ADTRAN ESU 120e User Manual

November 1998

61200420L1-1A

ESU 120e

User Manual

Part Number

1200420L1-1

Trademarks:

Windows is a registered trademark of Microsoft Corp.

T-Watch is a trademark of ADTRAN, Inc.

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

Phone: (256) 963-8000

© 1998 ADTRAN, Inc.

All rights reserved.

Printed in USA.

ii

ADTRAN Y ear 2000 (Y2K) Readiness Disclosure

ADTRAN has established a Year 2000 program to ensure that our products will

correctly function in the new millennium. ADTRAN warrants that all products

meet Y2K specifications regardless of model or revision.

Information about ADTRAN’s Y2K compliance program is available at the following locations:

ADTRAN Web Site

Product Matrix

Faxback Document Line

Y2K Project Line

E-mail

www.adtran.com

www.adtran.com/y2kfax.html

(256) 963-8200

Y2K plans and product certifications are

listed in the matrix

.

(256) 963-2200

year2000@adtran.com

iii

FEDERAL COMMUNICATIONS COMMISSION RADIO FREQUENCY

INTERFERENCE STATEMENT

This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio frequencies. Operation of this

equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own

expense.

Shielded cables must be used with this unit to ensure compliance with

Class A FCC limits.

Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

iv

CANADIAN EMISSIONS REQUIREMENTS

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus as set out in the interference-causing

equipment standard entitled “Digital Apparatus,” ICES-003 of the Department of Communications.

Cet appareil nuerique respecte les limites de bruits radioelectriques applicables aux appareils numeriques de Class A prescrites dans la norme

sur le materiel brouilleur: “Appareils Numeriques,” NMB-003 edictee

par le ministre des Communications.

v

CANADIAN EQUIPMENT LIMITATIONS

The Industry Canada Certification label identifies certified equipment.

This certification means that the equipment meets certain telecommunications network protective, operational, and safety requirements.

The Department does not guarantee the equipment will operate to the

user's satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local telecommunications company. The equipment must also be installed using an acceptable method

of connection. In some cases, the company's inside wiring associated

with a single line individual service may be extended by means of a certified connector assembly (telephone extension cord). The customer

should be aware that compliance with the above conditions may not

prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the supplier. Any repairs or alterations made by the user to this equipment, or equipment

malfunctions, may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines and internal metallic

waterpipe system, if present, are connected together. This precaution

may be particularly important in rural areas.

Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection authority, or an electrician, as appropriate.

The Load Number (LN) assigned to each terminal device denotes the

percentage of the total load to be connected to a telephone loop which is

used by the device, to prevent overloading. The termination on a loop

may consist of any combination of devices subject only to the equipment

that the total of the LNs of all devices does not exceed 100.

The ringer equivalence number (REN) assigned to each terminal adapter

is used to determine the total number of devices that may be connected

to each circuit. The sum of the RENs from all devices in the circuit

should not exceed a total of 5.0.

vi

Notes provide additional useful information.

Cautions signify information that could prevent service interruption.

Warnings provide information that could prevent damage to the

equipment or endangerment to human life.

vii

Important Safety Instructions

When using your telephone equipment, please follow these basic safety precautions to reduce the risk of fire, electrical shock, or personal injury:

1. Do not use this product near water, such as near a bath tub, wash bowl,

kitchen sink, laundry tub, in a wet basement, or near a swimming pool.

2. Avoid using a telephone (other than a cordless-type) during an electrical

storm. There is a remote risk of shock from lightning.

3. Do not use the telephone report a gas leak in the vicinity of the leak.

4. Use only the power cord, power supply, and/or batteries indicated in the

manual. Do not dispose of batteries in a fire. They may explode. Check

with local codes for special disposal instructions.

SAVE THESE INSTRUCTIONS

viii

Warranty and Customer Service

ADTRAN will replace or repair this product within five years from

the date of shipment if the product does not meet its published

specifications or if it fails while in service. For detailed warranty,

repair, and return information refer to the ADTRAN Equipment

Warranty and Repair and Return Policy Procedure.

Return Material Authorization (RMA) is required prior to returning

equipment to ADTRAN.

For Service, RMA requests, or more information, contact ADTRAN

Customer Service listed on the inside back cover of this manual.

ix

x

Table of Contents

Table of Contents ...................................................................................................... xi

List of Figures......................................................................................................... xvii

List of Tables ........................................................................................................... xix

Chapter 1 Introduction..................................................................................... 1-1

ESU 120e Overview .................................................................................................. 1-1

ESU 120e Features .............................................................................................1-2

ESU Option Modules ........................................................................................1-2

Option Module Architecture ...........................................................................1-3

ESU 120e Configuration Applications ...................................................................1-3

Router, PBX Application ...........................................................................1-3

Chapter 2 Installation....................................................................................... 2-1

Unpack, Inspect, Power Up .................................................................................... 2-1

Receipt Inspection .............................................................................................2-1

ADTRAN Shipments Include ..........................................................................2-1

Customer Provides ............................................................................................2-1

Power Connection .............................................................................................2-2

Grounding Instructions ........................................................................................... 2-2

Identification of Rear Panel Layout ....................................................................... 2-4

ESU120e Interfaces ...................................................................................................2-5

Network Interfaces ............................................................................................2-5

Network Test Interface ..............................................................................2-5

Nx56/64 Serial Interface ...........................................................................2-5

Drop (PBX) Interface ..................................................................................2-6

Control Port Input ......................................................................................2-6

Chain Port Output .....................................................................................2-6

10BaseT Interface .......................................................................................2-6

Power-Up Testing ..................................................................................................... 2-6

Self-Test ..............................................................................................................2-6

Initialization .......................................................................................................2-7

61200420L1-1 ESU 120e User Manual

xi

Table of Contents

Set User Passcode ...................................................................................... 2-7

Set Unit Identification ............................................................................... 2-7

Set Control Port ......................................................................................... 2-8

Chain In (PC) ............................................................................................. 2-8

Chain In/Chain Out ................................................................................. 2-8

Normal Power-Up Procedure ................................................................................. 2-9

Chapter 3 Operation ........................................................................................ 3-1

Front Panel .................................................................................................................3-1

LED Descriptions ........................................................................................... 3-3

CSU Status .................................................................................................. 3-3

DSU/Drop Status ...................................................................................... 3-3

Module Status ............................................................................................ 3-4

Operation keys .................................................................................................. 3-4

General Menu Operation ................................................................................ 3-5

Select and Activate a Menu Item ............................................................ 3-5

Set the Data Field ....................................................................................... 3-6

Exit Any Menu Field Operation Or Display ......................................... 3-7

Data Port Identification ................................................................................... 3-7

Front Panel Menu Structure ............................................................................ 3-7

Alternate Methods of Control ......................................................................... 3-8

T-Watch PRO (ADTRAN PC Program) ................................................. 3-8

SNMP ........................................................................................................ 3-10

Terminal Mode ........................................................................................ 3-10

Telnet ......................................................................................................... 3-10

Chapter 4 Status Menu.................................................................................... 4-1

Network Interface Performance Reports (NI PERF RPTS) ........................ 4-2

Network Interface Errors (NI ERRORS) ....................................................... 4-3

Active Alarms ................................................................................................... 4-3

View History ..................................................................................................... 4-4

Port Status .......................................................................................................... 4-5

0.1 Nx56/64 Menu Items .......................................................................... 4-5

DTE Data/CK .............................................................................. 4-5

DTE Status ................................................................................... 4-5

Port Rate ....................................................................................... 4-5

0.2 Drop Menu Items (DSX Errors) .......................................... 4-6

Remote Port ....................................................................................................... 4-6

Clear Port Alarm ............................................................................................... 4-6

ENET Status ...................................................................................................... 4-6

xii ESU 120e User Manual 61200420L1-1

Table of Contents

Chapter 5 Configuration Menu...................................................................... 5-1

Network (NI) ............................................................................................................. 5-3

Network (NI) Menu Items ...............................................................................5-3

ESU 120e Clock Sources ..........................................................................................5-5

Network Timed .................................................................................................5-6

Base Drop Timed ...............................................................................................5-7

Base DTE Timed ................................................................................................5-8

Internal Timing ..................................................................................................5-9

Normal (CSU) Timing ....................................................................................5-10

Unit Menu ........................................................................................................5-11

Map Exchange (Map Xchng) ........................................................................5-13

Map In Use: A(B) ............................................................................................5-13

TS0 Map A and TS0 Map B ............................................................................5-14

Port Configuration (Port Config) .................................................................5-17

0.1 Nx56/64 Port Configuration (Port Config) Menu Items ..............5-17

0.2 Drop Port Configuration (Port Config) Menu Items ....................5-19

Chapter 6 Utility Menu.................................................................................... 6-1

Time/Date ..........................................................................................................6-2

Factory Restore ..................................................................................................6-2

Set Passcode .......................................................................................................6-2

Enter Passcode from Other Menus ..........................................................6-2

Change/Set a Passcode .............................................................................6-3

Special Feature ............................................................................................6-3

No Passcode Desired .................................................................................6-3

Unit ID ................................................................................................................6-4

To Set the Unit Identification ...................................................................6-4

No Unit ID Desired ....................................................................................6-4

Software Revision (Software Rev) ..................................................................6-4

Port Utility ..........................................................................................................6-5

Enet Address ......................................................................................................6-5

CMD Mode .........................................................................................................6-5

Chapter 7 Test Menu ........................................................................................ 7-1

Network Tests ....................................................................................................7-2

Loopback Tests ..................................................................................................7-2

Network Interface Loopbacks ..................................................................7-2

LOCAL LOOPBCK ....................................................................................7-3

REMOTE LOOPBCK .................................................................................7-3

TEST PATTERN .........................................................................................7-3

All Ones .........................................................................................7-3

61200420L1-1 ESU 120e User Manual xiii

Table of Contents

All Zeros ....................................................................................... 7-3

QRSS Pattern ............................................................................... 7-4

PATTERN RESULT ................................................................................... 7-5

Run Self-Test ..................................................................................................... 7-6

Port Tests ........................................................................................................... 7-7

Port Test Menu Items for 0.1 Nx56/64 ................................................... 7-8

LOOPBK ....................................................................................... 7-8

511 PATT ...................................................................................... 7-8

DIS 511 RESLT ............................................................................. 7-8

Port Test Menu Items for 0.2 Drop ......................................................... 7-9

Loopback ...................................................................................... 7-9

Cancel Tests ....................................................................................................... 7-9

Chapter 8 Telnet/Terminal Menus ............................................................... 8-1

Main Menu ................................................................................................................8-1

TS0 Maps Configuration Menu ............................................................... 8-2

Initializing the Temp Map ......................................................... 8-3

Editing the Temp Map ............................................................... 8-3

Applying the Temp Map ........................................................... 8-3

Reviewing Temp Maps .............................................................. 8-3

Remote Menu Access ....................................................................................... 8-4

Management Configuration ....................................................................................8-4

SNMP Read Community ................................................................................. 8-4

SNMP Read/Write Community .................................................................... 8-4

SNMP Trap Community ................................................................................. 8-5

Host 1 Trap IP Address ............................................................................ 8-5

Host 2 Trap IP Address ............................................................................ 8-5

Host 3 Trap IP Address ............................................................................ 8-5

Host 4 Trap IP Address ............................................................................ 8-5

System Name ............................................................................................. 8-5

System Contact .......................................................................................... 8-5

System Location ......................................................................................... 8-5

Auth. Fail Traps Sent ............................................................................... 8-6

Poll Link Status Traps Sent ...................................................................... 8-6

Ping IP Host ............................................................................................... 8-6

Telnet/Terminal Timeout ........................................................................ 8-6

Telnet/Terminal Password ...................................................................... 8-6

Exit ............................................................................................................... 8-6

Flash Download ................................................................................................ 8-7

Quit Session ....................................................................................................... 8-7

xiv ESU 120e User Manual 61200420L1-1

Table of Contents

Appendix A. Understanding SNMP ................................................................. A-1

Appendix B. Connector Pinouts .........................................................................B-1

Appendix C. System Messages ...........................................................................C-1

Appendix D. Specifications ................................................................................ D-1

Index ................................................................................................................. Index-1

61200420L1-1 ESU 120e User Manual xv

Table of Contents

xvi ESU 120e User Manual 61200420L1-1

List of Figures

Figure 1-1. Router, PBX, Application Set Up ......................................................1-3

Figure 2-1. ESU 120e Rear Panel ...........................................................................2-4

Figure 2-2. ESU 120e Interfaces .............................................................................2-5

Figure 2-3. Example of Chain In ...........................................................................2-8

Figure 3-1. ESU 120e Front Panel Layout ............................................................3-2

Figure 3-2. Example of Basic Front Panel Menu Travel ....................................3-6

Figure 4-1. Status Menu Tree ................................................................................4-1

Figure 4-2. Network Interface Performance Report ..........................................4-2

Figure 4-3. Display of Alarm Messages ...............................................................4-4

Figure 5-1. Configuration Menu Tree ..................................................................5-2

Figure 5-2. Network Timed Clock Source ...........................................................5-6

Figure 5-3. Drop Timed Clock Source .................................................................5-7

Figure 5-4. Network Timed Clock Source ...........................................................5-8

Figure 5-5. Internal Clock Source .........................................................................5-9

Figure 5-6. Normal (CSU) ....................................................................................5-10

Figure 5-7. DS0 Map Designations .....................................................................5-14

Figure 5-8. Create Temp Selection Screen .........................................................5-15

Figure 6-1. Utility Menu Tree ................................................................................6-1

Figure 7-1. Test Menu Tree ....................................................................................7-1

Figure 7-2. Network Loopback Tests ...................................................................7-3

Figure 8-1. Telnet/Terminal Main Menu ............................................................8-1

Figure 8-2. TS0 Temp Map ....................................................................................8-2

61200420L1-1 ESU 120e User Manual

xvii

List of Figures

lxviii

ESU 120e User Manual 61200420L1-1

List of Tables

Table 5-1. Normal Mode of Operation .............................................................5-19

Table B-1. Network Pinouts ................................................................................ B-1

Table B-2. Control In/Chain-in Pinout ............................................................. B-2

Table B-3. Chain-Out Connector Pinout .......................................................... B-3

Table B-4. Nx56/64 Pin Assignments for EIA-530 and V.36 .......................... B-4

Table B-5. Nx56/64 Pin Assignments for V.35 Mode ..................................... B-5

Table B-6. Adapter Cable, DB 25 to V.35, 34-Pin Winchester ........................ B-6

Table B-7. Nx56/64 Pin Assignments for V.11/x.21 Mode ............................ B-7

Table B-8. Adapter Cable DB25 to X.21, DB15 Connector .............................. B-8

Table B-9. Pinout Connectors for Terminal Interface ...................................... B-8

Table B-10. 10BaseT Pinout ................................................................................... B-9

61200420L1-1 ESU 120e User Manual

xix

List of Tables

xx

ESU 120e User Manual 61200420L1-1

Chapter 1

ESU 120E OVERVIEW

The ESU 120e is an E1/FE1 multiplexer with an Nx56/64 data port,

a drop (PBX) interface, one option slot, and embedded SNMP management. The ESU 120e’s option slot accepts one of many available

option modules for voice and data applications.

The ESU 120e serves as the link between user data sources such as

local area network (LAN) bridges and routers, computers, CAD

systems, teleconferencing equipment, and PBXs. Through the use

of multiple data ports, the ESU 120e can simultaneously connect

one or more of these devices to a E1 circuit. The amount of bandwidth allocated to each port is custom-programmable. You can

manually allocate bandwidth or set the bandwidth to automatically

change at predetermined times to use the available bandwidth

most advantageously. Changes in the configuration do not disrupt

data flow in channels that are not being reconfigured. The unique

architecture and the availability of option modules provides a path

for growth to accommodate future requirements.

Introduction

The ESU 120e offers a wide variety of network management

options. You can manage via SNMP through the 10BaseT or chainin ports. If you are using T-Watch Pro, a Microsoft Windows® program, you can manage the ESU 120e via the same 10BaseT or chainin ports. An enhanced VT-100 terminal interface is also provided.

61200420L1-1 ESU 120e User Manual

1-1

Chapter 1. Introduction

ESU 120e Features

The following list describes the standard features in the ESU 120e.

• A single E1 interface

• An Nx56/64 data port and G.703 drop port interface

• Data port supports V.35, EIA-530, V.36 and X.21 electrical interfaces

• An inband communication channel requiring only 8k of bandwidth from a single TS0

• One option slot to house option modules with up to four additional ports, including voice and data

• Allows mix of port types to meet the data interface requirements.

• Easy configuration capabilities using simplistic menus displayed in a liquid crystal display (LCD) window operated by a

front panel keypad

• Two programmable configuration maps that define the bandwidth allocation between data ports

• Flash memory for software updates

• Selectable timing from the network, from the Nx56/64 or drop

ports, internally, or from a secondary interface

• QRSS; 511 test patterns using Nx option

• Extensive self-test and monitoring provides assurance of proper

operation

• SNMP, Telnet, and T-Watch Pro Management via SLIP or

10BaseT

ESU Option Modules

Some of the option modules available for the ESU 120e are:

• Nx56/64 serial interface. This module provides a V.35 serial interface in either single or dual versions.

• Router module. Integrated IP/IPX Router with 10BaseT interface.

• NxIQ. Provides extensive frame relay and monitoring capabilities.

1-2

ESU 120e User Manual 61200420L1-1

Option Module Architecture

The ESU 120e features a unique architecture that allows the addition of one option module and plug-on board providing an opportunity for growth to accommodate another application.

ESU 120E CONFIGURATION APPLICATIONS

The following examples illustrate possible configurations of

ESU 120e applications.

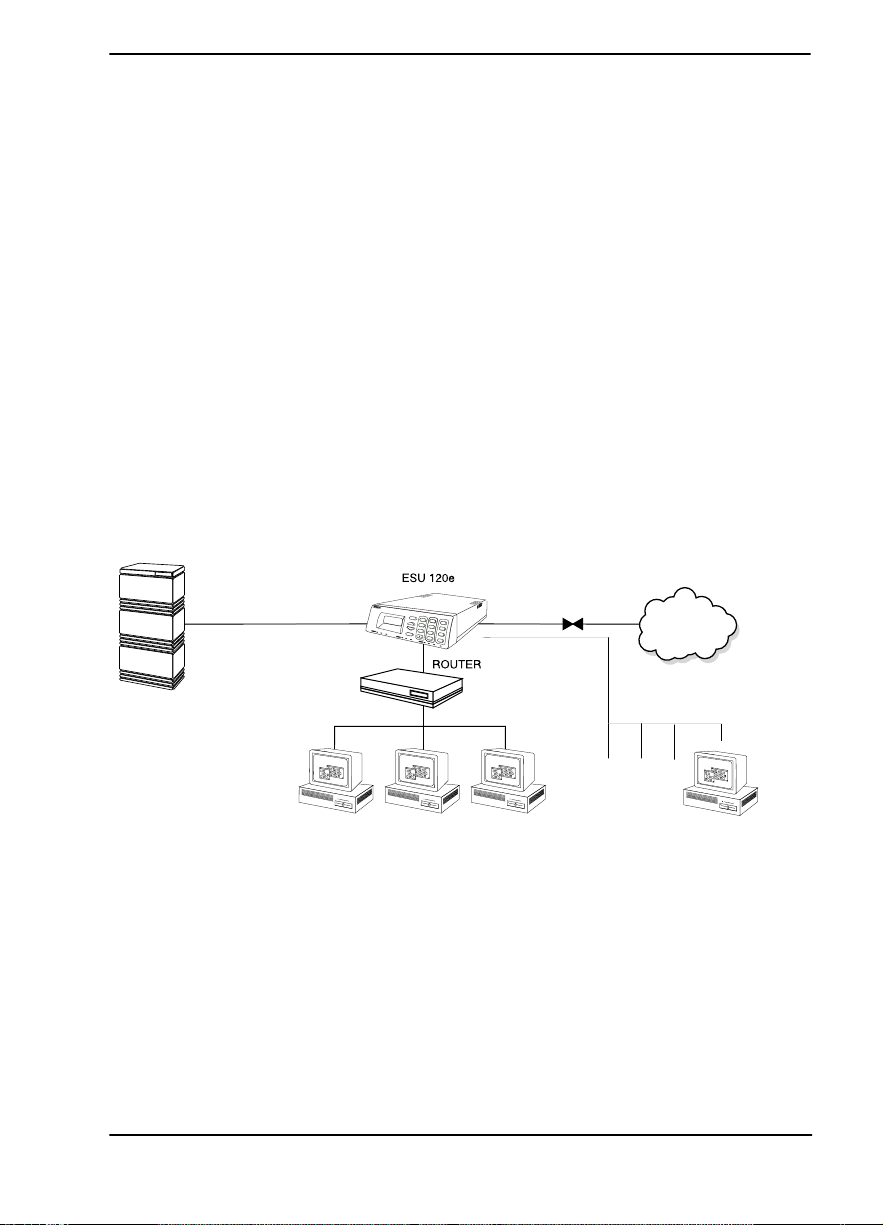

Router, PBX Application

In this application, the base Nx54/64 provides a V.35 interface to a

router. The PBX is interfaced to the ESU 120e with the base drop

interface. The 10BaseT port allows SNMP network management

over the LAN. See Figure 1-1.

PBX

ESU 120e

ENTER

1

2

3

4

5

6

ALARM

7

DSU

/DSX

CLEAR

OK

8

TEST

CANCEL

COPY

9

ALARM

HOME

M

O

DU

L

E

SHIFT

OK

0

TEST

ALARM

#

CSU

OK

TEST

ERROR

ALARM

Chapter 1. Introduction

Figure 1-1. Router, PBX, Application Set Up

61200420L1-1 ESU 120e User Manual

10 BaseT LAN

SNMP NETWORK

MANAGEMENT WORKSTATION

1-3

Chapter 1. Introduction

1-4

ESU 120e User Manual 61200420L1-1

Chapter 2

UNPACK, INSPECT, POWER UP

Receipt Inspection

Carefully inspect the ESU 120e for any shipping damages. If you

suspect damage, file a claim immediately with the carrier and then

contact ADTRAN Customer Service (see inside the last page of this

manual). If possible, keep the original shipping container for use in

shipping the ESU 120e back for repair or for verification of damage

during shipment.

AD TRAN Shipments Include

• The ESU 120e

• A DB-25 to modular adapter for VT-100 and T-Watch access.

• An 8-position modular cable for connection to the chain-in port

(6 ft.)

•The user manual

Installation

Customer Provides

•Power cord

• Cable(s) for connection to either the 120 Ω DB15 or 75 Ω BNC

network interfaces

• Cables for any expansion modules to be used with the ESU 120e

• 10BaseT cable for connection to a LAN or router (if you plan to

use remote management features)

61200420L1-1 ESU 120e User Manual

2-1

Chapter 2. Installation

Power Connection

Power is supplied to the ESU 120e through a IEC-type power connector on the rear of the unit.

Power to the ESU 120e must be from a grounded 90-240 VAC,

50/60Hz source.

GROUND ING INSTRUCTIONS

Grounding instruction information from the Underwriters' Laboratory UL 1950 3rd Edition is provided in this section.

An equipment grounding conductor that is not smaller in size than

the ungrounded branch-circuit supply conductors is to be installed

as part of the circuit that supplies the product or system. Bare, covered, or insulated grounding conductors are acceptable. Individually covered or insulated equipment grounding conductors shall

have a continuous outer finish that is either green, or green with

one or more yellow stripes. The equipment grounding conductor is

to be connected to ground at the service equipment.

2-2

The attachment-plug receptacles in the vicinity of the product or

system are all to be of a grounding type, and the equipment

grounding conductors serving these receptacles are to be connected

to earth ground at the service equipment.

A supplementary equipment grounding conductor shall be

installed between the product or system and ground that is in addition to the equipment grounding conductor in the power supply

cord.

The supplementary equipment grounding conductor shall not be

smaller in size than the ungrounded branch-circuit supply conductors. The supplementary equipment grounding conductor shall be

connected to the product at the terminal provided, and shall be

connected to ground in a manner that will retain the ground connection when the product is unplugged from the receptacle. The

connection to ground of the supplementary equipment grounding

conductor shall be in compliance with the rules for terminating

bonding jumpers at Part K or Article 250 of the National Electrical

ESU 120e User Manual 61200420L1-1

Chapter 2. Installation

Code, ANSI/NFPA 70. Termination of the supplementary equipment grounding conductor is permitted to be made to building

steel, to a metal electrical raceway system, or to any grounded item

that is permanently and reliably connected to the electrical service

equipment ground.

Bare, covered, or insulated grounding conductors are acceptable. A

covered or insulated grounding conductor shall have a continuous

outer finish that is either green, or green with one or more yellow

stripes.

The supplemental grounding conductor shall be connected to he

equipment using a number 8 ring terminal. The terminal should be

fastened to the grounding lug provided on the rear panel of the

equipment. The ring terminal should be installed using the appropriate crimping tool (AMP P/N 59250 T-EAD Crimping Tool or

equivalent).

61200420L1-1 ESU 120e User Manual

2-3

Chapter 2. Installation

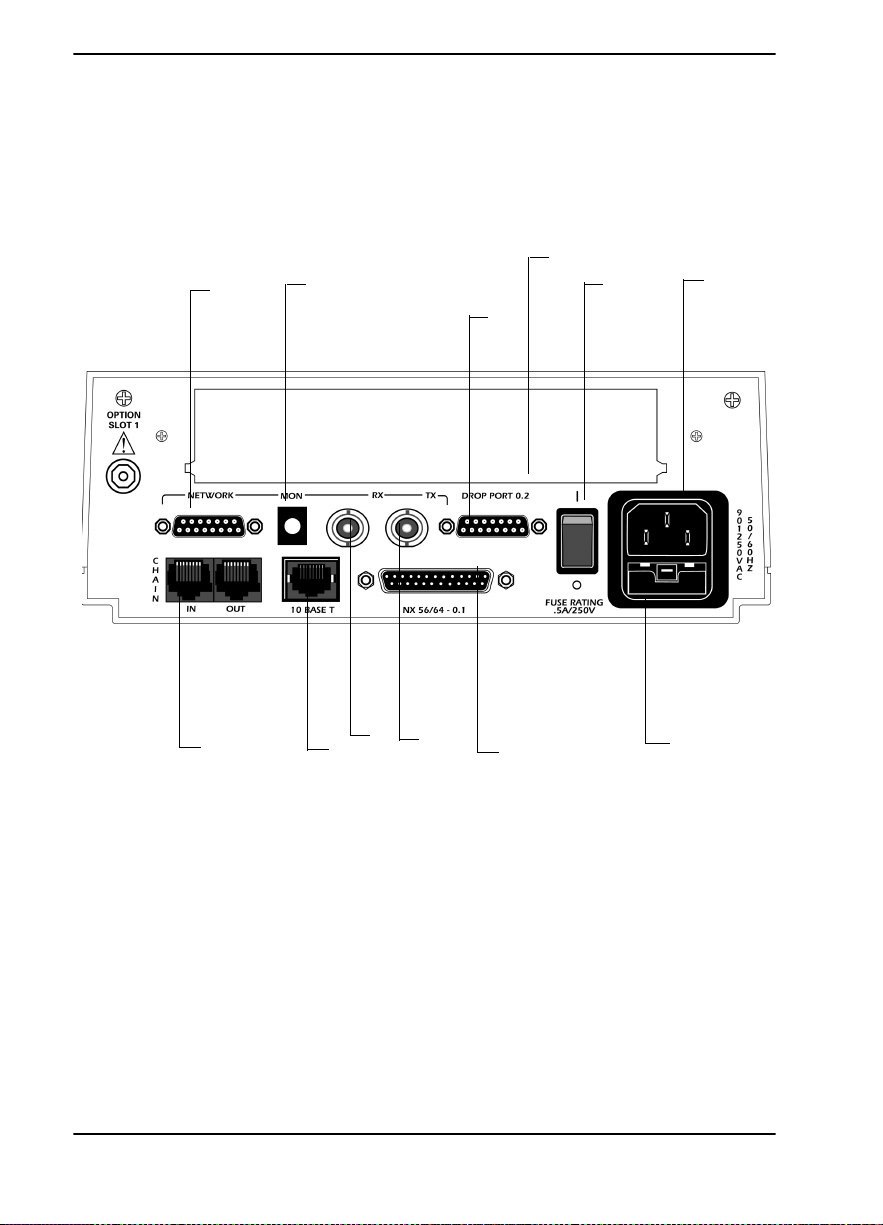

ID ENTIFICATION OF REAR PANEL LAYOUT

Figure 2-1 shows the configuration of the rear panel of the ESU

120e.

4

1

2

3

5

6

12

9

7

8

10

11

1 Network 120 ΩΩΩΩ Connector 7 Control In/Out Connection

2 Network Receive Monitor Jack 8 10BaseT Connector (To LAN for Management)

3 Drop Port Connector (To PBX) 9 Network 75 ΩΩΩΩ Receive Connector

4 Option Slot 10 Network 75 ΩΩΩΩ Transmit Connector

5 Power Switch 11 Data Port Connector

6 IEC Power Connector 12 Fuse Tray

Figure 2-1. ESU 120e Rear Panel

2-4

ESU 120e User Manual 61200420L1-1

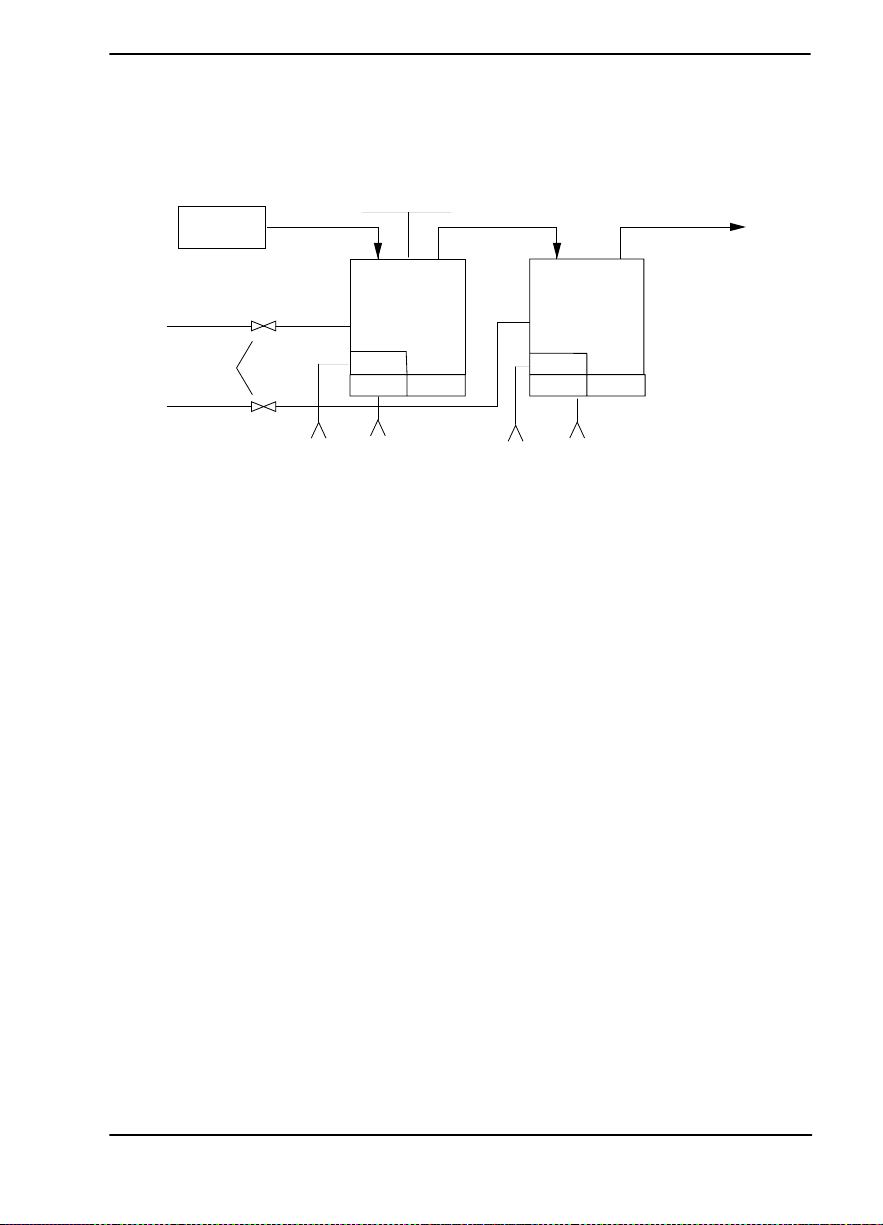

ESU120E INTERFACES

The ESU 120e is equipped with an Nx56/64 data port, a G.703 drop

interface, an option slot, management interfaces, and an E1 interface in the rear panel. See Figure 2-2.

PC or Modem

Chapter 2. Installation

10BaseT LAN

Network

PBX

Figure 2-2. ESU 120e Interfaces

Network Interfaces

The Network Interface (NI) port provides the connection to the E1.

This port complies with the applicable ANSI and CCITT standards.

Either the 120Ω DB15 or the 75Ω BNC interface may be used for

the Network Interface. The 75/120 selection must be made with

the front panel menus. For more information see Wiring on page B-

1.

Network Test Interface

Control

NI

Drop

Nx56/64 Nx56/64

RS530, V.11

Chain

Input

Output

ESU 120e

Option Option

V.35

PBX-1

Chain

Input

NI

Drop

RS530, V.11

Output

ESU 120e

V.35

Chain

The MON test jack provides a bridged access jack for non-intrusive

monitoring of the incoming E1.

Nx56/ 64 Serial Interface

The Nx56/64 provides a serial interface that operates from 56kbps

to 1.984Mbps. The Nx56/64 can be configured as a V.35, V.36, EIA530, or V.11 electrical interface through the front panel menus. This

port provides 511 pattern generation and detection, as well as

remote loopback capability.

61200420L1-1 ESU 120e User Manual

2-5

Chapter 2. Installation

D rop (PBX) Interface

The drop interface provides a G.703 interface for a PBX or other

equipment.

Control Port Input

The control port input provides an EIA-232 input from a PC or a

modem for control of the ESU 120e. You can also use it as a chain

input from another ESU 120e or ESU 100. For more information see

Wiring on page B-1.

Chain Port Output

The chain port output provides an EIA-232 output to chain control

to other ESU 120es. For more information see Wiring on page B-1.

10BaseT Interface

The 10BaseT interface provides the LAN interface for managing the

ESU 120e with SNMP or T-Watch Pro. For more information see

Wiring on page B-1.

POWER-UP TESTING

When shipped from the factory, the ESU 120e is set to factory

default conditions. At the first application of power, the unit automatically executes a memory self-test. A full self-test can be run

from the front panel, and a pass code and unit ID may be set using

the UTIL menu.

Self-Test

Upon a power-up, the LCD displays

and the Test LEDs are illuminated. When the self-test is completed

with no failures detected, the OK LED lights up and the LCD

momentarily displays

list of failures is displayed in the LCD window. The full self-test

procedure (invoked from the front panel or T-Watch PRO) consists

of the following tests:

2-6

Memory Test Now Testing

All Tests Passed

ESU 120e User Manual 61200420L1-1

. If a failure is detected, a

Loading...

Loading...