tube Rack

Serial Port Interface Computer Cable Computer

Connector, 3 Meters

Serial Port Interface Computer Cable Computer

Connector, 6 Meters

Serial Port Interface Computer Cable Computer

Connector, 9 Meters

Service Manual, 3D3/4D3

Stir/Freeze Coil

Stir/Freeze Wires

User’s Guide

Yoke

PART NO.

3LA700

3D3700

3LA846

3M3053

3M3056

3M3059

4D35SM

3D2404

3LH243

3D35

3LH230

xii

Page 13

Calibrators & Standards

To order calibrators and standards, contact the Advanced

Instruments Customer Service Department by using one of the

following numbers.

• 800-225-4034 (toll-free within the USA and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-3669 (fax)

DESCRIPTION

ClinitrolTMmOsm/kg Reference Solution (10 5mL ampules)

Five-Level Osmolality Linearity Set: 100, 500, 900, 1500

and 2000 mOsm (10 5mL ampules, 2 of each value)

Protinol®3-Level Protein Control Kit (9 3mL bottles, 3 of

each level)

Renol™ Urine Osmolality Controls (2 levels)

100 mOsm/kg Calibration Standard (110mL bottle)

100 mOsm/kg Calibration Standard (10 5mL ampules)

500 mOsm/kg Calibration Standard (110mL bottle)

500 mOsm/kg Calibration Standard (10 5mL ampules)

900 mOsm/kg Calibration Standard (110mL bottle)

900 mOsm/kg Calibration Standard (10 5mL ampules)

1500 mOsm/kg Calibration Standard (110mL bottle)

1500 mOsm/kg Calibration Standard (10 5mL ampules)

2000 mOsm/kg Calibration Standard (10 5mL ampules)

PART NO.

3LA029

3LA028

3MA028

3LA085

3LA010

3LA011

3LA050

3LA051

3LA090

3LA091

3LA150

3LA151

3LA201

3000 mOsm/kg Calibration Standard (10 5mL ampules)

3LA301

xiii

Page 14

The Advanced®Model 3D3 User’s Guide

Notes:

xiv

Page 15

Foreword

Principles of Freezing-Point Osmometry

When a solute is dissolved in a pure solvent, the following

changes in the solution's properties occur:

• the freezing point is depressed,

• boiling point is raised,

• osmotic pressure is increased, and

• vapor pressure is lowered.

These are the so-called "colligative" or concentrative properties

of the solution which, within reasonable limits, change in direct

proportion to the solute concentration; in other words, the number of particles in solution.

Of the colligative properties, measurement of the freezing point

allows the concentration of an aqueous solution to be easily

determined with great precision.

The freezing point of pure H

mole of a non-dissociating solute such as glucose (where the

solute does not dissociate into ionic species, but remains intact),

when dissolved in 1 kilogram (kg) of water will depress the

freezing point by 1.858°C. This change is known as the freezing point depression constant for water. The freezing point

depression also depends upon the degree of dissociation of the

2O is precisely +0.010°C. One

xv

Page 16

The Advanced®Model 3D3 User’s Guide

solute. If the solute is ionic, the freezing point is depressed by 1.858°C

for each ionic species. For example, if one mole of sodium chloride

were to completely dissociate into two ionic species (Na+ and Cl-) in 1

kg of water, the freezing point would be depressed by 3.716°C.

However, dissociation is never complete. Interference between solute

molecules reduces dissociation by a factor called the osmotic coefficient.

In a simple solution such as glucose or sodium chloride in water, the

freezing point can be measured and the unit concentration easily determined from an equation or a reference table. However, the equation is

unique for each solute. In a more complex solution, all ionized and

non-dissociated species contribute to the freezing-point depression and

the concentration of each solute cannot be easily determined.

Each of the colligative properties has a similar problem, and though

each of the colligative properties changes in direct proportion to the

solute concentration, each requires a different mode & unit of measurement. Osmolality is a common unit of concentration measurement that

can be used to relate all the colligative properties to each other, and to

other concentration units. Because of its universality, most osmometry

applications regularly use osmolality, expressed as "mOsm/kg H

2O", as

the common unit of concentration rather than applying further conversion factors.

Instrumentation

Advanced Osmometers are devices for the determination of the concentration of solutions by means of freezing-point measurement.

Advanced Osmometers utilize high-precision thermometers to sense the

sample temperature, to control the degree of supercooling and freeze

induction, and to measure the freezing point of the sample. They can

routinely determine differences of ±1 mOsm/kg H

xvi

2O.

Page 17

Foreword

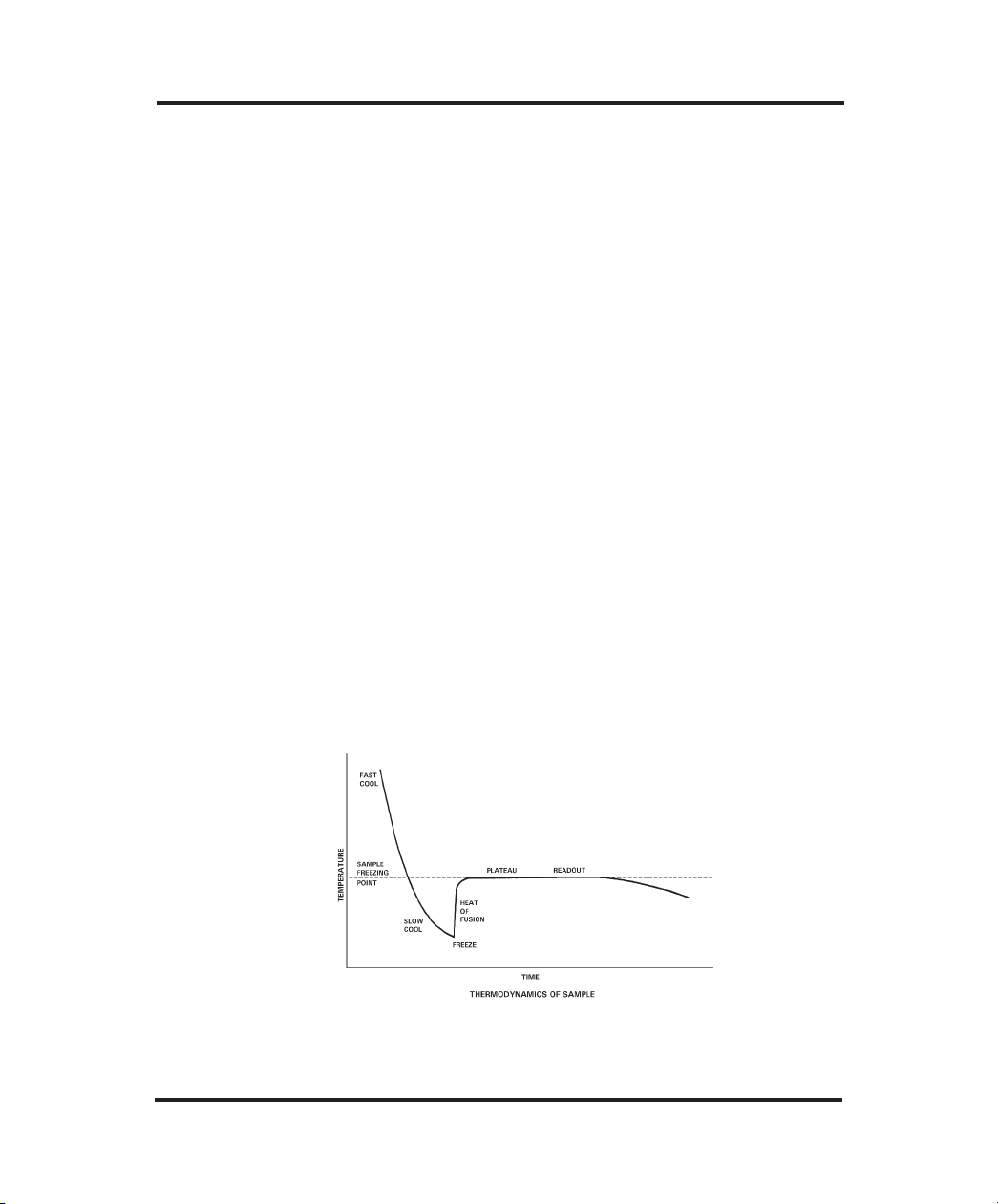

Freezing-Point Thermodynamics

The quickest and most precise way to measure the freezing point of a

solution is to supercool it several degrees below its freezing point. It is

unstable in this state, and a mechanical agitation induces crystallization.

The heat of fusion suddenly liberated causes the sample temperature to

rise toward a plateau temperature, where a liquid/solid equilibrium

occurs. The equilibrium temperature is, by definition, the freezing point

of the solution. Managing the plateau temperature for precise measurement is the basis for several patents issued to Augustus Fiske.

The time over which liquid/solid equilibrium develops and is maintained, is a function of the speed with which the heat-of-fusion is liberated vs. the speed it is transferred away, or absorbed, by the surrounding

environment. This ratio can be slowed and the equilibrium time

stretched, to give a distinct plateau height measurable to 0.001°C.

Sensitive thermistor probes monitor the sample temperature and control

the thermoelectric cooling element. Microprocessor control and automated operation minimize imprecision due to operator technique.

Figure 1 illustrates the temperature of a sample as it progresses through

the freezing cycle and shows the action of the instrument at each stage

of the cycle.

Figure 1: Standard Freezing Curve

xvii

Page 18

The Advanced®Model 3D3 User’s Guide

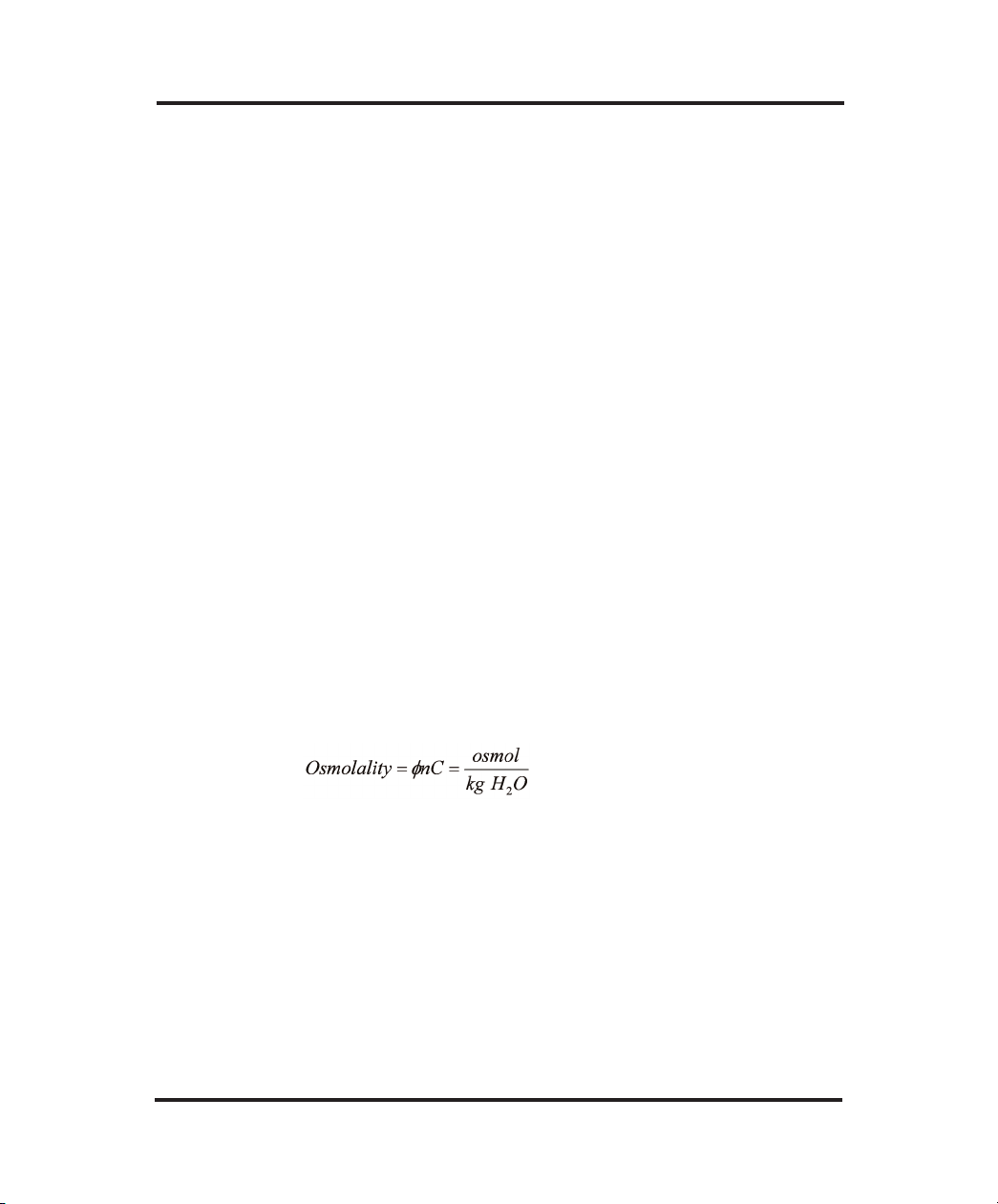

Definitions

Solution: A homogeneous mixture of solute and solvent in which the

solvent is usually the major component, and the solute is the minor

component.

Concentration: The ratio of solute to a given amount of solvent

(molal), or ratio of solute to solution (molar).

The amount of solute is usually expressed in terms of moles (i.e., gram

3

2

molecular weights). One mole = 6.028 x 10

molecules (Avogadro's

number). One mole of glucose (180.2 g) and one mole of sodium chloride (58.4 g) each contain Avogadro's number of molecules.

Common units of concentration are:

• Molality: Moles of solute per kilogram of pure solvent.

• Osmolality: Osmols of solute particles per kilogram of pure solvent. As noted above, most ionic solutes do not completely dissociate. Osmolality is a unit of concentration that takes into

account the dissociative effect. Osmolality is usually expressed

-3

in mOsm/kg H2O. One milliosmol (mOsm) is 10

osmols.

Osmolality is defined as:

where:

ø = osmotic coefficient, which accounts for the degree of mole-

cular dissociation.

n = number of particles into which a molecule can dissociate.

C = molal concentration of the solution.

• Molarity: Moles of solute per liter of solution.

• Osmolarity: Osmols of solute particles per liter of solution.

xviii

Page 19

Foreword

Although molarity and osmolarity may be common units of

measurement in other branches of chemistry, they are not used in

osmometry because the ratio of solute to solution is not linear.

Molality and osmolality are linear, independent of the effect of

temperature and volume displaced by solute. A calculated conversion between units of molality and molarity is complex and

generally unnecessary when the terms are properly understood.

Freezing Point/Melting Point: The temperature at which the liquid

and solid phases of a substance will remain together in equilibrium.

Freezing-Point Depression: When a solute is added to a solvent, the

freezing point of the solvent is lowered. In aqueous solutions, one

mOsm of solute per kilogram of water depresses the freezing point by

1.858 millidegrees Celsius (m°C).

Supercooling: The tendency of a substance to remain in the liquid

state when cooled below its freezing point.

Crystallization Temperature: Aqueous solutions can be induced to

freeze (i.e., crystallize) most reliably when supercooled. When supercooled, agitating the solution (freeze pulse) induces crystal formation.

The crystallization temperature is the temperature at which crystallization is induced. During crystallization, the heat of fusion raises the

temperature of the sample to an ice/water freezing-point plateau.

Heat of Fusion: The heat released when the mobile molecules of a liquid are frozen into rigid ice crystals.

Freezing-Point Plateau: The constant temperature maintained during

the time that ice and liquid exist in isothermal equilibrium after crystallization occurs.

xix

Page 20

The Advanced®Model 3D3 User’s Guide

Notes:

xx

Page 21

1

Installation & Setup

In order to set up your instrument properly, it is important that

you read and follow the steps in this section. Please follow these

steps carefully and be sure to read Chapter 2 — Instrument

Operation before attempting to run tests on your instrument.

A. Things to do in advance

1. Prepare bench space. The dimensions of the Advanced

3D3 osmometer are listed in Appendix B. The area beneath

the instrument should be kept clear and adequate space

should be provided around the top and sides to allow unimpeded air circulation.

2. Locate and test grounded outlet. A three-prong grounded

(earthed) 100-130V or 200-250V, 50-60Hz outlet capable of

continuously supplying 2 amperes (1 ampere for 200-250V)

is required within five feet of the instrument.

WARNING: This instrument must be properly grounded

(earthed). The grounding pin of the power plug is connected

to the cabinet to provide a noise shield around sensitive

components.

If the instrument is not grounded properly, its operation will

be impaired and a safety hazard may exist. It is not enough

to simply plug the instrument into a grounding outlet. Have

the outlet tested. Record the results.

1

Page 22

The Advanced®Model 3D3 User’s Guide

3. Obtain required items not supplied by the manufacturer:

• Soft, no-lint paper tissues for wiping the sample probe.

• Clean, dry 0.2-mL or 0.25-mL pipette (see Chapter 2, section F).

B. Storage of supplies

Unopened calibration standards and reference solutions should be stored

at 39ºF to 86ºF or 4ºC to 30ºC. Expiration dates are printed on the bottle labels. After opening, avoid contamination and evaporation; treat as

recommended in Chapters 2 and 3.

The heat transfer fluid supplied with the instrument should be installed

as described in section C below. A small amount of heat transfer fluid

clings to the outside of each sample tube and some gradually evaporates; another container should be ordered now, in anticipation of its

future requirement and may be stored at room temperature.

C. Installation

CAUTION Do not power the 3D3 for the first time until the volt-

age selection has been checked as instructed in this

section.

NOTE Make sure the Supervisor/Operator keyswitch is in the

Supervisor position as shown in figure 3, until power-up

has been completed as instructed in section D.

Heat Transfer Fluid and Filter Installation

1. Momentarily press the top of the heat transfer compartment door to

release the magnetic latch, then pull the door all the way open (see

figure 4).

2

Page 23

Installation & Setup

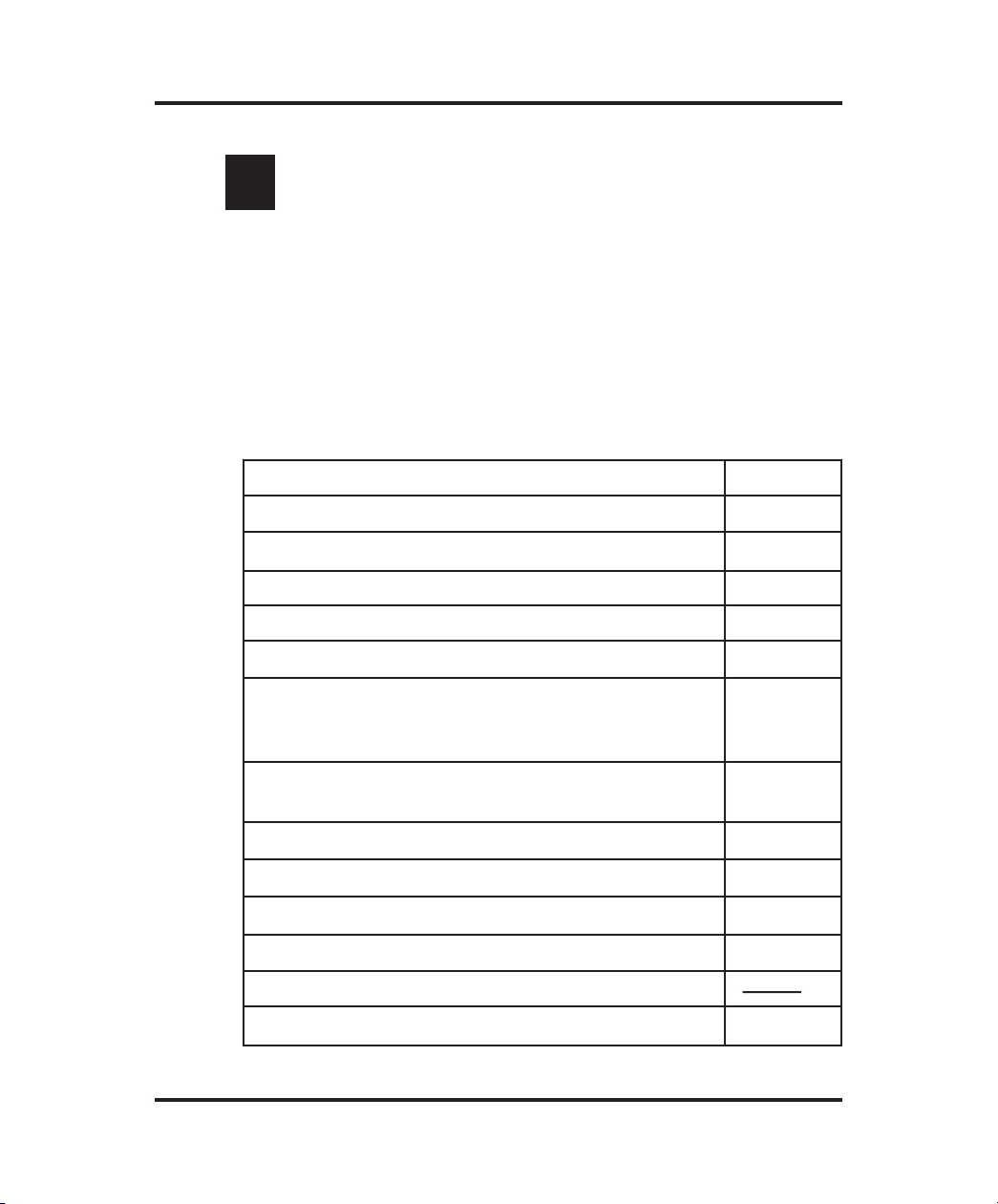

Figure 2: Model 3D3 Osmometer and Accessories

Quantity Part No. Description

1 3D3 The Advanced®Model 3D3 Osmometer

1 pack 3LA011 100 mOsm Standard

1 pack 3LA151 1500 mOsm Standard

1 pack 3LA301 3000 mOsm Standard

1 pack 3LA029 Clinitrol™ 290 mOsm Reference Solution

1 3LA827 1/16” Hex Wrench

2 bottles 3DA811 Heat Transfer Fluid

1 3D3185 Operator/Supervisor Keys (set of 2)

1 Power Cord (as specified)

1 3LA702 Probe/Stir Alignment Tool

1 3LA846 Sample Tube Rack

1 Sample Tubes Pack (re-order 500-pack as

3LA825)

1 3D35 User’s Guide

1 3D35-6 Warranty Card

Table 1: Model 3D3 Osmometer Packing List

3

Page 24

The Advanced®Model 3D3 User’s Guide

2. Locate the bagged plastic tubes protruding through the back wall of

the compartment. Remove and discard the plastic bag from the

ends of the tubes.

3. A heat transfer fluid filter (figure 4, item 6) should already be

mounted on the smaller of the two plastic tubes. If replacement is

necessary, force the tubular end of the heat transfer fluid filter at

least ¼” or 6 mm into the free end of the smaller of the two tubes.

4. Open a bottle of heat transfer fluid.

5. Insert the plastic tube with the heat transfer fluid filter into the bottle of heat transfer fluid so as to locate the filter at the bottom of

the bottle for most economical usage of the fluid. The 3D3 will

syphon heat transfer fluid into the freezing chamber as needed.

6. Insert the free end of the larger of the two plastic tubes into the

neck of the heat transfer fluid container to return the heat transfer

fluid to the container for recycling.

CAUTION The open end of the larger plastic tube must be above

the surface of the heat transfer fluid for proper circulation if necessary, remove some fluid.

7. Stand the container of heat transfer fluid in the plastic tray in the

heat transfer fluid compartment, making sure the filter remains

low in the heat transfer fluid.

8. Close the compartment door.

NOTE When the heat transfer fluid level reaches the REPLACE line

on the bottle label, discard remaining solution and replace the

heat transfer fluid. Continued use when fluid is below this

level will change the thermodynamics of the test.

Instrument Voltage Selection (see figure 3)

The 3D3 must be properly set for the voltage available on-site. The onsite power outlet voltage should have been recorded during the procedure recommended in section A.2.

4

Page 25

Installation & Setup

Check the nominal voltage indicated beside the two matching arrowheads on the voltage selector/fuseholder in the back of the 3D3, below

the power switch and power connector.

• If the AC voltage of the power outlet intended for the instrument is

within the 100-130V range, the matching arrowheads should indicate

110-120V.

• If the power outlet AC voltage is within the 200-250V range, the

matching arrowheads should indicate 220-240V.

• If the voltage selection requires correction, it can be accomplished

by matching the proper arrowheads as follows:

1. Unplug the power cord from the back of the instrument.

2. Use a small screwdriver to pry the fuseholder out of the back of

the instrument.

3. Check the values marked on the two 5mm x 20mm fuses inside

the fuseholder before re-installing. For 100-130V operation they

Printer Power

Outlet

Printer Port

Supervisor/Operator

Keyswitch

Power

Switch

Power

Connector

Voltage

Selector

RS-232

Port

Figure 3: Back Panel

5

Page 26

The Advanced®Model 3D3 User’s Guide

should be 2-Amp fuses; for 200-250V operation they should be

1-Amp fuses. Replace the fuses if incorrect.

4. Re-install the fuseholder into the back of the instrument with the

correct arrowheads matching.

5. Connect the power cord to the 3D3 and the power outlet.

6. Proceed to section D below.

D. Power-up

Each time the 3D3 is turned on, it will sequentially display for a few

seconds each, the software revision number, copyright notice, serial

number, date and time, and the probe bin numbers, similar to the following:

Revision

3D3.A02.0

(C) 1994 A. I., Inc.

Serial #:123456789012

03/02/94 08:08 am

Block: 5 Sample: 3

Then the operating head will rise and “Press START to Continue” (or

its equivalent in French, German or Spanish) will begin to scroll across

the display. Maintaining a record of the information displayed will

facilitate any necessary service.

All displayed messages will be in the language displayed at this time.

To avoid any misunderstanding that might arise due to an unfamiliar

display language, use the direct selection SETUP procedure described in

Chapter 2, Section C.0 to select setup item 12 and follow the instructions in Chapter 2, Section C.12 to select a different display language.

Power up the 3D3 in the following manner:

6

Page 27

Installation & Setup

1. If the 3D3 has been installed as instructed in sections A and C, turn

the POWER switch on ( I ). The display will begin to scroll.

2. Record the displayed software revision and the block and sample

probe bin numbers reported by your instrument in the service log in

the back of the user’s guide. The display does not pause for recording. If you need it repeated, turn the instrument off, pause, then turn

it on again to reset the instrument.

When all of the instrument data has been displayed, the operating

head will rise and “Press START to Continue” will begin to scroll

across the display. If for some reason the probe data has been lost

from memory, “Reset Probe Configuration” will begin to scroll

across the display after the instrument report instead of “Press

START to Continue” and one should contact Advanced

Instruments’ Hot-Line

®

service before proceeding further (see

Chapter 5, Section B).

3. When “Press START to Continue” begins to scroll across the dis-

play, make sure an empty sample tube is in the freezing chamber

(figure 4, item 9).

NOTE Step 4 must be accomplished before the 3D3 will cool the

first sample.

4. If the instrument is being started for the first time, the heat transfer

fluid pump should be “primed” using the TEST menu as follows:

a. Make sure the Supervisor/Operator keyswitch is in the Supervisor

position as shown in figure 3.

b. Press the TEST switchpad. The display will change to “Select

Test Item”.

c. Press the < switchpad once to step the display backward to

“Head Up/Down Test”.

7

Page 28

The Advanced®Model 3D3 User’s Guide

d. Press the START switchpad. The display will change to

“[START] Test [STOP]”.

e. Press the START switchpad.

f. Allow the operating head to cycle down and up approximately

twenty times to prime the heat transfer fluid pump. Then press

the STOP switchpad to raise the operating head and exit to the

test menu.

g. Press the STOP switchpad a second time to exit from the test

menu to “Press START to Continue”.

5. With an empty sample tube in the freezing chamber, press the

START switchpad.

The microprocessor will respond with the display, “Running

Diagnostics”, while it lowers the operating head, cools the freezing

chamber and completes a series of internal diagnostic checks. If

the diagnostic checks are not successfully completed or the freezing

chamber does not cool properly, a diagnostic message will be presented.

If the instrument has just been turned on, it takes a few minutes to

cool the freezing chamber. If the heat transfer fluid pump has not

been primed as described in step 4, the time will be longer.

When the freezing chamber has been cooled and the internal diagnostic checks have been completed, the operating head rises,

“Osmometer Ready” is displayed and an audible tone is sounded.

If “Osmometer Ready” is not displayed at this point, turn the instrument off ( O ) for about 5 seconds, then on ( I ) again. If

“Osmometer Ready” still does not appear, please refer to Chapter 5

for assistance.

Your 3D3 was calibrated at the factory. The probe and calibration parameters are stored in RAM which is powered by an internal battery

when the instrument power is off or disconnected. Thus, when

8

Page 29

Installation & Setup

“Osmometer Ready” is displayed, your osmometer is calibrated and

ready to run.

NOTE If your 3D3 has just been moved from a colder location to its

present environment, it should be allowed to warm up for 20 to

30 minutes before assuming that it should be recalibrated.

The 3D3 may be left on continuously. If it remains idle for five minutes

or more, it automatically enters standby mode: the fan slows, the freezing chamber warms slightly and the display changes to the date and

time. The 3D3 will remain in the standby mode until required to run a

freezing-point test. When required to run a freezing-point test, the 3D3

will automatically exit the standby mode, speed up the fan and cool the

chamber for the test.

CAUTION If a power interruption occurs, turn the instrument off at

once. Leave it turned off for at least 5 seconds after power

has been restored (to ensure internal circuitry is restarted

properly), even if power restoration is immediate.

Please continue to Chapter 2 for operating instructions.

9

Page 30

The Advanced®Model 3D3 User’s Guide

Notes:

10

Page 31

2

Instrument Operation

In order to run your instrument properly, it is important that

you read and adhere to the instructions in this section. For

information on calibration, see Chapter 4 — Calibration.

Hazardous material cautions

• WARNING: Handle all biohazardous materials according to

established good laboratory practices and follow your institution’s exposure control plan. Persons handling human blood

and body fluid samples must be trained in blood-borne hazards

and observe universal precautions. Universal precautions is an

approach to infection control, where all human blood and body

fluids are treated as if known to be infectious. Use personal

protective equipment such as gloves, gowns, etc., to prevent

exposure. Store biohazardous materials in regulated waste containers and dispose of these materials in a safe and acceptable

manner that is in compliance with all country, state and local

requirements.

• If a biohazardous material is spilled on or inside the equipment,

decontaminate the equipment using a 1% bleach solution, or as

outlined by those policies and procedures established within

your institution.

• To avoid injury or fire hazard, do not operate this product in an

explosive atmosphere.

A. Function of major components

Operation of the instrument will be quicker and easier if you

become familiar with the locations and functions of the components, systems and controls described below before proceeding further.

11

Page 32

The Advanced®Model 3D3 User’s Guide

Power Switch, Fuse

Holder, and RS-232

Connector on Back

Panel

Freezing

Chamber (9)

Air Filter (8)

Heat Transfer

Fluid Filter (6)

Replace Heat

Transfer Fluid

Filter Line (7)

Operating Head (2)

Stir/Freeze Wire (3)

Sample Probe (4)

Display Panel

and Keypad (5)

Figure 4: Model 3D3 Components and Controls

Functionally, this instrument consists of automatic sample holding and

centering devices, a microprocessor-controlled freezing chamber, a precision digital thermometer, measurement and control circuitry and a

message display panel. These basic systems include the following parts

and controls:

1. Power Entry Module (see figure 3): Contains the following power

components:

a. Power switch: Press "I" for power on, "O" for power off. The

power may be left on continuously; the 3D3 enters standby mode

automatically if idle for more than five minutes.

b. Power cord connector: To accommodate a power cord suitable

for the power available.

c. Fuse holder/voltage selector: For containing fuses suitable for

the power available and for selecting the proper voltage (see

Chapter 1, Section C).

12

Page 33

Instrument Operation

2. Supervisor/Operator Keyswitch (see figure 3): The Operator

position of the Supervisor/Operator keyswitch provides a means

of locking out the setup, test and calibration functions of the instrument to help prevent unauthorized changes.

The Operator keyswitch position allows access to the sample test

function only; the Supervisor keyswitch position allows access to

the setup, test and calibration functions, as well as the sample test

function. It may be necessary or desirable, therefore, to complete

some SETUP or TEST function (e.g., to prime the heat transfer

pump as in Chapter 1, Section D.4) before locking the

Supervisor/Operator keyswitch in the Operator position.

If the SETUP or TEST switchpad is pressed while the

Supervisor/Operator keyswitch is in the Operator position, a

"Supervisor Key Needed; Press STOP to Continue" message is

continually scrolled across the display until STOP is pressed.

When STOP is pressed, the message will change back to "Ready",

re-enabling the sample test function.

The CALIB switchpad has no effect until the instrument has completed the power-up diagnostic checks. If the CALIB switchpad is

pressed after the instrument has completed the power-up diagnostic

checks and the Supervisor/Operator keyswitch is in the Operator

position, a "Supervisor Key Needed; Press STOP to Continue"

message is continuously scrolled across the display until STOP is

pressed.

3. RS-232 Port (see figure 3): The DB-9 RS-232 port conforms to the

DTE RS-232C standard and has the following pin assignments (see

table on next page).

The serial port can reliably communicate over cable up to 10 meters

in length. Data is transmitted asynchronously as 1 start bit, 8 data

bits and 1 stop bit, with no parity. Hardware handshaking is

supported; XON-XOFF software handshaking may be selected by

means of the SETUP menu (see section C.7).

13

Page 34

The Advanced®Model 3D3 User’s Guide

Signal Pin Direction

Carrier Detect 1 to 3D3

Receive Data 2 to 3D3

Transmit Data 3 from 3D3

Data Terminal Ready 4 from 3D3

Signal Ground 5 common

Data Set Ready 6 to 3D3

Request to Send 7 from 3D3

Clear to send 8 to 3D3

Table 2: Communications Port Connections

The default serial data rate is 1200 bps (bits per second), though

300 bps and 9600 bps may alternatively be selected (see section

C.7).

Each message transmitted from the serial port is terminated by the

sequence, Carriage Return (0D Hex), Line Feed (0A Hex), Null (00

Hex). For display purposes, most messages consist of less than 20

characters but longer messages, which scroll across the display, are

transmitted no differently.

The 3D3 transmits a significant amount of information via the RS232 port. Almost every item of information displayed by the instrument is transmitted over the RS-232 port, including test results, all

error messages, and most display data from the "test" menu (see

Chapter 5, Section F).

4. Printer Power Outlet (see figure 3): A 3-pin DIN socket on the

back of the 3D3 automatically provides the proper power for the

optional Advanced Instruments printer listed in Table 3 (if cable

supplied with printer).

14

Page 35

Instrument Operation

Printer Power Connections

Pin 1 (left) +12 VDC

Pin 2 (center) not connected

Pin 3 (right) ground

Table 3: Printer Power Connections

5. Printer Port (see figure 3): The printer port connector on the back

of the 3D3 provides 8 data lines and the necessary handshaking signals for communication with most standard printers. The printer

port connections are listed in Table 4.

NOTE If the printer does not print, make sure to check both the

printer power and parallel cable connections before requesting service assistance as recommended in Chapter 5,

Section B.

6. Freezing Chamber (figure 4, item 9): The freezing chamber is

thermoelectric for reliability and precise control. The chamber contains a small amount of heat transfer fluid for optimum cooling

capacity.

7. Operating Head (figure 4, item 2): The operating head contains a

stir/freeze wire (item 3) with electrical means to vibrate it; an ultrastable, ultra-precise thermistor sample probe (item 4) with devices

to automatically locate the probe and sample in the freezing chamber.

8. Measurement and Control Circuits (inside): Microprocessor controlled. Provide operating mode and calibration selections on the

display during SETUP. Automatically measure and control the

dynamic temperature of the sample freezing chamber. Process calibration data and sample temperature information. Present calibrated

test results on the digital display.

15

Page 36

The Advanced®Model 3D3 User’s Guide

PIN-OUT

SIGNAL

Port

Connector

Cable

Output

STROBE

Data 0

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

READY

Ret. Gnd

Ret. Gnd

Ret. Gnd

Ret. Gnd

Ret. Gnd

8

2

3

4

5

6

14

7

15

1

9

10

11

12

13

1

2

3

4

5

6

7

8

9

11

19

20

21

22

23

Table 4: Printer Port Connections

9. Display Panel and Keypad (figure 4, item 5): The microprocessor

communicates with the instrument operator by means of alphanumeric messages displayed on the illuminated display panel located at the top of the keypad. These messages report the instrument

function currently being performed, the next operator function

required and the results of tests. The messages are displayed either

in English, French, German or Spanish, as selected via the SETUP

menu (see section C.12); the default language is English.

16

Page 37

Instrument Operation

The keypad contains spill-proof delineated pressure pads for operator input to the micro-processor. Keypad switch activation requires

firm finger pressure to the center of the pad. When pressed properly the RECALL, SETUP, TEST, CALIB, START and STOP pads

illuminate to indicate activation.

The function of each of the switchpads is as follows:

a. RECALL: Recalls the previous display (the last test result or

the last message).

b. SETUP: Activates the SETUP menu which may be used to set

the current date and time, activate the keypad "beeper", select

the serial-port communication parameters, etc. (see section C).

c. CALIB: Activates calibration prompts for calibration of the

instrument. Pressing STOP during a calibration test will cancel

the test in progress; pressing STOP a second time will cancel

recalibration and retain the previous calibration.

d. TEST: Activates a "test" menu for checking selected compo-

nents and subsystems (see section D).

e. Numbers 1 through 0: Allow prompted numeric operator

input, as required, during SETUP, CALIB and TEST procedures.

f. < and > : Allow stepping forward and backward through dis-

played menu items as an alternative to selection via the numeric

pads and allows making alternative two-item menu choices.

g. CLEAR: Can be used to empty the date and time memory

fields during SETUP. If sample identification has been

enabled, CLEAR can also be used to empty the sample identification memory field.

17

Page 38

The Advanced®Model 3D3 User’s Guide

h. ENTER: Confirms the selected SETUP menu item. If sample

identification has been enabled, ENTER is used to confirm the

sample identification.

i. START: Starts CALIB, TEST and SET-UP procedures, as

well as freezing-point tests.

j. STOP: Cancels the procedure in process. During multiple step

procedures such as calibration, pressing STOP once cancels the

current test; pressing STOP a second time cancels the procedure.

B. Fluid check and startup

Momentarily press the top of the heat transfer compartment door to

release the magnetic latch, then pull the door all the way open (see figure 4).

A container of heat transfer fluid and a heat transfer fluid filter are supplied with the 3D3 and should have been installed as instructed in

Chapter 1, Section C. Two plastic tubes of different sizes should be

observed, extending into the mouth of a container of heat transfer fluid.

The heat transfer fluid level should be visible through the semi-transparent container; if the heat transfer fluid level is below the "REPLACE"

line marked on the container, it should be replaced. When finished,

close the heat transfer fluid compartment door.

CAUTION The open end of the larger plastic tube must be above the

surface of the heat transfer fluid for proper circulation; if

necessary, remove some fluid.

If the date and time are being displayed, the 3D3 is in the standby

mode, ready for a test to be run.

18

Page 39

Instrument Operation

If the power switch on the back of the instrument is in the off ( O ) position and the power cord is connected to the 3D3 and the power outlet,

place the power switch in the on ( I ) position.

Each time the 3D3 is turned on, it sequentially displays, for a few seconds each, the software revision number, copyright notice, serial number, date and time and the probe bin numbers. Then "Press START to

Continue" will begin to scroll across the display.

Make sure an empty sample tube is in the freezing chamber (figure 4,

item 9); then press the START switchpad. The microprocessor will

respond with the display, "Running Diagnostics", while it lowers the

operating head, cools the freezing chamber and completes a series of

internal diagnostic checks. If the instrument has just been turned on, it

will take a few minutes to cool the freezing chamber.

When the freezing chamber has been cooled and the internal diagnostic

checks have been completed, the operating head rises, "Osmometer

Ready" is displayed and an audible tone is sounded.

C. Setup

Your 3D3 has been individually setup at the factory for normal operation, but SETUP may be required for changing the date and time or customizing the SETUP parameters for your own individual needs.

NOTE The Supervisor/Operator keyswitch must be in the Supervisor

position to enable the use of the SETUP menu. If the SETUP

switchpad is pressed while the Supervisor/Operator keyswitch

is in the Operator position a "Supervisor Key Needed; Press

STOP" message will be displayed (see section A.2).

The operating parameters that may be checked and set via SETUP are as

follows, listed in numerical order.

19

Page 40

The Advanced®Model 3D3 User’s Guide

Setup Menu Options

0. Select Setup Item

1. Set Block Bin #

2. Set Sample Bin #

3. Dis/Enable I.D. #

4. Set Stir Amplitude

5. Set Date/Time

6. Dis/Enable Beeper

7. Set Serial Rate

Enter SETUP, if required, at

"Osmometer Ready" or the

date and time display, by

pressing the SETUP switchpad. When SETUP is

pressed, the display will

change to "Select Setup

Item".

8. Dis/Enable Xon/Xoff

9. Serial Number

10. Select Range

11. Select "Buzz" Point

12. Select Language

There are two ways to select a

SETUP menu item, direct

selection and sequential selection, as described below:

13. Product/Test

Table 5: Setup Menu Options

0. Select Setup Item

This menu item is displayed first when SETUP is pressed and

allows either direct selection or sequential selection of a menu item.

Direct Selection: for direct selection, press START at "Select

Setup Item". The display will change to "Setup Menu #: 0". At

"Setup Menu #: 0", enter the number of the desired setup item

(from the list above) on the keypad and press ENTER. The display

will change to the selected menu item.

Sequential Selection: for sequential selection, repeatedly press the

> switchpad to step the display forward or < to step the display

backward through the setup menu list. The displayed parameter list

is cyclic; pressing > at the last item cycles the display to item 0.

Continue pressing > or < until the desired menu item is displayed.

Note that while direct, numerical selection is only available at

20

Page 41

Instrument Operation

"Select Setup Item", > or < stepping is available from any menu

position.

When the desired menu item is displayed, press the START switchpad

to select the item, display the current setting and enable changing the

setting.

The current setting is indicated either by the symbol "*" or a numeric

value and may be changed by pressing > or < (or using the item-specific

instructions below).

Press ENTER to store a new setting (or STOP to restore the original

setting). The display will revert to the title of the parameter selected.

Then one may press: START to display the new setting, > or < to step

to the next SETUP item, STOP to exit the SETUP menu, or TEST to

change to the TEST menu.

Recommended procedures for each of the other SETUP menu items are

as follows:

1. Set Block Bin #

This menu item displays the current block probe bin setting and

allows the setting to be changed. However, the block probe bin setting should only need to be changed when a new block probe of a

different bin number is installed. In that case, make sure the new

block probe bin number is recorded in the service log in the back of

the user’s guide and proceed as follows.

NOTE Changing the bin setting requires re-calibration of the

instrument.

At "Set Block Bin #", press the START switchpad. The display

will report the current block bin setting. Compare the current block

bin setting with the new block bin number recorded in the service

log.

21

Page 42

The Advanced®Model 3D3 User’s Guide

If the current block bin setting is the same as that recorded in the

service log, simply press the STOP switchpad to return to "Set

Block Bin #". If the current bin number is not the same as the new

bin number, enter the required bin number by means of the numeric

keypad.

Press ENTER to store the new setting (or STOP to restore the original setting).

Re-calibrate the instrument as instructed in Chapter 4.

2. Set Sample Bin #

This menu item displays the current sample probe bin setting and

allows the setting to be changed.

CAUTION Before changing the probe bin setting, the required set-

ting should be determined by means of the procedure

described in Chapter 5, Section F.3. Changing the bin

setting requires re-calibration of the instrument.

At "Set Sample Bin #", press the START switchpad. The display

will report the current sample bin setting. Compare the sample bin

setting with the sample bin number determined by means of the procedure described in Chapter 5, Section F.3.

If the current sample bin setting is the same as that determined in

Chapter 5, Section F.3, simply press the STOP switchpad to return

to "Set Sample Bin #". If the bin number is not the same, enter

the required bin number by means of the numeric keypad.

Press ENTER to store the new setting (or STOP to restore the original setting).

Re-calibrate the instrument as instructed in Chapter 4. Be sure to

record the new sample bin setting in the service log in the back of

the user’s guide.

22

Page 43

Instrument Operation

3. Dis/Enable I.D. #

This menu item enables a means of entering an identification number for each sample test result. When enabled, each test prompts

for an identification number to be entered via the numeric keypad.

The identification numbers entered are displayed and sent to the

printer port and the RS-232 port with the sample test results.

At "Dis/Enable I.D. #", press START to display " [on]< I.D.# *

[off] ". The current setting is indicated by the symbol, "*".

At " [on]< I.D.# * [off] ", press < or > to toggle the I.D.# option

on or off.

Press ENTER to store the new setting (or STOP to restore the original setting).

4. Set Stir Amplitude

This menu item displays the current sample stir amplitude setting

and allows the setting to be changed.

At "Set Stir Amplitude", press START to display "Amplitude =

xx".

At "Amplitude = xx", look across the tip of the stir/freeze wire

from the side to view and estimate the sample stir vibration amplitude. If properly adjusted, the stir/ freeze wire should vibrate principally fore and aft and should never strike the probe. The recommended stir amplitude adjustment procedure may be found in

Chapter 5, Section G.5. Pressing > increases the stir amplitude;

pressing < decreases the stir amplitude.

Press ENTER to store the new setting (or STOP to restore the original setting).

23

Page 44

The Advanced®Model 3D3 User’s Guide

5. Set Date/Time

This menu item enables changing the date/time format and resetting

the date and time.

At "Set Date/Time", press START to display the current date and

time. Any change must be made in this order:

a. Press CLEAR to clear the entire setting and display the present

format.

b. Use < to toggle to the date format you require ("mm/dd/yy" or

"dd/mm/yy").

c. Use > to toggle to "24hr" format, "am" or "pm", as required.

d. Enter the current date and time (including zeros), via the numer-

ic keypad, one digit at a time from left to right.

e. Press ENTER to store the new setting (or STOP to restore the

original setting). If an invalid setting is attempted, the instrument will reject the setting and beep when ENTER is pressed.

6. Dis/Enable Beeper

The 3D3 keypad in itself has no audible indication that a key has

been adequately pressed. The "Dis/Enable Beeper" menu item

enables an audible indication.

At "Dis/Enable Beeper", press START to display " [on]< beeper

* [off] ". The current setting is indicated by the symbol, "*".

At " [on]< beeper * [off] ", press < or > to toggle the keypad

beeper on or off. Neither selection will affect the invalid-selection

beeper except that when the keypad beeper is on, an invalid selection will invoke two beeps; when off, only one.

Press ENTER to store the new setting (or STOP to restore the original setting).

24

Page 45

Instrument Operation

7. Set Serial Rate

This menu item enables changing the serial rate of the data sent to

the RS-232 port.

At "Set Serial Rate", press START to display "Serial Rate =

xxxx".

At "Serial Rate = xxxx", the serial-port baud rate may be reset by

means of the < or > switchpad to either 300, 1200 or 9600 baud.

Press ENTER to store the new setting (or STOP to restore the orig-

inal setting).

8. Dis/Enable Xon/Xoff

This menu item enables or disables the Xon/Xoff "handshaking"

protocol for RS-232 communication.

At "Dis/Enable Xon/Xoff", press START to display " [on]<

Xon/Xof *[off] ". The current setting is indicated by the symbol,

"*"

At " [on]< Xon/Xof *[off] ", press < or > to enable or disable seri-

al-port Xon/Xoff handshaking.

Press ENTER to store the new setting (or STOP to restore the orig-

inal setting).

9. Serial Number

At "Serial Number", press START to display the instrument serial

number ("Serial#: 123").

Press ENTER to return to the setup menu.

10. Select Range

This menu item enables optimizing the 3D3 test parameters for a

wider osmolality range than can be accommodated by a single set

25

Page 46

The Advanced®Model 3D3 User’s Guide

of test parameters. Two ranges are provided: low range sets the

3D3 to operate between 0 and 2000 mOsm; high range sets the 3D3

to operate between 1400 and 4000 mOsm. Independent calibration

parameters are maintained for each range. Calibration instructions

are in Chapter 4.

Generally, each range requires a different crystallization temperature

("buzz" point). See item 11.

At "Select Range", press START to display " [low]* range

>[high] ". The current setting is indicated by the symbol, "*".

At " [low]* range >[high] ", press < or > to toggle between the

lowand high ranges.

Press ENTER to store the new setting (or STOP to restore the orig-

inal setting).

11. Select "Buzz" Point

This menu item enables setting the temperature at which crystalliza-

tion is induced by the freeze pulse (buzz) in each range.

Most freezing-point osmometers supercool all samples in the 0-

2000 mOsm range to approximately 3000 on the mOsm scale. The

3D3 buzz points default to 3000 for the lower range and 5400 for

the upper range.

Because the test results may be affected somewhat by the amount of

supercooling, these default buzz points are recommended for general use and for the most reliable comparison of data.

Certain fluids may not freeze reliably at the default buzz point,

however, or may give more repeatable results with either more or

less supercooling than the default buzz point provides. The Model

3D3 is designed to accommodate these, as well as the more ordinary types of samples.

26

Page 47

Instrument Operation

At "Select "Buzz" Point, press START to display the current crys-

tallization setting, displayed as "Buzz" Point = xxxx". To change

the crystallization point:

a. At "Buzz" Point = xxxx", the present setting must be cleared

before the buzz point can be changed. Press CLEAR to clear

the setting.

b. Enter the desired buzz point (including zeros), via the numeric

keypad, one digit at a time from left to right. Entries can be

erased one digit at a time from the rightmost entry using the <

switchpad. The 3D3 buzz points can be set between 2000 and

5400 on the mOsm scale.

Press ENTER to store the new setting (or STOP to restore the orig-

inal setting).

NOTE Each time the buzz point is changed, the instrument dis-

plays the message "Check Calibration", a reminder that the

instrument calibration is affected by the amount of supercooling.

12. Select Language

This menu item enables selecting English, French, German or

Spanish display-panel messages.

At "Select Language", press START to display the current setting.

Press < or > to select from available languages.

Press ENTER to store the new setting (or STOP to restore the orig-

inal setting).

13. Product/Test

Product/Test is for factory use only and has no field function.

27

Page 48

The Advanced®Model 3D3 User’s Guide

D. Test

The TEST switchpad activates a menu-driven program for testing

instrument functions (see Table 6). Instructions for performing these

tests are in Chapter 5, Section F.

Test Mode Options

1. A/D Tests

2. Stir/Freeze Test

3. Probe Bin Test

4. Serial Loop Test

5. Display/Print Test

6. Beeper Test

7. Keypad Test

8. Head Up/Down Test

Table 6: Test Mode Options

E. Sample preparation

No further preparation is required. Body fluids such as serum or plasma

may be used directly.

NOTE Additives such as anti-coagulants from collection tubes may

contribute significantly to the measured osmolality.

Particulate matter can cause premature crystallization; in blood it is normally eliminated by centrifugation. Particulate matter in urine may be

removed by centrifugation or filtration through an inert filter.

F. Sample tubes and sample sizes

Different sample tube styles and sample sizes should not be intermixed

because each may require a different instrument adjustment and/or calibration. Sample tubes should be as uniform as possible in composition,

shape and size.

28

Page 49

Instrument Operation

Glass tubes generally are not as uniform in shape and size as plastic

tubes, nor do they thermally isolate test samples as well. The 3D3 operating parameters are optimized for Advanced Instruments plastic sample

tubes - do not expect the same repeatability using glass tubes. If you

need further information concerning sample tube requirements, please

contact Advanced Instruments as recommended in Chapter 5, Section B.

Samples should always be pipetted or measured; 0.25-mL or 0.2-mL

samples may be used, in Advanced Instruments sample tubes. To

achieve the performance specified in Appendix B, we recommend that

you use 0.25-mL samples; 0.2-mL samples require somewhat more critical probe and stir/freeze wire adjustments for similar precision in

results. The 3D3 should be calibrated with the same sample size used

for testing.

G. Sample test procedure

Like most measuring instruments, osmometers need calibration against

standards. Both the high and low ranges of your Advanced Model 3D3

were calibrated at the factory using the procedure described in Chapter

4. The probe and calibration parameters are stored in parameter RAM

which is powered by an internal battery when the instrument power is

off or disconnected. Thus, when "Osmometer Ready" is displayed,

your 3D3 osmometer is calibrated and ready to run. However, the calibration should always be verified during operation to be sure that none

of the parameters affecting calibration have changed. (If re-calibration

is required, see Chapter 4.)

Instrument operation in the following manner is recommended:

1. Remove the sample tube from the freezing chamber (figure 4, item

9).

2. Gently wipe the probe, stir/freeze wire, mandrel and the top of the

freezing chamber (in that order) with a soft, lint-free, non-ionic

paper tissue dampened with distilled water to remove anything that

29

Page 50

The Advanced®Model 3D3 User’s Guide

might contaminate the sample to be tested. Be careful not to bend

the probe or stir/freeze wire.

3. Select a reference solution or NaCl standard with a freezing point

close to that expected for your unknown (Advanced Clinitrol™ reference solution is recommended for serum). Swirl and carefully

open an ampule of the reference solution (or NaCl standard) selected.

If the expected freezing point is in the 2000-4000 mOsm range, the

3D3 High range should be selected (see section C.10). If the freezing point is not within the range selected, an error message will be

displayed, requesting the range to be changed.

4. Select a clean sample tube (see Repeatability Tips).

5. Pipette or measure (see section F) a sample of the selected reference

solution or NaCl standard into the clean sample tube and place the

tube in the freezing chamber.

6. Press the START switchpad.

If I.D.# has been enabled via the setup menu (see section C.3), the

instrument operator will be prompted for a sample or user identification number of up to 13 digits at this time.

At the "I.D. # " prompt, the present setting may be retained by

pressing ENTER.

The present setting may be erased entirely by pressing CLEAR or

erased one digit at a time from the right by repeatedly pressing <.

A new number may be entered one digit at a time from the left viathe numeric keypad.

Press ENTER to store the new setting and continue the test. "Press

START to Continue" will begin to scroll across the display.

Press START (Pressing STOP would cancel the test).

30

Page 51

Instrument Operation

The rest of the test is completely automatic. The operating head

will lower the sample probe into the sample tube in the freezing

chamber. The fan will come up to full speed and the freezing chamber will cool.

The sample temperature will follow the freezing curve shown in figure 1 and will be displayed as soon as it falls below 0°C.

The 3D3 will freeze the sample at a crystallization point established

by the range and "buzz" point selections, follow the plateau development, determine the osmolality and lock the result on the display.

NOTE If the STOP button is pressed while a test is in progress, the

test will be discontinued and the 3D3 will reset itself for

the next test.

7. When the display reads "Osmolality XXX mOsm", the test results

may be recorded.

NOTE If the wrong osmolality range has been selected, an error

message will replace the osmolality report. Use the procedure described in section C.10 to select the required range;

then test another aliquot.

8. Gently wipe the probe, stir/freeze wire, mandrel and the top of the

freezing chamber (in that order) with a soft, clean, dry, lint-free

paper tissue after each test, to avoid contaminating the next sample.

Be careful not to bend the probe or stir/freeze wire.

9. Repeating steps 1-8, test two to four more aliquots of the same reference solution or standard to check repeatability and accuracy

before running tests on unknown samples. Follow the techniques

recommended in Repeatability Tips. When checking calibration and

repeatability with standards or reference solutions, it is usually best

to average the readings from three to five aliquots of each sample to

avoid error.

31

Page 52

The Advanced®Model 3D3 User’s Guide

If you are running the instrument for the first time, it is recommended that you follow the Clinitrol™ reference solution samples with

bracketing calibration standards to check the instrument accuracy

and linearity over the range of interest.

If the instrument accuracy on the reference solution (and/or calibration standards) is not satisfactory, refer to Chapters 3 and 4.

If the instrument repeatability on the reference solution (and/or calibration standards) is not satisfactory, review Repeatability Tips.

10. If the accuracy and repeatability on the reference solution (and/or

calibration standards) are satisfactory, you may begin testing

unknown samples, using exactly the same test procedure as for the

reference solution and standards.

11. Always wipe the probe, stir/freeze wire, mandrel and the top of the

freezing chamber with a soft, clean, dry, lint-free paper tissue after

the last test, to avoid having contaminating material dry on the

probe.

12. Leave an empty sample tube in the freezing chamber to help avoid

having to clean out accidently-introduced material.

The 3D3 may be left on continuously. When idle for five minutes or

more, it automatically enters standby mode: the fan slows, the freezing

chamber warms slightly and the display changes to the date and time.

The 3D3 remains in the standby mode until another test is needed. It

automatically exits from standby mode when any keypad is pressed.

NOTE When the instrument enters the standby mode with a determi-

nation on the display, the display will change to the date and

time but the last previous display may be recalled by pressing

RECALL. However, if the instrument is shut off during standby, the RECALL buffer is emptied.

32

Page 53

Instrument Operation

Repeatability Tips

1. Sample tube cleanliness is extremely important for repeatability. New Advanced plastic sample tubes may be expected to be

clean. If glass tubes are preferred, they should be washed in

hot water containing a non-ionic detergent, rinsed in distilled

water, and thoroughly dried before each use.

2. Always treat all samples uniformly before the test. Treat standards and reference solutions the same as the unknowns. Do

not intermix different tube styles.

3. Glass tubes generally are not as uniform in shape and size as

plastic tubes, nor do they thermally isolate test samples as well.

The 3D3 operating parameters are optimized for Advanced

Instruments plastic sample tubes-do not expect the same

repeatability using glass tubes.

4. To avoid contamination and evaporation, cover all samples not

immediately being tested.

5. Use the same sample size consistently (i.e., during calibration,

testing, etc.).

6. For repeat runs, use another sample from the same source or

thaw the original sample before repeating. If you must rerun

the same sample or use it for another procedure, remove it

from the freezing chamber as soon as possible and keep it covered between tests.

7. Always use the same operating procedure as described in section G, as proper, consistent procedure is the key to repeatable

results.

33

Page 54

The Advanced®Model 3D3 User’s Guide

Repeatability Tips

8. The first reading in any given period of operation may be

slightly off because of temperature conditioning or residual

contamination of the probe. Subsequent readings on aliquots

of the same sample should group within the specifications listed in Appendix B if you practice good operating techniques

(section G).

9. If an occasional sample produces irregular results, discard

obviously discrepant readings as long as the instrument has

been producing accurate readings repeatedly. Repeat the reading in question.

If all instructions are followed carefully and the instrument still

will not repeat, it is possible that the probe has been damaged. The

probe may be checked as recommended in Chapter 5, Section G.3.

If a new probe is installed, the sample probe bin number must be

reset as instructed in Chapter 2, Section C.2, and the instrument

must be re-calibrated as instructed in Chapter 4. If the instrument

is still not repeating, please call or write your dealer or Advanced

Instruments immediately for Hot-Line® service as instructed in

Chapter 5, Section B.

34

Page 55

Standards & Quality

3

Control

A. Purpose of quality control

The purpose of quality control is to ensure that the results

obtained through laboratory analysis are correct, that is, that the

results obtained are the closest to the truth that the analytical

technology used is able to determine.

B. Repeatability and accuracy

Two important measures of quality control are repeatability and

accuracy. Repeatability is sometimes called “reproducibility”

sometimes “precision”. However described, repeatability is

essential in nearly all forms of measurement, and is fundamental

to accuracy. Repeatability is not accuracy; repeatability underlies accuracy. Repeatability is a measure of the ability of a

method to obtain the same result time after time on the same

sample.

Repeatability or precision is usually quantified as the standard

deviation (S.D.) of a set of measurements normally distributed

about a mean: ±1 S.D. about the mean denotes the range of values within which 68% of the measurements will fall; ±2 S.D.,

95%.

By contrast, accuracy is a measure of how close to the “true”

value a method or measuring device has come. One can repeat

without being accurate, but one cannot be accurate without

repeating well.

35

Page 56

The Advanced®Model 3D3 User’s Guide

C. Standards and controls

To be accurate, all measurements ultimately must be referred to highly

reliable independent standards. Advanced osmometers are calibrated

with standards consisting of stable sodium chloride solutions of known

freezing points which bracket those of the expected unknowns. These

standards are related to the most fundamental work on freezing points

of dilute solutions published and are traceable to the National Institutes

of Standards and Technology (formerly the National Bureau of

Standards).

However, the most important osmometer determinations are made, not

on sodium chloride, but on biological solutions. How accurately they

determine the freezing points of precisely-known concentrations of

sodium chloride solutions, therefore, is only one measure of osmometer

accuracy. Another measure should involve determinations on biological

solutions or controls formulated to synthesize biological solutions.

The Advanced Protinol® protein-based controls, at 240, 280 and 320 ±5

mOsm, provide control values which closely bracket those of most

serum samples. Other commercially available biological controls may

be recommended or specified in your area but are not quality controlled

by Advanced Instruments. The Advanced 3LA028 Osmolality Linearity

Set provides two 5mL ampules each of 100, 500, 900, 1500, and 2000

mOsm NaCl standards for verifying osmometer linearity in accordance

with CLIA guidelines.

Please check with your associations and regulatory bodies for their

guidelines and/or requirements.

D. Maintenance of standards

Doubts about the accuracy of standards destroy confidence in the accuracy of the test. The Advanced osmometer standards are specified to be

within very close tolerances. Several of the sodium chloride based ref-

36

Page 57

Standards & Quality Control

erence and calibration solutions designed for the Advanced osmometers

are sealed in glass ampules to insure against any possibility of alteration

during transit or storage. However, we recommend that you test samples

from each newly-received lot and maintain records of your test results

on osmometer standards for reference.

E. Quality control implementation

The following recommendations outline the minimum requirements for

quality control:

1. Read, understand and follow the instructions and recommendations

in the user’s guide as closely as practical.

2. The instrument repeatability and accuracy should be checked each

time it is used, as recommended in step 10 of the sample test procedure outlined in Chapter 2, Section G. Run at least two levels of

standards or controls daily. Prepare, maintain and follow additional

verification procedures specifically adapted to your own laboratory

requirements as necessary.

3. Instrument repeatability is specified in Appendix B. It depends to a

certain extent upon operator technique and can usually be improved

by carefully following the Repeatability Tips in Chapter 2.

4. Instrument accuracy is determined by comparing your results on

precisely-known standards and/or controls with their specified values. The instrument accuracy is adjustable; if it is unsatisfactory, it

should be corrected by re-calibrating, as instructed in Chapter 4.

However, it has been shown that frequent unnecessary re-calibration

will introduce inaccuracy. The calibration of a freezing-point

osmometer in good condition and properly operated will not shift or

drift.

37

Page 58

The Advanced®Model 3D3 User’s Guide

Notes:

38

Page 59

Calibration

4

This chapter describes the procedure for calibrating your

instrument. If you have questions or problems regarding the

calibration procedure, please consult Chapter 5 —

Troubleshooting & Service.

Aside from requiring manual range selection and sample introduction, calibration of the 3D3 is automatic. Following the procedure suggested below, you simply make sure the

Supervisor/Operator keyswitch is in the Supervisor position,

use the SETUP menu to select the required range (see Chapter

2, Section C.10), then press CALIB to initiate freezing-point

tests on each of the two calibration standards required for the

selected range.

The calibration standards required are:

Low range: 100 and 1500 mOsm/kg H

High range: 1500 and 3000 mOsm/kg H

Internally, the 3D3 accomplishes calibration in two steps for

each range. First it records the raw means of the results of

freezing-point tests on standards at each of the two calibration

levels. Then it performs the necessary conversion calculations

and calibrates the display. Each range is independently calibrated.

Check the calibration frequently, as recommended in Chapter 2,

Section G, but do not re-calibrate when the calibration is satisfactory. It has been shown that unnecessary re-calibration will

introduce inaccuracy. The calibration of a freezing-point

O

2

O

2

39

Page 60

The Advanced®Model 3D3 User’s Guide

osmometer in good condition and properly operated will not shift or

drift.

Both the High and Low ranges were initially calibrated at the factory.

To re-calibrate either range, proceed as follows:

1. Make sure the Supervisor/Operator keyswitch remains in the

Supervisor position until re-calibration has been completed (see

figure 3 and Chapter 2, Section A.2).

2. At “Osmometer Ready” (or the date and time standby display),

use the SETUP menu, as necessary, to select the required range (see

Chapter 2, Section C.10); then press CALIB. The CALIB switchpad will light and the display will quickly change to “Calibration”,

then prompt you for the first calibration standard.

NOTES a. Your 3D3 will retain its previous calibration until re-cali-

bration has been completed and the display reads

“Calibration Complete”.

40

b. Pressing STOP during a calibration test will cancel the

current test but allow calibration to be resumed with

another sample. Pressing STOP a second time will cancel

re-calibration and retain the previous calibration.

c. If the instrument has calibration information in memory,

the first test result displayed should be very close to the

nominal value of the standard loaded. If the instrument

has no calibration information in memory, the test result

displayed may be far from the nominal value of the standard loaded; if the displayed values repeat consistently,

the calibration will be automatically adjusted when the

calibration test sequence has been successfully completed.

d. If the instrument has calibration information in memory,

the 100-mOsm low-range calibration level may be skipped

by pressing the CALIB switchpad a second time.

Page 61

Calibration

e. Although it is possible for the 3D3 to detect certain gross

calibration errors such as reversal of the standards, it

remains the responsibility of the operator to be sure to

introduce accurate standards of the specified freezingpoint values.