Page 1

Advanced

Advanced

®

Osmometer Model 3250

®

Cryoscope Model 4250

Service Manual

3255SM Rev22 020416

Page 2

Page 3

Table of Contents

1. Introduction

Specifications . . . . . . . . . . . . . . . . . . . . .7

General Description and Purpose . . . .11

Service Assistance . . . . . . . . . . . . . . . .11

Safety/Regulatory Information . . . . . .12

Symbol Conventions . . . . . . . . . . . . . .12

General Cautions . . . . . . . . . . . . . . . . .12

Service & Maintenance Cautions . . . .13

Hazardous Material Cautions . . . . . . .14

Regulatory Notices . . . . . . . . . . . . . . .14

Symbol Conventions . . . . . . . . . . . . . .14

FCC Requirements . . . . . . . . . . . . . . .15

2. General Overview

General Overview . . . . . . . . . . . . . . . .21

Calibration . . . . . . . . . . . . . . . . . . . . . .23

Circuit Description . . . . . . . . . . . . . . .24

Power Supply . . . . . . . . . . . . . . . . . . . .24

Front End . . . . . . . . . . . . . . . . . . . . . . .24

325605 Control Board Set . . . . . . . . . .24

325620/425620/325621/425621

Processor Board . . . . . . . . . . . . . . . .25

PCB605 Application Board . . . . . . . . .26

Other Circuit Components . . . . . . . . . .27

Design Changes . . . . . . . . . . . . . . . . . .29

Replacement Parts . . . . . . . . . . . . . . . .30

Supplies & Accessories . . . . . . . . . . . .32

3. Maintenance

Cleaning and Maintenance . . . . . . . . .35

Removing the Head & Instrument

Covers . . . . . . . . . . . . . . . . . . . . . . .36

Osmometer/Cryoscope Well Cleaning 37

Cleaning and Lubricating the Printer .39

Probe & Stir/Freeze Wire Alignment .40

4. Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . .43

Freeze “Buzz” Amplitude . . . . . . . . . .44

Stir Driver Noise . . . . . . . . . . . . . . . . .45

Head Sensor Adjustment . . . . . . . . . . .47

Head Up/Down Test . . . . . . . . . . . . . .48

Power On Diagnostics . . . . . . . . . . . . .49

A/D Tests . . . . . . . . . . . . . . . . . . . . . . .49

Sample Bin Setting . . . . . . . . . . . . . . .50

Block Bin Setting . . . . . . . . . . . . . . . .51

Stir Amplitude . . . . . . . . . . . . . . . . . .51

Display/Printer Test . . . . . . . . . . . . . . .51

Beeper Test . . . . . . . . . . . . . . . . . . . . .52

Keypad Test . . . . . . . . . . . . . . . . . . . . .52

Barcode Test . . . . . . . . . . . . . . . . . . . .52

Reset Serial Number . . . . . . . . . . . . . .52

Instrument Software Updates . . . . . . .54

Performing FLASH firmware update .54

Troubleshooting Table . . . . . . . . . . . . .56

5. Replacement Instructions

Block Probe (4D3340) . . . . . . .325P340

Clapper (3C2241R) . . . . . . . .3C2P241R

Control Board Set (325605R/425605R),

Application Board (PCB605R),

Processor Board (325621R/

425621R) . . . . . . . . . . . . . .325P620

Cooling Assembly (3D3300R/

4D3300R) . . . . . . . . . . . .325P300

Cooling Fan (4D3360) . . . . . . .325P360

Display Board (74051R/

702041R) . . . . . . . . . . . .325P051

Driver Board (PCB523R) . . .PCB523PM

Fuse (70011/70022) . . . . . . . . . . .325P11

Head Up Relay or Head Down

Relay (3D3109) . . . . . . . . . .325P109

Heat Transfer Fluid Pump

Assembly (4D3690), Fluid

Filter (4D3710R), One-way Check

Valve (4D3705R/99133R) . . . .4DP690

Keypad (325511R) . . . . . . . . . .325P511

Load Resistor (425150R) . . . . .42P150R

Mandrel (3LH500) . . . . . . . . . .3LHP500

Motor Assembly (4D3350R/

325304R) . . . . . . . . . . . . . .325P350

NVRAM Battery (71027R) . . . .71P27R

Power Supply Assembly (4D3950/

325950R) . . . . . . . . . . . . . .325P950

Printer Assembly (325400R) . . .325P401

Printer Assembly (325420R) .325420PM

Printer Mechanism

(325404R) . . . . . . . . . . . . . .325404PM

Probe Alignment Tool Kit

(3LA700) . . . . . . . . . . . . . . . . .3LP700

Sample Probe (3D3700) . . . . . . .3DP700

Sample Probe (3D3700) . . . . . .325P700

Sample Probe (4D3102) . . . . . . .4D3P02

Cryoscope Sample Probe

Versions FAQ . . . . . . . . . . . . .4DP002

Stir/Freeze Coil (3D2404R) . . .325P404

3

The Advanced®Model 3250/4250 Service Manual

Page 4

Stir/Freeze Wire (3LH243/

4LH243) . . . . . . . . . . . . . . . .4LHP243

Transistor (PCB520R) . . . . . . .PCP520R

Transistor (PCB522R) . . . . . . .PCP522R

Tube Ejector Spring (3D3312R/

4D3312) . . . . . . . . . . . . . . . 4DP312

Upgrade Kit, 3250/4250 Suffix

D to E (325024) . . . . . . . . .325025PM

Yoke (3LH230R) . . . . . . . . . . .3LHP230

6. Schematics

PCB402 Assembly Drawing

PCB402 Printer Interface Board

Schematic

PCB402 Schematic

PCB523 Assembly Drawing

PCB523 Driver Board Schematic

PCB523 Schematic

PCB605 Assembly Drawing

PCB605 Application Board Schematic

PCB605 Schematic

PCB620 Assembly Drawing

PCB620 Processor Board Schematic

210102 Assembly Drawing

210102 Schematic

3D3380 Assembly Drawing

3D3380 Schematic

325000 Interconnection Schematic

APPENDICES

A: Symbol Definitions

B: Product Disposal and Recycling

C: Service Log

Index

The Advanced®Model 3250/4250 Service Manual

4

Page 5

1. Introduction

Page 6

Page 7

Model 3250 Osmometer Specifications

Applies to Serial Suffix A - C. Refer to Design Changes for more information.

Electrical:

Voltage: 100 to 130 VAC (1.2 A) or 200 to 250

VAC (0.6 A)

Frequency: 50 or 60 Hz

Fuses: 2-Amp time delay for 100-130 VAC;

1-Amp time delay for 200-250 VAC

Power: 150 Watts

Memory Backup: integral lithium cell; 10 years

min. (not user-replaceable)

Sample Volume: 0.2 or .25 mL

Sample Capacity: single sample

Readout: 20-character digital display

Units: mOsm/Kg H2O

Range:

Low: 0 to 2000 mOsm/Kg H2O

High: 1400 to 4000 mOsm/Kg H2O

Resolution: 1 mOsm/Kg H2O

Performance Over Operating Conditions

Temperature Effects: Less than 1 mOsm/Kg H

for every 5°C (9°F) ambient

temperature change.

Operating Conditions

Temperature: 18°C to 35°C (64°F to 95°F)

Room Humidity: 5 to 80% relative humidity;

(non-condensing)

Storage Temperature: -40°C to +45°C

(-40°F to +113°F)

Start-up Time: From stand-by: immediately

From power on: under 5 minutes

Test Time: Approximately 2 minutes per sample

in 0 to 2000 mOsm range; moderately

longer in high range.

Dimensions inches centimeters

Width: 13 32

Depth: 18 46

Height: 16 41

O

2

Communications:

RS-232C and barcode scanner ports

Weight pounds kilograms

Net: 28 13

Shipping: 39 19

Performance at Reference Conditions

1

Warranty: One-year limited warranty on work-

Linearity: Less than ±0.5% from a straight line

manship and all parts except glass,

plastic and parts warranted by their

Repeatability:

makers.

0 to 400 mOsm ±2 mOsm/Kg (1 S.D.)

400 to 4000 mOsm ±0.5% (1 S.D.)

Drift: Less than 1 mOsm/Kg H

O per

2

Certification:

month

Refer to Regulatory Notices (see page 14) for applicable standards.

Installation Class: I

Over-Voltage Category: II

Pollution Degree: 2

Moisture Protection: IPX0 (Ordinary)

1

Reference Conditions: 20 to 25°C (68 to 77°F); 40 to 60% Relative Humidity; tolerances of reference or calibration solutions

excluded.

7

The Advanced®Model 3250/4250 Service Manual

Page 8

Model 3250 Osmometer Specifications

Applies to Serial Suffix D and Higher. Refer to Design Changes for more information.

Electrical:

Voltage: 100 to 250 VAC (0.6 A)

Frequency: 50 or 60 Hz

Fuses: 2-Amp time delay (Type T)

Power: 95 Watts

Memory Backup: integral lithium cell; 10 years

min. (not user-replaceable)

Sample Volume: 0.2 or .25 mL

Sample Capacity: single sample

Readout: 20-character digital display

Units: mOsm/Kg H2O

Range:

Low: 0 to 2000 mOsm/Kg H2O

High: 1400 to 4000 mOsm/Kg H2O

Resolution: 1 mOsm/Kg H2O

Communications:

RS-232C and barcode scanner ports

Performance at Reference Conditions

1

Linearity: Less than ±0.5% from a straight line

Repeatability:

0 to 400 mOsm: Std. Deviation < 2 mOsm/Kg H2O

400 to 4000 mOsm: Std. Deviation < 0.5% of value

mOsm/Kg H2O

Drift: Less than 1 mOsm/Kg H

O per

2

month

Performance Over Operating Conditions

Temperature Effects: Less than 1 mOsm/Kg H

2

for every 5°C (9°F) ambient

temperature change.

Operating Conditions

Temperature: 18°C to 35°C (64°F to 95°F)

Room Humidity: 5 to 80% relative humidity;

(non-condensing)

Storage Temperature: -40°C to +45°C

(-40°F to +113°F)

Start-up Time: From stand-by: immediately

From power on: under 5 minutes

Test Time: Approximately 2 minutes per sample

in 0 to 2000 mOsm range; moderately

longer in high range.

Dimensions inches centimeters

Width: 13 32

Depth: 18 46

Height: 16 41

Weight pounds kilograms

Net: 23 10

Shipping: 34 15

Warranty: One-year limited warranty on work-

manship and all parts except glass,

plastic and parts warranted by their

makers.

Certification:

O

Refer to Regulatory Notices (see page 14) for applicable standards.

Installation Class: I

Over-Voltage Category: II

Pollution Degree: 2

Moisture Protection: IPX0 (Ordinary)

1

Reference Conditions: 20 to 25°C (68 to 77°F); 40 to 60% Relative Humidity; tolerances of reference or calibration solutions

excluded.

The Advanced®Model 3250/4250 Service Manual

8

Page 9

Model 4250 Cryoscope Specifications

Applies to Serial Suffix A - C. Refer to Design Changes for more information.

Electrical:

Voltage: 100 to 130 VAC (1.2 A) or 200 to 250

VAC (0.6 A)

Frequency: 50 or 60 Hz

Fuses: 250V time delay (Type T):

2-Amp time delay for 100-130 VAC;

1-Amp time delay for 200-250 VAC

Power: 150 Watts

Memory Backup: integral lithium cell; 10-year

life (typical); (not userreplaceable)

Sample Volume: 2.0 to 2.5 mL

Sample Capacity: single sample

Readout: 20-character vacuum fluorescent

display

Units: mºC or mºH

Range: 0 to 1000 mºC or mºH

Resolution: 1 mºC or mºH

Communications: On-board printer, DTE EIA-

232/V.24 (RS-232) serial port

and optional barcode scanner

Performance at Reference Conditions

Linearity: Less than ±0.5% from a straight line

1

Performance Over Operating Conditions

Temperature Effects: Less than 1 unit for every

5°C (9°F) ambient tempera

ture change.

Operating Conditions

Temperature: 18°C to 35°C (64°F to 95°F)

Room Humidity: 5 to 80% relative humidity;

(non-condensing)

Storage Temperature: -40°C to +45°C

(-40°F to +113°F)

Start-up Time: From stand-by: immediately

From power on: under 5 minutes

Test Time: Approximately 90 seconds in 30-

second timed mode.

Dimensions inches centimeters

Width: 13.0 33.0

Depth: 18.0 45.7

Height: 12.0 30.5

with Head Up: 16.0 40.6

Weight pounds kilograms

Net: 28.0 12.7

Shipping: 39.0 17.7

Warranty: One-year limited warranty on work-

manship and all parts except glass,

plastic and parts warranted by their

makers.

Repeatability:

± 2 mºC or mºH (1 S.D.) between 0 and -400 mºC

± 0.5% (1 S.D.) between -400 and -1000 mºC

Drift: Less than 1 unit per month

Certification:

Refer to Regulatory Notices (see page 14) for applicable standards.

Installation Class: I

Over-Voltage Category: II

Pollution Degree: 2

Moisture Protection: IPX0 (ordinary)

9

The Advanced®Model 3250/4250 Service Manual

Page 10

Model 4250 Cryoscope Specifications

Applies to Serial Suffix D and Higher. Refer to Design Changes for more information.

Electrical:

Voltage: 100 to 250 VAC (0.6 A)

Frequency: 50 or 60 Hz

Fuses: 2-Amp time delay (Type T)

Power: 95 Watts

Memory Backup: integral lithium cell; 10-year

life (typical); (not userreplaceable)

Sample Volume: 2.0 to 2.5 mL

Sample Capacity: single sample

Readout: 20-character vacuum fluorescent

display

Units: mºC or mºH

Range: 0 to 1000 mºC or mºH

Resolution: 1 mºC or mºH

Communications: On-board printer, DTE EIA-

232/V.24 (RS-232) serial port

and optional barcode scanner

Performance at Reference Conditions

1

Performance Over Operating Conditions

Temperature Effects: Less than 1 unit for every

5°C (9°F) ambient tempera

ture change.

Operating Conditions

Temperature: 18°C to 35°C (64°F to 95°F)

Room Humidity: 5 to 80% relative humidity;

(non-condensing)

Storage Temperature: -40°C to +45°C

(-40°F to +113°F)

Start-up Time: From stand-by: immediately

From power on: under 5 minutes

Test Time: Approximately 90 seconds in 30-

second timed mode.

Dimensions inches centimeters

Width: 13.0 33.0

Depth: 18.0 45.7

Height: 12.0 30.5

with Head Up: 16.0 40.6

Weight pounds kilograms

Net: 23 10

Shipping: 34 15

Linearity: Less than ±0.5% from a straight line

Repeatability:

0 to -400 mºC: Std. Deviation <

-400 to -1000 mºC: Std. Deviation < 0.5% of value

mºC or mºH

Drift: Less than 1 unit per month

The Advanced®Model 3250/4250 Service Manual

2 mºC or mºH

Warranty: One-year limited warranty on work-

manship and all parts except glass,

plastic and parts warranted by their

makers.

Certification:

Refer to Regulatory Notices (see page 14) for applicable standards.

Installation Class: I

Over-Voltage Category: II

Pollution Degree: 2

Moisture Protection: IPX0 (ordinary)

10

Page 11

General Description and Purpose

Service Assistance

®

Advanced

Osmometers and Cryoscopes

determine the concentration of solutions

through freezing-point depression measurement. Osmometers are used primarily to

measure body fluids such as serum and urine,

and cryoscopes are used to determine the

freezing points of various liquids and to

detect added water in milk. Application information is available upon request.

Except for different cooling assemblies,

stir/freeze wires, sample sizes and software,

the 3250 and the 4250 are identical to one

another. For clarity when replacing parts or

troubleshooting, the instructions indicate any

significant differences between the two instruments.

The Service Manual

This Service Manual contains:

To contact Advanced Instruments Product

Service:

• Call (800) 225-4034 (toll-free within the

USA and Canada; after normal business

hours, dial extension 2191)

• Call +US (781) 320-9000 (elsewhere)

• Or fax (781) 320-3669

When calling Advanced Instruments, have the

model and serial number from the label on the

back of the instrument, and a description of

the problem. Use a telephone as close to the

instrument as possible in order to facilitate

making recommended diagnostic checks.

A service technician may assist in making

minor repairs over the phone, providing you

with recommended parts (or part numbers), or

may issue an authorization (RMA) to ship the

instrument for factory repair.

• instructions for performing repairs.

• guides for troubleshooting operational and

mechanical problems.

• circuit system illustrations.

• information about replacement parts and

service repairs.

This manual is designed to assist

service technicians, and does not

imply a license to perform repairs

without proper qualifications.

The RMA procedure is as follows:

1. Contact Advanced Instruments to obtain

an RMA.

2. Pack and ship the instrument in its original carton. Do not send instrument supply items.

3. Prepay shipment to the factory. Advanced

Instruments cannot accept collect ship-

ments. Insure the shipment or accept the

damage risk.

11

The Advanced®Model 3250/4250 Service Manual

Page 12

Safety / Regulatory Information

To reduce the risk of bodily injury,

electric shock, fire, and damage to

your instrument, please read and

observe the following precautions.

• If the product is used in a manner not in

accordance with the equipment design,

operating instructions or manufacturer's

recommendations, the operation of the

product may be impaired to the extent that

a safety hazard is created.

• Do not attempt to perform electrical work

if you are not fully qualified. This manual

is not a substitute for electrical training.

Symbol Conventions

The exclamation point within an

equilateral triangle is intended to

alert the user to the presence of

important operating and maintenance

(servicing) instructions in the literature accompanying this product.

The lightning flash with arrowhead

symbol within an equilateral triangle

is intended to alert the user to the

presence of uninsulated dangerous

voltage within the product's enclosure that may be of sufficient magnitude to constitute risk of electric

shock to persons.

The static symbol within an equilateral triangle is intended to alert the

user to the presence of internal components that could be damaged by

static electricity.

This symbol indicates the presence

of a fuse.

This symbol indicates the presence

of protective earth ground.

This symbol indicates the power is

ON.

This symbol indicates the power is

OFF.

NOTE Additional symbol definitions are

available in the Symbols section.

General Cautions

• This product should be operated only with

the type of power source indicated on the

product’s electrical ratings label. Refer to

the installation instructions included with

the product.

• If the power cord provided is replaced for

any reason or if an alternate cord is used,

the cord must be approved for use in the

local country. The power cord must be

approved for the product’s listed operating

voltage and be rated at least 20% greater

than the ampere ratings marked on the

product’s electrical ratings label. The cord

end that connects to the product must have

an IEC 60320 connector.

• Plug the product into an approved grounded electrical outlet.

This static symbol is intended to

alert the user to the presence of a

specific component that could be

damaged by static electricity.

This symbol indicates the presence

of alternating current (AC).

The Advanced®Model 3250/4250 Service Manual

• Do not disable the power cord’s grounding

plug.

• If an extension cord or power strip is used,

make sure that the cord or strip is rated for

the product, and that the total ampere ratings of all products plugged into the extension cord or strip do not exceed 80% of the

cord’s or strip’s rating limit.

12

Page 13

• Route power cords so that they will not be

walked on, tripped on, or pinched by items

placed upon or against them. Pay particular attention to the plug, electrical outlet,

and the point where the cord exits the

product.

• Do not pull on cords and cables. When

unplugging cords or cables, grasp the corresponding connector.

• Do not install or use this product in any

area subject to extreme short-term temperature variations, or locations that exceed

the specified operating environment temperatures.

• Never use this product in a wet area.

- The power cord, extension cord, power

strip or power input module is damaged.

- Liquid has been spilled into the interior

of the product.

- A foreign object has fallen into the

product.

- The product has been dropped or damaged by a falling object.

- There are noticeable signs of overheating or a burning odor.

- The product does not operate normally

when you follow the operating procedures.

• To avoid injury or fire hazard, do not operate this product in an explosive atmosphere.

• Do not install or use the product on an

unstable, non-level work surface.

• Do not operate this product with the covers

removed or unsecured.

Service & Maintenance Cautions

• Unplug the power cord prior to opening or

removing covers, or else you may be

exposed to electric shock, excessive temperatures, or mechanical hazards.

• Performing service or maintenance not

detailed in the User’s Guide, with or without this Service Manual, should only be

done by a qualified service technician.

• Never restrict airflow into or out of the

product. Occasionally, check the air vents

for blockage.

• Wipe the exterior of the product with a

soft, damp cloth as needed. Using cleaning

products other than those specified, may

discolor or damage the finish.

• If the product requires service for any of

the following reasons, unplug the product

from the electrical outlet and refer service

to a qualified service technician.

- The main supply fuse(s) or any internal

fuse(s) continually fail.

• A discharge of static electricity from contact with the human body or other conductor may damage system boards or static

sensitive devices. Never perform internal

maintenance without following recommended static protection procedures.

• The product is equipped with operator

accessible fuses. If a fuse blows, it may be

due to a power surge or failure of a component. Replace the fuse only once. If the

fuse blows a second time, it is probably

caused by failure of a component part. If

this occurs, refer service to qualified service personnel. Always replace the fuse

with one of the same rating, voltage, and

type. Never replace the fuse with one of a

higher current rating.

• When servicing the product, use only factory-specified parts.

• WARNING: When returning this product

for service, or shipping this product to a

second location, remove all hazardous

specimens and decontaminate the product

before packaging for shipment. If the

product cannot be decontaminated, consult

with your shipping agent on appropriate

packaging and marking.

13

The Advanced®Model 3250/4250 Service Manual

Page 14

Hazardous Material Cautions

• WARNING: Handle all biohazardous

materials according to established good

laboratory practices and follow your institution’s exposure control plan. Persons

handling human blood and body fluid

samples must be trained in blood-borne

hazards and observe universal precautions.

Universal precautions is an approach to

infection control, where all human blood

and body fluids are treated as if known to

be infectious. Use personal protective

equipment such as gloves, gowns, etc., to

prevent exposure. Store biohazardous

materials in regulated waste containers and

dispose of these materials in a safe and

acceptable manner that is in compliance

with all country, state and local requirements.

• If a biohazardous material is spilled on or

inside the equipment, decontaminate the

equipment using a 1% bleach solution, or

as outlined by those policies and procedures established within your institution.

• To avoid injury or fire hazard, do not operate this product in an explosive atmosphere.

Regulatory Notices

• This product has been designed and manu-

factured in accordance with U.S.,

Canadian, and European regulatory

requirements as outlined below.

Modifications made to this product that are

not expressly approved in writing by the

manufacturer will void the user’s authority

to operate this product, previously issued

factory approvals, and the user’s rights

under the warranty.

• The distributor or dealer may have applied

additional local, national, or international

approvals to this product. Consult the distributor or dealer for more information and

documentation.

• Connections to this product must be made

with shielded cables. Use of non-shielded

cables may violate RFI/EMI limits.

Symbol Conventions

This symbol indicates conformity to

relevant European directives.

This symbol indicates the product

was tested to conform to relevant

Canadian and U.S. safety standards

by Intertek Testing Services NA,

Inc. The ETL mark is approved in

the United States as a Nationally

Recognized Testing Lab (NRTL) by

OSHA, and in Canada by the

Standards Council of Canada.

In Vitro Diagnostic Medical Device

complying with EU Directive

98/79/EC.

This symbol, depending upon its

location, indicates the assembly,

component, and/or product are free

of lead. In respect to its inclusion

on a circuit component or assembly,

the following must be adhered to

when servicing. Failure to do so

may result in defects caused by dissimilar metals.

1. Do not repair or modify using a

lead-containing solder.

2. Do not repair or modify using any

soldering tools that have been in

contact with lead-containing solders.

3. Do not repair or modify with any

lead-free solder other than that

specified by the manufacturer or

as indicated by the symbology of

standard IPC-1066.

4. Do not repair or modify using any

soldering tools that have been in

contact with any other incompatible lead-free solders.

5. Contact factory service for further

information.

The Advanced®Model 3250/4250 Service Manual

14

Page 15

The number in this symbol indicates

the type of lead-free solder used in

the assembly of printed circuit

boards, per standard IPC-1066.

Repair or modification must be per-

XAMPLES

E

ONLY

formed using the same or compatible

type lead-free solder and matching

tools. Failure to do so may result in

defects caused by dissimilar metals.

Contact factory service for further

information.

FCC Requirements

• WARNING: Changes or modifications to

this unit not expressly approved by

Advanced Instruments could void the

user’s authority to operate the equipment.

• This equipment has been tested and found

to comply with the limits for a Class B

digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to

provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular

installation. If this equipment does cause

harmful interference to radio or television

reception, which can be determined by

turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

- Re-orient or relocate the receiving

antenna.

- Increase the separation between the

equipment and receiver.

- Connect the equipment into an outlet

on a circuit different from that to

which the receiver is connected.

- Consult the dealer or an experienced

radio TV technician for help.

15

The Advanced®Model 3250/4250 Service Manual

Page 16

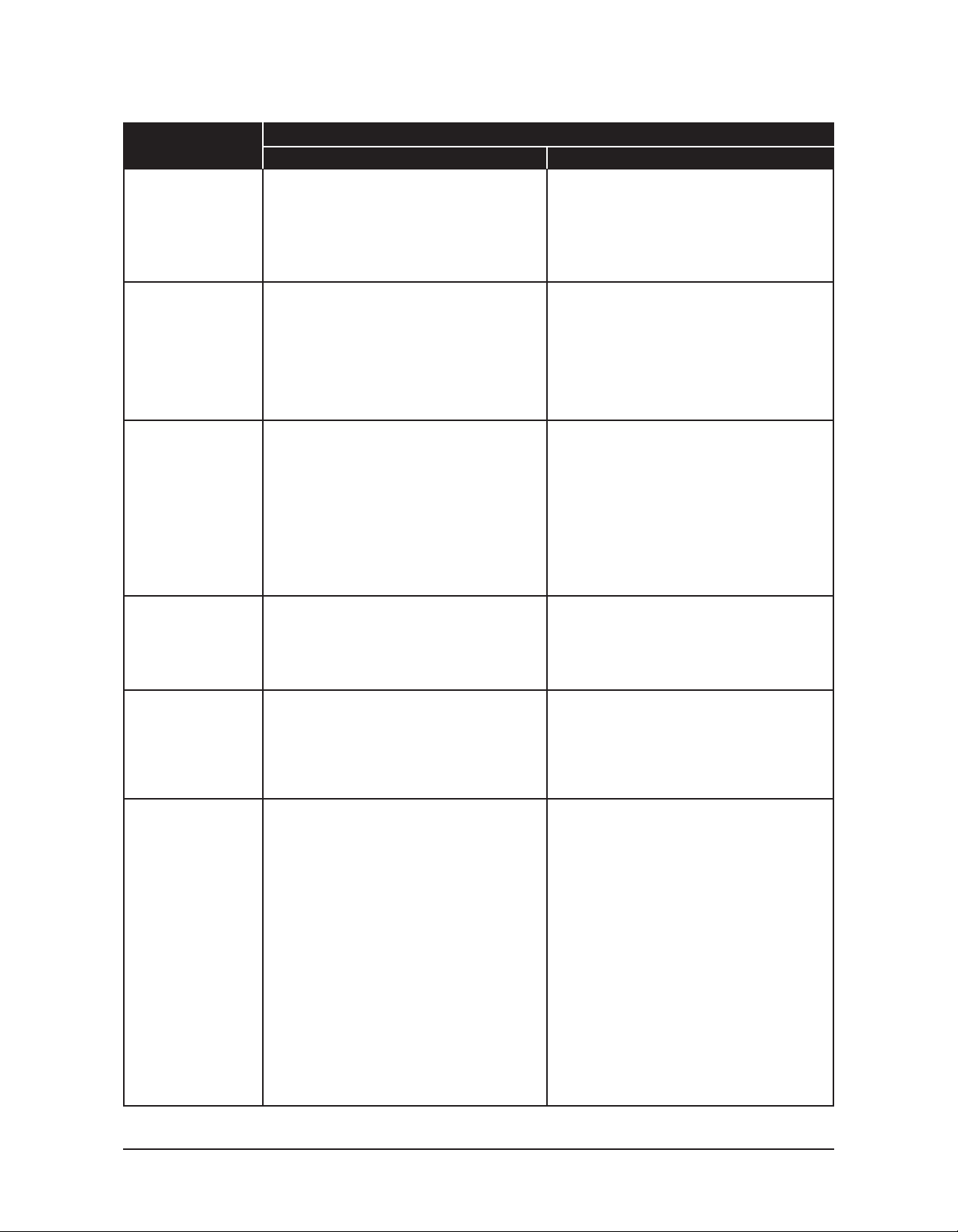

Regulatory Description

Approval Type Applies to Serial Suffix A - C Applies to Serial Suffix D and Higher

U.S. Safety

Canadian Safety

CE Declaration of

Conformity - EMC

CE Declaration of

Conformity - IVD

(3250 only)

This product has been listed by ETL testing laboratories as being in compliance with the requirements of UL 61010A-1, 1st Edition, "Electrical

Equipment for Laboratory Use; Part 1: General

Requirements". The "US" in the lower right of

the ETL mark demonstrates this listing.

This product has been listed by ETL testing laboratories as being in compliance with the requirements of CAN/CSA C22.2 No.1010.1-92, "Safety

Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use - Part

1: General Requirements"; Including Amendment

Two. The "C" in the lower left of the ETL mark

demonstrates this listing.

This product meets the intent of Directive

89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated using the following

standards, as listed in the Official Journal of the

European Communities: Consult the Declaration

of Conformance certificate shipped with the product for the latest update.

• EN 61326: 1997 with A1 & A2, Group 1, Class

B, "Electrical Equipment for Measurement,

Control, and Laboratory Use"

This product meets the intent of Directive

98/79/EC for In Vitro Diagnostic Medical

Devices. Consult the Declaration of Conformance

certificate shipped with the product (if required)

for the latest update.

This product has been listed by ETL testing laboratories as being in compliance with the requirements of UL 61010-1, "Electrical Equipment for

Laboratory Use; Part 1: General Requirements".

The "US" in the lower right of the ETL mark

demonstrates this listing.

This product has been listed by ETL testing laboratories as being in compliance with the requirements of CAN/CSA C22.2 No.61010.1, "Safety

Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use - Part

1: General Requirements"; Including Amendment

Two. The "C" in the lower left of the ETL mark

demonstrates this listing.

This product meets the intent of Directive

2004/108/EC Conformity - EMC for Electromagnetic Compatibility. Compliance was demonstrated using the following standards, as listed in the

Official Journal of the European Communities:

Consult the Declaration of Conformance certificate shipped with the product for the latest update.

• EN 61326-1:2006 & EN 55011:1998, Group 1,

Class B, "Electrical Equipment for

Measurement, Control, and Laboratory Use"

This product meets the intent of Directive

98/79/EC for In Vitro Diagnostic Medical

Devices. Consult the Declaration of Conformance

certificate shipped with the product (if required)

for the latest update.

CE Declaration of

Conformity - WEEE

CE Declaration of

Conformity - Low

Voltage

(3250 only)

This product meets the intent of Directive

2002/96/EC as amended by 2003/108/EC for

Waste Electrical and Electronic Equipment

(WEEE). Consult the Declaration of Conformance

certificate shipped with the product (if required)

for the latest update.

This product meets the intent of Directive

73/23/EEC, the Low Voltage Directive.

Compliance was demonstrated using the following

standards, as listed in the Official Journal of the

European Communities: Consult the Declaration

of Conformance certificate shipped with the product (if required) for the latest update.

• EN 61010-1 (2001), “Safety Requirements for

Electrical Equipment for Measurement, Control,

and Laboratory Use - Part 1: General

Requirements”.

• EN 61010-2-101: 2002, “Safety Requirements

for Electrical Equipment for Measurement,

Control, and Laboratory Use - Part 2-101:

Particular Requirements for In Vitro Diagnostic

(IVD) Medical Equipment”.

This product meets the intent of Directive

2002/96/EC as amended by 2003/108/EC for

Waste Electrical and Electronic Equipment

(WEEE). Consult the Declaration of Conformance

certificate shipped with the product (if required)

for the latest update.

This product meets the intent of Directive

2006/95/EC, the Low Voltage Directive.

Compliance was demonstrated using the following standards, as listed in the Official Journal of

the European Communities: Consult the

Declaration of Conformance certificate shipped

with the product (if required) for the latest update.

• EN 61010-1, “Safety Requirements for

Electrical Equipment for Measurement, Control,

and Laboratory Use - Part 1: General

Requirements”.

• EN 61010-2-101, “Safety Requirements for

Electrical Equipment for Measurement, Control,

and Laboratory Use - Part 2-101: Particular

Requirements for In Vitro Diagnostic (IVD)

Medical Equipment”.

The Advanced®Model 3250/4250 Service Manual

16

Page 17

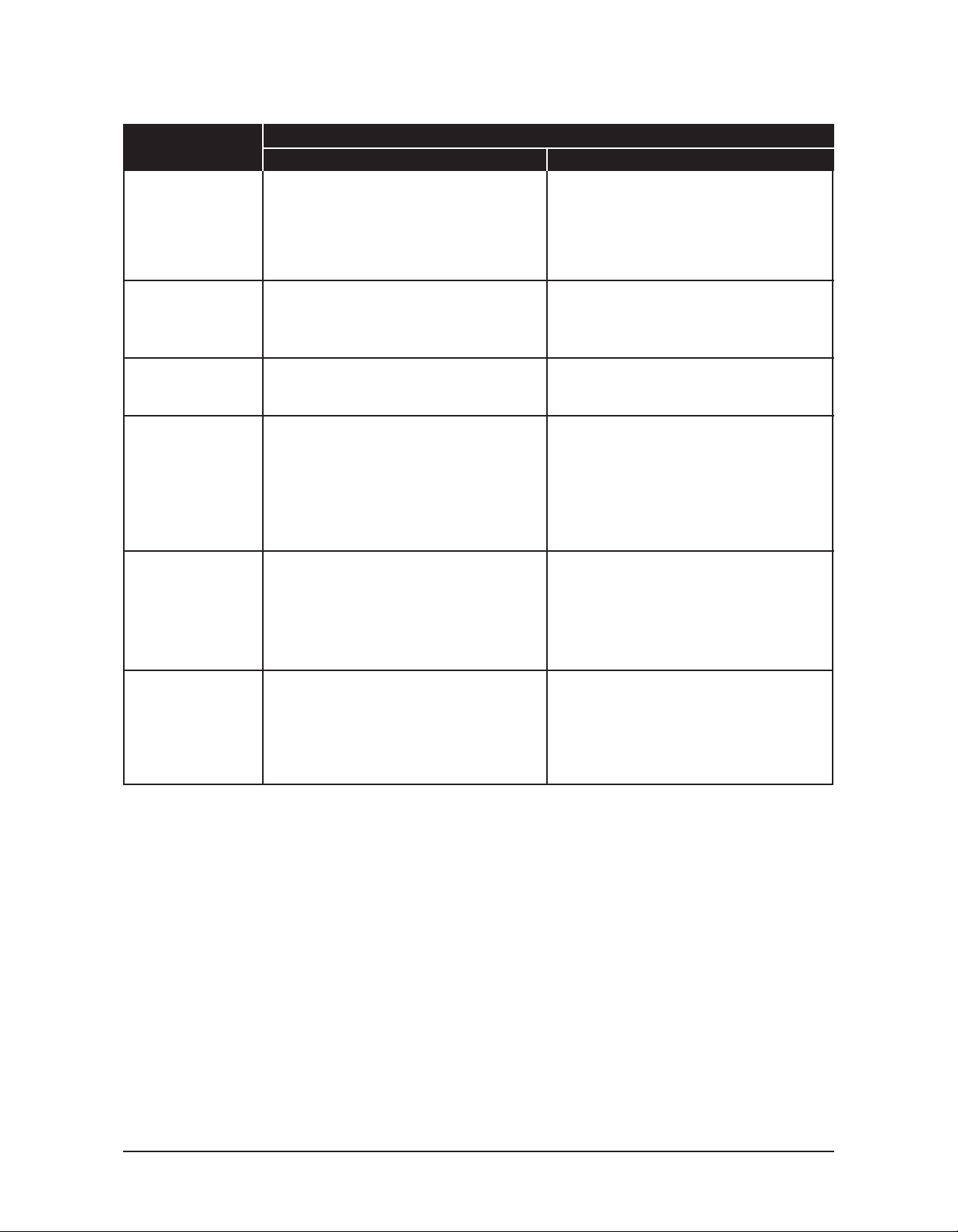

Regulatory Description

Approval Type Applies to Serial Suffix A - C Applies to Serial Suffix D and Higher

FCC - Part 15

Subpart B, Class B

Canadian ICES-003

CB Report

CB Certificate

U.S. FDA Listing

(3250 only)

Health Canada

License

(3250 only)

This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

This Class B digital apparatus complies with

Canadian ICES-003

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

-------------------------------

The osmometer, along with the calibrators and

controls manufactured by Advanced Instruments,

are listed with a U.S. Department of Health and

Human Services, Food and Drug Administration,

as:

Osmometer Class 1

Calibrators Class 2

Controls Class 1

The osmometer, along with the calibrators and

controls manufactured by Advanced Instruments,

are licensed with Health Canada, Therapeutic

Products Directorate, Medical Devices Bureau, as:

Osmometer Class 2

Calibrators Class 2

Controls Class 2

This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

This Class B digital apparatus complies with

Canadian ICES-003

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

A CB report and certificate have been issued for

this product. The standard used was IEC 61010-1.

The osmometer, along with the calibrators and

controls manufactured by Advanced Instruments,

are listed with a U.S. Department of Health and

Human Services, Food and Drug Administration,

as:

Osmometer Class 1

Calibrators Class 2

Controls Class 1

The osmometer, along with the calibrators and

controls manufactured by Advanced Instruments,

are licensed with Health Canada, Therapeutic

Products Directorate, Medical Devices Bureau, as:

Osmometer Class 2

Calibrators Class 2

Controls Class 2

CE Declaration of

Conformity - RoHS

This product meets the intent of Directive

2002/95/EC for the Restriction of Use of Certain

Hazardous Substances in Electrical and Electronic

Equipment” as an exempt medical device per

Article 2, Paragraph 1 and per Annex 1, Category

8 and/or 9 of Directive 2002/96/EC.

This product meets the intent of Directive

2002/95/EC for the Restriction of Use of Certain

Hazardous Substances in Electrical and Electronic

Equipment” as an exempt medical device per

Article 2, Paragraph 1 and per Annex 1, Category

8 and/or 9 of Directive 2002/96/EC.

17

The Advanced®Model 3250/4250 Service Manual

Page 18

Notes:

The Advanced®Model 3250/4250 Service Manual

18

Page 19

2. General Overview

Page 20

Page 21

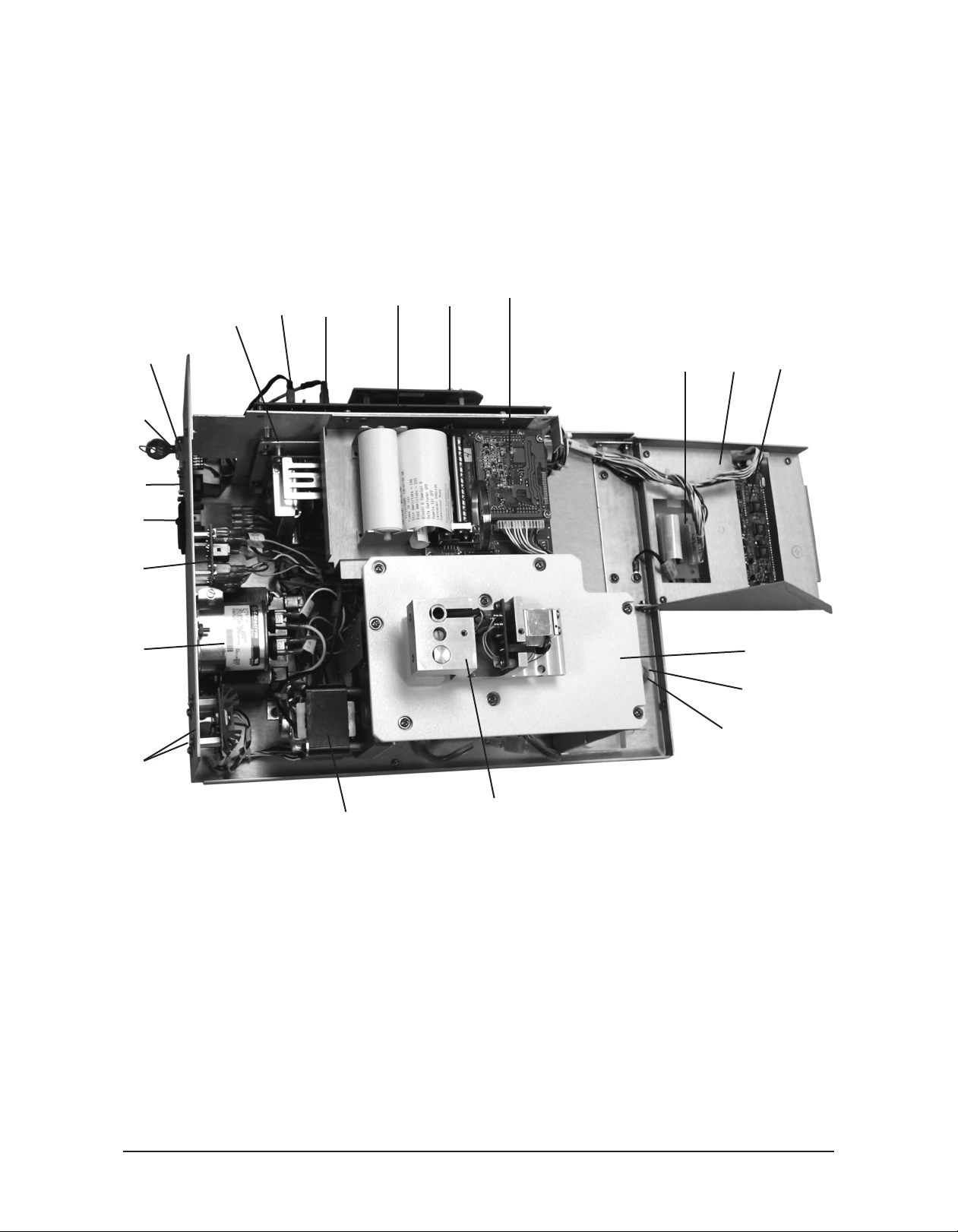

General Overview

(Intel Processor Systems)

Serial Suffix A - C

L

K

J

I

H

G

F

E

D

M

N

O

Q

P

R

S

T

C

B

A. Head

B. Motor

C. Driver Transistors (Stir, Thermoelectric)

D. Motor Capacitor

E. Head Up/Head Down Relays

F. Power Entry Module

G. RS-232C Port

H. Supervisor/Operator Keyswitch

I. Barcode Port

J. Power Supply

K. Sample Probe Plugin

21

U

A

L. Block Probe Plugin

M. Main Board Set, Application PCB

N. Main Board Set, Processor PCB

O. Printer

P. Keypad Transition Board

Q. Keypad

R. Display

S. Deck

T. Heat Transfer Return Tube

U. Heat Transfer Inlet Tube

The Advanced®Model 3250/4250 Service Manual

Page 22

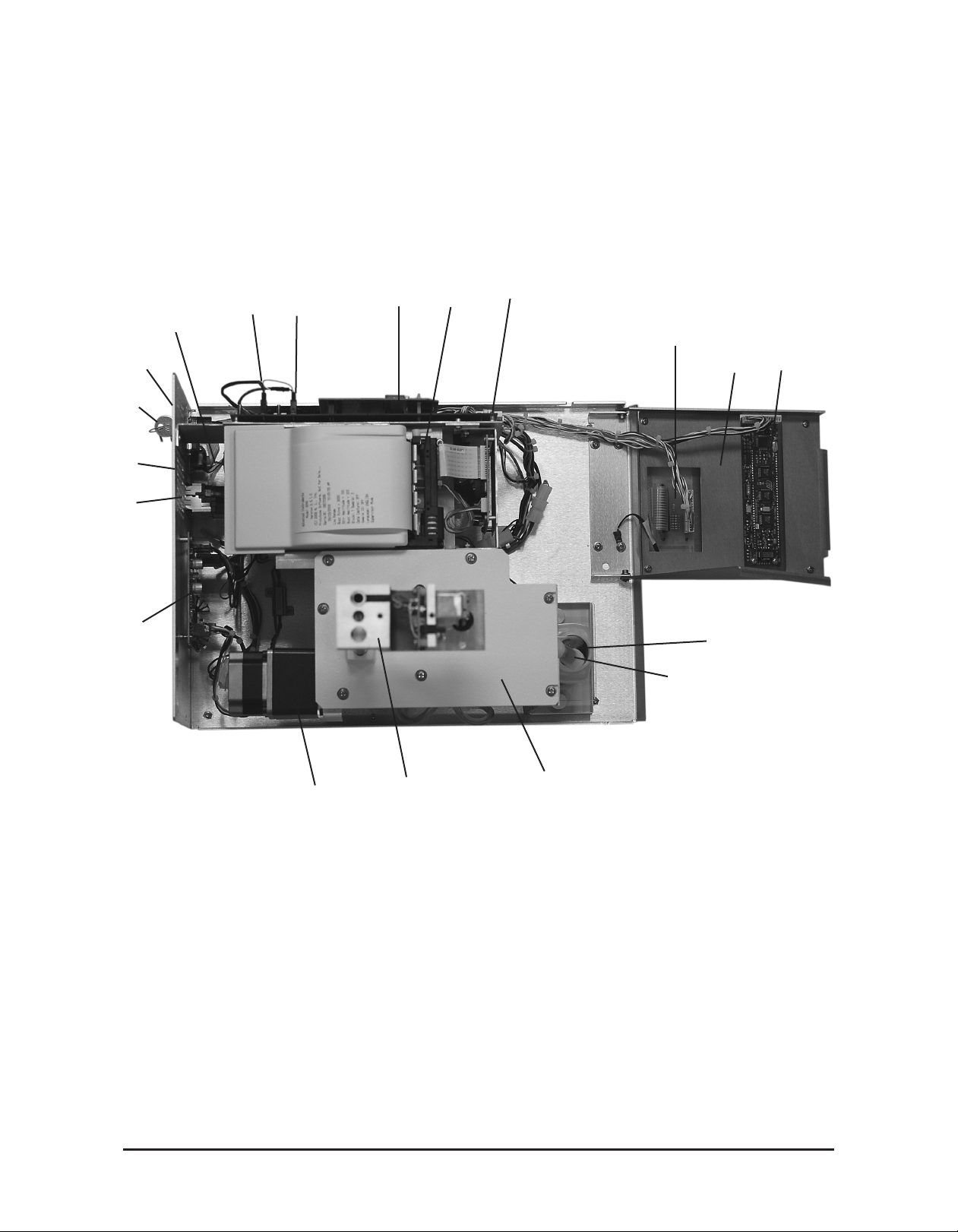

General Overview

(Intel Processor Systems)

Serial Suffix D and Higher

H

(underneath printer)

G

F

E

D

C

J

I

K

L

M

N

O

P

Q

R

B

A. Head

B. Motor

C. Driver PCB

D. Power Entry Module

E. RS-232C Port

F. Supervisor/Operator Keyswitch

G. Barcode Port

H. Power Supply (underneath printer)

I. Sample Probe Plugin

J. Block Probe Plugin

The Advanced®Model 3250/4250 Service Manual

A

S

K. Main Board Set, Processor PCB

L. Printer

M. Main Board Set, Application PCB

N. Keypad Transition Board

O. Keypad

P. Display

Q. Heat Transfer Return Tube

R. Heat Transfer Inlet Tube

S. Deck

22

Page 23

Calibration

The 3250 has two ranges, each with its own

calibration. To calibrate the low range, three

freezing-point tests are required at the 100

mOsm/kg level, and six tests are required at

the 1500 mOsm/kg level. To calibrate the

high range, six freezing-point tests are

required at both the 1500 mOsm/kg level and

the 3000 mOsm/kg level.

The 4250 allows timed or plateau-seeking calibration in either the Hortvet (m°H) or the

Celsius (m°C) scale. Six freezing-point tests

are required at each of the 4250’s two calibration levels:

-408 m°C (-422 m°H), and

-600 m°C (-621 m°H).

Note: If you see the message “Recalibration

Needed”, follow the instrument

prompts to complete the initial calibration. Your calibration may vary slightly

from that mentioned here.

Calibrate the instrument according to the

instructions below:

1. Turn the instrument on.

2. If there is a Supervisor/Operator keyswitch, turn it to the Supervisor position.

It must remain there throughout calibration.

3. Press CALIB to begin the calibration

sequence.

4. The display will prompt you at each calibration level. Place a sample of the first

calibration standard into the freezing

chamber and press START.

5. Continue loading and testing samples at

the first calibration level until the display

prompts you for samples at the second

calibration level.

Refer to the instrument User’s Guide for additional information on calibration.

6. Place the sample of the second calibration

standard into the freezing chamber and

press START.

7. When the instrument has completed calibration, the display will read

"Calibration Complete".

23

The Advanced®Model 3250/4250 Service Manual

Page 24

3250/4250 Circuit Description

The instrument is comprised of the following

functional blocks:

Power Supply

Serial Suffix A - C

The power entry assembly interfaces the AC

voltage presented to the instrument with the

transformer. The transformer provides 120

VAC to the power supply board and the head

motor. The power supply provides the power

to run the main printed circuit board (±12

VDC, ±5 VDC), the thermoelectrics (5 VDC),

the fan (12 VDC), the stir/freeze coil

(12 VDC), and the internal printer (5 VDC).

Note: The internal printer may be powered by

+5 VDC (red/orange wire) or +12

VDC (violet wire). Consult system

schematics for proper service.

Power Supply

Serial Suffix D and Higher

VDC), the stir/freeze coil (12 VDC), the internal printer (12 VDC), and the motor and control circuits (+24 V).

Front End

The sample thermistor measures the temperature of the sample. The thermoelectrics

(whose duty cycle is controlled through the

block probe/thermistor) supercool the sample.

The stir/freeze wire constantly stirs the sample

to guarantee uniform cooling. When the

supercooled sample reaches a set temperature

(3000 mOsm for the low range and 4800

mOsm for the high range, by default, in the

3250, and 3000 mºC in the 4250), the

stir/freeze wire "buzzes" causing the sample

to freeze. During a test, the fan duty cycle

tracks the thermoelectrics duty cycle -10%. If

duty cycle drops below 20%, the fan is off. In

between tests, the fan runs as required to

maintain the software controlled target temperatures.

The power entry assembly interfaces the AC

voltage presented to the instrument with the

AC/DC switching power supply. The power

supply provides the power to run the main

printed circuit board set (±12 VDC, +5 VDC),

the thermoelectrics (5 VDC), the fan (12

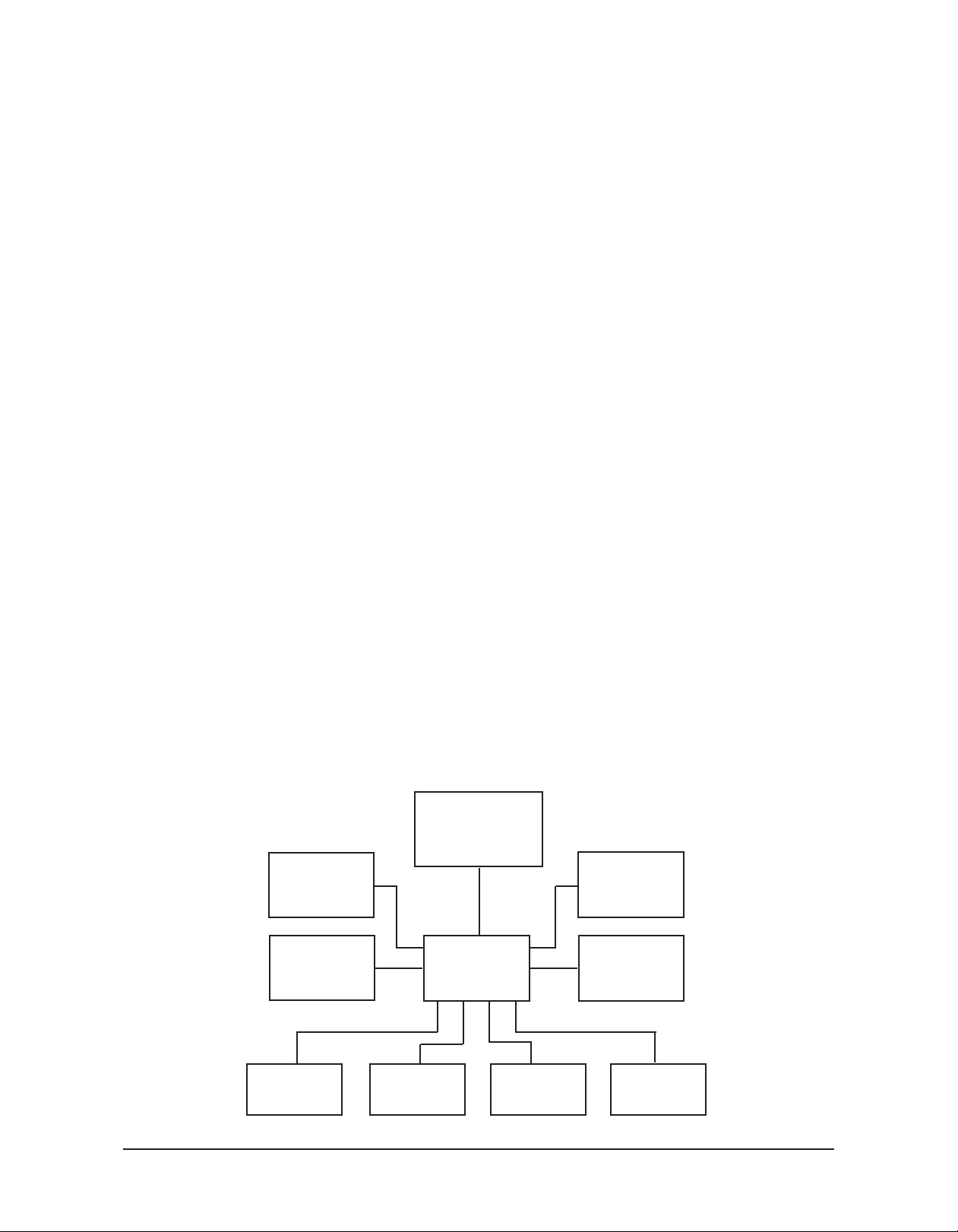

Barcode

Port

Serial Port

Head Motor

Controls

Processor

Board

Applications

Board

325605 Control Board Set Description

General: The control board set is made up of

two printed circuit boards in a motherboard/

daughterboard configuration.

Power

Supply

Cooling

System

PrinterKeypadDisplay

The Advanced®Model 3250/4250 Service Manual

24

Page 25

325620/425620/325621/425621

Processor Board

Processor: The processor used is an Intel

80C186 16-bit embedded processor. The

80C186 contains three programmable 16-bit

timers, two serial ports, programmable interrupts, 1 mega-byte of memory address space,

and 64 kilo-bytes of input/output (I/O)

address space. The processor uses an external

32 MHz crystal to generate the internal 16

MHz system clock. The processor controls

access to all memory and all I/O.

Memory Map: The 1 mega-byte of memory

address space contains read-only memory

(Flash EPROM), read/write memory (static

RAM), and the real time clock. About half of

the address space is unused, allowing for

future expansion. The read-only memory is

divided into four sections: reset vector, boot

code, parameter blocks (unused), and applicaiton code. The reset vector tells the processor where to first start executing code; in this

case, the boot code is executed first after

reset. The boot code determines if new software will be downloaded by checking if the

dip switch is in the “PROGRAM” position.

If it is, the boot code waits for new software

to be downloaded through the serial port. If

not, the application code starts.

The real time clock maintains the current date

and time, and contains nonvolatile memory

where the instrument’s operation parameters

are stored. A internal lithium battery preserves the contents of the nonvolatile memory

when the instrument is turned off. Finally, the

read-write memory is used for stacks, variables, etc., except for the small section allocated for the interrupt vectors. The interrupt

vectors tell the processor what code to run

when an interrupt occurs, and functions similarly to the reset vector.

Input/Output Map: The 64 kilo-bytes of

I/O address space control access to all peripherals such as the serial ports, application

board, etc. The processor uses 256 bytes,

called the Peripheral Control Block, to control

the integrated serial ports, timers, interrupts,

chip selects, and I/O pins. The Peripheral

Control Block is fully described in the

80C186EB/80C188EB Microprocessor User’s

Manual. The application board’s registers and

the CPU board’s registers control access to

various functions and are described later.

Memory: Two types of memory are available: read-only and read/write. The chips

used here have 8-bit wide data buses. Used in

pairs, the memory becomes compatible with

the processor’s 16-bit wide data bus. The

read-only memory is implemented using two

128 kilo-bytes x 8 bits Flash EPROMs. Flash

memory is only programmable when a programming voltage (in this case, 12 volts DC)

is applied to the memory; otherwise, it

behaves like read-only memory. The boot

code controls the programming voltage, since

this is the only place where new software can

be downloaded. The read/write memory is

implemented using two 128 kilo-bytes x 8

bits static RAMs.

Watchdog Timer: The watchdog timer provides a mechanism to reset the processor

when the software is not behaving normally.

The software “pets” the watchdog every 100 200 milliseconds. As long as the watchdog is

“petted”, nothing happens. However, if the

software stops “petting” the watchdog, the

watchdog “bites” the processor by activating

the processor’s RESET pin, causing the

processor to reset. The watchdog will also

reset the processor if the power supply falls

below 4.75 VDC. These two features allow

the instrument to recover from abnormal software and hardware conditions.

Please note that all memory addresses and

sizes are always defined in terms of bytes,

even though the processor handles words (1

word = 2 bytes, 1 byte = 8 bits; therefore, 16

bits = 1 word).

25

Real Time Clock (RTC): The real time

clock maintains the current date and time.

The RTC uses an internal clock circuit with

an internal, 10-year life, lithium battery to

The Advanced®Model 3250/4250 Service Manual

Page 26

perform timekeeping. The battery also pre-

erves the contents of internal memory.

s

Dip Switch: The three-position or fourposition dip switch allows the user to download new software via one switch. The other

two switches are available for selecting different operating modes. These operating modes

and the process for downloading software are

described later in this manual.

Voltages: Three voltages are present on the

CPU board: +5 VDC, +12 VDC, and V

.

PP

+5 VDC powers all the logic. +12 VDC is

switched on and off to create the flash memory’s programming voltage, V

.

PP

Glue Logic: The glue logic performs the

functions of creating the RAM memory chip

selects, the Flash memory write signals, the

V

control signal, the watchdog control sig-

PP

nal, and accessing the dip switch. The CPU

board has two software accessible hardware

registers to read the dip switch and to control

watchdog and V

.

PP

Connectors: A 64-pin connector provides

address, data and interrupt signals. A 16-pin

connector provides general chip selects and

serial receive/transmit signals. The application PCB uses a subset of the available signals.

to a 1 mOsm/1.86mºC change. A separate

heatstone bridge circuit is used to measure

W

the voltage across each thermistor probe.

This voltage is first filtered and then sampled

by the analog-to-digital converter. The analog-to-digital converter uses a sigma-delta

conversion technique with on-chip filtering

and a 6.25 VDC reference voltage.

I/O Ports: Circuitry for the two serial ports

(RS-232 and barcode) and the parallel printer

is present on the application board, with

cabling to the actual connectors on the back

panel and the internal printer.

Display & Keypad: The display and keypad

are interfaced to the processor via programmable logic devices (PLDs). The keypad is

polled in a row/column process which identifies the key pressed to the microprocessor.

The application logic, in response to processor commands, controls the LEDs located on

the keypad.

Light Emitting Diodes (LED): LEDs are

provided to indicate when a high current load

is active, a sensor is tripped, or a voltage supply is active. Green LEDs are used on the

power supply voltages, yellow LEDs are used

on driver signals such as the fan and head

motor controls, and red LEDs are used to

indicate that the head up and down optical

sensors have been tripped.

PCB605 Application Board

The application PCB contains all circuitry

specific to the instrument. The board includes

voltage supplies, indicators, analog-to-digital

converters, drive circuitry, parallel ports, serial ports, and various switches.

Analog-to-Digital Converters: Two analogto-digital converters are provided; one for the

sample thermistor probe, and one for the

block thermistor probe. The thermistors vary

in resistance from approximately 2 kilo-ohms

at room temperature, to approximately 10

kilo-ohms at -12ºC. Typically, a 0.6 ohm

change in the thermistor’s resistance equates

The Advanced®Model 3250/4250 Service Manual

Application Logic: The application logic is

made up mainly of two programmable logic

devices (PLDs). These provide software

accessible hardware registers, enabling the

software to read the keypad, sensors, and analog-to-digital converters. These also allow

manipulation of the display, external components such as the fan, head motor, etc., and

interface to the RS-232 ports. The printer is

controlled directly from the microprocessor

through an 8-pin D-latch.

Connectors: Connectors are supplied for the

CPU PCB, display, keypad, power, drives,

probes, and back panel I/O ports.

26

Page 27

Serial (RS-232) Port Interface: An RS-232

ine driver/receiver provides the microproces-

l

sor with a serial port interface that supports

both hardware and software handshaking.

The DB-9 RS-232 port conforms to the DTE

RS-232C standard and has the following pin

assignments:

The stir wire coil is controlled by the rear

anel-mounted darlington transistor

p

(PCB522). The drive circuit consists of a

programmable timer, D/A converter, and

interface op-amps. The timer provides a

square wave of approximately 71Hz, while

the D/A converter controls the output amplitude to the darlington transistor.

Signal Pin Direction

Carrier Detect 1 to 3250

Receive Data 2 to 3250

Transmit Data 3 from 3250

Data Terminal Ready 4 from 3250

Signal Ground 5 common

Data Set Ready 6 to 3250

Request to Send 7 from 3250

Clear to Send 8 to 3250

Note that your instrument is only designed to

support unidirectional communication with an

external device. At this time, there is no protocol for bidirectional communication.

For a sample RS-232 Port Setup, please see

the RS-232 Supplemental Information in the

Appendix at the end of this user’s guide.

Note: This instrument requires the use of a

null modem RS-232C cable. There are

several variations on null modem

cables. Advanced Instruments recommends that you purchase a RS-232C

cable direct from our factory.

Supervisor/Operator Keyswitch Interface:

A PLD is used to interface the supervisor/

operator keyswitch to the microprocessor. In

Operator position, the user cannot change

setup or calibration settings.

Other Circuit Components

Drive Circuitry, Serial Suffix A - C: Drive

circuitry is provided to turn on and off the

four high current loads such as the stir wire,

the head motor, the thermoelectric cooler, and

the fan.

The head motor is controlled by two relays

located at the rear of the chassis that interface

the 120 VAC motor to the DC logic. One

relay raises the head, while the other relay

lowers the head. The relays get their commands from the application board via two

FETs and the application logic. LEDs are

provided on the application board for monitoring the drive signals. LEDs are also provided to monitor the signals from the head

sensor board, described below.

The thermoelectric cooler is controlled by the

FET driver transistor mounted on the rear

panel (PCB520). The FET is, in turn, controlled by the microprocessor through the

PLD application logic. The processor varies

the duty cycle square wave in response to

software commands and block probe resistance.

Drive Circuitry, Serial Suffix D and

Higher: Drive circuitry is provided to turn

on and off four system loads such as the stir

wire, the head motor, the thermoelectric cooler, and the fan.

The stir wire coil drive circuit consists of a

programmable timer, D/A converter, and

interface op-amps on the application board

(PCB605). The timer provides a square wave

of approximately 71 Hz, while the D/A converter controls the output amplitude to the

darlington transistor mounted on the driver

board (PCB523).

The thermoelectric cooler is controlled by the

microprocessor through the PLD application

logic. The processor varies the duty cycle

square wave in response to software com-

27

The Advanced®Model 3250/4250 Service Manual

Page 28

mands and block probe resistance. These sig-

als are provided to the FET driver transistor

n

mounted on the driver board (PCB523).

The head motor is controlled by the application

board via two FETs and the PLD logic. LEDs

are provided on the application board for monitoring the drive signals. LEDs are also provided to monitor the signals from the head sensor

board, described below. Two active low head

up/head down signals are sent to the driver

board (PCB523) where they are converted into

acceleration, direction, and step commands for

the motor drive chip. The motor drive chip

translates these commands into current controlled outputs that move the DC stepper motor

and provide idle torque when no movement is

required. The following adjustments may be

available for the motor circuit: R10 and TP16

are used to set the initial acceleration to a rise

time of 4uS. R21 and TP15 are used to set the

run frequency to 8 Khz.

The fan is controlled by a FET transistor on

the application board, that is interfaced to the

processor through the application logic.

Head Transition Board (M20450) Description: The stir/freeze coil and the sample probe

are connected to the head transition board

which allows easy sample probe replacement.

Head Sensor Board (3D3380) Description:

This board provides two optical sensors that

interface to a PLD on the main board. These

two sensors detect the head-up and head-down

conditions.

Keypad Transition Board (FLO520)

Description: This board provides the interface

to the keypad along with pull-up resistors for

the keypad LEDs.

Barcode Port: A D-type, 15-pin barcode port

is provided in the back of the instrument for

connecting and providing power to such a

device. For proper operation, the barcode port

requires a 1200 bps, RS-232 signal providing

asynchronous serial data containing 1 start bit,

8 data bits, 1 stop bit, and no parity.

Signal Pin Direction

+5V DC 1 to reader

receive data 10 from reader

gnd/earth 9 common

Barcode Port Connections

A suitable barcode scanner is available from

Advanced Instruments. To interface with the

instrument, the barcode scanner must be programmed as follows, referring to the scanner

users guide.

1200 bps

CR suffix

disable beep after good decode

triggerless trigger mode (optional)

Internal Printer, Serial Suffix A - C: The

internal printer assembly (325400) consists of

the sheet metal mounting bracket, thermal print

head (FL0403), thermal printer PCB (FL0402),

and thermal printer PC board assembly

(PCB400). All of this is connected to the application board (PCB605) via cable (M20465).

Note: The internal printer may be powered by

+5 VDC (red/orange wire) or +12 VDC

(violet wire). Consult system schematics

for proper service.

Internal Printer, Serial D and Higher: The

internal printer assembly (325420) consists of

the sheet metal mounting bracket, thermal print

head (325404), main control board (325421),

printer interface board (PCB402), and the control cable (325419). All of this is connected to

the application board (PCB605) via cable

(325415), and on some models via cable

(325033).

The printer interface board (PCB402) contains

the power circuit converting +12 VDC into +5

VDC, a feed/self-test switch (S1), and some

diagnostic LEDs. If the self-test switch is

depressed as instrument power is applied, the

printer will enter self-test mode and print out

settings and a test character set. The LEDs

indicate the operation of the paper-out detector

(D1 yellow) and the door/platen-closed detector

(D2 red). POWER CONNECTION TO J1

The Advanced®Model 3250/4250 Service Manual

28

Page 29

SHOULD NOT BE RECONNECTED

WITH INSTRUMENT POWER ON, OR

DAMAGE TO THE INSTRUMENT MAY

RESULT.

The printer control board (325421) translates

the data from the application board (PDCB605)

into control signals for the print head thermal

elements and drive motor (325404). This board

also contains a factory-set configuration DIP

switch (DS1) and jumper (JP1).

On models equipped with cable (325033), a

compatible version of main board set (325605)

board (PCB402), diagnostic LEDs, and a test

switch are available in the lower right corner

of the larger board (PCB605). D19 is a red

LED that will indicate the printer door/platen

interface is not closed or, if blinking, one of

several printer errors have occurred, requiring

factory assistance. D20 is a yellow LED that

will indicate the paper is out or not detected

when the door is closed. SW1 is a momentary

switch that will cause the paper to advance

when pressed or, if held down while main

power is switched on, will place the printer

into self-test mode.

and a properly configured printer interface

Design Changes

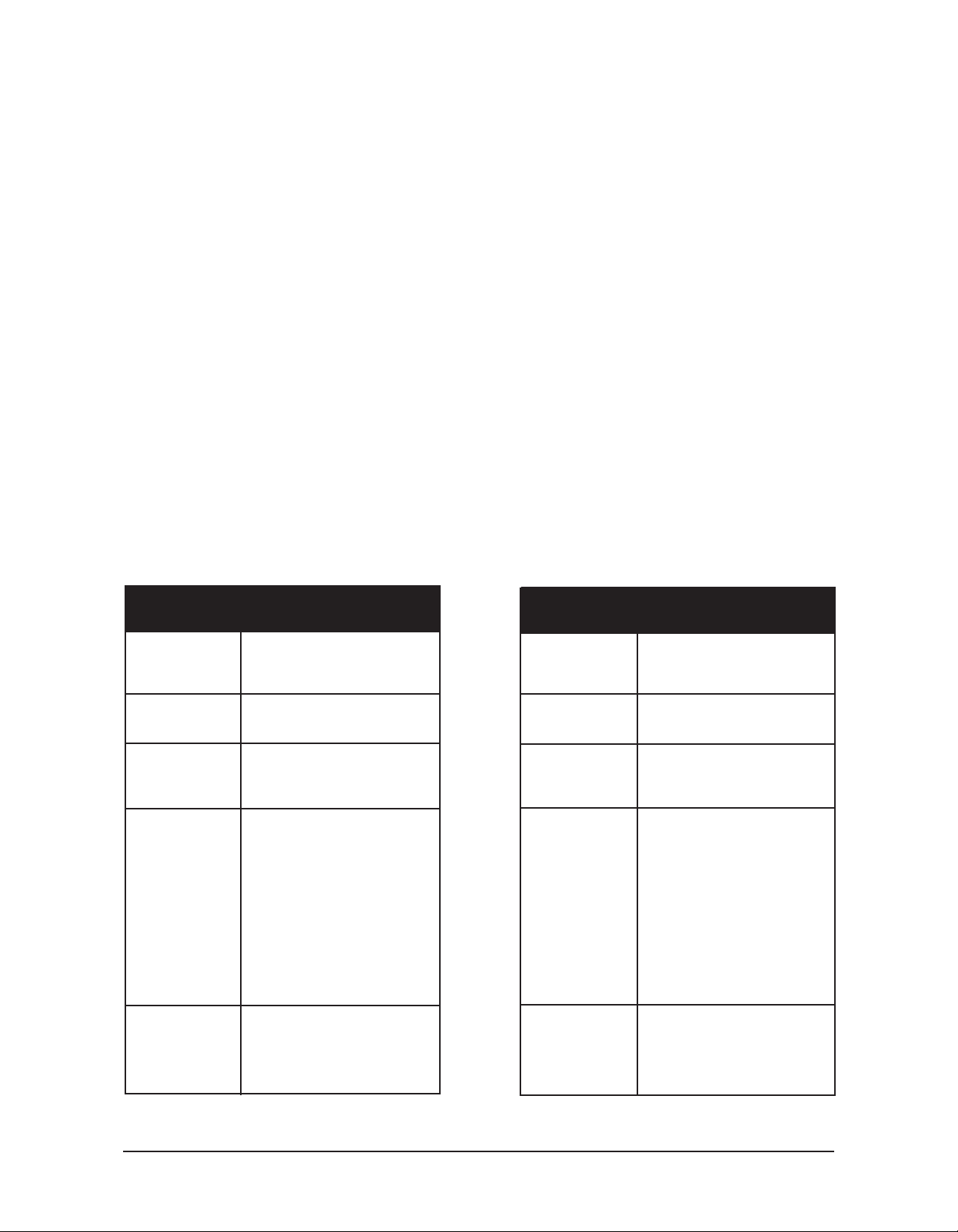

The serial number suffix (referred to in this manual simply as the suffix) indicates the revision of the

instrument. The chart below lists the major changes made at each revision of the 3250 Osmometer and

4250 Cryoscope.

Model 3250

Osmometer Description

Serial Suffix ‘A’ Original model released.

January 2004

Serial Suffix ‘B’ Base chassis and cover reMay 2007 designed.

Serial Suffix ‘C’ Up/Down relay PC boards reOctober 2007 designed into a single RoHS-

compliant PC board.

Serial Suffix ‘D’ **MAJOR REVISION**

September 2009 AC head motor and supporting

components replaced with a DC

stepper motor, multi-driver PC

board and power supply, Seiko

thermal printer assembly with

thread-through paper loading and

supporting components replaced

with a Citizen thermal printer

assembly with easy-load paper

loading.

Serial Suffix ‘E’ Application board redesigned to

October 2010 power display and keypad LEDs

from VCC +5 VDC line. Main

harness redesigned.

Model 4250

Cryoscope Description

Serial Suffix ‘A’ Original model released.

November 2005

Serial Suffix ‘B’ Base chassis and cover reMay 2007 designed.

Serial Suffix ‘C’ Up/Down relay PC boards reOctober 2007 designed into a single RoHS-

compliant PC board.

Serial Suffix ‘D’ **MAJOR REVISION**

September 2009 AC head motor and supporting

components replaced with a DC

stepper motor, multi-driver PC

board and power supply, Seiko

thermal printer assembly with

thread-through paper loading and

supporting components replaced

with a Citizen thermal printer

assembly with easy-load paper

loading.

Serial Suffix ‘E’ Application board redesigned to

October 2010 power display and keypad LEDs

from VCC +5 VDC line. Main

harness redesigned.

29

The Advanced®Model 3250/4250 Service Manual

Page 30

Replacement Parts

Serial Suffix D and higher has some different replacement parts from Serial Suffix A - C, although many

parts have remained common. Before selecting a replacement part, check the serial suffix of the instrument

on the serial suffix label on the rear of the instrument, then refer to the proper section. Refer to the Design

Changes section for additional information.

3250

Common Parts

Block Probe . . . . . . . . . . . . . . . . . . . .4D3340

Clapper . . . . . . . . . . . . . . . . . . . . . .3C2241R

Control Board Set . . . . . . . . . . . . . .325605R

Application Board (only) . . . . . . . .PCB605R

Processor Board (only) . . . . . . . . . .325621R

Cooling Assembly . . . . . . . . . . . . . .3D3300R

Cooling Fan . . . . . . . . . . . . . . . . . . . .4D3360

Cooling Well Inlet Check Valve . . . . .99133R

Firmware “FLASH” Update Kit . . . .SFW008

Fluid Filter . . . . . . . . . . . . . . . . . . . .4D3710R

Fuses: 2.0 Amp . . . . . . . . . . . . . . . . . .70022

1.0 Amp . . . . . . . . . . . . . . . . . .70011

Heat Transfer Fluid Intake

Check Valve . . . . . . . . . . . . . . . .4D3705R

Heat Transfer Fluid Pump Assembly .4D3690

Keypad . . . . . . . . . . . . . . . . . . . . . . .325511R

Load Resistor . . . . . . . . . . . . . . . . . .425150R

Mandrel . . . . . . . . . . . . . . . . . . . . . . .3LH500

NVRAM Battery . . . . . . . . . . . . . . . .71027R

Probe Alignment Tool Kit . . . . . . . . .3LA700

Sample Probe . . . . . . . . . . . . . . . . . . .3D3700

Stir/Freeze Coil . . . . . . . . . . . . . . . .3D2404R

Stir/Freeze Wire . . . . . . . . . . . . . . . . .3LH243

Tube Ejector Spring . . . . . . . . . . . .3D3312R

Yoke . . . . . . . . . . . . . . . . . . . . . . . .3LH230R

4250

Common Parts

Block Probe . . . . . . . . . . . . . . . . . . . .4D3340

Clapper . . . . . . . . . . . . . . . . . . . . . .3C2241R

Control Board Set . . . . . . . . . . . . . .425605R

Application Board (only) . . . . . . . .PCB605R

Processor Board (only) . . . . . . . . . .425621R

Cooling Assembly . . . . . . . . . . . . . .4D3300R

Cooling Fan . . . . . . . . . . . . . . . . . . . .4D3360

Cooling Well Inlet Check Valve . . . . .99133R

Firmware “FLASH” Update Kit . . . .SFW008

Fluid Filter . . . . . . . . . . . . . . . . . . . .4D3710R

Fuses: 2.0 Amp . . . . . . . . . . . . . . . . . .70022

1.0 Amp . . . . . . . . . . . . . . . . . .70011

Heat Transfer Fluid Intake

Check Valve . . . . . . . . . . . . . . . .4D3705R

Heat Transfer Fluid Pump Assembly .4D3690

Keypad . . . . . . . . . . . . . . . . . . . . . . .325511R

Load Resistor . . . . . . . . . . . . . . . . . .425150R

Mandrel . . . . . . . . . . . . . . . . . . . . . . .3LH500

NVRAM Battery . . . . . . . . . . . . . . . .71027R

Probe Alignment Tool Kit . . . . . . . . .3LA700

Sample Probe . . . . . . . . . . . . . . . . . .4D3102

Stir/Freeze Coil . . . . . . . . . . . . . . . .3D2404R

Stir/Freeze Wire . . . . . . . . . . . . . . . . .4LH243

Tube Ejector Spring . . . . . . . . . . . . . .4D3312

Yoke . . . . . . . . . . . . . . . . . . . . . . . .3LH230R

Serial Suffix A - C Parts

Display Board . . . . . . . . . . . . . . . . . .74051R

Head Up/Head down Relay . . . . . . . .3D3109

Motor Assembly . . . . . . . . . . . . . . .4D3350R

Power Supply Assembly . . . . . . . . . .4D3950

Printer Assembly without

Power Harness . . . . . . . . . . . . . .FL2401R

Printer Assembly with Power

Harness . . . . . . . . . . . . . . . . . . . .325400R

Stir Drive Transistor . . . . . . . . . . . .PCB522R

Thermoelectric Drive Transistor . .PCB520R

The Advanced®Model 3250/4250 Service Manual

Serial Suffix A - C Parts

Display Board . . . . . . . . . . . . . . . . . .74051R

Head Up/Head Down Relay . . . . . . .3D3109

Motor Assembly . . . . . . . . . . . . . . .4D3350R

Power Supply Assembly . . . . . . . . . .4D3950

Printer Assembly without

Power Harness . . . . . . . . . . . . . .FL2401R

Printer Assembly with Power

Harness . . . . . . . . . . . . . . . . . . . .325400R

Stir Drive Transistor . . . . . . . . . . . .PCB522R

Thermoelectric Drive Transistor . .PCB520R

30

Page 31

3250

4250

Serial Suffix D and Higher Parts

Display Board . . . . . . . . . . . . . . . . .702041R

Driver PCB . . . . . . . . . . . . . . . . . . .PCB523R

Motor Assembly . . . . . . . . . . . . . . . .325304R

Power Supply Assembly . . . . . . . . .325950R

Thermal Printer Assembly . . . . . . . .325420R

Thermal Printer Mechanism . . . . . .325404R

Upgrade Kit, 3250/4250 Suffix . . . . .325024

D to E

Serial Suffix D and Higher Parts

Display Board . . . . . . . . . . . . . . . . .702041R

Driver PCB . . . . . . . . . . . . . . . . . . .PCB523R

Motor Assembly . . . . . . . . . . . . . . . .325304R

Power Supply Assembly . . . . . . . . .325950R

Thermal Printer Assembly . . . . . . . .325420R

Thermal Printer Mechanism . . . . . .325404R

Upgrade Kit, 3250/4250 Suffix . . . . .325024

D to E

31

The Advanced®Model 3250/4250 Service Manual

Page 32

Supplies & Accessories

3250

100 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . .3LA011

500 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . .3LA051

900 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . .3LA091

1500 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . .3LA151

2000 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . .3LA201

3000 mOsm/kg Calibration Standard

(10 5-mL ampules) . . . . . . . . . . . .3LA301

100 mOsm/kg Calibration Standard

(110-mL bottle) . . . . . . . . . . . . . .3LA010

500 mOsm/kg Calibration Standard

(110-mL bottle) . . . . . . . . . . . . . .3LA050

900 mOsm/kg Calibration Standard

(110-mL bottle) . . . . . . . . . . . . . .3LA090

1500 mOsm/kg Calibration Standard

(110-mL bottle) . . . . . . . . . . . . . .3LA150

Clinitrol™ 290 Reference Solution

(10 5-mL ampules) . . . . . . . . . . . .3LA029

Osmolality Linearity Set (5 levels) . .3LA028

Protinol® Near Serum Reference

(3 levels) . . . . . . . . . . . . . . . . . . .3MA028

Renol™ Urine Osmolality Controls

(2 levels) . . . . . . . . . . . . . . . . . . . .3LA085

Air Filters, disposable . . . . . . . . . . . .3D2340

Barcode Scanner . . . . . . . . . . . . . . . . .330016

Heat Transfer Fluid . . . . . . . . . . . . . .3DA811

Power Cord (specify voltage and

country) . . . . . . . . . . . . . . . . . . . .----------

Printer Maintenance Kit . . . . . . . . . .FL0425*

Printer Paper, pkg rolls . . . . . . . . . . .FLA835

Printer Paper Roll Holder . . . . . . . . . .FL0408

Sample Tubes (0.2 mL, disposable) .3LA825

Sample Tube Rack . . . . . . . . . . . . . . .3LA846

Serial Port Computer Cable

with DB9S . . . . . . . . . . . .RS232-CABLE

Supervisor Keys . . . . . . . . . . . . . . . . .3D3185

Service Manual . . . . . . . . . . . . . . . . .3255SM

User’s Guide . . . . . . . . . . . . . . . . . . . . . .3255

4250

-422 m°H Calibration Standard

(-408 m°C) . . . . . . . . . . . . . . . . . .3LA023

-621 m°H Calibration Standard

(-600 m°C) . . . . . . . . . . . . . . . . . .3LA033

-530 m°H Lactrol® 530 Reference

Solution (-512 m°C) . . . . . . . . . .3LA030

Air Filters, Disposable . . . . . . . . . . . .3D2340

Barcode Scanner . . . . . . . . . . . . . . . . .330016

Heat Transfer Fluid . . . . . . . . . . . . . .3DA811

Power Cord (specify voltage and

country) . . . . . . . . . . . . . . . . . . . .----------

Printer Maintenance Kit . . . . . . . . . .FL0425*

Printer Paper (5 rolls) . . . . . . . . . . . .FLA835

Printer Paper Roll Holder . . . . . . . . . .FL0408

Sample Tubes marked at 2-mL

and 2.5-mL . . . . . . . . . . . . . . . . . .3LA823

Sample Tube Rack . . . . . . . . . . . . . . .3LA846

Serial Port Computer Cable

with DB9S . . . . . . . . . . . .RS232-CABLE

Service Manual . . . . . . . . . . . . . . . . .3255SM

Supervisor Keys . . . . . . . . . . . . . . . . .3D3185

User’s Guide . . . . . . . . . . . . . . . . . . . . . .4255

*Serial Suffix A - C, only.

How to order:

To order parts, supplies and accessories, contact the Advanced Instruments Customer

Service.

• 800-225-4034 (toll-free within the USA

and Canada)

• +US 781-320-9000 (elsewhere)

• +US 781-320-3669 (fax)

The Advanced®Model 3250/4250 Service Manual

32

Page 33

3. Maintenance

Page 34

Page 35

Cleaning and Maintenance

The cooling assembly should be cleaned once

every two months to insure optimal performance.

To flush the system:

1. Open the door and remove the heat transfer fluid bottle.

2. Empty the contents and fill the bottle

halfway with a solution of 1:5 bleach in

distilled water.

3. Replace the bottle and insert only the tube

with the filter (A). Completely immerse

the filter in the fluid.

4. Insert the return tube (B) into another

container.

5. If there is a Supervisor/Operator

keyswitch, turn it to the Supervisor position.

6. Press TEST to enter the test menu. Press

< or > to select "Head Up Down Test"

and press START.

7. Insert an empty sample tube into the

freezing chamber and press START.

8. Run this test for 10-15 minutes and then

press STOP.

Note: Using the manual primer pump to

complement the head pumping action

can help reduce the time required to

flush the system.

9. Remove the bottle with the diluted bleach

and install a new bottle of heat transfer

fluid. Insert only the tube with the filter

(A).

10. Press START twice. Run this test until

the colored fluid begins draining out of

the return tube, and then press STOP.

11. Remove the return tube from the container and insert it into the heat transfer fluid

bottle. Do not immerse the return tube in

the heat transfer fluid (B).

12 Press STOP to exit the menu.

To drain the system:

1. Turn off the power and unplug the instrument. Remove the cover.

2. Remove the heat transfer fluid bottle and

empty the contents.

B

A

35

3. Replace the empty bottle and insert the

tubes.

4. Press gently on the pump at the bottom of

the head. Slide until all liquid has been

expelled (the unit may need to be tipped

on its side to remove the liquid).

The Advanced®Model 3250/4250 Service Manual

Page 36

Removing the Head Cover & the Instrument Cover

Tools Needed: Flat-bladed screwdriver,

Phillips screwdriver.

Warning-Hazardous Voltage

Warning-Internal components may

be damaged by static electricity.

CAUTION: Improper connections

may cause damage to the instrument.

1. Turn off the power and unplug the instrument.

2. Remove the two screws from the head

cover (A) and lift off the head cover.

3. Serial Suffix A: Remove the two screws

from the front (B) and the four screws

from the rear panel (C).

Serial Suffix B & C: Remove the four

screws from the rear panel (C).

Serial Suffix D and Higher: Press the

printer cover release button (D), then

remove the four screws from the rear

panel (C).

4. Serial Suffix A: Slide the instrument

cover up and off.

Serial Suffix B and Higher: Slide the

instrument cover forward, then up and

off.

A

B

C

The Advanced®Model 3250/4250 Service Manual

D

36

Page 37

Osmometer/Cryoscope Well Cleaning

Use this procedure to clean the well and tubing of any foreign matter (e.g., broken glass)

that may have fallen into the well.

Tools needed: Flat-bladed screwdriver;

Phillips screwdriver; Tru-arc pliers; thin, stiff

wire; 4” cable tie; small wire cutters.

Osmometer Well Cleaning

1. Turn off the power and unplug the instru-

ment.

2. Remove the head cover and instrument

cover (see Removing the Head Cover &

the Instrument Cover).

3. Drain the cooling system (see Cleaning

and Maintenance).

4. Disconnect the fluid pump from the cool-

ing well, as follows:

C

6. Remove the white Delrin elevator and

spring (C). (Save for replacement when

cleaning is complete.)

7. Inspect the bottom of the well and

remove any visible debris. Be sure to

clean out the small hole at the bottom of

the well.

B

a. Unwrap refrigeration tape (A). Save

for re-use during reassembly.

b. Cut and remove the cable tie.

c. Pull the tubing off of the cooling well

inlet port.

5. Using a pair of Tru-arc pliers, remove the

Tru-arc retainer ring (B) from inside the

well. (Save the retainer ring for replacement when cleaning is complete.)

A

8. Using a thin stiff wire, insert it into the

well inlet port.

Note: The wire diameter MUST be small

enough to pass through, into the well.

The .050” diameter X 4.00” long

4LH243 stir wire is ideal.

9. Push the wire into the well. Repeat this

process several times, sliding the wire

back and forth until the end of the wire is

visible in the hole at the bottom of the

well. (This should loosen any deposit

trapped in the tube and the well.)

10. Reassemble the pump tubing to the well,

apply the cable tie, and then reapply the

refrigeration tape.

11. Using a solution of 1:5 bleach in distilled

water, place the filter and well return line

into this solution. Manually press the

pump up and down until the solution has

37

The Advanced®Model 3250/4250 Service Manual

Page 38

circulated through the pump and well,

nd into the bottle.

a

12. When satisfied that the solution is freeflowing, flush the bleach solution with

clean water, then stop and drain the cooling system.

13. Reassemble the instrument by replacing

the spring (C) and elevator (B), securing

with the Tru-arc retaining ring, then