Page 1

PXIe-3975

PXI Express™ Embedded Controller

User’s Manual

Manual Rev.: 2.00

Revision Date: Dec 29, 2011

Part No: 50-17035-1000

Advance Technologies; Automate the World.

Page 2

Revision History

Revision Release Date Description of Change(s)

2.00 2011/12/29 Initial Release

ii

Page 3

PXIe-3975

Preface

Copyright 2011 ADLINK TECHNOLOGY INC.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect,

special, incidental, or consequential damages arising out of the

use or inability to use the product or documentation, even if

advised of the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

PC, PS/2, and VGA are registered trademarks of International

Business Machines Corp. Borland®, Borland® C, C++ Builder®,

and Delphi® are registered trademarks of the Borland Software

Corporation. LabVIEW™ is a trademark of National Instruments

Corporation. Microsoft®, Visual Basic®, Visual C++®, Windows

Preface iii

®

Page 4

98, Windows® NT, Windows® 2000, Windows® XP, and Windows

Vista® are registered trademarks of Microsoft® Corporation.

PCI™, is a registered trademark of the Peripheral Component

Interconnect Special Interest Group (PCI-SIG).

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component

damage, data loss, and/or program corruption when try-

CAUTION:

ing to complete a task.

®

Information to prevent serious physical injury, component damage, data loss, and/or program corruption

when trying to complete a specific task.

iv Preface

Page 5

PXIe-3975

Table of Contents

Revision History....................................................................... ii

Preface .................................................................................... iii

List of Figures ........................................................................ ix

List of Tables.......................................................................... xi

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 2

1.2 Specifications....................................................................... 3

2 Getting Started ................................................................... 7

2.1 Package Contents ............................................................... 7

2.2 Operating System Installation.............................................. 8

2.3 Hardware Instructions.......................................................... 9

2.3.1 Faceplate Connectors & Indicators ............................ 9

2.3.2 PXI Trigger Connector.............................................. 10

2.3.3 DVI-I Connector........................................................ 11

2.3.4 GPIB Connector ....................................................... 12

2.3.5 Reset Button............................................................. 13

2.3.6 LED Indicators .......................................................... 13

2.3.7 USB 2.0 Ports........................................................... 14

2.3.8 Gigabit Ethernet Ports .............................................. 15

2.3.9 ExpressCard/34........................................................ 16

2.3.10 Onboard Connections and Settings.......................... 17

2.3.11 Installation Environment ...........................................18

2.3.12 Installing the PXIe-3975 ........................................... 19

2.3.13 Replacing the Hard Drive ......................................... 20

2.3.14 Replacing the Battery Backup ..................................21

2.3.15 Clearing CMOS Jumper (JP1) .................................. 24

Table of Contents v

Page 6

3 Driver Installation............................................................. 25

3.1 Installing Windows Drivers................................................. 25

3.2 Installing the Chipset Driver ............................................... 25

3.3 Installing the Graphics Driver............................................. 26

3.4 Installing the Ethernet Driver.............................................. 27

3.5 Installing the GPIB Driver................................................... 27

3.6 Installing the Management Engine Driver .......................... 28

3.7 Installing the PXI Trigger Driver ......................................... 28

3.8 Installing the WDT Driver ................................................... 28

4 BIOS Setup ....................................................................... 31

4.1 Starting the BIOS............................................................... 31

4.2 Main Setup......................................................................... 33

4.3 Advanced Setup................................................................. 34

4.4 Chipset Configuration ........................................................ 35

4.5 Boot Setup ......................................................................... 35

4.6 Security Setup.................................................................... 36

4.7 Save & Exit Setup.............................................................. 36

A Appendix: PXI Trigger I/O Function Reference.............. 39

A.1 Data Types......................................................................... 39

A.2 Function Library ................................................................. 40

A.2.1 TRIG_Init ..................................................................40

A.2.2 TRIG_Close .............................................................. 41

A.2.3 TRIG_SetSoftTrg ...................................................... 41

A.2.4 TRIG_Trigger_Route ................................................ 42

A.2.5 TRIG_Trigger_Clear ................................................. 44

A.2.6 TRIG_GetSoftTrg...................................................... 45

A.2.7 TRIG_Trigger_Route_Query ....................................46

A.2.8 TRIG_GetDriverRevision .......................................... 48

A.2.9 CONTROLLER_GetHwRevision ..............................49

A.2.10 CONTROLLER_GetManufacturer ............................ 50

vi Table of Contents

Page 7

PXIe-3975

A.2.11 CONTROLLER_GetModel ....................................... 51

A.2.12 CONTROLLER_GetSerialNumber ...........................51

B Appendix: Watchdog Timer.............................................. 53

B.1 WDT Function Library........................................................ 53

B.1.1 InitWDT..................................................................... 53

B.1.2 SetWDT .................................................................... 54

B.1.3 StartWDT.................................................................. 55

B.1.4 ResetWDT ................................................................ 55

B.1.5 StopWDT .................................................................. 56

Important Safety Instructions .............................................. 57

Getting Service...................................................................... 59

Table of Contents vii

Page 8

This page intentionally left blank.

viii Table of Contents

Page 9

PXIe-3975

List of Figures

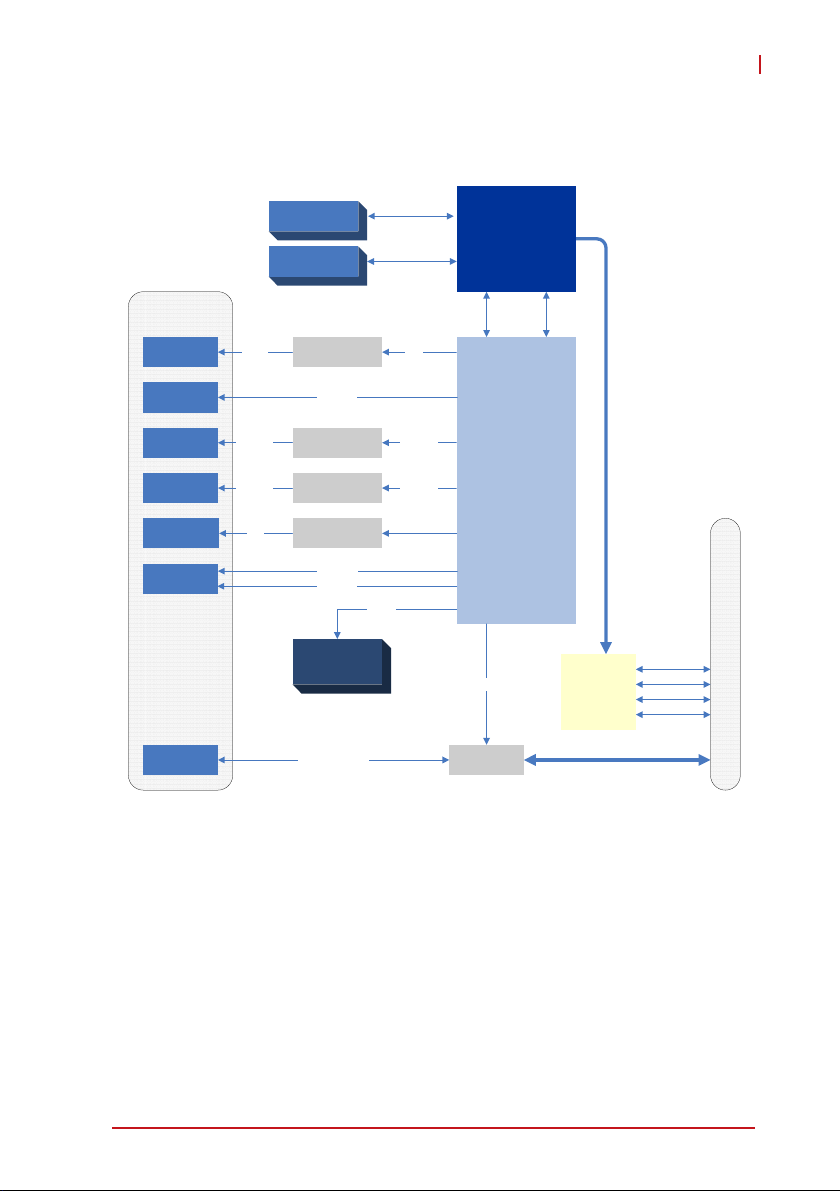

Figure 1-1: PXIe-3975 Functional Block Diagram......................... 3

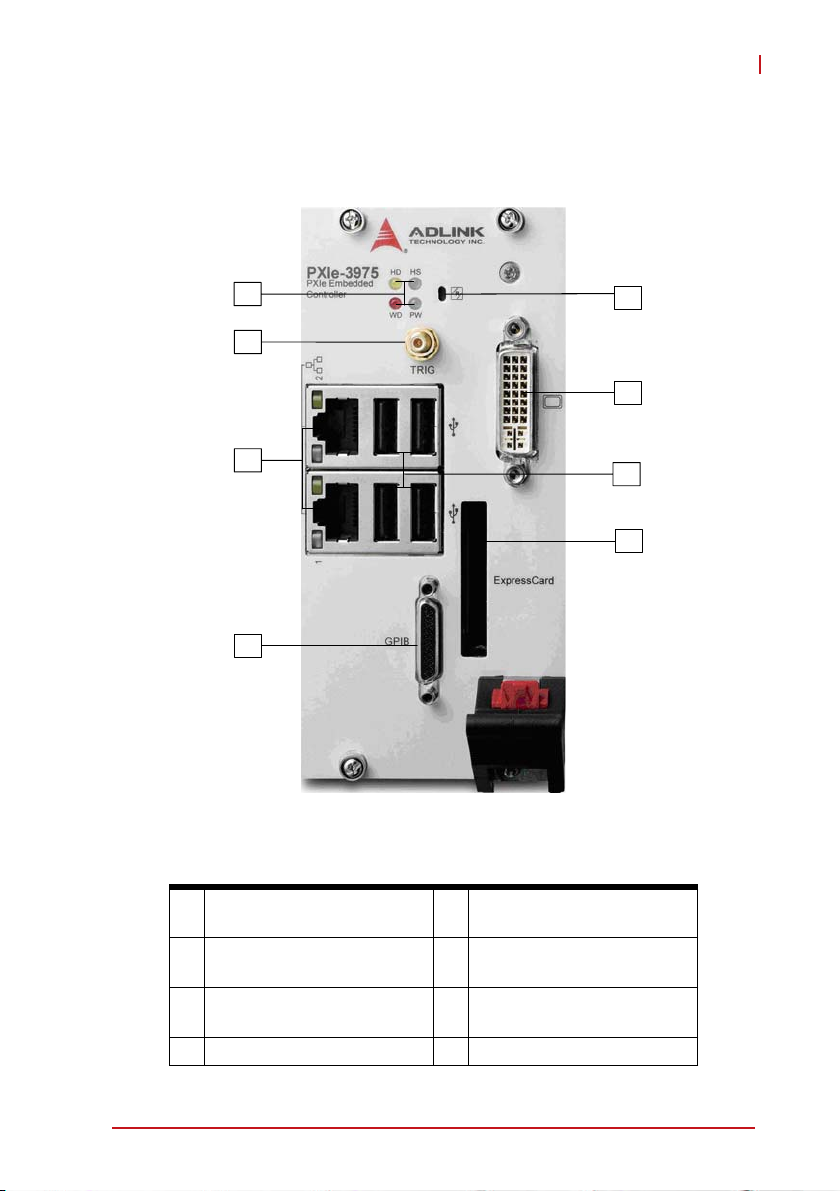

Figure 2-1: PXIe-3975 Faceplate.................................................. 9

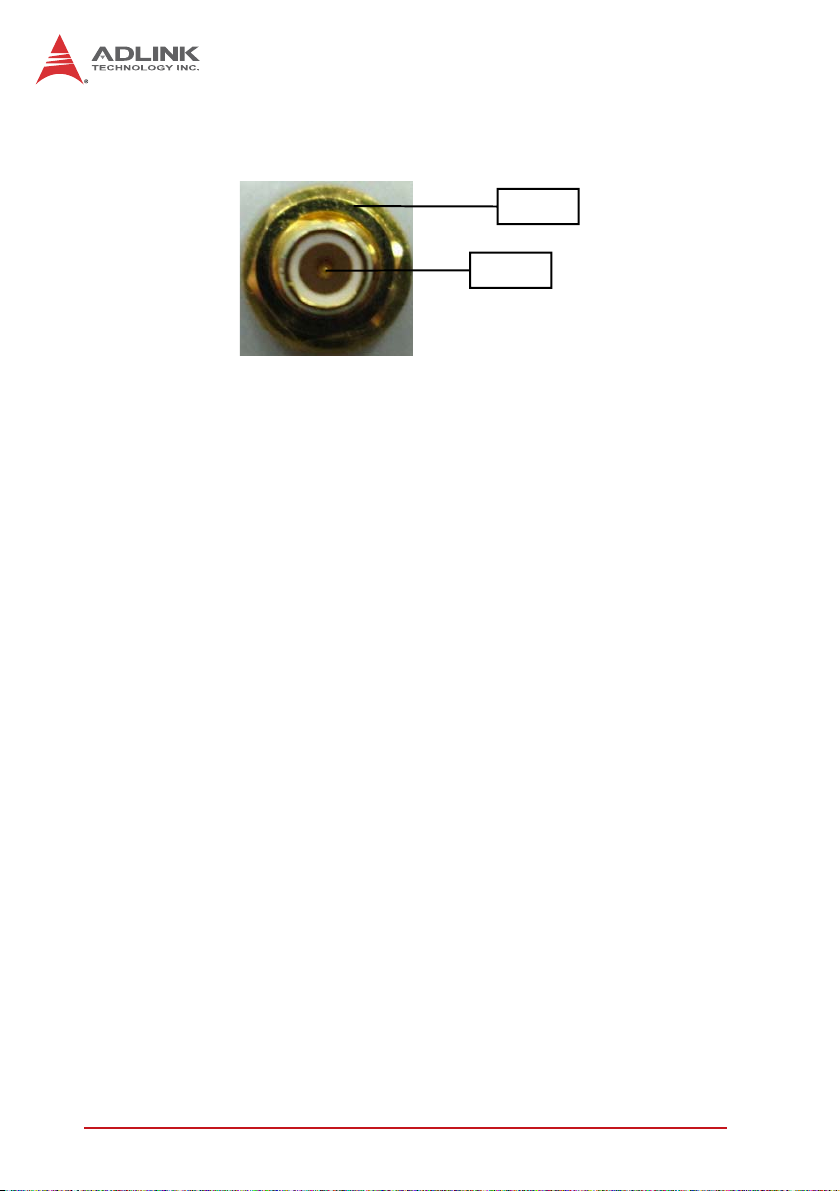

Figure 2-2: PXI Trigger SMB Jack .............................................. 10

Figure 2-3: PXIe-3975 LED Indicators ........................................ 13

Figure 2-4: PXIe-3975 Onboard Configuration ........................... 17

Figure 4-1: BIOS Setup Navigation............................................. 32

List of Figures ix

Page 10

This page intentionally left blank.

x List of Figures

Page 11

PXIe-3975

List of Tables

Table 2-1: DVI-I Pin Assignment..................................................... 11

Table 2-2: GPIB Pin Description ..................................................... 12

Table 2-3: LED Indicator Legend.................................................... 13

Table 2-4: USB 2.0 Port Pin Assignment........................................ 14

Table 2-5: PXIe-3975 Ethernet Port Pin Assignments.................... 15

Table 4-1: BIOS Hot Key Functions................................................ 32

Table 4-2: BIOS Main Setup Menu ................................................. 33

Table 4-3: BIOS Advanced Setup Menu......................................... 34

Table 4-4: BIOS Chipset Configuration Menu................................. 35

Table 4-5: BIOS Boot Setup Menu .................................................35

Table 4-6: BIOS Security Setup Menu............................................ 36

List of Tables xi

Page 12

This page intentionally left blank.

xii List of Tables

Page 13

1 Introduction

The ADLINK PXIe-3975 PXI Express™ embedded controller,

based on the Intel® Core™ i5 processor, is specifically designed

for PXI Express-based testing systems, providing a rugged and

stable operating environment for a wide variety of testing and

measurement applications.

Combining state-of-the-art Intel® Core™ i5-520E 2.4 GHz processors, and up to 8 GB of 1066 MHz DDR3 memory, the PXIe-3975

utilizes two separate computing engines on a single processor,

enabling execution of two independent tasks simultaneously in a

multi-tasking environment. With a configurable PCIe switch, the

PXIe-3975 can support four links x4 or two links x8 PXI Express

link capability, with maximum system throughput of up to 2 GB/s.

PXI Express-based testing systems typically make up a PXI

Express platform and diversified standalone instruments for complex testing tasks. The PXIe-3975 provides ample interface

choices, including GPIB, USB, and ExpressCard, for connecting

and controlling instruments. The PXIe-3975 series also provides

dual Gigabit Ethernet ports, one for LAN connection and the other

for controlling LXI instruments. With flexible instrument control

interfaces and mechanical and electronic reliability, the ADLINK

PXIe-3975 is more than equal to the challenges of the most

demanding PXIe-based testing systems.

PXIe-3975

8GB memory addressing is OS-dependent, such that a 32-bit

operating system may be unable to address the full 8GB of

NOTE:

NOTE:

Introduction 1

memory space. To fully utilize the 8GB memory, 64-bit operating systems are required.

Page 14

1.1 Features

X PXI™-5 PXI Express Hardware Specification Rev.1.0

X Intel

X Dual Channel DDR3 SODIMM

X Maximum System Throughput 2 GB/s

X PXI Express Link Capability

X Pre-installed SATA hard drive at 160 GB, 7200 RPM

X Integrated I/O

X Programmable watchdog timer

®

Core™ i5-520E 2.4 GHz processor for maximum

computing power

Z Up to 8 GB 1066 MHz

Z Four Link Configuration: x4 x4 x4 x4

Z Two Link Configuration: x8 x8

Z Supports 2.5" HDD or SSD

Z SATA 3.0 Gb/s

Z Supports AHCI

Z Dual Gigabit Ethernet ports

Z Four USB 2.0 Ports

Z Built-in GPIB (IEEE488) controller

Z DVI-I video connector

Z ExpressCard/34 expansion slot

Z Trigger I/O for advanced PXI™ trigger functions

2 Introduction

Page 15

1.2 Specifications

PXIe-3975

Front Panel

Connectors

GPIB

connector

USB

connector x4

GbE

connector

GbE

connector

DVI-I

connector

34mm

ExpressCard

SMB

Connector

GPIB

GbE I/F

GbE I/F

DVI

Channel A

204 pin SODIMM

Channel B

204 pin SODIMM

GPIB controller

USB 2.0

GbE controller

82574L

GbE controller

82574L

DVI level shifter

PCIe x 1

USB 2.0

2.5" SATA HDD

Trigger Signal

DDR3

800/1066MHz

DDR3

800/1066MHz

PCI

PCIe x1

PCIe x1

Digital

Display I/F

SATA

Intel® Core™

i5-520E 2.4GHz

Processor

Intel FDI DMI

Intel® QM57

Express Chipset

SMBUS

Trigger Bus

Controller

PCIe Gen1 x8

PCIe Gen2.0

swtich

Trigger Bus

PCIe 2.0x4

PCIe 2.0x4

PCIe 2.0x4

PCIe 2.0x4

PXIe Connector

Figure 1-1: PXIe-3975 Functional Block Diagram

Processor

X Intel

X DMI (Direct Media Interface) with 1 GB/s of bandwidth in

®

Core™ i5-520E 2.4GHz processor

each direction

Chipset

Mobile Intel® QM57 Express

Introduction 3

Page 16

Memory

X Two standard 204-pin DDR3 SODIMM sockets

X Support for +1.5 V DDR3, 800/1066 MHz RAM up to 8 GB

total

X Support for non-ECC unbuffered memory

Video

X DVI output supporting up to 1920x 1200 @ 60 Hz resolution

X CRT output for analog CRT route to DVI-I connector on the

faceplate, supporting up to 2048 x 1536 bpp at 75Hz

X DVI-I connector for both digital and analog video signal out-

put

Hard Drive

Built-in 2.5” 160 GB SATA hard drive, 7200 RPM

I/O Connectivity

Dual Gigabit Ethernet controllers through two RJ-45 connectors

with speed/link/active LED on the faceplate, with upper connector

supporting Wake on LAN.

USB

Four USB 2.0 ports on the faceplate.

GPIB

Onboard IEEE488 GPIB controller through Micro-D 25-pin connector on the faceplate.

ExpressCard/34

34mm wide ExpressCard expansion slot

Trigger I/O

One SMB connector on the faceplate to route an external trigger

signal to/from PXI trigger bus

4 Introduction

Page 17

Dimensions (3-slot 3U PXIe module)

3U/3-slot PXI/Compact PCI standard

60.5 W x 128.7 H x 213.2 D mm (2.38 x 5.07 x 8.39 in.)

Slot Requirements

System slot and 2 controller expansion slots

Weight

0.9 kg (exclusive of packaging)

Environmental

Operating temperature 0 to 55°C

Storage temperature -20 to 70°C

Relative humidity 5 to 95%, non-condensing

Shock and Vibration

Functional shock 30 G, half-sine, 11 ms pulse duration

Random vibration:

X Operating 5 to 500 Hz, 0.21 Grms, 3 axes

X Non-operating 5 to 500 Hz, 2.46 Grms, 3 axes

PXIe-3975

Certification

Electromagnetic compatibility:

X EMC/EMI: CE, FCC Class A

X CE Compliance EN 61326-1

The PXIe-3975 meets the essential requirements of applicable

European Directives.

Introduction 5

Page 18

Power Requirements

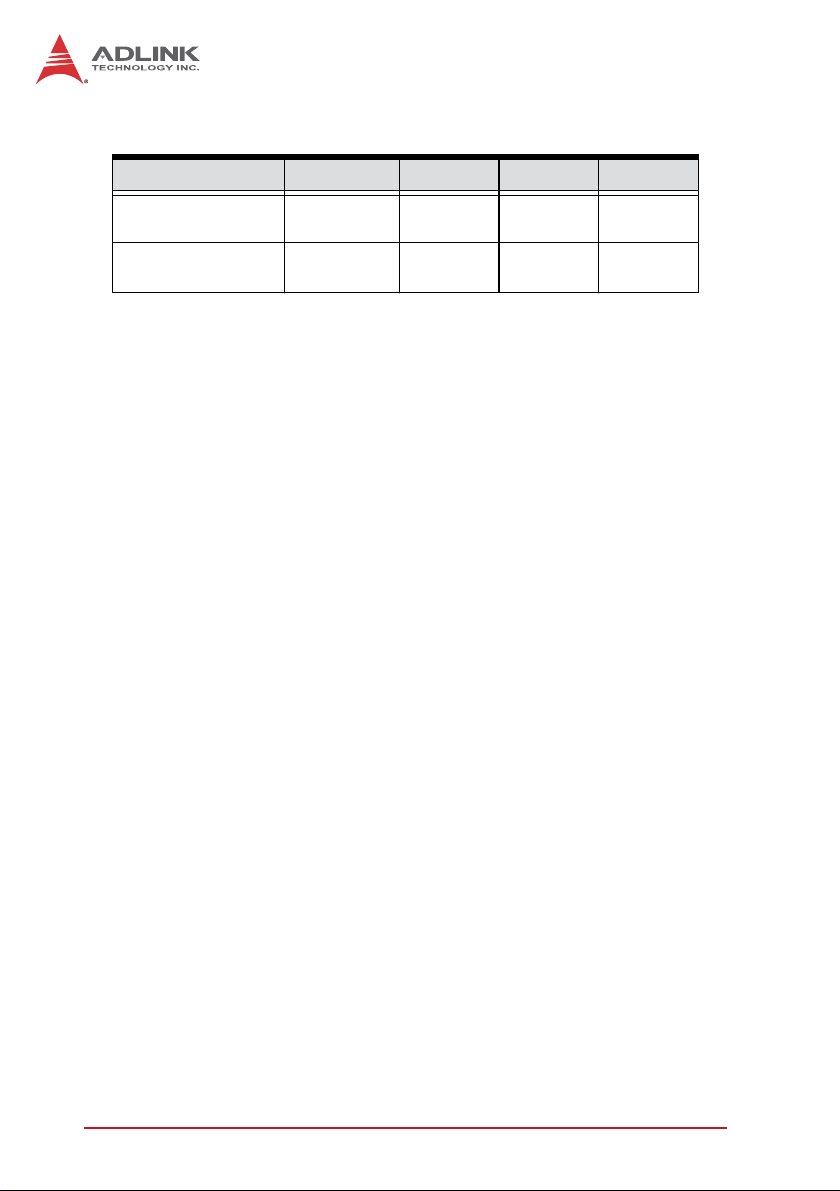

Voltage rail 5 V standby 3.3 V 5 V 12 V

Maximum power

consumption

Typical power

consumption

0.12 A 0.75 A 0.76 A 2.81 A

0.11 A 0.72 A 0.54 A 0.9 A

6 Introduction

Page 19

2 Getting Started

This chapter describes procedures for installing the PXIe-3975

and making preparations for its operation, including hardware and

software setup. Please note that the PXIe-3975 is shipped with

RAM and HDD pre-installed. Please contact ADLINK or authorized dealer if there are any problems during the installation.

Diagrams and illustrated equipment are for reference only.

Actual system configuration and specifications may vary.

NOTE:

NOTE:

2.1 Package Contents

Before beginning, check the package contents for any damage

and ensure that the following items are included:

X PXIe-3975 Controller (equipped with RAM and HDD)

X DVI-to-VGA adapter

X PXIe-3975 User’s Manual

X ADLINK All-In-One CD

If any of these items are missing or damaged, contact the dealer

from whom you purchased the product. Save the shipping materials and carton in case you want to ship or store the product in the

future.

PXIe-3975

Do not install or apply power to equipment that is damaged or

missing components. Retain the shipping carton and packing

materials for inspection. Please contact your ADLINK dealer/

vendor immediately for assistance and obtain authorization

before returning any product.

Getting Started 7

Page 20

2.2 Operating System Installation

For more detailed information about the operating system, refer to

the documentation provided by the operating system manufacturer. Preferred/supported operating systems for PXIe-3975 are:

X Windows XP

X Windows 7 32/64bits

X For other OS support, please contact ADLINK

Most operating systems require initial installation from a hard

drive, floppy drive, or CD-ROM drive. The PXIe-3975 controller

supports USB CD-ROM drive, USB flash disk, USB external hard

drive, or a USB floppy drive as the first boot device. Please see

Section 4.5: Boot Setup for information about setting the boot

devices. These devices should be configured, installed, and tested

with the supplied drivers before attempting to load the new operat-

ing system.

Read the release notes and installation documentation

provided by the operating system vendor. Be sure to

NOTE:

NOTE:

read all the README files or documents provided on the

distribution disks, as these typically note documentation

discrepancies or compatibility problems.

1. Select the appropriate boot device order from the BIOS

Boot Setup Menu based on the OS installation media

used. For example, if the OS is distributed on a bootable

installation CD, select USB CD-ROM as the first boot

device and reboot the system with the installation CD in

the USB CD-ROM drive

2. Proceed with the OS installation as directed and be sure

to select appropriate device types if prompted. Refer to

the appropriate hardware manuals for specific device

types and compatibility modes of ADLINK PXI products.

3. When installation is complete, reboot the system and set

the boot device order in the SETUP boot menu accordingly.

8 Getting Started

Page 21

2.3 Hardware Instructions

2.3.1 Faceplate Connectors & Indicators

PXIe-3975

E

A

G

C

Figure 2-1: PXIe-3975 Faceplate

D

B

F

H

A PXI Trigger Connector

E LED indicators

(SMB jack)

B DVI-I Connector F 4X Type-A USB

connectors

C GPIB Connector

G 2X Gigabit Ethernet

(Micro D-Sub 25P)

D Reset Button H ExpressCard/34

Getting Started 9

Page 22

2.3.2 PXI Trigger Connector

Ground

Trigger

Figure 2-2: PXI Trigger SMB Jack

The PXI trigger connector is a SMB jack, used to route external

trigger signals to or from the PXI backplane. Trigger signals are

TTL-compatible and edge sensitive. The PXIe-3975 provides four

trigger routing modes from/to the PXI trigger connector to synchronize PXI modules, including

X From a selected trigger bus line to PXI trigger connector

X From the PXI trigger connector to a selected trigger bus line

X From software trigger to a selected trigger bus line

X From software trigger to PXI trigger connector

All trigger modes are programmable by the provided driver. Please

refer to Section A: PXI Trigger I/O Function Reference for further

information.

10 Getting Started

Page 23

PXIe-3975

2.3.3 DVI-I Connector

The DVI-I connector connects the PXIe-3975 to a monitor, of

which both digital (DVI) and analog (VGA) are supported. If connecting to an analog (VGA) monitor, the included DVI-to-VGA

adapter must be installed on the DVI-I connector.

Pin Signal Pin Signal Pin Signal Pin Signal

TMDS

1

Data2-

TMDS

2

Data2+

Shield

3

Ground

10

11

TMDS

9

Data1-

TMDS

Data1+

Shield

Ground

17

18

19

TMDS

Data0-

TMDS

Data0+

Shield

Ground

C1

C2

C3

Analog

Red

Analog

Green

Analog

Blue

4 Reserved 12 Reserved 20 Reserved C4

5 Reserved 13 Reserved 21 Reserved C5

6 DDC Clock 14 +5V Power 22 Ground

7 DDC Data 15 Ground 23

Analog

8

VSYNC

Table 2-1: DVI-I Pin Assignment

Getting Started 11

16

Hot Plug

Detect

24

TMDS

Clock+

TMDS

Clock-

Analog

HSYNC

Analog

Ground

Page 24

2.3.4 GPIB Connector

The GPIB connector on PXIe-3975 is a micro D-sub 25P connector, controlling external bench-top instruments. Connection to

other instruments requires the ACL-IEEE488-MD1-A cable. The

on-board GPIB controller provides:

X Full compatibility with IEEE 488 standard

X Up to 1.5MB/s data transfer rates

X Onboard 2 KB FIFO for read/write operations

X Driver APIs compatible with NI-488.2 driver software

X Connection with up to 14 instruments

1 13

14 25

Pin Signal Description Pin Signal Description

1 DIO1# GPIB Data 1 14 DIO5# GPIB Data 5

2 DIO2# GPIB Data 2 15 DIO6# GPIB Data 6

3 DIO3# GPIB Data 3 16 DIO7# GPIB Data 7

4 DIO4# GPIB Data 4 17 DIO8# GPIB Data 8

5 EOI End Or Identify 18 REN Remote Enable

6 DAV Data Valid 19 Ground Signal Ground

7 NRFD

8 NDAC No Data Accepted 21 Ground Signal Ground

9 IFC Interface Clear 22 Ground Signal Ground

10 SRQ Service Request 23 Ground Signal Ground

11 ATN Attention 24 Ground Signal Ground

Chassis

12

Ground

13 Ground Signal Ground

Not Ready For

Data

20 Ground Signal Ground

Chassis Ground 25 Ground Signal Ground

Table 2-2: GPIB Pin Description

12 Getting Started

Page 25

PXIe-3975

2.3.5 Reset Button

The reset button, activated by insertion of any pin-like implement,

executes a hard reset for the PXIe-3975.

2.3.6 LED Indicators

Four LED indicators on the faceplate indicate operational status of

the PXIe-3975, as follows.

Watchdog

Figure 2-3: PXIe-3975 LED Indicators

LED

indicator

Color Description

Power LED Green

HDD LED Yellow

Watchdog Red

HS LED Blue

HDD

Status

Power

Indicates system power. Remains lit when the

system boots normally and main power supply is

functioning.

Indicates operating state of the HDD. Flashes

during access to or activity on the SATA HDD.

Indicates status of the watchdog timer, lighting

when watchdog timer has expired. Please refer

to Appendix B for watchdog timer programming

information.

Indicates system status, blinking on and off once

during boot when system status is good, and

continuously blinking or remaining lit when the

system malfunctions.

Table 2-3: LED Indicator Legend

Getting Started 13

Page 26

In the event of malfunction, clear the CMOS (please see

Section 2.3.15: Clearing CMOS Jumper (JP1)) and

NOTE:

NOTE:

reboot the system. If the system fails to respond properly, please contact ADLINK for assistance.

2.3.7 USB 2.0 Ports

The PXIe-3975 provides four USB 2.0 ports via USB Type A connectors on the faceplate, all compatible with hi-speed, full-speed

and low-speed USB devices. Supported boot devices include USB

flash drive, USB floppy, USB CD-ROM, and others, with boot priority and device settings configurable configured in BIOS. Please

see Section 4.5: Boot Setup for more information.

Pin Signal

1/5 Power 5V

2/6 USB Data-

3/7 USB Data +

4/8 Ground

Table 2-4: USB 2.0 Port Pin Assignment

14 Getting Started

Page 27

PXIe-3975

2.3.8 Gigabit Ethernet Ports

Two Intel 82574L GbE controllers via x1 PCI Express interface

provide dual Gigabit Ethernet connectivity, with the upper connec-

tor supporting Wake-on-LAN function.

Pin 1000Base-T Signal 100/10Base-T Signal

1 MDI0+ TX+

2 MDI0- TX-

3 MDI1+ RX+

4 MDI2+ Reserved

5 MDI2- Reserved

6 MDI1- RX-

7 MDI3+ Reserved

8 MDI3- Reserved

Table 2-5: PXIe-3975 Ethernet Port Pin Assignments

The Ethernet ports each include two LED indicators, one Active/

Link indicator and one Speed indicator, functioning as follows.

LED Status Description

Active/Link

(Yellow)

Speed

(Green/

Orange)

Off Ethernet port is disconnected

ON Ethernet port is connected with no

data transmission

Flashing Ethernet port is connected with

data transmitted/received

Off 10 Mbps

Green 100 Mbps

Orange 1000 Mbps

Although the port 2 Intel 82574 Ethernet device remains

powered even after shutdown and the Active/Link LED

NOTE:

NOTE:

may remain blinking, it is safe to remove the controller or

disconnect power.

Getting Started 15

Page 28

2.3.9 ExpressCard/34

The PXIe-3975 controller is equipped with an ExpressCard/34 slot

on the front panel, which provides I/O expansion. ExpressCard

connector signals are as follows.

Pin Signal Description Pin Signal Description

1 GND Ground 14 +3.3V Power

2 USBD- USB Data - 15 +3.3V Power

3 USBD+ USB Data + 16 CLKREQ# Clock Request

4 CPUSB# USB Presence 17 CPPE# PE Presence

5 RESERVED Reserved for

future use

6 RESERVED Reserved for

future use

7 SMBCLK SMBus Clock 20 GND Ground

8 SMBDATA SMBus Data 21 PERn0 PE Data

9 +1.5V Power 22 PERp0 PE Data

10 +1.5V Power 23 GND Ground

11 WAKE# PE Wake 24 PETn0 PE Data

12 +3,3VAUX Power 25 PETp0 PE Data

13 PERST# PE Reset 26 GND Ground

18 REFCLK- Reference

Clock-

19 REFCLK+ Reference

Clock+

Receive -

Receive +

Transmit -

Transmit +

16 Getting Started

Page 29

2.3.10 Onboard Connections and Settings

K

J

I

I

PXIe-3975

Figure 2-4: PXIe-3975 Onboard Configuration

I SATA Connector

J JP1 (CMOS)

K System Battery

Getting Started 17

Page 30

While the PXIe-3975 ships with a 2.5" SATA hard drive

pre-installed to the SATA port, no HDD is shown

NOTE:

NOTE:

installed, for clarity.

2.3.11 Installation Environment

When preparing to install any equipment described in this manual, please refer to Chapter C: Important Safety Instructions.

Only install equipment in well lit areas on flat, sturdy surfaces

with access to basic tools such as flat- and cross-head screwdrivers, preferably with magnetic heads as screws and standoffs are small and easily misplaced.

Recommended Installation Tools

Phillips (cross-head) screwdriver

Flat-head screwdriver

Anti-static wrist strap

Anti-static mat

ADLINK PXIe-3975 system controllers are electrostatically

sensitive and can be easily damaged by static electricity. The

equipment must be handled on a grounded anti-static mat, and

operators must wear an anti-static wristband, grounded at the

same point as the anti-static mat.

Inspect the carton and packaging for damage. Shipping and

handling may cause damage to the contents. Ensure that all

contents are undamaged before installing.

All equipment must be protected from static discharge

and physical shock. Never remove any of the socketed

CAUTION:

parts except at a static-free workstation. Use the antistatic bag shipped with the product to handle the equipment and wear a grounded wrist strap when servicing or

installing.

18 Getting Started

Page 31

2.3.12 Installing the PXIe-3975

1. Locate the system controller slot (Slot 1)

2. Depress the red locking lever and release the latch

3. Align the controller’s top and bottom edges with the card

guides, and carefully slide the PXIe-3975 into the chassis, as shown

PXIe-3975

4. Elevate the latch until the PXIe-3975 is fully seated in the

chassis backplane.

5. Fasten the four mounting screws on the faceplate of

PXIe-3975, and connect all peripheral devices.

Getting Started 19

Page 32

2.3.13 Replacing the Hard Drive

The PXIe-3975 provides a SATA 2.0 port with a pre-installed 2.5"

SATA hard drive. Alternatively, a 2.5" solid state disk (SSD) can be

used for shock/vibration resistance. This section explains procedures for replacing the HDD.

1. Locate the four screws attaching the hard drive to the

bracket on the rear of the PXIe-3975 controller.

2. Remove the screws, as shown.

3. Gently lift and remove the SATA hard drive, as shown,

being careful to not bend or break the SATA Board-toBoard connector.

20 Getting Started

Page 33

PXIe-3975

4. To replace the HD with a solid state hard drive or other

compatible SATA hard drive, reverse the steps and reinstall the PXIe-3975 to the PXI system.

2.3.14 Replacing the Battery Backup

The PXIe-3975 is provided with a 3.0 V “coin cell” lithium battery.

To replace the battery, proceed as follows.

1. Turn off the PXIe chassis.

2. Remove the PXIe-3975 embedded controller from the

chassis. Observe all anti-static precautions.

3. Locate the four screws attaching the hard drive to the

bracket on the rear of the PXIe-3975 controller.

4. Remove the screws, as shown.

Getting Started 21

Page 34

5. Gently lift and remove the SATA hard drive, being careful to not bend or break the SATA Board-to-Board connector.

6. The battery backup is exposed.

7. To remove the battery, gently insert a small (approx. 5

mm) flat-head screwdriver under the battery at the negative retaining clip. Gently pry the battery up, again, being

careful of the SATA connector. The battery should easily

pop out.

8. Place a fresh identical battery (CR2032 or equivalent) in

the socket, ensuring that the positive pole (+) is facing

upwards. The battery is most easily seated by first being

inserted under the positive retaining clip, and then

22 Getting Started

Page 35

PXIe-3975

pushed downward at the negative retaining clip. The battery should easily snap into position.

9. Replace the hard drive.

10.Reinstall the embedded controller into the PXIe chassis

and restore power.

Getting Started 23

Page 36

2.3.15 Clearing CMOS Jumper (JP1)

In the event of a system malfunction causing the PXIe-3975 to halt

or fail to boot, clear the CMOS and restore the controller BIOS to

its default settings. To clear the CMOS:

1. Shut down the controller operating system. Turn off the

PXIe Chassis.

2. Remove the PXIe-3975 from the chassis. Observe all

anti-static precautions.

3. Locate the JP1 jumper on the board. Move the jumper

from Normal to Clear (short pin#2 and pin#3), as shown.

4. Remount the controller into the PXIe chassis.

5. Power on the chassis and immediately depress the

Reset button on the faceplate, before any monitor display appears.

6. After the operating system starts, shut down the controller operating system and power down the PXIe chassis.

7. Once again, remove the PXIe-3975 controller from the

chassis.

8. Restore jumper JP1 to the Normal position (short pin#1

and pin#2).

9. Remount the controller into the PXIe chassis and restore

power.

24 Getting Started

Page 37

3 Driver Installation

After installing the operating system, all related drivers must be

installed for correct system operation. This section describes drivers needed for Windows operating systems and the procedures to

install them. For other OS support, please contact ADLINK.

3.1 Installing Windows Drivers

1. Fully install Windows, which contains most standard I/O

device drivers

2. Install the chipset driver

3. Install the graphic driver

4. Install the Ethernet driver

5. Install the GPIB driver

6. Install the management engine driver

7. Install the PXI trigger driver

8. Install the WDT (watchdog timer) driver

3.2 Installing the Chipset Driver

PXIe-3975

This section describes installation of the chipset driver for PXIe-

3975. The chipset driver directs the operating system to configure

the Intel® QM57 chipset components to ensure operation of:

X Core PCI and ISAPNP Services

X PCIe Support

X SATA Storage Support

X USB Support

X Identification of Intel® Chipset Components in the Device

Manager

Driver Installation 25

Page 38

To install the chipset driver:

1. Close any running applications

2. Insert the ADLINK All-in-One CD (x: denotes the CDROM drive)

Z The WinXP chipset driver is located in the directory x:\

Driver Installation\PXI Platform\PXI Controller\PXIe3975\Chipset\WinXP\INF_Update_Utility

Z The Win7 chipset driver is located in the directory x:\

Driver Installation\PXI Platform\PXI Controller\PXIe3975\Chipset\Win7\INF_Update_Utility

3. Execute infinst911autol.exe and follow on-screen

instructions to complete the setup

4. Reboot the system

3.3 Installing the Graphics Driver

To install the graphics driver:

1. Close any running applications

2. Insert the ADLINK All-in-One CD (x: denotes the CDROM drive)

Z The WinXP VGA driver is located in the directory x:\

Driver Installation\PXI Platform\PXI controller\PXIe3975\VGA\WinXP\32Bits

Z The 32bit Win7 VGA driver is located in the directory x:\

Driver Installation\PXI Platform\PXI controller\PXIe3975\VGA\Win7\32Bits

Z The 64bit Win7 VGA driver is located in the directory x:\

Driver Installation\PXI Platform\PXI controller\PXIe3975\VGA\Win7\64Bits

3. Execute setup.exe and follow on-screen instructions to

complete the setup

4. Reboot the system

26 Driver Installation

Page 39

3.4 Installing the Ethernet Driver

To install the Ethernet driver:

1. Close any running applications.

2. Insert the ADLINK All-in-One CD (x: denotes the CD-

ROM drive)

Z The WinXP Ethernet driver is located in the directory: x:\

Driver Installation\PXI Platform\PXI controller\PXIe3975\LAN\WinXP\32Bits\

Z The 32bit Win7 Ethernet driver is located in the directory

x:\ Driver Installation\PXI Platform\PXI controller\PXIe3975\LAN\Win7\32Bits\

Z The 64bit Win7 Ethernet driver is located in the directory

x:\ Driver Installation\PXI Platform\PXI controller\PXIe3975\LAN\Win7\64Bits\

3. Execute PROWin32.exe or PROWin64x.exe and follow

on-screen instructions to complete the setup.

4. Reboot the system

3.5 Installing the GPIB Driver

PXIe-3975

The PXI-3975 controller features an onboard GPIB controller, providing connectivity between PXI and GPIB instruments. The GPIB

driver package also contains function libraries and a utility to interact with GPIB instruments.

To install the GPIB driver:

1. Close any running applications.

2. Insert the ADLINK All-in-One CD (x: denotes the CD-

ROM drive); the GPIB driver is located in the directory x:\

Driver Installation\PXI Platform\PXI controller\PXIe3975\GPIB\

3. Execute setup.exe and follow on-screen instructions to

complete the setup

4. Reboot the system

Driver Installation 27

Page 40

3.6 Installing the Management Engine Driver

To install the management engine driver:

1. Close any running applications.

2. Insert the ADLINK All-in-One CD (x: denotes the CDROM drive)

Z The WinXP ME driver is located in the directory x:\ Driver

Installation\PXI Platform\PXI controller\PXIe3975\ME\WinXP\Intel ME

Z The Win7 ME driver is located in the directory x:\ Driver

Installation\PXI Platform\PXI controller\PXIe3975\ME\Win7\Intel ME

3. Execute MEI_ALLOS_6.1.0.1042_PV.exe or setup.exe

and follow on-screen instructions to complete the setup.

4. Reboot the system

3.7 Installing the PXI Trigger Driver

The PXIe-3975 controller provides a trigger I/O on the faceplate to

route the trigger signal to and from the PXI trigger bus. Please see

Appendix A: PXI Trigger I/O Function Reference for programming

information.

To install the PXI trigger driver:

1. Close any running applications.

2. Insert the ADLINK All-in-One CD (x: denotes the CDROM drive); the PXI trigger driver is located in the directory x:\ Driver Installation\PXI Platform\PXI controller\PXIe-3975\PXI_Trigger\ PXI Trigger 3.23

3. Execute PXI Trigger IO setup v323.exe and follow onscreen instructions to complete the setup

4. Reboot the system

3.8 Installing the WDT Driver

The WDT (watchdog timer) resets the system when the operating

system or application is halted. The WDT typically starts and periodically resets the timer, and when the timer is expired, the system

28 Driver Installation

Page 41

PXIe-3975

resets. Please refer to Appendix B: Watchdog Timer for programming information.

To install the WDT driver:

1. Close any running applications.

2. Insert the ADLINK All-in-One CD (x: denotes the CD-

ROM drive); the WDT driver is located in the directory x:\

Driver Installation\PXI Platform\PXI controller\PXIe3975\PXI_WDT\ PXI WDT 3.23

3. Execute PXI WDT Setup v323.exe and follow on-screen

instructions to complete the setup

4. Reboot the system

Driver Installation 29

Page 42

This page intentionally left blank.

30 Driver Installation

Page 43

4 BIOS Setup

The Basic Input/Output System (BIOS) provides a basic level of

communication between the processor and peripherals. In

addition, the BIOS also contains code for various advanced

features applied to the PXIe-3975 controller. The BIOS setup

program includes menus for configuring settings and enabling

PXIe-3975 controller features.

Changing BIOS settings may result in incorrect operation and

possibly an inability to boot. If this occurs, follow the instruc-

CAUTION:

4.1 Starting the BIOS

tions in Section 2.3.15: Clearing CMOS Jumper (JP1) to clear

CMOS and restore default settings. In general, do not change

a BIOS setting unless you are absolutely certain of the consequences.

1. Power on or reboot the PXIe-3975 controller.

2. Press the <Delete> key when the controller beeps. This

should be concurrent with the main startup screen. The

BIOS setup program loads after a short delay.

3. The Main menu is displayed when you first enter the

BIOS setup program.

PXIe-3975

In most cases, the < Delete > key is used to invoke the setup

screen. There are several cases that use other keys, such as <

NOTE:

NOTE:

F1 >, < F2 >, and so on.

The main BIOS setup menu is the first screen that you can navigate. Each main BIOS setup menu option is described in this

user’s guide.

The Main BIOS setup menu screen has two main frames. The left

frame displays all the options that can be configured. “Grayed”

options cannot be configured, “Blue” options can be.

The right frame displays the key legend. Above the key legend is

an area reserved for a text message. When an option is selected

in the left frame, it is highlighted in white. Often a text message will

accompany it.

BIOS Setup 31

Page 44

Navigation

The BIOS setup/utility uses a key-based navigation system called

hot keys. Most BIOS setup utility hot keys can be used at any time

during setup navigation, as follows.

Key(s) Function

Right Arrow, Left Arrow Moves between different setup menus

Up Arrow, Down Arrow Moves between options within a setup menu

<Enter> Opens a submenu or displays all available settings

for a highlighted configuration option

<Esc> Returns to the previous menu and shortcuts to the

Exit menu from top-level menus

<+> and <–> Cycles between all available settings

<Tab> Selects time and date fields

<F1> Opens the general help window for the BIOS

<F2> Loads previous values into the BIOS

<F3> Restores default values into the BIOS

<F4> Saves the current configuration and exits BIOS

setup

<F9> Loads the optimal default BIOS settings

Table 4-1: BIOS Hot Key Functions

Figure 4-1: BIOS Setup Navigation

32 BIOS Setup

Page 45

PXIe-3975

A hot key legend is located in the right frame on most setup

screens.

NOTE:

NOTE:

The < F8 > key on your keyboard is the Fail-Safe key. It is not displayed on the key legend by default. To set the Fail-Safe settings

of the BIOS, press the < F8 > key on your keyboard. It is located

on the upper row of a standard 101 keyboard. The Fail-Safe settings allow the motherboard to boot up with the least amount of

options set. This can lessen the probability of conflicting settings.

4.2 Main Setup

When you first enter the Setup Utility, you will enter the Main setup

screen. You can always return to the Main setup screen by selecting the Main tab.

The Main Setup menu provides basic controller information and

allows the system time and date to be set, as follows.

Item Detail

BIOS Information Includes BIOS version and the date on which the

BIOS was built

Memory Information Shows memory size, type and speed as detected

by the BIOS

ME Information Indicates the version of the management engine

Board Information Such as hardware revisions and serial number

System Date & Time

System Date Changes system date, date must be entered in

MM/DD/YY format

System Time Changes system time, time must be entered in

HH:MM:SS format.

Access Level Displays current access level, default is

Administrator

Table 4-2: BIOS Main Setup Menu

BIOS Setup 33

Page 46

4.3 Advanced Setup

Select the Advanced tab from the setup screen to enter the

Advanced BIOS Setup screen. You can select any of the items in

the left frame of the screen, such as SuperIO Configuration, to go

to the submenu for that item. Display an Advanced BIOS Setup

option by highlighting it using the < Arrow > keys. The Advanced

BIOS Setup options are as follows.

Item Detail

Legacy OpROM Support

Launch PXE

OpROM

Launch Storage

OpROM

Clock Spread

Spectrum

WatchDog Timer Shows whether the WatchDog Timer is enabled

PCI Subsystem

Settings

ACPI Settings Enables/disables AXCPI auto configuration (default is

CPU Configuration Displays processor type, speed, system bus speed, etc.

PCI Express Ports

Configuration

SATA Configuration Sets SATA mode and enables/disables SATA controller

Intel Video

Configuration

USB Configuration Provides USB support and lists the devices attached to

H/W Monitor Displays voltages on the backplane connector

Thermal

Configuration

Temperature

Monitor

Enables or disables legacy network device

(default is Disabled)

Enables/disables the option for Legacy Mass Storage

Devices with option ROM (default is Enabled)

Enables/disables spread spectrum for clock

(default is Disabled)

Allows viewing and configuration of PCI and PCIe

Subsystem settings

Disabled)

Enables/disables PCI Express ports and configures bus

and resource padding

Sets Intel Video function

the USB port (keyboard, mouse, and one hub)

(+3.3 V, +5.0 V, +12 V, 5 VSB, and Vbat)

Sets platform thermal configuration and Intelligent

Power Sharing

Shows the current operating temperature inside the

controller.

Table 4-3: BIOS Advanced Setup Menu

34 BIOS Setup

Page 47

4.4 Chipset Configuration

Item Detail

North Bridge

Configuration

South Bridge

Configuration

Table 4-4: BIOS Chipset Configuration Menu

Provides memory and PCIe compliance information

Provides SMBus, GbE Controller, Wake on LAN,

Audio, USB Configuration, and PCIe Port

Configuration information

4.5 Boot Setup

Item Detail

Boot Configuration

Quiet Boot When disabled, allows POST messages to be

viewed (default is Enabled).

Bootup NumLock

State

Selects default keyboard number lock setting

PXIe-3975

CSM16 Module

Version

Gate A20 Active Allows GA20 to be disabled by BIOS

Option ROM

Messages

Interrupt 19 Capture Allows Option ROMs to trap Int 19

Boot Option Priorities

Boot Option #1 Allows selection of the primary boot source (default

Boot Option #2 Allows selection of the secondary boot source

Network Device BBS

Priorities

Hard Drive BBS

Priorities

BIOS Setup 35

Displays the version of the CSM16 module, e.g.

07.60

Sets display mode for Option ROM

is the SATA HDD)

(default is Disabled)

Sets the order of legacy devices in this group

Sets the order of legacy devices in this group

Table 4-5: BIOS Boot Setup Menu

Page 48

4.6 Security Setup

The system can be configured to require all users to enter a password (either Administrator or User) every time the system boots or

when Setup is executed. Administrators and User passwords activate different levels of security.

If passwords are used, the system prompts for a three- to twentycharacter password. Typed passwords are not displayed.

Item Details

Password Description

Administrator

Password

User Password Sets user level passwords for the BIOS.

HDD Security Configuration

HDDO: INTEL

SSDSA2

Passwords are not recoverable. Please ensure that all passwords are recorded elsewhere. If your passwords are lost,

CAUTION:

NVRAM must be erased and reconfigured.

Sets an administrative level password for the BIOS.

sets HDD password

Table 4-6: BIOS Security Setup Menu

4.7 Save & Exit Setup

The following options for saving and exiting can be chosen in this

menu.

Save Changes and Exit

X Discard Changes and Exit

X Save Changes and Exit

X Discard Changes and Reset

X Save Changes and Reset

36 BIOS Setup

Page 49

Save Option

X Save Changes

X Discard Changes

X Restore Defaults

X Save as User Defaults

X Restore User Defaults

The "Restore the default values for all setup options” selection

does not restore the original boot priority sequence. You must

NOTE:

NOTE:

use the Boot Setup Menu (see Section 4.5: Boot Setup) to

manually restore the boot priority sequence.

PXIe-3975

BIOS Setup 37

Page 50

This page intentionally left blank.

38 BIOS Setup

Page 51

PXIe-3975

Appendix A - PXI Trigger I/O Function Ref-

erence

This appendix describes use of the PXI trigger I/O function library

for the PXIe-3975 controller, to program routing of trigger signals

between the trigger I/O SMB connector on the faceplate and the

PXI trigger bus on the backplane.

A.1 Data Types

The PXIe-3975 library uses these data types in pxitrigio.h in the

directory X:\ADLINK\PXI Trigger IO\Include. It is recommended

that you use these data types in your application programs. The

table shows the data type names, ranges, and corresponding data

types in C/C++, Visual Basic, and Delphi for reference.

Type

Type Description Range

U8

I16

U16

I32

U32

8-bit ASCII

character

16-bit signed

integer

16-bit unsigned

integer

32-bit signed

integer

32-bit unsigned

integer

0 to 255

-32768 to

32767

0 to 65535

-2147483648

to

2147483647

0 to

4294967295

C/C++

(for 32-bit

compiler)

unsigned

char

short Integer SmallInt

unsigned

short

long Long LongInt

unsigned

long

Visual Basic

Byte Byte

Not supported

by BASIC,

use the

signed integer

(I16) instead

Not supported

by BASIC,

use the

signed long

integer (I32)

instead

Pascal

(Delphi)

Word

Cardinal

PXI Trigger I/O Function Reference 39

Page 52

Type

Type Description Range

F32

F64

32-bit single-

precision

floating-point

64-bit double-

precision

floating-point

-3.402823E38

to

3.402823E38

1.7976831348

62315E308 to

1.7976831348

62315E309

C/C++

(for 32-bit

compiler)

float Single Single

double Double Double

Visual Basic

A.2 Function Library

This section provides detailed definitions of the functions available

in the PXIe-3975 function library. Each function includes a description, list of supported cards, syntax, parameter list and Return

Code information.

A.2.1 TRIG_Init

Description

Initializes trigger I/O function of PXIe-3975 controller.

TRIG_Init must be called before the invocation of any other

trigger I/O function.

Pascal

(Delphi)

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910, PXI-3800

Syntax

C/C++

I16 TRIG_Init()

Visual Basic

TRIG_Init As Integer

Parameter

None

40 PXI Trigger I/O Function Reference

Page 53

Return Code

ERR_NoError

ERR_BoardBusy

ERR_OpenDriverFail

ERR_GetGPIOAddress

A.2.2 TRIG_Close

Description

Closes trigger I/O function of PXIe-3975 controller, releasing resources allocated for the trigger I/O function. Users

must invoke TRIG_Close before exiting the application.

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910, PXI-3800

Syntax

C/C++

I16 TRIG_Close()

Visual Basic

TRIG_Close() As Integer

PXIe-3975

Parameter

None

Return Code

ERR_NoError

ERR_BoardNoInit

A.2.3 TRIG_SetSoftTrg

Description

Generates a TTL trigger signal to the trigger I/O SMB connector on the faceplate or the PXI trigger bus on the backplane by software command

PXI Trigger I/O Function Reference 41

Page 54

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910, PXI-3800

Syntax

C/C++

I16 TRIG_SetSoftTrg(U8 Status)

Visual Basic

TRIG_SetSoftTrg (ByVal status As Byte) As

Integer

Parameters

Status

Logic level of trigger signal.

Available value description:

0: Logic low

1: Logic high

Return Code

ERR_NoError

ERR_BoardNoInit

A.2.4 TRIG_Trigger_Route

Description

Routes the trigger signal between the trigger I/O SMB connector on the faceplate and the PXI trigger bus on the backplane. This function also allows routing of the softwaregenerated trigger signal to SMB connector or trigger bus.

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910, PXI-3800

Syntax

C/C++

42 PXI Trigger I/O Function Reference

Page 55

I16 TRIG_Trigger_Route (U32 source, U32 dest,

U32 halfway)

Visual Basic

TRIG_Trigger_Route (ByVal source As Long,

ByVal dest As Long, ByVal halfway As Long) As

Integer

Parameters

source

Source of trigger routing. It can be one of the following values.

Available value Description

PXI_TRIG_VAL_SMB SMB connector on the faceplate

PXI_TRIG_VAL_SOFT Software-generated trigger signal

PXI_TRIG_VAL_TRIG0 PXI trigger bus #0

PXI_TRIG_VAL_TRIG1 PXI trigger bus #1

PXI_TRIG_VAL_TRIG2 PXI trigger bus #2

PXI_TRIG_VAL_TRIG3 PXI trigger bus #3

PXI_TRIG_VAL_TRIG4 PXI trigger bus #4

PXI_TRIG_VAL_TRIG5 PXI trigger bus #5

PXI_TRIG_VAL_TRIG6 PXI trigger bus #6

PXI_TRIG_VAL_TRIG7 PXI trigger bus #7

PXIe-3975

dest

Destination of trigger routing. It can be one of the following

values.

Available value Description

PXI_TRIG_VAL_SMB SMB connector on the faceplate

PXI_TRIG_VAL_TRIG0 PXI trigger bus #0

PXI_TRIG_VAL_TRIG1 PXI trigger bus #1

PXI_TRIG_VAL_TRIG2 PXI trigger bus #2

PXI_TRIG_VAL_TRIG3 PXI trigger bus #3

PXI_TRIG_VAL_TRIG4 PXI trigger bus #4

PXI Trigger I/O Function Reference 43

Page 56

Available value Description

PXI_TRIG_VAL_TRIG5 PXI trigger bus #5

PXI_TRIG_VAL_TRIG6 PXI trigger bus #6

PXI_TRIG_VAL_TRIG7 PXI trigger bus #7

halfway

Halfway point of trigger routing. This parameter is used only

to route the software-generated trigger signal to the SMB

connector on the faceplate. In this case, the halfway should

be set as one of the trigger bus lines, otherwise as

PXI_TRIG_VAL_NONE.

Available value Description

PXI_TRIG_VAL_NONE No halfway point

PXI_TRIG_VAL_TRIG0 PXI trigger bus #0

PXI_TRIG_VAL_TRIG1 PXI trigger bus #1

PXI_TRIG_VAL_TRIG2 PXI trigger bus #2

PXI_TRIG_VAL_TRIG3 PXI trigger bus #3

PXI_TRIG_VAL_TRIG4 PXI trigger bus #4

PXI_TRIG_VAL_TRIG5 PXI trigger bus #5

PXI_TRIG_VAL_TRIG6 PXI trigger bus #6

PXI_TRIG_VAL_TRIG7 PXI trigger bus #7

Return Code

ERR_NoError

ERR_BoardNoInit

ERR_Set_Path

A.2.5 TRIG_Trigger_Clear

Description

Clears the trigger routing setting

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910, PXI-3800

44 PXI Trigger I/O Function Reference

Page 57

Syntax

C/C++

I16 TRIG_Trigger_Clear()

Visual Basic

TRIG_Trigger_Clear() As Integer

Parameters

None

Return Code

ERR_NoError

ERR_BoardNoInit

ERR_Trigger_Clr

A.2.6 TRIG_GetSoftTrg

Description

Acquires the current software trigger state, with default

state after system boot of Logic Low

PXIe-3975

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910, PXI-3800

Syntax

C/C++

I16 TRIG_GetSoftTrg(U8 *Status)

Visual Basic

TRIG_GetSoftTrg (status As Byte) As Integer

Parameters

Status

Returns the logic level of software trigger signal

Returned value:

0: Logic low

1: Logic high

PXI Trigger I/O Function Reference 45

Page 58

Return Code

ERR_NoError

ERR_BoardNoInit

ERR_Query_Status

A.2.7 TRIG_Trigger_Route_Query

Description

Acquires the current trigger signal routing path

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910, PXI-3800

Syntax

C/C++

I16 TRIG_Trigger_Route_Query (U32* source,

U32* dest, U32* halfway)

Visual Basic

TRIG_Trigger_Route_Query (source As Long, dest

As Long, halfway As Long) As Integer

Parameters

source

Returns to the current source of trigger routing, with possible values including:

Available Definition Defined Value

PXI_TRIG_VAL_NONE 0

PXI_TRIG_VAL_SMB 2

PXI_TRIG_VAL_SOFT 3

PXI_TRIG_VAL_TRIG0 111

PXI_TRIG_VAL_TRIG1 112

PXI_TRIG_VAL_TRIG2 113

PXI_TRIG_VAL_TRIG3 114

PXI_TRIG_VAL_TRIG4 115

46 PXI Trigger I/O Function Reference

Page 59

PXIe-3975

Available Definition Defined Value

PXI_TRIG_VAL_TRIG5 116

PXI_TRIG_VAL_TRIG6 117

PXI_TRIG_VAL_TRIG7 118

dest

Returns to the current destination of trigger routing, with

possible values including:

Available Definition Defined Value

PXI_TRIG_VAL_NONE 0

PXI_TRIG_VAL_SMB 2

PXI_TRIG_VAL_TRIG0 111

PXI_TRIG_VAL_TRIG1 112

PXI_TRIG_VAL_TRIG2 113

PXI_TRIG_VAL_TRIG3 114

PXI_TRIG_VAL_TRIG4 115

PXI_TRIG_VAL_TRIG5 116

PXI_TRIG_VAL_TRIG6 117

PXI_TRIG_VAL_TRIG7 118

halfway

Returns to the current halfway point of trigger routing, with

possible values including:

Available Value Description

PXI_TRIG_VAL_NONE 0

PXI_TRIG_VAL_TRIG0 111

PXI_TRIG_VAL_TRIG1 112

PXI_TRIG_VAL_TRIG2 113

PXI_TRIG_VAL_TRIG3 114

PXI_TRIG_VAL_TRIG4 115

PXI_TRIG_VAL_TRIG5 116

PXI_TRIG_VAL_TRIG6 117

PXI_TRIG_VAL_TRIG7 118

PXI Trigger I/O Function Reference 47

Page 60

Return Code

ERR_NoError

ERR_BoardNoInit

ERR_Query_Status

A.2.8 TRIG_GetDriverRevision

Description

Acquires the PXI Trigger software driver version; format of the

version number is major.minor1.minor2

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910, PXI-3800

Syntax

C/C++

I16 TRIG_GetDriverRevision(unsigned short

*major, unsigned short *minor1, unsigned short

*minor2)

Visual Basic

TRIG_GetDriverRevision (major As Integer,

minor1 As Integer, minor2 As Integer) As Integer

Parameters

major

Returns the major version number of the pxi trigger software

driver

minor1

Returns the first minor version number of the pxi trigger

software driver

minor2

Returns the second minor version number of the pxi trigger

software driver

48 PXI Trigger I/O Function Reference

Page 61

Return Code

ERR_NoError

ERR_Query_Revision

A.2.9 CONTROLLER_GetHwRevision

Description

Acquires the Controller Hardware version and revision number and the version of the trigger module CPLD

Supported Controllers

PXIe-3975

Syntax

C/C++

I16 CONTROLLER_GetHwRevision( U8* cpldMajor,

U8* cpldMinor, char* hwRevBuf,U32 hwRevBufSize)

Visual Basic

CONTROLLER_GetHwRevision (cpldMajor As Byte,

cpldMinor As Byte, hwRevBuf As String,

hwRevBufSize As Long) As Integer

PXIe-3975

Parameters

cpldMajor

Returns the major version number of the pxi trigger module

CPLD

cpldMinor

Returns the first minor version number of the pxi trigger

module CPLD

hwRevBuf

Character buffer of size declared by the caller of size

hwRevBufSize, returns a null-terminated string representation of the hardware revision

PXI Trigger I/O Function Reference 49

Page 62

hwRevBufSize

Size of the hwRevBuf, in bytes

Return Code

ERR_NoError

ERR_InvalidParameterValue

A.2.10 CONTROLLER_GetManufacturer

Description

Ascertains the hardware manufacturer

Supported Controllers

PXIe-3975

Syntax

C/C++

I16 CONTROLLER_GetManufacturer( char* Buf, U32

Bufsize )

Visual Basic

CONTROLLER_GetManufacturer (Buf As String,

Bufsize As Long) As Integer

Parameters

Buf

Character buffer of size declared by the caller of size BufSize, returns a null-terminated string representation of the

hardware manufacturer

BufSize

Size of the Buf, in bytes

Return Code

ERR_NoError

ERR_InvalidParameterValue

50 PXI Trigger I/O Function Reference

Page 63

A.2.11 CONTROLLER_GetModel

Description

Acquires the hardware model name

Supported Controllers

PXIe-3975

Syntax

C/C++

I16 CONTROLLER_GetModel( char* Buf, U32 Bufsize )

Visual Basic

CONTROLLER_GetModel (Buf As String, Bufsize As

Long) As Integer

Parameters

Buf

Character buffer of size declared by the caller of size BufSize, returns a null-terminated string representation of the

hardware model name

BufSize

Size of the Buf, in bytes

PXIe-3975

Return Code

ERR_NoError

ERR_InvalidParameterValue

A.2.12 CONTROLLER_GetSerialNumber

Description

Acquires the serial number of the hardware

Supported Controllers

PXIe-3975

PXI Trigger I/O Function Reference 51

Page 64

Syntax

C/C++

I16 CONTROLLER_GetSerialNumber( char* Buf, U32

Bufsize )

Visual Basic

CONTROLLER_GetSerialNumber (Buf As String,

Bufsize As Long) As Integer

Parameters

Buf

Character buffer of size declared by the caller of size BufSize, returns a null-terminated string representation of the

serial number of the hardware

BufSize

Size of the Buf, in bytes

Return Code

ERR_NoError

ERR_InvalidParameterValue

52 PXI Trigger I/O Function Reference

Page 65

Appendix B - Watchdog Timer

This appendix describes use of the watchdog timer (WDT) function library for the PXIe-3975 controller. The watchdog timer is a

hardware mechanism resetting the system when the operating

system or application halts. After starting, periodic reset of the

watchdog timer in the application before expiry is required. Once

the watchdog timer expires, a hardware-generated signal is sent

to reset the system.

B.1 WDT Function Library

B.1.1 InitWDT

Description

Initializes watchdog timer function. InitWDT must be called

before the invocation of any other WDT function.

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910

PXIe-3975

Syntax

C/C++

BOOL InitWDT()

Visual Basic

InitWDT() As Boolean

Parameter

None

Return Code

True If watchdog timer is successfully initialized

False If watchdog timer fails to initialize

Watchdog Timer 53

Page 66

B.1.2 SetWDT

Description

Sets the timeout value for watchdog timer. The timeout

value uses seconds as a unit. ResetWDT or StopWDT

should be called prior to expiration of the watchdog timer, or

the system will be reset.

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910

Syntax

C/C++

BOOL SetWDT(unsigned long second)

Visual Basic

InitWDT(ByVal second as Long) As Boolean

Parameter

second

Specifies the timeout value of the watchdog timer.

Value Description

Value Description

0 to 255 If the value of the second parameter is between 0

and 255, the resolution of the watchdog timer is 1

second

Over 255 If the value of the second parameter exceeds 255,

the resolution of the watchdog timer is 1 minute, that

is, if a value of 400 is given, the actual timeout value

is 400/60 + 1 = 7 minutes

Return Code

True If timeout value of watchdog timer is

successfully set

False If timeout value of watchdog timer fails to be set

54 Watchdog Timer

Page 67

B.1.3 StartWDT

Description

Starts watchdog timer function. Once invoked, the watchdog timer countdown starts, and ResetWDT or StopWDT

should be called before the expiration of the watchdog

timer, or the system will be reset.

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910

Syntax

C/C++

BOOL StartWDT()

Visual Basic

StartWDT() As Boolean

Parameter

None

PXIe-3975

Return Code

True If watchdog timer starts successfully

False If watchdog timer fails to start

B.1.4 ResetWDT

Description

Resets the watchdog timer to the initial timeout value specified in SetWDT function, and ResetWDT or StopWDT

should be called before the expiration of the watchdog

timer, or the system will be reset.

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910

Watchdog Timer 55

Page 68

Syntax

C/C++

BOOL ResetWDT()

Visual Basic

ResetWDT() As Boolean

Parameter

None

Return Code

True If watchdog timer resets successfully

False If watchdog timer fails to reset

B.1.5 StopWDT

Description

Stops the watchdog timer.

Supported Controllers

PXIe-3975, PXI-3950, PXI-3920, PXI-3910

Syntax

C/C++

BOOL StopWDT()

Visual Basic

StopWDT() As Boolean

Parameter

None

Return Code

True If watchdog timer stops successfully

False If watchdog timer fails to stop

56 Watchdog Timer

Page 69

PXIe-3975

Important Safety Instructions

For user safety, please read and follow all instructions,

WARNINGS, CAUTIONS, and NOTES marked in this manual and

on the associated equipment before handling/operating the

equipment.

X Read these safety instructions carefully.

X Keep this user’s manual for future reference.

X Read the specifications section of this manual for detailed

information on the operating environment of this equipment.

X When installing/mounting or uninstalling/removing

equipment:

Z Turn off power and unplug any power cords/cables.

X To avoid electrical shock and/or damage to equipment:

Z Keep equipment away from water or liquid sources;

Z Keep equipment away from high heat or high humidity;

Z Keep equipment properly ventilated (do not block or

cover ventilation openings);

Z Make sure to use recommended voltage and power

source settings;

Z Always install and operate equipment near an easily

accessible electrical socket-outlet;

Z Secure the power cord (do not place any object on/over

the power cord);

Z Only install/attach and operate equipment on stable

surfaces and/or recommended mountings; and,

Z If the equipment will not be used for long periods of time,

turn off and unplug the equipment from its power source.

Important Safety Instructions 57

Page 70

X Never attempt to fix the equipment. Equipment should only

be serviced by qualified personnel.

X A Lithium-type battery may be provided for uninterrupted,

backup or emergency power.

Risk of explosion if battery is replaced with an incorrect type;

please dispose of used batteries appropriately.

X Equipment must be serviced by authorized technicians

when:

Z The power cord or plug is damaged;

Z Liquid has penetrated the equipment;

Z It has been exposed to high humidity/moisture;

Z It is not functioning or does not function according to the

user’s manual;

Z It has been dropped and/or damaged; and/or,

Z It has an obvious sign of breakage.

58 Important Safety Instructions

Page 71

PXIe-3975

Getting Service

Contact us should you require any service or assistance.

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Zhonghe District

New Taipei City 235, Taiwan

ᄅקؑխࡉ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: Ϟ⍋Ꮦ⌺ϰᮄᓴ∳催⾥ᡔು㢇䏃 300 ো(201203)

300 Fang Chun Rd., Zhangjiang Hi-Tech Park,

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ(100085)

Tel: +86-10-5885-8666

Fax: +86-10-5885-8625

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

Pudong New Area, Shanghai, 201203 China

Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd., Beijing, 100085 China

A1 2 ὐ C (518057)

2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7,

High-Tech Industrial Park S., Shenzhen, 518054 China

Getting Service 59

Page 72

ADLINK Technology, Inc. (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 Massy CEDEX, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: ͱ101-0045 ᵅҀ䛑ҷ⬄⼲⬄䤯ފ⬎ 3-7-4

⼲⬄ 374 ɛɳ 4F

KANDA374 Bldg. 4F, 3-7-4 Kanda Kajicho,

Chiyoda-ku, Tokyo 101-0045, Japan

Tel: +81-3-4455-3722

Fax: +81-3-5209-6013

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 昢殾柢 昢爎割 昢爎壟 1675-12 微汾瘶捒娯 8猻

8F Mointer B/D,1675-12, Seocho-Dong, Seocho-Gu,

Seoul 137-070, Korea

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Singapore 349584

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: 1st Floor, #50-56 (Between 16th/17th Cross) Margosa Plaza,

Tel: +91-80-65605817, +91-80-42246107

Fax: +91-80-23464606

Email: india@adlinktech.com

ADLINK Technology, Inc. (Israeli Liaison Office)

Address: 6 Hasadna St., Kfar Saba 44424, Israel

Tel: +972-9-7446541

Fax: +972-9-7446542

Email: israel@adlinktech.com

60 Getting Service

Margosa Main Road, Malleswaram, Bangalore-560055, India

Loading...

Loading...