Page 1

16-CH, General-Purpose SPDT Relay

PXI-7901

Module

User’s Manual

Recycled Paper

Page 2

© Copyright 2004 ADLINK Technology Inc.

All Rights Reserved.

Manual Rev. 1.00: June 28, 2004

Part Number: 50-17010-100

The information in this document is subject to change without prior notice in

order to improve reliability, design, and function and does not represent a

commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special,

incidental, or consequential damages arising out of the use or inability to use

the product or documentation, even if advised of the possibility of such

damages.

This document contains proprietary information protected by copyright. All

rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic, or other means in any form without prior written

permission of the manufacturer.

Trademarks

NuDAQ

®

, NuIPC®, NuDAM®, NuPRO® are registered trademarks of ADLINK

Technology Inc. Other product names mentioned herein are used for

identification purposes only and may be trademarks and/or registered

trademarks of their respective companies.

Page 3

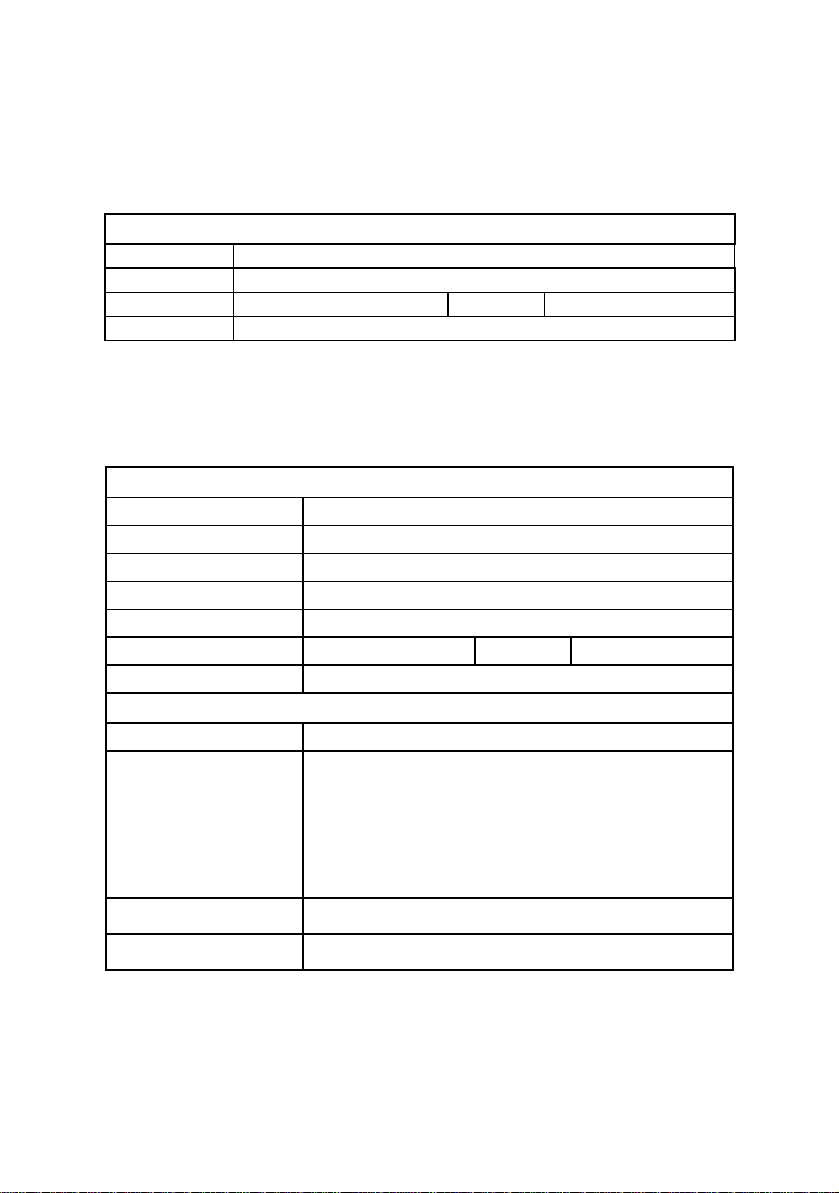

Getting Service from ADLINK

Customer Satisfaction is top priority for ADLINK Technology Inc. If you need

any help or service, please contact us.

ADLINK TECHNOLOGY INC.

Web Site http://www.adlinktech.com

Sales & Service Service@adlinktech.com

TEL +886-2-82265877 FAX +886-2-82265717

Address 9F , No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan

Please email or FAX your detailed information for prompt, satisfactory, and

consistent service.

Detailed Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX

Web Site

Questions

Product Model

OS:

Computer Brand:

M/B: CPU:

Environment

Detail Description

Chipset: BIOS:

Video Card:

NIC:

Other:

Suggestions for ADLINK

Page 4

Page 5

Table of Contents

How to Use This Manual.............................................................. ii

Chapter 1 Introduction ..............................................................1

1.1 Features............................................................................. 1

1.2 Applications........................................................................ 2

1.3 Specifications..................................................................... 2

1.4 Software Support ............................................................... 3

Chapter 2 Installation ................................................................5

2.1 Contents.............................................................................5

2.2 Unpacking.......................................................................... 5

2.3 Mechanical Drawing...........................................................6

2.4 Installing the switch module into a PXI Platform................ 6

Chapter 3 Signal Connection.................................................... 9

3.1 PXI-7901 Topology.............................................................9

3.2 PXI-7901 Pin assignment & Description ............................ 9

3.3 TB-6201 Terminal Board .................................................. 10

Chapter 4 Operation Theorem ................................................ 11

4.1 Hardware Block Diagram................................................. 11

4.2 Operation Mode ............................................................... 12

4.3 Handshaking.................................................................... 12

4.4 Trigger Bus.......................................................................16

4.5 Star Trigger ......................................................................17

4.6 Auxiliary Digital I/O ...........................................................18

4.7 Hot-Swap ......................................................................... 19

4.8 Emergency Shutdown......................................................19

4.9 Watchdog Timer ...............................................................20

Warranty Policy........................................................................23

Table of Contents • i

Page 6

How to Use This Manual

This User Manual is designed to assist users in the installation of the ADLINK

PXI-7901, 16-CH General Purpose SPDT Relay PXI Switch module.

Chapter 1 Introduction

Gives an outline and overview of ADLINK switch modules’

features, specifications, and applications.

Chapter 2 Installation

Describes how to install a switch module into a PXI chassis. For

software library and utilities installation, please refer to the

Software Users’ Guide.

Chapter 3 Signal Connection

Shows the pin assignments and terminal board connection of the

switch module.

Chapter 4 Operation Theorem

Describes function blocks on ADLINK switch modules and

operation instructions.

ii • How to use this Manual

Page 7

1

Introduction

ADLINK PXI-7901 is a general-purpose (GP) switch module implementing 16CH independent single-pole double-throw (SPDT) relays (1 Form C). PXI-7901

can connect one input to one output, and be used as signal switching or routing

for measurement systems as well as ATE.

Relays of PXI-7901 can be updated by either direct-update mode or auto-scan

mode. The latter mode supports scanlist of 1k-sample for deterministic

scanning.

PXI trigger functions are fully supported and software programmable. The

multiple switch modules can be synchronized and triggered without additional

field wiring.

For safety critical applications, PXI-7901 module can switch to the preset state

by either asserting emergency shutdown manually, or watchdog timer overflow

event.

1.1 Features

• PXI specifications Rev. 2.0 compliant

• 3U Eurocard form factor, CompactPCI compliant (PICMG 2.0 R3.0)

• PICMG 2.1 R2.0 CompactPCI Hot-Swap

• 16-CH SPDT (1 Form C) non-latching relays

• Contact rating

• 3A switching, 3A carrying

• 220V

• 125 operations per second

• 1k-sample scanlist for deterministic scanning

• Provides handshaking signals to trigger external instruments

• Programmable emergency shutdown function and Watchdog timer for

safety critical applications

• Eight auxiliary 3.3 V/TTL digital inputs/outputs with 5V tolerance

• Supports PXI backplane triggers to synchronize multiple modules

• Fully software programmable

, 250VAC

DC

specifications compliant

Introduction • 1

Page 8

1.2 Applications

• Industrial ON/OFF control

• External high power relay driving and signal switching

• Laboratory automation

• Industrial automation

• Switch contact status sensing

• Limit switch monitoring

• Cooperating with other modules such as A/D and D/A peripherals to

implement a data acquisition and control system

1.3 Specifications

Relay Output

• Number of channels: 16

• Relay type: SPDT (1 Form C), non-latching

• Switching capacity:

• Max. switching current: 3A

• Max. switching voltage: 220V

• Max. switching power: 50VA, 60W

♦ Max. carrying current: 3A

• Failure rate: 10µA

• Contact resistance: 150mΩ max.

• Relay set/reset time

• Operate time: 5ms max.

• Release time: 5ms max.

• Bounce time: 3ms max.

• Expected life:

• Mechanical life: 10

• Electrical life: 10

• Data transfer: Programmed I/O

8

operations min.

6

operations min. (0.4A @ 12VAC, resistive load)

, 250VAC

DC

Auxiliary Digital I/O

• Numbers of channel: 8 inputs/outputs

• Compatibility: 3.3 V/TTL (5V tolerant)

• Data transfers: programmed I/O

Handshaking Signals

• Programmable polarity

• Logic level: 3.3 V/TTL (5V tolerant)

• Trigger In source: AUX1, PXI trigger bus, PXI star trigger in

• Scanner Advanced destination: AUX0, PXI trigger bus, PXI star trigger

out

2 • Introduction

Page 9

Safety functions

• Emergency shutdown

• Logic level: 3.3 V/TTL (5V tolerant)

• Active with logic low (for AUX2/SHDNn pin)

• Emergency shutdown sources: AUX2/SHDNn, PXI star trigger

input, PXI trigger bus

• Watchdog timer

• Base clock available: 10MHz, fixed

• Counter width: 32-bit

• Watchdog Timer Overflow sources: Onboard 32-bit watchdog

timer, PXI star trigger input, PXI trigger bus

General Specifications

• I/O Connector: 62-pin D-sub male

• Operating temperature: 0 to 55°C

• Storage temperature: -20 to 70°C

• Humidity: 5 to 95% non-condensing

• Power requirements (when all relays are activated simultaneously)

+5V +3.3V

700mA 400mA

• Dimensions (not including connectors)

• 160 mm x 100 mm

1.4 Software Support

ADLINK's ADL-SWITCH driver package is for Microsoft Windows operating

systems, including Windows 98/ME/NT/2000/XP.

The driver package also provides utilities to test your switch module, as well as

programming samples and source codes in Microsoft Visual Basic and Visual

C/C++.

For other operating systems, please contact ADLINK for more information.

Introduction • 3

Page 10

Page 11

2

Installation

This chapter describes the installation process for the ADLINK switch module.

Please read the contents of the package and the disassembling information

carefully as they are important in the implementation of the ADLINK switch

module.

2.1 Contents

The package consists of the following items in addition to the User Manual:

• PXI-7901, 16-CH General Purpose SPDT Relay module

• This User’s Guide

• ADLINK Software CD

• ADL-Switch User’s Guide

If any of these items are missing or broken, please do not hesitate to contact

ADLINK or the dealer from whom the product was purchased. Keep the

shipping materials and carton for future storage or shipping.

2.2 Unpacking

ADLINK switch module contains sensitive electronic components that can be

easily damaged by static electricity. The switch module should be operated on a

grounded anti-static mat. It is strongly recommended that the operator wears an

anti-static wristband, grounded at the same point as the anti-static mat.

Inspect the box for any obvious damage. Check the unit to ensure there are no

shipping and handling damages that may have occurred before proceeding.

After opening, remove the system module and place it only on a grounded antistatic surface component side up.

Again, inspect the module for any damage. Press down on all the socketed IC’s

to make sure they are all properly seated. Please do this only on a firm and flat

surface.

Installation • 5

Page 12

Note: DO NOT APPLY POWER TO THE MODULE IF IT HAS BEEN

DAMAGED.

You are now ready to install the PXI-7901.

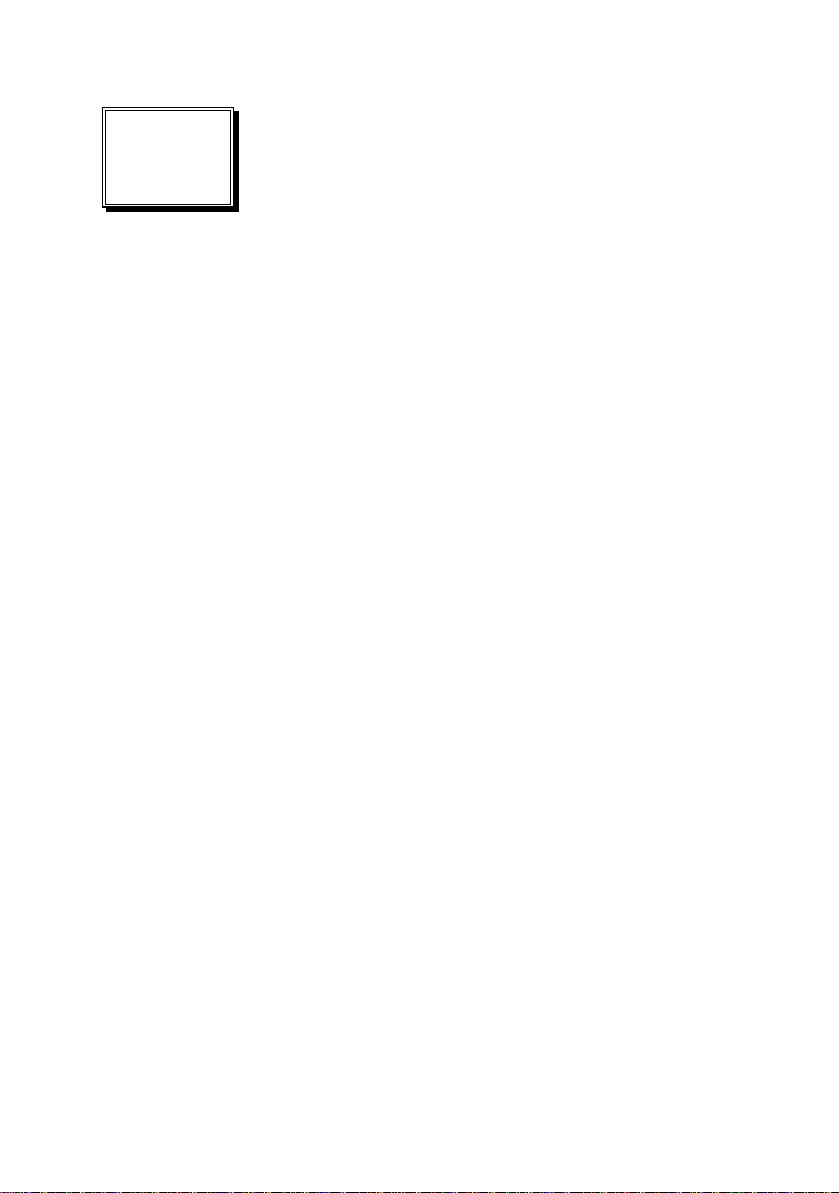

2.3 Mechanical Drawing

Figure 1: ADLINK Switch Module

ADLINK switch module is packaged in a Eurocard form factor compliant with

PXI Specifications measuring 160 mm in length and 100 mm in height (not

including connectors). A 62-pin connector is located at the front panel for wiring

purposes and the J1/J2 IEC connectors in the rear are used to link the chassis

backplane. With its modular, rugged, and high shock resistant mechanical

features, the switch module functions exceptionally well in any harsh

environment application.

2.4 Installing the switch module into a PXI Platform

To insert the ADLINK PXI switch module, align the module’s edge with the card

guide in the PXI chassis. Slide the switch module into the chassis, until

resistance is felt from the PXI connector. Push the ejector upwards and fully

insert the switch module into the chassis. Once inserted, a “click” can be heard

from the ejector latch. Tighten the screws on the front panel.

6 • Installation

Page 13

Figure 2: Installing the switch module into a PXI platform

Installation • 7

Page 14

Page 15

3

Signal Connection

3.1 PXI-7901 Topology

The PXI-7901 has 16 independent SPDT Relays onboard. Each relay has three

terminals, NC (normally closed), NO (normally opened), and COM (common).

When a relay is in its reset (de-energized) state, the NC connects to COM;

while in set (energized) state, the NO connects to COM. Thus all signal paths

on PXI-7901 are inherently break-before-make.

After power-up, all relays are in their reset (de-energized) state; i.e. NC

connects to COM.

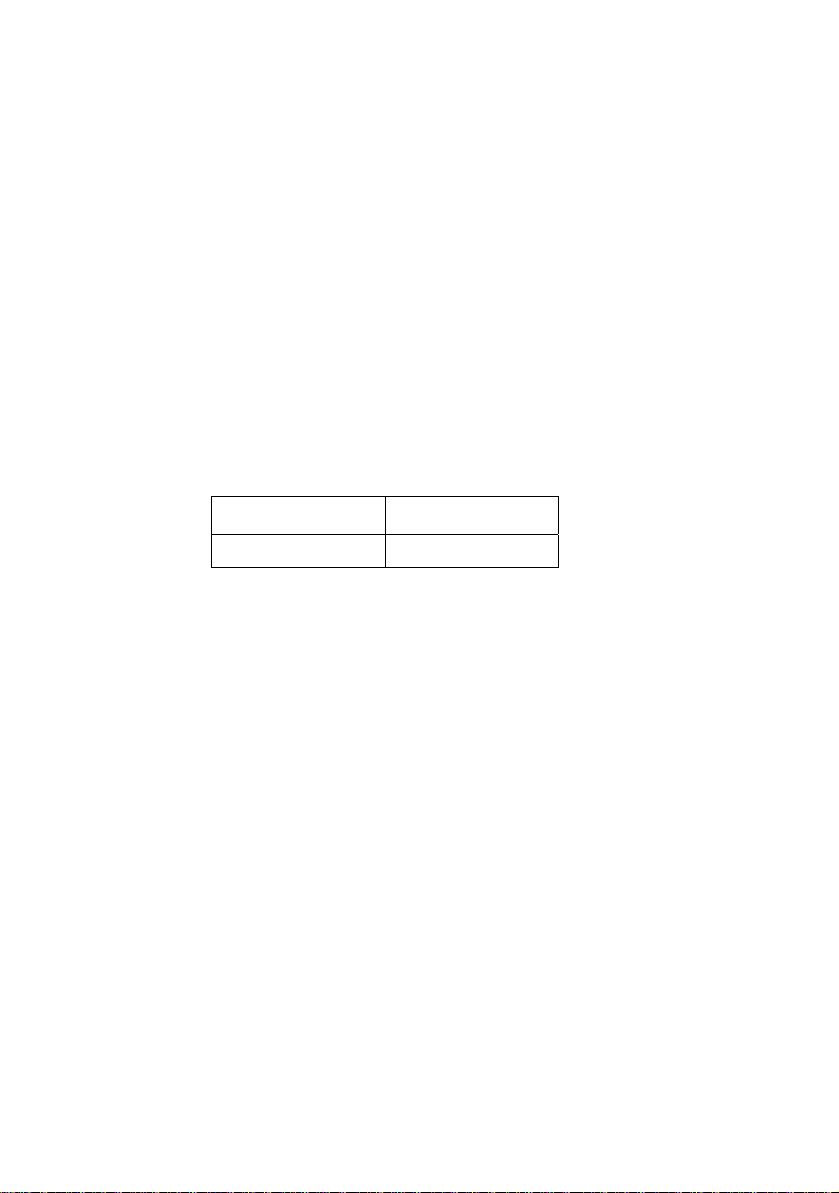

3.2 PXI-7901 Pin assignment & Description

22. COM0

43. NO0 23. COM1 1. NC0

44. NO1 24. COM2 2. NC1

45. NO2 25. COM3 3. NC2

46. NO3 26. COM4 4. NC3

47. NO4 27. COM5 5. NC4

48. NO5 28. COM6 6. NC5

49. NO6 29. COM7 7. NC6

50. NO7 30. COM8 8. NC7

51. NO8 31. COM9 9. NC8

52. NO9 32. COM10 10. NC9

53. NO10 33. COM11 11. NC10

54. NO11 34. COM12 12. NC11

55. NO12 35. COM13 13. NC12

56. NO13 36. COM14 14. NC13

57. NO14 37. COM15 15. NC14

58. NO15 38. NC 16. NC15

59. NC 39. NC 17. NC

60. AUX3 40. AUX4 18. AUX2/SHDNn

61. AUX6 41. +5V out 19. AUX5

62. AUX7 42. AUX1/TRG_IN 20. GND

21. AUX0/S_ADV

Table 1: Pin Assignment

Signal Connection • 9

Page 16

Signal Name Type Description

NO[15..0] Input/Output Normally opened terminal of relays

NC[15..0] Input/Output Normally closed terminal of relays

COM[15..0] Input/Output Common terminal of relays

Programmable Digital I/O with tri-state

AUX[7..0] Input/Output

TRG_IN Input Trigger input for handshaking operation

S_ADV Output

SHDNn Input Active-low Emergency Shutdown trigger

+5V out Output

GND Output Ground

NC Not Connected Unused pin

control.

AUX[2..0] are dual function pins used for

triggering, refer to chapter 4 for details.

Scanner Advanced trigger output for

handshaking operation

Unregulated +5V DC Source, maximum

100mA current loading

Table 2: Pin Description

3.3 TB-6201 Terminal Board

The TB-6201 is a screw terminal board with D-sub 62-pin female connector.

The terminal board can attach to PXI-7901 directly, or through ADLINK custommade high-capacity 62-pin D-sub cable.

The pin description is described in Table 2.

10 • Signal Connection

Page 17

4

Operation Theorem

4.1 Hardware Block Diagram

The ADLINK PXI Switch Module features an onboard FPGA for relay switching

control, trigger control, scanlist storage and sequencing. The PXI triggering and

synchronization functions, such as Star Trigger and Trigger Bus are also

supported. In addition to the Trigger In and Scanner Advanced signals for

external instruments handshaking, the switch module provides eight channels

of programmable digital I/O interface to facilitate general purpose control

applications.

To make full use of the flexible trigger and signaling system on the PXI platform,

the switch module has a built-in signal routing matrix that can exchange signals

between front panel digital I/O, Star Trigger, and Trigger Bus.

Scan Memory

Relay

DIO

Front Connector

Scan-

Trigger-in

Figure 3: Hardware Block Diagram

Relay

Control

Timing

Control

Signal

Routing

Matrix

Trigger

Control

PXI

Interface

Star Trigger In

Star Trigger Out

PXI Trigger Bus

Operation Theorem • 11

PXI Connector

Page 18

4.2 Operation Mode

The ADLINK PXI Switch Module provides two relay operation modes to

accommodate different application requirements.

Direct-update

The Switch Module updates the relay pattern immediately upon receiving a

software command. This mode provides a straightforward control over switch

module with minimal hardware intervention. If relay contact bouncing is of a

concern, users would need to insert software delay.

ADLINK recommends the debounce time to be at least 8ms on PXI-7901.

Auto-scan

The ADLINK PXI switch module features onboard memory to store user

specified scanlist of up to 1024-entry. In each scanlist entry, users can specify

relay pattern, pattern advancing delay time and criterion.

The switch module can set status bit or generate local interrupt to inform user’s

program whether the pattern has been debounced and advanced to the next

scanlist entry. Users can also specify one-time or cyclic scanning of scanlist

entries.

This operating mode supports trigger signals for instrument handshaking. For

more information on handshaking signals, please refer to section 4.3

.

4.3 Handshaking

In the Auto-scan mode, ADLINK PXI switch module accepts Trigger In and

generates Scanner Advanced signal to synchronize relay switching and

measurements with PXI instruments or external measurement devices.

Trigger In

The Trigger In signal from PXI instruments or external measurement devices

instruct the ADLINK PXI switch module to update the relay pattern according to

the one specified in the scanlist entry.

Users may specify wait-for-trigger instruction in a scanlist entry, to have the

switch module wait for the Trigger In before relay pattern is updated. The

polarity of Trigger In can be set to either rising-edge or falling-edge active.

For more information on scanlist configuration, please refer to the software

programming users’ guide.

12 • Operation Theorem

Page 19

Figure 4 illustrates the available signal sources for the Trigger In signal. Signal

names in the solid-line box represent the external (physical) signal on

connectors, and signals in the dotted-line box represents switch module’s

internal signal.

Software Trigger

TRG_IN

Trigger Bus

AUX[7…0]

Star Trigger In

Figure 4: Available signal sources for Trigger In

Trigger In Signal

Scanner Advanced

After updating the relay pattern, the switch module starts its debounce timer

and waits for the relay contacts to settle. When the debounce time elapses, the

switch module will generate a Scanner Advanced signal to notify the PXI

instruments or external measurement devices that the relay contacts have

settled, and ready to take a new measurement.

The waveform, polarity and pulse width of Scanner Advanced signal can also

be software programmed.

For more information on scanlist configuration, please refer to the software

programming users’ guide.

Figure 5 illustrates the available signal destinations for the Scanner Advance d

signal. Signal names in the solid-line boxes represent the external (physical)

signal on connectors, while signals in the dotted-line boxes represent switch

module’s internal signal.

Scanner Adv.

inl

Figure 5: Available signal destinations for Scanner Advanced

S_ADV

Trigger Bus [7…0]

AUX [7...0]

Star Trigger Out

Operation Theorem • 13

Page 20

Handshaking protocol

Figures 6 and 7 depict the relationship between Tr igger In, Scanner Advanced,

and relay pattern in handshaking mode. In Figure 7 the Scanner Advanced is

set to pulsating mode.

Trigger In

Scanner Advanced

Relay status

Operation start

Figure 6: Handshaking operation (Scanner Advanced set in pulsating mode)

Trigger In

Scanner Advanced

T

S

T

A1

#0 Pattern #2Pattern #1 Pattern #3 #4

TS

TA1

TS

TA2

TS

TA2

TS

T

TS

A

T

A

Relay status

#0

Pattern #2Pattern #1

Operation start

Figure 7: Handshaking operation (Scanner Advanced set in toggling mode)

14 • Operation Theorem

Pattern #3 #4

Page 21

Once the operation starts and has received a Trigger In signal, the switch

module updates the relay pattern to that specified in the first entry of scanlist.

is the default debounce time for a switch module, i.e. 8 ms for PXI-7901. T

T

S

An

is the user specified scan delay time in the scanlist entry, indicating the time

between the relay being debounced and the exact moment that a measurement

device takes a new measurement. The actual delay time would be the greater

of the two times, to guarantee that measurement devices take measurements

after the signal path is fully settled, and the relays switch as close as possible to

their maximum operating speed.

As the scan delay time elapses, the switch module generates Scanner

Advanced signal to inform the measurement device to take a new

measurement.

After the measurement completes, the measurement device will generate

another Trigger In signal to have the switch module update the relay pattern to

that specified in the second entry of scanlist.

The handshaking process will continue, until it reaches the end of the scanlist

(if one-time scanning mode is selected), or when a software scan-abort

command is received.

Connecting, Trigger and Synchronize with External DMM

In this example, Agilent® 33401A 6-1/2 Digital Multimeter (DMM) is used to

demonstrate signal connection for handshaking operation.

The DMM provides two terminals on the rear panel for the handshaking

operation process, Tr i g I n and VM Comp. The Tr i g I n connects to the Scanner

Advanced output on switch module, while the VM Comp to Trigger In. If the

terminal board is used, wire Tr i g I n to TRG_IN on terminal board, and the VM

Comp to S_ADV.

Follow the instructions below to ensure the handshake functions properly:

1. Configure ADLINK PXI switch module’s Tr i gger In to rising-edge

triggered, Scanner Advanced output in active-low pulsating

mode with pulse width of at least 2us.

2. Configure the DMM to wait for external Trig In before a

measurement, and generate VM Comp after a measurement.

Arm the DMM to wait for the first trigger.

3. Setup the scanlist and auto-scan mode. The first entry in the

scanlist should be set disable wait for the Trigger In, but enable

Scanner Advanced output. Succeeding entries should enable

both Trigg er I n and Scanner Advanced output. Download the

Operation Theorem • 15

Page 22

scanlist to the switch module afterward.

4. Start auto-scan by sending scan start command to the switch

module.

ADLINK

PXI Switch module

Scanner Advanced Output

(S_ADV)

Trigger Input

(Trig In)

(TRG_IN)

External Trigger Input

Wiring

Agilent 33401A

6-1/2 DMM

Measurement Complete

(VM Comp)

Figure 8: Signal Connection between Switch Module and Agilent DMM

For more information on scanlist configuration, scan mode setup, start, and

stop functions of the auto-scanning process, please refer to the software

programming users’ guide.

4.4 Trigger Bus

PXI specification defines eight bused-lines across slots in a segment. Users

can route various trigger signal to synchronize multiple PXI instruments, and/or

simplify field wiring across multiple ADLINK Switch Modules.

On ADLINK Switch Modules, the trigger bus driver is disconnected from PXI

trigger bus before users’ configuration.

Figure 9 illustrates the available signal destinations for Trigger Bus[7..0]. Signal

16 • Operation Theorem

Page 23

names in the solid-line boxes represent the external (physical) signals on

connectors while signals in the dotted-line boxes represent the switch module’s

internal signal.

Software Trigger

Trigger In Signal

Scanner Adv. Signal

AUX [3…2]

Star Trigger In

WDT Overflow

SHDNn

Figure 9: Available signal sources for Trigger Bus[7..0]

Trigger Bus[7..0]

4.5 Star Trigger

The PXI specification defined 13 matched trigger lines to connect to the first 13

PXI peripheral slots on a PXI backplane. Users can route various trigger signal

to synchronize multiple PXI instruments and achieve tight timing control.

On ADLINK Switch Modules, the star trigger driver is disconnected from the PXI

backplane before users’ configuration. The maximum skew between each star

trigger line is controlled to within 1ns.

Note the reverse input voltage protection range is -0.5V to +5.5V. When the

local bus is used on peripheral modules, make sure that the voltage level is

compatible with ADLINK Switch Module.

Figure 10 illustrates the available signal destinations for Star Trigger. Signal

names in the solid-line boxes represent the external (physical) signal on

connectors, while signals in the dotted-line boxes represent the switch module’s

internal signal.

Operation Theorem • 17

Page 24

Software Trigger

Trigger In Signal

Scanner Adv. Signal

Star Trigger Out Trigger Bus [7…0]

AUX [7…0]

WDT Overflow

SHDNn

Figure 10: Available signal sources for Star Trigger

4.6 Auxiliary Digital I/O

The eight auxiliary digital I/O lines on ADLINK Switch Modules provide

versatility to users’ control applications. Each digital I/O line can be input, output

or tri-stated. When in output mode, users can still read back the actual logiclevel on the I/O line. All digital lines are pulled-up to 5V with 10k ohm input

resistance.

Note that AUX[2..0] are dual function pins, driving these pins while enabling

handshaking or emergency shutdown functions, may falsely trigger the Switch

Module or external instruments.

Tri-state

Control

5VDC

10KΩ

DO

DI

Feedback from output

Figure 11: Auxiliary Digital I/O Function Block

18 • Operation Theorem

Bus-Switch

and Protection

AUX Pin

Page 25

4.7 Hot-Swap

The Switch Module can be hot-swapped during hardware failure in noninterruptible or high-availability systems where system shutdown is not an

option.

PXI-7901 incorporates an onboard hot-swap control mechanism. However the

extent of the hot-swap functionality support depends on the operating system

and the PXI platform.

Microsoft Embedded XP

system automatically releases system resources when a switch module is

extracted and recognizes the new device.

To remove a switch module, first release the screws on the front panel then

push down the red latch on the ejector. When the blue LED turns on, the Switch

module is ready to be removed by fully pushing down the ejector.

To insert another switch module, align the module’s edge with the card guide in

the PXI chassis. Slide the switch module into the chassis, until there is

resistance from the PXI connector. Push the ejector up and fully insert the

switch module into the chassis, a click should be heard from the ejector latch.

The blue LED on the front panel of the switch module will switch off when it is

ready for operation. Tighten the screws on the front panel.

Note: Microsoft Windows 2000

PXI-7901 can be hot-swapped by manual control via an additional hot-swap

driver. For the hot-swap driver on Windows 2000 and other operating systems

such as Linux, VxWorks, etc., please contact ADLINK for more information.

®

supports the native hot-swap function. The operating

®

does not natively support hot-swap however,

4.8 Emergency Shutdown

In safety-critical applications, users can enable the emergency shutdown

function on PXI Switch Module, to manually set the relay pattern to preset state.

To access this function, users must first configure the emergency shutdown

function by windows API. Generally the trigger source is on the front panel and

connected to a push button, which pulls the SHDNn pin to logic-low when

activated. When multiple PXI Switch modules are installed in a PXI chassis, the

trigger source can be routed through the PXI Trigger Bus and eliminate field

wiring across multiple devices. Figure 12 illustrates available trigger sources for

emergency shutdown. Signal names in the solid-line boxes represent the

external (physical) signal on connectors and signals in the dotted-line boxes

represent the switch module’s internal signal.

Operation Theorem • 19

Page 26

AUX2/SHDNn

Trigger Bus

Star Trigger In

Shutdown Trigger

Figure 12: Available trigger sources for emergency shutdown

The default relay pattern for emergency shutdown is All-Off on PXI-7901; users

can change the pattern by Windows API.

Upon receiving the emergency shutdown trigger, the Switch Module enters

shutdown mode, and the relay pattern is switched to the preset state. If the

Switch Module is in Auto-scan mode, the updating process would be stopped

immediately; in Direct Update mode where the switch module will not accept

any further update instructions.

To leave emergency shutdown mode, users must call adlSwitch_Recovery in

Windows API. The relay pattern would stay the same as they would in the

emergency shutdown mode, and the scanlist (if set) being rewound to the first

entry.

Note the auxiliary digital I/O function pin AUX2 shares the SHDNn pin; driving

AUX2 to logic-low while the emergency shutdown function is enabled. It will

falsely trigger the Switch Module to enter shutdown mode.

This function is disabled by default. For more information, please refer to the

software programming users’ guide.

4.9 Watchdog Timer

In safety-critical applications, users can enable the watchdog timer function on

PXI Switch Module to automatically set the relay pattern to preset state, in case

the operating system or PXI controller crashes.

To access this function, users must first configure the watchdog timer overflow

trigger source by windows API. Generally the trigger source would come from

the onboard 32-bit watchdog timer. When multiple ADLINK PXI Switch modules

are installed in a PXI chassis, the trigger source can be routed through the PXI

Trigger Bus and eliminate redundant watchdog timer setting on multiple devices.

Figure 13 illustrates the available trigger sources for watchdog timer overflow.

Signal names in the solid-line boxes represent the external (physical) signal on

connectors and signals in the dotted-line boxes represent the switch module’s

internal signal.

20 • Operation Theorem

Page 27

Int. WDTimer

Trigger Bus

Star Trigger In

WDT Overflow

Figure 13:.Available trigger sources for watchdog timer overflow

The watchdog timer overflow interval can be programmed through Windows

API. After enabling the watchdog timer, users must periodically reset the timer

by software command. If the timer is not being reset within the specified interval,

the switch module will generate an overflow signal and set the relay pattern to

the one specified by users.

This function is disabled by default. For more information, please refer to the

software programming users’ guide.

Operation Theorem • 21

Page 28

Page 29

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and enjoy all the

after-sales services we offer, please read the following carefully:

1. Before using ADLINK’s products please read the user manual and follow

the instructions exactly.

2. When sending in damaged products for repair, please attach an RMA

application form.

3. All ADLINK products come with a two-year guarantee, repaired free of

charge.

• The warranty period starts from the product’s shipment date from

ADLINK’s factory.

• Peripherals and third-party products not manufactured by ADLINK

will be covered by the original manufacturers’ warranty.

• End users requiring maintenance services should contact their local

dealers. Local warranty conditions will depend on local dealers.

4. This warranty will not cover repair costs due to:

a. Damage caused by not following instructions.

b. Damage caused by carelessness on the users’ part during product

transportation.

c. Damage caused by fire, earthquakes, floods, lightening, pollution,

other acts of God, and/or incorrect usage of voltage transformers.

d. Damage caused by unsuitable storage environments (i.e. high

temperatures, high humidity, or volatile chemicals.

e. Damage caused by leakage of battery fluid.

f. Damage from improper repair by unauthorized technicians.

g. Products with altered and/or damaged serial numbers.

h. Other categories not protected under our guarantees.

5. Customers are responsible for shipping costs to transport damaged

products to our company or sales office.

6. To ensure the speed and quality of product repair, please download a

RMA application form from our company website: www.adlinktech.com.

Damaged products with attached RMA forms receive priority.

For further questions, please contact our FAE staff.

ADLINK: service@adlinktech.com

Warranty Policy • 23

Loading...

Loading...