ADP Organizer User manual

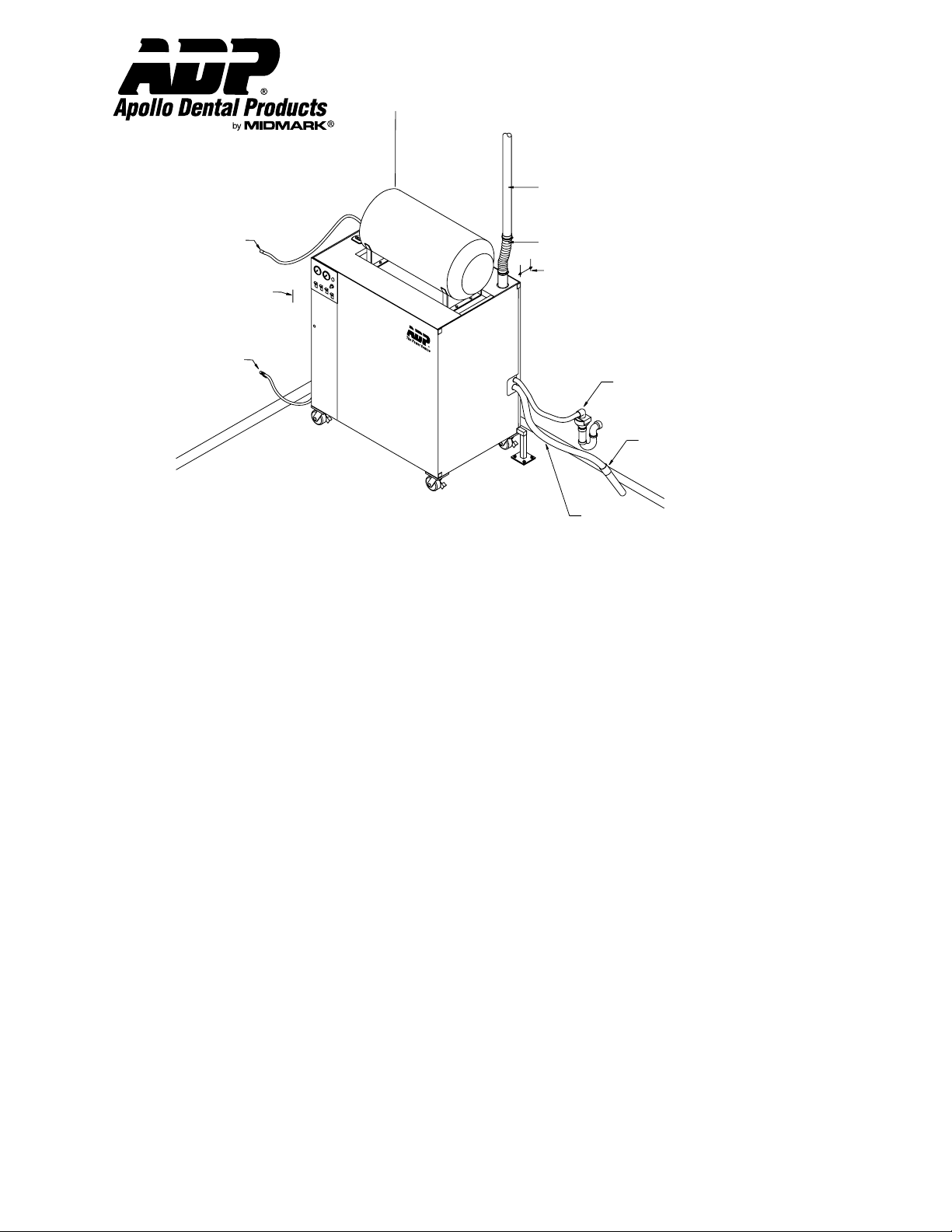

Compressed Air Line From Operatories

Terminating In 1/2" Or 3/8" FPT

(Provided By Plumber)

2' Clearance

Cold Water Inlet With Shut Off

Terminating In 1/2" Or 1/4" FPT

(Provided By Plumber)

Installation & Operation

Organizer™ Systems

Small, Medium & Large Cart Models

2" PVC Vent To Outside

(Provided By Plumber)

2 Ft. Flex Tube

6" Clearance

3/4" Flex Line To Sewer Drain

(1 1/2" P-Trap With 1" Air Gap Shown)

Vacuum Inlet From Operatories

(Size According To Unit/Office Sizing Chart)

(Provided By Plumber)

Vacuum Inlet Flex Line

(Provided)

Description:

Apollo Dental Products’ Organizer™ Vacuum and Air Systems have been tested and approved by various regulatory test agencies.

The following list contains ADP file numbers that may be helpful if questions arise regarding installation inspections;

Underwriter’s Laboratories .............................. File Number: MH13627

U.S. Food and Drug Administration .................... File Number: 2937927

City of Los Angeles Mechanical Test Labs............. File Number: M880066

The Organizer™ System should only be installed by qualified technical personnel. Should any questions arise during installation, call

our Technical Support Department between the hours of 6:00 am and 4:00 pm (PST) at 800/233 4151.

Unpacking the System:

1. Place boxed unit on level surface with enough space to lower the ramps and roll the unit onto the floor. This will require

36 inches plus the width of the pallet to clear the unit when it reaches the floor.

2. Remove cardboard shipping carton from pallet.

3. Unbolt shipping feet from platform.

4. Unpin shipping feet from front of unit; pull feet from mount in back of unit. DO NOT DISCARD MOUNTING FEET.

5. Fold down unloading ramps and verify the edges are on the pallet and ready to unload unit.

6. Unlock caster wheels to allow unit to roll.

7. With one person in front of the unit, and one behind it, gently roll the unit down the ramps and off the pallet to the floor.

8. Roll the unit to the equipment room or installation location.

9. Once unit is rolled into final installation location, lock caster wheels and re-install mounting feet by sliding feet into rear mounts

and bolting unit securely to the floor or wall.

Note: When installing the Organizer™ System, it is important to place the unit in an air conditioned room with

adequate ventilation. Failure to do so could cause premature loss of system performance and void warranty.

A 2 foot clearance is required on the left side and at least 6 inches on the back and right side.

Apollo Dental Products, Inc. • 245 W. Dakota Ave. • Clovis, CA 93612 • Technical Support

559/292-1444 • 800/233-4151 • Fax 559/292-1555 • www.apollodental.com

Page 1

AMI60900 Rev. 1/02

Installation & Operation

Organizer™ Systems

Technical Service - (800) 233-4151

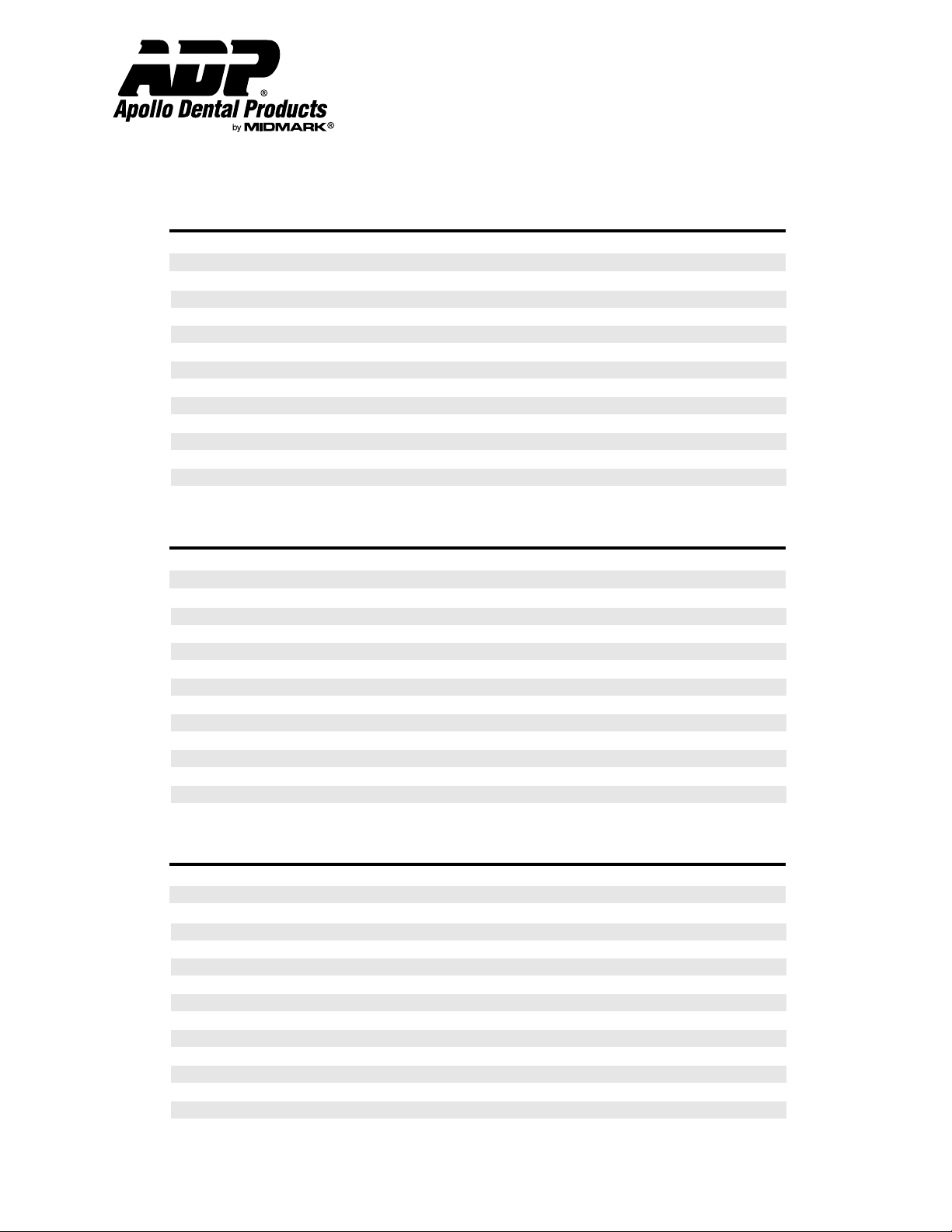

Organizer™ Specifications & Dimensions:

Small Cart 02SLB 02SLG 02SLU 02SOB 02SOG 02SOU

Max. Users 222 222

Width 24.25” 24.25” 24.25” 24.25” 24.25” 24.25”

Depth 29” 29” 29” 29” 29” 29”

Height 56” 56” 56” 56” 56” 56”

Weight 353 lbs 353 lbs 353 lbs 303 lbs 303 lbs 303 lbs

Vac HP 1111 11

Comp HP 1111 11

Volt 208 1Ph 208 1Ph 208 1Ph 208 1Ph 208 1Ph 208 1Ph

Vac. Amp 8.1 8.1 8.1 8.1 8.1 8.1

Comp. Amp 7.2 7.2 7.2 5.2 5.2 5.2

Hz 60 60 60 60 60 60

Wire Ga. 10 10 10 10 10 10

Vac. Breaker 20 20 20 20 20 20

Comp. Breaker 20 20 20 20 20 20

Vac. Inlet Size 3/4” 3/4” 3/4” 3/4” 3/4” 3/4”

Medium Cart 04MLB 04MLG 04MLU 04MOB 04MOG 04MOU

Max. Users 444 444

Width 37.25” 37.25” 37.25” 37.25” 37.25” 37.25”

Depth 29” 29” 29” 29” 29” 29”

Height 59” 59” 59” 59” 59” 59”

Weight 535 lbs 535 lbs 535 lbs 455 lbs 455 lbs 455 lbs

Vac HP 2222 22

Comp HP 2222 22

Volt 208 1Ph 208 1Ph 208 1Ph 208 1Ph 208 1Ph 208 1Ph

Vac. Amp 16.2 16.2 16.2 16.2 16.2 16.2

Comp. Amp 14.4 14.4 14.4 10.4 10.4 10.4

Hz 60 60 60 60 60 60

Wire Ga. 10 10 10 10 10 10

Vac. Breaker 30 30 30 30 30 30

Comp. Breaker 30 30 30 30 30 30

Vac. Inlet Size 1” 1” 1” 1” 1” 1”

Large Cart 06LLB 06LLG 06LLU 06LOB 06LOG 06LOU

Max. Users 666 666

Width 50” 50” 50” 50” 50” 50”

Depth 29” 29” 29” 29” 29” 29”

Height 61” 61” 61” 61” 61” 61”

Weight 889 lbs 889 lbs 889 lbs 770 lbs 770 lbs 770 lbs

Vac HP 3333 33

Comp HP 3333 33

Volt 208 1Ph 208 1Ph 208 1Ph 208 1Ph 208 1Ph 208 1Ph

Vac. Amp 24.3 24.3 24.3 24.3 24.3 24.3

Comp. Amp 21.6 21.6 21.6 15.6 15.6 15.6

Hz 60 60 60 60 60 60

Wire Ga. 10 10 10 10 10 10

Vac. Breaker 40 40 40 40 40 40

Comp. Breaker 40 40 40 40 40 40

Vac. Inlet Size 1 1/4” 1 1/4” 1 1/4” 1 1/4” 1 1/4” 1 1/4”

Page 2 AMI60900 Rev. 1/02

Installation & Operation

Organizer™ Systems

Technical Service - (800) 233-4151

A. Electrical Hook-up Requirements:

Line Voltage (208-220V 60Hz)

Depending on the cart size of the Organizer™ unit being installed, disconnects with correctly rated breaker sizes and ground

connections will be required; one for the vacuum equipment and one for the compressor equipment within the cart. Refer to

preceding table for proper breaker size for the unit you are installing.

Low Voltage Control (24V)

18-3 thermostat wire must be installed from each remote control switch to the back of the Organizer™ Gauge/Control Panel.

The thermostat wire is connected into the existing switch wiring using the wire nuts existing on the switches. Lighted

switches require red and white wires for bulb, the red and blue connection control low voltage switching of vacuum and

compressor units.

NOTES: Dedicated electrical circuits with circuit breakers and approved grounds must be provided for the vacuum system, and the compressor system. Ambient

temperature must be within the range of 40 degrees Fahrenheit minimum (4 degrees C) to 100 degrees Fahrenheit (38 degrees C) maximum. All systems to be

installed according to local plumbing and electrical codes. Never operate the equipment without complete and proper grounding.

B. Plumbing Hook-up Requirements:

Vacuum Units:

Water Supply Line (Recommended)

1/4 inch (13mm) cold water supply line with shut off valve terminating in 1/2 inch FPT. The line must be flushed out prior to

connection to the vacuum unit(s).

IMPORTANT: Water is essential for the operation and longevity of the vacuum pump. The supply must not be

restricted or interrupted during operation. Water with high mineral content may cause mineral build-up and

create water starvation, leading to seal failure. A water softener and filter are recommended for this

situation.

Waste Line

Water and air exhaust to sewer line terminating in:

Option A- Floor sink.

Option B- A “P”-trap adapted to 3/4 inch (19mm) PVC slip connection. Local building codes may require a 1 inch

(25mm) air gap. The “P”-trap must not be located more than 6” above the floor.

Vacuum Line

Refer to the preceding table to determine correct vacuum line termination size for the unit being installed.

Vacuum Vent Line

2 inch PVC pipe vent to outside.

IMPORTANT: Continuously running sinks or cuspidors must NEVER be connected to the vacuum

piping system.

Compressor Units:

Operatory Air Line Termination

3/8 inch or 1/2 inch FPT termination to office supply line. Connect flex line from shut off valve on top of Organizer™ cart

to office supply line.

Fresh Air Intake

1 1/2 inch vent to outside terminating in 1 inch slip connection (Small and Medium Carts).

1 1/2 inch vent to outside terminating in 1 1/2 inch slip connection (Large Cart).

Remove Oil Filler Plugs

Remove plug(s) from oil filler necks on lubricated compressor heads and check oil levels before operation.

Page 3

AMI60900 Rev. 1/02

Installation & Operation

Organizer™ Systems

Technical Service - (800) 233-4151

C. Installing the System:

1. Once the Organizer™ unit is in correct installation location, lock caster wheels (2 foot clearance is required on the left side,

and a 6 inch clearance in the back and right side).

2. Install floor or wall mounting feet horizontally on the floor or vertically into a secure wall to prevent unit from shifting.

3. Place condensate drain canister next to unit on the floor. Connect one end of 3/8 inch polyflow tubing into tee fitting below

desiccant chamber, and the other end into fitting on lid of canister.

4. Connect provided water supply line for vacuums into water supply line using provided 1/4 or 1/2 inch fitting.

Note: It is recommended that the water supply line be flushed with at least 5 gallons of water prior to connection

to the vacuum system. (Sediment in water lines of new buildings is common.)

5. Connect operatory vacuum line to the vacuum intake line located on either side of cart using provided suction hose.

Cement the suction hose using PVC glue.

6. Attach provided 3/4 inch vacuum drain hose to drain line on either side of cart and into a “P”-trap or floor sink.

Cement with PVC glue.

7. Connect vacuum exhaust line to 2 inch PVC vent pipe.

8. Install flexible compressed air line from valve on top of cart to operatory supply line.

9. Verify that all switches are in the off position, and connect high voltage electrical supply lines to approved disconnects with

proper breakers and grounds. See previous table for unit requirements.

D. Initial Start-Up:

Vacuum System

1. Open water supply valve at source and on manifold inside cart door. Check for water leaks.

2. Start the vacuum pump(s) by pressing all of the vacuum switches to the on position.

3. Check the drain line to verify that water is flowing through the system.

IMPORTANT: Do not run pump without full pressure water supply, or serious pump seal damage could result.

4. Check the vacuum gauge to ensure that all pumps are functioning properly. Vacuum pressure is preset at the factory to

10 inches Hg.

Compressor System

1. Make sure shut off valve on top of cart is closed.

2. Turn on compressor system. One switch controls all compressor heads in a multiple system.

3. The system will run until the storage tank pressure reaches 100 psi, then shut off automatically using a preset pressure switch.

4. Monitor tank pressure for two minutes to verify that there are no air leaks in the system. To check more closely apply soapy

water to plumbing joints to check possible leak paths. Care must be taken not to drip water on nearby electrical components

and avoid electrical shock.

5. Slowly open the supply valve on top of the cart to supply the office with compressed air. After intervals of 2 and 10 minutes

check the storage tank pressure gauge to confirm that no air leaks exist. If the pressure has dropped in this time, or the unit

has cycled, a leak exists. Locate all leaks and repair as necessary.

IMPORTANT: Seal All Air leaks! Air Leaks Are the Main Cause of Compressor Failure!

6. Be sure to complete and fax or mail in the warranty card for this unit within 10 days of installation to effect warranty.

7. Store this installation manual for future reference.

Page 4

AMI60900 Rev. 1/02

Installation & Operation

Organizer™ Systems

Technical Service - (800) 233-4151

E. Vacuum Level Adjustment:

1. Open front access panel on cart.

2. The vacuum valve and filter are located horizontally behind the vacuum inlet strainer.

3. Remove the filter and valve from the PVC elbow.

4. Using a 1/4 inch nutdriver and a phillips screwdriver adjust the center mounted screw within the valve. Each full clockwise

turn increases the vacuum level by approximately 2 inches Hg. The vacuum level range is between 6 and 13 inches Hg

(27 to 44 KPa).

5. Reinstall filter and valve to test vacuum level and repeat steps as necessary until desired vacuum level is reached.

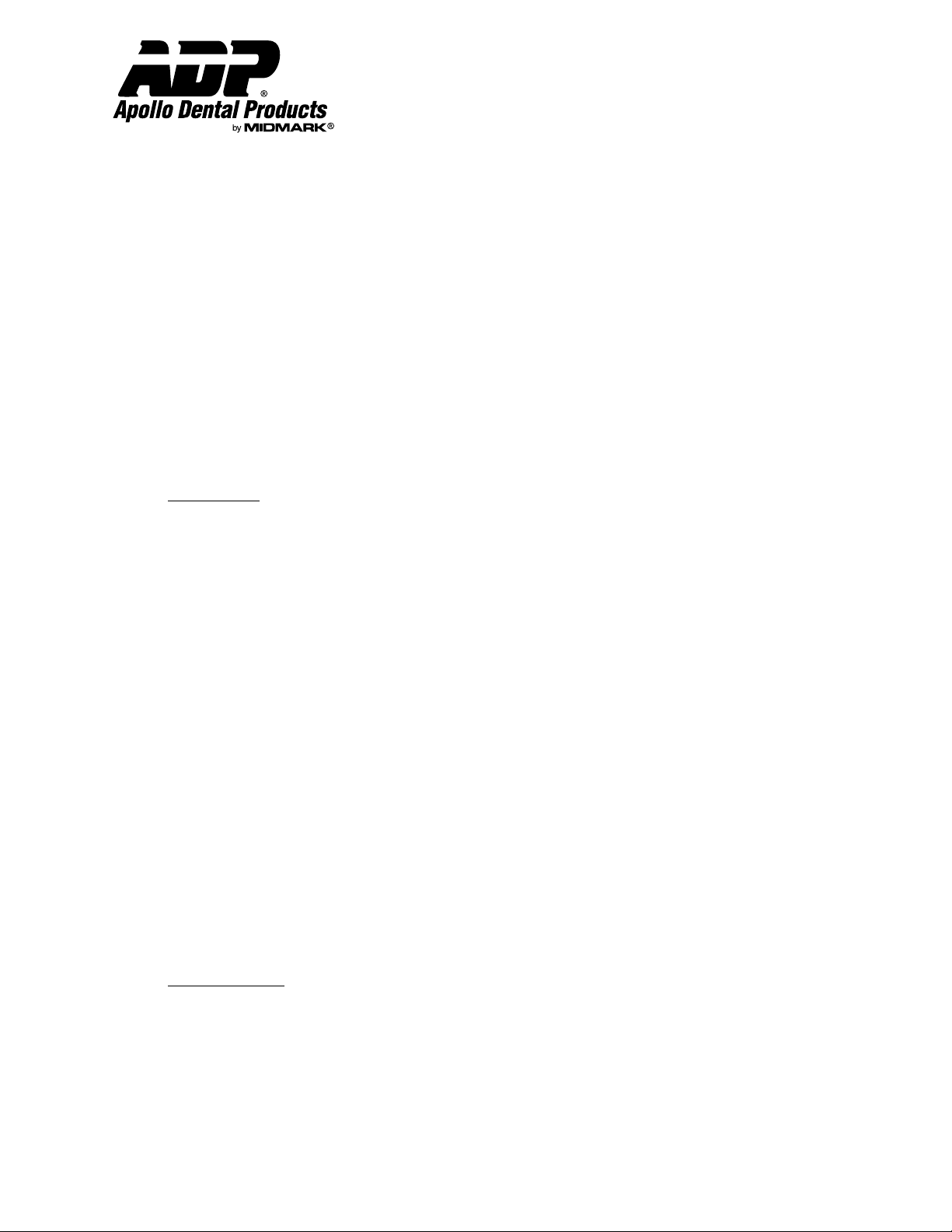

F. Maintenance:

Daily Weekly Monthly Semi-Annually Annually

Check/Verify Proper Operation of Cooling Fans •••

Check Drains In Vacuum Tray-Free of Debris •••

Vacuum System

Cleanse Vacuum Piping System •••

Cleanse Vacuum Pump Intake Strainer •••

Clean In-Operatory Strainers •••

Check Vacuum Level •••

Clean and Dust Off Vacuum Pump •••

Replace Recycler Return Line •••

Clean or Replace Relief/Regulator Filter •••

Clean Water Inlet Strainer •••

Compressor System

Check Oil Level (Lub. Comp Models Only) •••

Empty Condensate Drain Canister •••

Check Drying System Moisture Indicator •••

(If Pink or White = Run Manual Purge)

Check Pump-up Times (Between 25-40 secs) •••

Clean and Dust Off Air Compressor •••

Change Compressor Oil (Lub. Comp. Models) •••

Replace Air Intake Filters/Mufflers •••

Replace Ultrair Filter Element •••

Page 5

AMI60900 Rev. 1/02

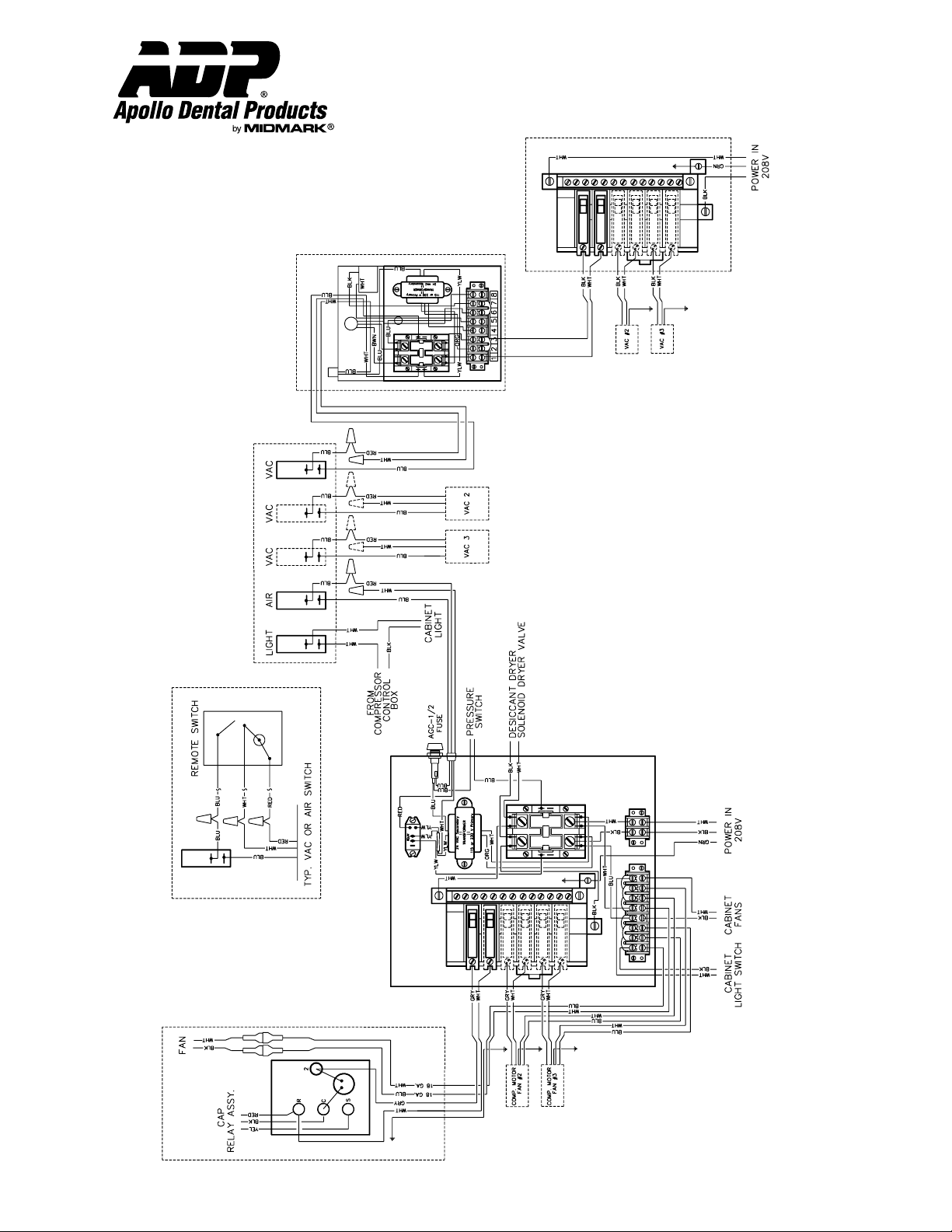

VAC. CIRCUIT BREAKER BOX

#1 VAC.

CONTROL PANEL

LOW VOLTAGE

REMOTE CONTROL

COMPRESSOR

CONTROL

BOX

#1 COMP. MOTOR & FAN

G. Wiring Diagram:

Installation & Operation

Organizer™ Systems

Technical Service - (800) 233-4151

Page 6

AMI60900 Rev. 1/02

Loading...

Loading...