Page 1

NuDAQ

PCI-7200 / PCIe-7200 / cPCI-7200

12MB/S High Speed Digital I/ O Card

User’s Manual

Manual Rev. 2.01

Revision Date: March 24, 2010

Part No: 50-11102-1040

Advance Technologies; Automate the World.

Page 2

Copyright 2010 ADLINK TECHNOLOGY INC.

All Rights Reserved.

The information in this document is subject to change without prior

notice in order to improve reliability , design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, elec tronic, or other means in a ny form

without prior written permission of the manufacturer.

Trademarks

NuDAQ is a registered trademark of ADLINK Technology, Inc.

Product names mentioned herein are used for identification pur-

poses only and may be trademarks and/or registered trademarks

of their respective companies.

Page 3

Getting Service from ADLINK

Contact us should you require any service or assistance.

ADLINK Technology Inc.

Address: 9F, No.166 Jian Yi Road, Chungho City,

Taipei County 235, Taiwan

קᗼխࡉؑ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ

(100085)

Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd., Beijing 100085, China

Tel: +86-10-5885-8666

Fax: +86-10-5885-8625

Email: market@adlinktech.com

ADLINK Technology Shanghai

Address: Ϟ⍋Ꮦⓩ⊇⋒催⾥ᡔᓔথ䩺∳䏃 333 ো 39 ᐶ 4 ሖ

(200233)

Tel: +86-21-6495-5210

Fax: +86-21-5450-0414

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

A1 2 ὐ C (518057)

2F, C Block, Bld. A1, Cyber-Tech Zone,

Gao Xin Ave. Sec 7, High-Tech Industrial Park S.,

Shenzhen, 518054 China

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

Page 4

ADLINK Technology Inc. (German Liaison Office)

Address: Nord Carree 3, 40477 Duesseldorf, Germany

Tel: +49-211-495-5552

Fax: +49-211-495-5557

Email: emea@adlinktech.com

ADLINK (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 MASSY Cedex, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: 151-0072 ᧲ㇺ⼱ᐈ䊱⼱㩷

1-1-2 ᦺᣣ↢ᐈ䊱⼱䊎䊦 8F

Asahiseimei Hatagaya Bldg. 8F

1-1-2 Hatagaya, Shibuya-ku, Tokyo 151-0072, Japan

Tel: +81-3-4455-3722

Fax: +81-3-5333-6040

Email: japan@adlinktech.com

ADLINK Technology Inc. (Korean Liaison Office)

Address: 昢殾柢 昢爎割 昢爎壟 1506-25 穢壊 B/D 2 猻

2F, Hando B/D, 1506-25, Seocho-Dong,

Seocho-Gu,Seoul, 137-070, Korea

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Singapore 349584

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte Ltd. (Indian Liaison Office)

Address: No. 1357, "Anupama", Sri Aurobindo Marg, 9th Cross,

JP Nagar Phase I, Bangalore - 560078, India

Tel: +91-80-65605817

Fax: +91-80-22443548

Email: india@adlinktech.com

Page 5

Table of Contents

List of Tables.......................................................................... iii

List of Figures........................................................................ iv

1 Introduction ........................................................................ 1

1.1 Applications ......................................................................... 1

1.2 Features............................................................................... 2

1.3 Specifications....................................................................... 3

1.4 Software Support................................................................. 5

Driver Support for Windows ............................................5

2 Installation ........................................................................ 11

2.1 Contents ............................................................................ 11

2.2 Unpacking.......................................................................... 12

2.3 Device Installation for Windows Systems.......................... 12

2.4 PCI-7200/cPCI-7200/PCIe-7200 Layout............................ 13

2.5 Hardware Installation Outline............................................. 16

2.6 Connector Pin Assignments .............................................. 17

PCI/PCIe-7200 Pin Assignments .................................. 17

cPCI-7200 Pin Assignments ......................................... 19

2.7 8254 for Timer Pacer Generation...................................... 20

2.8 Onboard Pull-ups and Terminations on the Digital Inputs. 21

3 Register Format................................................................ 23

3.1 I/O Registers Format ......................................................... 23

3.2 Digital Input Register (BASE + 10) .................................... 23

3.3 Digital Output Register (BASE + 14).................................. 24

3.4 DIO Status & Control Register (BASE + 18)...................... 24

3.5 Interrupt Status & Control Register (BASE + 1C) .............. 27

3.6 8254 Timer Registers (BASE + 0) ..................................... 30

4 Operation Theory ............................................................. 31

4.1 Direct Program Control...................................................... 31

4.2 Timer Pacer Mode............................................................. 32

4.3 External Clock Mode.......................................................... 33

4.4 Handshaking...................................................................... 34

4.5 Timing Characteristic......................................................... 36

Table of Contents i

Page 6

5 Double Buffer Mode Principle.......................................... 39

6 Limitations......................................................................... 41

ii Table of Contents

Page 7

List of Tables

Table 2-1: 7200 Series Termination ........................................ 21

List of Tables iii

Page 8

List of Figures

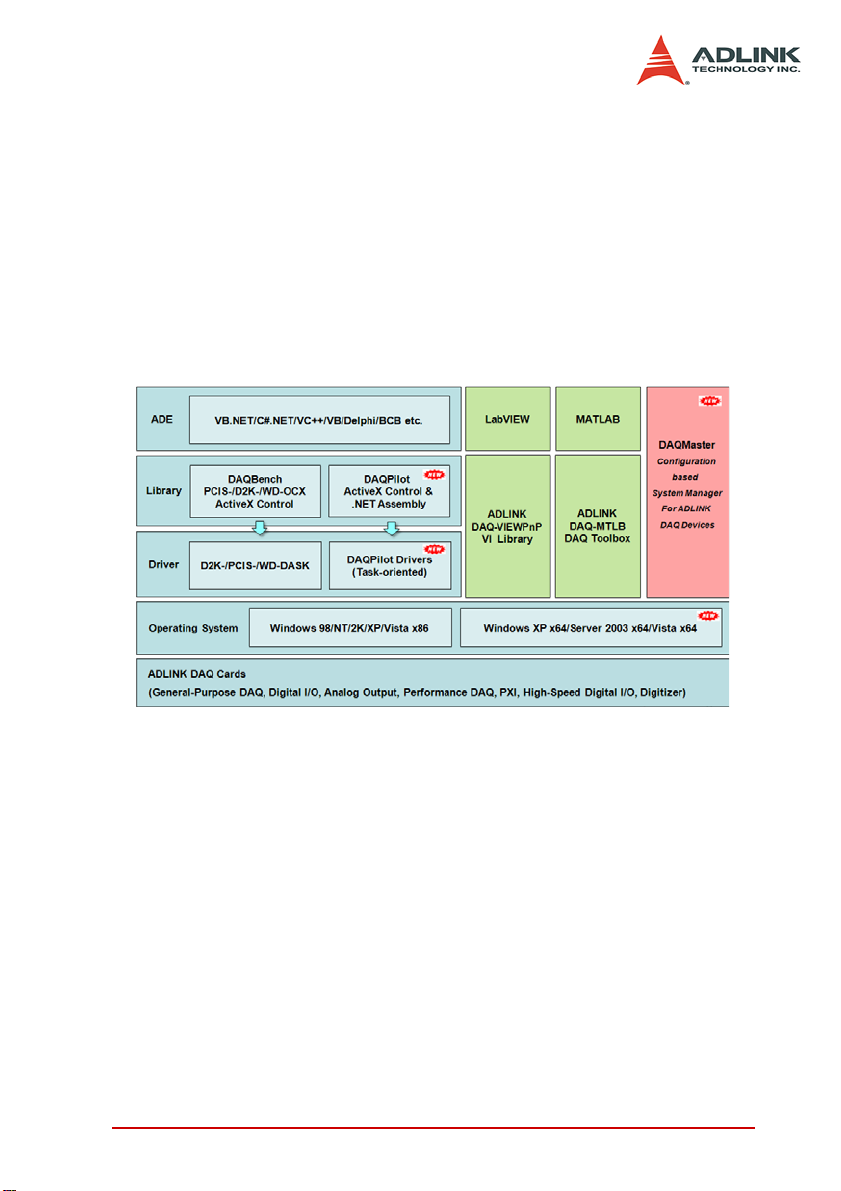

Figure 1-1: ADLINK Software Support Overview......................... 5

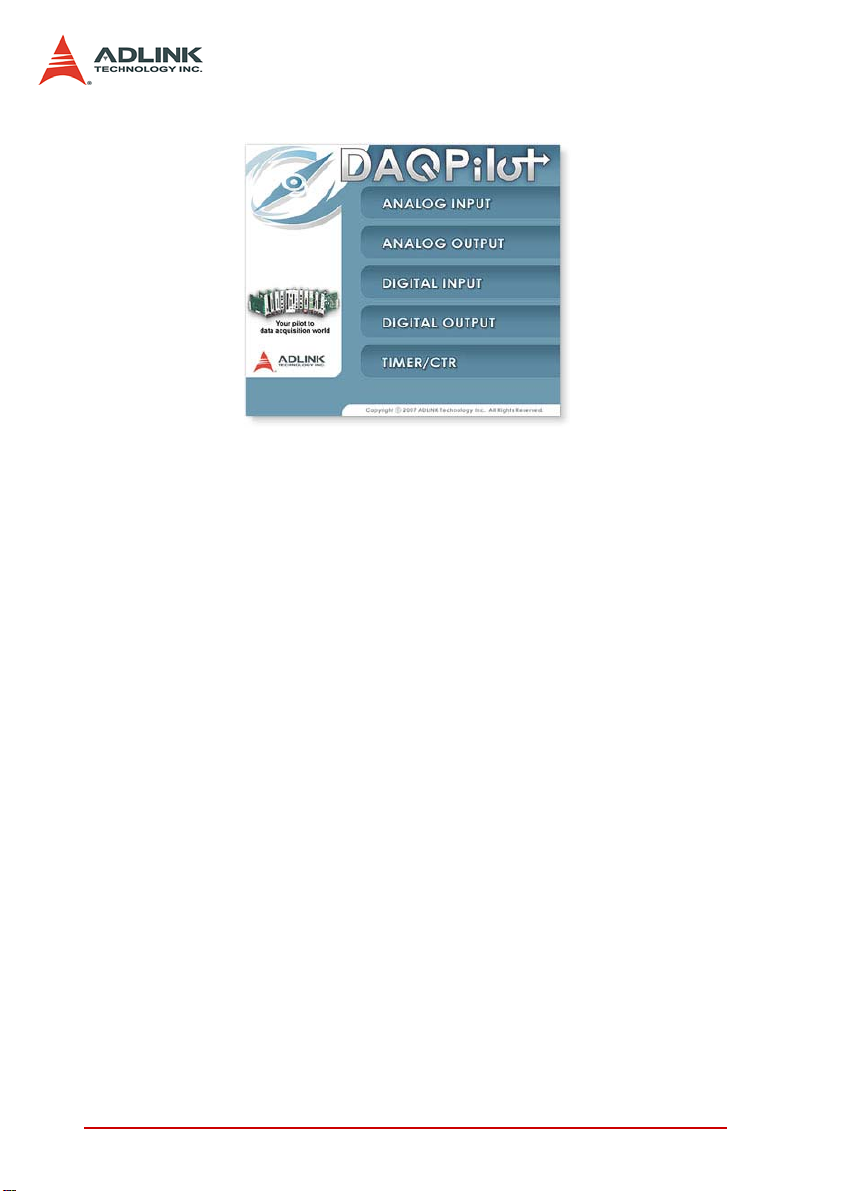

Figure 1-2: DAQPilot Main Interface ............................................ 6

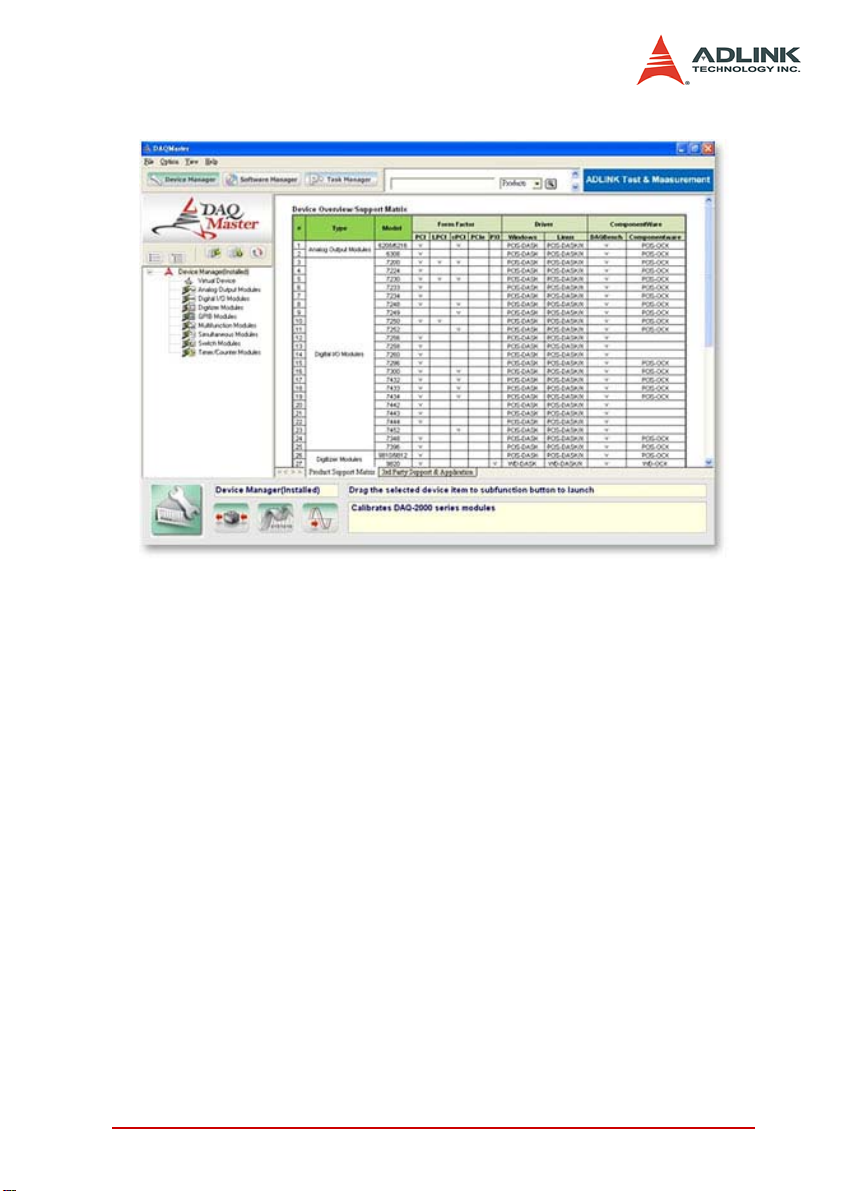

Figure 1-3: DAQMaster Device Manager..................................... 7

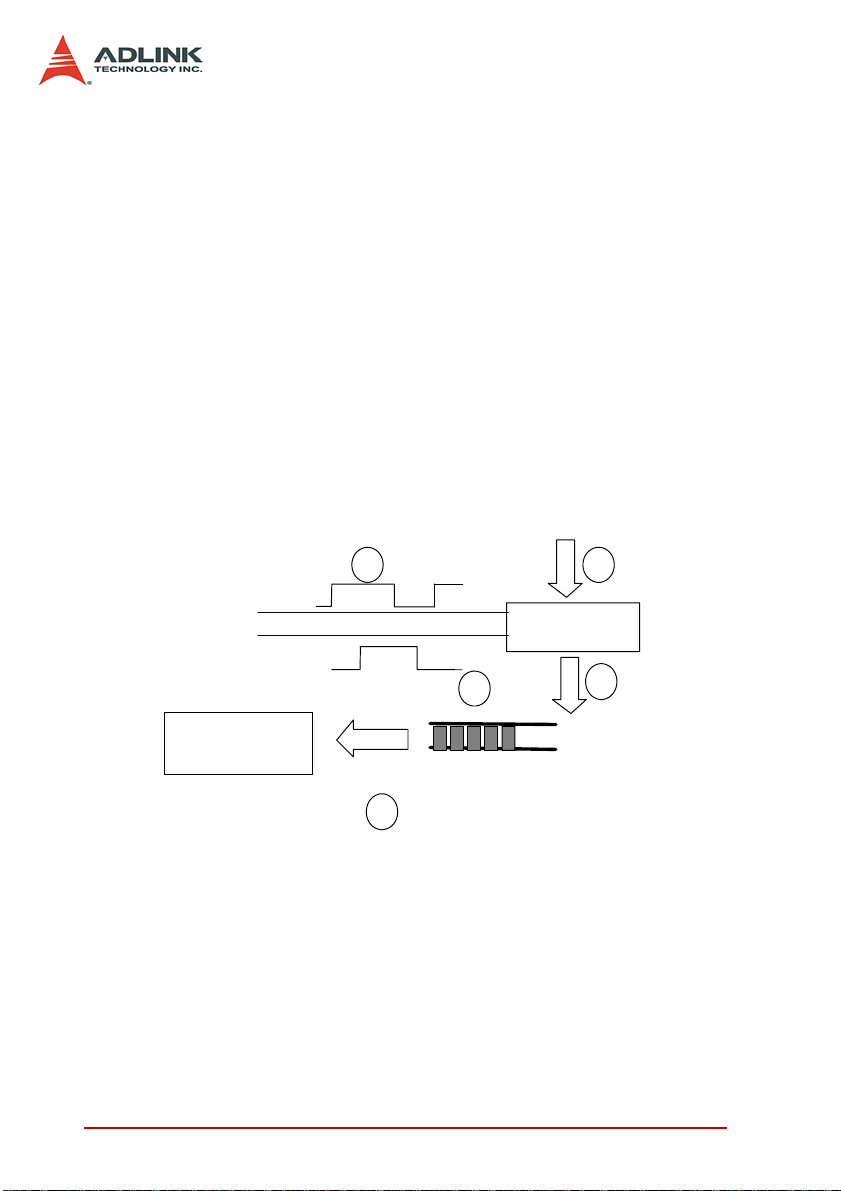

Figure 1-4: Legacy Software Support Overview .......................... 8

Figure 2-1: PCI-7200 Layout Diagram ....................................... 13

Figure 2-2: cPCI-7200 Layout Diagram ..................................... 14

Figure 2-3: PCIe-7200 Layout Diagram ..................................... 15

Figure 2-4: CN1 Pin Assignments.............................................. 18

Figure 2-5: CN2 Pin Assignments.............................................. 18

Figure 2-6: CN Pin Assignments................................................ 19

Figure 2-7: 8254 configuration................................................... 20

Figure 2-8: Digital Input Pull-up Resistor and

Termination Circuit Diagram.................................... 21

Figure 5-1: Double Buffer Mode................................................. 39

iv List of Figures

Page 9

Page 10

1 Introduction

The PCI-7200, cPCI-7200, and PCIe-7200 are PCI/CompactPCI/

PCI Express® form factor high-speed digital I/O cards, consisting

of 32 digital input channels, and 32 digital output channels. High

performance design and state-of-the-art technology make this

card suitable for high-speed digital input and output applications.

The 7200 series performs high-speed data transfers using busmastering DMA via the 32-bit PCI bus architecture. The maximum

data transfer rates can be up to 12MB per second - very suitable

for interfacing high-speed peripherals with your computer system.

Several different digital I/O operation modes are supported:

1. Direct Program Control: the digital inputs and outputs

can be accessed and controlled by its corresponding I/O

ports directly.

2. Timer Pacer Mode: the digital input and output operations are handled by internal timer pacer clock and transferred by bus mastering DMA.

3. External Clock Mode: the digital input operations are

handled by an external input strobe signal (I_REQ) and

transferred by bus mastering DMA.

4. Handshaking: through the REQ and ACK signals, digital I/O data can utilize simple handshaking data transfer.

1.1 Applications

Interface to high-speed peripherals

High-speed data transfers from other computers

Digital I/O control

Interface to external high-speed A/D and D/A converter

Digital pattern generator

Waveform and pulse generation

Introduction 1

Page 11

1.2 Features

The 7200 series high-speed DIO Card provides the following

advanced features:

32 TTL digital input channels

32 TTL digital output channels

Transfer rates up to 12 MB per second

High output driving and low input loading

32-bit PCI bus, Plug and Play

Onboard internal timer pacer clock

Internal timer controls input sampling rate

Internal timer controls digital output rate

ACK and REQ for handshaking

Onboard 32-byte FIFO for both digital input and output

Extra 2k double word digital input FIFO for cPCI-7200

Four auxiliary digital input and output channels (cPCI-7200

only)

Diode terminators for 32 input channels and contro l sign als

(cPCI-7200 only)

Multiple interrupt sources are selectable by software

2Introduction

Page 12

1.3 Specifications

Digital I/O (DIO)

Number of DI Channels: 32 TTL compatible

Number of DO Channels: 32 TTL compatible

Data Transfer Mode

Program I/O

Internal timer pacer transfer

External I_REG strobe input

Handshake data transfer

Maximum Transfer Speed:

3MHz (12MB/sec) by external clock, handshake or

external strobe

2MHz (8MB/sec) by internal timer pacer transfer

FIFO:

Eight words (32-bit) (for PCI-7200/PCIe-7200)

2k + 8 words (32-bit) (for cPCI-7200 Digital input chan-

nels)

Input Voltage:

Low: Min. 0V; Max. 0.8V

High: Min. +2.0V

Input Load:

Low: +0.5V @ -0.6mA max.

High: +2.7V @ +20A max.

Output Voltage:

Low: Min. 0V; Max. 0.5V

High: Min. +2.7V

Driving Capacity:

Low: Max. +0.5V at 24mA (Sink)

High: Min. 2.4V at -3.0mA (Source)

Introduction 3

Page 13

Programmable Counter

Device: 82C54-10, with a 4MHz time base

Timer 0: DI clock source

Timer 1: DO clock source

Timer 2: Base clock of Timer #0 and Timer #1

Pacer Output: 0.00046Hz to 2MHz

General Specifications

Operating Temperature: 0ºC to 60ºC

Storage Temperature: -20ºC to 80ºC

Humidity: 5 to 95%, non-condensing

Connector:

PCI-7200/PCIe-7200:one 37-pin D-type and one 40-pin

ribbon connector

cPCI-7200:one 100-pin SCSI-type connector

Dimensions:

PCI-7200:Compact size, only 148mm (L) X 102mm (H)

cPCI-7200:Standard 3U CompactPCI form factor

PCIe-7200: 168 mm (L) x 111 mm (H)

Power Consumption:

PCI-7200: +5 V @ 720 mA typical

cPCI-7200: +5 V @ 820 mA typical

PCIe-7200: +12 V @ 200 mA typical, +3.3 V @ 500 mA

typical

PCI signaling environment:

PCI-7200: 3.3 V and 5 V universal PCI BUS

cPCI-7200: 3U Eurocard form factor, CompactPCI com-

pliant (PICMG 2.0 R2.1)

PCIe-7200: x1 PCI Express®

4Introduction

Page 14

1.4 Software Support

ADLINK provides comprehensive software drivers and packages

to suit various user approach to building a system. Aside from programming libraries, such as DLLs, for most Windows-based systems, ADLINK also provides drivers for other application

environment such as LabVIEW

vides ActiveX component ware for measurement and SCADA/

HMI, and breakthrough proprietary software applications.

All software options are included in the ADLINK All-in-One CD.

®

and MA TLAB®. ADLINK also pro-

Figure 1-1: ADLINK Software Support Overview

Driver Support for Windows

DAQPilot

DAQPilot is a driver and SDK with a graphics-driven interface

for various application development environments. DAQPilot

comes as ADLINK's commitment to provide full support to its

comprehensive line of data acquisition products and is

designed for the novice to the most experienced programmer.

Introduction 5

Page 15

Figure 1-2: DAQPilot Main Interface

As a task-oriented DAQ driver, SDK and wizard for Windows

systems, DAQPilot helps you shorten the development time

while accelerating your learning curve for data acquisition programming.

You can download and install DAQPilot at

http://www.adlinktech.com/TM/DAQPilot.html

DAQMaster

The ADLINK DAQMaster is a smart device manager that

opens up access to ADLINK data acquisition an d test and measurement products. DAQMaster delivers all-in-one configurations and provides you with a full support matrix to properly and

conveniently configure ADLINK Test and Measurement products.

6Introduction

Page 16

Figure 1-3: DAQMaster Device Manager

As a configuration-based device manager for ADLINK DAQ

cards, DAQMaster enables you to manage ADLINK devices

and interfaces, install and upgrade software applications, and

manage ADLINK DAQPilot tasks.

Introduction 7

Page 17

PCIS-DASK (Legacy Drivers and Support)

PCIS-DASK is composed of advanced 32-bit kernel drivers for

customized DAQ application development. PCIS-DASK

enables you to perform detailed operations and achieve superior performance and reliability from your data acquisition system. DASK kernel drivers now support the revolutionary

Windows Vista

®

OS.

Figure 1-4: Legacy Software Support Overview

NOTE ADLINK strongly recommends installing DAQPilot and

avoid using legacy DASK drivers. For current DASK driver users or those who do not have Internet access, we offer an installation CD. Contact your ADLINK distributor for

details.

8Introduction

Page 18

PCIS-DASK drivers prepare legacy Windows users for

Windows Vista and 64-bit editions of Windows. PCIS-DASK

comes with the following features:

Supports Windows Vista 32-bit or 64-bit editions

Supports AMD64 and Intel x86-64 architectures

Digitally-signed for Windows Vista 64-bit edition

Utilizes WOW64 subsystem to ensure that 32-bit

applications run normally on 64-bit editions of Windows XP,

Windows 2003 Server , and Windows Vista without

modification

For more information about Windows Vista support, visit

http://www.adlinktech.com/TM/VistaSupport.html, or view the

user’s guide included in the ADLINK All-in-one CD.

Introduction 9

Page 19

10 Introduction

Page 20

2 Installation

This chapter describes how to install the 7200 series. Package

contents and unpacking information are described. Because the

7200 series is a Plug and Play device, there are no jumper or DIP

switch settings for configuration. The interrupt number and I/O port

address are assigned by the system BIOS during system boot up.

2.1 Contents

In addition to this User's Manual, the package includes the following items:

PCI-7200 or PCIe-7200 Digital I/O & Counter Card

ACL-10437: 40-pin to 37-pin D-Sub cable

or

cPCI-7200 Digital I/O & Counter Module for 3U

ADLINK CD

Software Installation Guide

If any of these items is missing or damaged, contact the ADLINK

dealer. Save the shipping materials and carton to ship or store the

product in the future.

Installation 11

Page 21

2.2 Unpacking

The 7200 series contains sensitive electronic components that can

be easily damaged by static electricity.

The work area should have a grounded anti-static mat. The operator should be wearing an anti-static wristband, grounded at the

same point as the anti-static mat.

Inspect the card module carton for obvious damage. Shipping and

handling may cause damage to the module. Ensure there is no

shipping and handling damage on the module before proceeding.

After opening the card module carton, remove the system module

and place it only on a grounded anti-static surface compo nent side

up.

Again inspect the module for damage. Press down on all the socketed IC's to ensure that they are properly seated. Do this only with

the module place on a firm flat surface.

Note: DO NOT APPLY POWER TO THE CARD IF IT HAS BEEN

DAMAGED.

You are now ready to install your 7200 series card.

2.3 Device Installation for Windows Systems

Once Windows XP/2000 has started, the Plug and Play function of

Windows system will find the new NuDAQ cards. If this is the first

time to installing NuDAQ cards in this system, Windows will

require device information source. Please refer to the “Software

Installation Guide” for instructions on installing the device.

12 Installation

Page 22

2.4 PCI-7200/cPCI-7200/PCIe-7200 Layout

Figure 2-1: PCI-7200 Layout Diagram

Installation 13

Page 23

Figure 2-2: cPCI-7200 Layout Diagram

14 Installation

Page 24

2X-#4-40UNC

Figure 2-3: PCIe-7200 Layout Diagram

Installation 15

Page 25

2.5 Hardware Installation Outline

Hardware configuration

These PCI cards (or CompactPCI, PCI Express© cards) are

equipped with a Plug and Play PCI controller that requests

base addresses and interrupts according to PCI standard. The

system BIOS will install the system resource based on the PCI

cards’ configuration registers and system parameters (which

are set by system BIOS). Interrupt assignment and memory

usage (I/O port locations) of the PCI cards can be assigned by

system BIOS only. These system resource assignments are

done on a board-by-board basis. It is not recommended to

assign the system resource by any other meth o ds .

PCI slot selection

The PCI and Low-Profile PCI cards can be inserted to any PCI

slot without any configuration for system resource. CompactPCI peripheral slots are marke d with a circle on the backplane.

Please note that the PCI, CompactPCI, and PCI Express© system board must provide bus-mastering capability to operate

this board well.

Installation Procedure

1. Turn off the computer

2. Turn off all accessories (printer, modem, monitor, etc.)

connected to the computer

3. Remove the cover from your computer

4. Select a 32-bit PCI slot. PCI slots are shorter than the

ISA or EISA slots, and are usually white or ivory in color.

5. Before handling the PCI cards, discharge any static

buildup on your body by touching the metal case of the

computer. Hold the edge of the card and do not touch

the components.

6. Position the board into the PCI selected slot.

7. Secure the card in place at the rear panel of the system.

16 Installation

Page 26

2.6 Connector Pin Assignments

PCI/PCIe-7200 Pin Assignments

The PCI/PCIe-7200 comes equipped with one 37-pin D-Sub connector (CN2) located on the rear mounting plate and one 40-pin

female flat cable header connector (CN1). The CN2 is located on

the rear mounting plate; the CN1 is on front of the board. Refer

section 2.4 PCI-7200‘s layout.

CN2 is used for digital inputs (DI 0 to DI 15) and digital outputs

(DO 0 to DO 15) The reminding digital I/O channels DI 16 to DI 31

and DO 16 to DO 31 are on CN1. The pin assignment of CN1 and

CN2 is illustrated in the Figures 2-5 and 2.3.

Legend:

DO n Digital Output CH n

DI n Digital Input CH n

GND Ground

ACK ACK handshaking signal

REQ REQ handshaking signal

I_TRG Input signal to start DI data sampling

O_TRG Output signa l can be controlled by software

Installation 17

Page 27

Figure 2-4: CN1 Pin Assignments

21

20

2

34

56

78

910

11 12

13 14

15 16

17

19

22

23 24

25 26

27 28

37

18

29

35

3433

32

30

31

36

1

39 40

38

DI27

DI28

DI29

DI30

DI31

+5V

O_ACK

O_REQ

DI16

DI17

DI18

DI19

DI20

DI21

DI22

DI23

DI24

DI25

DI26

N/C

N/C

N/C

DO16

DO17

DO18

DO19

DO20

DO21

DO22

DO23

DO24

DO25

DO26

DO27

DO28

DO29

DO30

DO31

GND

O_TR1

21

20

2

34

56

78

910

11 12

13 14

15 16

17

19

22

23 24

25 26

27 28

37

18

29

35

3433

32

30

31

36

1

39 40

38

21

20

3

56

78

910

11 12

13 14

15 16

17

19

22

23 24

25 26

27 28

37

18

29

35

3433

32

30

31

36

1

39

38

DI27

DI28

DI29

DI30

DI31

+5V

O_ACK

O_REQ

DI16

DI17

DI18

DI19

DI20

DI21

DI22

DI23

DI24

DI25

DI26

N/C

N/C

N/C

DO16

DO17

DO18

DO19

DO20

DO21

DO22

DO23

DO24

DO25

DO26

DO27

DO28

DO29

DO30

DO31

GND

O_TR1

1

2

3

4

5

6

10

11

12

13

14

15

7

8

9

16

17

18

19

20

21

22

23

24

25

26

27

28

30

31

32

33

29

35

36

37

34

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

DI10

DO10

DO11

DO12

DO13

DO14

DO15

DI 9

GND

I_TRG

DO0

DO1

DO2

DO3

DO4

DO5

DO6

DO7

DO8

DO9

DI 0

DI11

DI12

DI13

DI14

DI15

+5V

I_ACK

I_REQ

18 Installation

Figure 2-5: CN2 Pin Assignments

Page 28

cPCI-7200 Pin Assignments

Figure 2-6: CN Pin Assignments

Installation 19

Page 29

2.7 8254 for Timer Pacer Generation

Timer 0

Timer 1

Timer 2

CLK0

GATE0

OUT0

CLK1

GATE1

CLK2

GATE2

OUT1

OUT2

8254 Timer/C ounter

Digital Input Timer Pacer

Digital Output Timer Pacer

4MHz Clock

“H”

“H”

“H”

Figure 2-7: 8254 configuration

The internal timer/counter 8254 on the 7200 series is configured

as the above diagram (Figure 2.7). Users can use it to generate

the timer pacer for both digital input and digital output triggers.

The digital input timer pacer is from OUT0 (Timer 0), and the digital output timer pacer is from OUT1 (Timer 1). Besides, Timer 0

and Timer 2 can be cascaded together to generate more timer

pacer frequencies for digital input. Also, Timer 2 can be cascaded

with Timer 1 for digital output.

pacer rate = 4MHz / ( C0 * C2)

if Timer 0 & Timer 2 are cascaded

pacer rate = 4MHz / C0

if timer 0 & Timer 2 are not cascaded

The maximum pacer signal rate of input and output are 4MHz/2 =

2MHz. The minimum signal rate is 4MHz/65535/65535.

For example, to get a pacer rate of 2.5kHz, set C0 = 40 and C2 =

40. That is 2.5kHz = 4MHz / (40 x 40)

20 Installation

Page 30

2.8 Onboard Pull-ups and Terminations on the Digital Inputs

The PCI-7200, cPCI-7200 and PCIe-7200 have 32 digital input

channels. Onboard terminations for digital input circuits may be

needed for some applications. Schottky terminations can minimize

undershoot/overshoot disturbances caused by reflection noise on

high-speed bus lines. Table 2.1 lists the pull-ups and termination

status of PCI-7200, cPCI-7200, and PCIe-7200. Figure 2.8 is the

illustration of the pull-up resistor and terminations on-board.

Pull-up resistor Terminations

PCI-7200 /

PCIe-7200

cPCI-7200 None Schottky diode clamped to ground & power

None None

Table 2-1: 7200 Series Termination

Figure 2-8: Digital Input Pull-up Resistor and Termination Circu it Dia gram

Installation 21

Page 31

22 Installation

Page 32

3 Register Format

3.1 I/O Registers Format

The PCI/PCIe-7200 occupies eight consecutive 32-bit I/O

addresses in the PC I/O address space. The cPCI-7200 occupies

nine consecutive 32-bit I/O addresses. Table 4-1 shows the I/O

Map.

Address Read Write

Base + 0 Counter 0 Counter 0

Base + 4 Counter 1 Counter 1

Base + 8 Counter 2 Counter 2

Base + C --- CLK Control CW0

Base + 10 Digital Input Reg. --Base + 14 Digital Output (Read-back) Digital Output Reg.

Base + 18 DIO Status & Control DIO Status &Control

Base + 1C INT Status & Control INT Status & Control

Base + 20 (cPCI-7200 only) AUXDIO Reg. AUXDO Reg.

Note: (1) I/O port is 32-bits wide

(2) 8-bit or 16-bit I/O access is not allowed

3.2 Digital Input Register (BASE + 10)

32 digital input channels can be read from this register

Address: BASE + 10

Attribute: READ Only

Data Format:

Byte 7 6 5 4 3 2 1 0

Base +10 DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

Base +11 DI15 DI14 DI13 DI12 DI11 DI10 DI9 DI8

Base +12 DI23 DI22 DI21 DI20 DI19 DI18 DI17 DI16

Base +13 DI31 DI30 DI29 DI28 DI27 DI26 DI25 DI24

Register Format 23

Page 33

3.3 Digital Output Register (BASE + 14)

32 digital output channels can be written and read to/from this register

Address: BASE + 14

Attribute: READ/WRITE

Data Format:

Byte 7 6 5 4 3 2 1 0

Base +14 DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

Base +15 DO15 DO14 DO13 DO12 DO11 DO10 DO9 DO8

Base +16 DO23 DO22 DO21 DO20 DO19 DO18 DO17 DO16

Base +17 DO31 DO30 DO29 DO28 DO27 DO26 DO25 DO24

The digital output status can be read back through the same location (BASE + 14)

3.4 DIO Status & Control Register (BASE + 18)

The data transfer mode of digital input is controlled and status is

checked through this register.

Address: BASE + 18

Attribute: READ/WRITE

Data Format:

Byte 7 6 5 4 3 2 1 0

Base +18 O_ACK DIN_EN I_TRG TRGPL I_FIFO I_TIME0 I_REQ I_ACK

Base +19 ---- I_OVER ---- ---- O_TRG O_FIFO O_TIME1 O_REQ

Base +20 ---- ---- ---- ---- ---- ---- ---- O_UND

Base +21 ---- ---- ---- ---- ---- ---- ---- ----

Digital Input Mode Setting:

I_ACK: Input ACK Enable

1: Input ACK is enabled (input ACK will be asserted after input data is read by CPU or written to input FIFO)

0: Input ACK is disabled

24 Register Format

Page 34

I_REQ: Input REQ Strobe Enabled

1: Use I_REQ edge to latch input data

0: I_REQ is disabled

I_TIME0: Input Timer 0 Enable

1: Input is sampled by falling edge of Counter 0 output

(COUT0)

0: Input Timer 0 is disabled

I_FIFO: Input FIFO Enable Mode

1: Input FIFO is enabled (input data is saved to input FIFO)

0: Input FIFO is disabled

TRGPOL: Input Trigger Polarity

1: I_TRG is Rising Edge Active

0: I_TRG is Falling Edge Active

I_TRG: External Trigger Enable

1: Wait until I_TRG signal is active, digital input sampling will

begin after a rising or falling edge of I_TRG

0: Start input sampling immediately (if input control register

is set)

DIN_EN: Digital Input Enable

1: Digital Input Enable

0: Digital Input Disabled, when this bit is set as 0, all digital

input operation will be stopped

Digital Output Mode Setting:

O_ACK: Output ACK Enable

1: Output ACK is enabled; the output circuit will wait for

O_ACK after O_REQ strobe is asserted

0: Output ACK is disabled

O_REQ: Output REQ Enable

1: Output REQ is enabled; an O_REQ strobe will be generated after output data is ready

0: Output REQ is disabled

O_TIME1: Output Timer 1 Enable

1: Output Timer 1 is enabled; output data is moved from out-

Register Format 25

Page 35

put FIFO to DO registers when output of Counter1 goes low

0: Output Counter 1 is disabled

O_FIFO: Output FIFO Enable

1: Output FIFO is enabled (output data is moved from output

FIFO)

0: Output FIFO is disabled

O_TRG: Digital Output Trigger Signal

This bit is used to control the O_TRG output of PCI-7200; the

signal is on CN1 pin 36 of PCI-7200, CN1 pin 26 of cPCI7200, CN2 pin 34 of LPCI 7200S when

1: O_TRG 1 goes High (1)

0: O_TRG 1 goes Low (0)

Digital I/O FIFO Status:

I_OVR: Input data overrun

1: Digital Input FIFO is full (overrun) during input data transfer

0: No input data overrun occurred

Input data overrun occurred, the I_OVR bit is set when input

FIFO is full and there is new input data coming in. This bit

can be cleared by writing “1” to it.

O_UND: Output data FIFO is underrun

1: Output FIFO is empty during output data transfer

0: No output data underrun occurred

Output data underrun, the O_UND bit is set when output

FIFO is empty and the output request for new da ta , this bit

can be cleared by writing “1” to it.

26 Register Format

Page 36

3.5 Interrupt Status & Control Register (BASE + 1C)

The interrupt mode/status is set/checked through this register.

Address: BASE + 1C

Attribute: READ/WRITE

Data Format:

Byte 7 6 5 4 3 2 1 0

Base +1C SI_TO SI_REQ SO_ACK T2_EN T1_EN T0_EN I I_REQ IO_ACK

Base +1D FIFOFF FIFOEF FIFORST REQ_NEG T1_T2 T0_T2 SI_T2 SI_T1

Base +1E ---- ---- ---- ---- ---- ---- ---- ---Base +1F ---- ---- ---- ---- ---- ---- ---- ----

Interrupt Control:

With the 7200 series, interrupts can be triggered by many

signal sources such as O_ACK, I_REQ, timer 0, timer 1, and

timer 2. The following bits control the interrupt source:

IO_ACK: Interrupt is triggered by O_ACK signal.

1: O_ACK interrupt is enabled

0: O_ACK interrupt is disabled

II_REQ: Interrupt is triggered by I_REQ signal.

1: I_REQ interrupt is enabled

0: I_REQ interrupt is disabled

T0_EN: Interrupt is triggered by timer 0 output.

1: Timer 0 interrupt is enabled

0: Timer 0 interrupt is disabled

T1_EN: Interrupt is triggered by timer 1 output.

1: Timer 1 interrupt is enabled

0: Timer 1 interrupt is disabled

T2_EN: Interrupt is triggered by timer 2 output.

1: Timer 2 interrupt is enabled

0: Timer 2 interrupt is disabled

Interrupt Status:

Register Format 27

Page 37

The following bits are used to check interrupt stat us:

SO_ACK: Status of O_ACK interrupt

1: O_ACK Interrupt occurred

0: No O_ACK interrupt

SI_REQ: Status of I_REQ interrupt

1: I_REQ Interrupt occurred

0: No I_REQ Interrupt

SI_T0: Status of timer 0 interrupt

1: OUT0 (output of timer 0) Interrupt occurred

0: No timer 0 Interrupt

SI_T1: Status of timer 1 interrupt

1: OUT1 (output of timer 1) Interrupt occurred

0: No timer 1 Interrupt

SI_T2: Status of timer 2 interrupt

1: OUT2 (output of timer 2) interrupt occurred

0: No timer 2 Interrupt

Note: Writing “1” to the corresponding bit of the register can clear

all interrupt statuses. In order to make the interrupt work

properly, the interrupt service routine has to clear all the interrupt status before end of the ISR.

Timer Configuration Control:

The 8254 timer on the 7200 series can be configured as either timer 0 cascaded with timer 2 or timer 1 cascaded with

timer 2. These configurations are controlled by the following

bits:

T0_T2: Timer 0 is cascaded with timer 2

1: Timer 0 and timer 2 are cascaded together; output of timer

2 connects to the clock input of timer 0.

0: Not cascaded, the 4MHz clock is connected to the timer 0

clock input.

T1_T2: Timer 1 is cascaded with timer 2

1: Timer 1 and timer 2 are cascaded together; output of timer

2 connects to the clock input of timer 1.

28 Register Format

Page 38

0: Not cascaded, the 4MHz clock is connected to the timer 1

clock input.

I_R EQ Polarity Selection:

When the input sampling is controlled by the I_REQ signal

only, the I_REQ can be programmed to be rising edge active

or falling edge active.

REQ_NEG: I_REQ trigger polarity

1: latch input data on falling edge of I_REQ

0: latch input data on rising edge of I_REQ

FIFO Control and Status (cPCI-7200 only):

The cPCI-7200 has an extra 2k samples digital input FIFO.

The FIFO can be cleared and monitored by the following bits:

FIFORST (Write only): Clear the on-board DI FIFO

1: Write 1 to clear the data of the FIFO.

0: No operation.

FIFOEF (Read only): Empty flag of the DI FIFO

1: DI FIFO is empty.

0: DI FIFO is not empty.

FIFOFF (Read only): Full flag of the DI FIFO

1: DI FIFO is full.

0: DI FIFO is not full.

Note: The cPCI-7200 has two cascaded DI FIFOs. One is located

in the PCI controller chip, the other one is on the PCI-7200

board. The above bits only control the onboard FIFO. In order to control the on-chip FIFO, please refer to the AMCC5933 data book.

Register Format 29

Page 39

3.6 8254 Timer Registers (BASE + 0)

The 8254 timer/counter IC occupies four I/O address. Users can

refer to Tundra's or Intel's data sheet for a full description of the

8254 features. Download the 8254 data sheet from the following

web site:

http://support.intel.com/support/controllers/peripheral/231164.htm

or

http://www.tundra.com (for Tundra’s 82C54 datasheet).

Address Read Write

Base + 0 Counter 0 Counter 0

Base + 4 Counter 1 Counter 1

Base + 8 Counter 2 Counter 2

Base + C --- CLK Control CW0

30 Register Format

Page 40

4 Operation Theory

In the 7200 series, there are four data transfer modes can be used

for digital I/O access and control, these modes are:

1. Direct Program Control: the digital inputs and outputs

can be read/written and controlled by its corresponding I/

O port address directly.

2. Internal Timer Pacer Mode: the digital input and output

operations are paced by an internal timer pacer and are

transferred by bus mastering DMA.

3. External Clock Mode: the digital input operation is

clocked by external I_REQ strobe and transferred by bus

mastering DMA.

4. Handshaking: through REQ and ACK signals, the digital

I/O can have simple handshaking data transf er s.

4.1 Direct Program Control

Digital I/O operations can be controlled by I/O port BASE+10 for

digital input and BASE+14 for digital output.

The I/O port address BASE is assigned by system BIOS, please

refer to Section 5 for a more detailed description.

The digital OUT operation is:

outport (BASE+14, 0xAAAAAAAA) // (A : 0 to F)

The digital IN operation is:

value = inport (BASE+10) // The input status

is save in the // value variable

Operation Theory 31

Page 41

4.2 Timer Pacer Mode

Timer 0

Timer 1

Timer 2

CLK0

GATE0

OUT0

CLK1

GATE1

CLK2

GATE2

OUT1

OUT2

8254 Timer/Counter

Digital Input Timer Pacer

Digital Output Timer Pacer

4MHz Clock

“H”

“H”

“H”

The digital I/O access control is clocked by timer pacer, which is

generated by an interval programming timer/counter chip (8254).

There are three timers on the 8254. Timer 0 is used to generate

timer pacer for digital input and timer 1 is used for digital output.

The configuration is illustrated as below.

The operation sequences are:

1. Define the frequency (timer pacer rate)

2. The digital input data are saved in FIFO after a timer

pacer pulse is generated. The sampling is controlled by

timer pacer.

3. The data saved in FIFO will be transferred to main memory of the computer system directly and automatically.

This is controlled by bus mastering DMA control, this

function is supported by PCI controller chip.

The operation flow is show as following:

32 Operation Theory

Page 42

4.3 External Clock Mode

To Digital Input Trigger

Latch Digital

Input Data

Digital Input FIFO

Bus mastering

DMA data Transfer

PC's Main Memory

1

2

3

Pin 19 of CN2

The digital input is clocked by external strobe, which is from Pin 19

(I_REQ) of CN2 (PCI/PCIe-7200) or Pin 24 of CN1 (cPCI-7200).

The operation sequence is very similar to the Timer Pacer Trigger.

The only difference is the clock source.

1. The external input strobe is generated from outside

device, and goes through the Pin 19 (I_REQ) of CN2 to

latch the digital input.

2. The digital input data is saved in FIFO after an I/O strobe

signal is coming in.

3. The data saved in input FIFO will be transferred to main

memory on your computer system directly. This is controlled by bus mastering DMA control, this function is

supported by PCI.

Operation Theory 33

Page 43

4.4 Handshaking

Latch Digital Input

or Digital Output

Digital Input FIFO Bus mastering

DMA data Transfer

PC's Main Memory

2

4

3

1

Digital Input DATA

5

IN_REQ

IN_ACK

The 7200 series also supports a handshaking digital I/O transfer

mode. That is, after input data is ready, an I_REQ is sent from an

external device, and I_ACK will go high to acknowledge the data

already accessed.

I_REQ & I_ACK for Digital Input

1. Digital Input Data is ready.

2. An I_REQ signal is generated for digital input operation.

3. Digital input data is saved to FIFO.

4. An I_ACK signal is generated and sent to an outside

device.

5. If the FIFO is not empty and PCI bus is not occupied, the

data will be transferred to main memory.

34 Operation Theory

Page 44

O_REQ & O_ACK for Digital Output

Move Data to

Digital Output FIFO

Bus mastering

DMA data Transfer

PC's Main

Memory

2

4

3

1

Digital Output DATA

5

Digital Output

O_REQ

O_ACK

1. Digital Output Data is moved from PC memory to FIFO

of the 7200 series by using DMA data mastering data

transfer.

2. Move output data from FIFO to digital output circuit.

3. Output data is ready.

4. An O_REQ signal is generated and sent to outside

device.

5. After an O_ACK is captured, steps 2-5 will be repeated.

** If the FIFO is not full, the output data is moved form PC‘s

main memory to FIFO automatically.

Operation Theory 35

Page 45

4.5 Timing Characteristic

IN_ I_REQ

t

l

t

cyc

t

h

t

s

valid data

D10~DI31

t

n

valid data

t

s

valid data

D10~DI31

t

n

valid data

IN_R I_REQ

t

cyc

t

l

t

h

1. I_REQ as input data strobe (Rising Edge Active)

th 60ns tI 60ns tCYC 5 PCI CLK Cycle

ts 2ns tn 30ns

2. I_REQ as input data strobe (Falling Edge Active)

th

60ns tI 60ns tCYC 5 PCI CLK Cycle

ts 2ns tn 30ns

36 Operation Theory

Page 46

3. I_REQ & I_ACK Handshaking

valid data

D10~DI31

valid data

t1

t2

t5

t4t3

IN I_REQ

IN I_ACK

t1 0ns t5 60ns t3 2 PCI CLK Cycle

t2 0ns t4 1 PCI CLK Cycle

Note: I_REQ must be asserted until I_ACK asserts, I_ACK will be

asserted until I_REQ de-asserts.

4. O_REQ as output data strobe

ts

19ns th 2 PCI CLK Cycles Tcyc 500ns

5. O_REQ & O_ACK Handshaking

Note: O_ACK must be de-asserted before O_REQ asserts,

O_ACK can be asserted any time after O_REQ asserts,

O_REQ will be reasserted after O_ACK is asserted.

Operation Theory 37

Page 47

38 Operation Theory

Page 48

5 Double Buffer Mode Principle

Incoming DMA

input data

Circular Buffer

Transfer Buffer

a

b

c

d

> > >

> > >> >

Empty Buffer Untransferred Data Transferred Data

> >

The data buffer for a double-buffered DMA DI operation is logically

a circular buffer divided into two equal halves. The double buf fered

DI begins when the device starts writing data into the first half of

the circular buffer (Figure 6-1a). After device begins writing to the

second half of the circular buffer, users can copy the data from the

first half into the transfer buffer (Figure 6-1b). Users can now process the data in the transfer buffer according to application needs.

After the board has filled the second half of the circular buffer, the

board returns to the first half buffer and overwrites the old data.

Users can now copy the second half of the circular buffer to the

transfer buffer (Figure 6-1c). The data in the transfer buffer is

again available for process. The process can be repeated endlessly to provide a continuous stream of data to applications (Figure 6-1d).

Figure 5-1: Double Buffer Mode

Double Buffer Mode Principle 39

Page 49

40 Double Buffer Mode Principle

Page 50

6 Limitations

The 12 MB/sec data transfer rate can only be possibly achieved in

systems where the 7200 series card is the only device using the

bus, but the speed cannot be guaranteed due to the limited FIFO

depth.

The 7200 series supports three input clock modes, internal clock,

external clock, and handshaking modes. The first two modes cannot guarantee the input data integrity in high-speed data rate

because of the limited FIFO depth and PCI-bus late ncy variation.

The handshaking mode is the only mode that data integrity can be

guaranteed. During handshaking, expect 12 MB/sec data rate on

average, but the speed is not guaranteed.

The guaranteed data rate with internal clock or external clock

mode is 1 MB/sec on systems where 7200 series card is the only

device using the bus.

The largest transfer size (in bytes) 7200 series can perform is 64

MB.

Limitations 41

Page 51

42 Limitations

Loading...

Loading...