ADP Oil Sight Glass Replacement Kit User manual

Installation Instructions

Oil Sight Glass Replacement Kit

Part ASA85322

Description:

The Apollo Dental Products lubricated compressors come equipped with an oil level sight glass installed. This sight glass allows convenient

visual inspection of the oil level inside the compressor head.

If for any reason the sight glass becomes cracked and begins leaking, a replacement sight glass kit is available. The kit contains an o-ring,

sight glass, fiber gasket, and aluminum shim. An optional sight glass removal/installation tool is available for convenient removal and

replacement of the retaining ring. The tool part number is ACA-00050.

Installation:

1. Turn power “OFF” to compressor.

2. Drain oil from compressor head. See drawing for drain plug location. Do not re-use oil.

3. It may be necessary to unbolt the compressor head from the mount to access the sight glass.

4. Use the sight glass removal/installation tool or a hammer and punch to remove the retaining ring.

5. Remove the old sight glass along with the o-ring located behind it.

6. Install the new o-ring.

7. Insert the new sight glass along with the fiber gasket.

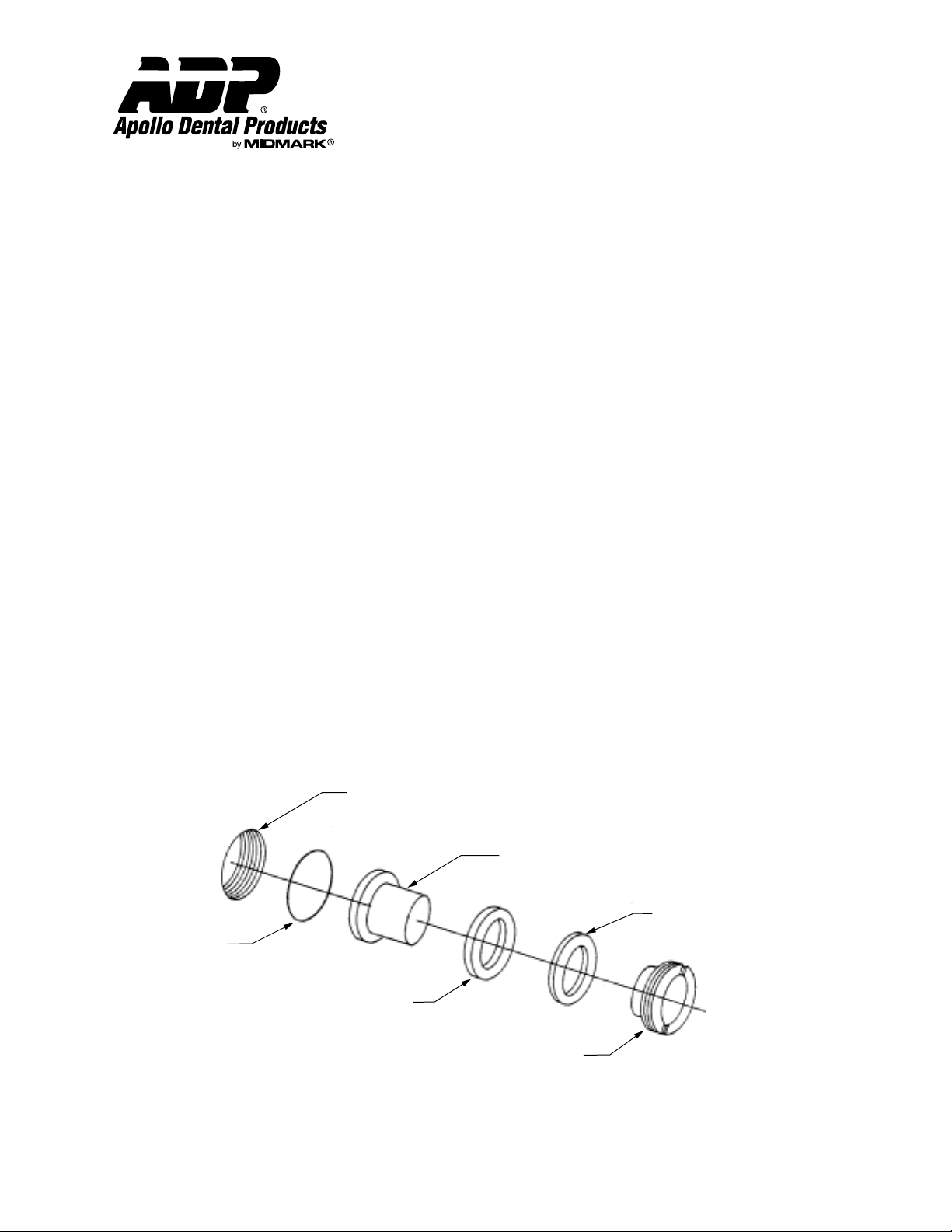

Note: See installation drawing for proper replacement sequence of components.

Sight Glass Opening

On The Side Of Head

Sight Glass

Aluminum Shim

O-Ring

Fiber Gasket

Retaining Clip

Apollo Dental Products, Inc. • 245 W. Dakota Ave. • Clovis, CA 93612 • Technical Support

559/292-1444 • 800/233-4151 • Fax 559/292-1555 • www.apollodental.com

Page 1

AMI60711 Rev. 7/98

Installation Instructions

Oil Sight Glass Replacement Kit

Technical Service - (800) 233-4151

Installation (Continued):

8. Place the aluminum shim on top of the fibre gasket.

9. Install the retaining ring with the sight glass removal/installation tool or a hammer and punch. Replacement retaining ring

part number HCA30631

Important: Do not over tighten the retaining ring. The retaining ring should be tightened no more than

1/4 turn beyond the point where resistance is encountered.

10. Refill compressor head with the proper amount of ADP Compressor Oil. Part number ACA85921.*

*Check for leaks.

11. Turn “ON” power to compressor.

*Be sure to check that the leak has been corrected.

Warranty:

All ADP units are thoroughly inspected and tested in accordance with rigid specifications and standards. Our products are guaranteed

against any defective material and workmanship from the date of shipment; provided, that the installation, operation, and maintenance

is done in accordance with ADP procedures as outlined in our Installation and Maintenance Guides. Warranty cards must be returned

to ADP within ten days of installation to effect warranty.

ADP’s obligation under the warranty is to provide parts for the repair or, at it’s option, to provide the replacement product (excluding

labor). All special, incidental and/or consequential damages are excluded. We will not issue credit for complete air compressors or

vacuum systems without first attempting to correct the problem in the field. Written notice of breach of warranty must be given to ADP

within the warranty period. The warranty does not cover damage resulting from the use of cleaning, disinfecting or sterilizating

chemicals and processes. Failure to follow instructions provided in ADP’s Installation and Maintenance Guides may void the warranty.

Replacement Parts and Accessories ...........................90 Days

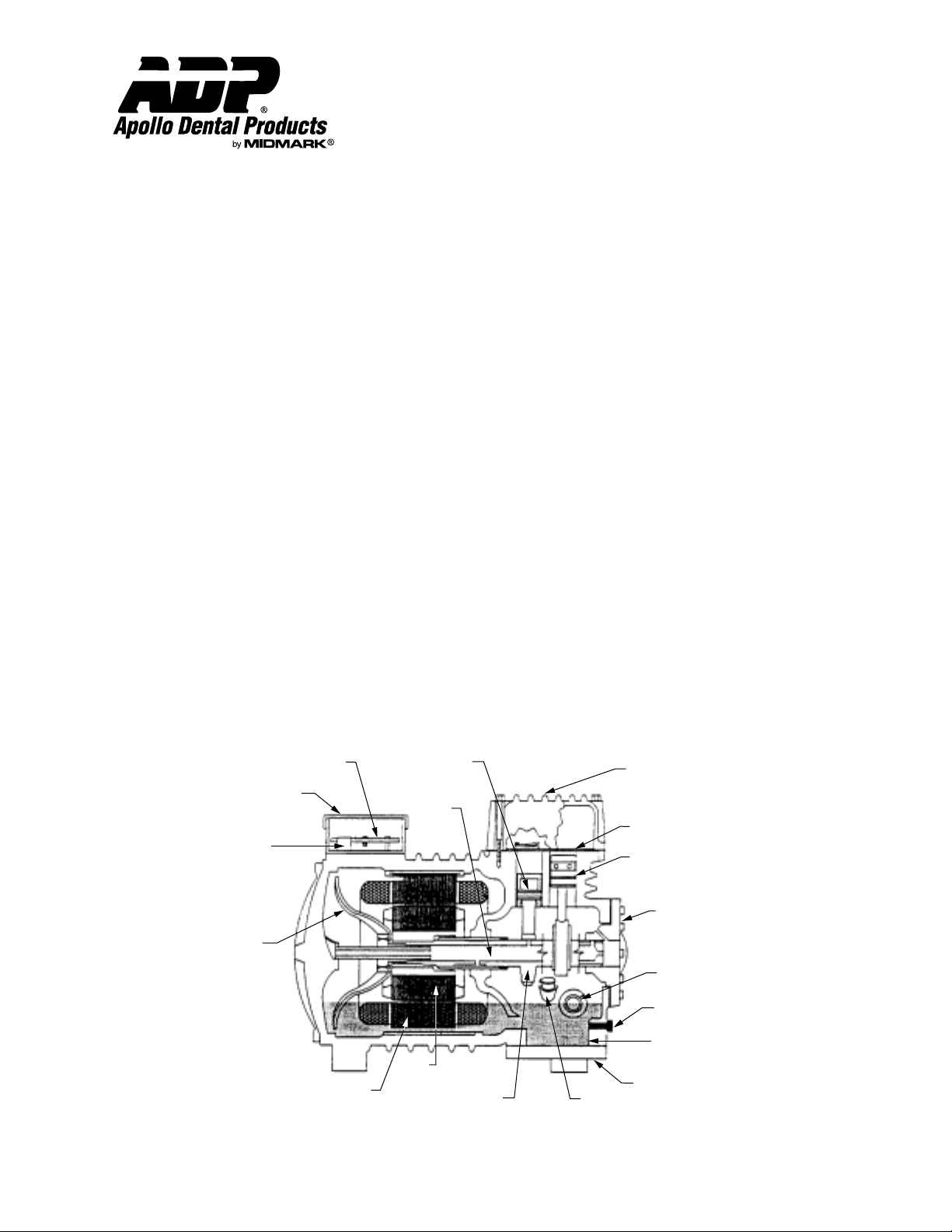

Terminal Board

Terminal Box

Thermal Motor

Protector

Oil Impeller

Stator

Piston, Pin & Rod

Assembly

Oil Feed

Passage

Rotor

Eccentric

Crankshaft

Cylinder Head

Valve Plate

Piston

Housing Cover

Oil Sight Glass

Oil Drain Plug

Oil

Bottom Plate

Oil Filler

Lubricated Compressor Cutaway View

Page 2 AMI60711 Rev. 7/98

Loading...

Loading...