Page 1

PXIS-2508/PXIS-2558T

3U 8-Slot Smart and Portable PXI Chassis

with Integrated LCD Touch Panel

User’s Manual

Manual Rev. 2.01

Revision Date: August 24, 2007

Part No: 50-17026-2010

Advance Technologies; Automate the World.

Page 2

Copyright 2007 ADLINK TECHNOLOGY INC.

All Rights Reserved.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability , design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, elec tronic, or other means in a ny form

without prior written permission of the manufacturer.

Trademark Information

PXI is registered trademarks of PXI Systems Alliance. Other product names mentioned herein are used for identification purposes

only and may be trademarks and/or registered trademarks of their

respective companies.

Page 3

Getting service

Customer satisfaction is our top priority. Contact us should you

require any service or assistance.

ADLINK TECHNOLOGY INC.

Web Site http://www.adlinktech.com

Sales & Service service@adlinktech.com

Telephone No. +886-2-8226-5877

Fax No. +886-2-8226-5717

Mailing Address 9F No. 166 Jian Yi Road, Chungho City,

Taipei Hsien 235, Taiwan, ROC

ADLINK TECHNOLOGY AMERICA, INC.

Sales & Service info@adlinktech.com

Toll-Free +1-866-4-ADLINK (235465)

Fax No. +1-949-727-2099

Mailing Address 8900 Research Drive, Irvine,

CA 92618, USA

ADLINK TECHNOLOGY EUROPEAN SALES OFFICE

Sales & Service emea@adlinktech.com

Toll-Free +49-211-4955552

Fax No. +49-211-4955557

Mailing Address Nord Carree 3, 40477 Düsseldorf, Germany

ADLINK TECHNOLOGY SINGAPORE PTE LTD.

Sales & Service singapore@adlinktech.com

Telephone No. +65-6844-2261

Fax No. +65-6844-2263

Mailing Address 84 Genting Lane #07-02A,

Cityneon Design Center, Singapore 349584

ADLINK TECHNOLOGY SINGAPORE PTE LTD.

(INDIA Liaison Office)

Sales & Service india@adlinktech.com

Telephone No. +91-80-57605817

Fax No. +91-80-26671806

Mailing Address No. 1357, Ground Floor, “Anupama”,

Aurobindo Marg JP Nagar (Ph-1)

Bangalore - 560078

Page 4

ADLINK TECHNOLOGY INC. (KOREA Liaison Office)

Sales & Service korea@adlinktech.com

Telephone No. +82-2-20570565

Fax No. +82-2-20570563

Mailing Address 4F, Kostech Building, 262-2,

Yangjae-Dong, Seocho-Gu,

Seoul, 137-130, South Korea

ADLINK TECHNOLOGY (BEIJING) CO., LTD.

Sales & Service market@adlinkchina.com.cn

Telephone No. + 86-10-5885-8666

Fax No. +86-10-5885-8625

Mailing Address Room 801, Building E, Yingchuangdongli

Plaza, No.1 Shangdidonglu,

Haidian District, Beijing, China

ADLINK TECHNOLOGY (SHANGHAI) CO., LTD.

Sales & Service market@adlinkchina.com.cn

Telephone No. + 86-21-6495-5210

Fax No. +86-21-5450-0414

Mailing Address Floor 4, Bldg. 39, Caoheting Science and

Technology Park, No.333 Qinjiang Road,

Shanghai, China

ADLINK TECHNOLOGY (SHENZEN) CO., LTD.

Sales & Service market@adlinkchina.com.cn

Telephone No. + 86-755-2643-4858

Fax No. +86-755-2664-6353

Mailing Address C Block, 2nd Floor, Building A1,

Cyber-tech Zone, Gaoxin Ave. 7.S,

High-tech Industrial Park S.,

Nanshan District, Shenzhen,

Guangdong Province, China

Page 5

Using this manual

Audience and scope

This manual guides you when using the portable ADLINK PXI

chassis. This manual is intended for system integrators, computer

programmers, and hardware engineers with advanced knowledge

of PXI/cPCI systems and PXI-based data acquisition.

How this manual is organized

This manual is organized as follows:

Chapter 1 Introduction: This chapter introduces the PXIS2508/2558T chassis including its features, specifications, and

package contents.

Chapter 2 Chassis Overview: This chapter presents the chassis layout, location of basic components, dimensions, and

backplane information.

Chapter 3 Installation: This part describes the procedures on

how to install a system controller and peripheral modules into

the PXIS-2508/2558T. It also contains information on OS and

driver installations and touch panel usage.

Chapter 4 Remote Management: The chapter illustrates the

remote management features of the PXIS-2508/2558T.

Appendix A: The Appendix comes with a troubleshooting section for common installation problems and tells you how to

maintain the PXIS-2508/2558T chassis.

Important Safety Instructions: This section lists important

safety reminders that you have to observe when using the

chassis.

War rant y Pol icy : This presents the ADLINK Warranty Policy

terms and coverages.

Page 6

Conventions

Take note of the following conventions used throughout the manual to make sure that you perform certain tasks and instructions

properly.

NOTE Additional information, aids, and tips that help you per-

form particular tasks.

IMPORTANTCritical information and instructions that you MUST perform to

WARNING Information that prevents physical injury, data loss, mod-

complete a task.

ule damage, program corruption etc. when trying to complete a particular task.

Page 7

Table of Contents

List of Figures........................................................................ iii

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 2

1.2 Specifications....................................................................... 3

1.3 Unpacking Checklist .................. ... ... .... ... ... ... ... .... ... ... ... .... ... 5

2 Chassis Overview............................................................... 7

2.1 Views................................................................................... 7

Front Panel .................................................... ... ... ...........7

Rear Panel ......................................................................9

Left Panel ............................ ... ... .... ... ... ... ... .... ... ... ... .... .. 10

Right Panel .................................................... ... ... ... .... .. 11

Top Panel .....................................................................12

Base Panel ....................................................... ... ... ......13

2.2 Backplane Features........................................................... 14

Inter-operability with CompactPCI ................................ 14

System Controller Slot ..................................................14

Star Trigger Slot ............................................................ 14

Peripheral Slots ............................................................15

Local Bus ......................................................................15

Trigger Bus ................................................................... 16

System Reference Clock ..............................................16

3 Installation ........................................................................ 17

3.1 Installing the System Controller......................................... 17

3.2 Installing Peripheral Modules............................................. 19

3.3 Cooling Considerations...................................................... 21

3.4 Powering up the System.................................................... 22

3.5 Installing the OS ................................................................ 24

3.6 Installing Device Drivers .................................................... 24

Installing the Chassis Description File (chassis.ini) ......24

Installing the VGA driver (PXIS-2558T only) ................25

Installing the Touch Panel Driver (PXIS-2558T only) ...26

Calibrating the Touch Panel .........................................27

Using the Touch Panel (PXIS-2558T only) ................... 29

Table of Contents i

Page 8

4 Remote Management........................................................ 31

4.1 Installing the Monitor Utility...... .... ... ... ... .... ... ... ... ... .... ... ... ... 32

4.2 Monitoring the System....................................................... 33

Using the Monitor Utility (PXISRemoteMonUtil) ...........33

Using the Monitoring/Control Function Library .............35

A Troubleshooting and

Maintenance........................................................................... 43

A.1 Installation Problems.................... ... ... ... .... ... ... ... ... .... ... ... ... 43

A.2 BIOS Beeps............................. .... ... ................................... 43

A.3 Basic Troubleshooting .................................... ... ... .... ... ... ... 44

A.4 Maintenance ...................................................................... 46

Taking Care of the Touch Panel LCD

(PXIS-2558T only) ..............................................46

Changing the Fan Filter ................................................46

Handling the Chassis ....................................................48

Handling Cables ...........................................................48

Cleaning the Exterior ....................................................48

Power Requirements ....................................................48

Important Safety Instructions............................................... 49

Warranty Policy ..................................................................... 51

ii Table of Contents

Page 9

List of Figures

Figure 2-1: PXIS-2508/2558T Front Panel .................................. 7

Figure 2-2: PXIS-2508/2558T Rear Panel................................... 9

Figure 2-3: PXIS-2508/2558T Left Panel................................... 10

Figure 2-4: PXIS-2508/2558T Right Panel ................................ 11

Figure 2-5: PXIS-2508/2558T Top Panel................................... 12

Figure 2-6: PXIS-2508/2558T Base Panel................................. 13

Figure 2-7: PXI Bus Signal Routing ........................................... 15

List of Figures iii

Page 10

Page 11

1 Introduction

The ADLINK PXIS-2508/2558T is a highly portable 3U PXI chassis equipped with advanced features and functionalities that comply with PXI and CompactPCI specifications. Offering one system

slot and seven peripheral slots, the PXIS-2508/2558T is set in a

sleek and lightweight chassis for superior portability, wider operating temperature range, lower operating noise, and robust system

build.

Equipped with an intelligent control board and sensors, the PXIS2508/2558T dynamically monitors and manages the chassis status including the fan speed, system voltages, and internal temperature. Remote management is supported as the control board

exports these sensor readings directly to a remote computer using

the standard RS-232 port.

The PXIS-2558T is a derivative model with an integrated 8.4” LCD

that supports an 800x600 resolution and touch panel capability.

The integrated display allows you to carry the PXI-based testing

equipment anytime and anywhere. Combined with the high-p erfo rmance ADLINK PXI-3800 Series (PXIS-2558T-A) or PXI-3900

Series (PXIS-2558T-B) controller , the PXIS-2558T delivers a complete testing equipment that is suitable for a variety of app lications.

These PXI chassis come with an industrial-grade 350 W AC power

supply, front panel LEDs, and easy-access PXI/CompactPCI slots

with card guides for convenient installation and use. With innovative features and robust design, the PXIS-2508 and PXIS-2558T

are your best choices of PXI platform for all your test and measurement requirements.

Introduction 1

Page 12

1.1 Features

X Compliant with PXI Specification Rev. 2.2

X Compact 8-slot PXI chassis with one system slot and seven

PXI/CompactPCI peripheral slots

X 0°C to 55°C extended operating temperature range

X 41.6 dBA silent operation

X Intelligent chassis management

Z Automatic fan speed control

Z Round-the-clock chassis status monitoring

Z Remote chassis management including on/off control

X 5.9 kg lightweight aluminum-metal construction

X 8.4" built-in LCD with touch panel (PXIS-2558T only)

X 350 W industrial-grade AC power supply

X Power, temperature, and fan monitoring LEDs

2Introduction

Page 13

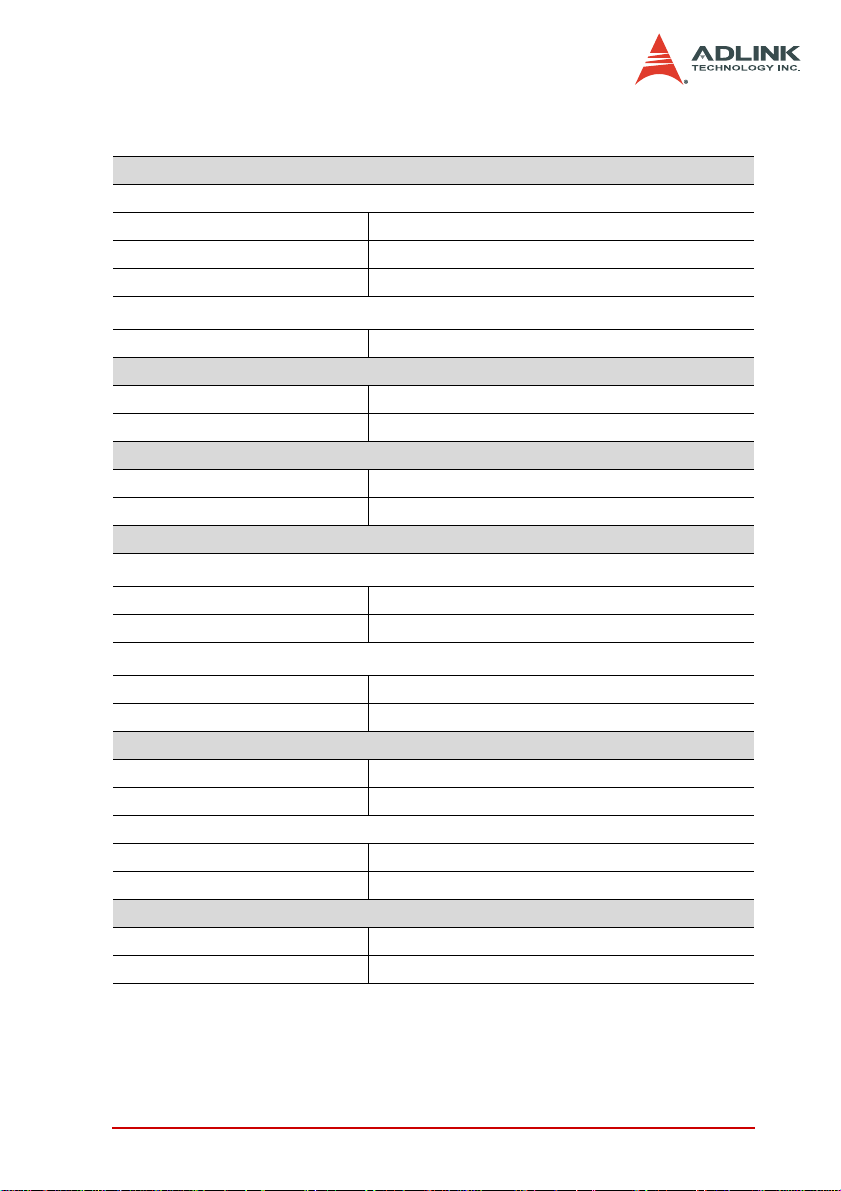

1.2 Specifications

Power supply

AC Input

Input voltage range 100 V to 240 V

Input voltage frequency 50 to 60 Hz

Input current rating 8 A/115 V or 4 A/230 V

DC Output

Total DC power output 350 W

Integrated devices (PXIS-2558T only)

Display 8.4” TFT LCD with 800x600 resolution

Input devices Built-in touch panel

Cooling

Fans 2 x 60 CFM fans with filters

Per slot cooling capacity 25 W (verified by 55°C chamber test)

Acoustic emissions

Sound Pressure Level (dBA) measure at operator position

Minimum fan speed 41.6 dBA

Maximum fan speed 47.3 dBA

Sound Power (dBA)

Minimum fan speed 51.9 dBA

Maximum fan speed 55.5 dBA

Physical

PXI slots 8 (1 system slot and 7 peripheral slots)

Dimension 280 mm x 177 mm x 303 mm (W x H x D)

Weight

PXIS-2508 5.9 kg (13 lbs)

PXIS-2558T 6.4 kg (14 lbs)

Operating environment

Ambient temperature 0°C to 55°C

Relative humidity 10% to 90%, non-condensing

1

2

3

Introduction 3

Page 14

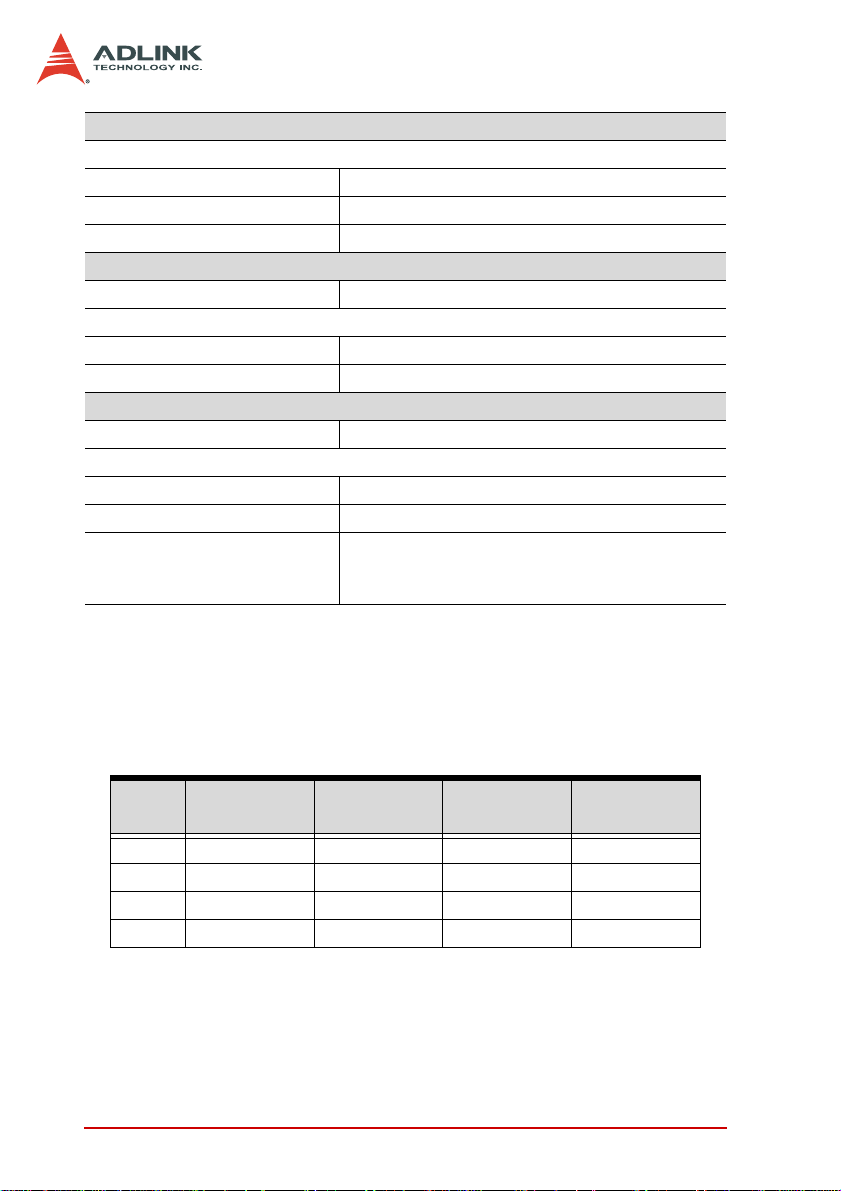

Storage environ m ent

Ambient temperature

PXIS-2508 -20°C to 70°C

PXIS-2558T 0°C to 70°C

Relative humidity 10% to 90%, non-condensing

Shock and vibration

Functional shock 30 G half-sine, 11 ms pulse duration

Random vibration

Operating 5 Hz to 500 Hz, 0.5 Grms, 3 axes

Non-operating 5 Hz to 500 Hz, 2.46 Grms, 3 axes

Certifications

Safety IEC 61010-1/EN 61010-1

Electromagnetic compatibility

Emissions EN 55011 Class A

Immunity EN 61326-1

CE compliance The PXIS-2508 and PXIS-2558T meet the

essential requirements of applicable European

Directives

1

See DC Output Table below.

2

Measured at operator position, tested in accordance with ISO 7779:1999/

Amd.1:2003(E)

3

Tested in accordance with ISO 7779:1999/Amd.1:2003(E)

*Specifications are subject to change without notice.

DC Output Table

VDC Minimum Maximum

Load

Regulation

Max. Ripple

& Noise

+5 V 3.0 A 35 A ±5% 50 mV

+12 V 2.0 A 18 A ±5% 120 mV

+3.3 V 1.0 A 20 A ±5% 50 mV

-12 V 0.1 A 2 A ±10% 150 mV

The combined output power of +5V and +3.3V shall not exceed 35A.

4Introduction

Page 15

1.3 Unpacking Checklist

Before unpacking, check the shipping carton for any damage. If

the shipping carton and/or contents are damaged, inform your

dealer immediately. Retain the shipping carton and packing materials for inspection. Obtain authorization from your dealer before

returning any product to ADLINK.

Check if the following items are included in the package.

Item PXIS-2508

3U 8-slot PXI chassis with 350 W

AC power supply and

3U 8-slot PXI chassis with 8.4”

touch panel LCD and 350 W AC

power supply

Power cords (110 V and 220 V) O O O

Filler panel kit for unused/reserved

slots including one 3-slot panel and

seven 1-slot panels

Touch panel stylus with two holders X O O

Two extra fan filters O O O

ADLINK All-in-One CD O O O

User’s manual O O O

OXX

XOO

OOO

PXIS-

2558T-A

PXIS-

2558T-B

NOTE OEM version package may vary depending on customer

requests. The assigned controller and/or peripheral modules may be pre-installed and shipped with the chassis.

Inquire with your dealer for additional information on

these options.

Introduction 5

Page 16

6Introduction

Page 17

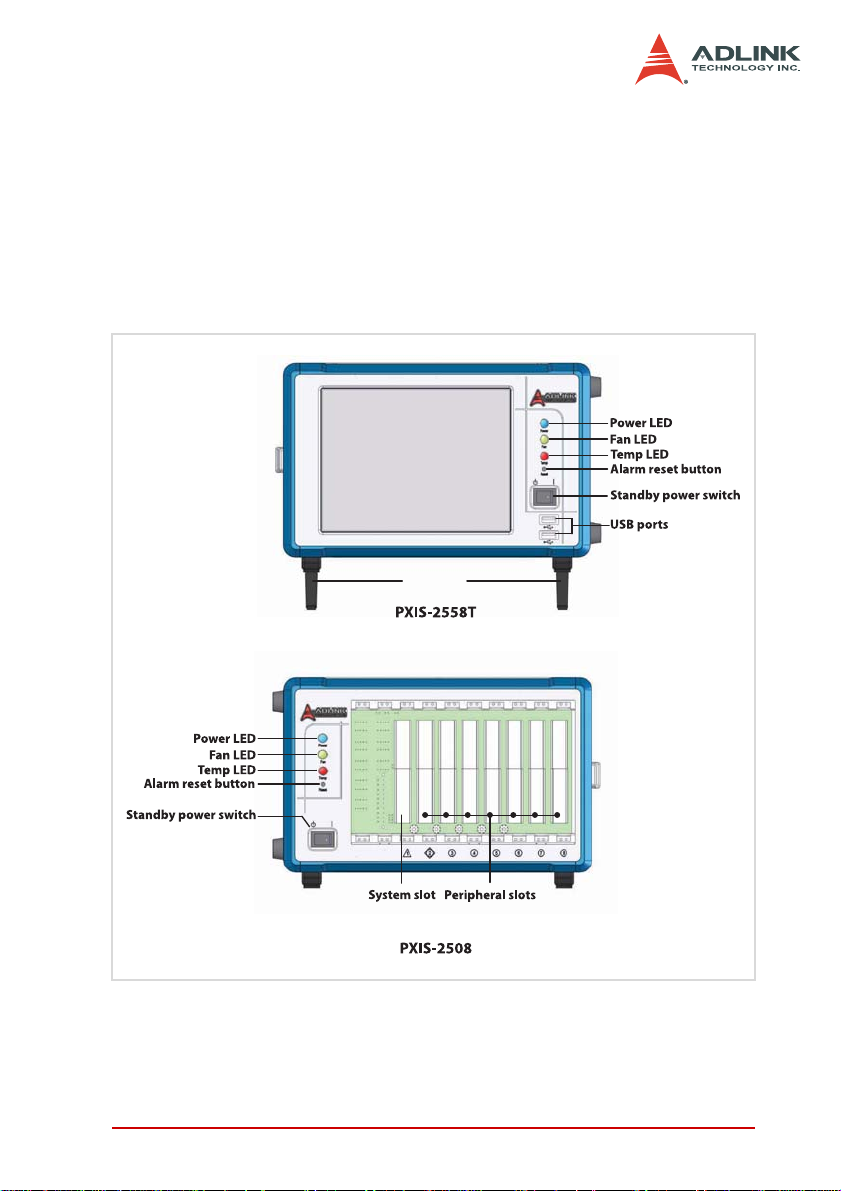

2 Chassis Overview

LCD

Foot stand

This section describes the PXIS-2508/2558T chassis including the

location of basic components and control, dimensions, and backplane features.

2.1 Views

Front Panel

Figure 2-1: PXIS-2508/2558T Front Panel

Chassis Overview 7

Page 18

LED Indications

LED

On Off Blinking

Power (Blue) DC voltages are

supplied

normally.

Fan (Green) Fans are

operating

normally.

Temp (Amber) Chassis

temperature is

normal

No DC power is

supplied.

The system is

off.

The system is

off.

Status

• 5 V or 3.3 V exceeds

±7% range

• 12 V or -12 V exceeds

±12% range

Any of the fans is

operating in a speed

lower than 500 RPM

Chassis temperature

exceeds 50°C

Alarm Reset Button

The alarm reset button enables you to stop the chassis alarm

during an error or critical system event. To stop the alarm,

press the alarm reset button.

8 Chassis Overview

Page 19

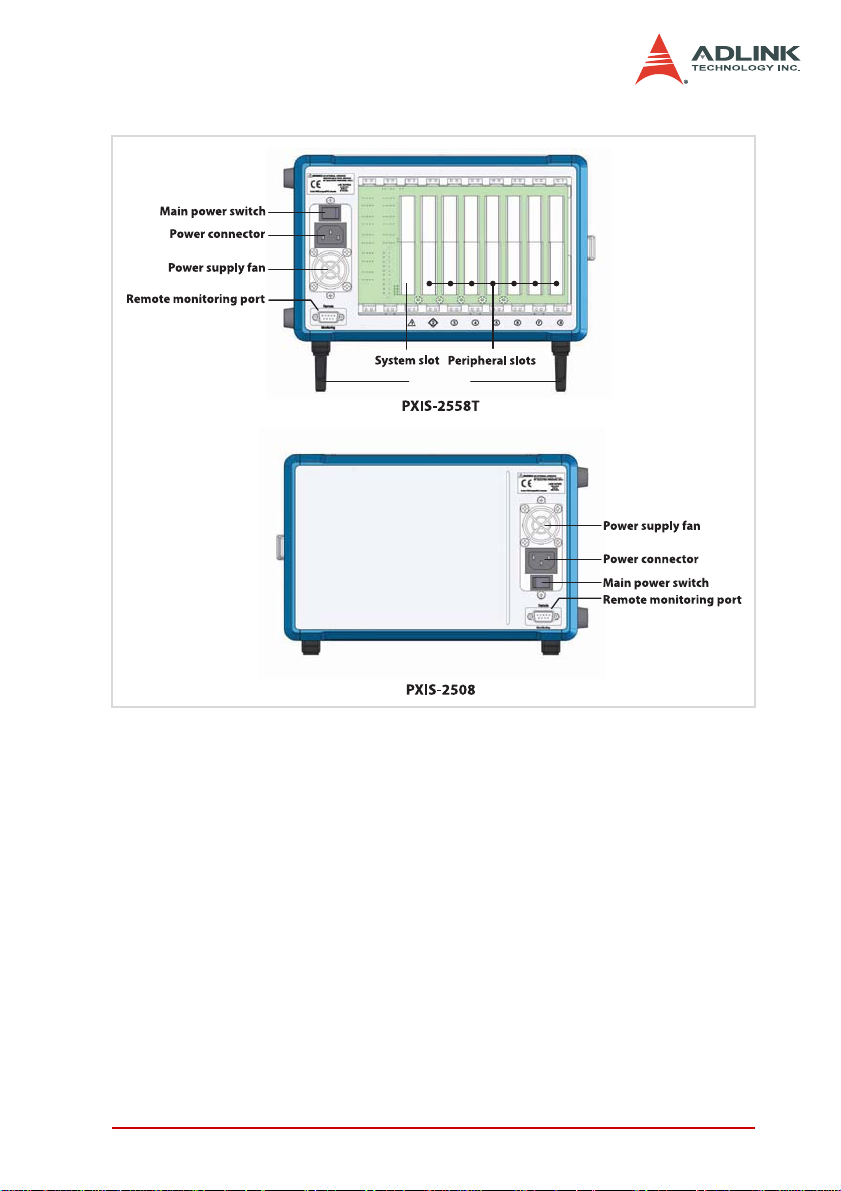

Rear Panel

Foot stand

Figure 2-2: PXIS-2508/2558T Rear Panel

Chassis Overview 9

Page 20

Left Panel

Figure 2-3: PXIS-2508/2558T Left Panel

10 Chassis Overview

Page 21

Right Panel

Figure 2-4: PXIS-2508/2558T Right Panel

Chassis Overview 11

Page 22

Top Panel

Figure 2-5: PXIS-2508/2558T Top Panel

12 Chassis Overview

Page 23

Base Panel

Figure 2-6: PXIS-2508/2558T Base Panel

Chassis Overview 13

Page 24

2.2 Backplane Features

Inter-operability with CompactPCI

With backplanes that are compliant with PXI Specification Rev.

2.2, the PXIS-2508 and PXIS-2558T are designed to support both

standard PXI and CompactPCI modules.

The signals on the backplane’s P1 connector meet the requirements of CompactPCI specifications for both peripheral and system modules. The PXI-specific signals located on P2 are reserved

or unused in CompactPCI 64-bit specifications. This allows peripheral modules with CompactPCI 64-bit specifications to function in

both PXIS-2508 and PXIS-2558T.

NOTE CompactPCI peripheral modules which operate with rear

I/O modules may not work in PXIS-2508/2558T due to

the conflict between rear I/O signals and PXI-specific signals on J2.

System Controller Slot

Slot 1 is designated as the system controller slot as defined by PXI

specifications. The PXIS-2508/PXIS-2558T can accommodate a

PXI system controller with up to 3-slot width. As defined in PXI

specifications, the system controller slot allows the controller to

expand to the left to prevent it from occupying the peripheral slot

space.

Star Trigger Slot

Slot 2 is designated as the star trigger (ST) slot. This slot comes

with dedicated trigger lines between itself and peripheral slots 3 to

8. The star trigger functionality is intended to provide precise trigger signals to the peripheral modules by installing a specific star

trigger controller modules in the ST slot. The star trigger slot can

be also used as a general peripheral slot if you will not use the star

trigger functionality.

14 Chassis Overview

Page 25

Peripheral Slots

The PXIS-2508/2558T comes with seven peripheral slots including the star trigger slot. Each peripheral slot supports a 3U PXI/

CompactPCI peripheral module.

Figure 2-7: PXI Bus Signal Routing

Local Bus

The PXI backplane local bus is a daisy-chained bus that connects

each peripheral slot with its adjacent (left/right) peripheral slots.

Each local bus has 13 lines and can transmit analog or digital signals between modules. It also provides a high-speed side-band

communication path that does not affect the PXI bandwidth.

Based on PXI specifications, the local bus connects all adjacent

slots except slots 1 and 2.

Chassis Overview 15

Page 26

Trigger Bus

The trigger bus is an 8-line bus that connects all PXI slots in the

same PCI segment. You can use the trigger bus as an intermodule

synchronization mechanism. PXI modules can transmit trigger or

clock signals to one another through the trigger bus, enabling precise timed responses to asynchronous external events that the

system is monitoring or controlling.

System Reference Clock

The backplane comes with a PXI 10 MHz system reference clock

(PXI_CLK10). An independent buffer (having source impedance

matched to the backplane and a skew of less than 1 ns between

slots) drives the clock signal generated from a high-p recision oscillator to each peripheral slot. You can use this common reference

clock signal to synchronize multiple modules in a PXI chassis.

16 Chassis Overview

Page 27

3 Installation

The chapter tells you how to install the system controller, peripheral modules, and drivers to the PXIS-2508/2558T chassis. It also

provides information on cooling considerations, and installation/

calibration of the touch panel (PXIS-2558T only)

3.1 Installing the System Controller

The PXIS-2508/2558T comes with a system controller slot that

supports a PXI system controller. We recommend the following

system controllers for use with the PXIS-2558T:

X PXI-3800 Series for PXIS-2558T-A model

X PXI-3900 Series for PXIS-2558T-B model

To install the system controller:

1. Make sure that the CPU, memory module(s), and storage device(s) are properly installed on the system controller module.

2. Locate the system controller slot (Slot 1).

3. Push down (loose) the system controller module’s ejector/injector handle(s).

Installation 17

Page 28

4. Align the module’s top and bottom edges to the card

guides, then carefully slide the module into the chassis,

5. Pull up the ejector/injector handle(s) until the module is

properly connected to the chassis backplane.

6. Fasten the screws on the module front panel, then connect all devices to the system controller.

18 Installation

Page 29

3.2 Installing Peripheral Modules

The PXIS-2508/2558T supports up to seven PXI/cPCI peripheral

modules, including a star trigger module.

To install a peripheral module:

1. Select an available peripheral slot (slots 2 to 8).

2. Push down (loose) the peripheral module’s ejector/injec-

tor handle(s), then align the module’s top and bottom

edges to the card guides.

3. Carefully slide the module into the chassis..

4. Pull up the ejector/injector handle until the module is

properly connected to the chassis backplane.

Installation 19

Page 30

5. Fasten the screw on the module front panel, then connect all devices.

20 Installation

Page 31

3.3 Cooling Considerations

The PXIS-2508/2558T implements a forced air-cooling mechanism to maintain a stable chassis and power supply temperature.

Room/cold air is taken in by internal chassis fans from the air inlet

apertures at the bottom of th e chassis while hot air is exhausted

though the air outlet apertures on top. Refer to the illustration

below.

For bench top installations, provide adequate clearance for the air

inlet and outlet apertures. Keep other objects or equipment at

least 5 cm (2 in) away from the outlet apertures and avoid covering these holes. For optimum airflow, provide ample clearance for

the air inlet apertures and open the foot stands, if possible.

There are also air inlet apertures on one side of the chassis for

power supply ventilation. Hot air from the power supply is

exhausted through the chassis rear. Maintain a 2.5 cm (1 in) clearance on the chassis sides for adequate power supply ventilation.

Installation 21

Page 32

3.4 Powering up the System

The PXIS-2508/2558T is equipped with a universal power supply

unit that does not require input voltage selection.

To turn on the system:

1. Connect one end of the supplied power cable to the

power connector located at the rear side of the chassis.

2. Plug the other end of the AC power cord to a properly

grounded wall socket or power strip.

3. Turn on the main power switch (|).

22 Installation

Page 33

4. Turn on the standby power switch at the front panel. The

power LED in the front panel lights up green and the

chassis fans start to operate.

To turn off the system:

1. Shut down the system via the operating system.

2. Move the standby power switch to standby position ( )

OR

3. Turn off the main power switch (O).

IMPORTANT When you put the system into standby mod e using the

standby power switch, wait three seconds before you

turn on the system again. This protects installed PXI

modules from damage.

If you turn on the system immediately from standy-by

mode, it may take at least three seconds for the POST

messages to appear on screen.

Installation 23

Page 34

3.5 Installing the OS

Install the operating system that your system controller supports.

For more information, refer to the documentation provided by the

operating system vendor and the system controller manual.

Most operating systems requires installation from a floppy or optical disk drive. These devices must be configured, installed, and

tested with the supplied drivers before attempting to install a new

operating system.

Consult the release notes and installation documentation provided

by the operating system vendor for documentation discrepancies

and/or compatibility issues, problems, and solutions.

3.6 Installing Device Drivers

Installing the Chassis Description File (chassis.ini)

To allow inter-operability of PXI platform and modules from different vendors, PXI specifications define the hardware description

files to describe the hardware characteristics in ASCII text format.

System integrators can use the hardware description files to configure the system with various PXI controller, PXI chassis, and PXI

modules.

ADLINK provides a complete list of the chassis description files

(chassis.ini) for the PXI chassis. You can find the chassis description files in X:\Driver Installation\PXI Platform\PXI Platform

Description\ (X: is the CD-ROM drive where you placed the

ADLINK All-in-One CD). A simple how to document is also existed

in the directory to illustrate the procedures of using the chassis

description file with third-party software to build up your PXI system.

24 Installation

Page 35

Installing the VGA driver (PXIS-2558T only)

The PXIS-2558T is equipped with a 8.4” LCD with touch p anel feature. You must install the correct drivers for the LCD and the touch

panel to function.

There are two PXIS-2558T chassis derivatives: PXIS-2558T-A for

use with an ADLINK PXI-3800 Series controller and PXIS-2558TB for use with an ADLINK PXI-3900 Series controller. Make sure

to install the correct drivers according to the installed controllers.

You may find the VGA drivers in the ADLINK All-in-One CD. Refer

to the list below:

X For PXIS-2558T-A with a PXI-3800 controller, the VGA

driver is located in this folder:

X:\Driver Installation\PXI Platform\PXI

controller\PXI-3800\VGA\

X For PXIS-2558T-B with a PXI-3910 or PXI-3920 controller,

the VGA driver is located in this folder:

X:\Driver Installation\PXI Platform\PXI

controller\PXI-3910_20\VGA\

X For PXIS-2558T-B with a PXI-3950 controller, the VGA

driver is located in this folder:

X:\Driver Installation\PXI Platform\PXI

controller\PXI-3950\VGA\

To install the VGA driver:

1. Connect an external monitor to the VGA port of the PXI

controller.

2. Adjust the PXI controller BIOS Setup to output the video

signals using the rear panel I/O. Refer to the PXI controller documentation for details.

3. Install the correct VGA driver according to the PXI con-

troller. Refer to the list above.

4. If the VGA driver support s dua l-display mod e, make sure

the video signal is output to both display devices (monitor and notebook). Refer to the PXI controller documentation for details.

Installation 25

Page 36

Installing the Touch Panel Driver (PXIS-2558T only)

The PXIS-2558T LCD is equipped with touch panel functionality

for convenient data input and GUI navigation.

To install the touch panel driver:

1. Connect a USB CD-/DVD-ROM to the system or PXI

controller.

2. Place the ADLINK All-in-Once CD in the optical drive.

3. Locate the touch panel drivers in:

X:\Driver Installation\PXI Platform\PXI

chassis\PXIS-2508_2558T\Touch Panel\

then double-click on the Setup.exe file to begin installation.

4. After installation is finished, a calibration program

appears. Refer to the next section for details.

26 Installation

Page 37

Calibrating the Touch Panel

After installing the touch panel driver, you need to calibrate the

screen for accurate touch operation. The calibration tool (XTouchware) is automatically installed together with the touch panel

driver.

To calibrate the touch panel:

1. Tap or double-click on the XTouchWare icon from the

desktop or launch the utility from the Windows Start

menu.

2. Tap or click on the Calibration button. A 4-point calibra-

tion window appears.

Installation 27

Page 38

3. Tap or click on the intersection of the blinking X symbol,

then hold for a few seconds until it stops blinking. Repeat

the process for all X symbols that will appear on four corners of the screen.

4. When finished, click OK to store the calibration data.

28 Installation

Page 39

Using the Touch Panel (PXIS-2558T only)

The PXIS-2558T touch panel LCD provides an intuitive way to

interact with the operating system. You can use the touch panel as

a replacement for a mouse. Use the supplied touch panel stylus or

your finger to move the cursor onscree n. The table below lists all

mouse operations and their corresponding touch panel equivalents.

Mouse operation Touch panel

Left-click Tap the screen once

Right-click Tap and hold the screen for 3 to 5 seconds

Double-click Tap the screen twice

Drag and drop Tap the screen, then drag the window by moving

the stylus or your finger

Installation 29

Page 40

30 Installation

Page 41

4 Remote Management

The PXIS-2508 and PXIS-2558T chassis provide an advanced

remote monitoring and control functions. The chassis status,

including it internal temperature, fan speed, and DC voltages, are

exported via the standard RS-232 port located in the rear panel

allowing you to monitor the system on a remote computer. You

may also use a remote computer to turn the system on or off

through the monitoring port by sending software commands.

To remotely monitor and control the PXIS-2508/2558T, you need

to connect the remote monitoring port to a remote computer using

a standard RS-232 cable.

Remote Management 31

Page 42

4.1 Installing the Monitor Utility

You can find a setup file to install the remote monitoring utility and

function library in ADLINK All-in-One CD.

To install the monitoring utility:

1. Connect a USB CD-/DVD-ROM to the system controller.

2. Place the ADLINK All-in-Once CD in the optical drive.

3. Locate the monitoring utility in this folder:

X:\Driver Installation\PXI Platform\PXI

chassis\PXIS-2508_2558T\RemoteMon\

then double-click on the Setup.exe file to begin installation.

32 Remote Management

Page 43

4.2 Monitoring the System

Using the Monitor Utility (PXISRemoteMonUtil)

To monitor the system using the monitor utility:

1. Launch the PXISRemoteMonUtil.

2. Select the COM port that connects the remote computer

with the PXIS-2508/2558T (COM5 in this example).

Remote Management 33

Page 44

3. Click Initialize to initialize the COM port. If the COM port

is successfully initialized, the RUN button is enabled.

4. Click the RUN to display the chassis temperature, fans’

speed, and DC voltages. These values automatically

update.

5. Click STOP to stop monitoring.

34 Remote Management

Page 45

Using the Monitoring/Control Function Library

You can use the monitoring/control function library to create a customized program that would monitor and control the PXIS-2508/

2558T. Refer to the data structure and function library below.

Data Structure

In the library, a data structure is defined to describe the chassis

status.

typedef struct tagChassisStatus

{

BYTE PowerStatus

//Fan status and RPM

BYTE Fan1Status;

BYTE Fan2Status;

BYTE Fan3Status;

BYTE Fan4Status;

BYTE Fan5Status;

BYTE Fan6Status;

float Fan1RPM;

float Fan2RPM;

float Fan3RPM;

float Fan4RPM;

float Fan5RPM;

float Fan6RPM;

//Temperature sensor status and reading in

degree centigrade

BYTE Temp1Status;

BYTE Temp2Status;

float Temp1Reading;

float Temp2Reading;

//DC status and reading

BYTE DC1Status;

BYTE DC2Status;

BYTE DC3Status;

BYTE DC4Status;

float DC1Reading;

float DC2Reading;

float DC3Reading;

float DC4Reading;

Remote Management 35

Page 46

BYTE Reserve1;

BYTE Reserve2;

} ChassisStatus;

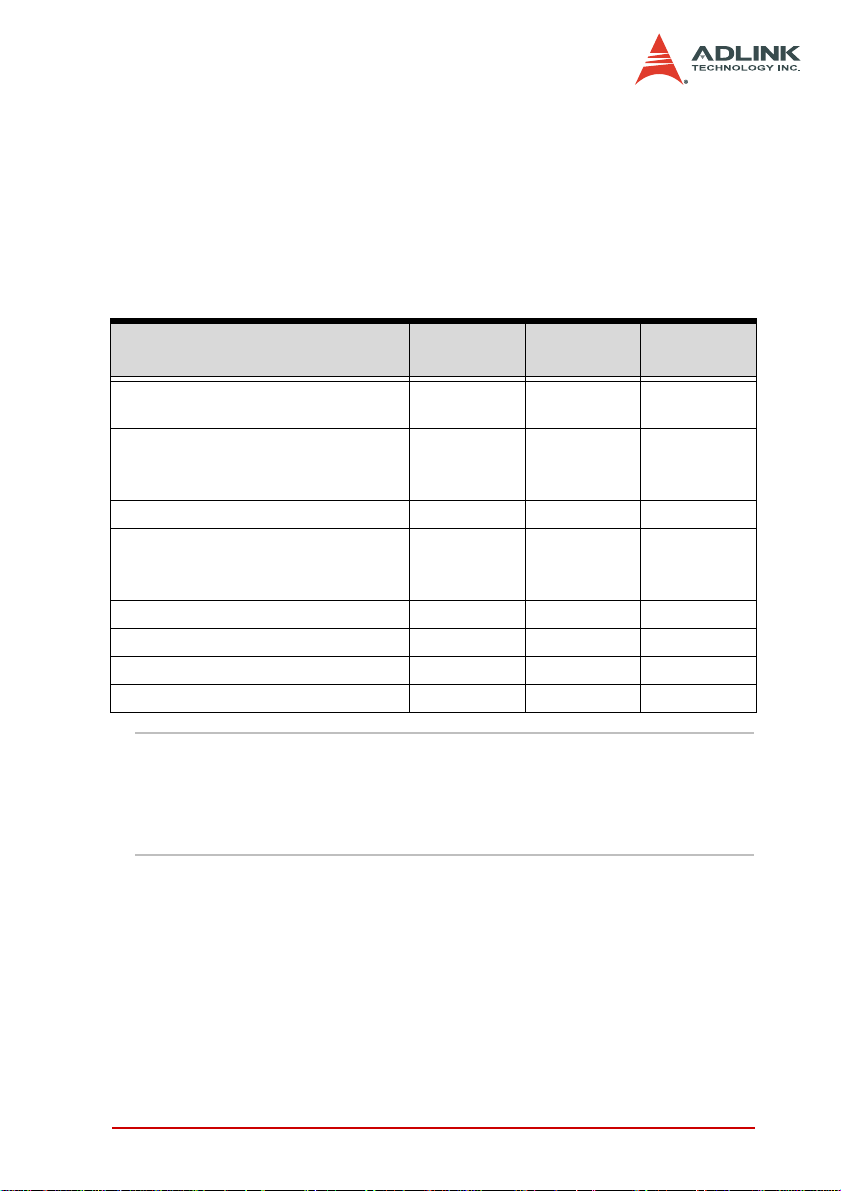

The variables in the data structure are illustrated below.

Variable Description Type Value

PowerStatus Power On/Off status BYTE 0: Off

1: On

Fan1Status Fan#1 operating status BYTE 0: Normal

1: Abnormal

Fan2Status Fan#2 operating status BYTE 0: Normal

Fan3Status Not used for PXIS-2508/2558T BYTE N/A

Fan4Status Not used for PXIS-2508/2558T BYTE N/A

Fan5Status Not used for PXIS-2508/2558T BYTE N/A

Fan6Status Not used for PXIS-2508/2558T BYTE N/A

Fan1RPM Fan#1 speed in RPM float RPM value

Fan2RPM Fan#2 speed in RPM float RPM value

Fan3RPM Not used for PXIS-2508/2558T float N/A

Fan4RPM Not used for PXIS-2508/2558T float N/A

Fan5RPM Not used for PXIS-2508/2558T float N/A

Fan5RPM Not used for PXIS-2508/2558T float N/A

Temp1Status Temperature sensor#1 status BYTE 0: Normal

Temp2Status Temperature sensor#1 status BYTE 0: Normal

Temp1Reading Reading of temperature sensor#1 in °C float Temperature value

Temp1Reading Reading of temperature sensor#2 in °C float Temperature value

DC1Status DC 12V status BYTE 0: Normal

DC2Status DC 5V status BYTE 0: Normal

DC3Status DC 3.3V status BYTE 0: Normal

DC4Status DC -12V status BYTE 0: Normal

DC1Reading DC 12V voltage reading float Voltage value

DC2Reading DC 5V voltage reading float Voltage value

DC3Reading DC 3.3V voltage reading float Voltage value

1: Abnormal

1: Abnormal

1: Abnormal

1: Abnormal

1: Abnormal

1: Abnormal

1: Abnormal

36 Remote Management

Page 47

Variable Description Type Value

DC4Reading DC -12V voltage reading float Voltage value

Function Reference

InitCOM

Description

Initializes the remote computer COM port connected to the remote

monitoring port of the PXIS-2508/2558T.

Syntax

HANDLE InitCOM(LPCSTR com)

Parameter

com A string denotes the COM port. Can be COM1 ~

COM8.

Return Value

A handle to the initialized COM port. If the function returns NULL,

the initialization of COM port failed.

Example

HANDLE hCOM;

hCOM= InitCOM(“COM1”);

Remote Management 37

Page 48

GetChassisStatus

Description

Gets the chassis status and stores the status in a ChassisStatus

structure. You can invoke this function periodically to u pdate the

chassis status.

Syntax

BOOL GetChassisStatus(HANDLE hCom, ChassisStatus*

Status)

Parameters

hCom The initialized COM port.

Status ChassisStatus data structure that stores the chassis

status

Return Value

TRUE if the function succeeded. FALSE if the function failed.

Example

ChassisStatus status;

BOOL ret;

ret= GetChassisStatus(hCom, &status);

38 Remote Management

Page 49

SetChassisPowerOn

Description

Powers on the PXIS-2508/2558T.

Syntax

BOOL SetChassisPowerOn (HANDLE hCom)

Parameter

com The initialized COM port.

Return Value

TRUE if the function succeeded. FALSE if the function failed.

Example

BOOL ret;

ret= SetChassisPowerOn (hCom);

Remote Management 39

Page 50

SetChassisPowerOff

Description

Powers off the PXIS-2508/2558T. You should shut down the system controller via the operating system before turning off the chassis power.

Syntax

BOOL SetChassisPowerOff (HANDLE hCom)

Parameter

com The initialized COM port.

Return Value

TRUE if the function succeeded. FALSE if the function failed.

Example

BOOL ret;

ret= SetChassisPowerOff (hCom);

40 Remote Management

Page 51

CloseCOM

Description

Closes the initialized COM port.

Syntax

BOOL CloseCOM(HANDLE hCom)

Parameter

com The initialized COM port.

Return Value

TRUE if the function succeeded. FALSE if the function failed.

Example

BOOL ret;

ret= CloseCOM (hCom);

Remote Management 41

Page 52

42 Remote Management

Page 53

Appendix A Troubleshooting and

Maintenance

A.1 Installation Problems

Failure to start the system usually results from incorrect installation of the system controller, peripheral modules, and other components. Go through the following che cklist befo re you start up the

system.

X The system controller is properly installed and secured.

X All peripheral modules are properly seated on the slots.

X All cables are properly connected to the system controller/

peripheral modules.

X All peripheral modules installed are compatible for use in

the chassis.

X The power cord is properly plugged into the chassis power

connector and power outlet/wall socket/power strip.

If the system fails to turn on even after all installation conditions

are met, remove all peripheral modules that you installed, then try

again. If the system turns on properly, try installing one peripheral

module at a time, then test if the system will power-up. You may

also try installing the modules into different slots until you get the

desired result.

A.2 BIOS Beeps

BIOS beeps indicate errors in system initialization. These beeps

are usually associated with video and memory errors. If the system beeps during start up, check if the display is properly connected to the system controller or if the integrated LCD drivers

(PXIS-2558T only) are properly installed. You may also check if

the memory modules are properly installed in the system controller.

Appendix 43

Page 54

A.3 Basic Troubleshooting

Problem What to Do

System fails to power up

There is no LCD display

(PXIS-2558T only)

There is no video output

in the external display

X Check if the power cord is properly

X Check if the wall socket/power strip

X Check if the main power switch at

X Make sure the standby power button

X Make sure the system is turned on.

X Connect an external display to the

X If video output is present on the

X If video output is not present on the

X If there is no video output even when

X Redirect the video output to the inte-

X Check if your external display is

X Check your display settings and

plugged into the chassis power connector and wall socket/power strip.

is live.

the back of the chassis is turned on.

at the chassis front panel is turned

on.

system controller’s VGA port, then

check if there is video output.

external display, adjust your display

settings and enable LCD video.

external display, check if the system

controller is properly installed.

the system controller is properly

installed, contact ADLINK for further

assistance.

grated LCD (PXIS-2558T only).

functioning.

make sure you enable external

video.

44 Appendix

Page 55

Problem What to Do

The touch panel doesn’t

work

The touch panel is not

responsive enough or is

very sensitive to stylus

and/or finger tap.

X Disconnect an external PS/2 or

USB mouse cable from the system

controller, if any.

X Make sure you installed the touch

panel drivers.

X Run the XTouchware utility to re-

calibrate the touch panel.

X Clean the LCD with a clean cloth.

Appendix 45

Page 56

A.4 Maintenance

Taking Care of the Touch Panel LCD (PXIS-2558T only)

Clean the LCD periodically with a moist cloth for better display.

Observe the following precautions when cleaning the LCD.

X Do not use any abrasive material to wipe the LCD screen to

avoid scratching the LCD surface.

X Do not apply too much pressure on the surface when wiping

the LCD screen.

X Do not use a cleaner that contains alcohol.

X Do not use a rough cloth that could scratch the LCD screen

surface.

X Clean the LCD screen with gentle wipes in one direction.

Changing the Fan Filter

The air inlet fans installed at the bottom of the chassis comes with

a filter to prevent dirt and dust from enteri ng the chassis. You need

to periodically replace the air filter to maintain good chassis airflow.

To change the fan filter:

1. Turn off the chassis, then disconnect all cables connected to the chassis, system controller, and peripheral

modules.

2. Lay the chassis upside down in a flat and stable surface.

3. Loosen five screws, lift the fan tray carefully, then lay it

on top of the chassis.

46 Appendix

Page 57

4. Loosen four screws to remove the fan tray cover.

5. Take off the old air filter.

6. Peel the adhesive on both ends of the new air filter, then

stick them on the fan tray edges. Stretch the filter to

cover the whole fan tray length.

Appendix 47

Page 58

WARNING Make sure the fan blades do not come in contact with the

air filter.

7. Replace the fan tray cover, then re-install the fan tray to

the chassis.

8. Connect all cables, then turn on the system.

Handling the Chassis

While the PXIS-2508/2558T is an ultra-portable testing system, it

is recommended that you transport or carry the chassis using the

handles. The handles are designed to carry the weight of the

chassis for superior portability and balance.

Handling Cables

Treat all cables with care. Do not over exten d any ca ble to prev ent

internal breaking. All cables and plugs must be handled or connected properly.

Cleaning the Exterior

Make sure that you turn the system off before cle aning the cha ssis

exterior. Wipe the exterior with a clean cloth starting from areas

that easily accumulate dust or dirt such as the area in and around

the chassis and power supply air inlet apertures.

Power Requirements

Make sure that the power cord is in good condition before plugging

it into the system. You also need to check the reliability of the

power source. The PXIS-2508/2558T power supply is capable of

handling 100 V to 240 V AC within the 50 Hz to 60 Hz range. Do

not connect the PXIS-2508/2558T on an already overloaded circuit.

48 Appendix

Page 59

Important Safety Instructions

Read and follow all instructions marked on the product and in the

documentation before operating the system. Retain all safety and

operating instructions for future use.

X Read these safety instructions carefully.

X Keep this user’s manual for future reference.

X The equipment should be operated in an ambient tempera-

ture between 0

X The equipment should be operated only from the type of

power source indicated on the rating label. Make sure the

voltage of the power source is correct when connecting the

equipment to the power outlet.

X If the user’s equipment has a voltage selector switch, make

sure that the switch is set to the proper position for the a rea.

The voltage selector switch is set at the factory to the correct voltage.

X For pluggable equipment, ensure they are installed near a

socket-outlet that is easily accessible.

X Secure the power cord to prevent unnecessary accidents.

Do not place anything over the power cord.

X If the equipment will not be in use for long periods of time,

disconnect the equipment from the power outlet to avoid

being damaged by transient over voltage.

X All cautions and warnings on the equipment must be noted.

X Keep this equipment away from humidity.

X Do not use this equipment near water or a heat source.

X Place this equipment on a stable surface when installing to

prevent injury.

X Never pour any liquid into the prod uct to prevent fir e or elec-

trical shock.

°C to 50°C.

Important Safety Instructions 49

Page 60

X Openings in the chassis are provided for ventilation. Do not

block or cover these openings. Make sure there is adequate

space around the system for ventilation when setting up the

work area. Never insert objects of any kind into the ventilation holes.

X To avoid electrical shock, always unplug all power and

modem cables from wall outlets before removing the system covers.

X The equipment must be serviced by authorized technicians

when:

Z The power cord or plug is damaged.

Z Liquid has penetrated the equipment.

Z It has been exposed to moisture.

Z It is not functioning or does not function according to the

user’s manual.

Z It has been dropped and damaged.

Z It has an obvious sign of breakage.

X Never attempt to fix the equipment. For safety reasons, the

equipment should only be serviced by qualified personnel.

50 Important Safety Instructions

Page 61

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and

enjoy all the after-sales services we offer, please read the following carefully.

1. Before using ADLINK’s products please read the user man-

ual and follow the instructions exactly. When sending in

damaged products for repair, please attach an RMA application form which can be downloaded from :

http://rma.adlinktech.com/policy/RMA.doc

2. All ADLINK products come with a limited two-year war-

ranty, one year for products bought in China:

Z The warranty period starts on the day the product is

shipped from ADLINK’s factory.

Z Peripherals and third-party products not manufactured

by ADLINK will be covered by the original manufacturers' warranty.

Z For products containing storage devices (hard drive s,

flash cards, etc.), please back up your data before sending them for repair. ADLINK is not responsible for any

loss of data.

Z Please ensure the use of properly licensed software with

our systems. ADLINK does not condone the use of

pirated software and will not service systems using such

software. ADLINK will not be held legally responsible for

products shipped with unlicensed software installed by

the user.

Z For general repairs, please do not include peripheral

accessories. If peripherals need to be included, be certain to specify which items you sent on the RMA Request

& Confirmation Form. ADLINK is not responsible for

items not listed on the RMA Request & Confirmation

Form.

Warranty Policy 51

Page 62

3. Our rep air ser vice is not covered b y ADLINK's g uarantee

in the following situations:

Z Damage caused by not following instructions in the

User's Manual.

Z Damage caused by carelessness on the user's part dur-

ing product transportation.

Z Damage caused by fire, earthquakes, floo ds , light en in g,

pollution, other acts of God, and/or incorrect usage of

voltage transformers.

Z Damage caused by unsuitable storage environments

(i.e. high temperatures, high humidity, or volatile chemicals).

Z Damage caused by leakage of battery fluid during or

after change of batteries by customer/user.

Z Damage from improper repair by unauthorized ADLINK

technicians.

Z Products with altered and/or damaged serial numbers

are not entitled to our service.

Z This warranty is not transferable or extendible.

Z Other categories not protected under our warranty.

4. Customers are responsible for shipping costs to transport

damaged products to our company or sales office.

5. To ensure the speed and quality of product repair, please

download an RMA application form from our company website: http://rma.adlinktech.com/policy. Damaged products

with attached RMA forms receive priority.

If you have any further questions, please email our FAE staff:

service@adlinktech.com.

52 Warranty Policy

Loading...

Loading...