Page 1

Appendix for PC/104-

Manual Rev. 1.03: September 19, 2002 Part No: 50-40035-200

plus

modules

1 Introduction

1.1 Introduction of PC/104-plus

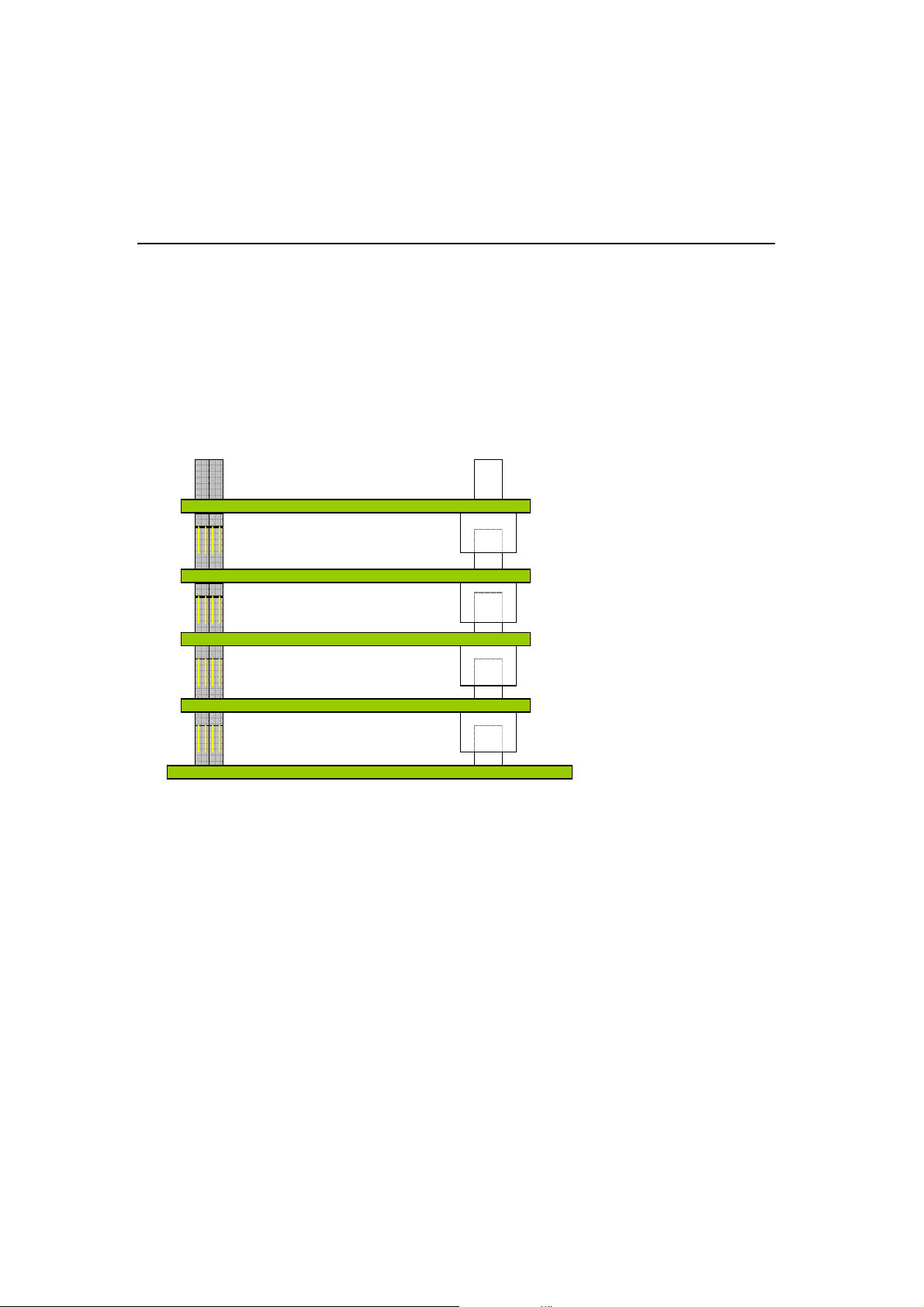

PC/104-plus is a special bus architecture designed for embedded systems. A third connector

opposite the PC/104 connectors supports the PCI bus. Basically the electrical specifications of the

PC/104-plus bus are compliant with the PCI signals, except 64-bit extensions, JTAG, PRSNT or

CLKRUN signals. The mechanical specifications are changed to “module stack”; please refer to the

figure shown below. According to the specifications of PC/104-plus, PC/104-plus modules are

installed and configured by switching CLK, IDSEL, INT, REQ and GNT signals through multiplexers

to the appropriate connections.

PC/104+ Module Slot 4

PC/104+ Module Slot 3

.

PC/104+ Module Slot 2

PC/104+ Module Slot 1

Figure 1: PC/104-plus module stack

Rotary switch on PCM-9112+ is used for these signals switching, please refer to section 2.4 for

details in this appendix.

1.2 Specifications for PCM-9112+

The specifications of the PCM-9112+ are the same as that of the PCI-9112 except for the Digital

Input and Digital Output functions have been removed from the PCM-9112+. To compensate for

the removal of the DI/DO functions, the AD FIFO has been enlarged to 512 words allowing it to

handle a wider range of applications. Please refer to section 1.3 of the PCI-9112 manual for further

details.

1.3 Supported Software

PC/104+ Host

The supported software is the same as that of the PCI-9112 without the DI/DO functions. Please

refer to section 1.4 of the PCI-9112 manual for further details.

1

Page 2

2 Installation procedures for PC/104-plus DAQ modules:

r

r

V

2.1 what you have

In addition to this appendix, the package includes the following items:

PCM-9112+ DAQ modules

Manual & Software Utility CD-ROM

If any of these items is missing or damaged, contact the dealer from whom you purchased the

product. Save the shipping materials and carton in case you want to ship or store the product in the

future.

2.2 unpacking

The card contains electro-static sensitive components that can be easily be damaged by static

electricity.

Therefore, the card should be handled on a grounded anti-static mat. The operator should be

wearing an anti-static wristband, grounded at the same point as the anti-static mat.

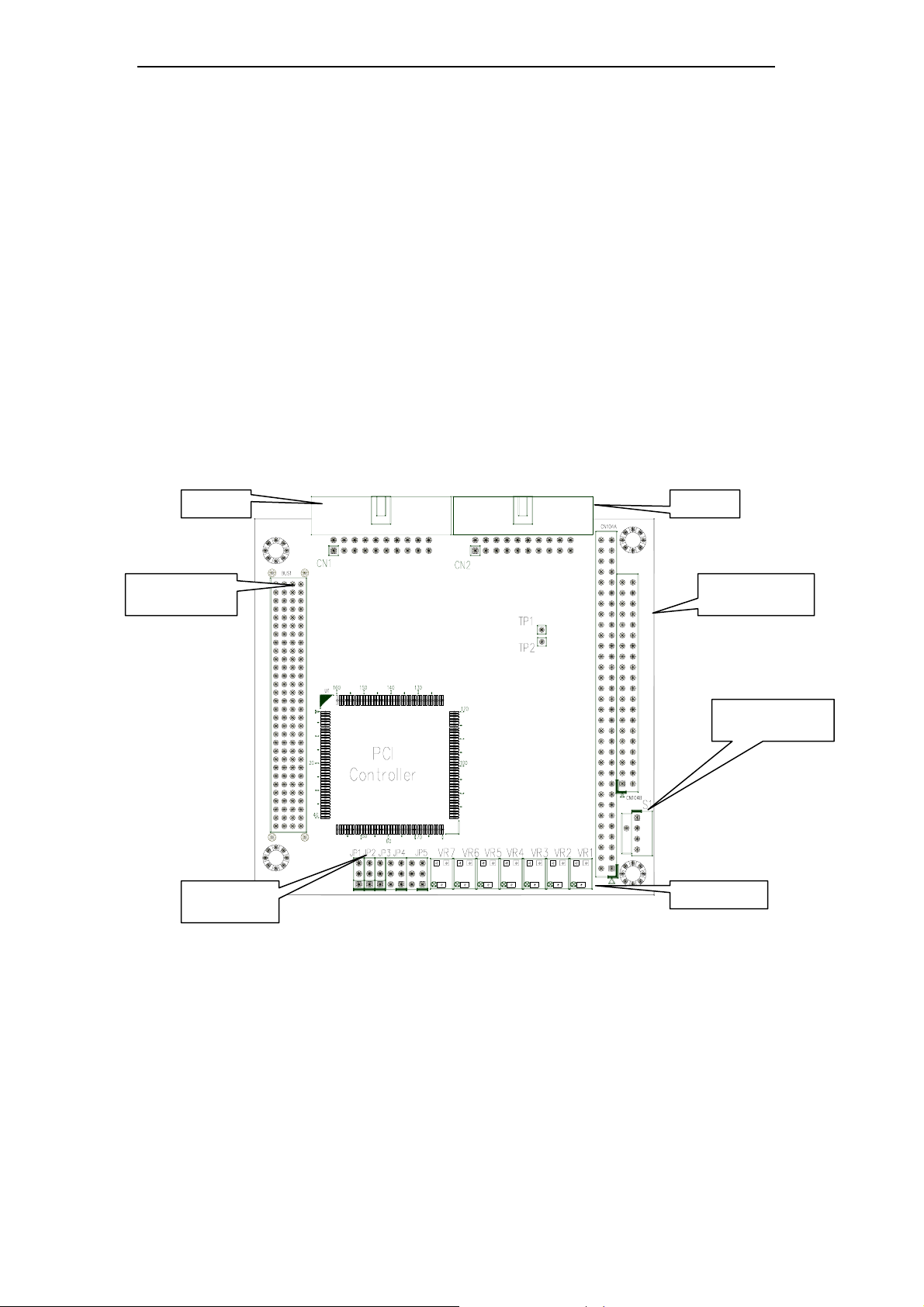

2.3 layout of modules

CN1 CN2

PC/104-plus

connecto

Jumper

JP1~JP5

PC/104

Figure 2: PCM-9112+ DAQ module layout

connecto

Rotary

switch

R1~VR7

2

Page 3

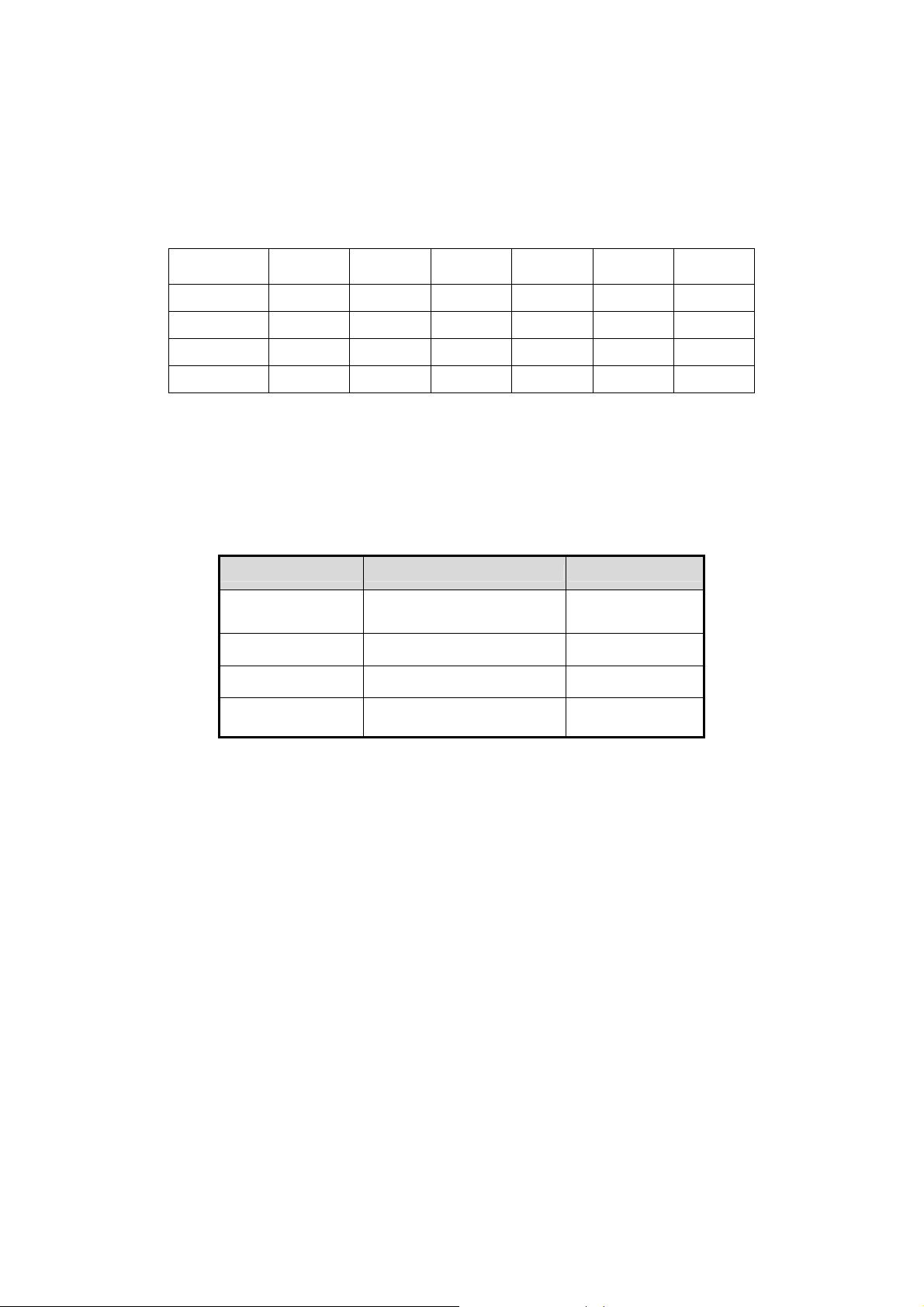

2.4 PC/104-plus configuration

A rotary switch on the PCM-9112+ is used for switching the appropriate CLK, IDSEL, INT, REQ

and GNT signals from the PCI bus. If the PCM-9112+ card is inserted in a position nearest to the

PC/104-plus motherboard, the switch must be set to 0 or 4. For signal stability, the rotary switch

should be set to the appropriate position with respect to the module slot. The module stack order

was shown in Figure 1. According to PC/104-plus specification, module slots 3 and 4 share

REQ2/GNT2, hence they cannot both have bus-mastering devices. In another word, module 3 and

4 cannot be stacked with 2 PCM-9112+ modules.

Rotary Switch

Position

0 or 4 1 CLK0 IDSEL0 INTA REQ0* GNT0*

1 or 5 2 CLK1 IDSEL1 INTB REQ1* GNT1*

2 or 6 3 CLK2 IDSEL2 INTC REQ2* GNT2*

3 or 7 4 CLK3 IDSEL3 INTD REQ2* GNT2*

* Only for Bus Master card

Module

Slot

CLK IDSEL INT REQ GNT

Table 1: Rotary switch setting

2.5 Jumpers Setting

On the PCM-9112+ DAQ module, there are 5 jumpers that need to be adjusted depending on

application requirements. The following table describes the attributes of these jumpers.

Configuration Attributes Jumpers

Analog Inputs

Clock Source

D/A Reference

Voltage

D/A Reference Source

Single-ended or

Differential Analog Input

Internal Clock or

External Clock

-10V or -5V JP3

Internal Reference or

External Reference

JP1 and JP4

JP2

JP5

Table 2: Jumpers setting

3

Page 4

2.5.1 Analog input mode configuration

The analog input channels on the PCM-9112+ DAQ module can be configured as 16 single-ended

or 8 differential inputs. Jumpers JP1 and JP4 control the analog input configuration. The setting of

JP1 and JP4 are specified below:

Single-ended

input (Default)

Differential input

Table 3: Analog input mode configurations

2.5.2 Clock Source Setting

The programmable 8254-interval timer is used in the PCM-9112+. It provides 3 independent 16-bit

programmable down counters. Input of counter 2 is connected to an accurate 2MHz oscillator used

as the internal pacer. Input of counter 1 is cascaded from the output of counter 2. Channel 0 is

free for user applications. There are two selections for the clock source of channel 0: the internal

2MHz clock or an external clock signal. The setting for clock signal is shown in the following table.

Analog Input Setting

Internal Clock

Source: 2MHz

(default)

External Clock

Source

Clock source setting

Table 4: Clock source setting

4

Page 5

2.5.3 D/A Reference Voltage External/Internal Setting

The D/A converter’s reference voltage source can be supplied either by internal or external sources.

For external reference voltage, pin 3 (ExtRef1) and 4 (ExtRef2) of connector CN2 are used.

Reference voltage source for D/A of channel 1 and 2 are selected by JP4. Possible settings are

shown below:

D/A Reference Voltage Setting

D/A CH1 is external

D/A CH2 is external

D/A CH1 is external

D/A CH2 is internal

D/A CH1 is internal

D/A CH2 is external

D/A CH1 is internal

D/A CH2 is internal

Table 5: D/A reference voltage setting

5

Page 6

2.5.4 Internal Reference Voltage Setting

The internal reference voltage can be set to either –5V or –10V by JP3. Possible configurations are

illustrated in the table below. Note that the internal reference voltage is used only when JP5 is set

to internal reference only. If –10V internal reference voltage is selected, the D/A output range is

0V~10V. On the other hand, if the –5V is selected, the D/A output range is 0V~5V.

Internal Reference Voltage Setting

-5V internal

reference

voltage

-10V internal

reference

voltage

Table 6: Internal reference voltage setting

6

Page 7

2.6 Connector Pin Assignment

g

N

N/CN

The PCM-9112+ DAQ module has two 20-pin connectors. CN1 is for analog input and CN2 for

analog output, timer/counter’s signals.

AI0

AI1

AI2

AI3

AI4

AI5

AI6

AI7

A.GND

A.GND

Figure 3: CN1 pin assignment for

1

3

5

7

9

11

13

15

17

19 20

single-ended connection

2

4

6

8

10

12

14

16

18

ExtRef2

COUT0

AI8

AI9

AI10

AI11

AI12

AI13

AI14

AI15

A.GND

A.GND

AIH0

AIH1

AIH2

AIH3

AIH4

AIH5

AIH6

AIH7

A.GND

A.GND

Figure 4: CN1 pin assignment for

V.REF AO1

10

12

14

16

18

2

4

6

8

ExtRef1

AO2

GATE0

GATE

COUT1

ExTCLK

+12V

A.GND

D.GND

ExtTr

N/C

+5V

N/C

1

3

5

7

9

11

13

15

17

19 20

1

3

5

7

9

10

11

12

13

14

15

16

17

18

19 20

differential connection

/C

/C

2

4

6

8

AIL0

AIL1

AIL2

AIL3

AIL4

AIL5

AIL6

AIL7

A.GND

A.GND

Legend:

AIn

AIHn

AILn

ExtRef n

AOn

ExtCLK

ExtTrig

GATE

COUT n

V.REF

A.GND

D.GND

Figure 5: CN2 pin assignment

: Analog input channel n (single-ended)

: Analog high input channel n (differential)

: Analog low input channel n (differential)

: External reference voltage for D/A channel n

: Analog output channel n

: External clock input

: External trigger signal

: Gate input for 8254

: Signal output of counter n

: Voltage reference

: Analog ground

: Digital ground

7

Page 8

2.7 Daughter Boards and Accessories

The PCM-9112+ DAQ module has several available accessories allowing for easy signal wiring for

measurements and control. Functionality and connections of the available accessories are describe

in the in the following sections.

2.7.1 Connect with ACLD-9137

Equipped with a 37-pin D-sub connector, the ACLD-9137 provides a simple way for connection.

Intuitively layout and reliable screw clamp terminal allows for easy wiring. In conjunction with the

ACL-10337 (two 20-pin headers to DB-37 cable), users can set up the connection immediately.

Figure 6: Connect with ACLD-9137

2.7.2 Connect with DIN-37D

The DIN-37D is a termination board with a DIN socket. When users need to mount the termination

board onto the DIN rail, it provides a convenient interface for installation. To achieve this

connection, use the following cables ACL-10337 and ACL-10137.

Figure 7: Connect with DIN-37D

8

Page 9

2.7.3 Connect with ACLD-8125

The ACLD-8125 has a 37-pin D-sub connector, which can connect to the PCM-9112+ through a

ACL-10337 and ACL-10137 cable. The most outstanding feature of this daughter board is the CJC

(cold junction compensation) circuit. You can directly connect a thermocouple onto the ACLD-8125

board. The CJC is only suitable for high gain analog input mode.

Figure 8: Connect with ACLD-8125

2.7.4 Connect with DIN-20P

The DIN-20P has a 20-pin ribbon connector with a DIN socket. This board is connected to the

PCM-9112+ via a 20-pin ribbon cable.

Figure 9: Connect with two DIN-20P termination boards

9

Page 10

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and enjoy all the after-sales services we

offer, please read the following carefully.

1. Before using ADLINK’s products please read the user manual and follow the instructions exactly.

When sending in damaged products for repair, please attach an RMA application form which can be

downloaded from: http://rma.adlinktech.com/policy/.

2. All ADLINK products come with a limited two-year warranty, one year for products bought in China.

The warranty period starts on the day the product is shipped from ADLINK’s factory.

z

Peripherals and third-party products not manufactured by ADLINK will be covered by the

z

original manufacturers' warranty.

For products containing storage devices (hard drives, flash cards, etc.), please back up your

z

data before sending them for repair. ADLINK is not responsible for any loss of data.

Please ensure the use of properly licensed software with our systems. ADLINK does not

z

condone the use of pirated software and will not service systems using such software.

ADLINK will not be held legally responsible for products shipped with unlicensed software

installed by the user.

For general repairs, please do not include peripheral accessories. If peripherals need to be

z

included, be certain to specify which items you sent on the RMA Request & Confirmation

Form. ADLINK is not responsible for items not listed on the RMA Request & Confirmation

Form.

3. Our repair service is not covered by ADLINK's guarantee in the following situations:

Damage caused by not following instructions in the User's Manual.

z

Damage caused by carelessness on the user's part during product transportation.

z

Damage caused by fire, earthquakes, floods, lightening, pollution, other acts of God, and/or

z

incorrect usage of voltage transformers.

Damage caused by inappropriate storage environments such as with high temperatures,

z

high humidity, or volatile chemicals.

Damage caused by leakage of battery fluid during or after change of batteries by

z

customer/user.

Damage from improper repair by unauthorized ADLINK technicians.

z

Products with altered and/or damaged serial numbers are not entitled to our service.

z

This warranty is not transferable or extendible.

z

Other categories not protected under our warranty.

z

4. Customers are responsible for all fees necessary to transport damaged products to ADLINK.

For further questions, please e-mail our FAE staff: service@adlinktech.com

10

Loading...

Loading...