Page 1

TSU 600

&

TSU 600e

User Manual

Part Numbers

1202076L1

1202076L1#DC

1202076L2

1202076L2#DC

October 1998

61202076L1-1C

Page 2

Trademarks:

Windows is a registered trademark of Microsoft Corp.

T-Watch is a trademark of ADTRAN, Inc.

SLC96 is a registered trademark of AT&T

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

Phone: (256) 963-8000

© 1998 ADTRAN, Inc.

All rights reserved.

Printed in USA.

Page 3

YEAR 2000 Compliance

All ADTRAN transmission hardware and software products have been tested

and found to be fully compliant with the YEAR 2000 requirements. This is true

for all models and revisions regardless of the date of manufacture or delivery.

Users who wish to independently verify that specific products are in compliance may contact ADTRAN Technical Support at 1-888-423-8726 for additional

information

Page 4

FCC REGULATIONS REQUIRE THAT THE FOLLOWING INFORMATION BE

PROVIDED TO THE CUSTOMER IN THIS MANUAL

1. This equipment complies with Part 68 of the FCC rules. The required

label is attached to the bottom of the chassis.

2. An FCC compliant telephone cord and modular plug is provided

with this equipment. This equipment is designed to be connected to

the telephone network or premises wiring using a compatible modular jack which is Part 68 compliant. See installation instructions for

details.

3. If your Product causes harm to the telephone network, the Telephone

Company may discontinue your service temporarily. If possible,

they will notify you in advance. If advance notice is not practical, you

will be notified as soon as possible. You will be advised of your right

to file a complaint with the FCC.

4. Your telephone company may make changes in its facilities, equipment, operations, or procedures that could affect the proper operation of your equipment. If they do, you will be given advance notice

so as to give you an opportunity to maintain uninterrupted service.

5. If you experience trouble with the equipment Product, please contact

ADTRAN at (256) 963-8000 for repair/warranty information. The

telephone company may ask you to disconnect this equipment from

the network until the problem has been corrected, or until you are

sure the equipment is not malfunctioning.

6. This unit contains no user serviceable parts.

7. The following information may be required when applying to your

local telephone company for leased line facilities.

Service Type REN/SOC FIC USOC

1.544 Mbps -SF 6.0N 04DU9-BN RJ-48C

1.544 Mbps - SF and B8ZS 6.0N 04DU9-DN RJ-48C

1.544 Mbps - ESF 6.0N 04DU9-1KN RJ-48C

1.544 Mbps - ESF and B8ZS 6.0N 04DU9-1SN RJ-48C

Page 5

FEDERAL COMMUNICATIONS COMMISSION RADIO FREQUENCY

INTERFERENCE STATEMENT

This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio frequencies. Operation of this

equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his

own expense.

Shielded cables must be used with this unit to ensure compliance with

Class A FCC limits.

Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

Page 6

CANADIAN EMISSIONS REQUIREMENTS

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus as set out in the interference-causing

equipment standard entitled “Digital Apparatus,” ICES-003 of the Department of Communications.

Cet appareil nuerique respecte les limites de bruits radioelectriques applicables aux appareils numeriques de Class A prescrites dans la norme

sur le materiel brouilleur: “Appareils Numeriques,” NMB-003 edictee

par le ministre des Communications.

Page 7

CANADIAN EQUIPMENT LIMITATIONS

The Industry Canada Certification label identifies certified equipment.

This certification means that the equipment meets certain telecommunications network protective, operational, and safety requirements.

The Department does not guarantee the equipment will operate to the

user's satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local telecommunications company. The equipment must also be installed using an acceptable method

of connection. In some cases, the company's inside wiring associated

with a single line individual service may be extended by means of a certified connector assembly (telephone extension cord). The customer

should be aware that compliance with the above conditions may not

prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the supplier. Any repairs or alterations made by the user to this equipment, or equipment

malfunctions, may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines and internal metallic

waterpipe system, if present, are connected together. This precaution

may be particularly important in rural areas.

Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection authority, or an electrician, as appropriate.

The Load Number (LN) assigned to each terminal device denotes the

percentage of the total load to be connected to a telephone loop which is

used by the device, to prevent overloading. The termination on a loop

may consist of any combination of devices subject only to the equipment

that the total of the LNs of all devices does not exceed 100.

The ringer equivalence number (REN) assigned to each terminal adapter is used to determine the total number of devices that may be connected to each circuit. The sum of the RENs from all devices in the circuit

should not exceed a total of 5.0.

Page 8

AFFIDAVIT REQUIREMENTS FOR CONNECTION

TO DIGITAL SERVICES

• An affidavit is required to be given to the telephone company whenever digital terminal equipment without encoded analog content and

billing protection is used to transmit digital signals containing encoded analog content which are intended for eventual conversion into

voiceband analog signals and transmitted on the network.

• The affidavit shall affirm that either no encoded analog content or

billing information is being transmitted or that the output of the device meets Part 68 encoded analog content or billing protection specifications.

• End user/customer will be responsible to file an affidavit with the local exchange carrier when connecting unprotected CPE to a 1.544

Mbps or subrate digital services.

• Until such time as subrate digital terminal equipment is registered for

voice applications, the affidavit requirement for subrate services is

waived.

Page 9

AFFIDAVIT FOR CONNECTION OF CUSTOMER PREMISES

EQUIPMENT TO 1.544 MBPS AND/OR SUBRATE DIGITAL SERVICES

For the work to be performed in the certified territory of

______________________________(telco name)

State of _________________________________

County of ________________________________

I, ___________________________________ (name),

(business address), ______________________ (telephone number) being

duly sworn, state:

I have responsibility for the operation and maintenance of the terminal

equipment to be connected to 1.544 Mbps and/or ________ subrate digital services. The terminal equipment to be connected complies with

Part 68 of the FCC rules except for the encoded analog content and billing protection specifications. With respect to encoded analog content

and billing protection:

( ) I attest that all operations associated with the establishment, maintenance, and adjustment of the digital CPE with respect to analog content and encoded billing protection information continuously complies

with Part 68 of the FCC Rules and Regulations.

( ) The digital CPE does not transmit digital signals containing encoded

analog content or billing information which is intended to be decoded

within the telecommunications network.

( ) The encoded analog content and billing protection is factory set and

is not under the control of the customer.

I attest that the operator(s)/maintainer(s) of the digital CPE responsible

for the establishment, maintenance, and adjustment of the encoded analog content and billing information has (have) been trained to perform

these functions by successfully having completed one of the following

(check appropriate blocks):

( ) A. A training course provided by the manufacturer/grantee of the

equipment used to encode analog signals; or

Page 10

( ) B. A training course provided by the customer or authorized representative, using training materials and instructions provided by the

manufacturer/grantee of the equipment used to encode analog signals;

or

( ) C. An independent training course (e.g., trade school or technical

institution) recognized by the manufacturer/grantee of the equipment

used to encode analog signals; or

( ) D. In lieu of the preceding training requirements, the operator(s)/

maintainer(s) is (are) under the control of a supervisor trained in accordance with _________ (circle one) above.

I agree to provide _________________ (telco's name) with proper documentation to demonstrate compliance with the information as provided

in the preceding paragraph, if so requested.

_________________________________Signature

_________________________________Title

_________________________________ Date

Transcribed and sworn to before me

This ________ day of ________, 199___

_________________________________

Notary Public

My commission expires:

_________________________________

Page 11

IMPORTANT SAFETY INSTRUCTIONS

When using your telephone equipment, please follow these basic safety

precautions to reduce the risk of fire, electrical shock, or personal injury:

1 Do not use this product near water, such as near a bath tub,

wash bowl, kitchen sink, laundry tub, in a wet basement,

or near a swimming pool.

2 Avoid using a telephone (other than a cordless-type) dur-

ing an electrical storm. There is a remote risk of shock from

lightning.

3 Do not use the telephone to report a gas leak in the vicinity

of the leak.

4 Use only the power cord, power supply, and/or batteries

indicated in the manual. Do not dispose of batteries in a

fire. They may explode. Check with local codes for special

disposal instructions.

Page 12

Warranty and Customer Service

ADTRAN will replace or repair this product within five years from the

date of shipment if the product does not meet its published specifications or if it fails while in service. For detailed warranty, repair, and return information refer to the ADTRAN Equipment Warranty and Repair

and Return Policy Procedure.

Return Material Authorization (RMA) is required prior to returning

equipment to ADTRAN.

For Service, RMA requests, or more information, contact ADTRAN Customer Service listed on the inside back cover of this manual.

Page 13

Table of Contents

Chapter 1 Introduction .......................................................................................... 1-1

TSU 600 Overview .................................................................................................... 1-1

Product Description.......................................................................................... 1-1

Standard Features in the TSU 600................................................................... 1-2

TSU Option Modules........................................................................................ 1-3

Option Module Architecture ........................................................................... 1-4

TSU 600 Configuration Applications .................................................................... 1-5

Router, PBX, Video Conferencing Application............................................. 1-5

Drop and Insert, Voice, and Router Application.......................................... 1-6

Chapter 2 Installation ............................................................................................ 2-1

Unpack, Inspect, Power Up .................................................................................... 2-1

Receipt Inspection ............................................................................................. 2-1

ADTRAN Shipments Include.......................................................................... 2-1

Customer Provides............................................................................................ 2-1

Power Connection............................................................................................. 2-2

DC Powered Units ..................................................................................... 2-2

Backup Power Supply (600e only) ...........................................................2-2

Installing and Replacing the Power Supply ................................... 2-3

Grounding Instructions ...........................................................................................2-4

Identification of Rear Panel Layout ....................................................................... 2-5

TSU 600 Interfaces............................................................................................. 2-9

Network Interface ...................................................................................... 2-9

Network Test Interface .............................................................................. 2-9

Control Port Input ...................................................................................... 2-9

Chain Port Output ..................................................................................... 2-9

10BaseT Interface (600e only) ................................................................. 2-10

Option Slot Arrangement............................................................................... 2-10

Power-up Testing ............................................................................................ 2-11

Self-Test ..................................................................................................... 2-11

Board level tests ................................................................................ 2-12

Unit level tests ................................................................................... 2-12

Initialization ..................................................................................................... 2-12

61202076L1-1 TSU 600 User Manual i

Page 14

Table of Contents

Set User Passcode ..................................................................................... 2-12

Set Unit Identification ..............................................................................2-12

Set Control Port ........................................................................................2-13

Chain-In (PC) ............................................................................................2-13

Chain In/Chain Out ................................................................................2-13

Normal Power-Up Procedure........................................................................ 2-14

Chapter 3 Operation ............................................................................................... 3-1

Front Panel .................................................................................................................3-1

CSU Status LEDs ............................................................................................... 3-2

Module Status LEDs ......................................................................................... 3-3

Operation Keys .................................................................................................. 3-5

General Menu Operation .......................................................................... 3-5

Selecting and Activating a Menu Item .................................................... 3-6

Editing the Data Field ................................................................................3-7

Display Only Data Fields ..........................................................................3-8

Exit Any Menu Field Operation Or Display ..........................................3-8

Data Port Identification .................................................................................... 3-9

Front Panel Menu Structure........................................................................... 3-10

Alternate Methods of Control........................................................................ 3-11

T-Watch PRO (ADTRAN PC Program) ................................................ 3-11

T-Watch PRO/LAN Connection .................................................... 3-11

T-Watch PRO/EIA-232 Connection............................................... 3-12

SNMP ......................................................................................................... 3-12

Terminal Mode Connection .................................................................... 3-13

Telnet Connection .................................................................................... 3-13

Chapter 4 Status Menu ..........................................................................................4-1

Network Performance Reports (NI PERF RPTS) .......................................... 4-2

Network Interface Errors (NI ERRORS) ........................................................ 4-3

Active Alarms .................................................................................................... 4-4

View History ...................................................................................................... 4-4

Port Status........................................................................................................... 4-5

Remote Port ........................................................................................................ 4-5

Clear Port Alarm................................................................................................ 4-5

ENET Status (600e only)................................................................................... 4-6

PS Status (600e only)......................................................................................... 4-6

Chapter 5 Configuration Menu ............................................................................5-1

Network (NI) ............................................................................................................. 5-2

Network (NI) Menu Items ............................................................................... 5-2

TSU 600 Clock Sources ..................................................................................... 5-4

Network Timing .........................................................................................5-4

DTE Timing ................................................................................................. 5-5

U-BR1TE (Slot 1) ......................................................................................... 5-5

ii TSU 600 User Manual 61202076L1-1

Page 15

Table of Contents

Internal Timing ...........................................................................................5-6

Secondary Timing ...................................................................................... 5-7

Normal (CSU) Timing ............................................................................... 5-8

Unit Menu .......................................................................................................... 5-9

Map Exchange (Map Xchng) Menu ............................................................. 5-11

MAP In Use: A(B) Menu ............................................................................... 5-11

DS0 Map A and DS0 Map B Menu .............................................................. 5-12

Create Temp Example ............................................................................. 5-13

Port Configuration (Port Config) ................................................................. 5-15

Chapter 6 Utility Menu ......................................................................................... 6-1

Time/Date.......................................................................................................... 6-2

Factory Restore .................................................................................................. 6-2

Set Passcode ....................................................................................................... 6-2

Enter Passcode from Other Menus .......................................................... 6-2

Change/Set a Passcode ............................................................................. 6-3

Automatic Time-out Feature .................................................................... 6-3

No Passcode Desired ................................................................................. 6-3

Unit ID ................................................................................................................ 6-3

Setting the Unit Identification .................................................................. 6-4

No Unit ID Desired .................................................................................... 6-4

Software Revision (Software Rev) .................................................................. 6-4

Port Utility.......................................................................................................... 6-4

ENET Address (600e only)............................................................................... 6-4

CMD Mode......................................................................................................... 6-4

Chapter 7 Test Menu .............................................................................................. 7-1

Network Tests.................................................................................................... 7-2

Loopback Tests ...........................................................................................7-2

Network Interface Loopbacks........................................................... 7-3

Local Loopbck.................................................................................................... 7-3

Remote Loopbk.................................................................................................. 7-4

Test Pattern ....................................................................................................... 7-5

QRSS Pattern ............................................................................................... 7-5

Pattern Result..................................................................................................... 7-6

Run Self-Test ...................................................................................................... 7-7

Board level tests ......................................................................................... 7-7

Unit level tests ............................................................................................ 7-7

Port Tests ............................................................................................................ 7-8

Cancel Tests........................................................................................................ 7-8

Chapter 8 Telnet/Terminal Menus ...................................................................... 8-1

Main Menu ................................................................................................................ 8-1

Status, Config, Util, and Test Menu Options ................................................ 8-2

DS0 Maps Configuration Menu ............................................................... 8-2

61202076L1-1 TSU 600 User Manual iii

Page 16

Table of Contents

Initializing the Temp Map ................................................................. 8-3

Editing the Temp Map ....................................................................... 8-4

Applying the Temp Map ................................................................... 8-4

Reviewing Maps.................................................................................. 8-4

Remote Menu Access ........................................................................................ 8-5

Management Configuration............................................................................. 8-5

Unit Access Table ....................................................................................... 8-5

Add New Unit..................................................................................... 8-6

Modify Unit ......................................................................................... 8-6

Delete Unit ........................................................................................... 8-6

Default Unit Passcode ........................................................................ 8-7

OK ......................................................................................................... 8-7

SNMP Read Community.................................................................................. 8-7

SNMP Read/Write Community .............................................................. 8-7

SNMP Trap Community ...........................................................................8-8

System Name ..............................................................................................8-8

System Contact ...........................................................................................8-8

System Location ..........................................................................................8-8

Auto. Fail Traps Sent .................................................................................8-9

Poll Link Status Traps Sent ....................................................................... 8-9

Ping IP Host ................................................................................................8-9

Telnet/Terminal Time-out ........................................................................8-9

Telnet/Terminal Password .......................................................................8-9

Exit ................................................................................................................8-9

Flash Download................................................................................................. 8-9

Quit Session........................................................................................................ 8-9

Appendix A Understanding SNMP ................................................................... A-1

Appendix B Understanding TR-08..................................................................... B-1

Appendix C Network Pinouts ............................................................................. C-1

Appendix D System Messages............................................................................ D-1

Appendix E Specifications.................................................................................... E-1

Index....................................................................................................................Index-1

iv TSU 600 User Manual 61202076L1-1

Page 17

List of Figures

Figure 1-1. TSU 600 Option Modules................................................................... 1-4

Figure 1-2. Router, PBX, Video Conferencing Application Set Up .................. 1-5

Figure 1-3. Drop and Insert, Voice, and Router Application Set Up ............... 1-6

Figure 2-1a. TSU 600 Rear Panel ............................................................................2-5

Figure 2-1b. TSU 600 with DC Power Rear Panel............................................... 2-6

Figure 2-1c. TSU 600e Rear Panel.......................................................................... 2-7

Figure 2-1d. TSU 600e with DC Power Rear Panel............................................. 2-8

Figure 2-2. TSU 600 Interfaces............................................................................... 2-9

Figure 2-3. TSU 600 Slot Designation (Rear View) ........................................... 2-10

Figure 2-4. Example of Chain In.......................................................................... 2-13

Figure 3-1. TSU 600 Front Panel Layout .............................................................. 3-4

Figure 3-2. Example of Basic Front Panel Menu Travel..................................... 3-6

Figure 3-3. Display and Data Fields...................................................................... 3-8

Figure 3-4. Module Slots, TSU 600........................................................................ 3-9

Figure 4-1. Complete Status Menu........................................................................ 4-1

Figure 4-2. Network Interface Performance Report ........................................... 4-2

Figure 4-3. Display of Alarm Messages ............................................................... 4-4

Figure 5-1. Configuration Menu............................................................................ 5-1

Figure 5-2. Network Timed Clock Source............................................................ 5-4

Figure 5-3. DTE Timed Clock Source ................................................................... 5-5

Figure 5-4. Internal Clock Source.......................................................................... 5-6

Figure 5-5. Secondary Clock Source ..................................................................... 5-7

Figure 5-6. Normal (CSU)....................................................................................... 5-8

Figure 5-7. DS0 Map Designations...................................................................... 5-12

Figure 5-8. Create Temp Selection Screen.......................................................... 5-14

Figure 6-1. Utility Menu Tree ................................................................................ 6-1

Figure 7-1. Test Menu ............................................................................................. 7-1

Figure 7-2. Network Loopback Tests.................................................................... 7-3

Figure 8-1. Telnet/Terminal Main Menu............................................................. 8-1

Figure 8-2. DS0 Temp Map .................................................................................... 8-2

Figure 8-3. Unit Access Table ................................................................................ 8-6

61202076L1-1 TSU 600 User Manual v

Page 18

List of Figures

vi TSU 600 User Manual 61202076L1-1

Page 19

List of Tables

Table B-1. Alarm Conditions ................................................................................. B-2

Table B-2. TR-08 DS0 Conversion Table .............................................................. B-3

Table C-1. Network Pinouts.................................................................................. C-1

Table C-2. Control In/Chain In Pinout ............................................................... C-2

Table C-3. Chain-Out Pinout ................................................................................ C-3

Table C-4. 10BaseT Ethernet ................................................................................. C-4

61202076L1-1 TSU 600 User Manual vii

Page 20

List of Tables

viii TSU 600 User Manual 61202076L1-1

Page 21

Chapter 1

TSU 600 OVERVIEW

This manual covers the use of the following products:

• TSU 600

• TSU 600 with DC power

• TSU 600e

• TSU 600e with DC power

Unless otherwise stated, the TSU 600 refers to all four products.

Product Description

The TSU 600 is a T1/FT1 multiplexer with six option slots and embed-

ded SNMP management. The TSU 600’s six option slots accept one of

many available option modules for voice and data applications. Each

module offers up to four ports for a total of 24 possible voice or data

ports.

The TSU 600 serves as the link between user data sources such as:

• local area network (LAN) bridges

•routers,

•computers,

• CAD systems,

• teleconferencing equipment, and

•PBXs.

Introduction

Through the use of multiple data ports, the TSU 600 can simultaneously

connect one or more of these devices to a T1 circuit. The amount of

bandwidth allocated to each port is custom-programmable. You can

manually allocate bandwidth or set the bandwidth to change automati-

cally at predetermined times to use the available bandwidth most ad-

vantageously.

61202076L1-1 TSU 600 User Manual 1-1

Page 22

Chapter 1. Introduction

Changes in the configuration do not disrupt data flow in channels that

are not being reconfigured. The unique architecture and the availability

of option modules provides a path for growth to accommodate future

requirements.

The TSU 600 offers a wide variety of network management options. You

can manage via SNMP through the 10BaseT (600e only) or chain-in

ports. If you are using T-Watch PRO, a Microsoft Windows® program,

you can manage the TSU 600 via the same 10BaseT (600e only) or chainin ports. An enhanced VT-100 terminal interface is also provided.

Standard Features in the TSU 600

The standard features of the TSU 600 are listed below:

•A single T1 interface

• Six slots to house option modules with up to four additional data

ports, including voice

• Architecture that allows mix of port types to meet the data interface

requirements

• Easy configuration capabilities using simplistic menus displayed in a

liquid crystal display (LCD) window operated by a front panel keypad

• SNMP, Telnet, and T-Watch PRO management via SLIP or 10BaseT

(600e only)

• Ability to proxy for “agentless” units

• Enhanced terminal mode

• Support for a redundant AC power supply (600e only)

• Two programmable configuration maps that define the bandwidth

allocation between data ports

• Data drop and insert, as well as full drop and insert

• Flash memory for software updates

• Timing selectable from the network, from the slot 1 data port, inter-

nally, or from a secondary interface

• QRSS; 511 test patterns using Nx option

• Fractional T1 loopbacks as defined in annex B of ANSI T1.403-1995

• Extensive self-testing and monitoring to ensure proper operation

1-2 TSU 600 User Manual 61202076L1-1

Page 23

Chapter 1. Introduction

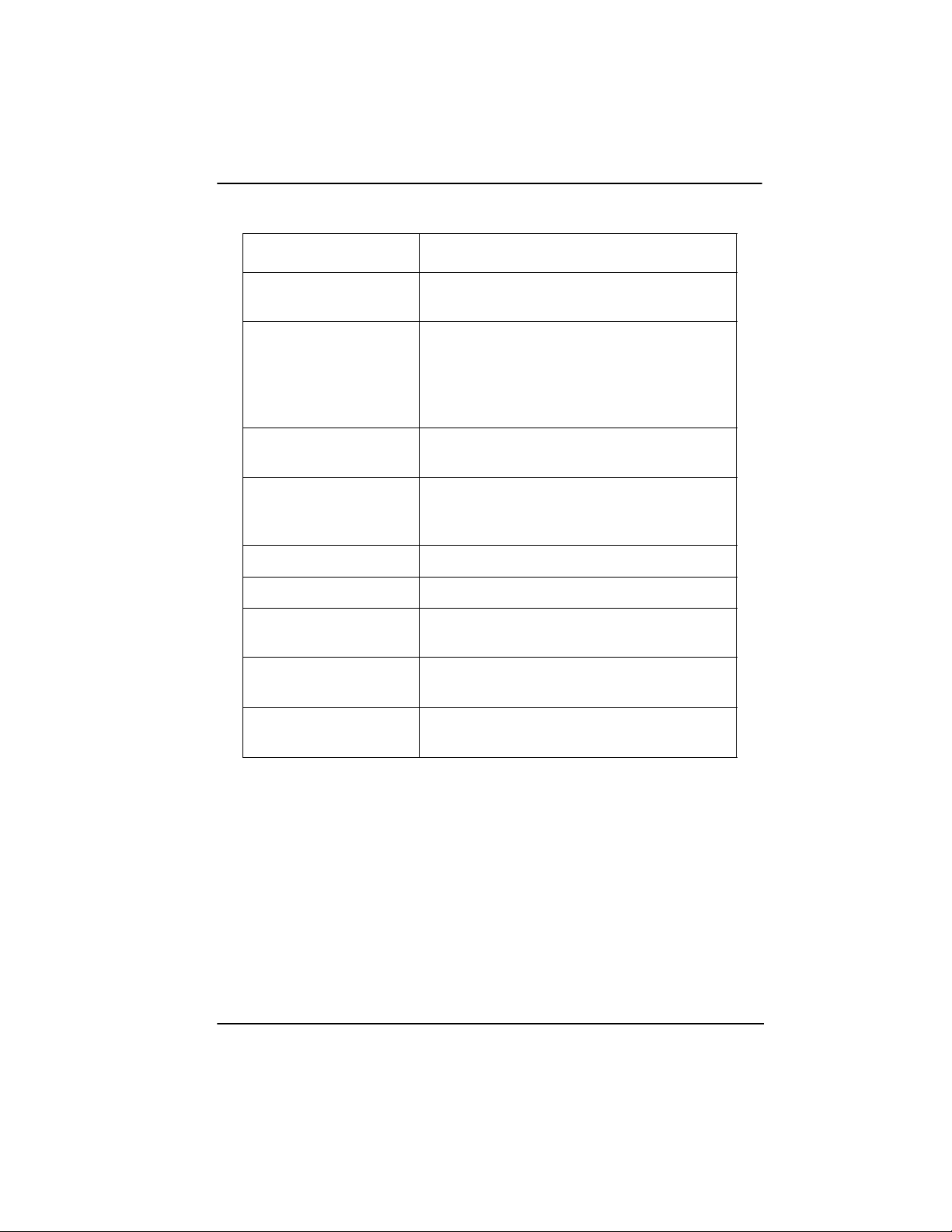

TSU Option Modules

Module Name Description

DSX1 Short haul T1 interface for operation with a

PBX (Terminal Interface).

Full Drop and Insert Permits the dropping of data and insertion of

new data into the same DS0 time slot. This

module includes a long haul DS1 interface. It

can also be used as a second DS1 interface to

provide up to 3 MB aggregate throughput.

Nx56/64 Serial Interface Provides a V.35 serial interface in either sin-

gle or dual versions.

NxIQ Frame-relay aware device that provides

detailed information regarding the health

and performance of the frame relay circuit.

Voice Interface 2/4 channel FXS/FX0/E&M.

OCU DP Interfaces to DDS or 4-wire Switched-56.

DSU DP Provides two sync or async ports (232 or

V.35).

Dial Backup Allows for backup of data upon network T1

failure.

U-BR1TE Allows ISDN lines to be extended over a T1

line.

61202076L1-1 TSU 600 User Manual 1-3

Page 24

Chapter 1. Introduction

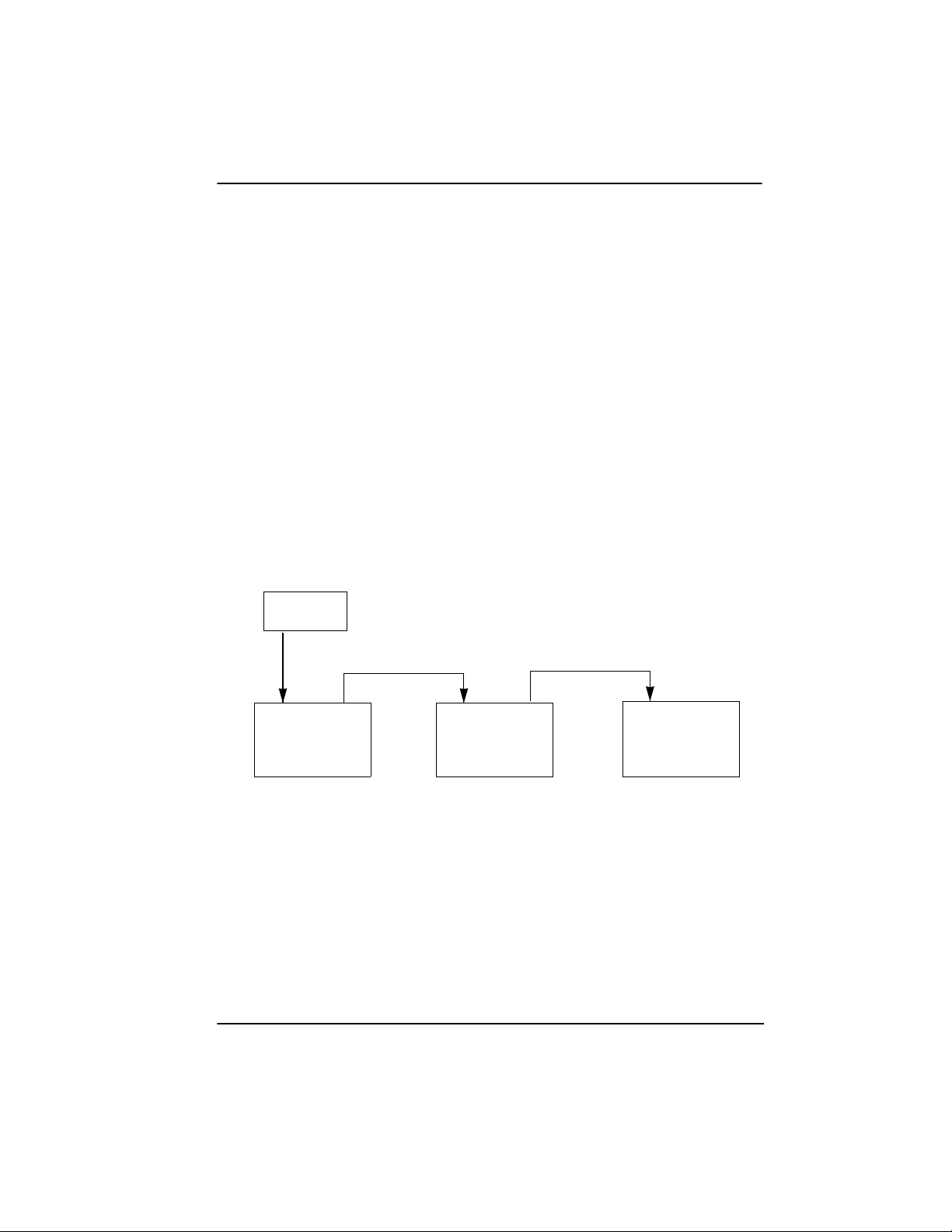

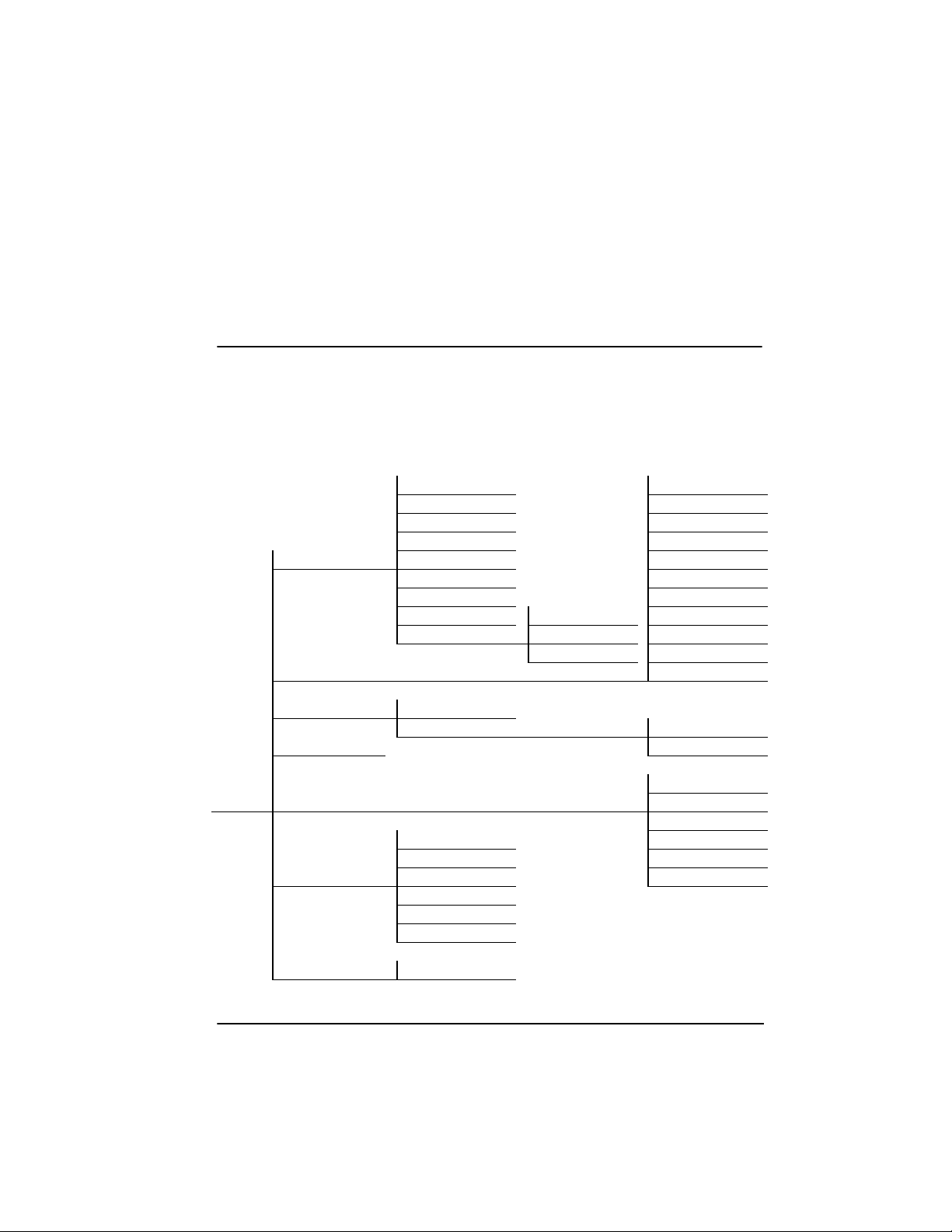

Option Module Architecture

The TSU 600 features a unique architecture that allows the addition of

six option modules and plug-on boards, providing an opportunity for

growth to accommodate many applications. See Figure 1-1. This unique

approach allows you to mix interface types to meet any application.

TSU 600

DSX-1

Module

OCU-DP

Module

V.35

Module

D&I

Module

DUAL

Voice

Plug on

V.35

Plug on

OCU DP

Plug on

Dual Voice

Figure 1-1.

TSU 600 Option Modules

1-4 TSU 600 User Manual 61202076L1-1

Page 25

Chapter 1. Introduction

TSU 600 CONFIGURATION APPLICATIONS

The following examples illustrate possible configurations of TSU 600

applications.

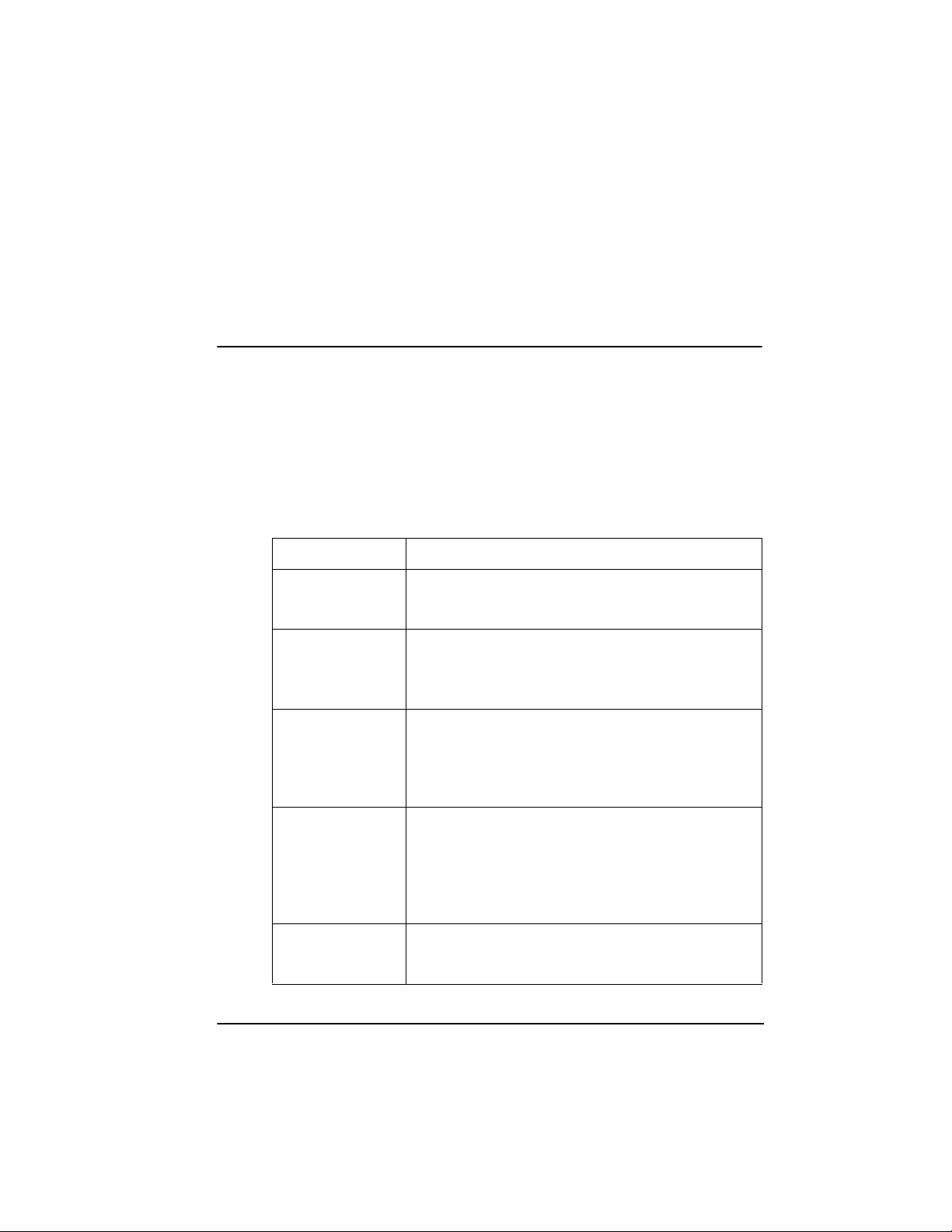

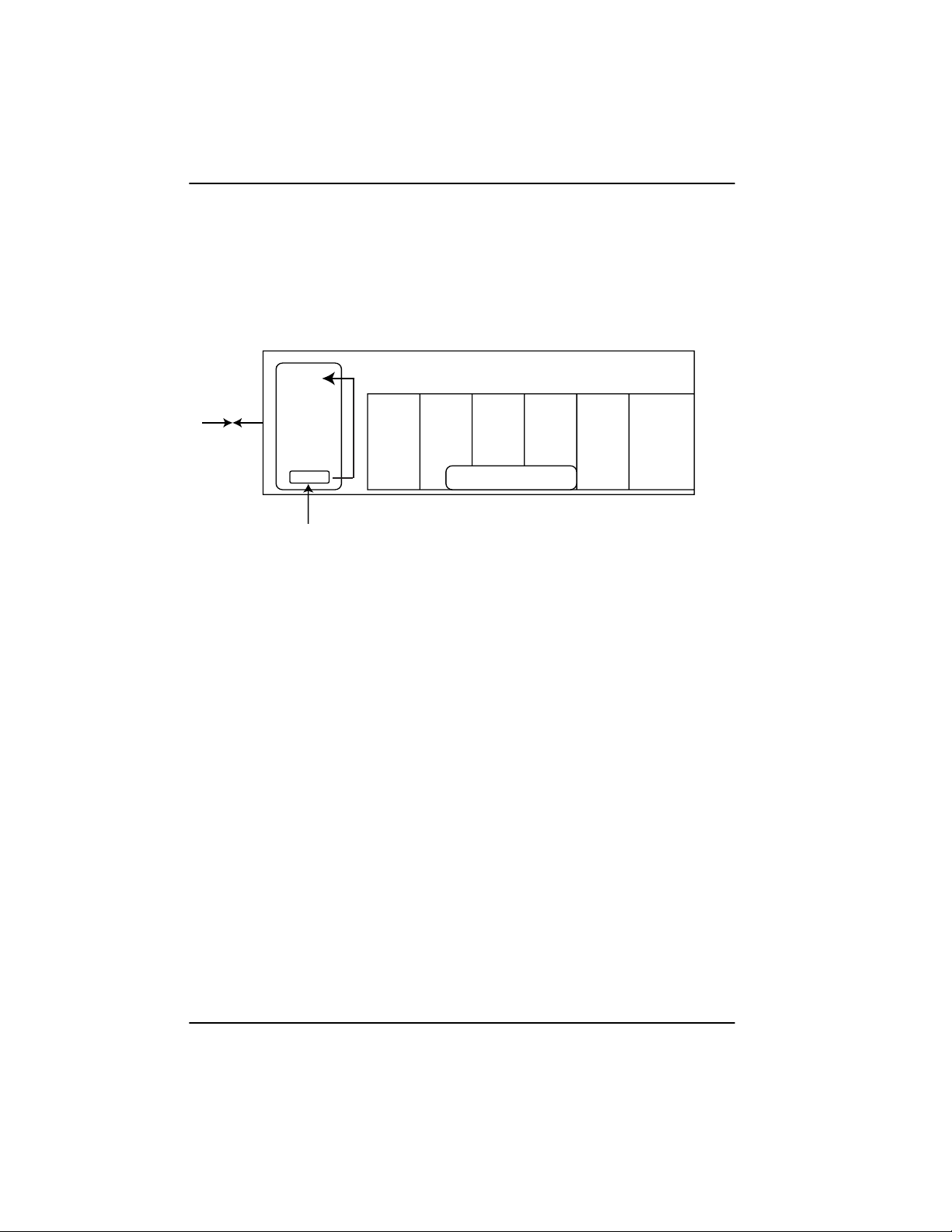

Router, PBX, Video Conferencing Application

In this application, an Nx54/64 module provides a V.35 interface to a

router. The PBX is interfaced to the TSU 600 with the DSX-1 module. An

OCU DP module and OCU DP plug-on board provide two switched 56

circuits for video conferencing. The SLIP port or 10BaseT port (600e

only) allows SNMP network management over the LAN. See Figure 1-2.

PBX

TSU 600

ROUTER

SLIP or 10BaseT (600e only)

VIDEO

CONFERENCING

Figure 1-2.

61202076L1-1 TSU 600 User Manual 1-5

Router, PBX, Video Conferencing Application Set Up

SNMP NETWORK

MANAGEMENT WORKSTATION

Page 26

Chapter 1. Introduction

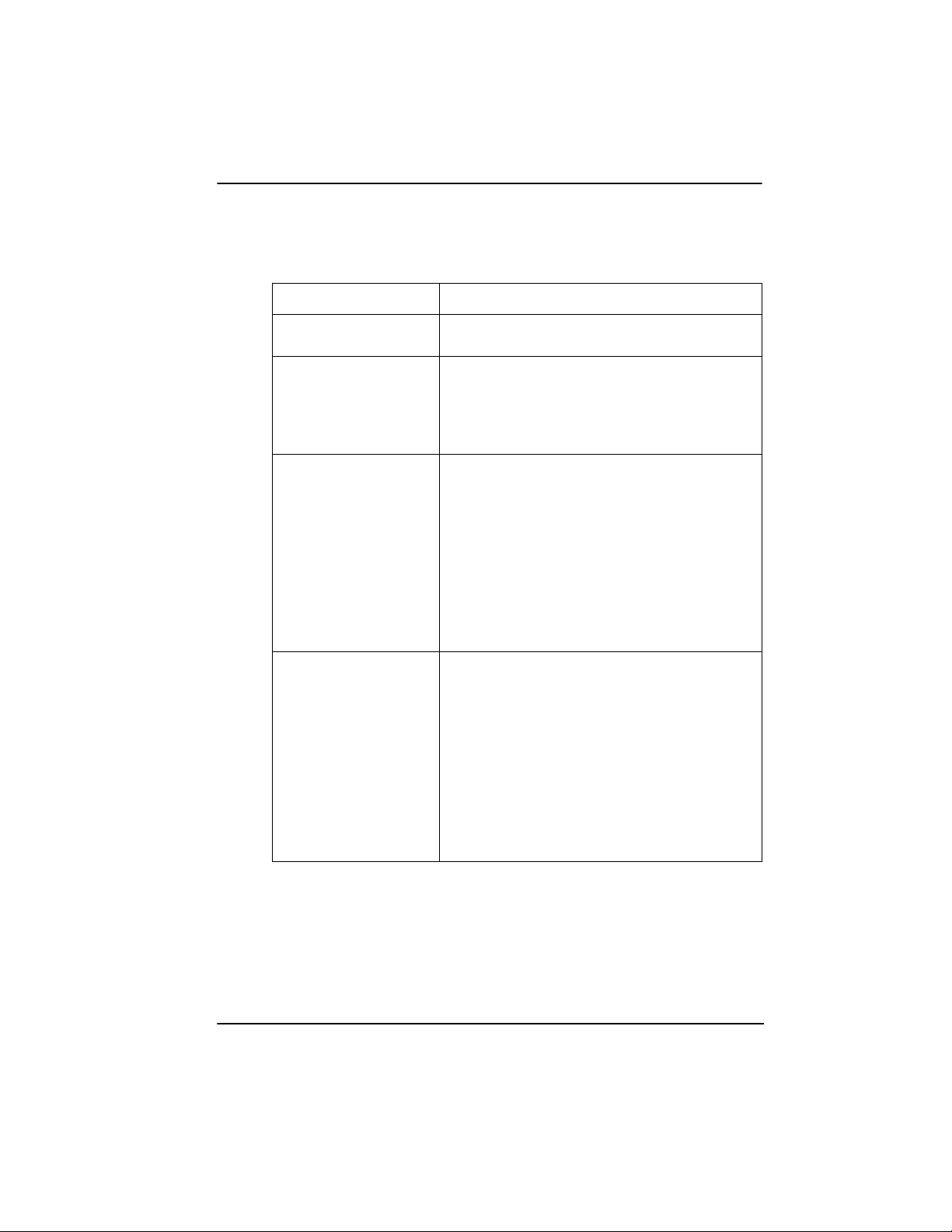

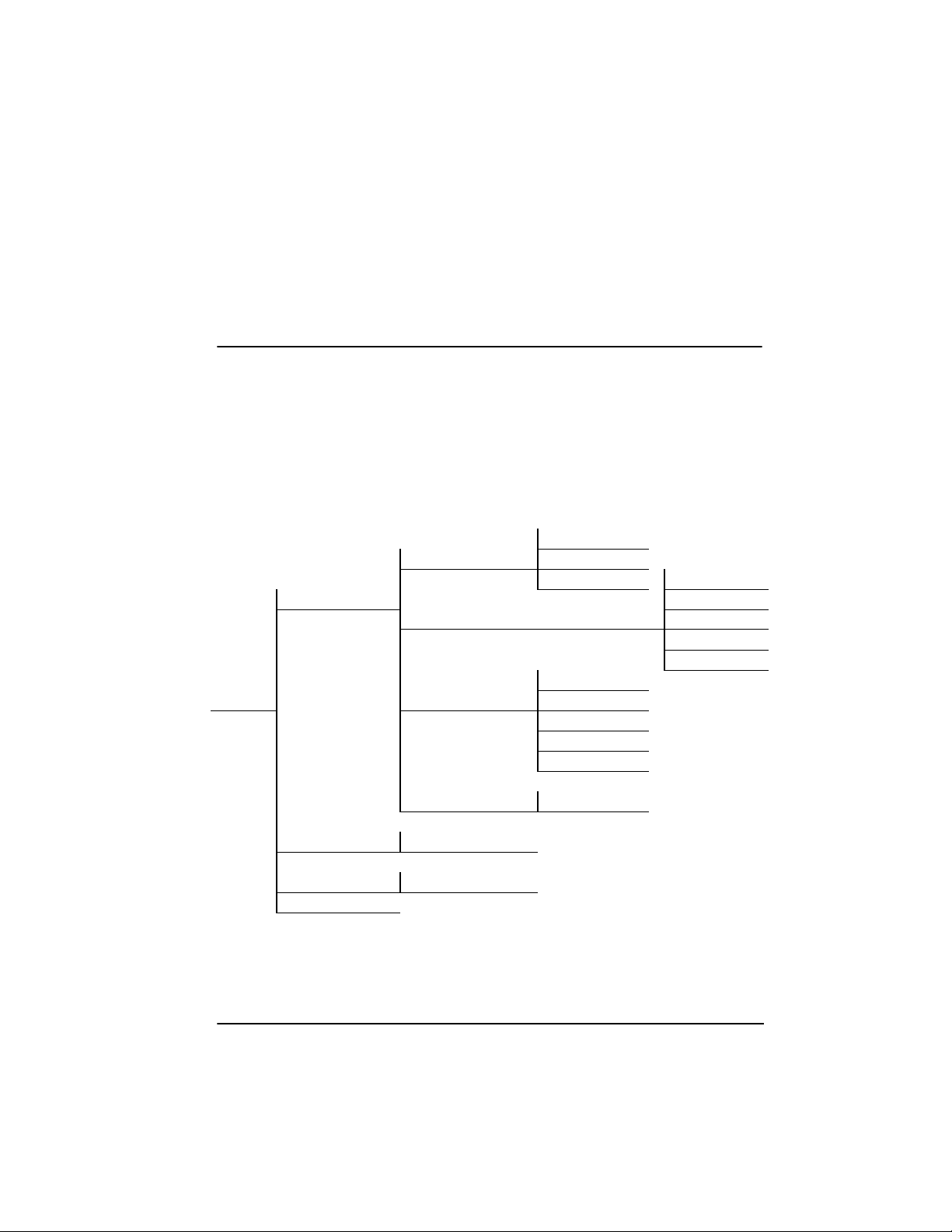

Drop and Insert, Voice, and Router Application

The TSU 600 provides a router interface with an Nx56/64 module. A

drop and insert module provides a second T1 interface to a remote TSU.

T-WATCH PRO (which runs on a PC) easily manages the network. FXO

modules are used to provide PBX extensions to remote sites. See Figure

1-3.

TSU 100

A

B

C

E

N

T

E

R

1

2

3

D

E

F

4

5

6

RE

M

O

TE

ALARM

C

L

E

A

R

7

8

0

ROUTER

T-WATCH

D

S

U

O

K

T

E

S

T

A

M

O

D

L

A

R

M

PBX

9

CO

PY

HOME

C

A

N

C

E

L

SH

IF

T

*

0

#

U

L

E

O

K

T

E

S

T

C

A

S

U

L

A

R

M

O

K

T

E

S

T

E

R

R

O

R

A

L

A

R

M

ROUTER

Figure 1-3.

Drop and Insert, Voice, and Router Application

Set Up

1-6 TSU 600 User Manual 61202076L1-1

Page 27

Chapter 2

UNPACK, INSPECT, POWER UP

Receipt Inspection

Carefully inspect the TSU 600 for shipping damages. If you suspect

damage, file a claim immediately with the carrier and then contact ADTRAN Customer Service (see the inside last page of this manual). If possible, keep the original shipping container for use in shipping the TSU

600 back for repair or for verification of damage during shipment.

ADTRAN Shipments Include

• The TSU 600

• A line interface cable: an 8-position modular to

8-position modular (15 ft.)

• A DB-25 to modular adapter

• An 8-position, 6-foot modular cable for the

Chain-In port connection

•The User Manual

• Rackmount Brackets

• Rackmount Data Sheet

Installation

Customer Provides

• Cables for any expansion modules to be used with the TSU 600

• 10BaseT cable for connection to a LAN or router (if you plan to use

remote management features). This is for 600e only.

61202076L1-1 TSU 600 User Manual 2-1

Page 28

Chapter 2. Installation

Power Connection

The AC- powered TSU 600 is equipped with a captive, 8-foot power

cord, terminated by a 3-prong plug which connects to a grounded power receptacle.

Power to the TSU 600 must be from a grounded 90-120 VAC, 50/

60Hz source.

DC Powered Units

The DC-powered TSU 600 (1202076L1#DC or 1202076L2#DC) is

equipped with a terminal strip on the rear of the unit. The power source

should be connected to the terminal strip according to the polarity markings on the unit.

Example:

A -48V source would be connected with the -48V return attached to the

(+) terminal and the -48VDC attached to the (-) terminal. Power must be

from a DC source in the range of 21 to 26 VDC or in the range of 40 to

56VDC.

The protective cover should be reinstalled over the terminal strip once

the power source is connected.

The DC-powered TSU 600 is to be installed only in restricted areas (dedicated equipment rooms, equipment closets, etc.) in accordance with Articles 110-16 and 110-18 of the National Electric Code, ANSI/NFPA 70.

Backup Power Supply (600e only)

The TSU 600e has two power supply slots on the right side of the chassis.

The base unit is shipped with a single power supply. The TSU 600e is

fully operational with only a single power supply, which may be installed on either the left (power supply A) or the right (power supply B).

You can install a backup supply in the unused slot. The red System

Alarm LED on the front panel will indicate failure of either supply.

2-2 TSU 600 User Manual 61202076L1-1

Page 29

Chapter 2. Installation

Installing and Replacing the Power Supply

The following steps show how to install a new supply or replace a failed

supply.

Power does not have to be turned off on a working supply to add a new supply

or replace a failed one.

Step Action

One Power Supply

1

If only one supply is installed in the chassis, remove the

blank panel covering the unused power supply slot.

Two Power Supplies

If two power supplies are installed, the failed supply can be

identified by the alarm on the front panel LCD. The alarm

message will identify a failure on Power Supply A or Power

Supply B. The option slot legend on the rear panel shows the

location of each power supply. Turn the power switch to Off

on the failed supply and unplug the power cord from the

power source.

Remove the two screws that secure the power supply mod-

2

ule to the TSU 600e chassis and remove the failed power supply module.

Remove the new power supply from the shipping con-

3

tainer. Make sure the power switch is in the

Plug the new supply into the open power supply slot and

4

install the two screws on the power supply module

Plug the new power supply cord into a grounded 115 VAC,

5

50/60 Hz power receptable.

Turn the power switch On.

6

61202076L1-1 TSU 600 User Manual 2-3

Off position.

Page 30

Chapter 2. Installation

GROUNDING INSTRUCTIONS

The grounding instruction information is from the Underwriters' Laboratory UL 1950, 3rd Edition.

An equipment grounding conductor that is not smaller in size than the

ungrounded branch-circuit supply conductors is to be installed as part

of the circuit that supplies the product or system.

• Bare, covered, or insulated grounding conductors are acceptable.

• Individually covered or insulated equipment grounding conductors

shall have a continuous outer finish that is either green, or green with

one or more yellow stripes.

• The equipment grounding conductor is to be connected to ground at

the service equipment.

• The attachment-plug receptacles in the vicinity of the product or system are all to be of a grounding type.

• The equipment grounding conductors serving these receptacles are

to be connected to earth ground at the service equipment.

• A supplementary equipment grounding conductor shall be installed

between the product or system and ground that is in addition to the

equipment grounding conductor in the power-supply cord.

• The supplementary equipment grounding conductor shall not be

smaller in size than the ungrounded branch-circuit supply conductors.

• The supplementary equipment grounding conductor shall be connected to the product at the terminal provided, and shall be connected to ground in a manner that will retain the ground connection

when the product is unplugged from the receptacle.

• The connection to ground of the supplementary equipment grounding conductor shall be in compliance with the rules for terminating

bonding jumpers at Part K or Article 250 of the National Electrical

Code, ANSI/NFPA 70.

• Termination of the supplementary equipment grounding conductor

is permitted to be made to building steel, to a metal electrical raceway

system, or to any grounded item that is permanently and reliably

connected to the electrical service equipment ground.

• The supplemental grounding conductor shall be connected to the

equipment using a number 8 ring terminal.

• The terminal should be fastened to the grounding lug provided on

the rear panel of the equipment.

• The ring terminal should be installed using the appropriate crimping

tool (AMP P/N 59250 T-EAD Crimping Tool or equivalent).

2-4 TSU 600 User Manual 61202076L1-1

Page 31

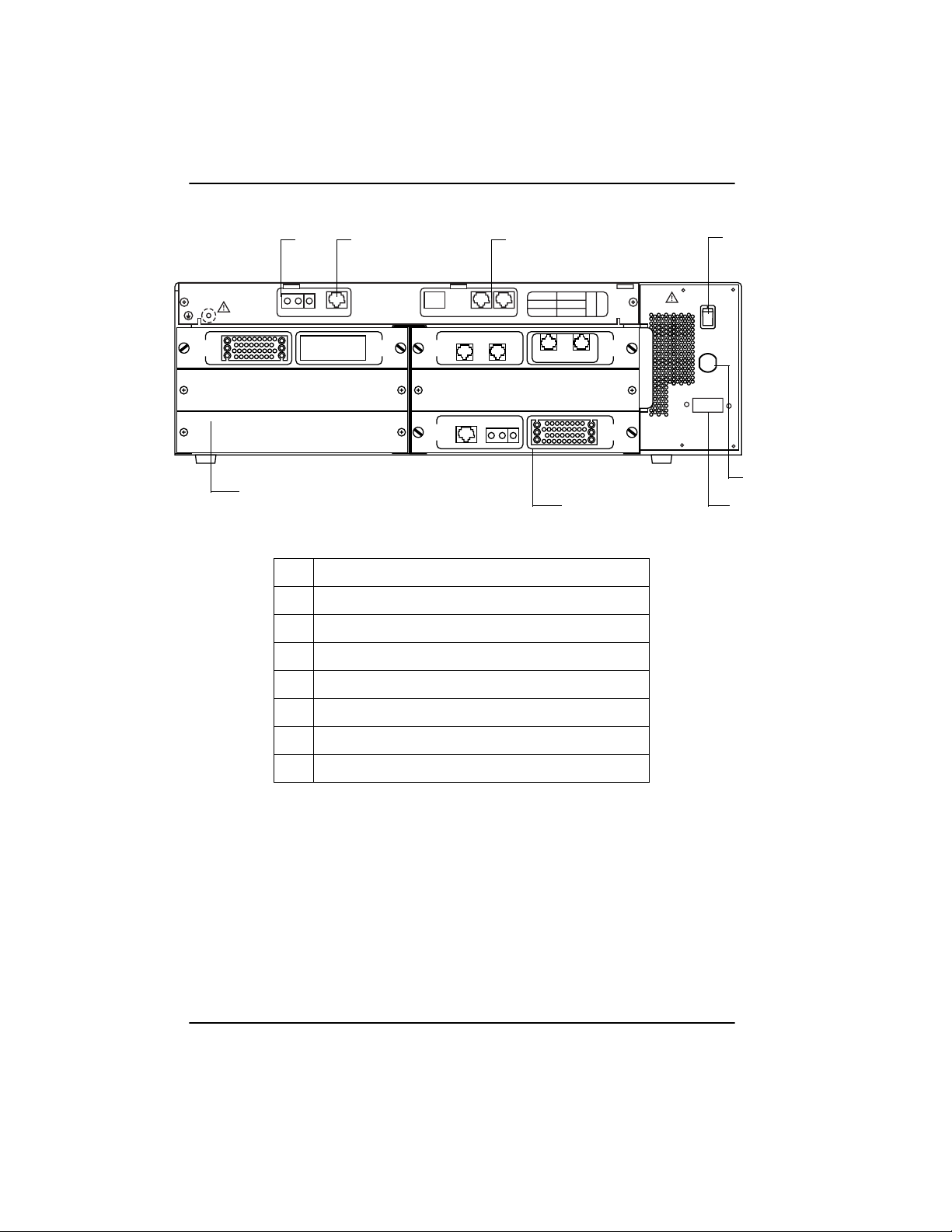

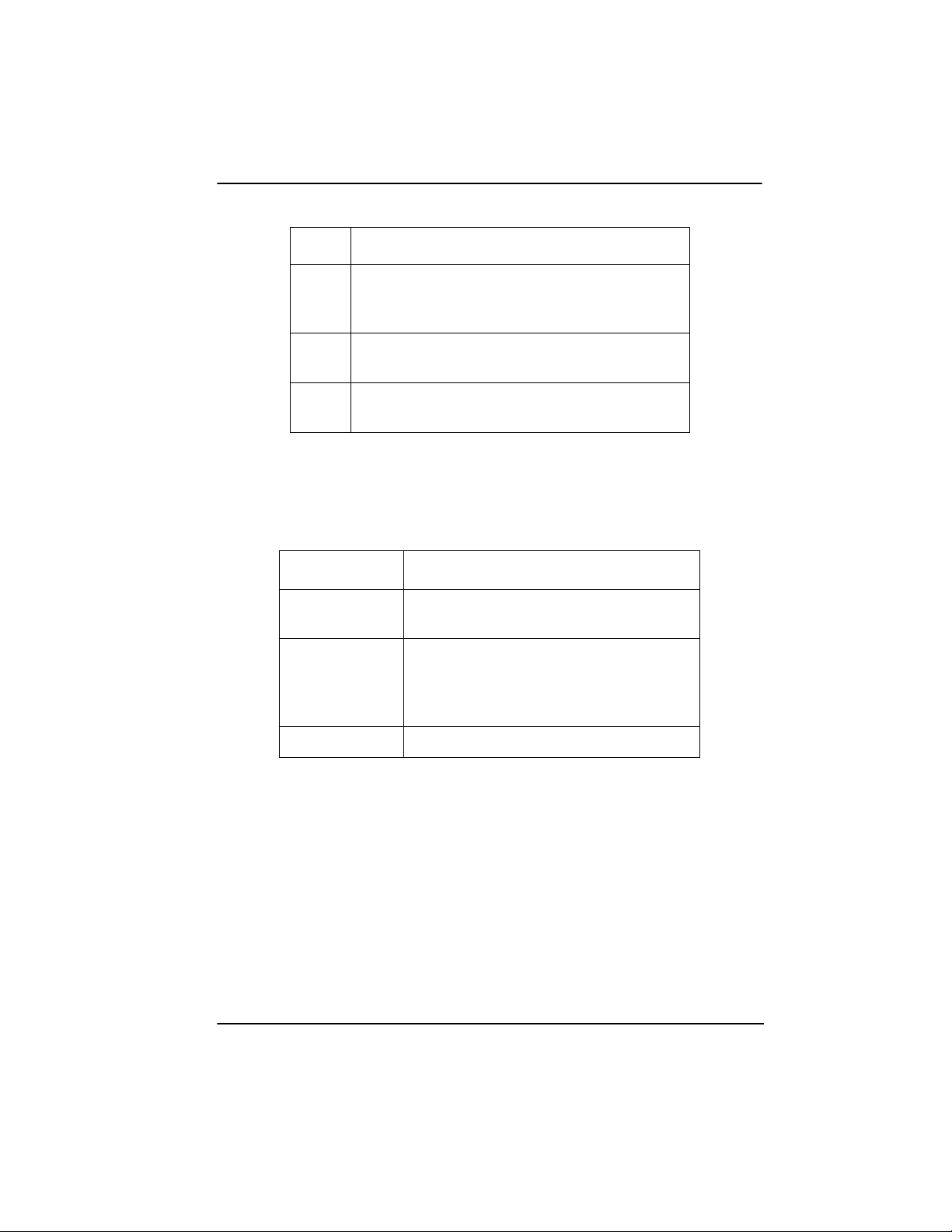

IDENTIFICATION OF REAR PANEL LAYOUT

Figures 2-1a, Figure 2-1b, Figure 2-1c, and Figure 2-1d show the configuration for the rear panels of the TSU 600, TSU 600 with DC Power, TSU

600e, and TSU 600e with DC power.

Chapter 2. Installation

CAUTION-RISK OF

ELECTRIC SHOCK

NX 56/64

PORT X.1

V.35

SUPPLEMENTAL EARTH GROUND MUST BE

CONNECTED PRIOR TO CONNECTION OF

TELECOMMUNICATION WIRING.

1

2

CAUTION:

MAINTENANCE TO BE

PERFORMED BY TRAINED

IN OUT MON NETWORK

SERVICE PERSONEL ONLY

ALL EMPTY SLOTS MUST BE

COVERED WITH BLANK PANELS

NX 56/64

PORT X.2

V.35

10 BASE T

DUAL

FXS

SEC. NI

PORT X.1

5

1T1 Monitor/Test Jacks

2 T1 Network Connection

3 Control In/Out Connection

4Power Switch

CONTROL

/CHAIN

PORT X.1 PORT X.2

DS-1

IN OUT

IN OUT MON

3

MODULE 4

MODULE 1

MODULE 5

MODULE 2

MODULE 6

MODULE 3

DUAL

FXS

PORT X.3 PORT X.4

4

P

P

W

R

A

(600e ONLY)

W

R

B

PORT X.3

NX 56/64

PORT X.2

V.35

SEE MANUAL BEFORE

REMOVING POWER SUPPLY

FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE, REPLACE

ONLY WITH SAME TYPE AND RATING

CAUTION:

OF FUSE

I

O

1A/250V

90-130 VAC

60 HZ

.7A MAX

8

6

7

5 Blank panel covering an unused option slot

6 Example of option modules installed

7Power Cord

8 1A/250V Fuse

Figure 2-1a.

61202076L1-1 TSU 600 User Manual 2-5

TSU 600 Rear Panel

Page 32

Chapter 2. Installation

CAUTION-RISK OF

ELECTRIC SHOCK

NX 56/64

PORT X.1

V.35

SUPPLEMENTAL EARTH GROUND MUST BE

CONNECTED PRIOR TO CONNECTION OF

TELECOMMUNICATION WIRING.

5

1

IN OUT MON NETWORK

2

CAUTION:

MAINTENANCE TO BE

PERFORMED BY TRAINED

SERVICE PERSONEL ONLY

ALL EMPTY SLOTS MUST BE

COVERED WITH BLANK PANELS

NX 56/64

PORT X.2

V.35

10 BASE T

DUAL

FXS

SEC. NI

PORT X.1

CONTROL

/CHAIN

PORT X.1 PORT X.2

DS-1

IN OUT

1 T1 Monitor/Test Jacks

2 T1 Network Connection

3 Control In/Out Connection

4Power Switch

3

IN OUT MON

MODULE 1

MODULE 4

MODULE 2

MODULE 5

MODULE 3

MODULE 6

DUAL

FXS

PORT X.3 PORT X.4

6

P

W

R

A

(600e ONLY)

P

W

R

B

PORT X.3

NX 56/64

PORT X.2

V.35

SEE MANUAL BEFORE

REMOVING POWER SUPPLY

CAUTION:

FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE, REPLACE

ONLY WITH SAME TYPE AND RATING

OF FUSE.

4

I

O

5A/250V

24/48 VDC

+-

8

7

5 Blank panel covering an unused option slot

6 Example of option modules installed

7 Power Input Terminals

8 5A/250V Fuse

Figure 2-1b.

2-6 TSU 600 User Manual 61202076L1-1

TSU 600 with DC Power Rear Panel

Page 33

Chapter 2. Installation

CAUTION-RISK OF

ELECTRIC SHOCK

NX 56/64

PORT X.1

V.35

SUPPLEMENTAL EARTH GROUND MUST BE

CONNECTED PRIOR TO CONNECTION OF

TELECOMMUNICATION WIRING.

6

1

IN OUT MON NETWORK

2

CAUTION:

MAINTENANCE TO BE

PERFORMED BY TRAINED

SERVICE PERSONEL ONLY

ALL EMPTY SLOTS MUST BE

COVERED WITH BLANK PANELS

NX 56/64

PORT X.2

V.35

10 BASE T

DUAL

SEC. NI

PORT X.1

3

CONTROL

/CHAIN

PORT X.1 PORT X.2

FXS

DS-1

1 T1 Monitor/Test Jacks

2 T1 Network Connection

3 10BaseT Connection

IN OUT

IN OUT MON

4

MODULE 1

MODULE 2

MODULE 3

PORT X.3 PORT X.4

MODULE 5

MODULE 6

DUAL

FXS

W

R

A

(600e ONLY)

W

R

B

PORT X.3

NX 56/64

PORT X.2

V.35

SEE MANUAL BEFORE

REMOVING POWER SUPPLY

OIOI

90-120 VAC

P

P

MODULE 4

7 8

50/60 HZ.

.7A MAX

SEE MANUAL BEFORE

REMOVING POWER SUPPLY

90-120 VAC

50/60 HZ.

.7A MAX

5

4 Control In/Out Connection

5Power Switch

6 Blank panel covering an unused option slot

7 Example of option modules installed

8 Power Supply B (if installed)

Figure 2-1c.

61202076L1-1 TSU 600 User Manual 2-7

TSU 600e Rear Panel

Page 34

Chapter 2. Installation

CAUTION-RISK OF

ELECTRIC SHOCK

NX 56/64

PORT X.1

V.35

SUPPLEMENTAL EARTH GROUND MUST BE

CONNECTED PRIOR TO CONNECTION OF

TELECOMMUNICATION WIRING.

7

1

IN OUT MON NETWORK

2

CAUTION:

MAINTENANCE TO BE

PERFORMED BY TRAINED

SERVICE PERSONEL ONLY

ALL EMPTY SLOTS MUST BE

COVERED WITH BLANK PANELS

NX 56/64

PORT X.2

V.35

10 BASE T

DUAL

SEC. NI

PORT X.1

CONTROL

/CHAIN

FXS

DS-1

1 T1 Monitor/Test Jacks

2 T1 Network Connection

3

IN OUT

PORT X.1 PORT X.2

IN OUT MON

4

MODULE 4

MODULE 1

MODULE 5

MODULE 2

MODULE 6

MODULE 3

DUAL

FXS

PORT X.3 PORT X.4

8

P

W

R

A

(600e ONLY)

P

W

R

B

PORT X.3

NX 56/64

PORT X.2

V.35

SEE MANUAL BEFORE

REMOVING POWER SUPPLY

CAUTION:

FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE, REPLACE

ONLY WITH SAME TYPE AND RATING

OF FUSE.

5

6

I

O

5A/250V

24/48 HZ.

+-

9

3 10BaseT Connection

4 Control In/Out Connection

5Power Switch

6 5A/250V Fuse

7 Blank panel covering an unused option slot

8 Example of option modules installed

9 Power Input Terminals

Figure 2-1d.

2-8 TSU 600 User Manual 61202076L1-1

TSU 600e with DC Power Rear Panel

Page 35

TSU 600 Interfaces

The TSU 600 is equipped with six option slots, management interfaces,

and a T1 interface, in the rear panel. See Figure 2-2.

Chapter 2. Installation

Control

Input

NI

LAN

Chain

10BaseT

(600e only)

Output

TSU 600

TSU 600 Interfaces

Chain

Input

NI

TSU 600

Chain

Output

Option

PC or Modem

Network

Figure 2-2.

Network Interface

The network interface (NI) port provides the connection to the T1. This

port complies with the applicable ANSI and AT&T standards. For more

information, see Wiring on page B-1.

Network Test Interface

The

IN and OUT test jacks for the network interface provide intrusive

test capability for the incoming T1. By connecting to these jacks with test

equipment, the T1 connection will be broken, and the test equipment

will terminate the incoming T1. The

MON test jack provides a bridged

access jack for non-intrusive monitoring of the incoming T1. When connected to this jack, the test equipment should be configured for a

bridged termination.

Control Port Input

The control port input provides an EIA-232 input from a PC or a modem

for control of the TSU 600. You can also use it as a chain input from another TSU 600 or TSU 100. For more information, see Wiring on page C-

1.

Chain Port Output

The chain port output provides an EIA-232 output to chain control to

other TSUs. For more information, see Wiring on page C-1.

61202076L1-1 TSU 600 User Manual 2-9

Page 36

Chapter 2. Installation

10BaseT Interface (600e only)

The 10BaseT interface provides the LAN interface for managing the TSU

600e with SNMP or T-watch PRO. For more information, see Wiring on

page C-1.

Option Slot Arrangement

As viewed from the rear of the TSU 600, the slots are numbered as

shown in Figure 2-3. All slots are functionally identical except slots one,

two, and six. These slots offer additional functions.

SLOT 1

DTE TIMING

SLOT 2

DIAL BACKUP

SLOT 3

Figure 2-3.

TSU 600 Slot Designation (Rear View)

SLOT 4

SLOT 5

SLOT 6

SECONDARY INTERFACE

DSX-1; FULL D&I

POWER SUPPLY

Slot 1 Slot 1 is used as the source of DTE timing when the

DTE timing mode is selected or as the source of

UBR1TE timing when the UBR1TE timing mode is

selected. If DTE timing is desired, the DTE interface

port sourcing the timing must be connected to Slot 1.

This slot will accept all other interface types except

Secondary Network interface option modules, including DSX-1 (PBX), the Full Drop and Insert (D&I) network interface, or the multiport Dial Backup (DBU).

Slot 2 Slot 2 is used for the multiport Dial Backup module if

it is installed. This slot accepts all other interface

types except Secondary Network interface option

modules, including DSX-1 (PBX) and the Full Drop

and Insert (D&I) network interface.

2-10 TSU 600 User Manual 61202076L1-1

Page 37

Slots 3-5 Slots 3-5 will accept any interface type except second-

Slot 6 Slot 6 services any option module type including sec-

You can use NxDBU modules in any slot.

Power-up Testing

When shipped from the factory, the TSU 600 is set to factory default conditions. At the first application of power, the unit automatically executes a memory self-test. A full self-test can be run from the front panel,

and a passcode and unit ID may be set using the UTIL menu.

Chapter 2. Installation

ary interface, the interface for DTE timing, or the multiport DBU. If other interfaces have any restriction on

their location, this will be specified in the individual

option card manual (provided with the option cards).

ondary network interface ports (DSX-1 (PBX) and Full

D&I), but not the DTE timing source. If a secondary

network interface port is to be used, it must be

installed in slot 6.

Self-Test

Upon a power-up, the LCD displays

Memory Test Now Testing

and the

Test LEDs are illuminated.

When . . . Then . . .

the self-test is complete

with no failures detected

OK LED lights up and the LCD

the

momentarily displays

All Tests

Passed.

a failure is detected a list of failures is displayed in the

LCD window

61202076L1-1 TSU 600 User Manual 2-11

Page 38

Chapter 2. Installation

The full self-test procedure (invoked from the front panel or

T-Watch PRO) consists of the following tests:

Board level tests

Each of the TSU 600 boards contains an on-board processor which executes a series of tests checking the circuitry on the board.

• RAM and EPROM tests

• Verify on-board circuitry

Unit level tests

• Front panel LED verification

• Board-to-board interface test

A test pattern is sent from the controller through a loopback on all other

boards and checked on the controller. This verifies the data path, clocks,

and control signals for the entire chassis.

Initialization

Set User Passcode

The TSU 600 is designed to operate with or without the use of a passcode. The default condition is without a passcode.

If the unit is to be remotely accessed using T-Watch PRO, you must enter

a passcode. When managing a number of units, the passcode can be the

same for all the units.

The passcode should be a number easily remembered. Once entered,

the passcode is required to access any operation other than viewing. See

Set Passcode on page 6-2.

Set Unit Identification

The Unit ID sets the unit to respond to remote control (controlled by a

device other than the front panel or terminal). If no Unit ID is recorded

it is not possible to operate from any remote control device, including

the local PC for T-Watch PRO or SNMP. See Unit ID on page 6-3 for details.

2-12 TSU 600 User Manual 61202076L1-1

Page 39

Chapter 2. Installation

Set Control Port

The TSU 600 can be configured from the control port when T-Watch

PRO, SNMP, or the terminal interface is being used.

If the control port is to be used, the control port baud rate must also be

selected.

Chain-In (PC)

The unit can be controlled from an external PC connected directly or via

modem to the Chain-In port. When using Chain-In, the selection of the

Control Port baud rate from 9600 (factory default), 1200, 2400, or 4800,

19200, or 38400 must be made using the Unit Configuration menu. Unless locked out externally, the front panel can also control the unit.

Chain In/Chain Out

TSU 600 units and other TSUs can be linked together to form a chain.

Figure 2-4 provides an example of a chain-in arrangement with a PC or

a modem. The first TSU 600 in the chain receives controlling input from

the PC or modem.

PC or Modem

Control

Input

TSU 600

Chain

Out

Figure 2-4.

ChainInChain

Out

TSU 600/

TSU 100/TSU

Example of Chain In

ChainInChain

Out

TSU 600/

TSU 100/TSU

Subsequent TSUs in the chain are in a position to intake information

from another TSU. This in-taking of information from another TSU in

the chain is identified as Chain-In. The baud rate for the chained units

must match that of the first unit.

Unless locked out externally, the front panel can also control the unit.

At this point, the Unit Initialization procedure is concluded. If the unit

is to be configured remotely, there are no additional items necessary to

complete prior to executing remote configuration.

61202076L1-1 TSU 600 User Manual 2-13

Page 40

Chapter 2. Installation

The Passcode, the Unit ID, and the Control Port settings are stored in a

nonvolatile memory. This ensures that they are operable for subsequent

power-up sequences.

Normal Power-Up Procedure

After the unit has been put into operation with the initial power-up and

initialization, subsequent power-up procedure includes only the PowerUp Self-Test followed by the request for a passcode (password) if this

option was selected during initialization.

Use the number keys to key in the previously recorded passcode and

press Enter.

2-14 TSU 600 User Manual 61202076L1-1

Page 41

Chapter 3

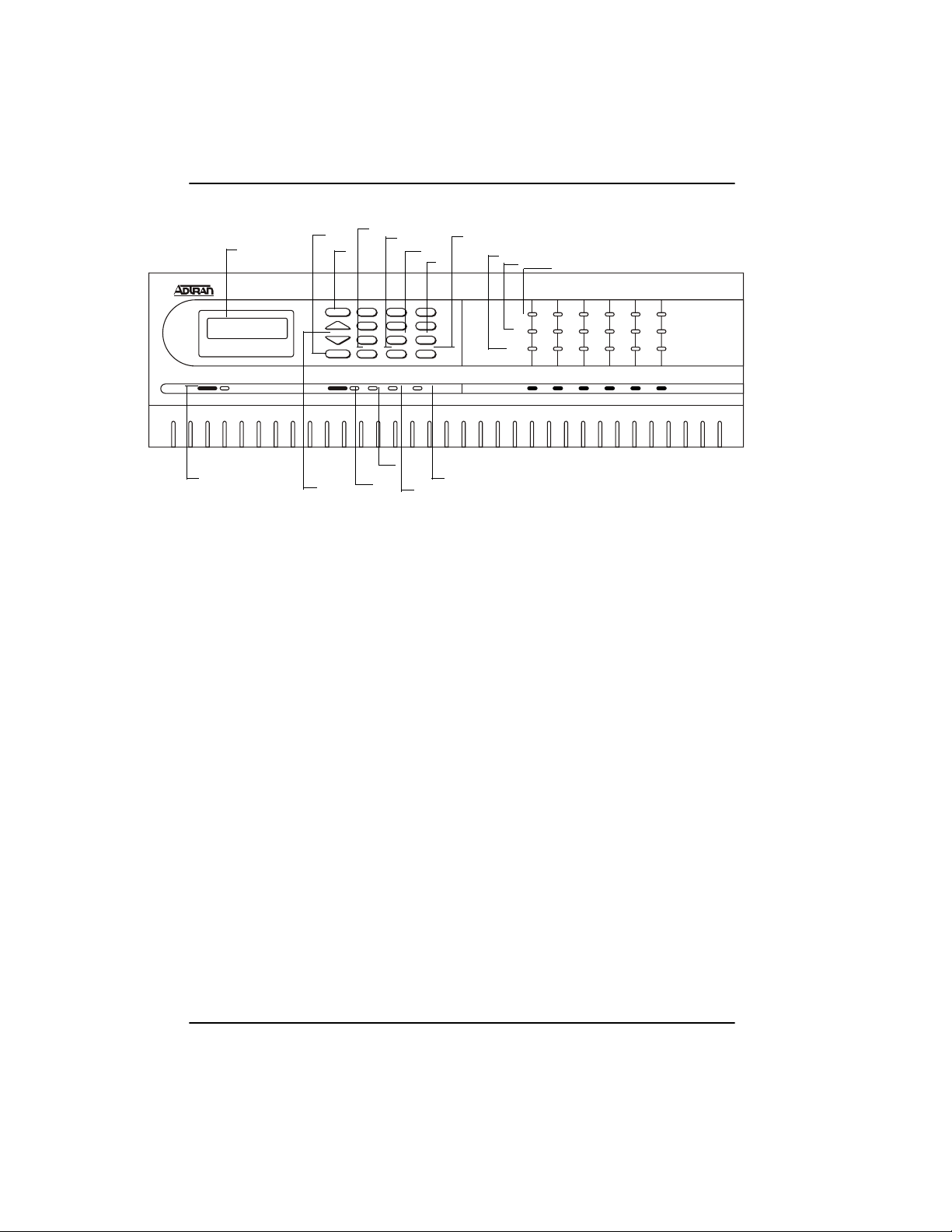

FRONT PANEL

The TSU 600 front panel both monitors operation and controls the configuration of the unit. The TSU 600 front panel is shown in Figure 3-1 on

page 3-4. Descriptions of each part of the front panel follow.

Name Description

LCD Window Displays menu items and messages in two lines by

Enter Selects active menu items. To select a menu item,

Up and down

arrows

Cancel Pressing the Cancel key stops the current activity

Numeric Keypad The numeric keypad contains the numbers 0

Operation

16 characters. It also displays alarm and status

information.

press the number of the item. The menu item

flashes, indicating it is activated. Press Enter to

select the menu item.

Up and down arrows are used to scroll through

and activate the submenu items available in the

current menu. When the submenu items are

scrolled, the flashing cursor indicates the active

parameters.

and returns the display to the previous menu.

Repeat until the desired menu level is reached.

When a submenu item is displayed, press Cancel

to exit the current display and return to the previous menu.

through 9 which are used to activate menu items

and enter information (such as the IP address).

61202076L1-1 TSU 600 User Manual 3-1

Page 42

Chapter 3. Operation

Name Description

Shift To enter special function keys, press and release

Shift before pressing the key representing the

desired character. See Operation Keys on page 3-5

for a description of the function keys.

To activate a special function key rather than a

number, press Shift and then the key. If you press

the key without using Shift, the numbered item

becomes active instead of the special function key.

CSU Status LEDs

The CSU status LEDs display the operational condition of the network

interface located on the controller board in the unit.

Name Description

OK (green) Indicates the operation is in the normal mode and no

errors have been detected.

Test (yellow) Indicates that the network interfaces are operating in a

test mode. This includes a self-test or a test loopback.

When lighted, this LED also indicates that normal data

flow is not occurring on the network interface.

Error (red) Indicates an error such as a BPV, OOF, or CRC.

Alarm (red) Indicates an alarm condition has been detected. When the

alarm condition is no longer valid, the OK LED activates

(turns on).

To view an alarm condition, select the

active alarm menu

item or select Alarm by pressing Shift 8.

If the alarm conditions have been corrected, the alarm

which caused the activation of the Alarm LED can be

viewed under the

3-2 TSU 600 User Manual 61202076L1-1

Unit History menu.

Page 43

Module Status LEDs

The module status LEDs display the operational condition of ports installed in the option slots.

Name Description

OK (green) Indicates the operation is in the normal mode

Test (yellow) Indicates that one of the interfaces is operat-

Alarm (red) Indicates an alarm condition has been

System (green) Indicates the status of the power supplies.

Chapter 3. Operation

and no errors have been detected.

ing in a test mode. This includes a self-test or

a test loopback. When lighted, this LED also

indicates that normal data flow is not occurring in at least one of the module ports.

detected. When the alarm condition is no

longer valid, the

To view an alarm condition, select the active

alarm menu item or select

shift 8. If the alarm conditions have been corrected, the alarm which caused the activation

Alarm LED can be viewed under the

of the

Unit History

OK LED activates (turns on).

Alarm by pressing

menu.

If the LED is illuminated green, all installed

power supplies are functioning properly.

If the LED is illuminated red, one or both

power supplies are not functioning normally.

This feature is for the AC-powered 600e only.

For the TSU 600 and DC- powered 600e, the

system LED is always green.

61202076L1-1 TSU 600 User Manual 3-3

Page 44

Chapter 3. Operation

1

.

2

3

123

ENTER

456

7

COPY*HOME0SHIFT

CANCEL

4

ALARM8CLEAR

5

8

6

7

9

11

10

TSU 600

OK

9

#

TEST

ALARM

1SYSTEM CSU 23456OK TEST ERROR ALARM

12

13

15

14

17

16

1. LCD Window Displays menu items and messages in 2 lines by 16 characters.

2. Cancel Stops cu r ren t ac tiv ity and retu r ns to the previo us menu .

3. Enter Selects active menu item

4. Copy Copies last data entered into the current DS0.

5. Home Returns to the main menu.

6. Alarm Quick access to the active alarm display menus.

7. Clear Clears data/results fields

8. Shift Provides access to special function keys

9. Alarm (Module Status) Active when an al arm condition has been detected.

10. Test (Module Status) Active when the module is in test mode.

11. OK (Module Status) Operation is in normal mode with no detected errors.

12. System LED Indic ates status of po wer supplies (600e only)

13. Up and Down Arrows Scroll through and activate the submenu items available in the

current menu. The flashing cursor indicates the active parameter.

14. OK (CSU Status) Operation is in normal mode with no detected errors.

15. Test (CSU Status) Active when the network interface is in test mode.

16. Error (CSU Status) Indicates errors such as BPV, OOF, and CRC.

17. Alarm (CSU Status) Active when an alarm condition has been detected on the net-

work interface.

Figure 3-1.

3-4 TSU 600 User Manual 61202076L1-1

TSU 600 Front Panel Layout

Page 45

Operation Keys

Name Description

Copy Used in the DS0 mapping menu operations to copy

the last data entered into the current DS0. This key

operates without pressing the Shift key.

Chapter 3. Operation

Home

Alarm Used as quick access to the active alarm display

Clear Used in various menus to clear data/result fields.

General Menu Operation

The TSU 600 uses a multilevel menu structure containing both menu

items and data fields. All menu operations and data are displayed in the

LCD window. The menu items are numbered and can be viewed by

scrolling with the up and down arrows.

Returns home to the

location.

menus. This can be activated while any other menu

item is in use. When the

unit returns to the location of the same menu that

was active when Alarm was selected.

Main Menu

Alarm Menu

from any menu

is exited, the

Name Description

Data Field You can edit menu items followed by a colon (:)

Display Only

Field

You cannot edit menu fields followed by an

equal symbol (=). This symbol identifies a field

used for value display only

Arrows Menus that display small up or down arrows in

the lower right corner indicate there are more

menu items than are visible on a two-line LCD.

Access the additional items with the up or

down arrows. You can also access undisplayed

menu items by using the appropriate menu

number.

61202076L1-1 TSU 600 User Manual 3-5

Page 46

Chapter 3. Operation

Selecting and Activating a Menu Item

Step Action

Choose a menu item by placing the cursor on the desired

1

menu item by either:

1. pressing the number corresponding to the menu item or,

2. highlighting it with the up and down arrows.

To activate the

2

Alarm List option

do the following:

1. Activate the

pressing

Status Menu using the arrow keys or by

1. The cursor will flash on the number next to

the activated selection.

2.Press Enter.

3. Use the arrow keys to view submenu items.

4.Choose an item on the submenu such as

ALARMS

.

5.Select the submenu with the arrow keys or by pressing

3.

6.Press Enter.

7. View the

Alarm List using the arrow keys.

The front panel menu tree is shown below.

1) NI PERF RPTS

2) NI ERRORS

3) ACTIVE ALARMS (ALARM LIST)

4)VIEW HISTORY END OF LIST

1)STATUS 5) PORT STATUS

6) REMOTE PORT

7) CLEAR PORT ALM

8) ENET STATUS

9) PS STATUS

from the

Status Menu

ACTIVE

Figure 3-2.

3-6 TSU 600 User Manual 61202076L1-1

Example of Basic Front Panel Menu Travel

Page 47

Chapter 3. Operation

Editing the Data Field

Use the following steps to edit data fields preceded by a colon (:).

Step Action Result

Position the cursor on the

1

submenu item number

and press Enter.

Using the arrows, scroll to

2

scan the available value

settings.

When the desired value is

3

displayed, press Enter to

set that value.

Select another submenu

4

field or press Cancel to

return to the submenu.

The cursor moves to the data field

(to the right of the submenu item

name).

The value settings display one-at-atime in the data field position.

When the value is set, the cursor

moves back to the submenu item

position, indicating the operation is

complete.

Pressing Cancel before pressing

Enter voids any data changes. The

original data value is restored and

the cursor returns to the submenu

field.

61202076L1-1 TSU 600 User Manual 3-7

Page 48

Chapter 3. Operation

Display Only Data Fields

Data fields preceded by an equal (=) symbol cannot be edited. See Figure

3-3 and the instructions listed below.

Data Field

Display Field

Figure 3-3.

Display and Data Fields

Step Action

1 Press Enter to move the cursor to the data field.

2

Use arrows to select

• The unit automatically sets the

• The display field shows the value actually set.

• The equal symbol after LBO in the second line indicates the information that follows is displayed

data and cannot be edited.

Exit Any Menu Field Operation Or Display

Press Cancel as many times as required to return to the desired menu

level or press Home to return to the main menu.

and press Enter.

AUTO

Line Build Out.

3-8 TSU 600 User Manual 61202076L1-1

Page 49

Data Port Identification

When configuring the unit, menu selections will include options from

data port submenus. Selecting of data ports is necessary because the

TSU 600 uses a Slot-Port method to identify which data port the menu

item is referencing. If a module containing a

with an

be designated as:

DSX-1 Passthru=6.1

Where slot=6 and port =1.

The DSX-1 is located in option slot 6 and is the first port in that slot.

Nx56/64=6.2

Where slot=6 and port=2.

The Nx is located in Slot 6 and is the second port in that slot.

Viewed from the rear of the TSU 600, the module slots are arranged as

shown in Figure 3-4.

Nx56/64 plug-on interface

Chapter 3. Operation

PBX DSX-1 option card

is installed in option slot 6, it would

SLOT 1

SLOT 2

SLOT 3

SLOT 4

SLOT 5

SLOT 6

POWER SUPPLY

Figure 3-4.

61202076L1-1 TSU 600 User Manual 3-9

Module Slots, TSU 600

Page 50

Chapter 3. Operation

Front Panel Menu Structure

The TSU 600 uses a multilevel menu structure containing both menu

items and data fields. All menu operations and data display in the LCD

window.

The opening menu is the access point to all other operations. Each

Menu item has several functions and submenus to identify and access

specific parameters.

The front panel LCD of the

Main Menu

contains the following options:

Option Description

Status Displays all relevant information for the network

and DTE interfaces. For detailed information on

status options, see Chapter 4, Status Menu.

Config

(Configuration)

Util (Utilities) Displays and sets system parameters. For detailed

Test The Test menu initiates different types of unit tests

Displays and sets the TSU 600 operational configuration, including all network interface parameters, the allocation of the DS0s, and the port

parameters.

For detailed information on configuration options,

see Chapter 5, Configuration Menu.

information on utility options, see Chapter 6, Util-

ity Menu.

and displays test results in the LCD window. For

detailed information on test options, see Chapter 7,

Test Menu.

Main

3-10 TSU 600 User Manual 61202076L1-1

Page 51

Alternate Methods of Control

T-Watch PRO (ADTRAN PC Program)

T-Watch PRO is the ADTRAN PC control program. It provides complete

control over the configuration of the TSU 600 using a graphical interface

and displays the same status and performance data as the front panel

LCD. This data is displayed in the form of tables and graphs.

The T-Watch PRO program has the following capabilities:

• Interfaces with a modem which permits dialing into a remote TSU

600 location to configure the unit or read the status or performance of

the unit.

• Receives traps from any TSU product.

• Records and creates display performance data over a 30 day period.

• Accesses units via the local area network.

T-Watch PRO/LAN Connection

To set up the TSU 600 to work with T-Watch PRO over the LAN, follow

these steps:

Step Action

Chapter 3. Operation

1

2

3

4

61202076L1-1 TSU 600 User Manual 3-11

Set the Unit ID using the Front Panel.

See Unit ID on page 6-3 for more information.

Set Control Port to SLIP or Normal for 10BaseT (600e

only) using the Front Panel.

Configure the

net mask using the Front Panel.

Follow the installation instructions for T-Watch PRO

to start the program and connect to the unit.

IP address default gateway

The default gateway and subnet masks are not used

for SLIP mode.

, and sub-

Page 52

Chapter 3. Operation

T-Watch PRO/EIA-232 Connection

To set up the TSU 600 to work with T-Watch PRO over a direct EIA-232

connection, the following steps are required:

Step Action

Set the

1

See Unit ID on page 6-3 and Change/Set a Passcode on page

6-3 for more details.

Set the Control Port rate to the same setting as the PC

2

Com port.

Connect the PC Com port to the Chain-In port on the

3

TSU 600 using the DB25 to modular adapter and 6-foot

modular cable.

Follow the installation instructions for T-Watch PRO to

4

start the program and connect to the unit.

SNMP