Page 1

PCI-9524

24-Bit Precision Load Cell Input Card

User’s Manual

Manual Revision: 2.02

Revision Date: August 26, 2008

Part No: 50-11236-1010

Advance Technologies; Automate the World.

Page 2

PCI-9524 ADLINK Technology, Inc.

User’s Manual Copyright 2008

Revision History

Revision Release Date Description of Change(s)

2.00 2008/04/09

2.01 2008/05/30 Minor revision

2.02 2008/08/26 Correct typo

Document Created

Initial Release

ii

Page 3

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Preface

Copyright 2008 ADLINK TECHNOLOGY INC.

This document contains proprietary infor mation protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufa cturer.

In no event will the manufacturer be liable for direct, indirect,

special, incidental, or consequential damages arising out of the

use or inability to use the product or documentation, even if

advised of the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

PC, PS/2, and VGA are registered trademarks of International

Business Machines Corp. Borland

and Delphi

Corporation. LabVIEW™ is a trademark of National Instruments

Corporation. Microsoft

Preface iii

®

are registered trademarks of the Borland Software

®

, Visual Basic®, Visual C++®, Windows

®

, Borland® C, C++ Builder®,

®

Page 4

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

98, Windows® NT, Windows® 2000, Windows® XP, and Windows

®

Vista® are registered trademarks of Microsoft® Corporation.

PCI™, is a registered trademark of the Peripheral Component

Interconnect Special Interest Group (PCI-SIG).

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

iv Preface

Page 5

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Using this Manual

Audience and Scope

The PCI-9524 User’s Manual is intended for hardware technicians

and systems operators with knowledge of installing, configuring

and operating industrial grade PCI cards.

Manual Organization

This manual is organized as follows:

Preface: Presents important copyright notifications,

disclaimers, trademarks, and associated information on the

proper understanding and usage of this document and its

associated product(s).

Chapter 1, Introduction: Introduces the PCI-9524, its

features, applications, specifications and operating software

environment.

Chapter 2, Installation: Describes how to install the PCI-9524

into your chassis and basic PCI configuration settings.

Chapter 3, Signal Connections: Describes signal

connections between PCI-9524 and external devices.

Chapter 4, Operation Theory: Describes A/D and D/A

conversions, pulse-commands, encoder inputs and isolated

digital I/O signals to assist users in understanding how to

configure and program the cPCI-9524 .

Chapter 5, Calibration: Presents the calibration process to

minimize measurement and output errors.

Important Safety Instructions: Presents safety instructions

all users must follow for the proper setup, installation and

usage of equipment and/or software.

Warranty Information: Presents important warranty

information for users/manufacturers rights and responsibilities

regarding ADLINK products and services.

Preface v

Page 6

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component

damage, data loss, and/or program corruption when try-

CAUTION:

WARNING:

ing to complete a task.

Information to prevent serious physical injury, component damage, data loss, and/or program corruption

when trying to complete a specific task.

vi Preface

Page 7

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Getting Service

Contact us should you require any service or assistance.

ADLINK TECHNOLOGY INC. (HEADQUARTERS)

Web Site: http://www.adlinktech.com

Sales & Service: service@adlinktech.com

Telephone No.: +886-2-8226-5877

Fax No.: +886-2-8226-5717

Mailing Address: 9F No. 166 Jian Yi Road, Chungho City,

Taipei 235, Taiwan

ADLINK TECHNOLOGY AMERICA INC.

Sales & Service: info@adlinktech.com

Toll-Free: +1-866-4 ADLINK

Fax No.: +1-949-727-2099

Mailing Address: 8900 Research Drive, Irvine,

CA 92618, USA

ADLINK TECHNOLOGY CO. LTD. (BEIJING)

Sales & Service: market@adlinktech.com

Telephone No.: +86-10-5885-8666

Fax No.: +86-10-5885-8625

Mailing Address: Rm. 801, Power Creative E, No. 1, B/D

Shang Di East Rd.

Beijing, 100085 China

ADLINK TECHNOLOGY CO. LTD. (SHANGHAI)

Sales & Service: market@adlinktech.com

Telephone No.: +86-21-6495-5210

Fax No.: +86-21-5450-0414

Mailing Address: 4F, Bldg. 39, No.333 Qinjiang Road,

Cao He Jing High-Tech Park

Shanghai, 200233 China

ADLINK TECHNOLOGY CO. LTD. (SHENZHEN)

Sales & Service: market@adlinktech.com

Telephone No.: +86-755-2643-4858

Fax No.: +86-755-2664-6353

Mailing Address: 2F, C Block, Bld. A1,

Cyber-Tech Zone, Gao Xin Ave. Sec. 7,

High-Tech Industrial Park S.,

Shenzhen, 518054 China

Preface vii

Page 8

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

ADLINK TECHNOLOGY INC. (EUROPEAN Liaison Office)

Sales & Service: emea@adlinktech.com

Telephone No.: +49-211-495-5552

Fax No.: +49-211-495-5557

Mailing Address: Nord Carree 3, 40477

Düsseldorf, Germany

ADLINK TECHNOLOGY JAPAN CORP.

Sales & Service japan@adlinktech.com

Telephone No. +81-3-4455-3722

Fax No. +81-3-5333-6040

Mailing Address Asahiseimei Hatagaya Bld. 8Fl. 1-1-2

Hatagaya Shibuya-ku, Tokyo, Japan

ADLINK TECHNOLOGY INC. (SOUTH KOREA Liaison Office)

Sales & Service: korea@adlinktech.com

Telephone No.: +82-2-2057-0565

Fax No.: +82-2-2057-0563

Mailing Address: #402, Dongsung B/D, 60-12,

Nonhyeon-dong Gangnam-gu,

Seoul, 135-010, South Korea

ADLINK TECHNOLOGY SINGAPORE PTE. LTD.

Sales & Service: singapore@adlinktech.com

Telephone No.: +65-6844-2261

Fax No.: +65-6844-2263

Mailing Address: 84 Genting Lane #07-02A,

Cityneon Design Center,

Singapore 349584

ADLINK TECHNOLOGY SINGAPORE PTE. LTD. (INDIA Liaison Office)

Sales & Service: india@adlinktech.com

Telephone No.: +91-80-6560-5817

Fax No.: +91-80-2244-3548

Mailing Address: No. 1357, Ground Floor, "Anupama",

Aurobindo Marg JP Nagar (Ph-1)

Bangalor, Karnataka 560078, India

viii Preface

Page 9

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Table of Contents

PCI-9524.....................................................................................i

Revision History...................................................................... ii

Preface.................................................................................... iii

Table of Contents................................................................... ix

List of Figures...................................................................... xiii

List of Tables......................................................................... xv

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 2

1.2 Applications ......................................................................... 2

1.3 Specifications....................................................................... 3

1.4 Software Support............................................................... 19

2 Getting Started ................................................................. 21

2.1 Installation Environment .................................................... 21

2.2 Package Contents ............................................................. 22

2.3 PCI-9524 Layout................................................................ 23

2.4 Installing the Card.............................................................. 24

2.5 PCI Configuration .............................................................. 25

3 Signal Connections.......................................................... 27

3.1 Connectors & Pin Assignments ......................................... 27

3.2 Analog Input Signal Connections....................................... 33

3.2.1 Signal Sources ......................................................... 33

3.2.2 Input Configurations ........................ ... ... .... ... ... ... .... .. 33

3.3.1 Signal Sources and Terminal Devices............. ... .... .. 38

3.3.2 Connecting to/from External Encoders..................... 40

Table of Contents ix

Page 10

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

3.3.5 Interfacing Isolated DI with External Devices ...........45

4 Operation Theory.............................................................. 47

4.1 PCI-9524 Function Diagram .............................................. 47

4.2 Analog Input Channels....................................................... 48

4.2.1 Signal Acquisition and Processing Flow............ ... ... .48

4.2.2 How to Define a 1 in 200,000 Count Resolution.......49

4.2.3 Data Rate versus Sampling Rate ............................ .51

4.2.4 Auto-scan, Multiplexing and Settling Time................51

4.2.5 Power Line Noise Rejection......................................53

4.2.6 Excitation and Remote-sensing................................54

4.2.7 Thermal EMF, 1/f Noise and Auto-zero....................55

4.2.8 Warm-up Requirement ................................... ... ... ... .58

4.2.9 Post-processing IIR Digital Filter ..............................58

4.2.10 RAW Data Format ......... .... ... ... ... .... ... ... ... ... .... ... ... ... .61

4.2.11 AD Data Format........................................................62

4.2.12 Data Transfer Modes.................................. .... ... .......64

4.2.13 Trigger Modes...........................................................66

4.3 D/A Conversion.................................................................. 67

4.4 Isolated Encoder Input Channels....................................... 67

4.5 Isolated Pulse-Command Generator ................................. 69

4.6 Isolated Digital I/O.............................................................. 69

4.6.1 Isolated Digital Inputs ...............................................70

4.6.2 Isolated Digital Outputs.............................................70

4.7 Trigger Sources ................................................................. 70

4.7.1 Software-Trigger.......................................................70

4.7.2 External Digital Trigger.............................................70

4.7.3 Pulse Comparator Trigger .............................. ... ... ... .71

4.7.4 Position Comparator Trigger.....................................72

5 Calibration......................................................................... 73

5.1 Loading Calibration Constants........................................... 73

x Table of Contents

Page 11

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

5.2 Auto-calibration.................................................................. 74

5.3 Saving Calibration Constants ............................................ 74

Important Safety Instructions.............................................. 75

Table of Contents xi

Page 12

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

This page intentionally left blank.

xii Table of Contents

Page 13

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

List of Figures

Figure 1-1: PCI-9524 Product Image .................................................1

Figure 1-2: Effective-number-of-bits vs. Gain .................................... 9

Figure 1-3: RMS Noise in µV vs. Gain............................................... 9

Figure 1-4: Spectral Response ±10 V range,

0.996094 Hz sine wave, -1 dB FS.................................10

Figure 1-5: Spectral Response ±5 V range,

0.996094 Hz sine wave, -1 dB FS.................................10

Figure 1-6: Spectral Response ±2.5 V range,

0.996094 Hz sine wave, -1 dB FS.................................11

Figure 1-7: Spectral Response ±1.25 V range,

0.996094 Hz sine wave, -1 dB FS.................................11

Figure 1-8: Frequency Response Sampling at 30,000 SPS ............ 12

Figure 1-9: Frequency Response Sampling at 15,000 SPS ............ 12

Figure 1-10: Frequency Response Sampling below 15,000 SPS...... 13

Figure 2-1: PCI-9524 PCB Layout and Mechanical Drawing........... 23

Figure 3-1: CN1 Connector & Pin Assignments...............................28

Figure 3-4: Connecting to a four-terminal load-cell transducer

using a four-wire connection.......................................... 34

Figure 3-5: Connecting to a six-terminal load-cell transducer

using a six-wire connection............................................35

Figure 3-6: Connecting to a four-terminal load-cell transducer

using a six-wire connection............................................36

Figure 3-7: Ground-referenced source and differential input...........36

Figure 3-8: Floating source and differential input.............................37

Figure 3-9: Connecting to an external encoder

with NPN sink drivers.....................................................40

Figure 3-10: Connecting to an external encoder

with PNP source drivers ................................................40

Figure 3-11: Connecting to an external encoder

with push-pull source drivers.........................................41

Figure 3-12: Connecting to an external encoder

with differential line-drivers............................................41

Figure 3-13: Connecting to an external servo-amplifier

with opto-coupler inputs.................................................42

Figure 3-14: Connecting to an external servo-amplifier

with differential line-receivers ........................................42

Figure 3-15: Connecting to an external resistive load

from the isolated DO sink driver ....................................43

List of Figures xiii

Page 14

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Figure 3-16: Connecting to an external inductive load

from an isolated DO sink driver .....................................44

Figure 3-17: Connecting to a low-side push button............................45

Figure 3-18: Connecting to an external sink driver ............................46

Figure 4-1: PCI-9524 Function Diagram ..........................................47

Figure 4-2: Signal acquisition and data processing flow

for transducer input channels ........................................48

Figure 4-3: SINC Filter Power Line Noise Rejection

at 60 Hz Multiples ..........................................................54

Figure 4-4: The Effect of Auto-zero on Thermal Noise and

1/f Noise, ADC running at 60 SPS.................................57

Figure 4-5: Digital Filter Tap Length Effects

on Signal Frequency Responses...................................59

Figure 4-6: Linked List of PCI address DMA descriptors .................65

Figure 4-7: Post trigger ....................................................................66

Figure 4-8: X4 Encoder mode..........................................................68

Figure 4-9: External digital trigger....................................................71

xiv List of Figures

Page 15

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

List of Tables

Table 1-1: -3dB small signal bandwidth: (Typical, 25°C)..................4

Table 1-2: System Noise (including Quantization, Typical, 25°C) ....4

Table 1-3: Transducer Input Impedance...........................................5

Table 1-4: Transducer CMRR (DC to 60 Hz, Typical 25°C) ............. 5

Table 1-5: Settling Error: (Typical, 25°C).......................................... 6

Table 1-6: Programmable input range and gain ...............................7

Table 1-7: -3dB small signal bandwidth vs. input range ................... 7

Table 1-8: -3dB small signal bandwidth vs. sampling rates,

in ±10V range ................................. ... ... ... ... .... ... ... ...........8

Table 1-9: General Purpose Input Impedance................................ 13

Table 1-10: General Purpose CMRR (DC to 60 Hz, Typical, 25°C).13

Table 1-11: Settling Error: (Typical, 25ºC)........................................ 14

Table 3-1: I/O Signal Descriptions.................................................. 31

Table 4-1: Data Rates vs. Multiplexing, Auto-zero &

ADC Sampling Rates, in Samples-per-second (SPS)...53

Table 4-2: Temperature Coefficient of different metal junctions..... 56

Table 4-3: Default Threshold Values (ADC counts) vs. ADC

Sampling Rates .............................................................61

Table 4-4: RAW Data Format ................................... ... .... ... ... ... .... .. 61

Table 4-5: Bipolar analog input ranges and

output digital codes for transducer input channels ........ 63

Table 4-6: Bipolar analog input ranges and

AD codes for general purpose input channels............. .. 63

Table 4-7: Bipolar output code table...............................................67

List of Tables xv

Page 16

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

This page intentionally left blank.

xvi List of Tables

Page 17

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

1 Introduction

The ADLINK PCI-9524 is a 24-bit high-resolution multifunction

DAQ card capable of up to 30 kS/s sam pling rate, providing 4- CH

load-cell transducer input channels, and 4-CH general purpose

analog input. In addition, the PCI-9524 comes with a 2-CH 16-bit

analog output, isolated motion I/O and digital I/O. The highly integrated function makes the PCI-9524 the ideal solution for combined data acquisition and motion control functionalities. Ideal for

manufacturing, laboratory research, and factory automation, the

PCI-9524 comes with all the features and performance you need

at an affordable price.

Figure 1-1: PCI-9524 Product Image

Introduction 1

Page 18

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

1.1 Features

PCI-9524 24-bit multifunction DAQ card provides the following

advanced features:

X Supports 32-bit 3.3 V or 5V PCI bus

X Load-cell transducer input channels

Z 4-CH differential analog input with remote-sense

Z 4-CH transducer excitation, 10 V or 2.5 V selectable

Z Auto-zero capability

Z Up to 30 kS/s sampling rate without auto-zero

Z IIR digital filter for post-processing

X General purpose analog input channels

Z 4-CH differential analog input

Z Programmable gains: x1, x2, x4, x8

Z Up to 30 kS/s sampling rate

X 2-CH 16-bit analog output

X 3-CH opto-isolated pulse-command output, supporting AB

phase, CW/CCW, CLK/DIR modes

X 3-CH opto-isolated encoder input, supports AB phase

inputs in quadrature mode

X 8-CH opto-isolated digital inputs

X 8-CH opto-isolated digital output s with N-MOS sink drivers

X Auto-calibration

1.2 Applications

X Materials Testing Systems

X Precision Weighting Systems

X Automotive Testing

X Process Control

X Laboratory Automation

X Biotech Measurements

2 Introduction

Page 19

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

1.3 Specifications

Analog Input (AI) for Transducers

X Number of channels: (programmable)

Z 4 differential inputs (DI)

X A/D converter:

Z ADS1255

X Maximum sampling rate:

Without Auto-zero

Z 30,000 samples/s (single channel)

Z 1,638 samples/s (multiplexed/sc an nin g)

With Auto-zero

Z 819 samples/s (single channel or multiplexed/scanning)

X Resolution:

Z 24-bit

X Input coupling: DC

X Input range and gain:

Z ±200 mV relative to a common-mode input voltage

Z A fixed gain of 25x

X Operational common-mode input range:

Z -2 V to +6 V

X Transducer Excitation Voltage Sources:

Z 4-CH differential output

Z 10 V or 2.5 V selectable (all 4-CH share same settings)

Z Driving up to four 120-ohm load-cells

Z Short-circuit protection

X Remote-sense input:

Z 4-CH differential input

Z 0 V to 10 V operating input range

X Overvoltage protection:

Transducer inputs

Z Power on: +28.7 V to -35.7 V (continuous)

Z Power off: ±15 V (continuous)

Introduction 3

Page 20

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Remote-sense inputs:

Z Power on: -40 V to +55 V (continuous)

Z Power off: -40 V to +55 V (continuous)

X FIFO buffer size: 1024 samples (1024 x 32 bit s)

X Data transfers:

Z Programmed I/O

Z Bus-mastering DMA with scatter/gather

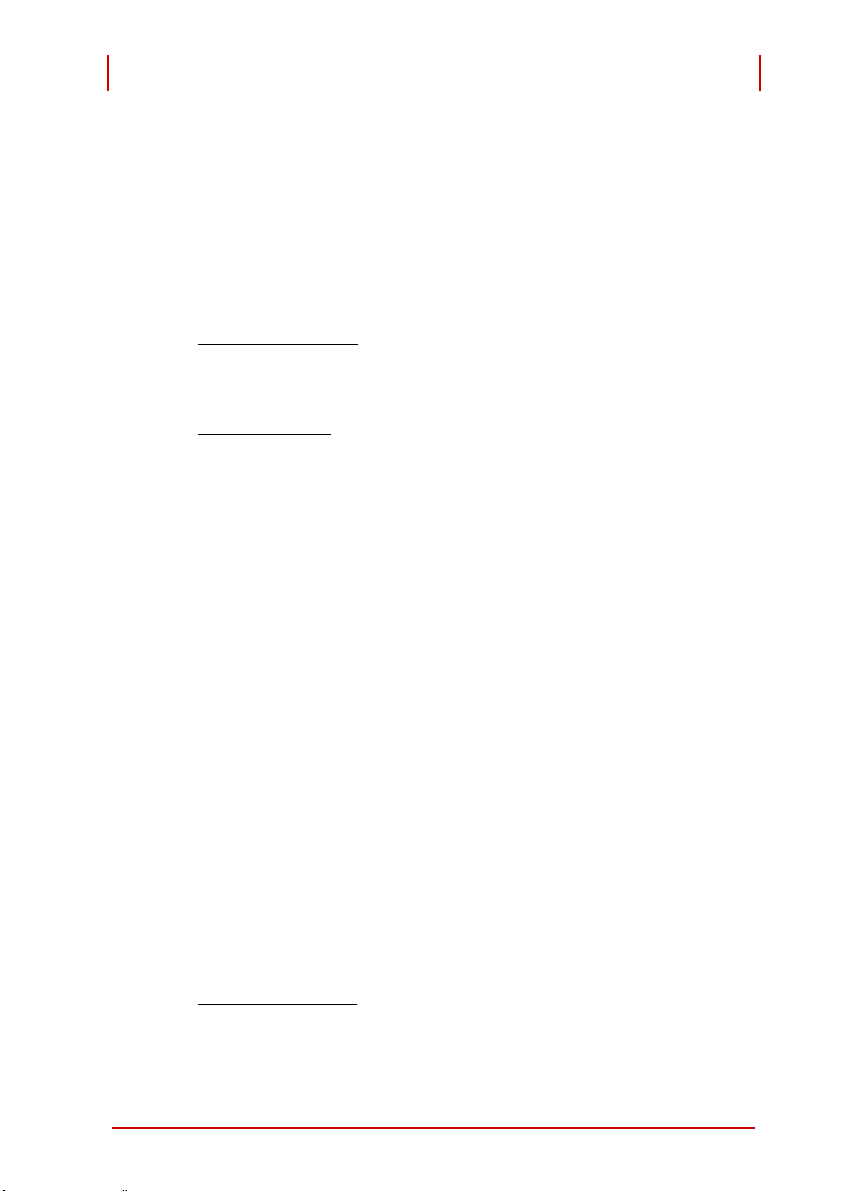

Table 1-1: -3dB small signal bandwidth: (Typical, 25°C)

Input Range Bandwidth (-3dB)

±200 mV 2,730 Hz

Table 1-2: System Noise (including Quantization, Typical, 25°C)

RMS

Res. in

Bits

(ENOB)

Peak

Res. in

Bits

RMS Res

in µV

Peak

Res. in

µV

Input

Range

Data

Rate in

SPS

System

Noise in

LSB

rms

1.25 0.5 23.0 21.0 0.013 0.053

2.5 0.6 22.8 20.4 0.014 -0.079

5.0 0.6 22.7 20.4 0.016 0.079

7.5 0.7 22.6 20.0 0.017 0.079

±200 mV

12 0.9 22.2 19.7 0.023 0.159

15 0.8 22.3 19.7 0.020 0.132

24 1.2 21.8 19.2 0.031 0.212

29 1.1 21.9 19.0 0.030 0.185

47 1.9 21.1 18.6 0.037 0.291

194 2.9 20.5 17.7 0.078 0.583

4 Introduction

Page 21

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

RMS

Res. in

Bits

(ENOB)

Peak

Res. in

Bits

RMS Res

in µV

Peak

Res. in

Input

Range

±200 mV

Data

Rate in

SPS

316 3.7 20.1 17.1 0.101 0.742

463 5.5 19.6 16.4 0.146 1.113

595 6.9 19.2 16.4 0.185 1.351

704 8.9 18.9 15.9 0.243 1.748

768 10.9 18.6 15.5 0.306 2.305

819 12.6 18.4 15.4 0.328 2.331

System

Noise in

LSB

rms

Test conditions: Rice Lake Load-cell Simulator IV set at 0mV/V

output, 10V excitation and six-wire remote-sense connection,

auto-zero enabled. The RMS resolution and peak resolution are

calculated relative to full-scale input range of ±200mV.

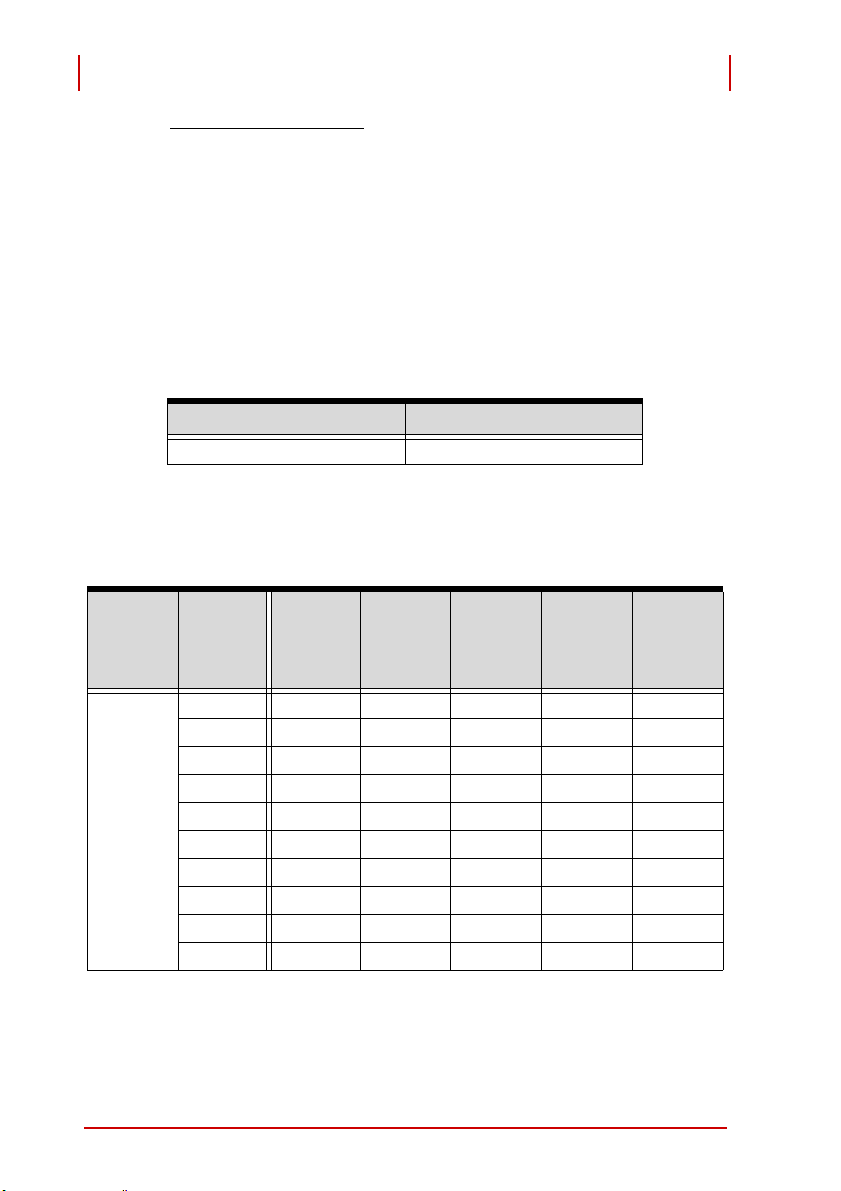

Table 1-3: Transducer Input Impedance

Normal Power On Power Off Overload

1 GΩ || 3 pF 1 K Ω 1 KΩ

µV

T able 1-4: Transducer CMRR (DC to 60 Hz, Typical 25°C)

Input Range CMRR

±200 mV

Introduction 5

90 dB (Auto-zero Disabled)

102 dB (Auto-zero Enabled)

Page 22

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Table 1-5: Settling Error: (Typical, 25°C)

Input Range Condition Settling Error

±200 mV Scanning 200 mV step max 0.01%

X Time-base source: Internal 40 MHz

X Trigger mode: post-trigger

X Offset error:

Z Before calibration: ±0.5 mV typical

Z After calibration: ±0.001 mV typical (auto-zero disabled),

< ±0.001 mV typical (auto-zero enabled)

X Transfer Linearity:

Z Better than: ±0.0035% over full-scale input range

X Gain error:

Z Before calibration: ±1% typical

Z After calibration: ±0.5% typi cal

Analog Input (AI) for General Purpose

X Number of channels: (programmable)

Z 4 differential input (DI)

X A/D converter:

Z ADS1255

X Maximum sampling rate:

Z 30,000 samples/s (single channel)

Z 1.638 samples/s (multiplexed/scanning)

X Resolution:

Z 24-bit

X Input coupling: DC

6 Introduction

Page 23

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Table 1-6: Programmable input range and gain

Bipolar Input Range Gain

±10 V 1

±5 V 2

±2.5 V 4

±1.25 V 8

X Operational common-mode input range: ±13V

X Overvoltage protection:

Z Power on: ±30 V (continuous)

Z Power off: ±15 V (continuous)

X FIFO buffer size: 1024 samples (1024 x 32 bits)

X Data transfers:

Z Programmed I/O

Z Bus-mastering DMA with scatter/gather

X -3dB small signal bandwidth (Typical, 25ºC)

Table 1-7: -3dB small signal bandwidth vs. input range

Input Range Bandwidth (-3dB)

±10 V 5,800 Hz

±5 V 5,900 Hz

±2.5 V 5,900 Hz

±1.25 V 5,900 Hz

Introduction 7

Page 24

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

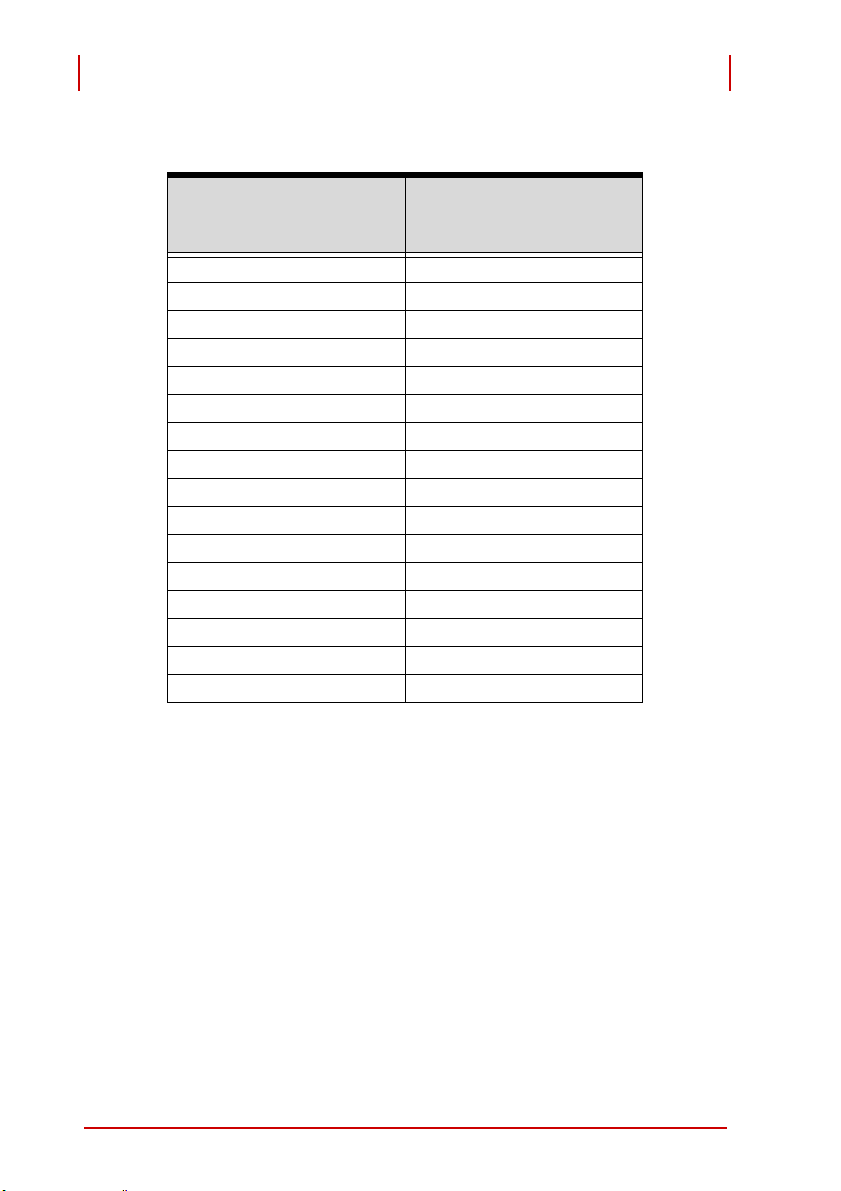

Table 1-8: -3dB small signal bandwid th vs. sampling rates,

in ±10V range

Sampling Rate

In Samples-per-second

(SPS)

2.5 1.1 Hz

5 2.2 Hz

10 4.4 Hz

15 6.6 Hz

25 11 Hz

30 13 Hz

50 22 Hz

60 26 Hz

100 44 Hz

500 220 Hz

1,000 440 Hz

2,000 880 Hz

3,750 1,600 Hz

7,500 3,000 Hz

15,000 4,800 Hz

30,000 5,800 Hz

Bandwidth (-3 dB)

8 Introduction

Page 25

ADLINK Technology Inc. PCI-9524

]

Copyright 2008 User’s Manual

System Noise (LSBrms, including Quantization, Typical, 25ºC)

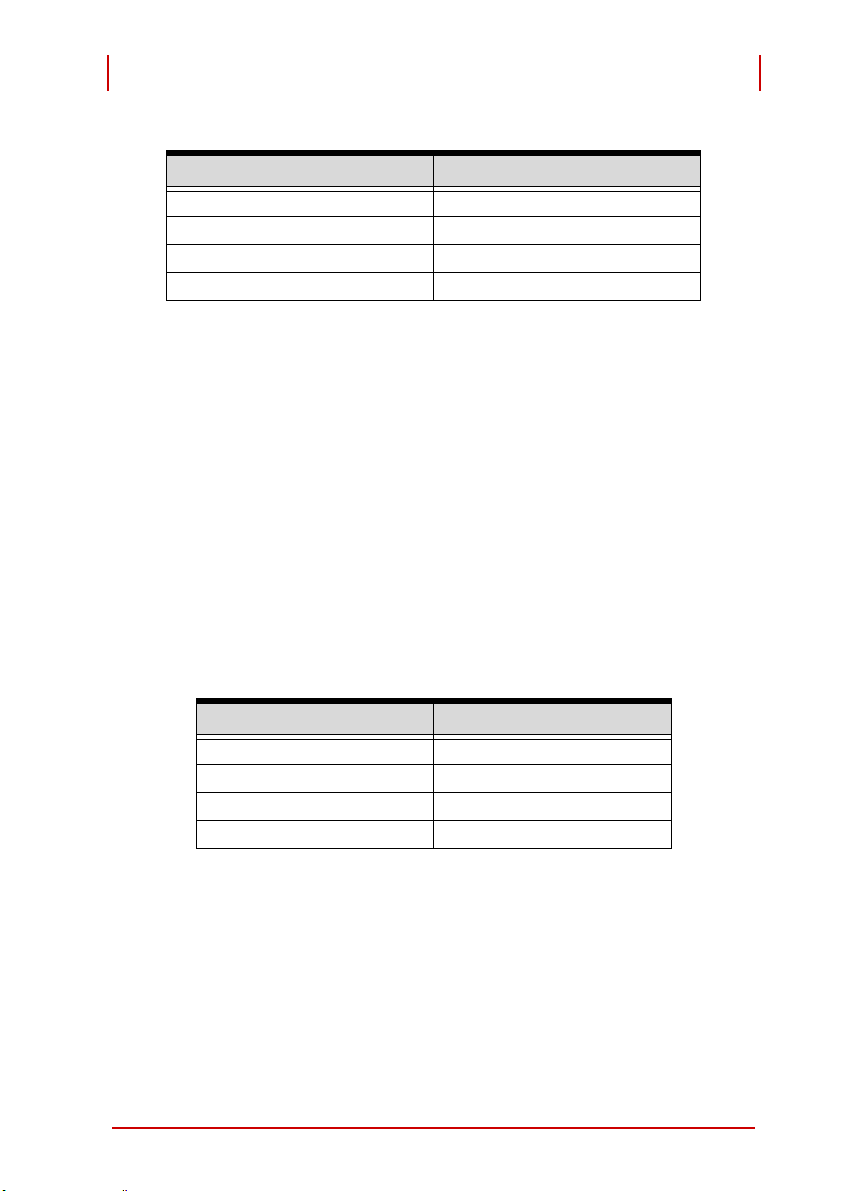

Figure 1-2: Effective-number-of-bits vs. Gain

25

24

23

22

21

20

19

ENOB [bits

18

17

16

15

14

2 5 10 15 25 30 50 60 100 500 1000 2000 3750 7500 15000 30000

Figure 1-3: RMS Noise in µV vs. Gain

1000

ENOB vs PGA Gain

[Input = AGND]

Sampling Rate [Sam ples pe r Se cond]

Gain = 1 Gain = 2 Gain = 4 Gain = 8

RMS Nois e vs PGA Gain

[I n p u t = AGND]

100

10

Noise [uV]

1

0.1

2 5 10 15 25 30 50 60 100 50 0 1000 2000 3750 7500 15000 30000

Sampling Rate [Sampl es per Second]

Gain = 1 Gain = 2 Gain = 4 Gain = 8

Test conditions: RMS resolution and peak resolution are calculated relative to the full-scale range of their gain settings, using

internal calibration voltage references.

Introduction 9

Page 26

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

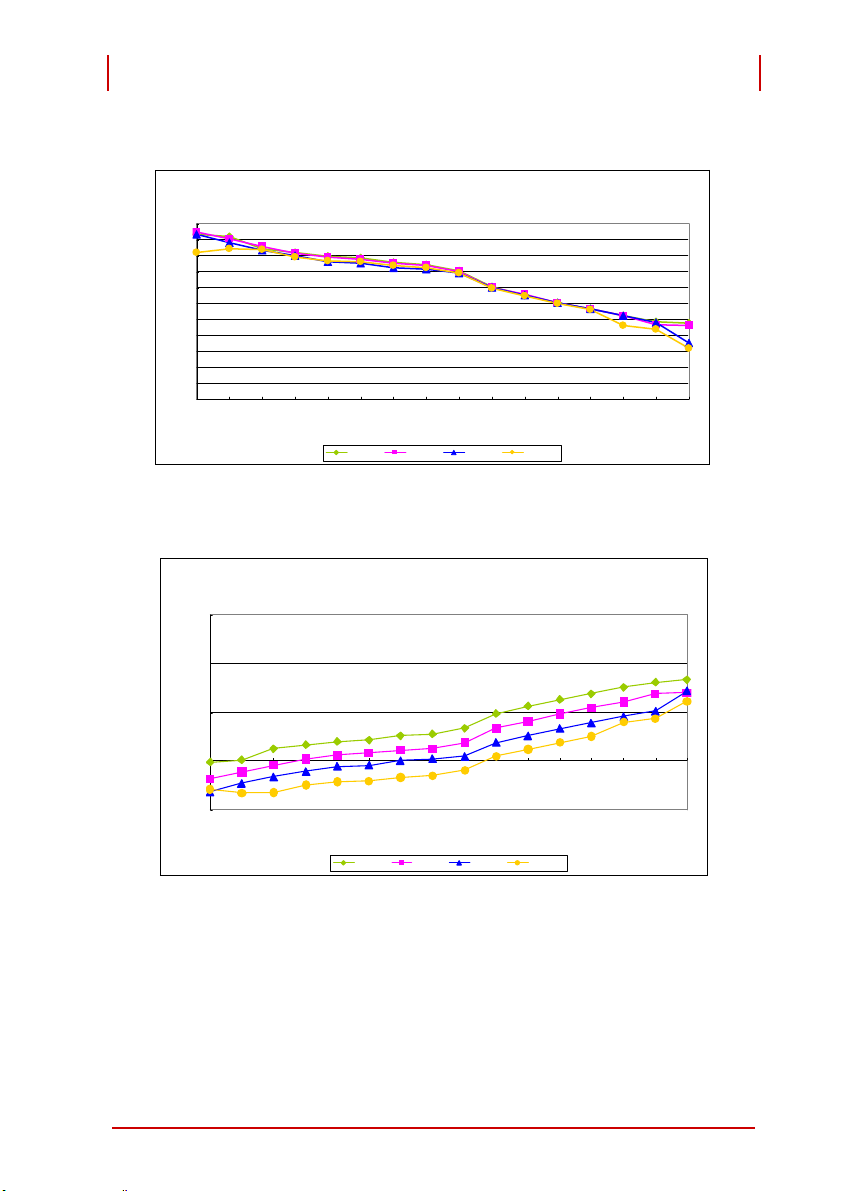

Spectral Response (At 30,000-SPS, Ty pical, 25ºC)

Figure 1-4: Spectral Response ±10 V range,

0.996094 Hz sine wave, -1 dB FS

Input Signal = 996.094 Hz @ -1 dBFS, Sampling rate = 30 KHz

0

-20

-40

-60

-80

Magnitude (dB)

-100

-120

-140

0 2000 4000 6000 8000 10000 12000 14000

Figure 1-5: Spectral Response ±5 V range,

0.996094 Hz sine wave, -1 dB FS

Input Signal = 996.094 Hz @ -1 dBFS, Sampling rate = 30 KHz

0

-20

-40

-60

-80

Magnitude (dB )

-100

-120

-140

-160

0 2000 4000 6000 8000 10000 12000 14000

SINAD = 99.5171 dB

SNR = 101.0395 dB

THD = -104.8086

ENOB = 16.2387 bit

SFDR = 105.8299

Frequency (Hz)

SINAD = 98.6425 dB

SNR = 99.4779 dB

THD = -106.2125

ENOB = 16.0934 bit

SFDR = 106.8945

Frequency (Hz)

10 Introduction

Page 27

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

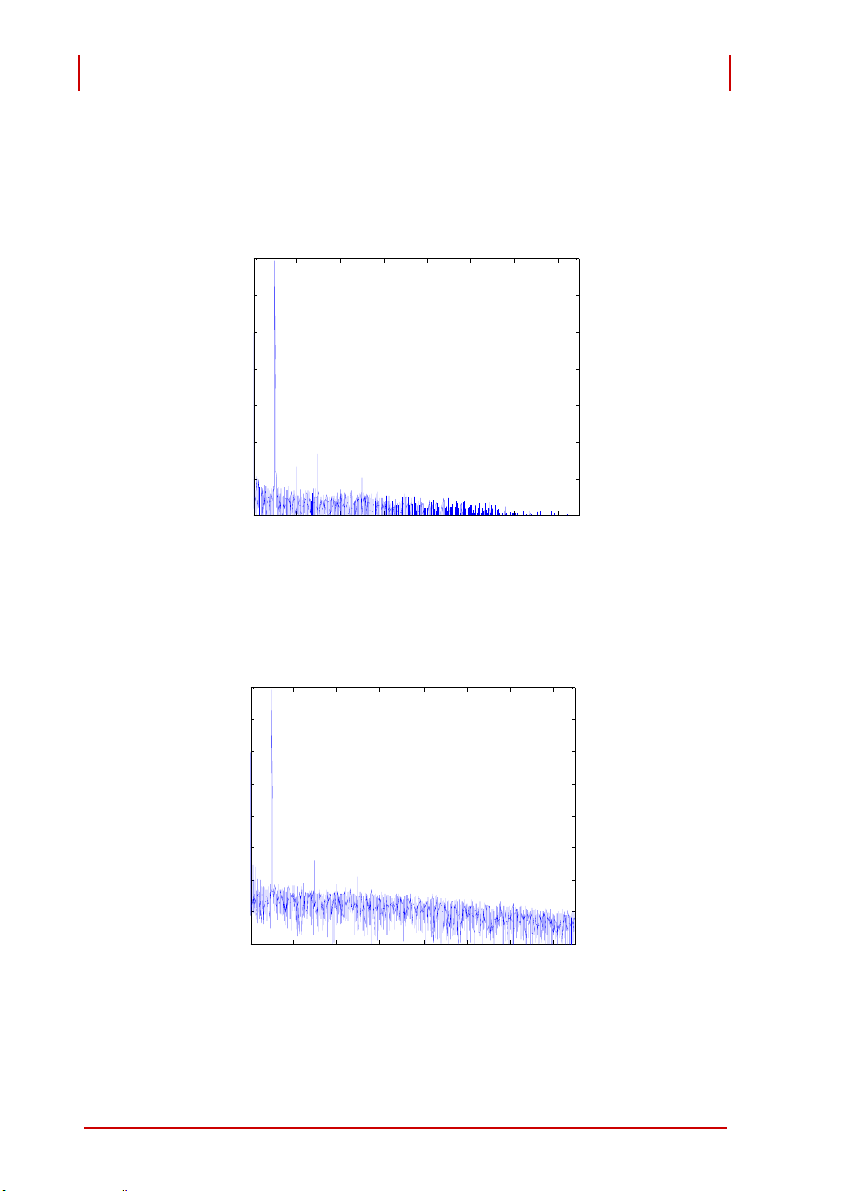

Figure 1-6: Spectral Response ±2.5 V range,

0.996094 Hz sine wave, -1 dB FS

Input Signal = 996.094 Hz @ -1 dBFS, Sampling rate = 30 KHz

0

-20

-40

-60

-80

Magnitude (dB )

-100

-120

-140

-160

0 2000 4000 6000 8000 10000 12000 14000

SINAD = 97.5555 dB

SNR = 98.0951 dB

THD = -106.8792

ENOB = 15.9129 bit

SFDR = 106.1694

Frequency (Hz)

Figure 1-7: Spectral Response ±1.25 V range,

0.996094 Hz sine wave, -1 dB FS

Input Signal = 996.094 Hz @ -1 dBFS, Sampling rate = 30 KHz

0

-20

-40

-60

-80

Magnitude (dB )

-100

-120

-140

-160

0 2000 4000 6000 8000 10000 12000 14000

SINAD = 98.1582 dB

SNR = 98.6841 dB

THD = -107.5872

ENOB = 16.013 bit

SF DR = 9 9 .1709

Frequency (Hz)

Introduction 11

Page 28

PCI-9524 ADLINK Technology Inc.

)

User’s Manual Copyright 2008

Frequency Response (vs. normalized sampling frequencies):

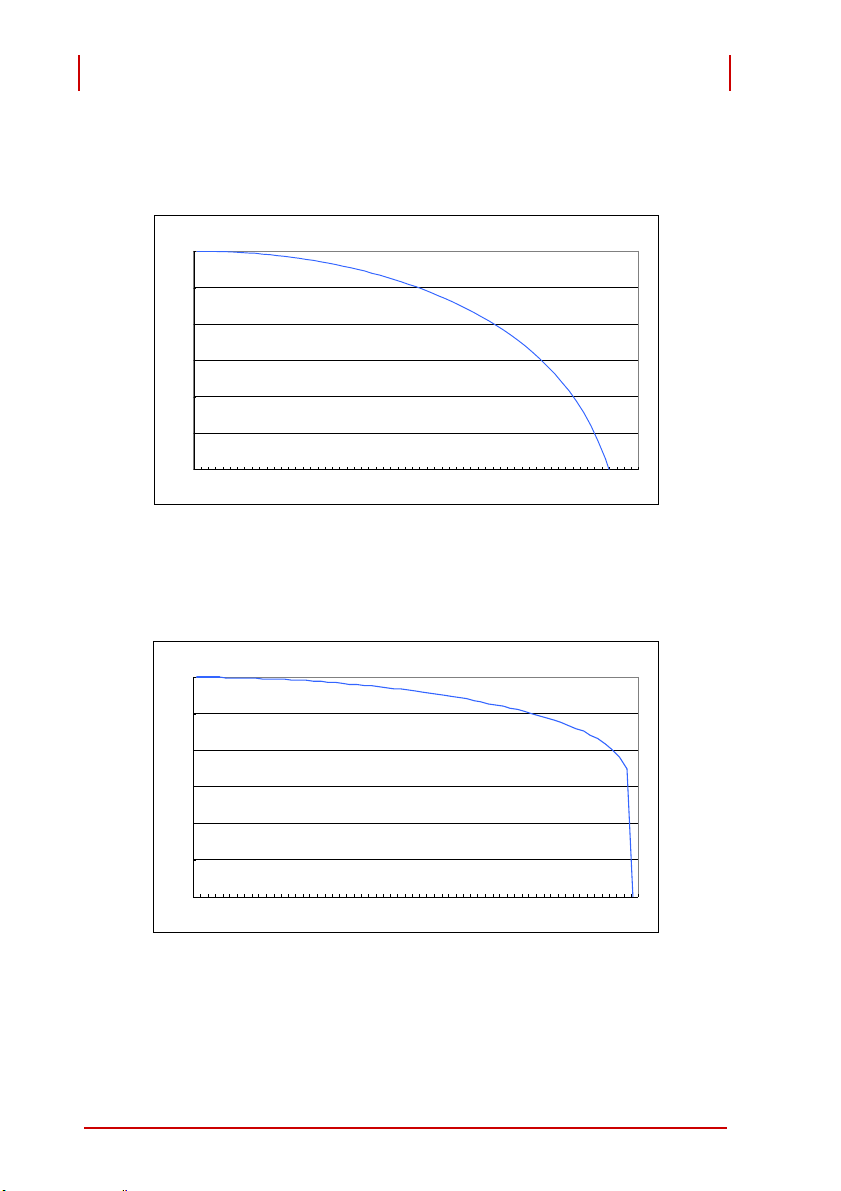

Figure 1-8: Frequency Response Sampling at 30,000 SPS

Frequency Response versus Norm. Sampling Frequency

0

-20

-40

-60

Attenuation (dB)

-80

-100

-120

0.00 0.17 0.33 0.50 0.67 0.83 1.00

Figure 1-9: Frequency Response Sampling at 15,000 SPS

Normalized S ampling Frequenc y (Fs)

Frequency Response versu s Norm. Sampl ing F reque ncy

0

-20

-40

-60

Attenuation (dB

-80

-100

-120

0.00 0.17 0.33 0.50 0.67 0.83 1.00

12 Introduction

Normal i ze d S am pl ing Fr equenc y (Fs)

Page 29

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Figure 1-10: Frequency Response Sampling below 15,000 SPS

Frequency Response versus Norm. Sampling Frequency

0

-20

-40

-60

Attenuation (dB)

-80

-100

-120

0.00 0.17 0.33 0.50 0.67 0.83 1.00

Normalized S ampling Frequenc y (Fs)

Table 1-9: General Purpose Input Impedance

Normal Power On Power Off Overload

1 GΩ || 3 pF 1 K Ω 1 KΩ

Table 1-10: General Purpose CMRR (DC to 60 Hz, Typical, 25°C)

Input Range CMRR

±10 V 80 dB

±5 V 86 dB

±2.5 V 94 dB

±1.25 V 98 dB

Introduction 13

Page 30

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Table 1-11: Settling Error: (Typical, 25ºC)

Input Range Condition Settling Error

±10 V Scanning 20 Vpp <0.0005%

±5 V Scanning 10 Vpp <0.0005%

±2.5 V Scanning 5 Vpp <0.0005%

±1.25 V Scanning 2.5 Vpp <0.0005%

X Time-base source: Internal 40 MHz

X Trigger mode: post-trigger

X Offset error:

Z Before calibration: ±2 mV typical 25ºC

Z After calibration: ±0.1 mV typical 25ºC

X Gain error:

Z Before calibration: ±0.5% typical 25ºC

Z After calibration: ±0.01% typical 25ºC

14 Introduction

Page 31

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Analog Output (AO)

X Number of channels: 2 analog voltage outputs

X D/A converter: DAC8812

X Maximum update rate: 10 K sample/s

X Resolution: 16-bit

X Data transfers: Programmed I/O

X Output range: ±10 V

X Settling time (0.1% of full scale): 2 µs

X Slew rate: 15 V/µS

X Output coupling: DC

X Protection: Short-circuit to ground, indefinitely

X Output impedance: 0.1 Ω max

X Output driving: ±5 mA max.

X Stability: Any passive load, up to 1500 pF

X Power-on state: Around 0 V steady-state

X Offset error:

Z Before calibration: ±4 mV typical 25ºC

Z After calibration: ±1 mV typical 25ºC

X Gain error:

Z Before calibration: ±0.8% of output max.

Z After calibration: ±0.015% of output max.

Introduction 15

Page 32

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Isolated Pulse Command Outputs

X Number of channels: 3

X Output type: AM26LS31 differential line-driver

X Compliant to ANSI TIA/EIA-422-B and ITU Recommenda-

tion V.11 standards

X Logic Compatibility: 5V TTL with complementary output

X Output voltage:

Z Logic low: VOL = 0.5 V max.; IOL = 20 mA max.

Z Logic high: VOH = 2.4 V min.; IIH = -20 mA max.

X Programmable duty cycle: 1% to 99%

X Maximum pulse frequency: 1 MHz

X Direction control modes: CLK/DIR & CW/CCW

X Pulse counter: 1 to 16777215

X Pulse Comparator Tri gger to initiate AI acquisition once

condition is met

X Data transfers: Programmed I/O

Isolated Quadrature Encoder Inputs

X Number of channels: 3

X Input type: AB-Phase differential inputs

X Input impedance: 249 Ω || 220 pF

X Input voltage:

Z Logic low: VIL = 0.8 V max.

Z Logic high: VIH = 3.8 V min.

Z Logic high: VIH = 9 V max.

X Maximum Encoder frequency: 1 MHz

X Decoder type: Quadrature, 4X resolution

X Decoder counts: -8388608 to +8388607

X Positional Comparator Trigger to initiate AI acquisition once

condition is met

X Data transfers: Programmed I/O

16 Introduction

Page 33

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Isolated Digital Inputs

X Number of channels: 8

X Input type: Bipolar, resistive differential

X Input impedance: 2.7 KΩ || 250 pF

X Input voltage:

Z Logic low: VIL = 0.7 V max.

Z Logic high: VIH = 4.8 V min.

Z Logic high: VIH = 24 V max.

X Maximum input frequency: 5 KHz

X Data transfers: Programmed I/O

X Digital Trigger to initiate AD conversion on DI channel 0,

with programmable detection polarity

Isolated Digital Outputs

X Number of channels: 8

X Output type: N-Type MOSFET current sinker with a com-

mand ground

X Maximum external power-supply voltage: 60 V DC

X Drain-off leakage current: 10 µA

X Drain-on resistance: 75 mΩ

X Maximum drain current: 5 A DC

X Maximum toggling frequency: 5 KHz

X Data transfers: Programmed I/O

Introduction 17

Page 34

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Isolated Power Supplies

X Number of channels: 2

X Nominal output voltage

Z ISO5VDD: 5 V ±0.05V

Z ISOPWR: 5 V ±0.15V

X Output current (Pulse Command channels are unused)

Z ISO5VDD: 160 mA max.

Z ISOPWR: 16 mA max.

X Maximum output current (n

th

channel of Pulse Command

channel is used)

Z ISO5VDD: 160 - (20 x n) mA max.

Z ISOPWR:1 6mA max.

Physical

X Dimensions: 156 mm x 116 mm

X I/O connectors: two 68-pin SCSI-VHDCI conn ec to rs

Power Requirement (typical, 25ºC)

X +5 V DC: 2A

Operating Environment

X Ambient temperature: 0ºC to 45ºC

X Relative humidity: 10% to 90% non-condensing

Storage Environment

X Ambient temperature: -20ºC to 80ºC

X Relative humidity: 5% to 95% non-condensing

18 Introduction

Page 35

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

1.4 Software Support

Software Support

ADLINK provides versatile software drivers and packages to suit

various user approach to building a system. Aside from programming libraries, such as DLLs, for most Windows-based systems,

ADLINK also provides drivers for other application environment

such as LabVIEW

All software options are included in the ADLINK All-in-One CD.

Commercial software drivers are protected with licensing codes.

Without the code, you may install and run the demo version for

trial/demonstration purposes only up to two hours. Contact your

ADLINK dealers if you want to purchase the software license.

Programming Library

For customers who want to write their own programs, ADLINK provides the PCIS-DASK function library that is compatible with various operating systems.

®

.

PCIS-DASK

The PCIS-DASK includes device drivers and DLL for Windows 98/

NT/2000/XP/Vista. DLL is binary compatible across Windows 98/

NT/2000/XP/Vista. This means all applications developed with

PCIS-DASK are compatible with these Windows operating systems. The developing environment may be VB, VC++, Delphi,

BC5, or any Windows programming language that allows calls to a

DLL. The PCIS-DASK user's and function reference manuals are

in the ADLINK All-in-One CD. (\\Manual\Software Package\PCISDASK).

Introduction 19

Page 36

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

This page intentionally left blank.

20 Introduction

Page 37

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

2 Getting Started

This chapter further describes the PCI-9524; a proper installation

environment, its package contents and basic information users

should be aware of.

2.1 Installation Environment

Whenever unpacking and preparing to install any equipment

described in this manual, please refer to the Important Safety

Instructions chapter of this manual.

Only install equipment in well lit areas on flat, sturdy surfaces with

access to basic tools such as flat and cross head screwdrivers,

preferably with magnetic heads as screws and standoffs are small

and easily misplaced.

Recommended Installation Tools

X Phillips (cross-head) screwdriver

X Flat-head screwdriver

X Anti-static Wrist Strap

X Anti-static mat

ADLINK PCI-9524 DAQ cards are electro-static sensitive equipment that can be easily damaged by static electricity. The equipment must be handled on a grounded anti-static mat. The oper ator

must wear an anti-static wristband, grounded at the same point as

the anti-static mat.

Inspect the carton and packaging for damage. Shipping and handling could cause damage to the equipment inside. Make su re that

Getting Started 21

Page 38

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

the equipment and its associated components have no damage

before installing.

The equipment must be protected from static discharge and

physical shock. Never remove any of the socketed parts

CAUTION:

except at a static-free workstation. Use the anti-static bag

shipped with the product to handle the equipment and wear a

grounded wrist strap when servicing.

2.2 Package Contents

Before continuing, check the package contents for any damage

and check if the following items are included in the packaging:

X PCI-9524 Multi-function Data Acquisition Card

X ADLINK All-in-one Compact Disc

X Software Installation Guide

X PCI-9524 User’s Manual

If any of these items are missing or damaged, contact the dealer

from whom you purchased the product. Save the shipping materials and carton in case you want to ship or store the product in the

future.

DO NOT install or apply powe r to equipment tha t is damaged or if there is missing/incomplete equipment. Retain

WARNING:

the shipping carton and packing materials for insp ection.

Please contact your ADLINK dealer/vendor immediately

for assistance. Obtain authorizatio n from your dealer

before returning any product to ADLINK.

22 Getting Started

Page 39

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

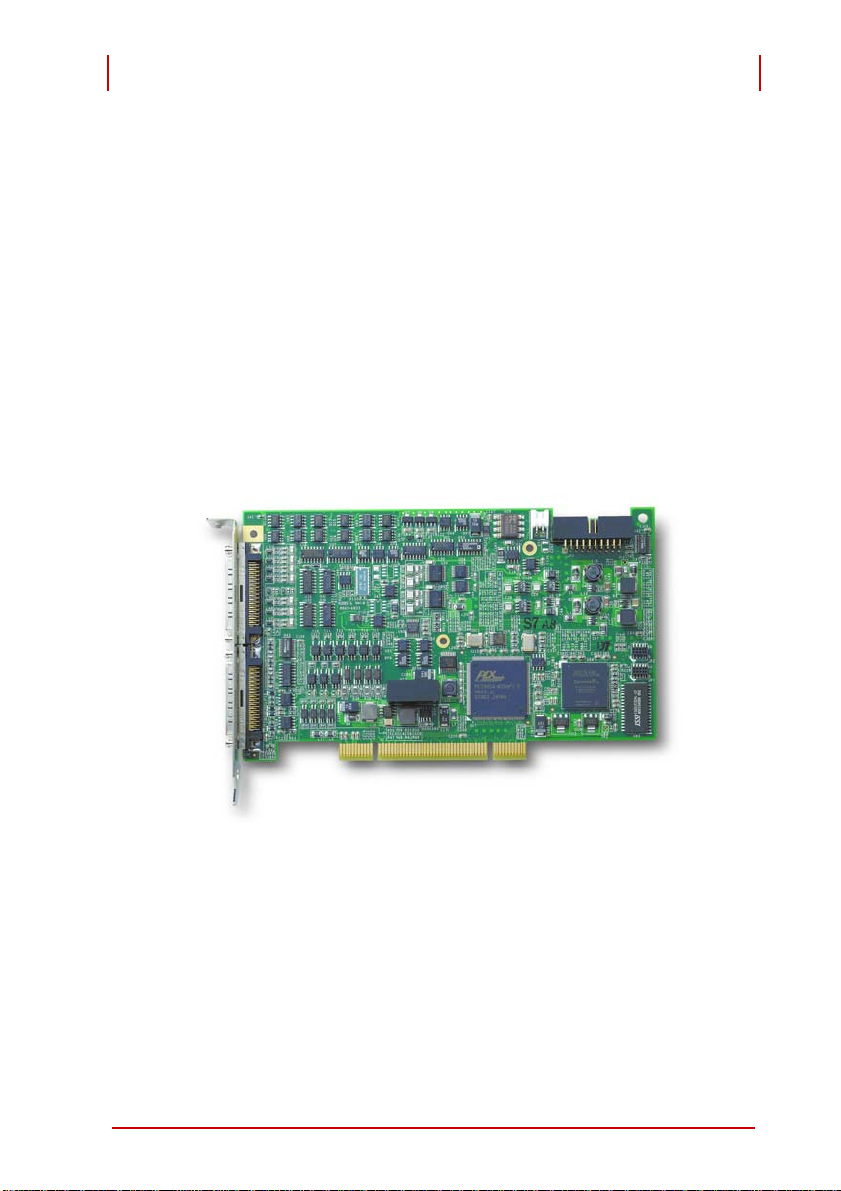

2.3 PCI-9524 Layout

Figure 2-1: PCI-9524 PCB Layout and Mechanical Drawing

Controller

Getting Started 23

Page 40

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

2.4 Installing the Card

To install the card:

1. Turn off the system/chassis and disconnect the power

plug from the power source.

2. Remove the system/chassis cover .

3. Select the PCI slot that you intend to use, then remove

the bracket opposite the slot, if any.

4. Align the card connectors (golden fingers) with the slot,

then press the card firmly until the card is completely

seated on the slot.

5. Secure the card to the chassis with a screw.

6. Replace the system/chassis cover.

7. Connect the power plug to a power source, then turn on

the system/chassis.

24 Getting Started

Page 41

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

2.5 PCI Configuration

1. Plug and Play:

As a plug and play component, the card requests an interrupt

number via its PCI controller. The system BIOS responds with

an interrupt assignment based on the card information and on

known system parameters. These system parameters are

determined by the installed drivers and the hardware load recognized by the system. Users can use the PCI_SCAN software

utility on the ADLINK All-in-One CD to read/check the system

configuration.

2. Configuration:

The board configuration is done on a board-by-board basis for

all PCI boards on your system. Because configuration is controlled by the system and software, there is no jumper setting

required for base-address, DMA, and interrupt IRQ.

The configuration is subject to change with every boot of the

system as new boards are added or removed.

3. Trouble shooting:

If your system doesn't boot or if you experience erratic operation with your PCI board in place, it's likely caused by an interrupt conflict (perhaps the BIOS Setup is incor rectly configured).

In general, the solution, once you determine it is not a simple

oversight, is to consult the BIOS documentation that comes

with your system.

Getting Started 25

Page 42

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

This page intentionally left blank.

26 Getting Started

Page 43

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

3 Signal Connections

This chapter describes the connectors of PCI-952 4, an d the signa l

connections between PCI-9524 and external devices. P lease see

Figure 3-1, Figure 3-2 and Figure 3-3 for details.

X CN1/CN2 - 68-pin VHDCI Connector

X SSI - SSI Connector

3.1 Connectors & Pin Assignments

PCI-9524 is equipped with two 68-pin VHDCI connectors. They

are used for digital input/output, analog input/output, etc. The SSI

connector is used for system synchronization.

Signal Connections 27

Page 44

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Figure 3-1: CN1 Connector & Pin Assignments

Pin # Pin #

AI0+ 34 68 AI0-

VEX0+ 33 67 VEX0-

VEX_SEN0+ 32 66 VEX_SEN0-

NC 31 65 NC

AI1+ 30 64 AI1-

VEX1+ 29 63 VEX1-

VEX_SEN1+ 28 62 VEX_SEN1-

NC 27 61 NC

AI2+ 26 60 AI2-

35

68

1

34

VEX2+ 25 59 VEX2-

VEX_SEN2+ 24 58 VEX_SEN2-

NC 23 57 NC

AI3+ 22 56 AI3-

VEX3+ 21 55 VEX3-

VEX_SEN3+ 20 54 VEX_SEN3-

NC 19 53 NC

AGND 18 52 AGND

AIH4 17 51 AIL4

AIH5 16 50 AIL5

AIH6 15 49 AIL6

AIH7 14 48 AIL7

AGND 13 47 AGND

AGND 12 46 AGND

AGND 11 45 AGND

AGND 10 44 AGND

AGND 9 43 AGND

AGND 8 42 AGND

AGND 7 41 AGND

AGND 6 40 AGND

AGND 5 39 AGND

AO0 4 38 AGND

AGND 3 37 AGND

AO1 2 36 AGND

AGND 1 35 AGND

28 Signal Connections

Page 45

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Figure 3-2: CN2 Connector & Pin Assignment s

Pin # Pin #

PULSE0_A+ 34 68 PULSE0_APULSE0_B+ 33 67 PULSE0_BISO5VDD 32 66 ISOGND

PULSE1_A+ 31 65 PULSE1_APULSE1_B+ 30 64 PULSE1_BISO5VDD 29 63 ISOGND

PULSE2_A+ 28 62 PULSE2_APULSE2_B+ 27 61 PULSE2_BISO5VDD 26 60 ISOGND

35

68

ENC0_A+ 25 59 ENC0_A-

1

ENC0_B+ 24 58 ENC0_BISOPWR 23 57 ISOGND

ENC1_A+ 22 56 ENC1_AENC1_B+ 21 55 ENC1_BISOPWR 20 54 ISOGND

ENC2_A+ 19 53 ENC2_AENC2_B+ 18 52 ENC2_BISOPWR 17 51 ISOGND

IDI0+ 16 50 IDI0IDI1+ 15 49 IDI1IDI2+ 14 48 IDI2IDI3+ 13 47 IDI3ISOPWR 12 46 ISOGND

IDI4+ 11 45 IDI4-

34

IDI5+ 10 44 IDI5IDI6+ 9 43 IDI6IDI7+ 8 42 IDI7ISOPWR 7 41 ISOGND

IDO0 6 40 IDO1

IDO2 5 39 IDO3

EXT_ISOPWR 4 38 ISOGND

ISOPWR 3 37 ISOGND

IDO4 2 36 IDO5

IDO6 1 35 IDO7

Signal Connections 29

Page 46

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Figure 3-3: SSI Connector & Pin Assignments

PIN Signal Name

11 SSI_AD_TRIG_IN

1, 3, 5, 7, 9, 13, 15 RS V

17 NC

19 NC

2, 4, 6,…, 20 DGND

1

19

2

20

30 Signal Connections

Page 47

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Table 3-1: I/O Signal Descriptions

Signal Name Reference Direction Description

Differential analog input channels.

AIn+ AIn- Input

VEXn+ VEXn- Output

VEX_SENn+ VEX_SENn+ Input

AGND -- -- Analog ground.

AOn AGND Output Single-ended analog output channel.

PULSEn_A+ PULSEn_A- Output

PULSEn_B+ PULSEn_B- Output

ENCn_A+ ENCn_A- Input Encoder phase A inputs.

ENCn_B+ ENCn_B- Input Encoder phase B inputs.

IDIn+ IDIn- Input

IDOn+ IDOn- Output

Channels 0 to 3 are for load-cell

transducer inputs

are for general purpose analog inputs.

Analog outputs for transducer voltage

excitation, in selectable ranges of 2.5V or

10V.

Connect one excitation source to only one

load-cell transducer; sharing a common

wiring between transducers will degrade

gain accuracy.

Up to four 120-ohm load-cells can be

connected to one PCI-9524. Load-cells

with larger impedance can also be used.

Remote-sense analog inputs for

transducer excitation sensing.

Always connect VEX_SENn+ to VEXn+,

VEX_SENn- to VEXn-, and as close as

possible to transducers excitation

terminals.

Pulse-command differential voltage

outputs.

As Clock signal in single phase mode.

As Clock signal in CLK/DIR mode.

As CW signal in CW/CCW mode.

Pulse-command differential voltage

outputs.

Unused in single phase mode.

As DIR signal in CLK/DIR mode.

As CWW signal in CW/CCW mode.

Isolated digital inputs.

Accepts bipolar input signal.

Isolated digital outputs. Using N-MOS as

current sinker.

(1) (2)

, and channels 4 to 7

Signal Connections 31

Page 48

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

ISO5VDD ISOGND Output

ISOPWR ISOGND Output

EXT_ISOPWR ISOGND Input

ISOGND -- -- Isolated digital ground.

NC -------- -------- Shall be le ft unconnec t ed.

Isolated 5V output from internal regulator.

Insignificant driving capacity, used for

resistor pull-ups only.

Isolated 5V output from internal regulator.

Insignificant driving capacity, used for

resist or pull-ups only. Ma y be m odi f i ed to

have 12 V outp ut c apability.

Use in conjuncti on with IDOn and external

power s uppl y, to provide current ret urn

path fo r fly -wheel diodes.

1) Short AIn+ and AIn- to AGND for unused transducer input

channels

NOTE:

NOTE:

2) Exceeding the maximum input voltage range may permanently degrade performance, or damage the input amplifier.

32 Signal Connections

Page 49

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

3.2 Analog Input Signal Connections

PCI-9524 provides eight differential analog input channels. To

avoid ground loops and to achieve accurate low-level-signal measurements the PCI-9524 provides only differential input mode.

3.2.1 Signal Sources

Ground-Referenced Signal Sources

A ground-referenced signal is connected in some way to th e bu ildings power system. That is, the signal source is already connected

to a common ground point with respect to PCI-9524, assuming

that the computer is plugged into the same power system. Nonisolated outputs of instruments and devices that plug into the

buildings power system are ground-referenced signal sources.

Floating Signal Sources

A floating signal source is not connected in any way to the buildings ground system. A device w ith an isolated output is a floating

signal source, such as optical isolator outputs, batteries, transformer outputs, load-cells and thermocouples.

3.2.2 Input Configurations

Differential input mode for transducer input channels

AI channels 0 to 3 are dedicated to connecting to load-cell transducers in differential mode.

A load-cell is comprised of four resist ive strain-gauges connec ted

in Wheatstone bridge form, and is inherently a floating differential

output device. Since a load-cell transducer is a passive device, it

requires voltage excitation in order to transform the resistive

change into electrical signals. A typical four-wire connection is

shown on Figure 3-4.

Signal Connections 33

Page 50

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Figure 3-4: Connecting to a four-terminal load-cell transducer

using a four-wire connection

+Vex

-Vex

+Vo

-Vo

Load-cell Transducer PCI-9524

VEXn+

VEX_SENn+

VEXn-

VEX_SENn-

AIn+

AIn-

NC

NC

It is recommended to enable the remote-sense function, and loopback the VEXn+/- to VEX_SENn+/- on the terminal board you're

using when connecting to the transducer. A lengthy extension

cable between PCI-9524 and the terminal board inevitably has

some lead resistance that result s in voltage drop; looping-back the

excitation on the terminal board creates a six-wire connection and

compensates for voltage drop.

A better approach is to use specially designed load-cell transducers having two additional SENSE terminals. The voltage dif ference

across the bridge excitation junctions is fed back to the voltage

excitation circuitry by two separate 'sense-wire s', to fu rthe r correc t

the voltage drops due to the resistance in the excitation wiring. Be

sure to enable the remote-sense function to take full advantage of

a six-wire connection. A typical six-wire connection is shown in

Figure 3-5.

34 Signal Connections

Page 51

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Figure 3-5: Connecting to a six-terminal load-cell transducer

using a six-wire connection

+Vex

+Sense

-Vex

-Sense

+Vo

-Vo

Load-cell Transducer

VEXn+

VEX_SENn+

VEXn-

VEX_SENn-

AIn+

AIn-

NC

NC

Whether to use a six-wire connection is dependent on the impedance of the load-cell transducers you are using, length of the wiring cable, wire-gauge inside the cable, and the required

measurement accuracy. We recommend you to use a six-wire

connection as the default connection method for high-accuracy

load-cell transducers.

To add remote-sense capability to a four-terminal load-cell trans ducer, simply run two separate sense-wires, and join them

together with the excitation wires at the transducer's excitation terminals.

Signal Connections 35

Page 52

PCI-9524 ADLINK Technology Inc.

A

A

A

A

User’s Manual Copyright 2008

Figure 3-6: Connecting to a four-terminal load-cell transducer

using a six-wire connection

+Vex

-Vex

+Vo

-Vo

VEXn+

VEX_SENn+

VEXn-

VEX_SENn-

AIn+

AIn-

NC

NC

Load-cell Transducer

PCI-9524

Differential input mode for general purpose input channels

AI channels 4 to 7 are designed for connecting to ground-referenced or floating sources in differential mode.

The differential input mode provides two inpu ts that re spond to signal voltage difference between them. If the signal source is

ground-referenced, the differential mode can be used for the common-mode noise rejection. Figure 3-7 presents an example of

ground-referenced signal source connections under differential

input mode.

Figure 3-7: Ground-referenced source and differential input

Ground

Referenced

Signal

Source

Commonmode noise &

Ground

potential

n = 4, ..., 7

Vcm

In+

In-

Input Multipexer

+

-

IGND

Instrumentation

mplifier

To A/D

+

Converter

-

36 Signal Connections

Page 53

ADLINK Technology Inc. PCI-9524

A

A

A

A

Copyright 2008 User’s Manual

Figure 3-8 shows how to connect a floating signal source to PCI9524 in differential input mode. For floating signal sources, you

need to add a resistor at each channel to provide a bias return

path. The resistor value should be about 100 times the equivalent

source impedance. If the source impedance is less than 10 0

Ω, you

can simply connect the negative side of the signal to AIGND as

well as the negative input of the Instrumentation Amplifier without

any resistors. In differential input mode, less noise couples in to the

signal connections than in single-ended mode.

Figure 3-8: Floating source and differential input

Ground

Referenced

Signal

Source

n = 4, ..., 7

In+

In-

Input Multipexer

+

-

IGND

Instrumentation

mplifier

To A/D

+

Converter

-

Signal Connections 37

Page 54

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

3.3 Isolated Digital Signal Connection

PCI-9524 provides three opto-isolated encoder input channels,

three opto-isolated pulse-command outputs, eight channel optoisolated digital inputs as well as eight channel isolated digital outputs. Also, a built-in isolated power supply can be used as a resistors pull-up source.

3.3.1 Signal Sources and Terminal Devices

Open-collector and open-drain outputs

Open-collector or open-drain output stages are commonly used in

industrial I/O. Open-collector/open-drain output stages made of

NPN or N-MOS type transistors are for sink-type drivers, while

those made of PNP or P-MOS type are for source-type drivers. A

sink-driver sinks current from the external pull-up resistor when it

is activated, and floats when it is inactivated; conversely, a sourcedriver sources current to the external pull-down resistor when it is

activated, and floats when it is inactivated. High-side voltage can

usually go as high as the output transistor can tolerate, and hence

offers a wider, more versatile output voltage selection. The drawback is that when the output stage is inactivated, either the signal

fall-time of a source-driver or the rise-time of a sink-driver, is determined by the RC time-constant formed by the pull-up/pull-down

resistor and the stray capacitance. The asymmetrical rise/fall-time

somehow limits the frequency response of the output stage.

Push-pull outputs

Push-pull output stages are comprised of a complementary transistor pair, say, a PNP plus a PNP, or a P-MOS plus an N-MOS.

Unlike open-collector output stages, they can sink or source current and hence a symmetrical rise/fall-time that is independent of

the external load resistance. Push-pull output st ages can generally

toggle at a much faster speed than open-collector output stages.

38 Signal Connections

Page 55

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Line-driver outputs

A Line-driver output stage is of differential output type, providing a

normal output and a complementary output for each signal port. A

Line-driver usually works at a much lower supply voltage and can

toggle quickly. By utilizing differential transmission topology, the

transmission distance can be extende d considerably and w ith relatively low EMI.

The line-driver used on PCI-9524 is of voltage-driving type

AM26LS31, compliant with ANSI TIA/EIA-422-B requirements.

Either one of the two complementary outputs can be regarded as

a single-ended push-pull output, and can be connected to an o ptoisolated input or a TTL input.

Opto-coupler Inputs

Opto-coupler inputs are of current inpu t type devices, made of a

light-emitting-diode (LED) and an integrated light-sensitive tran sistor. They accept wide input voltage ranges, provided that the input

current is limited by a series external resistor in order to protect

the integrated LED device.

Line-receiver inputs

The line-receiver, as its name implies, is used to accept signals

from line-drivers. It's of differential input type, providing a normal

input and a complementary input for each signal port.

1) The isolated ground (ISOGND) is shared between all isolated functions in PCI-9524. Make sure the ISOGND is con-

NOTE:

NOTE:

Signal Connections 39

nected to a known ground potential, only at one point in the

system.

2) Do not let the ISOGND float, nor connect it directly to a

chassis, as it may cause EMI and/or accumulate a charge that

lead to safety hazards.

3) Shield the exposed ISOGND pins, connectors, and wiring, if

possible to run a ground potential that is greater then 30-VDC.

4) Do not connect the ISOGND to analog ground (AGND), the

noise on ISOGND will ruin analog performance.

Page 56

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

3.3.2 Connecting to/from External Encoders

Figure 3-9: Connecting to an external encoder

with NPN sink drivers

Vcc

+ISOPWR

Phase A

Phase B

GND

ENCn_A+

249O

ENCn_A-

ENCn_B+

249O

ENCn_B-

ISOGND

Encoder PCI-9524

Figure 3-10: Connecting to an external encoder

with PNP source drivers

Vcc

Phase A

Phase B

GND

+ISOPWR

ENCn_A+

249O

ENCn_A-

ENCn_B+

249O

ENCn_B-

ISOGND

PCI-9524 Encoder

40 Signal Connections

Page 57

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

Figure 3-11 : Co nn e cti ng to an external encoder

with push-pull source drivers

Vcc

+ISOPWR

Phase A

Phase B

GND

ENCn_A+

249O

ENCn_A-

ENCn_B+

249O

ENCn_B-

ISOGND

PCI-9524 Encoder

Figure 3-12: Connecting to an external encoder

with differential line-drivers

Vcc

Phase A

Phase A'

Phase B

Phase B'

GND

+ISOPWR

ENCn_A+

249O

ENCn_A-

ENCn_B+

249O

ENCn_B-

ISOGND

PCI-9524 Encoder

Signal Connections 41

Page 58

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

3.3.3 Connecting to External Servo Amplifiers

Figure 3-13: Connecting to an external servo-amplifier

with opto-coupler inputs

ISO5VDD

VDD

PULSEn_A+

PULSEn_A-

PULSEn_B+

PULSEn_B-

ISOGND

CLK/CW

470O

COM0

DIR/CCW

470O

COM1

ISOGND

Servo AmplifierPCI-9524

Figure 3-14: Connecting to an external servo-amplifier

with differential line-receivers

ISO5VDD

PULSEn_A+

PULSEn_A-

PULSEn_B+

PULSEn_B-

ISOGND

VDD

CLK+/CW+

CLK-/CW-

DIR+/CCW+

DIR-/CCW-

ISOGND

Servo AmplifierPCI-9524

42 Signal Connections

Page 59

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

3.3.4 Interfacing Isolated DO with External Loads

Connecting to external resistive loads

Figure 3-15 presents connecting to external resistive loads. The

left side illustrates driving an external LED using the internal

ISOPWR source; the right side illustrates driving an external 5W,

24-VDC Bulb using an external power supply.

Figure 3-15: Connecting to an external resistive load

from the isolated DO sink driver

5 VDC

ISOPWR

5 VDC

ISOPWR

LED

330

O

PCI-9524

EXT_ISOPWR

Bulb

IDOn

24 VDC

ISOGND

EXT_ISOPWR

IDOn

ISOGND

PCI-9524

Connecting to external inductive loads

Figure 3-16 presents connecting to external resistive loads. The

left side illustrates driving a 5-VDC relay coil using the internal

ISOPWR source; the right side illustrates driving an external 12VDC relay coil using an external power supply.

Signal Connections 43

Page 60

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Figure 3-16: Connecting to an external inductive load

from an isolated DO sink driver

24 VDC

Coil

ISOPWR

5 VDC

ISOPWR

5 VDC

EXT_ISOPWR

EXT_ISOPWR

Coil

IDOn

ISOGND

PCI-9524

IDOn

ISOGND

PCI-9524

44 Signal Connections

Page 61

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

3.3.5 Interfacing Isolated DI with External Devices

Connecting to a low-side push button

Alternatively, the push button can be connected at the high-side,

i.e. between the ISOVDD and IDn+ pins . Also, the IDIn + and IDIn-

can be interchanged, since the opto-coupler accepts bipolar input

signals.

Figure 3-17: Connecting to a low-side push button

Push Button

ISO5VDD

IDIn+

IDIn-

ISOGND

5 VDC

2.7KO

PCI-9524

Signal Connections 45

Page 62

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

Connecting to an external sink driver

The sink driver can also be replaced by a mechanical switch, a

proximity-sensor, etc. An external power-supply can be used

instead of the internal isolated power source.

Figure 3-18: Connecting to an external sink driver

24 VDC

Open Collector /

Open Drain

GND

ISO5VDD

IDIn+

IDIn-

ISOGND

5 VDC

2.7KO

PCI-9524

46 Signal Connections

Page 63

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

4 Operation Theory

The operation theory of the functions of PCI-9524 are described in

this chapter. The functions include A/D conversion, D/A conversion, pulse-commands, encoder inputs, and isolated digital I/O.

Operation theory helps users understand how to configure and

program PCI-9524.

4.1 PCI-9524 Function Diagram

Figure 4-1: PCI-9524 Function Diagram

VEX0

2

VEX1

VEX2

VEX3

VEX_SEN0

VEX_SEN1

VEX_SEN2

VEX_SEN3

Input Filter

2

2

2

2

2

2

2

2

SOA Protection

M

U

X

2

2

2

AI0

2

AI1

2

AI2

2

AI3

2

AI4

2

AI5

2

AI6

2

AI7

2

AO0

AO1

OPAMP

M

U

X

Reference Bridge

Calibration Sources

M

U

X

Voltage

Regulator

INA

2 2

PGA

2 2

OPAMP

OPAMP

PCI 12V

ADC

Reference Voltage

Generator

ADC

DAC

DAC

Auto-zero

Controller

4

SPI BUS

IIR Filter

Block

Fast Polling

Port Control

AI Timing Control

SPI BUS

4

SPI BUS

AD FIFO #0

4

SPI BUS

4

AD FIFO #1 DMA

Interrupt

Controller

PCI Bus Controller

PULSE0

PULSE1

PULSE2

ENC0

ENC1

ENC2

ISO5VDD

ISOPWR

IDI[7..0]

ID0[7..0]

ISOGND

2

2

2

2

2

2

8

8

Diff Pulse Driver #0

Diff Pulse Driver #1

Diff Pulse Driver #2

Isolated DO MOSFET

Isolated Plane

ISO5VDD

DC-DC

Isolated

Barrier

Isolated

Barrier

Isolated

Power

Isolated

Barrier

Isolated

Barrier

Pulse Command Generator

6

6

8

8

Quadrature Decoder

PCI 5V

Isolated DIO

Trigger

Operation Theory 47

Page 64

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

4.2 Analog Input Channels

The following sub-sections depict the internal operations of signal

amplification, conversion, post-processing, and calibration.

4.2.1 Signal Acquisition and Processing Flow

PCI-9524 was designed to detect weak signals through proper signal conditioning, amplification and digital post filtering, as

depicted.

Figure 4-2: Signal acquisition and data processing flow

for transducer input channels

At the first stage, the voltage excitation applied to the load-cell

transducer transforms the resistive change into an electric signal,

in the range of tens of milli-volts. Before entering amplification

stage, the signal passes through a passive filter stage to filter out

unwanted interference. A custom-made, low temperature coefficient instrumentation amplifier provides a fixed gain of 25, and the

necessary level-shift (1). The amplified signal is fed into a sigmadelta modulator running at 1.92 MH z, pushing the in- band quantization noise to a higher frequency, and filtering most of which out

using a 5-order SINC filter. The filtered digital data passes through

an averager to tune down the data rate to a specific sa mpling r ate.

A built-in correction algorithm automatically calibrates the output

data, which can then be pushed into the on-board FIFO for data

transfer to PC memory, or sent to the next DSP stage described

below.

48 Operation Theory

Page 65

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

There are four programmable post-processing IIR digital filter

banks (2), one for each load-cell transducer input channel. Each

bank is a fixed-coefficient, variable-length IIR digital filter, and can

be instructed to flush itself once a large input-step is observed.

The processed data are pushed into the on-board FIFO for DMA

data transfer to PC memory; otherwise, they are read by user

applications directly, without buffering, through fast-polling data

transfers.

The software driver utilizes a look-up-table to correct the null offset

and gain error of the analog front-end, using a built-in 1.25k

Ω

bridge, to provide adequate absolute accuracy for applications

that do not calibrate load-cell transducers in the field. For applications that always perform null and gain calibrations in the field,

users can manipulate the 2's complementary binary code directly.

Throughout the acquisition and processing flow, remote-sensing

(3) and auto-zeroing (4) are working simultaneously to compensate voltage drops over excitation wires, and to remove thermal

drift and 1/f noise in signal paths. The dynamic error co mpensation

is essential to achieve high-stability measurements; otherwise the

output will drift at a very low frequency that is difficult to be reconstructed using any other post-filtering method.

1) For general purpose analog input channels, i.e. channels 4

to 7, the available gain ranges are 1, 2, 4, and 8.

NOTE:

NOTE:

2), 3), 4) The general purpose analog input channels, i.e. channel 4 to 7, do not support the remote-sensing and auto-zeroing

functions.

4.2.2 How to Define a 1 in 200,000 Count Resolution

It is common in the weight-scaling or material-testing industries to

specify the resolution capability of a measurement device such as

PCI-9524, in Counts or Digits, rather than in bits.

Operation Theory 49

Page 66

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

For example, a measureme nt de vice that is capable of resolving 1

in 1000 counts, can successfully register a 1-gram change on a 1kg capacity load-cell transducer. Consequently, a measurement

device that is capable of resolving 1 in 200,000 counts, can successfully register a 1-gram change on a 200-kg capacity load-cell

transducer.

In practical applications, the sensitivity of load-cell transducers

vary from model to model (typically form 1 to 4mV/V), and the fullscale output range of a tran sducer is u sually only a fraction of t he

full-scale input range of a measurement device. The convenience

of using Counts rather than Bits, is that the specified Count

achievable by a measurement device, is relative to the transducers full-scale output, rather than the full-scale input range of the

analog input amplifier. Thus, theoretically, no matter what the sensitivity of the 200-kg capacity load-cell transducer you are using, a

200,000 count measurement device can always resolve a 1-gram

measurement.

Please also note, as a weight/force indicator , the displayed Co unt s

or Digits shall be flicker-free while the applied force is in steady

state. Therefore, a measurement device specified to have a

200,000 count resolution, must guarantee peak-to-peak system

noise and short-term drift to below 1 / 200,000, or 5-ppm of the

full-scale output range of the transducer.

The specified 200,000 count resolution capacity of PCI-9524 is

verified by a precision load-cell simulator utilizing 3mV/V sensitivity, under 10-V excitation and using a six-wire remote-sense connection. The auto-zero function is enabled throughout acquisition,

while the ADC sampling rate is set to 60 samples-per-second (the

equivalent data rate is 29 samples-per-second, see Section 4.2.3

for details), and using an IIR post digital filter of 32-taps (see

Section 4.2.9 for details). Under these conditions, the peak-topeak system noise and drift are well below 150-nano-Volts, the

limit of 1 in 200,000 count resolution. The recording duration is 30

50 Operation Theory

Page 67

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

minutes, and the ambient temperature fluctuation is within ± 1ºC

throughout.

4.2.3 Data Rate versus Sampling Rate

Due to the internal delay time and manipulations require d for autozeroing and remote-sensing functions, the 'Sampling Rate' that

the ADC is actually running at can be different from the actual

'Data Rate'.

In the following sections, the term 'Sampling Rate' and 'Data Rate'

are of different meaning. The 'Samplin g Rate' st ands for the ADC's

internal conversion speed set by users, whereas the 'Data Rate'

stands for the output rate of the processed data.

See Table 4-1 for equivalent data rates versus ADC actual sampling rates, under different operating modes. When programming

through a software API, users must set the desired ADC sampling

rate, and the actual 'Data Rate' will be looked-up and returned by

the software API for your reference.

4.2.4 Auto-scan, Multiplexing and Settling Time

PCI-9524 uses multiplexing for transducer input channels, and up

to four transducers can be attached. When the Auto-scan feature

is enabled, the hardware multiplexes and scans the four transducers in sequence; AI0, AI1, AI2, AI3, and AI0…etc.

Multiplexing increases the number of transducers that a single

amplifier can deal with, it does however require additional time for

the signal to rise/fall and propagate through the circuit stages.

The time delay therefore required is called 'Settling Time'. Besides

the propagation delay within PCI-9524, the parasitic in the cabling,

the impedance of the transducers, and the amplitude difference

between channels, affect final settling time figures.

Operation Theory 51

Page 68

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008

PCI-9524 is programmed to have 400-µs defa ult set tling tim e, and

this works best with low impedance transducers, such as 120 or

350-ohm load-cells. Insufficient settling time may causes interchannel crosstalk; the new signal will not be able to fully settle to

its final value, and some 'residual' signals in the previous measurement will be present in the current measurement. Users may

increase the hardware settling time, to check if a lesser inter-channel crosstalk is perceived. See Table 4-1 for the equivalent Data

Rates versus ADC actual Sampling Rates, under different operating modes.

52 Operation Theory

Page 69

ADLINK Technology Inc. PCI-9524

Copyright 2008 User’s Manual

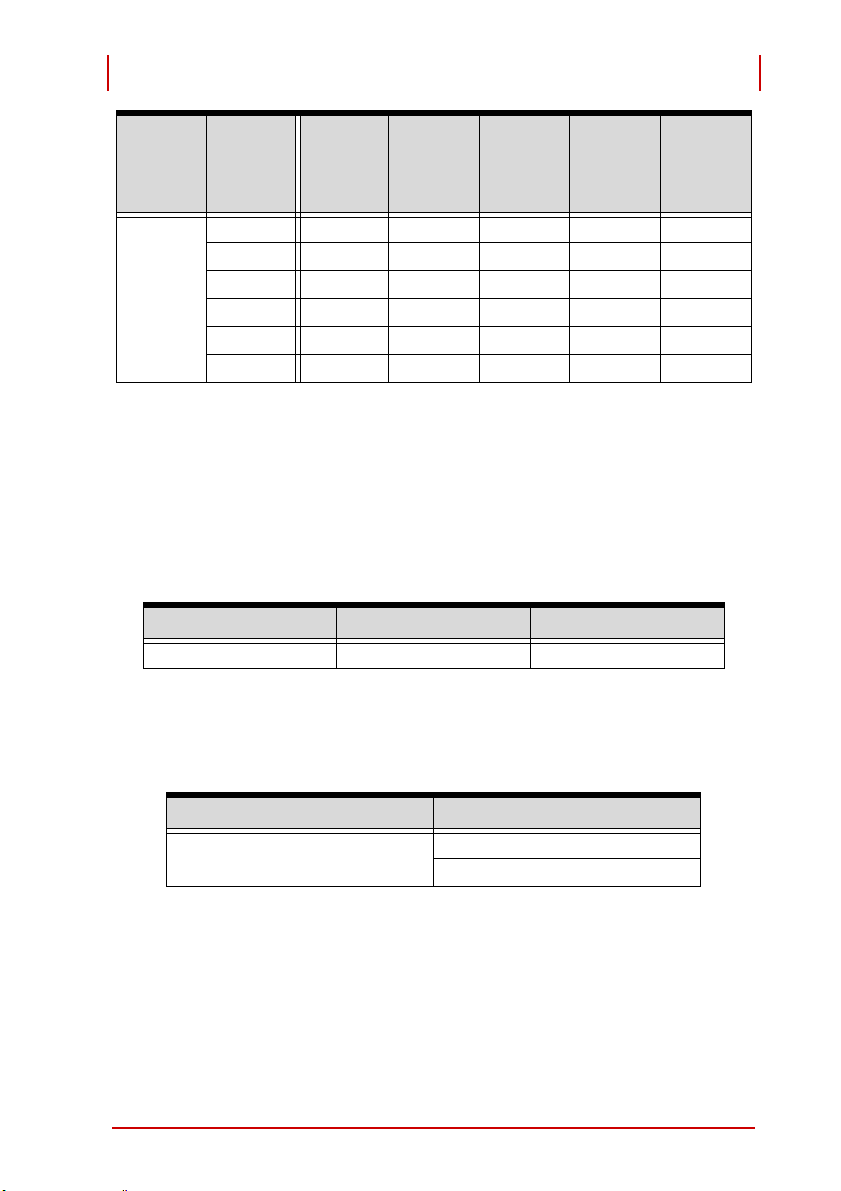

Table 4-1: Data Rates vs. Multiplexing, Auto-zero &

ADC Sampling Rates, in Samples-per-second (SPS)

Non-multiplexed Multiplexed ADC

Sampling

Rate

30,000

15,000

7,500

3,750

2,000

1,000

500

100

60*

50**

30*

25**

15*

10***

5***

2.5***

Auto-zero

Disabled

30,000

15,000

7,500

3,750

2,000

1,000

500

100

60

50

30

25

15

10

5

2.5

Auto-zero

Enabled

818.73 1637.47 818.73

768.40 1536.81 768.40

703.53 1407.06 703.53

594.74 1189.48 594.74

462.66 925.33 462.66

316.32 632.63 316.32

193.75 387.49 193.75

47.26** 94.51 47.26**

29.00 58.00 29.00

24.29 48.59 24.29

14.74 29.49 14.74

12.32 24.64 12.32

7.44 14.87 7.44

4.97 9.94 4.97

2.49 4.99 2.49

1.25 2.5 1.25

Auto-zero

Disabled

Auto-zero

Enabled

1) For the equivalent data rate per channel, divide the multiplexed data rate figures by four.

NOTE:

NOTE:

2) *60 Hz Rejection, **50 Hz Rejection, ***Simultaneous 50

and 60 Hz Rejection.

3) Auto-zero function is always disabled for general purpose

input channels, i.e. channels 4 to 7.

4.2.5 Power Line Noise Rejection

The SINC filter built into the PCI-9524 works best for suppressing

power line noise, if the ADC sampling rate is set to match power

line frequency. The harmonics of the power line noise can also be

suppressed as well, see Ta ble 4-3 for illustration. For applications

demanding high-stability, low-drifting measurements, selecting a

sampling rate that provides inherent power line noise rejection is

recommended.

Operation Theory 53

Page 70

PCI-9524 ADLINK Technology Inc.

User’s Manual Copyright 2008