Page 1

PCI-8254 / PCI-8258

DSP-Based 4/8

Advanced Motion Control Card

User manual

Ver si on: 2.00

Updated: August 13, 2014

P/N: 50-15085-1000

Advance Technologies; Automate the World.

Page 2

Revision History

Revision Date Description

2.00 2014-08-13 First release

ii

Page 3

PCI-8254 / PCI-8258

Preface

Copyright 2014 ADLINK Technology, Inc.

This document contains proprietary information protected by

copyright. All rights are reserved. No part of this manual may be

reproduced by any mechanical, electronic, or other means in any

form without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect,

special, incidental, or consequential damages arising out of the

use or inability to use the product or documentation, even if

advised of the possibility of such damages.

Environmental responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the

European Union's Restriction of Hazardous Substances (RoHS)

directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.We

have enforced measures to ensure that our products,

manufacturing processes, components, and raw materials have as

little impact on the environment as possible. When products are at

their end of life, our customers are encouraged to dispose of them

in accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademark

Product names mentioned herein are used for identification

purposes only and may be trademarks and/or registered

trademarks of their respective companies.

Preface iii

Page 4

Conventions

Take note of the following conventions used throughout this

reference to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform

tasks.

NOTE

NOTE

Information to prevent minor physical injury, component

damage, data loss, and/or program corruption when trying to

CAUTION

WARNING

complete a task.

Information to prevent serious physical injury, component

damage, data loss, and/or program corruption when trying to

complete a specific task.

iv Preface

Page 5

PCI-8254 / PCI-8258

Table of Contents

Revision History...................................................................... ii

Preface .................................................................................... iii

List of Figures ........................................................................ ix

List of Tables........................................................................ xiii

1 Introduction ........................................................................ 1

1.1 Product Specifications ......................................................... 4

1.2 Software Support ................................................................. 8

Software Support Library ................................................ 8

MotionCreatorPro 2 ........................................................ 8

1.3 Terminal Board .................................................................... 8

2 Getting Start with The Installation.................................. 11

2.1 Package Contents ............................................................. 11

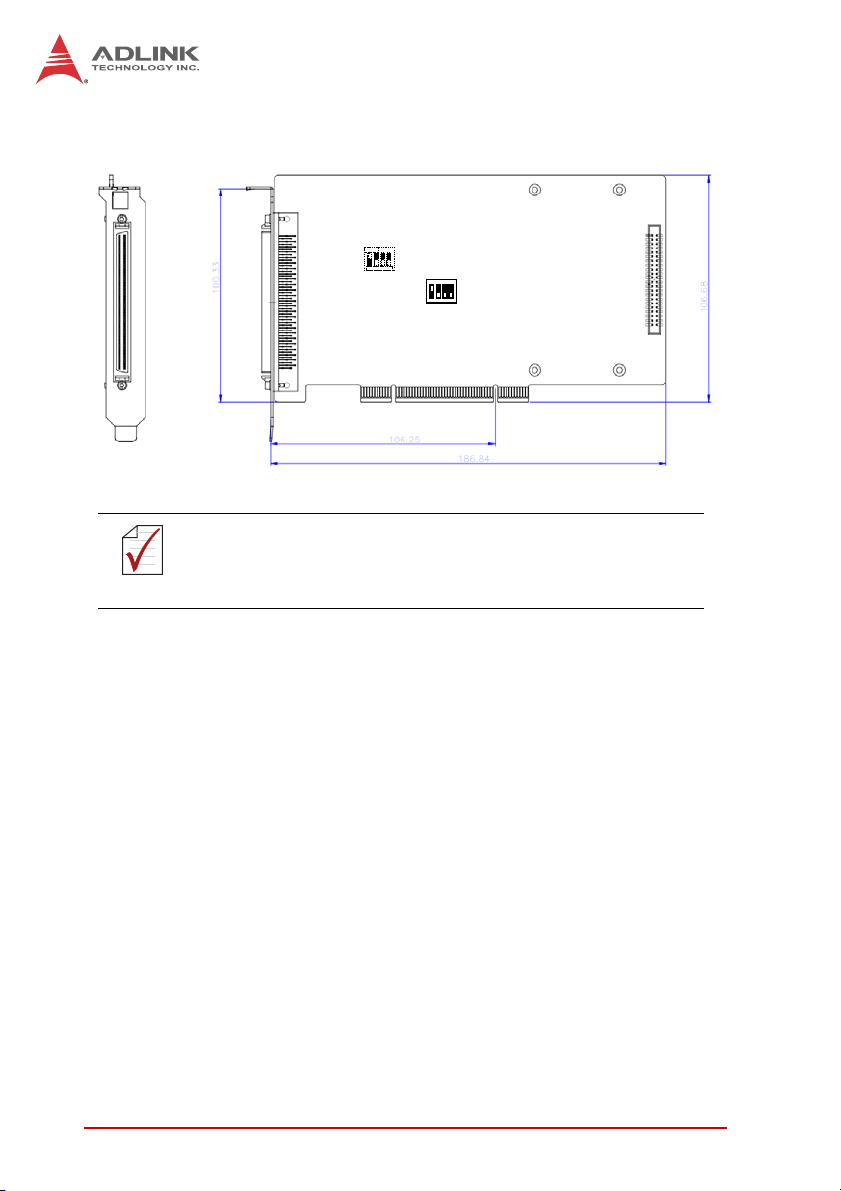

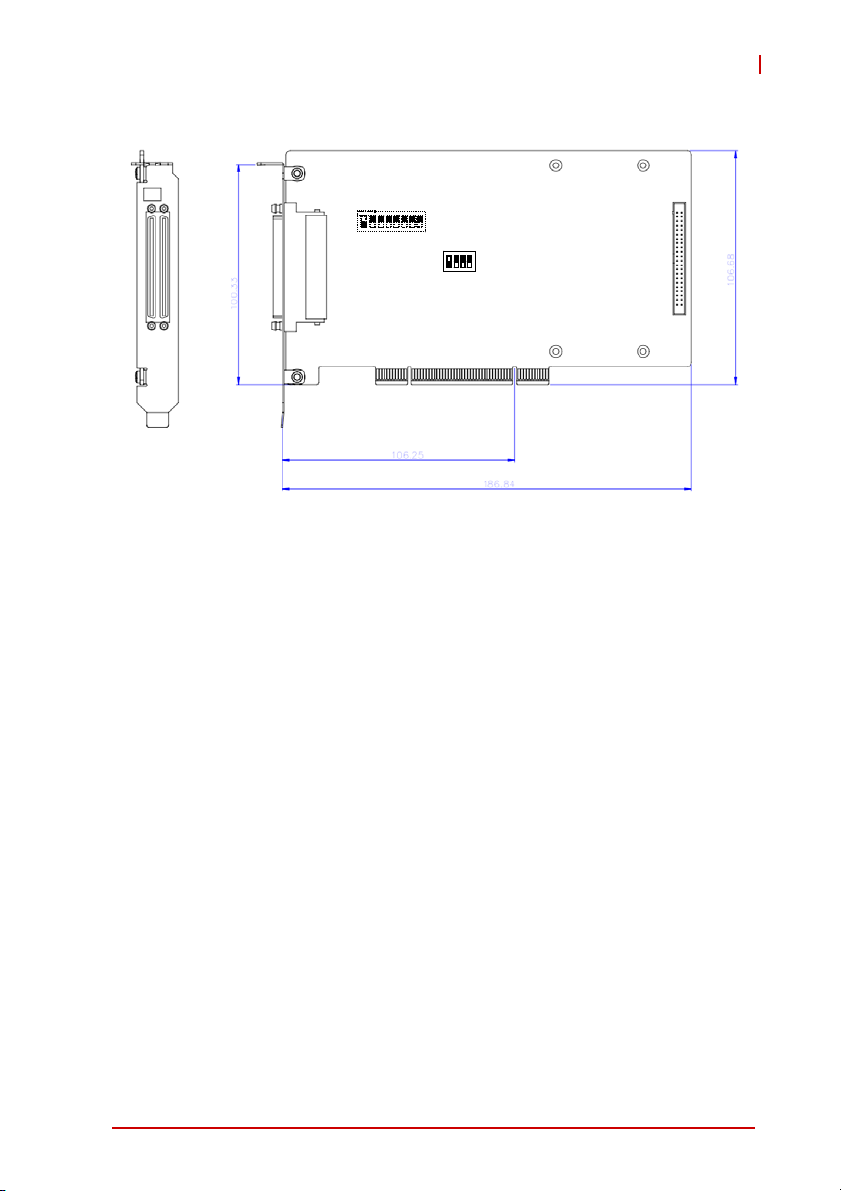

2.2 PCI-8254/PCI-8258 Exterior Profile Diagram .................... 12

2.3 Hardware Installation ......................................................... 14

Hardware Configuration ................................................ 14

Installation Procedures ................................................. 14

Troubleshooting ............................................................ 15

2.4 Software Installation Procedure......................................... 16

2.5 Definitions to Key Connector Signal .................................. 18

PCI-8254:

Connector ..................................................................... 18

PCI-8258: P1-A/B Connector ........................................ 20

PCI-8254/58:

P2 Connector ................................................................ 23

2.6 DIP Switch ......................................................................... 24

S1: Analog Output Mode Settings ................................ 24

SW2: Card ID Switch .................................................... 25

Table of Contents v

Page 6

2.7 IDE 44p – DSUB 37p Bus.................................................. 26

2.8 Exclusive Board - DIN-825-GP4 ........................................ 27

Definitions to Connector ...............................................28

Connector: For Connecting to

PCI-8254/PCI-8258/AMP-204C/AMP-208C ................. 30

S1, S2: EDO/ALM_RST Selection Switch .................... 39

3 Signal Connection ............................................................ 41

3.1 Analog Control Command Signal....................................... 42

3.1.1 Single-ended Type Signal: AOUT+ .......................... 42

3.1.2 Single-ended Type Signal: AOUT+, AOUT- ............. 42

3.2 Pulse Command ................................................................ 44

3.3 Encoder Input, EA & EB & EZ............................................ 47

3.4 Emergency Stop Input ....................................................... 49

3.5 PEL/MEL Input................................................................... 50

3.6 ORG Input.......................................................................... 52

3.7 INP / ZSP Input .................................................................. 53

3.8 ALM Input .......................................................................... 54

3.9 SVON Output ..................................................................... 55

3.10 Analog Input Signals .......................................................... 56

3.11 Compare & Trigger Output................................................. 57

3.12 Digital Output/Input ............................................................ 59

4 Motion Control Theory ..................................................... 65

4.1 Motion Control Mode and Interface Overview.................... 66

4.1.1 Motion Control Interface ........................................... 66

4.1.2 Control Cycle ............................................................ 73

4.2 Closed-loop Control ........................................................... 75

4.2.1 Close-loop Control Overview .................................... 75

4.2.2 Auto Servo Tuning....................................................80

4.2.3 Manual Servo Tuning................................................84

4.2.4 Filter..........................................................................85

4.2.5 Bode Plot .................................................................. 93

vi Table of Contents

Page 7

PCI-8254 / PCI-8258

4.3 Motion Control Operations................................................. 98

4.3.1 Coordinated System ................................................. 98

4.3.2 Unit Factor ................................................................ 99

4.3.3 Acc/Deceleration Profile ......................................... 102

4.4 Home Move ..................................................................... 108

4.4.1 OGR Signal Homing - Home Mode = 0 .................. 111

4.4.2 EL Signal Homing - Home Mode 1 ......................... 118

4.4.3 Single EZ Signal Homing........................................ 121

4.5 Velocity Move .................................................................. 124

4.6 Jog Move ......................................................................... 127

4.7 Point-to-Point Move ......................................................... 131

4.7.1 Point-to-Point Move ................................................ 131

4.7.2 Synchronous Start .................................................. 132

4.7.3 On The Fly Change ................................................ 133

4.7.4 Continuous PTP Move............................................ 133

4.8 Interpolation ..................................................................... 136

4.8.1 Linear Interpolation................................................. 136

4.8.2 Arc Interpolation ..................................................... 138

4.8.3 Continuous Interpolation......................................... 146

4.9 Motion Status Monitoring ................................................. 152

4.9.1 Motion Status.......................................................... 153

4.10 Application Functions....................................................... 162

4.10.1 Electronic Gearing .................................................. 162

4.10.2 High Speed Position Compare Trigger ................... 164

4.10.3 PWM Control (Laser Control) (VAO Table Control)170

4.10.4 Motion Control and I/O Sampling Function............. 178

4.10.5 Simultaneous Move ................................................ 184

4.10.6 Point Table Movement............................................ 187

4.11 Safety Protection ............................................................. 192

4.11.1 Hardware Protection ............................................... 192

4.11.2 Software Protection ................................................ 195

4.12 Host Interrupt ................................................................... 199

Table of Contents vii

Page 8

Important Safety Instructions............................................. 209

Getting Service .................................................................... 211

viii Table of Contents

Page 9

PCI-8254 / PCI-8258

List of Figures

Figure 1-1: PCI-8254/58 system block diagram............................ 2

Figure 1-2: System installation flow chart ..................................... 3

Figure 2-1: Exterior of your PCI-8254 ......................................... 12

Figure 2-2: Exterior of your PCI-8258 ......................................... 13

Figure 2-3: Exterior of DIN-825-GP4 .......................................... 27

Figure 2-4: Exterior of DIN-825-GP4 .......................................... 28

Figure 3-1: Connection example of differential analog output signal

43

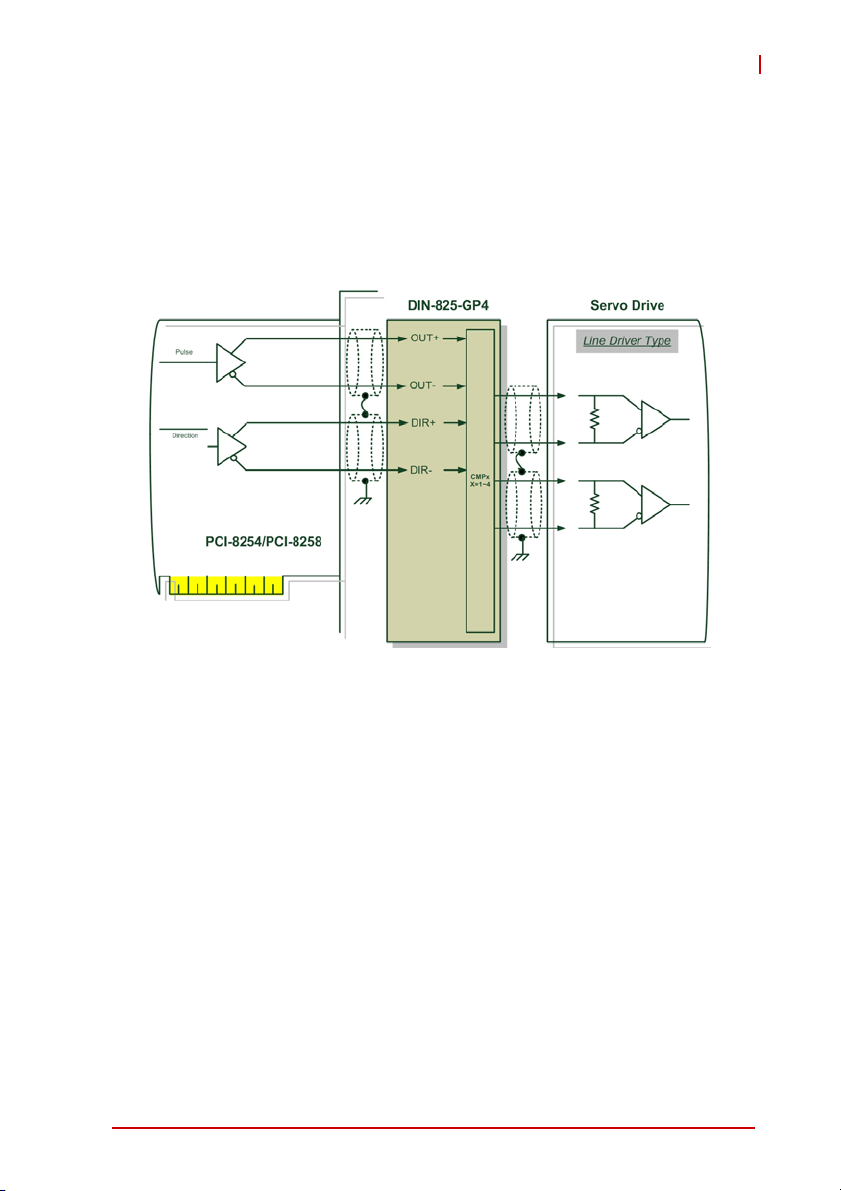

Figure 3-2: Line Driver type pulse control command signal connec-

tion example45

Figure 3-3: Open-Collector type pulse control command signal con-

nection example46

Figure 3-4: Line driver type encoder input signal connection example

48

Figure 3-5: Emergency stop signal connection example ............ 49

Figure 3-6: Mechanical limit switch signal connection example.. 51

Figure 3-7: Original position switch signal connection example . 52

Figure 3-8: Place / zero speed detection signal connection example

53

Figure 3-9: Servo alarm signal connection example................... 54

Figure 3-10: Servo-on signal connection example........................ 55

Figure 3-11: Analog input signal connection example .................. 56

Figure 3-12: Line Driver type compare trigger signal connection exam-

ple57

Figure 3-13: Open-Collector type compare trigger signal connection

example58

Figure 3-14: General purpose digital I/O signal connection example

60

Figure 3-15: General purpose digital I/O signal connection example

63

Figure 4-1: Format of pulse signal .............................................. 67

Figure 4-2: Illustration of analog command output...................... 68

Figure 4-3: Control cycle............................................................. 74

Figure 4-4: PCI-8254/PCI-8258 close loop control structure diagram

78

Figure 4-5: Gain and Gain shiftrelationship diagram .................. 78

Figure 4-6: The auto fine tuning setup page in MCP2 ................ 83

Figure 4-7: Structure of PCI-8254/8 biquad filters in serial connection

List of Figures ix

Page 10

86

Figure 4-8: Ideal low pass filter ................................................... 87

Figure 4-9: Simulation results of low pass filter with 1000Hz cutoff

frequency88

Figure 4-10: MCP2 low pass filter setup page .............................. 89

Figure 4-11: MCP2 notch filter setup page ................................... 89

Figure 4-12: An ideal notch filter (a) 50 Hz ................................... 90

Figure 4-13: Simulation results of notch filter with 100Hz cutoff fre-

quency92

Figure 4-14: MCP2 low pass filter setup page .............................. 92

Figure 4-15: MCP2 notch filter setup page ................................... 92

Figure 4-16: Controller coordinates system block......................... 98

Figure 4-17: Relation of trapezoidal speed profile's speed/accelera-

tion/jerk VS time102

Figure 4-18: Maximum speed by auto-planning.......................... 103

Figure 4-19: S-curve's velocity, acceleration, and jerk versus time104

Figure 4-20: Maximum speed by auto-velocity ........................... 106

Figure 4-21: Home mode 0 (Case: ORG) .................................. 112

Figure 4-22: Home mode 0 (Case: ORG) .................................. 114

Figure 4-23: Home mode 0 (Case: ORG+EZ) ............................ 115

Figure 4-24: Home mode 0 adverse (Case: ORG+EZ)..............116

Figure 4-25: Home mode 0 decelerate to stop (Case: ORG)..... 117

Figure 4-26: Home mode 1 (Case: EL) ......................................118

Figure 4-27: Home mode 1 (Case: EL+EZ) ............................... 120

Figure 4-28: Home mode 2 (Case: EZ)...................................... 122

Figure 4-29: Home mode 2 adverse (Case: EZ) ........................ 123

Figure 4-30: Relation between V-T chart of JOG movement and

JOG-ON signal127

Figure 4-31: Jog step mode ........................................................ 128

Figure 4-32: T-curve V-T chart.................................................... 131

Figure 4-33: Dynamically change position and velocity ..............133

Figure 4-34: Continuous three position V-T chart .......................134

Figure 4-35: Continuous three position V-T chart

(auto speed connection (1)134

Figure 4-36: Continuous three position V-T chart

(auto speed connection (2)134

Figure 4-37: Continuous three position V-T chart

(auto speed connection (3)135

Figure 4-38: Continuous three position V-T chart

(auto speed connection (4)135

xList of Figures

Page 11

PCI-8254 / PCI-8258

Figure 4-39: Two-dimension straight line interpolation ............... 137

Figure 4-40: Three-dimension arc interpolation (method 1)........ 139

Figure 4-41: Defining spatial normal vector ................................ 140

Figure 4-42: Determining arc direction in space ......................... 140

Figure 4-43: Three dimension arc interpolation (method 2)........ 141

Figure 4-44: Three dimension arc interpolation example............ 142

Figure 4-45: Three dimension spiral interpolation (method 1) .... 143

Figure 4-46: Three-dimension spiral interpolation (method 2) .... 144

Figure 4-47: Illustration on continuous interpolation (Buffer) move-

ment146

Figure 4-48: Velocity blending (method 1) .................................. 147

Figure 4-49: Velocity blending (method 2) .................................. 148

Figure 4-50: Velocity blending (method 3) .................................. 148

Figure 4-51: Velocity blending (method 4) .................................. 149

Figure 4-52: Velocity blending (method 5) .................................. 149

Figure 4-53: Velocity blending (method 6) .................................. 150

Figure 4-54: Velocity blending (method 7) .................................. 150

Figure 4-55: Continuous interpolation examples ........................ 151

Figure 4-56: Motion status monitoring process ........................... 152

Figure 4-57: Relation of different motion signals VS motions ..... 155

Figure 4-58: Relation of motion done (MDN) signals VS motion 156

Figure 4-59: Relation of motion done (MDN), In-homing (HMV) signals

VS motion157

Figure 4-60: Relation of WAIT signals VS motion....................... 158

Figure 4-61: Relation of JOG and motion done(MDN) signals VS mo-

tion159

Figure 4-62: Relation of ASTP VS motion .................................. 159

Figure 4-63: Relation of blending (BLD) signal VS motion ......... 160

Figure 4-64: Relation between pre- and post distance event signals

and movement161

Figure 4-65: Adjust electronic gear's auto engagement speed... 163

Figure 4-66: Compare trigger block diagram .............................. 165

Figure 4-67: Linear compare trigger example............................. 167

Figure 4-68: Table compare trigger example.............................. 168

Figure 4-69: Table compare trigger block diagram ..................... 169

Figure 4-70: Signal sampling structure diagram ......................... 178

Figure 4-71: Interruption flow chart ............................................. 199

List of Figures xi

Page 12

xii List of Figures

Page 13

PCI-8254 / PCI-8258

List of Tables

Table 1-1: Cross-reference table of exclusive cables for pulse servo

drive9

Table 1-2: Cross-reference table of exclusive cables for analog servo

drive9

Table 4-1: Encoder input format ..................................................... 69

Table 4-2: Encoder input format ..................................................... 70

Table 4-3: PCI-8254/8 Auto-Tuning setup ...................................... 83

Table 4-4: Board parameter table ................................................. 176

Table 4-5: Motion kernel signal table ............................................ 179

Table 4-6: Closed circuit control signal table ................................ 180

List of Tables xiii

Page 14

xiv List of Tables

Page 15

PCI-8254 / PCI-8258

1 Introduction

The PCI-8254/PCI-8258, is a fully in-house developed DSP-based

advanced motion control card from ADLINK. It supports 4/8 axis

pulse type or Analog type signal commands, provides Open-loop

and closed-loop circuit control options, and supports

position/speed/torque commands for several different servo

drivers.

The PCI-8254/PCI-8258 exchanges data with operating system

through high speed PCI bus including motion control command,

feedback data, parameter, etc. Used with the ADLINK exclusive

Softmove kernel, it offers scores of move control functions

including T/S speed profile planning, point-to-point movement,

multi-dimension interpolation, and master/slave motion.

To enable absolute real time motion control, ADLINK's multi-tasks

download function helps users to program with AMC code

(ADLINK Motion Code), a programming language similar to C, for

downloading to PCI-8254/58 embedded processors for execution.

It supports up to eight different programs for concurrent download

and execution.

With up to 20MHz high speed encoder feedback support and 4/8

axes independent hardware PID control plus Feed-forward gain

design, it ensures precision control and reduce following errors in

tandem with high speed motion feedback. The programmable

servo update rate allows excellent control performance because

different PID parameter adjustments can be made for individual

applications.

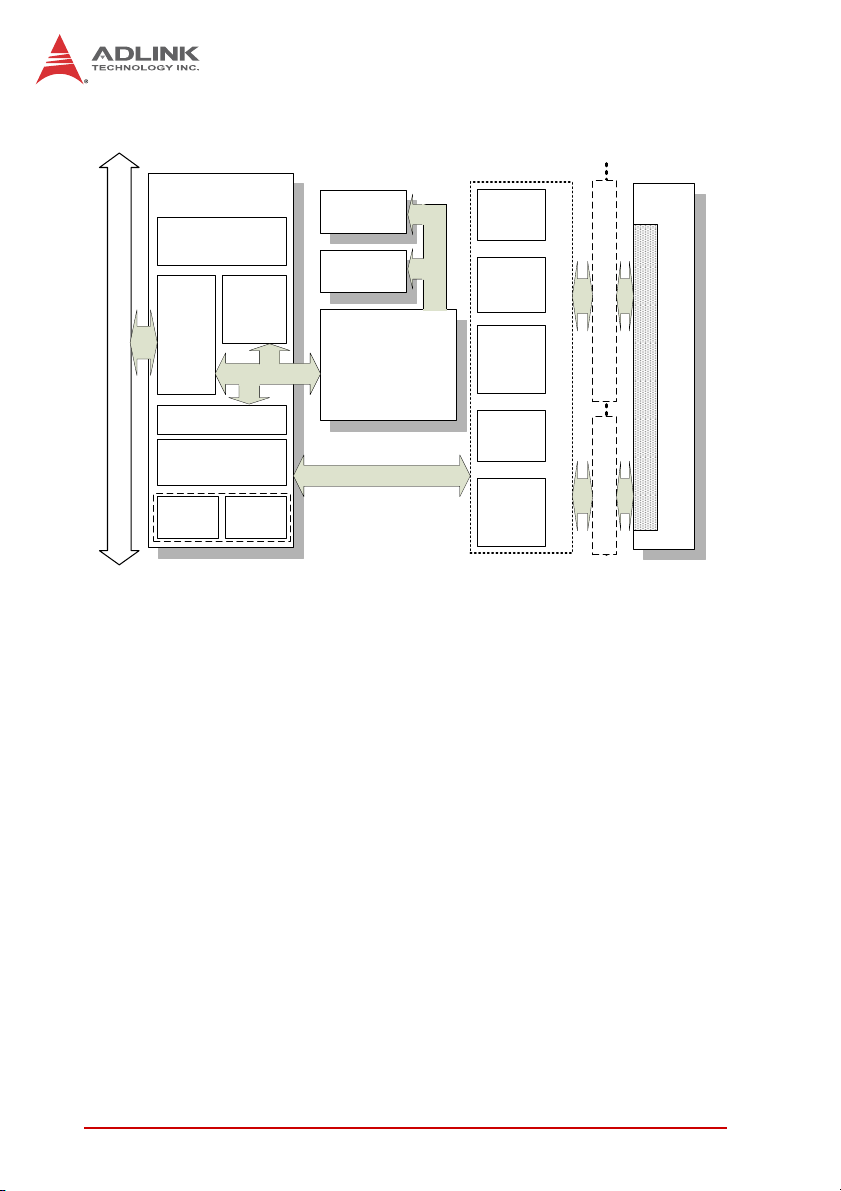

The PCI-8254/58, see Figure 1 below for its system functions,

uses one digital signal processor (DSP) from Texas Instrument

(TI) as its main computing unit and integrates high speed large

volume Field Programmable Gate Array (FPGA) to provide 4/8

independent PID control, high speed encoder output unit, 2/4 high

speed position compare and trigger output, move & general

purposed I/O and logic control. It separates isolation circuit into

exclusive terminal board DIN-825-GP4 to prevent the burning out

of PCI-8254/58 from incorrect wiring. Thanks to full range of

flexing resistant wires from ADLINK, it connects with market

available popular servo drives easily.

Introduction 1

Page 16

FPGA

Flash ROM

DPRAM

SDRAM

PCI Bus

PCI Bus

PCI

Bridge

Misc.

functions

DSP

A/D

circuitry

D/A

circuitry

Encoder

Input

SCSI 100P

EA

EB

EZ

DIN-825-GP4

Isolation

CMP & TRG

4/8 PID Controllers

Motion

I/Os

GPIO

TRG

Output

TTL I/Os

PEL

MEL

ORG

DIO

DSUB 37P

Figure 1-1: PCI-8254/58 system block diagram

Graphical motion control interface – MotionCreatorPro 2 is a

Windows-based motion control software development tool for

motion control and I/O status monitoring. You may employ this

development tool for axis, PID, and feed-forward gain setup as

well as analysis on motion variation curve and data. Embedded

Setup Wizard can guide you throughout the process of hardware

installation and wiring, close circuit PID parameter adjustments

and single axis operation for reduced development time and costs.

The Windows Programming Libraries supports Windows coding

environment including: Visual Studio C++ 6.0, Microsoft .NET

framework based VB.NET and C++, and Borland's C++ Builder.

There are sample programs available in the installation folders.

2Introduction

Page 17

PCI-8254 / PCI-8258

The flow chart below will guide you in using this manual as well as

help you to locate any required information effectively.

Hardware installation

Wiring and jumper setup

Set up card and adjust axis parameters

with MotionCreatorPro 2

Control axis with MotionCreatorPro 2

Develop application with APS library

No

Is the system running

successfully?

Yes

Chapter II and III

MotionCreatorPro 2

User's Manual

Chapter IV

Chapter II and III

MotionCreatorPro 2

User's Manual

APS and ADCNC

library

End

Figure 1-2: System installation flow chart

Introduction 3

Page 18

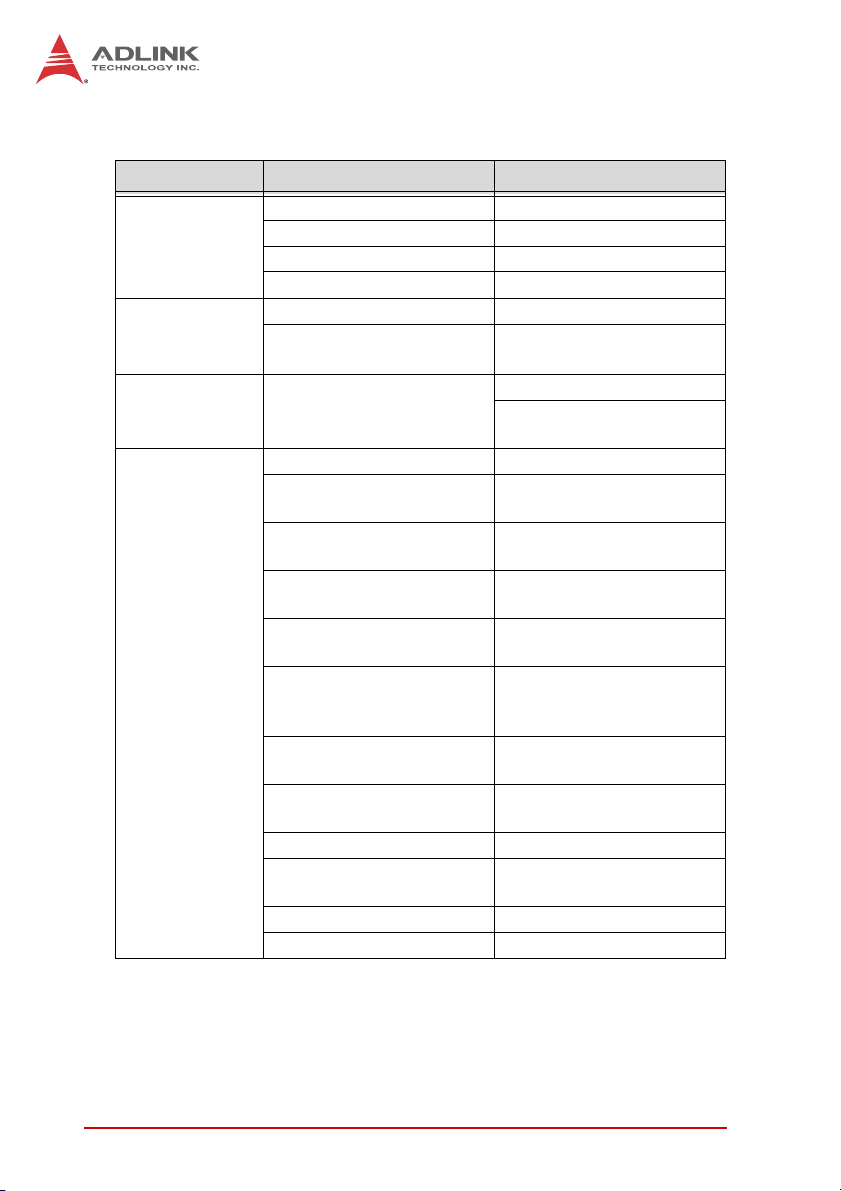

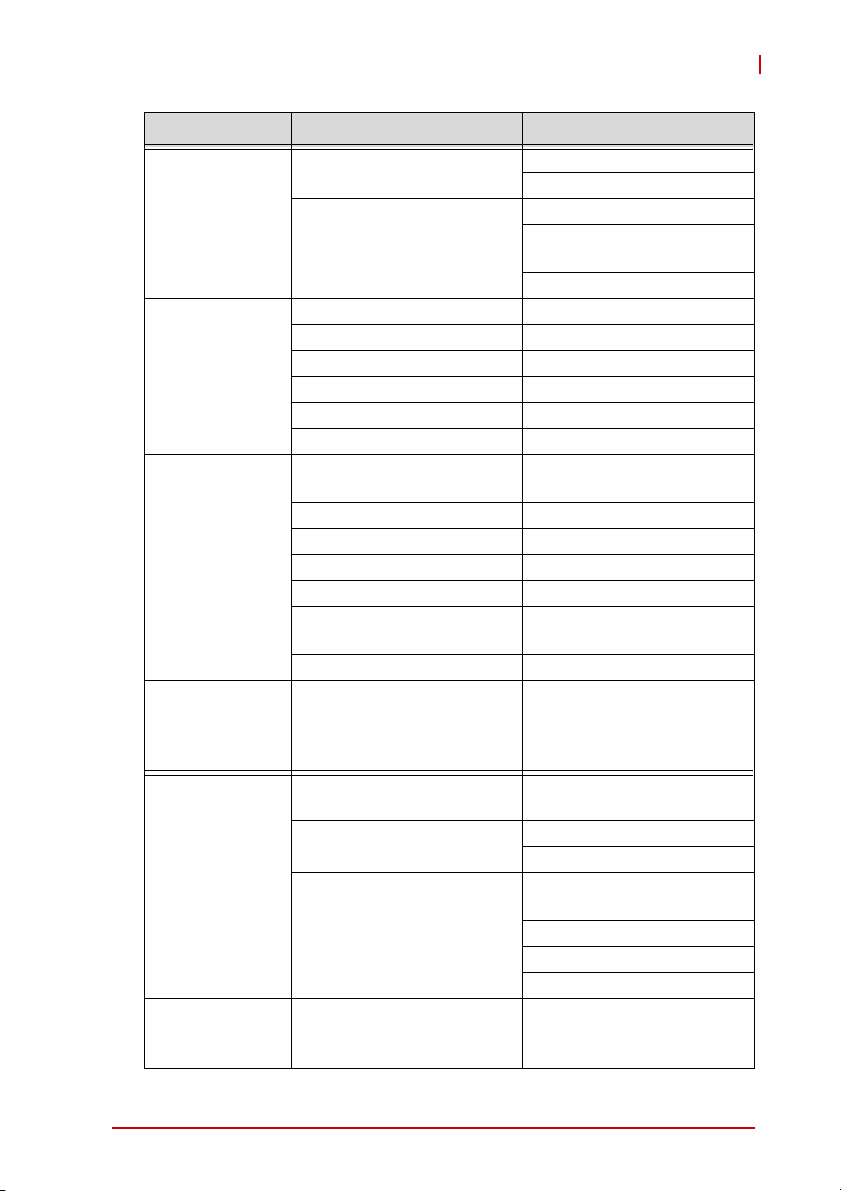

1.1 Product Specifications

Item Description

Bus information PCI Rev. 2.2, 33MHz

System

DSP

Board-to-board

interface

Closed circuit

control

PCI bus width 32-bit

PCI bus voltage 3.3V, 5V

PCI bus IRQ settings Assigned by PCI controller

Model TI 375MHz floating DSP

Memory

(for program and data)

Connector

Number of axes supported 4/8 axes for PCI-8254/8

Analog command output

resolution

Analog command output

interface

Maximum servo update

rate

PID (Kp, Ki and Kd) gain

range

Speed and acceleration

feed-forward (Aff, Vff) gain

range

Position / speed command

range

Acceleration / deceleration

range

Encoder input frequency 20 MHz @ 4x AB

Encoder input mode

Encoder input interface ±12 volts, TTL compatible

Filter

DDR2 SDRAM: 64Mx16bit

Flash ROM: 16M-bit

1x SCSI-II 100P for PCI-8254

1x Dual SCSI VHDCI 100P

for PCI-8258

±10 volts, resolution: 16 bit

Difference / single end

output

50us-500us

(programmable)

0 to 32,767

0 to 32,767

32 bit

32 bit

CW/CCW,

1x/2x/4x AB Phase

Biquad filter & low-pass filter

4Introduction

Page 19

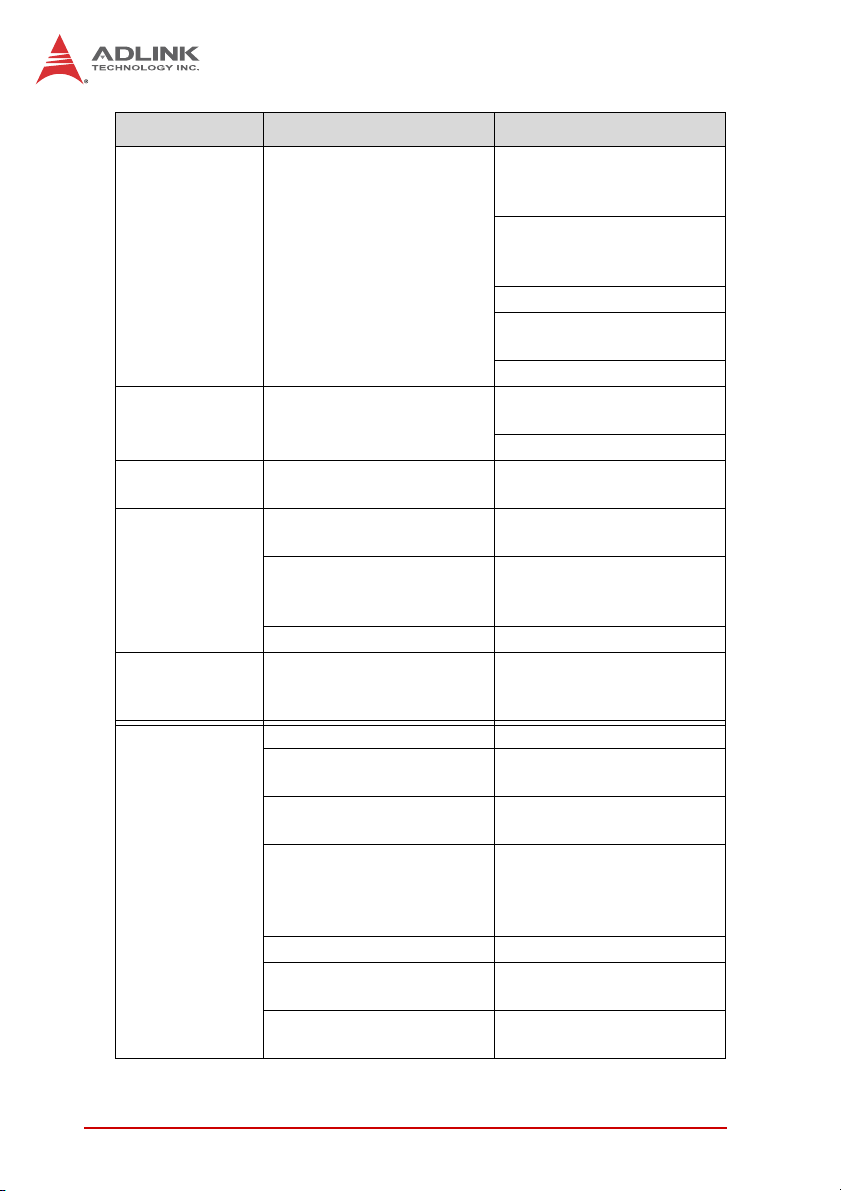

I/O interface

Analog input

Analog output

General

purpose digital

I/O

Motion control

function

PCI-8254 / PCI-8258

Item Description

Motion control relevant I/O

Drive relevant I/O

Max. input channel 4/8, single ended input

Input voltage range ±10 V

Sampling frequency 100 kHz

Resolution 12 bits, no missing codes

Accuracy ±1.5mV for ±10V input

Overload voltage ±15 V

Max. output channel

Output voltage range ±10V

Output current ±50mA (Typ.)

Resolution 16 bits, no missing codes

Accuracy ±1.2mV for ±10V output

Protection circuit

Settling Time 15us, full-scale step

General purpose I/O

Speed Profile Planning

Trajectory Planing

Linear interpolation:

2-6 axes

Home Return

Plus/Minus end limitsignal

Zero-position for each axis

Servo ON

In-position signal /

Zero-Speed detection

Alarm

4/8, difference/single

ended output

Earth short circuit

protection

20/24-CH input & 20/24-CH

TTL output (optical

isolation design for

DIN-825-GP4)

Trapezoidal Curve and

S-Curve

Jogging

Point-to-point movement

Online position/speed

change

3 axes arc interpolation

3 axes spiral interpolation

3 axes helix interpolation

User customizing (see

zero-position, limit switch,

EZ signals for reference)

Introduction 5

Page 20

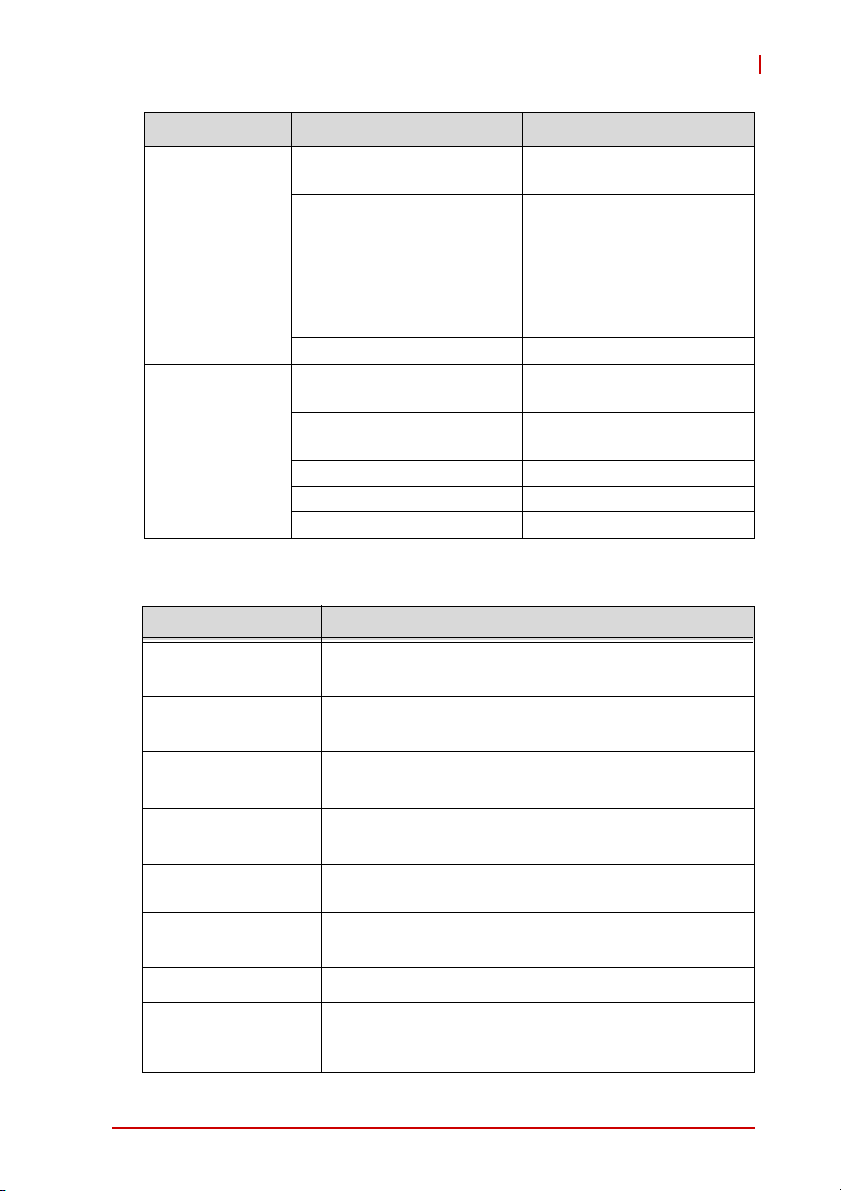

Industrial

application

Interrupt

Position

comparison

& trigger output

Item Description

Each axis supports 50

points buffer memory

(BUFs)

Supports

Point table

Motion Monitoring

Synchronous move

Master-client axes control

Data sampling

System error diagnostics Watchdog timer

Motion status event/error

alarm/in position/

emergency stop

Pulse output interface Difference output

Trigger channel

Pulse logic

Trigger output frequency

Minimum pulse width 100ns programmable

Position comparison mode

FIFO capacity

point-to-point/line/arc and

spiral interpolation

Supports dwell function

Supports pause/resume

function

Supports DO function

Motion control relevant I/O

monitoring

Motion monitoring

4/8 axes corresponding

PCI-8254/PCI-8258

Up to 4/8 axis (including

ganty control)

Motion speed profile/

motion status/motion

control relevant I/O

Planning in accordance

with the manual

2/4 corresponding

PCI-8254/PCI-8258

Programmable active-high

or active-low

Linear compare trigger:

1MHz

FIFO compare trigger:

255K ~ 1MHz

FIFO and linear

comparison

255 points

(channel independent)

6Introduction

Page 21

Item Description

Maximum number of

channels

PWM control

Program

download

Control modes

Resolution 16 bit

Max. number of

downloadable programs

Program size

Program logic Boolean function, circuit

Mathematical operation Yes

Motion event trigger Yes

Environment Condition

PCI-8254 / PCI-8258

2/4 CH correspondence

PCI-8254/PCI-8258

● Fixed frequency,

variable duty cycle ratio

● Variable frequency,

fixed duty cycle ratio

● Variable frequency,

variable duty cycle ratio

8

1,024 lines for each

program

Item

Working ambient

temperature

Storage ambient

temperature

Working ambient

humidity

Storage ambient

humidity

Noise impedance

Environment

condition

Cooling condition Self-cooling

Power

consumption

Introduction 7

0~55°C

-20~75°C

10~90%RH, without condensation

10~90%RH, without condensation

Noise voltage 1500VPP noise frequency 25~60Hz

using noise simulator

Minimal corrosive gas, dust

+3.3V @ 0.8A typical

+5V @ 0.8A typical

+/-12V @ 0.5A typical

Page 22

1.2 Software Support

1.2.1 Software Support Library

PCI-8254/PCI-8258 supports Windows XP/7 32/64 bit operating

system and provides a complete function library and DLL files for

easy application development by users.

1.2.2 MotionCreatorPro 2

MotionCreatorPro 2 is a user interface exclusively developed for

ADLINK motion control products in common Windows

environment. You may easily set up card and axis parameters with

the help of MotionCreatorPro 2. The Setup Wizard enables users

to complete hardware installation, signal configuration,

close-circuit PID gaining auto tuning and single-axis manipulation

to reduce application development time. MotionCreatorPro 2 not

only effectively reduces your development time but also enables

you to concurrently validate the overall mechanism and electric

design with all its single axis and interpolation motion operation

pages.

1.3 Terminal Board

The PCI-8254/58 exclusive terminal board "DIN-825-GP4" can

connect with several market available servo drives with special

cables including the Mitsubishi) J3A and the Yaskawa Sigma V

series or link with servo or stepper drives of other brands with

single ended open cables. Brands with exclusive cables support

are listed below:

8Introduction

Page 23

PCI-8254 / PCI-8258

Pulse command:

Cable Supported brands

HSL-4XMO-DM Mitsubishi J2S series

4XMO-DM-J3 Mitsubishi J3A series

HSL-4XMO-DP Panasonic A4 and A5 series

HSL-4XMO-DY Yaskawa Sigma V series

4XMO-DA Delta A2 series

4XMO-OPEN General purpose

Table 1-1: Cross-reference table of exclusive cables for pulse servo drive

Analog commands:

Cable Supported brands

ACL-DM-J3 Mitsubishi J3A series

ACL-DY Yaskawa Sigma V series

ACL-DP Panasonic MINAS A5/A4 series

4XMO-OPEN General purpose

Table 1-2: Cross-reference table of exclusive cables for analog servo drive

Introduction 9

Page 24

10 Introduction

Page 25

PCI-8254 / PCI-8258

2 Getting Start with The Installation

This chapter teaches you how to install PCI-8254/PCI-8258

hardware and software as well as its I/O wiring.

• Package Contents

• Hardware Installation

• Software Installation

• I/O Wiring

2.1 Package Contents

In addition to this manual you shall find the following item in the

product package box:

• PCI-8254 or PCI-8258 card X 1

• IDE 44p – DSUB 37p flat cable x 1

• Product warranty card X 1

Should there be any item missed or damaged, please consult with

your dealer immediately. Please keep the product along with items

included in its package for easy replacement or repair.

Getting Start with The Installation 11

Page 26

2.2 PCI-8254/PCI-8258 Exterior Profile Diagram

S1

SW2

P1

P2

Dimension in unit of millimeter (mm).

NOTE

NOTE

Figure 2-1: Exterior of your PCI-8254

P1: for Motion control command, Position feedback, and Servo I/O

feedback. (with SCSI 100-PINS connector)

P2: for 16 channel digital TTL input and 16 channel digital TTL

output.

SW2: Card ID setup (0-15)

S1: Analog command mode selection (differential mode /

single-ended mode)

12 Getting Start with The Installation

Page 27

PCI-8254 / PCI-8258

S1

P1

SW2

P2

Figure 2-2: Exterior of your PCI-8258

P1: for Motion control command, Position feedback, and Servo I/O

feedback. (with SCSI-VHDCI 200-PINS connector)

P2: for 16 channel digital TTL I/O. (with DSUB 37-PINS

connector)

SW2: Card ID setup (0-15)

S1: Analog command mode selection (differential / single-end

mode)

Getting Start with The Installation 13

Page 28

2.3 Hardware Installation

2.3.1 Hardware Configuration

PCI-8254/58 employs PCI Rev. 2.2 bus. System BIOS can auto

configure memory and IRQ channel.

Exclusive terminal board DIN-825-GP4 provides isolation circuit

and indicator lights for easy connection to varieties of servo drive

and stepper drive.

2.3.2 Installation Procedures

1. Please read this manual carefully and set up signal I/O in

proper mode.

2. Turn off computer power and relevant power on all

terminal boards then connect PCI-8254/58 to 32-bit PCI

slot in your computer. (The slot is usually in white color.)

(Please make sure you have proper ESD (Electrostatic

discharge) protection.)

3. Connect PCI-8254/58 and DIN-825-GP4 with SCSI 100p

cable

4. Set up motion control relevant limit switch on

DIN-825-GP4 board, servo signal and general purpose

digital signal wiring

5. Set up servo or stepper drive connection

6. Turn on system power including computer power,

terminal board relevant powers, and 24Vdc power

7. Verify all I/O signal and servo operation correctness with

MotionCreatorPro 2

Please ground the shielding end of the power terminal to the

earth to reduce risk of electric shock and ensure product

CAUTION

CAUTION

14 Getting Start with The Installation

operation of your electric appliances.

Please disconnect the motor drive from its load before using

the card for the first time to protect your safety. Do not connect

the motor drive to any mechanical devices before the

completion of the installation and fine tuning of the control

system. Connect the system only after the board is adjusted

and the drive parameters can control the motor. Serious

damage may be resulted in otherwise.

Page 29

PCI-8254 / PCI-8258

2.3.3 Troubleshooting

If the computer cannot power on normally or the motion control

system operates abnormally after system installation, please

follow steps described below for troubleshooting. If the problem

persists after you have taken steps described, please consult the

dealer where your product is purchased for technical services.

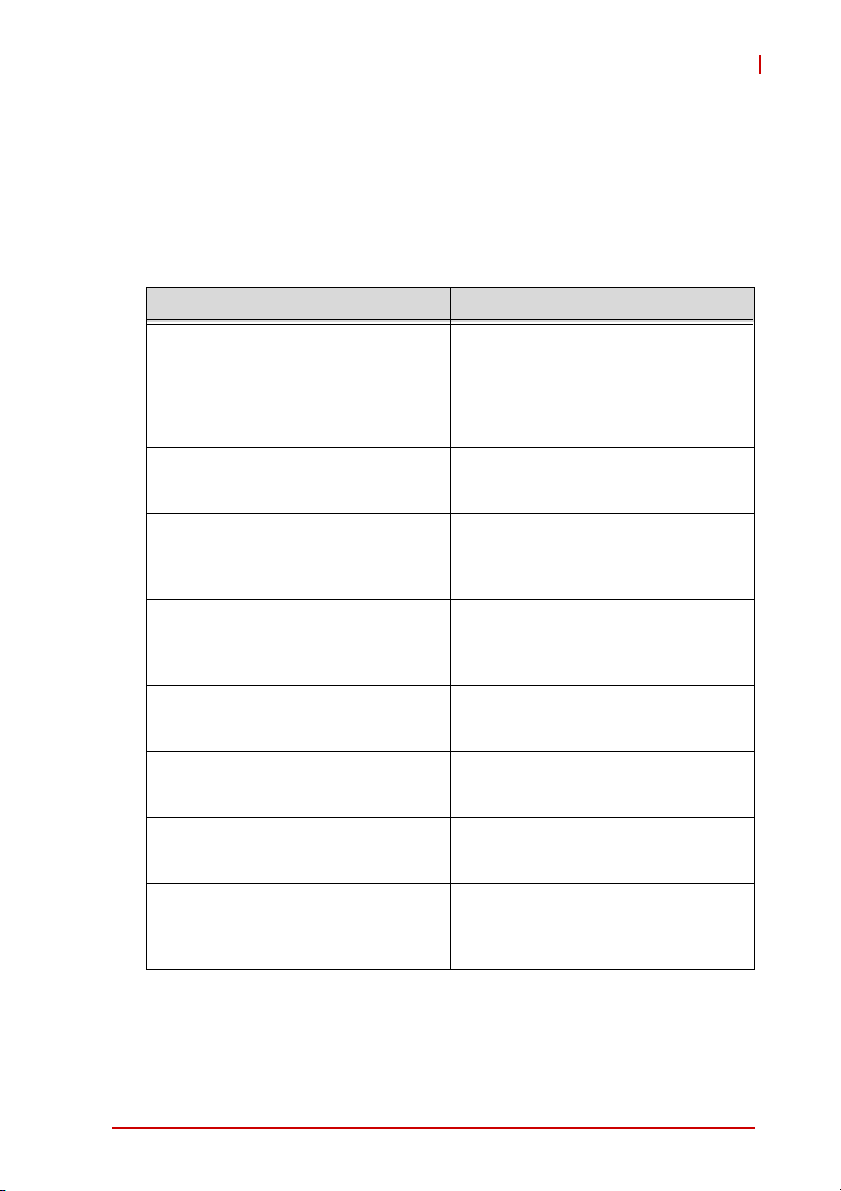

Abnormalities you encountered Potential causes

Please turn off your computer,

The card does not show up in

Windows Device Manager after its

driver has been installed

MotionCreatorPro2 cannot open

after installing driver in computer

The without signal indicator on

MotionCreatorPro2 lights up after

the motor is connected and the

motor does not work.

When using the MotionCreatorPro2,

all the control indicators of the drive

light correctly but the drive warns

Value of output command differ from

the feedback value from encoder

If motion control, the motor moves

only in one direction rather than back

and forth two way movement

The motor bursts after executing

Servo On command in speed control

operation

The motor makes loud noise after

executing Servo On command in

speed control operation

ensure the card is properly in PCI

slot and the driver is properly

installed by checking its proper

installation in Windows Control

Panel's "Add remove programs"

Ensure .NET framework v3.5 or later

version has been installed in your

system

Please ensure a 24Vdc power is

connected to the terminal board

Please ensure correctness of the

axis parameter setup, alarm logic

(ALM) and the EMG loop

configuration

Please ensure feedback signal

(CW/CCW, 1xAB, 2xAB, 4xAB)

settings comply with that of the drive

Please ensure setting of signal

pattern (CW/CCW, OUT/DIR)

comply with that of the motor drive

Please ensure that the control

direction of encoder and speed

controller comply with each other

Please make sure the actuator is

correctly adjusted and set up, reset

all the "I" and "D" values of PID

parameters, readjust PID gain

Getting Start with The Installation 15

Page 30

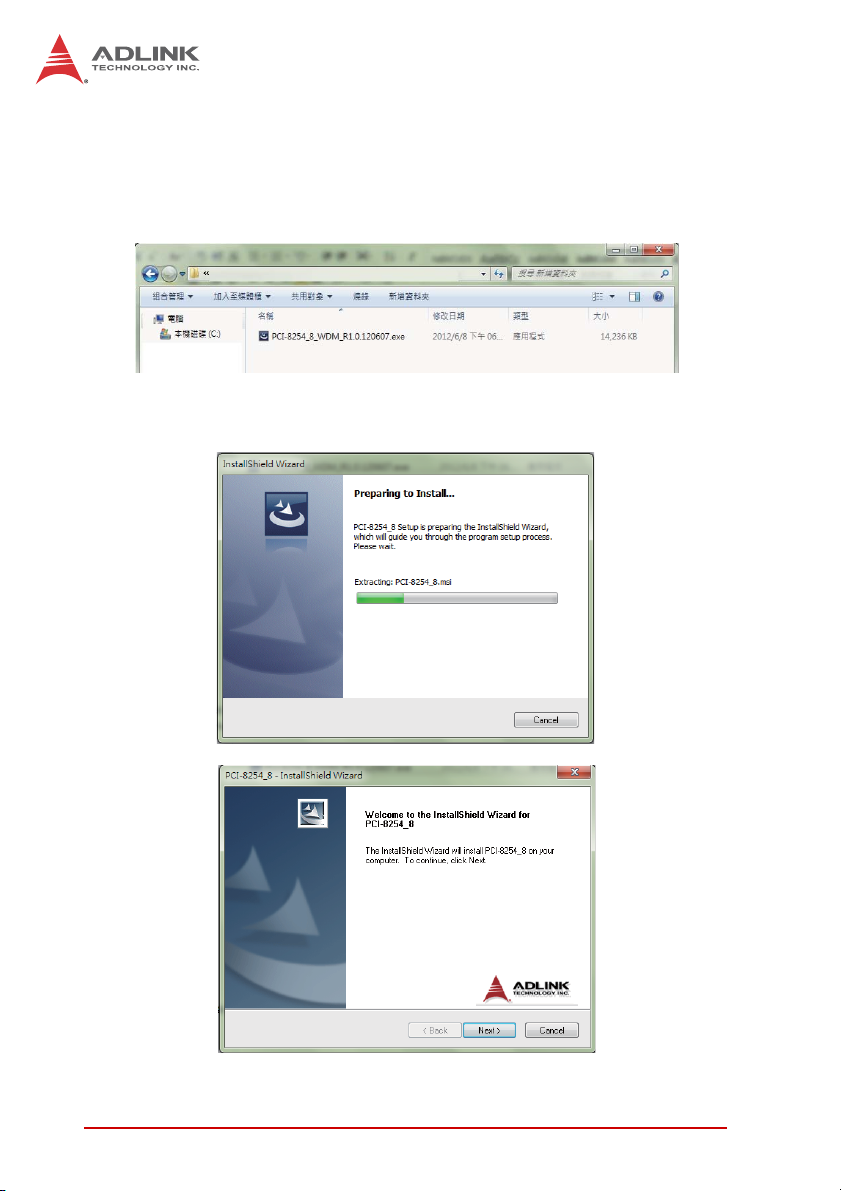

2.4 Software Installation Procedure

Windows driver installation procedure:

Step 1. Execute PCI-8254/PCI-8258 WDM file and run installation

procedure automatically.

Step 2. Click "Next" as prompted to complete the installation

process.

16 Getting Start with The Installation

Page 31

PCI-8254 / PCI-8258

Step 3. Restart your computer after installation is completed.

Step 4. Ensure the Windows Device Manager identify your

PCI-8254/PCI-8258 correctly.

Note: Recommendations: Please download latest installation

software from ADLINK official website to maintain the optimum

operation environment.

(http://www.adlinktech.com/Motion-Control/index.php

)

Getting Start with The Installation 17

Page 32

2.5 Definitions to Key Connector Signal

2.5.1 PCI-8254: Connector

•P1

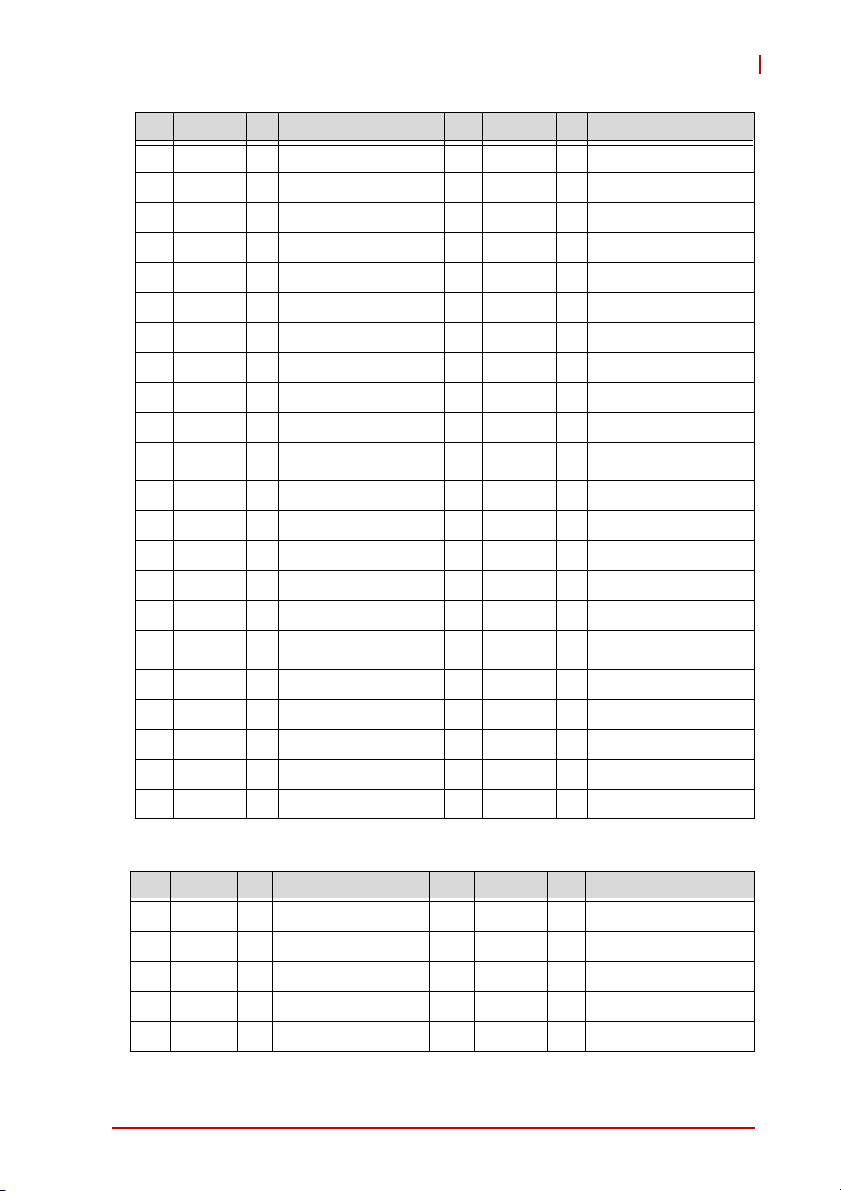

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DGND -- Digital ground 51 IEMG | Emergency stop input

2 DGND -- Digital ground 52 Rsv. -- Reserved

3 AGND -- Analog ground 53 AGND -- Analog ground

4 AGND -- Analog ground 54 AGND -- Analog ground

5 AOUT1+ c Analog output (+),(1) 55 AOUT3+ c Analog output (+),(3)

6 AOUT1- c Analog output (-),(1) 56 AOUT3- c Analog output (-),(3)

7 AOUT2+ c Analog output (+),(2) 57 AOUT4+ c Analog output (+),(4)

8 AOUT2- c Analog output (-),(2) 58 AOUT4- c Analog output (-),(4)

9 AIN1 | Analog input, (1) 59 AIN3 | Analog input, (3)

10 AIN2 | Analog input, (2) 60 AIN4 | Analog input, (4)

11 EA5V -- 5V power 61 DGND -- Digital ground

12 EA5V -- 5V power 62 DGND -- Digital ground

13 OUT1+ c Pulse output (+), (1) 63 OUT3+ c Pulse output (+), (3)

14 OUT1- c Pulse output (-), (1) 64 OUT3- c Pulse output (-), (3)

15 DIR1+ c Direction output (+), (1) 65 DIR3+ c Direction output (+), (3)

16 DIR1- c Direction output (-), (1) 66 DIR3- c Direction output (-), (3)

17 OUT2+ c Pulse output (+), (2)

18 OUT2- c Pulse output (-), (2) 68 OUT4- c Pulse output (-), (4)

19 DIR2+ c Direction output (+), (2) 69 DIR4+ c Direction output (+), (4)

20 DIR2- c Direction output (-), (2) 70 DIR4- c Direction output (-), (4)

21 TRG1+ c Trigger output (+), (1) 71 TRG2+ c Trigger output (+), (2)

22 TRG1- c Trigger output (-), (1) 72 TRG2- c Trigger output (-), (2)

23 EA1+ | Encoder A-phase (+),(1) 73 EA3+ | Encoder A-phase (+),(3)

24 EA1- | Encoder A-phase (-),(1) 74 EA3- | Encoder A-phase (-),(3)

25 EB1+ | Encoder B-phase (+),(1) 75 EB3+ | Encoder B-phase (+),(3)

26 EB1- | Encoder B-phase (-),(1) 76 EB3- | Encoder B-phase (-),(3)

67 OUT4+ c Pulse output (+), (4)

18 Getting Start with The Installation

Page 33

PCI-8254 / PCI-8258

No. Name I/O Function of Axis No. Name I/O Function of Axis

27 EZ1+ | Encoder Z-phase (+),(1) 77 EZ3+ | Encoder Z-phase (+),(3)

28 EZ1- | Encoder Z-phase (-),(1) 78 EZ3- | Encoder Z-phase (-),(3)

29 EA2+ | Encoder A-phase (+),(2) 79 EA4+ | Encoder A-phase (+),(4)

30 EA2- | Encoder A-phase (-),(2) 80 EA4- | Encoder A-phase (-),(4)

31 EB2+ | Encoder B-phase (+),(2) 81 EB4+ | Encoder B-phase (+),(4)

32 EB2- | Encoder B-phase (-),(2) 82 EB4- | Encoder B-phase (-),(4)

33 EZ2+ | Encoder Z-phase (+),(2) 83 EZ4+ | Encoder Z-phase (+),(4)

34 EZ2- | Encoder Z-phase (-),(2) 84 EZ4- | Encoder Z-phase (-),(4)

35 ALM1 | Servo alarm,(1) 85 ALM3 | Servo alarm,(3)

36 ORG1 | Origin Signal, (1) 86 ORG3 | Origin Signal, (3)

37 SVON1 c Servo-ON, (1) 87 SVON3 c Servo-ON, (3)

38 PEL1 | Positive limit, (1) 88 PEL3 | Positive limit, (3)

ZSP1 /

39

INP1

40 MEL1 | Negative limit, (1) 90 MEL3 | Negative limit, (3)

41 ALM2 | Servo alarm,(2) 91 ALM4 | Servo alarm,(4)

42 ORG2 | Origin Signal, (2) 92 ORG4 | Origin Signal, (4)

43 SVON2 c Servo-ON, (2) 93 SVON4 c Servo-ON, (4)

44 PEL2 | Positive limit, (2) 94 PEL4 | Positive limit, (4)

ZSP2 /

45

INP2

MEL2 | Negative limit, (2) 96 MEL4 | Negative limit, (4)

46

47 EDO1 c Digital Output, (1) 97 EDO3 c Digital Output, (3)

48 EDI1 | Digital Input, (1) 98 EDI3 | Digital Input, (3)

49 EDO2 c Digital Output, (2) 99 EDO4 c Digital Output, (4)

50 EDI2 | Digital Input, (2) 100 EDI4 | Digital Input, (4)

Zero Speed (1) /

|

In-Position (1)

Zero Speed (2) /

|

In-Position (2)

ZSP3 /

89

INP3

ZSP4 /

95

INP4

Zero Speed (3) /

|

In-Position (3)

Zero Speed (4) /

|

In-Position (4)

Getting Start with The Installation 19

Page 34

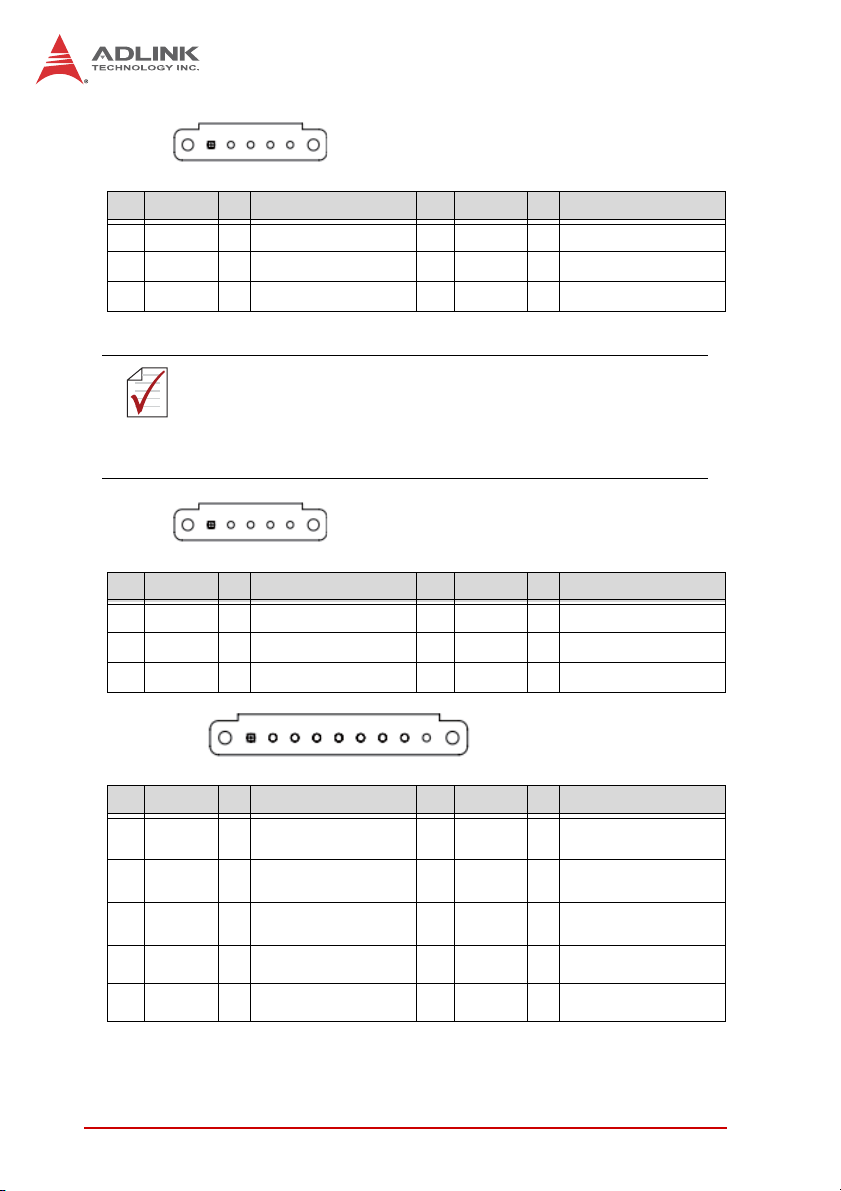

2.5.2 PCI-8258: P1-A/B Connector

•P1-A

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DGND -- Digital ground 51 IEMG | Emergency stop input

2 DGND -- Digital ground 52 Rsv. -- Reserved

3 AGND -- Analog ground 53 AGND -- Analog ground

4 AGND -- Analog ground 54 AGND -- Analog ground

5 AOUT1+ c Analog output (+),(1) 55 AOUT3+ c Analog output (+),(3)

6 AOUT1- c Analog output (-),(1) 56 AOUT3- c Analog output (-),(3)

7 AOUT2+ c Analog output (+),(2) 57 AOUT4+ c Analog output (+),(4)

8 AOUT2- c Analog output (-),(2) 58 AOUT4- c Analog output (-),(4)

9 AIN1 | Analog input, (1) 59 AIN3 | Analog input, (3)

10 AIN2 | Analog input, (2) 60 AIN4 | Analog input, (4)

11 EA5V -- 5V power 61 DGND -- Digital ground

12 EA5V -- 5V power 62 DGND -- Digital ground

13 OUT1+ c Pulse output (+), (1) 63 OUT3+ c Pulse output (+), (3)

14 OUT1- c Pulse output (-), (1) 64 OUT3- c Pulse output (-), (3)

15 DIR1+ c Direction output (+), (1) 65 DIR3+ c Direction output (+), (3)

16 DIR1- c Direction output (-), (1) 66 DIR3- c Direction output (-), (3)

17 OUT2+ c Pulse output (+), (2)

18 OUT2- c Pulse output (-), (2) 68 OUT4- c Pulse output (-), (4)

19 DIR2+ c Direction output (+), (2) 69 DIR4+ c Direction output (+), (4)

20 DIR2- c Direction output (-), (2) 70 DIR4- c Direction output (-), (4)

21 TRG1+ c Trigger output (+), (1) 71 TRG2+ c Trigger output (+), (2)

22 TRG1- c Trigger output (-), (1) 72 TRG2- c Trigger output (-), (2)

23 EA1+ | Encoder A-phase (+),(1) 73 EA3+ | Encoder A-phase (+),(3)

24 EA1- | Encoder A-phase (-),(1) 74 EA3- | Encoder A-phase (-),(3)

25 EB1+ | Encoder B-phase (+),(1) 75 EB3+ | Encoder B-phase (+),(3)

26 EB1- | Encoder B-phase (-),(1) 76 EB3- | Encoder B-phase (-),(3)

27 EZ1+ | Encoder Z-phase (+),(1) 77 EZ3+ | Encoder Z-phase (+),(3)

28 EZ1- | Encoder Z-phase (-),(1) 78 EZ3- | Encoder Z-phase (-),(3)

67 OUT4+ c Pulse output (+), (4)

20 Getting Start with The Installation

Page 35

PCI-8254 / PCI-8258

No. Name I/O Function of Axis No. Name I/O Function of Axis

29 EA2+ | Encoder A-phase (+),(2) 79 EA4+ | Encoder A-phase (+),(4)

30 EA2- | Encoder A-phase (-),(2) 80 EA4- | Encoder A-phase (-),(4)

31 EB2+ | Encoder B-phase (+),(2) 81 EB4+ | Encoder B-phase (+),(4)

32 EB2- | Encoder B-phase (-),(2) 82 EB4- | Encoder B-phase (-),(4)

33 EZ2+ | Encoder Z-phase (+),(2) 83 EZ4+ | Encoder Z-phase (+),(4)

34 EZ2- | Encoder Z-phase (-),(2) 84 EZ4- | Encoder Z-phase (-),(4)

35 ALM1 | Servo alarm,(1) 85 ALM3 | Servo alarm,(3)

36 ORG1 | Origin Signal, (1) 86 ORG3 | Origin Signal, (3)

37 SVON1 c Servo-ON, (1) 87 SVON3 c Servo-ON, (3)

38 PEL1 | Positive limit, (1) 88 PEL3 | Positive limit, (3)

ZSP1 /

39

INP1

40 MEL1 | Negative limit, (1) 90 MEL3 | Negative limit, (3)

41 ALM2 | Servo alarm,(2) 91 ALM4 | Servo alarm,(4)

42 ORG2 | Origin Signal, (2) 92 ORG4 | Origin Signal, (4)

43 SVON2 c Servo-ON, (2) 93 SVON4 c Servo-ON, (4)

44 PEL2 | Positive limit, (2) 94 PEL4 | Positive limit, (4)

ZSP2 /

45

INP2

46 MEL2 | Negative limit, (2) 96 MEL4 | Negative limit, (4)

47 EDO1 c Digital Output, (1) 97

48 EDI1 | Digital Input, (1) 98 EDI3 | Digital Input, (3)

49 EDO2 c Digital Output, (2) 99 EDO4 c Digital Output, (4)

50 EDI2 | Digital Input, (2) 100 EDI4 | Digital Input, (4)

Zero Speed (1) /

|

In-Position (1)

Zero Speed (2) /

|

In-Position (2)

ZSP3 /

89

INP3

ZSP4 /

95

INP4

EDO3 c Digital Output, (3)

Zero Speed (3) /

|

In-Position (3)

Zero Speed (4) /

|

In-Position (4)

•P1-B

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 Rsv. -- Reserved 51 Rsv. -- Reserved

2 Rsv. -- Reserved 52 Rsv. -- Reserved

3 AGND -- Analog ground 53 AGND -- Analog ground

4 AGND -- Analog ground 54 AGND -- Analog ground

5 AOUT5+ O Analog output (+),(5) 55 AOUT7+ O Analog output (+),(7)

Getting Start with The Installation 21

Page 36

No. Name I/O Function of Axis No. Name I/O Function of Axis

6 AOUT5- O Analog output (-),(5) 56 AOUT7- O Analog output (-),(7)

7 AOUT6+ O Analog output (+),(6) 57 AOUT8+ O Analog output (+),(8)

8 AOUT6- O Analog output (-),(6) 58 AOUT8- O Analog output (-),(8)

9 AIN5 I Analog input, (5) 59 AIN7 I Analog input, (7)

10 AIN6 I Analog input, (6) 60 AIN8 I Analog input, (8)

11 Rsv. -- Reserved 61 DGND -- Digital ground

12 Rsv. -- Reserved 62 DGND -- Digital ground

13 OUT5+ O Pulse output (+), (5) 63 OUT7+ O Pulse output (+), (7)

14 OUT5- O Pulse output (-), (5) 64 OUT7- O Pulse output (-), (7)

15 DIR5+ O Direction output (+), (5) 65 DIR7+ O Direction output (+), (7)

16 DIR5- O Direction output (-), (5) 66 DIR7- O Direction output (-), (7)

17 OUT6+ O Pulse output (+), (6) 67 OUT8+ O Pulse output (+), (8)

18 OUT6- O Pulse output (-), (6) 68 OUT8- O Pulse output (-), (8)

19 DIR6+ O Direction output (+), (6) 69 DIR8+ O Direction output (+), (8)

20 DIR6- O Direction output (-), (6) 70 DIR8- O Direction output (-), (8)

21 TRG3+ O Trigger output (+), (3) 71 TRG4+ O Trigger output (+), (4)

22 TRG3- O Trigger output (-), (3) 72 TRG4- O Trigger output (-), (4)

23 EA5+ I

24 EA5- I

25 EB5+ I

26 EB5- I

27 EZ5+ I

28 EZ5- I

29 EA6+ I

30 EA6- I

31 EB6+ I

32 EB6- I

33 EZ6+ I

34 EZ6- I

35 ALM5 I Servo alarm,(5) 85 ALM7 I Servo alarm,(7)

36 ORG5 I Origin Signal, (5) 86 ORG7 I Origin Signal, (7)

Encoder A-phase (+),(5)

Encoder A-phase (-),(5)

Encoder B-phase (+),(5)

Encoder B-phase (-),(5)

Encoder Z-phase (+),(5)

Encoder Z-phase (-),(5)

Encoder A-phase (+),(6)

Encoder A-phase (-),(6)

Encoder B-phase (+),(6)

Encoder B-phase (-),(6)

Encoder Z-phase (+),(6)

Encoder Z-phase (-),(6)

73 EA7+ I Encoder A-phase (+),(7)

74 EA7- I Encoder A-phase (-),(7)

75 EB7+ I Encoder B-phase (+),(7)

76 EB7- I Encoder B-phase (-),(7)

77 EZ7+ I Encoder Z-phase (+),(7)

78 EZ7- I Encoder Z-phase (-),(7)

79 EA8+ I Encoder A-phase (+),(8)

80 EA8- I Encoder A-phase (-),(8)

81 EB8+ I Encoder B-phase (+),(8)

82 EB8- I Encoder B-phase (-),(8)

83 EZ8+ I Encoder Z-phase (+),(8)

84 EZ8- I Encoder Z-phase (-),(8)

22 Getting Start with The Installation

Page 37

PCI-8254 / PCI-8258

No. Name I/O Function of Axis No. Name I/O Function of Axis

37 SVON5 O Servo-ON, (5) 87 SVON7 O Servo-ON, (7)

38 PEL5 I Positive limit, (5) 88 PEL7 I Positive limit, (7)

ZSP5 /

39

INP5

40 MEL5 I Negative limit, (5) 90 MEL7 I Negative limit, (7)

41 ALM6 I Servo alarm,(6) 91 ALM8 I Servo alarm,(8)

42 ORG6 I Origin Signal, (6) 92 ORG8 I Origin Signal, (8)

43 SVON6 O Servo-ON, (6) 93 SVON8 O Servo-ON, (8)

44 PEL6 I Positive limit, (6) 94 PEL8 I Positive limit, (8)

ZSP6 /

45

INP6

46 MEL6 I Negative limit, (6) 96 MEL8 I Negative limit, (8)

47 EDO5 O Digital Output, (5) 97 EDO7 O Digital Output, (7)

48 EDI5 I Digital Input, (5) 98 EDI7 I Digital Input, (7)

49 EDO6 O Digital Output, (6) 99 EDO8 O Digital Output, (8)

50 EDI6 I Digital Input, (6) 100 EDI8 I Digital Input, (8)

Zero Speed (5) /

I

In-Position (5)

Zero Speed (6) /

I

In-Position (6)

ZSP7 /

89

INP7

ZSP8 /

95

INP8

Zero Speed (7) /

I

In-Position (7)

Zero Speed (8) /

I

In-Position (8)

2.5.3 PCI-8254/58: P2 Connector

•P2

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 Rsv. - - Reserved 20 VDD | +5V power supply input

2 TDI1 | TTL input, (1) 21 TDO1 c TTL output, (1)

3 TDI2 | TTL input, (2) 22 TDO2 c TTL output, (2)

4 TDI3 | TTL input, (3) 23 TDO3 c TTL output, (3)

5 TDI4 | TTL input, (4) 24 TDO4 c TTL output, (4)

6 TDI5 | TTL input, (5) 25 TDO5 c TTL output, (5)

7 TDI6 | TTL input, (6) 26 TDO6 c TTL output, (6)

8 TDI7 | TTL input, (7) 27 TDO7 c TTL output, (7)

9 TDI8 | TTL input, (8) 28 TDO8 c TTL output, (8)

10 TDI9 | TTL input, (9) 29 TDO9 c TTL output, (9)

11 TDI10 | TTL input, (10) 30 TDO10 c TTL output, (10)

Getting Start with The Installation 23

Page 38

No. Name I/O Function of Axis No. Name I/O Function of Axis

12 TDI11 | TTL input, (11) 31 TDO11 c TTL output, (11)

13 TDI12 | TTL input, (12) 32 TDO12 c TTL output, (12)

14 TDI13 | TTL input, (13) 33 TDO13 c TTL output, (13)

15 TDI14 | TTL input, (14) 34 TDO14 c TTL output, (14)

16 TDI15 | TTL input, (15) 35 TDO15 c TTL output, (15)

17 TDI16 | TTL input, (16) 36 TDO16 c TTL output, (16)

18 DGND - Digital ground 37 DGND - Digital ground

19 VDD | +5V power supply input -- -- -- --

2.6 DIP Switch

2.6.1 S1: Analog Output Mode Settings

This switch is used for switching analog command output modes

with default settings at differential type output. In general, you

adjust according to individual servo drive interface. The PCI-8254

model uses switches 1-4 only.

differential mode

single-end mode

24 Getting Start with The Installation

Page 39

PCI-8254 / PCI-8258

2.6.2 SW2: Card ID Switch

This switch is used for adjusting card ID for easy identification in

user application programs. Take example. If you set card ID to

”0-0-0-1” (OFF-OFF-OFF-ON) then the card ID is ”1” and the ID

table should be set up as described below:

Card ID Switch Setting (ON=1)

0 0000

1 0001

2 0010

3 0011

4 0100

5 0101

6 0110

7 0 111

8 1000

9 1001

10 1010

11 1011

12 1100

13 1101

14 111 0

15 1111 ( de fault )

Getting Start with The Installation 25

Page 40

2.7 IDE 44p – DSUB 37p Bus

This card include one IDE cable from IDE 44 pin to DSUB 37 pin.

It is used for PCI-8254 / PCI-8258 P2 extension 16 channel digital

input and 16 channel digital output.

26 Getting Start with The Installation

Page 41

PCI-8254 / PCI-8258

2.8 Exclusive Board - DIN-825-GP4

The DIN-825-GP4 terminal board is designed for

PCI-8254/PCI-8258 and AMP-204C/AMP-208C exclusively. It

connects with market available servo drives with special cables

including the Mitsubishi's J3A and the Yaskawa Sigma V series or

other servo or stepper drives with single end open cables.

The DIN-825-GP4 board supports both PCI-8254/PCI-8258

and AMP-204C/AMP-208C. DO NOT connect it to other

CAUTION

ADLINK's motion controller or it may be damaged.

Main connector

(to PCI board)

Brake signal

Motion I/O signals

Analog commands

(Torque Control)

Analog input signals

Power &

EMG signal

Pulse commands

(Position Control)

Additional 16 Digital

output signals

Additional 16 Digital

Laser control signals

Figure 2-3: Exterior of DIN-825-GP4

I/O connector

(to PCI board)

input signals

Getting Start with The Installation 27

Page 42

2.8.1 Definitions to Connector

1. P1: This is one SCSI

100-PINS connector for

motion control signals.

2. CMA1–4: These are four

26-PINS connector for

connecting to servo

drive to do S/T mode

control and analog

CMA1

J4

CMA2

CMA3

CMA4

P1

control commands

output.

3. CMP1–4: These are four

26-PINS connectors for

connecting to servo

drive to do P mode

control or stepper drive

to output pulse control

commands. It may be

CMP1

CMP2

J3

CMP3

CMP4

CN1

S1

S2

J6

connected to Mitsubishi

J3A series, Yaskawa

Sigma II, III & V series,

IOIF2

IOIF3

and Panasonic MINAS

A4&A5 with exclusive

cables.

4. J1–J3: These are three

IOIF1

IOIF4

sets of 10-pins screw

lock connectors

(screwed series, Delta

P2

A2 series, or connection

to other servo or stepper

drives with single end

open cables). It may be

connected to any analog

Figure 2-4: Exterior of DIN-825-GP4

input signal, comparing

trigger signal, plus/minus limit switch and homing signal '.

5. J4: This is one 8-PINS connector for connecting to Brake

Signal.

6. J5: This is one 5-PINS connector for connecting to

terminal board main power and emergency stop signals.

J2 J1

J5

28 Getting Start with The Installation

Page 43

PCI-8254 / PCI-8258

7. J6: This is one 5-PINS connector for connecting to four

isolation digital output channel.

8. P2: This is one DSUB 37-PINS connector for connecting

to 16 channel digital input signal and 16 channel digital

output signal in the controller (TTL).

9. IOIF1-IOIF4: These are four 9-PINS connectors for

connecting to 16 channel digital input signal and 16

channel digital output signal for common uses.

10.Newly added CN1: This is one 9-pin connector for laser

control.

Getting Start with The Installation 29

Page 44

2.8.2 Connector: For Connecting to PCI-8254/PCI-8258/AMP-204C/AMP-208C

•P1:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DGND -- Digital ground 51 IEMG | Emergency stop input

2 DGND -- Digital ground 52 Rsv. -- Reserved

3 AGND -- Analog ground 53 AGND -- Analog ground

4 AGND -- Analog ground 54 AGND -- Analog ground

5 AOUT1+ c Analog output (+),(1) 55 AOUT3+ c Analog output (+),(3)

6 AOUT1- c Analog output (-),(1) 56 AOUT3- c Analog output (-),(3)

7 AOUT2+ c Analog output (+),(2) 57 AOUT4+ c Analog output (+),(4)

8 AOUT2- c Analog output (-),(2) 58 AOUT4- c Analog output (-),(4)

9 AIN1 | Analog input, (1) 59 AIN3 | Analog input, (3)

10 AIN2 | Analog input, (2) 60 AIN4 | Analog input, (4)

11 Rsv. -- Reserved 61 DGND -- Digital ground

12 Rsv. -- Reserved 62 DGND -- Digital ground

13 OUT1+ c Pulse output (+), (1) 63 OUT3+ c Pulse output (+), (3)

14 OUT1- c Pulse output (-), (1) 64 OUT3- c Pulse output (-), (3)

15 DIR1+ c Direction output (+), (1) 65 DIR3+ c Direction output (+), (3)

16 DIR1- c Direction output (-), (1) 66 DIR3- c Direction output (-), (3)

17 OUT2+ c Pulse output (+), (2)

18 OUT2- c Pulse output (-), (2) 68 OUT4- c Pulse output (-), (4)

19 DIR2+ c Direction output (+), (2) 69 DIR4+ c Direction output (+), (4)

20 DIR2- c Direction output (-), (2) 70 DIR4- c Direction output (-), (4)

21 TRG1+ c Trigger output (+), (1) 71 TRG2+ c Trigger output (+), (2)

22 TRG1- c Trigger output (-), (1) 72 TRG2- c Trigger output (-), (2)

23 EA1+ | Encoder A-phase (+),(1) 73 EA3+ | Encoder A-phase (+),(3)

24 EA1- | Encoder A-phase (-),(1) 74 EA3- | Encoder A-phase (-),(3)

25 EB1+ | Encoder B-phase (+),(1) 75 EB3+ | Encoder B-phase (+),(3)

26 EB1- | Encoder B-phase (-),(1) 76 EB3- | Encoder B-phase (-),(3)

67 OUT4+ c Pulse output (+), (4)

30 Getting Start with The Installation

Page 45

PCI-8254 / PCI-8258

No. Name I/O Function of Axis No. Name I/O Function of Axis

27 EZ1+ | Encoder Z-phase (+),(1) 77 EZ3+ | Encoder Z-phase (+),(3)

28 EZ1- | Encoder Z-phase (-),(1) 78 EZ3- | Encoder Z-phase (-),(3)

29 EA2+ | Encoder A-phase (+),(2) 79 EA4+ | Encoder A-phase (+),(4)

30 EA2- | Encoder A-phase (-),(2) 80 EA4- | Encoder A-phase (-),(4)

31 EB2+ | Encoder B-phase (+),(2) 81 EB4+ | Encoder B-phase (+),(4)

32 EB2- | Encoder B-phase (-),(2) 82 EB4- | Encoder B-phase (-),(4)

33 EZ2+ | Encoder Z-phase (+),(2) 83 EZ4+ | Encoder Z-phase (+),(4)

34 EZ2- | Encoder Z-phase (-),(2) 84 EZ4- | Encoder Z-phase (-),(4)

35 ALM1 | Servo alarm,(1) 85 ALM3 | Servo alarm,(3)

36 ORG1 | Origin Signal, (1) 86 ORG3 | Origin Signal, (3)

37 SVON1 c Servo-ON, (1) 87 SVON3 c Servo-ON, (3)

38 PEL1 | Positive limit, (1) 88 PEL3 | Positive limit, (3)

ZSP1 /

39

INP1

40 MEL1 | Negative limit, (1) 90 MEL3 | Negative limit, (3)

41 ALM2 | Servo alarm,(2) 91 ALM4 | Servo alarm,(4)

42 ORG2 | Origin Signal, (2) 92 ORG4 | Origin Signal, (4)

43 SVON2 c Servo-ON, (2) 93 SVON4 c Servo-ON, (4)

44 PEL2 | Positive limit, (2) 94 PEL4 | Positive limit, (4)

ZSP2 /

45

INP2

MEL2 | Negative limit, (2) 96 MEL4 | Negative limit, (4)

46

47 EDO1 c Digital Output, (1) 97 EDO3 c Digital Output, (3)

48 EDI1 | Digital Input, (1) 98 EDI3 | Digital Input, (3)

49 EDO2 c Digital Output, (2) 99 EDO4 c Digital Output, (4)

50 EDI2 | Digital Input, (2) 100 EDI4 | Digital Input, (4)

Zero Speed (1) /

|

In-Position (1)

Zero Speed (2) /

|

In-Position (2)

ZSP3 /

89

INP3

ZSP4 /

95

INP4

Zero Speed (3) /

|

In-Position (3)

Zero Speed (4) /

|

In-Position (4)

•P2:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 Rsv. - - Reserved 20 VDD c +5V power supply output

2 TDI1 | TTL input, (1) 21 TDO1 c TTL output, (1)

Getting Start with The Installation 31

Page 46

No. Name I/O Function of Axis No. Name I/O Function of Axis

3 TDI2 | TTL input, (2) 22 TDO2 c TTL output, (2)

4 TDI3 | TTL input, (3) 23 TDO3 c TTL output, (3)

5 TDI4 | TTL input, (4) 24 TDO4 c TTL output, (4)

6 TDI5 | TTL input, (5) 25 TDO5 c TTL output, (5)

7 TDI6 | TTL input, (6) 26 TDO6 c TTL output, (6)

8 TDI7 | TTL input, (7) 27 TDO7 c TTL output, (7)

9 TDI8 | TTL input, (8) 28 TDO8 c TTL output, (8)

10 TDI9 | TTL input, (9) 29 TDO9 c TTL output, (9)

11 TDI10 | TTL input, (10) 30 TDO10 c TTL output, (10)

12 TDI11 | TTL input, (11) 31 TDO11 c TTL output, (11)

13 TDI12 | TTL input, (12) 32 TDO12 c TTL output, (12)

14 TDI13 | TTL input, (13) 33 TDO13 c TTL output, (13)

15 TDI14 | TTL input, (14) 34 TDO14 c TTL output, (14)

16 TDI15 | TTL input, (15) 35 TDO15 c TTL output, (15)

17 TDI16 | TTL input, (16) 36 TDO16 c TTL output, (16)

18 EGND - External power ground 37 EGND - External power ground

19 VDD | +5V power supply input -- -- -- --

•J1:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DICOM -- Digital input common 6 EDI4 | Isolated digital input, (4)

2 EDI3 | Isolated digital input, (3) 7 PEL4 | Positive limit, (4)

3 PEL3 | Positive limit, (3) 8 ORG4 | Origin Signal, (4)

4 ORG3 | Origin Signal, (3) 9 MEL4 | Negative limit, (4)

5 MEL3 | Negative limit, (3) 10 DOCOM -- Digital output common

32 Getting Start with The Installation

Page 47

PCI-8254 / PCI-8258

•J2:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DICOM -- Digital input common 6 EDI2 | Isolated digital input, (2)

2 EDI1 | Isolated digital input, (1) 7 PEL2 | Positive limit, (2)

3 PEL1 | Positive limit, (1) 8 ORG2 | Origin Signal, (2)

4 ORG1 | Origin Signal, (1) 9 MEL2 | Negative limit, (2)

5 MEL1 | Negative limit, (1) 10 DOCOM -- Digital output common

1. Please connect DICOM to external power supply

(24VDC in general) if possible.

NOTE

NOTE

2. Please connect DOCOM to ground (GND) of

external power supply if possible.

•J3:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DGND -- Isolated digital ground 6 AGND -- Analog ground

2 TRG2- c Trigger output (-), (2) 7 AI4 | Analog input, (4)

3 TRG2+ c Trigger output (+), (2) 8 AI3 | Analog input, (3)

4 TRG1- c Trigger output (-), (1) 9 AI2 | Analog input, (2)

5 TG1+ c Trigger output (+), (1) 10 AI1 | Analog input, (1)

• J4: Brake Connector

No. Name I/O Function of Axis No. Name I/O Function of Axis

BRAKE 1+

1

BRAKE 1-

2

BRAKE 2+

3

BRAKE 2-

4

Getting Start with The Installation 33

-- Brake signal (+), (1) 6

| Brake signal (-), (1) 7

| Brake signal (+), (2) 8

| Brake signal (-), (2) 9

BRAKE 3+

BRAKE 3-

BRAKE 4+

BRAKE 4-

| Brake signal (+), (3)

| Brake signal (-), (3)

| Brake signal (+), (4)

| Brake signal (-), (4)

Page 48

•J5

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 I24V -- Ext. power supply, +24V 4 DOCOM -- Digital output common

2 IGND -- Ext. power ground 5

3 DICOM -- Digital input common 6 -- -- --

EEMG

| Ext. Emergency signal

1. Please connect DICOM to external power supply

(24VDC in general) if possible.

NOTE

NOTE

2. Please connect DOCOM to ground (GND) of

external power supply if possible.

•J6

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 EDO1 c Digital output, (1) 4 EDO4 c Digital output, (4)

2 EDO2 c Digital output, (2) 5 DOCOM c Digital output common

3 EDO3 c Digital output, (3) 6 -- c --

•IOIF1:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DI1 I

2 DI2 I

3 DI3 I

4 DI4 I

5 DI5 I

Additional isolated digital

input, (1)

Additional isolated digital

input, (2)

Additional isolated digital

input, (3)

Additional isolated digital

input, (4)

Additional isolated digital

input, (5)

6 DI6 I

7 DI7 I

8 DI8 I

9 DICOM -- Digital input common

-- -- -- --

34 Getting Start with The Installation

Additional isolated digital

input, (6)

Additional isolated digital

input, (7)

Additional isolated digital

input, (8)

Page 49

PCI-8254 / PCI-8258

•IOIF2:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DI9 I

2 DI10 I

3 DI11 I

4 DI12 I

5 DI13 I

Additional isolated digital

input, (9)

Additional isolated digital

input, (10)

Additional isolated digital

input, (11)

Additional isolated digital

input, (12)

Additional isolated digital

input, (13)

6 DI14 I

7 DI15 I

8 DI1 I

9 DICOM -- Digital input common

-- -- -- --

Additional isolated digital

input, (14)

Additional isolated digital

input, (15)

Additional isolated digital

input, (16)

•IOIF3:

No. Name I/O Function of Axis No. Name I/O Function of Axis

※DO1

1

※DO2

2

3 ※DO3 O

※DO4

4

5 ※DO5 O

Additional isolated digital

O

output, (1)

Additional isolated digital

O

output, (2)

Additional isolated digital

output, (3)

Additional isolated digital

O

output, (4)

Additional isolated digital

output, (5)

6 DO6 O

7 DO7 O

8 DO8 O

9 DOCOM -- Digital output common

-- -- -- --

Additional isolated digital

output, (6)

Additional isolated digital

output, (7)

Additional isolated digital

output, (8)

※ The digital output current may reach 250mA

NOTE

NOTE

Getting Start with The Installation 35

Page 50

•IOIF4:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 DO9 O

2 DO10 O

3 DO11 O

4 DO12 O

5 DO13 O

Additional isolated digital

output, (9)

Additional isolated digital

output, (10)

Additional isolated digital

output, (11)

Additional isolated digital

output, (12)

Additional isolated digital

output, (13)

6 DO14 O

7 DO15 O

8 DO16 O

9 DOCOM --

-- -- --

Additional isolated digital

output, (14)

Additional isolated digital

output, (15)

Additional isolated digital

output, (16)

Digital output common

--

1. Please connect DICOM to external power supply

(24VDC in general) if possible.

NOTE

NOTE

2. Please connect DOCOM to ground (GND) of

external power supply if possible.

• CN1:

No. Name I/O Function of Axis No. Name I/O Function of Axis

1 EDO4 O

2 TG1+ O

3 TG2+ O

4 AOUT4+ O

5 AGND --

Digital output (4)

Trigger output (+), (1)

Trigger output (+), (2)

Analog command output

(+), (4)

Analog ground

6 EDO4- O

7 TG1- O

8 TG2- O

9 DGND --

Digital output (-), (4)

Trigger output (-), (1)

Trigger output (-), (2)

Digital ground

36 Getting Start with The Installation

Page 51

• CMA1~CMA4:

PCI-8254 / PCI-8258

outputsignal

Resetdriversignal/Digital

O

DO

ALM_RST/

10

11 ALM I Servoalarmsignal

12 I24VͲͲExt.powersupply,+24V

13 IGNDͲͲ Ext.powerground

14 BRAKEͲ OBrakesignal(Ͳ)

15 AGNDͲͲ Analogground

16 EBͲ I EncoderBͲphase(Ͳ)

1 SVON O ServoOnsignal19 EMG I Emergencysignal

2 ZSP I Zerospeedsignal20 IGND ͲͲ Ext.powerground

3 Rsv. ͲͲ Reserved21 IGND ͲͲ Ext.powerground

4 Rsv. ͲͲ Reserved.22 IGND ͲͲ Ext.powerground

5 AOUTͲ O Analogcommandoutput(Ͳ)23 Rsv. ͲͲ Reserved

No. Name I/O Function No. Name I/O Function No. Name I/O Function

6 AOUT+ O Analogcommandoutput(+)24 Rsv. ͲͲ Reserved

17 EB+ I EncoderBͲphase(+)

18 AGNDͲͲ Analogground

7 EAͲ I EncoderAͲphase(Ͳ)25 EZͲ I EncoderZͲphase(Ͳ)

8 EA+ I EncoderAͲphase(+)26 EZ+ I EncoderZͲphase(+)

9 BRAKE+ O Brakesignal(+)

ALM_RST / DO: This signal may be selected as general

purpose digital output signal (EDO) or alarm clearance function

NOTE

NOTE

(ALM_RST) by switch S1 or S2.

Getting Start with The Installation 37

Page 52

•CMP1~CMP4:

outputsignal

Resetdriversignal/Digital

O

DO

ALM_RST/

10

11 ALM I Servoalarmsignal

12 I24VͲͲExt.powersupply,+24V

13 IGNDͲͲ Ext.powerground

14 BRAKEͲ OBrakesignal(Ͳ)

15 IGNDͲͲ Ext.powerground

1 SVON O ServoOnsignal19 EMG I Emergencysignal

2 INP I InͲpositionsignal20 IGN D ͲͲ Ext.powerground

3 ERC O Dev.ctr,clr.signal21 IGND ͲͲ Ext.powerground

4 RDY I Servoreadysignal22 IGND ͲͲ Ext.powerground

No. Name I/O Function No. Name I/O Function No. Name I/O Function

5 OUTͲ O Pulsesignal(Ͳ)23 DIRͲ O Dir.Signal(Ͳ)

16 EBͲ I EncoderBͲphase(Ͳ)

17 EB+ I EncoderBͲphase(+)

18 IGNDͲͲ Ext.powerground

6 OUT+ O Pulsesignal(+)24 DIR+ O Dir.Signal(+)

7 EAͲ I EncoderAͲphase(Ͳ)25 EZͲ I EncoderZͲphase(Ͳ)

8 EA+ I EncoderAͲphase(+)26 EZ+ I EncoderZͲphase(+)

9 BRAKE+ O Brakesignal(+)

ALM_RST / DO: You may set this signal to general purpose

digital output signal (EDO) or alarm clearance function

NOTE

NOTE

(ALM_RST) by switch S1 or S2.

38 Getting Start with The Installation

Page 53

PCI-8254 / PCI-8258

2.8.3 S1, S2: EDO/ALM_RST Selection Switch

DIN-825-GP4 is equipped with 4 servo drive reset signals. You

may set up CMA1~CMA4 PIN 10 and CMP1~CMP4 PIN 10 for

servo drive rest or J6 connector DO.1~DO.4 by switch S1 and S2.

Getting Start with The Installation 39

Page 54

40 Getting Start with The Installation

Page 55

PCI-8254 / PCI-8258

3 Signal Connection

PCI-8254/PCI-8258 must connect to servo or stepper motor drive

with exclusive terminal board DIN-825-GP4. All optical isolation

circuit of mechanical relevant I/O and servo relevant I/O are set to

DIN-825-GP4 to prevent damages to primary controller

PCI-8254/PCI-8258 from any invalid signal connection to it. This

may effectively reduce difficulties and times required in replacing

controller relevant products when doing customer service

maintenance tasks. See sections below for detailed descriptions

on precautions required to connect to various mechanical I/O and

servo I/O signals. Contents:

Section 3.1: Analog Command Signal

Section 3.2: Pulse Command Signal

Section 3.3: Encoder Input Signal

Section 3.4: Emergency Stop Signal

Section 3.5: Mechanical Limit Switch Signal

Section 3.6: Original Position Switch Signal

Section 3.7: In-position/Zero Speed Signal

Section 3.8: Servo Alarm Signal

Section 3.9: Servo On Signal

Section 3.10: Analog Input Signal

Section 3.11: Comparing Trigger Signal

Section 3.12: General Purpose Digital Input and Output Signal

Signal Connection 41

Page 56

3.1 Analog Control Command Signal

3.1.1 Single-ended Type Signal: AOUT+

PCI-8254/PCI-8258 provides 4/8 analog control command

channels respectively. Each analog command supports 16-bit

resolution and provides ±10V output range at accuracy smaller

than ± 1mV. Each analog control command can be set to single

ended or differential output mode by adjusting switch S1 to be

used by market available Japanese/Taiwanese and American/EU

servo motor drives. In general, a servo drive can be set to P/S/T

(position/speed/torque) mode. When control mode is set to S/T the

positioning function can be exercised by controlling motor speed

or torque with analog commands. When servo drive is set to P

mode, then pulse command of PCI-8254/PCI-8258 will be used for

open-loop control (see Section 3.2). This analog channel is then

defined as general purpose output one.

See below for corresponding pins of analog command output to

DIN-825-GP4:

CMAx Pin No

(x=1~4)

6 AOUT+ Analog Out Signal, (+) (n) 1~8

NOTE

NOTE

Signal Name

PCI-8258 need two DIN-825-GP4 for eight axes motion control

functions

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

Description

(n=1~8)

Axis #

3.1.2 Single-ended Type Signal: AOUT+, AOUT-

4/8 analog control commands of PCI-8254/PCI-8258 can be set to

single ended or differential output mode by adjusting switch S1 to

be used by market available Japanese/Taiwanese and

American/EU servo motor drives. See below for corresponding

pins of analog command output pins against differential analog

signals to DIN-825-GP4:

42 Signal Connection

Page 57

PCI-8254 / PCI-8258

CMAx Pin No

(x=1~4)

6 AOUT+ Analog Out Signal, (+) (n) 1~8

5 AOUT- Analog Out Signal, (-) (n) 1~8

Signal Name

Description

(n=1~8)

PCI-8258 need two DIN-825-GP4 for eight axes motion control

functions

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

• Signal connection template diagram:

Axis #

Figure 3-1: Connection example of differential analog output signal

Signal Connection 43

Page 58

3.2 Pulse Command

In addition to the analog command outputs described in Section

3.1, PCI-8254/PCI-8258 provides 4/8 pulse control command

channel. Each pulse control command can support up to 6.5MHZ

output frequency.

In general, a servo drive can be set to P/S/T (position/speed/

torque) mode. When control mode is set to P mode, then the pulse

command control of PCI-8254/PCI-8258 will be used for

open-loop control.

In addition to servo drive, the Stepper drive also employs pulse

command interface as the primary control input commands. See

below for corresponding pins of pulse command output against

differential pulse signals to DIN-825-GP4:

CMAx Pin No

(x=1~4)

6 OUT+ Pulse signal, (+) (n) 1~8

5 OUT- Pulse signal, (-) (n) 1~8

24 DIR+ Dir. Signal, (+) (n) 1~8

23 DIR- Dir. Signal, (-) (n) 1~8

Signal Name

Description

(n=1~8)

PCI-8258 need two DIN-825-GP4 for eight axes

motion control functions

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

Axis #

44 Signal Connection

Page 59

PCI-8254 / PCI-8258

Either servo motor drive or stepper motor drive employs one of the

two input interfaces described below:

1. Line Driver input interface provides better anti noise-resistant

and longer wiring length.

• Signal connection diagram:

Figure 3-2: Line Driver type pulse control command signal connection

example

2. Open-Collector input interface can increase passing

current capacity of signal by adjusting pull-up resistance

value at the shorter wiring length.

Signal Connection 45

Page 60

• Signal connection diagram:

Figure 3-3: Open-Collector type pulse control command signal connection

example

To avoid damages to Line Driver components on controller

caused by invalid wiring please connect the OUT-, DIR- pins of

CAUTION

controller to OUT, DIR pins of motor drive.

The controller employs Line Driver component -26LS31 with

maximum Sink Current at 20mA. Do not use it at current above

CAUTION

this value, the component may be damaged otherwise.

46 Signal Connection

Page 61

PCI-8254 / PCI-8258

3.3 Encoder Input, EA & EB & EZ

PCI-8254/PCI-8258 provides 4/8 encoder input channels

respectively which accept single end input frequency up to 5MHz

with each channel containing EA, EB, and EZ signal. Each group

of EA, EB, and EZ signal contains a pair of differential signal, e.g.

the EA signal contains EA+ and EA-. See Section 4.1.1.4 for how

to use the encoder. See below for corresponding pins of encoder

input on DIN-825-GP4

CMAx Pin No

(x=1~4)

8 EA+ Encoder A-phase (+),(n) 1~8

7 EA- Encoder A-phase (-),(n) 1~8

17 EB+ Encoder B-phase (+),(n) 1~8

16 EB- Encoder B-phase (-),(n) 1~8

26 EZ+ Encoder Z-phase (+),(n) 1~8

25 EZ- Encoder Z-phase (-),(n) 1~8

Signal Name

Description

(n=1~8)

PCI-8258 need two DIN-825-GP4 for eight axes motion control

functions

NOTE

NOTE

# 1 controls axes 1 ~ 4 and #2 controls axes 5 ~ 8

The controller employs Line Receiver component -26LS32 with

maximum Sink Current at 20mA@5V. Do not use it at current

CAUTION

above this value, the component may be damaged otherwise.

Axis #

Signal Connection 47

Page 62

• Signal connection diagram:

Figure 3-4: Line driver type encoder input signal connection example

48 Signal Connection

Page 63

PCI-8254 / PCI-8258

3.4 Emergency Stop Input

PCI-8254/PCI-8258 provides one hardware input emergency stop

signal (EMG). If the external emergency stop signal is triggered, all

motion control commands will be stopped immediately. In addition, the

DIN-825-GP4 is designed to transmit external emergency stop signal

to servo/stepper motor drive to stop operation of every motor

immediately. See below for corresponding pins of emergency stop

signal input on DIN-825-GP4

J5 Pin No Signal Name Description Axis #

5 EEMG

: