Page 1

IMPAC ISR 6 ADVANCED

Stationary, digital ratio pyrometer for noncontact temperature measurement in ranges

between 600 and 3000°C (1112 to 5432°F).

=

The Impac® ISR 6 Advanced pyrometer is a digital, compact

and fast 2-color pyrometer for non-contact temperature

measurement. The pyrometer measures in the 2-color

method (ratio method) in which two adjacent wavelengths

are used for the temperature determination.

PRODUCT HIGHLIGHTS

Widest temperature ranges for most flexible process adaptation

Highest accuracy and repeatability in its class

“Dirty Window” warning

Fully digital core for sub-ranging and adopted analog output

Very fast 2 ms response time for highly dynamic processes

Best optics in its class with manual focus capability

4 digit LED display

Robust, stainless steel sensor for harsh environments (IP65/NEMA4)

TYPICAL APPLICATIONS

Steel making

Metal processing - induction processes: hardening, welding, forging, brazing,

soldering, etc.

Metal processing - noble metals melting and purifying

Metal processing - wire/rod mill water box measurement, laying head & air

cooling conv.

Solar industry - silicon processing polycrystalline casting in vacuum melting

furnace, silicon ingot growth in CVD reactors (Siemens process), crystal pulling

of monocrystalline silicon (Czochralski process)

Glass industry - gob temperature measurement

Cement industry - clinker temperature in rotary kilns

AT A GLANCE

Temperature Ranges

600 to 1400°C (1112 to 2552°F)

700 to 1800°C (1292 to 3272°F)

800 to 2500°C (1472 to 4532°F)

1000 to 3000°C (1832 to 5432°F)

Spectral Range

Ch. 1: 0.9 μm

Ch. 2: 1.05 μm

Measurement Uncertainty

< 1500°C: 0.3% oR + 2°C

> 1500°C: 0.6% oR in °C

Repeatability

0.15% oR + 1°C

Field of View

min 350:1 (min. 0.6 mm)

Option: line optics

Alignment

Laser targeting or through-lens

sighting or color TV camera

©2019 Advanced Energy Industries, Inc.

Page 2

IMPAC ISR 6 ADVANCED

OVERVIEW

The ISR 6 Advanced ratio pyrometer uses two adjacent

wavelengths for the temperature determination. This

technique offers the following advantages compared to

standard 1-color pyrometers:

The temperature measurement is largely independent

of the object’s emissivity and in wide ranges unaffected

by dust and other contaminants in the field of view.

The measuring object can be smaller than the spot

size, measurements through dirty viewing windows are

The response time of only 2 ms facilitates the

measurement of fast processes. The ISR 6 is equipped

with a built-in “dirty window” warning.

The pyrometer can be connected to a PC through

an RS485 to USB connection, enabling parameter

adjustments to be made using the InfraWin software.

This can be used for temperature indication, data

logging and further analyzing of complete temperature

processes.

possible up to a certain contamination.

Additionally the pryometer can be switched to 1-color

mode and used like a conventional pyrometer in a

spectral range near 0.9 µm.

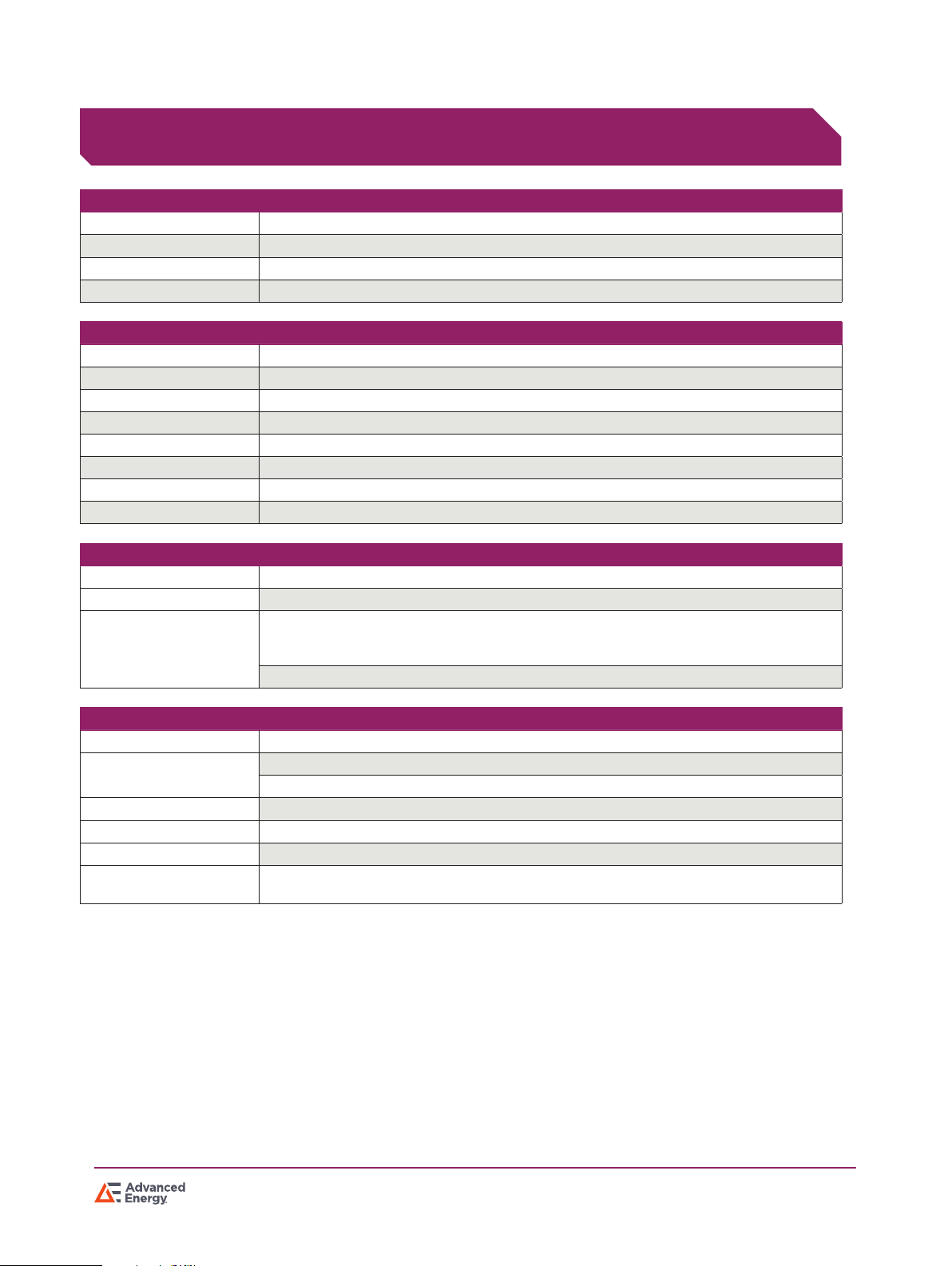

TECHNICAL DATA

Measurement Specifications

Temperature Range 600 to 1400°C (1112 to 2552°F) (MB 14)

700 to 1800°C (1292 to 3272°F) (MB 18)

800 to 2500°C (1472 to 4532°F) (MB 25)

1000 to 3000°C (1832 to 5432°F) (MB 30)

Sub Range Any range adjustable within the temperature range, minimum span: 50°C

Spectral Ranges Channel 1: 0.9 µm

Channel 2: 1.05 µm

Resolution 0.1°C or 0.2°F at interface

< 0.0015% of selected sub range at analog output, min. 0.1°C, 16 bit; 1°C or 1°F on display

Emissivity ε 0.050 to 1.000 in steps of 1/1000 (1-color mode)

Transmittance τ 0.050 to 1.000 in steps of 1/1000 (1-color mode)

Emissivity Slope κ 0.800 to 1.200 in steps of 1/1000 (2-color mode)

Measurement Uncertainty

(κ = 1, t90 = 1 s, T

Repeatability

(κ = 1, t90 = 1 s, T

amb

amb

= 25 °C)

.

= 25 °C)

.

< 1500°C: 0.3% of reading in °C + 2°C

> 1500°C: 0.6% of reading in °C

0.15% of reading in °C + 1°C

Optical Specifications

Sighting Built-in laser aiming light (max. power level < 1 mW, λ = 630 to 680 nm, CDRH class II) or through-lens sighting

Optics Manually focusable from rear cover measuring distance a = 210 to 5000 mm

Distance Ratio MB 14 approx. 100:1

MB 18 approx. 190:1

MB 25 and MB 30 approx. 350:1

2 advancedenergy.com

Page 3

IMPAC ISR 6 ADVANCED

TECHNICAL DATA (CONTINUED)

Electrical

Power Supply 24 VDC ±25%, ripple must be less than 50 mV

Power Consumption Approximately 3 W (including laser)

Load (analog output) 0 to 500 Ω

Isolation Power supply, analog output and digital interface are electrically isolated from each other

Environmental Specifications

Protection Class IP 65 IEC 60529 (value in mated condition)

Operating Position Any

Ambient Temperature 0 to 65°C (32 to 149°F) at housing

Storage Temperature -20 to 80°C (-4 to 176°F)

Relative Humidity Non-condensating conditions

Weight 0.6 kg (~1.32 lbs)

Housing Stainless steel

CE Label According to EU directives about electromagnetical immunity

Interface

Connection 12-pin connector

Display (in rear cover) LED, 4 digit matrix, 5 mm high for 2-color or 1-color temperature signal or measuring distance

Parameters Adjustable via interface: 2-color / 1-color temperature signal, metal mode, accordingly emissivity slope or

emissivity, temperature sub range, settings for maximum value storage, address, baud rate, switch off limit,

“dirty window” warning, transmittance, response time t90, 0 to 20 mA or 4 to 20

Readable via interface: measured value, internal temperature of the unit, measuring distance

Communication

Analog Output Adjustable 0 to 20 mA or 4 to 20 mA, linear (via digital interface)

Digital Interface RS485 addressable (half-duplex)

Baud rate: 1200 to 115.2 kBd (on request RS232, not addressable)

Switch Off Limit 2% to 50% (adjustable via interface)

“Dirty Window” Warning Relay contact, max. continuous current 0.4 A, setting of the warning level: 0 (off) to 99%

Response Time t

90

Maximum Value Storage Built-in single or double storage. Clearing with adjusted time t

2 ms (with dynamic adaption at low signal levels); adjustable to min; 0.01 s; 0.05 s; 0.25 s; 1 s; 3 s; 10 s

(off; 0.01 s; 0.05 s; 0.25 s; 1 s; 5 s; 25 s), via

clear

interface, automatically with the next measuring object, external contact, hold-function

1 MB i s a shortcut us ed for temperat ure range (in Ger man: Messbe reich).

The dete rmination of th e technical dat a of this pyromet er is carried ou t in accordance w ith VDI/VDE I EC TS 62942-2, the c alibration / adj ustment in acc ordance with V DI/VDE

3511, Par t 4.4.

advancedenergy.com 3

Page 4

IMPAC ISR 6 ADVANCED

该尺寸最大到160mm

PRODUCT SCHEMATIC

ISR 6 Advanced with rough-Lens Sighting

Dimensions in mm

SIGHTING

4 advancedenergy.com

ISR 6 Advanced with Laser Aiming

ISR 6 Advanced with Laser AimingISR 6 Advanced with rough-Lens Sighting

Page 5

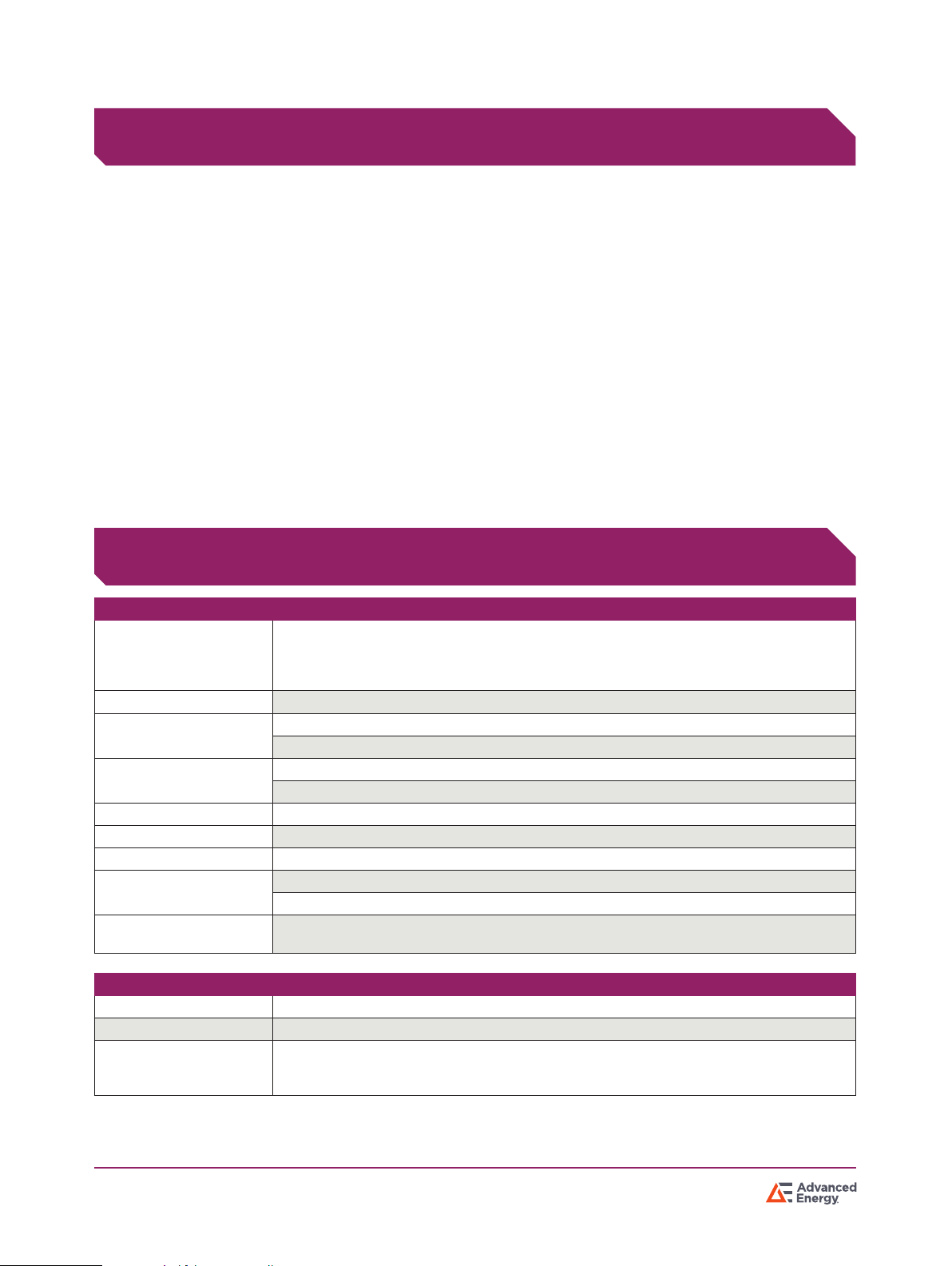

OPTICS

The optics can be manually adjusted at all distances between

210 mm and 5000 mm. The table shows examples of distances

and the corresponding spot diameters.

Effective aperture D for all temperature ranges: 13 mm (focused

to longest distance) to 15 mm (focused to shortest distance).

ISR 6 Advanced

Distance a [mm]

210 2.1 1.1 0.6 0.6

300 3 1.6 0.9 0.9

500 5 2.7 1.5 1.5

800 8 4.2 2.3 2.3

1300

2000 20 10.6 5.8 5.8

5000 50 27 15 15

600 to 1400°C 700 to 1800°C 800 to 2500°C 1000 to 3000°C

Spot Diameter M [mm]

13 6.9

3.7

IMPAC ISR 6 ADVANCED

3.7

Optional Integrated Line Optics

Besides the standard optical heads, the ISR 6 Advanced is also available with integrated line optics, which features

a special spot in the shape of a line. This provides additional advantages for some applications such as wire

production or pouring stream measurements.

The orientation of the line spot is vertical

for MB 14 (wire moves horizontally)

The orientation of the line spot is horizontal

for MB 25 (pouring stream runs vertical)

MB 14

MB 25

The width of the spot equals 5%

of the measuring distance

Spot

REFERENCE NUMBERS

ISR 6 Advanced

Temperature Range With Through-Lens Sighting With Laser Aiming

600 to 1400°C (MB 14) 3 904 020 3 904 010 3 904 050

700 to 1800°C (MB 18) 3 904 080 3 904 070 -

800 to 2500°C (MB 25) 3 904 150 3 904 140 3 904 180

1000 to 3000°C (MB 30) 3 904 220 3- 904 210 -

With Laser Targeting and

line shaped spot (5%)

Scope of Delivery

Pyrometer, PC adjustment and evaluation software

InfraWin, works certificate, and operating instructions.

Ordering Note

A connection cable is not included in scope of delivery

and must be ordered separately.

advancedenergy.com 5

Page 6

IMPAC ISR 6 ADVANCED

ACCESSORIES

PN Description

3 820 320 Special connection cable with plug and additional pilot light switch, 5 m

3 820 330 Connection cable, 5 m, straight connector

3 820 500 Connection cable, 10 m, straight connector

3 820 510 Connection cable, 15 m, straight connector

3 820 810 Connection cable, 20 m, straight connector

3 820 820 Connection cable, 25 m, straight connector

3 820 520 Connection cable, 30 m, straight connector

3 820 340 Connection cable, 5 m, 90° connector

3 820 530 Connection cable, 10 m, 90° connector

3 820 540 Connection cable, 15 m, 90° connector

3 820 830 Connection cable, 20 m, 90° connector

3 820 840 Connection cable, 25 m, 90° connector

3 820 550 Connection cable, 30 m, 90° connector

3 852 290 Power supply NG DC for DIN rail mounting; 100 to 240 VAC ⇒ 24 VDC, 1 A

3 852 550 Power supply NG 2D for DIN rail mounting; 85 to 265 VAC ⇒ 24 VDC, 600 mA with 2 settable limit switches

3 826 750 USB-RS485 adaptor cable, 1.8m, HS Version 4.5 Mbd

3 852 440 Protocol transducer RS485/RS232 (switch.) ⇔ Profibus-DP for 1 device

3 852 460 Protocol transducer RS485 ⇔ Profibus DP for 32 devices

3 852 620 Protocol converter UPP RS485 or RS232 ⇔ ProfiNet, for 1 pyrometer

3 852 630 Protocol converter UPP RS485 ⇔ ProfiNet, for max. 32 pyrometers

3 826 510 PI 6000: PID programmable controller, very fast, for digital IMPAC pyrometers

3 891 220 DA 4000: LED-display, 2-wire power supply, 2 limit switches (relay contacts), 115 VAC

3 890 650 DA 4000: LED-display, 2-wire power supply, 2 limit switches (relay contacts), 230 VAC

3 890 570 DA 6000-N digital display, to allow adjustment of pyrometer through RS485 interface

3 890 530 DA 6000: like the DA 6000-N, but with analog input and 2 limit switches for the RS485 interface.

3 843 490 SCA 5, External Scanner Series 5 & 6 with fused silica window, 24 VAC/DC

3 846 260 Instrument’s support (Series 5 and 6)

3 834 210 Adjustable mounting support (Series 5 and 6)

3 846 290 Instrument’s support (Series 5 and 6) with fused silica window

3 835 590 90° mirror with quartz glass window (Series 5 and 6)

3 843 250 ROT 5 scanning mirror attachment up to 70°

3 835 160 Air purge unit, aluminium

3 837 230 Water cooling jacket (heavy duty) with integrated air purge unit

3 837 280 Water cooling jacket (heavy duty) with fused silica window

3 837 500 Water cooling jacket (light duty, with air purge unit (only for instruments with laser targeting)

3 837 510 Water cooling jacket (light duty), with fused silica window (only for instruments with laser targeting)

3 837 540 Cooling plate for series 5 and 6, with air purge

3 846 590 Vacuum flange KF16 with quartz glass window

1

All connection cables include a short adapter cable with a 9-pin SUB-D connector.

This con nector may be us ed in combinati on with the RS4 85 to USB adapte r.

1

1

1

1

1

1

1

1

1

1

1

1

6 advancedenergy.com

Page 7

INFRAWIN OVERVIEW

InfraWin is easy-to-use measurement and evaluation

software for remote configuration of stationary, digital

IMPAC brand pyrometers.

This software allows the user to remotely adjust

and control settings for one or two pyrometers from

a single computer. InfraWin also allows the user to

simultaneously monitor and control temperatures.

Display temperature data as color bars and online

graphics

Capture downstream evaluations as tables, graphics

or text files

Calculate the spot size for different measuring

distances

Features UPP standard (Universal Pyrometer

Protocol)

IMPAC ISR 6 ADVANCED

Pyrometer Settings

An IMPAC digital pyrometer connected to a PC will be

automatically detected by the software. All available

parameters are adjustable, including emissivity,

response time, maximum value storage, output signal

and sub range.

Further special functions are adjustable for example

controllers or TV parameters on instruments available

with these functions. Changes are transmitted directly

to the pyrometer.

Measurement with Color Bar

In this window a temperature value for the upper or

lower limit can be adjusted numerically or with the

mouse.

The acquired minimum and maximum value is indicated

as well as the inner temperature of the pyrometer. The

emissivity is changeable during the measurement at

any time.

Infrared Calculator

After input of the aperture and the focused spot

size per datasheet, the calculation of spot sizes at

non-focused distances is possible.

Measurement with Internal Temperature of radiation

temperature and internal instrument temperature.

Parameters can be changed during the measurement.

I/O Module allows users to trigger measurement externally

and gives a potential free output contact.

advancedenergy.com 7

Page 8

DS TITLE

For international contact information,

visit advancedenergy.com.

sales.support@aei.com

+1 970 221 0108

ABOUT ADVANCED ENERGY

Advanced Energy (AE) has devoted more than three

decades to perfecting power for its global customers. AE

designs and manufactures highly engineered, precision

power conversion, measurement and control solutions

for mission-critical applications and processes.

AE’s power solutions enable customer innovation

in complex semiconductor and industrial thin film

plasma manufacturing processes, demanding high

and low voltage applications, and temperature-critical

thermal processes.

With deep applications know-how and responsive

service and support across the globe, AE builds

collaborative partnerships to meet rapid technological

developments, propel growth for its customers

and power the future of technology.

Specifications are subject to change without notice. Not responsible

for errors or omissions. ©2019 Advance d Energy Industries, Inc. All rights

reser ved. Advanced Energy®, Impac®, and AE® are U.S. trademarks

of Advanced Energy Industries, Inc.

ENG-ISR6-235-02 12.19

Loading...

Loading...