Page 1

NuDAQ PCI-9812/9810

4-CH, 20 MHz Simultaneous

Analog Input Card

User’s Manual

Manual Rev. 3.02

Revision Date: December 2, 2008

Part No: 50-11116-2040

Advance Technologies; Automate the World.

Page 2

Copyright 2008 ADLINK TECHNOLOGY INC.

All Rights Reserved.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability , design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, elec tronic, or other means in a ny form

without prior written permission of the manufacturer.

Trademark Information

NuDAQ, NuIPC, DAQBench are registered trademarks of ADLINK

TECHNOLOGY INC.

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Page 3

Getting service

Customer satisfaction is our top priority. Contact us should you

require any service or assistance.

ADLINK TECHNOLOGY INC.

Web Site http://www.adlinktech.com

Sales & Service service@adlinktech.com

Telephone No. +886-2-8226-5877

Fax No. +886-2-8226-5717

Mailing Address 9F No. 166 Jian Yi Road, Chungho City,

Taipei Hsien 235, Taiwan

ADLINK TECHNOLOGY AMERICA, INC.

Sales & Service info@adlinktech.com

Toll-Free +1-866-4-ADLINK (235465)

Fax No. +1-949-727-2099

Mailing Address 8900 Research Drive, Irvine,

CA 92618, USA

ADLINK TECHNOLOGY EUROPEAN SALES OFFICE

Sales & Service emea@adlinktech.com

Toll-Free +49-211-4955552

Fax No. +49-211-4955557

Mailing Address Nord Carree 3, 40477 Düsseldorf, Germany

ADLINK TECHNOLOGY SINGAPORE PTE LTD.

Sales & Service singapore@adlinktech.com

Telephone No. +65-6844-2261

Fax No. +65-6844-2263

Mailing Address 84 Genting Lane #07-02A,

Cityneon Design Center, Singapore 349584

ADLINK TECHNOLOGY SINGAPORE PTE LTD.

(INDIA Liaison Office)

Sales & Service india@adlinktech.com

Telephone No. +91-80-57605817

Fax No. +91-80-26671806

Mailing Address No. 1357, Ground Floor, “Anupama”,

Aurobindo Marg JP Nagar (Ph-1)

Bangalore - 560078

Page 4

ADLINK TECHNOLOGY INC. (KOREA Liaison Office)

Sales & Service korea@adlinktech.com

Telephone No. +82-2-20570565

Fax No. +82-2-20570563

Mailing Address 4F, Kostech Building, 262-2,

Yangjae-Dong, Seocho-Gu,

Seoul, 137-130, South Korea

ADLINK TECHNOLOGY (BEIJING) CO., LTD.

Sales & Service market@adlinkchina.com.cn

Telephone No. + 86-10-5885-8666

Fax No. +86-10-5885-8625

Mailing Address Room 801, Building E, Yingchuangdongli

Plaza, No.1 Shangdidonglu,

Haidian District, Beijing, China

ADLINK TECHNOLOGY (SHANGHAI) CO., LTD.

Sales & Service market@adlinkchina.com.cn

Telephone No. + 86-21-6495-5210

Fax No. +86-21-5450-0414

Mailing Address Floor 4, Bldg. 39, Caoheting Science and

Technology Park, No.333 Qinjiang Road,

Shanghai, China

ADLINK TECHNOLOGY (SHENZEN) CO., LTD.

Sales & Service market@adlinkchina.com.cn

Telephone No. + 86-755-2643-4858

Fax No. +86-755-2664-6353

Mailing Address C Block, 2nd Floor, Building A1,

Cyber-tech Zone, Gaoxin Ave. 7.S,

High-tech Industrial Park S.,

Nanshan District, Shenzhen,

Guangdong Province, China

Page 5

Using this manual

Audience and scope

This manual guides you when using ADLINK NuDAQ® multi-function PCI card. The card’s hardware, signal connections, and calibration information are provided for faster application building.

This manual is intended for computer programmers and hardware

engineers with advanced knowledge of data acquisition and highlevel programming.

How this manual is organized

This manual is organized as follows:

Chapter 1 Introduction: This chapter introduces the PCI9812/9810 card including its features, specifications, software

support information, and package contents.

Chapter 2 Hardware Information: This chapter presents the

card’s layout and connector pin definition.

Chapter 3 Installation: This part describes the PCI-9812/9810

installation, configuration, and options for signal connections.

Chapter 4 Registers: Descriptions of the register format and

structure of the PCI-9812/9810 are specified in this chapter.

Chapter 5 Operation Theory: The operation theory of the

PCI-9221 functions including A/D conversion, D/A conversion,

and programmable function I/O are discussed in this chapter.

Chapter 6 Function Reference: The chapter includes a software library necessary for operating the PCI-9812/9810 card in

DOS or Windows 95.

Chapter 7 Calibration: The chapter offers information on how

to calibrate the PCI-9812/9810 for accurate data acquisition

and output.

Chapter 8 Software Utility: The chapter offers information on

how to use the software utility to configure, calibrate, and test

the PCI-9812/9810 card.

War rant y Pol icy : This presents the ADLINK Warranty Policy

terms and coverages.

Page 6

Conventions

Take note of the following conventions used throughout the manual to make sure that you perform certain tasks and instructions

properly.

NOTE Additional information, aids, and tips that help you per-

form particular tasks.

IMPORTANTCritical information and instructions that you MUST perform to

WARNING Information that prevents physical injury, data loss, mod-

complete a task.

ule damage, program corruption etc. when trying to complete a particular task.

Page 7

Table of Contents

List of Tables.......................................................................... iv

List of Figures......................................................................... v

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 1

1.2 Applications ......................................................................... 1

1.3 Specifications....................................................................... 2

1.4 Unpacking Checklist .................. ... ... .... ... ... ... ... .... ... ... ... .... ... 4

1.5 Software Support................................................................. 5

Software Support ............................................................5

Programming Libraries .................. ... ... ... ........................5

Drivers for Third-Party Programming Languages ...........6

2 Hardware Information........................................................ 9

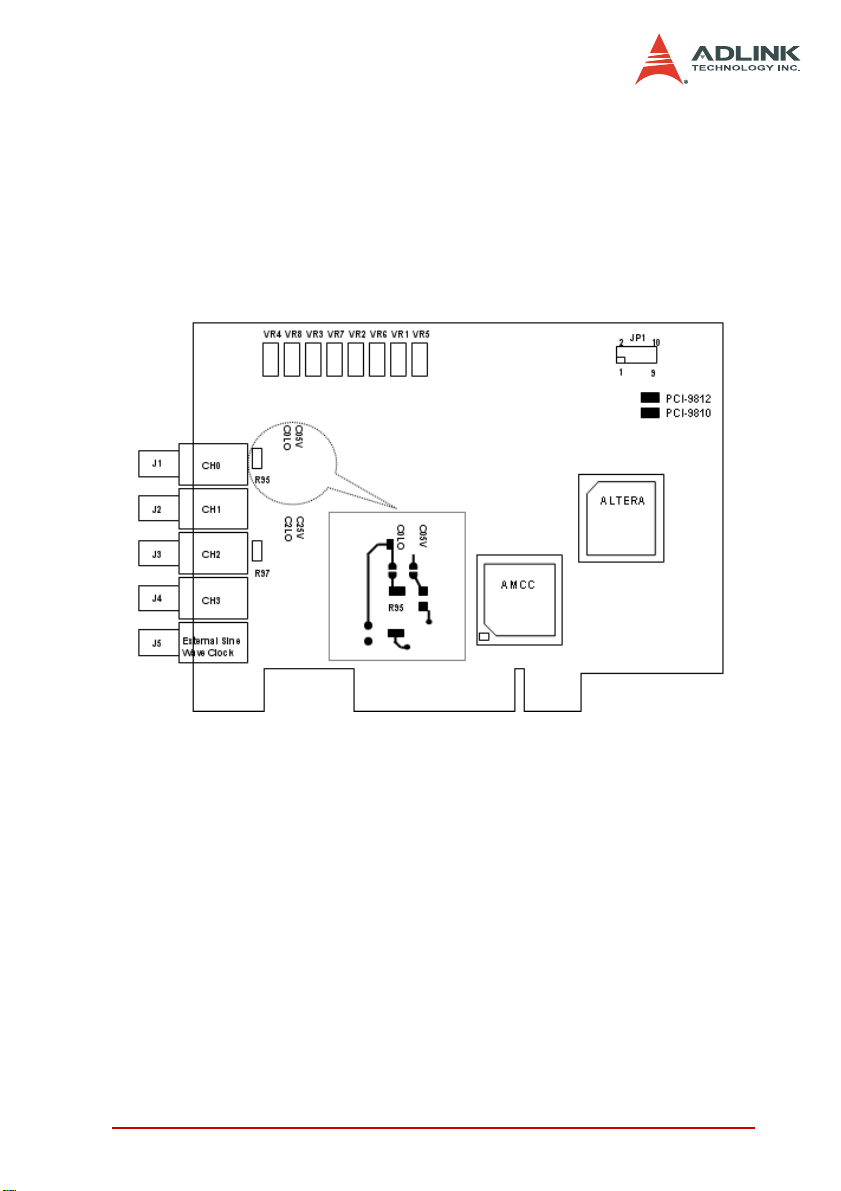

2.1 Layout.................................................................................. 9

2.2 Connectors ........................................................................ 10

JP1 Pin Definition ......................................................... 11

2.3 Input Settings..................................................................... 12

Analog Input ................................................................. 12

External Clock 0 ............................................................14

External Clock 1 ............................................................14

Digital Input ...... .... ... ... .......................................... ... .... .. 14

3 Installation ........................................................................ 15

3.1 Before You Proceed .......................................................... 15

3.2 Installing the Card.............................................................. 15

3.3 Configuring the Card.......................................................... 16

Troubleshooting ................................ ............................ 16

3.4 Installing the Drivers for Windows ..................................... 16

4 Registers........................................................................... 17

4.1 I/O Port Address ................................................................ 17

ADC Channel Enable Register ..................................... 18

ADC Clock Divisor Register . ... ... .... ... ... ... ... .... ... ... ... .... .. 19

Trigger Mode Register .................................................. 20

Trigger Level Register .................................................. 21

Trigger Source Register .................................... ... ... .... .. 22

Table of Contents i

Page 8

Post Trigger Counter Register ......................................23

FIFO Status Register ....................................................24

FIFO Control Register ...................................................25

Acquisition Enable Register ..........................................26

Clock Source Register ..................................................27

4.2 High Level Programming ................................................... 28

4.3 Low Level Programming.................................................... 28

5 Operation Theory............................................................ .. 29

5.1 Conversion Procedure....................................................... 29

5.2 Signal Source Control........................................................ 31

5.3 Trigger Source Control....................................................... 32

Trigger Sources ............................................................32

Trigger Modes ...............................................................34

5.4 Clock Source Control......................................................... 36

A/D Clock Sources ........................................................36

5.5 Data Transfer..................................................................... 38

Data Transfer ................................................................38

Simultaneous Sampling of Four AD Channels .............38

Total Data Throughput ................................. .................39

Maximum Acquiring Data Length ..................................39

Bus-mastering Data Transfer ........................................40

Host Memory Operation ................................................40

5.6 Data Format....................................................................... 42

6 Function Reference .......................................................... 45

6.1 Installing the Libraries........ ... ... .... ... ... ... .... ... ... ... ................ 45

6.2 Programming Guide........................................................... 46

Naming Convention ............................... ... ... ... .... ... ... ... .46

Data Types ...................................................................47

6.3 Function Reference............................................................ 48

_9812_Initial .................................................................48

_9812_Close ....................................... ................... .......50

_9812_AD_DMA_Start ................................................. 51

_9812_AD_DMA_Status ........................................ .......54

_9812_AD_DMA_Stop .................................................55

_9812_Set_Clk_Src ..................................... .................56

_9812_Set_Clk_Rate .......................................... ..........57

_9812_Set_Trig ............................................................ 58

W_9812_Alloc_DMA_Mem ...........................................60

ii Table of Contents

Page 9

W_9812_Free_DMA_Mem ........................................... 61

W_9812_Get_Sample .................................................. 62

7 Calibration......................................................................... 63

7.1 Before You Proceed .......................................................... 63

7.2 VR Assignment.................................................................. 63

7.3 A/D Calibration................................................................... 64

A/D Calibration for Channel 0 ........................... ... ... .... .. 64

A/D Calibration for Channels 1/2/3 ............................... 64

8 Software Utility................................................................. 65

8.1 Running the Utility.............................................................. 65

8.2 System Configuration ........................................................ 66

8.3 Calibration.......................................................................... 67

8.4 Functional Testing ............................................................. 69

Table of Contents iii

Page 10

List of Tables

Table 2-1: JP1 Pin Definition ................................................... 11

Table 2-2: JP1 Pin Definition Connected to

9-pin D-type Connector ........................................... 11

Table 2-3: Analog Input ........................................................... 12

Table 2-4: Switches and Resistors .......................................... 13

Table 4-1: I/O Address ............................................................. 17

Table 4-2: Five Trigger Modes ................................................. 20

Table 6-1: Data Types ....................... ... ... ... .... ... ... ... ... .... ... ... ... 47

Table 7-1: Functions of VRs .................................................... 63

Table 7-2: AD Calibration for Channels 1/2/3 .......................... 64

iv List of Tables

Page 11

List of Figures

Figure 2-1: Location of Connectors............................................ 10

Figure 5-1: Post-trigger Acquisition............................................ 34

Figure 5-2: Pre-trigger Acquisition ............................................. 34

Figure 5-3: Middle-trigger Acquisition ........................................ 35

Figure 5-4: Delay-trigger Acquisition.......................................... 35

Figure 5-5: Data Transfer Diagram of PCI-9812/9810............... 38

List of Figures v

Page 12

Page 13

1 Introduction

The PCI-9812/9810 is an advanced performance data acquisition

card based on the 32-bit PCI bus architecture. With maximum

sampling rate of up to 20 million samples per second, the PCI9812/9810 delivers continuous and high-speed streaming of A/D

samples to the host memory. The high-performance design and

state-of-the-art technology make these cards ideal for DSP, FFT,

digital filtering, and image processing applications.

1.1 Features

The PCI-9812/9810 advanced DAQ card is designed with the following features:

X 32-bit PCI bus with bus mastering DMA data transfer

X 12-bit (PCI-9812)/10-bit (PCI-9810) analog input resolution

X Onboard 32K words (samples) A/D FIFO memory

X Up to 20 MHz A/D sampling rate

X Four single-ended analog input channels

X Bipolar input signals

X Four A/D converters with simultaneously sampling

X Five A/D trigger modes including software trigger, pre-trig-

ger, post-trigger, middle trigger, and delay trigger

1.2 Applications

X IF and BASEBAND digitization

X Ultrasound imaging

X Gamma cameras

X Test instrument

X CCD imaging

X Video digitizing

Introduction 1

Page 14

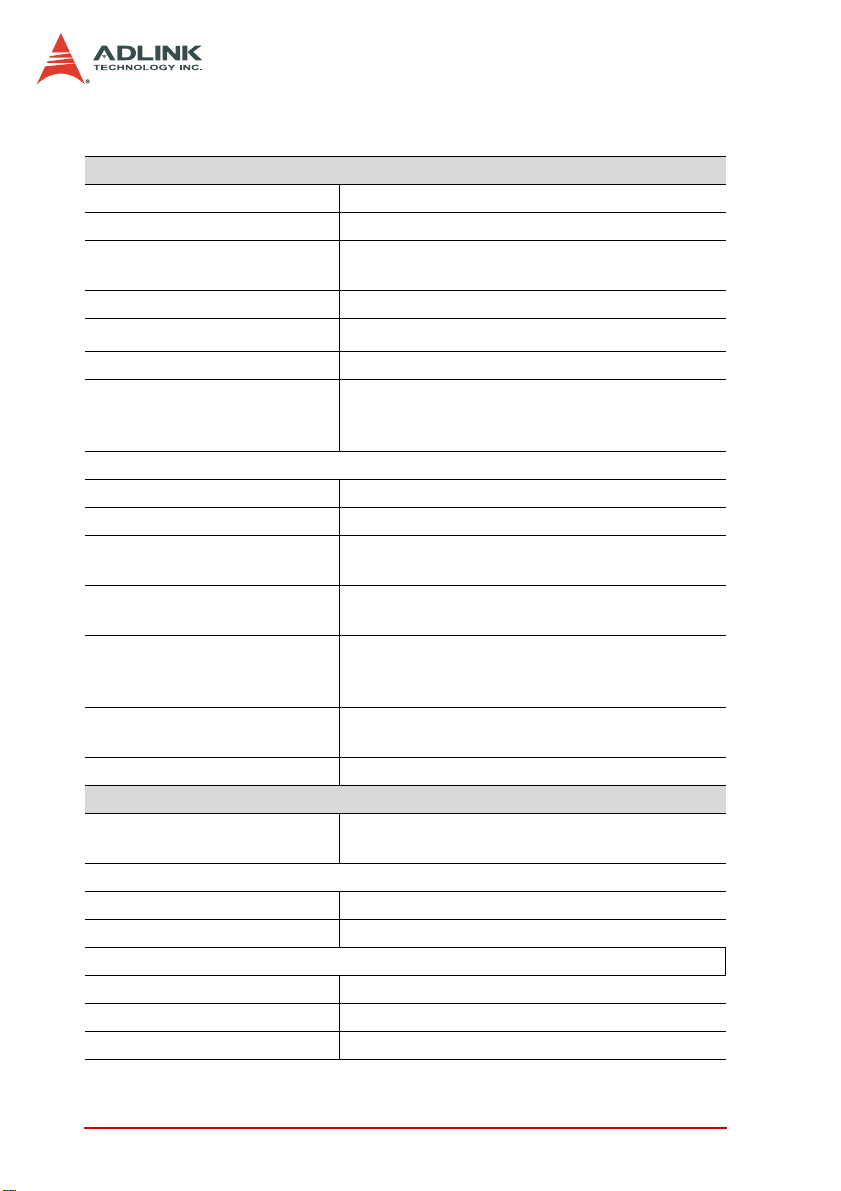

1.3 Specifications

Analog Input (AI)

Converters B.B. ADS800 series

Input Channels Four single-ended

Resolution 12-bit (PCI-9812)

10-bit (PCI-9810)

Over Voltage Protection Bipolar ±1 V, or ±5 V by soldering selection

1

Maximum Sampling Rate

Accuracy Gain error ±1.5% at 25°C

Input Impedance (soldering

selectable)

Dynamic Characteristic

Differential Linearity Error ±0.4 LSB (Typ.) ±1.0 LSB (Max.) at 25°C

Integral Linearity Error ±1.9 LSB at 25°C

A/D Clock Sources Internal clock, continuous external digital clock,

Input Impedance of External

Clock Source

Trigger Sources Software, analog threshold comparator using

Trigger Modes Software-trigger, pre-trigger, post-trigger,

AD Data Transfer Method DMA (bus mastering)

Digital Input (DI)

Channels Three TTL compatible inputs with 10 KW pull

Input Voltage

Low Min. 0 V, Max. 0.8 V

High Min. +2.0 V, Max. 5.5 V

Input Load

Low ±1 uA 0 V

High +2.7V min. 20 mA max.

20 MHz samples/second

50 Ω (±1 V and ±5 V)

1.25 KΩ (±5 V only)

5 MΩ (±1 V only)

and continuous external sine wave

50 Ω

internal D/A to set trigger level, and external

digital trigger

middle-trigger, and delay-trigger

down resistor

0.5 mA 5V

2Introduction

Page 15

General Specifications

Connectors 5 BNC-type, one 10-pin header

Operating Temperature 0°C to 40°C

Storage Temperature -20°C to 80°C

Humidity 5% to 85%, non-condensing

Power Consumption +5 V 2.5 A (maximum)

Dimension 101 mm (H) X 173 mm (L)

1

With a single channel enabled, the maximum sampling rate is 20 MHz. With

two channels enabled, the 20 MHz sampling rate may only be reached when

the number of samples accessed for each channel is smaller than 16K. With

four channels enabled, the 20 MHz sampling rate may only be reached when

the number of samples accessed for each channel is smaller than 8K. Refer

to section 5.5 for more information on sampling rates and data length limitations.

Introduction 3

Page 16

1.4 Unpacking Checklist

Before unpacking, check the shipping carton for any damage. If

the shipping carton and/or contents are damaged, inform your

dealer immediately. Retain the shipping carton and packing materials for inspection. Obtain authorization from your dealer before

returning any product to ADLINK.

Check if the following items are included in the package.

X PCI-9812/9810 multi-function DAQ card

X Five BNC terminators

X ADLINK All-in-One CD

X User’s Manual

X Software Installation Guide

If any of the items is damaged or missing, contact your dealer

immediately.

CAUTION The card must be protected from static discharge and

physical shock. Neve r r emove any of the socketed parts

except at a static-free workstation. Use the anti-static bag

shipped with the product to handle the card. Wear a

grounded wrist strap when servicing.

4Introduction

Page 17

1.5 Software Support

Software Support

ADLINK provides versatile software drivers and packages to suit

various user approach to building a system. Aside from programming libraries, such as DLLs, for most Windows-based systems,

ADLINK also provides drivers for other application environment

such as LabVIEW

™

trol

, and ISaGRAFTMLabVIEW®.

All software options are included in the ADLINK All-in-One CD.

Commercial software drivers are protected with licensing codes.

Without the code, you may install and run the demo version for

trial/demonstration purposes only up to two hours. Contact your

ADLINK dealers if you want to purchase the software license.

Programming Libraries

For customers who want to write their own programs, ADLINK provides the following function libraries which are compatible with various operating systems.

DOS Library

Borland C/C++ and Microsoft C++, the functions descriptions

are included in this user’s guide.

Windows 95 DLL

For VB, VC++, Delphi, and BC5 the functions descriptions are

included in this user’s guide.

®

, HP VEETM, DASYLabTM, InTouch™, InCon-

PCIS-DASK

The PCIS-DASK includes device drivers and DLL for Windows

98/NT/2000. DLL is binary compatible across Windows 98/NT/

2000. This means all applications developed with PCIS-DASK

are compatible with these Windows operating systems. The

developing environment may be VB, VC++, Delphi, BC5, or

any Windows programming language that allows calls to a

DLL. The PCIS-DASK user's and function reference manuals

are in the ADLINK All-in-One CD. (\\Manual_PDF\Software

\PCIS-DASK).

Introduction 5

Page 18

PCIS-DASK/X

Include device drivers and shared library for Linux. The

developing environment can be Gnu C/C++ or any

programming language that allows linking to a shared library.

The user's guide and function reference manual of PCISDASK/X are in the CD. (\Manual_PDF\Software\PCIS-DASKX).

These software drivers are shipped with the card. Refer to the

Software Installation Guide for details.

Drivers for Third-Party Programming Languages

PCIS-LVIEW: LabVIEW® Driver

The PCIS-LVIEW contains virtual instruments (VIs) which are

used to interface with the LabVIEW software package. PCISLVIEW supports Windows 95/98/NT/2000. The LabVIEW

driver is shipped free with the card. These may be installed and

used without a license. For more information on PCIS-LVIEW,

refer to the user’s guide in the All-in-One CD

(\\Manual_PDF\Software\PCIS-LVIEW).

PCIS-VEE: HP-VEE Driver

The PCIS-VEE includes user objects that interface with HP

VEE software package. The PCIS-VEE supports Windows 95/

98/NT. The HP-VEE drivers are shipped free with the card.

These may be installed and used without license. For more

information on PCIS-VEE, refer to the user’s guide in the All-inOne CD (\\Manual_PDF\Software\PCIS-VEE).

DAQBench

For customers who are familiar with ActiveX controls and VB/

VC++ programming, it is recommended to use the DAQBench

ActiveX Control components library for developing applications. DAQBench is designed for Windows NT/98. For more

information on DAQBench, ref er to the user ’s guide in the Allin-One CD (\\Manual_PDF\Software\DAQBench\DAQBench

Manual.PDF).

™

: ActiveX Controls

6Introduction

Page 19

DASYLab™ PRO

DASYLab is an easy-to-use software package that provides

easy-setup instrument functions such as FFT analysis. Contact

ADLINK for DASYLab PRO support, including DASYLab and

ADLINK hardware drivers.

Introduction 7

Page 20

8Introduction

Page 21

2 Hardware Information

This chapter describes the PCI-9812/9810 layout, connectors,

signal connection with external devices, and switch settings for

various applications.

2.1 Layout

Hardware Information 9

Page 22

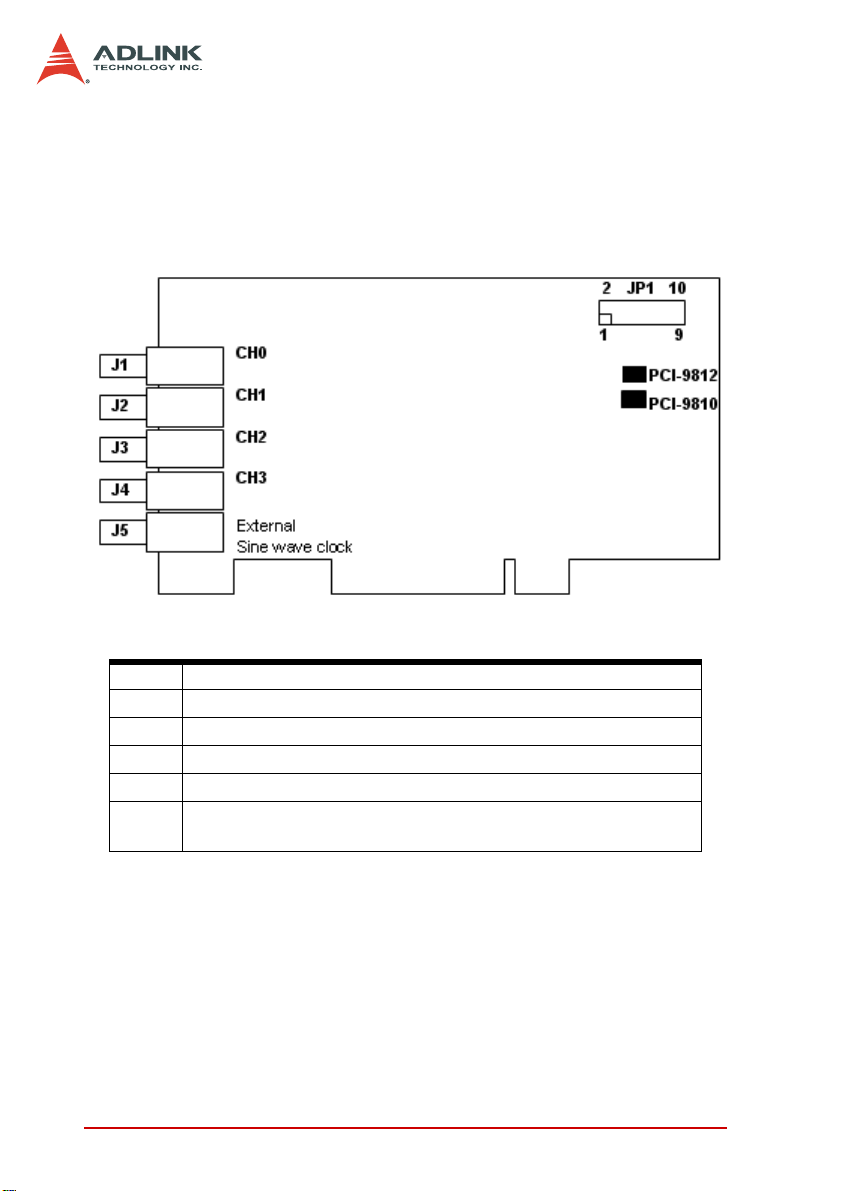

2.2 Connectors

The PCI-9812/9810 connects to external devices via five BNC

connectors and one 10-pin dual-in -line header. Figure 2-1 show s

the location of these connectors.

Figure 2-1: Location of Connectors

J1 Input signal of channel 0 A/D converter.

J2 Input signal of channel 1 A/D converter.

J3 Input signal of channel 2 A/D converter.

J4 Input signal of channel 3 A/D converter.

J5 Input signal of external clock 0.

This 10-pin connector is for digital input signal, including a

JP1

digital clock, a digital trigger, and three digital inputs.

10 Hardware Information

Page 23

JP1 Pin Definition

Below is the default JP1 pin assignment.

Pin Signal

1 External Clock Input 1

2 Ground

3 External Digital Trigger Input

4 Ground

5 Digital Input 0

6 Ground

7 Digital Input 1

8 Ground

9 Digital Input 2

10 Ground

Table 2-1: JP1 Pin Definition

When JP1 is connected to a 9-pin D-type connector using a ribbon

cable, the pin-out of the D-type connector is changed to:

Pin Signal

1 External Clock Input 1

2Ground

3 External Digital Trigger Input

4Ground

5 Digital Input 0

6Ground

7 Digital Input 1

8Ground

9 Digital Input 2

10 N/A

Table 2-2: JP1 Pin Definition Connected to 9-pin D-type Connector

Hardware Information 11

Page 24

2.3 Input Settings

This section describes the characteristics and settings of the PCI9812/9810 inputs.

Analog Input

The PCI-9812/9810 has four analog input channels which are

connected through the J1 to J4 connectors. The input impedance

and input amplitude range can be changed through soldering the

gap switches on the board (refer to PCI-9812/9810 layout). A

solder gap switch consists of two copper pads. The switch can be

turned on by soldering the copper pads. As all four channels use

the same method to configure their input characteristics, only

channel 0 is discussed here. There are two solder gap switches

labeled as C0LO (channel 0 low impedance) and C05V (channe l 0

5 V input) to setup the input of channel 0. Refer to Figure 2-1.

C0LO C05V Input Impe da n ce Input Range

Open Open High (~15 MΩ)

Open Close 1.25 KΩ

Close Open Low (50 Ω)

Close Close Low (50 Ω)

Table 2-3: Analog Input

12 Hardware Information

±1 V

±5 V

±1 V (default)

±5 V

Page 25

CAUTION DO NOT leave the input connector unconnected when it

is configured as high impedance input. The input connector must be connected to a low impedance signal source

to provide a return path for the input bias current. Since

the OPAMP has a maximum input bias current of 35 µA

in the input stage, it will be placed in an abnormal environment when the input is left unconnected and will lead

to saturation in the output stage. Although a curren t-limiting resistor is present to protect the ADC, the large current brought by the saturation will damage the ADC.

Offset problems will occur if you use high impedance

(~15 MΩ) with signal sources having high output impedance. The high output impedance and the input bias current of up to 35 µA introduces a voltage drop of several

volts. Adjusting the variable resistor does not eliminate

this large offset voltage.

NOTE 75 Ω input impedance can be achieved by: (1) replacing

R95 with a 75-ohm resistor and close C0LO or (2) placing

a T-connector with a 75-ohm terminator on J1 and open

C0LO.

The corresponding switches and resistors of other channels are

listed below:

Channel Switches Resistor

Channel 0 C0LO C05V R95

Channel 1 C1LO C15V R96

Channel 2 C2LO C25V R97

Channel 3 C3LO C35V R98

Table 2-4: Switches and Resistors

Hardware Information 13

Page 26

External Clock 0

The external clock 0 (J5) is a sine wave signal that is converted to

a TTL signal inside the PCI-9812/9810. This signal is AC coupled.

The input impedance of external clock 0 is 50 Ω and the input l evel

is 2 V peak-to-peak.

Note that the external clock frequency is the system clock. The

maximum A/D clock frequency is half of the system clock. When

using the external sine clock for PCI-9812, take note that the

frequency of the sine clock must be above 300 KHz. Otherwise the

sine clock will be converted into a digital clock with a long rise

time. When the rise time of a clock signal is too long, the CPLD

may not work as specified and the real sample clock fed into the

ADC will not be continuous. This explains why users will see a

different sampled waveform when using a slo we r s ine wa ve clock.

If slower sampling rate is necessar y when using PCI-9812/9810,

you could feed a sine wave clock that has the frequency higher

than 300 KHz, and use the clock divisor to obtain a slower

sampling rate.

External Clock 1

The external clock 1 (JP1 pin 1) is a digital clock. The input

impedance is 50 Ω and the input level into the 50 ohm-load should

be between 2.4 V and 5 V. This signal is DC coupled.

Digital Input

The PCI-9812/9810 has four digital inputs: an external digital

trigger (JP1 pin3) and three general-purpose digital inputs (JP1

pin 5, 7, and 9). These inputs are TTL-compatible with 10 KΩ pulldown resistors.

The PCI-9812/9810 also performs an automatic configuration of

the IRQ and I/O port address. There is no need to set any

configuration, as you would use in an ISA form factor DAQ card.

For system reliability, it is necessary to manually assign some

critical settings for analog input/output as these settings will not be

changed after your data acquisition system configuration is

decided. The software package cannot change this configuration

when the system is running.

14 Hardware Information

Page 27

3 Installation

3.1 Before You Proceed

The PCI-9812/9810 card has electrostatic sensitive components

that can be easily damaged by static electricity. The card must be

handled on a grounded anti-static mat. The operator must wear an

anti-static wristband, grounded at the same point as the anti-static

mat.

Inspect the card module carton for damages. Shipping and handling could cause damage to the module. Make sure that the card

has no damage before installing.

After opening the card packaging, get the module an d place it on a

grounded anti-static surface with component side up, then carefully inspect the module for any damage. Press down all socketed

IC's to make sure that they are properly seated. Do this only with

the module placed on a firm flat surface.

WARNING Do not attempt to install a damaged board into the com-

puter.

3.2 Installing the Card

1. Turn off the system/chassis and disconnect the power

plug from the power source.

2. Remove the system/chassis cover.

3. Select the PCI slot that you intend to use, then remove

the bracket opposite the slot, if any. The selected slot

must provide bus-mastering capability.

4. Align the card connectors (golden fingers) with the slot,

then press the card firmly until the card is completely

seated on the slot.

5. Secure the card to the chassis with a screw.

6. Replace the system/chassis cover.

7. Connect the power plug to a power source, then turn on

the system/chassis.

Installation 15

Page 28

3.3 Configuring the Card

As a plug and play component, the card requests an interrupt

number through its PCI controller. The system BIOS responds

with an interrupt assignment based on the card information and o n

known system parameters. These syst em parameters are determined by the installed drivers and the hardware load detected by

the system.

Troubleshooting

If your system fails to boot or if you experience erratic operation

with your PCI board in place, this is likely caused by an interrupt

conflict (i.e. the BIOS Setup is incorrectly configured). Refer to the

BIOS documentation that came with the system for details.

3.4 Installing the Drivers for Windows

The Plug and Play function of Windows 95/98/2000 automatically

detects the newly installed card. If this is the first time you installed

the card in the system, you will be prompted to search for the

device information source. Refer to the Software Installation Guide

for instructions on how to install the device drivers.

16 Installation

Page 29

4Registers

Descriptions of the register format and structure of the PCI-9812/

9810 are specified in this chapter. This information is for programmers that want to handle the card using low-level programming.

4.1 I/O Port Address

The PCI-9812/9810 functions as a 32-bit PCI target device to any

master on the PCI bus. It supports burst transfer to memory sp a ce

by using 32-bit data — where both data read and write are based

on 32-bit data transfer. Table 4-1 lists the I/O address of each register according to the base address and the register function.

I/O Address Read Write

Base + 0 — ADC Channel Enable Register

Base + 4 — ADC Clock Divisor Register

Base + 8 — Trigger Mode Register

Base + C — Trigger Level Register

Base + 10 — Trigger Source Register

Base + 14 — Post Trigger Counter Register

Base + 18 FIFO Control & Status Reg FIFO Control & Status Register

Base + 1C — Acquisition Enable Register

Base + 20 — Clock Source Register

T able 4-1: I/O Address

Registers 17

Page 30

ADC Channel Enable Register

The PCI-9812/9810 has four analog input channels: CH0, CH1,

CH2, and CH3. CH0 to CH3 may be enabled or disabled by bit 0

to bit 3 of the ADC channel enable register.

Address: BASE + 0

Attribute: Write only

Data Format:

Bit 7 6 5 4 3 2 1 0

BASE+0————

BASE+1————————

BASE+2————————

BASE+3————————

Bit 31->4 Any value

Bit 3 CH3EN

Bit 2 CH2EN

Bit 1 CH1EN

Bit 0 CH0EN

Allowed combinations (refer to section 5.5) of these bits include:

0000 No channel is enabled.

0001 Only CH0 is enabled.

0011 CH0 and CH1 are enabled.

1 111 All channels are enabled.

CH3EN CH2EN CH1EN CH0EN

18 Registers

Page 31

ADC Clock Divisor Register

Feeding the ADC source clock to a clock frequency divider generates the ADC sampling clock. Th e ou tput of the freq uency div ider

becomes the sampling clock. The frequency of the ADC sampling

clock is:

Frequency of source clock / ADC clock divisor

Address: BASE+04h

Attribute: Write only

Data Format:

Bit 7 6 5 4 3 2 1 0

Base+4 DIV7 DIV6 DIV5 DIV4 DIV3 DIV2 DIV1 DIV0

Base+5 DIV15 DIV14 DIV13 DIV12 DIV11 DIV10 DIV9 DIV8

Base+6————————

Base+7————————

DIV15...0 AD clock frequency devisor.

— Any value

NOTE The minimum value of this register is 2, and the DIV0 is

hardwired to 0.

Registers 19

Page 32

Trigger Mode Register

The PCI-9812/9810 has five trigger modes: software trigger, post

trigger, pre-trigger, middle trigger and delay trigger. The trigger

mode register is used to specify which trigger mode is currently

used.

Address: BASE + 08h

Attribute: write only

Data Format:

Bit 7 6 5 4 3 2 1 0

Base + 8—————

Base + 9————— — — —

Base + A————— — — —

Base + B————— — — —

TRGMOD2...0 Trigger mode. See trigger mode table below.

— Any value

TRGMOD2 TRGMOD1 TRGMOD0 Trigger Mode

0 0 0 Software trigger

0 0 1 Post trigger

0 1 0 Pre-trigger

0 1 1 Delay trigger

1 0 0 Middle trigger

Table 4-2: Five Trigger Modes

TRGMOD2 TRGMOD1 TRGMOD0

NOTE All other values for this register is not allowed. The card

will fail to acquire data if you set an unsupported value to

this register.

20 Registers

Page 33

Trigger Level Register

The trigger condition of the PCI-9812/9810 includes a trigger level

and a trigger slope. This register sets the trigger level and the

trigger source register described in the next section, and sets the

trigger slope.

Address: BASE + 0ch

Attribute: Write only

Data Format:

Bit 7 6 5 4 3 2 1 0

BASE+Ch TRGLVL7 TRGLVL6 TRGLVL5 TRGLVL4 TRGLVL3 TRGLVL2 TRGLVL1 TRGLVL0

BASE+Dh — — — — — — — —

BASE+Eh — — — — — — — —

BASE+Fh — — — — — — — —

TRGLVL7...0 Trigger level

— Any value

Relationship between the 8-bit trigger level and the trigger volt age:

TRGLVL7..0(bit 7..0)

0xFF 0.992 V 4.96 V

0xFE 0.984 V 4.92 V

|||

0x81 0.008 V 0.04 V

0x80 0.000 V 0.00 V

0x7F -0.008 V -0.04 V

|||

0x01 -0.992 V -4.96 V

0x00 -1.000 V -5.00 V

Registers 21

Trigger voltage(±1 V) Trigger voltage(±5 V)

Page 34

Trigger Source Register

The PCI-9812/9810 supports five trigger sources: CH0, CH1,

CH2, CH3, and external digital trigger.

Address: BASE + 10h

Attribute: Write only

Data Format:

Bit 7 6 5 4 3 2 1 0

Base + 10 -- -- -- -- TRGSLP TRGSRC2 TRGSRC1 TRGSRC0

Base + 11 -- -- -- -- — — — —

Base + 12 -- -- -- -- — — — —

Base + 13 -- -- -- -- — — — —

TRGSLP Trigger slope

0: Positive slope trigger

1: Negative slope trigger

TRGSRC2 > TRGSRC0 Trigger source

TRIGSRC2 TRIGSRC2 TRIGSRC2 Trigger source

00 0 CH0

00 1 CH1

01 0 CH2

01 1 CH3

1 X X EX_DIG_trigger

When the external digital trigger is selected, the positive slope

trigger equals to the rising edge trigger, the negative slope trigger

equals to the falling edge trigger, and the value of trigger level

register becomes meaningless.

22 Registers

Page 35

Post Trigger Counter Register

The post trigger counter is a 16-bit down counter. The counter is

pre-loaded with the value in the post trigger counter register and

will count down on the rising edge of ADC sampling clock after the

trigger condition is met. When the count reaches 0, the counter

stops. The counter is used to control the delay time in delay trigger

mode and to control the post trigger sampling count in middle

trigger mode.

Address: BASE + 14h

Attribute: write only

Data Format:

Bit 7 6 5 4 3 2 1 0

BASE+Ch PSTCN 7 PSTCN 6 PSTCN 5 PSTCN 4 PSTCN 3 PSTCN 2 PSTCN 1 PSTCN0

BASE+Dh PSTCN15 PSTCN14 PSTCN13 PSTCN12 PSTCN11 PSTCN10 PSTCN9 PSTCN8

BASE+Eh — — — — — — — —

BASE+Fh — — — — — — — —

PSTCNT15...0 This value is pre-loaded to the post trigger counter when

the post trigger counter register is written.

— Any value

Registers 23

Page 36

FIFO Status Register

Monitors some of the PCI-9812/9810 status.

Address: BASE + 18h

Attribute: Read

Data Format:

Bit 7 6 5 4 3 2 1 0

BASE+18h — — ACQ TD PTCO FIFOOR FIFOHF FIFOIR

BASE+19h — — — — — — — —

BASE+1Ah — — — — — — — —

BASE+1Bh — — — — — — — —

Bit 0 FIFOIR, FIFO input ready flag.

0: FIFO is not ready for input; FIFO is full.

1: FIFO is ready for input (not full).

Bit 1 FIFOHF, FIFO half full flag.

0: FIFO is not half-full yet.

1: FIFO is at least half-full.

Bit 2 FIFOOR, FIFO output ready flag

0: FIFO is not ready for output; FIFO is empty.

1: FIFO is ready for output (not empty).

Bit 3 PTC0, post trigger counter is 0

0: Post trigger counter is not 0.

1: Post trigger counter reached 0.

Bit 4 TD, trigger detection flag

0: No trigger condition has been met; no trigger is detected.

1: Trigger is detected.

Bit 5 ACQ, acquisition flag

0: Card is not acquiring data. Card maybe disabled or is waiting

for a trigger.

1: Card is acquiring data.

Bit 6..31 Any value

24 Registers

Page 37

FIFO Control Register

Controls the onboard FIFO memory.

Address: BASE + 18h

Attribute: Write

Data Format:

Bit 7 6 5 4 3 2 1 0

BASE+18h — — — — — — CLRTRG CLRFIFO

BASE+19h — — — — — — — —

BASE+1Ah — — — — — — — —

BASE+1Bh — — — — — — — —

Bit 0 CLRFIFO, clear the onboard FIFO

When a “1” is written to this bit, the entire onboard FIFO is

cleared.

Bit 1 CLRTRG, clear trigger detection flag

When a “1” is written to this bit, the trigger detection bit is

cleared.

Bit 2..31 Any value

Registers 25

Page 38

Acquisition Enable Register

Enables or disables the ADC acquisition.

Address: BASE + 1ch

Attribute: Write only

Data Format:

Bit 7 6 5 4 3 2 1 0

BASE+18h ———————ACQEN

BASE+19h ——————— —

BASE+1Ah ——————— —

BASE+1Bh ——————— —

Bit 31...1 No value

Bit 0 ACQEN, acquisition enable

When a “1” is written to this bit, the PCI-9812/9810 is ready to

sample data. When a “0” is written, the PCI-9812/9810 is

disabled.

26 Registers

Page 39

Clock Source Register

Selects the system clock source.

Address: BASE + 20h

Attribute: Write only

Data Format:

Bit 7 6 5 4 3 2 1 0

BASE+18h — — — — — CLKSRC1 CLKSRC0 Freq_Sel

BASE+19h — — — — — — — —

BASE+1Ah — — — — — — — —

BASE+1Bh — — — — — — — —

Bit 31...3 Any value

Bit 2...1 CLKSRC1...0, ADC clock source

Bit 0 Freq_Sel: Frequency selection. Values include:

1: Frequency of A/D clock source is higher than the PCI clock

frequency (33 MHz)

0: Frequency of A/D clock source is lower than the PCI clock

frequency (33 MHz)

CLKSRC2 CLKSRC1 Selected clock source

0 0 Internal clock (40 MHz)

0 1 External sine wave clock

1 0 External digital clock

1 1 Illegal

NOTE When selected, the external clock is divided by the fre-

quency divider as mentioned. Thus, the frequency of the

external clock should be at least twice as the desired

sampling frequency.

Registers 27

Page 40

4.2 High Level Programming

The PCI-9812/9810 card can be controlled directly using highlevel Application Programming Interface (API) that bypasses the

detailed register structures. The software libraries, including DOS

for Borland C++ and DLL driver for Windows 95 are included in the

ADLINK All-in-One CD. For further information, refer to Chapter 6.

4.3 Low Level Programming

You are not required to write any hardware dependent low-level

programs to operate the PCI-98 12/9810 card. Since this process

is more complex and the relevant information are not described in

this manual, ADLINK does not recommend low-level application

programming. The PCI-9812 uses the AMCC-S5933 PCI

controller. For more information on the s5933 PCI controller, visit

www.amcc.com.

28 Registers

Page 41

5 Operation Theory

The operation theorem of the PCI-9812/9810 card functions is

described in this chapter. These functions include A/D conversion

and digital input. This section aims to assist you in understanding,

operating, and programming the PCI-9812/9810.

5.1 Conversion Procedure

Before programming the PCI-9812/9810 to perform A/D

conversions, you must first understand the following concepts:

X A/D signal source control

When using an A/D converter, you must be familiar with the

properties of the signal to be measured, and you must decide

which channels to use and connect the signals to the PCI9812/9810 card. In addition, you must define and control the A/

D signal sources, including the A/D channe ls, A/D gains, and

A/D signal types. Refer to section 5.2 for A/D signal source

control.

X A/D trigger source control

After identifying the A/D signal source, you must decide how to

trigger the A/D conversion and define or control the trigger

source. The A/D converter will start to convert the signal to a

digital value when a trigger condition is met. Refer to section

5.3.

X A/D clock control

The A/D clock is controlled by an internal or external clock

source. The operation of the A/D clock source is described in

section 5.4.

Operation Theory 29

Page 42

X A/D data transfer mode

In the end of an A/D conver sion, the A/D data is buffered in a

FIFO. The total FIFO size on PCI-9812/9810 is 32K samples.

This buffer size is relative to the highest data transfer rate. The

A/D data should be transferred to the computer’s memory for

further processing. The cards use DMA to transfer the A/D data

to host memory. Refer to section 5.5.

X A/D data format

To process the A/D data, programmers must be familiar with

the A/D data format. Refer to section 5.6.

30 Operation Theory

Page 43

5.2 Signal Source Control

To control the A/D signal source, the signal type, signal channel,

and signal range must be determined.

Signal Type

The A/D signal sources of PCI-9812/9810 are single-ended (SE).

Channels

There are four channels for SE mode. The ADC Channel Enable

Register controls the channel number. Refer to section 4.1.

Signal Range and Input impedance

The proper signal range is important for data acquisition. The

available signal input ranges for the PCI-9812/9810 are

V, which are set by soldering the copp er pads on the PCB. The

input impedance for high-speed applications should also be

considered. The selectable input impedance values are 50 Ω, 1.25

K, 15 MΩ. Refer to section 2.3 for details.

±5 V or ±1

Operation Theory 31

Page 44

5.3 Trigger Source Control

When performing trigger acquisition in the PCI-9812/9810, the

following parameters have to be specified before DMA operation

starts:

X Clock source. Refer to section 5.4

X Clock rate. Refer to section 5.4

X Trigger sources. Refer to next section.

X Trigger level. The trigger eve nt occurs when the trig ger sig-

nal crosses the specified trigger voltage. Refer to Trigger

Level Register section for the relationship between the 8-bit

trigger level and the trigger voltage.

The trigger is detected while the trigger event occ ur s. F or

post-trigger and middle-trigger, the data acquisition is performed after the trigger event. However, the time that the

AD conversion starts is 350 ns slower than the trigger

detection time. This 350 ns delay has some minor effect to

high-speed data acquisition.

X Trigger polarity. Trigger slope with a 0 value indicates a

positive trigger while a 1 value indicates a negative trigger.

Trigger Sources

X Internal trigger

This is a software trigger. The trigger event occurs when you

call _9812_AD_DMA_Start( ) function to start the operation.

X External analog trigger

You can use the signal on any analog input channel (CH0,

CH1, CH2, or CH3) as the trigger signal for external analog

trigger. Be low are two conditions for analog triggers.

Z Positive-slope trigger

The trigger event occurs the first time the trigger signal (analog

input signal) changes from a voltage that is lower than the

32 Operation Theory

Page 45

specified trigger level to a voltage that is higher than the specified trigger level.

Z Negative-slope trigger

The trigger event occurs the first time the trigger signal (analog

input signal) changes from a voltage that is higher than the

specified trigger level to a voltage that is lower than the

specified trigger level.

Z External Digital Trigger

An external digital trigger occurs when a rising edge or a falling

edge is detected on the digital signal connected to pin3 of JP1

for external digital trigger.

X Simultaneous trigger for multiple cards

When multiple PCI-9812/9810 cards are installed in a single

system, the trigger sources of each card may be connected

together to achieve simultaneous trigger. Note that simultaneous trigger is not equivalent to simultaneous A/D conversion.

The theoretical time difference between the samples on two

different cards will be ½ of the clock period. Refer to section 5 .4

for more information on A/D conversion clock control.

Operation Theory 33

Page 46

Trigger Modes

X Software-trigger acquisition

This trigger mode does not require any external trigger source.

The trigger event occurs when the _9812_AD_DMA_Start( )

function is called to start the operation.

X Post-trigger acquisition

Use post-trigger for applications where data needs to be

collected after a specified trigger event. The trigger can either

be an external analog trigger or digital trigger.

Figure 5-1: Post-trigger Acquisition

X Pre-trigger acquisition

Use pre-trigger to collect data before a specified trigger event.

The trigger can either be an external analog trigger or digital

trigger. Data acquisition starts when DMA operation starts. The

operation stops when the external trigger event occurs. If the

external trigger occurs before the specified count of data is

read (Specified by the _9812_AD_DMA_Start( ) function.

Refer to section 6.2), the amount of retrieved data would be

less than the specified count. However, if the external trigger

occurs after the specified count of data is read, the application

only samples the specified count of data.

Figure 5-2: Pre-trigger Acquisition

34 Operation Theory

Page 47

X Middle-trigger acquisition

Use middle-trigger acquisition to collect data before and after a

specified trigger event. The amount of data acquired before a

trigger event occurs when using middle trigger may not equal

to the specified count of data, just like the pre-trigger mode.

Figure 5-3: Middle-trigger Acquisition

The desired number of samples after trigger event is preloaded in post trigger counter register and will count down on

the rising edge of ADC sampling clock after the trigger

condition is met. When the count reaches 0, the counter stops.

The trigger can either be an external analog trigger or digital

trigger.

X Delay-trigger acquisition

Use delay trigger acquisition to delay the data collection after

the specified trigger event occurs. The delay time is controlled

by the value that is pre-loaded in the post trigger counter

register. The counter then counts down on the rising edge of

ADC sampling clock after the trigger condition was met.

When the count reaches 0, the counter stops and PCI-9812/

9810 starts to acquire data.

Figure 5-4: Delay-trigger Acquisition

Operation Theory 35

Page 48

5.4 Clock Source Control

The AD clock source determines how the board regulates the

timing of conversions when acquiring multiple samples from a

single-channel or from a group of multiple channels. The A/D clock

sources on the PCI-9812/9810 must use a pacer clock, but not

single-shot as the A/D converters are in a pipelined structure, that

require eight conversion clocks to complete the conversion of

digital data.

A/D Clock Sources

The A/D converters operate under the paced mode, which uses

pacer clock for A/D conversion at a fixed rate. PCI-9812/9810

supports three clock sources for analog input conversion

X Internal Pacer Clock (default)

An onboard timer/counter is used as the internal A/D pacer

clock. The frequency of the pacer is software-controllable. The

maximum pacer signal rate is 40 MHz / 2 = 20 MHz, which is

also the maximum sampling rate of PCI-9812/9810. Note that

40 MHz is the onboard clock. Feeding the clock source into a

frequency divider generates the ADC sampling frequency. The

following formula determines the ADC sampling frequency:

Sampling Rate = Frequency of Source Clock / ADC

Clock Divisor

NOTE The ADC Clock Divisor must be 2, 4, 6, 8,…65534 (max).

X External Pacer Clock

You can connect an external pacer clock to the EXTCLK1 (pin

1) on JP1 (for square wave) or Ext. Sine wave clock (for sine

wave). Since you can handle the external signal with outside

devices, the conversion rate of this mode is more flexible than

the previous mode. When the external clock is selected, the

frequency divider as mentioned also divides this external clock.

Therefore the frequency of the external clock sh ould be a t least

twice the sampling frequency. The formula is shown below:

Sampling Rate = Frequency of Source Clock / ADC

Clock Divisor

36 Operation Theory

Page 49

NOTE The clock divider must be an even number (2, 4, 6, 8,

10… 65534), with the minimum divider value being 2. Refer to section 6.2 to set the clock source and frequency divider.

The first AD sample takes several clocks to convert because of the ADC’s pipelined architecture. Therefore, the

external clock must be continuous for correct AD operation.

X Multiple cards operation

When multiple cards are installed in a single system, 4-channels on one card can achieve simultaneous conversion since

they have the same internal clock source. However, the channels between two cards cannot be synchronized because the

clock sources on different cards come from different sources.

Even when the same external clock source is applied to all

cards, the A/D conversion time is still possibly asynchronous

because an onboard clock divider (divisible by 2) is used.

Therefore, when the same exte rnal clock source is applied to

multiple cards, the time difference of the sampling clocks

between two cards will be half of the sampling clock period.

The A/D clock cannot synchronize multiple cards.

Operation Theory 37

Page 50

5.5 Data Transfer

Data Transfer

There are several function blocks on the PCI-9812/9810 designed

to acquire AD data. Even as the maximum sampling rate is

specified at up to 20 MHz, there are certain limitations due to the

high total data throughput. Refer to the data transfer diagram

below to understand how analog signal is converted to di gital form

and transferred to the host computer’s memory. The data transfer

rate limitation and bottleneck are discussed in this section.

Figure 5-5: Data Transfer Diagram of PCI-9812/9810

Simultaneous Sampling of Four AD Channels

The PCI-9812/9810 is equipped with four AD converters that

support a maximum 20 MHz simultaneous sampling rate.

For single-channel applications, only channel 0 can be selected

with a total FIFO length of 32K samples. For simultaneous twochannel applications, use channel 0 and channel 1 to optimize

FIFO usage. The onboard circuit does not allow use of channel 0

and 2 or channel 2 and 3 simultaneously. Take note that the card

only supports 2 or 4 channels for simultaneous sampling

applications.

38 Operation Theory

Page 51

Total Data Throughput

When four channels start simultaneousl y, the total data throughput

from the AD converter to the onboard FIFO memory is:

Sampling Rate x number of channels x 2 bytes/channel

Therefore, the maximum total data throughput is 160 Mbytes/sec.

160MB/s = 20MHz x 4 channels x 2 bytes/channel

This extremely high data rate is beyond the 32 -bit/33 MHz PCI bus

bandwidth. To address this two 16K words (samples) FIFO are

designed to buffer the data.

A total of 32K word (32K samples) is used when FIFO is onboard.

When four channels are used, the FIFO size is 8K samples per

channel. When two channels (#0 and #1) are used, the FIFO size

is 16K samples per channel. When only one (#0) is used, the FIFO

size is 32K samples.

You need to calculate the total data throughput for your

applications, as this value would be relative to the tot a l data length

that can be continuously acquired.

Maximum Acquiring Data Length

The burst PCI bandwidth is 132 MB/s. However, the effective

sustained data rate is usually less than 100 MB/s. This value may

even be lower when additional PCI devices are used

simultaneously. If the total AD data throughput is lower than the

PCI bandwidth, the AD data can be stored into the host memory

through bus-mastering DMA and the total acquiring data length

could be up to 64 MB (32M samples) which is the PCI controller’s

maximum. If the total AD data throughput is higher than the PCI

bandwidth, the maximum data length will either be 16K or 8K

samples, which is the maximum length from the size of onboard

FIFO.

Operation Theory 39

Page 52

Bus-mastering Data Transfer

PCI bus-mastering DMA is necessary for high speed DAQ in order

to utilize the maximum PCI bandwidth. The bus-mastering

controller—built into the AMCC-5933 PCI controller ASIC—

controls the PCI bus when it becomes the master of the bus. Busmastering reduces the size of onboard memory and CPU loading

since data is directly transferred to the compute r’s memory without

CPU intervention.

The bus-mastering DMA provides the fastest data transfer rate on

the PCI bus. Once the analog input operation starts, control

returns to your program. The hardware temporarily stores the

acquired data into the onboard A/D FIFO and transfers the data to

a user-defined DMA buffer memory in the computer.

NOTE Even when the acquired data length is less than the

As DMA transfer mode is very complex to program, ADLINK

recommends using a high-level program library to control th e card.

If you want to apply a software that can handle the DMA bus

master data transfer, visit www.amcc.com for more information on

the PCI controller.

FIFO, the AD data is directly transferred to the host memory by bus-mastering DMA.

Host Memory Operation

The DMA data transfer does not allow processing of AD data

simultaneously with the data transfer. You must process the AD

data after the completion of one DMA cycle. If the total data

throughput in your application is relatively high (>20 MB/s), the

processing time of AD data and the CPU computation power

consumption must be considered. For example, if the CPU can

only process data at a rate of 10 MB/s and you want to

continuously acquire data at the rate of 20 MB/s; the FIFO

eventually becomes full and data acquisition becomes

discontinuous.

40 Operation Theory

Page 53

Storing data from the host memory to a hard disk or other storage

devices must also be considered. The burst data rate of current

HDD technology could be between 90 and 80 MB/s. However in

reality, the effective bandwidth of a HDD is usually less than 10

MB/s, especially when the HDD seek time is longer. For example,

if the HDD seek time is 20 ms, the FIFO is already full and the

acquired data cannot be continuous.

Several limitations may be due to the OS and h ost memory size.

In DOS, the maximum allocated memory size is less than 640K,

except when you use an extended memory managing software. In

Windows 95 or Windows NT, it is relatively difficult to get a

continuously large memory size such as 64 MB. It is possible to

allocate a large memory size by keeping the memory clean. The

PCI bus-mastering DMA controller of the PCI-9812 needs

continuous memory to store the AD data.

Operation Theory 41

Page 54

5.6 Data Format

The A/D data of 12-bit PCI-9812 is on the 12 MSB of the 16-bit A/

D data. The 4 LSB of the 16-bit A/D data must be truncated by

software (Refer to section 6.2). The relationship between the real

signal voltage and the sampled value is shown below:

A/D Data

(Hex)

7FF 0 +32752 +1.0000 +5.0000

400 0 +16384 +0.5002 +2.5010

001 0 +16 +0.0005 +0.0025

000 0 0 0.0000 0.0000

FFF 0 -16 0.0005 -0.0025

C00 0 -16384 -0.5002 -2.5010

801 0 -32752 -1.0000 -5.0000

800 0 -32768 -1.0049 -5.0024

Decimal

Value

V

(-1 V to +1 V)V(-5 V to +5 V)

The A/D data of 10-bit PCI-9810 is on the 10 MSB of the A/D data.

The 6 LSB of the 16-bit A/D data must be truncated by software.

The relationship between the real signal voltage and the sampled

value is shown below:

A/D Data

(Hex)

7FC 0 +32704 +1.0000 +5.0000

400 0 +16384 +0.5002 +2.5010

0040 +64 +0.0005 +0.0025

000 0 0 0.0000 0.0000

FFC 0 -64 -0.0005 -0.0025

C00 0 -16384 -0.5002 -2.5010

804 0 -32704 -1.0000 -5.0000

800 0 -32768 -1.0020 -5.0098

Decimal

Value

V

(-1 V to +1 V)V(-5 V to +5 V)

42 Operation Theory

Page 55

The formula showing the relationship of the A/D data and the

analog value is:

Voltage = AD_data x (1/K) x (Gain)

Where Gain and K are constants.

For analog input range -1 V to 1 V, Gain=1

For analog input range -5 V to 5 V, Gain=5.

For PCI-9812, K=2047x16=32752

For PCI-9810, K=511x64=32704.

Operation Theory 43

Page 56

44 Operation Theory

Page 57

6 Function Reference

This chapter describes the software library for operating the PCI9812/9810 card. Only the functions for DOS and Windows 95 DLL

are described. Refer to the PCIS-DASK function reference manual

in the ADLINK All-in-One CD for descriptions of DLL functions for

Windows 98/NT/2000.

The function prototypes and some us eful constants are defined in

the header files LIB directory (DOS) and INCLUDE directory

(Windows 95). For Windows 95 DLL, the developing environment

can be Visual Basic 4.0 or higher, Visual C/C++ 4.0 or higher,

Borland C++ 5.0 or higher, Borland Delphi 2.x (32-bit) or higher, or

any Windows programming language that allows calls to a DLL.

6.1 Installing the Libraries

Refer to the Software Installation Guide for more information on

how to install the software libraries for DOS, Windows 95 DLL, or

PCIS-DASK for Windows 98/NT/2000.

The device drivers and DLL functions of Windows 98/NT/2000 are

included in the PCIS-DASK. Refer to the PCIS-DASK user’s guide

and function reference in the ADLINK All-in-One CD for

programming information.

Function Reference 45

Page 58

6.2 Programming Guide

Naming Convention

The functions of NuDAQ and NuIPC PCI/CompactPCI cards’ software driver use the following naming convention rules:

In DOS:

_{hardware_model}_{action_name}

For example:

_9812_Initial()

All functions in the PCI-9812 driver uses 9812 as

{hardware_model}. However, these may also be used by PCI-

9810.

To differentiate the DOS from Windows 95 libraries, a capital W is

placed in the beginning of each function name for Windows 95

DLL driver.

For example:

W_9812_Initial()

46 Function Reference

Page 59

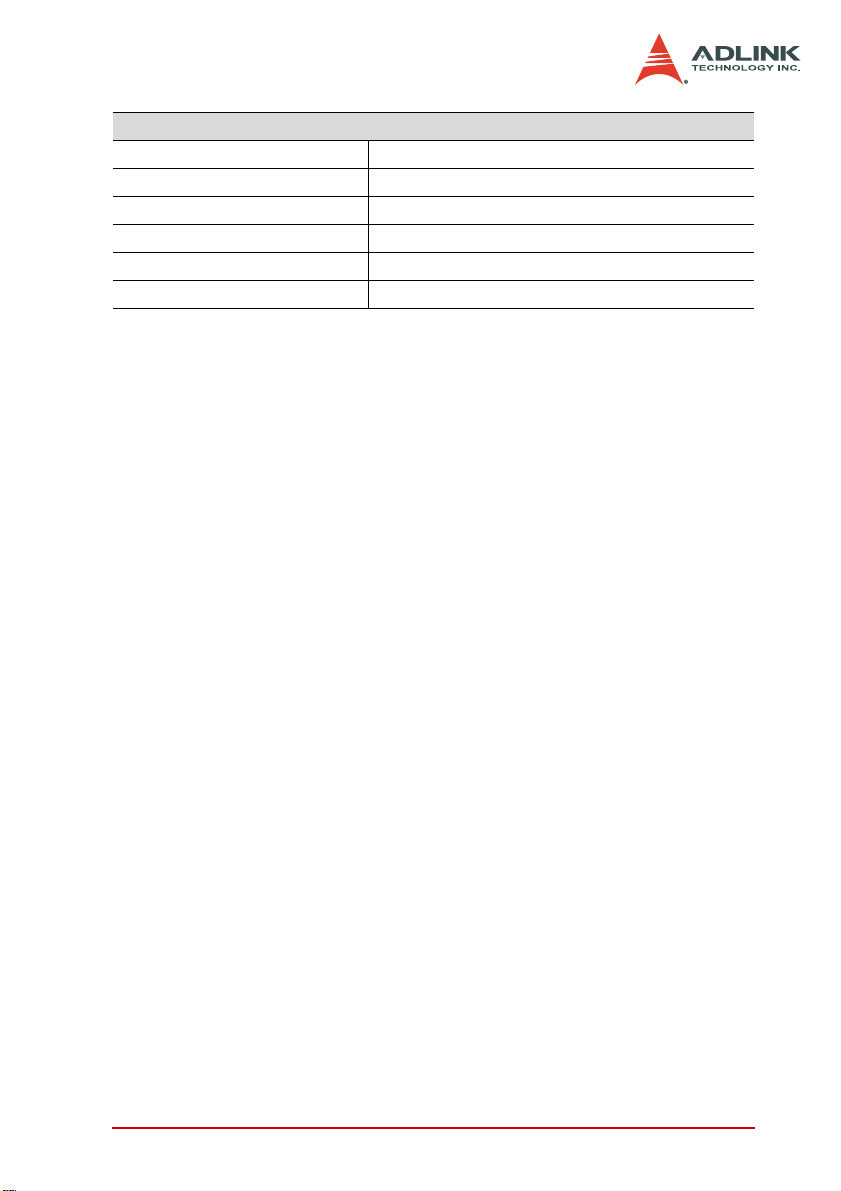

Data Types

Some data types were defined in Pci_9812.h (DOS) and Acl_pci.h

(Windows 95). These data types are used by the NuDAQ card

library. It is recommended that you use these data types for your

application programs. The following table lists the data type

names and their ranges.

Type

Name

U8

I16

U16

I32

U32

F32

F64

Boolea

n

Description Range

8-bit ASCII character 0 to 255

16-bit signed integer -32768 to 32767

16-bit unsigned integer 0 to 65535

32-bit signed integer -2147483648 to 2147483647

32-bit single-precision floating-point 0 to 4294967295

32-bit single-precision floating-point -3.402823E38 to 3.402823E38

64-bit double-precision floating-point -1.797683134862315E308 to

1.797683134862315E309

Boolean logic value TRUE, FALSE

Table 6-1: Data Types

Function Reference 47

Page 60

6.3 Function Reference

_9812_Initial

Description

Initializes the PCI-9812/9810 card. Each PCI-9812/9810 card has

to be initialized by this function before calling other functions.

Syntax

C/C++ (DOS)

int _9812_Initial (int card_number, U16

*op_base_address,U16 *pt_base_address, U16

*irq_no, U16 *pci_master)

C/C++ (Windows 95)

int W_9812_Initial (int card_number, U16

*op_base_address,U16 *pt_base_address, U16

*irq_no, U16 *pci_master)

Visual Basic (Windows 95)

W_9812_Initial (ByVal card_number As Long,

op_base_address As Integer, pt_base_address

As Integer, irq_no As Integer, pci_master As

Integer) As Long

Argument(s)

card_number Card number of the card to be initialized. Valid card

numbers are from 0 to 9.

op_base_address

Physical location of S5933 operation registers in the

I/O space.

pt_base_address

Physical location of add-on registers in the passthrough I/O space.

irq_no Interrupt IRQ level of the PCI-9812/9810 card. IRQ

value is automatically assigned by the system BIOS.

pci_master Tells whether the BIOS enabled or disabled bus

mastering in the PCI Command Register.

48 Function Reference

Page 61

Return Code(s)

PCICardNumErr

PCIBiosNotExist

PCIBaseAddrErr

NoError

Function Reference 49

Page 62

_9812_Close

Description

Closes a previously initialized 9812/9810 card.

Syntax

C/C++ (DOS)

int _9812_Close (int card_number)

C/C++ (Windows 95)

int W_9812_Close (int card_number)

Visual Basic (Windows 95)

W_9812_Close (ByVal card_number As Long) As Long

Argument(s)

card_number Card number of the card to be initialized. Valid card

numbers are from 0 to 9.

Return Code(s)

PCICardNumErr

PCICardNotInit

NoError

50 Function Reference

Page 63

_9812_AD_DMA_Start

Description

Starts an operation of A/D conversion N times with DMA data

transfer. It will take place in the background, which will not stop

until the Nth conversion has been completed or until your program

executes _9182_AD_DMA_Stop to stop the operation. After executing this function, check the status of the operation by using the

_9812_AD_DMA_Status function.

Syntax

C/C++ (DOS)

int _9812_AD_DMA_Start (int card_number, int

ch_cnt, U32 *buff, U32 count)

C/C++ (Windows 95)

int W_9812_AD_DMA_Start(int card_number, int

ch_cnt, HANDLE memID, U32 count)

Visual Basic (Windows 95)

W_9812_AD_DMA_Start (ByVal card_number As Long,

ByVal ch_cnt As Long, ByVal handle As Long,

ByVal count As Long) As Long

Argument(s)

card_number Card number of the selected card.

ch_cnt Number of A/D channel enabled. Valid values:

0 No channel is enabled.

1 Only channel 0 is enabled.

2 Channel 0 and 1 are enabled, and the sequence of

channel scan is 0, 1, 0, 1, …

4 All channels are enabled and the sequence of channel

scan is 0, 1, 2, 3, 0, 1, 2, 3, …

Function Reference 51

Page 64

buff (DOS) Start address of the memory buffer that stores the A/

D data. The buffer size must be larger than the

number of A/D conversions. This memory should be

in double-word alignment. Th e resolution o f A/D data

is 12-bit for PCI-9812 and 10-bit for PCI-9810. Refer

to section 5.6 for the A/D data format.

The buffer format is:

DATA 1 DATA 2 DATA 3 DATA 4 ............

16-bit 16-bit 16-bit 16-bit 16-bit 16-bit 16-bit

DATA

N-1

DATA N

Each 16-bit data:

D11 D10 D9 ... D1 D0 b3 b2 b1 b0

where:

D11, D10, ... , D0: A/D converted data (9812) or

D11, D10, ... , D2: A/D converted data (9810).

b2, b1, b0: Digital input data from channel DI2, DI1,

DI0.

b3: Trigger detection flag. Valid values:

0 No trigger is detected.

1 Trigger is detected.

memID (Win-95)

Memory ID of the allocated system DMA memory. In

Windows 95, before calling W_9812_AD_DMA_Start,

W_9812_Alloc_DMA_Mem must be called to allocate

a contiguous DMA memory.

W_9812_Alloc_DMA_Mem returns a memory ID for

identifying the allocated DMA memory and the linear

address of the DMA memory t o acces s the da ta. The

format of the A/D data is the same as the DOS buffer

(buff).

count Number of A/D conversion.

52 Function Reference

Page 65

Return Code(s)

PCICardNumErr

PCICardNotInit

InvalidDMACnt

BufNotDWordAlign

DMATransferNotAllowed

NoError

Function Reference 53

Page 66

_9812_AD_DMA_Status

Description

Since _9812_AD_DMA_Start is executed in the background, the

function _9812_AD_DMA_Status can be used to check its operation status.

Syntax

C/C++ (DOS)

int _9812_AD_DMA_Status(int card_number, int

*count, int *status, U32 *start_idx)

C/C++ (Windows 95)

int W_9812_AD_DMA_Status(int card_number, int

*count, int *status, U32 *start_idx)

Visual Basic (Windows 95)

W_9812_AD_DMA_Status (ByVal card_number As Long,

count As Long, status As Long, start_idx As

Long) As Long

Argument(s)

card_number Card number of the selected card.

count Current amount of DMA transferred data.

status DMA data transfer status. Valid values:

0 DMA_done

1 DMA_continue

2 DMA_wait_trig

3 DMA_wait_delay

start_idx The index where the data starts from is in the user’s

buffer. For example, the sequence of read data is:

buff[start_idx], buff[start_idx+1], _,

buff[0], buff[1],_.,buff[start_idx-1].

Return Code(s)

PCICardNumErr

PCICardNotInit

NoError

54 Function Reference

Page 67

_9812_AD_DMA_Stop

Description

Stops the DMA data transfer. After executing this function, the

_9812_AD_DMA_Start function stops. The function returns the

number of transferred data, whether the A/D DMA data transfer is

stopped by this function or by the DMA terminal count ISR.

Syntax

C/C++ (DOS)

int _9812_AD_DMA_Stop(int card_number, U32

*count)

C/C++ (Windows 95)

int W_9812_AD_DMA_Stop(int card_number, U32

*count)

Visual Basic (Windows 95)

W_9812_AD_DMA_Stop (ByVal card_number As Long,

count As Long) As Long

Argument(s)

card_number Card number of the selected card.

count Amount of transferred A/D data.

Return Code(s)

PCICardNumErr

PCICardNotInit

NoError

Function Reference 55

Page 68

_9812_Set_Clk_Src

Description

Specifies the ADC clock source.

Syntax

C/C++ (DOS)

int _9812_Set_Clk_Src (int card_number, int

clk_src, int ftpci)

C/C++ (Windows 95)

int W_9812_Set_Clk_Src (int card_number, int

clk_src, int ftpci)

Visual Basic (Windows 95)

W_9812_Set_Clk_Src (ByVal card_number As Long,

ByVal clk_src As Long, ByVal ftpci As Long)

As Long

Argument(s)

card_number The card number of PCI-9812/9810 to be selected

clk_src The ADC clock source, the valid values are as

follows:

0 INT_CLK: internal clock

1 SIN_CLK: external sin wave clock

2 SQR_CLK: external square clock

ftpci Frequency selection.

AD2_GT_PCI The frequency of A/D clock source is higher

AD2_LT_PCI The frequency of A/D clock source is lower

than PCI clock frequency.

than PCI clock frequency.

Return Code(s)

PCICardNumErr

PCICardNotInit

InvalidClkSrc

NoError

56 Function Reference

Page 69

_9812_Set_Clk_Rate

Description

Specifies the clock divider for the ADC clock. The value of the

clock divider must be even and between 2 to 65534.

Syntax

C/C++ (DOS)

int _9812_Set_Clk_Rate (int card_number, U16

clk_div)

C/C++ (Windows 95)

int W_9812_Set_Clk_Rate (int card_number, U16

clk_div)

Visual Basic (Windows 95)

W_9812_Set_Clk_Rate (ByVal card_number As Long,

ByVal clk_div As Integer) As Long

Argument(s)

card_number The card number of the selected card.

clk_div ADC clock divisor. The value must be an even

number and the minimum value is 2.

Return Code(s)

PCICardNumErr

PCICardNotInit

InvalidClkDiv,NoError

Function Reference 57

Page 70

_9812_Set_Trig

Description

Sets up the trigger. The function specifies the trigger mode, trigger

level (voltage), trigger source, trigger slope, and post trigger count.

Refer to Chapter 5 for details.

Syntax

C/C++ (DOS)

int _9812_Set_Trig (int card_number, int

trig_mode, int trig_src, int trig_pol, int

trig_lvl, U16 post_trig_cnt)

C/C++ (Windows 95)

int W_9812_Set_Trig (int card_number, int

trig_mode, int trig_src, int trig_pol, int

trig_lvl, U16 post_trig_cnt)

Visual Basic (Windows 95)

W_9812_Set_Trig (ByVal card_number As Long, ByVal

trig_mode As Long, ByVal trig_src As Long,

ByVal trig_pol As Long, ByVal trig_lvl As

Long, ByVal post_trig_cnt As Integer) As

Long

Argument(s)

card_number Card number of the selected card.

trig_mode Selected trigger mode. Valid values:

SOFT_TRIG Software trigger

POST_TRIG Post trigger

PRE_TRIG Pre-trigger

DLY_TRIG Delay trigger

MID_TRIG Middle trigger

trig_src Selected trigger source, the valid trigger sources are:

CH0_TRIG Channel 0

CH1_TRIG Channel 1

CH2_TRIG Channel 2

CH3_TRIG Channel 3

58 Function Reference

Page 71

AUX_TRIG External digital trigger

trig_pol Trigger slope.

0 Positive slope trigger

1 Negative slope trigger

trig_lvl Trigger level. Refer to section 4.1.

post_trig_cnt Post trigger count. This value is pre-loaded to the

post trigger counter when the post trigger counter

register is written. It will count down on the rising

edge of ADC sampling clock after the trigger

condition is met. When the count reaches 0, the

counter stops. The counter is used to control the

delay time in delay trigger mode and to control the

post trigger sampling count in middle trigger mode.

Return Code(s)

PCICardNumErr

PCICardNotInit

InvalidClkDiv

NoError

Function Reference 59

Page 72

W_9812_Alloc_DMA_Mem

Description

Tells the Windows 95 system to allocate a block of contiguous

memory for DMA transfer. This function is available only for Windows 95.

Syntax

C/C++

int W_9812_Alloc_DMA_Mem (U32 buf_size, HANDLE

*memID, U32 *linearAddr)

Visual Basic

W_9812_Alloc_DMA_Mem (ByVal buf_size As Long,

memID As Long, linearAddr As Long) As Long

Argument(s)

buf_size Bytes to allocate. Note thay the unit of this argument

is byte and not sample.

memID If memory allocation is successful, the driver returns

the ID of that memory in this argument. You may use

this memory ID in W_9812_AD_DMA_Start function

call.

linearAddr Linear address of the allocated DMA memory. This

linear address can be used as a pointer in C/C++ to

access DMA data.

Return Code(s)

NoError

AllocDMAMemFailed

60 Function Reference

Page 73

W_9812_Free_DMA_Mem

Description

Releases a system DMA memory in Windows 95. This function is

only available for Windows 95.

Syntax

C/C++

int W_9812_Free_DMA_Mem (HANDLE memID)

Visual Basic

W_9812_Free_DMA_Mem (ByVal memID As Long) As Long

Argument(s)

memID Memory ID of the system DMA memory to de-

allocate.

Return Code(s)

NoError

Function Reference 61

Page 74

W_9812_Get_Sample

Description

For languages without pointer support such as Visual Basic, programmers can use this function to acce ss the data in DMA buffer.

This function is available only for Windows 95.

Syntax

C/C++

int W_9812_Get_Sample (U32 linearAddr, U32 index,

I16 *ai_data)

Visual Basic

W_9812_Get_Sample (ByVal linearAddr As Long,

ByVal idx As Long, ai_data As Integer) As

Long

Argument(s)

linearAddr Linear address of the allocated DMA memory.

index Index of the sa mp le . The first sample has an index 0.

ai_data Returns the samples retrieved.

Return Code(s)

NoError

62 Function Reference

Page 75

7 Calibration

In data acquisition, you must calibrate your me asurement de vices

to maintain accuracy. You can calibrate the analog input and

analog output channels using your operating environment to

optimize accuracy. This chapter describes the calibration process

for the PCI-9812/9810 card.

7.1 Before You Proceed

You need the following equipment for the calibration process:

X Calibration utility. This application guides you through the

calibration process and is available from the card package.

X Voltage calibrator or a stable and noise-free DC voltage