Page 1

PCI/PXI-9816/26/46

4-CH 16-Bit 10/20/40 MS/s Digitizer

with 512 MB SDRAM

User’s Manual

Manual Rev. 2.02

Revision Date: October 5, 2010

Part No: 50-17031-1020

Advance Technologies; Automate the World.

Page 2

Copyright 2010 ADLINK TECHNOLOGY INC.

All Rights Reserved.

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Trademarks

NuDAQ, NuIPC, DAQBench are registered trademarks of ADLINK

TECHNOLOGY INC.

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Page 3

Getting Service from ADLINK

Contact us should you require any service or assistance.

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Chungho City,

Taipei County 235, Taiwan

קᗼխࡉؑ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110, San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: Ϟ⍋Ꮦ⌺ϰᮄᓴ∳催⾥ᡔು㢇䏃 300 ো(201203)

300 Fang Chun Rd., Zhangjiang Hi-Tech Park,

Pudong New Area, Shanghai, 201203 China

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ(100085)

Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd., Beijing, 100085 China

Tel: +86-10-5885-8666

Fax: +86-10-5885-8625

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

A1 2 ὐ C (518057)

2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7,

High-Tech Industrial Park S., Shenzhen, 518054 China

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

Page 4

ADLINK Technology (Europe) GmbH

Address: Nord Carree 3, 40477 Duesseldorf, Germany

Tel: +49-211-495-5552

Fax: +49-211-495-5557

Email: emea@adlinktech.com

ADLINK Technology, Inc. (French Liaison Office)

Address: 15 rue Emile Baudot, 91300 Massy CEDEX, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: 151-0072 ᧲ㇺ⼱ᐈ䊱⼱㩷

1-1-2 ᦺᣣ↢ᐈ䊱⼱䊎䊦 8F

Asahiseimei Hatagaya Bldg. 8F

1-1-2 Hatagaya, Shibuya-ku, Tokyo 151-0072, Japan

Tel: +81-3-4455-3722

Fax: +81-3-5333-6040

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 昢殾柢 昢爎割 昢爎壟 1506-25 穢壊 B/D 2 猻

2F, Hando B/D, 1506-25, Seocho-Dong, Seocho-Gu,

Seoul 137-070, Korea

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre,

Singapore 349584

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: No. 1357, "Anupama", Sri Aurobindo Marg, 9th Cross,

JP Nagar Phase I, Bangalore - 560078, India

Tel: +91-80-65605817

Fax: +91-80-22443548

Email: india@adlinktech.com

Page 5

Table of Contents

Table of Contents..................................................................... i

List of Tables.......................................................................... iii

List of Figures ........................................................................ iv

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 3

1.2 Applications ......................................................................... 3

1.3 Specifications....................................................................... 4

2 Getting Started ................................................................. 19

2.1 Installation Environment .................................................... 19

2.2 Package Contents ............................................................. 20

2.3 Mechanical Drawing and I/O Connectors .......................... 21

2.4 Installing the module.......................................................... 23

2.5 Software Support ............................................................... 24

Driver Support for Windows .......................................... 24

WD-DASK (Legacy Drivers and Support) ..................... 26

3 Operation Theory ............................................................. 27

3.1 Functional Block Diagram.................................................. 27

3.2 Basic AI Acquisition ........................................................... 28

Analog Input Path ......................................................... 28

Basic Acquisition Timing ............................................... 28

AI Data Format ............................................................. 30

3.3 ADC Sampling Rate and TIMEBASE Control.................... 31

Internal Oscillator .......................................................... 31

External Clock Through Front Panel ............................. 31

External Clock from PXI Interfaces ............................... 32

Sampling Rate Control .................................................. 32

Timebase Exporting ...................................................... 33

3.4 Trigger Sources ................................................................. 34

Software Trigger ........................................................... 34

External Digital Trigger ................................................. 35

Analog Trigger .............................................................. 36

PXI STAR Trigger ......................................................... 37

PXI Trigger Bus ............................................................ 37

Table of Contents i

Page 6

Trigger Signal Exporting ............................................... 38

3.5 Trigger Modes.................................................................... 39

Post-trigger Acquisition ................................................. 39

Pre-trigger Acquisition .................................................. 40

Middle-trigger Acquisition ............................................. 41

Delay-trigger Acquisition ............................................... 41

Post-trigger or Delay-trigger Acquisition

with Re-trigger .................................................... 42

3.6 Data Transfers ................................................................... 43

3.7 Synchronizing Multiple Modules ........................................ 44

SSI_TIMEBASE ............................................................ 47

SSI_TRIG1 ................................................................... 48

SSI_TRIG2 and SSI_START_OP ................................. 49

Comparing the Different Trigger Sources from SSI ...... 50

3.8 Physical Location of the PXI and PCI Digitizer .................. 52

Identify PXI Digitizer’s Physical Location

by Geographic Address ...................................... 52

Assign a Board ID to a PCI Digitizer ............................. 52

Important Safety Instructions............................................... 55

ii Table of Contents

Page 7

List of Tables

Table 1-1: Analog Input Specifications ...................................... 4

Table 1-2: Offset and Gain Error ............................................... 4

Table 1-3: -3dB Bandwidth, typical ............................................ 5

Table 1-4: System Noise ........................................................... 7

Table 1-5: Spectral Characteristics – PCI/PXI-9816 .................. 8

Table 1-6: Spectral Characteristics – PXI-9826 ....................... 10

Table 1-7: Spectral Characteristics – PCI/PXI-9846 ................ 12

Table 1-8: Timebase ................................................................ 14

Table 1-9: Triggering ............................................................... 15

Table 1-10: Data Storage and Transfer ..................................... 16

Table 1-11: Onboard Reference ................................................ 16

Table 1-12: General Information ................................................ 17

Table 2-1: Connector Pin Assignments ................................... 22

Table 3-1: Basic Counters ....................................................... 29

Table 3-2: AI Data Format ....................................................... 30

Table 3-3: Ideal Transfer Characteristics for Analog Triggers . 36

Table 3-4: Summary of SSI timing Signals and

the Corresponding Function ................................... 44

Table 3-5: SSI Signal Locations and Pin Definition ................. 47

Table 3-6: Board ID Combination Conditions .......................... 54

List of Tables iii

Page 8

List of Figures

Figure 1-1: PCI/PXI-9816 Bandwidth Chart

(50 Ω input impedance) ............................................. 6

Figure 1-2: PCI/PXI-9826 Bandwidth Chart

(50 Ω input impedance) ............................................. 6

Figure 1-3: PXI-9846 Bandwidth Chart (50 Ω input impedance).. 7

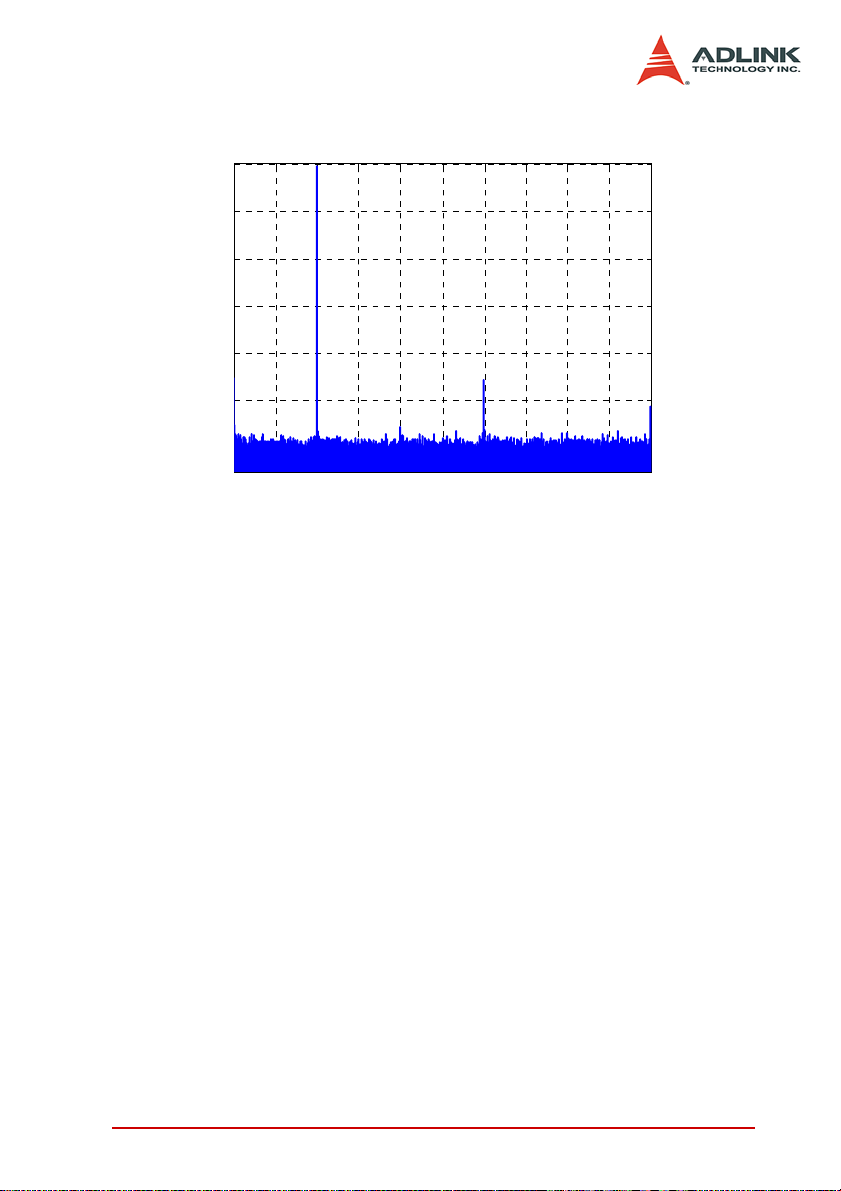

Figure 1-4: PXI-9816 FFT with ±0.2 V Input Range..................... 8

Figure 1-5: PXI-9816 FFT with ±1 V Input Range........................ 9

Figure 1-6: PXI-9826 FFT with ±0.2 V Input Range................... 10

Figure 1-7: PXI-9826 FFT with ±1 V Input Range...................... 11

Figure 1-8: PXI-9846 FFT with ±0.2 V Input Range................... 12

Figure 1-9: PXI-9846 FFT with ±1 V Input Range...................... 13

Figure 2-1: PXI-98x6 Mechanical Drawing................................. 21

Figure 2-2: PCI-98x6 Mechanical Drawing ................................ 21

Figure 2-3: DAQPilot Main Interface .......................................... 24

Figure 2-4: DAQMaster Device Manager................................... 25

Figure 2-5: Legacy Software Support Overview ........................ 26

Figure 3-1: PXI-98x6 Functional Block Diagram ....................... 27

Figure 3-2: PCI-98x6 Functional Block Diagram........................ 27

Figure 3-3: Analog Input Signal Block Diagram ......................... 28

Figure 3-4: Basic Acquisition Timing Of Digitizer ....................... 30

Figure 3-5: PCI/PXI-98x6 Timebase Source and Architecture... 31

Figure 3-6: Configuring Different Sampling Rate of a Digitizer. . 33

Figure 3-7: PCI/PXI-98x6 Trigger Architecture .......................... 34

Figure 3-8: External Digital Trigger Polarity

and Pulse Width Requirement. ................................ 35

Figure 3-9: Analog Trigger Conditions ....................................... 37

Figure 3-10: TRG IO Output Signal Timing.................................. 38

Figure 3-11: Post-trigger Acquisition............................................ 39

Figure 3-12: Pre-trigger Mode Operation ..................................... 40

Figure 3-13: Pre-trigger Mode Operation ..................................... 40

Figure 3-14: Middle-trigger Mode Operation ................................ 41

Figure 3-15: Delay-trigger Mode Operation ................................. 41

Figure 3-16: Re-trigger Mode Operation. ..................................... 42

Figure 3-17: Scatter-Gather DMA for Data Transfer .................... 43

Figure 3-18: SSI Architecture....................................................... 45

Figure 3-19: SSI Connector Location on the PCI-9816/26/46...... 46

Figure 3-20: Installation of ACL-SSI-2 Cable ............................... 46

Figure 3-21: SSI_TRIG1 Input and Output Timing

iv List of Figures

Page 9

Characteristics......................................................... 48

Figure 3-22: SSI_TRIG2 Output Timing....................................... 49

Figure 3-23: SSI_TRIG2 Input Timing Requirement.................... 49

Figure 3-24: SSI_START_OP Output and Input Timing

Characteristics......................................................... 50

Figure 3-25: The Location of Board ID Switch ............................. 53

Figure 3-26: Enlargement of Board ID setting. ............................ 53

List of Figures v

Page 10

vi List of Figures

Page 11

1 Introduction

The ADLINK PCI/PXI-9816/26/46 are 10 MS/s, 20 MS/s, and 40

MS/s sampling 16-bit 4-CH digitizers designed for digitizing high

frequency and wide dynamic range signals with an input frequency

up to 20 MHz. The analog input range can be programmed via

software to ±1 V or ±0.2 V. With deep onboard acquisition memory

up to 512 MB, the PCI/PXI-9816/26/46 are not limited by the data

transfer rate of the PCI bus to enable the recording of waveforms

for extended periods of time.

The PCI/PXI-9816/26/46 are equipped with four high linearity 16bit A/D converters ideal for demanding applications with a high

dynamic range such as radar, ultrasound, and software-defined

radio.

Analog Input

The PCI/PXI-9816/26/46 each feature four analog input channels.

The bandwidth of each channel can be up to 5 MHz, 10 MHz, and

20 MHz for PCI/PXI-9816, PCI/PXI-9826, and PCI/PXI-9846,

respectively. The input ranges are software programmable as

either ±1 V or ±0.2 V. Software selectable 50 Ω input impedance

makes it easy to interface with high-speed, high-frequency signals.

Acquisition System and On-board Memory

The PCI/PXI-9816/26/46 include four 16-bit A/D converters to digitize the input signals. These four channels sample signals simultaneously at a maximum sampling rate of 10 MS/s, 20 MS/s, and 40

MS/s, respectively. The PCI/PXI-9816/26/46 supports a total of

512 MB on-board memory. The digitized data is stored in the onboard memory before being transferred to the host memory. The

data transfer is performed using scatter-gather DMA, which provides a high data throughput rate and uses system memory more

effectively.

Introduction 1

Page 12

Flexible Triggering

The PCI/PXI-9816/26/46 feature flexible triggering options such as

a software trigger, external digital trigger, an analog trigger from

any of the analog input channels and triggers from the PXI trigger

bus. These versatile trigger sources allow you to configure the

PCI/PXI-9816/26/46 to fit your application needs. Post-trigger,

delay-trigger, pre-trigger and middle-trigger modes are also available to acquire data around the trigger event. The PCI/PXI-9816/

26/46 also features repeated trigger acquisition, so you can

acquire data in multiple segments with successive trigger events

at extremely short rearming intervals.

Multiple-Module Synchronization

The versatile trigger options provided by the PXI backplane allow

the PCI/PXI-9816/26/46 to achieve multi-module synchronization

in a simplified way. Utilizing the PXI Trigger bus, the PCI/PXI9816/26/46 can output trigger signals and the timebase to the PXI

trigger bus when configured as a master, or receive trigger signals

and the timebase from the PXI trigger bus when configured as a

slave. Moreover, when the PCI/PXI-9816/26/46 is plugged into a

peripheral slot of a PXI system, they can also receive triggers or

the timebase from the PXI star trigger controller slot. The precision

10 MHz clock that comes from the PXI backplane can also be

used as one of the timebase sources. Combining these PXI trigger

features with the interface of the PCI/PXI-9816/26/46 makes it

very easy to synchronize multiple modules.

Calibration

The PCI/PXI-9816/26/46 include a precision on-board reference

with very low temperature drift. This feature not only provides a

stable calibration source for auto-calibration but also maintains

stable acquisition accuracy over a wide temperature range. The

automated calibration process can be done through software without need for any manually adjustments. Once the calibration process has completed, the calibration information will be stored in

the on-board EEPROM so that the values can be loaded and used

as needed by the board.

2Introduction

Page 13

1.1 Features

3U Eurocard form factor (PXI version)

Standard height, half-length PCI form factor (PCI version)

Support 5 V and 3.3 V PCI signaling

Support 32-bit / 66 MHz PCI interface

4 channels simultaneous single-ended analog input

16-bit high resolution ADC

Up to 10 MS/s, 20 MS/s and 40 MS/s per channel

512 MB onboard memory for data storage

Software selectable 50 Ω or 1 MΩ input impedance

Programmable input voltage range: ±0.2V/±1V or ±1V/±5V

5 MHz, 10 MHz and 20 MHz analog input bandwidth for

PCI/PXI-9816, PCI/PXI-9826 and PCI/PXI-9846, respectively

Multiple modules synchronization through PXI trigger bus

Support scatter gather DMA transfer

Fully auto calibration

90 dBc SFDR, 79 dBc SINAD and 12.8-bit ENOB (PXI-

9816)

1.2 Applications

Software radio/wireless communication

Radar/Sonar/Lidar

Ultrasound

Imaging

Military/Laboratory/Research

Introduction 3

Page 14

1.3 Specifications

Analog Input

Specification Value

Number of Channels 4 single-ended channels

Input Connector BNC

Input Impedance 50 Ω or 1 MΩ, software selectable, default 50Ω

Input Coupling DC

Input Range (±0.2V, ±1V) or (±1V, ±5V), software selectable

Overvoltage Protection

ADC Resolution 16-Bit, 1 in 65536

Crosstalk

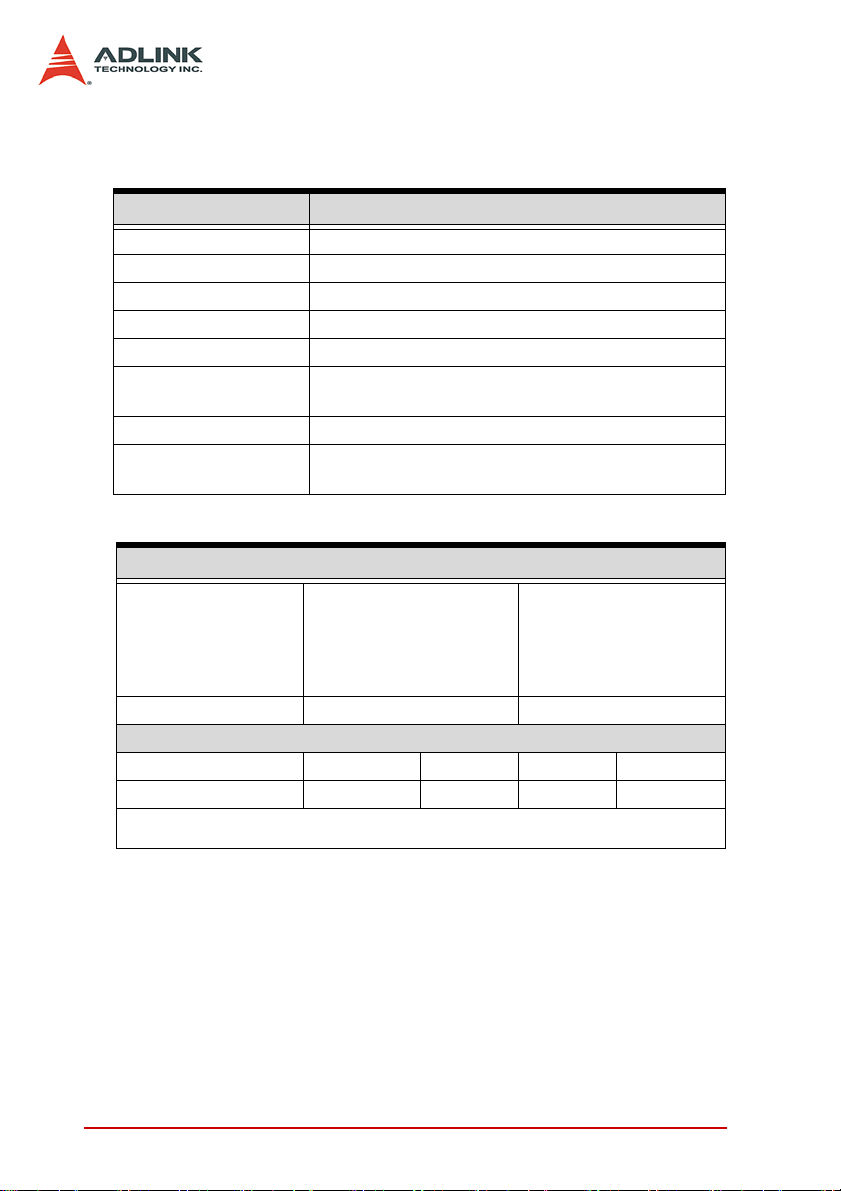

Table 1-1: Analog Input Specifications

Offset Error

Model Name

Offset Error ±0.2 mV ±0.3 mV

Gain Error

Input Range ±0.2 V ±1 V ±1 V ±5 V

Gain Error ±0.1% ±0.05% ±0.1% ±0.06%

Note: When calculating offset error and gain error, sampled data are averaged with 65536 points

and AI channel configured with 50 Ω input impedance.

±5V for (±0.2V, ±1V)

±15V for (±1V, ±5V)

≤-80 dB at 1MHz, for all input ranges at 50 Ω input

impedance

PXI-9816D

PXI-9826D

PXI-9846D

PXI-9846W

PCI-9846D

PXI-9846H,

PCI-9816H

PCI-9826H

PCI-9846H

Table 1-2: Offset and Gain Error

4Introduction

Page 15

-3dB Bandwidth, typical

Input Range PXI-9816D PXI -9826D

@50 Ω and 1 MΩ impedance

±0.2 V, ±1 V 5.1 MHz 9.6 MHz 20 MHz

Input Range PCI-9816H PCI-9826H

@50 Ω and impedance

±1 V, ±5 V 5.1 MHz 9.6 MHz 20 MHz ---

@ 1 MΩ impedance

±1 V, ±5 V 90 KHz ---

Table 1-3: -3dB Bandwidth, typical

PXI-9846D

PCI-9846D

PXI-9846H

PCI-9846H

PXI-9846W

80 MHz (±1 V)

50 MHz (±0.2 V)

---

Introduction 5

Page 16

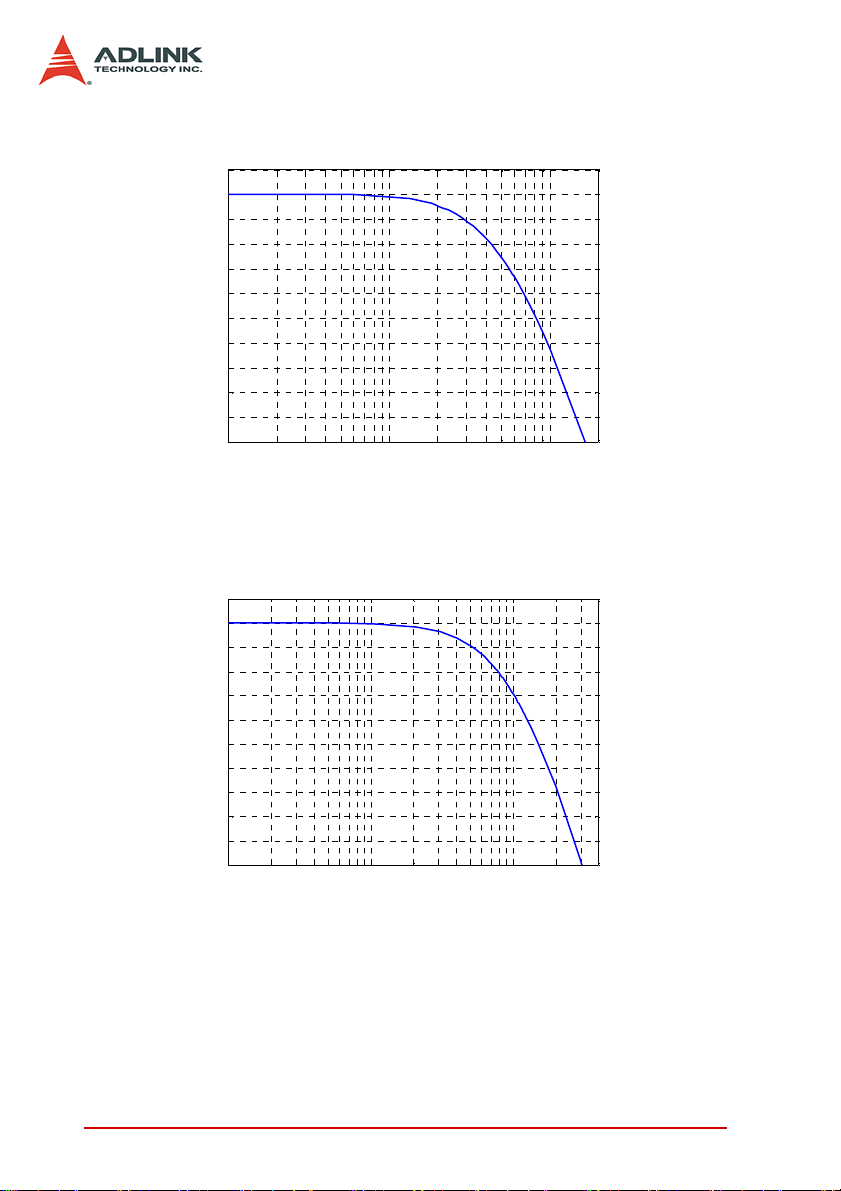

Figure 1-1: PCI/PXI-9816 Bandwidth Chart (50 Ω input impedance)

0.1M 1M 10M

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

Frequen cy (Hz)

Amplitude (dB)

PXI-9816

0.1M 1M 10M

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

Frequen cy (Hz)

Amplitude (dB)

PXI-9826

Figure 1-2: PCI/PXI-9826 Bandwidth Chart (50 Ω input impedance)

6Introduction

Page 17

Figure 1-3: PXI-9846 Bandwidth Chart (50 Ω input impedance)

0.1M 1M 10M

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

Frequen cy (Hz)

Amplitude (dB)

PXI-9846

System Noise (measured and calculated under 50 Ω input impedance)

Input Range PXI-9816D PXI-9826D PXI-9846D PXI-9846W PCI-9846D

±0.2 V

±1 V

5.0 LSB

3.0 LSB

RMS

RMS

6.0 LSB

4.0 LSB

RMS

RMS

8.0 LSB

5.0 LSB

RMS

RMS

15.0 LSB

7.0 LSB

RMS

RMS

8.0 LSB

5.0 LSB

RMS

RMS

Input Range PCI-9816H PCI-9826H PCI-9846H PXI-9846H

±1 V

±5 V

5.0 LSB

3.0 LSB

RMS

RMS

6.0 LSB

4.0 LSB

RMS

RMS

8.0 LSB

5.0 LSB

RMS

RMS

8.0 LSB

5.0 LSB

RMS

RMS

Table 1-4: System Noise

Introduction 7

Page 18

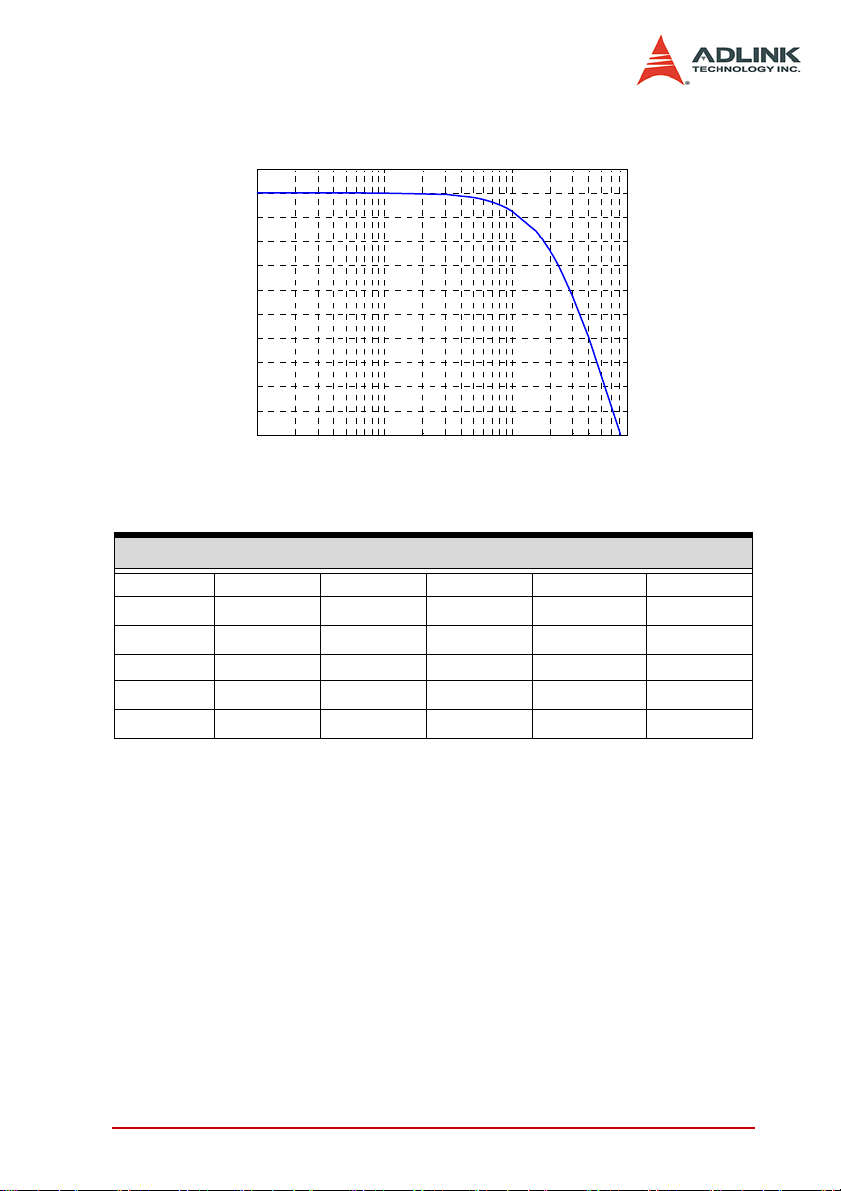

Spectral Characteristics – PXI-9816

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

x 10

6

-1 20

-1 00

-80

-60

-40

-20

0

Freq uency (Hz)

Magnitu de (dB)

PXI- 9816, +/-0.2V , S-Rate = 10 MS/s, Input Signal = 0 .998 MHz @ -0.97 d BFs

Specification Input Range

±1 V ±0.2 V

Signal to Noise and Distortion (SINAD), typical 79.11 dBc 75.93 dBc

Signal-to-Noise Ratio (SNR), typical 79.36 dBc 75.96 dBc

Total Harmonic Distortion (THD), typical -89.90 dBc -95.77 dBc

Spurious Free Dynamic Range (SFDR), typical 90.37 dBc 98.65 dBc

Effective Number of Bit (ENOB), typical 12.85-Bit 12.32-Bit

Test Conditions: Input signal frequency is 0.998 MHz. Digitizer sampling

rate at 10 MHz with 50 Ω input impedance. Calculated with 64 K-point data.

Note that these dynamic parameters may vary from one unit to another, with

input frequency and with the full scale input range selected.

Table 1-5: Spectral Characteristics – PCI/PXI-9816

Figure 1-4: PXI-9816 FFT with ±0.2 V Input Range

8Introduction

Page 19

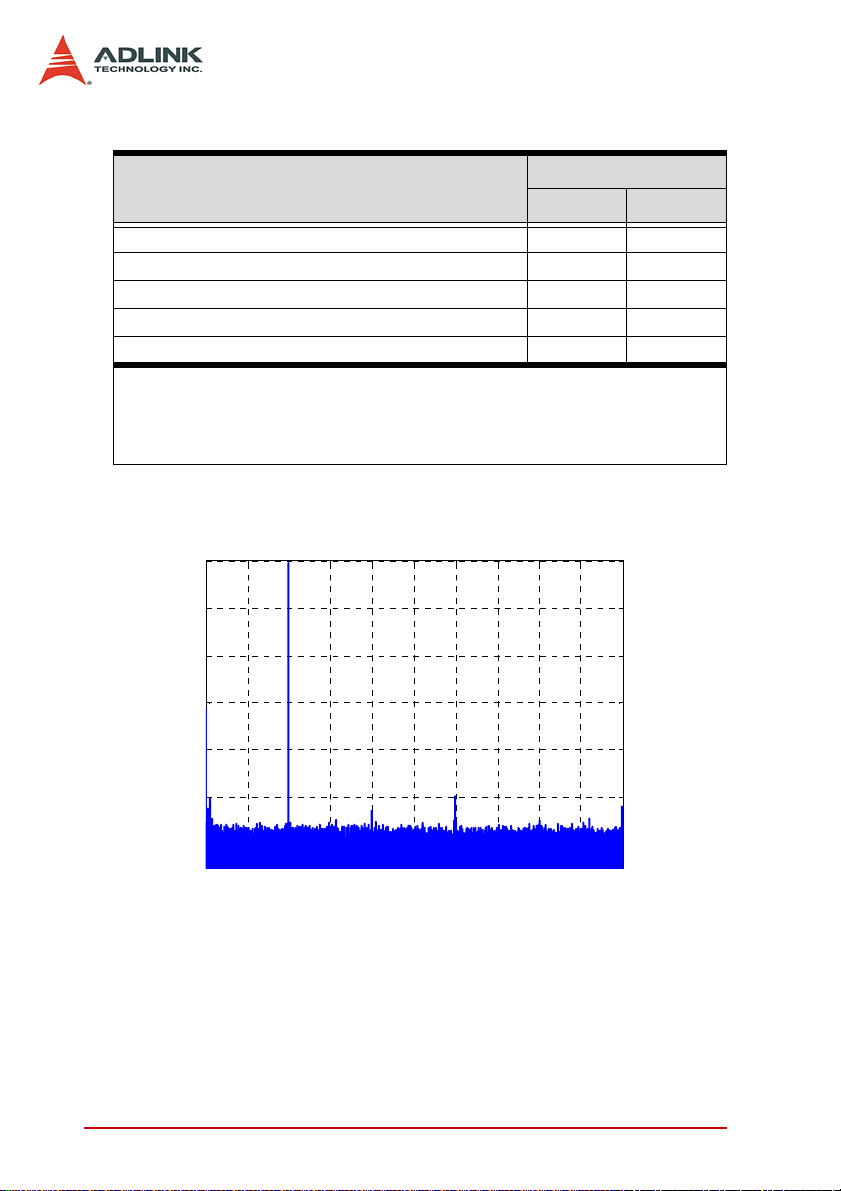

Figure 1-5: PXI-9816 FFT with ±1 V Input Range

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

x 10

6

-1 20

-1 00

-80

-60

-40

-20

0

Freq uency (Hz)

Magnitu de (dB)

PXI- 9816, +/-1V, S -Rate = 10MS/s, I nput Signal = 0. 998 MHz @ -1.1993 dBFS

Introduction 9

Page 20

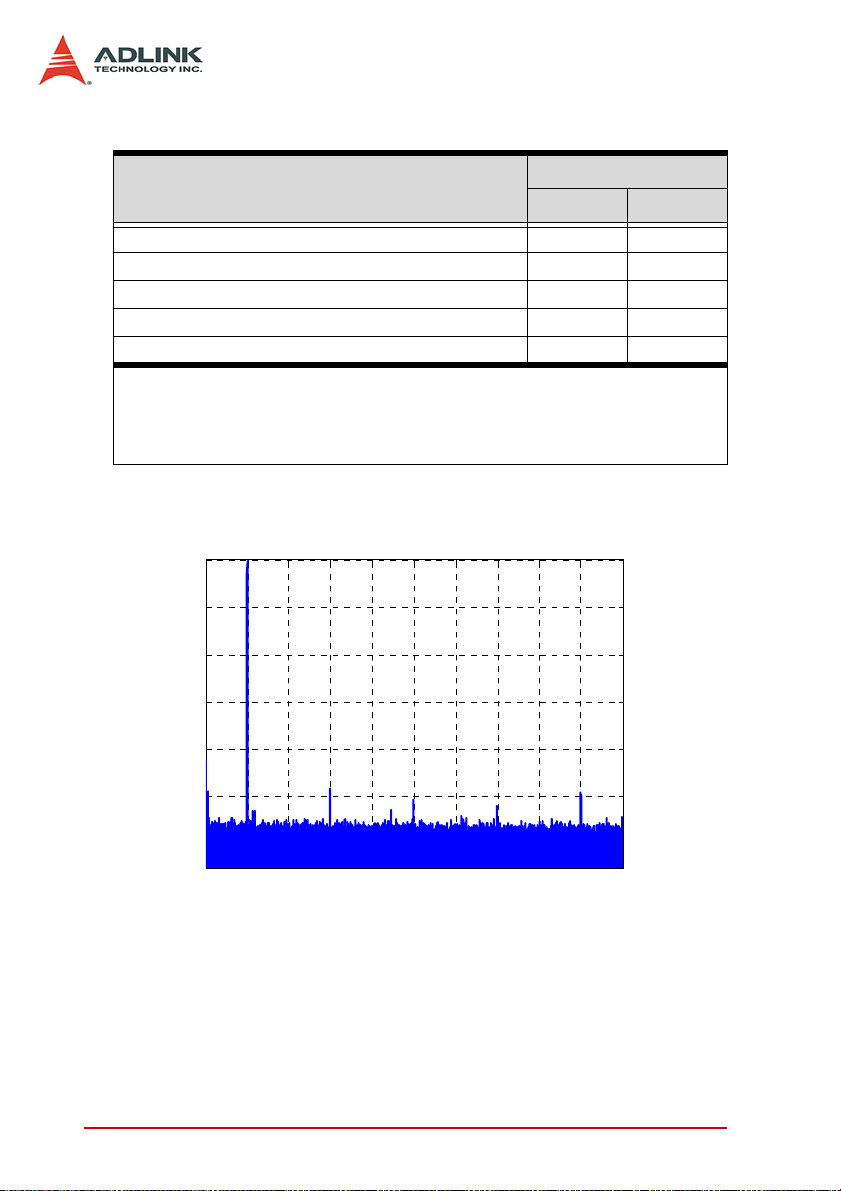

Spectral Characteristics – PXI-9826

0 1 2 3 4 5 6 7 8 9 10

x 10

6

-1 20

-1 00

-80

-60

-40

-20

0

Freq uency (Hz)

Magnitu de (dB)

PX-9 826, + /-0.2 V, S-R ate = 2 0MS/s , Input Signal = 0.9 98 MHz @ - 0.87 54 dB Fs

Specification Input Range

±1 V ±0.2 V

Signal to Noise and Distortion (SINAD), typical 78.63 dBc 74.44 dBc

Signal-to-Noise Ratio (SNR), typical 79.95 dBc 74.48 dBc

Total Harmonic Distortion (THD), typical -88.29 dBc -93.52 dBc

Spurious Free Dynamic Range (SFDR), typical 88.88dBc 95.52 dBc

Effective Number of Bit (ENOB), typical 12.77-Bit 12.07-Bit

Test Conditions: Input signal frequency is 0.998 MHz. Digitizer sampling

rate at 20 MHz with 50 Ω input impedance. Calculated with 64 K-point data.

Note that these dynamic parameters may vary from one unit to another, with

input frequency and with the full scale input range selected.

Table 1-6: Spectral Characteristics – PXI-9826

Figure 1-6: PXI-9826 FFT with ±0.2 V Input Range

10 Introduction

Page 21

Figure 1-7: PXI-9826 FFT with ±1 V Input Range

0 1 2 3 4 5 6 7 8 9 10

x 10

6

-1 20

-1 00

-80

-60

-40

-20

0

Freq uency (Hz)

Magnitu de (dB)

PXI -9826 +/-1 V, S-R ate = 2 0MS/s, Input Signal = 0.99 8 MHz @ -1. 0796 dBF

Introduction 11

Page 22

Spectral Characteristics – PXI-9846

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

x 10

7

-1 20

-1 00

-80

-60

-40

-20

0

Freq uency (Hz)

Magnit ude (dB)

PXI -9846, +/-0.2 V, S-Rate = 4 0MS/s, Input Si gnal = 0.998 MHz @ -0 .9758 dBF s

Specification Input Range

±1 V ±0.2 V

Signal to Noise and Distortion (SINAD), typical 76.06 dBc 71.97 dBc

Signal-to-Noise Ratio (SNR), typical 76.17 dBc 71.98 dBc

Total Harmonic Distortion (THD), typical -90.65 dBc -95.78 dBc

Spurious Free Dynamic Range (SFDR), typical 91.62 dBc 96.15 dBc

Effective Number of Bit (ENOB), typical 12.34-Bit 11.66-Bit

Test Conditions: Input signal frequency is 0.998 MHz. Digitizer sampling

rate at 40 MHz with 50 Ω input impedance. Calculated with 64 K-point data.

Note that these dynamic parameters may vary from one unit to another, with

input frequency and with the full scale input range selected.

Table 1-7: Spectral Characteristics – PCI/PXI-9846

Figure 1-8: PXI-9846 FFT with ±0.2 V Input Range

12 Introduction

Page 23

Figure 1-9: PXI-9846 FFT with ±1 V Input Range

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

x 10

7

-1 20

-1 00

-80

-60

-40

-20

0

Freq uency (Hz)

Magnitu de (dB)

PXI -9846 , +/-1 V, S-R ate = 4 0MS/s , Input Signal = 0.9 98 MHz @ - 1.17 32 dB Fs

Introduction 13

Page 24

Timebase

Specification Value

Sample Clock

Sources

Timebase Frequency Range

Sampling Rate

Range (24-bit

divided counter)

Internal Oscillator Stability

CLK IN (external clock from front panel)

Connector

Type

Clock Type Sine wave or square wave

Input Impedance

Input Coupling AC

Input Range 1VP-P to 2VP-P

Overvoltage

Protection

Internal: onboard oscillator

External: CLK IN (front panel SMB connector), PXI STAR,

PXI Trigger Bus[0..7], PXI 10MHz, SSI bus

PCI/PXI-9816 PCI/PXI-9826 PCI/PXI-9846

10 MHz-1 MHz 20 MHz-1 MHz 40 MHz-1 MHz

10 MS/s-0.596 S/s 20 MS/s-1.192 S/s 40 MS/s-2.384 S/s

±25 ppm

SMB

50 Ω

2.5 V

P-P

Table 1-8: Timebase

14 Introduction

Page 25

Triggering

Specification Val ue

Software, TRG IO (front panel SMB connector),

Trigger Sources

Trigger Modes

TRG IO, as input port

Connector type SMB

Compatibility 3.3 V LVTTL, 5 V tolerant

Input Level

Maximum Input Overload -0.5 V to +5.5 V

Trigger Polarity

Minimum Pulse Width 20 ns

TRG IO, as output port

Connector Type SMB

Compatibility 3.3 V TTL

Output Level

Driving Capability 8 mA

Minimum Output Pulse

Width

Analog Trigger

Sources AI channel 0 - 3

Trigger Slope Rising or falling, software selectable

Trigger Level Range Full scale input range

Trigger Level Resolution 8-bit, 256 steps in full scale range

analog trigger from CH0~CH3, PXI STAR, PXI

Trigger Bus[0..7], SSI bus

Pre-trigger, Post-trigger, Middle-trigger, Delaytrigger

High threshold (V

Low threshold (V

): 2.0 V, minimum

IH

): 0.8 V, maximum

IL

Rising edge or falling edge, software programmable

High threshold (VOH): 2.4V, minimum

Low threshold (VOL): 0.2, maximum

20 ns

Table 1-9: Triggering

Introduction 15

Page 26

Data Storage and Transfer

Specification Value

Onboard Memory Size 512 MB, share for four channels

Data Transfer Scatter-gather DMA

Table 1-10: Data Storage and Transfer

Onboard Reference

Specification Value

Onboard Reference Voltage 5 V

Temperature Drift ±3 ppm/°C

Recommended Warm-up Time 15 minutes

Table 1-11: Onboard Reference

16 Introduction

Page 27

General Information

Specification Value

Environment

Ambient temperature:

Operating Environment

Storage Environment

Physical

PCB Dimension

(not including connectors)

PCI Slot Width 1-slot

PCI Bus Interface

PCI Signaling Support 3.3 V and 5 V signaling

PCI Interface 32-bit, 66 MHz

Electromagnetic Compatibility

Emission EN 55022

Immunity EN 55024

Typical Power Requirements

+12 V 0.3 A 0.3 A 0.3 A

+5 V 1.4 A 1.5 A 2.0 A

+3.3 V 0.8 A 0.8 A 0.8 A

Total Power 13.2 W 13.7 W 16.2 W

0°C to +55°C for PXI version,

0°C to +50°C for PCI version

Relative humidity: 10% to 90%, non-condensing

Ambient temperature: -20°C to +85°C

Relative humidity: 10% to 90%, non-condensing

PXI version: Single 3U PXI module, 100 mm by

160 mm

PCI version: Standard height, half length PCI

card, 167.64 mm by 106.68 mm

PCI/PXI-9816 PCI/PXI-9826 PCI/PXI-9846

Table 1-12: General Information

Introduction 17

Page 28

18 Introduction

Page 29

2 Getting Started

This chapter describes the proper installation environment, installation procedures, its package contents and basic information user

should be aware of.

NOTE: Diagrams and images of equipment mentioned are used

for reference only. Actual system configuration and specs

may vary.

2.1 Installation Environment

Whenever unpacking and preparing to install any equipment

described in this manual, please refer to the Important Safety

Instructions chapter of this manual.

Only install equipment in well lit areas on flat, sturdy surfaces with

access to basic tools such as flat and cross head screwdrivers,

preferably with magnetic heads as screws and standoffs are small

and easily misplaced.

Recommended Installation Tools

Philips (cross-head_ screwdriver

Flat-head screwdriver

Anti-static wrist strap

Anti-static mat

The PCI/PXI-9816/26/46 contain several electro-static sensitive

components that can be easily be damaged by static electricity.

The equipment should be handled on a grounded anti-static mat

and the operator should wear an anti-static wristband during the

unpacking and installation procedure.

Please also inspect the components for apparent damage.

Improper shipping and handling may cause damage to the components. Be sure this is no shipping and handling damage on the

components before continuing.

CAUTION The equipment must be protected from static discharge

and physical shock. Never remove any of the socketed

parts except at a static-free workstation. Use the anti-

static bag shipped with the product to handle the equip-

ment and wear a grounded wrist strap when servicing.

Getting Started 19

Page 30

2.2 Package Contents

Before continuing, check the package contents for any damage

and check if the following items are included in the packaging:

PCI/PXI-9816/26/46 digitizer card

ADLINK All-in-one CD.

Software installation guide

PCI/PXI-9816/26/46 User’s Manual.

CAUTION Do not install or apply power to equipment that is dam-

aged or if there is missing/incomplete equipment. Retain

the shipping carton and packing materials for inspection.

Please contact your ADLINK dealer/vendor immediately

for assistance. Obtain authorization from your dealer before returning any product to ADLINK.

20 Getting Started

Page 31

2.3 Mechanical Drawing and I/O Connectors

TRG IO

CH 0

CH 1

CH 2

CH 3

122.50

20.00

130.63

100.00

210.03

CLK IN

160.00

Unit in mm

Figure 2-1: PXI-98x6 Mechanical Drawing

Figure 2-2: PCI-98x6 Mechanical Drawing

The ADLINK PXI-9816/PXI-9826/PXI-9846 is packaged in a Eurocard form factor with PXI specifications measuring 160 mm in

length and 100 mm in height (not including connectors). The PCI9816/9826/9846 is a half-length and standard height PCI form factor. Please refer to above figure for detail dimension.

Getting Started 21

Page 32

The connector types and functions are described as follows.

Connector Direction Type Description/Function

CLK IN Input SMB

TRG IO

CH0

CH1

CH2

CH3

Input

Output

Input BNC

Table 2-1: Connector Pin Assignments

The CLK IN is a 50Ω, AC-coupled

external timebase input.

The TRG IO is a bidirectional port

SMB

for external digital trigger input or

output.

These channels are for attaching

the analog input signals.

22 Getting Started

Page 33

2.4 Installing the module

To install the PXI-9816/PXI-9826/PXI-9846 module:

1. Turn off the PXI system/chassis and disconnect the

power plug from the power source.

2. Align the module’s edge with the card guide in the PXI

chassis.

3. Slide the module into the chassis, until resistance is felt

from the PXI connector.

4. Push the ejector upwards and fully insert the module into

the chassis.

5. Once inserted, a “click” can be heard from the ejector

latch.

6. Tighten the screw on the front panel.

7. Power on the PXI system/chassis.

To remove the module, reverse step 2 through 6 above.

To install the PCI-9816/PCI-9826/PCI-9846 module:

1. Turn off your computer

2. Remove the top cover of your computer

3. Select an available PCI slot and remove the bracketretaining screw and the bracket cover.

4. Line up the PCI digitizer with the PCI slot on the back

panel. Slowly push down on the top of the PCI digitizer

until its card-edge connector is resting on the slot receptacle.

5. Reinstall the bracket-retaining screw to secure the PCI

digitizer to the back panel rail.

6. Restore the computer cover.

Getting Started 23

Page 34

2.5 Software Support

ADLINK provides comprehensive software drivers and packages

to suit various user approaches to building a system. Aside from

programming libraries, such as DLLs, for most Windows-based

systems, ADLINK also provides drivers for other application environment such as LabVIEW® and MATLAB®. ADLINK also provides ActiveX component ware for measurement and SCADA/

HMI, and breakthrough proprietary software applications.

All software options are included in the ADLINK All-in-One CD.

2.5.1 Driver Support for Windows

DAQPilot

DAQPilot is a driver and SDK with a graphics-driven interface for

various application development environments. DAQPilot comes

as ADLINK's commitment to provide full support to its comprehensive line of data acquisition products and is designed for the novice to the most experienced programmer.

As a task-oriented DAQ driver, SDK and wizard for Windows systems, DAQPilot helps you shorten the development time while

accelerating your learning curve for data acquisition programming.

Figure 2-3: DAQPilot Main Interface

24 Getting Started

Page 35

You can download and install DAQPilot at:

http://www.adlinktech.com/TM/DAQPilot.html

DAQMaster

The ADLINK DAQMaster is a smart device manager that opens up

access to ADLINK data acquisition and test and measurement

products. DAQMaster delivers all-in-one configurations and provides you with a full support matrix to properly and conveniently

configure ADLINK Test and Measurement products.

As a configuration-based device manager for ADLINK DAQ cards,

DAQMaster enables you to manage ADLINK devices and interfaces, install and upgrade software applications, and manage

ADLINK DAQPilot tasks.

Figure 2-4: DAQMaster Device Manager

Getting Started 25

Page 36

2.5.2 WD-DASK (Legacy Drivers and Support)

WD-DASK is composed for advanced 32-bit kernel drivers for customized DAQ application development. WD-DASK enables you to

perform detailed operations and achieve superior performance

and reliability from your digitizer system. DASK kernel drivers now

support the revolutionary Windows Vista OS.

Figure 2-5: Legacy Software Support Overview

26 Getting Started

Page 37

3 Operation Theory

PXI-98X6 Local Bus

Controller

Analog Input Path

16-bit ADC

Analog Input Path

16-bit ADC

Analog Input Path

16-bit ADC

16-bit ADC

PCI Bus

Memory

PCI Controller

Timing Control

PXI Trigger Bus

Trigger Routing

32-bit/66MHz

Analog Input Path

Analog Trigger

Circuit

CH3

CH2

CH1

CH0

TRG IO

CLK IN

PXI Trigger Bus[7..0]

PXI STAR Trigger

PXI 10MHz CLK

Precision Reference

Source

Calibration Circuit

PCI-98X6 Local Bus

Controller

Analog Input Path

16-bit ADC

Analog Input Path

16-bit ADC

Analog Input Path

16-bit ADC

16-bit ADC

PCI Bus

Memory

PCI Controller

Timing Control

SSI Bus

Trigger Routing

32-bit/66MHz

Analog Input Path

Analog Trigger

Circuit

CH3

CH2

CH1

CH0

TRG IO

CLK IN

Precision Reference

Source

Calibration Circuit

The operation theory of the PCI/PXI-9816/26/46 is described in

this chapter, including the control and setting of signal sources,

trigger sources, trigger modes, data transfers, and synchronizing

multiple modules.

3.1 Functional Block Diagram

Figure 3-1: PXI-98x6 Functional Block Diagram

Operation Theory 27

Figure 3-2: PCI-98x6 Functional Block Diagram

Page 38

3.2 Basic AI Acquisition

50O

Anti-aliasing

Filter

Calibration Source

Protection

Circuitry

Gain Amplifier

Hi Impedance

Buffer

16-bit

40M/20M/10M

ADC

Onboard

Memory

PCI Interface

In this section, we are going to explain the basic acquisition timing.

3.2.1 Analog Input Path

The following figure shows the block diagram of the single analog

input path of a digitizer. Each path provides a choice of 50 Ω input

impedance or high impedance. The gain amplifier is optimized for

each input range with low noise and high dynamic range. An antialiasing filter is also adopted to eliminate high frequency noise.

The 16-bit ADC provides not only accurate DC performance but

also high signal-to-noise ratio, high spurious-free dynamic range

in AC performance.

Figure 3-3: Analog Input Signal Block Diagram

3.2.2 Basic Acquisition Timing

The trigger is a signal that starts or stops the acquisition. In posttrigger mode and delay trigger mode, the trigger is used to initiate

acquisition. In pre-trigger mode, the trigger is used to stop acquisition. In middle-trigger mode, the trigger is used to inform the acquisition engine to acquire the specific number of data and then stop.

Timebase is a clock that sent to the ADC of each channel and the

acquisition engine for essential timing functionality. The source of

timebase can be either internal oscillator or external clock generator. Usually the maximum sampling rate of a digitizer is determined

by the speed of timebase. However, other sampling rate can be

achieved by specifying a scan interval counter. Please refer to

Table 3-1 below and Section “3.3.4” on page 32 for more details.

28 Operation Theory

Page 39

Table 3-1 shows several basic counters required for operating digitizers.

Counter Name Length Valid value Description

Scan Interval Counter

This counter is a TIMEBASE divider to

the achieve equivalent sampling rate of

digitizer. The equation is:

ScanIntrv 24-bit 1 - 16777215

DataCnt 29-bit 1 - 536870911

trigDelayTicks 32-bit 1 - 536870911

ReTrgCnt 24-bit 1 - 16777215

Sampling rate = TIMEBASE / ScanIntrv

The value of TIMEBASE depends on the

card type. Take the PCI/PXI-9846

(40 MS/s) as an example, ScanIntrv = 1

results in 40 MS/s and ScanIntrv = 2

results in 20 MS/s, and so on.

Data Counter

You can specify the amount of data to be

acquired. The digitizer equips 512MB

memory to store acquired data.

Delay Trigger Counter

The delay trigger counter is used to indicate the time between a trigger event

and the start of an acquisition. The unit of

a delay count is the period of the TIMEBASE. For PCI/PXI-9816, the unit is

100ns and for PCI/PXI-9846 the unit is

25ns. Refer to section 3.5.4 for more

detail.

Re-Trigger Counter

The digitizer can enable re-trigger to

accept multiple triggers. Refer to section

3.5.5 for more detail.

Table 3-1: Basic Counters

Refer to Figure 3-4 and use post trigger mode as an example.

When a trigger is accepted by digitizer, the acquisition engine of

the digitizer will begin to acquire data that coming from ADC and

store these sampled data to onboard memory. The sampled data

is generated continuously at the rising edge of timebase according

to the scan interval counter setting. While sampled data reaches

customer specified number, in this example is 256, the acquisition

ends. Once the acquisition ends, acquisition engine begins to

send request to system and transfer data from onboard memory

back to system by DMA.

Operation Theory 29

Page 40

Figure 3-4: Basic Acquisition Timing Of Digitizer

TIMEBASE

DATA

D1

D253

D254

Acquisition

In Progress

Trigger

Acquisition starts right after this clock edge

D2

D3 D4 D255

D256

Analog

signal

Trigger mode = post-trigger, DataCnt = 256, ScanIntrv = 1

3.2.3 AI Data Format

The following table illustrates the idea transfer characteristics of

various input ranges of the PCI/PXI-9816/26/46. The data format

of the PCI/PXI-9816/26/46 is straight binary.

Description Analog Input Range Digital Code (HEX)

Full-scale Range ±1 V ±0.2 V

Least significant bit 30.52 μV6.10 μV

FSR – 1LSB 0.999969 V 0.199993 V FFFF

Midscale + 1LSB 30.5 μV6.10 μV 8001

Midscale 0.0 V 0.0 V 8000

Midscale - 1LSB -30.5 μV -6.10 μV7FFF

-FSR -1.000 V -0.200 V 0000

Table 3-2: AI Data Format

30 Operation Theory

Page 41

3.3 ADC Sampling Rate and TIMEBASE Control

8-to-1 MUX

Timebase Clock Mux

PXI Interface

PXI Trigger Bus[0:7]

PXI_STAR

Ext. CLK IN

SMB

Connector

ADC3

PXI Trigger Bus or SSI

PXI_10M

Onboard

Oscillator

ADC0

ADC1

ADC2

8-to-1 MUX

1-to-5 Clock

Buffer

CLK Buffer

The PXI/PCI-98X6 supports several timebase sources for analog

input conversion:

Internal oscillator

External clock through front panel

PXI_STAR (PCI version)

PXI Trigger Bus[0..7] (PXI version)

PXI 10M (PXI version)

SSI (PCI version)

The following diagram shows the timebase architecture of the PXI/

PCI-98X6.

Figure 3-5: PCI/PXI-98x6 Timebase Source and Architecture.

3.3.1 Internal Oscillator

The PCI/PXI-9816/26/46 equips a high stability, low jitter oscillator

for the ADCs. The oscillators are 10 MHz, 20 MHz and 40 MHz for

PCI/PXI-9816, PCI/PXI-9826 and PCI/PXI-9846, respectively.

3.3.2 External Clock Through Front Panel

When you need a specific timebase in some applications that the

onboard oscillator is not achievable, a clock from an external

device can replace onboard oscillator. In addition, external timebase also provides a method to synchronize digitizers to other

measurement modules by distributing/receiving a common clock

to/from multiple modules. The PCI/PXI-9816/26/46 can receive an

Operation Theory 31

Page 42

external timebase from the front panel connector (CLK IN), PXI

STAR or one of the PXI Trigger Bus lines.

You can supply the timebase from external SMB connector CLK

IN, which should be a sine wave or square wave signal. This signal is AC coupled with 50 Ω input impedance and the valid input

level is from 1 to 2 volts peak-to-peak. Note that the external clock

must be continuous for correct ADC operation because of the

pipeline architecture of the ADC.

3.3.3 External Clock from PXI Interfaces

The PCI/PXI-9816/26/46 can receive timebase via one of the PXI

Trigger Bus lines by software selection. The eight PXI Trigger Bus

lines (PXI_TRIG[0..7]) provide inter-module synchronization and

communication. Note that this function is only available when the

PCI/PXI-9816/26/46 is in a PXI system. It’s not supported when

PCI/PXI-9816/26/46 is in a CompactPCI system.

When the PCI/PXI-9816/26/46 is plugged into a generic peripheral

slot in a PXI system, it can receive timebase from PXI_STAR. The

PXI_STAR signal comes from star trigger controller is matched in

propagation delay within 1 ns and the delay from star trigger slot to

peripheral slot is less than 5 ns. According these hardware features, the PCI/PXI-9816/26/46 can achieve very good synchronization performance when using PXI_STAR as timebase clock

source. Note that the function is only available when the PCI/PXI98x6 is in a PXI system. It’s not supported when the PCI/PXI9816/26/46 is in a CompactPCI system.

3.3.4 Sampling Rate Control

By specifying different scan interval counter (24-bit) value, different sampling rate can be achieved. The following formula determines the ADC sampling rate.

Sampling Rate = TIMEBASE / ScanIntrv

Where ScanIntrv is scan interval counter, value can be 1, 2, 3, 4…

24

2

- 1.

32 Operation Theory

Page 43

Refer to Figure 3-6 for detail timing.

TIMEBASE

DATA

D1

Acquisition

In Progress

Trigger

Acquisition starts right after this clock edg e

D1

ScanIntrv = 1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D2 D3 D4 D5 D6

D1

D2 D3 D4

ScanIntrv = 2

ScanIntrv = 3

Figure 3-6: Configuring Different Sampling Rate of a Digitizer.

3.3.5 Timebase Exporting

The PCI/PXI-9816/26/46 can export timebase to one of the eight

PXI trigger bus lines. By software programming, you can pick up a

trigger line to transmit timebase clock. This feature is very useful

when synchronize to multiple measurement modules.

Operation Theory 33

Page 44

3.4 Trigger Sources

Trigger Source Mux

Analog

Trigger

PXI Interface

PXI_STAR

PXI Trigger Bus[0:7]

Software Trigger

Analog CH0

Analog CH1

Analog TRG

Circuit

TRG IO

SMB Connector

Digital Trigger Input

Trigger

Decision

Trigger Output Mux

TRG IO

SMB Connector

PXI Interface or SSI

SSI_TRIG1

SSI_TRIG2

SSI_START_OP

To Internal

Circuit

Analog CH2

Analog CH3

Digital Trigger Output

SSI Bus

(Only available in

PCI version)

In addition to the internal software trigger, the PCI/PXI-9816/26/46

also supports external analog triggers, external digital triggers,

PXI_STAR triggers, PXI Trigger Bus[0..7] and SSI bus.. You can

configure the trigger source by software command. Please refer to

Figure 3.7 for trigger architecture.

Figure 3-7: PCI/PXI-98x6 Trigger Architecture

3.4.1 Software Trigger

Software trigger is generated by software command. The trigger

asserts right after executing specified function calls to begin the

operation.

34 Operation Theory

Page 45

3.4.2 External Digital Trigger

Rising edge

trigger event

Falling edge

trigger event

Pulse Width > 20 ns Pulse Width > 20 ns

An external digital trigger occurs when a TTL rising edge or a falling edge is detected at the SMB connector TRG IO on the front

panel. As illustrated in Figure 3-8, the trigger polarity can be

selected by software. Note that the signal level of the external digital trigger signal should be TTL-compatible, and the minimum

pulse width is 20 ns.

Figure 3-8: External Digital Trigger Polarity and Pulse Width Requirement.

Operation Theory 35

Page 46

3.4.3 Analog Trigger

You can choose either CH0, CH1, CH2 or CH3 as the trigger signal while using external analog trigger source. The trigger level

can be set by software with 8-bit resolution. Please refer to

Table 3-3 for the ideal transfer characteristic.

Trigger Level

Setting (Hex)

0xFF 0.992V 0.1984V

0xFE 0.984V 0.1968V

--- --- ---

0x81 0.0078V 1.56mV

0x80 0V 0V

0x7F -0.0078V -1.56mV

--- --- ---

0x01 -0.992V -0.1984V

Table 3-3: Ideal Transfer Characteristics for Analog Triggers

Trigger Voltage

(-1V to +1V Range)

Trigger Voltage

(-0.2V to +0.2V)

The trigger conditions for analog triggers are illustrated in

Figure 3-9 and described as follows:

Positive-slope trigger: The trigger event occurs when the

trigger signal (analog input signal) changes from a voltage

that is lower than the specified trigger level to a voltage that

is higher than the specified trigger level.

Negative-slope trigger: The trigger event occurs when the

trigger signal (analog input signal) changes from a voltage

that is higher than the specified trigger level to a voltage that

is lower than the specified trigger level.

36 Operation Theory

Page 47

Trigger Level

Positive-Slope Trigger Event

Occurs

Negative-Slope Trigger

Event Occurs

Analog

Signal

Figure 3-9: Analog Trigger Conditions

3.4.4 PXI STAR Trigger

When you select PXI STAR as the trigger source, the PXI-9816/

PXI-9826/PXI-9846 can accept a TTL-compatible digital signal as

a trigger signal. The trigger occurs when a rising edge or falling

edge is detected at PXI STAR. You can use software to configure

the trigger polarity. The minimum pulse width requirement of this

digital trigger signal is 20 ns.

3.4.5 PXI Trigger Bus

The PXI-9816/PXI-9826/PXI-9846 utilizes PXI Trigger Bus[0..7] as

System Synchronization Interface (SSI). Using the interconnected

bus provided by PXI Trigger Bus, you can easily synchronize multiple modules.

When configured as input, the PXI-9816/PXI-9826/PXI-9846 is

served as a slave module and can accept three different SSI signals, SSI_TRG1, SSI_TRG2 and SSI_START_OP. When configured as output, the PXI-9816/PXI-9826/PXI-9846 is served as a

master module and can output SSI_TRG1, SSI_TRG2 or

SSI_START_OP to PXI Trigger Bus. Each signal can be routed

from one of the PXI Trigger Bus[0..7] by software programming.

For more detail about these signals, please refer to Section “3.7”

on page 44.

Operation Theory 37

Page 48

3.4.6 Trigger Signal Exporting

TRG IO

(Output)

Tw

Tw = 2 TIMEBASE Clocks

The PCI/PXI-9816/26/46 can export trigger signals to following

connectors/bus: TRG IO on front panel and PXI Trigger Bus[0..7].

The TRG IO on the front panel can also be programmed to output

the trigger signal when the trigger source is from software trigger,

analog trigger, PXI STAR, or PXI Trigger Bus[0..7]. The timing

characteristic is in Figure 3-10.

Figure 3-10: TRG IO Output Signal Timing

The PCI/PXI-9816/26/46 utilizes PXI Trigger Bus[0..7] as System

Synchronize Interface. When configured as output, the PCI/PXI9816/26/46 is served as a master module and can output 3 different trigger signals, SSI_TRG1, SSI_TRG2 and SSI_START_OP.

You can route these signals to any of PXI Trigger Bus[0..7] signals

via software programming.

38 Operation Theory

Page 49

3.5 Trigger Modes

Time

Operation

start

Trigger

N samplesData

Trigger Event Occurs

Acquisition start

Acquisition stop

Begin to transfer data to system

There four trigger modes working with trigger sources to initiate

different data acquisition timing when a trigger event occurs. They

are described in this section.

3.5.1 Post-trigger Acquisition

Use post-trigger acquisition when you want to collect data after the

trigger event, as illustrated in Figure 3-11.

Figure 3-11: Post-trigger Acquisition

Operation Theory 39

Page 50

3.5.2 Pre-trigger Acquisition

Time

Operation start

Acquisition start

Trigger

Data

Trigger Event Occurs

Acquisition stop

Begin to transfer data to

system

N samples

These data will be

discarded.

Only acquired N

samples will be

transfer back to

system.

Time

Operation start

Acquisition start

Trigger

Data

Trigger Event Occurs

Acquisition stop

Begin to transfer data to system

N samples

X samples have been acquired

before trigger occurs, where

X<N

Trigger signals that occur before

the specified amount of data has

been acquired will be ignored.

Use pre-trigger acquisition to collect data before the trigger event.

The acquisition starts once specified function calls are executed to

begin the pre-trigger operation, and it stops when the trigger event

occurs.

If the trigger event occurs after the specified amount of data has

been acquired, the system only stores the data before the trigger

event with specified amount, as illustrated in Figure 3-12.

Figure 3-12: Pre-trigger Mode Operation

The trigger event occurs after the specified amount of data has

been acquired. However, if the trigger event occurs before the

specified amount of data has been acquired, the acquisition

engine will ignore the trigger signal until the specified amount of

data has been acquired. Refer to Figure 3-13 for an example.

40 Operation Theory

Figure 3-13: Pre-trigger Mode Operation

Page 51

3.5.3 Middle-trigger Acquisition

Time

Operation start

Acquisition start

Trigger

Data

Acquisition stop

Begin to transfer data to system

N samplesM samples

Trigger event occurs

Time

Operation

start

Trigger

Data

Trigger Event

Occurs

Acquisition stop

Begin to transfer data to

system

N samples

Acquisition start

Delay Time

Use middle-trigger acquisition when you want to collect data

before and after the trigger event. The amount of stored data

before and after trigger event can be set individually (M and N

samples), as illustrated in Figure 3-14.

Figure 3-14: Middle-trigger Mode Operation

Please note that trigger event can only accepted when the specified amount of data has been acquired (M samples). If the sampled data is not enough, the trigger event will be ignored.

3.5.4 Delay-trigger Acquisition

Use delay-trigger acquisition to delay the data collection after the

trigger event, as illustrated in Figure 3-15. The delay time is specified by a 32-bit counter value so that the maximum delay time is

the period of TIMEBASE X (2

the period of timebase.

32

- 1), while the minimum delay is

Figure 3-15: Delay-trigger Mode Operation

Operation Theory 41

Page 52

3.5.5 Post-trigger or Delay-trigger Acquisition with Re-

Time

Operation

start

Trigger

Data

1st Trigger Event Occurs

N samples N samples

2nd Trigger Event Occurs

trigger

Use post-trigger or delay trigger acquisition with re-trigger function

to collect data after several trigger events, as illustrated in

Figure 3-16. You can program the number of triggers then the digitizer will acquire a specific sample data each time a trigger is

accepted. All of sampled data will be stored in onboard memory

first until all trigger events occurred. Thus the time between last

sampled data and next trigger event can be only one clock period

of timebase. After the initial setup, the process does not require

software intervention.

Figure 3-16: Re-trigger Mode Operation.

42 Operation Theory

Page 53

3.6 Data Transfers

PCI Bus

Local

Memory

512MB

PXI-9816/PXI-9826

/PXI-9846

First PCI Address

First Local Address

Transfer Size

Next Descriptor

PCI Address

Local Address

Transfer Size

Next Descriptor

PCI Address

Local Address

Transfer Size

Next Descriptor

System Memory

Since the maximum data throughput on the PCI/PXI-9846 (40MS/

s * 4 channels *2 Bytes/channel = 320MB/s) is much higher than

the 32bit/33MHz PCI-bus bandwidth, samples are acquired into

the onboard SDRAM memory before being transferred to the host

computer. Since the number of stored samples per acquisition is

limited by the amount of on-board memory, the PCI/PXI-9816/26/

46 supports maximum 512MB in order to meet application requirements.

Once all the data has been stored in the on-board memory, the

data will be transferred to the host computer’s memory through

bus-mastering DMA.

In a multi-user or multi-tasking OS, like Microsoft Windows, Linux,

and so on, it is difficult to allocate a large continuous memory

block to do the DMA transfer. Therefore, the PCI/PXI-9816/26/46

provides the function of scatter-gather DMA to link the non-continuous memory blocks into a linked list so that you can transfer very

large amounts of data without being limited by the fragment of

small size memory, as illustrated in Figure 3-17.

Operation Theory 43

Figure 3-17: Scatter-Gather DMA for Data Transfer

Page 54

3.7 Synchronizing Multiple Modules

The eight interconnected lines on PXI backplane named as PXI

Trigger Bus[0:7] provide a flexible interface for multiple modules

synchronization. The PXI-9816/26/46 utilizes the PXI Trigger

Bus[0:7] as the System Synchronization Interface (SSI). By providing flexible routing of timebase clock and trigger signals onto

PXI Trigger Bus, the PXI-9816/26/46 makes the synchronization

between multiple modules easy and simple.

For PCI-9816/26/46, a dedicate connector is served as system

synchronization interface. With this interface, PCI-9816/26/46 is

capable of achieving multiple module synchronization. Following

figure shows the installation of multiple module synchronization.

The bi-directional SSI I/Os provide a flexible connection between

modules, which allows one SSI master PCI/PXI-9816/26/46 to output the SSI signals to other slaves modules to receive the signals.

Table 3-4 lists the summary of SSI timing signals and the functionalities. Figure 3-18 shows the architecture of SSI. Note that it’s not

allowed to route different signals onto the same trigger bus line.

SSI Timing Signals Functionality

SSI_TIMEBASE Input/output timebase signal through SSI

SSI_TRIG1 Input/output trigger signal through SSI

SSI_TRIG2 Input/output clocked trigger signal through SSI

SSI_START_OP

Table 3-4: Summary of SSI timing Signals and the Corresponding Function

Input/output the acquisition start signal in pre-trig-

ger or middle-trigger mode

44 Operation Theory

Page 55

Figure 3-18: SSI Architecture

Trigger

Decision

SSI_TRG1

SSI_TRG2

SSI_START_OP

SSI_TIMEBASE

PXI Interface or SSI

PXI Trigger

Bus[0:7]

or

SSI

Timing Control

For PCI-9816/26/46, a dedicate connector is served as system

synchronization interface. Refer to Figure 3-19 for the connector

position. All the SSI signals are routed to the 20-pin connector

from FPGA. With this interface, PCI-9816/26/46 is capable of

achieving multiple module synchronization. Users can use ACLSSI-2/ACL-SSI-3/ACL-SSI-4 cables to synchronize 2, 3, or 4 modules. Please refer to Figure 3-20 for the installation of an ACL-SSI

cable.

Note: When powering-up or reseting, the synchronization sig-

nals are reset to use internal generated timing signals.

Operation Theory 45

Page 56

Figure 3-19: SSI Connector Location on the PCI-9816/26/46

Figure 3-20: Installation of ACL-SSI-2 Cable

19 17 15 13 11 9 7 5 3 1

CN11

20 18 16 14 12 10 8 6 4 2

PCB

46 Operation Theory

Page 57

Signal Name Direction Description Location

SSI_TIMEBASE Input/Output

SSI_TRIG1 Input/Output

SSI_TRIG2 Input/Output

SSI_START_OP Input/Output

GND - Ground

NC - No Connection pins 3, 13

Reserved Input/Output Reserved for future use pins 5, 15, 17, 19

Table 3-5: SSI Signal Locations and Pin Definition

Timebase signal through

SSI

Trigger signal through

SSI

Clocked trigger signal

through SSI

Acquisition start signal

in pre-trigger or middletrigger mode

pin 1

pin 11

pin 9

pin 7

pins 2, 4, 6, 8,

10, 12, 14, 16,

18, 20

3.7.1 SSI_TIMEBASE

As an output, the SSI_TIMEBASE signal outputs the onboard

LVTTL timebase through PXI trigger bus.

As an input, the PCI/PXI-9816/26/46 accepts the SSI_TIMEBASE

signal to be the source of timebase.

Operation Theory 47

Page 58

3.7.2 SSI_TRIG1

SSI_TRIG1

(Output)

Two

Two = 3-4 TIMEBASE Clocks

SSI_TRIG1

(Input)

Twi

Twi = 20 ns minimum

As an output, the SSI_TRIG1 signal reflects the trigger event signal in an acquisition sequence. You can use the function

SSI_SourceConn() to output the SSI_TRIG1 signal.

As an input, the PCI/PXI-9816/26/46 accepts the SSI_TRIG1 signal to be the trigger event source. The signal is configured in the

rising edge-detection mode. When selecting the trigger sources of

the PCI/PXI-9816/26/46, you can select TRSRC_SSI_1 to set

SSI_TRIG1 as the source of trigger event.

Figure 3-21: SSI_TRIG1 Input and Output Timing Characteristics

48 Operation Theory

Page 59

3.7.3 SSI_TRIG2 and SSI_START_OP

SSI_TRIG1

Tw

Tw = 2 TIMEBASE Clocks

TIMEBASE

SSI_TRIG2

SSI_TRIG2

Tw

Tw = 20 ns minimum

As an output, the SSI_TRIG2 signal is a clocked SSI_TRIG1 signal by TIMEBASE, as illustrated in Figure 3-22.

Figure 3-22: SSI_TRIG2 Output Timing

As an input, the PCI/PXI-9816/26/46 accepts the SSI_TRIG2 signal to be the source of a one-clock delayed trigger event. The controller on the PCI/PXI-9816/26/46 will then compensate the oneclock delay if using SSI_TRIG2 as the source of trigger event. The

signal is configured in the rising edge-detection mode.

Figure 3-23: SSI_TRIG2 Input Timing Requirement

As an output, the SSI_START_OP signal reflects the operation

start signal in a pre-trigger or middle-trigger acquisition sequence.

Please refer to Figure 3-12 - Figure 3-14 for the relationship

between the operation start signal and the acquisition sequence.

As an input, the PCI/PXI-9816/26/46 accepts the SSI_START_OP

signal to be the operation start signal in a pre-trigger or middletrigger acquisition sequence. The signal is configured in the rising

edge-detection mode. Figure 3-24 show the SSI_START_OP signal input and output timing requirements.

Operation Theory 49

Page 60

SSI_START_OP

(Output)

Two

Two = 2 TIMEBASE Clocks

Twi

Twi = 20 ns minimum

SSI_START_OP

(Input)

For enabling output operations, you can use the function

SSI_SourceConn() to output the SSI_TRIG2 and SSI_START_OP

signals.

For the input operations, you can select TRSRC_SSI_2 to set

SSI_TRIG2 and SSI_START_OP as the source of the trigger

event and operation start signal.

Figure 3-24: SSI_START_OP Output and Input Timing Characteristics

3.7.4 Comparing the Different Trigger Sources from SSI

When selecting TRSRC_SSI_1 as the trigger source input, the

signal SSI_TRIG1 reflects the trigger event signal in an acquisition

sequence. However, when synchronizing multiple PCI/PXI-9816/

26/46 devices, each module may recognize the trigger signal with

one-clock time difference because the signal is not related to the

timebase.

There is another phenomenon if using TRSRC_SSI_2 in pre-trigger and middle-trigger mode. The operation start signal is generated by a software command so multiple PCI/PXI-9816/26/46

modules don’t start the data acquisition simultaneously, which

may result in the fact that the amount of stored samples are different if the trigger event occurs before the specified amount of data

has been acquired.

When selecting TRSRC_SSI_2 as the trigger source input,

SSI_TRIG2 and SSI_START_OP can achieve better synchroniza-

50 Operation Theory

Page 61

tion between multiple PCI/PXI-9816/26/46 devices. A clocked

SSI_TRIG2 can guarantee all PCI/PXI-9816/26/46 devices recognize the trigger event at the same clock edge if they use the same

timebase. In pre-trigger and middle-trigger mode,

SSI_START_OP guarantees all the PCI/PXI-9816/26/46 devices

start the data acquisition at the same time.

Operation Theory 51

Page 62

3.8 Physical Location of the PXI and PCI Digitizer

3.8.1 Identify PXI Digitizer’s Physical Location by Geographic Address

CompactPCI and PXI chassis accommodate slot numbering

mechanism based on the definition of Geographical Address pins

on its backplane. Users can identify module’s physical location by

reading back Geographical Address. This is a useful feature especially when multiple modules are installed in one host system. The

PXI-9816/26/46 can read back the Geographical Address through

software driver. Please refer to software function reference manual for more detail description.

3.8.2 Assign a Board ID to a PCI Digitizer

When users plug two or more PCI-9816/26/46 modules in one

computer, board ID provides an effective mechanism for user to

identity the specific module. With this method, users can access to

specific module in accordance with board ID. The dip switch of

board ID is located on the top of the module. Please refer to following figure and table for detail setting.

Please note that users have to assign a unique board ID to each

module that are installed in the same computer, otherwise software driver will not allocate correct system resource to these modules. Once users assign identical board ID to different module,

please turn off your computer first and then adjust the board ID

again. After correct board ID is assigned, then users can power up

computer again.

52 Operation Theory

Page 63

Figure 3-25: The Location of Board ID Switch

Figure 3-26: Enlargement of Board ID setting.

Note: Only dip switches 1-5 are valid for board ID settings. Dip

switches 6- 9 are unused. When a dip switch is switched

to ‘ON’, it represents ‘1’, the opposite direction represents

‘0’.

Operation Theory 53

Page 64

1: ON

0: OFF

Board ID

Switch Number

1 2 3 4 5

011111

101111

210111

300111

411011

501011

610011

700011

811101

901101

10 1 0 1 0 1

11 0 0 1 0 1

12 1 1 0 0 1

13 0 1 0 0 1

14 1 0 0 0 1

15 0 0 0 0 1

16 1 1 1 1 0

17 0 1 1 1 0

18 1 0 1 1 0

19 0 0 1 1 0

20 1 1 0 1 0

21 0 1 0 1 0

22 1 0 0 1 0

23 0 0 0 1 0

24 1 1 1 0 0

25 0 1 1 0 0

26 1 0 1 0 0

27 0 0 1 0 0

28 1 1 0 0 0

29 0 1 0 0 0

30 1 0 0 0 0

31 0 0 0 0 0

Table 3-6: Board ID Combination Conditions

54 Operation Theory

Page 65

Important Safety Instructions

Please read and follow all instructions marked on the product and

in the documentation before operating the system. Retain all

safety and operating instructions for future use.

Please read these safety instructions carefully.

Please keep this User’s Manual for future reference.

The equipment should be operated in an ambient tempera-

ture between 0 to 50

The equipment should be operated only from the type of

power source indicated on the rating label. Make sure the

voltage of the power source is correct when connecting the

equipment to the power outlet.

If the user’s equipment has a voltage selector switch, make

sure that the switch is set to the proper position for the area.

The voltage selector switch is set at the factory to the correct voltage.

For pluggable equipment, ensure they are installed near a

socket-outlet that is easily accessible.

Secure the power cord to prevent unnecessary accidents.

Do not place anything over the power cord.

If the equipment will not be in use for long periods of time,

disconnect the equipment from mains to avoid being damaged by transient overvoltage.

All cautions and warnings on the equipment should be

noted.

Please keep this equipment away from humidity.

Do not use this equipment near water or a heat source.

Place this equipment on a reliable surface when installing.

A drop or fall could cause injury.

Never pour any liquid into the opening, this could cause fire

or electrical shock.

C.

Important Safety Instructions 55

Page 66

Openings in the case are provided for ventilation. Do not

block or cover these openings. Make sure there is adequate

space around the system for ventilation when setting up the

work area. Never insert objects of any kind into the ventilation openings.

To avoid electrical shock, always unplug all power and

modem cables from the wall outlets before removing covers.

Lithium Battery provided (real time clock battery)

“CAUTION - Risk of explosion if battery is replaced by

an incorrect type. Dispose used batteries as instructed

in the instructions”

The equipment should be checked by service personnel if

one of the following situation arises:

The power cord or plug is damaged.

Liquid has penetrated the equipment.

The equipment has been exposed to moisture.

The equipment is not functioning or does not function

according to the user’s manual.

The equipment has been dropped and damaged.

If the equipment has obvious sign of breakage.

Never open the equipment. For safety reasons, the equip-

ment should only be opened by qualified service personnel.

56 Important Safety Instructions

Loading...

Loading...