Page 1

PCIe-7350

32-CH High-speed DIO Board

User’s Manual

Manual Rev. 2.00

Revision Date: April 8, 2009

Part No: 50-11039-1000

Advance Technologies; Automate the World.

Page 2

Copyright 2009 ADLINK TECHNOLOGY INC.

All Rights Reserved.

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Trademarks

NuDAQ, NuIPC, DAQBench are registered trademarks of ADLINK

TECHNOLOGY INC.

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Page 3

Getting Service from ADLINK

Contact us should you require any service or assistance.

ADLINK Technology Inc.

Address: 9F, No.166 Jian Yi Road, Chungho City,

Taipei County 235, Taiwan

קᗼխࡉؑ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ

(100085)

Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd., Beijing 100085, China

Tel: +86-10-5885-8666

Fax: +86-10-5885-8625

Email: market@adlinktech.com

ADLINK Technology Shanghai

Address: Ϟ⍋Ꮦⓩ⊇⋒催⾥ᡔᓔথ䩺∳䏃 333 ো 39 ᐶ 4 ሖ

(200233)

Tel: +86-21-6495-5210

Fax: +86-21-5450-0414

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

A1 2 ὐ C (518057)

2F, C Block, Bld. A1, Cyber-Tech Zone,

Gao Xin Ave. Sec 7, High-Tech Industrial Park S.,

Shenzhen, 518054 China

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

Page 4

ADLINK Technology Inc. (German Liaison Office)

Address: Nord Carree 3, 40477 Duesseldorf, Germany

Tel: +49-211-495-5552

Fax: +49-211-495-5557

Email: emea@adlinktech.com

ADLINK (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 MASSY Cedex, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: 151-0072 ᧲ㇺ⼱ᐈ䊱⼱㩷

1-1-2 ᦺᣣ↢ᐈ䊱⼱䊎䊦 8F

Asahiseimei Hatagaya Bldg. 8F

1-1-2 Hatagaya, Shibuya-ku, Tokyo 151-0072, Japan

Tel: +81-3-4455-3722

Fax: +81-3-5333-6040

Email: japan@adlinktech.com

ADLINK Technology Inc. (Korean Liaison Office)

Address: 昢殾柢 儛單割 嚂笊壟 60-12 壟昷捒娯 4猻 402 笾

No.402, Dongsung B/D, 60-12, Nonhyeon-Dong

Gangnam-gu, Seoul, 135-010, Korea.

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Singapore 349584

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte Ltd. (Indian Liaison Office)

Address: No. 1357, "Anupama", Sri Aurobindo Marg, 9th Cross,

JP Nagar Phase I, Bangalore - 560078, India

Tel: +91-80-65605817

Fax: +91-80-22443548

Email: india@adlinktech.com

Page 5

Table of Contents

List of Tables.......................................................................... iii

List of Figures........................................................................ iv

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 1

1.2 Applications ......................................................................... 1

1.3 Specifications....................................................................... 2

1.4 Software Support ............................................................... 10

Programming Library .................................................... 10

2 Hardware Information...................................................... 11

2.1 Card Layout ....................................................................... 11

2.2 Connector Pin Assignment ................................................ 12

2.3 LED indicator ..................................................................... 15

2.4 Installing the Card.............................................................. 16

2.5 Unpacking Checklist .......................................................... 17

2.6 Cables and Termination board .......................................... 17

3 Function Block and Operation Theory........................... 19

3.1 Block Diagram ................................................................... 20

3.2 Programmable Logic Level ................................................ 21

3.3 Digital I/O Configuration..................................................... 22

DI Row Data Mapping ................................................... 23

3.4 Phase Shift of Sample Clock ............................................. 27

3.5 Bus-mastering DMA Data Transfer.................................... 29

3.6 Sample Clock..................................................................... 31

Digital Input (DI) Sample Clock ..................................... 31

Digital Output (DO) Sample Clock ................................ 32

3.7 Operation Mode ................................................................. 35

Polling Mode (Single Read/Write) ................................. 35

DI DMA in Continuous Mode ........................................ 35

DO DMA in Continuous Mode ...................................... 38

DI DMA in Handshaking Mode ..................................... 41

DO DMA in Handshaking Mode .................................... 44

DI DMA in Burst Handshaking Mode ............................ 46

DO DMA in Burst Handshaking Mode .......................... 48

3.8 Trigger Source and Trigger Mode...................................... 52

i

Page 6

3.9 Application Function I/O..................................................... 56

I2C Master .................................................................... 60

SPI Master .................................................................... 62

External Digital Trigger ................................................. 64

Trigger Out .................................................................... 65

Event Out ...................................................................... 66

Handshaking ................................................................. 67

Sample Clock In/Out ..................................................... 68

3.10 Pattern Match..................................................................... 69

3.11 COS (Change of State) Event............................................ 71

3.12 Termination........................................................................ 72

Appendix A ADLINK DIN-68H........................................... 73

ii

Page 7

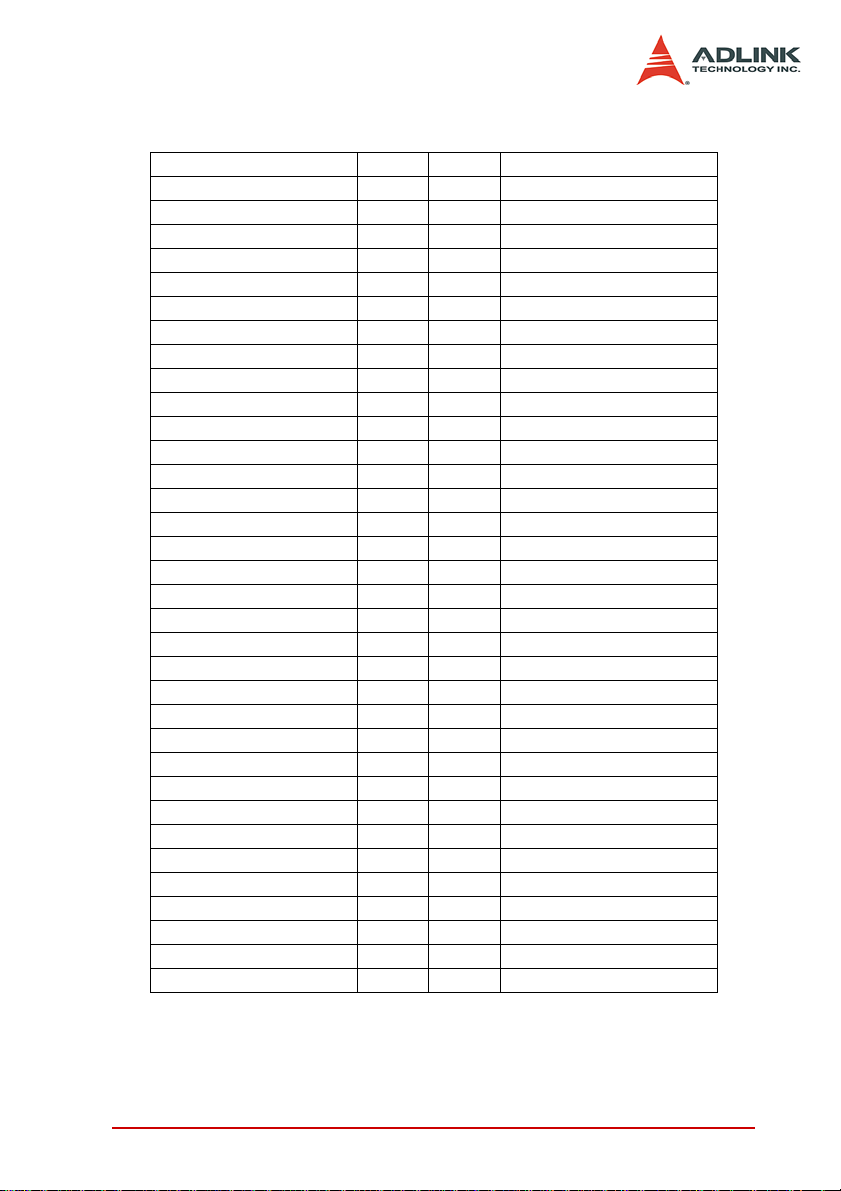

List of Tables

Table 2-1: Connector CN1 Pin Assignment ............................. 13

Table 2-2: I/O Signal Descriptions ........................................... 14

Table 2-3: SMB Jack Connector Signal Descriptions .............. 14

Table 2-4: LED indicator .......................................................... 15

Table 3-1: PCIe-7350 Logic Levels ......................................... 21

Table 3-2: PCIe-7350 High-Speed Digital I/O Configuration ... 22

Table 3-3: Phase Shift Configuration of PCIe-7350 ................. 28

Table 3-4: DI/DO Sample Clock Configuration

of the PCIe-7350 .................................................... 34

Table 3-5: PCIe-7350 AFI I/O Configuration ............................ 56

Table 3-6: PCIe-7350 AFI Signal Description .......................... 57

Table 3-7: Logic States of Pattern Match ................................ 69

Table A-1: DIN-68H Pin Assignment ........................................ 73

Table A-2: Pad Position of User-Defined Resistor Termination 75

List of Tables iii

Page 8

List of Figures

Figure 1-1: Acquisition Timing Diagram ....................................... 6

Figure 1-2: Generation Timing Diagram....................................... 7

Figure 2-1: PCB Layout and Mechanical Drawing

of the PCIe-7350 ..................................................... 11

Figure 3-1: PCIe-7350 Block Diagram ....................................... 20

Figure 3-2: DI Row Data Mapping for 8 Bits Data Width............ 24

Figure 3-3: DI Row Data Mapping for 16 Bits Data Width.......... 25

Figure 3-4: DI Row Data Mapping for 24 bits Data Width .......... 26

Figure 3-5: DI Row Data Mapping for 32 Bits Data Width.......... 26

Figure 3-6: Phase Shift of Sample Clock ................................... 27

Figure 3-7: Maximum Data Throughput of the PCIe-7350......... 29

Figure 3-8: Scatter-Gather DMA for Data Transfer .................... 30

Figure 3-9: DI/DO Sample Clock Architecture ........................... 33

Figure 3-10: DI Continuous Mode Architecture............................ 36

Figure 3-11: DI Timing Diagram................................................... 37

Figure 3-12: DO Continuous Mode Architecture .......................... 39

Figure 3-13: DO Timing Diagram ................................................. 40

Figure 3-14: DI Handshaking Mode Architecture ......................... 42

Figure 3-15: DI Handshaking Timing Diagram............................. 43

Figure 3-16: DO Handshaking Mode Architecture ....................... 45

Figure 3-17: DO Handshaking Timing Diagram ........................... 45

Figure 3-18: DI Burst Handshaking Mode Architecture................ 47

Figure 3-19: DI Burst Handshaking Timing Diagram ................... 48

Figure 3-20: DO Burst Handshaking Mode Architecture.............. 50

Figure 3-21: DO Burst Handshaking Timing Diagram.................. 51

Figure 3-22: DI Post Trigger......................................................... 52

Figure 3-23: DO Post Trigger....................................................... 53

Figure 3-24: DI Post Trigger with Re-trigger ................................ 53

Figure 3-25: DO Post Trigger with Re-Trigger ............................. 54

Figure 3-26: DI Gated Trigger ...................................................... 54

Figure 3-27: DO Gated Trigger .................................................... 55

Figure 3-28: I2C Master of PCIe-7350 ......................................... 60

Figure 3-29: Data Transfer on the I2C Bus .................................. 60

Figure 3-30: I2C Data Format ...................................................... 61

Figure 3-31: SPI Master of PCIe-7350......................................... 62

Figure 3-32: Data Transfer on SPI Bus........................................ 63

Figure 3-33: Clock Mode of SCK ................................................. 63

Figure 3-34: External Digital Trigger Input Configuration............. 64

iv List of Figures

Page 9

Figure 3-35: Configured AFI as Internal Software

Trigger Output ......................................................... 65

Figure 3-36: Pattern Match and COS Event Configuration.......... 66

Figure 3-37: Configured AFI as Handshaking Interface............... 67

Figure 3-38: Configured AFI7 as DI Sampled Clock In/Out ......... 68

Figure 3-39: Configured AFI6 as DO Sampled Clock In/Out ....... 68

Figure 3-40: Example of Pattern Match ....................................... 70

Figure 3-41: Example of Pattern Match ....................................... 71

Figure A-1: DIN-68H Layout ...................................................... 73

Figure A-2: Resistor Termination Schematic.............................. 74

Figure A-3: DIN-68H Layout (Back Side) ................................... 75

List of Figures v

Page 10

vi List of Figures

Page 11

1 Introduction

ADLINK’s PCIe-7350 is a high-speed digital I/O board with 32channel bi-direction parallel I/O lines. The data rate can achieve

up to 200 MB/s through the x1 PCI Express® interface. The clock

rate can support up to 50 MHz internal clock or 100 MHz external

clock, which is ideal for the applications of high-speed and largescale digital data acquisition or exchange, such as digital image

capture, video playback and IC testing.

1.1 Features

The PCIe-7350 comes with the following advanced features:

x1 lane PCI Express® Interface

Maximum 50 MHz clock rate from internal timer or 100 MHz

from external clock

200 MB/s maximum throughput

Software selectable voltage level of 1.8 V, 2.5 V, and 3.3 V

(5 V compatible)

16-steps phase shift in external clock mode

Per group (8-bit) input/output direction selectable

Supports I

external device communication

Scatter-gather DMA support

Flexible handshaking and external digital trigger modes

8-channel auxiliary programmable I/O support

2

C and SPI programmable serial interfaces for

1.2 Applications

High-speed digital data exchange

Digital pattern generation and acquisition

IC testing

Interface to external high-speed A/D and D/A converter

ATE

Introduction 1

Page 12

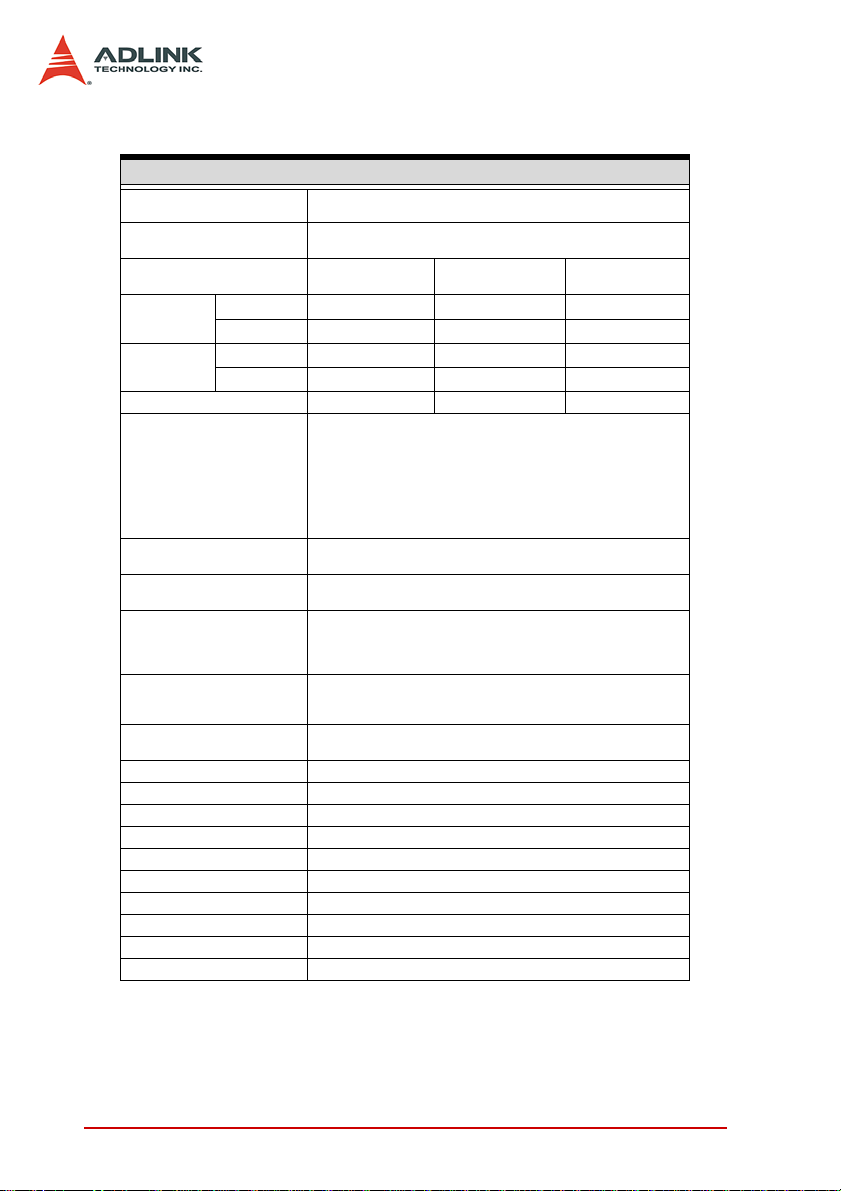

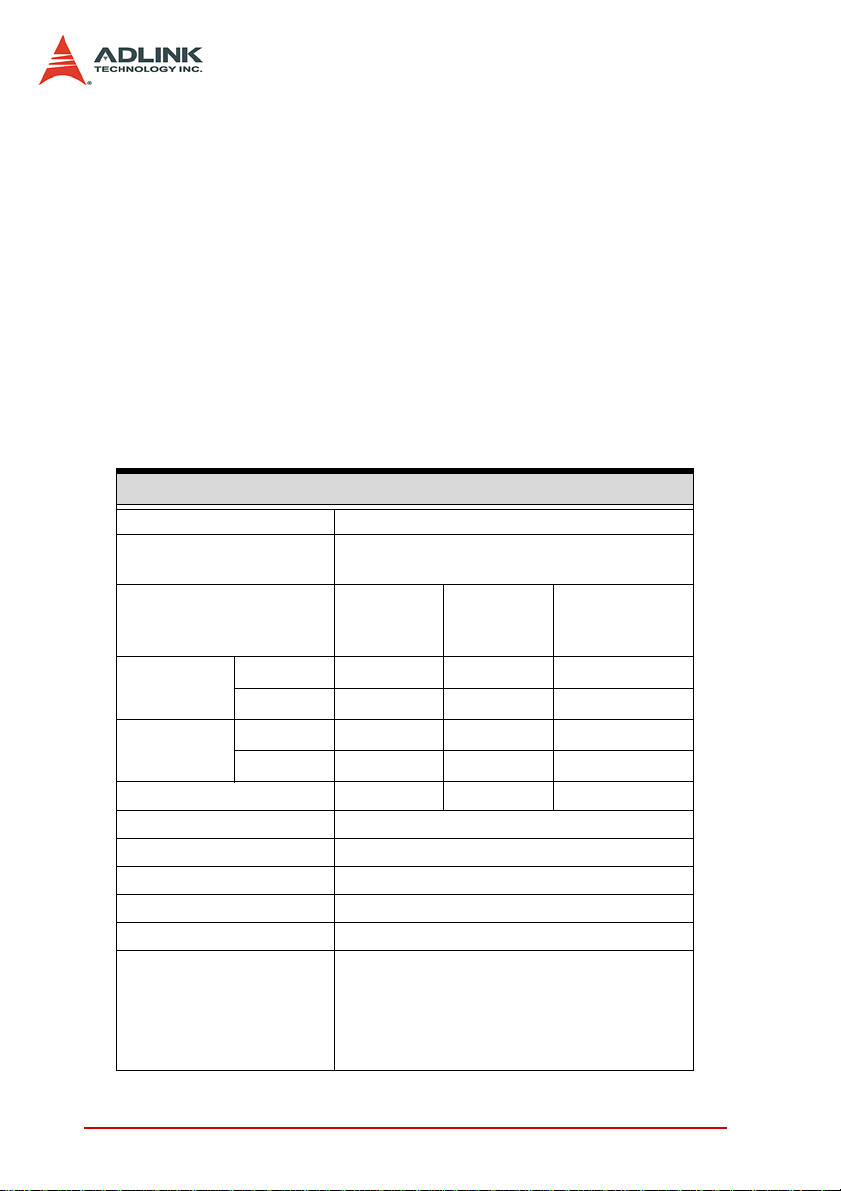

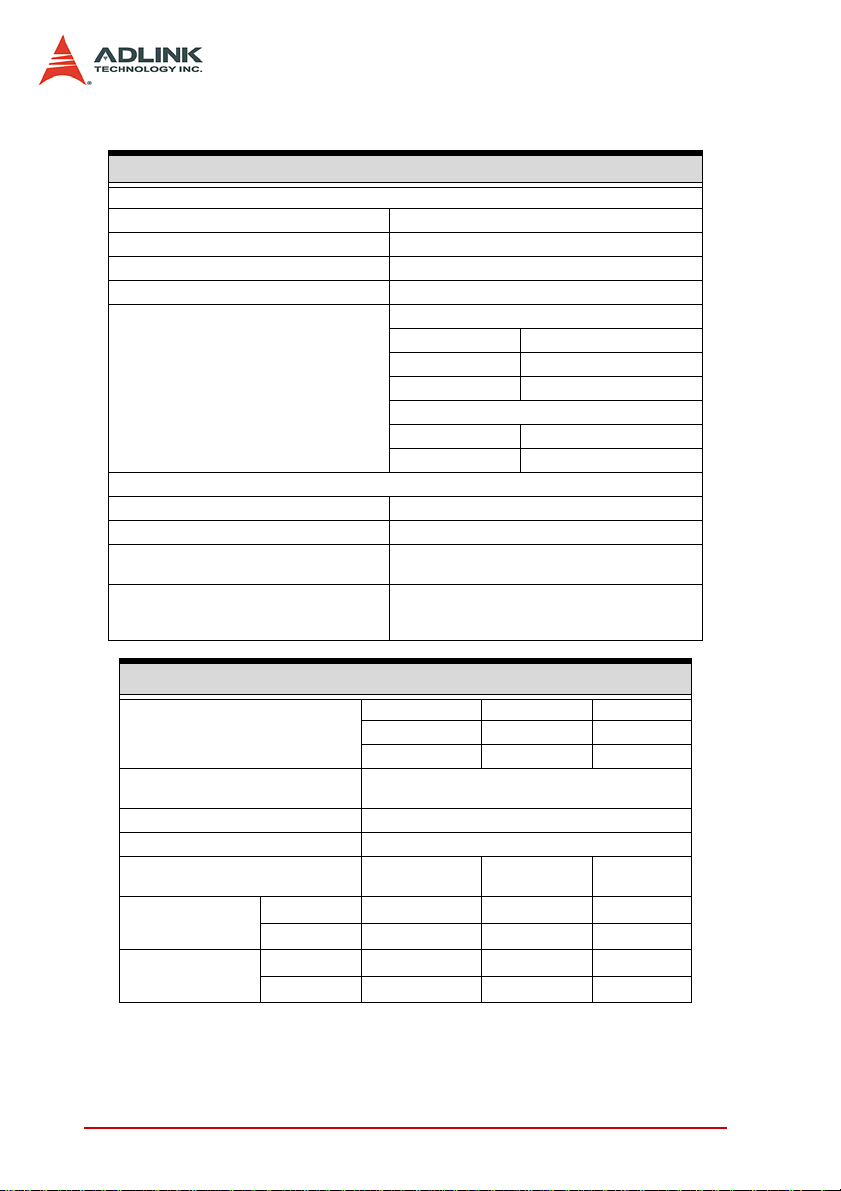

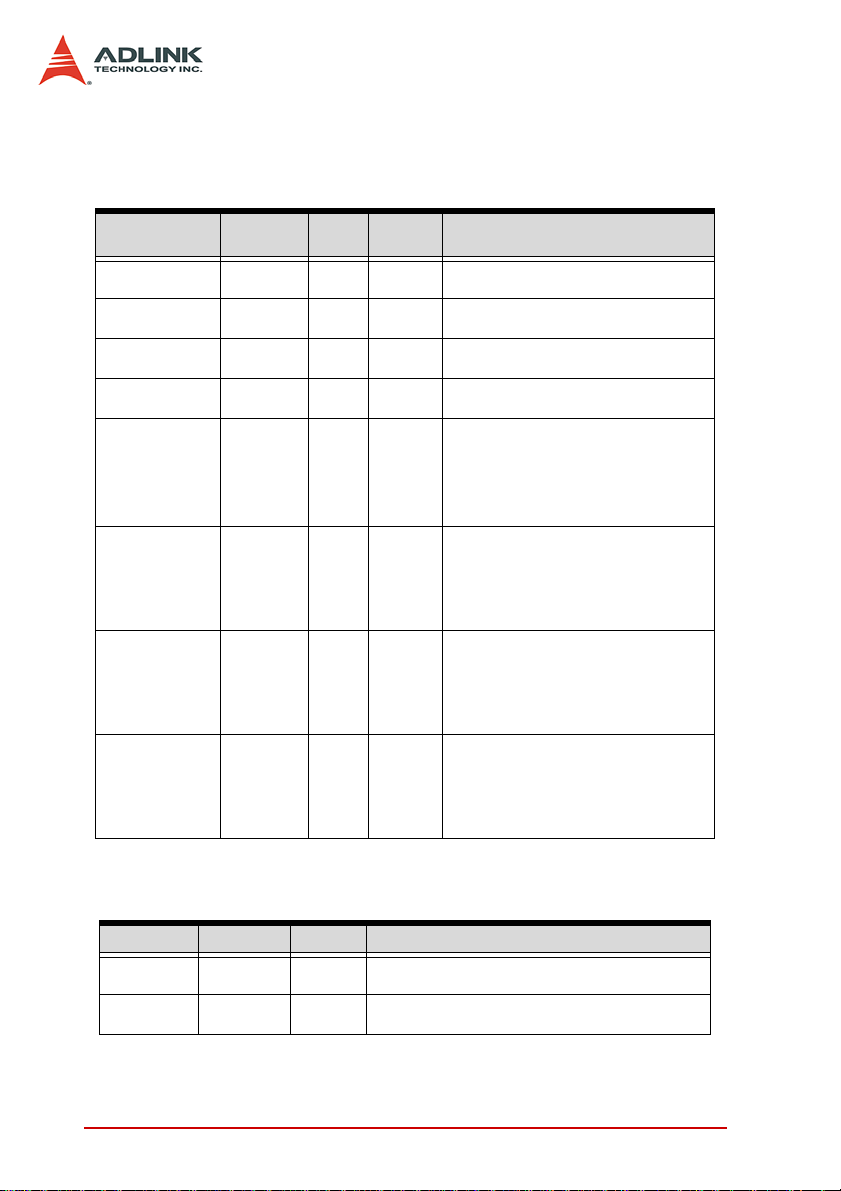

1.3 Specifications

Digital I/O Specifications

Number of

Channels

Direction

(programmable)

Logic Level

(programmable)

Min. V

Input

Voltage

Output

Voltage

Driving capacity(max.) ±8 mA ±16 mA ±32 mA

Throughput

FIFO Size

Data Transfer

Clocking Modes

Trigger Source

Trigger Modes

Input impedance 10 KΩ

Input protection range -1 to 6 V

Output impedance 50 Ω

Power-up initial state Tri-State / All digital inputs

Output protection range -0.5 V to 3.8 V

Dimensions 168 mm x 112 mm (not including connectors)

Connectors 68-pin VHDCI female x1 SMB x2

Operating Temp. 0 to 55° C

Storage Temp. -20 to 70° C

Relative Humidity 5 to 95%, non-condensing

Max. V

Min. V

Max. V

IH

IL

OH

OL

1.8 V 2.5 V

1.2 V 1.6 V 2 V

0.63 V 0.7 V 0.8 V

1.6 V 2.3 V 3.1 V

0.2 V 0.2 V 0.2 V

Digital Input:

Maximum: 200 MByte/s (32-bits input @ 50 MHz) (data size≤250k

samples)

Sustained: 192 MByte/s (data size>250k samples) (Note* )

Digital Output:

Maximum: 200 MByte/s (32-bit output @ 50 MHz) (FIFO load mode,

max. 8k samples)

Sustained: 119.2 MByte/s (Note**)

Digital Input: 8k samples

Digital Output: 8k samples

Software Polling

Bus-mastering DMA with Scatter-Gather

Internal clock: max. 50 MHz

External clock: max. 100 MHz

Handshaking

Burst handshaking

Software

External Digital signal

Pattern match

Post trigger with re-trigger

Gate trigger

per group (8 channel) basis

32

Input or output,

(5 V compatible)

3.3 V

2 Introduction

Page 13

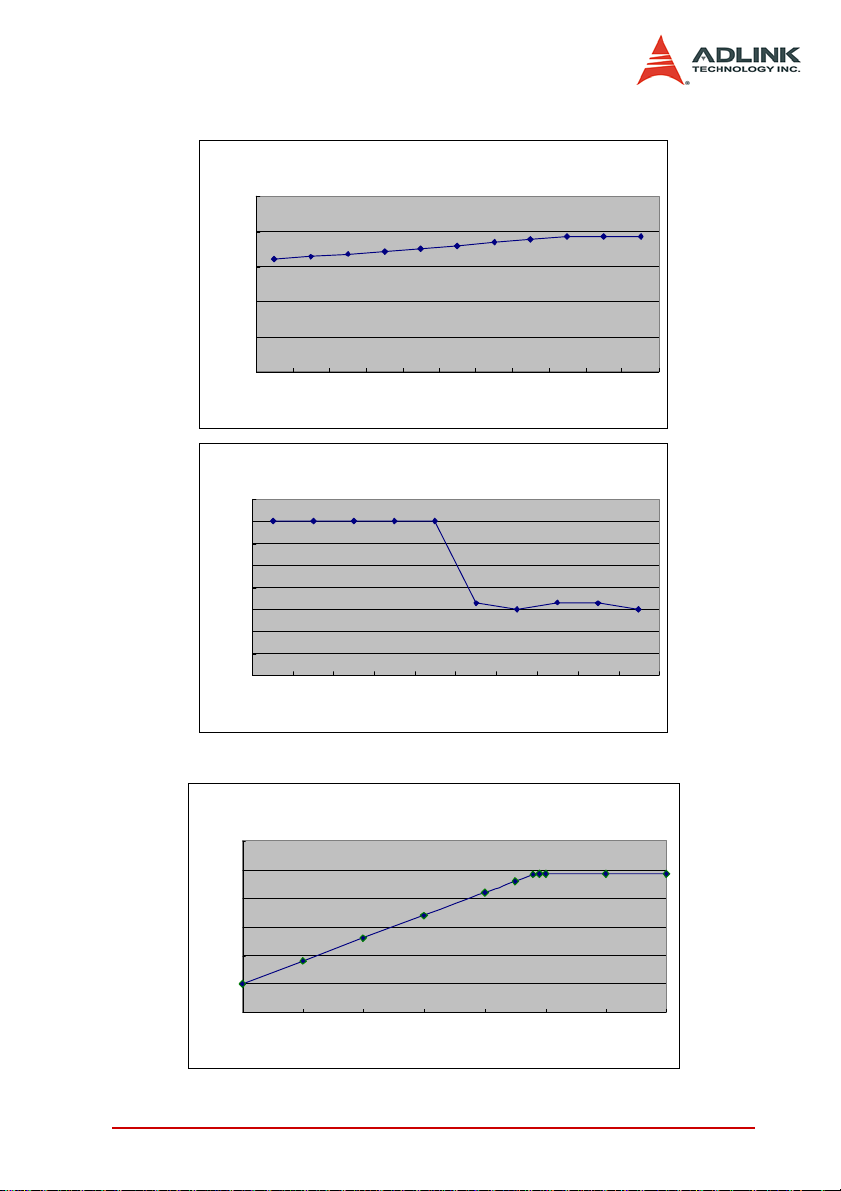

Note*: DI DMA throughput

DI DMA Bandwidth Test

160

164

168

172

176

180

184

188

192

192.7058

192.7138

0

50

100

150

200

250

40 41 42 43 44 45 46 47 48 49 50

External Clock Rate (MHz)

BW (MB/s)

DI DMA Bandwidth T est

200 200 200 200 200

192.58

192.01

192.64

192.56

191.98

186

188

190

192

194

196

198

200

202

50 100 150 200 250 300 350 400 450 500

Data Count (K samples)

BW (MB/s)

DO DMA Bandwidth Test

100

118

116

112

108

104

119.32

119.28

119. 2

119.34

119.32

95

100

105

110

115

120

125

25 26 27 28 29 30 31 32

Clock Rate (MHz)

BW (MB/s)

Note**: DO DMA throughput

Introduction 3

Page 14

If you want to have DO throughput to be up to 200M Byte/s, the

data size is limited to less than the 8K FIFO size by the following

steps:

Step1: Read 8K DO data from system memory into DO FIFO

by DMA before writing 8K DO data from DO FIFO to

the external device

Step2: After 8K DO data are all stored into DO FIFO, and

then start writing these 8K DO data to the external

device with 50MHz DO sample clock rate and 32-bit

data width.

External clock rate can be up to 100 MHz, but only support 8 or

16-bit data width because the DI data throughput can’t exceed 200

MB/s

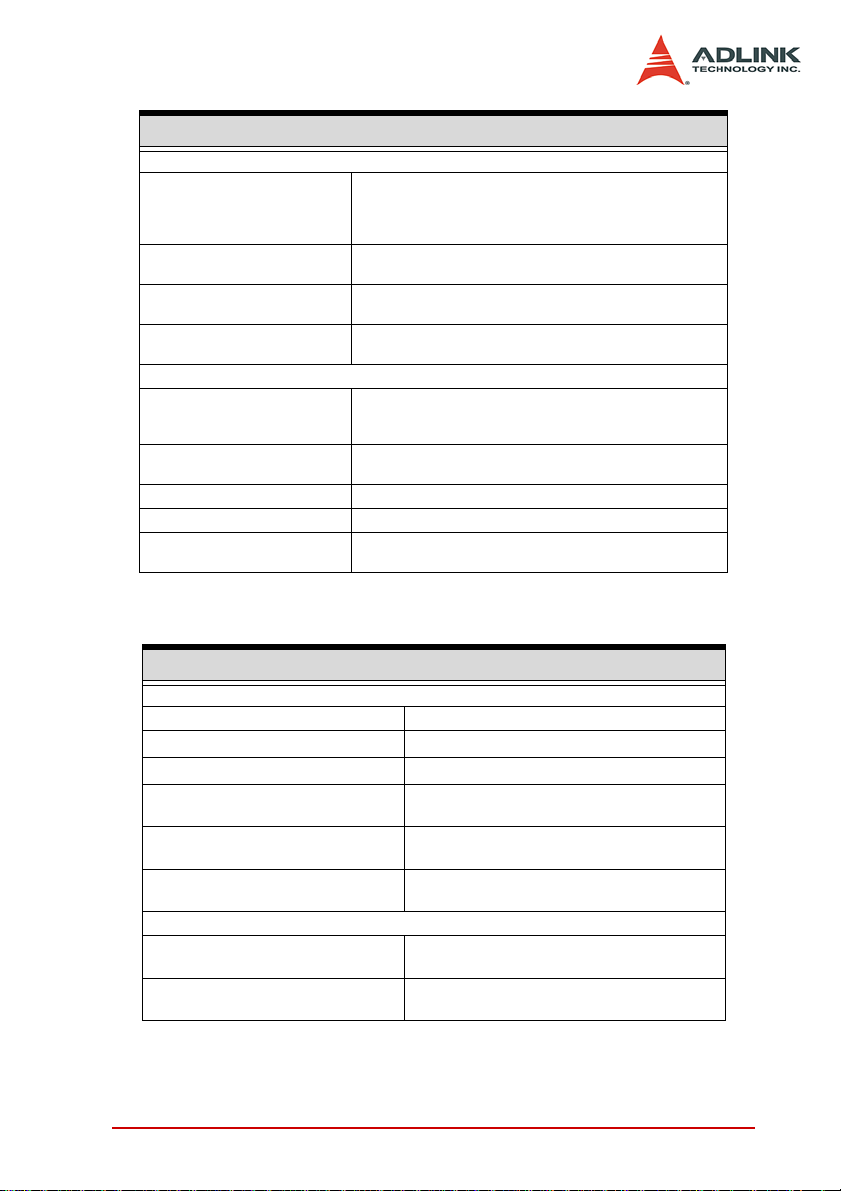

Application Function I/O (AFI)

Number of channels 8

Direction

(programmable)

Logic Levels

(programmable)

Min. V

Max. V

Min. V

Max. V

IH

IL

OH

OL

Input

Voltage

Output

Voltage

Driving capacity (max.) ±8 mA ±16 mA ±32 mA

Input impedance 10 KΩ

Input protection range -1 to 6 V

Output impedance 50 Ω

Power-up initial state Tri-State / All digital inputs

Output protection range -0.5V to 3.8V

Supported Mode

(programmable)

1.8 V 2.5 V

1.2 V 1.6 V 2 V

0.63 V 0.7 V 0.8 V

1.6 V 2.3 V 3.1 V

0.2 V 0.2 V 0.2 V

2

I

C master

SPI master

Handshaking

External trigger in/out

DI/DO sample clock in/out

Input or output,

per channel basis

3.3 V

(5 V Compati-

ble)

4 Introduction

Page 15

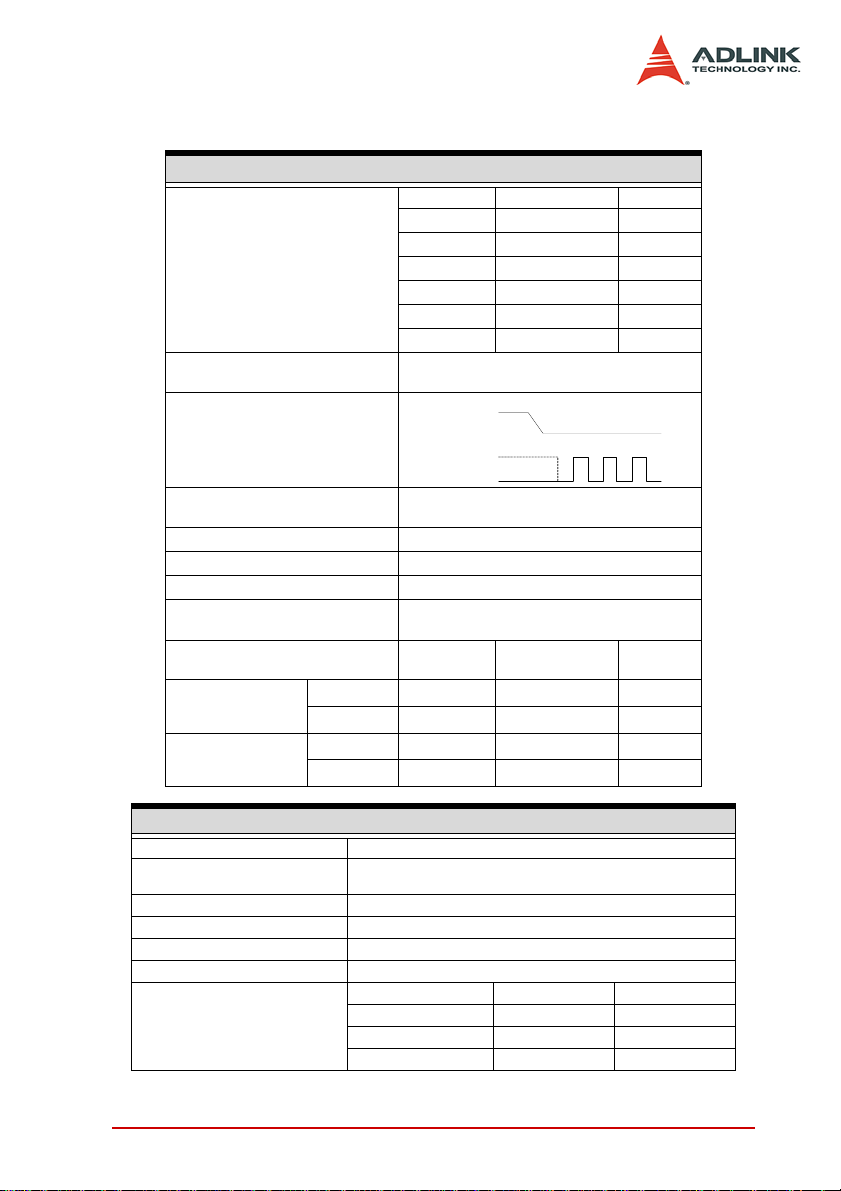

Timing Specifications

Sample Clock

Internal clock: on-board 100MHz with 16-bit divider

Clock Sources

Internal Clock Rate

(programmable)

Ext. frequency range

Phase shift

Sample Clock Exporting

Destination

Frequency range

Clock jitter Period jitter: 160 ps

Clock duty cycle 50%

Phase shift resolution

External clock: 1. AFI6 (for DO)

0 - 100 MHz (no phase shift)

2 MHz - 50MHz (phase shift enabled)*

Internal clock: N/A

External clock: 16 steps; 1 step = 22.5°

1. AFI6 (only for DO)

2. AFI7 (only for DI)

3. SMB CLK out

0 ~ 50 MHz (no phase shift)

2 MHz ~ 50MHz (phase shift enabled) (note3)

1/16 of external sampled clock period

2. AFI7 (for DI)

3. SMB CLK in

1526 Hz – 50 MHz

(100 MHz/ N; 2≤N≤65,535)

(16 steps; 1 step = 22.5°)

When you enable phase shift, the clock must be continuous and

free-running

Timing Accuracy

Acquisition Timing

Channel-to-Channel skew ±1.08 ns

Setup time to sampled clock (t

Hold time to sampled clock (t

Time delay of external sampled clock

from AFI7 to internal (t

Time delay of external sampled clock

from SMB CLK in to internal (t

Time delay of DI data from VHDCI

connector to internal (t

Generation Timing

Exported Clock SkewAFI6 -to- SMB

CLK out(t

Exported Clock (AFI6) -to- DO Data

Delay (t

ECskew

AF62D

)

AF7D

DID

)

)

SU

)

H

)

)

SMBID

)

2 ns

2 ns

7.22 ns

8.02 ns

3.26 ns - 4.34 ns

3.24 ns

600 ps - 5 ns

Introduction 5

Page 16

DI Sampled Clock

(AFI7)

t

AF7D

= Time delay of external sampled clock from AFI7 to internal

t

DID

= Time delay of DI data from VHDCI connector to internal

D0 D1 D2 D3

t

AF7D

Trace & component delay

D0 D1 D2 D3

t

DID

DI Data

(connector)

DI Sampled Clock

(into FPGA)

DI Data

(into FPGA)

tSUt

H

Figure 1-1: Acquisition Timing Diagram

6 Introduction

Page 17

D0

DO Sampled Clock

(internal)

DO Data

Write data to

external device

t

SC2AF6

= Time delay from sampled clock (internal) to exported sampled clock (AFI6)

t

AF62D

= Time delay from exported sampled clock (AFI6) to do data

Exported DO Sampled Clock

(AFI6/ non-inverted)

t

SC2AF6

Exported DO Sampled Clock

( AFI6/ inverted)

Exported DO Sampled Clock

(AFI6/ phase delay)

Phase delay (0° ~ 360°)

D1 D2

t

AF62D

Gerenation start

t

ECskew

t

ECskew

= Time delay from exported clock (AFI6) to exported clock (SMB CLK out)

Exported DO Sampled Clock

(SMB CLK out/ non-inverted)

Trace & component delay

Introduction 7

Figure 1-2: Generation Timing Diagram

Page 18

External Clock I/O Specification

CLK IN (SMB Jack Connector)

Destination DI or DO sample clock

Input coupling AC

Input Impedance 50 Ω

Minimum detectable pulse width 8 ns

Square Wave

Voltage 0.2 Vpp to 5 Vpp

Frequency 100 KHz - 50 MHz

External sampled clock range

CLK OUT (SMB Jack Connector)

Sources DI or DO sample clock

Source impedance 50 Ω

Logic Levels

(programmable)

Driving Capacity (Max.)

I2C Master Specification

Signal

Supported clock rate

(programmable)

Transfer size of Data 0 - 4 Bytes

Transfer size of Cmd/ Addr 0 - 4 Bytes

Logic families

(programmable)

Min. V

Input Voltage

Output Voltage

Max. V

Min. V

Max. V

IH

IL

OH

OL

Duty cycle 40% - 60%

Sine Wave

Voltage 0.2 Vpp to 5 Vpp

Frequency 100 KHz – 50 MHz

The same logic level of AFI I/O

(1.8 V, 2.5 V, or 3.3 V)

±8 mA at 1.8 V

±16 mA at 2.5 V

±32 mA at 3.3 V

Direction Pin

SCL O AFI0

SDA I/O AFI1

1.9 kHz -244.14 kHz;

488.28125 kHz / (n + 1); 1 ≤ n ≤ 255

1.8 V 2.5 V 3.3 V

1.2 V 1.6 V 2.0 V

0.63 V 0.7 V 0.8 V

1.6 V 2.3 V 3.1 V

0.2 V 0.2 V 0.2 V

8 Introduction

Page 19

CS#

SCK

Mode =1

Mode =0

Signal

Supported clock rate

(programmable)

Clock mode

SPI Master Specification

SCK O AFI0

SDO O AFI1

SDI I AFI2

CS_0 O AFI3

CS_1 O AFI4

CS_2 O AFI5

244.14 kHz -62.5 MHz,

62.5 MHz / (n + 1); 0 ≤ n ≤ 255

Direction Pin

The first bit be transferred

MSB/ LSB

(Default: MSB)

Transfer size of Data 0 - 32 bits

Transfer size of Cmd/ Addr 0 - 32 bits

Dummy size 0 - 15 bits

SPI Slave selection

Logic families

(programmable)

Min. V

Input Voltage

Output Voltage

Interface x1 PCI Express interface

Connector

Operation Temperature 0°C - 45°C

Storage Temperature -20°C - 70°C

Humidity 5 - 95%, non-condensing

Dimension 168 mm (L) x 112 mm (H), not including connectors

Power Consumption

IH

Max. V

IL

Min. V

OH

Max. V

OL

General Specification

1. SMB Jack Connector x2 (CLK IN & OUT)

2. 68-pin SCSI-VHDCI x1 (32-bit Data Lines & 8-ch AFI)

+3.3 VDC 450 mA 780 mA

+12V VDC 625 mA 680 mA

Total Power 9 W 10.8 W

Max. 3 slave devices

(selected by CS_0 / CS_1 / CS_2

1.8 V 2.5 V 3.3 V

1.2 V 1.6 V 2 V

0.63 V 0.7 V 0.8 V

1.6 V 2.3 V 3.1 V

0.2 V 0.2 V 0.2 V

Typical Maximum

Introduction 9

Page 20

1.4 Software Support

ADLINK provides versatile software drivers and packages for

users’ different approach to building up a system. ADLINK not only

provides programming libraries such as DLL for most Windows

based systems, but also provide drivers for other software packages such as LabVIEW®.

All software options are included in the ADLINK CD. Non-free software drivers are protected with licensing codes. Without the software code, you can install and run the demo version for two hours

for trial/demonstration purposes. Please contact ADLINK dealers

to purchase the formal license.

1.4.1 Programming Library

For customers who are writing their own programs, we provide

function libraries for many different operating systems, including:

PCIS-DASK: Include device drivers and DLL for Windows

98/NT/2000/XP/Vista. DLL is binary compatible across

Windows 98/NT/2000/XP/Vista. This means all applications

developed with PCIS-DASK are compatible across Windows 98/NT/2000/XP/Vista. The developing environment

can be VB, VC++, Delphi, BC5, or any Windows programming language that allows calls to a DLL. The user’s guide

and function reference manual of PCIS-DASK are in the

CD.

(\\Manual\Software Package\PCIS-DASK)

10 Introduction

Page 21

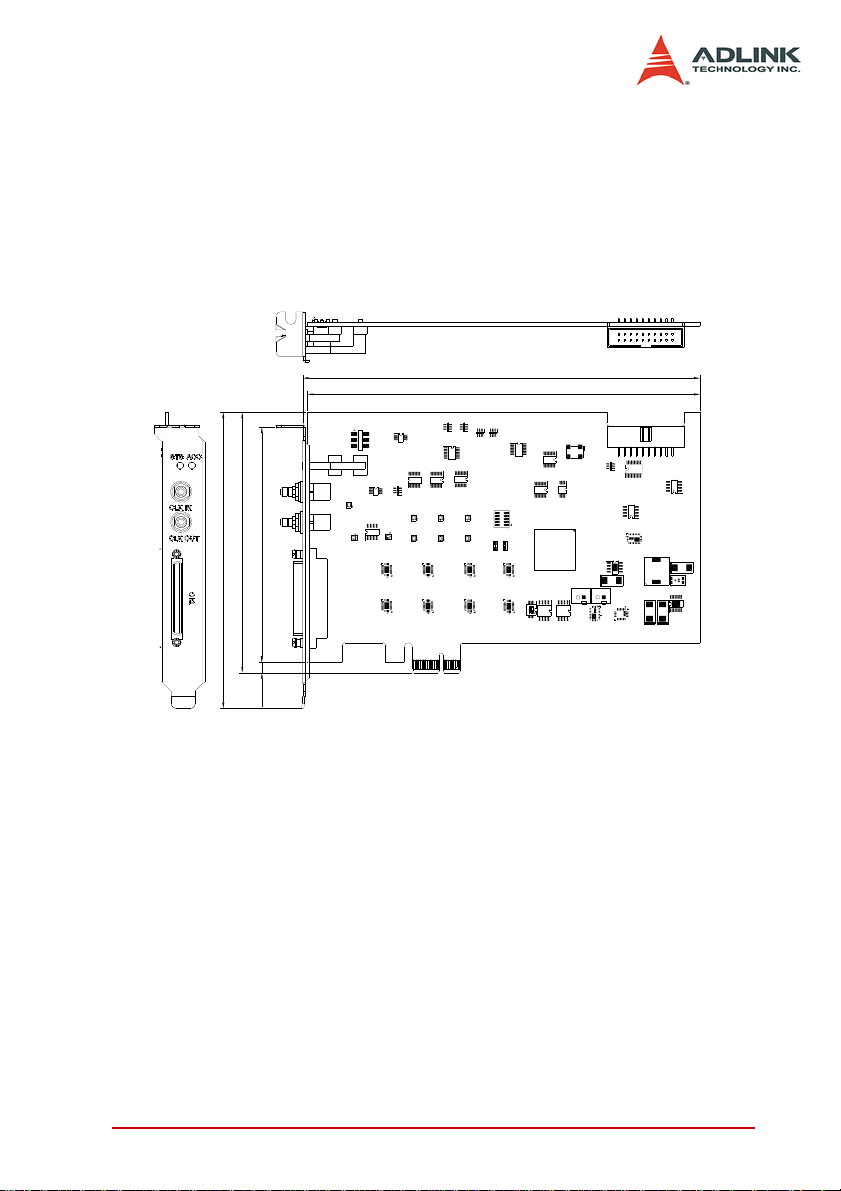

2 Hardware Information

167 .65

169 .65

100.36

126.37

(4.5)

111.15

CN1

CN2

CN3

CN4

JP1

U1

CN5

CN6

LED5

LED6

T1

U12

U23

U24

U25

U6

U50

U7

U18

U22

U17

U21

U16

U20

U15

U19

U41 U43 U4 4

U44

U38

U39

U51

U52

U14 U13 U11

U9 U8 U11

LED1

LED2

U46

U36 U33

U35

OSC 1

SW1

U3 U4

U28 U30

C248

U47

U40

U26

U31

U29

U32

L23

C190

Q3

U27

C189

C195

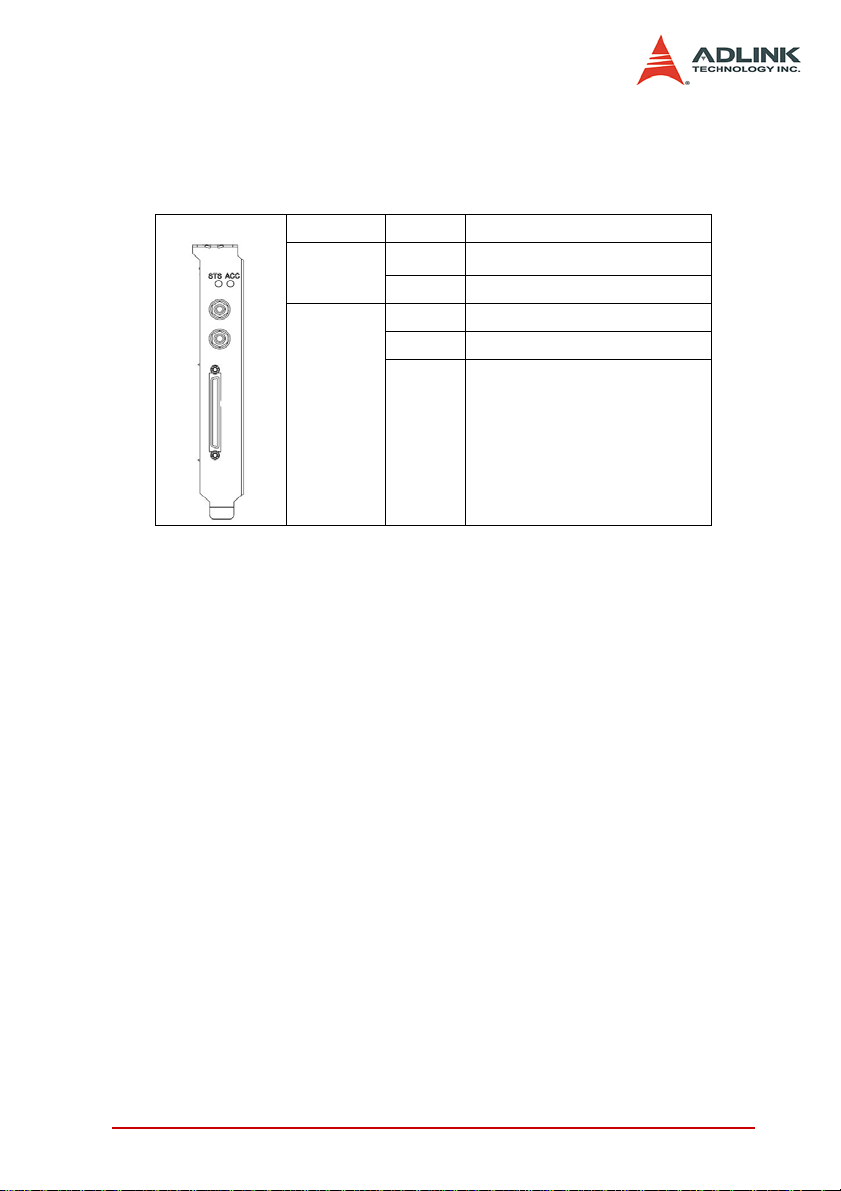

This chapter provides information on the PCIe-7350 layout, connectors, and pin assignments.

2.1 Card Layout

Figure 2-1 shows the PCIe-7350 board layout and dimensions.

Figure 2-1: PCB Layout and Mechanical Drawing of the PCIe-7350

Hardware Information 11

Page 22

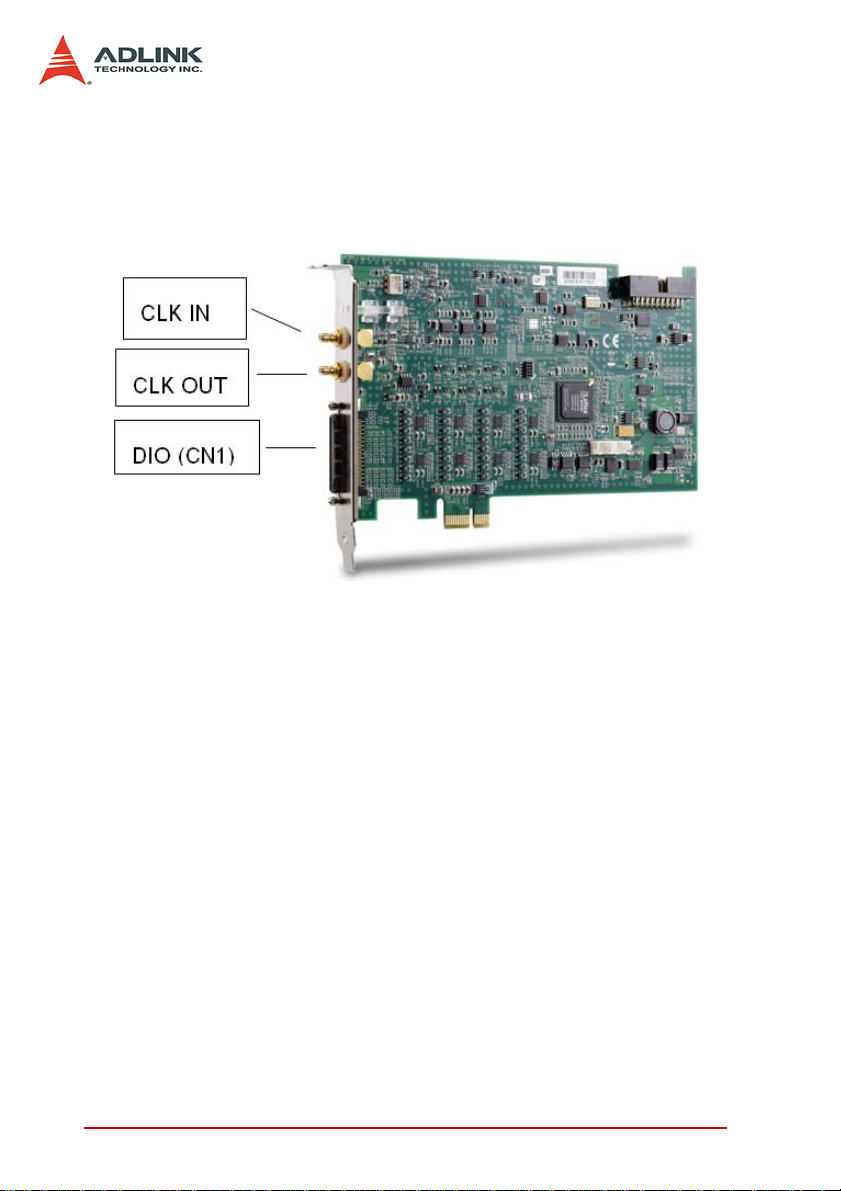

2.2 Connector Pin Assignment

The PCIe-7350 card is equipped with one 68-pin SCSI-VHDCI

connector and two SMB connectors. The SCSI-VHDCI connector

is for high-speed digital I/O and programmable function I/O, while

the SMB connectors are for sample clock input or exporting.

12 Hardware Information

Page 23

Pin # Pin #

GND 68 34 GND

(DI CLK) AFI7 67 33 AFI6 (DO CLK)

GND 66 32 GND

D0 65 31 D1

AFI5 64 30 AFI4

D2 63 29 D3

GND 62 28 GND

D4 61 27 D5

AFI3 60 26 AFI2

D6 59 25 D7

GND 58 24 GND

D8 57 23 D9

GND 56 22 GND

D1055 21D11

GND 54 20 GND

D1253 19D13

AFI1 52 18 GND

D1451 17D15

GND 50 16 GND

D1649 15D17

GND 48 14 GND

D1847 13D19

GND 46 12 GND

D20 45 11 D21

GND 44 10 GND

D22 43 9 D23

GND 42 8 AFI0

D24 41 7 D25

GND 40 6 GND

D26 39 5 D27

GND 38 4 GND

D28 37 3 D29

GND 36 2 GND

D30 35 1 D31

Table 2-1: Connector CN1 Pin Assignment

Hardware Information 13

Page 24

Signal Descriptions

Below are the signal descriptions for the SCSI-VHDCI and SMB

connectors:

Pin

Number

25, 27, 29, 31, 59,

61, 63, 65

17, 19, 21, 23, 51,

53, 55, 57

9, 11, 13, 15, 43,

45, 47, 49

1, 3, 5, 7, 35, 37,

39, 41

8, 26, 30, 52, 60,

64

33 AFI6

67 AFI7

2, 4,6, 10, 12, 14,

16, 18,20, 22, 24,

28, 32, 34, 36, 38,

40, 42, 44, 46, 48,

50, 54, 56, 58, 62,

66, 68

Signal

Name

D0 – D7 Data I/O Port_A bi-directional digital data lines

D8 – D15 Data I/O Port_B bi-directional digital data lines

D16 – D23 Data I/O Port_C bi-directional digital data lines

D24 – D31 Data I/O Port_D bi-directional digital data lines

AFI0 – AFI5

GND Ground -------- Ground reference for Data I/O and AFI I/O

Signal

Type

Control

/Data

Control

/Data

Control

/Data

Direction Description

Application Function I/O, can be configured as the following control signals:

I

I/O

Handshaking signal

External trigger in/out

Event out

Application Function I/O, can be configured as the following control signals:

Handshaking signal

I/O

External trigger in/out

Event out

DO sampled clock in/out

Application Function I/O, can be configured as the following control signals:

Handshaking signal

I/O

External trigger in/out

Event out

DI sampled clock in/out

Table 2-2: I/O Signal Descriptions

SMB Jack Connector Signal Description

2

C/ SPI

Signal Name Signal Type Direction Description

CLK IN Clock I

CLK OUT Clock O

External clock input for DI/DO sampled clock from

external device to the PCIe-7350

DI/DO sampled clock exporting from the PCIe-7350 to

an external device

Table 2-3: SMB Jack Connector Signal Descriptions

14 Hardware Information

Page 25

2.3 LED indicator

There are two LEDs on the bracket which display the I2C & SPI

communication and digital I/O status of the PCIe-7350.

LED Color Mode

2

I

C mode enabled

STS

(Status)

ACC

(Access)

Table 2-4: LED indicator

Red

Yellow SPI mode enabled

Red DI DMA operation

Yellow DO DMA operation

Amber DI & DO DMA operation

Hardware Information 15

Page 26

2.4 Installing the Card

IMPORTANT Install the card driver before you install the card into

your computer system. Refer to section 1.5 for driver support information.

To install the card:

1. Turn off the system/chassis and disconnect the power

plug from the power source.

2. Remove the system/chassis cover.

3. Select the PCI Express slot that you intend to use, then

remove the bracket opposite the slot, if any.

4. Align the card connectors (golden fingers) with the slot,

then press the card firmly until the card is completely

seated on the slot.

5. Secure the card to the chassis with a screw.

6. Replace the system/chassis cover.

7. Connect the power plug to a power source, then turn on

the system.

Configuration

The card configuration is done on a card-by-card basis for all PCI/

PCI Express cards on your system. Because configuration is controlled by the system and the software, there is no jumper setting

required for base address, DMA, and interrupt IRQ. The configuration is subject to change with every boot of the system as new

PCI/PCI Express® cards are added or removed.

Troubleshooting

If your system fails to boot or if you experience erratic operation

with your PCI/PCI Express card in place, this is likely caused by

an interrupt conflict (such as when the BIOS Setup is incorrectly

configured). Refer to the BIOS documentation that came with the

system for details.

16 Hardware Information

Page 27

2.5 Unpacking Checklist

Before unpacking, check the shipping carton for any damage. If

the shipping carton and/or contents are damaged, inform your

dealer immediately. Retain the shipping carton and packing materials for inspection. Obtain authorization from your dealer before

returning any product to ADLINK. Check if the following items are

included in the package.

PCIe-7350 high-speed DIO card

ADLINK All-in-One CD

User’s manual

If any of the items is damaged or missing, contact your dealer

immediately.

CAUTION The card must be protected from static discharge and

physical shock. Never remove any of the socketed parts except at

a static-free workstation. Use the anti-static bag shipped with the

product to handle the card. Wear a grounded wrist strap when servicing.

2.6 Cables and Termination board

The PCIe-7350 is a high-speed digital I/O card. The impedance

matching is very important to the high-speed application for eliminate the signal reflection generated by the cable or PCB trace.

The following cable and termination board is recommended to

improve the signal quality during high-speed signal transfer.

DIN-68H – Termination board with one 68-pin SCSI-VHDCI con-

nector and user selectable impedance. Refer to Appendix A for

more information.

ACL-10279 – 68-pin SCSI-VHDCI cable with 50Ω impedance

SMB-SMB-1M – SMB to SMB cable, 1 M, for sample clock in/out

SMB-BNC-1M – SMB to BNC cable, 1 M, for sample clock in/out

Hardware Information 17

Page 28

18 Hardware Information

Page 29

3 Function Block and Operation Theory

The operation theory of the PCIe-7350 card is described in this

chapter. These functions include high-speed digital pattern acquisition, digital pattern generation, application function I/O, and etc.

The operation theory can help you understand how to configure

and operate the PCIe-7350 card.

Function Block and Operation Theory 19

Page 30

3.1 Block Diagram

There are 32-channel bi-direction high-speed digital I/O lines, 8channel AFI (Application Function I/O) lines, and two sample clock

input/output channels available on the PCIe-7350 card. All the 32channel high-speed digital I/O lines are connected to level shifter,

Fairchild FXL4245 and can be programmed as 1.8 V, 2.5 V, or 3.3

V (5 V compatible) logic levels. These channels can be also programmed as input channels for digital pattern acquisition or output

channels for digital pattern generation.

The 8-channel application function I/O lines are connected to level

shifter, Fairchild FXL2T245, too. These application function I/O

can be programmed as I2C or SPI serial interface, handshaking

interface, external digital trigger input, event output and external

clock input/output with 1.8 V or 2.5 V or 3.3 V (5 compatible) logic

levels by direction and logic level control of level shifter and by AFI

controller implemented in FPGA.

The digital pattern acquisition/generation and corresponding flexible sample timing are controlled by ADLINK Smart Control Engine

implemented by FPGA. Please refer to Figure 3-1 PCIe-7350

block diagram.

Figure 3-1: PCIe-7350 Block Diagr am

20 Function Block and Operation Theory

Page 31

3.2 Programmable Logic Level

To interface different logic level applications, the PCIe-7350 supports three software selectable logic levels of 1.8 V, 2.5 V, or 3.3 V

(5 V compatible) for all digital I/O lines, sample clocks, I

triggers, and events. When you choose one of these three logic

levels, all the I/O lines will be at the same logic level you choose.

Below are the definition and high/low range for different logic levels. When connecting PCIe-7350 to a device under test (DUT),

you must ensure that the interface voltage levels are compatible.

V

: The digital input voltage at logic high; senses a binary

IH

one (1)

V

: The digital input voltage at logic low; senses a binary

IL

zero (0)

V

: The digital output voltage at logic high; generates a

OH

binary one (1)

V

: The digital output voltage at logic low; generate a

OL

binary zero (0)

2

C, SPI,

Logic Levels 1.8 V 2.5 V

Digital Input

Digital Output

Function Block and Operation Theory 21

Min. VIH 1.2 V 1.6 V 2 V

Max. VIL 0.63 V 0.7 V 0.8 V

Min. VOH 1.6 V 2.3 V 3.1 V

Max. VOL 0.2 V 0.2 V 0.2 V

Table 3-1: PCIe-7350 Logic Levels

3.3 V

(5 V compatible)

Page 32

3.3 Digital I/O Configuration

The 32-channel high-speed digital I/O lines are bi-direction and

divided into four groups. Each group contains 8 channels and can

be configured as input port or output port individually. At power-up

status, all the I/O lines are preset to input ports. When configuring

to digital output mode, the initial status of digital outputs are in tristate. The possible configuration modes are as follows:

Port Channel Power-up status Direction

Port A D0 ~ D7 Input Input or output

Port B D8 ~ D15 Input Input or output

Port C D16 ~ D23 Input Input or output

Port D D24 ~ D31 Input Input or output

Table 3-2: PCIe-7350 High-Speed Digital I/O Configuration

22 Function Block and Operation Theory

Page 33

3.3.1 DI Row Data Mapping

For digital pattern acquisition, the data width can be configured to

8-bit, 16-bit, 24-bit, or 32-bit and the data transfer is based on 32bit data width. Below is the mapping table for different DI port combination.

Data Width Input Ports Row Data Mapping

D C B A Refer to Figure 3-2

8 bits

16 bits

24 bits

32 bits DCBA Refer to Figure 3-5

DCB A Refer to Figure 3-2

D C BA Refer to Figure 3-2

D CBA Refer to Figure 3-2

DCBA Refer to Figure 3-3

D C B A Refer to Figure 3-3

D CBA Refer to Figure 3-3

D CBA Refer to Figure 3-3

D C B A Refer to Figure 3-3

DCBA Refer to Figure 3-3

D CBA Refer to Figure 3-4

D C BA Refer to Figure 3-4

DCB A Refer to Figure 3-4

DCBA Refer to Figure 3-4

Function Block and Operation Theory 23

Page 34

CH7 ~ CH0

(sample #1)

CH7 ~ CH0

(sample #2)

CH7 ~ CH0

(sample #3)

CH7 ~ CH0

(sample #4)

CH15 ~ CH8

(sample #1)

CH15 ~ CH8

(sample #2)

CH15 ~ CH8

(sample #3)

CH15 ~ CH8

(sample #4)

CH23 ~ CH16

(sample #1)

CH23 ~ CH16

(sample #2)

CH23 ~ CH16

(sample #3)

CH23 ~ CH16

(sample #4)

CH31 ~ CH24

(sample #1)

CH31 ~ CH24

(sample #2)

CH31 ~ CH24

(sample #3)

CH31 ~ CH24

(sample #4)

Configured

input ports

A

BCD

A

B

CD

AB

C

D

ABC

D

Configured

input ports

Configured

input ports

Configured

input ports

Figure 3-2: DI Row Data Mapping for 8 Bits Data Width

24 Function Block and Operation Theory

Page 35

CH15 ~ CH0

(sample #1)

CH7 ~ CH0CH23 ~ CH16

Configured

input ports

AB

CD

A

B

C

D

A

BC

D

A

BC

D

Configured

input ports

Configured

input ports

Configured

input ports

CH15 ~ CH0

(sample #2)

CH23 ~ CH8

(sample #1)

CH23 ~ CH8

(sample #2)

A

B

C

D

Configured

input ports

(sample #1)

CH7 ~ CH0CH23 ~ CH16

(sample #2)

CH7 ~ CH0CH31 ~ CH24

(sample #1)

CH7 ~ CH0CH31 ~ CH24

(sample #2)

CH15 ~ CH8CH31 ~ CH24

(sample #1)

CH15 ~ CH8CH31 ~ CH24

(sample #2)

AB

CD

Configured

input ports

CH31 ~ CH16

(sample #1)

CH31 ~ CH16

(sample #2)

Figure 3-3: DI Row Data Mapping for 16 Bits Data Width

Function Block and Operation Theory 25

Page 36

CH23 ~ CH0

(sample #1)

CH7 ~ CH0

(sample #2)

CH15 ~ CH0CH31 ~ CH24

CH7 ~ CH0

(sample #2)

CH7 ~ CH0

CH7 ~ CH0

(sample #2)

CH15 ~ CH8

(sample #2)

Configured

input ports

ABC

D

AB

C

D

A

B

CD

A

BCD

Configured

input ports

Configured

input ports

Configured

input ports

(sample #1)

CH31 ~ CH16

(sample #1)

CH31 ~ CH8

(sample #1)

ABCD

Configured

input ports

CH31 ~ CH0

(sample #1)

Figure 3-4: DI Row Data Mapping for 24 bits Data Width

Figure 3-5: DI Row Data Mapping for 32 Bits Data Width

26 Function Block and Operation Theory

Page 37

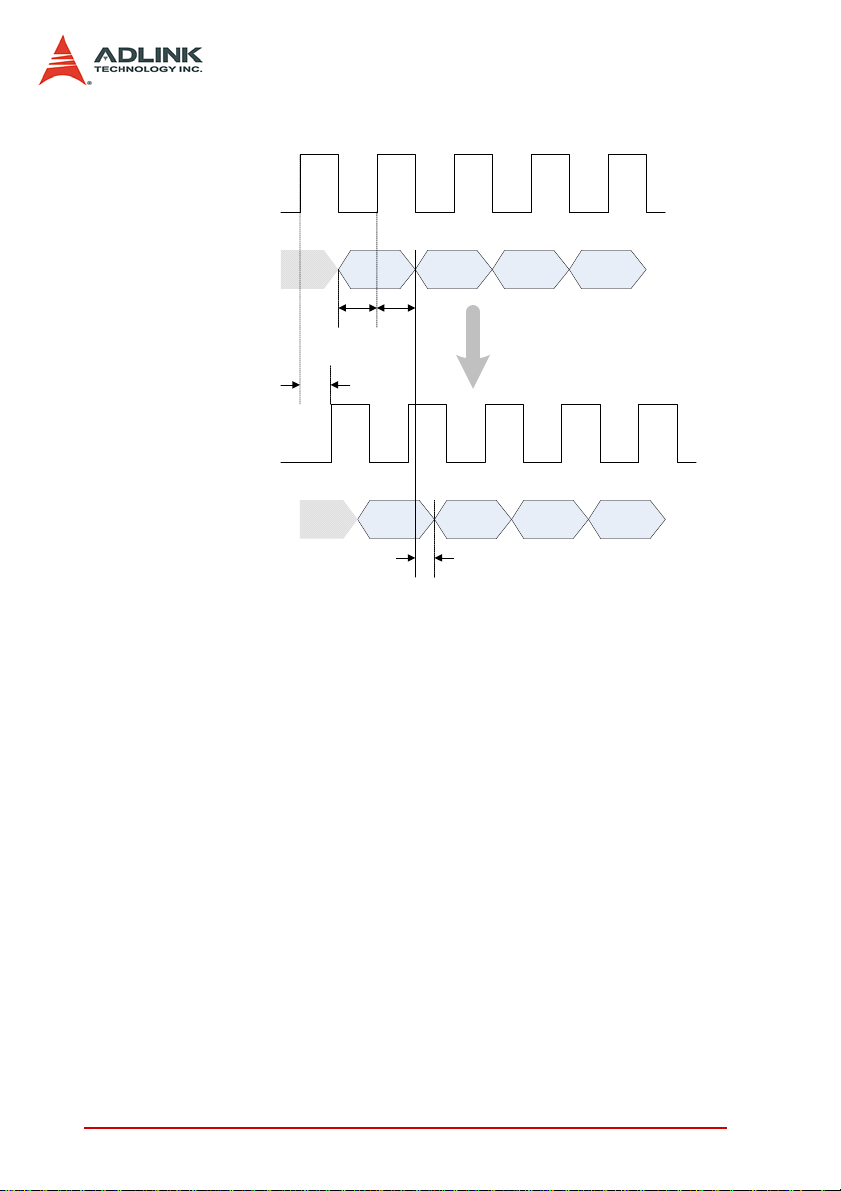

3.4 Phase Shift of Sample Clock

Acquisition of Digital Data

External

sampled clock

(from DUT)

DI Data

(from DUT)

Generation of Digital Data

Exported

sampled clock

(to DUT)

DO Data

(to DUT)

D0 D1 D2 D3

D0 D1 D2 D3

D0 D1 D2 D3

D0 D1 D2 D3

16 steps phase shift

16 steps phase shift

PCIe-7350 Card

Valid area

Transition area

Valid area Transition area

PCIe-7350 features phase shift of sample clock (on SMB connector or AFI6 & AFI7 of SCSI-VHDCI connector). The sample clock

can be from external DUT or can be the exporting clock generated

from internal time base. The resolution of phase shift is 4-bit (16

steps) implemented by Phase-Locked Loop (PLL) function of

FPGA. In other words, the phase shift of sample clock is 22.5° x N,

where N is any integer from 1 to 15. Furthermore, in phase shifting

mode, the supported clock frequency is from 2 MHz to 50 MHz.

This function can optimize the timing of digital pattern acquisition

or generation to avoid sampling/exporting the data from/to DUT at

transition state. Therefore, for digital input, the data can be sampled in clean and valid timing instead of transition timing. For digital output, it can fine tune the exporting clock to avoid the sampling

of DUT at setup time or hold time instead of aligning the data.

Figure 3-6: Phase Shift of Sample Clock

Function Block and Operation Theory 27

Page 38

Value

Revolution 16 steps (1 step = 22.5°)

Supported

Frequency Range

Supported CLK

Table 3-3: Phase Shift Configuration of PCIe-7350

User can shift the clock phase ofthe following clock:

External DI sample clock (from SMB CLK IN or AFI7)

External DO sample clock (from SMB CLK IN or AFI6)

Exported DI sample clock (from SMB CLK IN or AFI7)

Exported DO sample clock (from SMB CLK IN or AFI6)

2MHz ~ 50MHz

28 Function Block and Operation Theory

Page 39

3.5 Bus-mastering DMA Data Transfer

System

Memory

NB

Chipset

120MB/s 250MB/s

PC Main-board

PCI-Express

IP Core

8K

FIFO

500MB/s 200MB/s

DUT

PCIe-7350

Digital I/O data transfer between PCIe-7350 and PC’s system

memory is through bus mastering DMA, which is controlled by

PCIe IP Core.

Figure 3-7: Maximum Data Throughput of the PCIe-7350

The bus-mastering controller controls the PCI/PCIe bus when it

becomes the master of the bus. Bus mastering reduces the size of

the on-board memory and reduces the CPU loading because data

is directly transferred to the computer’s memory without host CPU

intervention.

Bus-mastering DMA provides the fastest data transfer rate on PCIbus. Once the analog/digital input operation starts, control returns

to your program. The hardware temporarily stores the acquired

data in the on-board Data FIFO and then transfers the data to a

user-defined DMA buffer memory in the computer. Please note

that even when the acquired data length is less than the Data

FIFO, the data will not be kept in the Data FIFO but directly transferred into host memory by the bus-mastering DMA.

The DMA transfer mode is very complex to program. We recommend using a high-level program library provided by our driver to

configure this card. By using a high-level programming library for

high speed DMA data acquisition, users simply need to assign the

sampling period and the number of conversion into their specified

counters. After the trigger condition is matched, the data will be

transferred to the system memory by the bus-mastering DMA.

The PCI/PCIe controller also supports the function of scatter/

gather bus mastering DMA, which helps the users to transfer large

amounts of data by linking all the memory blocks into a continuous

linked list.

Function Block and Operation Theory 29

Page 40

In a multi-user or multi-tasking OS, like Microsoft Windows, Linux,

and so on, it is difficult to allocate a large continuous memory

block to do the DMA transfer. Therefore, the PCI/PCIe controller

provides the function of scatter -gather or chaining mode DMA to

link the non-continuous memory blocks into a linked list so that

users can transfer very large amounts of data without being limited

by the fragment of small size memory. Users can configure the

linked list for the input DMA channel or the output DMA channel.

Figure 4.7 shows a linked list that is constructed by three DMA

descriptors. Each descriptor contains a PCI/PCIe address, PCI/

PCIe dual address, a transfer size, and the pointer to the next

descriptor. PCI/PCIe address and PCI/PCIe dual address support

64-bit addresses which can be mapped into more than 4GB of the

address space. Users can allocate many small size memory

blocks and chain their associative DMA descriptors altogether by

their application programs. The software driver provides simple

settings of the scatter-gather function, and some sample programs

are also provided within the ADLINK all-in-one CD.

Figure 3-8: Scatter-Gather DMA for Data Transfer

Choose Finite or Continuous Operation

You can transfer data continuously to or from computer memory

(continuous operation), or you can specify the number of samples

you want to transfer (one-shot operation). In either case, the PCIe7350 transfers the data using direct memory access (DMA) without occupying CPU resources.

30 Function Block and Operation Theory

Page 41

3.6 Sample Clock

The sample clock controls the data rate of digital pattern acquisition and generation. For PCIe-7350, the sample clock can be configured from internal timer pacer or external clock through the

SMB connectors or SCSI-VHDCI connector.

3.6.1 Digital Input (DI) Sample Clock

For the operation of digital pattern acquisition in continuous mode

or burst handshaking mode, the PCIe-7350 card can acquire digital data from external devices at a specific sampling rate (DI sample clock). DI sample clock can be selected as the following two

clock sources:

Internal DI sample clock – the PCIe-7350 can internally

generate the sample clock signal for digital data acquisition.

With an internal base clock source of 100 MHz, the PCIe7350 can generate any clock frequency of 100 MHz/n,

where n is any integer from 2 to 65535.

External DI sample clock – the PCIe-7350 can receive

external clock signal from AFI7 or SMB CLK as the DI sample clock for synchronization applications.

In addition, the PCIe-7350 can also export DI sample clock to

external devices through AFI7 pin or SMB CLK connector.

Function Block and Operation Theory 31

Page 42

3.6.2 Digital Output (DO) Sample Clock

For the operation of digital pattern generation in continuous mode

or burst handshaking mode, PCIe-7350 card can generate digital

data to external devices at a specific update rate (DO sample

clock). DO sample clock can be selected as the following two

clock sources:

Internal DO sample clock – the PCIe-7350 can internally

generate the sample clock signal for digital data generation.

With an internal clock source of 100MHz, the PCIe-7350

can generate any clock frequency of 100 MHz/n, where n is

any integer from 2 to 65535.

External DO sample clock – the PCIe-7350 can receive an

external sample clock signal from AFI6 or SMB CLK connector as the DO sample clock for synchronization applications.

In addition, the PCIe-7350 can also export DO sample clock to

external devices through AFI6 pin or SMB CLK connector. Figure

3-8 shows the DI/DO sample clock architecture of PCIe-7350.

32 Function Block and Operation Theory

Page 43

16 steps

phase shift

I

AFI7

1/N

DI CLK

Mux

Int. DI sampled clk

16 steps

phase shift

DI Sampled CLK

Acquisition

Engine

Int. Timebase

Ext. DI sampled clk

SMB CLK out

I

AFI6

Ext. DO CLK

Mux

Ext. DI CLK

Mux

Export. DI/DO CLK

Mux

Export. DI CLK

Mux

16 steps

phase shift

AFI6

O

Export. DO CLK

Mux

DO sampled clk

SMB CLK in

DO CLK

Mux

16 steps

phase shift

Int. DO sampled clk

1/N

DO Sampled CLK

Gereration

Engine

Ext. DO sampled clk

O

AFI7

100MHz

DI sampled clk

Figure 3-9: DI/DO Sample Clock Architecture

Function Block and Operation Theory 33

Page 44

DI Sample CLK DO Sample CLK

Internal

clock

External

clock

Sample

clock

exporting

Table 3-4: DI/DO Sample Clock Configuration of the PCIe-7350

Source

Freq.

Source

Freq. 0 – 100 MHz 0 – 100 MHz

Freq.

(phase shift)

Destination

Freq. 0 – 50 MHz 0 – 50 MHz

Freq.

(phase shift)

On-board 100 MHz

oscillator

100 MHz/n

(n = 2~65535)

AFI7

SMB CLK in

2 MHz – 50 MHz 2 MHz – 50 MHz

AFI7

SMB CLK out

2 MHz – 50 MHz 2 MHz – 50 MHz

On-board 100 MHz

oscillator

100 MHz/n

(n = 2~ 65535)

AFI6

SMB CLK in

AFI6

SMB CLK out

34 Function Block and Operation Theory

Page 45

3.7 Operation Mode

The PCIe-7350 supports four different modes for acquisition and

generation operation, including software polling, continuous,

handshaking, and burst handshaking mode..

3.7.1 Polling Mode (Single Read/Write)

The PCIe-7350 supports a software polling mode to read or write a

single chunk of data via a software command. That is, the 32-bit

high-speed I/O lines can be used as a static I/O. The data width

can be 8-bit, 16-bit, 24bit, or 32-bit.

3.7.2 DI DMA in Continuous Mode

For the DI pattern acquisition operation in continuous mode, PCIe7350 card can acquire input data from external devices at a specific sampling clock rate (DI sampled clock). DI sample clock can

be selected from internal or external clock source. The operation

sequences are listed as follows:

Steps:

Define DI port configuration (32/24/16/8-bits data width)

Define DI logic level configuration (3.3/2.5/1.8 V)

Define DI sample clock configuration (internal/external)

If choose internal sampled clock, you can define sam-

pling clock rate to be 100MHz/n (n = 2~65535)

If choose external sampled clock, the phase shift func-

tion is available when external clock is a free-running

clock (not a strobe signal) and external clock rate is from

2 MHz ~ 50 MHz.

Define DI starting mode configuration (NoWait or WaitTRIG)

If choose WaitTRIG, you can define start trigger source

to be software trigger or external trigger (DI-Start) from

AFI0 ~ AFI7.

Define DI data count

Execute DI DMA Read Command (continuous mode)

Function Block and Operation Theory 35

Page 46

The operation architecture of DI DMA in continuous mode is

1/N

DI CLK

Mux

Int. DI sampled clk

16 steps

phase shift

Ext. DI sampled clk

Ext. DI CLK

Mux

Bus Master DMA

100MHz

8K FIFO Flip Flop

D[31:0]

I

AFI7

SMB CLK in

AFI[7:0]

DI sampled clk

Start Trigger

Mux

NoWait/

WaitTRIG

Software trigger DI-Start

PCIe-7350 Card

DI Data DI Data

External trigger in

External clock in

clk

enable

Software trigger out

shown as below:

Figure 3-10: DI Continuous Mode Architectu re

36 Function Block and Operation Theory

Page 47

The timing diagram of DI DMA in continuous mode is shown as

DO D1 D2 D3 D4 D5 D6

DI Sampled Clock

Start Trigger

DI Data

Read data into DI FIFO

Wait for

start trigger

t

H

t

SU

t

H

t

SU

t

H

t

SU

= Maximum required setup time

= Maximum required hold time

below:

Figure 3-11: DI Timing Diagram

Note: In the continuous mode of DI pattern acquisition, the input

data will be stored in the DI FIFO of the PCIe-7350. The data

then transfer to system memory by bus mastering DMA if

PCIe bus is available. If the speed of translation from external device to the DI FIFO on board is higher than that from

DI FIFO to system memory or the PCIe bus is busy for a long

time, the DI FIFO become full and the DI pattern acquisition

controller will stop to write data into DI FIFO until the DI FIFO

is not full. So the data will be lost when the DI FIFO is full.

Function Block and Operation Theory 37

Page 48

3.7.3 DO DMA in Continuous Mode

For the DO pattern generation operation in continuous mode,

PCIe-7350 card can generate digital data to external devices at a

specific update clock rate (DO sample clock). DO sample clock

can be selected from internal or external clock source. The operation sequences are listed as follows:

Steps:

Define DO port configuration (32/24/16/8-bits data width)

Define DO logic level configuration (3.3/2.5/1.8 V)

Define DO sample clock configuration (internal/external)

If choose internal sample clock, you can define sampling

clock rate to be 100MHz/n (n = 2~65535)

If choose external sample clock, the phase shift function

is available when external clock rate is 2MHz ~ 50MHz.

Define DO exporting sample clock configuration (AFI6/SMB

CLK out)

PCIe-7350 can also export DO sample clock to external

devices. The destination of DO sample clock exporting

can be AFI6 or SMB CLK out connector.

The phase shift function is available when exported

clock is a free-running clock and the clock rate is 2MHz ~

50MHz.

Define DO starting mode configuration (NoWait or Wait-

TRIG)

If choose WaitTRIG, you can define start trigger source

to be software trigger or external trigger (DO-Start) from

AFI0 ~ AFI7.

Define DO data count.

Execute DO DMA Write Command (continuous mode)

38 Function Block and Operation Theory

Page 49

The operation architecture of DO DMA in continuous mode is

1/N

DO CLK

Mux

Int. DO sampled clk

16 steps

phase shift

Ext. DO sampled clk

Ext. DO CLK

Mux

Bus Master DMA

100MHz

8K FIFO Flip Flop

D[31:0]

I

AFI6

SMB CLK in

AFI[7:0]

DO sampled clk

Start Trigger

Mux

NoWait/

WaitTRIG

Software trigger DO-Start

PCIe-7350 Card

DO Data DO Data

External trigger in

External clock in

clk

enable

16 steps

phase shift

O

AFI6

Export. DO CLK

Mux

SMB CLK out

Exported sampled

clock out

clk valid

Export

clk gate

Software trigger out

shown as below:

Figure 3-12: DO Continuous Mode Architecture

Function Block and Operation Theory 39

Page 50

The timing diagram of DO DMA in continuous mode is shown as

D0 D1 D2

DO Sampled Clock

Start Trigger

(DO-Start)

DO Data

Write data to

external device

Wait for

start trigger

t

W

t

W

= Minimum detectable trigger width

D3 D4

t

ET2D

t

ET2D

= Delay from external trigger to do data out (about 5 cycle)

Exported DO Sampled Clock

(falling edge)

Software Trigger out

(DO-SW)

t

IT2D

t

IT2D

= Delay from software trigger out to do data out (about 4 cycle)

below:

Figure 3-13: DO Timing Diagram

40 Function Block and Operation Theory

Page 51

3.7.4 DI DMA in Handshaking Mode

For the DI pattern acquisition operation in handshaking mode,

PCIe-7350 card can acquire input data from external devices by

handshaking data transfer through DI-REQ input signal and DIACK output signal of AFI interface. The operation sequences are

listed as follows:

Step1: Configuration

Define DI port configuration (32/24/16/8-bits data width)

Define DI logic level configuration (3.3/2.5/1.8V)

Define DI-REQ and DI-ACK signal (AFI0 ~ AFI7)

For example: if configure AFI3 as DI-REQ and AFI4 as

DI-ACK, and then you must connect the handshaking

signal (DI-REQ and DI-ACK) of external device to the

AFI3 and AFI4.

Define DI starting mode configuration (NoWait or WaitTRIG)

If choose WaitTRIG, you can define start trigger source

to be software trigger or external trigger (DI-Start or DITRIG) from AFI0 ~ AFI7.

Define DI data count

Step2: Execute DI DMA Read Command (handshaking mode)

After DI data is ready on device side, the peripheral device

strobe data into the PCIe-7350 by asserting a DI-REQ signal. (action_1)

The DI-REQ signal caused the PCIe-7350 to latch DI data

and store it into DI FIFO. (action_2)

The PCIe-7350 asserts a DI-ACK signal when it is ready for

another input. (action_3)

The action_1 to action_3 is repeated in handshaking

mode.

The DI data in the DI FIFO will be transferred into system

memory directly and automatically by bus mastering DMA.

Function Block and Operation Theory 41

Page 52

The operation architecture of DI DMA in handshaking mode is

Bus Master DMA

8K FIFO Flip Flop

D[31:0]

AFI[7:0]

Start Trigger

Mux

NoWait/

WaitTRIG

Software trigger

DI-Start or DI-TRIG

PCIe-7350 Card

DI Data DI Data

External trigger in

DI-REQ

enable

Software trigger out

DI-ACK

AFI[7:0]

clk

ack

DI-REQ

DI-ACK

shown as below:

Figure 3-14: DI Handshaking Mode Architecture

42 Function Block and Operation Theory

Page 53

The timing diagram of DI DMA in handshaking mode is shown as

DO D1 D2

DI -REQ

DI Data

Read data int o DI FI FO

Wait for

DI-REQ

t

H

t

SU

t

H

t

SU

= Maxi mum required se tup time

= Maxi mum required ho ld time

DI -ACK

t

1

t2t

3

t

1

≥

20 ns

t

2

≥

10 ns

t

3

≥

50 ns

below:

Figure 3-15: DI Handshaking Timing Diagram

Function Block and Operation Theory 43

Page 54

3.7.5 DO DMA in Handshaking Mode

For the DO pattern generation operation in handshaking mode,

PCIe-7350 card can generate output data to external devices by

handshaking data transfer through DO-REQ output signal and

DO-ACK input signal of AFI interface. The operation sequences

are listed as follows:

Step1: Configuration

Define DO port configuration (32/24/16/8-bits data width)

Define DO logic level configuration (3.3/2.5/1.8V)

Define DO-REQ and DO-ACK signal (AFI0 ~ AFI7)

For example: if configure AFI3 as DO-REQ and AFI4 as

DO-ACK, and then you must connect the handshaking

signal (DO-REQ and DO-ACK) of external device to the

AFI3 and AFI4.

Define DO starting mode configuration (NoWait or Wait-

TRIG)

If choose WaitTRIG, you can define start trigger source

to be software trigger or external trigger (DO-Start or

DO-TRIG) from AFI0 ~ AFI7.

Define DO write count

Step2: Execute DO DMA Write Command (handshaking mode)

The DO data saved in the system memory will be trans-

ferred to DO FIFO directly and automatically by bus mastering DMA.

After DO data are ready, DO-REQ signal is generated and

DO data are sent to the external device. (action_1)

After DO-ACK signal from external device is gotten

(action_2)

The action_1 to action_2 is repeated in handshaking

mode.

44 Function Block and Operation Theory

Page 55

The operation architecture of DO DMA in handshaking mode is

Bus Master DMA

8K FIFO Flip Flop

D[31:0]

AFI[7:0]

Start Trigger

Mux

NoWait/

WaitTRIG

Software trigger

DO-Start or DO-TRIG

PCIe-7350 Card

DO Data DO Data

External trigger in

DO-REQ

enable

Software trigger out

DO-ACK

AFI[7:0]

strobe out

ack

DO-REQ

DO-ACK

DO D1 D2

DO -REQ

DO Data

Write data to external device

DO -ACK

t2t

3

t

2

≥

40 ns

t

3

≥

50 ns

shown as below:

Figure 3-16: DO Handshaking Mode Architecture

The timing diagram of DO DMA in handshaking mode is shown as

below:

Figure 3-17: DO Handshaking Timing Diagram

Function Block and Operation Theory 45

Page 56

3.7.6 DI DMA in Burst Handshaking Mode

The burst handshaking mode is a fast and reliable data transfer

protocol. It has both advantage of handshaking mode and continuous mode.

In DI burst handshaking mode, DI-REQ signal will be active by

external device when it is ready to send DI data and sample clock.

And then DI-ACK signal will be generated by PCIe-7350 when it is

ready to receive DI data from external device.

External device should start to send DI data after it detect DI-ACK

signal is active. DI data transfer between PCIe-7350 and external

device should be continued when both DI-REQ and DI-ACK are

active. When DI FIFO of PCIe-7350 becomes almost full, DI-ACK

signal will be inactive. External device should stop to send DI data

and sample clock after it detects DI-ACK signal inactive. The operation sequences are listed as follows:

Step1: Configuration

Define DI port configuration (32/24/16/8-bits data width)

Define DI logic level configuration (3.3/2.5/1.8 V)

Define DI sample clock configuration (only external)

The phase shift function is available when external clock

is a free-running clock (not a strobe signal) and external

clock rate is from 2 MHz – 50 MHz.

Define DI-REQ and DI-ACK signal (AFI0 ~ AFI7)

For example: if configure AFI3 as DI-REQ and AFI4 as

DI-ACK, and then you must connect the handshaking

signal (DI-REQ and DI-ACK) of external device to the

AFI3 and AFI4.

Define DI starting mode configuration (NoWait or WaitTRIG)

If choose WaitTRIG, you can define start trigger source

to be software trigger or external trigger (DI-Start or DITRIG) from AFI0 ~ AFI7.

Define DI data count

46 Function Block and Operation Theory

Page 57

Step2: Execute DI DMA Read Command (burst handshaking

16 steps

phase shift

Ext. DI sampled clk

Ext. DI CLK

Mux

Bus Master DMA

8K FIFO Flip Flop

D[31:0]

I

AFI7

SMB CLK in

AFI[7:0]

DI sampled clk

Start Trigger

Mux

NoWait/

WaitTRIG

Software trigger DI-Start or DI-TRIG

PCIe-7350 Card

DI Data DI Data

External trigger in

External clock in

clk

enable

Software trigger out

DI-REQ

DI-ACK

DI-REQ

DI-ACK

DI-REQ

DI-ACK

DI CLK

Mux

mode)

PCIe-7350 will generate DI-ACK signal when it is ready to

receive DI data after DI-REQ signal is active.

External device starts to send DI data and DI sample clock

after DI-ACK signal is active.

PCIe-7350 starts to receive DI data and DI sample clock

from external device when DI-REQ and DI-ACK are all

active.

The DI data in the DI FIFO will be transferred into system

memory directly and automatically by bus mastering DMA.

The operation architecture of DI DMA in burst handshaking mode

is shown as below:

Figure 3-18: DI Burst Handshaking Mode Architecture

Function Block and Operation Theory 47

Page 58

The timing diagram of DI DMA in burst handshaking mode is

DO

DI Data

DI Sampled Clock

(from external)

DI -REQ

(Active High)

DI -ACK

(Active High)

D1 D2 D3 D9D7 D8

PCIe-7350 is ready to

receive DI data

External Device is ready to send DI data

DI data transfer starts

D5

PCIe-7350 is not ready

to receive DI data

Wait DI-REQ

asserted

Wait DI-ACK

asserted

DI data transfer stops

DI data transfer re-start

(DI FIFO is full)

(DI-REQ & DI-ACK

are all asserted)

(DI-ACK is de-asserted)

(DI-REQ & DI-ACK

are all asserted)

shown as below:

Figure 3-19: DI Burst Handshaking Timing Diagram

3.7.7 DO DMA in Burst Handshaking Mode

In DO burst handshaking mode, DO-REQ signal will be active by

PCIe-7350 when it is ready to send out DO data. And then DOACK signal should be generated by external device when it is

ready to receive DO data. Once DO-ACK is active, external device

has to keep DO-ACK active until its input buffer is almost full. The

operation sequences are listed as follows:

48 Function Block and Operation Theory

Page 59

Step1: Configuration

Define DO port configuration (32/24/16/8-bits data width)

Define DO logic level configuration (3.3/2.5/1.8 V)

Define DO sample clock configuration (internal/external)

If choose internal sampled clock, you can define sam-

pling clock rate to be 100 MHz/n (n = 2-65535)

If choose external sampled clock, the phase shift func-

tion is available when external clock rate is from 2 MHz 50 MHz.

Define DO exporting sample clock configuration (AFI6/SMB

CLK out)

The PCIe-7350 can also export DO sampled clock to

external devices. The destination of the exported DO

sampled clock can be AFI6 or SMB CLK out connector.

The phase shift function is available when exported

clock rate is from 2 MHz – 50 MHz.

Define DO-REQ and DO-ACK signal (AFI0 - AFI7)

For example: if configure AFI3 as DO-REQ and AFI4 as

DO-ACK, and then you must connect the handshaking

signal (DO-REQ and DO-ACK) of external device to the

AFI3 and AFI4.

Define DO starting mode configuration (NoWait or Wait-

TRIG)

If choose WaitTRIG, you can define start trigger source

to be software trigger or external trigger (DO-Start or

DO-TRIG) from AFI0 - AFI7.

Define DO data count

Function Block and Operation Theory 49

Page 60

Step2: Execute DO DMA Write Command (burst handshaking

1/N

DO CLK

Mux

Int. DO sampled clk

16 steps

phase shift

Ext. DO sampled clk

Ext. DO CLK

Mux

Bus Master DMA

100MHz

8K FIFO Flip Flop

D[31:0]

I

AFI6

SMB CLK in

AFI[7:0]

DO sampled clk

Start Trigger

Mux

NoWait/

WaitTRIG

Software trigger DO-Start or DO-TRIG

PCIe-7350 Card

DO Data DO Data

External trigger in

External clock in

clk

enable

16 steps

phase shift

O

AFI6

Export. DO CLK

Mux

SMB CLK out

Exported sampled

clock out

clk valid

Export

clk gate

Software trigger out

DO-REQ

DO-ACK

DO-REQ

DO-ACK

DO-REQ

DO-ACK

mode)

The DO data saved in the system memory will be trans-

ferred to DO FIFO directly and automatically by bus mastering DMA.

After DO data are ready, DO-REQ signal is asserted.

PCIe-7350 start to send DO data and DO sampled clock to

external device after DO-ACK signal is asserted.

If input buffer of external device has no much space for new

DO data, DO-ACK signal will be inactive and PCIe-7350 will

be only allowed to send 4 more data to the receiver.

If DO data are not ready (DO FIFO is empty), DO-REQ sig-

nal will be inactive and PCIe-7350 stops to send DO data

and DO sample clock until DO data are ready again.

The operation architecture of DO DMA in burst handshaking mode

is shown as below:

50 Function Block and Operation Theory

Figure 3-20: DO Burst Handshaking Mode Architecture

Page 61

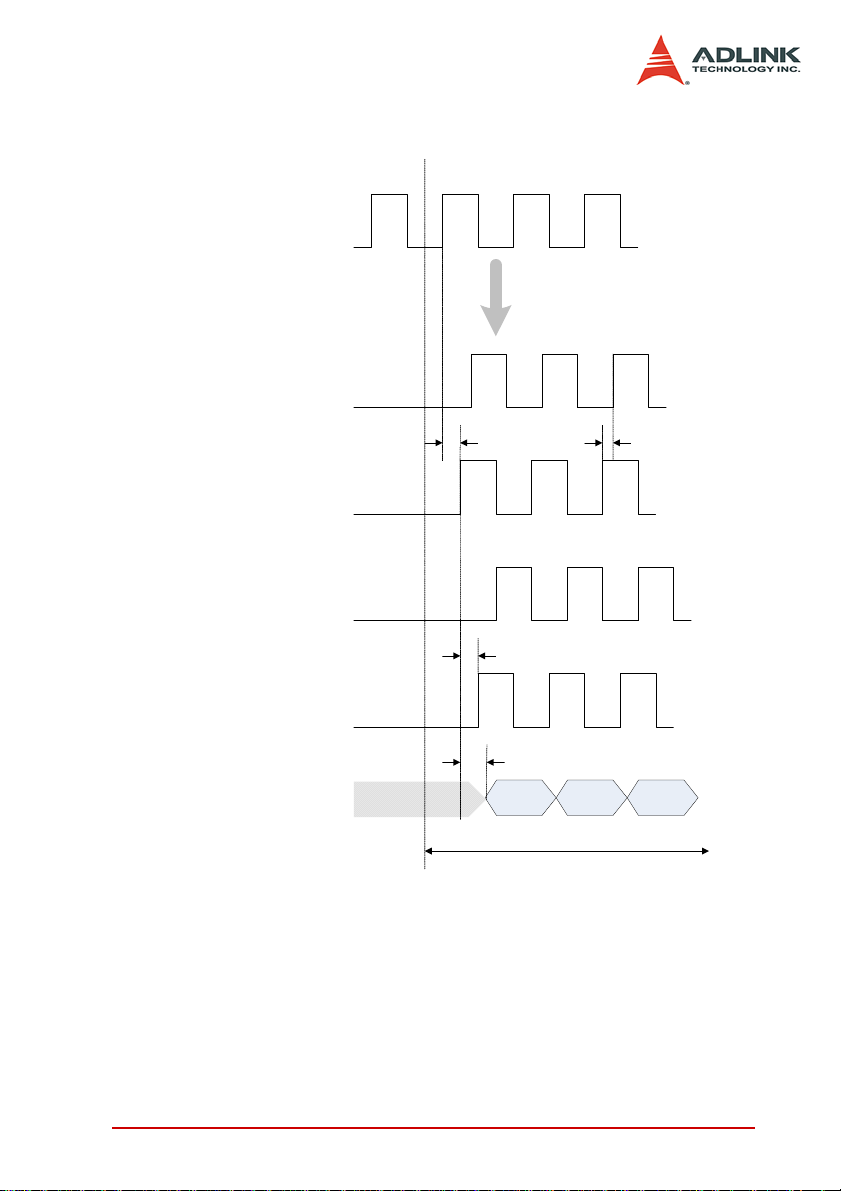

The timing diagram of DO DMA in burst handshaking mode is

DO

DO Data

Exported DO Sampled Clock

(falling edge)

DO Sampled Clock

DO -REQ

(Active High)

DO -ACK

(Active High)

D1 D2 D3 D4 D5 D6 D7 D8

Up to 4 samples are allowed to

transfer after de-assertion of DO-ACK

External device is ready

to receive DO data

PCIe-7350 is ready to send DO data

shown as below:

Figure 3-21: DO Burst Handshaking Timing Diagram

Function Block and Operation Theory 51

Page 62

3.8 Trigger Source and Trigger Mode

DI Sampled Clock

DI-Start

(rising)

DI Data

Read 8 data

into DI FIFO

Wait for

DI-Start

t

w

t

w

= Minimum required pulse width time

Operation End

The PCIe-7350 supports 2 trigger sources, software command

trigger and external digital trigger, to start or pause the DI or DO

operation. In addition, the PCIe-7350 supports 3 trigger modes,

including post trigger, gated trigger, and post trigger with re-trigger.

In post trigger mode and post trigger with re-trigger mode, the

polarity of digital trigger signal can be configured to rising edge or

falling edge. In gated trigger mode, the level of trigger signal will

start or pause the operation of digital pattern acquisition or generation. Below are the examples of these trigger conditions.

[Example 1] External digital trigger with post trigger mode

DI data Count: 8 samples

Trigger Event: DI-Start (rising edge)

52 Function Block and Operation Theory

Figure 3-22: DI Post Trigger

Page 63

[Example 2] External digital trigger with post trigger

DO Sampled Clock

DO-Start

(rising)

DO Data

Write 8 data

to external device

Wait for

DO-Start

t

w

t

w

= Minimum required pulse width time

Operation End

DI Sampled Clock

DI-Start

(rising)

DI Data

Read 4 data

into DI FIFO

Wait for

Trigger

t

w

t

w

= Minimum required pulse width time

Operation End

Wait for

Trigger

Read 4 data

into DI FIFO

Wait for

Trigger

Read 4 data

into DI FIFO

DO data Count: 8 samples

Trigger Event: DO-Start (rising edge)

Re-Trigger Count: 3

Figure 3-23: DO Post Trigger

[Example 3] External digital trigger with post trigger and re-trigger

DI data Count: 4 samples per trigger

Trigger Event: DI-Start (rising edge)

Re-Trigger Count: 3

Function Block and Operation Theory 53

Figure 3-24: DI Post Trigger with Re-trigger

Page 64

[Example 4] External digital trigger with post trigger and re-trig-

DO Sampled Clock

DO-Start

(rising)

DO Data

Write 4 data

to external

device

Wait for

Trigger

t

w

t

w

= Minimum required pulse width time

Operation End

Wait for

Trigger

Wait for

Trigger

Write 4 data

to external

device

Write 4 data

to external

device

DI Sampled Clock

DI-Pause

(logic high)

DI Data

Read 4 data

into DI FIFO

Operation End

Read 8 data

into DI FIFO

Operation Start

DI Acquisition

Paused

ger

DO data Count: 4 samples per trigger

Trigger Event: DO-Start (rising edge)

Re-Trigger Count: 3

Figure 3-25: DO Post Trigger with Re-Trigger

[Example 5] External digital trigger with gated trigger

DI data Count: 12 samples

Trigger Event: DI-Pause (logic high)

54 Function Block and Operation Theory

Figure 3-26: DI Gated Trigger

Page 65

[Example 6] External digital trigger with gated trigger

DO Sampled Clock

DO-Pause

(logic high)

DO Data

Write 4 data

to external device

Operation End

Operation Start

DO Generation

Paused

Write 8 data

to external device

DO data Count: 12 samples

Trigger Event: DO-Pause (logic high)

Figure 3-27: DO Gated Trigger

Function Block and Operation Theory 55

Page 66

3.9 Application Function I/O

PCIe-7350 features eight AFI (Application Function I/O) lines.

These bi-direction digital I/O lines allow you to route I2C, SPI, trigger, event, handshaking, and clock signals to/from the SCSIVHDCI I/O connector. The following table lists the supporting functions of AFI lines and the corresponding pin out.

Function Signal I/O AFI0 AFI1 AFI2 AFI3 AFI4 AFI5 AFI6 AFI7

2

C Master

I

SPI Master

External

Trigger in

Trigger out

Event

Handshake

Clock

SCL O ●

SDA I/O ●

SCLK O ●

SDO O ●

SDI I ●

CS_0 O ●

CS_1 O ●

CS_2 O ●

DI-Start I ●●●●●●●●

DO-Start I ●●●●●●●●

DI-Pause I ●●●●●●●●

DO-Pause I ●●●●●●●●

DI_SW O ●●●●●●●●

DO_SW O ●●●●●●●●

PM O ●●●●●●●●

COS O ●●●●●●●●

DI-REQ I ●●●●●●●●

DI-ACK O ●●●●●●●●

DI-TRIG I ●●●●●●●●

DO-REQ O ●●●●●●●●

DO-ACK I ●●●●●●●●

DO-TRIG I ●●●●●●●●

DO-SCLK I/O ●

DI-SCLK I/O ●

Table 3-5: PCIe-7350 AFI I/O Configuration

56 Function Block and Operation Theory

Page 67

Function Signal I/O Description

2

C Master

I

SCL O

SDA I/O

2

C Clock– I

I

device capable of clock rate up to

1953.125KHz.

2

C Serial Data– Data signal for I

I

write communication.

2

C clock signal to slave

SPI Clock– SPI clock signal to slave

SCK O

device capable of clock rate up to

62.5MHz.

Master Input Slave Output– Data signal

for SPI read communication.

Master Output Slave Input– Data signal

for SPI write communication.

Chip Select of Slave Device 0– Output

signal to select the desired SPI slave

SPI Master

SDI I

SDO O

CS_0 O

device 0.

Chip Select of Slave Device 1– Output

CS_1 O

signal to select the desired SPI slave

device 1.

Chip Select of Slave Device 2– Output

CS_2 O

signal to select the desired SPI slave

device 2.

DI Start Trigger in– External digital trigger

signal to begin an acquisition operation.

DO Start Trigger in– External digital trig-

ger signal to begin a generation operation.

DI Gate Trigger in– External digital signal

to start/pause an acquisition operation.

DO Gate Trigger in– External digital sig-

nal to start/pause a generation operation.

External

Trigger in

DI-Start I

DO-Start I

DI-Pause I

DO-Pause I

DI Trigger out– A pulse signal output gen-

DI_SW O

Trigger out

DO_SW O

erated by PCIe-7350 when receiving a

software start command of DI.

DO Trigger out– A pulse signal output

generated by PCIe-7350 when receiving a

software start command of DO.

Table 3-6: PCIe-7350 AFI Signal Description

2

C read/