Page 1

The Advanced® Micro-Osmometer

Model 3300

User’s Guide

3305 Rev20 051109

Page 2

Copyright

This user’s guide is copyrighted by Advanced Instruments, Inc. with all

rights reserved. Under copyright laws, this guide may not be reproduced

in any form, in whole or part, without the prior written consent of

Advanced Instruments.

© 2002 Advanced Instruments, Inc.

Windows

®

is a registered trademark of Microsoft Corporation in the

United States and other countries. Intel®is a registered trademark of

Intel Corporation in the United States and other countries. All other

trademarks are the property of Advanced Instruments, Inc.

Advanced Instruments has reviewed this guide thoroughly. All material

contained within is believed reliable, but the accuracy and completeness

are not guaranteed or warranted, and are not intended to be representations or warranties concerning the product described.

Hot-Line®Service

If you have any questions or problems regarding the proper operation of

your instrument, please contact our Hot-Line Service department:

• 800-225-4034 (toll-free within the USA and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-0811 (fax)

ii

Advanced®Micro-Osmometer Model 3300 User’s Guide

Page 3

Table of Contents

Parts & Accessories v

Calibrators & Standards vii

Safe Use ix

Symbol conventions ix

General cautions x

Foreword: Theory and Technique xiii

Chapter 1 — Installation & Setup 1

Step 1 — Find a location for your instrument 1

Step 2 — Unpack your instrument 1

Step 3 — Obtain additional items 2

Step 4 — Power up your instrument 2

Step 5 — Set your date and time 4

Step 6 — Check your initial calibration 4

Step 7 — Proceed to instrument operation 5

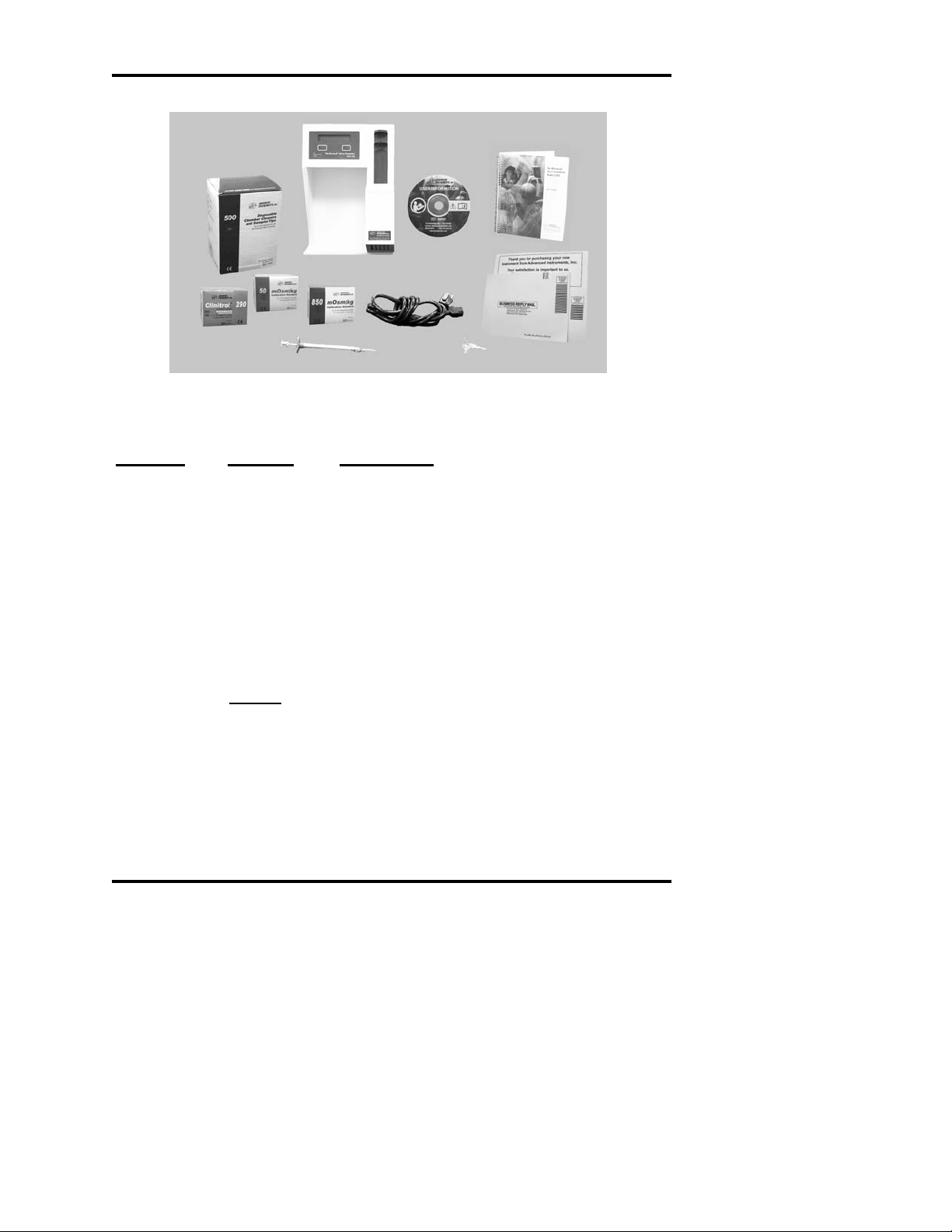

Figure 1: Model 3300 Micro-Osmometer and Accessories 3

Table 1: Model 3300 Micro-Osmometer Packing List 3

Chapter 2 — Instrument Operation 7

Hazardous material cautions 7

Function of major components 7

Sample handling 12

Standards & controls 12

Sample test procedure 13

Sample test errors 14

Recall results 15

Repeatability tips 15

Statistics 16

iii

Page 4

Changing operating settings 17

Using a barcode scanner with the Model 3300 20

Using a printer with the Model 3300 21

Using the Model 3300’s RS-232 port 21

Instrument software update 22

Figure 2: Model 3300 Components and Controls 8

Figure 3: Model 3300 Back Panel 10

Figure 4: Sample Cell Tips and Sample Levels 13

Table 2: Barcode Port Connections 11

Chapter 3 — Calibration 23

Calibration procedure 23

Calibration notes 24

Chapter 4 — Troubleshooting & Service 27

Service & maintenance cautions 27

Obtaining service 29

Troubleshooting checks 30

Internal diagnostics 30

Fuse replacement 34

Chamber cleaning 35

Sample plunger replacement and calibration 36

Figure 5: Fuse Replacement 35

Figure 6: Sample Plunger Replacement and Calibration 37

Appendices

Appendix A: Troubleshooting Table 39

Appendix B: Product Specifications 45

Appendix C: Regulatory Notices 47

Appendix D: Warranty and Warranty Duties 51

Appendix E: Supplemental RS-232 Information 55

Appendix F: Symbol Definitions 57

Appendix G: Service Log 61

Index 63

iv

Advanced®Micro-Osmometer Model 3300 User’s Guide

Page 5

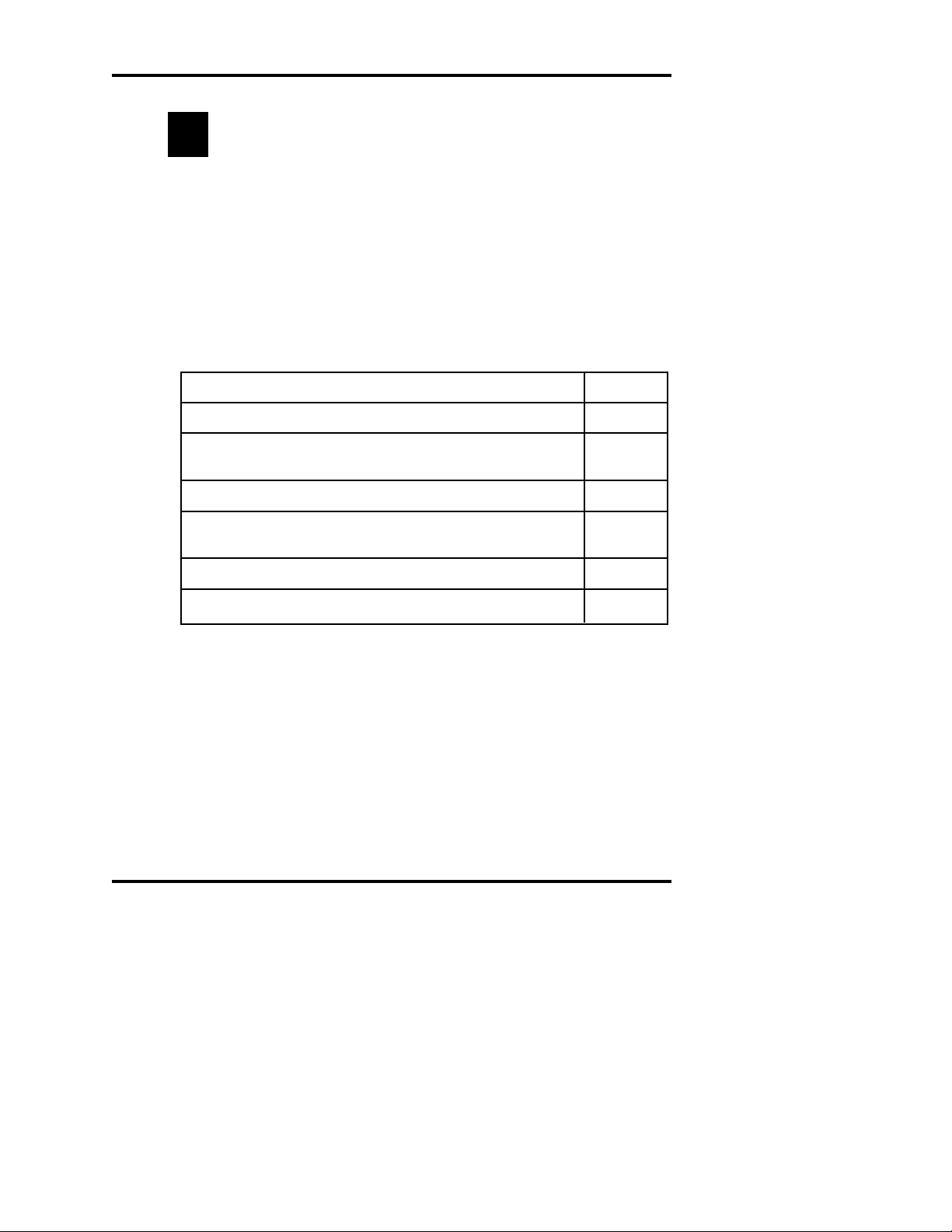

Parts & Accessories

v

To order parts and accessories, contact the Advanced

Instruments Customer Service Department:

• 800-225-4034 (toll-free within the USA and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-3669 (fax)

PART DESCRIPTION

20-µL Sampler

Replacement Sample Probe

Micro-Sample Test Kit (500 tests)

Sampler Plunger Wires (2)

Thermal Printer with Interface Cable, Operation Manual,

Thermal Paper Roll, and Printer Power Supply (100-120

VAC)

Thermal Printer with Interface Cable, Operation Manual,

Thermal Paper Roll, and Printer Power Supply (230 VAC)

Printer Paper (5 rolls)

User’s Guide

Service Manual

Serial Cable

Software Upgrade*

Barcode Scanner

PART NO.

3M0825

330700

3MA800

3M0828

210555_NA

210555_EU

3D3835

3305

3305SM

RS232-Cable

330990

330016

* Note: 330990 upgrade kit comes with a 3-meter serial cable #330053.

Page 6

vi

Advanced®Micro-Osmometer Model 3300 User’s Guide

Notes:

Page 7

vii

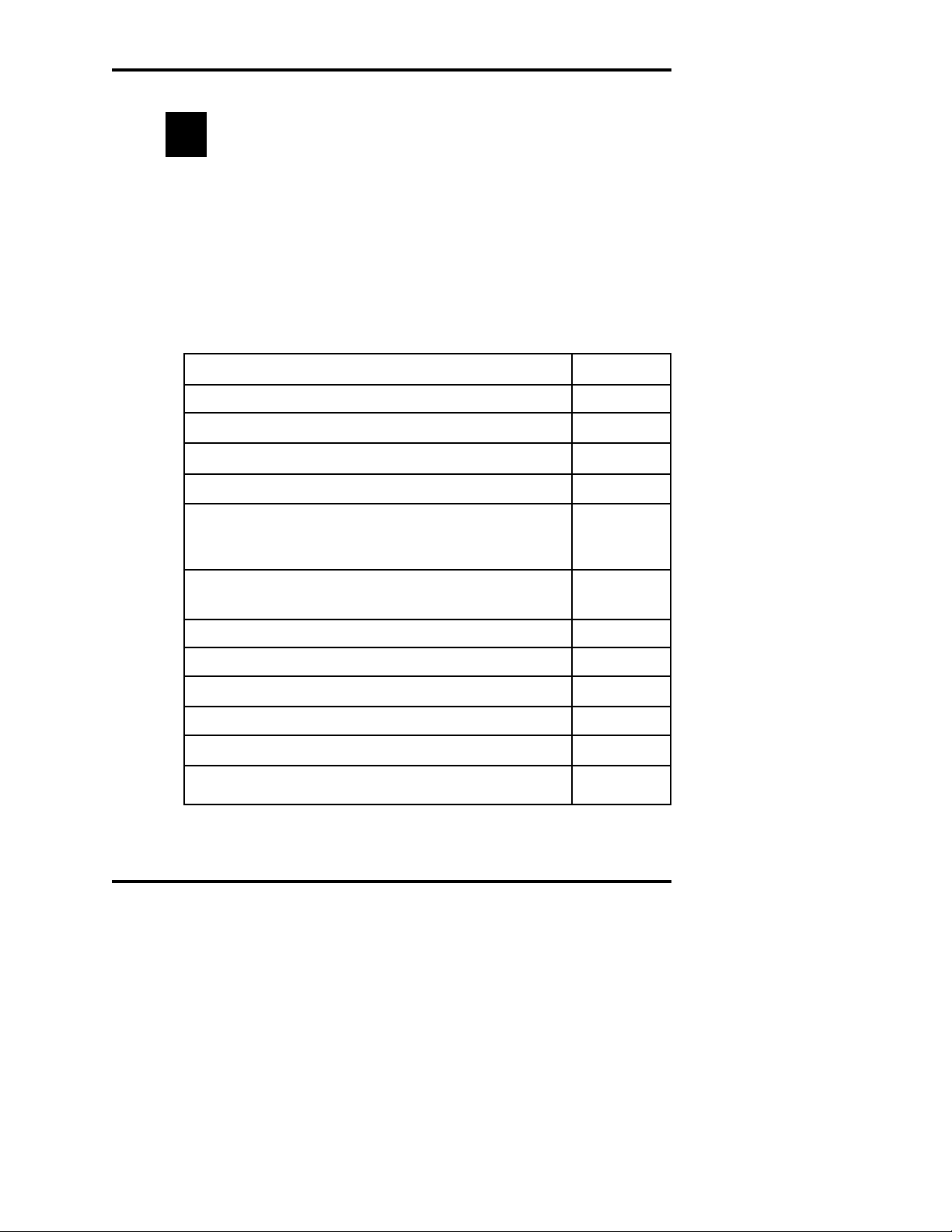

Calibrators & Standards

To order calibrators and standards, contact the Advanced

Instruments Customer Service Department:

• 800-225-4034 (toll-free within the USA and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-3669 (fax)

DESCRIPTION

ClinitrolTMReference Solution (10 2-mL ampules)

Protinol®3-Level Protein Control Kit (9 3-mL bottles, 3 of

each level)

Renol™ Urine Osmolality Controls (2 levels)

5-Value Osmolality Linearity Set (10 5-mL ampules, 2 of

each value)

50 mOsm/kg Calibration Standard (10 2-mL ampules)

850 mOsm/kg Calibration Standard (10 2-mL ampules)

P ART NO.

3MA029

3MA028

3LA085

3LA028

3MA005

3MA085

Page 8

viii

Advanced®Micro-Osmometer Model 3300 User’s Guide

Notes:

Page 9

Safe Use

To reduce the risk of bodily injury, electric shock, fire, and

damage to your instrument, please read and observe the precautions in this User’s Guide.

• If the product is used in a manner not in accordance with the

equipment design, operating instructions or manufacturer's

recommendations, the operation of the product may be

impaired to the extent that a safety hazard is created.

• Do not attempt to perform electrical work if you are not fully

qualified. This manual is not a substitute for electrical training.

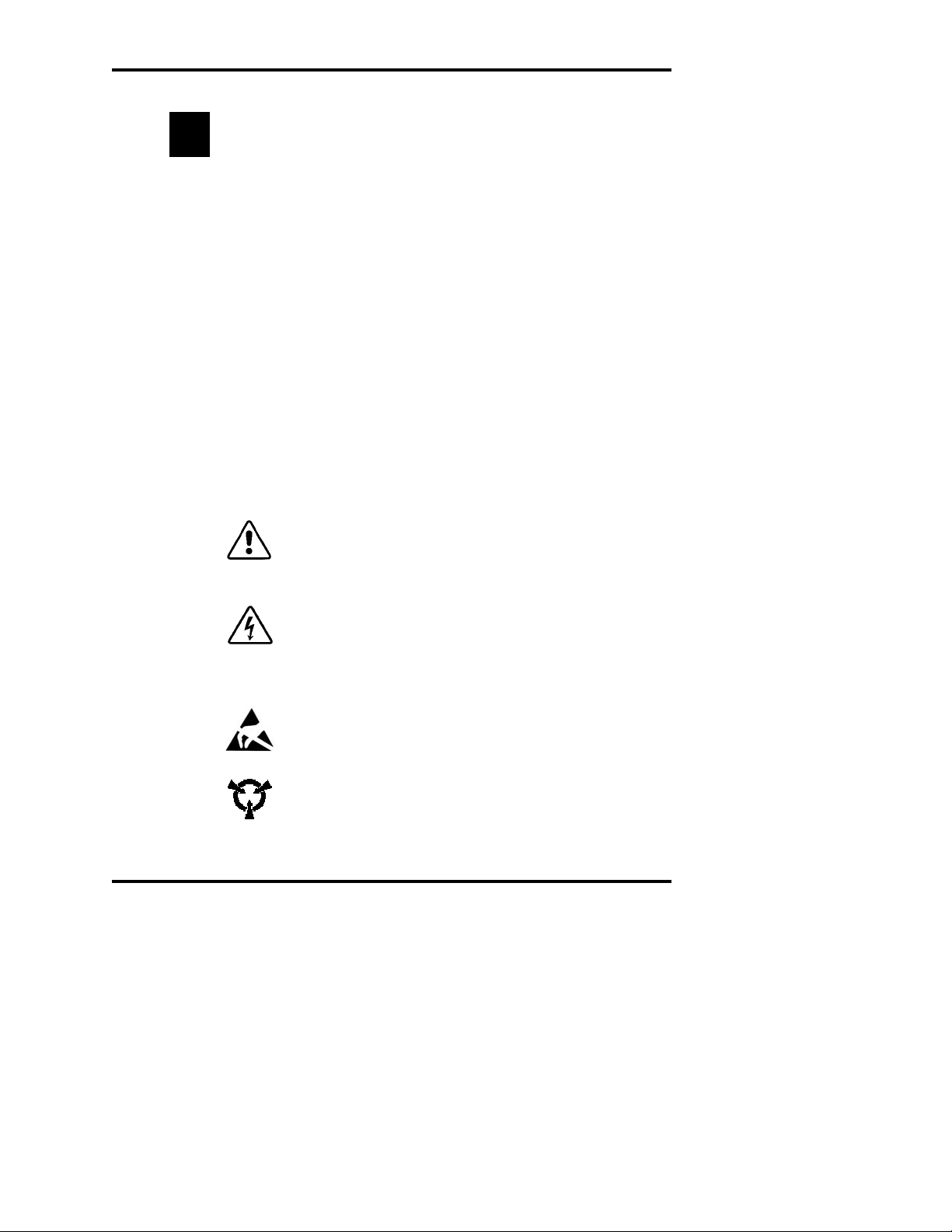

Symbol conventions

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important operating and maintenance (servicing) instructions in the literature

accompanying this product.

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the user to the presence of

uninsulated dangerous voltage within the product's enclosure

that may be of sufficient magnitude to constitute risk of electric shock to persons.

The static symbol within an equilateral triangle is intended to

alert the user to the presence of internal components that

could be damaged by static electricity.

This static symbol is intended to alert the user to the presence of a specific component that could be damaged by static electricity.

ix

Page 10

This symbol indicates the presence of alternating current (AC).

This symbol indicates the presence of a fuse.

This symbol indicates the presence of protective earth ground.

General cautions

• This product should be operated only with the type of power source

indicated on the product’s electrical ratings label. Refer to the installation instructions included with the product.

• If the power cord provided is replaced for any reason or if an alternate cord is used, the cord must be approved for use in the local

country. The power cord must be approved for the product’s listed

operating voltage and be rated at least 20% greater than the ampere

ratings marked on the product’s electrical ratings label. The cord

end that connects to the product must have an IEC 60320 connector.

• Plug the product into an approved grounded electrical outlet.

• Do not disable the power cord’s grounding plug.

• If an extension cord or power strip is used, make sure that the cord

or strip is rated for the product, and that the total ampere ratings of

all products plugged into the extension cord or strip do not exceed

80% of the cord’s or strip’s rating limit.

• Route power cords so that they will not be walked on, tripped on, or

pinched by items placed upon or against them. Pay particular attention to the plug, electrical outlet, and the point where the cord exits

the product.

• Do not pull on cords and cables. When unplugging cords or cables,

grasp the corresponding connector.

x

Advanced®Micro-Osmometer Model 3300 User’s Guide

Page 11

• Do not install or use this product in any area subject to extreme

short-term temperature variations, or locations that exceed the specified operating environment temperatures.

• Never use this product in a wet area.

• To avoid injury or fire hazard, do not operate this product in an

explosive atmosphere.

• Do not install or use the product on an unstable, non-level work surface.

• Do not operate this product with the covers removed or unsecured.

xi

Safe Use

Page 12

xii

Advanced®Micro-Osmometer Model 3300 User’s Guide

Notes:

Page 13

Foreword

xiii

Intended Use

Advanced®Osmometers use the technique of freezing-point

depression to measure osmolality. Osmolality is the total solute

concentration of an aqueous solution. Osmometers measure the

number of solute particles irrespective of molecular weight or

ionic charge. This information is useful to the following disciplines:

Clinical, emergency and sports medicine

Medical research

Biotechnology and pharmaceutical research and

manufacturing

Food and beverage manufacturing

Environmental research and monitoring

Academic research

Industrial applications

When used by a trained operator in clinical applications, the

osmometer provides results that assist in establishing the proper

diagnoses and treatments for patients with disorders involving

water and electrolyte imbalances. Osmometers will test virtually any biological fluid including, but not limited to, whole

blood, plasma, urine, feces, sweat, and tissue homogenate.

Operation of the instrument is deemed to be low-complexity

under CLIA and FDA guidelines.

Page 14

xiv

Advanced®Micro-Osmometer Model 3300 User’s Guide

Principles of Freezing-Point Osmometry

When a solute is dissolved in a pure solvent, the following changes in

the solution's properties occur:

• the freezing point is depressed,

• boiling point is raised,

• osmotic pressure is increased, and

• vapor pressure is lowered.

These are the so-called "colligative" or concentrative properties of the

solution which, within reasonable limits, change in direct proportion to

the solute concentration; in other words, the number of particles in solution.

Of the colligative properties, measurement of the freezing point allows

the concentration of an aqueous solution to be easily determined with

great precision.

The freezing point of pure H

2

O is precisely +0.010°C. One mole of a

non-dissociating solute such as glucose (where the solute does not dissociate into ionic species, but remains intact), when dissolved in 1 kilogram (kg) of water will depress the freezing point by 1.858°C. This

change is known as the freezing point depression constant for water.

The freezing point depression also depends upon the degree of dissociation of the solute. If the solute is ionic, the freezing point is depressed

by 1.858°C for each ionic species. For example, if one mole of sodium

chloride were to completely dissociate into two ionic species (Na+ and

Cl-) in 1 kg of water, the freezing point would be depressed by

3.716°C. However, dissociation is never complete. Interference

between solute molecules reduces dissociation by a factor called the

osmotic coefficient.

Page 15

xv

In a simple solution such as glucose or sodium chloride in water, the

freezing point can be measured and the unit concentration easily determined from an equation or a reference table. However, the equation is

unique for each solute. In a more complex solution, all ionized and

non-dissociated species contribute to the freezing-point depression and

the concentration of each solute cannot be easily determined.

Each of the colligative properties has a similar problem, and though

each of the colligative properties changes in direct proportion to the

solute concentration, each requires a different mode & unit of measurement. Osmolality is a common unit of concentration measurement that

can be used to relate all the colligative properties to each other, and to

other concentration units. Because of its universality, most osmometry

applications regularly use osmolality, expressed as "mOsm/kg H2O", as

the common unit of concentration rather than applying further conversion factors.

Instrumentation

Advanced Osmometers are devices for the determination of the concentration of solutions by means of freezing-point measurement.

Advanced Osmometers utilize high-precision thermometers to sense the

sample temperature, to control the degree of supercooling and freeze

induction, and to measure the freezing point of the sample. They can

routinely determine differences of ±1 mOsm/kg H

2

O.

Freezing-Point Thermodynamics

The quickest and most precise way to measure the freezing point of a

solution is to supercool it several degrees below its freezing point. It is

unstable in this state, and a mechanical agitation induces crystallization.

The heat of fusion suddenly liberated causes the sample temperature to

rise toward a plateau temperature, where a liquid/solid equilibrium

occurs. The equilibrium temperature is, by definition, the freezing point

Foreword

Page 16

of the solution. Managing the plateau temperature for precise measurement is the basis for several patents issued to Augustus Fiske.

The time over which liquid/solid equilibrium develops and is maintained, is a function of the speed with which the heat-of-fusion is liberated vs. the speed it is transferred away, or absorbed, by the surrounding

environment. This ratio can be slowed and the equilibrium time

stretched, to give a distinct plateau height measurable to 0.001°C.

Sensitive thermistor probes monitor the sample temperature and control

the thermoelectric cooling element. Microprocessor control and automated operation minimize imprecision due to operator technique.

The following Standard Freezing Curve illustrates the temperature of a

sample as it progresses through the freezing cycle and shows the action

of the instrument at each stage of the cycle.

Definitions

Solution: Ahomogeneous mixture of solute and solvent in which the

solvent is usually the major component, and the solute is the minor

component.

Concentration: The ratio of solute to a given amount of solvent

(molal), or ratio of solute to solution (molar).

xvi

Advanced®Micro-Osmometer Model 3300 User’s Guide

Standard Freezing Curve

Page 17

The amount of solute is usually expressed in terms of moles, i.e., gram

molecular weights. One mole = 6.028 x 10

23

molecules (Avogadro's

number). One mole of glucose (180.2 g) and one mole of sodium chloride (58.4 g) each contain Avogadro's number of molecules.

Common units of concentration are:

• Molality: Moles of solute per kilogram of pure solvent.

• Osmolality: Osmols of solute particles per kilogram of pure sol-

vent. As noted above, most ionic solutes do not completely dissociate. Osmolality is a unit of concentration that takes into

account the dissociative effect. Osmolality is usually expressed

in mOsm/kg H

2

O. One milliosmol (mOsm) is 10-3osmols.

Osmolality is defined as:

where:

ø = osmotic coefficient, which accounts for the degree of mole-

cular dissociation.

n = number of particles into which a molecule can dissociate.

C = molal concentration of the solution.

• Molarity: Moles of solute per liter of solution.

• Osmolarity: Osmols of solute particles per liter of solution.

Although molarity and osmolarity may be common units of

measurement in other branches of chemistry, they are not used in

osmometry because the ratio of solute to solution is not linear.

Molality and osmolality are linear, independent of the effect of

temperature and volume displaced by solute. Acalculated conversion between units of molality and molarity is complex and

generally unnecessary when the terms are properly understood.

xvii

Foreword

OHkg

osmol

nCOsmolality

2

==

φ

Page 18

Freezing Point/Melting Point: The temperature at which the liquid

and solid phases of a substance will remain together in equilibrium.

Freezing-Point Depression: When a solute is added to a solvent, the

freezing point of the solvent is lowered. In aqueous solutions, one

mOsm of solute per kilogram of water depresses the freezing point by

1.858 millidegrees Celsius (m°C).

Supercooling: The tendency of a substance to remain in the liquid state

when cooled below its freezing point.

Crystallization Temperature: Aqueous solutions can be induced to

freeze (i.e., crystallize) most reliably when supercooled. When supercooled, agitating the solution (freeze pulse) induces crystal formation.

The crystallization temperature is the temperature at which crystallization is induced. During crystallization, the heat of fusion raises the temperature of the sample to an ice/water freezing-point plateau.

Heat of Fusion: The heat released when the mobile molecules of a liquid are frozen into rigid ice crystals.

Freezing-Point Plateau: The constant temperature maintained during

the time that ice and liquid exist in isothermal equilibrium after crystallization occurs.

xviii

Advanced®Micro-Osmometer Model 3300 User’s Guide

Page 19

1

Installation & Setup

In order to set up your instrument properly, it is important that

you read and follow the steps in this section. Please follow these

steps carefully and be sure to read Chapter 2 — Instrument

Operation before attempting to run tests on your instrument.

Step 1 — Find a location for your instrument

When choosing a location for your new osmometer, be sure to

meet the following criteria.

• Adequate space. The dimensions of the instrument are 13

× 10.5 × 15.5 inches (26.7 × 33 × 39.4 cm). Be sure to keep

your workplace free of debris, especially near the front of

the instrument where proper ventilation is needed.

• Electric outlet availability.Your instrument will need to

operate within five feet of a properly grounded, three-prong

electrical outlet capable of continuously supplying 1 ampere

at 200-250V to 1.25 amperes at 100-130V. If the instrument

is not grounded properly, its operation may be impaired and

a safety hazard may exist. Therefore, be sure to test the outlet and record the results before operating your instrument.

Step 2 — Unpack your instrument

To unpack your osmometer, take the following steps.

a. Carefully unpack your osmometer, accessories and supplies

and inspect them for shipping damage. Use the enclosed

packing list to verify that all items have been received.

1

Page 20

b. Save your osmometer's shipping boxes and packaging material in

case future transport of the instrument becomes necessary.

c. If any item on the packing list appears to be missing from your ship-

ment, please search carefully through and under all packing materials. If the item is not found, notify your receiving department immediately. Advanced Instruments can only be responsible for items

reported missing within 10 days of a shipment’s arrival.

d. If you receive any damaged items, save the cartons and packing

material those items came in for inspection by the insurer. The carrier, dealer, and Advanced Instruments must be notified within 24

hours in order for your warranty and insurance to apply. Have the

transportation company inspect items, fill out a “Report of Concealed

Damage,” and file your claim. Then, notify Advanced Instruments

immediately for repair or replacement.

e. Fill out the postage-paid “(U.S.A. Only)” warranty card enclosed.

Mark the appropriate boxes if you wish to receive additional information. Customers outside of the United States may fax the warranty

card to 781-320-8181.

Step 3 — Obtain additional items

Soft, no-lint, non-ionic paper tissues are needed for wiping the sample

cells prior to testing. Please be sure that you have an adequate supply on

hand before attempting to run tests on your instrument.

Step 4 — Power up your instrument

Turn your instrument on by pushing the rocker-style power switch on

the instrument’s back panel into the on ( | ) position.

Each time your instrument is turned on, it automatically runs a oneminute setup and self-diagnostic program. During these diagnostics, your

display and printer (if in use) display critical instrument information, such

as software version and block and sample probe bin numbers. The first

time you power up your osmometer, record the software revision and

Advanced®Micro-Osmometer Model 3300 User’s Guide

2

Page 21

3

Figure 1: Model 3300 Micro-Osmometer and Accessories

Quantity

Part No. Description

1 3300 The Advanced®Model 3300 Micro-Osmometer

1 pack 3MA029 Clinitrol

™

290 mOsm/kg Reference Solution

(ten 2 mL ampules)

1 pack 3MA005 50 mOsm/kg Calibration Standard (ten 2 mL

ampules)

1 pack 3MA085 850 mOsm/kg Calibration Standard (ten 2 mL

ampules)

1 kit 3MA800 Micro-Sample Kit: includes 500 disposable

sample cells (tips) and 500 chamber cleaners

2 3D3185 Operator/Supervisor Keys

1 3MO825 20-µL Sampler

1 Power Cord (as specified)

1 90P01 Advanced

®

User Information CD-ROM

1 3305 User’s Guide

1 3305-6 Warranty Card

1 3D3P021 Customer Satisfaction Card

Table 1: Model 3300 Micro-Osmometer Packing List

Installation & Setup

Page 22

block and sample probe bin numbers in the Service Log at the end of this

user’s guide. Maintaining a record of this information will facilitate any

necessary service.

When the self-diagnostics have been completed and the instrument is

ready for testing, the display reads “Osmometer Ready”.

NOTE To avoid any misunderstanding that might arise due to an

unfamiliar display language, all displayed messages may be

changed from English to several other languages. (For language selection instructions, see Chapter 2.)

CAUTION If a power interruption occurs, turn the instrument off at

once. Leave it turned off for at least 5 seconds after power

has been restored (even if power restoration is immediate).

Step 5 — Set your date and time

If you wish, you may now change your date and time settings by using

the instructions found on page 17 of this user ’s guide.

Step 6 — Check your initial calibration

Your instrument has been carefully calibrated by the manufacturer, but

to verify that this calibration is accurate within your operating environment, run tests on the 290 mOsm/kg reference solution and/or Protinol

®

biological controls before testing samples. The number and type of tests

that you run should be determined by your own laboratory’s standard

protocol. Use the operating technique described in Chapter 2 when running these controls.

If you determine that the initial calibration is incorrect, re-calibrate as

described in Chapter 3.

NOTE If your Model 3300 has just been moved from a different loca-

tion, it should be allowed to warm up for 20 to 30 minutes

before you run calibration verification tests.

4

Advanced®Micro-Osmometer Model 3300 User’s Guide

Page 23

Step 7 — Proceed to instrument operation

If you have followed the steps outlined in this chapter, your instrument

is ready for use. To learn how to operate your instrument, read the next

chapter, “Instrument Operation”. We strongly recommend that you read

the entire second chapter before attempting to operate your osmometer.

5

Installation & Setup

Page 24

6

Advanced®Micro-Osmometer Model 3300 User’s Guide

Notes:

Page 25

2

Instrument Operation

In order to run your instrument properly, it is important that

you read and adhere to the instructions in this section. For

information on calibration, see Chapter 3 — Calibration.

Hazardous material cautions

• WARNING: Handle all biohazardous materials according to

established good laboratory practices and follow your institution’s exposure control plan. Persons handling human blood

and body fluid samples must be trained in blood-borne hazards and observe universal precautions. Universal precautions

is an approach to infection control, where all human blood and

body fluids are treated as if known to be infectious. Use personal protective equipment such as gloves, gowns, etc., to prevent exposure. Store biohazardous materials in regulated waste

containers and dispose of these materials in a safe and acceptable manner that is in compliance with all country, state and

local requirements.

• If a biohazardous material is spilled on or inside the equip-

ment, decontaminate the equipment using a 1% bleach solution, or as outlined by those policies and procedures established within your institution.

• To avoid injury or fire hazard, do not operate this product in

an explosive atmosphere.

Function of major components

The major components of the Model 3300 Micro-Osmometer

are an operating cradle; a sample port to precisely position

each sample for the osmolality test; a high-precision thermistor

7

Page 26

Advanced®Micro-Osmometer Model 3300 User’s Guide

probe; measurement and control circuitry; and a message display

panel. A sample handling pipette is also used in the testing process.

The function of many of these parts is described below.

Electronic circuits (inside)

The main circuitry is contained on two printed circuit boards in a motherboard/daughterboard configuration. More in-depth technical details

are available in the unit service manual, sold separately.

Processor Board: The processor board is the smaller of the two printed

circuit boards and contains the Intel 80C186EB central processor, two

flash EPROM’s, RAM, Realtime clock, watchdog circuit, and glue

logic.

8

Figure 2: Model 3300 Components and Controls

Display

Panel

Multifunction

Soft keys

Operating

Cradle

Sampler

Cooling

Chamber

(inside)

Chamber

Cleaners

Sample

Tips

Page 27

Application Board: The application board contains the circuits for controlling and interfacing with the other subsystems such as the keypad,

display, cooling assembly, RS-232, printer and barcode ports, etc. The

application board also contains two 20-bit A/D converters for reading

the sample and block probe thermistors.

Sampler (Figure 2)

The sampler is a specialized pipette which contains and positions a very

specific volume of sample for each test. The sampler consists of the

pipette body and disposable plastic sample tip that must be replaced

after each test.

Operating cradle (Figure 2)

The operating cradle is a sliding mechanism that guides and introduces

the sampler to the freezing chamber.

Cooling chamber & measurement and control circuits:

A high-reliability thermoelectric module controls cooling chamber temperature, while a thermistor sample probe measures the dynamic temperature of a sample. Test results, based on the freezing point of the

sample, are automatically sent to the instrument’s display.

Display panel (Figure 2)

The display panel displays:

• Test status and results.

• Status messages when the instrument is turned on or when functions are

selected.

• Pertinent error messages when fault conditions occur. (Messages longer

than 24 characters wrap to the second line.)

Multifunction soft keys (Figure 2)

Other than starting osmolality tests, which are initiated by the operating

cradle, all operator communication to the Model 3300 is accomplished by

means of the two multifunction soft keys.

9

Instrument Operation

Page 28

Advanced®Micro-Osmometer Model 3300 User’s Guide

Power module (Figure 3)

The power module on the rear of the instrument contains the following

components.

• Power switch

The rocker-style power switch controls the power to the instrument.

• Power cord connector

The power cord connector accommodates a power cord suitable for the

power available.

• Fuse holder & fuses

The fuse holder contains the instrument’s necessary fuses. For instructions on replacing fuses, see Chapter 4.

Printer port (Figure 3)

The printer port on the rear panel allows you to use a printer in conjunction with this instrument. For instructions on using a printer with this

instrument, see “Using a printer with the Model 3300” in this chapter.

RS-232 port (Figure 3)

The RS-232 port allows you to output your instrument’s data/messages to

an external device, such as a computer, and to upgrade your instrument

software. For more detailed information dealing with the RS-232 port,

please read the sections titled “Using the Model 3300’s RS-232 Port” and

“Instrument Software Update”, found later in this chapter.

10

Figure 3: Model 3300 Back Panel

Page 29

Barcode port (Figure 3)

A D-type, 15-pin barcode port is provided in the back of the 3300 for

connecting and providing power to such a device. For proper operation,

the barcode port requires a 1200 bps, RS232-level signal providing

asynchronous serial data containing 1 start bit, 8 data bits, 1 stop bit and

no parity.

A suitable RS232 barcode scanner is available from Advanced

Instruments, Inc. To interface with the 3300, the barcode scanner must

be programmed as follows, referring to the scanner users guide.

10 msec Intercharacter Delay

Disable Line Feed Suffix

No Parity

1200 BAUD Rate

8 Data Bits

Supervisor/operator keyswitch (Figure 3)

The supervisor/operator keyswitch allows certain instrument functions to

be locked. The Supervisor keyswitch position is required for re-calibration

and for access to the following diagnostic menu items: Set Probe Bin #s,

Set Serial Rate, Serial Comm Set and Select Language.

If a restricted function is attempted while Supervisor/Operator keyswitch

is in the operator position, a “Supervisor Key Needed” message is displayed and may be cleared by pressing both function buttons simultaneously before selecting any other function.

To utilize the supervisor/operator keyswitch you must use the key supplied with your instrument.

+5V DC 1 to reader

receive data 10 from reader

gnd/earth 9 common

Signal Pin Direction

Table 2: Barcode Port Connections

11

Instrument Operation

Page 30

Advanced®Micro-Osmometer Model 3300 User’s Guide

Sample handling

The sampling system kit supplied with your Model 3300 contains a special sampler and a starter supply of disposable sample cells and chamber cleaners. Each kit contains re-order information.

Be sure to replace the sampler plunger with each new test kit (500 samples). For instructions on this procedure, see “Sample plunger replacement and verification” in Chapter 4.

The Model 3300 measures the osmolality of a sample inside the

sample cell while on the pipette. This feature requires sample

cells specially designed to match both the sampler and the

Model 3300. Do not use any other sample-handling system

with your Model 3300 osmometer, and do not use the Model

3300 sampling system with any other laboratory procedure.

Standards & controls

Advanced Instruments offers and recommends the use of specific standards and controls with your Model 3300 osmometer. Each type may be

used to assess a different aspect of your instrument’s performance. For

information on obtaining these standards and controls, contact

Advanced Instruments or an authorized representative.

Clinitrol 290 Reference Solution (Part No. 3MA029)

We recommend that you run samples of Clinitrol 290 Reference

Solution daily to check your instrument operation and confirm your calibration. You should also run the Clinitrol 290 Reference Solution when

you receive erratic results. Doing so will allow you to verify proper

operation or recognize and diagnose problems promptly.

Protinol(Part No. 3MA028)

Advanced Protinol protein-based controls, at 240, 280 and 320 mOsm

(±5 mOsm), provide control values that closely bracket those of most

serum samples. These controls are formulated to mimic the freezing

characteristics of actual serum samples, and they can be used to verify

12

Page 31

the precision and reliability of your osmometer results. Protinol should

be used once every shift.

Advanced Five-Level Linearity Set (Part No. 3LA028)

The Advanced Linearity Set contains five controls (100, 500, 900, 1500,

and 2000 mOsm). Use this set to verify or establish the reportable range

of patient test results.

Sample test procedure

Use the following procedure to run sample tests.

1. Snap a sample tip into place on the sampler. The sample cell must be

straight and firmly seated. Be careful not to crack the sample tip.

2. Depress the sampler ’s plunger and insert the sample tip at least

¼ inch (6 mm) below the surface of the fluid to be tested. Gently

release the plunger to load a 20-µL sample.

3. Visually inspect the sample. If there are any large voids or bubbles in

the sample, expel the sample and load a bubble-free sample.

4. Blot the sides of the loaded sample cell with a soft, no-lint, non-ionic

paper tissue to remove any clinging droplets. Then blot the end of

the cell tip to remove any fluid protruding beyond the tip. Be careful

not to wick out any of the sample. The meniscus remaining may be

13

Instrument Operation

Figure 4: Sample Cell Tips and Sample Levels

Page 32

slightly concave, but the sample must be slightly longer than it is

wide. (See figure 4.)

5. Remove the chamber cleaner from the sample port and discard.

6. Holding the sampler by the barrel and letting the filled sample tip

follow the guide groove into the sample port, rest the sampler within

the operating cradle and beneath the cradle top.

7. To start the test, push the entire operating cradle down until it reaches a positive stop. Your instrument will run the test for approximately one minute and display the result in the format “Osmolality xxx

mOsm”.

8. Record the results and raise the operating cradle to a positive stop.

9. Remove the sampler from the operating cradle.

10.Insert a clean, dry chamber cleaner into the sample port and rotate it

four or five times in both a clockwise and counterclockwise direction. Withdraw chamber cleaner and insert the opposite end. Rotate

the chamber cleaner in the same manner and leave it in the sample

port until your next test.

11.Remove the used sample tip from the sampler by pressing firmly

enough on the sampler plunger to dislodge the tip. Discard the used

sample tip.

12.Blot the Teflon plunger tip with a soft, no-lint, non-ionic paper tissue. Be careful not to dislodge the tip.

13.To run additional tests, repeat this procedure beginning with step 1.

Sample test errors

Occasionally a test will not run to completion and your instrument will

display an error message. Refer to the Troubleshooting Table appendix

at the end of this user’s guide for an explanation of a particular message.

Advanced®Micro-Osmometer Model 3300 User’s Guide

14

Page 33

Recall results

The recall results feature of the Model 3300 allows you display or print

the results of your last 30 tests. If you need to see any or all of these

results, take the following steps.

1. At “Osmometer Ready”, the two multifunction soft keys are labeled

[CALIB] and [DIAG], respectively. Press the soft key labeled

[DIAG] to enter the diagnostic test menu.

2. While you are within the diagnostic test menu, the soft key labels will

change to [START] and [INDEX]. Use the [INDEX] keypad to cycle

through your choices until you see “1. Recall Results”.

15

Instrument Operation

Repeatability Tips

• Treat all samples, as well as standards and reference solutions, uni-

formly before the test.

• Microsamples are more susceptible to contamination and evapora-

tion than larger samples. Avoid leaving sample containers open.

Cold samples are susceptible to condensation; warmer samples are

susceptible to evaporation.

• Use only the Advanced Model 3300 sampling system. Each system

comes with specific operating instructions and re-order information.

• If an occasional sample produces irregular results, discard obvious-

ly discrepant readings as long as the instrument has been producing

accurate readings repeatedly. Repeat the sample in question.

• For repeat runs, use additional samples from the same source.

• Keep the cooling chamber clean between tests. Never inject any-

thing into the cooling chamber.

Page 34

Advanced®Micro-Osmometer Model 3300 User’s Guide

3. Press [STAR T] to enter the recall results mode. Your instrument will

display the data of the most recent test result.

4. Press the right soft key to see the result of the next-to-last test result.

5. Continue in this manner until you have recalled the necessary results.

6. To return to the diagnostic menu, press the two soft keys simultaneously .

7. To return to “Osmometer Ready”, again press the two function keypads simultaneously.

Statistics

The statistics option allows you to recall the stored results from a selected

last number of tests stored in the recall buffer and calculate their average,

standard deviation and coefficient of variance. If any test errors are stored

in the range you select, they will be filtered out of the calculations. To use

this option, follow this procedure:

1. At “Osmometer Ready”, the two multifunction soft keys are

labeled [CALIB] and [DIAG], respectively. Press the soft key

labeled [DIAG] to enter the diagnostic test menu.

2. While you are within the diagnostic test menu, the soft key labels

will change to [START] and [INDEX]. Use the [INDEX] soft key

to cycle through your choices until you see “2. Statistics”.

3. Press [START] to enter the statistics mode. Your instrument will dis-

play the number of tests to be considered when computing statistics.

4. Press the right [INDEX] soft key to index to the number of results

that you wish to consider.

NOTE If you request calculations for more samples than are stored

in the recall buffer, you will receive incorrect results.

5. Press the left [START] soft key to display and print (if using exter-

nal printer or serial port) the average of the selected number of last

results.

16

Page 35

6. Press the left [START] soft key again to display and print the stan-

dard deviation of the selected number of last results.

7. Press the left [START] soft key a third time to display and print the

coefficient of variance of the selected number of last results.

8. To return to the diagnostic menu, press the two multifunction soft

keys simultaneously.

9. To return to “Osmometer Ready”, again press the two function keypads simultaneously.

Changing operating settings

Date and time

To reset the date and time, take the following steps:

1. At “Osmometer Ready”, the two multifunction soft keys are labeled

[CALIB] and [DIAG], respectively. Press the soft key labeled

[DIAG] to enter the diagnostic test menu.

2. While you are within the diagnostic test menu, the soft key labels

will change to [START] and [INDEX]. Use the [INDEX] soft key

to cycle through your choices until you see “13. Set Date/Time”.

3. Press [START] to enter the Set Date/Time mode. Your instrument

will display the current date and time.

4. Press the left soft key to select the date or the right soft key to select

the time.

5. If you choose to set the date:

a) Select between DD/MM/YYYY and MM/DD/YYYY formats.

Your instrument will display the current date in the format you

selected and a blinking cursor element.

b) Use the left soft key to increment the number at the cursor and

the right soft key to change between digits in the date until the

correct date is displayed.

17

Instrument Operation

Page 36

c) Press both soft key buttons to save the new date setting and

return to the diagnostic test menu.

6. If you choose to set the time

a) Select between AM/PM and 24-hour formats. After you select a

display format, your instrument will display the current time in

the selected format.

b) Use the right keypad to toggle between hours and minutes and

the left keypad to change the number of hours or minutes displayed.

c) Press both soft key buttons to save the new time setting and

return to the diagnostic test menu.

Set Probe Bin #'s

To reset the block and sample probe bin numbers, take the following

steps:

1. At “Osmometer Ready”, the two multifunction soft keys are labeled

[CALIB] and [DIAG], respectively. Press the soft key labeled

[DIAG] to enter the diagnostic test menu.

2. While you are within the diagnostic test menu, the soft key labels

will change to [START] and [INDEX]. Use the [INDEX] soft key

to cycle through your choices until you see “3. Set Probe Bin #’s”.

3. Press [START] to enter the selection menu.

4. Press the right [INDEX] soft key to advance the probe bin #, or

press the left [NEXT] soft key to advance to the next probe bin #.

Be sure to record the new bin settings in the Service Log at the back

of this user's guide.

5. Press [NEXT] soft key to advance to the save options.

6. Select [YES] to save the new setting, or [NO] if no change was

made.

Advanced®Micro-Osmometer Model 3300 User’s Guide

18

Page 37

Data Capture

To change the RS-232 output between standard mode and capture mode,

take the following steps:

NOTE With Capture selected, freezing curve output data will be

presented to the serial port in real time. This data is updated

every 50 msec after crossing 0ºC, and may be captured with

any RS-232 compatible computer program for use in plotting freezing curves.

In Standard mode, ony the final result and some status messages will be presented to the serial port.

1. At “Osmometer Ready”, the two multifunction soft keys are labeled

[CALIB] and [DIAG], respectively. Press the soft key labeled

[DIAG] to enter the diagnostic test menu.

2. While you are within the diagnostic test menu, the soft key labels

will change to [START] and [INDEX]. Use the [INDEX] soft key

to cycle through your choices until you see “12. Data Capture”.

3. Press [START] to enter the selection menu.

4. Select the soft key for the mode you want to use.

5. Press the two soft keys simultaneously to lock in your selection.

6. Press the two soft keys again simultaneously to return to

“Osmometer Ready”.

Language

To reset the display language, take the following steps:

1. At “Osmometer Ready”, the two multifunction soft keys are

labeled [CALIB] and [DIAG], respectively. Press the soft key

labeled [DIAG] to enter the diagnostic test menu.

2. While you are within the diagnostic test menu, the soft key labels

will change to [START] and [INDEX]. Use the [INDEX] keypad to

cycle through your choices until you see “14. Select Language”.

19

Instrument Operation

Page 38

Advanced®Micro-Osmometer Model 3300 User’s Guide

3. Press [START] to enter the Select Language mode. Your instrument

will display the currently set language.

4. Press the left soft key to switch between languages.

5. To lock in the selected language and return to the diagnostic menu,

press the two soft keys simultaneously.

6. Press the two soft keys again simultaneously to return to

“Osmometer Ready”.

Using a barcode scanner (Part # 330016) with the

Model 3300

The barcode option provides a means of entering an identification code

with an internally decoding barcode scanner connected to the barcode

port. To interface with the Model 3300, the barcode scanner must be

programmed as follows, referring to the scanner users guide:

10 msec Intercharacter Delay

Disable Line Feed Suffix

No Parity

1200 BAUD Rate

8 Data Bits

When the barcode scanner (part # 330016) is connected to the Model

3300, the instrument operator may scan an identifying barcode before

introducing a sample.

NOTE The barcode configuration may work with many different

scanners, but not all are recommended and supported by

Advanced Instruments. For information on which scanners are

supported by Advanced Instruments, please contact Advanced

Instruments customer service department.

NOTE To avoid possible damage to your instrument or the barcode

scanner, turn off the instrument power before connecting to

the barcode port.

20

Page 39

If you introduce a sample without a prior barcode scan, the test results

will display without further identification. If you scan a barcode, the

Model 3300 will display “Successful Scan [Cancel]” on the first line

and the decoded barcode on the second line. During that display, the

instrument operator may introduce a sample for test and identification

with the decoded barcode or may cancel and either re-scan or introduce

a sample without barcode identification.

Using a printer with the Model 3300

The 25-pin output printer port on the back of the Model 3300 allows the

use of most standard printers. For information on ordering a compatible

printer, contact the Customer Service Department at Advanced

Instruments. See page v for ordering information.

The use of a printer cable and/or printer power cable other than supplied

by Advanced Instruments may result in excessive electromagnetic noise

and unintended interference with other devices.

Using the Model 3300’s RS-232 port

The RS-232 port allows you to output to an external device, such as a

computer, and to update your instrument software. Almost every item of

information displayed by your instrument is also transmitted over the

RS-232 port, including test results, all error messages, and most display

data from the diagnostic menu.

The default serial data rate for communications is 9600 bps (bits per

second), though you may alternatively select 1200, 2400, 4800, and

19200 bps.

The DB-9 RS-232 port on your instrument conforms to the DTE EIA232 standard and can reliably communicate over shielded cable up to 10

meters in length, depending on the baud rate you use.

Note Your instrument is only designed to support unidirectional com-

munication with an external device. At this time, there is no protocol for bidirectional communication.

21

Instrument Operation

Page 40

For a sample RS-232 Port Setup, please see the Supplemental RS-232

Information Appendix at the end of this user’s guide.

Instrument software update

Your instrument software contained in two flash EPROMs on the main

processor board may be updated via the RS-232 port. Such software

updates are made available as new features and other improvements are

added during the life cycle of the instrument. For information on the

availability of software updates contact Advanced Instruments, Inc. or

an authorized distributor (see Chapter 4, page 29). For directions on

performing the RS-232 serial port software upgrade consult the documentation supplied with the upgrade package.

Advanced®Micro-Osmometer Model 3300 User’s Guide

22

Page 41

3

Calibration

This chapter describes the procedure for calibrating your

instrument. If you have questions or problems regarding the

calibration procedure, please consult Chapter 4 —

Troubleshooting & Service.

Calibration procedure

Calibration of the Model 3300 is a simple procedure that

requires no adjustment of the instrument by the user. Simply

run the menu-driven calibration program requiring the testing

of standards at each of two calibration points. If the repeatability is acceptable on these calibration points, the instrument

automatically performs internal calibration.

The calibration procedure is as follows. Note that maintaining

and loading accurate, uncontaminated standard samples is

extremely important.

1. At “Osmometer Ready,” press the left soft key, labeled

[CALIB] to initiate the calibration process. The calibration

program will prompt you to run a sample of the 50 mOsm

calibration standard.

2. Run the 50 mOsm calibration standard as you would an

actual sample (see Chapter 2 — Operation). When the

instrument completes each test and reports the results (not

necessarily the exact standard value), raise the operating cradle, remove the sampler, and clean the chamber as recommended in Chapter 2.

23

Page 42

3. The calibration program will prompt you for a second 50 mOsm calibration standard. Run the second 50 mOsm calibration standard.

When the test finishes, your instrument will display a result and

prompt you for an 850 mOsm calibration standard.

4. Run your first 850 mOsm calibration standard as described above.

The program will report a result and request another 850 mOsm calibration standard. Continue in this manner until the instrument display reads “Calibration complete”. The program can require anywhere between three and six 850 standard samples, depending on the

repeatability of the results.

5. Verify the calibration by running a Clinitrol 290 reference solution

before running unknown samples.

If the instrument display shows “Calibration Not Complete” after six

samples at either calibration level, the calibration procedure has failed

and you should carefully repeat the procedure. If you experience

“Calibration Not Complete” more than once, you have a repeatability

problem and should consult Chapter 4 for troubleshooting and service

information.

Calibration notes

• The Model 3300 will retain its previous calibration data until it completes a re-calibration and the display reads “Calibration

Complete”.

• If the instrument has calibration information in memory and you

have not changed any probes, the first test result displayed should be

close to the nominal value of the standard loaded. If the instrument

has no calibration information in memory or a probe has been

changed, the test result displayed may be far from the nominal value

of the standard loaded. If the displayed values repeat consistently,

the calibration will automatically adjust when the calibration test

sequence is complete.

Advanced®Micro-Osmometer Model 3300 User’s Guide

24

Page 43

• You may terminate the calibration procedure at any time by raising

the operating cradle and pressing [CANCEL]. The Model 3300 will

display “Test Canceled”, beep once, then display “Calib. Canceled”

and beep again. The existing calibration will not be affected.

• If you accidentally press a function soft key during a series of regu-

lar tests, the same procedure will terminate the calibrate mode without affecting the calibration and normal testing may be continued.

25

Calibration

Page 44

Advanced®Micro-Osmometer Model 3300 User’s Guide

26

Notes:

Page 45

4

Troubleshooting & Service

This chapter contains very basic information to help you solve

problems that might arise with your osmometer. Please read all

instructions very carefully, and if a solution cannot be found in

this guide, contact Advanced Instruments for Hot-Line Service.

Service & maintenance cautions

• Do not perform any service or maintenance yourself, except

as detailed in the User’s Guide.

• Unplug the power cord prior to opening or removing covers,

or else you may be exposed to electric shock, excessive temperatures, or mechanical hazards.

• Performing service or maintenance not detailed in the User’s

Guide, with or without a Service Manual, should only be

done by a qualified service technician.

• Never restrict airflow into or out of the product. Occasion-

ally, check the air vents for blockage.

• Wipe the exterior of the product with a soft, damp cloth as

needed. Using cleaning products other than those specified,

may discolor or damage the finish.

• If the product requires service for any of the following rea-

sons, unplug the product from the electrical outlet and refer

service to a qualified service technician.

- The power cord, extension cord, power strip, or power

input module is damaged.

27

Page 46

Advanced®Micro-Osmometer Model 3300 User’s Guide

- Liquid has been spilled into the interior of the product.

- A foreign object has fallen into the product.

- The product has been dropped or damaged by a falling object.

- There are noticeable signs of overheating or a burning odor.

- The product does not operate normally when you follow the oper-

ating procedures.

- The main supply fuse(s) or any internal fuse(s) continually fail.

• A discharge of static electricity from contact with the human body or

other conductor may damage system boards or static sensitive

devices. Never perform internal maintenance without following recommended static protection procedures.

• The product is equipped with operator accessible fuses. If a fuse

blows, it may be due to a power surge or failure of a component.

Replace the fuse only once. If the fuse blows a second time, it is

probably caused by failure of a component part. If this occurs, refer

service to qualified service personnel. Always replace the fuse with

one of the same rating, voltage, and type. Never replace the fuse

with one of a higher current rating.

• When servicing the product, use only factory-specified parts.

• WARNING: When returning this product for service, or shipping

this product to a second location, remove all hazardous

specimens and decontaminate the product before packaging for shipment. If the product cannot be decontaminated, consult with your shipping agent on appropriate packaging and marking.

28

Page 47

Obtaining service

Before contacting Advanced Instruments for Hot-Line®Service, be sure

to read through this user's guide for instructions on routine adjustments,

instrument care and troubleshooting. If this information does not solve

your problem, call the appropriate number below.

• 800-225-4034 (toll-free within the USA and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-0811 (fax)

If you purchased your instrument outside of the U.S. or Canada, please

contact your Advanced Instruments authorized dealer for service or

repair.

When contacting our service personnel, please have the model and serial numbers from the label on the back of your instrument, your user’s

guide or service manual, and the symptoms of your problem ready. You

should use a telephone as close to your instrument as possible to facilitate making recommended diagnostic checks. If you need to order parts

or service, a purchase order from your purchasing agent will be necessary.

After Hot-Line diagnosis, your service technician may assist you in

making minor repairs over the phone, dispatch a local service representative, or have you ship your instrument for factory repair.

If you need to return an instrument for repair or replacement:

• Notify our service department to obtain an RMA.

• Be sure to telephone Advanced Instruments before shipping to avoid

any delays.

• Carefully pack and send everything except your instrument’s supply

items.

• Be sure to prepay for any shipment to the factory. Advanced

Instruments cannot accept collect shipments without prior factory

approval. Please insure the shipment or accept the damage risk.

29

Troubleshooting & Service

Page 48

Troubleshooting checks

Check operational requirements. If you are experiencing difficulties

with your instrument, first carefully review the operational requirements

listed in the product specifications and the recommended setup and

operating procedures.

Check fuses. You will find the power switch and fuse holder beside

the power cord connector on the back panel of the instrument. Switch

the power switch to the off position and disconnect the power cord.

Use a small flat-bladed screwdriver or similar tool to pry out the fuse

holder. Visually check for a blown fuse. If there is any doubt, test the

fuses with a continuity checker or ohmmeter or simply replace them

with new fuses.

Check error messages. The software of your instrument is designed

in such a way that any incomplete task will be associated with an error

message, many self-explanatory, that will help you discover the source

of your problem. You can find all error messages and descriptions of

what they mean in Appendix B.

Internal diagnostics

The diagnostic menu allows any of a series of tests to be run to check

one functional subsystem of the instrument, or to perform some necessary adjustment or set-up.

At “Osmometer Ready”, the function keypads are respectively labeled

[CALIB] and [DIAG] with the supervisor/operator keyswitch in the

Supervisor position.

1. If necessary, press both soft keys simultaneously to display [DIAG].

2. When [DIAG] is displayed, press the function button under [DIAG].

When you press the [DIAG] soft key, “1. Recall Results” and the

choice of [START] or [INDEX] is displayed.

3. While any diagnostic menu item is being displayed, use either the

Advanced®Micro-Osmometer Model 3300 User’s Guide

30

Page 49

[START] soft key to start the displayed test; the [INDEX] soft key to

display the next menu item; or both soft keys simultaneously to exit

from the menu.

4. If you choose to press the [START] soft key, execution of the cho-

sen function may require the use of either of the soft keys for further

selections, as designated below. To end any function and return to

the menu, press both soft keys and release them simultaneously.

5. You may then use [INDEX] to index to another item on the menu or

press both soft keys and release them simultaneously to exit from the

diagnostic menu to “Osmometer Ready”.

Any instructions necessary for the menu function started are provided

on the display. Adescription of each menu item follows:

A/D Test

This set of tests may be used to test the block probe, the sample-cooling

assembly, or the sample probe.

On entry, the A/D tests display the target sample cooling block temperature, the channel being read, and the current channel reading or duty

cycle. The display is in the form, “off Blk NNNN.NN ohm”, where

“off” indicates that a target temperature has not yet been selected, “Blk”

indicates that the block probe channel is being tested, “NNNN.NN” is a

numeric readout of the probe and “ohms” indicates the units of the readout. These readings are updated continuously.

Pressing the left function soft key sequentially changes the target cooling block temperature from “off” to “+1”°C, to “0”°C, to “-1”°C, to

“-2”°C, to “-4”°C, to “-8”°C, to “-12”°C, to “off”, etc.

Pressing the right function soft key sequentially changes the channel

and readout units from probe resistance in ohms, to probe temperature

in tenths of a degree Celsius, to cooling-block duty cycle (“NN%” on)

to probe resistance in ohms, etc.

31

Troubleshooting & Service

Page 50

CAUTION The temperature values displayed are based on the block

probe resistance which the instrument is configured for.

Thus, if the block probe bin # has been incorrectly set,

both the displayed temperatures and resistances will be

incorrect, as well as the actual temperature of the cooling

block.

Press both soft keys and release them simultaneously to exit to the

menu.

Probe Bin Test

This test is used to determine the resistance of the sample probe at a

specific temperature. It is essentially the same as any other sample test

except that the sample probe resistance and correct bin # are determined

and displayed in place of the sample osmolality. Use the following procedure to run the test.

1. On entry, the probe bin test will display “Probe Bin Test [YES]

Ready? [CANCEL]”.

2. Press [YES] to start the test. When [YES] is pressed, the display

changes to: “Insert 50 mOsm Sample [CANCEL]”.

3. To continue, load a sample from a freshly-opened ampule of

Advanced 50-mOsm standard and run the test using the sample test

procedure detailed in Chapter 2.

4. “Cooling Sample” is displayed (as in a normal test), then the sample

probe resistance in ohms is dynamically displayed as the sample is

cooled. At the end of each test, the final display will be the test

result in ohms and the sample probe bin # (e.g., “5801.02 Ohms Bin

6”).

5. Record your results in the Service Log before running another test or

canceling to the diagnostic menu.

6. Raise the operating cradle to complete the test.

7. When the operating cradle is raised, “[YES] Ready? [CANCEL]”

Advanced®Micro-Osmometer Model 3300 User’s Guide

32

Page 51

provides the opportunity to either run another 50-mOsm probe test

or finish (cancel) the procedure. Run two more bin tests and average

the results of the three to determine your bin number.

8. Press both soft keys and release them simultaneously (or press the

[CANCEL] soft key) to exit to the menu.

Barcode Test

This test performs a continuous check of the barcode port.

1. Press the START key to enter the test.

2. At “[YES] Ready? [CANCEL]” you may press YES once the bar-

code scanner is connected, or press CANCEL to return to the main

menu.

After you press YES you may begin scanning barcodes. If your code

will not scan, check the manufacturers user’s guide to verify correct

setup of the scanner for your symbologies.

3. Press CANCEL or both keys to exit to the test menu.

Display/Print Test

This menu item is a simple check of the display, serial port and printer

(if connected). On entry, a single line of characters will be displayed

and sent to the serial and parallel ports. The characters displayed have

been chosen to exercise every dot in the character matrix. This makes it

possible to distinguish any dots that no longer work (on the printer, if

connected, as well as on the display).

Press both soft keys and release them simultaneously to exit to the

menu.

Beeper Test

This menu item exercises the beeper. On entry, this test displays “[ON]

Beeper [OFF]”. Press the [ON] soft key to cause the beeper to beep

repeatedly; press the [OFF] soft key to stop the beeper.

Press both soft keys and release them simultaneously to exit to the

menu.

33

Troubleshooting & Service

Page 52

Advanced®Micro-Osmometer Model 3300 User’s Guide

Solenoid Test

This test is used to exercise the freeze pulse solenoid.

On entry into this test, press the [IMPACT] soft key for a single impact

or the [BUZZ] soft key for a set of repeated impacts. If either or both

of these do not occur when the appropriate soft key has been pressed,

contact Advanced Instruments for Hot-Line Service.

Press both soft keys and release them simultaneously to exit to the

menu.

Key Test

This menu item allows individually testing the switches in the soft keys.

On entry, this test displays [PRESS] over each soft key. When each

soft key is pressed the beeper should sound and an asterisk should

appear above the pressed soft key to indicate proper operation.

Event Record

On entry, this menu item enables downloading the internally stored

event record to both the serial and parallel ports. When ready, press

[YES] to download.

Press [CANCEL] (or both soft keys and release them simultaneously)

to exit to the menu.

Toggle the [INDEX] soft key to select another menu item or press both

soft keys and release them simultaneously to exit from the diagnostic

menu. As necessary on exit from the diagnostic menu, the power-up

tests will automatically begin and should finish with the display,

“Osmometer Ready”.

Fuse replacement

If you determine that your instrument is not functioning because of

blown fuses, you will need to replace the fuses using the following procedure.

1. Switch the power switch to the off position and disconnect the power

cord.

34

Page 53

2. Use a small flat-bladed screwdriver or similar tool to pry open the

fuse holder door. Remove the fuse holder located inside.

3. Double-check the values marked on the fuses. The Model 3300 will

automatically adjust for voltages between 100VAC and 250VAC but

appropriately rated fuses must be installed. Use 5 × 20mm, 250V,

time delay (Type T) fuses. For 100-130V operation, use 1.25-Amp

fuses; for 200-250V operation use 1-Amp fuses.

4. Re-install the fuse holder into the back of the instrument and close

the fuse holder door.

5. Re-connect the power cord and switch the power switch to the on

position. The instrument should start up as normal.

Chamber cleaning

The cooling chamber and probe are easy to keep clean and dry by faithfully following the operating instructions for cleaning the freezing

chamber after each test. If traces of standards or biological samples are

left in the sample chamber, however, the task will be more difficult and

damp cleaning will probably be required. Two indicators that damp

cleaning may be required are:

• The instrument has been in use but no clean, dry chamber cleaner is

found in the sample port and successive results on aliquots of the

same sample indicate chamber contamination (the first aliquot read-

35

Troubleshooting & Service

Figure 5: Fuse Replacement

FUSE HOLDER

Page 54

Advanced®Micro-Osmometer Model 3300 User’s Guide

ing very high and subsequent readings progressively lower).

•“Sample Pre-freeze” errors begin to occur quite frequently.

When indicated, the cooling chamber may be damp cleaned as follows.

1. Dampen (do not saturate) the end of a chamber cleaner with 70% isopropanol solution.

2. Firmly insert the dampened chamber cleaner all the way into the sample port, rotate it four or five times (clockwise and counter-clockwise)

and withdraw.

3. Repeat with a dry chamber cleaner. Insert and leave a clean, dry

chamber cleaner in the sample port until the next sample is to be

tested.

Sampler plunger replacement and verification

To ensure proper instrument operation, you should replace the plunger

tip of the sampler every 500 tests (or every package of sample cells).

To replace the plunger tip, use the following procedure.

1. Unscrew the calibration gauge and key.

2. Rotate the sampler shaft until the calibration setscrew appears

beneath the access hole in the side of the sampler body.

3. Place the key end of the calibration gauge in the access hole and turn

counter-clockwise to loosen the setscrew.

4. Carefully remove the old sampler plunger wire.

5. Place a sample tip on the sampler to help you place new wire correctly.

6. Slip the sampler plunger wire into the sample cell so the Teflon

plunger tip protrudes about 1/16” or 1.6 mm from the end of the

sample cell.

7. Using the key end of the calibration gauge, push the plunger into the

36

Page 55

sampler as far as it will

go.

8. Tighten the calibration

setscrew with the calibration gauge.

9. Screw the calibration

gauge and key back into

the top of the sampler.

Your 20-µL sampler is now

calibrated and ready to use.

For verification that the wire

is calibrated correctly, use

the following procedure.

1. Place a new sample tip on

the sampler

2. Unscrew the calibration

gauge and key.

3. Insert the key end of the

calibration gauge into the

sample tip.

4. Visually inspect the position of the end of the

sampler plunger tip and

the end of the calibration

key. There should be no

gap between the two.

5. If necessary, reset the

sampler plunger wire as described above.

37

Figure 6: Sample Plunger Replacement

and Calibration

Troubleshooting & Service

Page 56

Advanced®Micro-Osmometer Model 3300 User’s Guide

38

Notes:

Page 57

39

Troubleshooting Table

Appendix A

Abrupt loss of power

No response when

sampler is lowered

into operating position

Results not repeatable

(too scattered)

“Block Probe Failure”

If you lose power to your instrument, we

recommend that you check that your outlet

is providing the correct amount of power.

Check that your cord is firmly plugged into

both the instrument and the outlet. Visually

inspect the fuses, and change as necessary.

If there is no response when you lower the

operating cradle into operating position,

there could be a problem with the internal

switch that initiates the test. Try turning the

instrument on and then off. If the problem

persists, please consult an Advanced

Instruments Model 3300 Service Manual or

contact Advanced Instruments for Hot-Line

Service.

Most often, poor repeatability comes as a

result of poor technique or not following

procedure. Be sure all sample tips are clean,

as well as the sampler itself. If the sampler

plunger wire has not been changed in 500

tests, change it as described in Chapter 4. If

the sampler is not properly calibrated, recalibrate it using the procedure described in

Chapter 4.

This message indicates a problem with your

block probe. Contact Advanced Instruments

for Hot-Line Service.

Problem/Message

Explanation

Page 58

Advanced®Micro-Osmometer Model 3300 User’s Guide

40

“Block Probe Open?”

“Calibration out of

Range; Repeat Calib”

“Cooling System

Error”

“Event Record Lost”

“Fan Driver Failure”

“Key Input Timeout”

“Lift Operating

Cradle”

This message indicates a problem with your

block probe. Check the block probe bin

number and change if necessary. If this does

not solve your problem, contact Advanced

Instruments for Hot-Line Service.

This message indicates that your calibration

could not be accepted because the results

were not consistent enough. Retry the calibration, paying particular attention to technique.

This message indicates that your cooling

system is not functioning properly. Contact

Advanced Instruments for Hot-Line Service.

This message indicates that the event record

stored in memory has been corrupted. Try

restarting your instrument. If this does not

solve your problem, Contact Advanced

Instruments to obtain Hot-Line Service.

Try restarting your instrument. If this does

not solve your problem, contact Advanced

Instruments for Hot-Line Service.

This message is caused either by a button

being pressed continuously or a keypad

malfunction. Restart your instrument, and if

the problem persists, contact Advanced

Instruments for Hot-Line Service.

Raise the operating cradle to a positive stop.

Restart your instrument if necessary. If this

does not solve your problem, contact

Advanced Instruments for Hot-Line Service.

Page 59

41

Troubleshooting Table

“Lift Operating

Cradle”

“Clean Sample

Chamber”

“No Plateau

Detected...”

“Parameter RAM

Failed or New

Software Version”

“Recalibration

Needed”

“Reset Probe Config.”

“Result = 0, Bad

Calibration?”

This message, along with audible beeps, indicates the test sample was left in the sample

chamber for an extended period. Lift cradle,

remove sample, and clean chamber. The final

result will appear only for 10 seconds once

you lift the cradle.

Your instrument was unable to detect a freezing plateau, and was therefore unable to give

a result. Check your technique and try again.

If the message persists, obtain Hot-Line

Service.

This informative message tells you that a new

software version has been installed since you

last powered the instrument or that the information stored in parameter RAM has been

corrupted. The instrument will reload factory

defaults..

This message indicates that you need to recalibrate your instrument. Re-calibrate closely

following the instructions in Chapter 3. If the

error message repeats after successful re-calibration, obtain Hot-Line Service.

Most likely, this message indicates that you

should reset your block and sample probe bin

numbers as described in Chapter 4. If this does

not solve the problem, contact Advanced

Instruments for Hot-Line Service.

Unless you are running a sample of distilled

water or some other fluid with an osmolality of

zero, you should not see this message. If you

were expecting a sample to test above zero,

then you may need to re-calibrate your instrument.

Page 60

Advanced®Micro-Osmometer Model 3300 User’s Guide

42

“ROM Serial Number

Error”

“Sample Freeze

Error...”

“Sample Pre-freeze...”

“Sample Probe

Failure”

“Sample Probe Open?”

Try restarting your instrument. If this does

not solve your problem, contact Advanced

Instruments for Hot-Line Service.

This message can be displayed for a number

of reasons. Check your technique and the

condition of your sampler. If neither of these

is the source of the problem, you should

check your sample and block probe numbers.

If this does not solve your problem, contact

Advanced Instruments for Hot-Line Service.

A sample pre freeze message usually

appears as a result of an unclean freezing

chamber. Clean your chamber as described

in Chapter 4, and be sure that the chamber

is cleaned after each test. If this does not

solve your problem, you should check the

probe bin number and obtain service if necessary .

Switch the instrument off, then on. Check

the sample probe by running the A/D tests.

If the error message does not persist and

other error messages are not displayed,

ignore this message. Otherwise, contact

Advanced Instruments for Hot-Line Service.

Switch the instrument off, then on. Check

the sample probe by running the A/D tests.