Page 1

PCI-7260

8-CH High-Power Relay Outputs &

8-CH Isolated Digital Inputs Card

User’s Manual

Manual Rev. 2.01

Revision Date: December 21, 2006

Part No: 50-12019-100

Advance Technologies; Automate the World.

Page 2

Copyright 2005 ADLINK TECHNOLOGY INC.

All Rights Reserved.

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Page 3

Getting Service from ADLINK

Customer Satisfaction is top priority for ADLINK Technology Inc.

Please contact us should you require any service or assistance.

ADLINK TECHNOLOGY INC.

Web Site: http://www.adlinktech.com

Sales & Service: Service@adlinktech.com

TEL: +886-2-82265877

FAX: +886-2-82265717

Address: 9F, No. 166, Jian Yi Road, Chungho City,

Taipei, 235 Taiwan

Please email or FAX this completed service form for prompt and

satisfactory service.

Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX:

Web Site

Product Information

Product Model

OS:

Environment

M/B: CPU:

Chipset: Bios:

Please give a detailed description of the problem(s):

Page 4

Page 5

Table of Contents

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 2

1.2 Applications ......................................................................... 3

1.3 Specifications....................................................................... 4

1.4 Software Support ................................................................. 6

Programming Library ...................................................... 6

DAQ-LVIEW PnP ............................................................ 6

2 Installation .......................................................................... 7

2.1 What you have..................................................................... 7

2.2 Unpacking............................................................................ 7

2.3 PCB Layout.......................................................................... 8

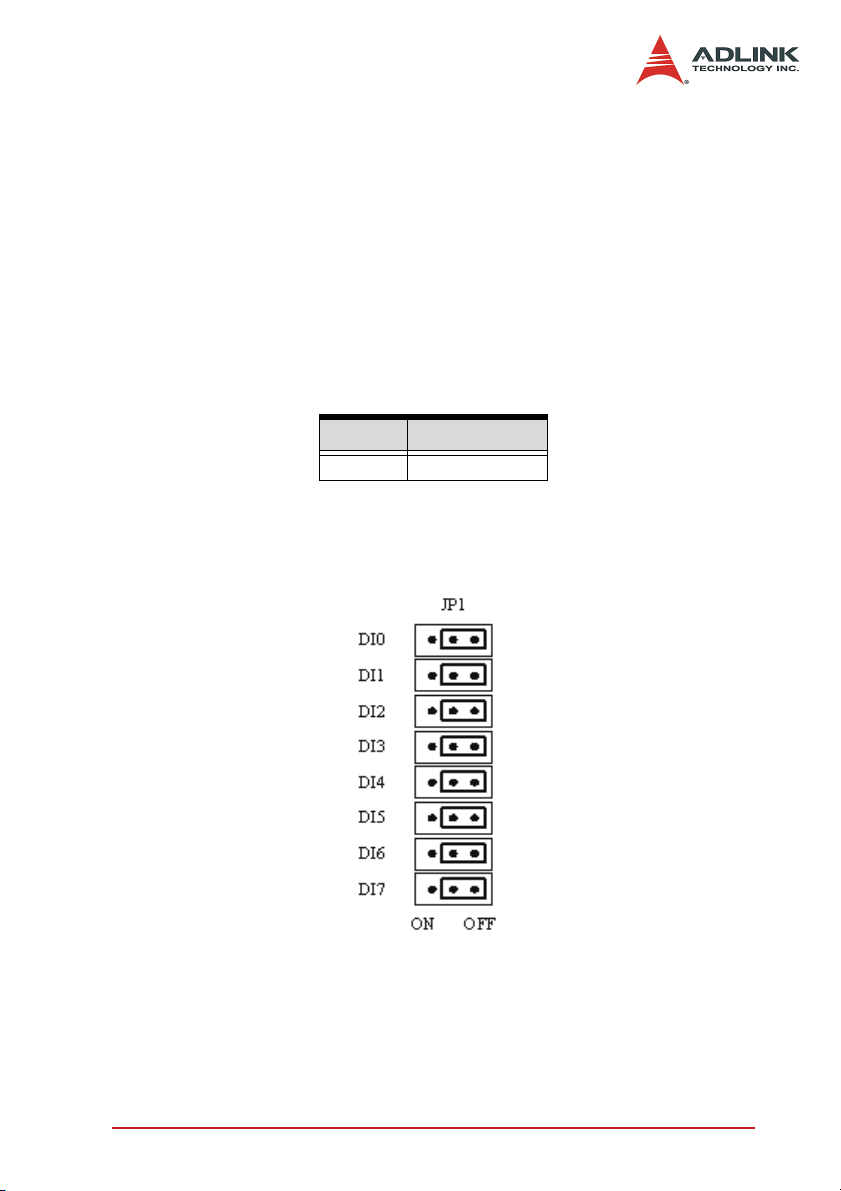

2.4 AC/non-AC filter setting (JP1).............................................. 9

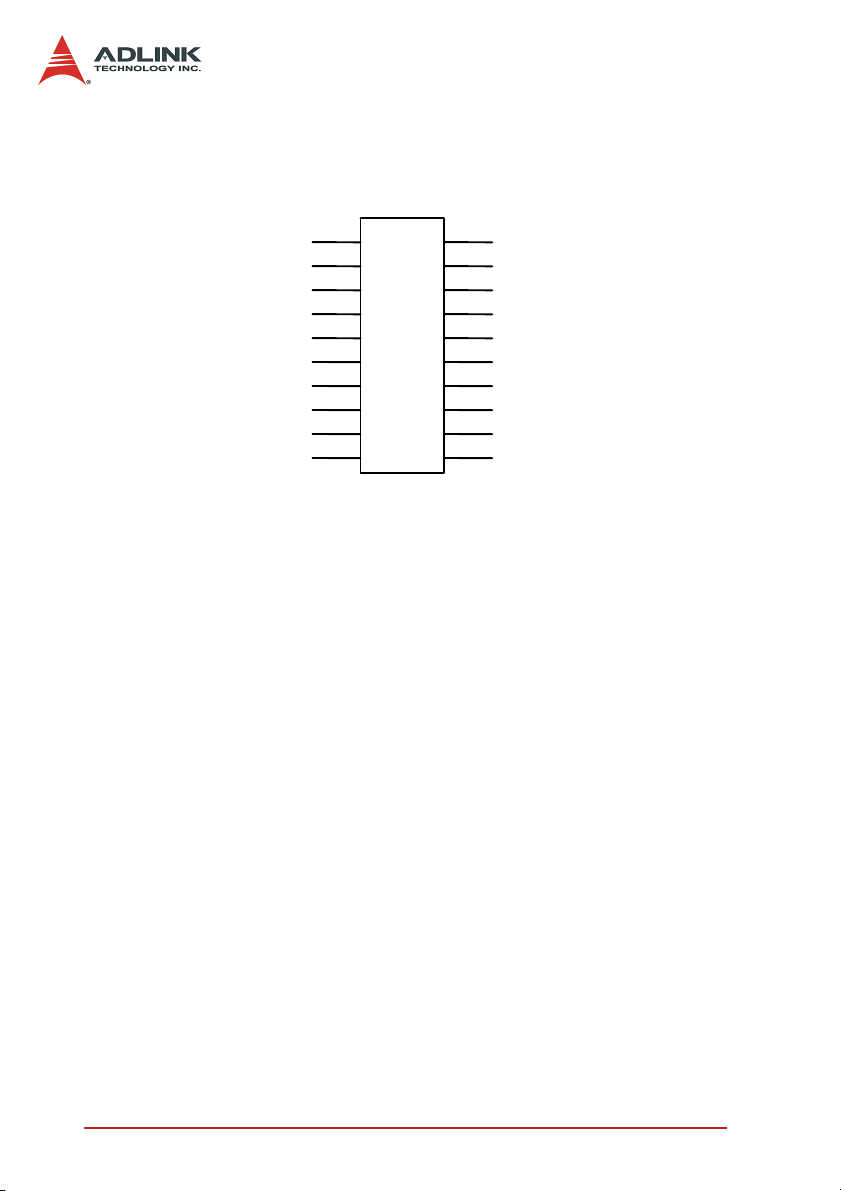

2.5 Isolated digital input connector (JP2)................................. 10

2.6 Relay status output connector (JP3).................................. 11

2.7 Board ID (S1)..................................................................... 12

2.8 Initial state DIP switch (S2) ................................................ 13

2.9 Emergency shutdown state DIP switch (S3)...................... 13

2.10 Connector Pin Assignments (CN1).................................... 14

3 Register Format................................................................ 15

3.1 I/O Address Map................................................................ 16

3.2 Relay Output Control Register........................................... 17

3.3 WDTimer Load Config Register......................................... 18

3.4 Relay Output Read Back Register ..................................... 19

3.5 Emergency Shutdown Setup Register ............................... 20

3.6 Isolated Digital Input Register............................................ 21

3.7 COS Setup Register .......................................................... 22

3.8 COS Latch Register........................................................... 23

3.9 Interrupt / WDT Control Register ....................................... 24

3.10 Interrupt / EMG_SHDN / WDT Status Register ................. 26

3.11 Handling PCI Controller Registers..................................... 27

4 Operation Theorem .......................................................... 29

4.1 Non-Latching Relay Output ............................................... 29

4.2 Emergency Shutdown........................................................ 30

4.3 Watchdog Timer ................................................................ 31

4.4 Isolated Digital Input .......................................................... 32

Table of Contents i

Page 6

4.5 Interrupt Architecture ......................................................... 33

4.6 Change of State(COS) Interrupt ........................................ 33

5 C/C++ DOS Libraries......................................................... 35

5.1 Programming Guide........................................................... 35

Naming Convention ...................................................... 35

Data Types ................................................................... 35

5.2 _7260 Initial ....................................................................... 36

@ Description ............................................................... 36

@ Syntax ...................................................................... 36

@ Argument .................................................................. 36

@ Return Code ............................................................. 36

5.3 _7260_DO ......................................................................... 37

@ Description ............................................................... 37

@ Syntax ...................................................................... 37

@ Argument .................................................................. 37

@ Return Code ............................................................. 37

5.4 _7260_DO_Read_Back ..................................................... 38

@ Description ............................................................... 38

@ Syntax ...................................................................... 38

@ Argument .................................................................. 38

@ Return Code ............................................................. 38

5.5 _7260_DI ........................................................................... 39

@ Description ............................................................... 39

@ Syntax ...................................................................... 39

@ Argument .................................................................. 39

@ Return Code ............................................................. 39

5.6 _7260_COS_Channel........................................................ 40

@ Description ............................................................... 40

@ Syntax ...................................................................... 40

@ Argument .................................................................. 40

@ Return Code ............................................................. 40

5.7 _7260_COS_Latch ............................................................ 41

@ Description ............................................................... 41

@ Syntax ...................................................................... 41

@ Argument .................................................................. 41

@ Return Code ............................................................. 41

5.8 _7260_INT_Control............................................................ 42

@ Description ............................................................... 42

@ Syntax ...................................................................... 42

ii Table of Contents

Page 7

@ Argument ................................................................. 42

@ Return Code ............................................................. 43

5.9 _7260_CLR_IRQ ............................................................... 44

@ Description ............................................................... 44

@ Syntax ...................................................................... 44

@ Argument ................................................................. 44

@ Return Code ............................................................. 44

5.10 _7260_GET_IRQ_Status................................................... 45

@ Description ............................................................... 45

@ Syntax ...................................................................... 45

@ Argument ................................................................. 45

@ Return Code ............................................................. 45

5.11 _7260_WDTimerSReload_Config ..................................... 46

@ Description ............................................................... 46

@ Syntax ...................................................................... 46

@ Argument ................................................................. 46

@ Return Code ............................................................. 46

5.12 _7260_EMG_SETUP......................................................... 47

@ Description ............................................................... 47

@ Syntax ...................................................................... 47

@ Argument ................................................................. 47

@ Return Code ............................................................. 47

5.13 _7260_EmgShdnDipSwitch_status ................................... 48

@ Description ............................................................... 48

@ Syntax ...................................................................... 48

@ Argument ................................................................. 48

@ Return Code ............................................................. 48

5.14 _7260_InitDipSwitch_status .............................................. 49

@ Description ............................................................... 49

@ Syntax ...................................................................... 49

@ Argument ................................................................. 49

@ Return Code ............................................................. 49

6 Appendix........................................................................... 51

6.1 Relay Contact Protection Circuits ...................................... 51

RC Circuit ..................................................................... 51

Diode Circuit ................................................................. 52

Diode & Zener diode Circuit .......................................... 52

Varistor Circuit .............................................................. 53

Table of Contents iii

Page 8

List of Tables

Table 1-1: Digital Input Specifications ........................................ 4

Table 1-2: Relay Output Specifications ...................................... 4

Table 1-3: Power Supply Specifications .................................... 5

Table 1-4: General Specifications .............................................. 5

Table 1-5: Power Consumption Specifications .......................... 5

Table 2-1: The jumpers and DI channels ................................... 9

Table 2-2: Board ID Setting Conditions ................................... 12

Table 2-3: Pin Assignment of PCI-7260 CN1 .......................... 14

Table 3-1: PCI-7260 Register Map .......................................... 16

Table 3-2: Interrupt Source Set Up .......................................... 25

Table 5-1: Data Types ............................................................. 35

iv List of Tables

Page 9

List of Figures

Figure 2-1: PCI-7260 PCB Layout ............................................... 8

Figure 2-2: Default Input Signal Jumper Setting .......................... 9

Figure 2-3: Isolated Digital Input Connector .............................. 10

Figure 2-4: Relay Status Output Connectors ............................. 11

Figure 2-5: Board ID setting ....................................................... 12

Figure 2-6: Initial State DIP Switch Setting ................................ 13

Figure 2-7: Emergency Shutdown State DIP Switch Setting ..... 13

Figure 4-1: 1 Coil Non-Latching Relay (RESET Condition) ....... 29

Figure 4-2: 7260 Card with EMG_SHDN Trigger....................... 30

Figure 4-3: CPLD with WDTimer Function................................. 32

Figure 4-4: Photo Coupler.......................................................... 32

Figure 4-5: Dry contact .............................................................. 33

Figure 4-6: COS Timing ............................................................. 34

List of Figures v

Page 10

Page 11

1 Introduction

The PCI-7260 is a high-power non-latching relay actuator and isolated digital input card for industrial automation and machine control.

This PCI-7260 provides 8 high-power non-latching relay outputs

and 8 opto-isolated digital inputs. The relay outputs are SPSTNO+SPST-NC (1 Form A 1 Form B) type and each channel is

capable to switch up to 5A current at 250VAC or 30VDC. The status of each relay output is indicated by either an on-board LED or

an external relay status output channel. When the non-latching

relay is in CLOSE condition, the corresponding on-board LED will

be turn ON and the corresponding relay status output will be set

as HIGH.

All of the digital input channels are identical non-polarity opto-isolated. Each of them is jumper selectable to use a AC filter or nonAC filter. All channels are isolated and therefore are suitable for

collecting digital inputs in noisy environments. The function of

“Change-of-State” (COS) interrupt is provided, which will generate

an interrupt to the host system when any of these digital inputs

changes its state.

Some advanced features for industrial applications are designed

for the PCI-7260. The emergent shutdown input (EMG_SHDN) on

the front panel lets users get back to a safety state set by a DIP

switch regardless the system condition. The initial output status

when powering on can be also set by a DIP switch. And the built-in

watchdog timer guarantees you that all the relays go back to the

safety state when your compute halts.

The I/O connectors are also considered. The 18-pin pluggable

connector for relay outputs and emergency shutdown on the front

panel allows easy wiring and high current carrying. Two extra 20pin ribbon connectors provide capacities of isolated digital inputs

and relay status outputs.

Introduction 1

Page 12

1.1 Features

The PCI-7260 high-power relay outputs and isolated digital inputs

card provides the following advanced features:

X Supports universal 32-bit 3.3V and 5V PCI bus

X 8-CH high power relay outputs

Z 5A at 250VAC

Z 5A at 30VDC

X 8-CH isolated digital inputs

X 8-CH relay status outputs

X 1-CH emergent stop input

X Pluggable connector for high current input

X On-board LEDs for relay status display

X Initial and safety state setting by DIP switches

X Interrupt generated from

Z COS (Change of State)

Z CH0 & CH1 positive edge

X Built-in watchdog timer

X Jumper selectable AC-filtered/non-AC-filtered for digital

inputs

2Introduction

Page 13

1.2 Applications

X Industrial ON/OFF control

X External high-power relay driving & signal switching

X Laboratory automation

X Industrial automation

X Switch contact status sensing, limit switch monitoring,

X Cooperating with A/D and D/A cards to implement a data

acquisition & control system

Introduction 3

Page 14

1.3 Specifications

Digital input

Input channels 8

Photo-coupler PC-3H4

Input current

Input Voltage

Input impedance

Input mode Isolation AC-filter/ Non-AC-filter

Isolated voltage 2,500 Vrms channel-to-system

Table 1-1: Digital Input Specifications

50 mA max. for isolated input

Relay Output

Output channels 8

Relay type 8 Non-latching SPST-NO + SPST-NC

Contact rating 250VAC, 5 A 30VDC, 5A

Breakdown voltage

Release time 10 ms max.

Operate time 10 ms max.

Contact resistance

Insulation resistance

Life expectancy

(min. operations)

Vibration Resistance

LED indicators

Power supply of Relay + 5V from the PCI-Bus

Table 1-2: Relay Output Specifications

1000 Vrms (open contacts), for 1 min

2000 Vrms (contacts and coil), for 1 min

1000MΩ min. (at 500 VDC)

> 5 X 107 times Mechanical

> 105 times Electrical

176.4m/s

Monitor Contact/Open status of each

relay; external LED connectors could be

10 mA rated

Up-to 24 VDC or 24V AC

Logic Low: 0~2V

Logic High: 5~24V

4.7 KΩ

30m

Ω

2

(18G), 10 to 55Hz at double

amplitude of 3mm

applied

4Introduction

Page 15

Isolated +5V Power Supply

Output Voltage +5V

Output Current

Table 1-3: Power Supply Specifications

170mA max. (@ 40°C)

General Specifications

Dimension 174.7 mm x 106.7 mm, standard PCI half size

Bus 32-bit PCI bus

Operating temperature

Storage temperature

Humidity 5 to 85% non-condensing

Table 1-4: General Specifications

0°C ~ 60°C

-40

°C ~ 80°C

Power Consumption

PCI-7260

+5V @ 510 mA typical

990mA maximum when all relays are acting simultaneously

Table 1-5: Power Consumption Specifications

Introduction 5

Page 16

1.4 Software Support

ADLINK provides versatile software drivers and packages for

users’ different approach to built-up a system. We provide not

only the programming library such as DLL for DOS and Windows,

but also drivers for many 3rd-party software packages. You may

find the programming library and 3rd-party software supports in

ADLINK All-in-One CD.

Programming Library

For customers who are writing their own programs with programming languages, we provide function libraries for different operating systems, including:

DOS libaray

Function libarary for DOS based on Turbo C. Please refer to

chapter 5 for descriptions of functions.

PCIS-DASK

Device driver and libarary packge for Windows 98/NT/2000/XP.

The PCIS-DASK is binary compatible across Windows 98, NT,

2000 and XP. That means all applications developed with

PCIS-DASK can be migrated to any Windows OS. The developing environment can be VB, VC++, Delphi, BC5, or any Windows programming language that allows DLL invokation. You

can find the driver package, user’s guide, and function reference of PCIS-DASK are in ADLINK All-in-One CD. Please refer

to the manuals in x:\Manual\Software Package\PCIS-DASK\

for more information. (x: denotes your CD-ROM drive)

DAQ-LVIEW PnP

DAQ-LVIEW PnP is the “Plug & Play” VI set to interface with

National Instruments LabVIEW under Windows 98/NT/2000/XP.

The DAQ-LVIEW PnP is free of charge and included in ADLINK

All-in-One CD. Please refer to the manuals in x:\Manual\Software

Package\DAQ-LVIEW PnP\ for more information. (x: denotes your

CD-ROM drive)

6Introduction

Page 17

2 Installation

This chapter outlines the contents of package, describes unpacking procedure, and describes how to install PCI-7260 into your

host system.

2.1 What you have

In addition to the User’s Manual, the package includes the following items:

X PCI-7260 non-latching relay and digital input cards

X ADLINK All-in-One CD

X This User’s Manual

If any of these items are missing or damaged, contact your

ADLINK dealer. Save the shipping materials and carton in to ship

or store the product in the future.

2.2 Unpacking

Your PCI-7260 card contains sensitive electronic components that

can be easily damaged by static electricity.

The card should be operated on a grounded anti-static mat. The

operator should be wearing an anti-static wristband, grounded at

the same point as the anti-static mat.

Inspect the card module carton for obvious damage. Shipping and

handling may cause damage to your module. Be sure there are no

shipping and handling damages on the module before processing.

After opening the card module carton, extract the system module

and place it only on a grounded antistatic surface with component

side up.

Again inspect the module for damage. Press down on all the

socketed IC's to make sure that they are properly seated. Do this

only with the module place on a firm flat surface.

Note: DO NOT APPLY POWER TO THE CARD IF IT HAS BEEN

Installation 7

DAMAGED.

You are now ready to install your PCI-7260.

Page 18

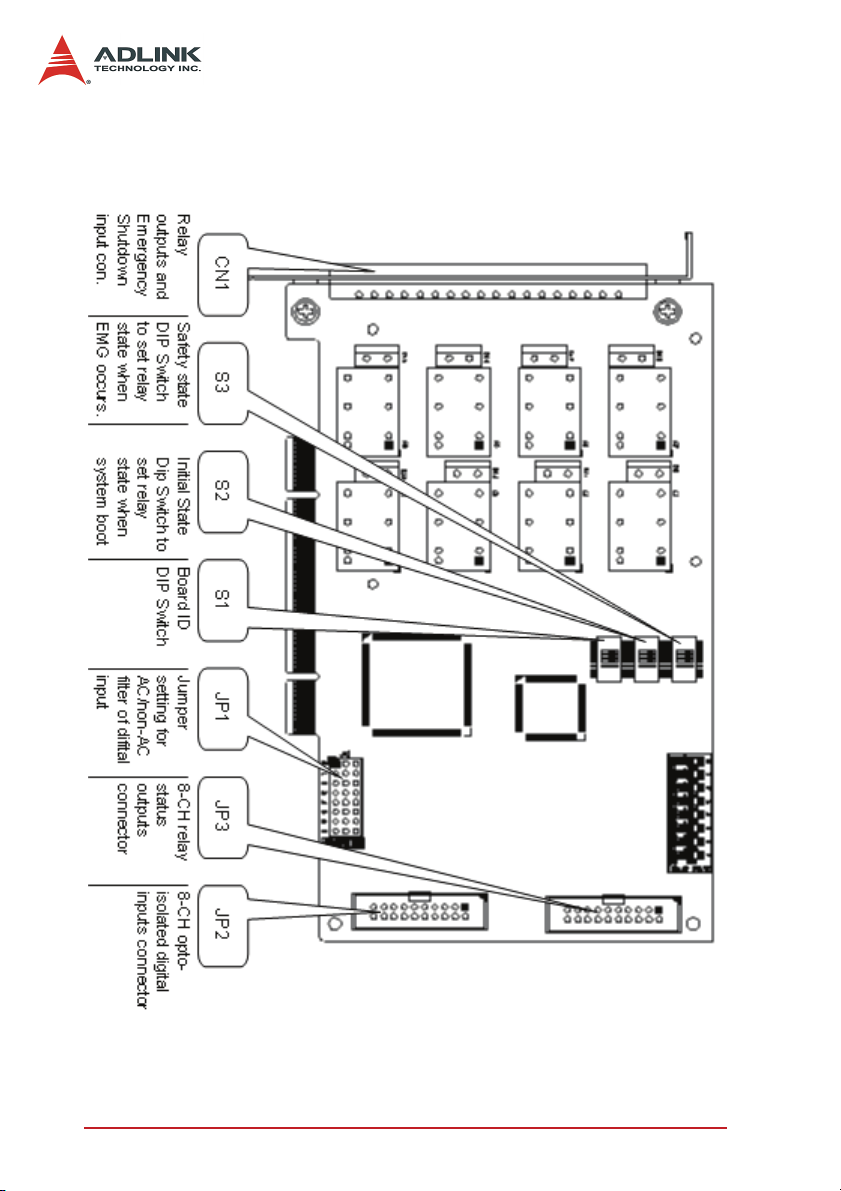

2.3 PCB Layout

The location of connectors, DIP switches and jumpers are shown

in Figure 2.1. They are described in the following sections.

Figure 2-1: PCI-7260 PCB Layout

8Installation

Page 19

2.4 AC/non-AC filter setting (JP1)

The PCI-7260 is a ‘plug and play’ add-on card for PCI bus. It is not

necessary for user to setup its base address and IRQ level to fit

the hardware of your computer system. However, to fit user’s versatile operation, there are still a few jumpers to set for the digital

input.

The JP1 on PCI-7260 card are used to configure the digital input

channels as AC-Filtered or Non-AC-Filtered inputs. AC-filter is

used to filter unexpected noise in the digital signal. Each digital

input channel and its corresponding jumper are shown in the following Table2.1.

JUMPER INPUT SIGNAL

JP1 DI0 ~ DI7

Table 2-1: The jumpers and DI channels

The default setting of the input signal selection is Non-AC-Filtered

(DC signal input), which is shown as below :

Figure 2-2: Default Input Signal Jumper Setting

Installation 9

Page 20

2.5 Isolated digital input connector (JP2)

DI 0+

DI 1+

DI 2+

DI 3+

DI 4+

DI 5+

DI 6+

DI 7+

GND

+5V

Figure 2-3: Isolated Digital Input Connector

The PCI-7260 card contains 8 opto-isolated digital input channels.

Utilizing the 20-pin ribbon connector (JP2) , users can connect

digital inputs to the isolated channels of PCI-7260.

Each row of JP2 corresponds to one of the eight DI channels. The

corresponding channel connection is shown in Figure 2.3. The digital input channels are isolated by photo couplers and accept

0~24V input voltage. The logic high is 5~24V and the logic low is

0~2V.

JP2

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

DI 0DI 1DI 2DI 3DI 4DI 5DI 6DI 7GND

+5V

10 Installation

Page 21

2.6 Relay status output connector (JP3)

EXT.LED 0EXT.LED 1EXT.LED 2EXT.LED 3EXT.LED 4EXT.LED 5EXT.LED 6EXT.LED 7-

Figure 2-4: Relay Status Output Connectors

The PCI-7260 card has 8 on-board LEDs to indicate the operation

status of the relay outputs. In addition, PCI-7260 also has 8 relay

status output channels for users who need external relay status

indicatros. Utilizing 20-pin ribbon connector(JP3) , users can have

their relays status shown outside the chassis. The relay status outputs support LEDs which have forward voltage (Vf) lower than 3V

and power consumption lower than 15mA. Each relay output

channel has a current limiting resistor (330O) connected with +5V

power, so users do not need to add a resistor to limit the current

flow through LED.

The direction of the external LED’s connection is shown in Figure

2.4. Before your connect LEDs on JP3 connectors, make sure the

LEDs are in the right direction.

JP3

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

A K

EXT.LED 0+

EXT.LED 1+

EXT.LED 2+

EXT.LED 3+

EXT.LED 4+

EXT.LED 5+

EXT.LED 6+

EXT.LED 7+

Installation 11

Page 22

2.7 Board ID (S1)

When users need more that two pieces of PCI-7260 plugged in

one host system, board ID is an effective mechanism to identity

the card. Users can set board ID to different PCI-7260 via the onboard DIP switch (S1) so that they can access the card correctly in

their programs. For more details about using Board ID in your program, please refer to Chapter 5.

Table 2.2 shows all conditions of the board ID setting .

Figure 2-5: Board ID setting

Board ID

01111 1

10111 1

21011 1

30011 1

41101 1

50101 1

……… ………… ………. ………….. ………… ……………

23 0 0 0 1 0

24 1 1 1 0 0

25 0 1 1 0 0

26 1 0 1 0 0

27 0 0 1 0 0

28 1 1 0 0 0

29 0 1 0 0 0

30 1 0 0 0 0

31 0 0 0 0 0

123 4 5

Table 2-2: Board ID Setting Conditions

Switch No.

Note: 1=on, 0=off

12 Installation

Page 23

2.8 Initial state DIP switch (S2)

When host system powers on, PCI-7260 will set the status of relay

outputs to the initial state set by initial state DIP switch (S2). When

the DIP switch is ON, the corresponding relay will be CLOSED

when power on. When the DIP switch is OFF, the corresponding

relay will be OPENED when power on. The default setting is ALL

OFF.

Figure 2-6: Initial State DIP Switch Setting

2.9 Emergency shutdown state DIP switch (S3)

When Emergency Shutdown input (from CN1) is set to HIGH, PCI7260 will switch the relay outputs to the state set by emergency

shutdown state DIP switch (S3). The transaction is done by onboard CPLD circuit and is irrelevant to host system. When the DIP

switch is ON, the corresponding relay will be CLOSED when

emergency shutdown. When the DIP switch is OFF, the corresponding relay will be OPENED when emergency shutdown. The

default setting is ALL OFF.

Figure 2-7: Emergency Shutdown State DIP Switch Setting

Installation 13

Page 24

2.10 Connector Pin Assignments (CN1)

The PCI-7260 card is equipped with a 18-pin pluggable connector

(CN1) on the front panel to provide relay outputs and emergency

shutdown input. The pin assignment of CN1 is described in Table

2-3.

NO0

COM0

NO1

COM1

NO2

COM2

NO3

COM3

NO4

COM4

NO5

COM5

NO6

COM6

NO7

COM7

EMG_SHDN+

EMG_SHDN-

Table 2-3: Pin Assignment of PCI-7260 CN1

Legend:

NO x Normal open pin of channel x, x=0~7

COM x Common pin of channel x, x=0~7

EMG_SHDN+ Emergency shutdown input +

EMG_SHDN- Emergency shutdown input -

14 Installation

Page 25

3 Register Format

The detailed descriptions of the register format are specified in this

chapter. This information is quite useful for the programmers who

want to handle the card by low-level programming. However, we

suggest user understand more about the PCI interface before

starting low-level programming.

Register Format 15

Page 26

3.1 I/O Address Map

The 7260 registers are all 16-bit wide. Users can access these

registers only by 16 bits I/O instructions. The control of the relays

and status of the isolation input is by means of accessing registers. The following table shows the register map, including

descriptions and their offset addresses relative to the base

address.

Offset Write Read

0x00h Relay Output CH. 0~7 Relay Output Read back CH.0~7

0x02h WDTimer Load Config

0x04h

0x06h COS Setup Register COS Latch Register

0x08h

0x0Ah --- Initial Dip Switch State

Emergency Shut Down Setup

Register (EMG_SHDN)

Interrupt / WDT Control

Register

Table 3-1: PCI-7260 Register Map

Emergency Shut Down Dip

Switch State

Isolated Input CH. 0~7

Interrupt / EMG_SHDN / WDT

Status Register

16 Register Format

Page 27

3.2 Relay Output Control Register

There are 8 non-latching relays on each PCI-7260 board. Each

non-latching relay is controlled by each bit of the control register.

The setting “1” means the non-latching relay is in RESET condition. Under the RESET condition, the normal open(NO) signal line

is ‘open’ from the common(COM) line and the normal close(NC)

signal line is connected with the common line. The setting “0”

means the normal open signal line is now closed, while the NC

signal is open.

For more information about the non-latching relay and software

function library, please refer to sections 4.1 and 5.3, respectively.

Address: BASE + 0x00

Attribute: Write

76543210

DO7DO6DO5DO4DO3DO2DO1DO0

15 14 13 12 11 10 9 8

--- --- --- --- --- --- --- ---

Register Format 17

Page 28

3.3 WDTimer Load Config Register

Watch Dog Timer Asynchronous load input. Asynchronously loads

the counter with the value on the data written in the follow

address. The corresponding hexadecimal value setted by user

determines WDTimer overflow time. The overflow time is calculated by the value that users set (Cnt_value) multiplied 1/2048 ms.

Address:BASE + 0x02

Attribute: Write

76543210

WDT

Data7

15 14 13 12 11 10 9 8

WDT

Data15

WDT

Data6

WDT

Data14

WDT

Data5

WDT

Data13

WDT

Data4

WDT

Data12

WDT

Data3

WDT

Data11

WDT

Data2

WDT

Data10

WDT

Data1

WDT

Data9

WDT

Data0

WDT

Data8

18 Register Format

Page 29

3.4 Relay Output Read Back Register

The status of the non-latching relay can be readback from the

readback register. If the relay is in RESET condition, the corresponding bit value is ‘0’. If the relay is in SET condition, the bit

value is ‘1’.

Address: BASE + 0x00

Attribute: Read

76543210

RBK7 RBK6 RBK5 RBK4 RBK3 RBK2 RBK1 RBK0

15 14 13 12 11 10 9 8

--- --- --- --- --- --- --- ---

RBKx: Read back data of relay x, x=0~7

1: relay is in SET status

0: relay is in RESET status

Register Format 19

Page 30

3.5 Emergency Shutdown Setup Register

The emergency shut down setup register allow user to enable or

disable the emergency stop function and clear EMG_SHDN status.

The default Emg_SHDN enable value is “1”. When The bit 0 value

“1” means the function is enable and “0” menas that is disable.

When Emergency Shutdown’s Input Pin (from the terminal connector) is one shot high, it will force PCI7260 enter the state of

“SHDN”( Relay Output pattern is determined on EMG_SHDN Dip

Swith(S3)). Whenever the users wants to control the relay output

by “Relay Output Control Register”, the relay pattern won’t

change until users acess the “EMG_SHDN Recovery bit”.

Address: BASE + 0x04

Attribute: Write

7 654321 0

Recovery --- --- --- --- --- --- EMG_EN

15 14 13 12 11 10 9 8

--- --- --- --- --- --- --- ---

EMG_EN: Emergengy shutdown enable

1: emergency shutdown is enable

0: emergency shutdown is disable

Recovery: Emergency shutdown status recovery

1: EMG SHDN Status is clear

0: No effects

20 Register Format

Page 31

3.6 Isolated Digital Input Register

There are 8 isolated input channels on PCI-7260 card. The status

of the 8 channels can be read from the isolated input register.

Each bit corresponds to each channel. The bit value “1” means the

input logic is high and “0” menas the input logic is low.

Address: BASE + 0x04

Attribute: Read

76543210

DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

15 14 13 12 11 10 9 8

--- --- --- --- --- --- --- ---

DIx: isolated digiatal input channel x, x=0~7

1: input voltage is in high level

0: input voltage is in low level

Register Format 21

Page 32

3.7 COS Setup Register

The PCI-7260 provides a Change-of-State(COS) interrupt function

on any one of digital input channel. This function allows users to

monitor the status of input channels. By enabling the COS Setup

registers, it will generate an interrupt when the corresponding

channnel changes its state, whether a rising edge signal or a falling edge signal. For more detailed information, please refer to

Section 4.4.

Address: BASE + 0x06

Attribute: Write

76543210

COS

SET7

15 14 13 12 11 10 9 8

--- --- --- --- --- --- --- ---

COS

SET6

COS SETx: change-of-state setup of DI channel x,

COS

SET5

x=0 ~7

1: enable the COS interrupt

0: disable the COS interrupt

COS

SET4

COS

SET3

COS

SET2

COS

SET1

COS

SET0

22 Register Format

Page 33

3.8 COS Latch Register

When COS occurs, the COS Latch register will also latch the DI

data. Once the user clear the interrupt request, the COS Latch

register will be cleared automatically. The COS function releases

the CPU from the burden of polling all of the input channels, and

enables the computer to handle higher I/O performance.

Address: BASE + 0x06

Attribute: Read

76543210

CL7CL6CL5CL4CL3CL2CL1CL0

15 14 13 12 11 10 9 8

--- --- --- --- --- --- --- ---

CL x: COS latch register of DI channel x, x = 0 ~

7

1: digital input voltage is in high level

0: digital input voltage is in low level

Register Format 23

Page 34

3.9 Interrupt / WDT Control Register

There are three different interrupt modes in PCI-7260. In the first

mode, users enable the COS interrupt function to monitor the

enabled input channel’s status whenever the status changes from

0 to 1 or 1 to 0. In the second mode, users can select digital input

channel 0, channel 1 or both channels as the interrupt sources. In

this mode, interrupt only assertes when the DI status changes

from 0 to 1, i.e., rising edge. In the third mode, users can enable

WDTimer and let it count down. The interrupt assertes when

WDTimer is overflow. Because the three different modes share the

same interrupt signal in hardware, users are not allowed to enable

these tree modes at the same time.

After processing the interrupt request event, users have to clear

the interrupt request in order to handle another interrupt request.

To clear the interrupt request, write 1 to the corresponding bit.

Address: BASE + 0x08

Attribute: Write

7 6543 2 1 0

WDT CLR --- --- --- --- CH1 CLR CH0 CLR COS CLR

15 14 13 12 11 10 9 8

WDT Int_EN --- --- --- --- CH1 Int_EN CH0 Int_EN COS Int_EN

COS CLR (bit 0): write 1 to clear the COS

interrupt.

1 : clear the COS interrupt

0 : no effect

CH0 CLR (bit 1): write 1 to clear DI channel 0

interrupt.

1 : clear DI channel 0 interrupt

0 : no effect

CH1 CLR (bit 2): write 1 to clear DI channel 1

interrupt.

1 : clear DI channel 1 interrupt

0 : no effect

WDT CLR (bit 7): write 1 to clear WDT interrupt.

1 : clear WDT interrupt

0 : no effect

COS Int_EN (bit 8): Write/Read

Change-of-State interrupt enable control

24 Register Format

Page 35

1 : enable

0 : disable

CH0 Int_EN (bit 9): Write/Read

DI channel 0 interrupt enable control

1 : enable

0 : disable

CH1 Int_EN (bit 10): Write/Read

DI channel 1 interrupt enable control

1 : enable

0 : disable

WDT Int_EN (bit 15): Write/Read

WDTimer counter/interrupt enable control

1 : enable

0 : disable

The following table shows all possible combinations of interrupt

source.

Interurpt type Bit 15 Bit 10 Bit 9 Bit 8 IRQ source IRQ trigger condition

Disable 0 0 0 0 Interrupt disable --

Mode 1 0 0 0 1 COS interrupt

Mode 2 0 0 1 0

Mode 2 0 1 0 0

Mode 2 0 1 1 0

Mode 3 1 0 0 0

Forbidden X 0 1 1

Ch.0 interrupt

enable

Ch.1 interrupt

enable

Ch.0 & 1 interrupt

enable

WDTimer Couner

interrupt enable

Not allowed (dis-

able)

Change of state in

the enabled channel

Rising edge of DI

channel 0

Rising edge of DI

channel 1

Rising edge of DI

channel 0 or 1

WDTimer is overflow

---

Table 3-2: Interrupt Source Set Up

Register Format 25

Page 36

3.10 Interrupt / EMG_SHDN / WDT Status Register

When interrupt occurs, this register provides information for users

to recognize the interrupt status and the interrupt setup condition.

Address: BASE + 0x08

Attribute: Read

765 4 3 2 1 0

--- --- ---

15 14 13 12 11 10 9 8

--- --- ---

WDT Int

Status

WDT

Int_EN

COS Int. Status (bit 0): COS interrupt Status

register

0: COS interrupt de-asserts

1: COS interrupt asserts

CH0 Int. Status (bit 1): Digital input channel 0

interrupt status

0: Ch0 interrupt de-asserts

1: Ch0 interrupt asserts

CH1 Int. Status (bit 2): Digital input channel 1

interrupt status

0: Ch1 interrupt de-asserts

1: Ch1 interrupt asserts

EMG SHDN Status (bit 3): Emergency Shutdown

status

0: EMG_SHDN de-asserts

1: EMG_SHDN asserts

CH1 Int. Status (bit 4): WDTimer interrupt status

0: WDTimer interrupt de-asserts

1: WDTimer interrupt asserts

EMG SHDN

Status

EMG EN

CH1 Int.

Status

CH1

Int_EN

CH0 Int.

Status

CH0

Int_EN

COS Int.

Status

COS

Int_EN

26 Register Format

Page 37

3.11 Handling PCI Controller Registers

The PCI bus controller adopted in PCI-7260 is PCI-9030 which is

provided by PLX technology Inc. When users attempt to handle

low-level programming, some registers in PCI-9030 should be

noticed. The interrupt control register(INTCSR; 0x4Ch) of PCI9030 takes charge of all interrupt information from local bus to PCI

bus. When users want to develop their own interrupt function

driver, both interrupt registers in PCI-9030 and in PCI-7260 have

to work together. For more detailed information about the interrupt

control register in PCI-9030, please refer to the PCI-9030

databook.

In PCI-7260 software funciton library, we provide simple and easyto-use functions to handle the procedure of interrupt. Using these

functions, users don’t need to care about the interrupt register in

PCI controller. We suggest users use these functions instead of

developing interrupt functions by themselves. For more information about PCI-7260 funciton library, please refer to Chapter 5.

Register Format 27

Page 38

28 Register Format

Page 39

4 Operation Theorem

4.1 Non-Latching Relay Output

One of the innovative features on PCI-7260 is the 8-channel nonlatching relay output. The PCI-7260 contains only one type of nonlatching relay : 1 coil 1 Form A 1 Form B. Figure 4.1 shows the

latching relay contact arrangement under RESET condition.

Figure 4-1: 1 Coil Non-Latching Relay (RESET Condition)

Each non-latching relay on PCI-7260 has one coil which controls

each non-latching relay, we need only one control bit. What we

have to do is to energize and deenergize the coil when switching

RESET condition to SET condition. After the contact switches to

the opposite position at a steady state, we still cann’t cut out the

current on the coil and the contact will not change. Under the

scheme of controlling latching relay, we define the SET condition

control bit as “0” and the RESET condition control bit as “1”. For

more details about the non-latching relay control register, refer to

section 3.3.

PCI-7260 also provides a software function for user to control the

non-latching relays. Using this function, relay control is as simple

as the general relay. Instead of writing 32-bit data to the relay output register, user only needs to prepare 8-bit data and each bit

represents a relay’s status. Value ‘0’ represents SET condition

and value ‘1’ represents RESET condition. For more details about

the relay output function library, refer to section 5.3.

The relay output contacts are rated for a maximum of 5A at

250VAC (resistive), or 5A 30VDC. You should reduce these ratings for inductive loads. For more detailed information of relay

contact, please refer to Appendix A.

Operation Theorem 29

Page 40

4.2 Emergency Shutdown

In safety-critical applications, users can enable the emergency

shutdown function on PCI 7260, to manually set the relay pattern

to preset state. To access this function, users must first configure

the emergency shutdown function by On Board Switch. Generally

the trigger source is on the front panel and connected to a push

button, which pulls the SHDNn pin to logic-High when activated.

The trigger source can be routed through the Onboard Local Bus.

The default relay pattern for emergency shutdown is All-Off on

PCI-7260 switch; users can change the pattern by change the Dip

Switch. Upon receiving the emergency shutdown trigger, the

Switch Module enters shutdown mode, and the relay pattern is

switched to the preset state.

The Emergency Shutdown function operation flow is as follows:

1. Emergency Shutdown button one shot trigger as shown

in Figure 4.2

Figure 4-2: 7260 Card with EMG_SHDN Trigger

2. When the trigger is active, the relay output will change

corresponding to EMG_SHDN Dip Switch(S3)

3. When entering Emergency Shutdown state, users can

not access the relay output pattern until they clear the

state through function _7260_EMG_SETUP().

30 Operation Theorem

Page 41

4.3 Watchdog Timer

In safety-critical applications, users can enable the watchdog timer

function on PCI 7260 to automatically set the relay pattern to preset state, in case the operating system or PCI 7260 crashes. To

access this function, users must first configure the watchdog timer

overflow counter by windows API. Generally the trigger source

would come from the onboard 30-bit watchdog timer.

The watchdog timer overflow interval can be programmed through

Windows API. After enabling the watchdog timer, users must periodically reset the timer by software command. If the timer is not

being reset within the specified interval, the WDT module will generate an overflow signal and set the relay pattern to the one specified by users. This function is disabled by default. For more

information, please refer to the software programming users’

guide.

The Watch Dog Timer function operation flow is as follows:

1. Load the WDTimer counter value through the function

_7260_WDTimerSReload_Config(), this function allows

users to set WDTimer overflow time from 32 s to 2 ms.

2. Enable the WDTimer counter to count down through the

function _7260_INT_Control(), this function allows WDT

function in the CPLD (as Figure 4.3) starting to count

down. After enabling the function, users must reload

WDTimter by step (1) before it overflows. This makes

PCI-7260 work normally under WDT monitoring. When it

overflows, CPLD interrupt will occurs and emergency

shutdown will be active too to make relay output in a

safety pattern unless user disable the emergency shutdown function through function_7260_EMG_SETUP().

3. When WDTimer interrupt occurs, users must reload the

WDTimer through function

_7260_WDTimerSReload_Config() to clear WDTimer

carry out, and then clear the system interrupt through

function _7260_CLR_IRQ(). After doing this, the

WDTimer will count again unless user disable WDTimer

counter.

Operation Theorem 31

Page 42

Figure 4-3: CPLD with WDTimer Function

4.4 Isolated Digital Input

The PCI-7260 contains 8 opto-isolated digital input channels. The

circuit diagram of the isolated input channel is shown below.

Figure 4-4: Photo Coupler

The digital input is first routed through a photo-coupler (PC3H4),

so that the connection are not polarity sensitive whether using

positive or negative voltage.

In addition, a first order-filter with time constant about 1.5ms is

provided to filter high frequency noise. The normal input voltage

range for high state is 5 to 24V.

The PCI-7260 provides an isolated +5V power for dry contact

input. When the external circuit has no voltage source(e.g. a

switch), users can use the on board +5V to respond the change of

32 Operation Theorem

Page 43

external circuit. The maximum output current of the on board isolated power is 170mA (@40?). Please pay attention to the current

consumption of the external circuit not exceeding the limit. The dry

contact architecture is shown in Figure 4.3.

Figure 4-5: Dry contact

4.5 Interrupt Architecture

PCI-7260 has a powerful dual interrupt routing scheme including

change-of-state detection and interrupt sources on digital input

channel 0 and channel 1. Using these interrupts well can make

you handle more complicated information from outside enviroment

and release your computer from a heavy burden in dealing with

digital input data. Note that the dual interrupts do not mean the

card occupies two IRQ levels.

There are two interrupt modes in PCI-7260, but you can only

choose one of them at one time. Table3.2 shows all of the combinations of interrupt modes.

4.6 Change of State(COS) Interrupt

What is COS?

The COS (Change of State) means either the input state(logic

level) changes from low to high, or from high to low. The COS

detection circuit will detect the edge of level change. In the

PCI-7260 card, the COS detection circuit is applied to all the

input channels. When any channel changes its logic level, the

Operation Theorem 33

Page 44

COS detection circuit generates an interrupt request to PCI

controller.

COS Detection

The following timing is an example of COS operation. All of the

enabled DI channels’ signal level change will be detected to

generate the interrupt request.

While the interrupt request generates, the corresponding DI

data will also be latched into the COS latch register. In our COS

architecture, the DI data are sampled by a 8.25MHz clock. It

means the pulse width of the digital input have to last longer

than 122 ns, or the COS latch register won’t latch the correct

input data. The COS latch register will be erased after clearing

the interrupt request.

Figure 4-6: COS Timing

34 Operation Theorem

Page 45

5 C/C++ DOS Libraries

5.1 Programming Guide

Naming Convention

The functions of the NuDAQ PCI cards or NuIPC CompactPCI

cards’ software driver are using full-names to represent the functions' real meaning. The naming conventions are:

_{hardware_model}_{action_name}. e.g.

_7260_Initial().

All functions in the PCI-7260 drivers are with 7260 as

{hardware_model}.

Data Types

We have defined some data types in Pci_7260.h. These data

types are used by NuDAQ Cards’ library. We suggest you use

these data types in your application programs. The following table

shows the data type names and their range.

Typ e N ame Description Range

U8 8-bit ASCII character 0 to 255

I16 16-bit signed integer -32768 to 32767

U16 16-bit unsigned integer 0 to 65535

I32 32-bit signed integer -2147483648 to 2147483647

U32 32-bit single-precision floating-point 0 to 4294967295

F32 32-bit single-precision floating-point

F64 64-bit double-precision floating-point

Boolean Boolean logic value TRUE, FALSE

Table 5-1: Data Types

-3.402823E38 to

3.402823E38

-1.797683134862315E308 to

1.797683134862315E309

C/C++ DOS Libraries 35

Page 46

5.2 _7260 Initial

@ Description

The PCI-7260 cards are initialized according to the card number.

Because the PCI-7260 is PCI bus architecture and meets the plug

and play design, the IRQ and base_address ( pass-through

address) are assigned by system BIOS directly. Every PCI-7260

card has to be initialized by this function before using other functions.

@ Syntax

U16 _7260_Initial (U16 *existCards, PCI_INFO

*pciInfo)

@ Argument

existCards: The number of installed PCI-7260 cards. The

returned value shows how many PCI-7260 cards are installed in

your system.

pciInfo: It is a structure to memorize the PCI bus plug and play initiallization information which is decided by p&p BIOS. The

PCI_INFO structure is defined in ACL_PCI.H. The base I/O

address and the interrupt channel number is stored in pciinfo

which is for reference.

@ Return Code

ERR_NoError, ERR_PCIBiosNotExist,

ERR_BoardNoInit, ERR_InvalidBoardNumber

36 C/C++ DOS Libraries

Page 47

5.3 _7260_DO

@ Description

This function is used to write data to digital output port which can

energize the Non-latching relay coils. You can control all 8

RELAYs through _7260_DO by using this function. Althought the

register map of latching relays is 32 bit width, we use 8-bit access

to control the non-latching relay through this function. Bit ‘1’ represent the RESET condition, and Bit ‘0’ represent the SET condition.

@ Syntax

U16 _7260_DO (U16 boardID, U16 doData)

@ Argument

boardID: Board ID to the specific borad.

doData: value which will be written to digital output port.

@ Return Code

ERR_NoError, ERR_BoardNoInit

C/C++ DOS Libraries 37

Page 48

5.4 _7260_DO_Read_Back

@ Description

This function is used to read data back from digital output port control by 7260_DO function. There are 8-bit digital outputs on the

PCI-7260. You can get back all RELAYs status (SET or RESET)

by using this function.

@ Syntax

U16 _7260_DO_Read_Back (U16 boardID, U16

*DoReadBackData)

@ Argument

boardID: Board ID to the specific borad.

DoReadBackData: value read back from digital output port. ‘0’

represents the non-latching relay is under RESET condition and

‘1’ represents the non-latching relay is under SET condition.

@ Return Code

ERR_NoError, ERR_BoardNoInit

38 C/C++ DOS Libraries

Page 49

5.5 _7260_DI

@ Description

This function is used to read data from digital input port. There are

8-bit digital inputs on the PCI-7260. You can get all 8 input data by

using this function.

@ Syntax

U16 _7260_DI (U16 boardID, U16 *diData)

@ Argument

boardID: Board ID to the specific borad.

diData: return 8-bit value from digital input port.

@ Return Code

ERR_NoError, ERR_BoardNoInit

C/C++ DOS Libraries 39

Page 50

5.6 _7260_COS_Channel

@ Description

This function is used to enable the COS channel.

@ Syntax

U16 _7260_COS_Channel (U16 boardID, U16

COS_Enable_Data)

@ Argument

boardID: Board ID to the specific borad.

COS_Enable_Data: COS channel enable. ‘1’ enable the corre-

sponding channel and ‘0’ disable the corresponding channel.

@ Return Code

ERR_NoError, ERR_BoardNoInit

40 C/C++ DOS Libraries

Page 51

5.7 _7260_COS_Latch

@ Description

This function is used to latch digital input data after COS interrupt

occurs.

@ Syntax

U16 _7260_COS_Latch (U16 boardID, U16

*COS_Latch_Data)

@ Argument

boardID: Board ID to the specific borad.

COS_Latch_Data: Digital input data when COS occurs. This reg-

ister will be erased when clearing IRQ.

@ Return Code

ERR_NoError, ERR_BoardNoInit

C/C++ DOS Libraries 41

Page 52

5.8 _7260_INT_Control

@ Description

This function is used to control the interrupt source of PCI-7260.

For more details about interrupt sources, refer to section 3.7

@ Syntax

U16 _7260_INT_Control (U16 boardID, U16

COS_Enable, U16 CH0_Enable, U16 CH1_Enable,

U16 WDT_Enable)

@ Argument

boardID: Board ID to the specific borad.

COS_Enable: COS interrupt function enable/disable.

CH0_Enable: Digital input channel 0 interrupt enable/disable.

CH1_Enable: Digital input channel 1 interrupt enable/disable.

WDT_Enable: Watch Dog Timer interrupt counter enable/disable

The possible combinations of interrupt source are shown in the following table.

WDT_Enable CH1_Enable CH0_Enable COS_Enable

0000

0001

0010

0100

0110

1000

42 C/C++ DOS Libraries

IRQ

source

Interrupt

disable

COS inter-

rupt

Ch.0 inter-

rupt enable

Ch.1 inter-

rupt enable

Ch.0 & 1

interrupt

enable

WDT inter-

rupt enable

IRQ trigger condition

--

Change of state in the

enabled channel

Rising edge of DI

channel 0

Rising edge of DI

channel 1

Rising edge of DI

channel 0 & 1

Rising edge of WDT

carry out overflow

Page 53

WDT_Enable CH1_Enable CH0_Enable COS_Enable

01

X

10

1

@ Return Code

ERR_NoError, ERR_BoardNoInit, ERR_INTNotSet

IRQ

source

Not allowed

(disable

IRQ trigger condition

---10

C/C++ DOS Libraries 43

Page 54

5.9 _7260_CLR_IRQ

@ Description

This function is used to clear the interrupt request of PCI-7260.

@ Syntax

U16 _7260_CLR_IRQ (U16 boardID, U16 COS_CLR, U16

CH0_CLR, U16 CH1_CLR, U16 WDT_CLR)

@ Argument

boardID: Board ID to the specific borad.

COS_CLR: Clear COS interrupt request.

CH0_CLR: Clear digital input channel 0.

CH1_CLR: Clear digital input channel 1.

WDT_CLR: Clear Watch Dog Timer interrupt request.

@ Return Code

ERR_NoError, ERR_BoardNoInit

44 C/C++ DOS Libraries

Page 55

5.10 _7260_GET_IRQ_Status

@ Description

This function is used to get the interrupt status of PCI-7260.

@ Syntax

U16 _7260_GET_IRQ_Status (U16 boardID, U16

*COS_Status, U16 *CH0_Status, U16

*CH1_Status, U16 *EMG_SHDN_Status, U16

*WDT_Status)

@ Argument

boardID: Board ID to the specific borad.

COS_Status: COS interrupt status.

X ‘1’ represents interrupt asserts.

X ‘0’ represents interrupt de-asserts.

CH0_Status: Digital input channel 0 interrupt status. ‘1’ represents

interrupt asserts.

X ‘0’ represents interrupt de-asserts.

CH1_Status: Digital input channel 1 interrupt status. ‘1’ represents

interrupt asserts.

X ‘0’ represents interrupt de-asserts.

EMG_SHDN_Status: Emergency Shutdown status.

X ‘1’ represents EMG SHDN asserts.

X ‘0’ represents EMG SHDN de-asserts.

WDT_Status: Watch Dog Timer interrupt status.

X ‘1’ represents interrupt asserts.

X ‘0’ represents interrupt de-asserts.

@ Return Code

ERR_NoError, ERR_BoardNoInit

C/C++ DOS Libraries 45

Page 56

5.11 _7260_WDTimerSReload_Config

@ Description

This function is used to clear the WDTimer overflow state of PCI7260 and reload the count value.

@ Syntax

U16 _7260_ WDTimerSReload_Config (U16 boardID,

Int WDT_CountData)

@ Argument

boardID: Board ID to the specific borad.

WDT_CountData: decimal value from 2 (ms) to 31999 (ms) which

will be written to WDT reload value.

@ Return Code

ERR_NoError, ERR_BoardNoInit

46 C/C++ DOS Libraries

Page 57

5.12 _7260_EMG_SETUP

@ Description

This function is used to enable/disable the emergency stop function of PCI-7260.

@ Syntax

U16 _7260_EMG_EN (U16 cardNo,U16

EMG_EN_BUTTON,U16 EMG_Recovery)

@ Argument

boardID: Board ID to the specific borad.

EMG_EN_BUTTON: Emergency Stop enable/disable. ‘1’ repre-

sents EMG enable. ‘0’ represents EMG disable.

EMG_Recovery: Emergency Stop status recovery. ‘1’ represents

EMG state clear. ‘0’ has no effect.

@ Return Code

ERR_NoError, ERR_BoardNoInit

C/C++ DOS Libraries 47

Page 58

5.13 _7260_EmgShdnDipSwitch_status

@ Description

This function is used to read data from emergency shutdown dip

switch. There are 8-bit digital inputs on the Emergency shutdown

dip switch. You can get all 8 input data by using this function.

@ Syntax

U16 _7260_EmgShdnDipSwitch_status (U16 boardID, U16

*diData)

@ Argument

boardID : Board ID to the specific borad.

diData :return 8-bit value from emergency shutdown dip switch.

@ Return Code

ERR_NoError, ERR_BoardNoInit

48 C/C++ DOS Libraries

Page 59

5.14 _7260_InitDipSwitch_status

@ Description

This function is used to read data from initial state dip switch.

There are 8-bit digital inputs on the Initial State dip switch. You can

get all 8 input data by using this function.

@ Syntax

U16 _7260_DI (U16 boardID, U16 *diData)

@ Argument

boardID: Board ID to the specific borad.

diData: return 8-bit value from initial state dip switch.

@ Return Code

ERR_NoError, ERR_BoardNoInit

C/C++ DOS Libraries 49

Page 60

50 C/C++ DOS Libraries

Page 61

6 Appendix

6.1 Relay Contact Protection Circuits

The contacts are the most important elements of relay constructions, Contact performance is conspicuously influenced by contact

material, voltage and current values applied to the contacts.

Another important issue is contact protection, a right contact protection circuit can suppress the counter EMF to a low level. However, note that incorrect use will result in an adverse effect. Typical

contact protection circuits are given below :

RC Circuit

This circuit is suitable for DC application. If the load is a timer,

leakage current flows through the RC circuit causing faulting operation.

Contact

RC

Inductive

Load

The below circuit is suitable for both AC and DC applications. If

the load is a relay or solenoid, the release time lengthens. It’s

effective when connected to both contacts if the power supply voltage is 24V or 48V and the voltage cross the load is 100 to 200V.

Device Selection:

As a guide in selecting R and C,

Z R : 0.5 to 1Ω per 1V contact voltage

Z C : 0.5 to 1μF per 1A contact current

Values vary depending on the properties of the capacity C acts to

suppress the discharge the moment the contacts open. Resistor R

acts to limit the current when the power is turned on the next time.

Appendix 51

Page 62

Test to confirm. Use a capacitor with a breakdown voltage of 200

to 300V. Use AC type capacitors (non-polarized) for AC circuits.

Diode Circuit

This circuit is suitable for DC application. The diode connected in

parallel causes the energy stored in the coil to flow to the coil in

the form of current and dissipates it as joule heat at the resistance

component of the inductive load. This circuit further delays the

release time compared to the RC circuit.

Contact

Diode

Inductive

Load

Device Selection:

Use a diode with a reverse breakdown voltage at least 10 times

the circuit voltage and a forward current at least as large as the

load current. In electronic circuits where the circuit voltages

reverse breakdown voltage of above 2 to 3 times the power

supply voltage.

Diode & Zener diode Circuit

This circuit is also suitable for DC application. Effective when the

release time i the diode circuit is too long.

Contact

Diode

Inductive

Load

52 Appendix

Page 63

Device Selection:

Use a zener diode with a zener voltage about the same as the

power supply voltage.

Varistor Circuit

This circuit is also suitable for both AC & DC applications. Using

the stable voltage characteristics of the varistor, this circuit prevents excessively high voltages from being applied across the

contacts. This circuit also slightly delays the release time. Effective

when connected to both contacts of the power supply voltage is 24

or 48V and the voltage across the load is 100 to 200 V.

Contact

Diode

Inductive

Load

Appendix 53

Page 64

54 Appendix

Page 65

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and

enjoy all the after-sales services we offer, please read the following carefully.

1. Before using ADLINK’s products please read the user manual and follow the instructions exactly. When sending in

damaged products for repair, please attach an RMA application form which can be downloaded from: http://

rma.adlinktech.com/policy/.

2. All ADLINK products come with a limited two-year warranty, one year for products bought in China:

X The warranty period starts on the day the product is

shipped from ADLINK’s factory.

X Peripherals and third-party products not manufactured

by ADLINK will be covered by the original manufacturers' warranty.

X For products containing storage devices (hard drives,

flash cards, etc.), please back up your data before sending them for repair. ADLINK is not responsible for any

loss of data.

X Please ensure the use of properly licensed software with

our systems. ADLINK does not condone the use of

pirated software and will not service systems using such

software. ADLINK will not be held legally responsible for

products shipped with unlicensed software installed by

the user.

X For general repairs, please do not include peripheral

accessories. If peripherals need to be included, be certain to specify which items you sent on the RMA Request

& Confirmation Form. ADLINK is not responsible for

items not listed on the RMA Request & Confirmation

Form.

Warranty Policy 55

Page 66

3. Our repair service is not covered by ADLINK's guarantee

in the following situations:

X Damage caused by not following instructions in the

User's Manual.

X Damage caused by carelessness on the user's part dur-

ing product transportation.

X Damage caused by fire, earthquakes, floods, lightening,

pollution, other acts of God, and/or incorrect usage of

voltage transformers.

X Damage caused by unsuitable storage environments

(i.e. high temperatures, high humidity, or volatile chemicals).

X Damage caused by leakage of battery fluid during or

after change of batteries by customer/user.

X Damage from improper repair by unauthorized ADLINK

technicians.

X Products with altered and/or damaged serial numbers

are not entitled to our service.

X This warranty is not transferable or extendible.

X Other categories not protected under our warranty.

4. Customers are responsible for shipping costs to transport

damaged products to our company or sales office.

5. To ensure the speed and quality of product repair, please

download an RMA application form from our company website: http://rma.adlinktech.com/policy. Damaged products

with attached RMA forms receive priority.

If you have any further questions, please email our FAE staff:

service@adlinktech.com.

56 Warranty Policy

Loading...

Loading...